Page 1

OPERATOR'S

MANUAL

SW20Series

Walk-BehindMowers

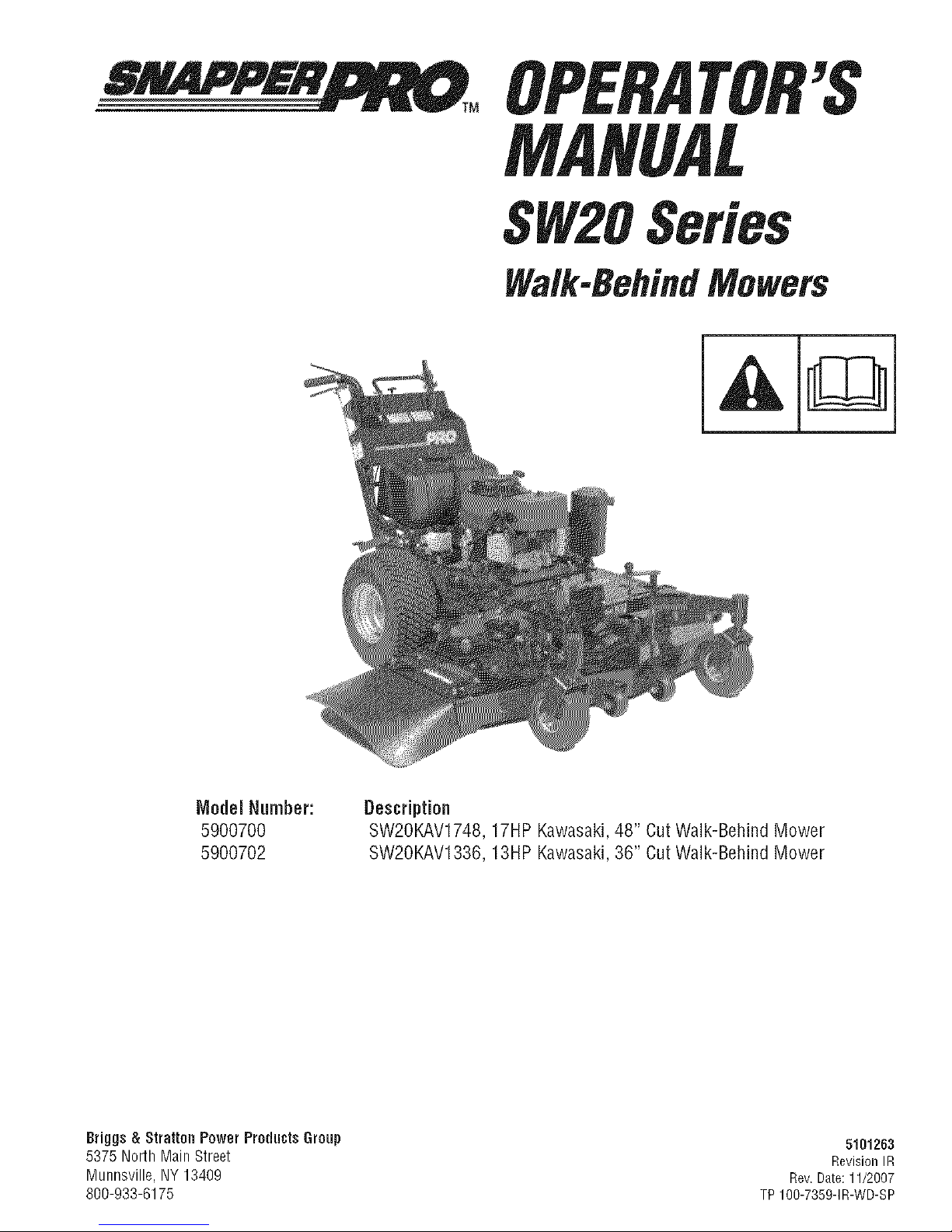

Model Humber:

5900700

5900702

Briggs & Stratton PowerProductsGroup

5375 North Main Street

Munnsville, NY 13409

800-933-6175

Description

SW20KAV1748, 17HP Kawasaki, 48" Cut Walk-Behind Mower

SW20KAV133B, 13HP Kawasaki, 36" Cut Walk-Behind Mower

5101263

RevisionIR

Rev.Date:11/2007

TP100-7359-1R-WD-SP

Page 2

Thankyoufor purchasingthis quality-built SnapperProproduct. We'repleasedthat

you've placedyour confidencein the SnapperProbrand. Whenoperatedand maintained

accordingto the instructions inthis manual,your SnapperProproductwill provide many

yearsof dependableservice.

This manualcontainssafety informationto makeyou awareof the hazardsand

risksassociatedwith this machineand howto avoidthem. Thismachineis designedand

intendedto be usedand maintainedaccordingto the manualandoperatedbytrained

professionalsfor finish cutting of establishedlawnsand is not intendedfor any other

purpose. It is importantthat you readand understandtheseinstructions thoroughly

beforeattemptingto start or operatethis equipment

Unit Model Number

MowerDeck ModelNumber

DealerName

EngineMake EngineModel

EngineType/Spec EngineCode/SerialNumber

SeeFeatures and Controls for the location of Identification Numbers

DATEPURCHASED

Briggs & Stratton PowerProducts Group

Copyright {©2008 Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

TheSnapper Pro logo is atrademark of Briggs & Stratton

Corporation Milwaukee,WI, USA.

Contact Information:

Briggs & Stratton PowerProducts Group

5375 N. MainSt.

Munnsville, NY 13409-4003

(800) 933-6175

www.SnapperPro.com

Unit SERIALNumber

Mower DeckSERIALNumber

DatePurchased

,AI WARNING

The engineexhaustfrom this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

Page 3

Table of Contents

Operator Safety ..................................................... 2

Safety Rulesand Information...........................................2

Safety Decals....................................................................8

Safety InterlockSystem....................................................9

Features& Controls.............................................. 10

IdentificationNumbers...................................................10

Control Functions...........................................................11

Operation ........................................................... 13

General...........................................................................13

Checks Before Starting.................................................. 13

CheckingTire Pressures.................................................14

Pushingthe Unit by Hand...............................................14

Cutting HeightAdjustment..............................................15

Starting the Engine.........................................................17

Stopping the Mower.......................................................17

Driving the Mower..........................................................18

Mowing...........................................................................20

Mowing Recommendations............................................20

Mowing Methods............................................................21

Attaching a Trailer...........................................................22

RegularMaintenance ............................................ 23

MaintenanceSchedule....................................................23

Checking/Adding Fuel.....................................................24

FuelFilter........................................................................24

Oil & FilterChange..........................................................24

Lubrication......................................................................25

Check/Fill Transmission Oil...........................................26

Transmission Oil Filter Change.......................................26

Servicing the Mower Blades...........................................27

NeutralAdjustment .........................................................29

Speed BalancingAdjustment ..........................................29

ParkingBrakeAdjustment ..............................................30

DeckLevelingAdjustment ..............................................31

Mower Belt Replacement................................................32

Transmission Drive Belt Replacement............................34

ReverseSpeedControl LeversAdjustment ....................35

Storage...........................................................................36

Starting After Long Term Storage...................................36

Troubleshooting................................................... 37

Troubleshootingthe Mower............................................37

Troubleshootingthe Mower Deck...................................38

Troubleshooting Common Cutting Problems..................39

Specifications ...................................................... 40

Slope identification Guide....................................... 41

NOTE,"In this manual, "left" and "rigtit" are referred to as seen

from the operating position.

Page 4

$a{etyRules& Ifl{ormUofl

Readthe Manual

OperatingSafety

Congratulations on purchasing a superior-quality pieceof lawn and

garden equipment. Our products are designed and manufactured to meet

or exceedall industry standardsfor safety.

Do not operatethis machine unless you have beentrained. Readingand

understanding this operator's manual is a way to train yourself.

Power equipment is only as safe asthe operator. If it is misused, or not

properly maintained, it can be dangerous! Remember,you are

responsible for your safety and that of those aroundyou.

Use common sense,and think through what you are doing. If you are

not sure that the task you are about to perform can be safely done with

the equipment you havechosen ask a professional: contact your local

authorized dealer.

Theoperator's manualcontains important safety information

you needto be awareof BEFOREyou operateyour unit as

well as DURINGoperation.

Safeoperatingtechniques, an explanation of the product's

features andcontrols, and maintenanceinformation is

included to helpyou get the most out of your equipment

investment.

Be sure to completely readthe Safety Rulesand Information

found on the following pages. Also completely readthe

Operationsection.

Children

Tragic accidents can occur with children. Do not

allowthem anywherenear the areaof operation.

Childrenare often attractedto the unit and mowing

activity. Neverassumethat children will remain

where you last sawthem. If there is a risk that

children may enterthe areawhere you are mowing,

haveanother responsibleadult watch them.

2 www.SnapperPro.com

Page 5

2O

5.4

Thrown Objects

SafetyRules& Iflformatiofl

Slope Operation

You could be seriously injured if you usethis unit on too steep of aslope.

Usingthe unit on a slope that is too steep whereyou do not haveadequate

footing and unit traction (and control) can cause you to lose control and

possibly slip andfall or roll the unit over.

Always mow across slopes, not up and down (you could slip and fall.)

You should not operate on a slope greaterthan a 5.4 foot rise overa 20

foot length (15 degrees).

Also, notethat the surface you are on can greatly impact your ability to

safely operatethis machine. Wet grass or soft soil can seriously affect your

footing and traction of the unit. Do not operateon slopesthat are slippery,

wet, or havesoft soil.

Thisunit has spinning mower blades. Thesebladescar/pick up and throw

debris that could seriously injure a bystander. Be sureto clean up tile areato

be mowed and remove objects that could bethrown by the blade BEFOREyou

start mowing.

Do not operatethis unit without the entiregrass catcher or discharge guard

(deflector) in place.

Also, do not allow anyone in the areawhile the unit is running! If someone

does enterthe area.shut the unit off immediately until they leave.

This equipment has many moving parts that can injure you or

someone else. However,if you stay in the operator zone(area

behind the handlesand controls), and follow the safety rules in

this operator's manual,the unit is safeto operate.

The mower deck hasspinning mower bladesthat canamputate

hands and feet, Do not allow anyonenear the unit while it is

running! Keepsafetydevices (guards, shields, and switches) in

placeand working.

Tohelp you, the operator, usethis equipment safely, it is

equippedwith an operator-presentsafety system. Do NOT

attempt to alter or bypass the system. Seeyour dealer

immediately if the system does not passall the safety interlock

system tests found in this manual.

Moving Parts

Page 6

Sa{etyRules& Ifl{ormUofl

Fueland Maintenance

Always disengageall drives, shutoff the engine and removethe

key beforedoing anycleaning, refueling or servicing.

Gasolineand its vaporsare extremely flammable. Do not smoke

while operating or refueling. Do not add fuel while engine is hot

or running. Allow engine to cool for at least 3 minutes prior to

adding fuel.

Do not addfuel indoors, in an enclosedtrailer, garage or other

enclosed areathat is not well ventilated. Gasolinespills should

be cleaned up promptly and before operation begins.

Gasolineshould be stored only insealedcontainers approvedfor

fuel.

Proper maintenanceis critical to the safety and performance of

your unit. Keepthe unit free of grass, leavesand excessoil. Be

sureto perform the maintenanceprocedures listed in this

manual, especially periodicallytesting the safety system.

