Page 1

DEALER SET-UP INSTRUCTIONS and PRE-SALE CHECKLIST for SNAPPER

EUROPEAN LARGE FRAME SNOW THROWERS

INTRODUCTION: The Snapper Large Frame Snow Throwers are shipped almost fully assembled and require

minimal set-up. Setting up the machine will require the handles to be unfolded and secured, and the attachment

of the chute crank rod. Some models may also require the installation of the electric start kit to the engine.

Complete each of the following steps carefully.

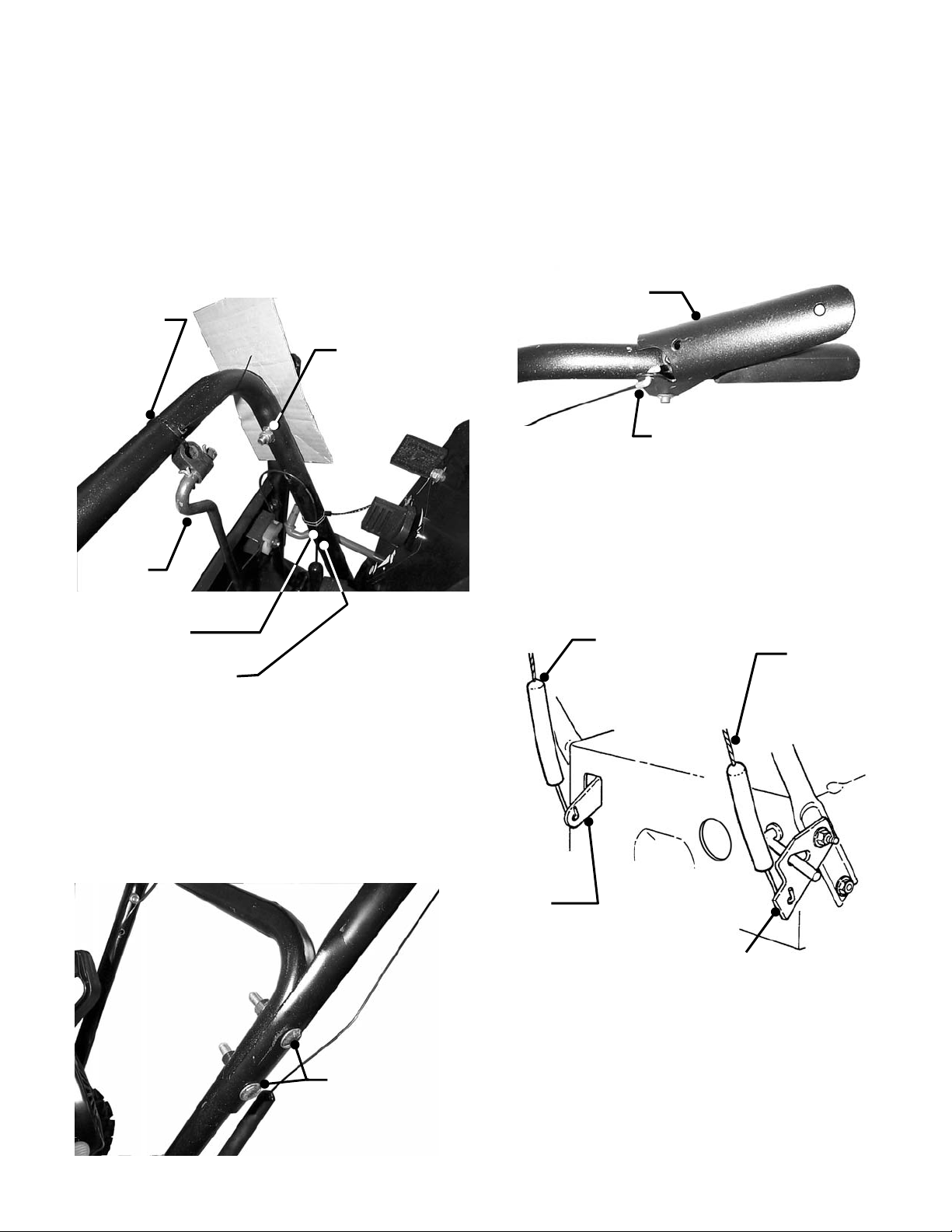

STEP 1: HANDLES: Cut both wire ties that secure the

control cables to the handles. Be very careful and DO

NOT cut the control cables. Cut the wire tie that secures

the chute crank to the handle. See Figure 1.

