Page 1

Safety Instructions and Operator’s Manual for

PRO GEAR EXPRESS

WALK BEHIND MOWERS

MID-SIZE

SERIES 0

POWER UNIT

MODEL

SPE1250KW

SPE140KW

SPE150KH

MOWER UNIT

MODEL

SPE360

SPE480

MODEL NUMBER EXPLANATION

S P E 125

MODEL DESIGNATION ENGINE TYPE

MODEL TYPE SERIES DESIGNATION

MODEL OPTION ENGINE HP

S – Snapper Commercial Model ENGINE HORSE POWER CUTTING DECK WIDTH 0 - Series Designation KW – Kawasaki Engine

P – Pro Mid Size M odel 125 – 12.5 Engine HP 360 – 36” Cutting Deck KH – Kohler Engine

E – Express Model 140 – 14.0 Engine HP 480 – 48” Cutting Deck

150 – 15.0 Engine HP

Thank you for buying a SNAPPER Product! Before operating your PRO GEAR WALK BEHIND, read this manual

carefully and pay particular attention to the “IMPORTANT SAFETY INSTRUCTIONS” on Pages 2 & 3. Remember that all

power equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

0 KW

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 4-5192 (REV. 2, 8/20/99)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerf ul cutting machine is capab le of amputating hand s and feet and can throw objects that

can cause injury and damage! Failure to comply with the follow ing SAFETY instru ctions could resu lt in serious

injury or death to the operator or other persons. The owner of the machine must understand these instructions

and must allow only persons who understand these instructions to operate machine. Each person operating the

machine must be of sound mind and body and must not be under the influence of any substance, which might

impair vision, dexterity or judgment. If you have any questions pertaining to your machine which your dealer

cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough,

Georgia 30253. Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

Tragic accidents can occu r if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you last

saw them.

1. KEEP children out of the mowing area and under

the watchful care of a responsible adult.

2. DO NOT allow children in yard when machine is

operated (even with the blades OFF).

3. DO NOT allow children or others to ride on

machine or on attachments (even with the blades

OFF). They may fall and be seriously injured.

4. DO NOT allow pre-teenage children to operate

machine.

5. ALLOW only adults or responsible teenagers with

mature judgment under close adult supervision to

operate machine.

6. DO NOT operate blades in reverse. STO P BLADES.

LOOK and SEE behind an d down for children, pets

and hazards before and while backing.

7. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

SLOPE OPERATION

1. Slopes are a major factor related to slip and fall

accidents, which can result in severe injury. All

slopes require extra caution. If you feel uneasy on

a slope, DO NOT mow it.

2. Mow across slopes, never up and down. Exercise

extreme CAUTION when changing directions on

slopes. Practice operation of machine on slopes

with blades off.

3. Use extra care with grass catchers or other

attachments: these affect the handling and the

stability of the machine.

4. DO NOT use tow behind attachments on slopes.

5. AVOID uphill starts.

6. DO NOT operate machine under any condition

where traction, steering or stability is doubtful.

PREPARATION

1. Read, understand and follow instructions and

warnings in this manual and on the machine,

engine, and attachments. Know the controls and

the proper use of the machine before starting.

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

3. Data indicates that operators age 60 and above,

are involved in a large percentage of mowerrelated injuries. These operators should evaluate

their ability to operate the mower safely enough to

protect themselves and others from serious injury.

4. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved

fuel container. DO NOT remove fuel cap or add

fuel with engine running. Add fuel outdoors only

with engine stopped and cool. Clean spilled fuel

from machine. DO NOT smoke.

5. Practice operation of machine with BLADES OFF

to learn controls and develop skills.

6. Check the area to be mowed and remove all

objects such as toys, wire, rocks, limb s and other

objects that could cau se injury if thrown by blade

or interfere with mowing.

7. Keep people and pets out of mowing area.

Immediately, STOP blades, STOP engine, and Stop

machine if anyone enters the area.

8. Check shields, deflectors, switches, blade

controls and other safety devices frequently for

proper operation and location.

9. Make sure all safety decals are clearly legible.

Replace if damaged.

10. Protect yourself when mowing and wear safety

glasses, long pants and substantial footwear.

11. Know how to STOP blades and engine quickly in

preparation for emergencies.

12. Use extra care when loading or unloading the

machine into a trailer or truck.

13. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or worn spots.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

OPERATION

1. DO NOT put hands or feet near or under rotating

parts. Keep clear of the discharge area w h ile th e

engine is running.

2. Stop Blades w hen crossing gravel drive, w alks,

and under any conditions where thrown objects

might be a hazard.

3. Mow only in daylight or good artificial light.

4. DO NOT operate the machine while under the

influence of alcohol or drugs.

5. After striking a foreign object or if the mower

vibrates abnormally, STOP the blades and

engine. Remove the key. Disconnect and secure

the spark plug wire. Inspect the mower for any

damage and repair the damage.

6. DO NOT operate machine near drop offs,

ditches, or embankments. Operator could lose

footing or balance.

7. STAY ALERT for holes and other hidden

hazards. Tall grass can hide obstacles. Keep

away from ditches, washouts, culverts, fences

and protruding objects.

8. DO NOT operate machine on wet grass. Always

be sure of your footing: keep a firm grip on the

handle and walk: never run. Slipping could

cause injury.

9. DO NOT leave the machine with the engine

running. STOP BLADES, STOP ENGINE and

REMOVE KEY before leaving the operator

position for any reason.

10. Before cleaning, repairing, or inspecting make

certain blades, engine and all moving parts

have STOPPED. Remove key and secure spark

plug wire away from spark plug key to prevent

accidental starting.

11. STOP BLADES and ENGINE and make sure

blades have stopped before removing grass

catcher or unclogging mower to prevent loss of

fingers or hand.

12. Blades must be OFF except when cutting grass.

Set blades in highest position when mowing

over rough ground.

13. Keep hands and feet away from rotating blades

underneath deck.

14. DO NOT operate machine without entire grass

catcher or guards in place. DO NOT point

discharge at people, passing cars, windows or

doors.

15. Slow down before turning.

16. Watch out for traffic when near or crossing

roadways.

17. Move motion control levers SLOWLY to

maintain control during speed and directional

changes.

18. DO NOT operate engine in enclosed areas.

Engine exhaust gases contain carbon

monoxide, a deadly poison.

MAINTENANCE

1. DO NOT store machine or fuel container inside

where fumes may reach an open flame, spark or

pilot light such as in a water heater, furnace,

clothes dryer or other gas appliance. Allow

engine to cool before storing machine in an

enclosure. Store fuel container o ut of the reach

of children in a well ventilated, unoccupied

building.

2. Keep engine free of grass, leaves or excess grease

to reduce fire hazard and engine overheating.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from open

flame.

4. Check brakes frequently (if equipped); adjust,

repair or replace as needed.

5. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

6. Always provide adequate ventilation when running

engine. Exhaust gases contain carbon monoxide,

an odorless and deadly poison.

7. Disconnect negative (black) cable from battery

(if equipped) before performing maintenance or

service. Cranking engine could cause injury.

8. DO NOT work under machine without safety

blocks.

9. Service engine and make adjustments only

when engine is stopped. Remove key. Remove

spark plug wire(s) from spark plug(s) and

secure wire(s) away from spark plug(s).

10. DO NOT change engine governor speed

settings or overspeed engine.

11. Lubricate machine at intervals specified in

manual to prevent controls from binding.

12. Mow er blades are sharp and can cut. Wrap the

blades or wear heavy leather gloves and use

CAUTION when handling them.

13. DO NOT test for spark by grounding spark plug

next to spark plug hole; spark plug could ignite

gas exiting engine.

14. Have machine serviced by an authorized

SNAPPER dealer at least once a year and have

the dealer install any new safety devices.

15. Use only genuine SNAPPER replacement parts

to assure that original standards are

maintained.

3

Page 4

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS...................................................................................2-3

TABLE OF CONTENTS................................................................................................................4

SECTION 1 - FAMILIARIZATION.................................................................................................5

SECTION 2 - Safety Messages & Decals ...................................................................................6

Controls.................................................................................................................7

SECTION 3 - OPERATING INSTRUCTIONS..........................................................................8-14

Before Operating............................................................................................................8

Emergency Stop – Pistol Grip.......................................................................................8

Normal Operating Stop – Pistol Grip............................................................................8

Pre-Start Checklist .........................................................................................................9

Starting and Operating .............................................................................................9-11

Reverse Operation........................................................................................................11

Traction Lock Operation – Pistol Grip........................................................................12

Turning Mower..............................................................................................................12

Mowing and Turning on Hillsides...............................................................................12

Cutting Height Adjustment (Fixed Decks) .................................................................13

Adjusting Caster Wheels.............................................................................................13

Adjusting Blade on Cutter Spindle........................................................................13-14

Adjusting Fixed Deck Attachment ..............................................................................14

SECTION 4 - TROUBLESHOOTING.....................................................................................15-16

Engine Troubleshooting..............................................................................................15

Mower Troubleshooting .........................................................................................15-16

Transmission Troubleshooting...................................................................................16

Service & Lubrication...................................................................................................16

SECTION 5 - ADJUSTMENTS ..............................................................................................17-18

Steering and Brakes.....................................................................................................17

Traction Levers & Rods...............................................................................................17

Handle Height ...............................................................................................................18

Ground Speed Control Lever Adjustment .................................................................18

SECTION 6 - POWER UNIT SERVICE ......................................................................................19

Replacement Parts.......................................................................................................19

Transmission Parts & Service.....................................................................................19

General Transmission Servicing ................................................................................19

Transmission/Lube ......................................................................................................19

SECTION 7 - MOWER ATTACHMENT SERVICE.....................................................................20

Transmission Belt Removal/Installation ....................................................................20

Traction Belt Removal/Installation .............................................................................20