EnclosedAreas

Only operatethis unit outdoors and away

from unventilatedareassuch as inside

garagesor enclosedtrailers. Theengine

emits poisonous carbon monoxidegas and

prolonged exposure in an enclosedarea can

result in serious injury or death.

4 www.SnapperPro.com

Page 7

SsfetyRules& information

Readthese safety rules and follow them closely. Failureto obey these rulescould result in loss of control of unit,

severe personal injury or death to you, or bystanders, or damageto property or equipment. This mowing deck is

capableof amputating hands and feet and throwin_ Thetriangle _ in text signifies important cautions

or warnings which must be followed.

TRAINING

1. Read,understand,and follow all instructions in the

manualand on the unit before starting. If the

operator e or mechanic s can not readEnglishit is the

ownersresponsb tytoexpanthsmatera to them.

2. Becomefamiliar with the safeoperation of the

equipment, operator controls, and safety signs.

3. All operators and mechanics should betrained. The

owner is responsiblefor training the users.

4. Only allow responsible adults,who are familiar with the

instructions, to operate the unit.

5. Neverlet children or untrained people operateor service

the equipment. Localregulations may restrict the age of

the operator.

6. The owner/user can preventand is responsible for

accidents or injuries occurring to themselves,other

people or property.

7. Dataindicatesthat operators, age60 years and above,

are involved in a large percentageof riding mower-

relatedinjuries. Theseoperators should evaluatetheir

ability to operate the riding mower safelyenough to

protect themselvesand others from serious injury.

PREPARATION

1. Evaluatethe terrain to determinewhat accessoriesand

attachments are neededto properly and safely perform

the job. Use only accessoriesand attachments

approved by the manufacturer.

2. Wear appropriate clothing including safety shoes, safety

glassesand ear protection. Long hair,loose clothing or

jewelry may get tangled in moving parts.

3. Inspect the areawhere the equipment isto beusedand

removeall objects such as rocks, toys and wire, which

can be thrown by the machine.

4. Useextra carewhen handling gasoline and other fuels.

They are flammable and vapors areexplosive.

a) Useonly an approvedcontainer.

b) Neverremove fuel cap or add fuel with the engine

running. Allow engineto cool before refueling. Do

not smoke.

c) Neverrefuel or drainthe machine indoors.

5. Checkthat operator's presencecontrols, safety switches

and shields are attached and functioning properly. Do

not operate unlessthe _are functioning properly.

OPERATION

1. Neverrun an engine In an enclosed area.

2. Mow only in the daylight or with good artificial light,

keepingawayfrom holes and hidden hazards.

3. Besure all drives are in neutral and parking brakeis

engaged before starting engine. Only start engine from

the operator's position. Useseat belts if provided.

4. Besure of your footing while using pedestriancontrolled

equipment, especiallywhen backing up. Walk,don't

run. Reducedfooting could causeslipping.

5. Slow down and use extra careon hillsides. Besure to

travel in the recommendeddirection on hillsides. Turf

conditions can affect the machinesstability. Usecaution

when operating neardrop-offs.

6. Do not mow in reverse unless absolutely necessary.

Always look down and behind beforeand while traveling

in reverse.

7. Beawareof the mower discharge direction and do not

point it at anyone. Do not operatethe mower without

either the entire grass catcheror the deflector in place.

8. Slow down and use caution when makingturns and

when changing directions on slopes.

9. Neverraise deckwith the blades running.

10. Neverleavea running unit unattended. Always

disengagethe PTO,set parking brake,stop engine,and

remove keys before dismounting. Keephandsand feet

away from the cutting units.

11. Turn off the PTOswitch to disengagethe bladeswhen

not mowing.

12. Neveroperatewith guards not securely in place. Be

sure all interlocks are attached,adjusted properly and

functioning properly.

13. Neveroperatewith the dischargedeflector raised,

removed or altered, unless using a grass catcher.

14. Do not changethe engine governor setting or overspeed

the engine.

15. Stop on levelground, lower implements, disengage

drives, engageparking brake, shut off engine before

leavingthe operator's positionfor anyreason including

emptying the grass catchers or unclogging the chute.

16. Stop equipment and inspect bladesafter striking objects

or abnormalvibration occurs. Make necessaryrepairs

before resuming operations.

17. Keephandsand feet awayfrom the cutting units.

18. Look behind and down before backing up to be sure of a

clear path.

19. Nevercarry passengersand keeppets and bystanders

away.

20. Do not operatethe unit while underthe influenceof

alcohol or drugs.

21. Slow down and usecaution when makingturns and

crossing roads and sidewalks. Stop blades if not

mowing.

22. Usecare when loading or unloading the machine into a

trailer or truck.

23. Usecare when approaching blind corners, shrubs, trees

or other objects that mayobscure vision.

24. To reducefire hazard,keepunit free of grass, leaves&

excess oil. Do not stop or park over dry leaves,grass or

combustible materials.

25. The enginein this unit is not factory equippedwith a

Page 8

SafetyRules& information

spark arrester. It is a violation of California Public

ResourceCode Section 4442 to useor operatethe

engine on or near any forest-covered, brush-covered, or

grass-covered land unless the exhaustsystem is

equipped with a spark attester meeting any applicable

local or state laws. Otherstates or federal area may

havesimilar laws.

26. OSHAregulations may require the use of hearing

protection when exposedto sound levels greaterthan 85

dBA for an 8 hour time period.

tLCAUTION

excess of 85 dBAat the operator's ear and

Thismachine produces sound levels in

cancausehearing lossthoughextended

periods of exposure.

Wear hearingprotection when operating this machine.

SLOPEOPERATION

Slopesare a majorfactor relatedto loss-of-control and tip-

overaccidents,which can result in severeinjury or death.All

slopes requireextra caution. If you cannotbackupthe slope

or if youfeel uneasyon it, do not driveon it.

, WARNING

Never operate on slopes greater than 15° which isa

rise of 5.4 feet (165 cm) vertically in 20 feet (607 cm)

horizontally.

Select slew ground speed before driving ontoslope.

Useextra cautionwhen operating on slopes with rear-

mounted grass catchers.

l/low across the face of slopes, not up and down, use

caution when changingdirections and DONOTSTART

ORSTOPONSLOPE.

Do

1, Mow across slopes, not up and down.

2. Remove obstaclessuch as rocks, tree limbs, etc.

3. Watch for holes, ruts, or bumps. Uneventerrain could

overturn the unit. Tallgrass can hide obstacles.

4. Useslow speed. Choosea slow speed so that you will

not haveto stop or changespeedwhile on the slope.

5. Useextra carewith grass catchers or other attachments.

Thesecan change the stability of the unit.

6. Keepall movement on the slopes slow and gradual. Do

not make suddenchanges in speedor direction.

7. Seeyour authorized dealerfor recommendations of

availableweights to improve stability.

Do Not

1. Avoid starting, stopping, or turning on a slope. If tires

losetraction (i.e. machine stops forward motion on a

slope), disengagethe blade(s) (PTO)and drive slow off

the slope.

2. Do not turn on slopes unless necessary,and then, turn

slowly.

3. Do not mow near drop-offs, ditches, or embankments.

The operator could losefooting or balanceor mower

could suddenly turn over if awheel is overthe edgeof a

cliff or ditch, or if an edge cavesin.

4. Do not mow on wet grass. Reducedfooting or traction

could causesliding.

5. Do not try to stabilizethe unit by putting your foot on

the ground. (ride-on units)

6. Do not mow excessivelysteep slopes.

7. Do not use grass catcher on steep slopes.

TOWEDEQUIPMENT(RIDE-ONUNITS)

1. Tow only with a machinethat hasa hitch designedfor

towing. Do not attach towed equipment except atthe

hitch point.

2. Follow the manufacturer's recommendations for weight

limit for towed equipment and towing on slopes. See

attaching a trailer under OPERATION.

3. Neverallow children or others in or on towed

equipment,

4. Onslopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travelslowly and allow extra distanceto stop.

6. Do not shift to neutral and coast down hill.

CHILDREN

Tragicaccidentscanoccur if the operatoris not alert to the

presenceof children.Children areoften attractedto the unit

andthe mowing activity. Neverassumethat childrenwill

remainwhereyou lastsawthem.

1. Keepchildren out of the mowing areaand under the

watchful care of another responsible adult.

2. Bealert and turn unit off if children enter the area.

3. Before and during reverseoperation, look behind and

down for small children.

4. Neverallow children to operate the unit,

5. Useextra carewhen approaching blind corners, shrubs.

trees, or other objectsthat may obscure vision.

EMISSIONS

1. Engineexhaustfrom tHs product contains chemicals

known, in certain quantities, to cause cancer,birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Periodand Air

Index information onthe engine emissions label.

6 www.SnapperPro.com

iGNiTiON SYSTEM (GASOLINE MODELS)

1. ThissparkignitionsystemcomplieswithCanadian

ICES-O02.

Page 9

SafetyRules& Iflformtiofl

SERVICEAND MAINTENANCE

Toavoid personal injuryor property damaqe, use extreme

care in handling gasoline. Gasolineis extremely flammable

and the vaporsare explosive.

Safe Handling ofGasoline

1. Extinguish all cigarettes,cigars, pipes, and other

sources of ignition.

2. Useonly approvedgasoline containers.

3. Neverremove the gas cap or add fuel with the engine

running. Allow the engineto cool beforerefueling.

4. Neverfuel the machine indoors.

5. Neverstore the machine or fuel containerwhere there is

an open flame, spark, or pilot light such as neara water

heateror other appliance.

6. Neverfill containers insidea vehicle or on a truck bed

with a plastic bed liner. Always placecontainers on the

ground away from your vehicle beforefilling.

7. Removegas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible.

then refuel such equipment on a trailer with a portable

container, ratherthan from a gasoline dispenser nozzle.

8. Keepnozzlein contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzlelock-open device.

9. If fuel is spilled on clothing, changeclothing

immediately.

10. Neverover-fill the fuel tank. Replacegas capand

tighten securely.

11. Useextra care in handling gasoline and other fuels. They

are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine awayfrom the area of spillage and

avoid creating anysource of ignition until fuel vapors

havedissipated.

13. Replaceall fuel tank capsand fuel containercaps

securely.

Maintenance and Storage

1. Always observe safe refueling and fuel handling

practices when refuelingthe unit after transportation or

storage.

2. Always follow the engine manualinstructions for storage

preparations before storing the unit for both short and

long term periods.

3. Always follow the engine manualinstructions for proper

start-up procedureswhen returning the unit to service.

4. Neverstore the machine or fuel container insidewhere

there is an openflame, such as in a water heater. Allow

unit to cool beforestoring.

5. Shut off fuel while storing or transporting. Donot store

fuel near flames ordrain indoors.

6. Keepall hardware,especially blade attachment bolts.

tight and keepall parts in good working condition.

Replaceall worn or damaged decals.

7. Nevertamper with safety devices. Checktheir proper

operation regularly.

8. Disengagedrives, lower implement, set parking brake,

stop engineand remove key or disconnect spark plug

wire. Wait for all movement to stop before adjusting,

cleaning or repairing.

9. Cleangrass and debris from cutting units, drives,

mufflers, and engineto prevent fires. Cleanup oil or

fuel spillage.

