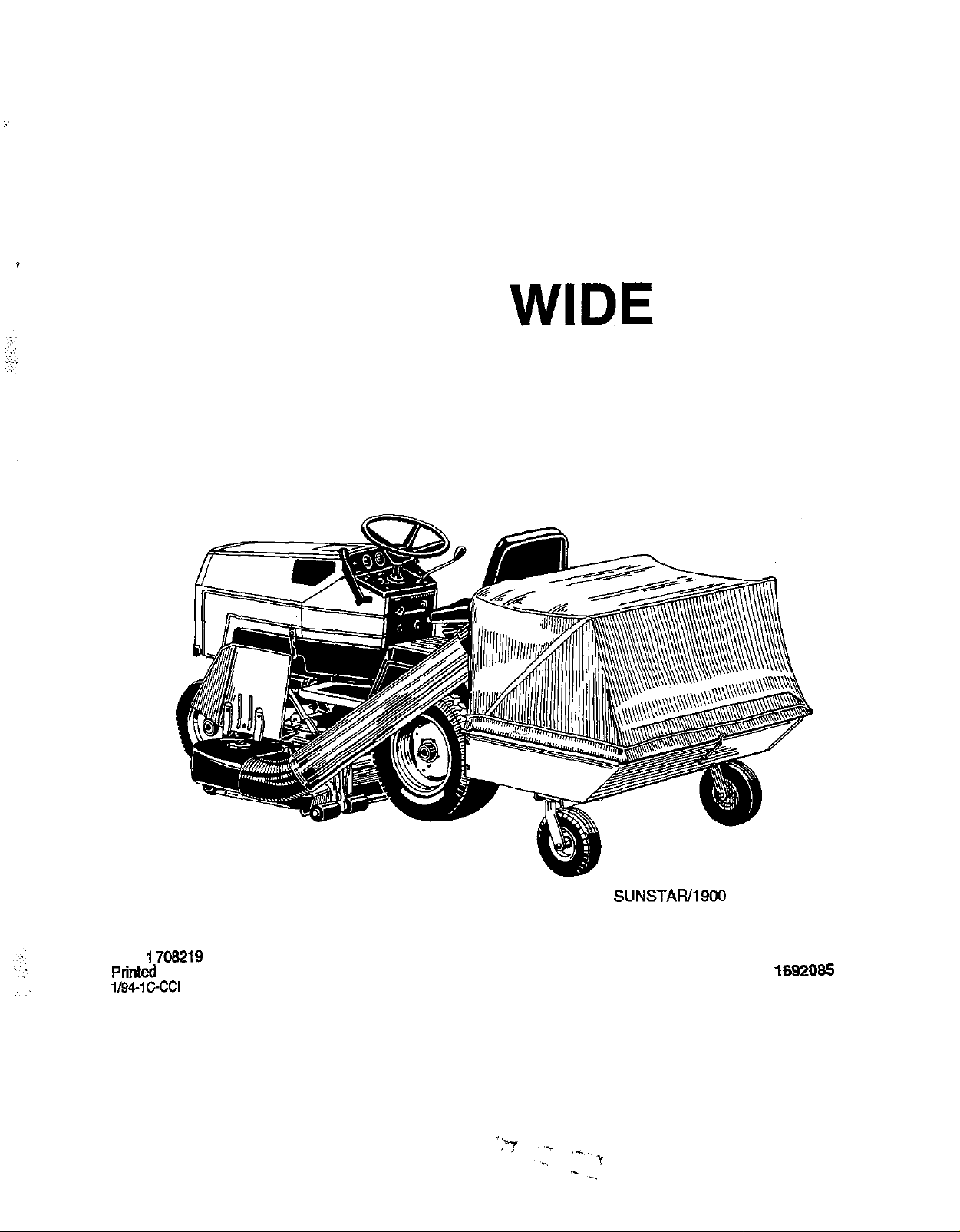

Page 1

OPERATOR’S

MANUAL

CART COLLECTOR

Dual Wheel Cart For Use With

Turbo Collection System

Form

708219

SERIES CART

SOVEREIGN/900 SERIES CART

MFG. NO. 1691526

LANDLORD/1700 SERIES CART

MFG. NO.

Page 2

,..

::

Page 3

Table of Contents

Page

Standard Fastener Identification

Decals

Specifications

Decals

.......................................................................................................................................

...........................................................................................................................

........................................................................................................................................