Cutter Deck Belt Removal/Installation .......................................................................20

Cutting Blade Service: Removal, Sharpening, Balancing & Replacement.............21

Mower Spindles (Field Serviceable Spindles) Bearing Replacement.....................22

ELECTRICAL.........................................................................................................................23-24

WARRANTY................................................................................................................................25

PRIMARY MAINTENANCE....................................................................................................26-29

4

Page 5

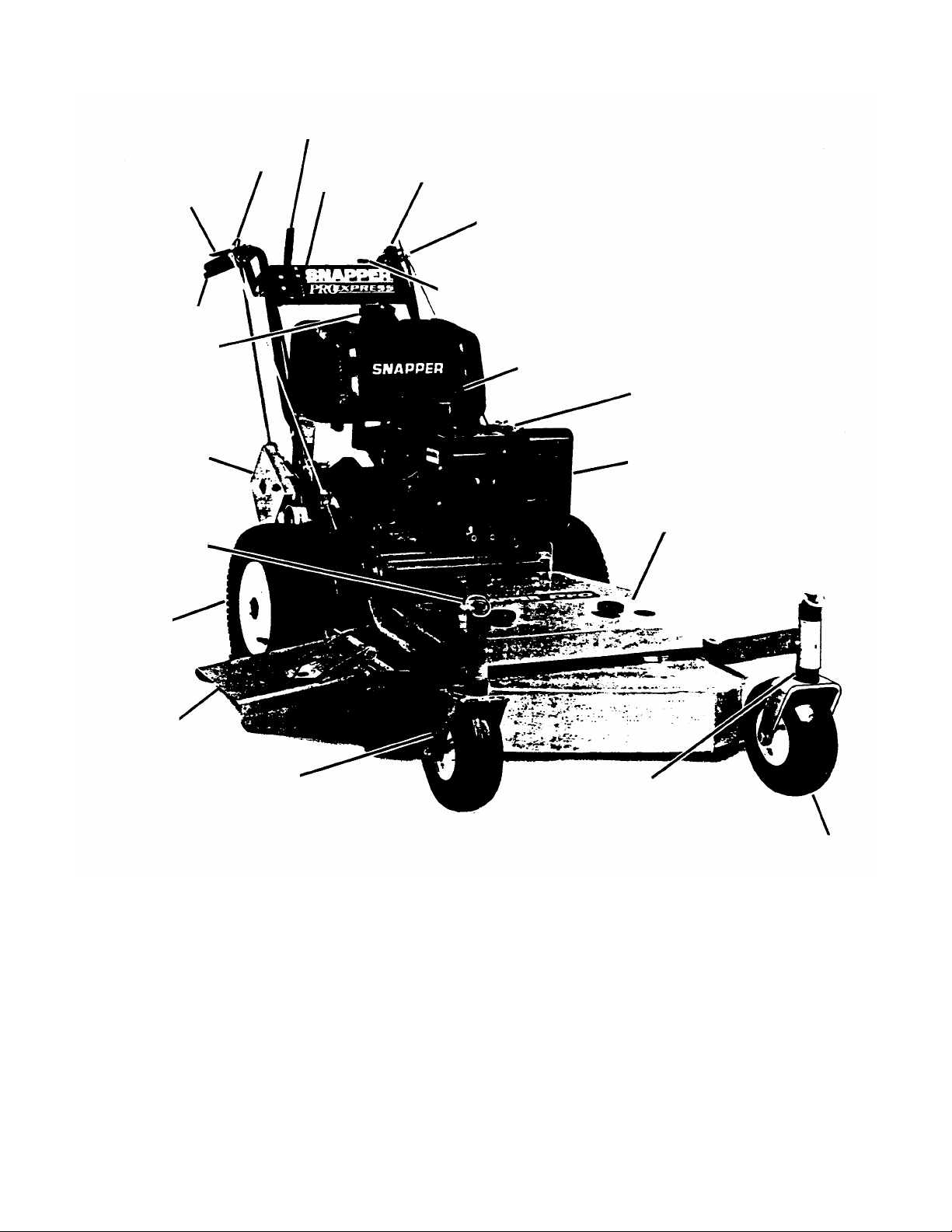

SECTION 1 - FAMILIARIZATION

TRANSMISSION SHIFT

OPERATOR’S

PRESENCE

CONTROL (OPC)

R.H. TRACTION

TRACTION

LOCK LEVER

LEVER

KEY

SWITCH

OPERATOR’S

PRESENCE

CONTROL (OPC)

ENGINE SPEED

CONTROL

L.H. TRACTION

LEVER

BELT

COVER

COVER

RETAINING

KNOBS

REAR TIRES

DISCHARGE

DEFLECTOR

FUEL

CAP

CASTER

WHEEL

ASSEMBLY

STARTER ROPE

AIR FILTER

MUFFLER

DECK COVER

DECK

(36” SHOWN)

DECK HEIGHT

ADJUSTMENT SPACERS

FRONT TIRES

FIGURE 1.1

1.1 INTRODUCTION

This manual has been prepared for the operator’s of the

SNAPPER PRO GEAR WALK BEHIND MOWER. Its

purpose, aside from recommending standard operating

procedures and routine service requir ements , is to prom ote

SAFETY through the use of ac cepted operating practices.

Read, Understand and Follow the IMPORTANT SAFETY

INSTRUCTIONS on Pages 2 & 3 of this manual and All

SAFETY messages on the PRO GEAR WALK BEHIND

MOWER and its attachments before operating. SNAPPER

recommends returning the MACHINE to an authorized

SNAPPER dealer annually for inspection and addition of any

new devices which might upgrade the safety of the mower.

1.2 NOMENCLATURE

It is recommended that all operator’s of this equipment

become thoroughly familiar with the controls,

components, and operation of this machine before

operating. Specific details involving the engine are found

in the separate engine owner’s manual. Study these

manuals before operating and k eep both handy for future

reference. For the nearest SNAPPER dealer in your

area, check the yellow pages under the heading LAWN

MOWERS. For engine parts and service, look for the

engine manufacturer’s dealers under the heading,

ENGINES - gasoline.

5

Page 6

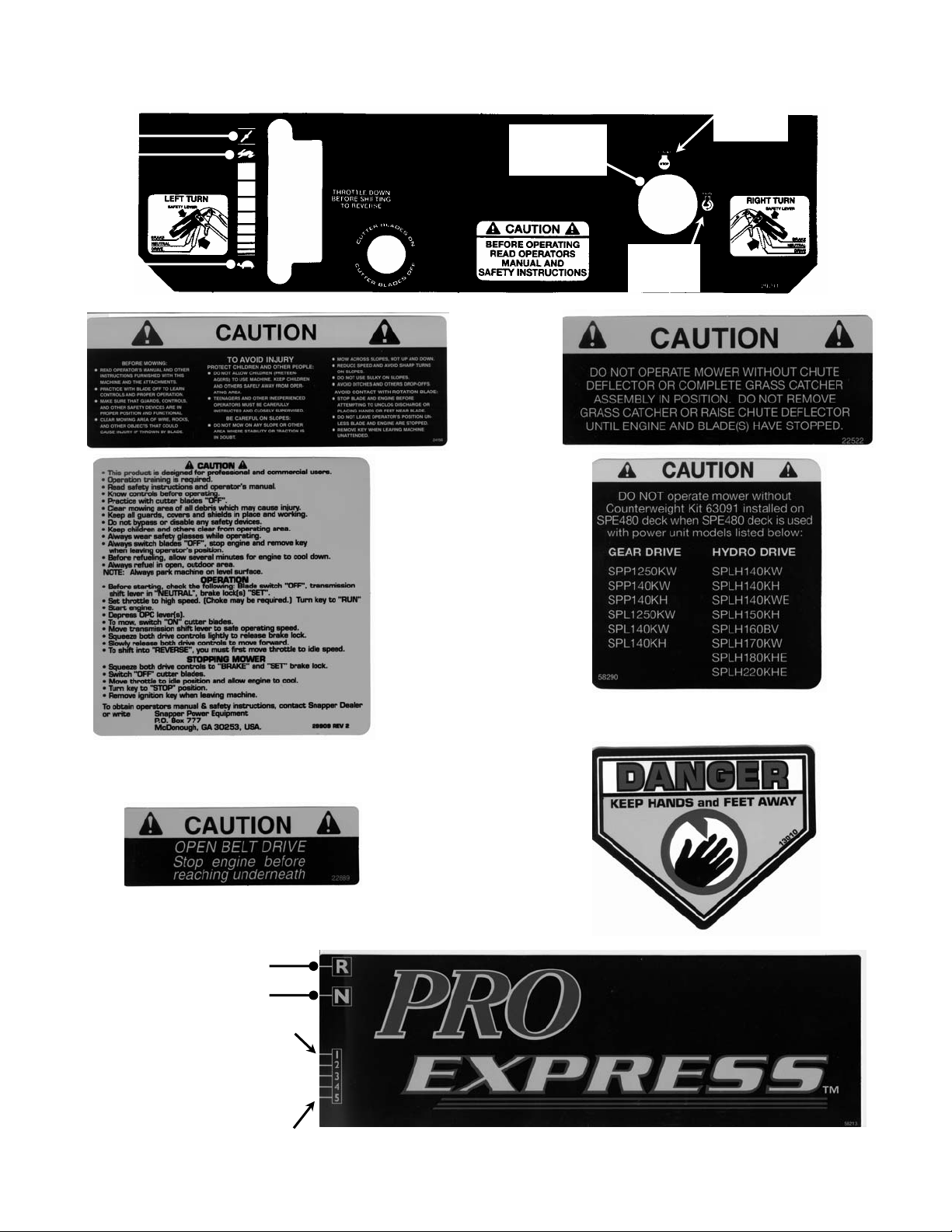

SECTION 2 - SAFETY MESSAGES AND DECALS

SYMBOL

SPEED

CHOKE

RABBIT

“FAST”