10. Let enginecool before storing and do not store near

flame.

11. Stop and inspect the equipment if you strike anobject.

Repair,if necessary,before restarting.

12. Park machine on level ground. Neverallow untrained

personnelto service machine.

13. Usejack stands to support components when required.

14. Carefully releasepressure from components with stored

energy.

15. Disconnect batteryor removespark plug wire before

making any repairs. Disconnectthe negativeterminal

first and the positive last. Reconnectpositive first and

negativelast.

16. Usecare when checking blades. Wrapthe blade(s) or

wear gloves, anduse caution when servicing them.

Onlyreplaceblades. Neverstraighten or weld them.

17. Keephandsand feet awayfrom moving parts. If

possible, do not makeadjustments with the engine

running.

18. Chargebatteries in an open well ventilated area,away

from spark andflames. Unplug charger before

connecting or disconnecting from battery. Wear

protective clothes and useinsulated tools.

19. Grasscatcher components are subject to wear,damage,

and deterioration, which could exposemoving parts or

allow objects to bethrown. Frequentlycheck

components and replacewith manufacturer's

recommendedparts, when necessary.

20. Checkbrake operationfrequently. Adjust and service as

required.

21. Useonly factory authorized replacement parts when

making repairs.

22. Always comply with factory specifications on all settings

and adjustments.

23. Only authorized service locations should beutilized for

major service andrepair requirements.

24. Neverattempt to makemajor repairs on this unit unless

you have been properly trained. Improper service

procedures can result in hazardous operation,

equipment damageand voiding of manufacturer's

warranty.

25. Units with hydraulic pumps, hoses,or motors:

WARNING:Hydraulicfluid escaping under pressure may

havesufficient force to penetrateskin and causeserious

injury. If foreign fluid is injected into the skin it must be

surgically removed within a few hours bya doctor

familiar with this form of injury or gangrenemay result.

Keepbody and hands awayfrom pin holes or nozzles

that eject hydraulic fluid under high pressure. Use paper

or cardboard, and not hands,to searchfor leaks. Make

sure all hydraulic fluid connectionsare tight and all

hydraulic hosesand lines arein good condition before

applying pressureto the system. If leaks occur, have

the unit serviced immediately byyour authorized dealer.

26. WARNING:Storedenergy device. Improper releaseof

springs can result in serious personal injury. Springs

should be removed by anauthorizedtechnician.

Page 10

OperatorSafety

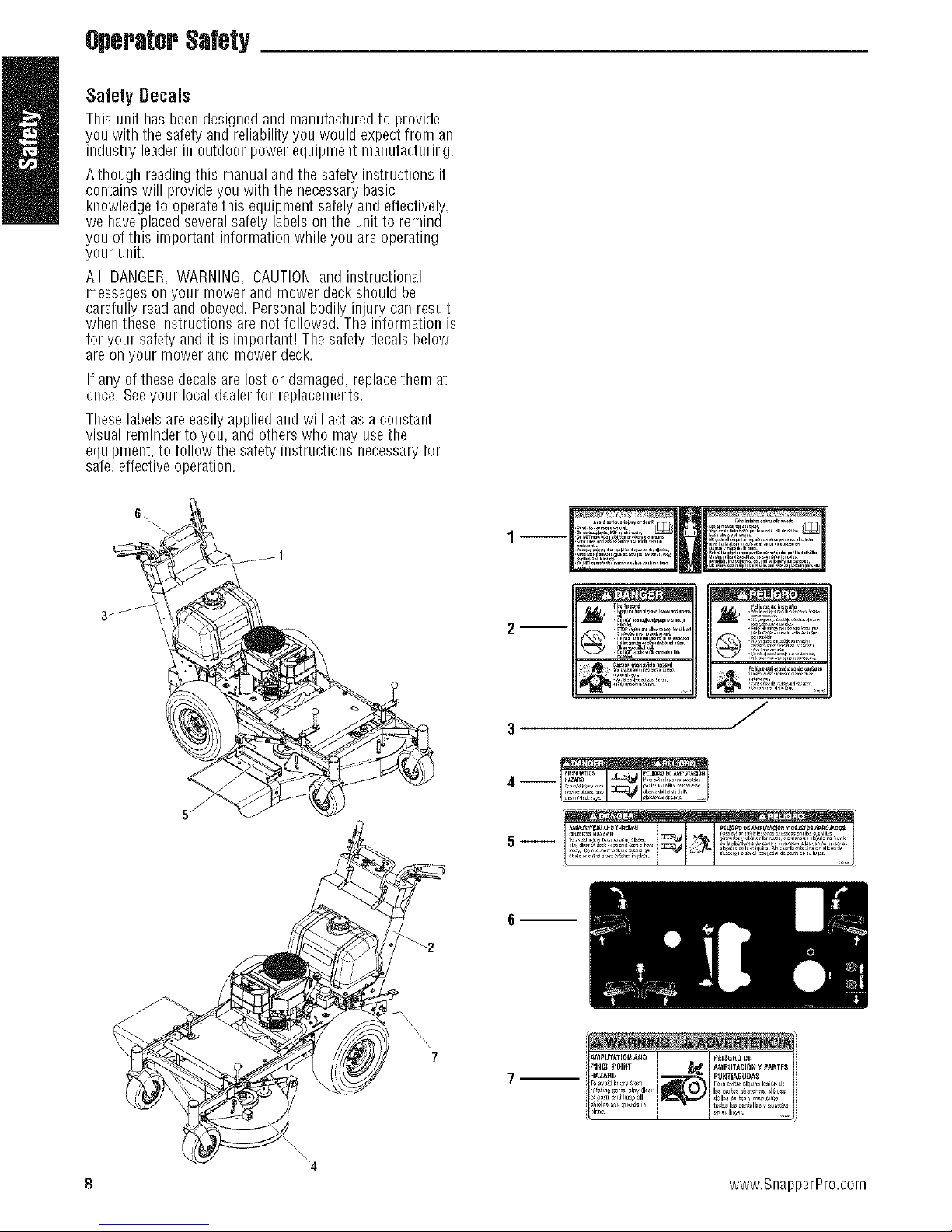

Safety Decals

Thisunithasbeendesignedandmanufacturedto provide

youwiththesafetyandreliabilityyouwouldexpectfrom an

industryleaderin outdoorpowerequipmentmanufacturing.

Although reading this manualand the safety instructions it

contains will provideyou with the necessary basic

knowledge to operatethis equipment safely and effectively,

we haveplaced several safety labelson the unit to remind

you of this important information while you areoperating

your unit.

All DANGER,WARNING, CAUTION and instructional

messageson your mowerand mower deckshould be

carefully read and obeyed. Personal bodily injury can result

whenthese instructions are not followed. The information is

for your safetyand it is important! Thesafety decals below

are on your mower and mower deck.

If any of these decals are lost or damaged, replacethem at

once. Seeyour local dealerfor replacements.

Theselabelsare easilyapplied and will act as a constant

visual reminderto you, and others who may use the

equipment,to follow the safety instructions necessaryfor

safe,effective operation.

J

7

7

\

\\\

4

8 www.SnapperPro.com

Page 11

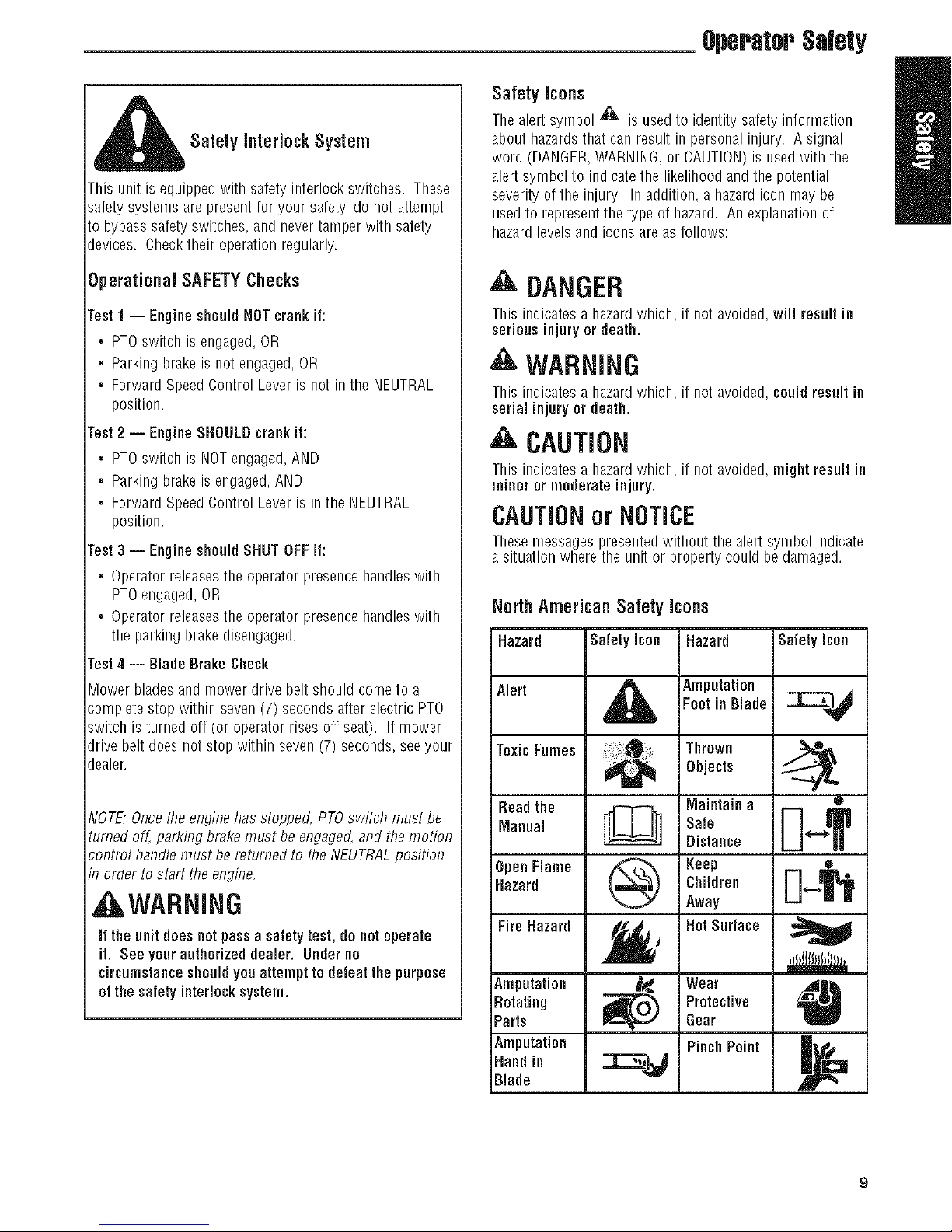

SafetyinterlockSystem

this unit is equipped with safety interlockswitches. These

_afetysystems are presentfor your safety,do not attempt

:o bypasssafety switches, and nevertamper with safety

Jevices. Check their operation regularly.