CUT CABLE TIE

THAT SECURES

CHUTE CRANK

LOOSEN NUT

REMOVE

CARDBOARD

CHUTE

CRANK

CUT CABLE TIES

ON BOTH

HANDLES

DO NOT CUT

CONTROL CABLE

FIGURE 1

STEP 2: HANDLES: Loosen handle nuts and speed

control rod nut. Rotate handles up to the operating

position. Remove shipping cardboard from in between

handles. See Figure 1. Insert bolts through both upper

& lower handles and secure with nuts. Make sure the

square necks of the bolts are recessed into the square

holes of upper handles. Tighten nuts securely. See

Figure 2.

SECURE UPPER

HANDLES WITH

BOLTS AND NUTS

TIGHTEN SECURELY

FIGURE 2

STEP 3: HANDLES: Cut both wire ties that secure the

control levers to the handles. See Figure 3.

CONTROL

LEVER

CHECK “Z” BEND END OF CABLE

IS SECURELY INSE RTED INTO

HOLE ON CONTROL LEVER

FIGURE 3

STEP 4: CABLES: Make sure that the cables are

connected to the traction clutch rod and blower clutch

bracket. IMPORTANT : Cables should have some slack

and should not be under tension. Both controls must

pivot freely. See Figure 4.

TRACTION

CLUTCH

CABLE

(LEFT SIDE)

BLOWER

CLUTCH

CABLE

(RIGHT SIDE)

TRACTION

CLUTCH

ROD

BLOWER

CLUTCH

BRACKET

FIGURE 4

INSTRUCTION No. 7-4367 (I.R. 05/9/01)