TURTLE

“SLOW”

SPEED

TRANSMISSION SHIFT

LEVER POSITIONS

REVERSE

NEUTRAL

LOWEST SPEED

HIGHEST SPEED

KEYSWITCH

POSITIONS

ENGINE

“RUN”

ENGINE

“OFF”

6

Page 7

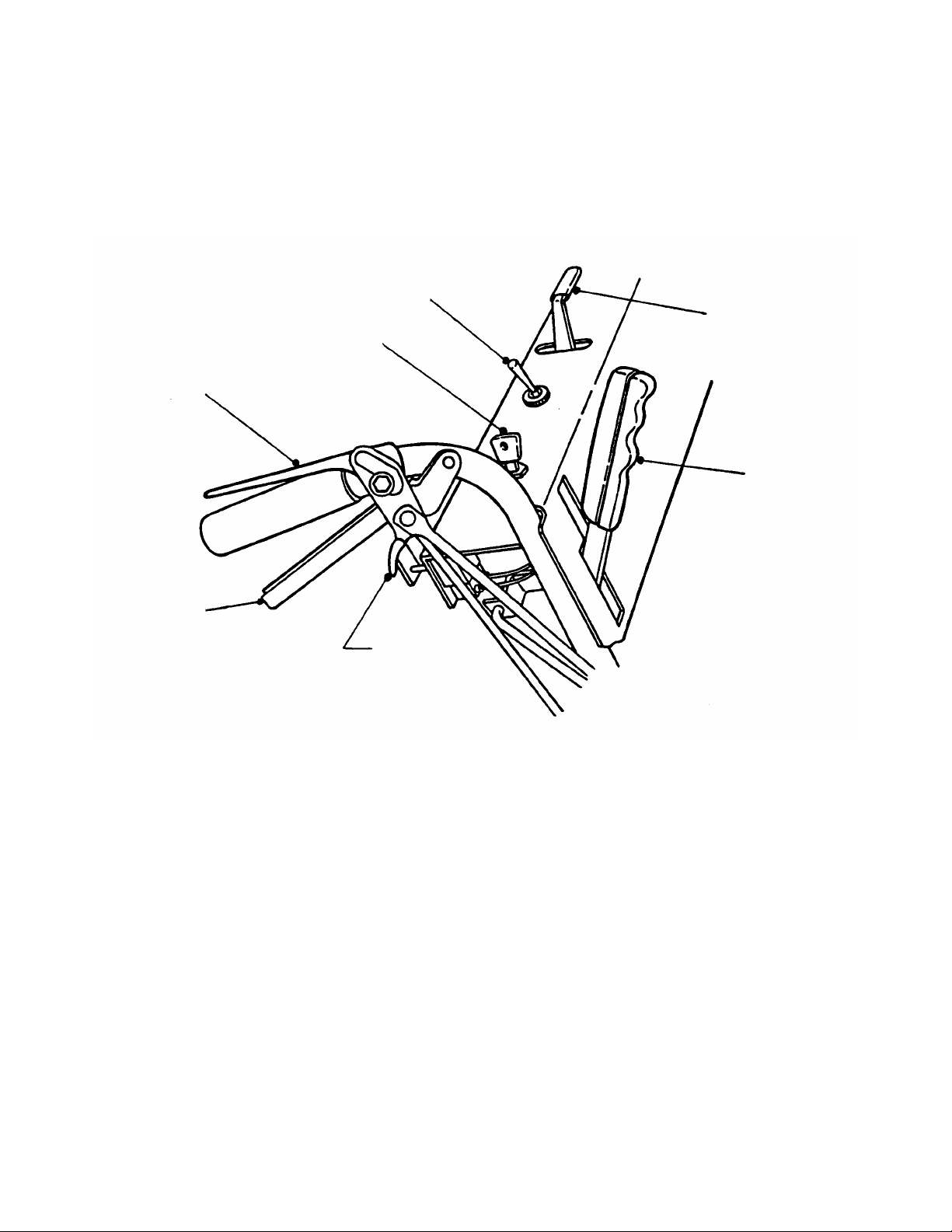

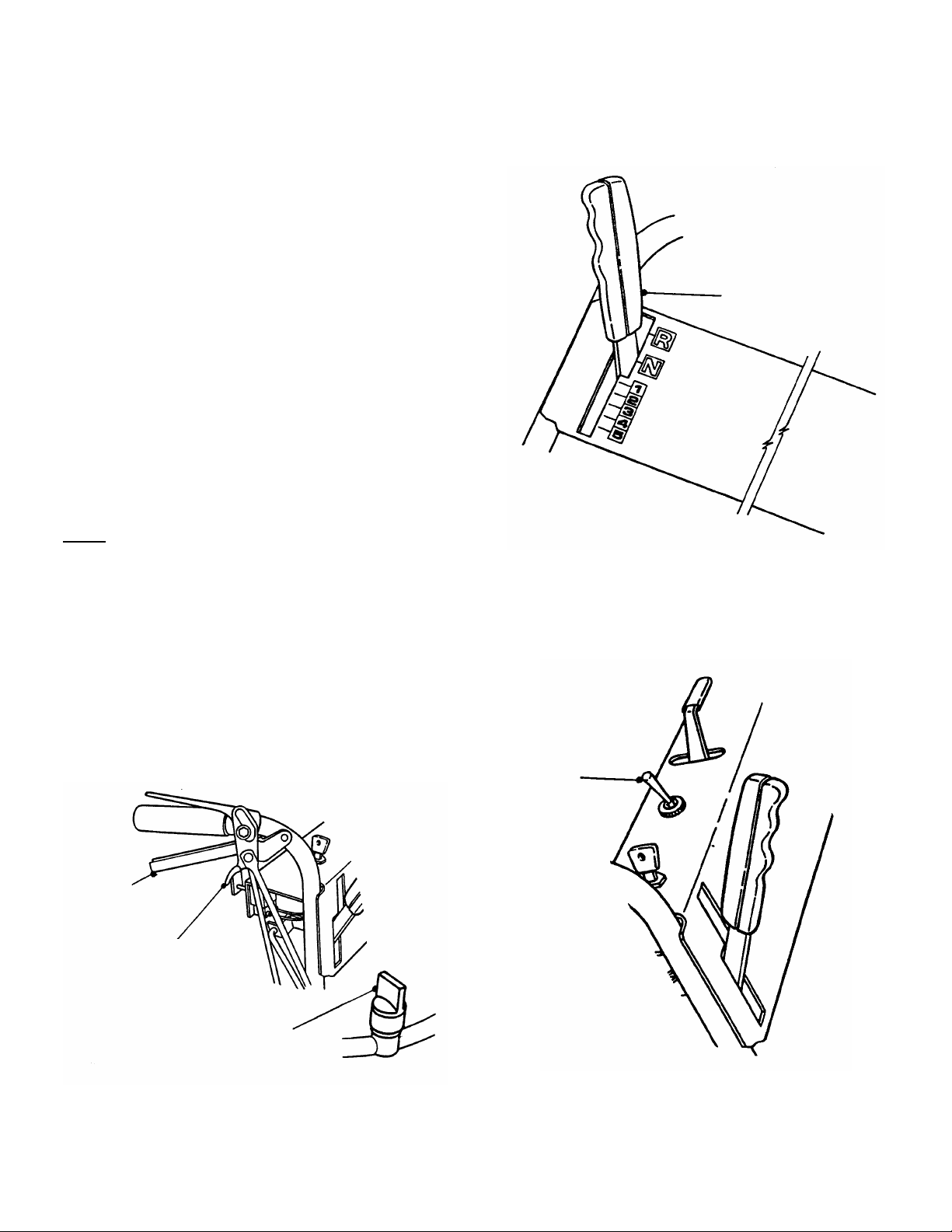

SECTION 2 - CONTROLS

BLADE CLUTCH

SWITCH

KEY SWITCH

OPERATOR’S

PRESENCE

CONTROL

(OPC)

ENGINE SPEED

CONTROL

TRANSMISSION

SHIFT LEVER

RIGHT HAND

TRACTION LEVER

TRACTION

LOCK LEVER

FIGURE 2.1

7

Page 8

SECTION 3 - OPERATING INSTRUCTIONS

3.1 BEFORE OPERATING

Be Thoroughly familiar with all controls and how to use

them before

operating the machine. Know beforehand

how to STOP the Traction Wheel Drives, Mower Blades

and Engine in preparation for possible emergencies.