OperatorSafety

Safety icons

Thealert symbol '_ is used to identity safety information

about hazardsthat can result in personalinjury. A signal

word (DANGER,WARNING,or CAUTION)is used with the

alert symbol to indicatethe likelihood and the potential

severity of the injury. In addition, a hazardicon may be

usedto represent the type of hazard. An explanation of

hazardlevels and icons are asfollows:

Operational SAFETYChecks

rest1 -- Engine shouldNOTcrank if:

,, PTOswitch is engaged,OR

,, Parking brakeis not engaged,OR

,, Forward SpeedControl Leveris not in the NEUTRAL

position.

rest2 -- EngineSHOULDcrankif:

,, PTOswitch is NOTengaged,AND

,, Parking brakeis engaged,AND

,, Forward SpeedControl Leveris inthe NEUTRAL

position.

rest3 -- EngineshouldSHUTOFFif:

', Operatorreleasesthe operator presencebandieswitb

PTOengaged,OR

• Operatorreleasesthe operator presencehandles with

the parking brakedisengaged.

rest4 -- Blade BrakeCheck

_ower blades and mower drive belt should come to a

:;ompletestop within seven (7) seconds after electric PTO

_witchis turned off (or operator rises off seat). If mower

Jrive belt does not stop within seven (7) seconds, see your

Jealer.

DANGER

This indicatesa hazardwhich, if not avoided, will result in

serious injuryor death.

WARNING

This indicatesa hazardwhich, if not avoided, could result in

serial injury or death.

CAUTION

This indicatesa hazardwhich, if not avoided, might result in

minor or moderate injury.

CAUTIONor NOTICE

Thesemessages presentedwithout tbe alert symbol indicate

a situation wherethe unit or property could be damaged.

NorthAmerican Safety Icons

Hazard Safety icon Hazard Safety icon

Alert _ Amputation _---"1_

ToxicFumes _ ThrOwnObjects

Footin Blade

_IOTE:Oncethe enginehas stopped, PTOswitch must be

turned off, parking brake must be engaged,and themotion

:ontml handlemust be returned to the NEUTRALposition

_norder to start the engine,

, WARNING

if the unit does notpassa safety test, do notoperate

it. See your authorized dealer. Underno

circumstanceshouldyou attempt to defeat the purpose

of the safety interlocksystem.

Read the Maintain a •

Manual [[_ Safe _ _"">T

Hazard Children

OpenFlame @ Keep [_ ,_,_

Fire Hazard _,_ BatSurface _

Rotating Protective

Amputation _) Wear

Parts Gear

AmputatiOnHandin _r_%'_ PinchPoint I_11

Blade A

Distance

Away

,JI_IIII_IN}I)_,

9

Page 12

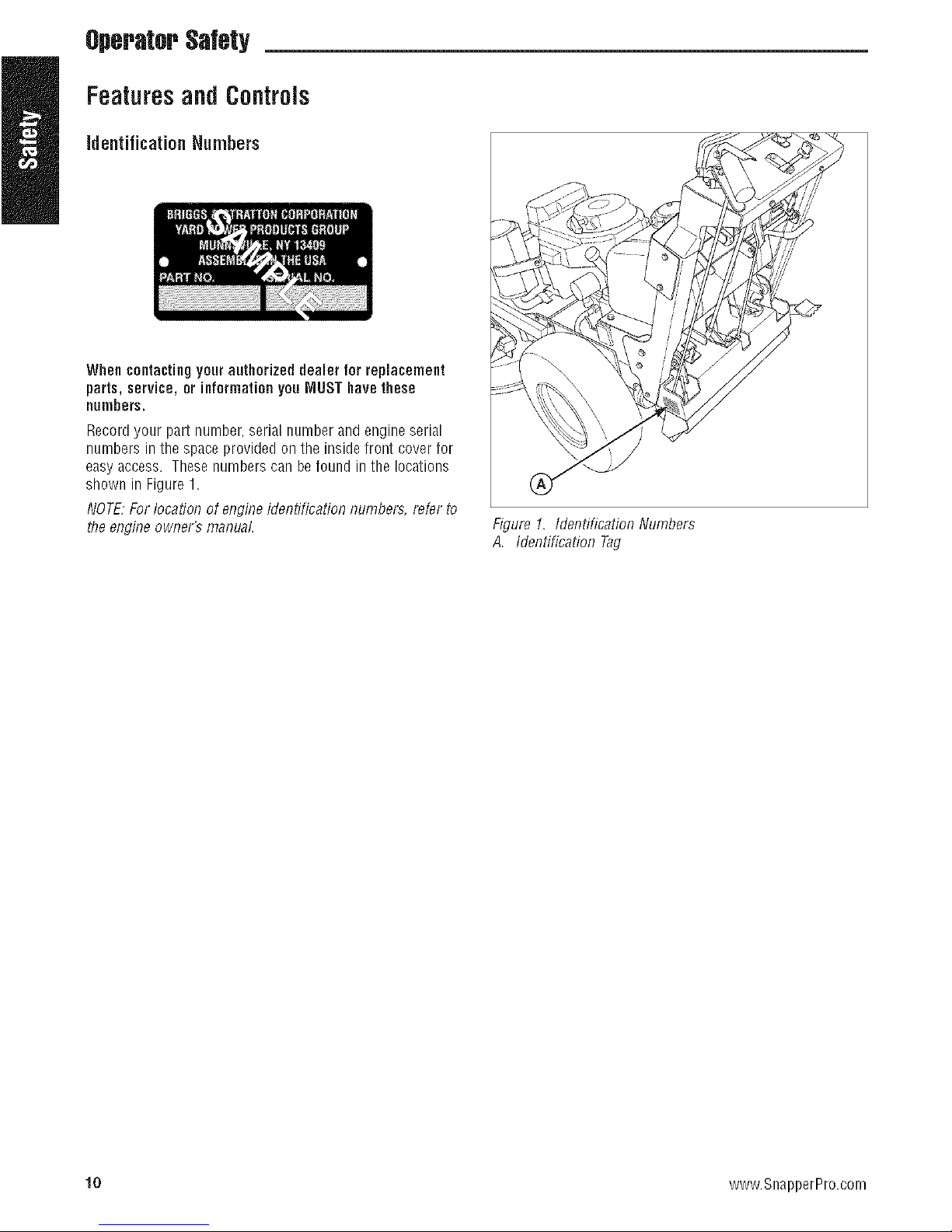

OperatorSafety

Featuresand Controls

Identification N.rnbers

Whencontactingyourauthorized dealer for replacement

parts, service, or informationyou MUSThavethese

numbers.

Recordyour part number, serial number andengine serial

numbers in the space provided on the inside front cover for

easyaccess. Thesenumbers can befound in the locations

shown in Figure1.

NOTE,Forlocationof engineidentification numbers, refer to

theengine owner's manual.

Figure 1. Identification Numbers

A. Identification Tag

10 www.SnapperPro.com

Page 13

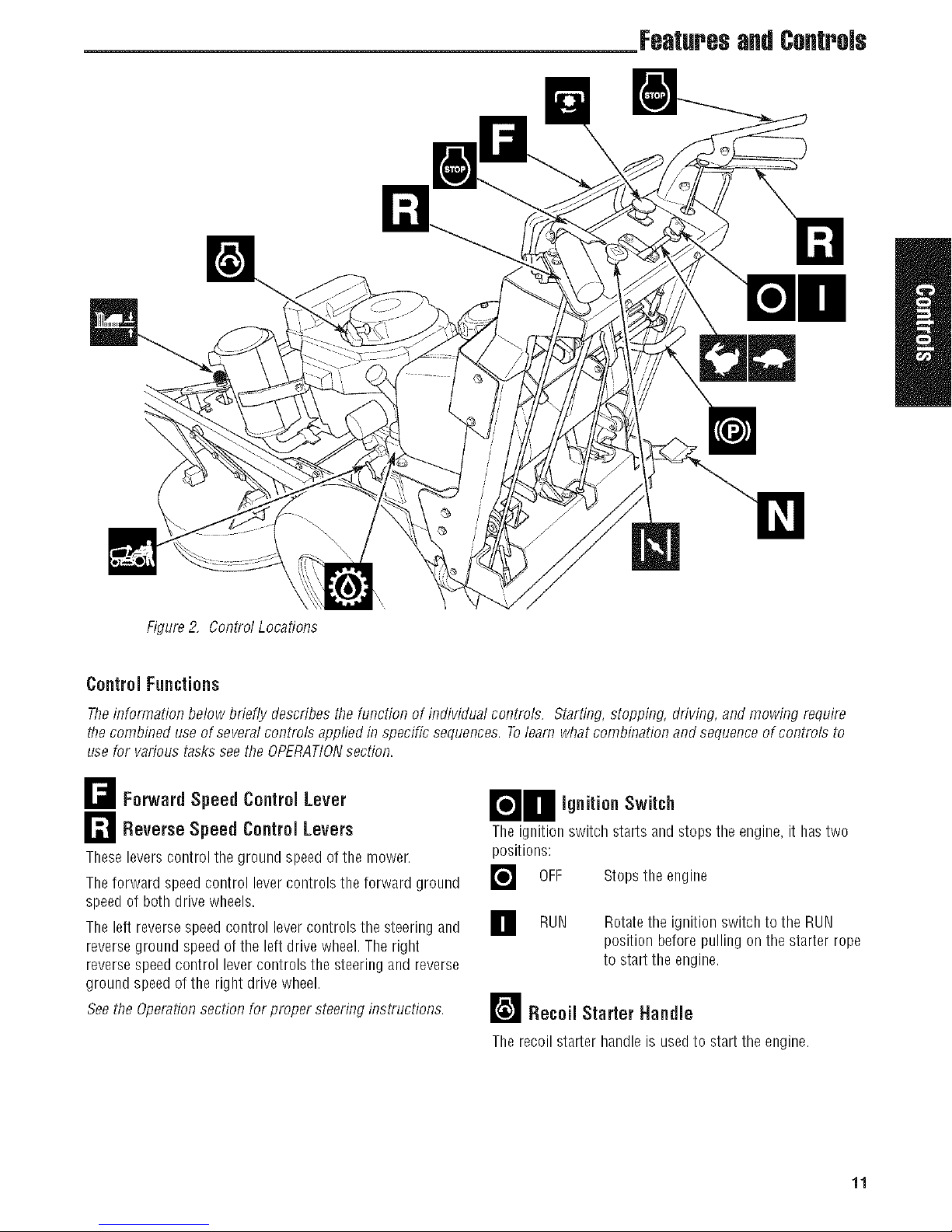

,FeaturesandControls

Figure2, Control Locations

Control Functions

Theinformation below briefly describes the tiJnctionof individual controls. Starting, stopping, driving, and mowing require

thecombined use of several controls applied in specific sequences. Tolearn what combination and sequenceof controls to

usefor various tasks see the OPERATIONsection.

_F_ Forward Speed Control Lever

BO ignition Switch

r--'_ Reverse Speed Control Levers

Theseleverscontrol the groundspeed of the mower,

Theforward speedcontrol levercontrols the forward ground

speedof both drive wheels.

The left reverse speedcontrol levercontrols the steering and

reverse ground speed of the left drive wheel. The right

reverse speed control levercontrols the steering and reverse

ground speedof the right drive wheel.

Seethe Operationsection for proper steering instructions.

The ignition switch starts andstops the engine, it hastwo

positions:

] OFF Stopsthe engine

] RUN Rotatethe ignition switch to the RUN

position before pulling on the starter rope

to start the engine.

r__ Recoil Starter Handle

The recoil starter handle is used to start the engine.

11

Page 14

Features& Centrols

ParkingBrake

DISENGAGE Releasesthe parking brake.

