0 5implicilq

®

TM

0

A

ATO

UAL

520M Models

Mfg. No. Description

1693643 520M, 5HP Snowthrower, Manual Start

1693645 520M, 5HP Snowthrower, Manual Start (CE)

85630 SS5200R, 5HP Snowthrower, Manual Start

520E Models

Mfg. No. Description

1693644 520E, 5HP Snowthrower, Electric Start

85631 SS5200E, 5HP Snowthrower, Electric Start

1720536-03

Rev 5/2003

TP 100-2290-03-SW-SN

(ableofContents

Safety Rules & Information

General ................................................................... 2

Slope Operation ...................................................... 2

Children ................................................................... 3

Emissions ................................................................ 3

Service & Maintenance ........................................... 3

ANSI B71.3-1995 Warnings .................................... 4

Identification Numbers ............................................ 5

Safety Decals .......................................................... 6

International Symbols ............................................. 6

Assembling the Snowthrower .................................... 7

Controls & Operation

Snowthrower Controls ............................................. 8

Engine & Starting Controls ...................................... 9

General Operation ................................................ 10

Checks Before Each Start-Up ............................... 10

Mixing Fuel ............................................................ 11

Starting the Engine ............................................... 12

Stopping the Engine .............................................. 12

Operating the Snowthrower .................................. 13

Snowthrowing Tips ................................................ 13

After Each Use ...................................................... 13

Off-Season Storage .............................................. 13

Starting After Storage ........................................... 11

Regular Maintenance

Removing Belt Cover ............................................ 14

Lubrication ............................................................ 14

Troubleshooting & Service

Troubleshooting .................................................... 15

Removing Engine Cover ....................................... 15

Auger Control Cable Adjustment .......................... 16

Carburetor Adjustment (Ref. only) ........................ 16

Replacing the Drive Belt ....................................... 17

Replacing the Scraper Blade ................................ 17

Servicing the Spark Plug ....................................... 17

Appendices

Specifications ........................................................ 18

Parts & Accessories .............................................. 18

Technical Manuals ................................................ 18

,_ WARNING

Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

Readthesesafetyrulesandfollowthemclosely.Failuretoobeytheserulescouldresultinlossofcontrol

ofunit,severepersonalinjuryordeathtoyou,orbystanders,ordamagetopropertyorequipment.

Thetriangle_, intextsignifiesimportantcautionsorwarningswhichmustbefollowed.

GENERAL OPERATION

= Read, understand, and follow all instructions inthe

manual and on the unit before starting.

• Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

• Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown.

• Be sure the area is clear of other people. Stop unit if

anyone enters the area.

• Always look down and behind before and while trav-

elling in reverse.

Be aware of the discharge direction and do not point

it at anyone. Do not point the discharge at glass

enclosures, automobiles, or windows.

Disengage all clutches (release drive and auger con-

trol levers) before starting the engine.

Never leave a running unit unattended. Always disen-

gage the auger and traction controls, stop engine,

and remove keys.

Stop engine before unclogging chute.

• Operate only in daylight or good artificial light.

Do not operate the unit while under the influence of

alcohol or drugs.

• Watch for traffic when operating near or crossing

roadways.

Use extra care when loading or unloading the unit

into a trailer or truck.

• Keep in mind the operator is responsible for acci-

dents occurring to other people or property.

Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the unit safely enough

to protect themselves and others from injury.

• All operators should seek and obtain professional

and practical instruction.

Always wear substantial footwear and appropriate

winter clothing. Wear foot-ware that improves trac-

tion on slippery slopes. DO NOT wear long scarves

or loose clothing that could become entangled in

moving parts.

• Before using, always visually check that all hardware

is present, in-tact, and secure. Replace worn or

damaged parts.

• Never operate the machine with defective guards, or

without safety protective devises in place.

Stop engine before: refuelling, removing an attach-

ment, making adjustments (unless the adjustment

can be made from the operator's position).

• Follow the manufacturer's recommendation for wheel

weights or counterweights.

• Adjust skid shoe height to clear gravel or crushed

rock surfaces.

• Do not touch snowthrower parts which may be hot

from operation. Allow such parts to cool before

attempting to service the unit.

SLOPE OPERATION

WARNING

Never operate on slopes greater than 17.6 percent (10 °) which

is a rise of 3=1/2 feet (106 cm) vertically in 20 feet (607 cm)

horizontally.

