Page 1

ASSEMBLY INSTRUCTIONS

OPERATOR'S MANUAL

PARTS LIST

Z

-VAC

Large Clamshell

Grass Catcher

Kit for NZM

Actual product may differ from product pictured above

Manual No. 7100651 (I.R. 4/5/2006)

TP 900-5178-IR-AT-N

Mid Mount

Riders

Models covered:

Includes Clamshell, Blower

and Weight Kits

48” Kit P/N 7600026

52” Kit P/N 7600027

61” Kit P/N 7600028

Page 2

1

preliminaries

Congratulations!

You have just purchased one of the finest pieces of outdoor power equipment on the market today. If properly cared for,

your new Z-Vac Grass Catcher Kit will provide years of dependable service. Please read and follow this instruction manual carefully in order to get the most out of your new equipment.

As you carefully unpack your unit, you will find the following items:

1 Blower Kit (48” P/N 3071107, 52” P/N 3071108, 61” P/N 3063348)

1 Large Clamshell Catcher Kit (All, 7600019)

1 Weight Kit (All, 7600025)

1 Package containing operating manuals and warranty registration

Each product leaves our factory in excellent condition; occasionally, however, some damage may occur during shipment.

If any such damage is found upon initial inspection, immediately notify the transport carrier who delivered your machine,

as they are solely responsible for such damage, as well as any subsequent adjustments necessary.

Before assembly, please take a moment and record your model number and serial number below for future reference (both

numbers are located on the serial tag attached to the blower):

Model number_______________________________

Serial number________________________________

Also be sure to promptly fill out and return the warranty registration enclosed in your manual packet.

Your new unit requires very little assembly. Simply follow the instructions contained within this manual to begin enjoying

the benefits of your new unit.

2

Page 3

safety rules regarding outdoor power equipment

IMPORTANT! READ CAREFULLY THE FOLLOWING SAFETY RULES BEFORE

ASSEMBLING OR OPERATING UNIT.

2

TRAINING

-- Read, understand, and follow all instructions in the man-

ual and on the unit before starting. If the operator(s) or

mechanic(s) can not read English it is the owner's responsibility to explain this material to them.

-- Become familiar with the safe operation of the equipment,

operator controls, and safety signs.

-- All operators and mechanics should be trained. The

owner is responsible for training the users.

-- Only allow responsible adults, who are familiar with the

instructions, to operate the unit.

-- Never let children or untrained people operate or service

the equipment. Local regulations may restrict the age of the

operator.

-- The owner/user can prevent and is responsible for accidents or injuries occurring to themselves, other people or

property.

PREPARATION

-- Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform the

job. Use only accessories and attachments approved by

the manufacturer.

-- Wear appropriate clothing including safety shoes, safety

glasses and ear protection. Long hair, loose clothing or jewelry may get tangled in moving parts.

-- Inspect the area where the equipment is to be used and

remove all objects such as rocks, toys and wire, which can

be thrown by the machine.

-- Use extra care when handling gasoline and other fuels.

They are flammable and vapors are explosive.

a) Use only an approved container.

b) Never remove fuel cap or add fuel with the engine running. Allow engine to cool before refueling. Do not smoke.

c) Never refuel or drain the machine indoors.

-- Check that operator's presence controls, safety switches

and shields are attached and functioning properly. Do not

operate unless they are functioning properly.

OPERATION

-- Never run an engine in an enclosed area.

-- Operate only in the daylight or with good artificial light,

keeping away from holes and hidden hazards.

-- Be sure of your footing while using pedestrian controlled

equipment, especially when backing up. Walk, don't run.

-- Do not operate in reverse unless absolutely necessary.

Always look down and behind before and while traveling in

reverse.

-- Be aware of the blower discharge direction and do not

point it at anyone. Do not operate the blower without hose

and bagger hood in place.

-- Never leave a running unit unattended. Always stop

engine before leaving unit.

-- Never operate with guards not securely in place. Be sure

all safety features are attached, adjusted properly and functioning properly.

-- Never operate with the hose or cover removed or altered.

-- Do not change the engine governor setting or over speed

the engine.

-- Stop on level ground, shut off engine before leaving the

operator's position for any reason.

-- Stop equipment and inspect impeller blades after striking

objects or abnormal vibration occurs. Make necessary

repairs before resuming operations.

-- Keep hands and feet away intake and discharge areas.

-- Keep pets and bystanders away.

-- Do not operate the unit while under the influence of alco-

hol or drugs.

-- Use caution when crossing roads and sidewalks. Stop

engine if not blowing.

-- Use care when loading or unloading the machine into a

trailer or truck.

-- Use care when approaching blind corners, shrubs, trees

or other objects that may obscure vision.

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tipover accidents, which can result in severe injury or death.

All slopes require extra caution. If you cannot back up the

slope, or if you feel uneasy on it, do not drive on it.

Do

-- Mow up and down slopes, never across face.

-- Remove obstacles such as rocks, tree limbs, etc.

-- Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

-- Keep all movement on the slopes slow and gradual. Do

not make sudden changes in speed or direction.

Do Not

-- Do not start or stop on a slope. If tires lose traction, pro-

ceed slowly straight down the slope.

-- Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

-- Do not use near drop-offs, ditches, or embankments. The

operator could lose footing or balance or blower could suddenly turn over if a wheel is over the edge of a cliff or ditch,

or if an edge caves in.

-- Do not operate on slopes with wet grass. Reduced footing or traction could cause sliding.

-- Do not operate machine on slopes in excess of 10

degrees (18% grade) when equipped with a grass catcher.

-- Do not operate machine without weight kit installed when

equipped with a grass catcher.

3

Page 4

2

safety rules regarding outdoor power equipment

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and its activity. Never assume that children will remain

where you last saw them.

-- Keep children out of the mowing area and under the

watchful care of another responsible adult.

-- Do not allow children or others to ride on the machine,

attachment, or towed equipment (even with the blades off).

-- Be alert and turn unit off if children enter the area.

-- Before and during reverse operation, look behind and

down for small children.

-- Never allow children to operate the unit.

-- Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

EMISSIONS

-- Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

-- Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

MAINTENANCE AND STORAGE

-- Always observe safe refueling and fuel handling practices

when refueling the unit after transportation or storage.

-- Always follow the engine manual instructions for storage

preparations before storing the unit for both short and long

term periods.

-- Always follow the engine manual instructions for proper

start-up procedures when returning the unit to service.

-- Never store the machine or fuel container inside where

there is an open flame, such as in a water heater. Allow unit

to cool before storing.

-- Shut off fuel while storing or transporting. Do not store fuel

near flames or drain indoors.

-- Keep all hardware tight and keep all parts in good working condition. Replace all worn or damaged decals.

-- Never tamper with safety devices. Check their proper

operation regularly.

-- Clean leaves and debris from mufflers and engine to prevent fires. Clean up oil or fuel spillage.

-- Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

-- Never make adjustments or repairs with the engine running unless specified otherwise.

-- Park machine on level ground. Never allow untrained personnel to service machine.

-- Carefully release pressure from components with stored

energy. (e.g. springs)

-- Only replace impellers. Never straighten or weld them.

-- Keep hands and feet away from moving parts.

-- Frequently check components and replace with manufac-

turer's recommended parts, when necessary.

-- Use only factory authorized replacement parts when making repairs.

-- Always comply with factory specifications on all settings

and adjustments.

-- Only authorized service locations should be utilized for

major service and repair requirements.

-- Never attempt to make major repairs on this unit unless

you have been properly trained. Improper service procedures can result in hazardous operation, equipment damage and voiding of manufacturer's warranty.

