Page 1

SET-UP INSTRUCTION & PRE-OPERATION CHECKLIST

SCREWS

HEAD BOLTS

SNAPPER 21" STEEL DECK COMMERCIAL WALK BEHIND MOWERS

INTRODUCTION: The SNAPPER Walk Behind Mowers are shipped almost fully assembled and require minimal

set-up. Complete each of the following steps carefully. Review and complete each item as inst ructed on the PreOperation checklist. The Snapper Product Registration card must be filled out and sent to Customer Service

department at Snapper when completed.

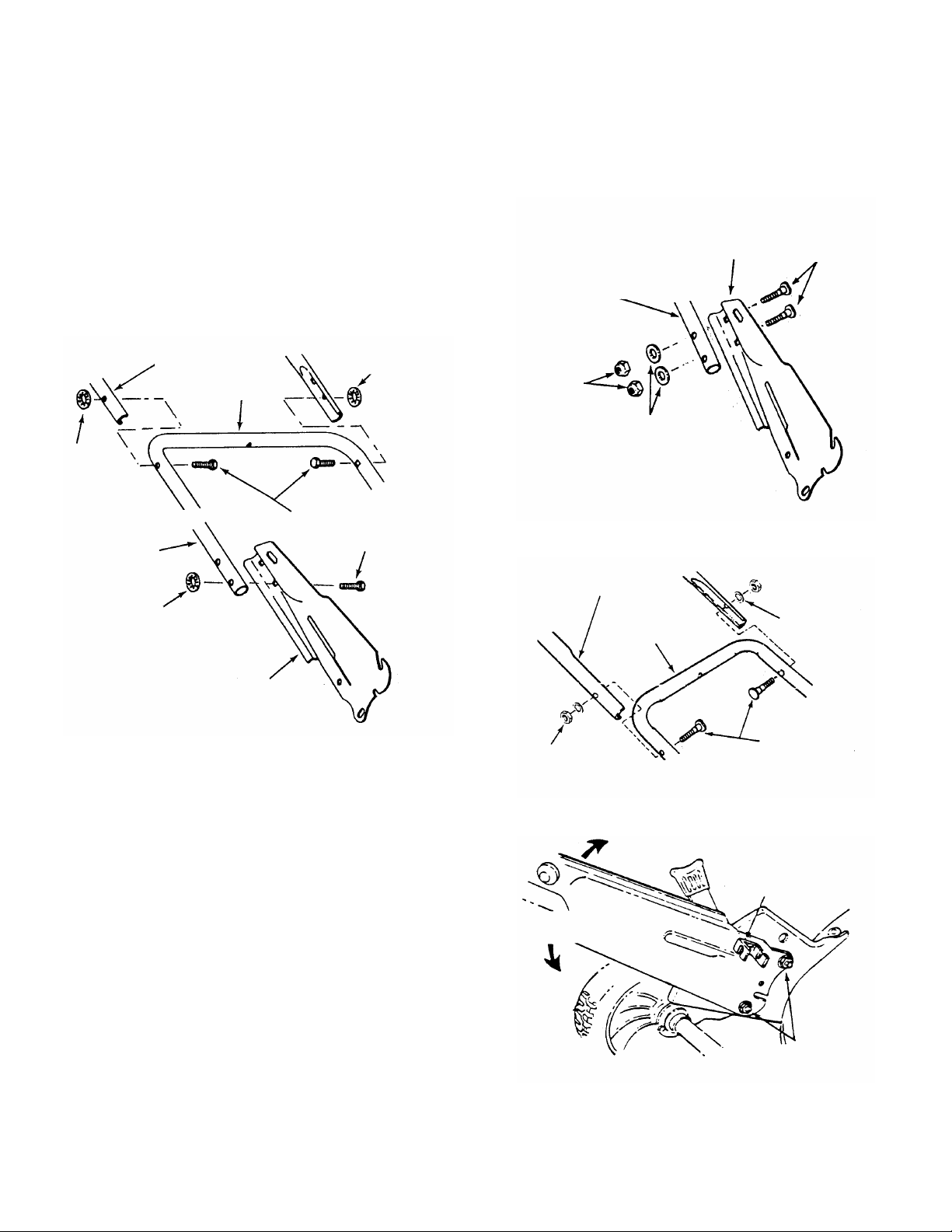

STEP 1: Remove mower from shipping carton. These

mowers are m anuf actured with (4) 5/16- 18 x 2” hex cap

screws, and (4) 5/16 bolt retainers that secure the

upper, middle handles and lower handle brackets

together for packaging purposes. This hardware will

have to be removed and discarded. See Figure 1.

UPPER

HANDLE

MIDDLE

HANDLE

5/16 BOLT

RETAINER

5/16 X 1-1/2” MACHINE

MIDDLE

HANDLE

5/16 BOLT

RETAINER

5/16 BOLT

RETAINER

5/16 X 2” HEX

HEAD CAP

SCREWS

MIDDLE

HANDLE

5/16 HEX

NUTS

5/16 LOCK

WASHERS

UPPER

HANDLE

MIDDLE