When operating on slopes use additional wheel weights or

counterweights. See your dealer to determine which weights

are available and appropriate for your unit.

Select slow ground speed before driving onto slope. Travel

UP and DOWN the slope, never across the face, use caution

when changing directions and DO NOT START OR STOP ON

SLOPE.

Slopes are a major factor related to loss-of-control and tip-

over accidents, which can result in severe injury or death.

All slopes require extra caution. If you cannot back up the

slope or if you feel uneasy on it, do not operate on it.

TP-600-3606-00-LW-UV

Do

See your authorized dealer for recommendations

counterweights to improve stability.

• Travel up and down slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Snow can hide obstacles.

• Use slow speed. Tires may lose traction on slopes.

Choose a low gear so that you will not have to stop or

shift while on the slope.

Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

Always keep unit in gear especially when traveling

downhill.

Do Not

• Do not start or stop on a slope. If tires lose traction,

disengage the auger and proceed slowly straight

down the slope.

• Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

• Do not operate near drop-offs, ditches, or embank-

ments. The unit could suddenly turn over if a wheel is

over the edge of a cliff or ditch, or if an edge caves in.

Do not operate on wet surfaces. Reduced traction

could cause sliding.

Do not shift to neutral and coast down hills.

Safety Rules

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

unit and the operating activity. Never assume that children

will remain where you last saw them.

* Keep children out of the area and under the watchful

care of another responsible adult.

* Be alert and turn unit off if children enter the area.

* Before and during reverse operation, look behind and

down for small children.

* Never allow children to operate the unit.

* Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

SERVICE AND MAINTENANCE

* Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

a) Use only an approved container.

b) Never remove gas cap or add fuel with the

engine running. Allow engine to cool

before refueling. Do not smoke.

c) Never refuel the unit indoors.

* Iffuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

* Replace all fuel tank caps and fuel container caps

securely.

* Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on

the ground away from your vehicle before filling.

* Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possi-

ble, then refuel such equipment on a trailer with a

portable container, rather than from a gasoline dis-

penser nozzle.

* Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is com-

plete. Do not use a nozzle lock-open device.

* If fuel is spilled on clothing, change clothing immedi-

ately.

* Maintain or replace safety and instruction labels as

necessary.

* Never run a unit in an enclosed area.

* Keep nuts and bolts tight and keep equipment in

good condition.

* Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

EMISSIONS

* Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

* Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

* Keep unit free of debris build-up. Clean up oil or fuel

spillage.

* Stop and inspect the equipment if you strike an

object. Repair, if necessary, before restarting.

* Never make adjustments or repairs with the engine

running unless specified otherwise in the engine

manufacturer's manual.

* Components are subject to wear, damage, and dete-

rioration. Frequently check components and replace

with manufacturer's recommended parts, when nec-

essary.

* Check control operation frequently. Adjust and ser-

vice as required.

* Use only factory authorized replacement parts when

making repairs.

* Always comply with factory specifications on all set-

tings and adjustments.

* Only authorized service locations should be utilized

for major service and repair requirements.

* Never attempt to make major repairs on this unit

unless you have been properly trained. Improper ser-

vice procedures can result in hazardous operation,

equipment damage and voiding of manufacturer's

warranty.

* Do not change engine governor settings or over-

speed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

* Disengage auger and traction, stop the engine,

remove the key, and disconnect the spark plug

wire(s) before: clearing blockages and chutes, per-

forming service work, striking an object, or if the unit

vibrates abnormally. After striking an object, inspect

the machine for damage and make repairs before

restarting and operating the equipment.

3

Safety Rules

ANSI B71.3-1995 WARNINGS

Training

1. Read the operating and service instruction manual

carefully. Be thoroughly familiar with the controls and

the proper use of the equipment. Know how to stop

the unit and disengage the controls quickly.

2. Never allow children to operate the equipment.

Never allow adults to operate the equipment without

proper instruction.

3. Keep the area of operation clear of all persons, par-

ticularly small children and pets.

4. Exercise caution to avoid slipping or falling especially

when operating in reverse.

Preparation

1. Thoroughly inspectthe area where the equipment is

to be used and remove all doormat, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting engine (motor).

3. Do not operate the equipment without wearing ade-

quate winter outer garments. Wear footwear that will

improve footing on slippery surfaces.