[ ENGAGE

Pullthe parking brake handleup to engagethe parking

brake. Pushthe parking brakehandle down to disengage

the parking brake. NOTE,Tostart the unit the parking brake

must be engaged.

Locks the parking brake.

[PTO (Power TakeOff) Switch

The PTOswitch engagesand disengagesthe mower. Pull UP

on the switch to engage,and push DOWNto disengage.

r_ Neutral Return Pedal

The neutralreturn pedal provides a hands-free return to

neutral. The pedal is used in conjunction with the Reverse

SpeedControl Leversto properly stop the machine.

Seethe Operationsection for Driving Instructions.

Fuel Tank Cap

Toremove the cap, turn counterclockwise.

Engine Kill / Operator Presence Handles

Thesehandlesare a major factor in the safety interlock

system of the mower. Both handlesare tied together so

depressing one handledepressesboth. Theoperator must

depressthe handlesin order to deactivatethe enginekill

system. Handlesmust bedepressed to disengage the

parking brakeand engagethe PTOswitch.

Transmission Release Valves

Thetransmission release leversdeactivatethe transaxle so

that the unit can be pushedby hand. SeePUSHINGTHE

UNIT BY HANDfor operational information.

TransmissionOil Fill

Transmissionoil is addedthrough the transmission oil

reservoirs. It also serves as extra holding capacity for oil as

the transmissions heat upand the oil expands. SeeCHECK

TRANSMISSIONOILfor oil levelcheck andfill procedures.

ThrottleControl

Thethrottle controls the engine speed. Movethe throttle

control forward towards the FASTpositionto increasethe

engine speed and back towards the SLOWposition to

decreasethe enginespeed. Always operate at FULLthrottle.

FAST Speedsup the engine speed.

SLOW Slows down the engine speed.

Cutting HeightAdjustment Handles

Thecutting height adjustment handlescontrol the mower

deck cutting height. To raise the mower deck cutting height

crank the cutting height adjustment handlesclockwise. To

lower the mowerdeck cutting height,crank the cutting

height adjustment handlescounter-clockwise. Toensure an

evencut, both cutting height adjustment handles must be

adjusted to the same height.

[]Choke Control

Closethe chokefor cold starting. Openthe choke oncethe

engine starts. A warm engine may not requirechoking. Pull

the knob UPto close the choke. Pushthe knob DOWNto

open the choke.

12 www.SnapperPro.com

Page 15

Operation

Operatiofl

GeneralOperatingSafety

Beforefirst time operation:

,. Besure to read all information inthe Safetyand

Operationsections before attempting to operatethis

unit.

,. Becomefamiliar with all of the controls and how to stop

the unit.

,. Drive in an open areawithout mowing to become

accustomedto the unit.

_WARNING

Beforeleavingthe operator'sposition for any reason,

engagethe parking brake, disengage the PTO,stopthe

engineand removethe key.

Toreducefire hazard,keepthe engine, unit free of

grass, leaves and excessgrease. Do notstopor park

unit overdry leaves, grass or combustiblematerials.

Gasolineis highlyflammable and must behandled

with care. Never fill the tank when the engineis still

hotfrom recent operation.Donotallow openflame,

smokingor matchesin thearea. Avoid over-fillingand

wipe up any spills.

AWARNING

Never operate on slopesgreater than 15° which is a

rise of 5.4 feet (1,6 m) vertically in 20 feet (607 cm)

horizontally.

Select a slowground speedbefore driving onto a

slope.

Mow across theface of slopes, not up and down, use

cautionwhen changingdirections and DONOTSTART

ORSTOPONSLOPE.

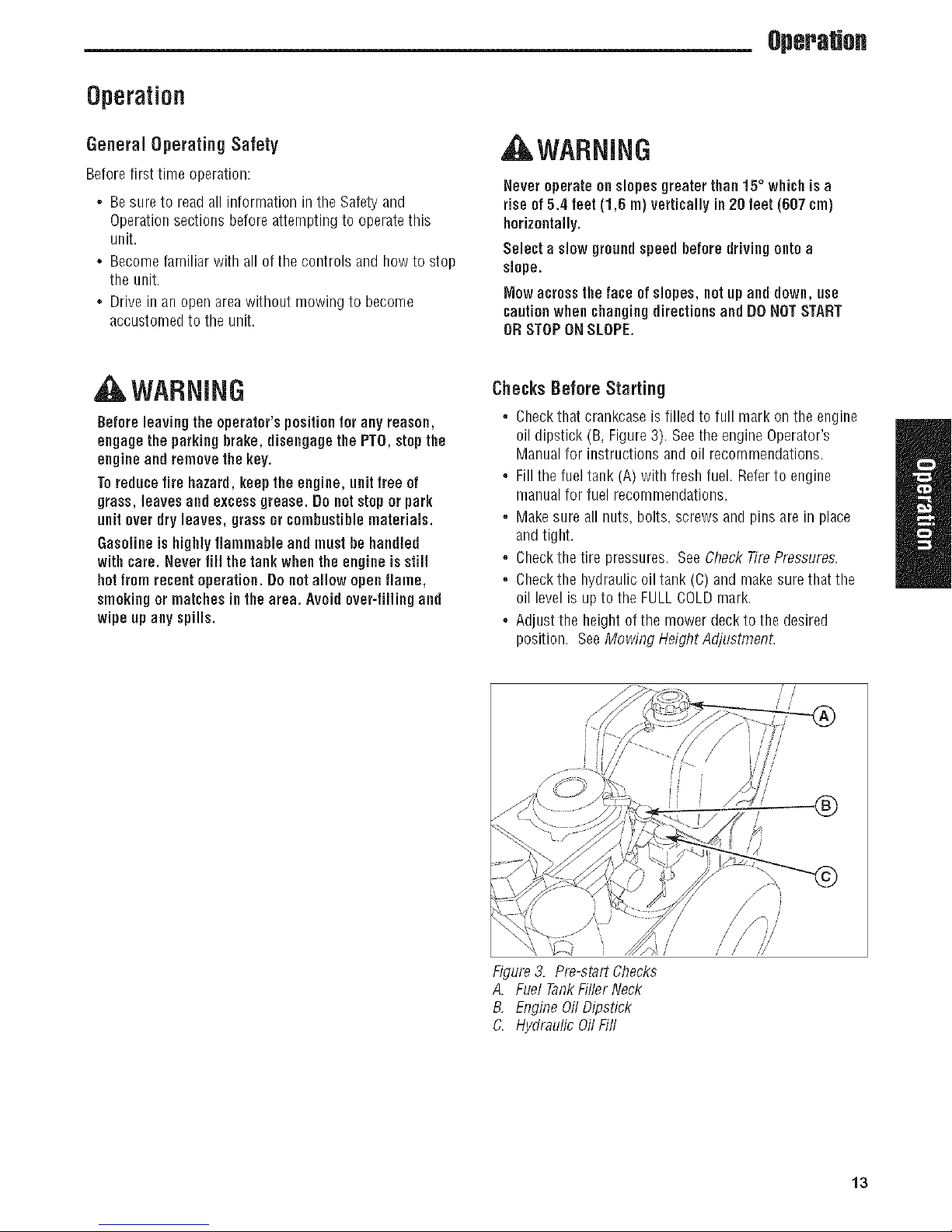

Checks Before Starting

,. Checkthat crankcaseis filled to full mark on the engine

oil dipstick (B, Figure3). Seethe engine Operator's

Manualfor instructions and oil recommendations.

,. Fillthe fuel tank (A) with fresh fuel. Referto engine

manualfor fuel recommendations.

,. Makesure all nuts, bolts, screws andpins are in place

and tight.

,. Checkthe tire pressures. See Check Tire Pressures.

,. Checkthe hydraulic oil tank (C) and make sure that the

oil level is upto the FULLCOLDmark.

,. Adjust the height ofthe mower deck to the desired

position. SeeMowing Height Adjustment,

Figure3. Pro-start Checks

A. Fuel TankFiller Neck

B, Engine Oil Dipstick

C, Hydraufic Oil Fill

13

Page 16

Operation

CheckTire Pressures

Tire pressure should bechecked periodically,and

maintained at the levels shown in the chart. Note that these

pressures may differ slightly from the "Max Inflation"

stamped on the side-wall of the tires. Thepressures shown

provide proper traction, improve cut quality, andextendtire

life.

Tire Pressure

Front 25 psi (1,72 bar)

Rear 15 psi (1,03 bar)

Figure4. CheckingTire Pressure

Pushing the Mower By Hand

NOTICE

DONOTTOW MOWER

Towingthe units will causehydraulic pumpand wheel

motor damage. De nat use another vehicleto pushor

pull this unit.

1. Disengagethe PTO,engagethe parking brake,turn the

ignition OFEand remove the key.

2. Locatethe transmission releaselevers (A, Figure5) by

the rear wheels of the unit.

3. To disengagethe pumps (free-wheel position), pull both

transmission releaselevers back and out sothey lock in

the disengaged(free-wheel) position.

4. Disengagethe parking brake.

The unit can now bepushed by hand.

5. After moving the unit, re-engagethe pumps (drive

position) by pulling the transmission releaselevers

rearwardand inward to releasethem from the

disengaged position andthen allow them to moveto the

engaged (drive) position.

I

t

I

,/

//

/

14 www.SnapperPro.com

J

Figure5. TransmissionReleaseLevers (LH Shown

A. TransmissionReleaseLevers

B, EngagedPosition (Drive Position)

C. DisengagedPosition (Free-WheelPosition)

Page 17

CuttingHeightAdjustment

Thecutting height can be adjusted within two different

ranges. Thelower cutting rangeis adjustable between

1-1/2" (3,8 cm) and2-3/4" (6,9 cm). Theupper cutting

range is adjustable between 2-3/4" (6,9 cm) and 4-1/2"

(11,5 cm).

Beforeadjusting the cutting height, you must first determine

the averagecutting height. Dependingon the rangeyou

plan to use, it may be necessaryto adjust which pulley the

deck drive belt runs in.

ToAdjust the CuttingRange:

1. Removethe mower deck guard (A, Figure6) to gain

access to the mower deck drive belt.

, ,WARNING

Useextremecautionwhen rotating theidler arm with

the breaker bar, due to the increasedtensionin the

spring as the idler arm isbeing rotated, injurymay

result if the breaker bar is prematurely released while

the spring isunder tension.

Operatiofl

Figure 6, Removethe Cutter Deck Guard

A. Cutter DeckGuard

2. Using a 1/2" breakerbar (A, Figure7), placethe square

end in the squarehole locatedon the end of the idler

arm (B). Carefullyrotate the breaker bar CLOCKWISE,

which will relieve the tension on the beltexerted from

the idler arm.

3. Slidethe drive belt over the edge of the Stationary idler

pulley (C). Carefully releasethe tension onthe breaker

bar until the idler arm comes to astop.

4. SeeFigure8. If you are adjusting the cutting height

range between1-1/2" (3,8 cm) and 2-3/4" (6,9 cm)

position the belt in the lower pulley on PTOclutch. If

you areadjusting the cutting height range between2-

3/4" (6,9 cm) and4.5" (11,5 cm) position the belt in the

upper pulley on the PTOclutch.

5. Carefully rotate the breakerbar CLOCKWISEand install

the drive belt on the stationary idler pulley. Carefully

releasethe tension on the breakerbar. The belt should

be routed exactly as shown in figure 9.