HANDLE

LOWER

HANDLE

(Left Side)

FIGURE 2

5/16 X 2”

CURVED

HEAD BOLT

INTERNAL

TOOTH LOCK

WASHER

LOWER

HANDLES

REMOVE EXISTING HARDWARE

FIGURE 1

STEP 2: New hardware can be found in hardware bag.

Attach middle handle to lower handle brackets using

5/16-18 x 2” curved head bolts, installed fr om the inside

of handles as shown, and secure with 5/16 internal

tooth lock washers and hex nuts. Do Not tighten at this

time. See Figure 2.

STEP 3: Attach the upper handle assem bly to the middle

handle using 5/16-18 x 1-1/2” curved head bolts,

installed from the inside of handles as shown, and

secure with 5/16 internal tooth lock washers and hex

nuts. Do Not tighten at this time. See Figure 3.

STEP 4: To adjus t handle height loosen bolts on both

lower handle brackets. See Figure 4. Move handles up

or down for desir ed height. T ighten all bolts and nuts on

all handles and brackets.

HEX NUT

5/16 X 1-1/2”

CURVED

FIGURE 3

LOOSEN ANCHOR

HARDWARE

MOVE HANDLES

UP OR DOWN

LOOSEN NUTS

ON BOTH SIDES

FIGURE 4

INSTRUCTION No. 7-4361 (I.R. 2/16/01)