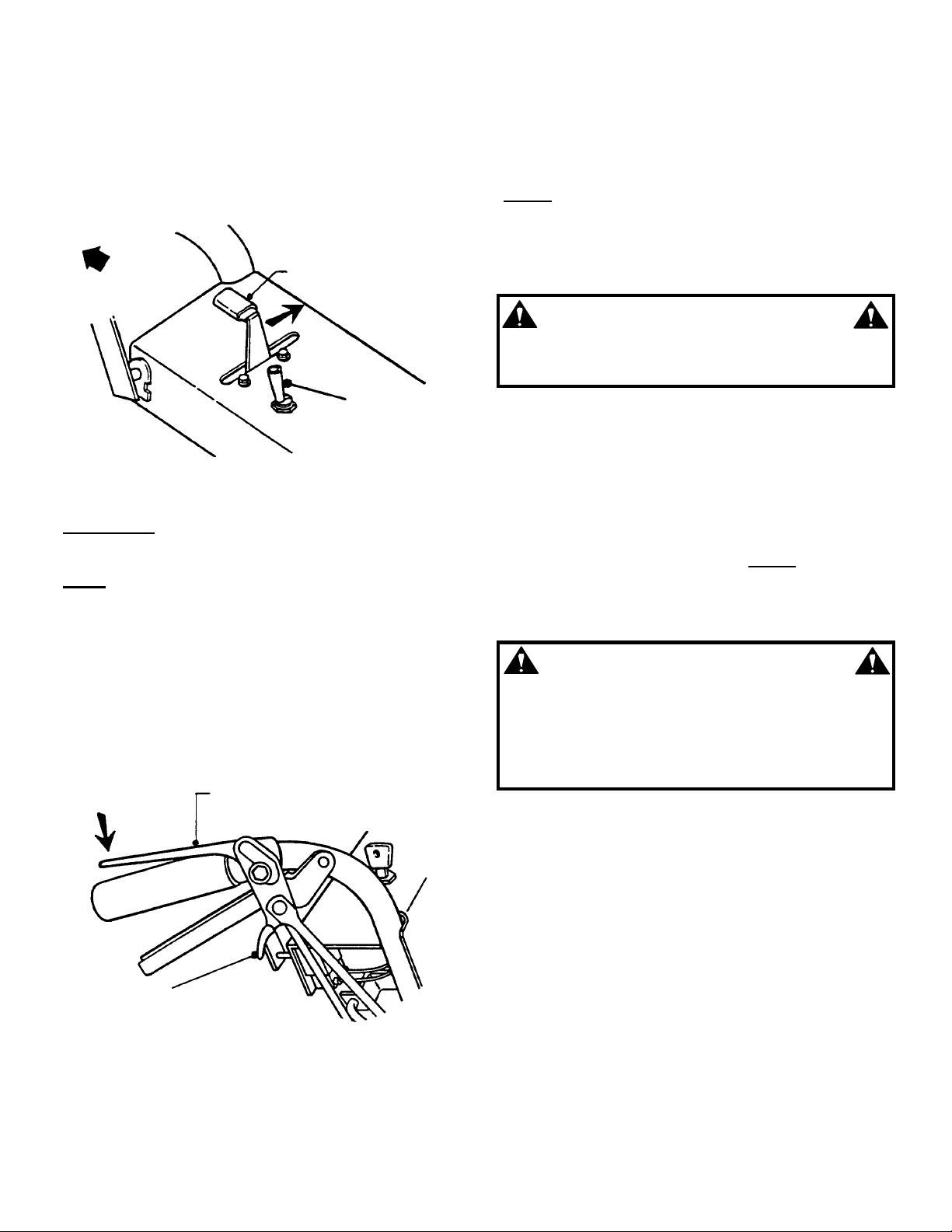

3.2 EMERGENCY STOP - PISTOL GRIP

1. Firmly squeeze both Traction Levers towards the

handle to STOP forward or reverse motion. Using

your index finger, pull Traction Lock Lever until it

locks in Brake Locked position. See Figure 3.1.

2. Pull Blade Clutch Switch backward to the OFF

position. See Figure 3.1.

3. Move Engine Speed Control Lever to SLOW (turtle)

position. See Figure 3.1.

STOP ENGINE by turning Key Switch to OFF position.

See Figure 3.1.

RIGHT HAND

TRACTION

LEVER

BLADE CLUTCH

SWITCH

SHOWN IN OFF

POSITION

ENGINE

SPEED

CONTROL

3.3 NORMAL OPERATING STOP -

PISTOL GRIP

1. Pull both Traction Levers towards the handle to stop

forward or reverse m otion while pulling the Traction

Lock Lever rearward until it lock s the Traction Lever

in Brake Locked position. See Figure 3.1.

2. Pull the Blade Clutch Switch backward to the OFF

position. See Figure 3.1.

3. Place Transmission Shift Lever in NEUTRAL(N)

position. See Figure 3.2.

4. Move Engine Speed Control Lever to SLOW (turtle)

position. See Figure 3.1.

STOP ENGINE by turning Key Switch to OFF.

NOTE

: Close Fuel Shut-Off Valve at the end of each

mowing operation.

RIGHT HAND

TRACTION

LEVER

BLADE CLUTCH

SWITCH SHOWN

IN OFF POSITION

ENGINE

SPEED

CONTROL

TRACTION LOCK

LEVER SHOWN IN

BRAKE LOCKED

FIGURE 3.1

WARNING

When the Operator’s Presence Control (OPC) is

released, the machine will continue to operate a few

feet. DO NOT use this Operator’s Presence Control

(OPC) to routinely stop the machine.

TRANSMISSION

SHIFT LEVER

TRACTION LOCK

LEVER SHOWN IN

BRAKE LOCKED

POSITION

FIGURE 3.2

8

Page 9

SECTION 3 - OPERATING INSTRUCTIONS

3.4 PRE-START CHECK LIST

Make the following checks and perform the services as

required before each start-up:

1. If required, make cutting height adjustm ents. Refer

to Section “CUTTING HEIGHT ADJUSTMENT”..

2. Check tires and add air as needed to bring pressure

to 25 psi in front and 12-15 psi in rear tires.

3. Check Guards, Deflector, and Belt Covers to make

sure all are in place and secure.

4. Check Condition of Cutter Deck Belt(s). If damaged, replace with original part. Refer to Section

“CUTTER DECK BELT REMOVAL”.

5. Clean Interior and Exterior Surfaces of cutting deck

and clean Engine of any accum ulation of dirt, gr as s,

oil, etc. Keep Engine air intak e s c reens and c ooling

fins clear at all times.

6. Check Engine Oil and add oil as needed to bring

level up to (but not over) the FULL mark . (Refer to

Engine manual for oil specifications).

7. Add Fuel to tank after pushing the Mower outside

where fumes can be dissipated. Make sure Fuel

Tank Cap is tightened after refueling. (Refer to

Engine manual for fuel specifications).

: DO NOT add fuel while engine is running. Use

NOTE

fresh, clean, lead-free gasoline. DO NOT use gasoline

that has been stored for long periods . Leaded gasoline

or gasohol is NOT recommended.

3.5 STARTING & OPERATING

3.5.1. ENGINE: START ENGINE AS FOLLOWS:

1. Turn Fuel Shut-Off Valve ON. See Figure 3.3.

2. Pull both Traction Levers toward the Handle while

pulling Traction Lock Lever s rearward until BOTH

traction levers are LOCKED in the Brake Locked

position. See Figure 3.3.

3. Place Transmission Shift Lever in NEUTRAL(N)

position. See Figure 3.4.

4. PISTOL GRIP - Pull Blade Clutch Switch backward

to the OFF position. See Figure 3.5.

BLADE CLUTCH

SWITCH

SHOWN IN OFF

POSITION

TRANSMISSION

SHIFT LEVER

FIGURE 3.4

RIGHT HAND

TRACTION

LEVER

TRACTION LOCK

LEVER SHOWN IN

BRAKE LOCKED

POSITION

FUEL SHUT OFF

VALVE SHOWN IN

CLOSED POSITION

(ROTATE HANDLE 90

DEGREES TO OPEN)

FIGURE 3.3

FIGURE 3.5

(Continued on next page)

9

Page 10

SECTION 3 - OPERATING INSTRUCTIONS

3.5 STARTING & OPERATING -

PISTOL GRIP (Continued from previous page)

5. Move Engine Speed Control Lever to the CHOKE

position. See Figure 3.6.

6. Turn Key Switch to RUN position.

MOVE ENGINE SPEED

CONTROL TO CHOKE

LEFT

SIDE

FIGURE 3.6

IMPORTANT

: DO NOT jerk the engine recoil starter

handle or allow it to snap back.

NOTE

: Engine will not start unless the transmission is in

NEUTRAL position and Blade Clutch Switch is in OFF

position.

7. Pull Engine Recoil Starter Handle until you hear the

first firing sound. Move Engine Speed Control

Lever to the FAST (rabbit) position. Pull Recoil

Starter Handle and Engine should start.

8. PISTOL GRIP - Depress Operator’s Presence

Control (OPC) against handle. See Figure 3.7.

OPERATOR’S PRESENCE

CONTROL (OPC)

TRACTION LOCK

LEVER SHOWN IN

BRAKE LOCKED

POSITION

FIGURE 3.7

POSITION

SWITCH

SHOWN IN

“OFF”

POSITION

9. Place Transmission Shift Lever in No. 1 position

(first gear). See Figure 3.4.

10. PISTOL GRIP - Push Blade Clutch Switch to ON

position. See Figure 3.5.

NOTE:

Releasing the Operator’s Presence Control

(OPC) while Transmission is in GEAR and/or Blades

ON, will Ground the Ignition Circuit and cause the

Engine to STOP, allowing the Machine to trav el only a

few feet before coming to a complete STOP.

Start mowing with a slow ground speed and

gradually increase speed to determine the most

comfortable travel speed.

11. To START MACHINE MOVEMENT, squeeze both

Traction Levers firmly against the handlebar

allowing the Traction Lock Lever to release.

Simultaneously move both Traction Lever s forward

slowly, allowing machine to start forward

movement.

IMPORTANT: Always STOP machine movement and

engage both traction lock levers before

a different ground speed. Transmission damage

could result if ground speed is changed when

machine is moving.

During initial training time with machine, it is

advised that the operator(s) practice all mower

movements while operating the mower with the

transmission shift lever in no. 1 (first gear) travel

speed position and blade clutch switch in off

position! DO NOT make sharp turns at high speeds!

12. The machine is TURNED by declutching wheel

drive belts while engaging wheel brakes - turn left

by squeezing the left hand traction lever or turn

right by squeezing the right hand traction lever.

See Figure 3.11 pistol grip. The more pressure

applied while squeezing the traction lever, the

sharper the mower will turn.

(Continued on next page)

10

WARNING

changing to

WARNING

Page 11

SECTION 3 - OPERATING INSTRUCTIONS

3.5 STARTING & OPERATING

(Continued from previous page)

13. PISTOL GRIP - TO STOP MACHINE,

Simultaneously squeeze both Traction Levers

firmly against the handle while pulling the Trac tion

Lock Levers rearward with index finger until

latched.