Illustrations and Parts Lists

Cart and Cover Assembly

Hitch and Tube Assembly

Hitch and Tube Assembly

Hitch Assembly

Safety Rules

Sovereign/900 Series..

..............................................................................................................................

Chart..

.................................................................................................. 2-3

.......................................................................................................

Landlord0700 Series..

Carl Assembly...........................................................................................................................

Cover Assembly

........................................................................................................................

Hitch Assembly .........................................................................................................................

Series

(Mfg.

Landlord11700 Series (Mfg.

1691526).

No.

No. 1692086).

Sovereign1900 Series (Mfg. No. 1691526).

Discharge Tube Installation..

...................................................................................................

Landlord0 700 Series (Mfg. No. 1692085).

Series (Mfg. No. 1691526).

Sovereign1900 Series (Mfg.

Connecting Cart to Tractor

Maintenance

Cover ...................................................................................................................................

Wheels

Tires

Operation

Before

Operation

............................................................................................................................

.................................................................................................................................

.....................................................................................................................................

................................................................................................................................

Operation

..................................................................................................................

.............................................................................................................................

Dumping Grass and Leaves

Operating

Reinstallation

Without

After

Collection System’

Removal

Torque Specifications Chart

No. 1691526).

....................................................................................................

................................................................................................

................................................................................................

......................

..................................................... inside Front Cover

Series

..................................................................

...............................................................

...............................................................................

..............................................................................

.............................................................................

.............................................................................

.............................................................................

............................................................................

...........................................................................

..................................................................................

_l~.

.........................................

Inside Rear Cover

2

3

3

3

4

5

6

8

8

8

8

9

9

10

10

10

11

11

11

11

11

11

11

11

12

12

Decals

NOTE: To clean clear mid-tube on Deluxe Grass

Catcher wash with warm water and mild soap or

use abrasive. alkaline, or petroleum based cleaners.

Overall Length

Width

Height

usea

........................................................................................................................

................................................................................................................................. 46 in.

.........................

.......................................................................................

Inside Box Length ..................................................................................................

Width

Height

Box Capacity

Weight Capacity

Grass Capacity

Pneumatic Tire Size .....................................

.................................................................................................................................

..................................................................................................................................

.......................................................................................................................

................................................................................................................

.............................................................................................................

1

MAX. CAPACITY 400 LBS.

.........

.............. 31 in.

...

........................................ 41 O/350 x

...

.

17 bushels

42 in.

41.4

in.

7 in.

5 cu. ft.

400 Ibs.

4

Page 4

Series

1

Tube Assy.

2

Nut, Hex Full, Lock, #lo-32

3

Washer, Plain,

4

Screw. Phillips, Truss Head,

5

6

Clamp,

7

Decal, Cleaning Inst.

Capscrew, Hex Hd.,

9

10

11

13

14

15

16

17

18

Lo&washer, 7/16

Nut, Hex, Full, 7/16

Nut, Hex, Full, l/2-13

Lo&washer,

Bracket, Hitch (Frame)

Nut. Hex. Full.

Bracket, Hitch (Cart)

Capscrew, Hex Hd., 5/8-l 1 x

C. Hitch Assembly

Ref. No. 38)

0

Hex, 1/2-13x

Sovereign/900 Series

1

4

4

4

1

1

1

4

2

2

2

2

2

2

NOTE: For Sovereign/s00 Series tractors, use tube assembly,

parts 1-7 as shown above. The hitch assembly is packaged

assembly, parts

Blower, Mfg. No.

shown above.

Do not use the hitch

Item Description

1

Locknut. Hex Hd.. l/2-13

2

Hitch, &Bracket

3

Washer, Flat, 1/2x 1 x 9/64

4 Clip, Safety

5

Pin, Clevis,

6

Bracket, Support

7 Carmrew, Hex Hd., 1/2-13x l-112

6 x l-314 2

2

1

3

1

1

2

Mfg. No. 1692257

with Turbo

9

10

Clip, Spring,

Pin, Clevis, 1/2x

x 9/16

D. Hitch and Tube Assembly

Item

10

11

12

1

2

3

4

7

9

Description

Clip, Spring

Lower Tube Assy.