1

Page 2

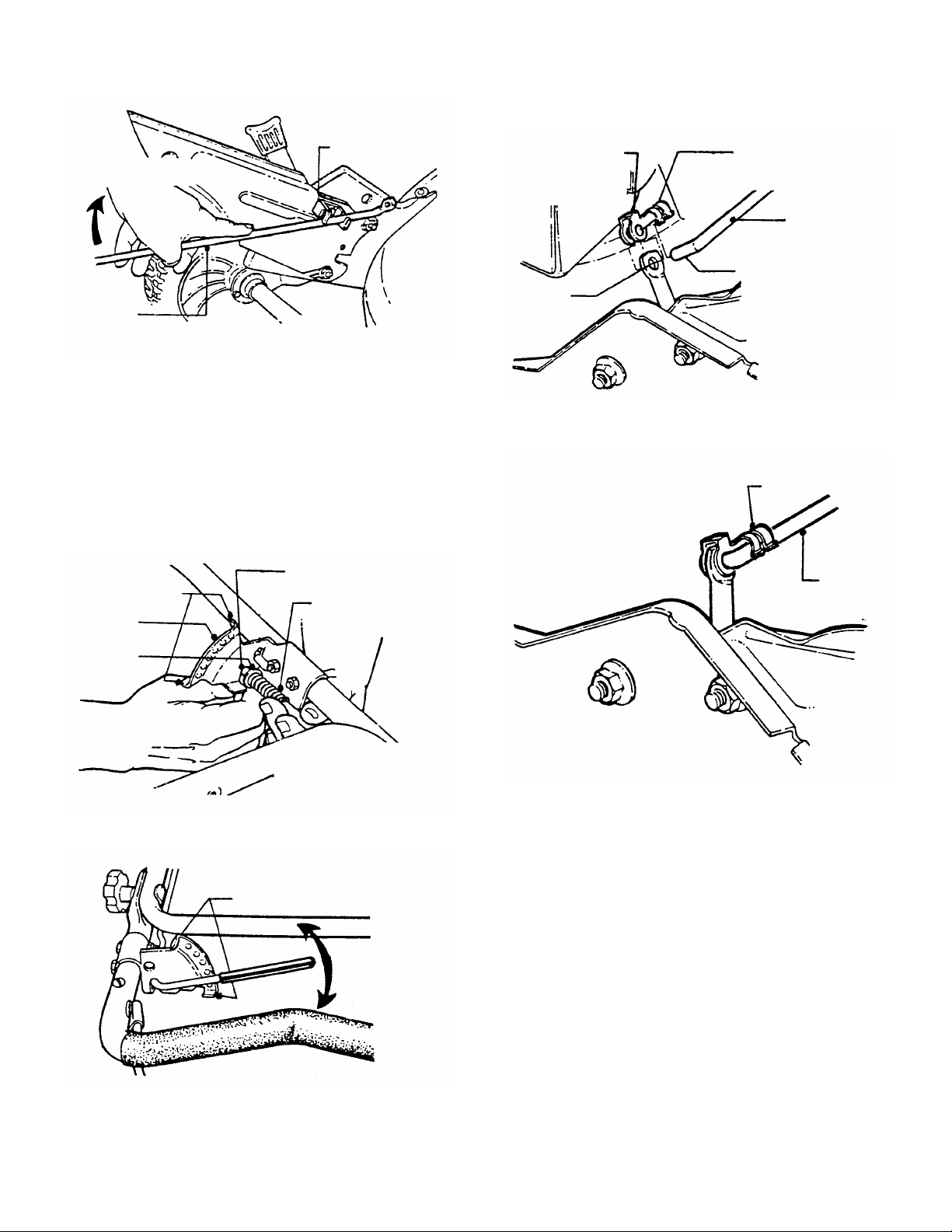

STEP 5: Install speed control rod by tilting the lever

SECTOR

down in a horizontal position and insert into the anchor

from the side as shown in Figure 5.

ANCHOR

ROTATE UPWARD TO

SPEED SECTOR

SPEED

CONTROL

ROD

FIGURE 5

STEP 6: Rotate control rod up to be connected to the

speed sector. Slide flat washer and spring in front of

speed sector. See Figure 6. Compr ess spring by pulling

backwards and pulling control lever into the notch. Pull

backwards far enough to clear the sector flanges . This

will lock speed control lever handle into position. Contr ol

rod should move bac k and forth freely between sector

flanges. See Figure 7.

SECTOR

FLANGES

SPEED

NOTCH

SPRING

STEP 7: Insert the transf er rod into the hole in the end

of the control rod and clip as shown in Figure 8. Hold

transfer rod in place rotate clip over until it snaps into

position onto transfer rod. See Figure 9.

1. PLACE END OF

CLIP OVER END OF

CONTROL ROD.

HOLE IN

CONTROL

ROD

3. PRESS END OF

CLIP DOWN ONTO

TRANSFER ROD.

TRANSFER

ROD

2. INSERT END OF

TRANSFER ROD

THRU HOLE IN CLIP

AND CONTROL ROD.