14. Pull the Blade Clutch Switch backward to the OFF

position. See Figure 3.8.

BLADE CLUTCH

SWITCH SHOWN

IN OFF POSITION

BLADE

CLUTCH

SWITCH

FIGURE 3.8

15. Place the Transmission Shift Lever into the

NEUTRAL (N) position.

16. Move engine speed control to slow (Turtle)

position.

17. Stop engine. Turn key switch to “OFF” position.

See Figure 3.8.

DO NOT operate blades in reverse. Stop blades.

LOOK and SEE behin d and down for child ren, pets

and hazards before and while backing. Engine

speed must be set to SLOW before operating in

reverse.

3.6 REVERSE OPERATION

3.6.1. TO REVERSE DIRECTION

1. To REVERSE DIRECTION OF MACHINE, STOP

Machine and latch Traction Lock Lever(s).

2. Pull Blade Clutch Switch backward to the OFF

position. Move Engine Speed Control Lever to

IDLE.

3. Move Transmission Shift Lever to REVERSE (R)

position.

4. Hold Operator’s Presence Control (OPC) against

handlebar.

5. To START MACHINE M OVEM EN T, s im ultaneously

squeeze both Traction Levers firmly against the

handle allowing the Traction Lock Lever to release.

6. Slowly release both Traction Levers, allowing machine

to start rearward movement.

7. PISTOL GRIP - TO STOP MACHINE,

Simultaneously squeeze both Traction Levers firmly

against the handle while pulling the Traction Lock

Lever rearward with index finger until latched. See

Figure 3.9.

WARNING

SQUEEZE TRACTION LEVER

TO STOP PULL LOCK LEVER

REARWARD TO LOCK

WARNING

DO NOT leave machine with engine running. Stop

engine. Stop blades. Latch Traction Lock Levers.

Remove key. DO NOT park machine on slopes.

11

TRACTION LEVER

(RIGHT HAND - RELEASED

POSITION SHOWN)

TRACTION LOCK LEVER

FIGURE 3.9

Page 12

SECTION 3 - OPERATING INSTRUCTIONS

WARNING

Brakes require maintenance. Inspect for proper

operation before operating machine. Refer to

Section “ADJUSTMENTS, STEERING AND

BRAKES”.

3.7 TRACTION LOCK OPERATION PISTOL GRIP

1. Simultaneously squeeze both Traction Levers

toward the handle, to stop mower movement.

2. Using index finger, pull Traction Lock Lever

rearward until it latches Traction Levers in Brake

Lock position.

3. To release Traction Lock, squeeze both Traction

Levers firmly against the handle. Simultaneously

release both Traction Levers slowly, allowing

machine to start forward movement. See Figure 3.10.

TRACTION LEVER

(LEFT HAND)

3.8 TURNING MOWER

3.8.1. GRADUAL RIGHT & LEFT HAND TURN

IMPORTANT: Squeezing the right or lef t traction lever

applies the brake to the right or left wheel. The brake

turns the machine right or left.

1. With machine in motion gradually squeeze the right

hand traction lever. The machine will turn to the right.

2. With machine in motion gradually squeeze the left

hand traction lever. The machine will turn to the left.

TRACTION LEVER POSITION

BRAKE POSITION

LEFT HAND

TRACTION LOCK LEVER

TRACTION LEVER

(RIGHT HAND - RELEASED

POSITION SHOWN)

FIGURE 3.10

WARNING

Machine should always be in forward motion before

attempting a turn. DO NOT attempt a turn from a

stopped position.

DRIVE POSITION

FIGURE 3.11

3.9 MOWING AND TURNING ON

HILLSIDES

1. Always mow hillsides starting at bottom of hill. Mow

across slopes, never up and down. Exercise

caution when changing directions on slopes. DO

NOT mow steep slopes!

DO NOT mow on steep slopes. DO NOT use with

any type rider attachment on slopes. DO NOT park

machine on slopes.

1. Hillside mowing is accomplished by squeezing

Traction Lever on the UPHILL SIDE of machine.

This helps reduce side slipping of mower.

2. When turning mower on hillsides, always turn

toward the UPHILL SIDE of mower for better

control and balance.

12

WARNING

Page 13

SECTION 3 - OPERATING INSTRUCTIONS

3.10 CUTTING HEIGHT ADJUSTMENT

(Fixed Decks)

Mower has three methods of adjusting cutting height:

1. Moving position of BLADE on cutter spindle shaft.

2. Moving position of CASTER WHEEL on support.

3. Moving position of MOWER DECK on power unit.

WARNING

DO NOT attempt any maintenance, adjustments or

service with the engine running. Stop engine. Stop

blades. Latch Traction Lock Levers. Remove key.

Disconnect spark plug wires from spark plugs and

secure wires away from spark plugs. Engine and

components are HOT. Avoid serious burns by

allowing all parts sufficient time to cool before

working on machine.

3.11. ADJUSTING CASTER WHEELS

The Caster W heel Assembly has four (4) 1/2” and one

(1) 1/4” thick spacer. When placed above or below

Caster Support Tube, they raise or lower cutting height in

1/2” increments, thus providing a “Q uick- Adjust” m ethod.

The deck m ounting has to be changed to correspond to

the caster repositioning as described in ADJUSTING

FIXED DECK ATTACHMENT.

1. Remove Retainer Pin from Caster Shaft. See Figure

3.12.

CASTER

CASTER

SHAFT

SUPPORT

3.12 ADJUSTING BLA DE ON CUTTER

SPINDLE

To change cutting height of Blades , move the Spacers from

under the Cutter Housing to above the Cutter Housing

Pulley. Each Spacer moved above the Cutter Housing

Pulley will provide an additional 1/4” of cutting height. DO

NOT put any Spacers below Blade. See Figure 3.14.

FLAT

HEIGHT

ADJUSTING

SPACERS

SLOT

NOTE:

REMOVED FROM BOTTOM

OF CASTER SHOULD BE

REINSTALLED AT TOP

BEFORE INSERTING

RETAINER PIN.

FIGURE 3.13

SPACERS

THOSE SPACERS

AIR LIFT

BEVEL

WASHER

BLADE

MOUNTING

BOLT

BLADE

TIGHTEN TO 60-75 FOOT POUNDS

FIGURE 3.14

RETAINER

PIN

3.12.1 ADJUSTING BLADE ON CUTTER SPINDLE

NOTE: Changing cutting height of blades does not

FIGURE 3.12

2. Lift Caster Support while adding or removing bottom

spacer. See Figure 3.13.

NOTE: Remove (or add) spacers by rotating slots to

align with flat area on caster shaft.

change the deck ground clearance. If an undesirable

cutting pattern results, then cutting height adjustment

must be made by adjusting mower deck height and

caster wheels.

Install Blades (Air Lift Up) with retaining hardware as

shown below and tighten to 60 to 75 ft.-lbs. See Figure 3.15.

(Continued on Next Page)

13

Page 14

SECTION 3 - OPERATING INSTRUCTIONS

3.12.1 ADJUSTING BLADE ON CUTTER SPINDLE

(Continued)

CUTTER

HOUSING

PULLEY

BLADE

SPACERS

ON TOP

CUTTER

HOUSING

SPACERS ON

BOTTOM

SPACERS

FIGURE 3.16C: MIDDLE HIGH CUT 3” TO 4”

FIGURE 3.15

3.13 ADJUSTING FIXED DECK ATTA CHMENT

The mower deck has f our dif f er ent positions for attaching

it to the power unit. The lowest setting provides a cutting

height range of 1-1/2” to 2-1/2”, the m iddle low cut is 21/4” to 3-1/4”, the m iddle high cut is 3” to 4”, and highest

cut is 3-3/4” to 4-3/4”. Make sure the spacers on the

caster wheels are moved up or down as shown to

correspond with the bolt positions to keep deck level.

Once a desired cutting height is reached, attach the

mower deck to the power unit by installing 3 bolts on

each side in selected height of cut holes. Tighten bolts to

70 to 80 foot pounds torque. See Illustration.

FIGURE 3.16A: LOW CUT 1-1/2” TO 2-1/2”

FIGURE 3.16B: MIDDLE LOW CUT 2-1/4” TO 3-1/4”

SIDE PROFILE OF UNIT

SPACERS

DECK

CASTER

WHEEL

SPACER

FIGURES 3.16A-B

POWER

UNIT

BLACK DOTS

REPRESENT

BOLT

ANCHOR

REAR

WHEEL

FIGURE 3.16D: HIGH CUT 3-3/4” TO 4-3/4”

SPACERS

FIGURES 3.16C-D

14

Page 15

SECTION 4 - TROUBLESHOOTING

ENGINE TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Engine ...................Key OFF................................................................................................Turn Key to Run.

does not ................Fuel Tank empty. ..................................................................................Fill Fuel Tank.

start........................Fuel Shut-Off Closed.............................................................................Open Fuel Shut-Off.

...............................Engine Throttle Control not at FAST (Rabbit) position..........................Put Engine Throttle Control to FAST

...............................Choke NOT closed................................................................................Put Throttle Control in CHOKE position.

Check choke adjustment.

...............................Spark Plug Wire loose or disconnected................................................Connect Spark Plug Wire.

...............................Operator Presence Control (OPC) Switch out of adjustment................Adjust Switch

...............................Blade Clutch Switch in ON position.......................................................Pull Blade Clutch Lever to OFF position.

...............................Spark Plug bad......................................................................................Install new Spark Plug.

...............................Dirty Air Filter. .......................................................................................Clean Air Filter.

...............................Transmission not in NEUTRAL. ............................................................Shift Transmission Lever to NEUTRAL.

Engine ...................Dirt or water Fuel Tank..........................................................................Drain and c lean Fuel Tank. Fill with

Starts Hard fresh Fuel.

or Loses ................Vent in Gas Cap plugged......................................................................Clean Vent or install new Gas Cap.

