Page 1

Safety Instructions & Operator’s Manual for

PUSH YARD VACUUM

SERIES 0

RESIDENTIAL MODELS

Model Mfg. No.

SV25550HC

SV25650B

COMMERCIAL MODELS

7085638

7085687

Model Mfg. No.

SV25500HV

SV25550HV

Before operating your new machine, read this manual carefully and pay particular attention to the “IMPORTANT

SAFETY INSTRUCTIONS” on Pages 2 & 3. Remember that all power equipment can be dangerous if used

improperly. Also keep in mind that SAFETY requires careful use in accordance with the operating instructions

and common sense!

NOTE: Specifications are correct at time of printing and are subject to change without notice.

Actual sustained equipment horsepower will likely be lower due to operating limitations and environmental factors.

COPYRIGHT © 2004

SNAPPER – A DIVISION OF SIMPLICITY MFG., INC.

ALL RIGHTS RESERVED

MANUAL No. 7050477 (I.R. 9/17/04)

7085644

7085642

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful machine is capable of amputating hands and feet and can throw objects that can

cause injury and damage! Failure to comply with the following SAFETY instructions could result in serious

injury or death to the operator or other persons. The owner of the machine must understand these instructions

and must allow only persons who understand these instructions to operate machine. Each person operating

the machine must be of sound mind and body and must not be under the influence of any substance, which

might impair vision, dexterity or judgment. If you have any questions pertaining to your machine, contact your

local authorized dealer.

PROTECTION FOR CHILDREN

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the machine and the work activity.

Never assume that children will remain where you

last saw them.

1. KEEP children out of the work area and under

the watchful care of a responsible adult.

2. DO NOT allow children in the work area when

machine is operated and turn machine OFF if

anyone enters the area.

3. DO NOT allow pre-teenage children to operate

machine.

4. ALLOW only responsible adults & teenagers

with mature judgment under close adult

supervision to operate machine.

5. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that

may obscure vision.

SLOPE OPERATION

1. Slopes are a major factor related to slip and fall

accidents, which can result in severe injury. All

slopes require extra caution. If you feel uneasy

on a slope, DO NOT operate the machine on it.

2. Use extra care, as the debris bag fills, the

weight will affect the stability and handling of

the machine.

3. DO NOT park machine on slopes.

PREPARATION

1. Read, understand, and follow instructions and

warnings in this manual and on the machine,

engine and attachments. Know the controls and

the proper use of the machine before starting.

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

3. Data indicates that operators age 60 and above,

are involved in a large percentage of machinerelated injuries. These operators should

evaluate their ability to operate the machine

safely enough to protect themselves and others

from serious injury.

PREPARATION

(Continued From Previous Column)

4. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved

fuel container. DO NOT remove fuel cap or add

fuel with engine running. Add fuel outdoors

only with engine stopped and cool. Clean

spilled fuel and oil from machine. DO NOT

smoke.

5. Check the work area and remove all objects

such as toys, wire, rocks, limbs and other

objects that could cause injury and damage to

the machine. Also note the location of holes,

stumps, and other possible hazards.

6. Keep people and pets out of the work area.

Immediately, Stop engine if anyone enters the

area.

7. Check shields, deflectors, switches, engine

controls and other safety devices frequently for

proper operation and location.

8. Make sure all safety decals are clearly legible.

Replace if damaged.

9. Protect yourself when operating machine and

wear safety glasses, hearing protection,

breathing protection, long pants and

substantial footwear. DO NOT operate

barefooted or with sandals.

10. Know how to STOP engine quickly in

preparation for emergencies.

11. Use extra care when loading or unloading the

machine into a trailer or truck.

12. Check debris bag and components frequently

for signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or torn spots.

SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage, use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive

1. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

2. Use only an approved fuel container.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

SAFE HANDLING OF GASOLINE

(Continued From Previous Page)

3. DO NOT remove fuel cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. DO NOT refuel the machine indoors.

5. DO NOT store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as on a water heater or other appliances.

6. DO NOT fill fuel containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always place

the containers on the ground away from the vehicle

before filling.

7. Remove gas-powered equipment from the vehicle or

trailer and refuel it on the ground. If this is not

possible, then refuel equipment using a portable

container, rather than a gasoline dispenser nozzle.

8. DO NOT start gas powered equipment in enclosed

vehicles or trailers.

9. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. DO NOT use a nozzle lock-open device

10. If fuel is spilled on clothing, change clothing

immediately.

11. DO NOT overfill a fuel tank. Replace fuel cap and

tighten securely.

OPERATION

1. DO NOT put hands or feet near rotating parts. Keep

clear of intake and discharge areas while engine is

running.

2. STOP engine when crossing gravel drives.

3. Operate machine only in daylight or good artificial

light.

4. DO NOT operate machine while under the influence

of alcohol or drugs.

5. If machine vibrates abnormally, STOP the engine,

disconnect and secure spark plug wire. Inspect the

machine for any damage and repair the damage

before resuming operation.

6. DO NOT operate machine near drop offs, ditches or

embankments. Operator could lose footing or

balance.

7. STAY ALERT for holes and other hidden hazards.

Keep away from ditches, washouts, culverts, fences

and protruding objects.

8. DO NOT operate machine on wet grass. Always be

sure of your footing. Keep a firm hold on the handle

and walk, never run. Slipping could cause injury.

9. DO NOT leave the machine unattended with the

engine running.

10. Before cleaning, repairing or inspecting make

certain engine has completely STOPPED.

Disconnect and secure spark plug wire away from

plug to prevent accidental starting.

11. DO NOT start or operate machine with debris bag

zipper open.

OPERATION

(Continued From Previous Column)

12. Engine must be completely STOPPED before

removing debris bag.

13. DO NOT operate machine without the entire debris

bag and guards in place.

14. Slow down before turning.

15. Watch out for traffic when near or crossing

roadways.

16. DO NOT operate engine in enclosed areas. Engine

exhaust gases contain carbon monoxide, a deadly

poison.

17. If vacuum inlet or discharge becomes plugged,

STOP engine. Disconnect sparkplug wire and

secure away from sparkplug. Use a stick to clear the

plug when possible. If hands must be used to

remove plug, always wear heavy gloves as the

debris may be sharp.

MAINTENANCE AND STORAGE

1. DO NOT store machine or fuel container inside

where fumes may reach an open flame, spark or

pilot light such as in a water heater, furnace, clothes

dryer or other gas appliance. Allow engine to cool

before storing machine in an enclosure. Store fuel

container out of reach of children in a well

ventilated, unoccupied building.

2. Keep machine and engine free of grass, leaves or

excess grease to reduce fire hazard and engine

overheating.

3. When draining fuel tank, drain fuel into an approved

container outdoors and away from open flame.

4. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

5. Alw ays provide adequate ventilation when running

engine. Engine exhaust gases contain carbon

monoxide, a deadly poison.

6. Service engine and make adjustments only when

engine is stopped. Removed spark plug wire from

spark plug and secure wire away from spark plug to

prevent accidental starting.

7. DO NOT change engine governor speed settings or

overspeed engine.

8. Check debris bag assembly frequently for wear or

deterioration to avoid thrown objects and exposure

to moving parts. Replace with new bag if loose

seams or tears are evident. Replace bag adapter if

worn, broken or cracked.

9. DO NOT test for spark by grounding spark plug next

to spark plug hole; spark plug could ignite gas

exiting engine.

10. Have machine serviced by an authorized dealer at

least once a year and have the dealer install any new

safety devices.

11. Use only genuine replacement parts purchased

from your authorized dealer to assure that original

standards are maintained.

Page 4

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ........................................................................2-3

TABLE OF CONTENTS .....................................................................................................4

SETUP INSTRUCTIONS.................................................................................................... 5

SECTION 1 – FAMILIARIZATION ..................................................................................6-7

Nomenclature.................................................................................................................6

Safety and Instruction Labels....................................................................................... 7

SECTION 2 - OPERATING INSTRUCTIONS.................................................................8-9

Pre-start Checklist......................................................................................................... 8

Starting Engine .............................................................................................................. 9

Stopping Engine ............................................................................................................ 9

Operation........................................................................................................................9

Vacuum Hose (Optional)............................................................................................... 9

SECTION 3 – MAINTENANCE INSTRUCTIONS............................................................10

Service – After First 5 Hours ...................................................................................... 10

Change Engine Oil....................................................................................................10

Service Engine Air Cleaner......................................................................................10

Inspect Machine........................................................................................................10

Service – Every 25 Operating Hours..........................................................................10

Storage – Out of Season.............................................................................................10

SECTION 4- ADJUSTMENTS AND REPAIR..................................................................11

Engine Adjustments & Repair....................................................................................11

Impeller Replacement..................................................................................................11

Impeller Housing Liner Replacement........................................................................11

TROUBLESHOOTING .....................................................................................................12

MAINTENANCE SCHEDULE...........................................................................................13

PRODUCT REGISTRATION FORM ................................................................................ 14

IMPORTANT: The figures and illustrations in this manual are provided for reference only and

may differ from your specific model. Contact your authorized dealer if you have questions.

