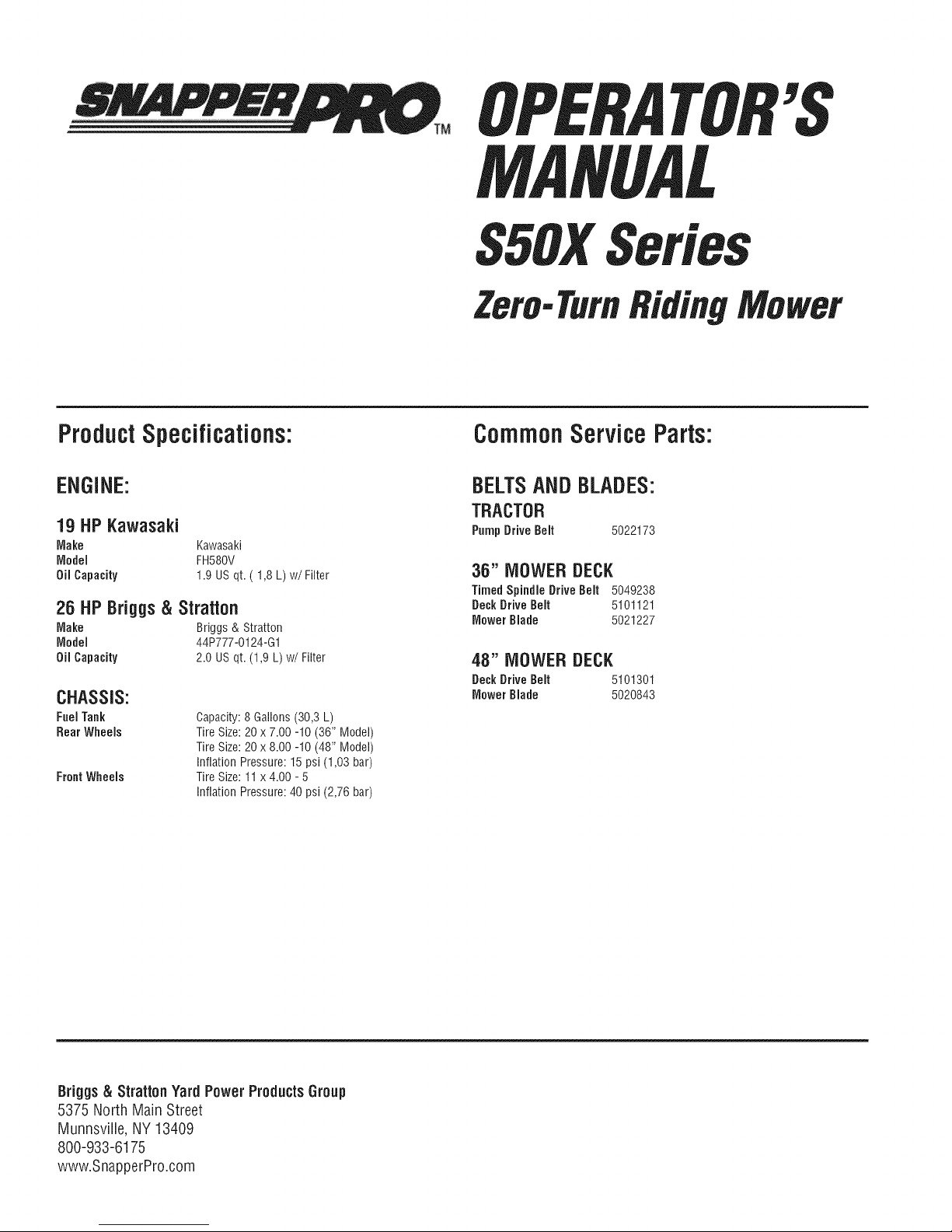

Snapper S50XBS2648, S50XKAV1948, S50XKAV1936, Pro S50XBS2648, Pro S50XKAV1948 Operator's Manual

...Page 1

M

Series

Model Number:

5900683

5900709

5900734

Briggs& Stratton Yard PowerProductsGroup

5375 North Main Street

Munnsville, NY 13409

800-933-6175

Description

S50XKAV1936, 19HP Kawasaki, 36" Cut Zero-Turn Riding Mower

$50XBS2648, 26HP Briggs & Stratton, 48" Cut Zero-Turn Riding Mower

S50XKAV1948, 19HP Kawasaki, 48" Cut Zero-Turn Riding Mower

5101098

RevisionIR

Rev.Date:12/2007

TPlO0-7362-1R-M5-SP

Page 2

Thankyoufor purchasingthis quality-built SnapperPro product. We'repleasedthat

you've placedyour confidencein the SnapperPro brand. When operatedand maintained

accordingto the instructions in this manual,your SnapperPro productwill provide many

yearsof dependableservice.

Thismanual containssafetyinformationto makeyou awareof the hazardsand

risksassociatedwith this machineand howto avoidthem. This machineis designedand

intendedto beusedand maintainedaccordingto the manualand operatedbytrained

professionalsfor finish cutting of establishedlawnsandis not intendedfor any other

purpose. It is importantthat you readand understandthese instructions thoroughly

beforeattemptingto start or operatethis equipment

Unit Model Number Unit SERIALNumber

MowerDeck Model Number MowerDeck SERIALNumber

DealerName Date Purchased

Engine Make

EngineType/Spec.

SeeFeaturesand Controls for the location of identification Numbers

DATEPURCHASED

Briggs & Stratton YardPower Products Group

Copyright © 2007 Briggs & Stratton Corporation

Milwaukee, Wl, USA. All rights reserved.

TheSnapperPro logois a trademark of Briggs & Stratton

Corporation Milwaukee,Wl, USA.

Contact information:

Briggs & Stratton YardPower Products Group

5375 N. Main St.

Munnsville, NY 13409-4003

(800) 933-6175

www.SnapperPro.com

EngineModel

EngineCode/SerialNumber

AWARNING

The engine exhaustfromthis productcontainschemicals

knownto the State of California tocausecancer, birth

defects, or other reproductive harm.

Page 3

Tableof Contents

OperatorSafety..................................................... 2

Safety Rulesand Information ...........................................2

Safety Decals....................................................................8

Safety interlock System....................................................9

Features& Controls .............................................. 10

Identification Numbers ...................................................10

Control Functions...........................................................11

Operation ........................................................... 13

General...........................................................................13

Checks BeforeStarting ...................................................13

CheckingTire Pressures.................................................14

SeatAdjustment.............................................................14

Mowing Height Adjustment ............................................15

Foot PedalAdjustment....................................................15

Starting the Engine.........................................................16

Stopping the Rider..........................................................16

Pushingthe Riderby Hand.............................................16

Zero Turn Driving Practice..............................................17

Mowing ...........................................................................19

Mowing Reccomendations.............................................19

Mowing Methods............................................................20

Attaching a Trailer...........................................................21

Regular Maintenance ............................................ 22

MaintenanceSchedule....................................................22

Checking/Adding Fuel.....................................................23

FuelFilter........................................................................23

Oil & Filter Change..........................................................23

Lubrication......................................................................24

CheckTransmissionOil Level.........................................25

Transmission Oil Filter Change.......................................25

Servicing the Mower Blades...........................................26

Ground Speed Control LeverAdjustment .......................28

Speed BalancingAdjustment ..........................................28

Neutral Adjustment.........................................................28

ParkingBrakeAdjustment ..............................................29

Returnto Neutral Adjustment.........................................30

DeckRodTiming Adjustment.........................................31

DeckLevelingAdjustment ..............................................31

Mower BeltReplacement................................................32

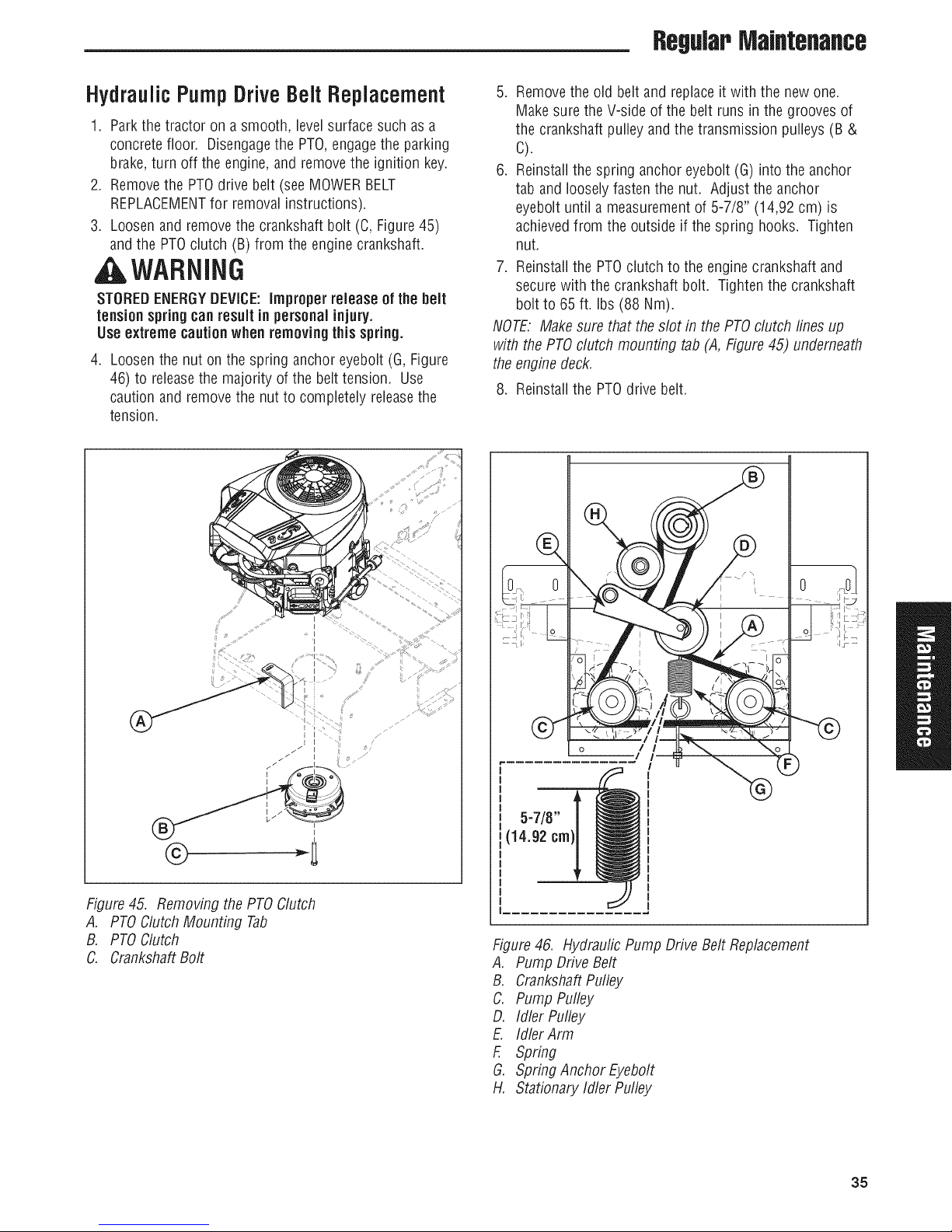

Hydraulic Pump Drive Belt Replacement........................35

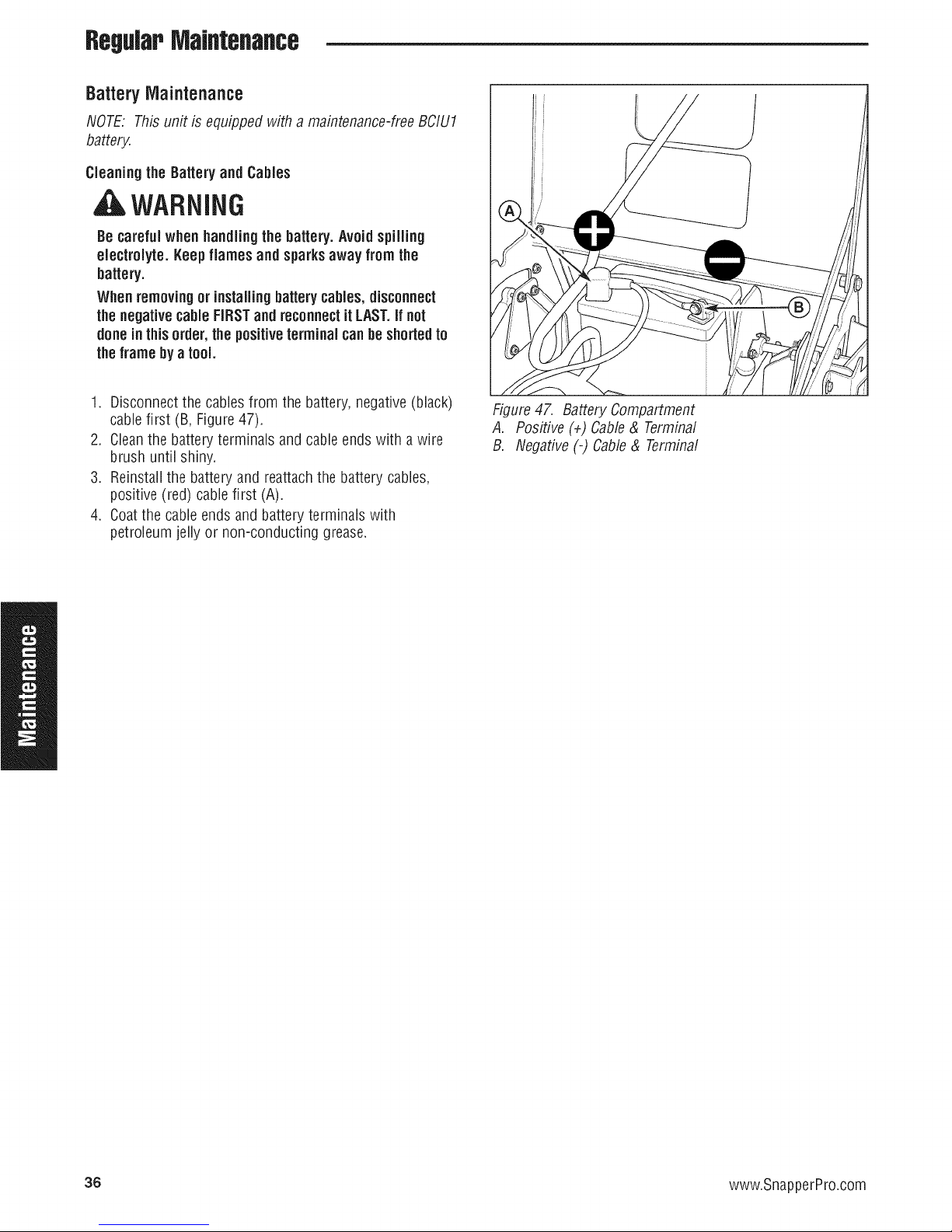

BatteryMaintenance.......................................................36

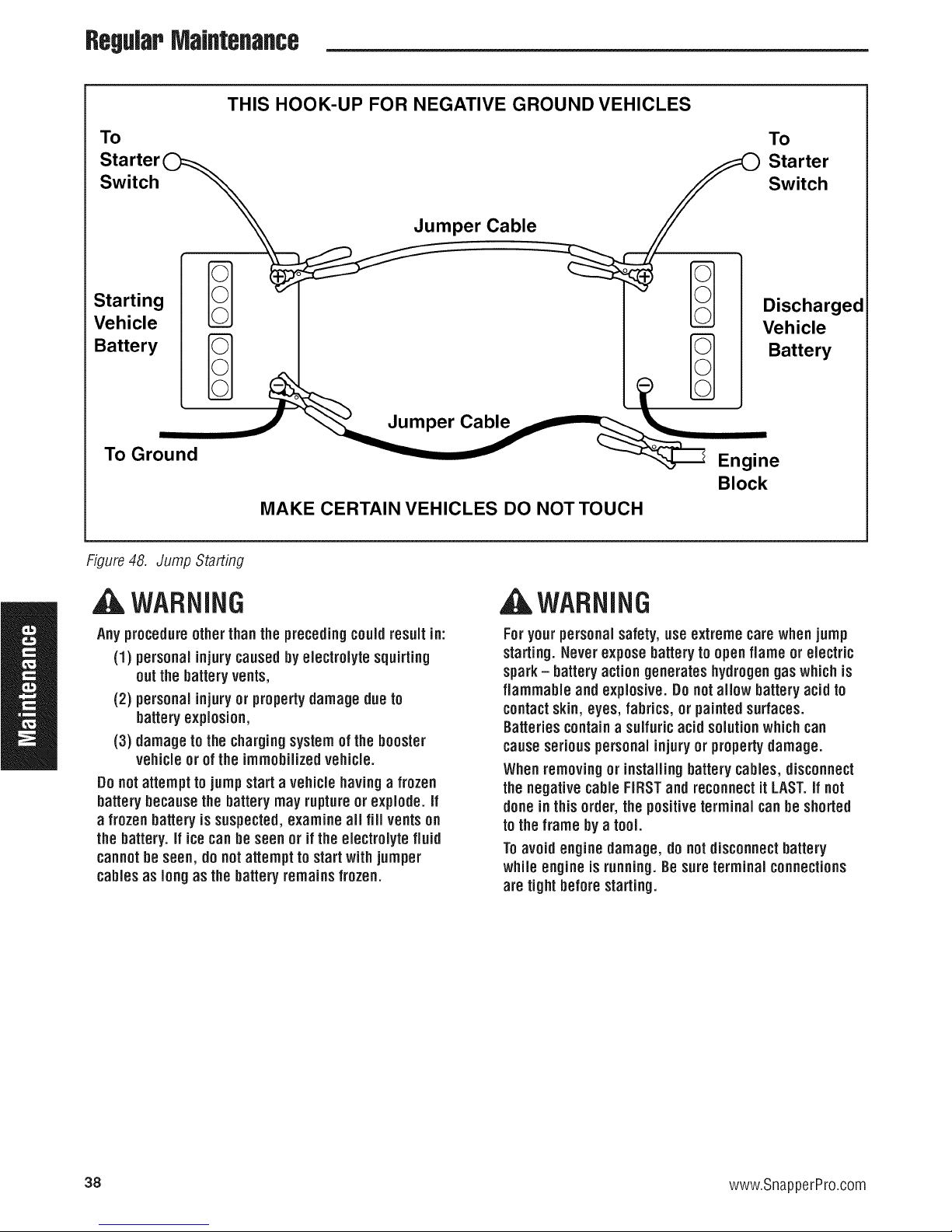

BatteryService...............................................................37

Storage...........................................................................39

Starting After Long Term Storage...................................39

Troubleshooting................................................... 40

Troubleshootingthe Rider..............................................40

Troubleshootingthe Mower............................................41

Troubleshooting Common Cutting Problems..................42

Specifications ...................................................... 43

Slope Identification Guide....................................... 44

NOTE.In this manual, "left" and "right" are referredto as seen

from the operating position.