4

Page 5

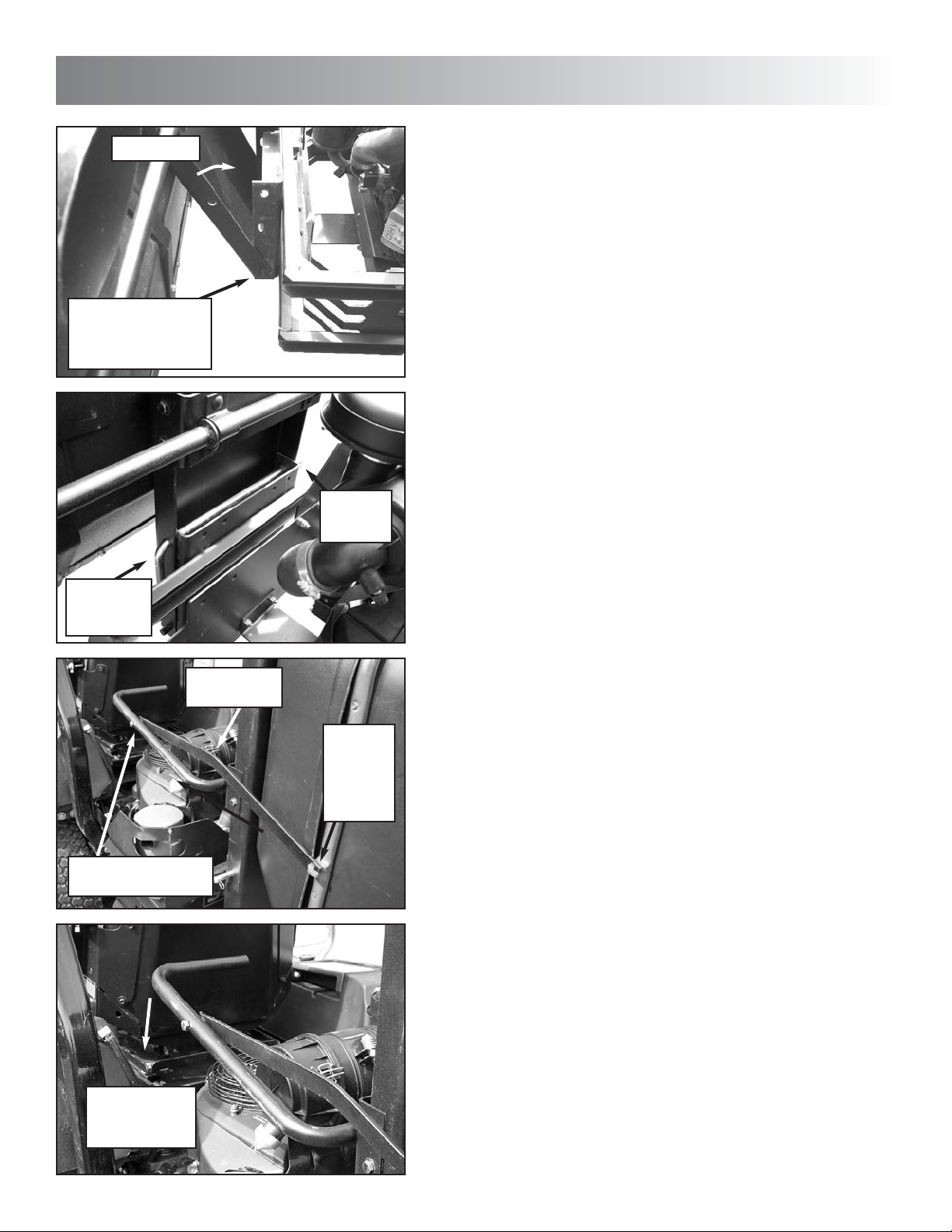

unit assembly

3

BLOWER KIT INSTALLATION

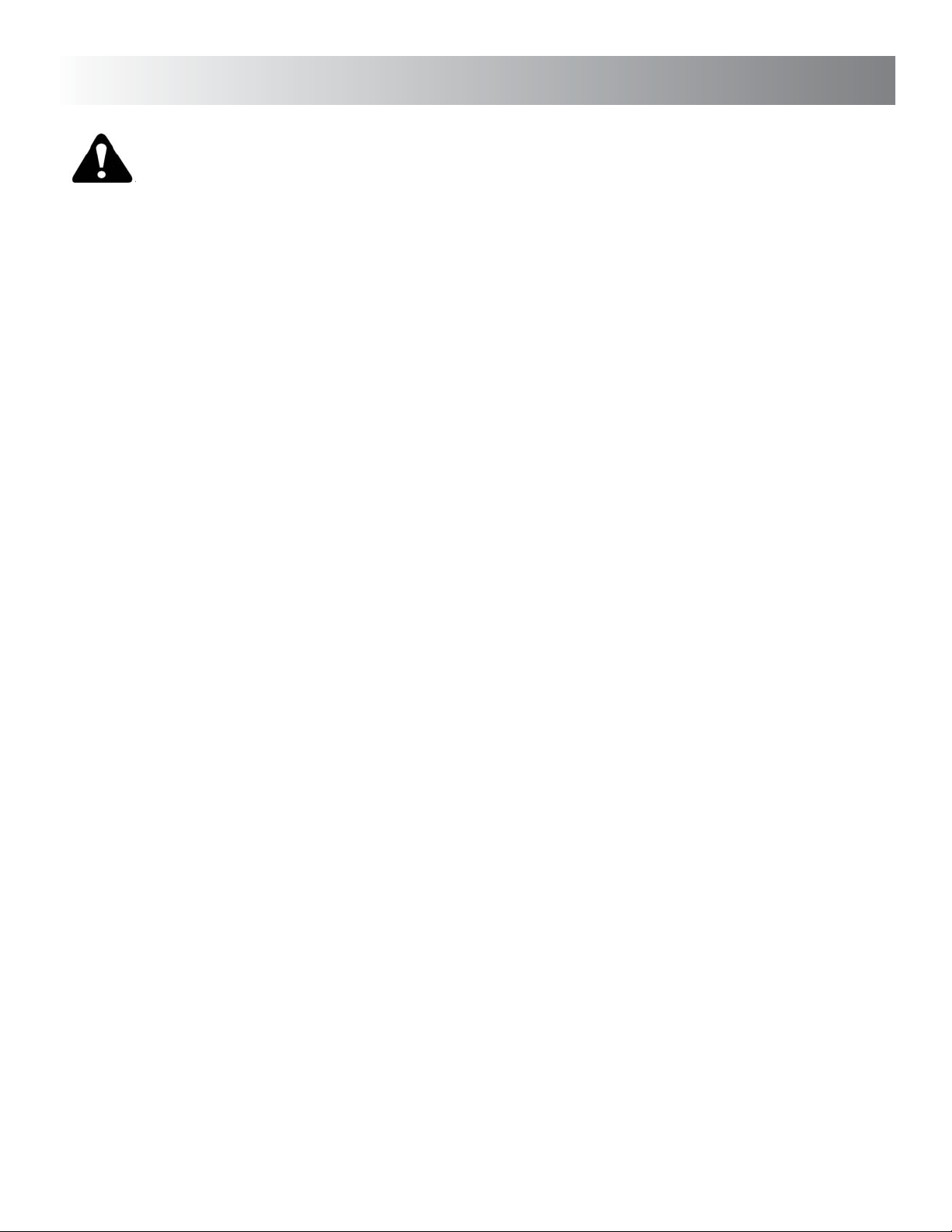

STEP 1: Remove pin, rod and spring securing dis-

charge deflector to mower deck, and remove

deflector. Set rod and pin aside for future assembly step. Store deflector for future use. IMPOR-

TANT: Never operate mower without discharge

deflector or grass catcher securely in place.