WARNING

GAS ENGINES MAY REQUIRE A SPARK ARRESTER

If the engine on this machine is not equipped with a

spark arrester and is to be used on any forest, brush, or

grass-covered unimproved land, a spark arrester must

be added to the muffler before using the engine on such

land. The spark arrester must be maintained in effective

working order by the operator. In the state of California,

the above is required by law (Section 4442 of the

California Public Resources Code). Other states may

have similar laws. Federal laws apply on federal lands.

See your authorized engine service center for muffler

spark arrester options.

4

Page 5

SETUP INSTRUCTIONS

The majority of the assembly has been completed at the factory. After removing the machine from the shipping container

you will be required to unfold the handles, attach the debris bag, and insert the accessory plug into the vacuum nozzle.

Initial adjustments and operational tests were performed prior to shipping the machine. Due to the effects of shipping,

handling and storage, the machine must be carefully inspected for loose, damaged parts and any necessary final

adjustments completed at the time of setup. It is very important that you register your purchase to insure warranty

coverage. Please fill out your product registration form and mail it to the address listed on the form.

1. Carefully remove the contents from the shipping

container. You can avoid having to lift the machine

by cutting the rear out of the box. The machine can

then be rolled out.

2. Unfold the handles being careful not to kink the

control cables and place in the operating position.

Tighten the hardware securely.