Page 4

OperatorSafety

OperatorSafety

Safety Rules and Information

Congratulations on purchasing a superior-quality pieceof lawn and

garden equipment. Our products are designed and manufacturedto meet

or exceedall industry standards for safety.

Donot operatethis machine unless you have beentrained. Readingand

understanding this operator's manual is a way to train yourself.

Powerequipmentis only as safe asthe operator. If it is misused, or not

properly maintained,it can be dangerous! Remember,you are

responsiblefor your safety and that of those aroundyou.

Usecommon sense, and think through what you are doing. If you are

not surethat the task you are about to perform can be safely done with

the equipment you have chosen,ask a professional: contact your local

authorized dealer.

READTHEMANUAL

Theoperator's manual contains important safety information

you need to be awareof BEFOREyou operateyour unit as

well as DURINGoperation.

Safeoperating techniques,an explanation of the product's

featuresand controls, and maintenanceinformation is

included to helpyou get the most out of your equipment

investment.

OPERATINGSAFETY

Be sureto completely readthe Safety Rules and Information

found on the following pages. Also completely read the

Operationsection.

CHILDREN

Tragic accidents canoccur with children. Do not

allow them anywhere near the areaof operation.

Childrenareoften attractedto the unit and mowing

activity. Neverassumethat children will remain

where you lastsaw them. Ifthere is a risk that

children may enter the areawhereyou are mowing,

haveanother responsibleadult watch them.

2 www.SnapperPro.com

Page 5

2O

OperatorSafety

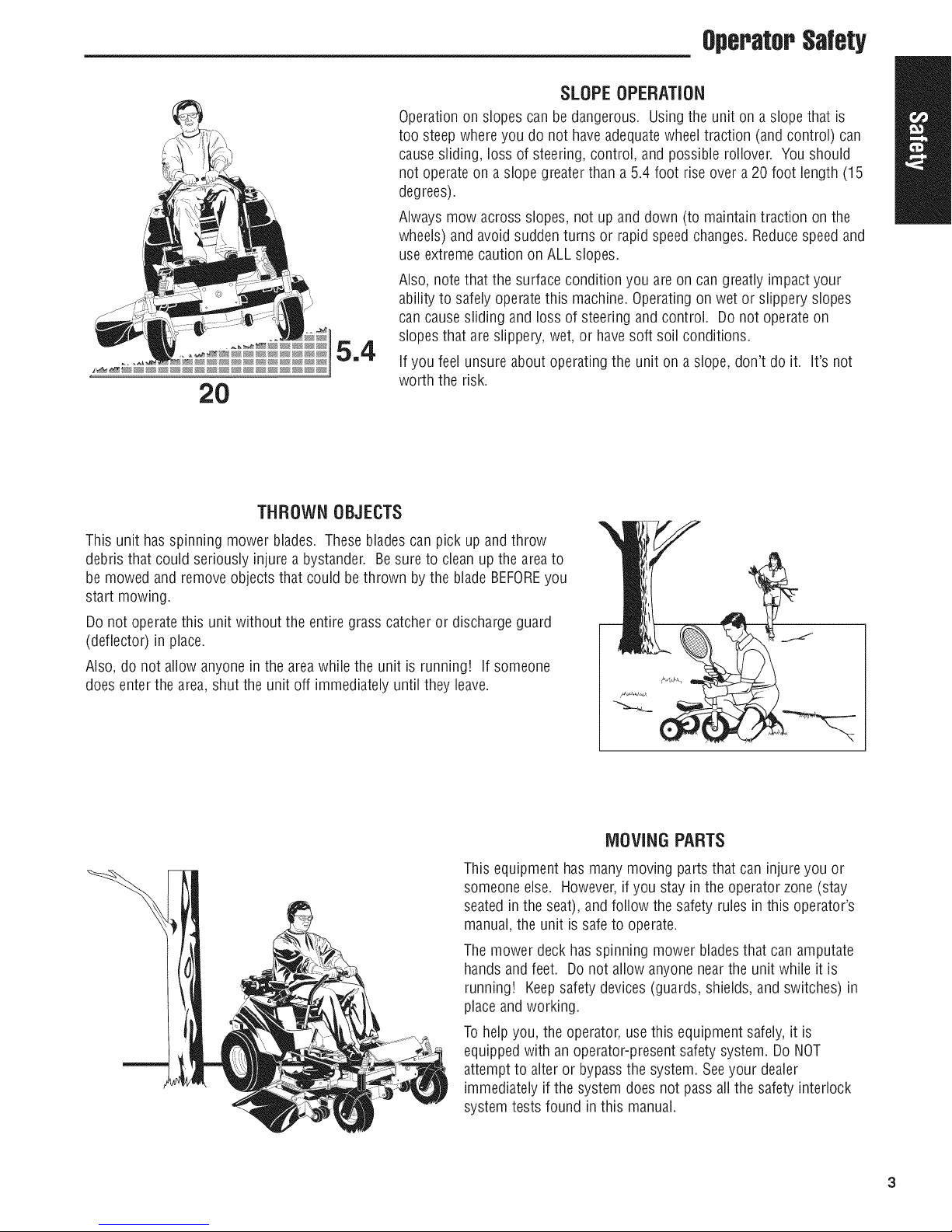

SLOPEOPERATION

Operationon slopes can be dangerous. Using theunit on a slope that is

too steepwhere you do not have adequatewheeltraction (and control) can

cause sliding, loss of steering, control, and possible rollover. You should

not operateon a slope greaterthan a 5.4 foot rise over a 20 foot length (15

degrees).

Always mow across slopes, not up and down (to maintain traction on the

wheels) and avoidsudden turns or rapid speedchanges. Reducespeedand

useextremecaution on ALL slopes.

Also, note that the surface condition you are on can greatly impact your

ability to safelyoperatethis machine. Operatingon wet or slippery slopes

can causesliding and loss of steering and control. Do not operate on

slopes that are slippery, wet, or havesoft soil conditions.

If you feel unsure about operating the unit on a slope, don't do it. It's not

worth the risk.

THROWNOBJECTS

This unit has spinning mower blades. Thesebladescan pick up andthrow

debris that could seriously injure a bystander. Be sure to clean up the areato

be mowed and remove objects that could bethrown by the blade BEFOREyou

start mowing.

Do not operatethis unit without the entire grass catcher or discharge guard

(deflector) in place.

Also, do not allow anyonein the areawhile the unit is running! If someone

does enterthe area,shut the unit off immediately until they leave.

This equipment has many moving parts that can injure you or

someone else. However,if you stay in the operator zone(stay

seated in the seat), and follow the safety rules in this operator's

manual, the unit is safe to operate.

Themower deck has spinning mower bladesthat can amputate

hands and feet. Donot allow anyone near the unit while it is

running! Keepsafety devices(guards, shields,and switches) in

placeandworking.

Tohelpyou, the operator,usethis equipment safely, it is

equipped with an operator-present safety system. Do NOT

attempt to alter or bypassthe system. Seeyour dealer

immediately if the system does not pass all the safety interlock

system tests found in this manual.

lOVING PARTS

Page 6

OperatorSafety

RETAiNiNGWALLS,DROP-OFFS,ANDWATER

Retaining walls and drop-offs around steps and water are a common hazard. Giveyourself a minimum of two mower widths

of clearancearound thesehazardsand hand-trim with a walk behind mower or string trimmer. Wheels dropping over

retaining walls, edges, ditches, embankments,or into water cancause rollovers, which may result in serious injury, death, or

drowning.

FUELAND MAINTENANCE

Alwaysdisengageall drives, shutoff the engine,and removethe

key before doing anycleaning, refueling, or servicing.

Gasolineandits vaporsare extremely flammable. Do not smoke

while operating or refueling. Do not add fuel while engine is hot

or running. Allow engine to cool for at least 3 minutes prior to

adding fuel.

Do not add fuel indoors, in an enclosed trailer, garage,or any

other enclosed areathat is not well ventilated. Gasolinespills

should becleaned up promptly and beforeoperation begins.

Gasolineshould bestored only in sealed containers approvedfor

fuel.

Proper maintenanceis critical to the safety and performance of

your unit. Keepthe unit free of grass, leaves,and excess oil. Be

sure to perform the maintenanceprocedureslisted in this

manual, especiallyperiodically testing the safety system.

4 www.SnapperPro.com

ENCLOSEDAREAS

Only operatethis unit outdoors and away from

unventilated areassuchas inside garagesor enclosed

trailers. The engine emits poisonous carbon

monoxide gas and prolonged exposure in an enclosed

area can result in serious injury or death.

Page 7

OperatorSafety

Readthese safety rules and follow them closely. Failureto obey these rulescould result in loss of control of unit,

severe personalinjury or deathto you, or bystanders,or damageto property or equipment. This mewing deck is

capableof amputating hands and feet and throwinq objects. The triangle _ in text signifies important cautions

or warnings which must be followed.

TRAINING

1. Read,understand,and follow all instructions in the

manualandon the unit beforestarting, if the

operator(s) or mechanic(s) can not read English it is the

owner's responsibility to explain this material to them.

2. Becomefamiliar with the safe operation of the

equipment,operator controls, and safety signs.

3. All operators andmechanics should betrained. The

owner is responsiblefor training the users.

4. Onlyallow responsibleadults, who are familiar with the

instructions, to operatethe unit.

5. Neverlet children or untrained peopleoperate or service

the equipment. Localregulations may restrict the age of

the operator.

6. The owner/user can prevent and is responsiblefor

accidentsor injuries occurring to themselves, other

peopleor property.

7. Dataindicatesthat operators, age60 years and above,

are involved in a large percentageof riding mower-

relatedinjuries. Theseoperators should evaluatetheir

ability to operate the riding mower safelyenough to

protect themselvesandothers from serious injury.

PREPARATION

1. Evaluatethe terrain to determine what accessoriesand

attachmentsare neededto properly and safely perform

the job. Useonly accessoriesand attachments

approvedby the manufacturer.

2. Wear appropriate clothing including safety shoes,safety

glassesandear protection. Long hair,looseclothing or

jewelry mayget tangled in moving parts.

3. inspect the areawhere the equipment is to be usedand

remove aii objects such as rocks, toys and wire, which

canbethrown by the machine.

4. Useextra care when handlinggasoline and other fuels.

They are flammable and vapors areexplosive.

a) Useonly an approvedcontainer.

b) Never remove fuel cap or addfuel with the engine

running. Allow engine to cool before refueling. Do

not smoke.

c) Neverrefuel or drain the machine indoors.

5. Checkthat operator's presencecontrols, safety switches

and shields areattachedand functioning properly. Do

not operateunlessthey arefunctioning properly.

OPERATION

1. Neverrun an engine in an enclosed area.

2. Mow only in the daylight or with good artificial light,

keepingawayfrom holes and hidden hazards.

3. Besure all drives are in neutral and parking brakeis

engaged beforestarting engine. Only start engine from

the operator's position. Useseat belts if provided.

4. Besure of your footing while using pedestriancontrolled

equipment, especiallywhen backing up. Walk, don't

run. Reducedfooting could causeslipping.

5. Slow down and use extra care on hillsides. Besure to

travel in the recommendeddirection on hillsides. Turf

conditions can affect the machinesstability. Usecaution

when operating neardrop-offs.

6. Do not mow in reverseunless absolutely necessary.

Always look down and behind beforeand while traveling

in reverse.

7. Beawareof the mower discharge direction and do not

point it at anyone. Do not operate the mower without

either the entiregrass catcher or the deflector in place.

8. Slow down and use caution when making turns and

when changing directions on slopes.

9. Never raisedeckwith the blades running.

10. Neverleave a running unit unattended. Always

disengagethe PTO,set parking brake, stop engine, and

remove keysbefore dismounting. Keephandsand feet

away from the cutting units.

11. Turn off the PTOswitch to disengagethe bladeswhen

not mowing.

12. Neveroperate with guards not securely in place. Be

sure all interlocks are attached, adjusted properly and

functioning properly.

13. Neveroperate with the discharge deflector raised,

removed or altered, unless using a grass catcher.

14. Do not changethe engine governor setting or overspeed

the engine.

15. Stop on levelground, lower implements, disengage

drives, engageparking brake, shut off engine before

leavingthe operator's position for any reason including

emptying the grass catchers or unclogging the chute.

16. Stop equipment and inspect blades after striking objects

or abnormal vibration occurs. Makenecessary repairs

before resuming operations.

17. Keephands and feet awayfrom the cutting units.

18. Look behind and down before backing up to be sure of a

clear path.

19. Nevercarry passengersand keeppets and bystanders

away.

20. Do not operatethe unit while under the influence of

alcohol or drugs.

21. Slow down and usecautionwhen making turns and

crossing roads and sidewalks. Stop blades if not

mowing.

22. Usecare when loading or unloading the machine into a

trailer or truck.

23. Usecare when approaching blind corners, shrubs, trees

or other objects that may obscure vision.

24. To reducefire hazard,keepunit free of grass, leaves&

excess oil. Donot stop or park over dry leaves,grass or

combustible materials.

25. The engine in this unit is not factory equippedwith a

Page 8

OperatorSalety

spark arrester. It is aviolation of California Public

ResourceCode Section 4442 to use or operatethe

engineon or near any forest-covered, brush-covered, or

grass-covered land unlessthe exhaustsystem is

equippedwith a spark arrester meetingany applicable

local or state laws. Other states or federal area may

havesimilar laws.

26.

OSHAregulations may require the use of hearing

protection when exposedto sound levels greaterthan 85

dBAfor an 8 hour time period.

, CAUTION

excessof 85 dBA at the operator's ear and

=_ his machine producessound levels in

cancausehearingloss thoughextended

"J periodsof exposure.

Wear hearingprotectionwhenoperating this machine.

SLOPEOPERATION

Slopesare a majorfactor relatedtoloss-of-controlandtip-

overaccidents,which can resultin severeinjury or death.All

slopes requireextracaution.Ifyou cannot backuptheslope

or if you feel uneasyon it, do not driveon it.

AWARNING

Never operate on slopesgreater than15 degrees which

is a rise of 5.4 feet (165 cm) vertically in 20 feet (607

cm) horizontally.

Select slow ground speedbeforedriving onto slope.

Useextra cautionwhenoperating on slopeswith rear-

mountedgrass catchers.

Mow across the face of slopes,notup and down, use

cautionwhen changingdirections and D0 NOTSTART

ORSTOPONSLOPE.

[}o

1. Mow across slopes, not up and down.

2. Removeobstacles such as rocks, tree limbs, etc.

3. Watch for holes, ruts, or bumps. Uneventerrain could

overturn the unit. Tallgrass can hide obstacles.

4. Useslow speed. Choosea slow speed so that you will

not haveto stop or changespeedwhile on the slope.

5. Useextra care with grass catchers or other attachments.

Thesecan changethe stability of the unit.

6. Keepall movementon the slopes slow and gradual. Do

not make sudden changesin speedor direction.

7. Seeyour authorized dealerfor recommendationsof

availableweights to improve stability.

Do Not

1. Avoid starting, stopping, or turning on aslope, if tires

losetraction (i.e. machine stops forward motion on a

slope), disengage the blade(s) (PTO) and drive slow off

the slope.

2. Do not turn on slopes unless necessary,and then, turn

slowly and gradually uphill, if possible. Nevermow

down slopes.

3. Do not mow near drop-offs, ditches, or embankments.

The operator could lose footing or balanceor mower

could suddenly turn over if a wheel is over the edgeof a

cliff or ditch, or if an edge cavesin.

4. Do not mow on wet grass. Reducedfooting or traction

could causesliding.

5. Do not try to stabilizethe unit by putting your foot on

the ground. (ride-on units)

6. Do not mow excessivelysteep slopes.

7. Do not use grass catcher on steep slopes.

8. Do not mow slopes if you cannot back up them.

TOWED EQUIPMENT (RIDE-ON UNITS)

1. Tow only with a machine that has a hitch designedfor

towing. Donot attachtowed equipmentexcept atthe

hitch point.

2. Follow the manufacturer's recommendationsfor weight

limit for towed equipment and towing on slopes. See

attaching a trailer under OPERATION.

3. Neverallow children or others inor on towed

equipment.

4. Onslopes, the weight of the towed equipment may

cause loss of traction and lossof control.

5. Travelslowly and allow extra distanceto stop.

6. Do not shift to neutral and coast down hill.

CHILDREN

Tragicaccidentscanoccur if the operatoris notalertto the

presenceof children. Childrenareoften attractedto the unit

andthe mowing activity. Neverassumethat childrenwill

remainwhereyou lastsawthem.

1. Keepchildren out of the mowing area and under the

watchful care of another responsible adult.

2. Bealert and turn unit off if children enterthe area.

3. Beforeandduring reverseoperation, look behind and

down for small children.

4. Nevercarry children, even with the blade(s)off. They

may fall off and be seriously injured or interfere with

safe unit operation. Childrenwho have beengiven rides

in the past may suddenly appear in the mowing areafor

another ride and be run over or backedover by the

machine.