STEP 2: Remove two bolts securing right deck pulley guard to mower deck and remove guard. Set

bolts aside for future assembly step. Store guard

for future use. IMPORTANT: Never operate mower

without a pulley guard securely in place.

STEP 3: Lift off and set aside foot rest/center deck

cover to expose senter blade deck. Pull blade belt

deck idler arm in direction indicated to relieve belt

tension, and slip blade belt off of right blade drive

pulley.

NOTE: Assistance may be needed for removal of

blade belt.

REMOVE PULLEY

GUARD

REMOVE

DEFLECTOR

REMOVE PIN,

ROD AND SPRING

REMOVE BELT FROM

RIGHT BLADE PULLEY

PULL ON IDLER

TO RELIEVE

BELT TENSION

STEP 4: Remove nut securing pulley to blade

spindle, and install supplied blower pulley on top of

existing pulley. Replace nut, and torque to 70-80 ftlbs. Replace deck belt onto groove of bottom pulley.

NOTE: Nut secures blade bolt in place. Support

bolt from beneath while installing pulley.

IMPORTANT: Use gloves when working under

deck. Sharp blades can cause injury.

STEP 5: Set blower against deck discharge. Align

holes in blower mount with holes in deck discharge

tabs, and secure blower with discharge deflector

rod removed in Step 1, securing with pin. NOTE:

Do not reinstall the deflector spring when installing

the rod.

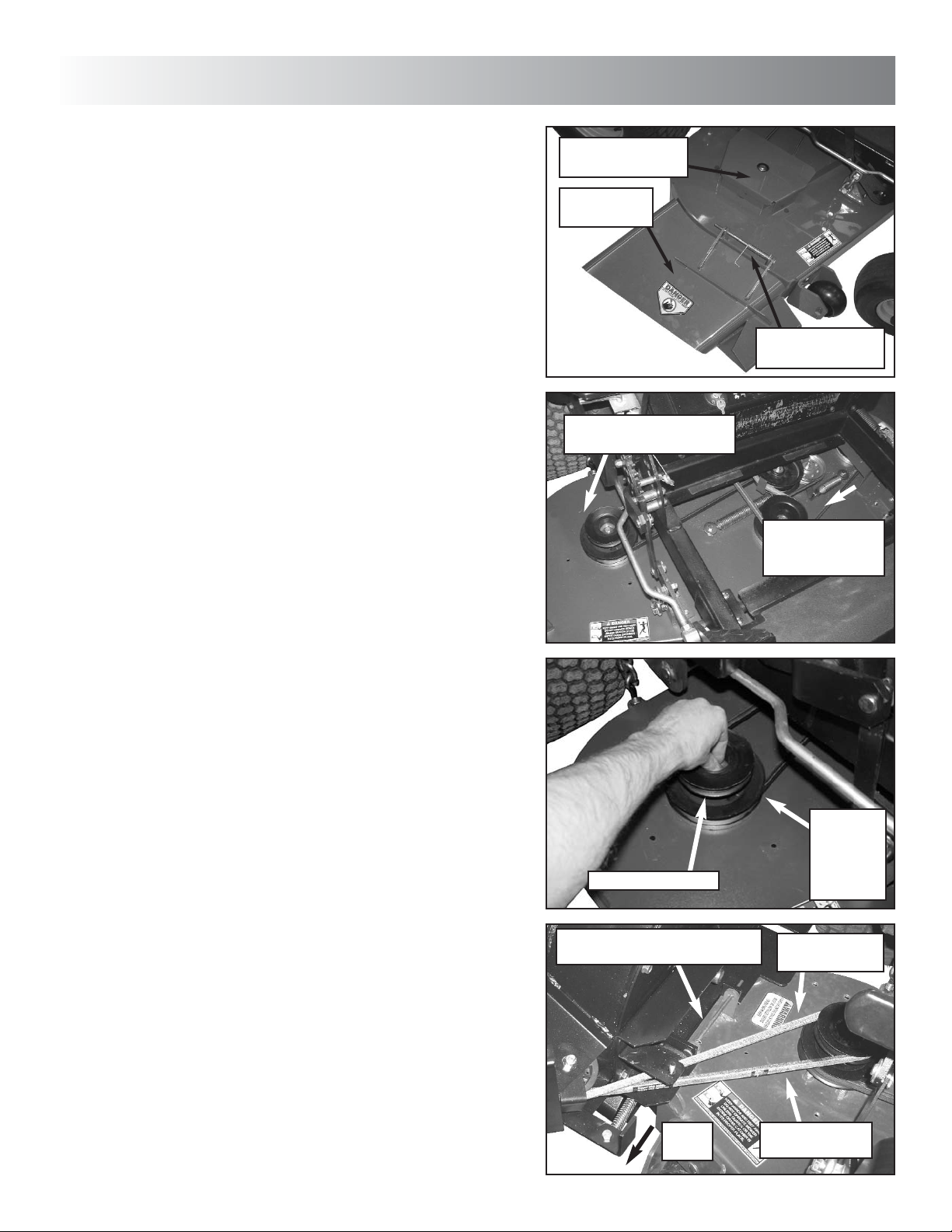

STEP 6: Pull back on idler tension release handle,

and install blower belt around top groove of deck

pulley. NOTE: Make sure belt is not rolled or

twisted when installing.

BLOWER PULLEY

INSTALL BLOWER AND

SECURE WITH ROD AND PIN

PULL

BACK

REPLACE

BELT

ONTO

BOTTOM

PULLEY

FROM UPPER

IDLER PULLEY

TO LOWER

IDLER PULLEY

5

Page 6

3

unit assembly

REMOVE BOLTS,

THEN REMOVE

COVER

STEP 6a: Remove bolts securing impeller pulley

cover to blower, and remove cover.

CHECK TO SEE

THAT BELT IS

ON PULLEYS

DRILL

HOLES &

INSTALL

BOLTS

INSERT

PIN

ALIGN

BRACKET

WITH REAR

OF DECK

STEP 6b: Check to see that blower belt is routed

around impeller pulley and idler pulleys after belt is

installed onto deck pulley. Replace cover, tightening bolts securely. IMPORTANT: Never operate

any mower without a pulley guard securely in

place.

STEP 7: Slip tube of locking pin bracket into blower mount, and secure with T-handle pin, making

sure pin goes through both upper and lower holes

in blower mount. Then align base of pin bracket

parallel with rear of deck, and, using bracket as a

template, drill two 7/16” holes through deck. Insert

two 3/8-16 x 1” hex bolts up through deck and

bracket, securing with hex flange lock nuts.

Tighten securely. IMPORTANT: Use gloves when

working under deck. Sharp blades can cause

injury.

INSTALL

BOLTS

STEP 8: Lay supplied pulley guard onto deck,

aligning holes in guard with holes in deck. Install

with bolts securing original guard, tightening

securely.

NOTE: 48” deck shown; 52” and 61” deck guard

configurations may differ.