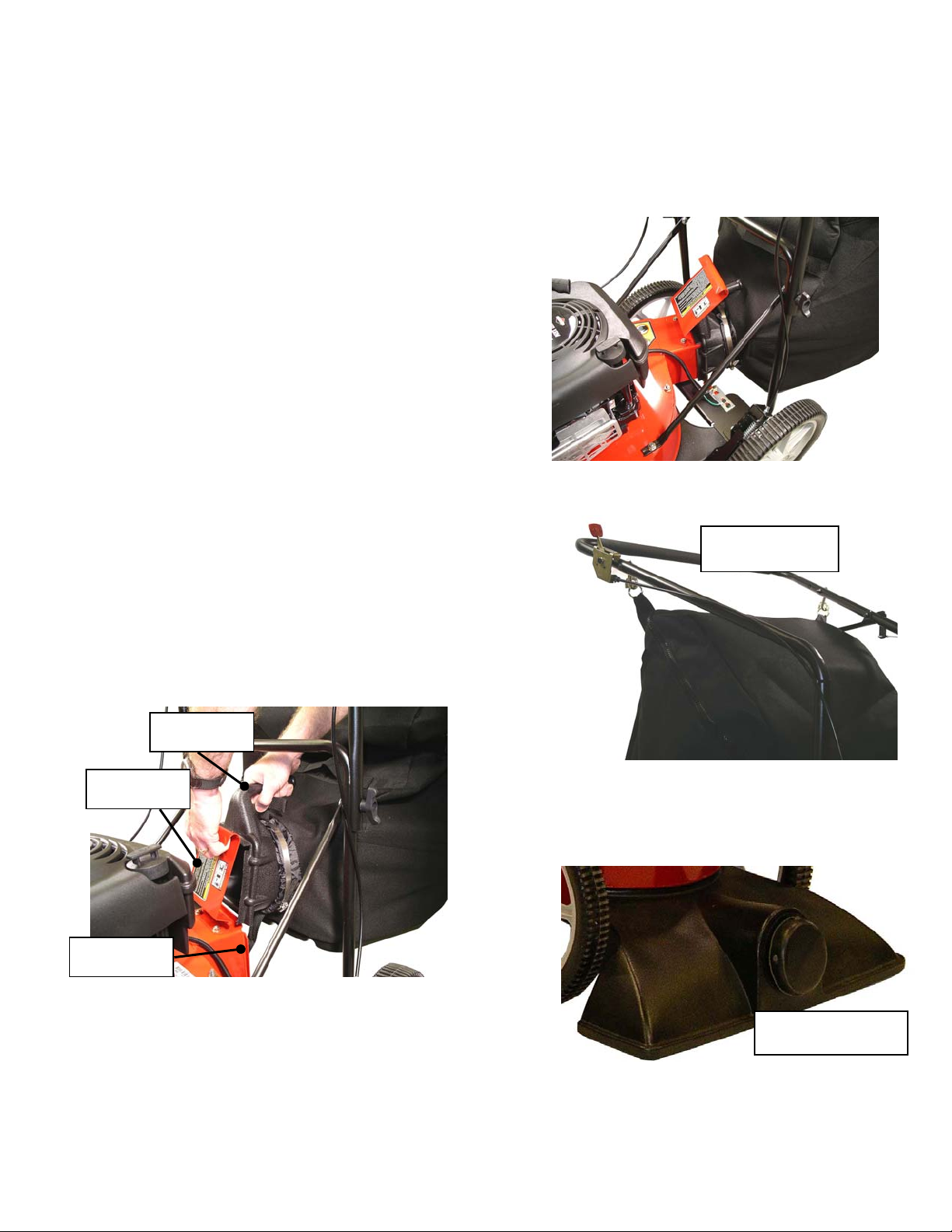

3. Attach the bag adapter to the discharge opening.

Open the discharge door and slide the adapter down

over the two flanges at the opening. Make sure the

adapter is secured in place on both sides. Close

door. See Figures 1 and 2.

4. Attach two rear straps located near the top of the

debris bag to the handles. See Figure 3.

5. Install accessory plug. Line up the two lugs on the

plug with the two notches in the vacuum nozzle.

Insert nozzle and rotate 90 degrees to lock in place.

See Figure 4.

6. Fill engine crankcase with oil to proper level. Refer

to engine owner’s manual for specifications.

7. Move machine to open area where fumes can safely

dissipate and away from all sources of ignition. Fill

fuel tank. Refer to engine owner’s manual for

specifications. Do not over fill.

8. Setup is complete. Please proceed to the Pre-Start

Check List. Follow and complete each step carefully.

BAG

ADAPTER

DISCHARGE

DOOR

MOUNTING

FLANGE

FIGURE 1

FIGURE 2

ATTACH STRAPS

TO HANDLES

FIGURE 3

INSERT ACCESSORY

PLUG INTO NOZZLE

FIGURE 4

5

Page 6

Section 1 – FAMILIARIZATION

A

ENGINE SPEED

CONTROL

DEBRIS BAG

HEIGHT

CONTROL

ENGINE SPEED CONTROL

CHOKE

FAST

SLOW

STOP

VENT, WITH

ZIPPERS

BRIGGS

(PRIMER)

DISCHARGE

DOOR

HONDA

(CHOKE)

ENGINE

PRIMER

VACUUM

NOZZLE

FIGURE 1.1

CCESSORY PLUG

1.1 INTRODUCTION

This manual has been prepared for the operator’s of the

Yard Vacuum. Its purpose, aside from recommending

standard operating procedures and routine service

requirements, is to promote SAFETY through the use of

accepted operating practices. Read, Understand and

Follow the IMPORTANT SAFETY INSTRUCTIONS on

Pages 2 & 3 of this manual and All SAFETY messages

on the machine and its attachments before operating.

6

2.2.2 NOMENCLATURE

The nomenclature picture above, Figure 1.1, shows the

essential parts of the Yard Vacuum. It is recommended

that all operators of this equipment become thoroughly

familiar with the controls, components, and operation of

this machine before operating. Specific details involving

the engine are found in the separate engine owner’s

manual. Study these manuals before operating and

keep both handy for future reference.

Page 7

Section 1 – FAMILIARIZATION

1.3 SAFETY AND INSTRUCTION LABELS

The safety and instruction labels included with your

Yard Vacuum are very important. Read, understand

and follow all instructions and warnings. Keep these

labels clean and legible at all times. Replace any labels

that are lost or can no longer be read.