6. Reinstall the mower deck guard.

Figure 7. Removethe Cutter Deck Belt

A. BreakerBar

B, Idler Arm

C. Stationary Idler Pulley

15

Page 18

,Operation

ToAdjust the gutting Height:

Thecutting range must be adjusted to the correct range

beforethe cutting height can beadjusted. Thecutting

height indicators will help you identify the cutting height.

1. Pull the cutting height adjustment handle (A, Figure10)

up and out of the handle lock position (B) and crank the

handle CLOCKWISEto raise the deckto the desired

cutting height. Crankthe handle COUNTER-CLOCKWISE

to lower the deck to the desired cutting height. After the

desired cutting heights areachievedposition the cutting

height adjustment handlesinto the handle lock position.

2. Repeatthe processfor the other side of the machine.

NOTE,BoB1sides of the cutter deck must beadjusted to the

same height to insure a proper cut.

Figure 9. Mower DeckBeltRouting

A. Mower Deck Belt

B, Adjustable Idler Pulley

C. Spindle Pulley

D. Stationary Idler Pulley

Figure8. BeltPositioning for Cutting Range

A. Deck DriveBelt Positioned for Lower Cutting Range

B. Deck Drive Belt Positioned for Upper Cutting Range

16 www.SnapperPro.com

Figure 10. Removethe Cutter Deck Guard

A. Cutter Height Adjustment Handle

B, Handle Lock Position

C. Cutting Height Indicator

Page 19

Operation

Starting the Engine

AWARNING

ifyoude netunderstandhow a specificcontrol

functions, or havenotyet thoroughlyreadthe

FEATURES& CONTROLSsection, do so new.

DoNOTattempt to operate the unit without first

becoming familiar with the locationand function ofALL

controls.

1. Engagethe parking brake and make surethat the PTO

switch is disengagedand the forward speedcontrol

leveris in the NEUTRALposition.

2. NOTE:A warm enginemay not require choking.

Setthe enginethrottle control to FULLthrottle position,

Thenfully close the choke by pulling the knob OUTfully.

3. Insert the key into the ignition switch and turn it to RUN.

4. Graspthe recoil starter handle and pull slowly until

resistance is felt and then pull rapidly. (You may haveto

pull severaltimes beforethe engine starts. Ifthe engine

fails to start within a reasonablenumber of attempts,

discontinue and check enginemanual for further

instructions.

Stopping the Mower

1. Gentlysqueezeboth reversespeedcontrol leversevenly

to stop the unit.

2. Oncethe unit is stopped, firmly depressthe neutral

return pedalto placethe transmission in neutral.

3. Disengagethe PTOby pushing down on the PTOswitch.

3. Engagethe parking brake by pulling the handleup until

it locks into position.

4. Move the throttle control to mid-throttle position and

turn the ignition keyto OFE Removethe key.

, WARNING

_ impactHazard

Rapid retractionof startercord(kickback) will pull

handand arm towardengine faster thanyou can let go.

Brokenbones, fractures, bruises orsprainscould

result.

When startingengine,pull starter cordslowly until

resistanceis felt and then pull rapidlyto avoid

kickback.

4. After the engine starts, gradually open the choke (push

knob down fully). Reduceto half throttle speedand

allow to warm up.

Warm up the engineby running it for at least a minute

before engaging the PTOswitch or driving the uniL

5. After warming the engine,ALWAYSoperate the unit at

FULLTHROTTLEwhen mowing.

In the eventof an emergencythe enginecan he stopped

hy simply turning the ignition switch to STOP. Use this

method only in emergencysituations. Fornormal engine

shut down follow the procedure given in STOPPINGTHE

MOWER,

17

Page 20

Operation

DrivingThe Mower

NOTE:Before attempting to drive the mower make sureyou

haveread theFeaturesand Controls section and understand

thelocation and function of the controls.

The hydrostatictransmission hasan infinite number of

speeds betweenfull speed forward and reverse, with the

faster speeds being achievedby moving the forward speed

control leverand reversespeed control leversfarthest in the

direction of travel.

For normal use,the throttle should be kept fully open and

the ground speedof the machine determined bythe forward

speedcontrol lever. When transporting the machine or when

loading or unloading from a truck or trailer, partial throttle

should be usedto slow the reaction time of the controls and

reduce noise.

Practicemaneuveringthe machineat a slow engine speedon

levelground with the PTOswitch in the "OFF"position until

you are familiar with the controls.

TO MOVEFORWARDAND SETFORWARDSPEED(See

Figure 11.)

1. Disengagethe parking brake.

2. Gentlymove the forward speedcontrol lever (A, Figure

11) forward until desired speed is achieved.

\

Figure 11. Forward Travel

A. Forward SpeedControl Lever

TOMOVEBACKWARD(See Figure12.)

1. Disengagethe parking brake.

2. Gentlysqueezeboth reversespeedcontrol levers (A,

Figure12) evenly,until desired speed is achieved.

TOSLOWORSTOPMACHINE

1. Gentlysqueezeboth reversespeedcontrol leversevenly

to slow the machine.

2. Continuing to squeezethe reverse speedcontrol levers

will stop the machine.

3. Oncethe machine is stopped,firmly depress the neutral

return pedalto placethe transmissions in neutral.

4. Engagethe parking brake.

NOTE,Continuingto squeezethe reverse speed control

levers after the machine is stopped, will causethe

machine to move in reverse.

|

Figure 12. ReverseTravel

A. ReverseSpeedControl Levers

18 www.SnapperPro.com

Page 21

TOTURNMACHINE

NOTE"ALWAYSREDUCESPEEDIN A TURN

Tomake a left-hand turn (See Figure 13):

Gently squeezethe left hand reversespeedcontrol lever (A,

Figure 13) A sharp or gentleturn is determined by the

amount of force appliedto the steering control lever

Tomake a right-handturn(See Figure14):

Gently squeezethe right hand reversespeedcontrol lever (A,

Figure 14) A sharp or gentleturn is determined by the

amount of force appliedto the steering control lever

Operatiofl

Figure 13 Left Turn Travel

A Left HandReverseSpeedControl Lever

i

Figure 14, Right Turn Travel

A Right HandReverseSpeedControl Lever

19

Page 22

Operation

Mowing

Before mowing, setthe cutting height asdescribed in

CUTTINGHEIGHTADJUSTMENT.

1. Engagethe parking brake. Make sure the PTOswitch is

disengagedand the forward speedcontrol leveris in the

NEUTRALposition

2. Start the engine (see Starting TheEngine).

3. Set the throttle to FULL.

4. Engagethe PTOby pulling up on the PTOswitch.

5. Begin mowing. See Mowing Recommendationsfor tips

on mowing patterns, lawn care, and trouble shooting

information.

6. When finished, shut off the PTOby pushingthe PTO

switch down completely.

7. Stop the engine (seeStopping TheEngine).

Mowing Recommendations

Severalfactors can affect how well your machine cuts grass,

Following proper mowing recommendationscan improve

the performance andlife of your machine.

Heightof Grass

Often cutting height is a matter of personalpreference.

Typically,you should mow the grasswhen it is is between

three and five inches high. The propercutting height range

for a specific lawnwill depend upon several factors,

including the type of grass,the amount of rainfall, the

prevailing temperature, and the lawn's overallcondition.

Cutting the grasstoo short causesweak,thin grass plants,

which are easily damaged by dry periods and pests. Cutting

too short is often more damagingthan allowing the grass to

be slightly higher.

Letting grass grow a bit longer--especially when it is hot

and dry--reduces heat build-up, preservesneededmoisture

and protects the grass from heatdamageand other

problems. However,allowing grass to grow too high can

causethin turf andadditional problems.

Cutting off too much at one time shocks the plant's growth

system and weakensthe grass plants. A good rule ofthumb

is the 1/3 rule: to cut nomore thanone third of the grass

height, and nevermare than 1 inchat a time.

Theamount of grass you are ableto cut inone pass is also

effected by thetype of mowing system you are using (for

example,broadcasting with side discharge decks can

process a much larger volume of grass than mulching

does).

I

Figure 15. Proper Cutting Height

Tall GrassRequires IncrementalCutting

Forextremely tall grass, set the cutting height at maximum

for the first pass, andthen resetit to the desired height and

mow a second or third time.

Don't cover the grass surface with aheavy layerof

clippings. Consider using agrass collection system and

starting a compost pile.

Cut HereOn

First Pass Cut Here

_j/, Pass

Figure 16. IncrementalCutting

__ On Second

20 www.SnapperPro.com

Page 23

Whenand HowOften toMow

Thetime of day and condition of the grass greatly affect the

results you'll get when mowing. For the best results, follow

these guidelines:

1. Mow when the grass is betweenthree and five inches

high.

2. Mow with sharp blades. Short clippings of grass one

inch or shorter decompose more quickly than longer

blades.Sharp mower bladescut grass cleanly and

efficiently, preventing frayed edgeswhich harm the

grass.

3. Mow at time of day whenthe grass is cool and dry. Late

afternoon or early eveningoften provide these ideal

mowing conditions.

4. Avoid mowing after rain or evenheavy dew,and never

mulch when the grass is wet (moist grass does not

mulch well, and clumps beneaththe mower deck).

Mowing Patterns

Always start mowing ona smooth, levelarea.

Thesize and type of areato be mowedwill determinethe

best mowing pattern to use. Obstructions such astrees,

fencesand buildings, and conditions such asslopes and

grades must also be considered.

1. Cut long straight strips overlapping slightly.

2. Where possible, changepatterns occasionallyto

eliminate matting, graining or a corrugated appearance.

3. For a truly professional cut, mow across the lawn in one

direction, then recut the lawn by mowing perpendicular

to the previous cut.

Note:Alwaysoperate the engine at full throttle when

mowing,

If you hearthe engine slowing down, you are mowing too

fast--using a slower ground speedwill improve the cutting

efficiency of the bladesand prevents many common cutting

problems. Usean appropriate ground speedfor the

thickness and height ofthe grass you arecutting (3rd gear

or slower for manual gear models). If you hearthe engine

slowing down you aremowing too fast. usea slower ground

speed.

Operatiofl

Wherepossible, make one or two passes around the outside

of the areadischarging the grass INTOthe lawn to keep the

cut grass off fences and walks.

Theremainderof the mowing should be done in the

opposite direction so that the clippings are dispersed OUT

onto the areaof lawn previously cut.

Mowing Methods

ProperBroadcastMowing

Broadcasting, or side-discharging, disperses fine clippings

evenly over the entire lawn. Many golf courses use this

method. Your mower hasa deep dish deck to allow freer

circulation of clippings so they are broadcast evenlyover the

lawn.

Engine Speed & GroundSpeed for Broadcasting

Always operatethe engineatfull throttle when mowing. If

you hearthe engine slowing down, you are mowing too

fast--using a slower ground speedwill improve the cutting

efficiency of the bladesand prevents many common cutting

problems.

ALWAYSusean appropriate ground speed for the thickness

and height of the grass you arecutting (3rd gear or slower

for manual gear models). If you hearthe engine slowing

down you aremowing too fast, usea slower ground speed.