6

Page 7

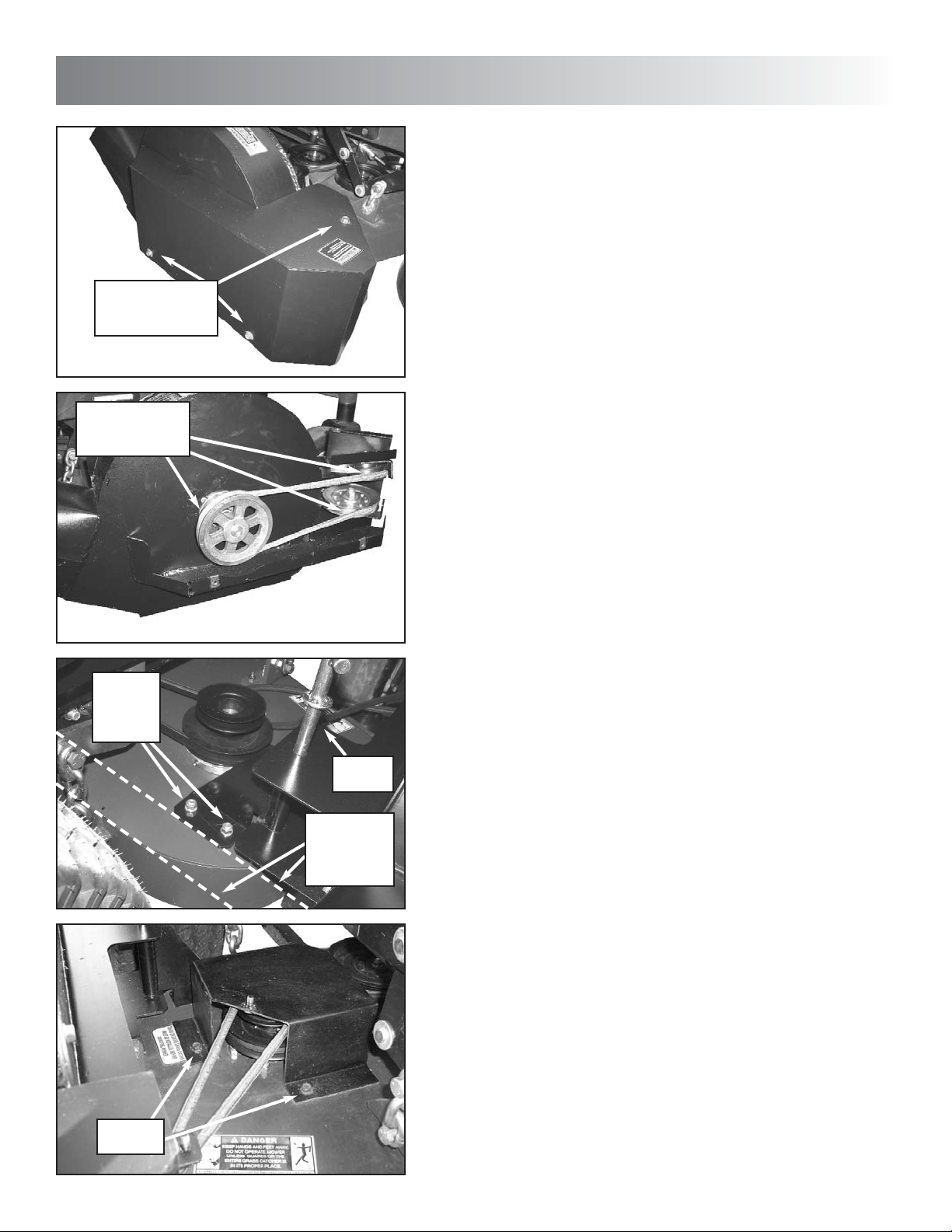

STEP 9: Install belt guard between pulley guard

and belt guard support clip on front part of blower

mount. Secure with two 5/16 nylon wing nuts.

Tighten nuts securely.

WEIGHT KIT INSTALLATION

!! Warning: Weight kit must be installed prior to

installing clamshell kit. Failure to do so may

result in longitudal tipping of unit.

!! Warning: Assistance is required when

installing weight kit.

unit assembly

INSTALL BELT GUARD

AND SECURE WITH

WING NUTS

3

STEP 10: Lay weight mount channel, with installed

weights, across front end of machine as shown.

Secure to machine with two clamp plates, one

under each caster arm, each held on with two 3/816 x 4” hex bolts and lock nuts. See Inset. Tighten

securely.

CLAMSHELL KIT INSTALLATION

STEP 11: Install bumper mount standoffs onto rear

bumper of machine, utilizing existing hardware on

machine. NOTE: Invert hardware when installing

standoffs, installing bolts out through bumper with

nuts facing out.

NOTE: When installing standoffs, be sure that the

bumper mount plate mounting holes along the

back bar of both standoffs are oriented towards the

right side of the machine. Refer to the Parts List

section of the manual.

STEP 12: Install bumper mount plate onto standoffs with four 5/16-18 x 3/4 hex bolts, securing with

four 5/16-18 hex flange lock nuts. Tighten securely.

WEIGHT

MOUNT

CHANNEL

USE EXISTING

HARDWARE

CLAMP

PLATE

7

Page 8

3

unit assembly

RAISE UNIT

HOOK CLAMSHELL

MOUNT ONTO

BUMPER MOUNT

PLATE PINS

SECURE

WITH

HAIR PIN

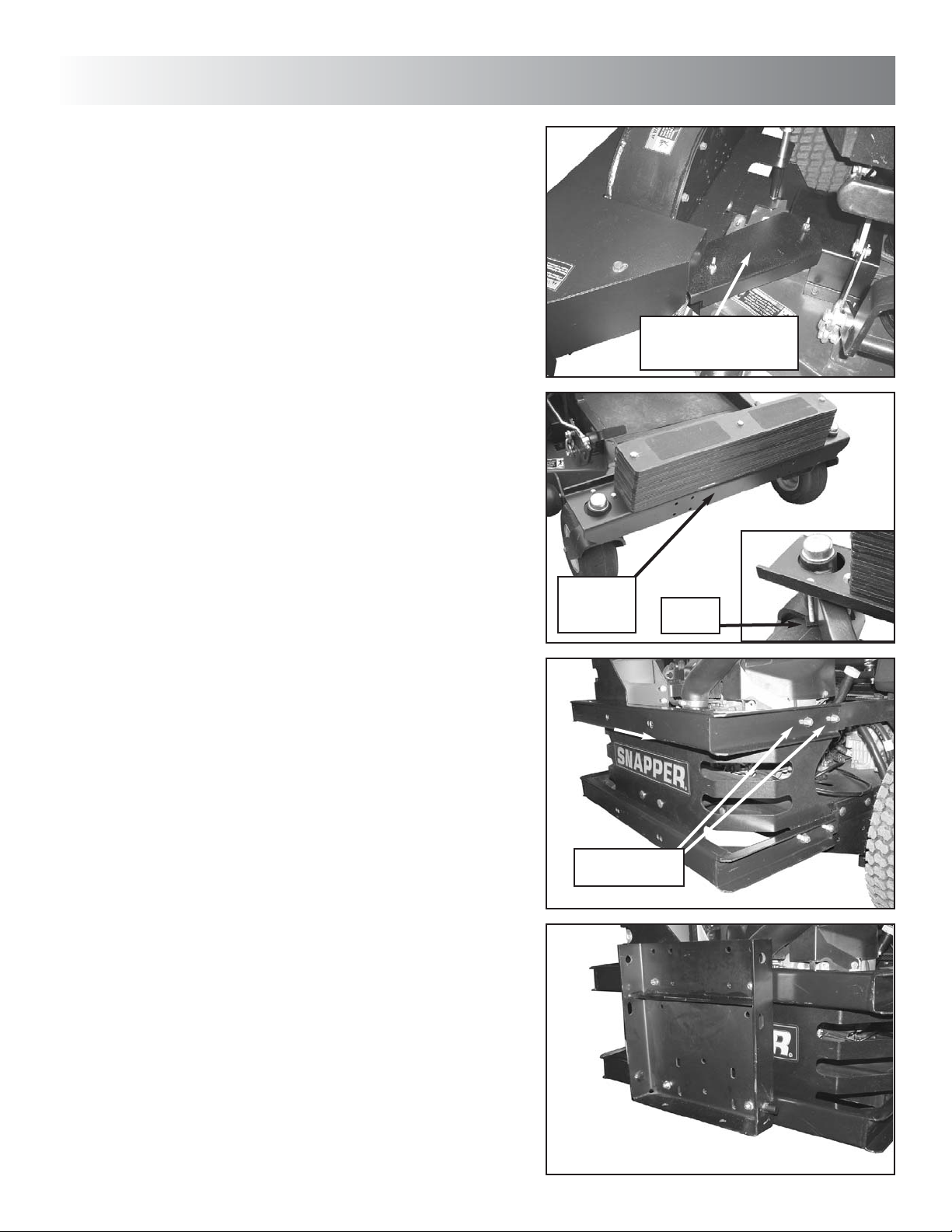

STEP 13: Hook bottom of clamshell mount onto

pins in bottom of bumper mount plate, then raise

clamshell assembly up against bumper mount.