5. Neverallow children to operate the unit.

6. Useextra carewhen approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

EMISSIONS

1. Engineexhaustfrom this product contains chemicals

known, in certain quantities, to cause cancer,birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Periodand Air

indexinformationon the engine emissions label.

6 www.SnapperPro.com

IGNITION SYSTEM (GASOLINE MODELS)

1. This spark ignition systemcomplies with Canadian

ICES-O02.

Page 9

OperatorSafety

SERVICEANDMAINTENANCE

Toavoidpersonalin_v or orooertvdamaoe,useextreme

careinhandlincLQasoline.Gasolineisextremelyflammable

andthevaporsareexplosive.

Safe Handlingof Gasoline

1. Extinguishall cigarettes,cigars, pipes, and other

sourcesof ignition.

2. Useonly approvedgasoline containers.

3. Neverremove the gas capor add fuel with the engine

running. Allow the engine to cool before refueling.

4. Neverfuel the machine indoors.

5. Neverstore the machine or fuel container where there is

an open flame, spark, or pilot light such as near a water

heateror other appliance.

6. Neverfiii containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground awayfrom your vehicle beforefilling.

7. Removegas-powered equipment from the truck or

trailer and refuelit on the ground. If this is not possible,

then refuelsuch equipment on a trailer with a portable

container,rather thanfrom a gasoline dispenser nozzle.

8. Keepnozzlein contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Donot usea nozzlelock-opendevice.

9. If fuel is spilled on clothing, change clothing

immediately.

10. Neverover-fill the fuel tank. Replacegas capand

tighten securely.

11. Useextra care in handling gasoline and other fuels. They

areflammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine awayfrom the area of spillage and

avoidcreating anysource of ignition until fuel vapors

havedissipated.

13. Replaceall fuel tank caps and fuel container caps

securely.

IVlaintenanceand Storage

1. Always observe safe refueling and fuel handling

practiceswhen refueling the unit after transportation or

storage.

2. Always follow the engine manualinstructions for storage

preparations beforestoring the unit for both short and

long term periods.

3. Always follow the engine manualinstructions for proper

start-up procedureswhen returning the unit to service.

4. Neverstore the machine or fuel container inside where

there is an open flame, such as ina water heater. Allow

unit to cool before storing.

5. Shut off fuel while storing or transporting. Donot store

fuel near flames or drain indoors.

6. Keepall hardware,especiallyblade attachment bolts,

tight and keepall parts in good working condition.

Replaceall worn or damaged decals.

7. Nevertamper with safety devices. Checktheir proper

operation regularly.

8. Disengagedrives, lower implement, setparking brake,

stop engine and remove key or disconnect spark plug

wire. Wait for all movementto stop before adjusting,

cleaningor repairing.

9. Cleangrass and debris from cutting units, drives,

mufflers, and engineto prevent fires. Cleanup oil or

fuel spillage.

10. Letengine cool before storing and do not store near

flame.

11. Stop and inspect the equipment if you strike an object.

Repair,if necessary,before restarting.

12. Parkmachine on levelground. Neverallow untrained

personnelto servicemachine.

13. Usejack stands to support components when required.

14. Carefullyreleasepressure from components with stored

energy.

15. Disconnectbattery or removespark plug wire before

making any repairs. Disconnectthe negativeterminal

first and the positive last. Reconnectpositive first and

negativelast.

16. Usecare when checking blades. Wrap the blade(s) or

wear gloves, and use caution when servicing them.

Only replaceblades. Neverstraighten or weld them.

17. Keephands and feet awayfrom moving parts, if

possible, do not make adjustmentswith the engine

running.

18. Chargebatteries inan openwell ventilated area,away

from spark and flames. Unplug charger before

connecting or disconnectingfrom battery. Wear

protective clothes and useinsulatedtools.

19. Grasscatcher components are subject to wear,damage,

and deterioration, which could expose moving parts or

allow objects to bethrown. Frequentlycheck

components and replacewith manufacturer's

recommendedparts, when necessary.

20. Checkbrake operationfrequently. Adjust and service as

required.

21. Useonly factory authorized replacementpartswhen

making repairs.

22. Always comply with factory specifications on all settings

and adjustments.

23. Onlyauthorized service locations should be utilized for

major service and repair requirements.

24. Neverattempt to makemajor repairs on this unit unless

you havebeen properly trained, improper service

procedures can result in hazardousoperation,

equipment damage and voiding of manufacturer's

warranty.

25. Unitswith hydraulic pumps, hoses,or motors:

WARNING:Hydraulicfluid escapingunder pressure may

havesufficient force to penetrateskin and causeserious

injury. If foreign fluid is injected into the skin it must be

surgically removed within a few hours by a doctor

familiar with this form of injury or gangrenemay result.

Keepbody and hands awayfrom pin holes or nozzles

that eject hydraulic fluid under high pressure. Use paper

or cardboard, and not hands,to search for leaks. Make

sure aii hydraulic fluid connections are tight and all

hydraulic hosesand lines are in good condition before

applying pressureto the system, if leaks occur,have

the unit serviced immediately byyour authorized dealer.

26. WARNING:Stored energydevice, improper releaseof

springs can result in serious personal injury. Springs

should be removedby an authorizedtechnician.

27. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily injury

from hot coolant or steam blow-out, neverattemptto

removethe radiator cap while the engine is running.

Stop the engine and wait until it is cool. Eventhen, use

extreme carewhen removing the cap.

Page 10

,OperatorSafety

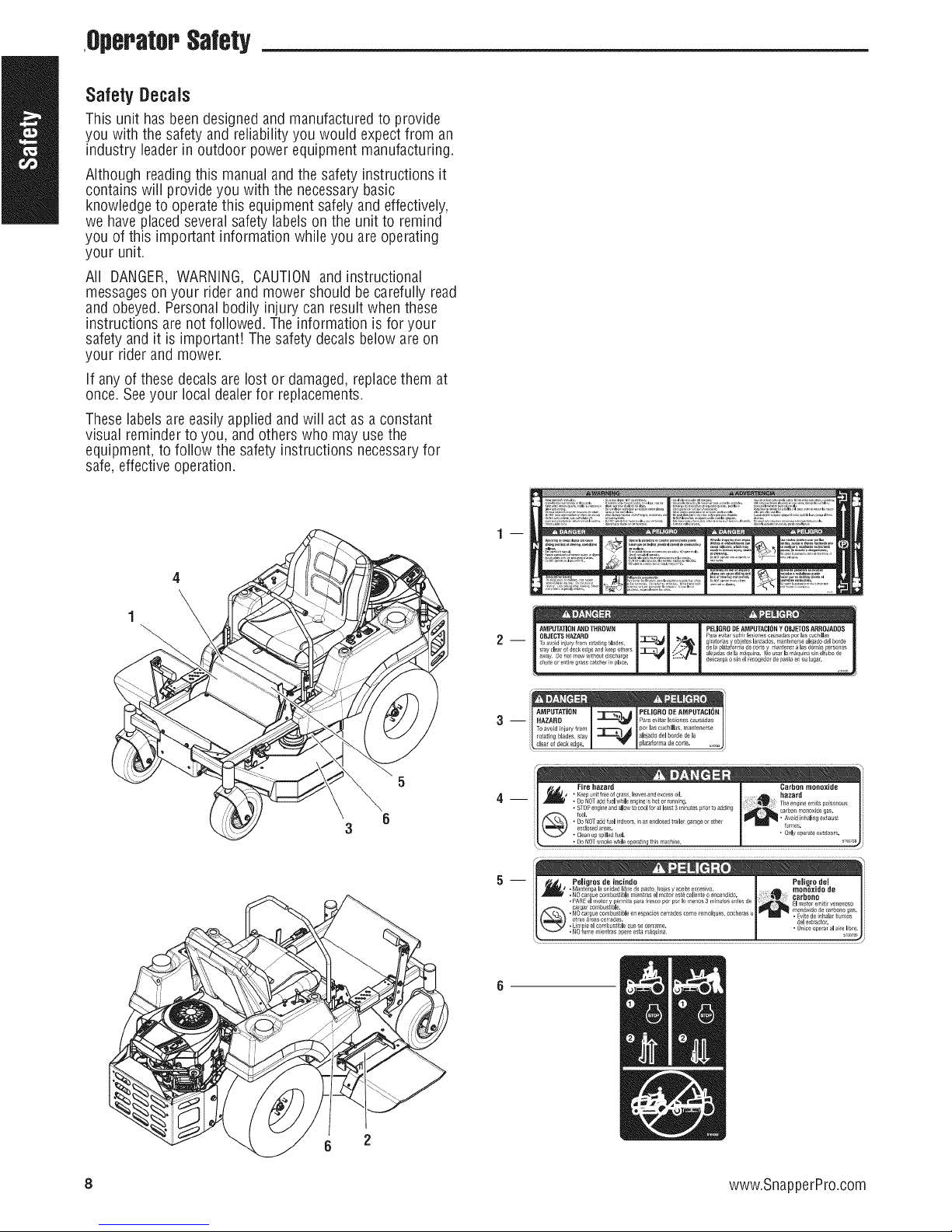

Safety Decals

This unit has beendesigned and manufactured to provide

you with the safety and reliability you would expectfrom an

industry leader in outdoor power equipment manufacturing.

Although readingthis manualand the safety instructions it

contains will provide you with the necessary basic

knowledge to operatethis equipment safely and effectively,

we haveplacedseveral safety labels on the unit to remind

you of this important information while you are operating

your unit.

All DANGER,WARNING, CAUTION and instructional

messageson your rider and mower should be carefully read

and obeyed. Personalbodily injury can result when these

instructions are not followed. The information is for your

safety and it is important! Thesafety decals below are on

your rider and mower.

If any of these decals are lost or damaged, replacethem at

once. Seeyour local dealerfor replacements.

Theselabels areeasily applied andwill act as a constant

visual reminder to you, and others who may usethe

equipment, to follow the safety instructions necessaryfor

safe,effective operation.

1 m

OBJECTS HAZARD =_ Papaev_ar SLff[_; les or_escausadas por I_s c?ch_llas

IAOPOTA"OOA"OTR OW°I I I O0000EAOPOOO'ON'OOJE'OSA"" AOOS

2 -- ill avoid in ury from rotat rig blades _ ".,_ glralor as y oberos la izades, ma_lier!_rse ale ado del horde

s ay cea _ deck eSge and keeg o e s /_;: de la }lataforuFa de cone y T_anfener a Ins demos personas

i o , , ,_ b izlJi.:.'_::_--I..................................................

" Y g _ :--_'_ d ca g I _ed de p i e I ga

AMPUTATION _--_-_._ PEMORODEAMPUTACION

3 -- HAZARD _ Paraevitarlesionescausadas

4 m

5 m

.....................i..........................

8 www.SnapperPro.com

6 2

Page 11

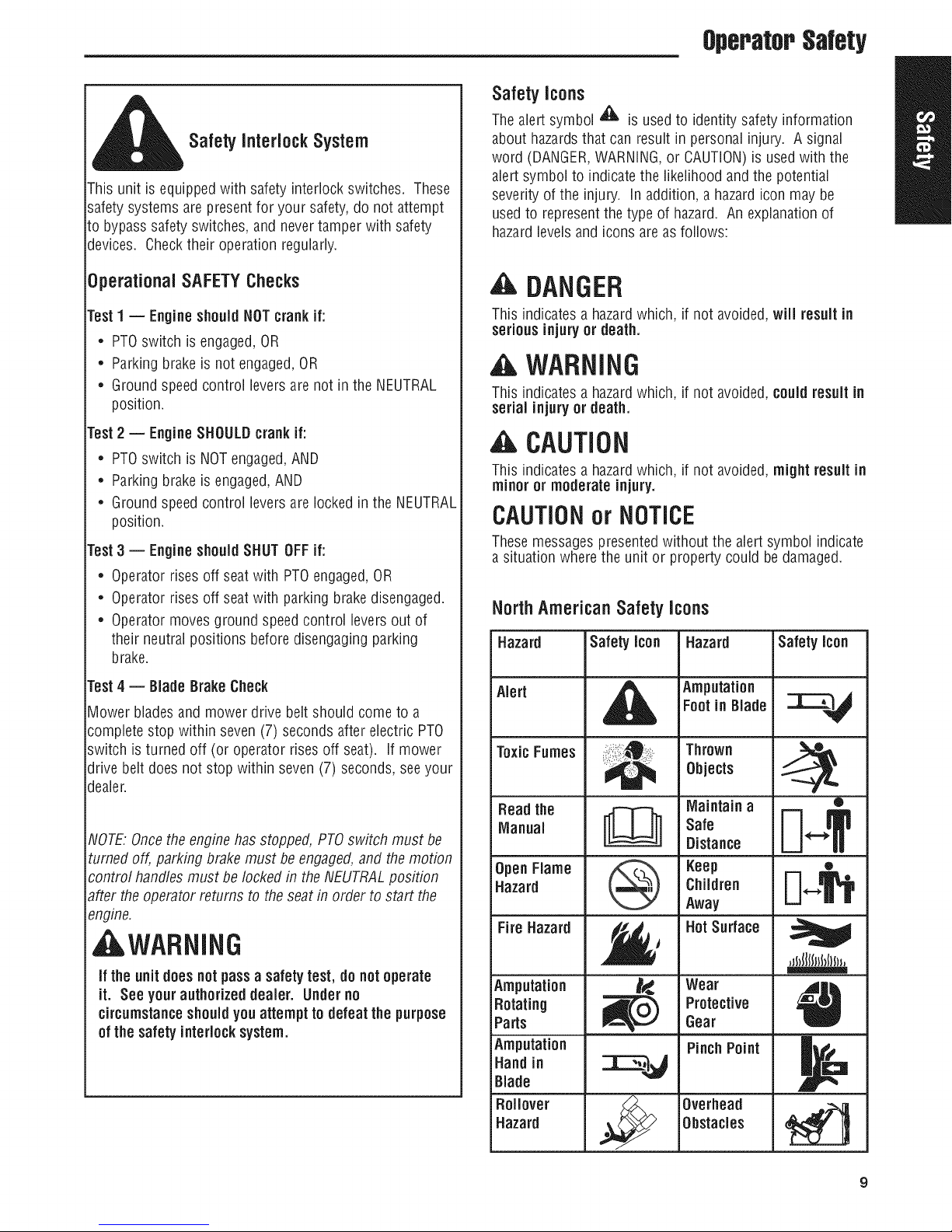

Safety interlockSystem

This unit is equippedwith safety interlock switches. These

safety systems are presentfor your safety,do not attempt

to bypasssafety switches, and nevertamper with safety

devices. Checktheir operation regularly.

OperatorSafety

Safety icons

Thealert symbol _ is usedto identity safety information

about hazardsthat can result in personalinjury. A signal

word (DANGER,WARNING,or CAUTION)is used with the

alert symbol to indicate the likelihood and the potential

severity of the injury. In addition, a hazard icon may be

usedto representthe type of hazard. An explanationof

hazardlevelsand icons are as follows:

Operational SAFETYChecks

Test1 -- EngineshouldNOTcrankif:

* PTOswitch is engaged, OR

. Parkingbrake is not engaged,OR

. Groundspeedcontrol leversare not in the NEUTRAL

position.

Test2 -- Engine SHOULDcrankif:

. PTOswitch is NOTengaged,AND

. Parkingbrake is engaged,AND

. Groundspeedcontrol leversare locked in the NEUTRAL

position.

Test3 -- EngineshouldSHUT OFFif:

* Operatorrisesoff seatwith PTOengaged,OR

. Operatorrises off seatwith parking brakedisengaged.

. Operatormoves ground speed control leversout of

their neutral positions before disengagingparking

brake.

Test4 = Blade BrakeCheck

Mower blades and mower drive belt should cometo a

complete stop within seven (7) seconds after electric PTO

switch is turned off (or operator rises off seat). If mower

drive belt does not stop within seven (7) seconds, seeyour

dealer.

NOTE.Once the enginehas stopped, PTOswitch must be

turned off, parking brake must be engaged,and the motion

control handlesmust be locked in the NEUTRALposition

after the operator returns to the seat in order to start the

engine.

AWARNING

DANGER

This indicates a hazardwhich, if not avoided, will result in

seriousinjuryor death.

WARNING

This indicates a hazardwhich, if not avoided, could result in

serial injuryor death.

,A CAUTION

This indicates a hazardwhich, if not avoided, might result in

minor or moderate injury.

CAUTIONor NOTICE

Thesemessagespresented without the alert symbol indicate

a situation where the unit or property could be damaged.

NorthAmerican Safety icons

Hazard

Alert

Toxic Fumes

Read the

Manual

Open Flame

Hazard

Fire Hazard

Safety Icon

A

@

Hazard

Amputation

Foot in Blade

Maintain a

Safe

Distance

Keep

Children

Away

HotSurface

iSafety icon

0

o

if the unitdoes not pass a safetytest, do not operate

it. See yourauthorized dealer. Under no

circumstanceshouldyouattempt to defeat thepurpose

of the safetyinterlocksystem.