Page 2

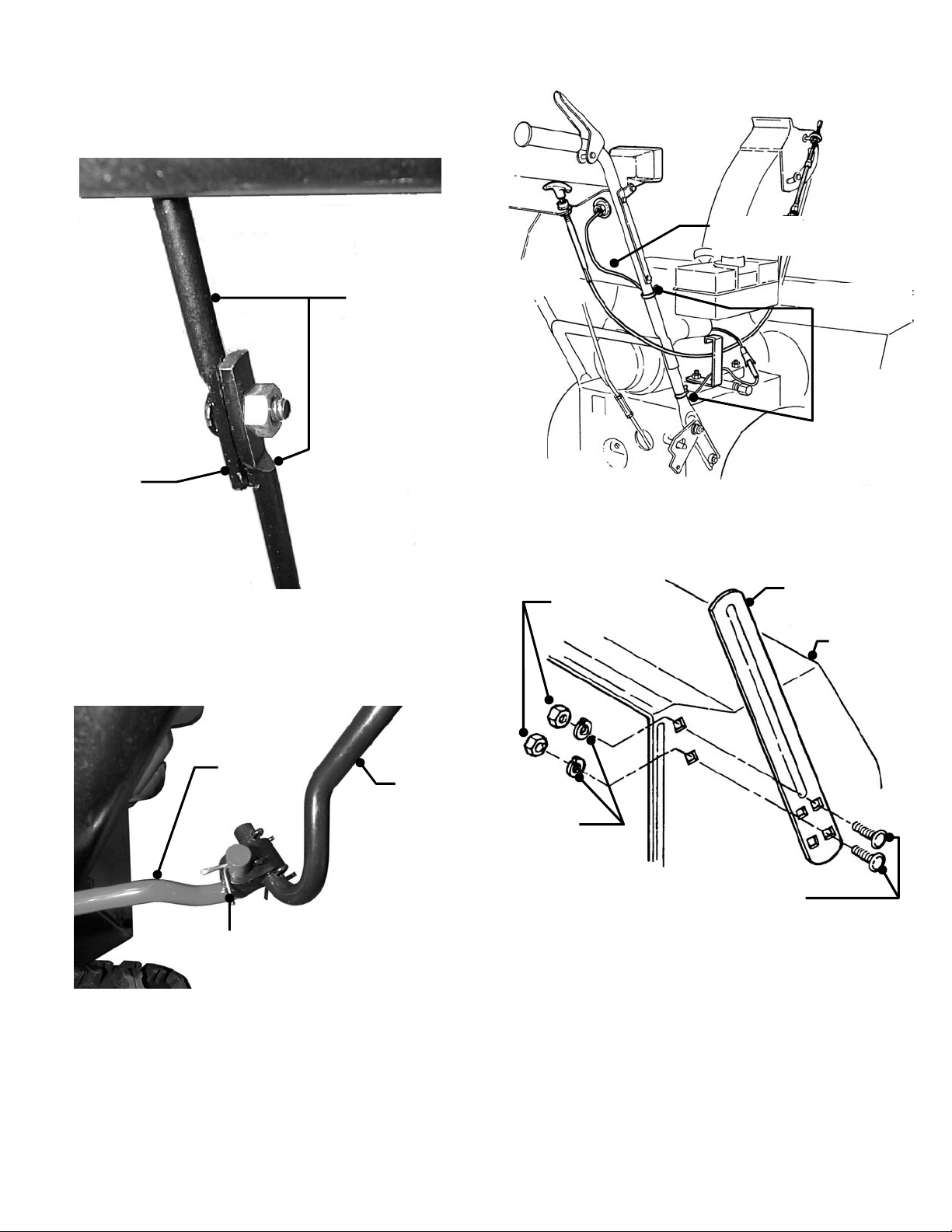

STEP 5: CONTROL ROD: : Cut wire ties that secure the

BOLT

ground speed control handle and control rods. Secure both

halves of the ground speed control rod together.

IMPORTANT: Make sure alignment tab and slot on the

two rod halves are engaged together. Tighten nut securely.

See Figure 5.

GROUND SPEED

CONTROL ROD

MAKE SURE TAB

AND SLOT ARE

ENGAGED

FIGURE 5

STEP 6: CHUTE CRANK: Connect chute crank to worm

gear shaft and secure with cotter pin. See Figure 6.

WORM

GEAR

SHAFT

CHUTE

CRANK

SECURE WITH

COTTER PIN

FIGURE 6

STEP 7: HEAD LIGHT: Use the wire ties supplied in k it

to secure the head light wire to the handles. Connect

headlight and engine harness together. See Figure 7.

STEP 8: DRIFT CUTTER Remove drift cutters from the

side of the auger housing and attach as shown. Note:

Bolts are inserted into rear holes of drift cutter. T ighten

nuts securely. See Figure 8.

HEAD LIGHT

WIRE

SECURE WITH

WIRE TIES

FIGURE 7

HEX

NUT

DRIFT

CUTTER

AUGER

HOUSING

LOCK

WASHER

CARRIAGE

FIGURE 8

NOTE: Drift Cutters are optional on some model

Snow Throwers. After set-up the hardware bag will

contain: two shear bolts and two nuts and a cotter

pin.

IMPORTANT: All necessary adjustments are made

to the machine at the factory. The following steps

are provided for reference only. Complete ALL

items on the Dealer Pre-Sale Checklist.

2

Page 3

STEP 9: ADJUSTMENT – CONTROL CABLES:

“UP”

“DOWN”

Both clutch cables s hould be s lac k when the contr ol lever s

are released. The cable spring on each control should

stretch 3/8" when each lever is depressed. To adjust cable,

loosen locking nut and turn cable connector as needed to

obtain the 3/8" extension. Tighten locking nut. See Figur e

9.

LOCKING

NUT

SPRING SHOULD

STRETCH 3/8”

WHEN LEVER IS

DEPRESSED

CABLE

CONNECTOR

CABLE SPRING

FIGURE 9

STEP 10: ADJUSTMENT - CLUTCH CONTROLS:

A. Hold the traction clutch control lever down against

the handle (L.H. Side) See Figure 10.

B. Check position of the cam lock - it must align with

the adjusting line on the cam lock bracket.

C. To adjust, loosen the nuts on the cable guide

support bracket and m ove br ack et in or out until the

cam lock aligns with the adjusting line. Tighten nuts.