IMPORTANT: Assistance is required when

installing clamshell unit.

STEP 14: Slide hitch rod through aligned holes in

clamshell mount and bumper mount plate, securing with hair pin.

IMPORTANT: Assistance is required when

installing clamshell unit.

SLIDE ROD

THROUGH

HOLES

BOLT ARM TO

INSIDE OF HANDLE

MAKE SURE

BEND IS UP

HOOK

LARGE

HOLE OF

ARM

HERE

STEP 15: Hook the large hole of each actuating

arm onto the hook on each side of the rear cover.

Then secure the other end of the arm onto the

inside of each side of the handle weldment with

one 3/8-16 x 2” hex bolt and nyloc nut. Tighten

snugly. NOTE: Make sure bend of arm is up.

Push handle down to lock cover.

PUSH HANDLE

DOWN TO

LOCK COVER

8

Page 9

unit assembly

3

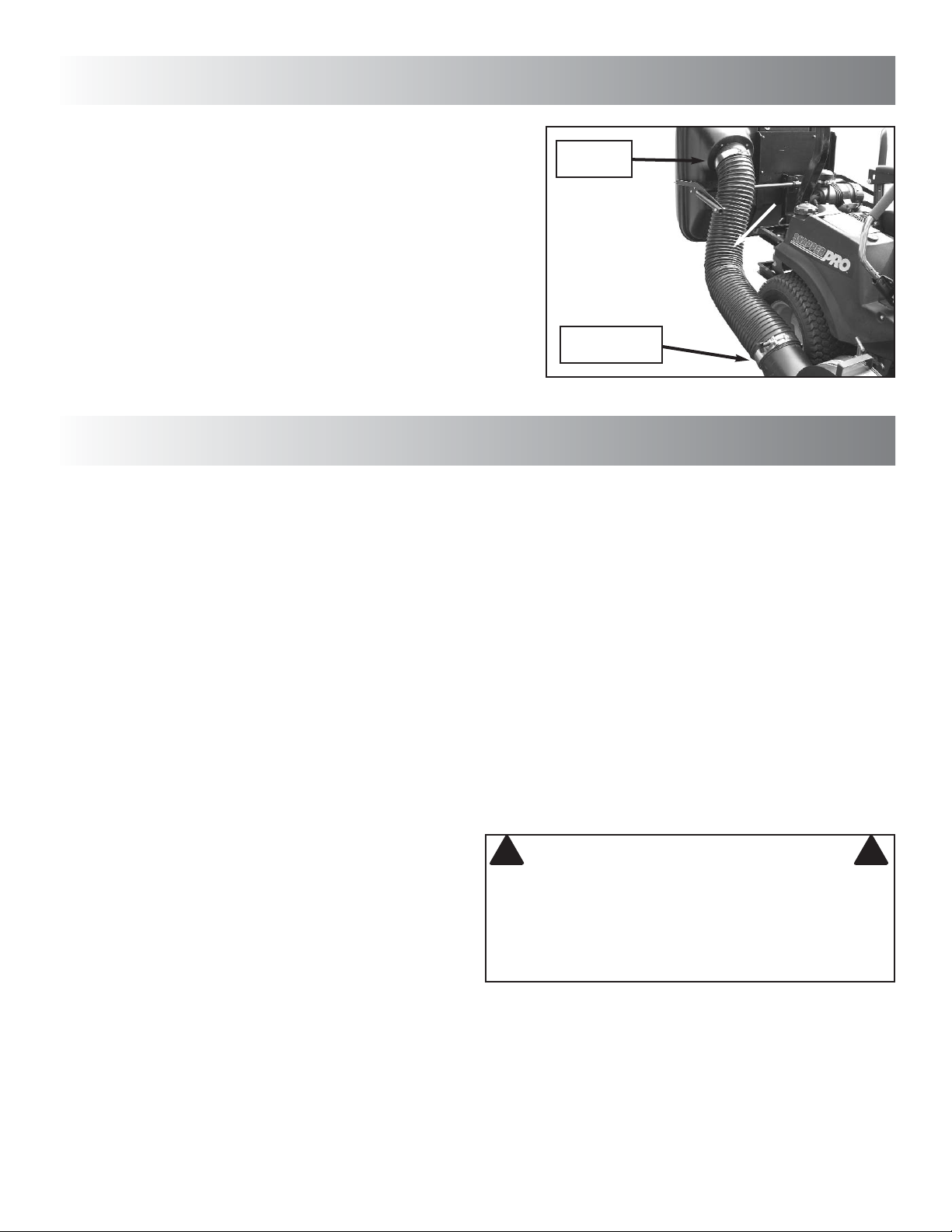

STEP 16: Slip one hose clamp onto each side of

discharge hose, and install hose between blower

and clamshell. NOTE: Install hose so that clamp

with nut is on the clamshell side, and the clamp

with the black quick-release knob is on the blower

side. Tighten both clamps securely.

INTRODUCTION

Follow operation and maintenance instructions in the

Operator’s Manual provided with the Snapper MidMount Z-Rider.

GRASS CATCHER OPERATION

1. Select desired cutting height. Choose a setting that will

not attempt to cut off too much at once, overloading the

machine.

2. After starting engine and allowing a brief warm up period, move engine speed control to highest setting.

3. Drive machine to cutting area. Engage blades.

4. Select a slow forward ground speed until familiar with

conditions. Do not select a speed that is too fast, causing the machine to become overloaded.

5. The weight of the grass catcher and contents will affect

the stability and handling of the machine. Avoid sudden

starts and sharp turns. Reduce speed on slopes, and

DO NOT operate machine on slopes exceeding 10

degrees (18% grade). Operate machine up and down

slopes. DO NOT operate machine across the face of

slopes. Turn blades off when traveling up slope.

6. Empty grass catcher often to minimize effect on stability and handling. Over filling the catcher will reduce performance and cause clogging of the hose, blower and

deck.

7. Do not operate the machine with the Grass Catcher

open. The entire Grass Catcher must be installed, the

catcher closed and latched properly before operating.

EMPTYING GRASS CATCHER

1. Empty Grass Catcher often to avoid overfilling.

Overfilling reduces performance and causes clogging of

hose, blower and deck.

2. Turn blades off. Drive machine to location the clippings

are to be dumped. DO NOT operate blades in reverse.

CLAMP

WITH NUT

CLAMP WITH

BLACK KNOB

unit operation & maintenance

If you must back machine to dump clippings in desired

location, LOOK and SEE behind and down for children,

pets and hazards before and while backing.

3. Stop motion of machine by returning Motion Control(s)

to Neutral (N). Set Park Brake. Stop engine.

4. Lift up on handle sufficiently to allow all clippings to exit

catcher. If the dumped pile is too high to allow the catcher to close, you may be required to use a rake or similar implement to distribute the clippings.

5. After dumping, to maintain peak performance, check

the catcher screen located on the inside of the Rear

Cover Assembly to make sure it is clean and free of any

build up. Clean as required with brush or broom.

6. Close catcher. Push down firmly on handle to insure it

is properly latched.

7. Re-start engine and drive machine to cutting area. Set

engine speed to highest setting, engage blades and

resume operation.