Amputation

Rotating

Parts

Amputation

Handin

Blade

Rollover

Hazard

Wear

Protective

Gear

PinchPoint

Overhead

Obstacles

0

9

Page 12

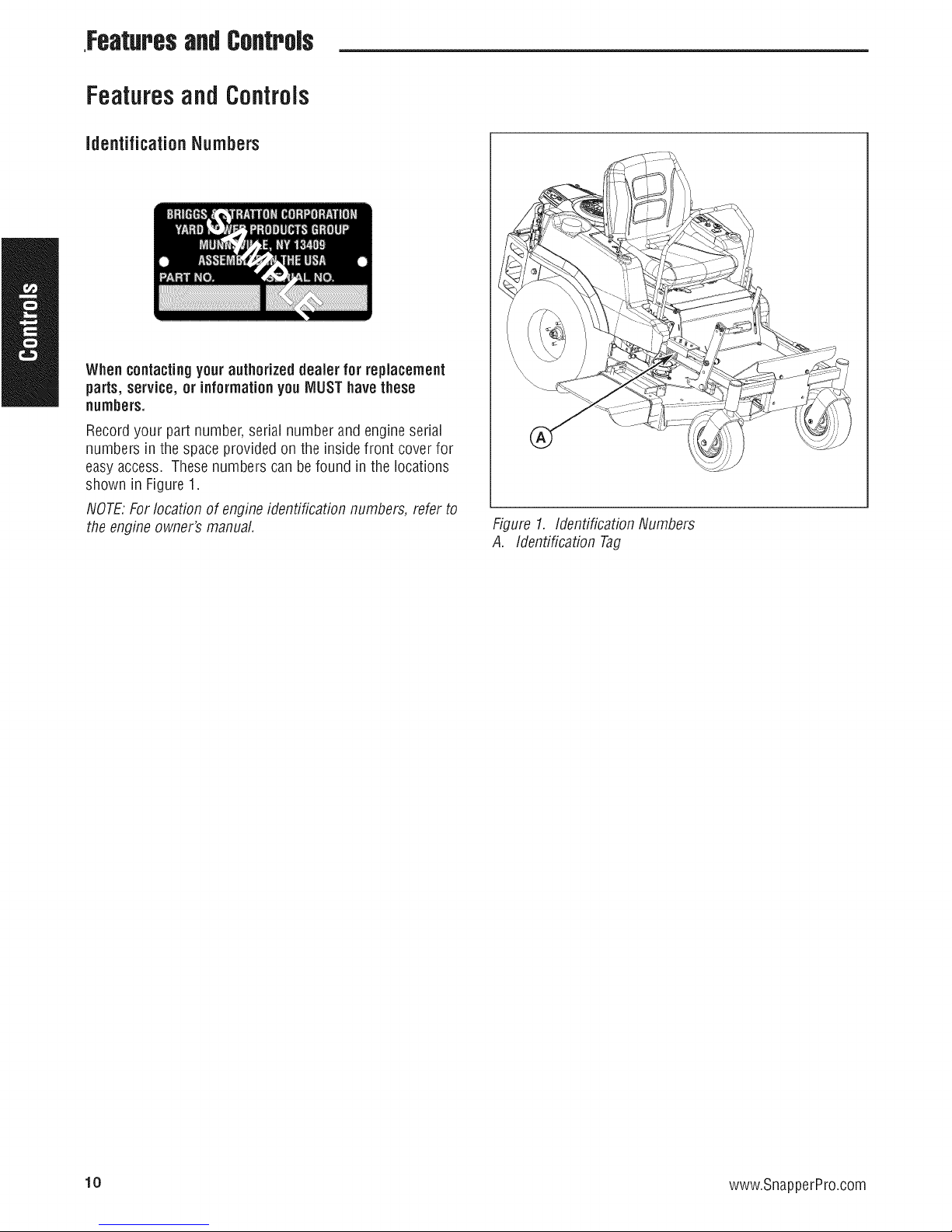

FeaturessndControls

FeaturesandControls

identificationNumbers

Whencontacting your authorizeddealer for replacement

parts, service,or informationyou MUSThavethese

numbers.

Record your part number, serial number and engine serial

numbers in the space provided on the inside front cover for

easy access. Thesenumbers can be found in the locations

shown in Figure1.

NOTE.For location of engineidentification numbers, refer to

the engineowner's manual.

Figure 1. Identification Numbers

A. Identification Tag

10 www.SnapperPro.com

Page 13

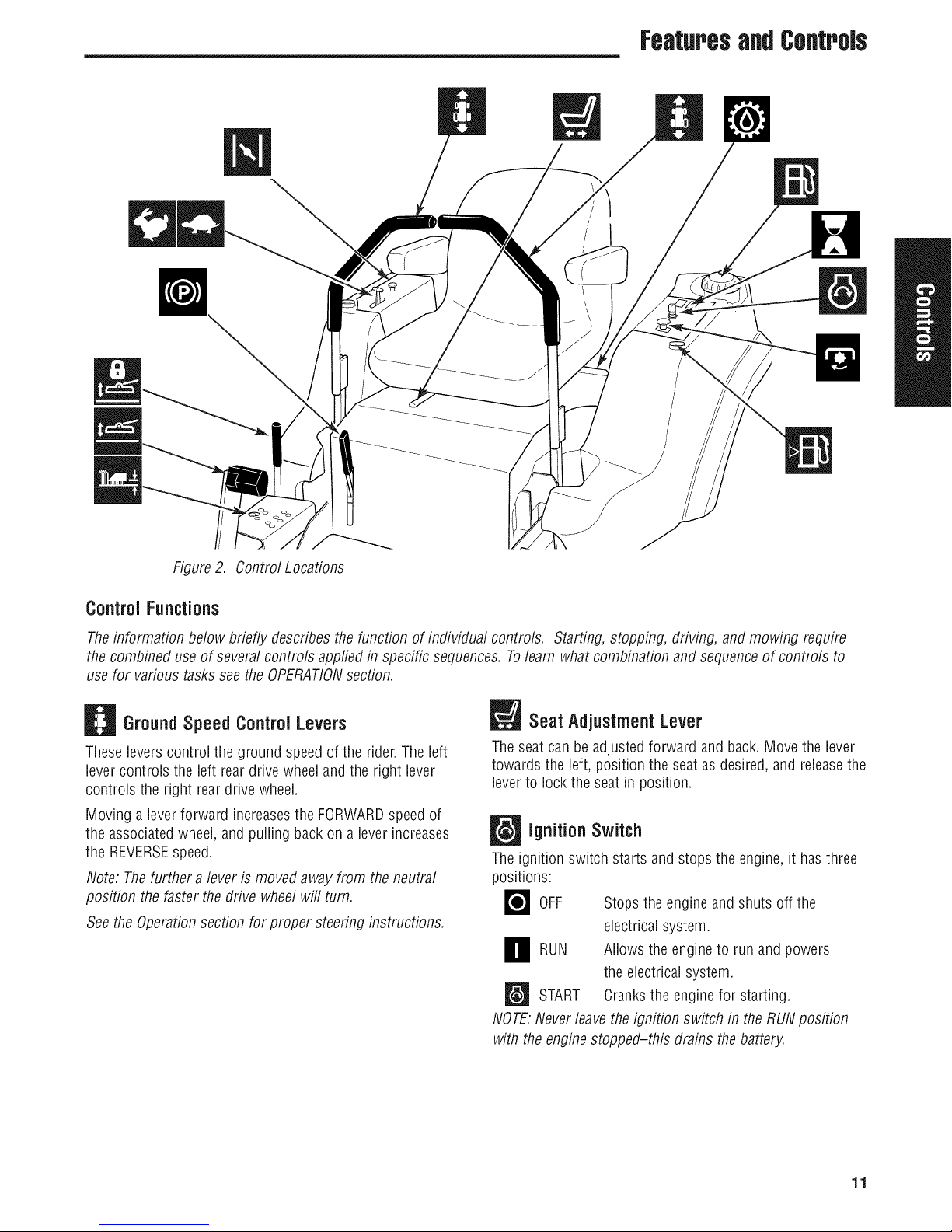

FeaturessndControls

Figure2. Control Locations

ControlFunctions

Theinformation below briefly describes the function of individual controls. Starting, stopping, driving, and mowing require

the combined use of several controls appfiedin specific sequences. Tolearn what combination and sequenceof controls to

use for various tasksseethe OPERATIONsection.

GroundSpeed Control Levers

Theselevers control the ground speedof the rider.The left

lever controls the left rear drive wheeland the right lever

controls the right rear drive wheel.

Moving a leverforward increasesthe FORWARDspeedof

the associatedwheel, and pulling back on a lever increases

the REVERSEspeed.

Note: Thefurther a lever is moved away from theneutral

position the faster the drive wheelwill turn.

See the Operationsection for proper steering instructions.

Seat Adjustment Lever

Theseatcan be adjusted forward and back.Move the lever

towards the left, position the seat as desired, and releasethe

leverto lock the seat in position.

IgnitionSwitch

Theignition switch starts and stops the engine, it has three

positions:

_OFF Stops the engine and shuts off the

electrical system.

O RUN Allows the to and

the electrical system.

_'_ START Cranks the engine for starting.

NOTE.Neverleave the ignition switch in theRUNposition

with the enginestopped-this drains thebattery.

engine

run

powers

11

Page 14

Features& Controls

_ ParkingBrake

_ DISENGAGE

ENGAGE

Pull the parking brake lever up to engagethe parking brake.

Push the leverdown to disengagethe parking brake. NOTE.

Tostart the unit theparking brakemust be engaged.

_PTO (Power Take Off) Switch

The PTOswitch engagesand disengagesthe mower. Pull UP

on the switch to engage,and push DOWNto disengage.

Releasesthe parking brake.

Locks the parking brake.

DeckLift Pedal, Cutting Height

Adjustment Pin & DeckLift Lock

Lever

Thesecontrol the cutting height of the mower deck.

Depressthe pedaluntil it locks into the 4-1/2" (11,47 cm)

position. Placethe adjustment pin in the desired cutting

height and releasethe lift lock lever.

FuelTankCap

To removethe cap, turn counterclockwise.

FuelLevel Gauge

Displaysthe fuel level in the tank.

TransmissionOil Fill

This unit is equippedwith two transmission oil reservoirs.

Thetransmission oil reservoirs are located beneaththe

operator's seat and in front of the engine. Transmission oil

is added through the transmission oil reservoirs. It also

servesas extraholding capacityas the transmissions heat

up and the oil expands. SeeCHECKTRANSMISSIONOIL

LEVELfor oil levelcheckandfill procedures.

ThrottleControl

Thethrottle controls engine speed. Movethe throttle

forward to increaseengine speed and back to decrease

engine speed. Always operateat FULLthrottle.

W Choke

Closethe choke for cold starting. Openthe choke oncethe

engine starts. A warm engine may not require choking. Pull

the knob UPto close the choke. Push to knob DOWNto

open the choke.

B HourMeter / MaintenanceReminder

Measuresthe time of the PTObeing engaged. The hour

meter measuresthe number of hours the PTOhas been

engaged. The hour meterwill flash an initial oil change

indicator at 5 hours, and a lubrication reminder every50

hours. These reminders display for approximately two

hours andwill automatically reset themselves.

Note: Thehour meter wilt register thepassageof time only

whenthe PTOis engaged. Thehour meter has a self

contained power source so the total hours arealways

visible.

12 www.SnapperPro.com

Page 15

Operation

Operation

GeneralOperating Safety

Beforefirst time operation:

• Besure to read all information in the Safetyand

Operationsectionsbefore attempting to operatethis

tractor and mower.

• Becomefamiliar with all of the controls and how to stop

the unit.

• Drive in an open areawithout mowing to become

accustomedto the unit.

WARNING

Never allow passengersto rideon the unit.

Beforeleavingthe operator's positionfor any reason,

engage the parkingbrake, disengage the PTO,stopthe

engine and removethe key.

Toreducefire hazard, keepthe engine, tractor and

mowerfree of grass, leaves and excess grease. Do not

stopor parktractor over dry leaves, grass or

combustiblematerials.

Gasolineis highly flammable and mustbe handled

with care. Never fill the tank whenthe engine is still

hotfrom recentoperation. Do notallow open flame,

smokingor matchesin the area. Avoid over-filling and

wipe up any spills.

WARNING

WARNING

Never operate on slopesgreater than (15°) whichisa

riseof 5.4 feet (1,6 m) vertically in20 feet (607 cm)

horizontally.

Select slow ground speed beforedriving onto a slope.

Useextra cautionwhen operating on slopeswith a

rear-mountedgrass catcher.

Mowacross the face of slopes,notup and down, use

cautionwhen changingdirections and DO NOTSTART

ORSTOPONSLOPE.

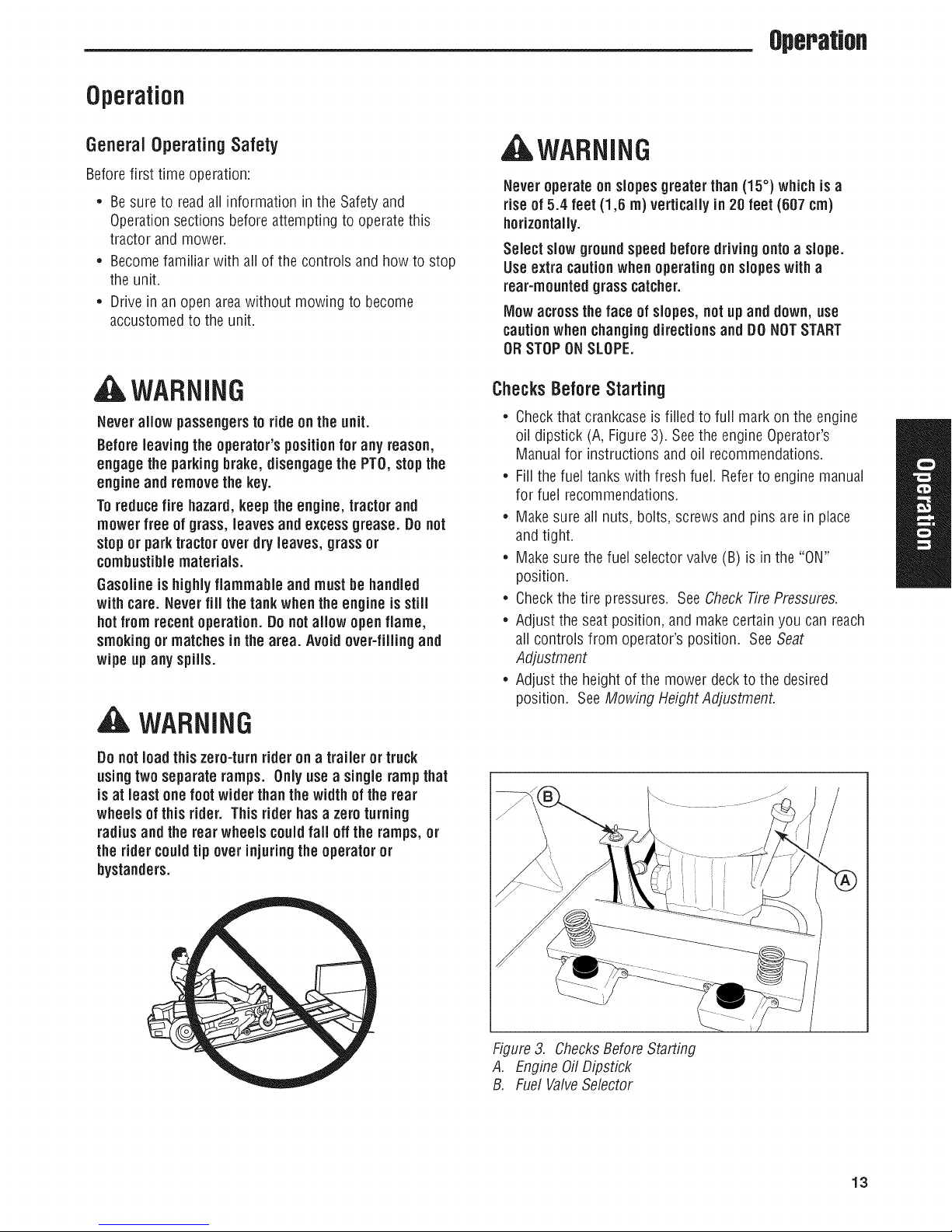

ChecksBeforeStarting

• Checkthat crankcaseis filled to full mark on the engine

oil dipstick (A, Figure 3). Seethe engine Operator's

Manualfor instructions and oil recommendations.

• Fillthe fuel tanks with fresh fuel. Referto engine manual

for fuel recommendations.

• Makesure all nuts, bolts, screws and pins are in place

and tight.

• Makesure the fuel selectorvalve(B) is in the "ON"

position.

• Checkthe tire pressures. See CheckTire Pressures.

• Adjust the seatposition, and make certain you can reach

all controls from operator's position. SeeSeat

Adjustment

• Adjust the height of the mower deckto the desired

position. See Mowing Height Adjustment.

Do notload this zero-turn rider on a trailer or truck

usingtwo separateramps. Only useasingle rampthat

is at least one foot widerthan the widthof the rear

wheels of this rider. This rider hasazero turning

radiusand the rear wheels couldfall off the ramps, or

the ridercouldtip over injuringthe operator or

bystanders.

Figure3. ChecksBefore Starting

A. EngineOil Dipstick

B. Fuel ValveSelector

13

Page 16

Operatm

CheckTire Pressures

Tire pressure should be checkedperiodically, and

maintained at the levels shown in the chart. Note that these

pressures may differ slightly from the "Max Inflation"

stamped on the side-wall of the tires. Thepressures shown

provide proper traction, improve cut quality, and extend tire

life.

Tire Pressure

Front 40 psi (2,76 bar)

Rear 15 psi (1,03 bar)

Seat Adjustment

SeeFigure5. The seatcan be adjusted forward and

backward. Move the lever towards the left, position the seat

as desired, and releasethe lever to lock the seat into

position.