4. Handle fuel with care; itis highly flammable.

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

(d) Replace fuel cap securely and wipe up spilled

fuel.

5. Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive

motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or

crushed rock surfaces.

7. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by the manufacturer).

8. Let engine (motor) and machine adjust to outdoor

temperatures before starting to clear snow.

9. Always wear safety glasses or eye shields during

operation or while performing an adjustment or repair

to protect eye from foreign objects that may be

thrown from the machine.

Operation

1. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

3. After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug, discon-

nect the cord on electric motors, thoroughly inspect

the snowthrower for any damage, and repair the

damage before restarting and operating the

snowthrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the

operating position, before unclogging the

collector/impeller housing or discharge guide, and

when making any repairs, adjustments, or inspec-

tions.

6. When cleaning, repairing, or inspecting make certain

the collector/impeller and all moving parts have

stopped. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

7. Do not run the engine indoors except for starting the

engine or for transporting the snowthrower in or out

of the building. Open the outside doors; exhaust

fumes are dangerous.

8. Do not clear snow across the face of slopes.

Exercise extreme caution when changing direction on

slopes. Do not attempt to clear steep slopes.

9. Never operate the snowthrower without proper

guards plates, or other safety protective devises in

place.

10. Never operate the snowthrower near glass enclo-

sures, automobiles, window wells, drop-offs, and the

like without proper adjustment of the discharge angle.

Keep children and pets away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12. Never operate the machine at high transport speeds

on slippery surfaces. Look behind and use care

when backing.

13. Never direct discharge at bystanders or allow anyone

in front of the unit.

14. Disengage power to the collector/impeller when

snowthrower is transported or not in use.

15. Use only attachments and accessories approved by

the manufacturer of the snowthrower (such as wheel

weights, counterweights, cabs, and the like).

16. Never operate the snowthrower without good visibility

or light. Always be sure of your footing, and keep a

firm hold on the handles. Walk, never run.

Maintenance and Storage

1. Check shear bolts and other bolts at frequent inter-

vals for proper tightness to be sure the equipment is

in safe working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water and spacer heaters, clothes dryers,

and the like. Allow the engine to cool before storing

in any enclosure.

3. Always refer to the operator's guide instructions for

important details if the snowthrower is to be stored for

an extended period.

4. Maintain or replace safety and instruction labels as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

* Always observe safe refueling and fuel handling prac-

tices when refueling the unit after transportation or

storage.

* Always follow the engine manual instructions for stor-

age preparations before storing the unit for both short

and long term periods.

* Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

Manufacturing, Inc,

W] 53074-0997 U,S,A,

SERIAL

169XXXX

Mfg. Ng'._' 169XXXX _' _"