Power. ...................Air Filter dirty.........................................................................................Clean or install new Air Filter.

...............................Spark Plug not gapped correctly...........................................................Check and set Spark Plug gap.

...............................Spark Plug bad......................................................................................Install new Spark Plug.

Engine ..................Spark Plug bad......................................................................................Install new Spark Plug.

Runs ......................Spark Plug not gapped correctly...........................................................Clean and set Spark Plug gap.

Erratically..............Fuel Filter plugged or dirty. ...................................................................Replace Fuel Filter.

Engine ..................Dirty Air Filter. .......................................................................................Clean or replace Filter.

Idles Poorly...........Fuel Filter plugged ................................................................................Replace Fuel Filter.

Engine ..................Engine Oil low in Crankcase.................................................................Add Oil.

Overheats..............Engine Cooling Fins clogged ................................................................Clean Engine Cooling Fins.

Machine ................Blade Mounting Bolts loose...................................................................Tighten Blade Mounting Bolts.

Vibrates.................Blade out of Balance.............................................................................Sharpen and balance Blade.

Excessive..............Engine Mounting Bolts loose.................................................................Tighten Mounting Bolts.

...............................Damaged or Severed Belt.....................................................................Replace Belt

Engine ...................Mowing grass too tall. ...........................................................................Adjust cutting height.

Dies........................Mowing too fast.....................................................................................Reduce travel speed.

MOWER TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Mower does ............. Transmission in neutral. ....................................................................Select Gear

not move .................. Traction Control Rod adjustment.......................................................Adjust Rod

when Traction.......... Engine to Transmission Belt Damaged or Broken.............................Replace Belt

Levers released.......Idler Spring Damage or Broken.........................................................Replace Spring

Mower does ............. Slipping or broken Traction Belt. .......................................................Adjust or replace Belt.

not track...................Tire pressure in both Traction Wheels ..............................................Ad just air pressure.

straight.....................not the same.

Blades DO................Belt slipping or broken.......................................................................Replace or adjust Belt.

NOT engage............. Clutch does not engage.....................................................................Check Electrical Connections & Clutch

Mower....................... Travel speed too fast.........................................................................Reduce ground speed.

mows........................Operator making mower turn corner too fast. ..................................Reduce ground speed.

unevenly................... Rough terrain.....................................................................................Change mowing pattern.

.................................. Unequal number of Blade Spacers on

......................................Cutter Shafts or Caster Wheels.....................................................Install equal number of Spacers.

.................................. Low Or No Air Pressure in Tires........................................................Fill Tires with Correct Air Pressure

.................................. Dull Blades ........................................................................................Sharpen Blades or Install new Blades

15

Page 16

SECTION 4 - TROUBLESHOOTING

MOWER TROUBLESHOOTING (Continued)

SYMPTOM PROBLEM SOLUTION

Mower not ......................................Broken or slipping Blade Belt.......................................Replace Belt.

cutting full......................................Dull, Damaged or Worn Blades ...................................Sharpen Blades or Install new Blades

width.

Discharge.......................................Grass wet.....................................................................Let Grass dry.

Deflector Becomes........................Mower too low..............................................................Raise cutting height

Obstructed.....................................Engine overloaded. ......................................................Run Engine at full Throttle and reduce

travel speed.

TRANSMISSION TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Unit is ............................................Gearing is overly noisy - chatter, etc............................Return to Authorized Snapper Dealer

Noisy...............................................Worn Gears.

........................................................Worn Bearings - mainly input Shaft

........................................................Ball Bearing.

Unit Jumps.....................................Teeth of Gears are worn beyond tolerances.

Out of Gear.....................................Spring in Shifter Fork weak or broken.

SERVICE & LUBRICATION

HOURS PROCEDURE COMMENTS

BREAK-IN.......................................Check all Grease Points and add if necessary

........................................................Check all Fasteners for proper tightness.

........................................................Change Engine Oil and Filter at 5 hours......................(See Engine Manual)

DAILY..............................................Check Engine Oil. ........................................................Change Oil if extreme dusty conditions.

........................................................Clean Air Filter. ............................................................More often if needed.

........................................................Clean Air Intake Screen...............................................More often if needed.

........................................................Remove Debris from under Belt Cover. .......................More often if needed.

........................................................Sharpen Cutter Blades.................................................Tighten to 60-75 Ft.-Lbs.

........................................................Grease Cutter Spindle Bearings. .................................Use Chevron SRI Grease or equal.

........................................................ ..................................................................................... (NLGI No. 2)

........................................................Inspect Interlock Switches for Damage........................Replace if Needed.

........................................................Inspect Belts for Wear or Damage...............................Replace if Needed.

........................................................Inspect brakes..............................................................Adjust for proper steering / stopping.

WEEKLY.........................................Check Tire Pressure. ...................................................Add or Adjust as required.

........................................................Check Safety Interlock System....................................Inspect OPC Switch for proper Operation.

........................................................Lube Traction (Drive) Levers........................................One Shot General Purpose Grease.

........................................................Inspect Traction Lock for Wear....................................Replace if Worn.

........................................................Change Engine Oil and Filter.......................................More often if needed.

........................................................Replace Air Filter..........................................................More often if needed.

........................................................Grease Caster Wheel Bearings. ..................................General Purpose Grease.

........................................................Grease Caster Support Arms.......................................General Purpose Grease.

........................................................Grease Traction Wheels. .............................................General Purpose Grease.

........................................................Grease Idler Arm Pivots on Cutter Deck......................General Purpose Grease.

........................................................Fuel Filter.....................................................................Replace with SNAPPER P.N. 1-4359

........................................................Grease Traction Idler Pulley (Located on the

Underside of Power Unit)..........................................General Purpose Grease.

MONTHLY.......................................Clean and Adjust Spark Plugs. ....................................(See Engine Manual)

........................................................Lube Controls and Linkages. .......................................Use Medium Duty Oil.

16

Page 17

SECTION 5 - ADJUSTMENTS

5.1 STEERING/BRAKES

If machine is not as responsive as des ired when either

Traction lever is squeezed, one or both brakes should

be adjusted as follows:

1. Operate mower on level terrain with Transmission

Shift Lever in No. 1 position. Determine which

brake requires adjustment.

2. Stop engine, remove the key from switch and

disconnect spark plug wire fr om spark plug. Secure

wire away from plug.

3. Tur n nut clockwise to increase br ake tension. See

Figure 5.1.

BRAKE ROD

MORE

TENSION

TURN

NUT

LESS

TENSION

BRAKE ARM

FIGURE 5.1

4. Place spark plug wire onto spark plug. Star t engine

and operate mower with transmission in the No. 1

position to check for proper adjustment. If further

adjustment is required, follow all steps above.

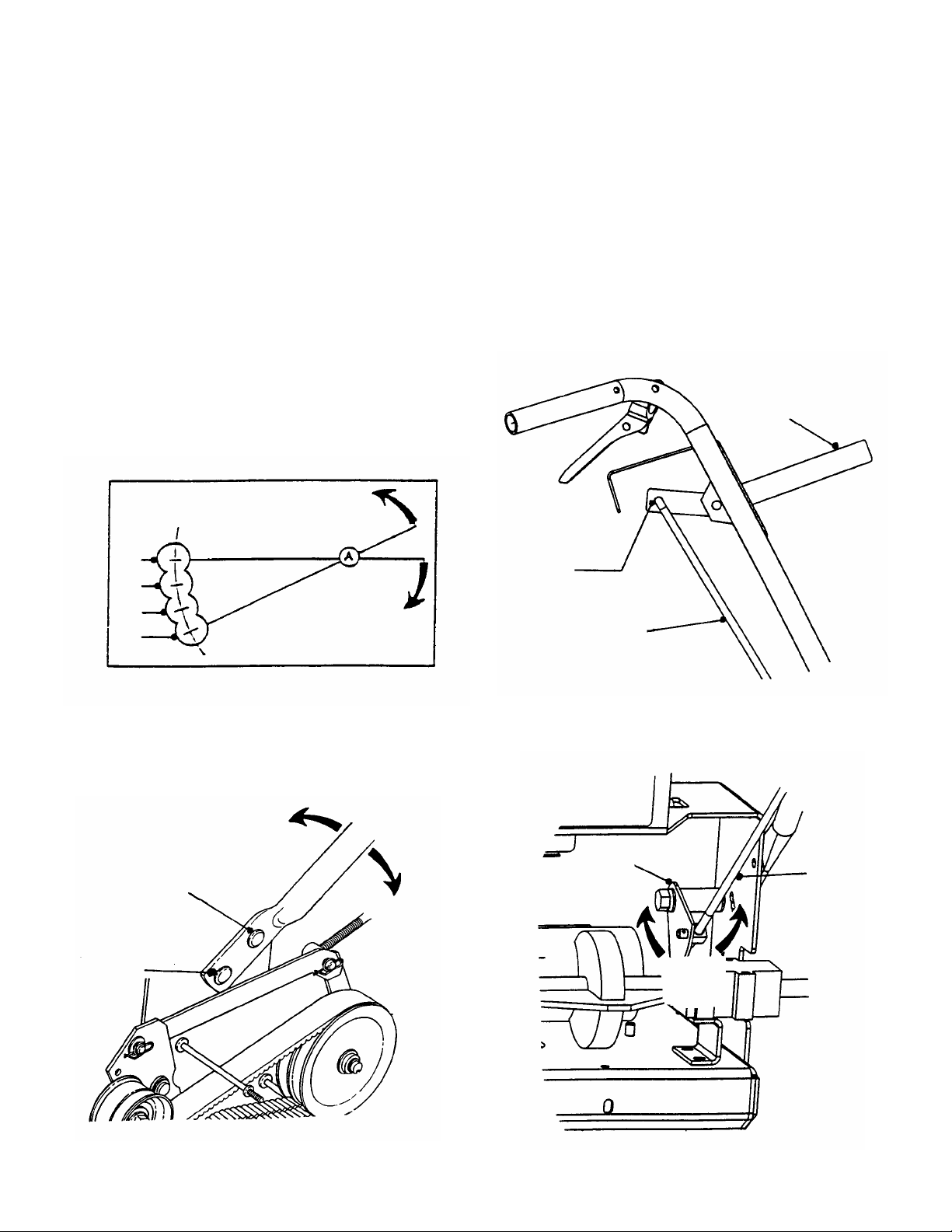

5.2 TRACTION LEVERS/RODS

If the Trac tion Wheel Drive Belts becom e slack or new

belts have been installed, it will be necessary to adjust

the Traction Levers as follows:

1. Move the machine to a smooth, level surface and

turn the engine OFF. Release the traction locks.