Figure4. CheckingTirePressure

Figure5. SeatAdjustment

A. SeatAdjustment Lever

14 www.SnapperPro.com

Page 17

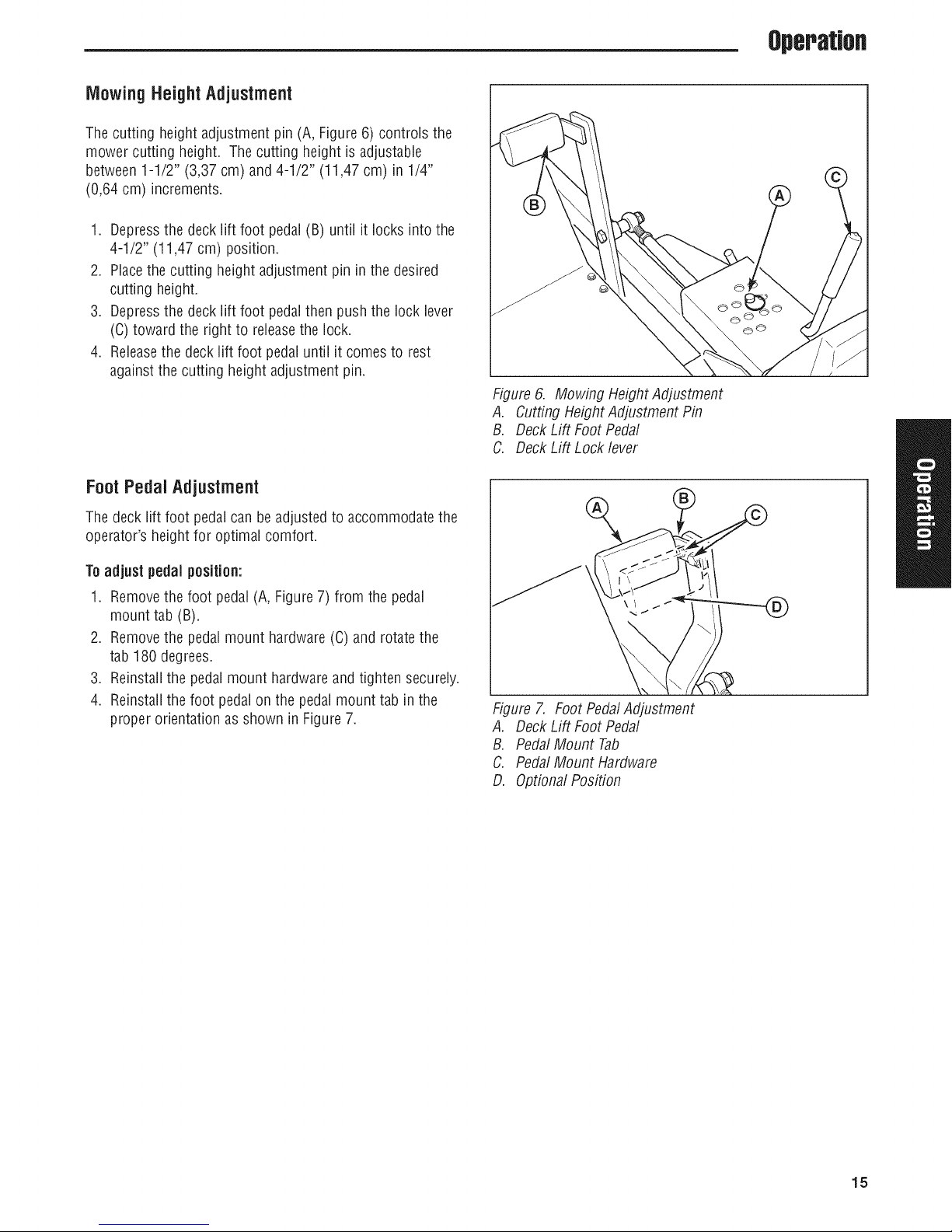

Mowing HeightAdjustment

Thecutting height adjustment pin (A, Figure6) controls the

mower cutting height. The cutting height is adjustable

between 1-1/2" (3,37 cm) and 4-1/2" (11,47 cm) in 1/4"

(0,64 cm) increments.

1. Depressthe deck lift foot pedal (B) until it locks into the

4-1/2" (11,47 cm) position.

2. Placethe cutting height adjustment pin in the desired

cutting height.

3. Depressthe deck lift foot pedalthen push the lock lever

(C)toward the right to releasethe lock.

4. Releasethe deck lift foot pedal until it comes to rest

againstthe cutting height adjustment pin.

FootPedalAdjustment

Operation

Figure 6. Mowing Height Adjustment

A. Cutting HeightAdjustment Pin

B. Deck Lift Foot Pedal

C. Deck Lift Lock lever

Thedeck lift foot pedalcan be adjusted to accommodate the

operator's height for optimal comfort.

Toadjust pedalposition:

1. Removethe foot pedal (A, Figure7) from the pedal

mount tab (B).

2. Removethe pedalmount hardware (C) and rotatethe

tab 180 degrees.

3. Reinstallthe pedalmount hardware and tighten securely.

4. Reinstallthe foot pedalon the pedal mount tab in the

proper orientation as shown in Figure7.

Figure 7. Foot PedalAdjustment

A. Deck Lift Foot Pedal

B. Pedal Mount Tab

C. Pedal Mount Hardware

D. Optional Position

15

Page 18

OperaUon

Starting the Engine

AWARNING

if youdo notunderstandhowa specificcontrol

functions, or havenotyet thoroughlyreadthe

FEATURES& CONTROLSsection, do sonow.

Do NOTattempt tooperate thetractorwithout first

becomingfamiliar with the locationandfunction ofALL

controls.

1. While sitting in the operator's seat, engagethe parking

brakeby pulling the parking brakelever up, make sure

the PTOswitch is disengaged (pressed down fully) and

the ground speedcontrol levers are locked in the

NEUTRALposition.

2. NOTE:A warm engine may notrequire choking.

Setthe enginethrottle control to FULLthrottle position.

Thenfully close the choke by pulling the knob OUTfully.

3. insert the key into the ignition switch and turn it to

START.

4. After the engine starts, gradually open the choke (push

knob down fully). Reduceto half throttle speed and

allow to warm up.

Warm up the engineby running it for at least a minute

before engaging the PTOswitch or driving the rider.

5. After warming the engine, ALWAYSoperate the unitat

FULLTHROTTLEwhen mowing.

In the event of an emergencythe enginecan fie stopped

bysimply turning the ignition switch to STOP. Usethis

method only in emergencysituations. Fornormal engine

shut down follow the procedure given in STOPPINGTHE

RIDER.

Pushingthe Rider ByHand

NOTICE

DONOTTOW RIDER

Towingthe unitswill causetransmissiondamage. Do

notuse another vehicleto pushor pull this unit.

1. Disengagethe PTO,engagethe parking brake,turn the

ignition OFEand removethe key.

2. Locatethe transmission releaselevers (A, Figure8)

located underneaththe front of the fuel tanks.

3. Pull both transmission releaselevers back and down so

that they lock inthe disengaged(free-wheel position)

(c).

4. Disengagethe parking brake.

Thetractor cannow be pushed by hand.

5. After moving the tractor, re-engagethe transmissions by

pulling the transmission releaseleversup andpushing

them forward to the engaged (drive) position (B).

Stopping the Rider

1. Returning the ground speedcontrol leversto the middle

position will stop rider movement. Pivot the levers

outward and lockthem in NEUTRAL.

2. Disengagethe PTOby pushing down on the PTOswitch.

3. Engagethe parking brakeby pulling the handleup until

it locksinto position.

4. Move the throttle control to mid-throttle position and

turn the ignition keyto OFF. Removethe key.

16 www.SnapperPro.com

Figure 8. TransmissionReleaseLevers(LH shown)

A. TransmissionReleaseLever

B. EngagedPosition (Drive Position)

C. DisengagedPosition (Free-wheelPosition)

Page 19

Operation

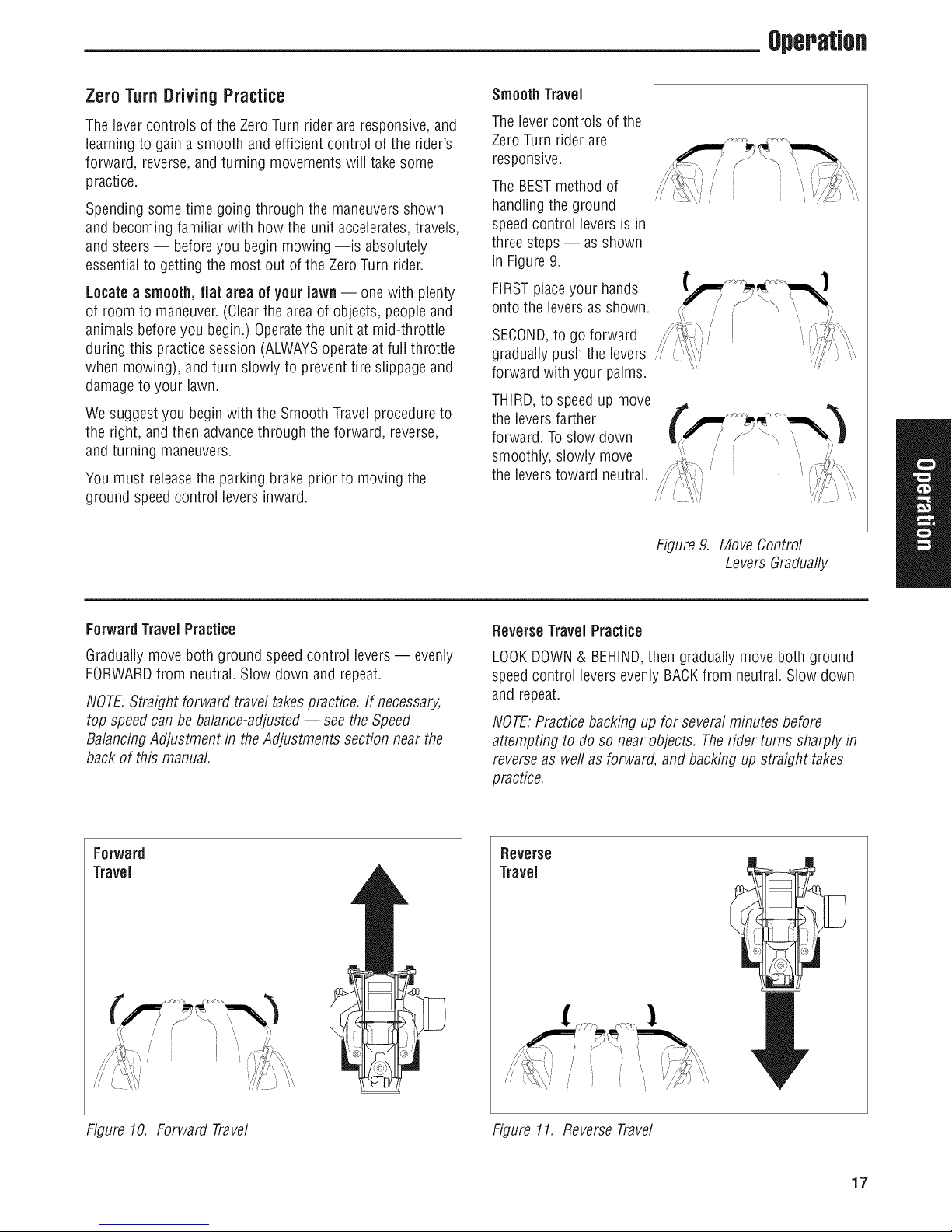

Zero TurnDrivingPractice

Thelever controls of the ZeroTurn rider are responsive,and

learning to gain a smooth and efficient control of the rider's

forward, reverse,and turning movementswill take some

practice.

Spending some time going through the maneuversshown

and becoming familiar with how the unit accelerates,travels,

and steers-- beforeyou begin mowing --is absolutely

essentialto getting the most out of the Zero Turn rider.

Locatea smooth,fiat area of yourlawn-- one with plenty

of room to maneuver.(Clearthe area of objects, peopleand

animals beforeyou begin.) Operatethe unit at mid-throttle

during this practice session (ALWAYSoperateat full throttle

when mowing), and turn slowly to preventtire slippageand

damageto your lawn.

Wesuggest you beginwith the Smooth Travelprocedureto

the right, andthen advancethrough the forward, reverse,

and turning maneuvers.

You must releasethe parking brake prior to moving the

ground speed control levers inward.

Smooth TraveJ

Thelever controls of the

ZeroTurn rider are

responsive.

The BESTmethod of

handling the ground

speedcontrol levers is in

three steps-- as shown

in Figure 9.

FIRSTplaceyour hands

onto the levers as shown.

SECOND,to go forward

gradually push the levers

forward with your palms.

THIRD,to speed up move

the levers farther

forward. Toslow down

smoothly, slowly move

the levers toward neutral.

Forward TraveJPractice

Graduallymove both ground speedcontrol levers-- evenly

FORWARDfrom neutral. Slow down and repeat.

NOTE.Straight forward travel takespractice. If necessary,

top speedcan be balance-adjusted-- seethe Speed

BalancingAdjustment in theAdjustments section near the

back of this manual.

Forward

Travel

Figure9. Move Control

Levers Gradually

ReverseTravelPractice

LOOKDOWN& BEHIND,then graduallymove both ground

speedcontrol levers evenly BACKfrom neutral. Slow down

and repeat.

NOTE.Practicebacking up for severalminutes before

attempting to do so near objects. The rider turns sharplyin

reverseas weftas forward, and backing up straight takes

practice.

Reverse

Travel

Figure 10. Forward Travel Figure 11. ReverseTravel

/

/'

/

17

Page 20

OperaUon

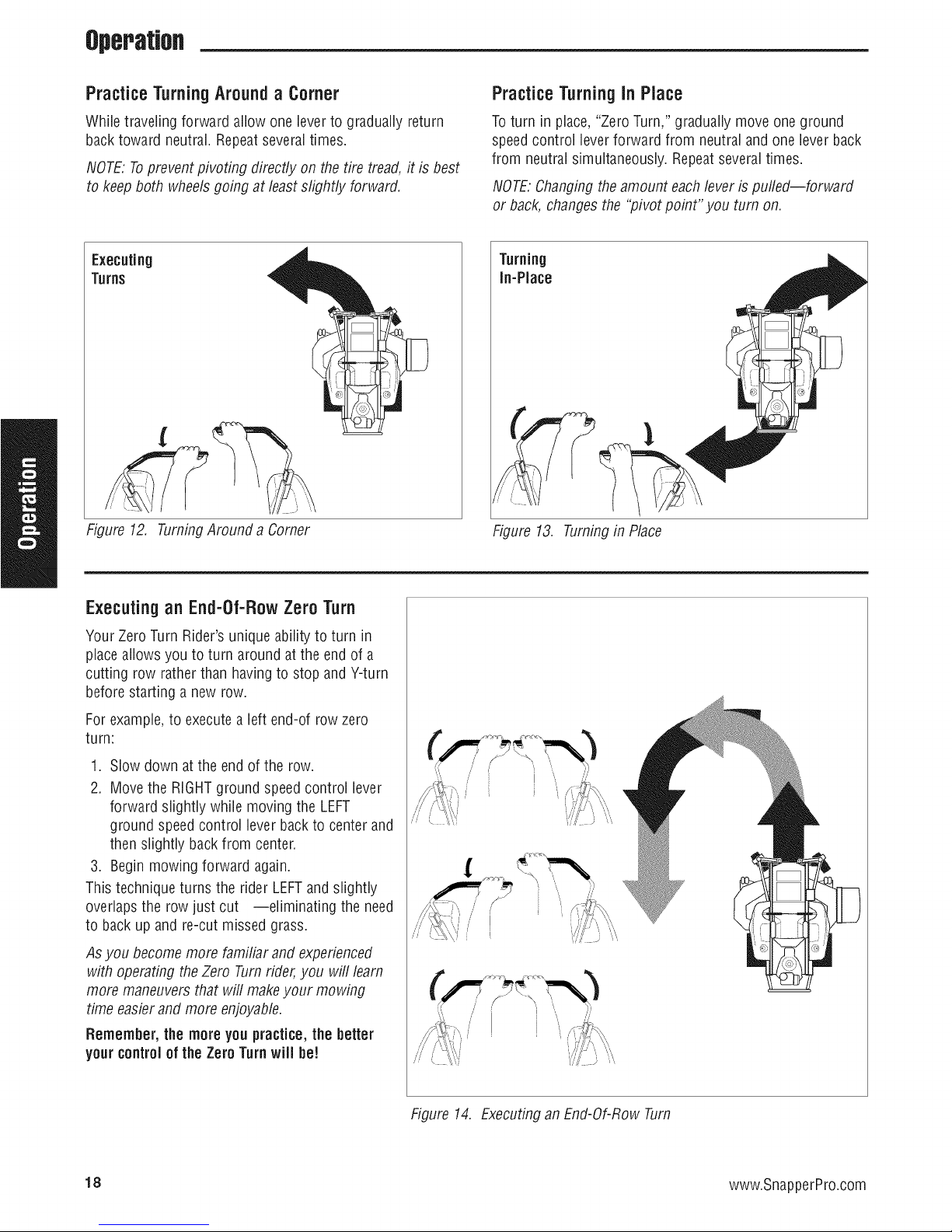

Practice TurningAround a Corner

While traveling forward allow one leverto gradually return

back toward neutral. Repeatseveral times.

NOTE:Topreventpivoting directly on the tire tread,it is best

to keepboth wheelsgoing at least slightly forward.

Figure 12. TurningAround a Corner

Practice Turningin Place

Toturn in place, "Zero Turn," gradually move one ground

speedcontrol lever forward from neutraland one leverback

from neutral simultaneously. Repeatseveraltimes.

NOTE.Changingtheamount eachlever is puffed--forward

or back, changes the "pivot point" you turn on.

Turning

In-Place

Figure 13. Turningin Place

Executingan End-Of-RowZeroTurn

Your ZeroTurn Rider's unique ability to turn in

placeallows you to turn around at the endof a

cutting row rather than having to stop and Y-turn

before starting a new row.

For example,to executealeft end-of row zero

turn:

1. Slow down at the end of the row.

2. Move the RIGHTground speedcontrol lever

forward slightly while moving the LEFT

ground speed control lever back to center and

then slightly backfrom center.

3. Begin mowing forward again.

This technique turns the rider LEFTand slightly

overlaps the row just cut --eliminating the need

to back up and re-cut missed grass.

Asyou become more familiar and experienced

with operating the Zero Turn rider,you will learn

more maneuversthat will makeyour mowing

time easier and more enjoyable.

Remember, the moreyou practice, the better

yourcontrol of the Zero Turnwill be!

18 www.SnapperPro.com

Figure 14. Executing an End-Of-Row Turn

Page 21

Operation

Mowing

1. Engagethe parking brake. Make sure the PTOswitch is

disengaged,the ground speedcontrol leversarelocked

in the NEUTRALposition and the operator is on the seat.