IMPORTANT SAFETY OPERATING INSTRUCTIONS

DANGER, THROWN OBJECTS

KEEP BYSTANDERS AWAY FROM MACHINE

WARNING – HEARING, EYE AND BREATHING PROTECTION REQUIRED

7

Page 8

Section 2 – OPERATING INSTRUCTIONS

2.1 PRE-START CHECK LIST

Read, understand and follow instructions and

warnings in this manual and on the machine, engine

and attachments before operating. Know the controls

and the proper use of the machine before starting.

Make the following checks and perform the service

required before each start-up.

2.1.1. Check guards, deflectors and covers to make

sure all are in place and securely tightened.

2.1.2. Carefully inspect machine for loose, missing,

damaged or worn components. Repair or replace as

necessary before operating the machine.

2.1.3. Carefully inspect the debris bag and bag

adapter for wear and deterioration. IMPORTANT –

open top of bag to inspect interior of bag and the

discharge deflector end of the bag adapter. Replace

bag and bag adapter if they display signs of

deterioration. The debris bag must be attached to the

bag adapter, the bag adapter mounted onto the

machine, and the zippered top fully closed before

starting engine. The top rear corners of the bag are

attached to the handles by using the cloth straps

located near the top of the bag. See Figures 2.2 and

2.3.

2.1.4. Check engine oil and add oil as needed to

bring level up to the FULL mark. Refer to engine

owner’s manual for oil specifications. See Figure 2.1.

SAFE LEVEL

AREA

FIGURE 2.1

2.1.5. Check engine speed control to insure it

works freely.

2.1.6. Clean exterior surfaces of machine and

engine of any accumulation of dirt, grass, oil, etc.

Keep engine air intake screen and cooling fins clear

at all times.

2.1.7. Add fuel to tank after pushing the machine

outside where fumes can dissipate. Make sure fuel

filler cap is tight after refueling. Refer to engine

owner’s manual for fuel specifications.

2.1.8. Adjust height of vacuum inlet. Lift up on

handles. Squeeze height control lever against handle.

Raise or lower handles until desired inlet height has

been obtained. Release control lever. See Figure 2.4.

BAG ADAPTER

MOUNTED.

BAG

ATTACHED TO

HANDLES. TOP

ZIPPER FULLY

FIGURE 2.2

DEBRIS BAG

AND BAG

ADAPTER

MOUNTED TO

DISCHARGE

OPENING

FIGURE 2.3

HEIGHT

CONTROL

LEVER

FIGURE 2.4

8

Page 9

Section 2 – OPERATING INSTRUCTIONS

WARNING

Entire debris bag and bag adapter must be properly

installed before starting engine. The debris bag and

bag adapter are subject to deterioration during

normal use. Inspect frequently and replace if signs

of deterioration are observed.

2.2 STARTING, STOPPING & OPERATION

2.2.1. STARTING ENGINE

Before starting engine complete all items in the Pre-Start

Check List. The discharge opening is equipped with a

safety interlock. The entire debris bag and bag adapter

must be properly installed for the engine to start.

1. Move machine to flat open area.

2. Turn fuel valve to “ON” (Honda engine – refer to

engine owner’s manual).

3. Move engine speed control all the way forward. On

Briggs models this places the control in the “FAST”

(Rabbit) position. On Honda models this places the

control in the “CHOKE” position. NOTE: the

“CHOKE” may not be required to restart a hot engine.

4. Briggs models, depress primer 3 times to start a cold

engine. NOTE: the primer may not be required to

restart a hot engine.

5. Pull out on recoil rope until resistance is felt. Pull

sharply until engine starts. Guide rope back into

engine.

6. Honda models, move engine speed control rearward

to the “FAST” (Rabbit) position.

2.2.3 STOPPING ENGINE

1. Move engine speed control rearward to the “STOP”

position.

2. Allow all rotation to come to a complete stop before

removing or emptying the debris bag.

3. When possible it is good practice to bring the engine

speed control to the “SLOW” (Turtle) position to allow

the engine to cool down before stopping engine.

4. Honda models, turn fuel valve to “OFF” position.

WARNING

DO NOT operate machine without the entire debris

bag and bag adapter installed and the zipper fully

closed. Always wear eye, ear and breathing

protection when operating machine.

2.2.4 OPERATION

This Yard Vacuum has been designed to pick up

dry organic debris such as leaves, grass clippings,

shavings and sawdust as well as debris mixed with

cans, bottles and small amounts of sand.