FIGURE 8

RETAINING

CLIP

SNAP CLIP ONTO

TRANSFER

TRANSFER

ROD

FLAT

WASHER

PUSH UP INTO NOTCH AND PULL

TOWARD OPERATOR UNTIL HANDLE

CLEARS SECTOR FLANGES

FIGURE 6

SECTOR FLANGES

FIGURE 7

MOVE BACK AND

FORTH BETWEEN

FLANGES

FIGURE 9

2

Page 3

STEP 8: Check the clearance between the clutch cable

CLEARANCE

OUTSIDE EDGE

POSITION

and clutch spring. NOTE: Clearance between spring and

cable is very important. Excessive clearance will cause

drive system not to operate when wheel drive control

handle is depressed. No clearance at all will cause mower

to continue to propell itself when wheel drive control handle

is released to stop the mowers f orward movement. Slide

vinyl spring cover (located at the end of clutch cable) up

clutch cable to gain access to the end of spring and cable

loop. With wheel drive contr ol handle released, clearance

between spring hook and cable loop should be 1/16” to

1/8”. If clearance is more or less than specified, unhook

spring from clutc h cable eye, then adjust by turning inner

spring in an opposite direction than the outer spring.

Rehook spring to clutch cable eye. Slide vinyl cover over

the spring when correct clear ance is reached. See Figure

10.

CLUTCH CABLE

B. Remove driven disc spring from driven disc

assembly as shown. Loosen connector hex-nut.

See Figure 12.

DRIVEN DISC

ASSEMBLY

DRIVE

DISC

DRIVEN

DISC

SPRING

VINYL SPRING COVER

1/16” - 1/8”

OUTER

SPRING

INNER

SPRING

CABLE

CLUTCH

CABLE EYE

SPRINGS

FIGURE 10

STEP 9: Driven disc to drive disc adjustment is set up

at the factory. In case dr iven dis c may need adjustment,

proceed as follows:

A. Place speed control r od in the number six speed

position. See Figure 11.

MOVE GROUND

SPEED CONTROL TO

SIX SPEED POSITION

TRANSFER

ROD

CONNECTOR

HEX NUT

FIGURE 12

C. Slide driven disc assembly over until 1/8” from

outside edge of drive disc. Maintaining the 1/8”

measurement, remove any looseness from the

linkage. This can be done by holding the transfer

rod and applying pressure to the left, (as viewed

from operators position), then retighten the

connector hex-nut securely. See Figure 13. Move

shift rod to the number one speed position, then

back to the num ber s ix s peed position. Rec hec k the

1/8” measurement described previously. Reinstall

driven disc spring to driven disc assembly.

1/8” MEASUREMENT

TO OUTSIDE EDGE OF

DRIVE DISC

SLIDE DRIVEN DISC

ASSEMBLY TOWARD

DRIVE

DISC

SIX

SIX SPEED POSITION

ONE

ONE SPEED

FIGURE 11

TRANSFER

ROD

3

OUTSIDE

EDGE

CONNECTOR HEX NUT

FIGURE 13

Page 4

STEP 10: Install the grass bag adapter and secure to

DECK WITH NUTS

SUPPORT ROD

ROPE GUIDE

the side of the dec k with the two 5/16-18 nuts (P/N 9-

0951) provided in the hardware bag. See Figure 14.

SECURE ADATER TO

FIGURE 14

STEP 11: KAWASAKI ENGINE. Attach support rod to

deck adapter by first removing the nut and bolt at the

rope guide pulley. Reassemble with the support rod

underneath the pulley and the flattened end of the rod

towards the engine. Attach the support rod to the top of

the engine. Remove the nut and washer from the right

rear corner of the recoil housing as shown. Place the

support rod over the threaded engine stud. Install nut

only (washer not needed) and re-tighten the nut. See

Figure 15.

STEP 11: ROBIN 4-CYCLE ENGINE. The installation

of the support rod on the Robin 4-cycle engine is

saimilar to the installation on the Kawasaki engine

described above. On the Robin installation, the rope

guide end of the support rod is on top of the pulley and

the flattened end is attached to the engine with a 6 MM

hex bolt and flat washer (included in the hardware bag

with the mower). A support rod is not required on

mowers equiped with Robin 2-cycle engines. See

Figure 16.