2. Start the engine (see Starting The Engine).

3. Setthe mower cutting height (see Mowing Height

Adjustment).

4. Setthe throttle to FULL.

5. Engagethe PTOby pulling up on the PTOswitch.

6. Begin mowing. See Mowing Recommendationsfor tips

on mowing patterns, lawn care, and trouble shooting

information.

7. When finished, shut off the PTOby pushing the PTO

switch down completely_

8. Stopthe engine (seeStopping TheRiderand Engine).

Mowing Recommendations

Severalfactors can affect how wenyour machine cuts grass,

Following proper mowing recommendations canimprove

the performance and life of your machine.

Heightof Grass

Often cutting height is a matter of personal preference.

Typically,you should mow the grass when it is is between

three and five inches high. The proper cutting height range

for a specific lawn will depend upon several factors,

including thetype of grass,the amount of rainfall, the

prevailing temperature, and the lawn's overall condition.

Cutting the grass too short causesweak,thin grass plants,

which are easily damaged by dry periods and pests. Cutting

too short is often more damaging than allowing the grassto

be slightly higher.

Letting grass grow a bit Ionger--especiaNy when it is hot

and dry--reduces heat build-up, preservesneededmoisture

and protects the grass from heatdamageand other

problems. However,allowing grass to grow too high can

causethin turf and additional problems.

Cutting off too much at onetime shocksthe plant's growth

system and weakensthe grass plants.A good rule of thumb

is the1/3 rule: to cut no more thanone third of the grass

height, and nevermore than1 inchat a time.

Theamount of grass you are able to cut in one pass is also

effected by the type of mowing system you are using (for

example,broadcasting with side discharge decks can

process a much larger volume of grass than mulching

does).

I

,li i.iILl4<,it,,/',

t! I

Figure 15. Proper Cutting Height

Tail GrassRequires Incremental Cutting

Forextremelytall grass, set the cutting height at maximum

for the first pass, and then reset it to the desired height and

mow a second or third time.

Don't cover the grass surfacewith a heavy layerof

clippings. Consider using a grass collection system and

starting a compost pile.

Cut Here On

First Pass Cut Here

Is ,/ Pass

IItlih,l ltlilt

Figure 16. Incremental Cutting

On Second

19

Page 22

Operatm

Whenand How Often to Mow

Thetime of day and condition of the grass greatly affectthe

results you'll get when mowing. Forthe best results, follow

these guidelines:

1. Mow when the grass is betweenthree and five inches

high.

2. Mow with sharp blades. Short clippings of grassone

inchor shorter decomposemore quickly than longer

blades.Sharp mower blades cut grass cleanly and

efficiently, preventing frayed edgeswhich harm the

grass.

3. Mow at time of day when the grass is cool and dry. Late

afternoon or early eveningoften provide these ideal

mowing conditions.

4. Avoid mowing after rain or evenheavy dew,and never

mulch when the grass is wet (moist grass does not

mulch well, and clumps beneaththe mower deck).

Mowing Patterns

Alwaysstart mowing on a smooth, level area.

Thesizeand type of areato be mowed wiii determine the

best mowing pattern to use. Obstructions such astrees,

fencesand buildings, and conditions such as slopes and

grades must also be considered.

1. Cut long straight strips overlapping slightly.

2. Where possible, change patterns occasionally to

eliminate matting, graining or a corrugated appearance.

3. Foratruly professional cut, mow across the lawn in one

direction, then recut the lawn by mowing perpendicular

to the previous cut.

Note:A/ways operate the engine at fu// tflrott/e when

mowing.

If you hearthe engine slowing down, you are mowing too

fast--using a slower ground speedwill improve the cutting

efficiency of the bladesand prevents many common cutting

problems. Usean appropriate ground speed for the

thickness and height of the grass you are cutting (3rd gear

or slower for manualgear models), if you hear the engine

slowing down you are mowing too fast, useaslower ground

speed.

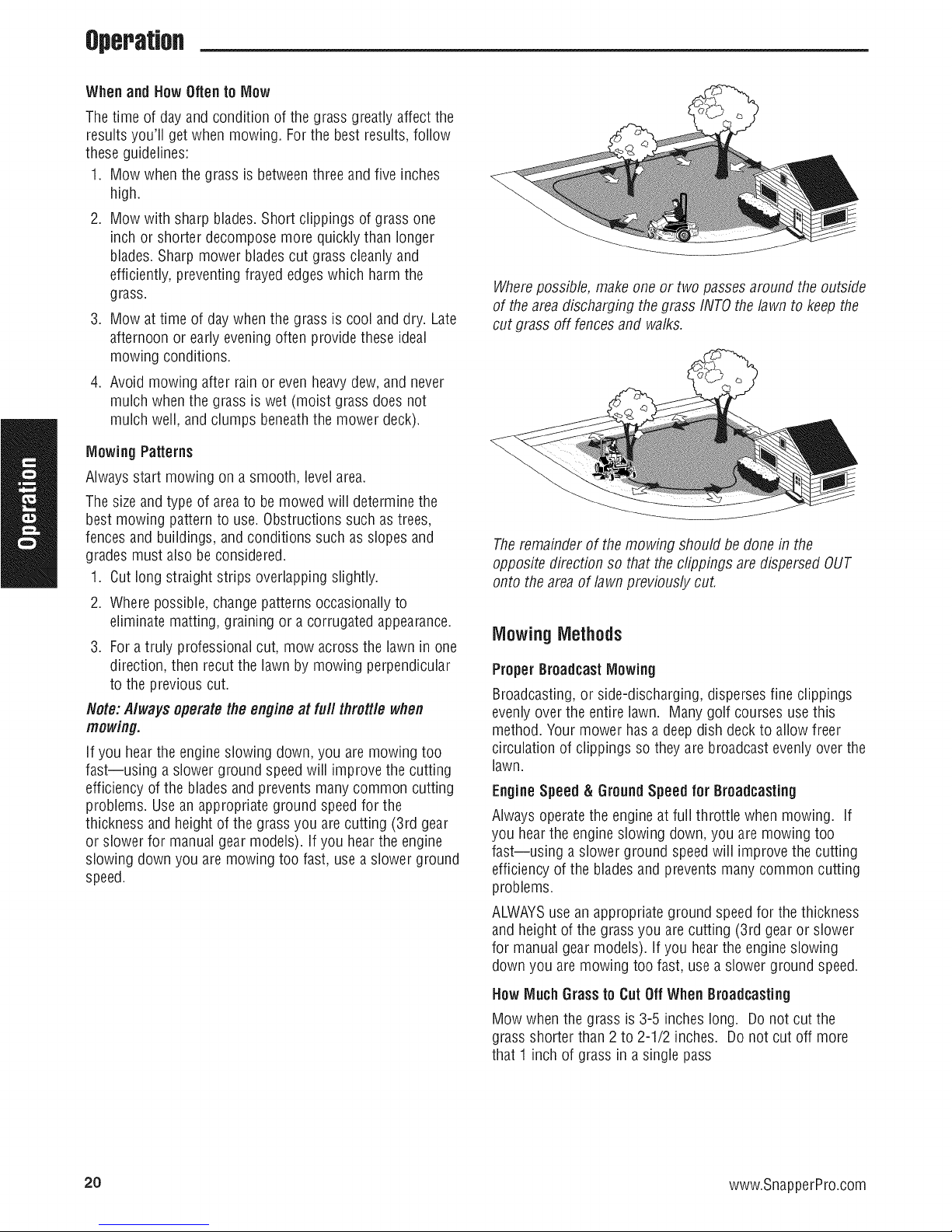

Wherepossible, make one or two passesaround the outside

of the areadischarging the grass INTOthe lawn to keep the

cut grass off fences and walks.

Theremainderof the mowing should be done in the

opposite direction so that the clippings are dispersed OUT

onto the areaof lawn previously cut.

MowingMethods

Proper Broadcast Mowing

Broadcasting,or side-discharging, disperses fine clippings

evenly overthe entire lawn. Manygolf courses use this

method. Your mower has a deep dish deck to allow freer

circulation of clippings so they are broadcast evenlyover the

lawn.

Engine Speed & GroundSpeed for Broadcasting

Always operatethe engineat full throttle when mowing. If

you hear the engine slowing down, you are mowing too

fast--using a slower ground speedwill improve the cutting

efficiency of the bladesand prevents many common cutting

problems.

ALWAYSusean appropriate ground speedfor the thickness

and height of the grass you are cutting (3rd gear or slower

for manualgear models). If you hearthe engine slowing

down you are mowing too fast, use a slower ground speed.

20 www.SnapperPro.com

How Much Grassto Cut Off When Broadcasting

Mow when the grass is 3-5 incheslong. Do not cut the

grass shorter than 2 to 2-1/2 inches. Donot cut off more

that 1 inchof grass in a single pass

Page 23

Operation

ProperMulching

Mulching consists of a mower deckwhich cuts and recuts

clippings intotiny particles and which then blows them

down iNTOthe lawn. These tiny particles decompose rapidly

into by-products your lawn can use. UNDERPROPER

CONDITIONS,your mulching mower will virtually eliminate

noticeable clippings on the lawn surface.

NOTE:When mulching under heavycutting conditions, a

rumbling sound may bepresent and is normal.

IVluichingRequires EXCELLENTMowing Conditions

Mulching mowers cannot function properly if the grass is

wet, or if the grass is simply to high to cut. Evenmore than

normal mowing, mulching requires that the grass be dry

and the the appropriate amount is cut.

Do not usethe mower as a mulching mower during the first

two or three mowings in the spring. Thelong grass blades,

quick growth, and often wetter conditions are more suitable

for broadcasting (side-discharging) or grass bagging

operation.

Engine Speed & GroundSpeed for Mulching

Usefuji enginethrottle matchedwith a slow ground speed

so that clippings will be finely cut. Ground speedwhile

mulching should be HALFof the speedthat would be used

when broadcasting (side discharging) under similar

conditions. Since mulching requires more horsepowerthan

broadcasting, using a slower ground speedis vitally

important for proper mulching operation.

Row Much Grassto Mulch

Thebest mulching action typically results from cutting only

the top 1/2 inch to 3/4 inch of grass blade. This provides

short clippings which decomposeproperly (much more

quickly than longer clippings). The ideal cutting height will

vary with climate, time of year, and quality of your lawn. We

recommend that you experiment with both the cutting height

and ground speed until you achievethe best cut. Start with a

high cutting height and using progressivelylower settings

until you find a cutting height that is matchedto your

mowing conditions and preferences.

Attaching A Trailer

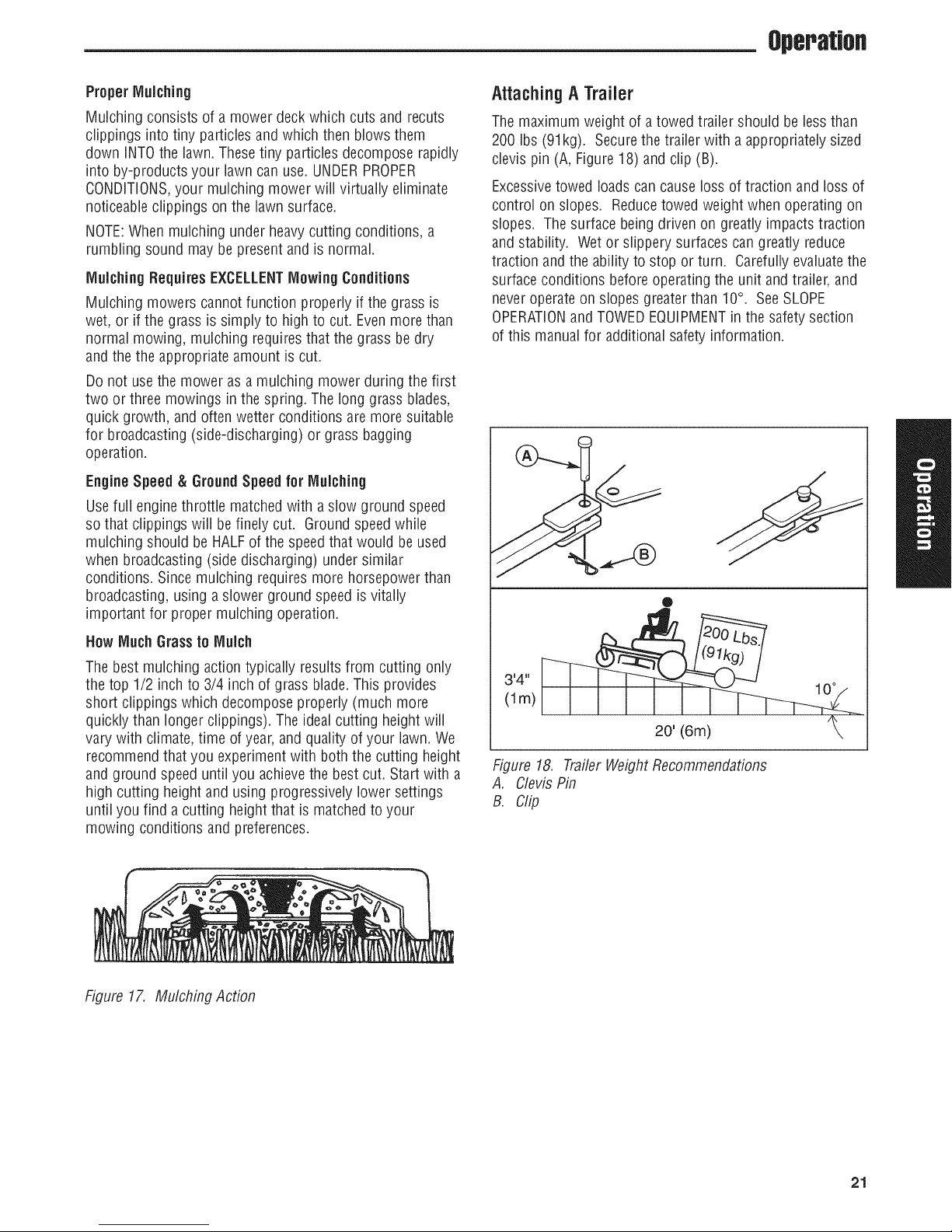

Themaximum weight of a towed trailer should be less than

200 Ibs (91kg). Secure the trailer with a appropriately sized

clevis pin (A, Figure18) and clip (B).

Excessivetowed loads cancause loss of traction and loss of

control on slopes. Reducetowed weight when operating on

slopes. The surface being driven on greatlyimpacts traction

and stability. Wet or slippery surfaces can greatly reduce

traction and the ability to stop or turn. Carefullyevaluatethe

surface conditions beforeoperating the unit and trailer, and

neveroperateon slopes greaterthan 10°. SeeSLOPE

OPERATIONand TOWEDEQUIPMENTin the safety section

of this manualfor additional safety information.

®

3'4"

(lm)

20' (6m) ?

Figure 18. TrailerWeightRecommendations

A. Clevis Pin

B. Clip

Figure 17. Mulching Action

21

Page 24

RegWPMaJflteflaflce

RegularMaintenance

MaintenanceSchedule

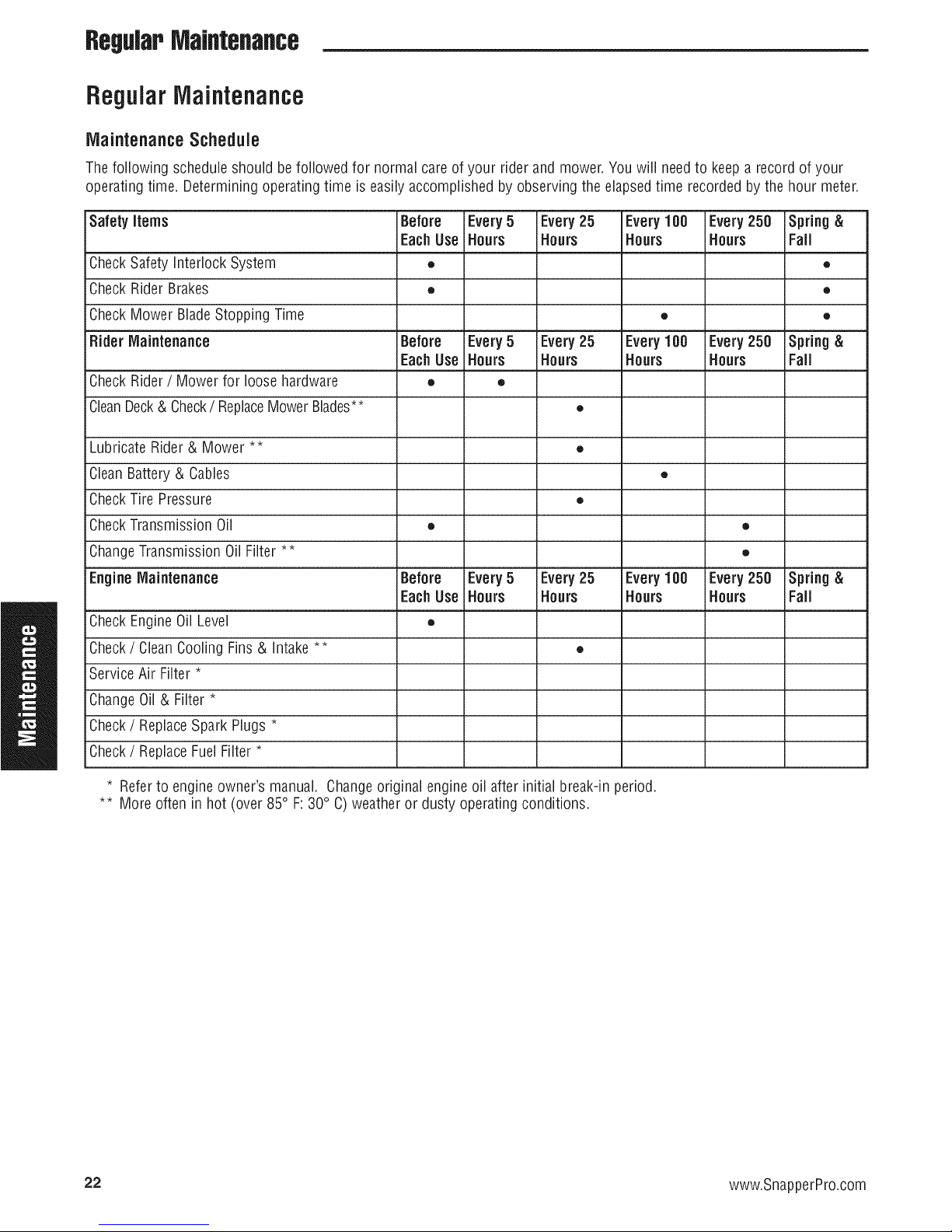

Thefollowing schedule should be followed for normal care of your rider and mower.You will needto keepa record of your

operating time. Determiningoperating time is easily accomplished by observing the elapsedtime recorded bythe hour meter.