! !

DO NOT attempt to remove any clogs from deck, blower, or hose with engine or blade running. STOP engine.

STOP blades. Set brake. Remove key. Make sure

blades and all rotating components have come to a

complete stop before removing any catcher or unclogging any catcher component.

IF THE GRASS CATCHER BECOMES CLOGGED

The grass catcher may become plugged if the conditions

are too severe, the catcher is overfilled, or the machine is

used improperly. If plugging does occur, attempt the following:

1. Engine speed too slow – set engine speed control to

“FAST” position.

WARNING

(Continued On Next Page)

4

9

Page 10

4

unit operation & maintenance

IF THE GRASS CATCHER BECOMES CLOGGED

(Continued From Previous Page)

2. Empty catcher more often.

3. Clean screen on rear cover assembly.

4. Ground speed too fast – cut at slower speed.

5. Removing too much grass – raise cutting height, cut

partial width, and cut lawn more frequently.

6. Grass is too wet from rain or dew – allow grass to dry.

7. Blades are dull or worn – inspect blades and replace as

necessary. Use only genuine SNAPPER replacement

blades.

8. Deck, blower, or hose has clipping build up – clean all

clippings from all internal surfaces.

! !

DO NOT put fingers or hands inside blower! STOP

blades. STOP engine. Remove key. Use only a stick, or

other suitable means, to clear the blower of clogs or

other obstructions!

! !

DO NOT attempt any adjustments, maintenance or

repairs with engine running. STOP blades. STOP

engine. Remove key.

! !

Grass Catcher components are subject to deterioration. Inspect frequently. Replace worn or damaged

components immediately. Use only genuine SNAPPER

replacement parts.

To Clear A Plugged Hose

1. Stop blades. Stop engine. Remove key.

2. After all rotating components (engine, blower, blades)

have come to a complete stop, loosen hose clamp at

outlet of blower, and remove hose from blower.

3. Clear any obstructions from hose. If necessary, use a

stick to reach into the hose.

4. Reinstall hose to blower and securely tighten hose

clamp.

WARNING

WARNING

WARNING

To Clear A Plugged Blower

1. Stop blades and blower. Stop engine. Remove key.

2. After all rotating components have come to a complete

stop, loosen the hose clamp at the outlet of the blower.

3. Remove hose from blower.

4. Using a stick or similar object, clear all obstructions

from blower. DO NOT INSERT HAND.

5. Reinstall hose to blower and securely tighten hose

clamp.

GRASS CATCHER MAINTENANCE

Grass Catcher components are subject to wear and deterioration during normal usage. Inspect all components frequently for signs of wear and deterioration. Replace worn or

damaged components immediately.

BEFORE EACH USE

1. Perform pre-start checklist and maintenance as

instructed in the SNAPPER Mid-Mount Z-Rider

Operator’s Manual and Engine Owner’s Manual included with the machine.

2. Clamshell Catcher. Inspect all catcher components.

Replace all worn or damaged parts.

3. Deck, Blower, Hose. Clean grass build up from deck,

blower, hose, covers and rear cover screen. To maintain

peak performance make sure screen is clean at each

dumping.

4. Hose. Check hose for wear, tears and holes. Replace

as needed.

5. Blades. Check blades for sharpness, wear, flatness

and damage. Refer to MMZ Operator’s Manual for

blade wear limits and sharpening/replacement instructions.

6. Blower. Check blower impeller, blower housing and

inlet/outlets for signs of wear and deterioration. Replace

as needed. Check all fasteners and hardware to insure

none are missing and all are tightened securely.

Lubricate impeller shaft bearings with 1 to 3 shots of

General Purpose grease from a grease gun.

7. Belts. Check belts for wear and fraying. Replace as

needed.

8. Idler Arm. Check idler arm to insure it pivots freely and

bushings are not worn. Replace worn bushings as

needed.

10

Page 11

warranty statement

5

2 YEAR LIMITED WARRANTY

For two (2) years from purchase date for the original purchaser's residential, non-commercial use, SNAPPER, through any

authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon

examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

For one (1) year from purchase date for the original purchaser's commercial, non-residential use, SNAPPER, through any

authorized SNAPPER dealer will replace, free of charge, any part or parts found upon examination by the factory at

McDonough, Georgia, to be defective in material or workmanship or both.

For ninety (90) days from purchase date for the original purchaser's rental use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge, any part or parts found upon examination by the factory at McDonough, Georgia,

to be defective in material or workmanship or both

All transportation costs incurred by the purchaser in submitting material to an authorized SNAPPER dealer for replacement under this warranty must be paid by the purchaser.

This warranty does not apply to certain transmissions, to engines and their components, and batteries, as these items are

warranted separately. This warranty does not apply to parts that have been damaged by accident, alteration, abuse,

improper lubrication, normal wear, or other cause beyond the control of SNAPPER. This warranty does not cover any

machine or component part that has been altered or modified changing safety, performance, or durability.

Batteries have a one (1) year warranty period with free replacement if required for one (1) year from the original purchase

date. SNAPPER will not be responsible for any installation cost incurred. The battery warranty only covers original equipment batteries and does not cover damage to the battery or machine caused by neglect or abuse, destruction by fire,

explosion, freezing, overcharging, improper maintenance, or use of improper electrolyte.

There is no other express warranty.

DISCLAIMER OF WARRANTY

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to two (2) years from

purchase date for the original purchaser's residential or other non-commercial use, and one (1) year from purchase for the

original purchaser's commercial, non-residential use, and ninety (90) days from purchase for the original purchaser's rental

use and to the extent permitted by law, any and all implied warranties are excluded. This is the exclusive remedy. Liabilities

for consequential damages, under any and all warranties are excluded.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY IMPAIR THE

SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND WARRANTY BY SNAPPER ASSOCIATED

WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill out the SNAPPER Product Registration Card immediately and mail to:

Snapper's Product Registration Center, P.O. Box 1379, McDonough, Georgia 30253

11

Page 12

6

unit breakdown & parts list

12

Page 13

unit breakdown & parts list

Snapper Z-Vac Blower Unit Group 48”, 52”, 61” Models

Item Part No. Qty Description

1 3046782 1 WELDMENT, Blower Belt Guard

2 91121 1 NUT, 1/2-13 Hex Nyloc

3 90183 1 WASHER, 1/2" Flat SAE

4 3021097 1 PULLEY, A Groove Idler, Steel

5 44995 1 IDLER STUD (3/8-24 thread)

6 91804 2 FLAT WASHER, 9/16 Type Narrow

7 14409 2 FLANGE BEARING, 9/16" I.D. (powdered metal)

8 10776 1 RETAINING RING, 1/2"

9 3046824 1 BELT RETAINER, Idler

10 91527 1 SCREW, 5/16-18 x 1-1/4" Hex Head Cap, GR5

11 3047253 1 WELDMENT, Idler Arm

12 91601 1 NUT, 5/16-18 Hex Flange Lock

13 91218 1 SCREW, 1/2-13 x 2-1/2" Hex Head Cap, GR5

14 3046781 1 WELDMENT, Blower Housing

15 3046853 1 BACK PLATE, Blower

16 91541 7 SCREW, 5/16-18 x 3/4" Hex Washer Self-Tap

17 7100021 2 BEARING (differs from shown)

18 91601 6 NUT, 5/16-18 Flange Lock (differs from shown)

19 91508 3 BOLT, 5/16-18 x 3/4" Carriage (differs from shown)

20 3046854 1 IMPELLER, Fast Vac Blower (weldment)

21 91508 3 BOLT, 5/16-18 x 3/4" Carriage (differs from shown)

22 90613 2 NUT, 3/8-16 Hex Flange Lock

23 3046813 2 BELT RETAINER

24 3043613 2 PULLEY, Flat Idler, 2-3/4" O.D.