Vacuuming hard non-organic debris will affect the

life of your machine. Sand is abrasive and will

produce wear of items including the blower

housing, impeller and bag adapter.

1. Adjust height of vacuum inlet. For maximum

debris pickup, inlet should be as close to debris

as possible without blocking airflow and engine

speed set to “FAST”.

2. Inspect debris bag. It must be properly attached

to machine, in good condition, clean and dry

with the top zipper fully closed. Make sure that

the accessory plug is installed into front hole in

vacuum nozzle.

3. Start engine. Not all debris pickup will require

that the engine speed be set to “FAST”. You can

experiment with vacuum inlet height and engine

speed to best suit your conditions.

4. Operating in dry dusty conditions may require

that the engine be set to the “SLOW” position.

The debris bag can quickly become plugged

with fine dust, reducing vacuum action. A

zippered vent flap has been provided on the

side of the bag. It can be opened to improve

airflow. DO NOT open top zipper when engine is

running.

5. For peak performance, keep debris bag clean

and do not overfill. The bag must be completely

dry before use.

DO NOT remove bag adapter from machine or open

debris bag with engine running. STOP engine and

allow all rotation to stop.

6. If the vacuum inlet or discharge becomes

plugged, STOP ENGINE. Engine must come to

a complete stop before removing debris bag or

attempting to remove plug from inlet area. To

avoid accidental starting, always remove the

sparkplug wire from the sparkplug and secure

away from sparkplug. When possible use a stick

to remove the plug. If that does not work, and

hands must be used, wear heavy gloves. The

debris could contain sharp items.

DO NOT vacuum any debris that is burning, wet,

flammable, explosive, or poisonous.

DO NOT store with debris in the bag. Decaying

organic debris generates heat that could damage the

bag or result in a fire.

2.3 VACUUM HOSE KIT (Optional Accessory)

A vacuum hose kit is available that plugs into the

front of the Yard Vacuum. The hose allows easy

access for hard to reach places. Contact your

authorized dealer for information.

WARNING

WARNING

9

Page 10

Section 3 – MAINTENANCE

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. STOP

engine. Remove spark plug wire from spark plug and

secure away from plug. Engine and components are

HOT. Avoid serious burns, allow all parts to cool before

working on machine.

3.1 INTRODUCTION

To retain the quality of the Yard Vacuum, use genuine

replacement parts obtained only through your

authorized dealer. Contact a local authorized dealer

for parts and service assistance. For the correct part

or information for a particular Yard Vacuum, always

mention the model/part number and serial number.

We recommend returning the Yard Vacuum to an

authorized dealer annually for inspection and addition

of any new devices, which might upgrade the safety of

the machine. For the nearest authorized dealer in your

area, check the yellow pages under the heading

LAWN MOWERS. For engine parts and service, look

for the engine manufacturer’s dealers under the

heading, ENGINES - gasoline.

3.2 SERVICE - AFTER FIRST 5 HOURS

Routine maintenance is important to the performance

and life of your Yard Vacuum. Service performed

properly and at the recommended interval is essential.

Refer to Section “MAINTENANCE SCHEDULE” in this

manual and in the Engine Owner’s Manual. Carefully

complete all of the recommended service procedures.

3.2.1. CHANGE ENGINE OIL

The design of the machine restricts access to the oil

drain plug on some model engines. The quickest

and cleanest method to drain the oil is to tip the

machine on its side, remove the dip stick, and allow

the oil to drain into a pan. Refer to the Engine

Owners Manual for recommended oil change

interval and oil specifications.

3.2.2. SERVICE ENGINE AIR CLEANER

The engine is equipped with a dual element air

cleaner. Both the foam pre-cleaner and cartridge

require service. Refer to Engine Owner’s Manual

for recommended service procedures.

3.2.3 INSPECT MACHINE

Carefully inspect entire machine for loose,

missing, damaged or worn parts. Run the machine

and check for unusual noise or vibration. After

stopping engine, open top of debris bag and

inspect the interior of the bag and the discharge

deflector end of the bag adapter. Repair or replace

debris bag, bag adapter, and machine as

necessary before operating. Contact your

authorized dealer for assistance.

3.3 SERVICE – EVERY 25 HOURS

Refer to Section “MAINTENANCE SCHEDULE” in this

manual and in the Engine Owner’s Manual. Carefully

complete all of the recommended service procedures.