Safety items Before Every5 Every25 Every100 Every250 Spring &

EachUse Hours Hours Hours Hours Fall

CheckSafetyInterlock System • •

CheckRider Brakes • •

CheckMower BladeStopping Time • •

Hider Maintenance Before Every5 Every25 Every100 Every250 Spring &

EachUse Hours Hours Hours Hours Fall

CheckRider/ Mower for loose hardware • •

CleanDeck& Check/ ReplaceMower Blades** •

Lubricate Rider& Mower ** •

CleanBattery& Cables •

CheckTire Pressure •

CheckTransmission Oil • •

ChangeTransmission Oil Filter ** •

EngineMaintenance Before Every5 Every25 Every100 Every250 Spring &

EachUse Hours Hours Hours Hours Fall

CheckEngineOil Level •

Check/ CleanCooling Fins& intake ** •

Service Air Filter *

ChangeOil& Filter *

Check/ ReplaceSpark Plugs *

Check/ ReplaceFuelFilter *

• Referto engine owner's manual. Changeoriginal engine oil after initial break-in period.

•* More often in hot (over 85° F: 30° C)weather or dusty operating conditions.

22 www.SnapperPro.com

Page 25

RegWPMaJflteflaflce

Checking/ Adding Fuel

Toaddfuel:

1. Removethe fuel cap.

2. Fillthe tank to about 1-1/2" (3,81 cm) of the bottom of

the filler neck. This will allow for fuel expansion.

NOTE. Donot overfill. Refer toyour engine manualfor

specific fuel recommendations.

3. Install and hand tighten the fuel cap.

Fuel Filter

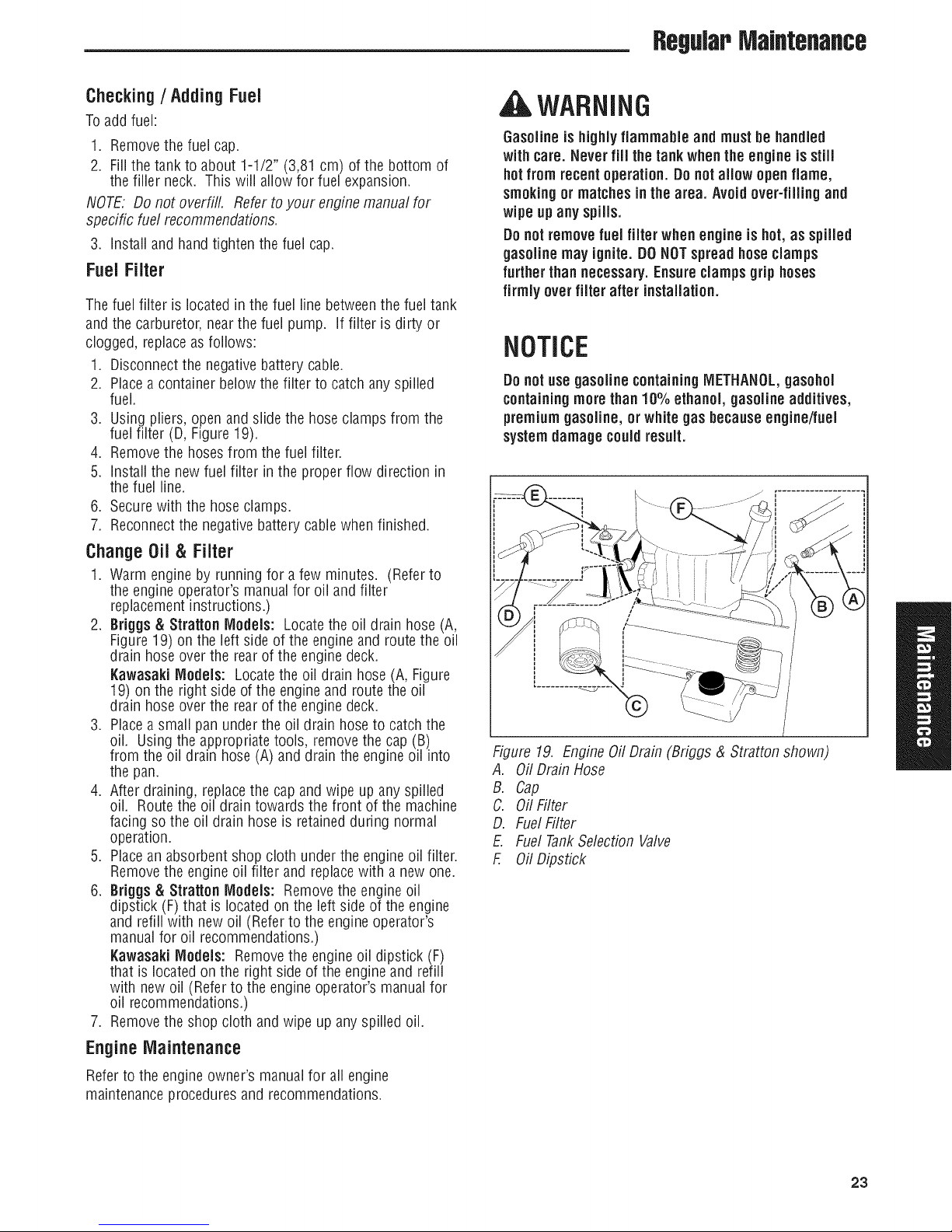

Thefuel filter is locatedin the fuel line betweenthe fuel tank

and the carburetor, nearthe fuel pump. If filter is dirty or

clogged, replaceas follows:

1. Disconnectthe negativebattery cable.

2. Placea container below the filter to catch any spilled

fuel.

3. Using pliers, open and slide the hose clamps from the

fuel filter (D, Figure 19).

4. Removethe hosesfrom the fuel filter.

5. Install the new fuel filter in the proper flow direction in

the fuel line.

6. Securewith the hose clamps.

7. Reconnectthe negative battery cablewhen finished.

ChangeOil & Filter

1. Warm engine by running for a few minutes. (Referto

the engine operator's manualfor oil and filter

replacementinstructions.)

2. Briggs & Stratton Models: Locatethe oil drain hose (A,

Figure19) on the left side of the engine and route the oil

drain hose over the rear of the engine deck.

KawasakiModels: Locatethe oil drain hose (A, Figure

19) on the right side of the engine and route the oil

drain hose over the rear of the engine deck.

3. Placea small panunder the oil drain hoseto catch the

oil. Using the appropriate tools, remove the cap (B)

from the oil drain hose (A) and drain the engineoil into

the pan.

4. After draining, replacethe capand wipe up any spilled

oil. Route the oil drain towards the front of the machine

facing so the oil drain hose is retained during normal

operation.

5. Placean absorbent shop cloth under the engineoil filter.

Removethe engine oil niter and replacewith a new one.

6. 8riggs & Stratton Models: Removethe engineoil

dipstick (F) that is located on the left side of the engine

and refill with new oil (Refer to the engine operator's

manualfor oil recommendations.)

l(awasaki Models: Removethe engine oil dipstick (F)

that is locatedon the right sideof the engine and refill

with new oil (Refer to the engine operator's manual for

oil recommendations.)

7. Removethe shop cloth and wipe up anyspilled oil.

, WARNING

Gasolineis highlyflammable and mustbe handled

with care. Never fill thetankwhen the engine is still

hotfrom recentoperation. Donot allow open flame,

smokingor matchesin the area. Avoid over-filling and

wipe up any spills.

Donotremovefuel filter when engine is hot, as spilled

gasoline may ignite. DONOTspreadhoseclamps

further thannecessary.Ensureclampsgrip hoses

firmly over filter after installation.

NOTICE

Donot use gasoline containing METHANOL,gasohol

containingmorethan10% ethanol, gasoline additives,

premiumgasoline, or white gas becauseengine/fuel

systemdamage couldresult.

Figure 19. Engine OilDrain (Briggs & Stratton shown)

A. OilDrain Hose

B. Cap

C. Oil Filter

D. FuelFilter

E. Fuel TankSelection Valve

E OilDipstick

EngineMaintenance

Refer to the engine owner's manualfor all engine

maintenanceproceduresand recommendations.

23

Page 26

,ReguJapMaJflteflaflce

Lubrication

Lubricatethe unit at the locations shown in Figures 20

through 23 aswell asthe following lubrication points.

Grease:

• deck lift pivot blocks

i * front casterwheel axles & yokes

Use greasefittings when present. Disassembleparts to

apply greaseto moving parts when greasefittings are not

installed.

Not all greases are compatible. RedGrease(p/n 5022285)

is recommended,automotive-type high-temperature, lithium

greasemaybe usedwhen this is not available.

Oih

• mower deck spindles

• mower deck idler arm

* control handle pivots

* deck lift pivots

* seat plate pivots

* discharge chute hinge

Figure20. DeckLubrication

/

/

/,

// /

Generally,all moving metal partsshould be oiled where

contact is made with other parts. Keepoil and greaseoff

belts and pulleys. Rememberto wipe fittings and surfaces

cleanboth beforeand after lubrication.

Lubricatingthe FrontCasters:

NOTE.Front casters should be lubricated annually.

1. Removethe 1/4-28 bolt (A, Figure23) screwed into the

front caster and installa 1/4-28 greasefitting.

2. Greasethe front caster.

3. Removethe 1/4-28 greasefitting and reinstall the 1/4-28

bolt.

4. Repeatprocessfor the other side of the machine.

Figure21. ControlHandlePivots & Seat PlatePivots

Figure22. DeckLift Linkage Pivots

24 www.SnapperPro.com

\

Figure23. Front Caster& Wheel

A. 1/4-28Bolt

Page 27

Check/ Fiil TransmissionOil

Oil Type: 20W-50 conventional detergent motor oil.

1. Checkthe oil levelwhen the unit is cold. Locatethe

transmission oil reservoirs (A, Figure24) locatedon the

seatsupport plate. The oil should be up to the "FULL

COLD"mark (B). If the oil is below this level, proceed

to step 2.

2. Beforeremovingthe reservoir caps,makesure the area

around the reservoir capandfill neck of the reservoir is

free of dust, dirt, or other debris. Removethe reservoir

cap.

3. Add oil up to the "FULL COLD"mark (B).

4. Reinstallthe reservoir caps.

TransmissionOil Filter Change

Change Interval: Every 200 Hours

Replacement Filter Number: 5101026X1

1. Locatethe transmission oil filters (A, Figure25)

underneaththe rear of the machineon the

transmissions.

Figure24.

A.

B.

CheckingTransmissionOil Level

TransmissionOilReservoirs

"FULLCOLD"mark

RegularIVlaJntenance

2. Removethe three 1/4" filter guard screws (C) and the

filter guard (B).

3. Cleanthe areaaround thefilter baseand removethe

filter.

4. Apply afilm of new oil to the gasket of the new

replacementfilter. After the oil hasdrained,thread the

newfilter onto the filter base until the gasketmakes

contact,then tighten 3/4 of a turn more.

5. Reinstallthe filter guard with the three 1/4" filter guard

screws

6. Using a hex bit swivel socket or a modifiedallen wrench

removethe top port plug from the transmissions.

7. Removethe transmission reservoir cap and fiii with oil

until oil appearsatthe bottom of the transmission's top

port (approximately 2 qts (1,89L).

8. Reinstallthe top port plug and tighten to 15 ft Ibs (20,38

Nm).

9. Continueto add oil to the transmission oil reservoirs

until the oil levelreachesthe "FULL COLD"mark.

Reinstallthe oil reservoir cap.

10. Repeatthis processfor the other sideof the machine.

11. Runthe unit for several minutes and checkthe

transmission oil level.

Figure25. Transmission(Left Side Shown.)

A. TransmissionOil Filter

B. Filter Guard

C. 1/4" Filter Guard Screws

D. TopPort Plug

IMPORTANTNOTE:Usecaution after changing the filter, air

in thehydraulic system may affect the responsiveness of the

ground speed control levers. Repeatstep 11 until theair is

out of thesystem.

25

Page 28

RegWPMaintenance

Servicing The Mower Blades

Removing the MowerBlade

, CAUTION

Avoidinjury! Mower blades are sharp.

* Alwayswear gloves when handlingmower blades or

workingnear blades.

1. To removethe mower blade, use a 1" wrench on the

flats of the spindle shaft and remove the mower blade

mounting bolt with a 15/16" wrench (Figure26).

2. If there are no flats on the spindle shaft, wedgea

wooden block betweenthe mower blade andthe mower

deck housing to keepthe mower bladefrom turning.

inspectingthe MowerBlades

, DANGER

Avoid injury! A worn or damaged blade can break, and

a pieceof the mowerbladecouldbe throwninto the

operator's or bystander'sarea, resultingin serious

personalinjuryor death.

* Inspect the mowerblade every 25 hoursor at least

once a year.

* if the mower blade hits a solid object, stopthe

engine immediatelyand inspectthe mower blade.

. Never weld or straightenbentmower blades.

1. Removethe mower bladefrom the unit. SeeRemoving

the Blade.

2. inspect the mower blade (Figures 27 & 28). Discard the

mower blade if it has any of the below conditions.

A.) Has more than .5" (12,7 ram) of the mower blade

metal removed from previous sharpening or wear (D,

Figure27).

B.)The air lifts are excessivelyeroded (B & C, Figure

28) andthe notch (C) is .25" (6,35 mm) deepor greater.

C.) Mower blade is bent or broken.

3. If the cutting edgesarenot sharp or have nicks, sharpen

the blades. SeeSharpeningthe Mower Blades.

Figure26. Loosening theMower Blade for Removal

Figure27. Inspecting theMower Blade Tips

A. Mower BladeCutting Edge

B. SquareCorner

C. Air Lift

D. WearMeasurement - DISCARDMower BladeIf greater

than .5" (12,7 mm)

®

Figure28. inspecting the Mower BladeAir Lifts

A. New Mower Blade

B. Mower Bladeat WearLimit (A notch begins to form)

C. Mower Bladein DangerousCondition (Notch measures.25" (6,35 mm) or greater DONOTUSE.Replacewith new mower

blade.)

26 www.SnapperPro.com

Page 29

Sharpening the Mower 8Jade

ACAUTION

Avoidinjury! Mower blades are sharp.

• Alwayswear gloves whenhandlingthe mower

blades.

RegWPMaJflteflaflce

• Alwayswear safetyeye protectionwhen grinding.

1. Sharpenthe mower bladeswith grinder, handfile, or

electric bladesharpener.

2. Sharpenthe mower blade by removing an equal amount

of material from eachend of the mower blade.

3. Keepthe original bevel(A, Figure 29) when grinding. DO

NOTchangethe mower blade bevel.

4. The mower blade should have a maximum 1/64" (0,40

mm) cutting edge (B) or less.

5. Balancethe mower bladesbefore installing.

BaJancingthe MowerBJades

|CAUTION

Avoid injury! Keepmower bladesbalanced.

• An unbalancedmower blade cancreate excessive

vibrationand damage the unit or causemowerbJade

faiJnre.

1. Cleanthe mower bladeto removeany dried grass or

other debris.

2. SeeFigure30. Put the mower bladeon a nail in a vise

andturn the mower bladeto the horizontal position.

3. Checkthe balance of the mower blade. If either end of

the mower blademoves downward, sharpenthe heavy

end until the mower blade is balanced. SeeSharpening

the Mower Bladesfor proper sharpening instructions.

4. Repeatthe process until the mower blade remains in the

horizontal position.

®

Figure29. Sharpeningthe Mower Blade

A. Mower BladeBevel

B. Mower BladeCutting Edge

Figure30. Balancing the Mower Blade

A. Nail

Reinstalling the Mower Blades

1. Reinstalleachmower blade with the air lifts pointing up

towards the mower deckas shown in Figure31.

36" IVlodeis:Makesure the bladeis firmly seated in the

bladesaddle. Secure with the mower blademounting

bolt and flat washer (A & B, Figure31) and torque to 70

ft. ibs (94 Nm).

48" lVlodels:Securewith the mower blade mounting

bolt and flat washer (A & B, Figure31) and torque to 70

ft. Ibs (94 Nm).

2. If there are no fiats on the spindle shaft, wedgea

wooden block betweenthe mower blade andthe mower

deck housing to keepthe mower bladefrom turning.

\

\

Figure31. Tighteningthe Mower Blade for Installation

A. Mower Blade Mounting Bolt

B. Flat Washer

C. Mower BladeAir Lift (Points UpFor Installation)

D. 4 X 4 WoodenBlock

27

Page 30

RegWPMaJflteflaflce

GroundSpeed ControlLeverAdjustment

Thecontrol levers can be adjusted in three ways. The

alignment of the control levers, the placement of the levers

(how close the ends areto one another) and the height of

the levers can be adjusted.

ToAdjust the Handle Alignment

Loosenthe mount bolts (A, Figure32) and pivot the lever(s)

(B) to align with each other.

ToAdjust the Handle Placement

Loosenthe jam nuts and adjust the placementbolt (C,

Figure33) in or out to properly adjust the leverend spacing.

ToAdjust the Handle Height

Removethe mounting hardware and reposition the handle

either up or down from its original position. Youwill need

to readjust the handle alignment as described above.