How Much Grassto CotOff When Broadcasting

Mow when the grass is 3-5 inches long. Do not cut the

grass shorter than 2 to 2-1/2 inches. Do not cut off more

that 1 inch of grass in asingle pass

21

Page 24

Operation

ProperMulching

Mulching consists of a mower deck which cuts and recuts

clippings into tiny particles and which then blows them

down INTOthe lawn.Thesetiny particles decomposerapidly

into by-products your lawn can use.UNDERPROPER

CONDITIONS,your mulching mower will virtually eliminate

noticeable clippings on the lawn surface.

NOTE:When mulching under heavycutting conditions, a

rumbling sound may be presentand is normal.

Mulching RequiresEXCELLENTMowing Conditions

Mulching mowers cannot function properly if the grass is

wet, or ifthe grass is simply to high to cut, Evenmorethan

normal mowing, mulching requiresthat the grass be dry

and the the appropriate amount is cut.

Do not usethe mower as amulching mower during the first

two or three mowings in the spring. The long grass blades,

quick growth, and often wetter conditions are more suitable

for broadcasting (side-discharging) or grass bagging

operation.

EngineSpeed & GroundSpeed for Mulching

Use full enginethrottle matchedwith a slow ground speed

so that clippings will befinely cut. Ground speed while

mulching should be HALFof the speed that would be used

when broadcasting (side discharging) under similar

conditions. Since mulching requires more horsepowerthan

broadcasting, using a slower ground speedis vitally

important for proper mulching operation.

Now Much Grassto Mulch

The best mulching action typically results from cutting only

the top 1/2 inch to 3/4 inch of grass blade. This provides

short clippings which decompose properly (much more

quickly than longerclippings). The ideal cutting heightwill

vary with climate, time of year,and quality of your lawn. We

recommend that you experimentwith both the cutting height

and ground speed until you achievethe best cut. Start with a

high cutting height and using progressively lower settings

until you find a cutting height that is matchedto your

mowing conditions and preferences.

Figure 17. Mulching Action

22 www.SnapperPro.com

Page 25

RegularMaintenance

RegularMaintenance

Maintenance Schedule

Thefollowing schedule should be followed for normal careof your mower and mower deck. Youwill needto keepa record of

your operating time. Determining operating time is easily accomplished by observing the elapsedtime recorded by the hour

meter.

Safety items Before Every 5 Every25 Every100 Every200 Spring &

EachUse Hours Hours Hours Hours Fall

CheckSafetyInterlock System • •

CheckMower Brakes • •

i

iCheck Mower BladeStopping Time • •

Mower Maintenance Before Every 5 Every25 Every100 Every200 Spring &

EachUse Hours Hours Hours Hours Fall

CheckUnit for Loose Hardware • •

CleanDeck& Check/ReplaceMowerBlades** •

Lubricate Mower & Mower Deck ** •

CheckTire Pressure •

CheckHydraulic Oil • •

ChangeHydraulicOil Filter ** •

EngineMaintenance Before Every5 Every25 Every100 Every200 Spring &

i

iCt/eck EngineOil Level =

Check/Clean Cooling Fins& Intake ** •

ServiceAir Filter * •

jChangeOil & Filter *** •

Check/ ReplaceSpark Plugs * •

Check/ ReplaceFuelFilter * •

* Referto engine owner's manual. Changeoriginal engine oil after initial break-in period.

** More often in hot (over 85° F:30° C) weather or dusty operating conditions.

*** Changeoriginal engine oil after first 8 hours of operation.

EachUse Hours Hours Hours Hours Fall

23

Page 26

RegularMaintenance

Checking/Adding Fuel

Toadd fuel:

1. Removethe fuel cap (E, Figure 18).

2. Fill thetankto the bottom ofthefiller neck. Thiswill

allow for fuel expansion.

NOTE. Donot overfill, Refertoyour enginemanual for

specific fuel recommendations.

3. Install and handtighten the fuel cap.

Fuel Filter

Thefuel filter is located in the fuel line betweenfuel tank and

carburetor, nearthe fuel pump. Iffilter is dirty or clogged,

replaceasfollows:

1. Placea container below the fuel filter (F) to catch spilled

fuel.

2. Using pliers, open and slide hose clamps from fuel filter.

3. Remove hosesfrom filter.

4. Install new filter in proper flow direction in fuel line.

5. Securewith hose clamps.

6. Reconnectthe negative batterycablewhen finished.

Change OiJ & FiJter

1. Warm engine by running for a few ndnutes. (Referto

the engineoperator's manualfor oil and filter

replacementinstructions.)

2. Routethe oil drain hose (A) over the front end of the

engine deck. Placethe drain hose down betweenthe

front of the enginedeck andthe back of the cutter deck.

3. Placea small pan under the oil drain hoseto catchthe

oil. Using the appropriate tools, removethe cap B,

from the oil drain hose anddrain the engine o nto the

pan.

4. After draining, replacethe capand wipe up any spilled

oil. Reposition the oil drain hose so that it is facing

towards the back of the machine.

5. Placean absorbent shop cloth underthe engineoil filter

(C). Removethe engine oil filter and replacewith a new

one.

6. Removethe oil dipstick (D) and refill with oil. (Refer to

the engineoperator's manualfor oil recommendations.)

7. Removethe shop cloth and wipe up any spilled oil.

EngineMaintenance

Referto engineowner's manualfor all engine maintenance

procedures and recommendations.

, WARNING

Gasolineis highly flammable and must be handled

with care. Never fill thetank when the engineis still

hotfrom recent operation.Do notallow open flame,

smokingor matchesin thearea. Avoid over-fillingand

wipe up any spills.

Donotremove fuel filter when engineishot, as spilled

gasoline may ignite. DONOTspreadhoseclamps

further than necessary.Ensureclampsgrip hoses

firmly ever filter after installation.

NOTICE

Donat use gasoline containingMETHANOL,gasohol

containingmore than 10% ethanol, gasoline additives,

premium gasoline, or white gas because engine/fuel

systemdamage couldresult.

Figure 18. Engine Oil Drain

A. Oil Drain Hose

B, Cap

C. Oil Filter

D. Oil Dipstick

E Fuel TankCap

E Fuel Filter

24 www.SnapperPro.com

Page 27

RegularMaintenance

Lubrication

Lubricate the unit at the locationsshown in Figures19 as

well asthe following lubricationpoints.

Grease:

,.deck lift pivot blocks

f ,.front casterwheel axles & yokes

Use greasefittings when present. Disassemble parts to

apply greaseto moving parts when greasefittings are not

installed.

Not all greases arecompatible. RedGrease(p/n 5022285)

is recommended,automotive-type high-temperature, lithium

greasemay be usedwhenthis is not available.

Oil:

,.mower deck spindles

,.mower deck idler arm

,.control handle pivots

,.deck lift pivots

,.discharge chute hinge

,.neutral return pedal pivots

Generally,all moving metal parts should be oiled where

contact is madewith other parts. Keepoil and greaseoff

belts and pulleys. Rememberto wipe fittings and surfaces

clean both before and after lubrication.

LubricatingtheFront Casters:

NOTE,Frontcasters should be lubricated annually.

1. Removethe 1/4-28 bolt (A, Figure20) screwed into the

front caster and install a 1/4-28 grease fitting.

2. Greasethe front caster.

3. Removethe 1/4-28 greasefitting and reinstall the 1/4-28

bolt.

4. Repeatprocessfor the other side of the machine.

Figure20. Front Caster & Wheel

A. 1/4-28Bolt

©

Figure 19, Lubrication Points

A, Mower Deck Lubrication Points B. HandleBar Lubrication Points

C. GeneralLubrication Points (Left Side Shown, Right Sidepoints identical.)

25

Page 28

RegularMaintenance

Check/ Fiii Transmission Oil

Oil Type: 20W-50 conventionaldetergent motor oil.

1. Checkthe oil levelwhenthe unit iscold. Locatethe

transmissionoil reservoirs (A, Figure21) locatedon the

bythe fuel tank. The oil should be up to the 'FULL

COLD"mark (B). Ifthe oil is belowthis level, proceed

to step 2.

2. Before removing the reservoir caps, makesure the area

around the reservoir cap andfill neckof the reservoir is

free of dust. dirt. or other debris. Removethe reservoir

cap.

3. Add oil up to the "FULL COLD"mark (B).

4. Reinstall the reservoir caps.

TransmissionOil Filter Change

ChangeInterval: Every200 Hours

Replacement Filter Number: 5101026X1

1. Locatethe transmission oil filters (A, Figure22)

underneaththe rear of the machine on the

transmissions.

Figure21. TransmissionOil Reservoir (LH Shown)

A. TransmissionOil Reservoir

B. "FULLCOLD"Mark

2. Removethe three 1/4" filter guard screws (C) and the

filter guard (B).

3. Cleanthe areaaround the filter baseand removethe

filter.

4. Apply a film of new oil to the gasket of the new

replacementfilter. After the oil has drained, thread the

newfilter onto the filter baseuntil the gasketmakes

contact, then tighten 3/4 of aturn more.

5. Reinstall the filter guard with the three 1/4" filter guard

screws

6. Using a hex bit swivel socket or a modified allenwrench

removethe top port plug from the transmissions.

7. Removethe transmission reservoir cap and fill with oil

until oil appearsat the bottom of the transmission's top

port (approximately 2 qts (1,89L).

8. Reinstall the top port plug and tighten to 15ft Ibs (20.38

Nm).

9. Continueto addoil to the transmission oil reservoirs

until the oil levelreachesthe "FULLCOLD"mark.

Reinstallthe oil reservoir cap.

10. Repeatthis process for the other side of the machine.

11. Run the unit for several minutes and checkthe

transmission oil level.

Figure22. Transmission(Left Side Shown.)

A. TransmissionOil Filter

B, Filter Guard

C. 1/4" Filter Guard Screws

D. TopPort Plug

IMPORTANTNOTE:Use caution after changing thefilter, air

in the hydraulic system mayaffect the responsivenessof the

ground speed control levers. Repeatstep 11until theair is

out of thesystem,

26 www.SnapperPro.com

Page 29

Servicing The Mower Blades

Removing the Mower Blade

, ,CAUTION

Avoid injury! Mower blades are sharp.

* Always wear gloves when handling mower blades or

working near blades.

1. To removethe mower blade,use a 1" wrench on the

flats of the spindle shaft and remove the mower blade

mounting bolt with a 15/16" wrench (Figure 23).

2. If there are no flats on the spindle shaft, wedge a

wooden block betweenthe mower bladeand the mower

deck housing to keepthe mower bladefrom turning.

inspecting the Mower Blades

, ILDANGER

Avoid injury! A worn or damaged blade can break, and

a piece of the mower blade couldbe thrown intothe

operator's or bystander's area, resulting in serious

personal injury or death.

,, inspect the mower blade every 25 hours or at least

oncea year.

,,if the mower blade hitsa solid object, stop the

engine immediatelyand inspectthe mower blade.

,, Never weld or straighten bent mower blades.

1. Removethe mower bladefrom the unit. BeeRemoving

the Blade,

2. Inspect the mower blade (Figures 24 & 25). Discardthe

mower blade if it hasany ofthe below conditions.

A.) Has morethan .5" (12,7 mm) of the mower blade

metal removed from previous sharpening or wear (D,

Figure24).

B.)The air lifts are excessivelyeroded (B & C, Figure

25) andthe notch (C) is .25" (6,35 mm) deep or greater.

C.) Mower blade is bent or broken.