Middle Tube

Upper Tube

Carriage Bolt, 1/4-20x

Nut, Hex, Flange, Lock, l/4-20

Screw, Truss Hd., 10-32x

Washer, Flat,

Nut-Hex Washer Assembly, 1032

Hitch, U-Bracket

Nut, Hex, Lock, l/2-13

Capscrew, Hex Hd., 1/2-13x

Landlord11700 Series

1

1

1

2

6

12

6

1

2

2

Page 5

Cart Assembly

NOTE: Sort out the hardware and arrange by size and

type. Refer to figure 1.

1. Install the wheel assemblies (A, figure 2) to the

frame (B). Place the head of the

end of the frame. Align the holes and place four

16 x 1 hex bolts up through the frame and head of

the swivel. Secure with four flat washers (13/32 I.D.,

wheel on the

3. Turn box upside down and install the frame to the U-

bracket (figure 4). Align the two prong end (A) in the

frame with the ends of the U-bracket and secure with

two

overtighten the locknuts, since the box pivots at this

point for dumping.

A. Prong End

Figure 2

A. Wheel Assembly

2. Install the U-bracket (A, figure 3) to the bottom of the

box (B). Place the three

head bolts and three flat washers (1 l/32 I.D., 3/4

O.D.) through the inside of the box and the U-bracket. Secure with three

x

slotted truss

lo&washers and nuts.

NOTE: The latch handle (A, figure 5) is located on the

right hand side on cart, Mfg. No. 169 1526 and on the left

hand side on cart, Mfg. No. 1692085.

4. Turn box with frame upright and install the latch handle (A, figure 5) and two lii handles (B) as follows:

a. Latch Handle: Place one 5116-18 x 1 hex bolt with

Next place a

outside of the box, the latch handle, a

washer, a

jam nut. Tighten the nuts so that when the latch

handle turns the bolt and nut will not turn. (Be

sure the cups of the spring washers are facing

toward the box surface on both sides.)

b. Lii Handles: Install the two

side of the box. Place two l/4-20

truss head

the Iii handle. Secure with two

and nuts.

flat washer over the bolt on the

flat

spring washer and a

handles on the out-

through the inside of the box and

nut and

slotted

lo&washers

Figure 3

A. U-Bracket

B. Box

B.

5

Page 6

6. Install the sleeve clamp (C, figure 11) to the connecting sleeve (A) with

screw (D) and

sleeve inside the collar of the cover and position

sleeve clamp (C) over the support tube (B).

Figure 11

A. Connecting Sleeve

B. Support Tube

C. Sleeve Clamp

7. Thread the straight rod (A, figure 12) which has an

eyelet on each end through the sleeve at the front of

the cover.

x

slotted truss head

D. Truss Head Screw,

E.

Nut

A. Straight Rod

Figure 13

B. Cord Loop

C. Bolt

Figure 12

A.

Straight Rod

8. Pinch the black cord loop (B, figure 13) and thread

through the eyelet on each end of the rod. Next, pull’

the loop over the top bolt (C) on each side of the

box. The rod gives added support to the cover at the

front of the box.

9. Inside the cover at the front, there is a long tab with

an eyelet on the end. Pull this tab over the top of the

support tube (A, figure 14) and back under the sup

port tube before threading it through the slot in the

cover. This locking tab (B) secures the cover to the

support tube when the cover assembly is locked into

the open position for dumping.

Figure 14

A. Support Tubes B. Locking Tab

10. Install the six inch rubber strap (A, figure 15)

back of the box. Hook the strap over the metal loop

(B) on the frame rod, which protrudes through the

cover. Close the hook with a pair of pliers. Hook the

other end of the strap over the door lock (C) on the

Figure 15

A. Metal

B. Rubber Strap

Loop

the

7

Page 7

Discharge Tube Installation

Landlord/1700 Series (Mfg. No. 1692095)

Install the spring clip (D, figure 18) with two 10-32 x

truss head screws (E), four flat washers (F), and

two locknuts (G).

2. Install

turbo housing. Secure with

3. Position the lower tube (C) onto turbo housing and

hook inside spring clip onto flange locknut (I,

installed in step 2). Mark hole location on opposite

side of turbo housing for outer spring clip.

4. Remove lower tube and drill 9/32 hole in turbo

ing and install

hole. Secure with

x

carriage bolt (H) through hole in

flange locknut (I).

x 5/8 carriage bolt (H) through

flange locknut (1).

5. Assemble the upper tube (A) onto middle tube (B) as

shown in figure 2 with two 1032

screws (E), four flat washers (F), and two locknuts

6. Install two

flat washers (F), and two locknuts (G) to the top

holes in the lower tube (C). Leave hardware loose.