3.4 STORAGE – OUT OF SEASON

DO NOT store machine or fuel container inside where

fumes may reach an open flame, spark or pilot light

such as in a water heater, furnace, clothes dryer or

other gas appliance. Allow engine to cool before storing

machine in an enclosure. Store fuel container out of

reach of children in a well ventilated, unoccupied

building. Refer to Sections “Safe Handling of Fuel” and

“Maintenance and Storage”, pages 2-3.

1. Thoroughly clean entire machine, engine and

debris bag.

2. Perform maintenance and lubrication as

required. Refer to Section “Maintenance

Schedule”.

3. With engine cool, drain fuel from fuel tank

outdoors into an approved container away

from all sources of ignition.

4. Run engine to remove all fuel from the

carburetor.

5. Refer to Engine Owner’s Manual for additional

engine storage procedures.

10

Page 11

Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. Stop

engine. Remove spark plug wire from spark plug

and secure away from plug. Engine and components

are HOT. Avoid serious burns, allow all parts to cool

before working on machine.

4.1 ENGINE ADJUSTMENTS & REPAIR

Refer to the engine owner’s manual for those

adjustments and repairs that can be performed by the

owner.

4.2 IMPELLER REPLACEMENT

The impeller is a wear item. The actual wear rate is

dependant on the types of debris the machine has

been used to pickup. If the machine develops

unusual noise and/or vibration STOP the engine

immediately. After allowing the engine to cool,

proceed with the following steps.

1. In an open area where fumes can safely

dissipate, drain fuel into an approved container.

2. Drain engine oil.

3. Remove sparkplug wire from sparkplug and

secure away from sparkplug.

4. With engine still attached, remove engine

mounting plate from top of impeller housing.

5. Remove bolt from end of engine crankshaft and

remove impeller. NOTE: a puller may be

required to remove the impeller from the

crankshaft.

6. Inspect the impeller blades, hub keyway, key

and crankshaft for wear or damage. Contact

your authorized dealer if you have any questions

about the impeller or associated parts.

7. Install new impeller onto crankshaft. It is

recommended that you use a new key and new

crankshaft bolt and washer. Torque bolt to 40 ftlb.

8. Reinstall engine plate to top of blower housing.

Tighten hardware securely.

9. With sparkplug wire disconnected, pull recoil

rope slowly, checking to make sure engine and

impeller rotates freely.

10. Connect sparkplug wire.

11. Fill engine crankcase to proper level with oil as

specified in the engine owner’s manual

12. Add fuel to tank.

4.3 IMPELLER HOUSING LINER REPLACEMENT

(Commercial Models Only)

The impeller housing liner is a wear item and can

be replaced. To inspect the impeller housing and

liner you must first carefully follow the WARNING

instructions listed on this page. Open up the

discharge door and visually inspect the housing

and liner (if equipped) for damage and wear. The

liner will fit commercial models only and is available

through your local authorized dealer.

11

Page 12

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Engine Will Not

Start Using

Recoil Starter

4. Fuel valve (Honda) turned “OFF”. 4. Turn fuel valve to “ON.

5. Engine speed control in “STOP” position. 5. Move control to “FAST” or “CHOKE”.

6. Engine air cleaner dirty/plugged. 6. Service/replace. See Engine Manual.

7. Faulty sparkplug. 7. Replace sparkplug. See Engine Manual.

Engine Stalls After

Running

3. Fuel tank empty. 3. Fill fuel tank with fresh fuel to proper level.

4. Engine air pre-cleaner and or air cleaner dirty. 4. Clean free of all debris.

5. Spark plug defective or gap set improperly. 5. Service or replace spark plug.

6. Fuel filter restricted (if equipped). 6. Replace fuel filter.

7. Water, debris or stale fuel in fuel system. 7. Drain and clean fuel system.

Engine Loses

Power

3. Spark plug faulty. 3. Service or replace spark plug.

4. Water, debris or stale fuel in fuel system. 4. Drain and clean fuel system. Replace filter.

5. Debris build up on engine cooling screen. 5. Clean all debris from engine cooling

Engine Backfires

When Turned To

“STOP”

Excessive Vibration

or Noise

2. Loose impeller or engine components. 2. Tighten impeller bolt, service engine.

3. Loose or missing hardware. 3. Inspect machine, tighten hardware.

Poor Vacuum

Performance

1. Fuel tank empty. 1. Fill fuel tank with fresh fuel to proper level.

2. Engine needs choking or priming. 2. Move control to “CHOKE”, press primer.

3. Spark plug wire disconnected. 3. Place spark plug wire onto spark plug.

1. Choke control in the “CHOKE” position. 1. Move control to “FAST” position.

2. Fuel valve (Honda) turned “OFF”. 2. Turn fuel valve to “ON.

1. Excessive load on engine. 1. Lessen load.

2. Engine air pre-cleaner or air cleaner dirty. 2. Clean or replace filters.

screen.