se,al_\_J/ _xxx _00_'IV ._.._.1

kw "_Z_/x I ..... I

Vibration @ Whee 2

Product Idefltificatiofl

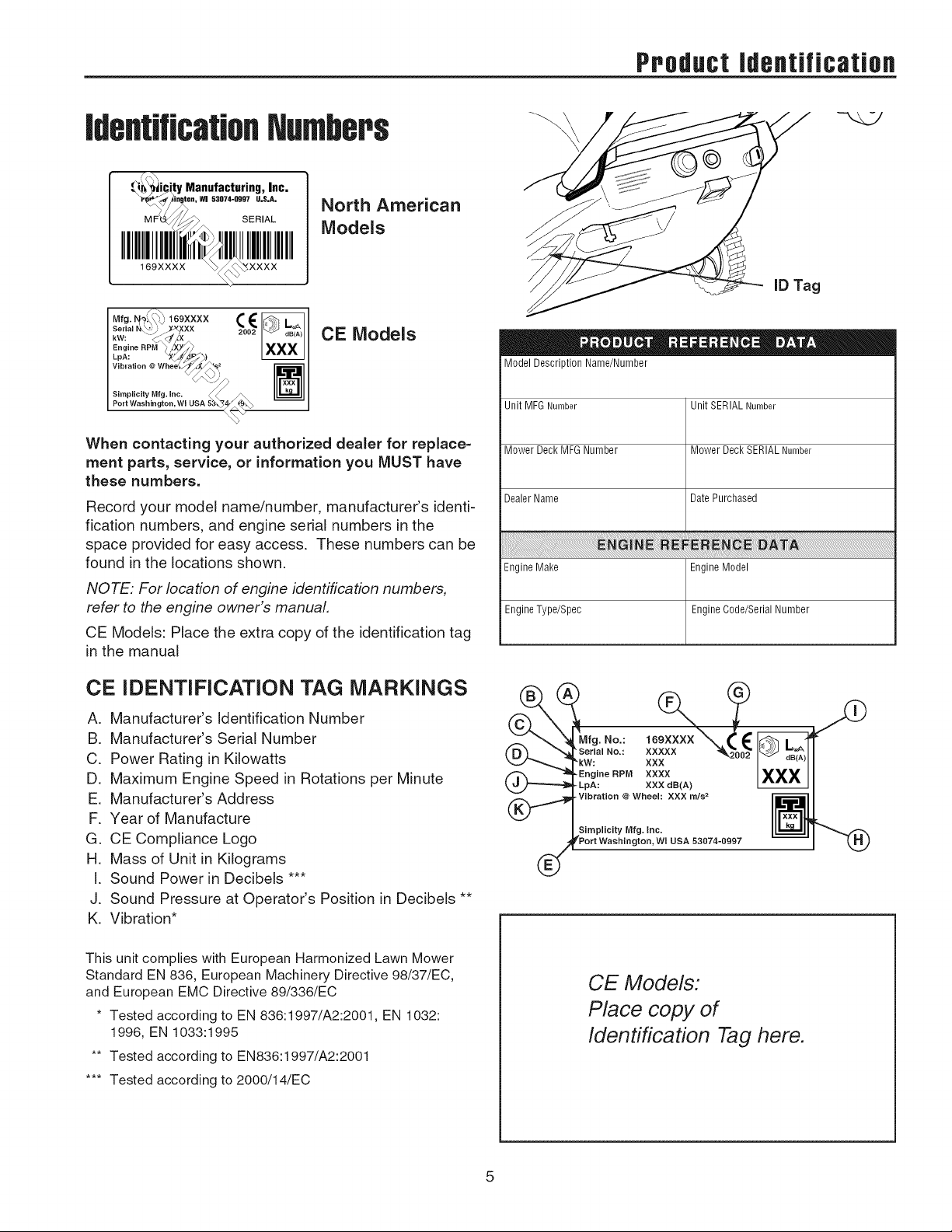

North American

iVlodels

ID Tag

CE iVlodels

Model Description Name/Number

Simplicity Mfg. inc. _ _ /_

I Po_twa_hi.gto.,wlusas_

_'_

When contacting your authorized dealer for replace-

ment parts, service, or information you MUST have

these numbers.

Record your model name/number, manufacturer's identi-

fication numbers, and engine serial numbers inthe

space provided for easy access. These numbers can be

found in the locations shown.

NOTE: For location of engine identification numbers,

refer to the engine owner's manual.

CE Models: Place the extra copy of the identification tag

in the manual

CE iDENTiFiCATiON TAG MARKINGS

A. Manufacturer's Identification Number

B. Manufacturer's Serial Number

C. Power Rating in Kilowatts

D. Maximum Engine Speed in Rotations per Minute

E. Manufacturer's Address

F. Year of Manufacture

G. CE Compliance Logo

H. Mass of Unit in Kilograms

I. Sound Power in Decibels ***

J. Sound Pressure at Operator's Position in Decibels **

K. Vibration*

Unit MFGNumber

Mower Deck MFG Number

Dealer Name

Engine Make

Engine Type/Spec

M,g.,o.:'xx"xxx" 2o02

k Serial No.:

_'kW: XXX

_Engine RPM XXXX

LpA: XXX dB(A)

-Vibration @ Wheel: XXX m/a 2

Simplicity Mfg. inc.

f'Port Washington, Wl USA 53074-0997

Unit SERIAL Number

Mower Deck SERIAL Number

Date Purchased

Engine Model

Engine C0de/SerialNumber

This unit complies with European Harmonized Lawn Mower

Standard EN 836, European Machinery Directive 98/37/EC,

and European EMC Directive 89/336/EC

* Tested according to EN 836:1997/A2:2001, EN 1032:

1996, EN 1033:1995

** Tested according to EN836:1997/A2:2001

*** Tested according to 2000/14/EC

CE Models:

Place copy of

Identification Tag here.

5

Loading...

Loading...