Disconnect the Brake Rods from the Brake Arms

keeping the hairpins in the swivels.

2. Remove the key from the switch, rem ove the spark

plug wire from the spark plug and secure it away

from the plug.

3. Shift the transmission to No. 1 position.

PISTOL GRIP: Pull rearward hard on the traction

levers. The space used to lock the traction lock

lever should not bottom in the slot. Set the Tr action

Lock Levers into the Brake Lock positions. The

Idler Pulleys, Upper and Lower should have

completely declutched the belt. Release the traction

locks and adjust as required.

4. Remove the hairpins from the traction rod

adjustment blocks and remove the adjustment

blocks from the traction links on each side of the

mower. See Figure 5.2.

ROTATE

1/16” TO 1/8”

GAP

BETWEEN

IDLER ARM

AND STUDS

IDLER

ARM

BELT

COVER

STUD

ADJUSTMENT

BLOCK

REMOVE

HAIR PIN

FIGURE 5.2

5. Rotate the adjustment block as required to make

the idler arms almost touch against the belt cover

studs when the traction levers are locked. There

should be about 1/16” to 1/8” gap between the idler

arms and studs.

6. Reinstall the adjustment blocks and the hairpins.

Check the settings as des cribed above. Repeat as

necessary.

7. Reassemble the Brake Rods to the Brake Arms

with the hairpins removed earlier.

8. Replace the Spark Plug Wire onto the Spark Plug.

Start the mower according to the Safety Instructions

and operate it to check the adjustments.

: It may be necessary to adjust the Traction Brakes

NOTE

after adjustment of the Traction Belts is complete.

WARNING

DO NOT attempt to operate machine without belt

cover and studs secured into the proper position.

17

Page 18

SECTION 5 - ADJUSTMENTS

(4)

*(2)

ROD

5.3 HANDLE HEIGHT

The operator handle can be adjusted for operator

comfort as follows:

1. Loosen the upper carriage bolt and nut on both sides

of handlebar.

2. Remove lower carriage bolt and nut on both sides of

handlebar.

3. Raise or lower handlebar to desired height. See

Figure 5.4.

4. Install the carriage bolt and nut in the lower hole in

handlebar and securely tighten nut. See Figure 5.4.

5. Securely tighten the upper carriage bolt and nut.

6. After adjusting the handle height readjust traction

links as described earlier. Shift rod (Connects the

ground speed control lever and the transm is sion) will

have to be readjusted.

7. Readjust traction levers/rods when handle height is

changed.

5.4 GROUND SPEED CONTROL LEVER

ADJUSTMENT

1. Disconnect the hair pin from shift rod that connects

to the ground speed control lever. See Figure 5.5.

2. Move the ground speed control lever to the neutral

position. Move the shift lever, located on the

transmission, to the neutral position.

3. Rotate the shift rod clockwise or counter clockwise to

allow the upper portion of shift rod to be inser ted into

the ground speed control lever without moving the

speed control lever or the transmission shift lever.

Reinstall hair pin. See Figure 5.6.

GROUND

SPEED

CONTROL

LEVER

(3)

(1)

UPPER

CARRIAGE

BOLT

LOWER

CARRIAGE

BOLT

*FACTORY SETTING

FIGURE 5.3

RAISE

U

DOWN

LOWER

DISCONNECT

SHIFT ROD

FROM THIS

SHIFT

ROD

SHIFT

LEVER

FIGURE 5.5

SHIFT

ROD

ROTATE

SHIFT

FIGURE 5.4

18

FIGURE 5.6

Page 19

SECTION 6 - POWER UNIT SERVICE

6.1 REPLACEMENT PARTS

To retain the quality of your mower, use Genuine

SNAPPER Replacement Parts only! Contact your local

SNAPPER dealer for parts and service as sistance. For

the correct part or information for your mower, always

mention Model and Serial Number of Power Unit and

Mower Attachment. We recommend returning your

mower to an author ized SNAPPER Dealer on a yearly

basis for inspection and addition of any new devices

which might upgrade the performance and safety of

your mower. For the nearest SNAPPER Dealer, chec k

the Yellow Pages under the heading LAW N MOW ERS.

For Engine Parts and Service, look for the Engine

Manufacturer’s Dealers under the heading ENGINESGasoline. For transm ission parts and service, look for

Tecumseh Engines & Transmission under EnginesGasoline.

WARNING

DO NOT attempt any maintenance, adjustments or

service with the engine running. Stop engine. Stop

blades. Latch Traction Lock Levers. Remove key.

Disconnect spark plug wires f rom spark plugs and

secure wires away from spark plugs. Engine and

components are HOT. Avoid serious burns by

allowing all parts sufficient time to cool before

working on machine.

NOTE: All mid-size mowers should be tilted with

engine carburetor side UP.

6.2 TRANSMISSION PARTS & SERVICE

For the nearest Peerless Transmission Dealer, check

the Yellow Pages under heading, Engine-Gasoline.

Look for Tecumseh Engine and Transmission under

Engine-Gasoline.

6.2.1. GENERAL TRANSMISSION SERVICING

1. GENERAL TRANSMISSION SERVICING

Introduction:

The following service procedures should be

understood and practiced whenever service must

be performed on a Peerless MST 205 Series

Transmission.

2. Before removing transmission from mower, make

sure another part of machine is not causing

problem, look for:

a) Loose drive belt.

b) Sheared keys in pulleys.

c) Oil saturated drive belts.

d) Transmission shift lever secure.

6.2.2. TRANSMISSION

The Peerless MST 205 Series Transmission requires

no routine maintenance. Return machine to an

authorized Snapper dealer for service, maintenance or

problems.

6.2.3. TRANSMISSION LUBE

The transmission is permanently sealed. But, lubrication

can be added if leakage should occur. The transmission

case holds 16 ounces of 80W-90 gear oil. To Lubricate:

1. Remove trans mission switch wire plug and remove

the transmission interloc k switch. Remove the fiber

washer seated on switch.

2. Transmission oil is added through the switch hole.

3. Install new fiber washer, part number 2-9662, onto

switch. Install switch into transmission and tighten

securely. Attach wire plug onto switch.

19

Page 20

SECTION 7 - MOWER ATTACHMENT SERVICE

WING NUT

PULLEY

7.1 TRANSMISSION BELT

REMOVAL/REPLACEMENT

Should it become necessary to replace the transmission

drive belt, contact an authorized SNAPPER Dealer for

service.

WARNING

DO NOT attempt any maintenance, adjustments or

service with the engine running. Stop engine. Stop

blades. Latch Traction Lock Levers. Remove key.

Disconnect spark plug wires f rom spark plugs and

secure wires away from spark plugs. Engine and

components are HOT. Avoid serious burns by

allowing all parts sufficient time to cool before

working on machine.

1. Disconnect idler arm spring.

2. Remove existing belt. Replace with new belt, part

no. 2-9118.

3. Reconnect idler arm spring. See Figure 7.1.

TRANSMISSION

IDLER BELT

IDLER ARM

ELECTRIC

CLUTCH

SHOWN FROM UNDERNE ATH

FIGURE 7.1

7.2 TRACTION BELT REMOVAL &

REPLACEMENT

7.2.1. TRACTION BELT REMOVAL

1. STOP ENGINE! Remove two wing-nuts retaining

fender. Remove fender. See Figure 7.2.

2. Remove Traction Belt from Wheel Pulley first by

running Belt off as Wheel is turned. Remove belt

from Transmission output Pulley next.

3. Lay new Traction Belt par t no. 4-6240 flat on ground

(around tire) and roll Mower W heel over T raction Belt,

removing Traction Belt from machine.

7.2.2. TRACTION BELT INSTALLATION

1. STOP ENGINE! Lay Traction Belt flat on ground in

front of Traction Wheel, roll Traction Wheel over

Traction Belt until wheel is in middle of belt.

SPRING

2. Place Traction Belt on Wheel Pulley followed by

Transmission Output Pulley.

3. Reinstall Fender and tighten two wing-nuts.

4. Adjust Traction Rod and Br ake Rod as necessary.

Refer to Section “ADJUSTMENTS STEERING/BRAKES and TRACTION

LEVERS/RODS”.

(WHEEL PULLEY

NOT SHOWN)

BELT COVER

FIGURE 7.2

7.3 CUTTER DECK BELT REMOVAL &

INSTALLA TION

1. Remove mower deck belt cover.

2. Remove idler spring and swing idler away from belt.

3. Remove old belt from spindle pulleys and electric

clutch pulley.

4. Route new belt, part number 3-5710 f or 36” Deck &

2-9261 for 48” Deck around spindle pulleys.

NOTE: 36” Deck Belt also connects to electric clutch.

5. Move idler to belt and re-attach tension spring.

6. For 48” Deck to electric clutch use belt 2-9262.

36” DECK SHOWN

REMOVE

BELT

FIGURE 7.3

TRACTION BELT

TRANSMISSION

OUTPUT PULLEY

ELECTRIC CLUTCH

IDLER

IDLER ARM SPRING

SPINDLE

PULLEY

20

Page 21

SECTION 7 - MOWER ATTACHMENT SERVICE

BOLT

7.4 CUTTING BLADE SERVICE

Check blades after each use for signs of excessive

wear and damage. See Figure 7.4 for blade wear limits.