1. Throttle control set too “FAST”. 1. Set throttle control to “SLOW” and allow

engine to idle. Then “STOP” engine..

1. Damaged, out of balance or bent impeller

blades.

1. Debris bag dirty or full. 1. Clean and empty bag.

2. Accessory plug missing from nozzle. 2. Install accessory plug.

3. Vacuum inlet set too high or too low. 3. Adjus t height.

4. Engine speed control set too low. 4. Incre ase engine speed.

5. Vacuum inlet or discharge plugged with debris. 5. Remove debris.

1. Contact authorized dealer.

12

Page 13

MAINTENANCE SCHEDULE

SUBJECT SERVICE

TO BE PERFORMED

Engine Check Oil Level Page 8 X

Engine Initial Oil Change Page 10 X

Engine Periodic Oil Change Page 10 X*

REFERENCE

PAGES

EACH

USE 5 HOURS

25

HOURS

50

HOURS

100

HOURS

EACH

SEASON

Air Pre-Cleaner Service Sponge Pre-

Cleaner Element

Air Cleaner Replace Element Engine Manual X**

Spark Plug Replace Plugs Engine Manual X

Fuel Filter (if

equipped)

Engine Cooling

System

Debris Bag/Adapter Clean and inspect Page 8 & 10 X X

Inspect Machine

Hardware/Vibration

*Change oil every 25 hours when operating under heavy load or high temperatures.

**Clean more often under dusty conditions or when air debris is present

Replace Filter Engine Manual X

Clean Shrouds & Fins Engine Manual X**

Check for loose

hardware/vibration

Engine Manual X**

Page 10 X

WARNING

Grass Catcher bags used on SNAPPER products are made of woven fabric, and are subject to deterioration

and wear during normal usage. Check condition of bag before each use. Immediately replace worn or

damaged catcher bags with only bags recommended by SNAPPER.

13

Page 14

PRODUCT REGISTRATION FORM

IMPORTANT: KEEP THIS INFORMATION FOR YOUR PERSONAL RECORDS

(Complete the following information on your new purchase)

Model _____________________________________________________________________

Manufacturer Number ______________________________________________________

Serial Number _____________________________________________________________

Date of Purchase ___________________________________________________________

Retailer____________________________________________________________________

Retailer’s Phone Number____________________________________________________

A product registration card has been included with your new purchase. It is very

important that you register your purchase with the manufacturer to ensure

warranty coverage. If you have questions regarding the registration of your new

machine, please contact your local dealer.

14

Page 15

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

15

Page 16

Safety Instructions & Operator’s Manual for

PUSH YARD VACUUM

SERIES 0

IMPORTANT

These products are built using engines that meet or exceed all applicable emissions requirements on the date

manufactured. The labels on those engines contain very important emissions information and critical safety

warnings. Read, Understand, and Follow all w arnings and instructions in this manual, the engine manual, and

on the machine, engine and attachments. If you have any questions about your machine, contact your local

authorized dealer.

WARNING

BATTERY POSTS, TERMINALS AND RELATED ACCESSORIES CONTAIN LEAD AND LEAD COMPOUNDS,

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER AND BIRTH DEFECTS OR

OTHER REPRODUCTIVE HARM. WASH HANDS AFTER

WARNING

ENGINE EXHAUST, SOME OF ITS CONSTITUENTS, AND CERTAIN VEHICLE COMPONENTS CONTAIN OR

EMIT CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER OR OTHER

REPRODUCTIVE HARM.

COPYRIGHT © 2004

SNAPPER – A DIVISION OF SIMPLICITY MFG., INC.

ALL RIGHTS RESERVED

HANDLING.

MANUAL No. 7050477 (I.R. 9/17/04)

16

Loading...

Loading...