25 90122 9 WASHER, 3/8" Flat SAE

26 91560 1 SCREW, 3/8-16 x 2-1/4" Hex Head Cap, GR5

27 91518 1 NUT, 3/8-24 Hex Nyloc

28 91305 1 SCREW, 3/8-16 x 2" Hex Head Cap, GR5

29 92111 3 U-CLIP, 5/16-18

30 91541 3 SCREW, 5/16-18 x 3/4" Hex Washer Self-Tap

6

13

Page 14

6

unit breakdown & parts list

14

Page 15

unit breakdown & parts list

Snapper Z-Vac Blower Mount Group 48”, 52”, 61” Models

Item Part No. Qty Description

1 3036323 1 BELT, A Section, 91.125" effective length (used on 48” & 52” Models)

1 3022844 1 BELT, A Section, 92.0" effective length (used on 61” Models)

2 3037161 1 WELDMENT, Belt Cover, Deck (used on 48” & 52” Models)

2 33867 1 WELDMENT, Belt Cover, Deck (used on 61” Models)

3 ----- -- NOT USED

4 91537 2 WING LOCKNUT 5/16-18

5 3037162 1 BELT GUARD, 48" Deck

5 3037163 1 BELT GUARD, 52" Deck

5 33847 1 BELT GUARD, 61" Deck

6 3046806 1 PULLEY, Blower Input, 48" & 52"

6 3046809 1 PULLEY, Blower Input, 61"

7 3036324 1 PULLEY, 48"/52" Spindle

8 3027505 1 WELDMENT, 48" Blower Mount

8 3027506 1 WELDMENT, 52" Blower Mount

8 33873 1 WELDMENT, 61" Blower Mount

9 3027507 1 WELDMENT, Guard Support Bracket

10 91541 4 SCREW, 5/16-18 x 3/4" Hex Washer Self-Tap

11 3027508 1 WELDMENT, Deck Mount Bracket

12 91304 2 SCREW, 3/8-16 x 1" Hex Head Cap, GR5

13 90613 4 NUT, 3/8-16 Hex Flange Lock

14 3032118 1 WELDMENT, T-Handle Pin

15 91527 1 SCREW, 5/16-18 x 1-1/4" Hex Head Cap, GR5

16 91601 1 NUT, 5/16-18 Hex Flange Lock

17 90951 2 NUT, 5/16-18 Hex Large Flange Center Lock

18 3020807 1 SPRING, Idler, Fast Vac

19 12315 1 KEY, 1/4 Square x 1.44

20 91617 1 SCREW, 3/8-16 x 6" Hex Head Cap, GR5

-- 33740 1 BRACKET, Spring (Not Shown; used on 61” Models)

-- 33868 1 WELDMENT, Spring Bracket (Not Shown; used on 61” Models)

6

15

Page 16

6

unit breakdown & parts list

16

Page 17

unit breakdown & parts list

Snapper Z-Vac Large Clamshell Catcher Group

Item Part No. Qty Description

1 7100564 1 COVER, Rear, Large Clamshell Bagger

-- 7300365 1 SCREEN, Large Clamshell (Not Shown)

-- 73525 8 RIVET, 5/32 (Not Shown)

2 7400119 1 WELDMENT, Rear Cover Brace

3 73179 1 HINGE, Rear Cover

4 91265 5 SCREW, #10-24 x 1-1/2” Hex Washer Machine

5 36422 18 WASHER, .190 ID x .75 OD Flat

6 91079 18 NUT, 10-24 Hex Flange Lock

7 73145 13 BOLT, #10-24 x 1-1/2” Oval Head

8 91304 2 SCREW, 3/8-16 x 1" Hex Head Cap, GR5

9 91514 4 WASHER, .40 ID x .81 OD Flat

10 91299 8 NUT, 3/8-16 Nyloc

11 7100565 1 COVER, Front, Large Clamshell Bagger

-- 72874 1 DEFLECTOR, Clamshell Bagger (Not Shown)

-- 91631 2 SCREW, #10-24 x 1/2” Hex Head Machine (Not Shown)

-- 36422 2 WASHER, .190 ID x .75 OD Flat (Not Shown)

-- 91079 2 NUT, 10-24 Hex Flange Lock (Not Shown)