3. If the cutting edges are not sharp or havenicks, sharpen

the blades. See Sharpening theMower Blades.

RegularMaintenance

Figure23. Loosening theMower Bladefor Removal

\

Figure24, inspecting the Mower Blade Tips

A. Mower BladeCutting Edge

B, Square Comer

C. Air Lift

D. WearMeasurement- DISCARDMower Bladelf greater

than .5" (12,7 ram)

®

Figure25. inspecting the Mower BladeAir Lifts

A. New Mower Blade

B, Mower Bladeat WearLimit (A notch begins to form)

C. Mower Bladein Dangerous Condition (Notch measures .25" (6,35 ram) or greater DONOTUSE,Replacewith new mower

blade.)

27

Page 30

RegularMaintenance

Sharpening the Mower Blade

, CAUTION

Avoid injury! Mower blades are sharp.

,, Alwayswear gloves when handling the mower

blades.

,, Alwayswear safety eye protectionwhen grinding.

t

®

1. Sharpenthe mower blades with grinder, handfile. or

electric blade sharpener.

2. Sharpenthe mower blade by removing anequal amount

of material from eachend ofthe mower blade.

3. Keepthe original bevel(A, Figure26) when grinding. DO

NOTchangethe mower blade bevel.

4. The mower bladeshould havea maximum 1/64" (0,40

ram) cutting edge(B) or less.

5. Balancethe mower bladesbefore installing.

Balancing the ['/lowerBlades

, CAUTION

Avoidinjury! Keepmower blades balanced.

• Anunbalanced mower blade cancreate excessive

vibrationand damage the unit or cause mower blade

failure.

1. Cleanthe mower bladeto remove any dried grass or

other debris.

2. SeeFigure27. Put the mower blade on a nail in a vise

and turn the mower bladeto the horizontal position.

3. Checkthe balanceof the mower blade. If either end of

the mower blade movesdownward, sharpen the heavy

end until the mower bladeis balanced. SeeSharpening

the Mower Bladesfor propersharpening instructions.

4. Repeatthe process until the mower blade remains in the

horizontal position.

Figure26, SharpeningtheMower Blade

A. Mower BladeBevel

B. Mower BladeCutting Edge

Figure27. Balancingthe Mower Blade

A. Nail

Reinstallingthe ['/lowerBlades

1. Reinstall eachmower bladewith the air lifts pointing up

towards the mower deck as shown in Figure28. Secure

with the mower blade mounting bolt and flat washer (A

& B, Figure28) and torque to 70 ft. Ibs(94 Nm).

2. If there are no flats on the spindle shaft, wedge a

wooden block betweenthe mower bladeand the mower

deck housing to keepthe mower bladefrom turning.

28 www.SnapperPro.com

Figure28, Tighteningthe Mower Blade for Installation

A. Mower Blade Mounting Bolt

B, Flat Washer

C. Mower BladeAir Lift (Points Up For Installation)

D. 4X4 WoodenBlock

Page 31

Nentral Adjustment

Iftheunit"creeps"wHletheforwardspeedcontrolleveris

lockedinthe NEUTRALposition,thenit maybenecessary

toadjustthe linkagerod.

NOTE:Perform this adjustment on a hard, level surface such

as a concrete floon

1. Disengagethe PTO,engagethe parking brakeand turn

off the engine.

2. There are two jam nuts (B, Figure29) on the linkage rod

(A). Loosen the jam nutson the linkagerod and turn

the linkage rod to adjust. Ifthe machine creepsforward,

turn the rod COUNTER-CLOCKWISE(while standing at

the rear of the machine, looking down), if the machine

creeps backward,turn the rod CLOCKWISE.

3. Lock the jam nuts (B) against the ball studs when

neutral is achieved.

NOTE: This adjustment should not be performed while the

machine is running, It may take severalattempts to achieved

neutral, depending upon how much themachine creeps.

RegularMaintenance

Figure29. Neutral Adjustment

A. Ball Stud

B, Nuts

C. Adjustment LinkageRod

Speed Balancing Adjnstment

If the unit veersto the right or left when you aredriving the

machine,the top speedof eachwheel can be balancedby

turning the linkage adjuster rod (C, Figure30). Onlyadjust

the speedof the wheel that is traveling faster,

ToReducethe Speed of the FasterWheel:

1. Loosen the jam nut (B).

2. Turn the linkageadjuster rod COUNTER-CLOCKWISEto

reducethe speed.

3. Retighten the jam nut whenadjustment is complete.

, WARNING

DONOTadjust the unit for a faster overall speed

forward or reverse thanit was designed for.

Figure30, Adjusting the Speedof the Faster Wheel

(RHside shown)

A. Contml Ramp Rod

B, Jam Nut

C. LinkageAdjuster Rod

29

Page 32

RegularMaintenance

ParkingBrakeAdjustment

1. Disengagethe PTO,stup theengine, removethe ignitiun

key,and engagethe parking brake.

2. Locatethe brake spring (A, Figure31) underneaththe

rear of the machine.

3. With the parking brake engaged, measurethe

compressed spring length of the brakespring. The

spring should be 2-3/8" (6,03 cm) when compressed.

If not, position the lock nut until the measurement

equals 2-3/8" (6,03 cm).

4. Measurethe distance betweenthe backof the brake

pivot link (G) and the front edge of the set collar (F).

The measurementshould be 1/8" (0,32 cm). If not,

position the set collar until the measurementequals 1/8"

(0,32 cm).

if this dues notcorrectthe brakingproblem, seeyuur

Snapper Prudealer.

Figure31. ParkingBrake Adjustment

A. Brake Spring

B, First Measurement - .2-3/8" (6,03 cm)

C. Brake Spring Rod

D. LockNut

E, SecondMeasurement - 1/8" (0,32 cm)

F. Set Collar

G, Brake Pivot Link

30 www.SnapperPro.com

Page 33

Deck Leveling Adjustment

ToLeveltheMowerDeck:

1. Park the machine on a flat. level surface. Disengagethe

PTO,stop the engine and engagethe parking brake.

Reartires must be inflated to 15 psi (1,03 bar); front

tires to 25 psi (1,72 bar).

2. Pull the cutting height adjustment handle (A, Figure32)

up and out of the handle lock position (B) and crank the

handle CLOCKWISEand adjust the deck to the 3" (7,6

cm) position.

3. Repeatprocessfor other side of machine.

NOTE:Both sides of the deckmust be adjusted to the same

heighL

4. Place2 x 4 blocks under the rear of the mower deck

with the 3-1/2" sidesbeing vertical. SeeFigure33.

5. Loosen the deck leveling hardware(D, Figure 32) on

both sides of the machine.

6. Makesure that the rear of the deck is resting onthe 2x

4's. Tightenthe deck leveling hardwareon both sides of

the machine.

7. Removeall 2 x 4 blocks from under the mowerdeck.

RegWr MaJflteflaflce

Figure3! Removethe CutterDeckGuard

A. Cutter Height Adjusflnent Handle

B, Handle Lock Position

C. Cutting Height Indicator

D. Deck Leveling Hardware

®

Figure33. 2 x4 Locations

A. 36"Mower Deck

B, 48" Mower Deck

C. 2 x 4 Blocks

D. Arrow Indicating theFront of the Machine

®

31

Page 34

RegWr Maintenance

Mower Belt Replacement

NOTICE

Toavoid dan]agingbelts, DONOTPRY BELTSOVER

PULLEYS.

1. Park the unit ona smooth, level surface such asa

concrete floor. Disengagethe PTO,engagethe parking

brake,turn offthe engine,and removethe ignition key.

2. Lower the mower deck to its lowest cutting position and

removethe mowerdeck guard.

3. Using a 1/2" breakerbar (A, Figure34), placethe square

end in the squarehole locatedon the end of the idler

arm (B). Carefullyrotate the breaker bar CLOCKWISE,

which will relieve the tension on the beltexerted from

the idler arm.

,tI&WARNING

Use extremecautionwhen rotatingtheidler arm with

the breaker bar,due tothe increasedtensionin the

springas the idler arm isbeingrotated, injurymay

result if the breakerbar is prematurelyreleasedwhile

the spring is under tension.

®

4. Slidethe mower drive belt over the edge of the

stationary idler pulley (C). Carefully releasethe tension

on the breakerbar.

5. Removethe old belt and replacewith a newone. Make

sure the V-side of the belt runs in the pulley grooves

(Figure35).

6. Install the mower drive belt on the PTOpulley,the

spindle pulleys and all idler pulleys exceptthe stationary

pulley (C, Figure34). Carefully rotate the breaker bar

counter-clockwise and install the belt on the stationary

idler pulley. Carefully releasethe tension on the breaker

bar.

7. 36" Models: Using the cutting height adjustment

handles,adjust the cutting height of the mower deckto

1-1/2" (3,8 cm).

NOTE:Make sure that both sides of the deckare adjusted to

thesame cutting heighL

Measurethe mower belt tensioner spring (C, Figure

36). Themeasurementshould equal 12-1/4" (31,1 cm).

If the measurementdoes not equal 12-1/4" (31,1 cm),

adjust the anchor eyebolt(A) by turning the adjustment

nut (B) until ameasurement of 12-1/4" (31,1 cm) is

achieved.

8. Reinstall the mower deck guards.

9. Run the mower under no-load condition for about 5

minutes to break-inthe new belt.

Figure34. Removethe Mower Belt

A. BreakerBar

B, Idler Arm

C. Stationary Idler Pulley

D. 36" Mower Deck

f 48"Mower Deck

32 www.SnapperPro.com

Page 35

® ®

Figure35, Mower DeckBelt Routing

A. Mower Drive Belt

B, Adjustable Idler Pulley

C. Spindle Pulley

D. Stationary Idler Pulley

E, 36" Mower Deck

£ 48"Mower Deck

RegWr MsJflteflsflce

Figure36, Mower Belt TensionerSpring Measurement (36"

Models)

A. Anchor Eyebolt

B, Adjustment Nut

C. Mower Belt TensionerSpring

33

Page 36

RegularMaintenance

TransmissionDriveBelt Replacement

1. Park the unit ona smooth, level surface such asa

concrete floor. Disengagethe PTO,engagethe parking

brake,turn offthe engine,and remove the ignition key.

2. Removethe PTOdrive belt (see MOWERBELT

REPLACEMENTfor removal instructions).

3. Loosen and removethe crankshaft bolt (C, Figure37)

and the PTOclutch (B) from the engine crankshaft.

WARNING

STOREDENERGYDEVICE:improperrelease ofthe belt

tension springcan resultin personalinjury.

Useextreme cautionwhen removingthisspring.

4. Loosen the nut onthe spring anchor eyebolt (G, Figure

38) to releasethe majority of the belt tension. Use

caution and removethe nut to completely releasethe

tension.

5. Removethe old belt and replaceit with the new one.

Makesure the V-side of the belt runs in the grooves of

the crankshaft pulley and transmission pulleys (B & C).

6. Reinstall the spring anchor eyebolt (G) into the anchor

tab and loosely fastenthe nut. Adjust the anchor

eyebolt until a measurement of 8-3/8" (21,2 cm) is

achieved from the outside of the spring hooks. Tighten

nut.

7. Reinstall the PTOclutch to the engine crankshaft and

secure with the crankshaft bolt. Tighten the crankshaft

bolt to 65ft. Ibs (88 Nm).