SpeedBalancingAdjustment

If the rider veers to the right or left when the ground speed

control levers are inthe maximum forward position, the top

speedof eachof theselevers can be balancedby turning the

adjustment bolt(s) (A, Figure 33). 0nly adjust the speed of

the wheelthat is traveling faster.

ToReduce the Speedof the FasterWheel

1. Loosenthe securing nut.

2. Turn the top speed adjustment bolt COUNTER-

CLOCKWISEto reducethe speed.

3. Retightenthe securing nut when adjustment is

complete.

AWARNING

DO NOTadjust thetractorfor a faster overall speed

forward or reverse thanit was designed for.

Figure32. ControlLeverAdjustment

A. PlacementHardware

B. GroundSpeedControl Lever

Figure33. TopSpeedAdjustment

A. TopSpeedAdjustment Bolt

B. Control Lever Base

C. Alignment Hardware

Neutral Adjustment

if the tractor "creeps" while the ground speed control levers

are locked in their NEUTRALpositions, seeyour dealer.

28 www.SnapperPro.com

Page 31

ParkingBrakeAdjustment

1. Disengagethe PTO,stop the engine,engagethe parking

brake,and removethe key from the ignition.

2. Raisethe seat plate to gain accessto the parking brake

components.

3. Measurethe distancefrom the top of the brake spring

rod (C, Figure34) to the top of the lock nut (D) on both

sides of the unit. The measurementshould be .50"

(1,27 cm). If not, adjust the Iocknut to achievethe

measurementof .50" (1,27 cm)

4. Measurethe distance betweenthe bottom of the brake

shaftweldment (G) and the top of the set collar (F). The

measurementshould be .375" (0,95 cm). If not,

position the set collar until the measurementequals

.375" (0,95 cm).

if this dues not currectthe brakingprobJem,see yuur

Snapper Pru deaJer.

ReguiapMaJflteflaflce

Figure34.

A.

BrakeSpring

B.

First Measurement - .50" (1,27 cm)

C.

BrakeSpring Rod

D.

Lock Nut

E.

SecondMeasurement- .375" (0,95 cm)

F.

Set Collar

G.

BrakeShaft Weldment

ParkingBrakeAdjustment

29

Page 32

RegularMaintenance

Return-to-Neutral Adjustment

Todetermineif it is necessaryto adjust the neutral return,

perform the following steps.

1. Disengagethe PTO,engagethe parking brake and turn

off the engine.

2. Move the ground speedcontrol levers into the operating

position, pull the levers rearward and release.

3. Move the ground speedcontrol levers out towards the

neutral position. Ifthe leversdo not align with the

notches in the neutral lock plate, it is necessaryto

adjust the neutral return rod (B, Figure35).

Adjustment

WARNING

Toavoidseriousinjury, performadjustments only with

the engine stopped,the key removedand the tractoron

JeveJground.

1. Disengagethe PTO,engagethe parking brake and turn

off the engine.

2. There arethree jam nuts (A, Figure35) on the linkage

rod (B). The first two are usedtogetherto turn the rod

andthe third (towards the front of the machine) is used

to lock the rod in place. Loosenthe jam nut that locks

againstthe ball joint and turn the linkage rod to adjust.

If the machine creepsforward, turn the linkagerod

CLOCKWISE(while standing at the rear of the machine,

facing forward). If the machinecreeps backward,turn

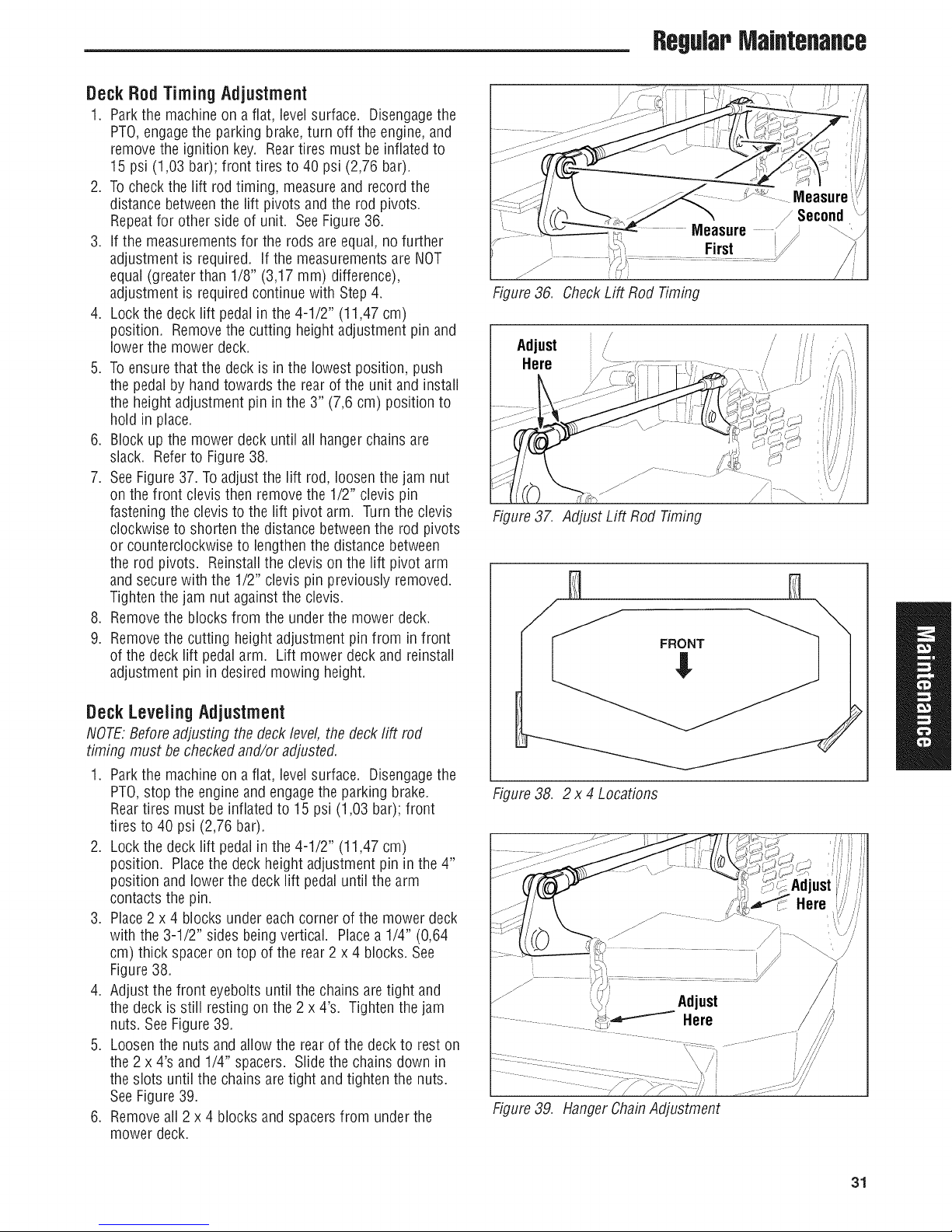

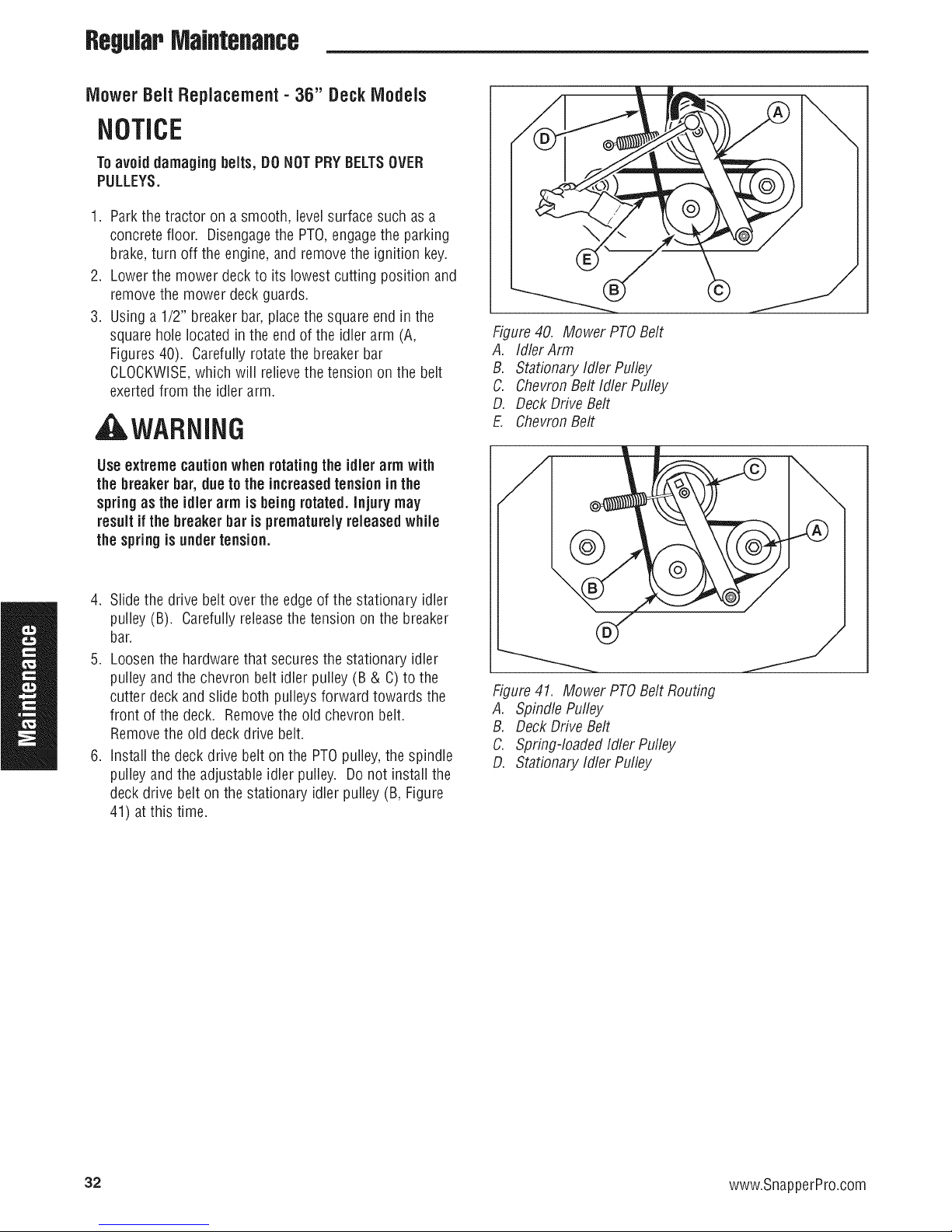

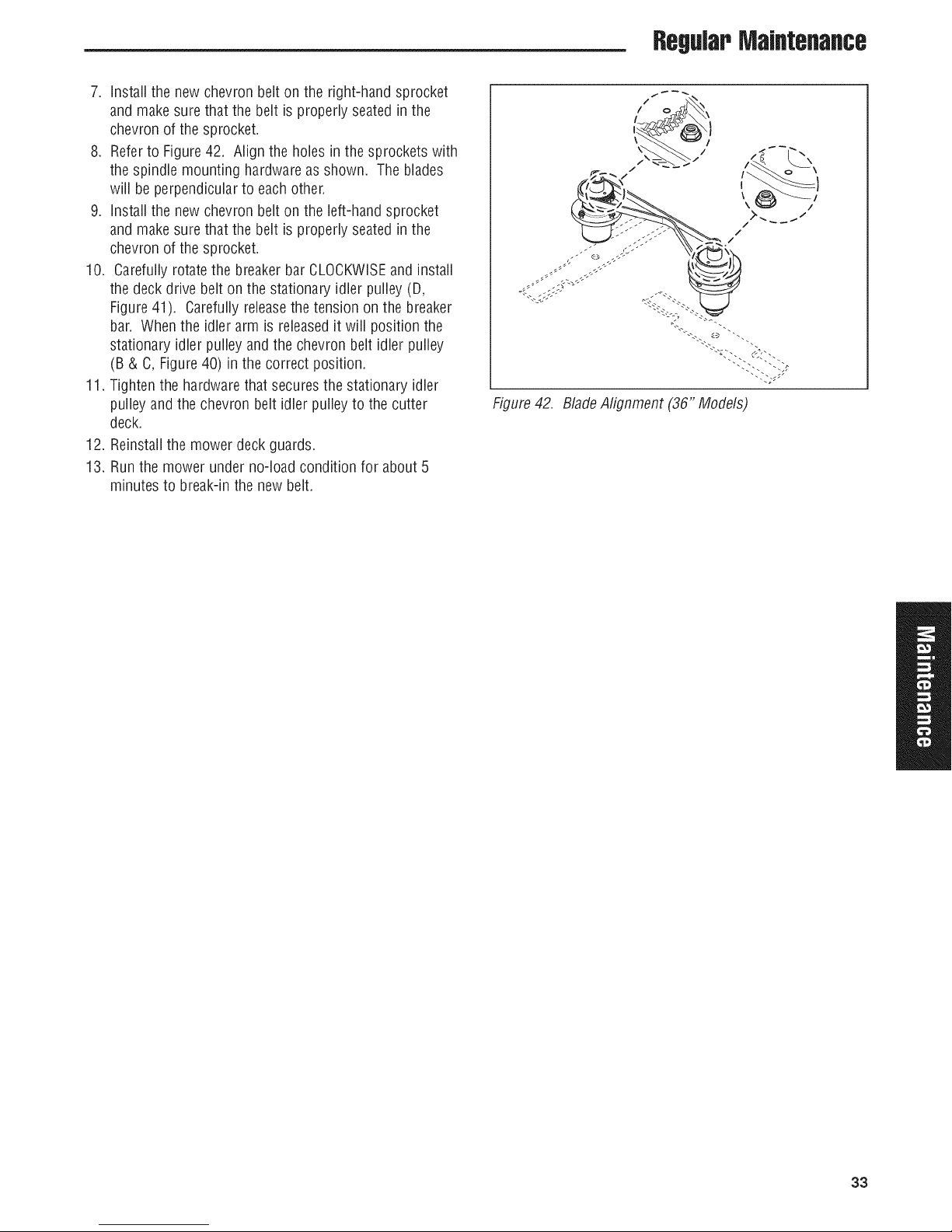

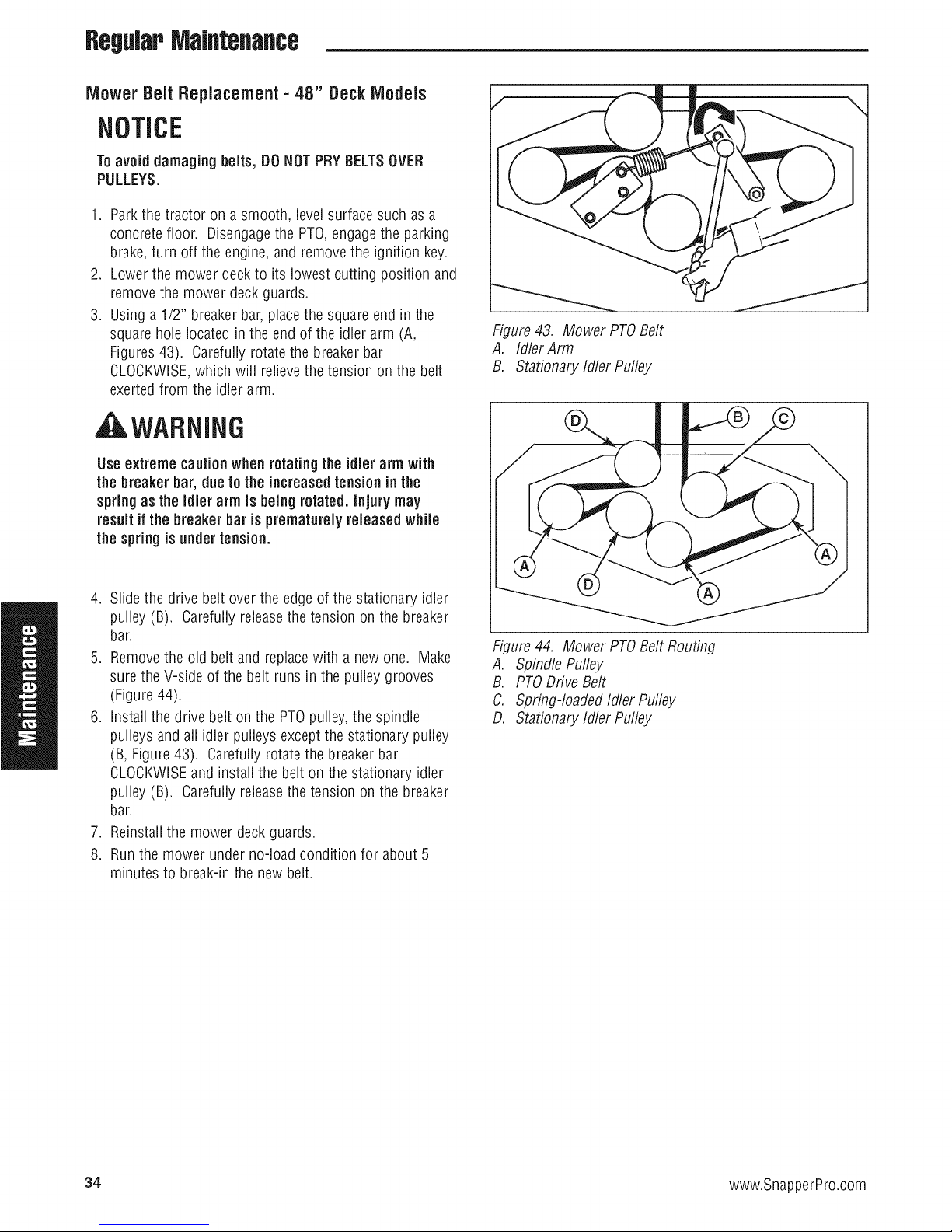

the rod COUNTER-CLOCKWISE.