NEW BLADE

WEAR LIMIT

(NOTCH STARTS)

Blades are extremely sharp and can cause severe

injury. Wear heavy leather gloves when handling or

working around blades. DO NOT use a blade that is

excessively worn or damaged.

BLADE

WARNING

HEAVY

END OF

BLADE

22º TO 28º

BLADE TIP

1/64”

DANGEROUS CONDITION!

DO NOT USE ON MOWER!

REPLACE WITH NEW BLADE.

FIGURE 7.4

1. Use the following chart for ordering replacement

Blades for the 36” & 48” Mowing Decks.

STANDARD REPLACEMENT BLADES

36” DECK 48” DECK

2-9246 2-9247

7.4.1. BLADE REMOVAL AND SHARPENING

1. Place the mower on a smooth level surface, turn

engine OFF, rem ove k ey, disconnect Spark Plug Wire

from Spark Plug and secure Wire away from Plug.

2. Remove blades.

IMPORTANT:

Note the number of blade spacers that

are under the Blade Mounting Nuts and on the Spindle

side of the Blade.

3. Clean and inspect each Blade for excessive wear and

damage. Refer to Section “BLADE WEAR LIMITS”.

4. Refer to the STANDARD REPLACEMENT BLADE

chart above for correct SNAPPER Replacement Blades.

5. Should Blades be in acceptable condition, sharpen at

22 to 28 degrees. DO NOT sharpen beyond original

cutting edge. See Figure 7.5.

6. Balance each Blade after sharpening by grinding

metal from the heavy end of the Blade.

7. Place the Blade m ounting bolt through bevel washer

and into Blade and place Blade Spacers over Bolt.

Make certain each Blade is installed with the same

amount of Spacers.

ORIGINAL CUTTING EDGE

FIGURE 7.5

NOTE

: When sharpening Blades, leave 1/64”

untouched. Razor sharp Blades dull quicker and

damage easier. Commercial balancers are available

and should be used in accordance with the

manufacturers instructions.

8. Install Blade Mounting Bolt with spacers and Blade

into spindle.

9. Install an equal amount of Blade Spacers onto each

blade mounting bolt.

10. Install the Blade Mounting Nut on each Blade

Mounting Bolt. See Figure 7.6.

11. Tor que each Blade Mounting Bolt and Nut to 60 to

75 ft. lbs of torque.

AIR LIFT

HEIGHT

ADJUSTING

SPACERS

BEVEL

WASHER

BLADE

TIGHTEN TO 60-75 FOOT POUNDS

BLADE

MOUNTING

FIGURE 7.6

21

Page 22

SECTION 7 - MOWER ATTACHMENT SERVICE

PULLEY

BEARING

HOUSING

BEARING

SHAFT

7.5 MOWER SPINDLES (Field Serviceable

Spindles) BEARING REPLACEMENT

In the event that a spindle bearing requires

replacement, the SNAPPER Field Serviceable

Spindles have been designed so that no special

tools or presses are required.

1. Remove belt. Loosen blade nut and remove.

Allow blade bolt, washer, blade and four spacers to

drop down out of the spindle housing.

See Figure 7.7.

REMOVE NUT

REMOVE BELT

FROM SPINDLE

REMOVE BLADE

BOLT

FIGURE 7.7

2. Remove spindle pulley from spindle shaft.

3. Locate circular retaining ring on spindle shaft at

top bearing. Remove retaining ring. Allow spindle

shaft to drop out of housing.

4. Top and bottom bearings are now removable.

Pull out on inner race to slide bearing from

housing. See Figure 7.8.

BEARING

SPINDLE

INNER RACE

RETAINING RING

BEARING SEAL

SPINDLE

FIGURE 7.8

5. Thoroughly clean all parts removing all old

contaminated grease.

6. Install new bottom bearing first.

NOTE: The bearing is sealed/shielded on one side

only. The bottom bearing must be installed with the

sealed/shielded side DOWN.

7. Insert spindle shaft up through the bottom

bearing. Slide spacer down over spindle shaft.

8. Install new top bearing. Inst all the top bearing

with the seal/shield UP.

9. Slide circular retaining ring down spindle shaft

until it fully locks into groove on shaft.

10. Place spindle pulley and spacer on top of

spindle shaft.

11. Reinstall blade bolt, washer, blade and four

spacers.

12. Torque blade bolt and nut to 60 to 75 ft. lbs.

IMPORTANT: Spindle housing must be filled

with grease bef ore operating mo wer. Failure to

fill housing will cause premature bearing

failure.

13. Pump grease into spindle housing until grease

purges from vent on housing.

14. After the first 5 hours of operation, grease

spindle housing to insure it is full, then every 25

hours.

22

Page 23

(PISTOL GRIP MODELS)

KAWASAKI

ENGINE ONLY

OPC SWITCH

KEY WITH

COVER

KEYSWITCH

ELECTRICAL

CONNECTOR

NOTCH

TO

TRANSMISSION

SWITCH

15 AMP

FUSE

(PISTOL GRIP MODELS ONLY)

OPC SWITCH

BLADE

CLUTCH

SWITCH

MAIN

WIRE

HARNESS

KAWASAKI

CAPACITOR

GROUND TO ENGINE

KAWASAKI MODULE

KAWASAKI

PIGTAIL

TO ELECTRIC CLUTCH

TO MAIN

HARNESS

TO ENGINE

TERMINAL

* NOTE: THIS TERMINAL HAS A LOCK-OUT BARB

WHICH MUST SLIDE INTO THE CONNECTOR

NOTCH.

FIGURE 7.9

23

Page 24

ELECTRICAL

BLACK

ENGINE

GREEN

BLACK

OPC R.H.

GREEN (14 GA)

PTO SWITCH

WIRE AND TERMINAL TABLE

ELECTRIC CLUTCH

15A FUSE

GREEN

RED

RED

TRANSMISSION

BLUE

WHITE

OPC L.H.

YELLOW

BLACK

YELLOW

BLADE

SWITCH

IGNITION

RED

WIRING SCHEMATIC FOR PISTOL GRIP HANDLE & ELECTRIC BLADE BRAKE CLUTCH

FIGURE 7.10

TRANS SWITCH

(SEE NOTE)

RED (16 GA)

R.H. OPC

ENGINE

ELECTRIC CLUTCH

YELLOW (16 GA)

L.H. OPC

NOTE:

NUMBERS SHOW N ARE CIRCUIT NUMBERS

WHICH CORRESPOND TO ONES SHOWN IN

WIRING AND TERMINAL TABLE BELOW.

WHITE (16 GA)

IGNITION

FIGURE 7.11

24

Page 25

2 YEAR LIMITED WARRANTY

For two (2) years from purchase date for the original purchaser's use, SNAPPER, through any authorized

SNAPPER dealer will replace, free of c harge (except for taxe s where applicable), any part or parts found upon

examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

SNAPPER FIELD SERVICEABLE SPINDLES and their components used on SNAPPER PRO® Mid Size walks

and SNAPPERZRIDER® ride on commer cial equipment have a three (3) year limited warranty against defects

in material or workmanship or both.

All transportation costs incurred by the purchaser in submitting m aterial to an authorized SNAPPER dealer for

replacement under this warranty must be paid by the purchaser.

This warranty does not apply to engines and their components, and batteries, as these items are warranted

separately. This warranty does not apply to parts that have been damaged by accident, alteration, abuse,

improper lubrication, normal wear, or other cause beyond the control of SNAPPER. This warranty does not

cover any machine or component that has been altered or modified, changing safety, performance, or durability.

Batteries have a one (1) year prorated warranty period with free replacement if required during the first ninety

(90) days from the original purchase date. SNAPPER will not be responsible for any installation cost incurred.

The battery warranty only covers original equipment batteries and does not cover damage to the battery or

machine caused by neglect or abuse, destruction by fire, explosion, freezing, overcharging, improper

maintenance, or use of improper electrolyte.

There is no other express warranty.

DISCLAIMER OF WARRANTY

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited t o

two (2) years from purchase date f or the original p urchaser's use, and up to the extent permitted by law

and all implied warranties are excluded. This is the exclusive remedy. Liabilities for consequential

damages, under any and all warranties are excluded.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the

exclusion or limitation of incidental o r conseq uent ial damag es, so t he abo v e limitat ion or exclusion may

not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY

IMPAIR THE SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND WARRANTY BY

SNAPPER ASSOCIATED WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill out the attached SNAPPER Product Registration Card immediately and mail to:

Snapper’s Product Registration Ce nter, P.O. Box 1379, McDonough, Georgia. 30253

25

Page 26

PRIMARY MAINTENANCE

26

Page 27

PRIMARY MAINTENANCE

27

Page 28

PRIMARY MAINTENANCE

28

Page 29

PRIMARY MAINTENANCE

29

Page 30

NOTES

30

Page 31

NOTES

31

Page 32

Safety Instructions and Operator’s Manual for

PRO GEAR EXPRESS

MID-SIZE

WALK BEHIND

MOWERS

SERIES 0

IMPORTANT

Snapper products are built using engines that meet or exceed all applicable emissions requirements on the

date manufactured. The labels on those engines contain very important emissions information and critical

safety warnings. Read, Understand, and Follow all warnings and instructions in this manual, the engine

manual, and on the machine, engine and attachments. If you have any questions about your Snapper product,

contact your local authorized Snapper dealer or contact Snapper Customer Service at Snapper, McDonough,

GA. 30253. Phone: (1-800-935-2967).

WARNING:

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 4-5192 (REV. 2, 8/20/99) Printed in U.S.A.

The engine exhaust from this product contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm.

32

Loading...

Loading...