D. Hold the traction clutch lever down while pressing

the blower clutch lever down into its engaged

position and hold.

E. Check the position of the cable ferrule shown in

Figure 10.

F. The ferrule shown in Figure 10 must be located

1/16" (.060) above the hook of the cam lock. To

adjust, loosen the three nuts on the cam lock

bracket and slide it up or down until adjustm ent is

correct. Tighten nuts and release both control

levers.

HOLD DOWN HOLD DOWN

TRACTION CLUTCH

CONTROL LEVER

(L.H. SIDE)

CABLE GUIDE

SUPPORT BRACKET

“IN”

“OUT”

CABLE GUIDE

BLOWER CLUTCH

CONTROL LEVER

CAM LOCK BRACKET

ADJUSTING LINE

(ON BRACKET)

(R.H. SIDE)

CABLE

CAM LOCK

CABLE FERRULE

.060

(1/16”)

CAM LOCK HOOK

CABLE

FIGURE 10

3

Page 4

DEALER PRE-SALE CHECKLIST

The following must be accomplished upon the sale of the snow thrower. It is very important that the Dealer

performs and accomplishes the set-up and the operational tests as listed below. Check (

performed and signed on this page.

✓) items actually

LUBRICATION

_____ ENGINE OIL added to bring level up to full mark on 4-cycle engines (Refer to Engine Manual).

_____ GEAR CASE grease level checked, add Benalene 900 grease (Snapper Part No. 2-9577) if needed.

OPERATIONAL TEST

_____ AUGER DRIVE CONTROL check ed for proper engagem ent and disengagement to ins ure auger stops within 5

seconds after auger clutch control is released.

_____ WHEEL DRIVE CONTROL checked for proper engagement and disengagement of wheel drive.

_____ ENGINE started, engine speed control settings checked and adjusted as needed.

_____ IGNITION SWITCH checked to insure engine stops when turned to OFF position.

_____ ENGINE ELECTRIC STARTER checked for proper operation.

_____ FUEL SYSTEM checked for leaks around tank and connections.

______DISCHARGE CHUTE CRANK checked for proper operation and free rotation.

______AUGER and WHEEL DRIVE CONTROL CABLES checked and adjusted per instructions in the Operator’s Manual.

_____ GROUND SPEED CONTROL checked and adjusted per instructions in the Operator’s Manual.

_____ CHOKE CONTROL checked for proper operation during start up.

_____ TIRE PRESSURE checked. 15 to 20 PSI if chains are to be installed or 12 PSI if chains are not being used.

_____ AUGER DRIVE CONTROL stops auger when released.

_____ WHEEL DRIVE CONTROL stops wheel drive when released.

_____ CHECK LIGHT checked for proper operation.

DEMONSTRATION & INSTRUCTION

_____ PERSONALLY HANDED Operator’s Manual & Snow Thrower Safety Booklet to purchaser.

_____ INSTRUCTED purchaser to read and follow instructions in Operator’s Manual.

_____ DEMONSTRATED proper starting procedure and operation of snow thrower to purchaser.

_____ INSTRUCTED purchaser how to service air cleaner, maintain oil level (4-cycle).

_____ ASSISTED purchaser in completing Product Registration Card.

DEALER’S RECORDS & CONSUMER/OPERATOR PRODUCT REGISTRATION CARD

Purchase Date __________________ Model_______________________ Serial No. _______________________

Retailers Name ___________________________________ Signature ____________________________________

Address _____________________________________ City ____________________ State _______ Zip ______

MACHINE WILL BE USED COMMERCIALLY? _____ YES _____ NO

Purchaser’s Name ________________________________ Signature ____________________________________

Address ____________________________________ City _____________________ State _______ Zip _______

IMPORTANT: This form is to be retained by the Dealer for future reference regarding Warranty, proof of

purchase, traceability for product recall or service, etc. Complete the Product Registration Card and Mail to

Customer Service Department at SNAPPER, P.O. Box 1379, McDonough, Georgia, 30253.

INSTRUCTION No. 7-4367 (I.R. 05/9/01) Printed in U.S.A.

4

Loading...

Loading...