FIGURE 15

SUPPORT ROD

ON TOP OF ROPE

GUIDE PULLEY

6 MM HEX BOLT

AND FLAT

WASHER

FIGURE 16

4

Page 5

STEP 12: Fold bag opening into a "Z" and install slider.

FIGURE 17

See Figure 17.

GRASP SLIDER.

PULL Z-FOLD INTO

SLIDER

FIGURE 15

PULL

STEP 13: Install grass bag on the mower. Slide bag

connector over flange on the bag adapter. Attach grass

bag handle to middle handle cross bar. See Figure 18.

ROPE

GUIDES

BLADE CONTROL

HANDLE

BAG CONNECTOR

FIGURE 18

IMPORTANT: DO NOT tip machine with carburetor or

spark plug down. Oil f rom crank case will saturate the air

filter and cause the engine to be hard to s tart or not start

at all. If contamination does occ ur, the air filter will have

to be replaced.

STEP 14: Tip m o wer back against the upper handle to gain

access to the unders ide of the cutting blade. Remove f oam

shipping block from cutting blade. This must be removed

before starting the engine.

STEP 15: Pull blade control up against handle. Pull recoil

rope out and route rope around pulley guide on bag adapter

and loop rope into guide on upper handle. See Figure 18.

STEP 16: CHECKLIST: Complete all items on the PreOperation Checklist as instructed.

5

Page 6

PRE-OPERATION CHECKLIST for SNAPPER

21” STEEL DECK SERIES 12 WALK BEHIND MOWERS

Snapper has completed initial adjustments and performed operational tests prior to shipping the machine. Due to

the possible effects of shipping, handling and storage, Snapper intends for all of the following items to be

verified and necessary final adjustments made at time of setup. It remains good practice and is strongly

recommended that all the items also be checked prior to placing the machine into service. It is very important that

setup is verified and all operatio nal tests completed and results are acceptable. After completing this form, sign

and retain for future reference.

SET-UP (Details on Pages 1 through 4 of this Instruc tion)

_____ FOAM SHIPPING BLOCK removed from cutting blade.

_____ UPPER HANDLE & LOWER HANDLE secured in place and hardware tightened securely.

_____ SIDE CHUTE or GRASS BAG installed on mower.

_____ BLADE retaining bolt(s) checked and tighten securely.

_____ GROUND SPEED LEVER installed and connected to drive system.

LUBRICATION

_____ ENGINE OIL added to bring level up to full mark on 4-cycle engines (Refer to Engine Manual).

_____ OIL mixed with FUEL in specified ratio (2 Cycle Engines Only).

_____ DIFFERENTIAL grease checked and added if needed.

OPERATIONAL TEST

_____ ENGINE started, engine control settings checked and adjusted as needed.

_____ WHEEL DRIVE checked for proper operation and adjusted as needed.

_____ CHUTE INTERLOCK checked to insure proper functioning.

_____ GROUND SPEED control checked and adjusted as needed.

CPSC (Consumer Product Safety Commission) COMPLIANCE TEST

_____ BLADE CONTROL stops engine when released.

CONSUMER INFORMATION

Purchase Date ___________________ Model________________________ Serial No. _______________________

Retailers Name ____________________________________ Signature_____________________________________

Address ______________________________________ City ____________________ State ________ Zip ______

MOWER WILL BE USED COMMERCIALLY? ______ YES _____ NO

Purchaser’s Name __________________________________ Signature ____________________________________

Address _____________________________________ City _____________________ State _______ Zip _______

IMPORTANT: This fo rm is to be retained for future reference regarding Warranty, proof of purchase, traceability

for product recall or service, etc. Complete the Product Registration Card and Mail to Customer Service

Department at SNAPPER, P.O. BOX 1379, McDonough, Georgia, 30253.

INSTRUCTION No. 7-4361 (I.R. 2/16/01)

6

Loading...

Loading...