7. Install upper tubes (A and B) to lower tube (C) and

tighten hardware.

8. Install tube assembly into cart sleeve and onto turbo

housing. Hook spring clips (D) onto flange locknuts

installed on turbo housing.

truss head

Figure 18

A. Upper Tube

B. Middle Tube

Lower Tube

D. Spring Clip

E.

F. Washer

G. Locknut, 10-32

H. Carriage Bolt, 1/4-20x

I. flange Locknut, l/4-20

x

Page 8

Maintenance

The cart cover

tion. Check the cover frequently. Use an

Cover

The cover can be rinsed with a hose when dirty. A dirty

cover will inhibit the fast flow of grass clippings into the

cover. Do not leave grass or leaves in the cart for a long

period of time.

Wheels

Lubricate the wheel assembly before using the cart and

as necessary thereafter. A grease fitting is located at

swivel base. Use SAE multi-purpose type grease.

Tires

The tire pressure should be 30 psi.

subject to wear and

Operation

Grass should be cut often, and not too short. If grass is

too long or lush it may be necessary to keep ground

speed to a minimum or to cut only half the width to prevent clogging. If grass is high, operate with mower in

high cutting position. Cut the grass again in lower cutting

position, if desired.

The collector is full when grass builds at the window.

Always operate with throttle at full speed.

Dumping Grass and Leaves

Back the tractor to the desired place for unloading.

2. Unhook the strap from the door lock and raise the

Shut the tractor’s engine off before getting off the

tractor’s seat.

cover assembly to the open position. Lock the cover

in place by hooking the strap to the locking tab in

place by hooking the strap to the locking tab (figure

21). Also see figure 22.

Figure 21

Weight limit in cart is 400 Ibs.

Operation

Before Operation

Clear the lawn of all sticks, stones, wire and other debris

which may be caught or thrown by the mower blades.

Clean the tube with mild detergent (other products may

damage tube). The flow of grass can be seen through

the tube while mowing.

Check grass condition. If wet, wait until later in the day. If

grass is wet, plugging may occur.

For efficient bagging, air circulation under the mower

deck, through the chute and into the bag is very important. For this reason, you should remove grass and

debris from underside of mower deck, discharge chute

and cover.

The blower, tube and elbow can be removed for clean-“7

ing.

Figure 22

3. Move the latch handle to the unlock position and

4. If bagging the grass clippings is desired, the grass

, plastic lawn bag. Also, the grass can be dumped

dump the cart’s box using one of the front lift handles. The connecting

charge chute and the cart’s box will dump at a 90°

angle for quick unloading.

can be pulled from the

11

Page 9

TORQUE SPECIFICATIONS FOR

STANDARD MACHINE HARDWARE

TOLERANCE

SIZE

8-32

8-36

O-24

1 O-32

318-l 6

6-20

6-18

1-8

l-12

1

8

0

SAE GRADE #2

0

Nm.

19

20 2.3 31 3.5 43 4.9

27

31

66 7.6 8 10.9 12 16.3

76

11

12 16.3 19 25.8 25 34.

20 27.2 30 40.8 45 61.2

23 31.3 35 47.6 50 68.

30 40.8 50 68. 70 95.2

35 47.6 55 74.8 80 108.8

50

55 74.8 90 122.4 120 163.2

65 88.4 110’ 149.6 150 204.

75

90, 122.4 150 204. 220 299.2

100 136. 180 244.8 240 326.4

160

180

140

155 210.8

220

240 326.4

2.1

3.1

3.5 49 5.5 68 7.7

8.6 10 13.6 14 19.

15. 17 23.1 25 34.

68. 75 102. 110 149.6

102. 120 163.2 170 231.2

217.6 260 353.6 386 525.

244.8 300 408. 420 571.2

190.4 400 544. 600 816.

299.2 580 788.8 900 1,224.

SAE GRADE #5 SAE GRADE

Nm.

30 3.4

43 4.9 60 6.8

---

4.6

Nm.

NOTE:

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread

forming screw., sheet metal screws and socket head

setscrews.

2. Recommended seating torqwvalues for locknuts:

a. For prevailing torque locknuts

b. For flange whiilock

of

3. Unle&

torque values must meet this specification.

noted on assembly drawings all

use 65% of arede 5

(and screws)

use 135%

BOLT HEAD MARKING

S.A.E. GRADE:

Loading...

Loading...