12 7400150 1 BRACE, Front Cover Weldment

13 91527 17 SCREW, 5/16-18 x 1-1/4" Hex Head Cap, GR5

14 91528 25 WASHER, .375 ID x .875 OD Flat

15 91298 20 NUT, 5/16-18 Nyloc

16 11292 1 MOUNT, Clamshell

17 16314 4 WASHER, .33 ID x 1.25 OD Flat

18 11296 1 HANDLE BRACE, Clamshell

19 91303 7 BOLT, 5/16-18 x 1” Carriage

20 43334 1 TUBE ADAPTER WELDMENT

21 91814 4 SCREW, 1/4-20 x 1-1/4” Hex Head Cap, GR5

22 91315 4 WASHER, 1/4” Split Lock

23 91576 4 NUT, 1/4-20 Hex

24 3022833 1 HOSE, Snapper Fast Vac

25 3022875 1 HOSE CLAMP, Upper

26 3022876 1 HOSE CLAMP, Lower

27 11293 1 BRACKET, Handle Mount

28 27198 4 BOLT, 3/8-16 x 1” Hex Flange

29 7400120 1 HANDLE WELDMENT

30 11870 1 GRIP

31 72951 1 ENDCAP, Tube

32 43803 2 BRACKET, Hanger

33 91601 4 NUT, 5/16-18 Hex Flange Lock

34 11295 2 ARM, Clamshell Actuating

35 91305 2 SCREW, 3/8-16 x 2" Hex Head Cap, GR5

6

17

Page 18

6

unit breakdown & parts list

18

Page 19

unit breakdown & parts list

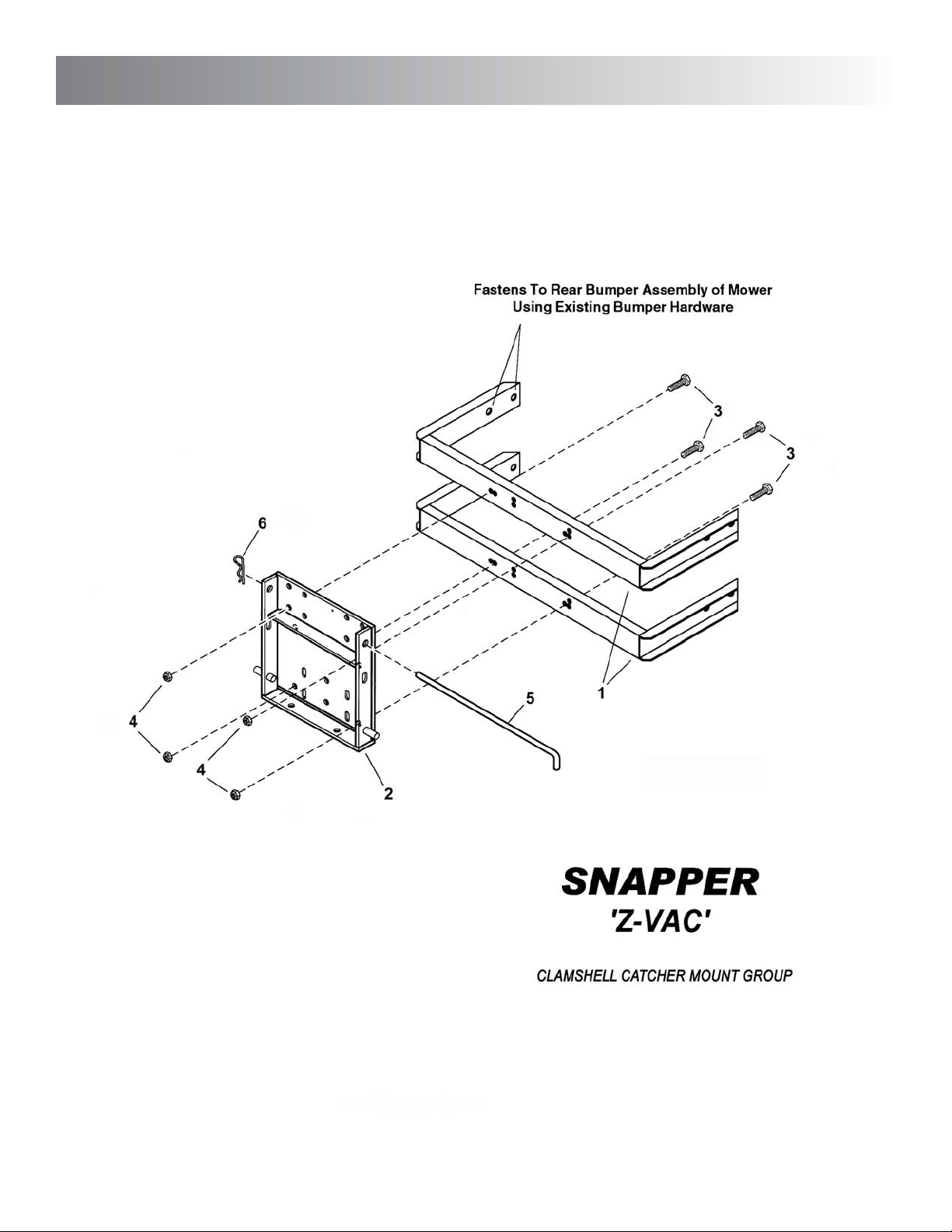

Snapper Z-Vac Clamshell Catcher Mount Group

Item Part No. Qty Description

1 50551 2 STANDOFF, Bumper Mount (weldment)

2 1723436 1 WELDMENT, Bumper Mount Plate

3 91318 4 SCREW, 5/16-18 x 3/4" Hex Head Cap, GR5

4 91601 4 NUT, 5/16-18 Hex Flange Lock, GR5

5 1717085 1 ROD, Hitch

6 15067 1 HAIR PIN, 3/32 x 1-1/2" Cotter

6

19

Page 20

6

unit breakdown & parts list

20

Page 21

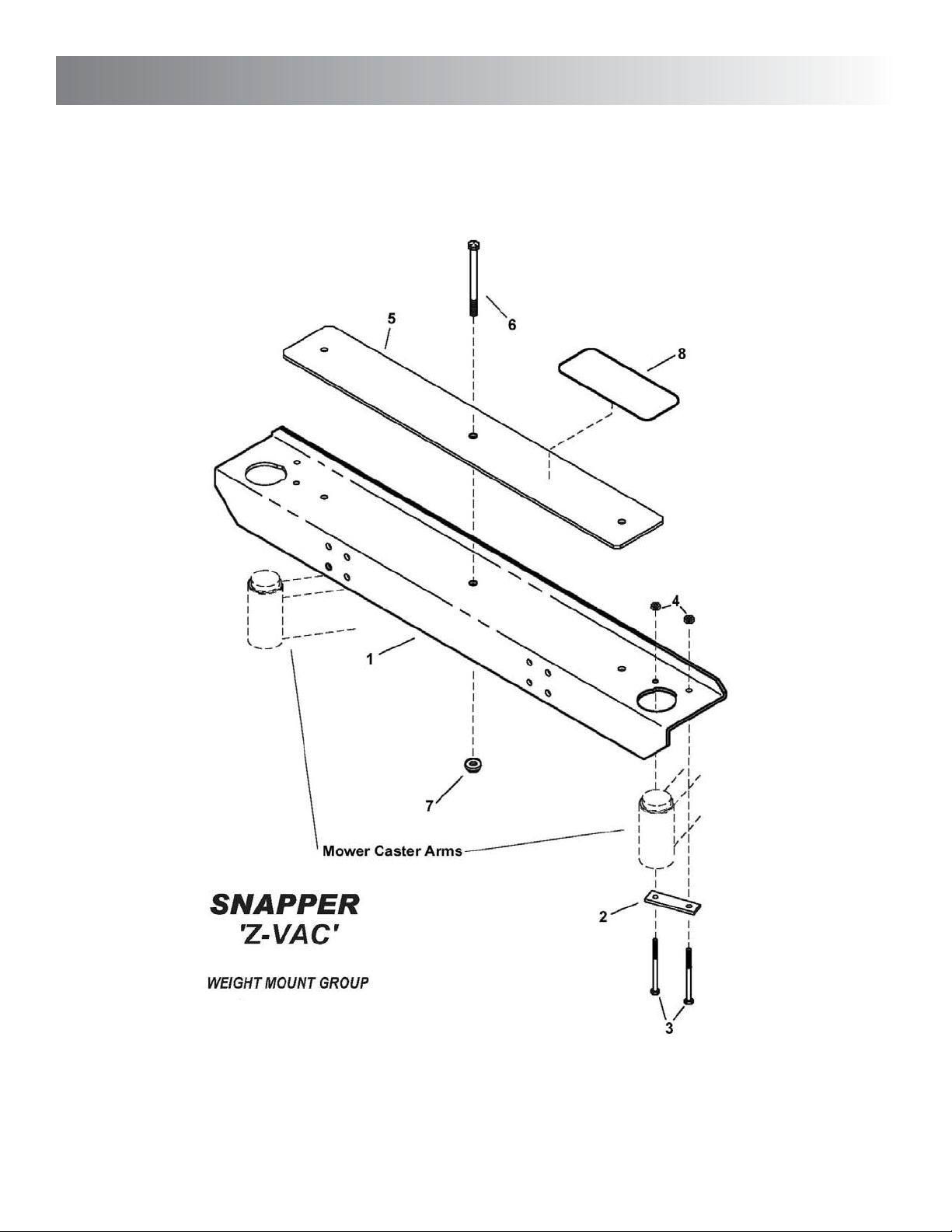

unit breakdown & parts list

Snapper Z-Vac Weight Mount Group

Item Part No. Qty Description

1 3027501 1 CHANNEL, Weight Mounting

2 3046992 2 BAR, Clamp

3 91131 4 BOLT, 3/8-16 x 4" Hex Tap, GR5

4 90546 4 NUT, 3/8-16 Hex Center Lock, GR5 or B

5 3027502 26 BAR, Weight

6 92072 3 SCREW, 1/2-13 x 7-1/2" Hex Head Cap

7 90619 3 NUT, 1/2-13 Hex Flange Lock

8 3032142 2 PAD, Anti-Skid, Self-Adhesive

6

21

Page 22

6

unit breakdown & parts list

22

Page 23

unit breakdown & parts list

Item Part No. Qty Description

1 3079231 1 DECAL, Z-Vac

2 3046850 1 DECAL, Danger, Fast-Vac

3 3046851 1 DECAL, Warning, Fast Vac

4 3046883 1 DECAL, Warning, Fast-Vac

5 73956 1 DECAL, Warning, Billboard (on clamshell unit)

6

Snapper Z-Vac Decal Group

23

Page 24

ASSEMBLY INSTRUCTIONS

OPERATOR'S MANUAL

PARTS LIST

Z

-VAC

Large Clamshell

Grass Catcher Kit

for NZM

Mid Mount

Riders

McDonough, GA 30253 U.S.A.

Manual No. 7100651 (I.R. 4/5/2006)

TP 900-5178-IR-AT-N

Loading...

Loading...