Page 1

Safety Instructions & Operator’s Manual for

21” STEEL DECK

WALK MOWERS

SERIES 12

ELECTRIC START

MODELS

PROPELLED MODELS

P216012E

FRP216012E

NFRP216012E

MODEL NUMBER EXPLANATION

N F R P 21 60 12 E

MODEL DESIGNATION ENGINE OPTIONS

SELF-PROPELLED SERIES DESIGNATION

CUTTING WIDTH ENGINE HORSE POWER

N – California Model F – Flange Deck

R – Recycling Mower P – Self-Propelled Mower

21 – 21” Cutting Width

60 – 6.0 HP (Engine Horse Power)

12 - Series Designation

E -Electric Start

Thank you for buying a SNAPPER Product! Before operating your Walk Behind, read this manual carefully and pay

particular attention to the “IMPORTANT SAFETY INSTRUCTIONS” on Pages 2 & 3. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in accordance

with the operating instructions and common sense.

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 3-5769 (REV. 1, 9/2/99)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerf ul cutting machine is capab le of amputating hand s and feet and can throw objects that

can cause injury and damage! Failure to comply with the follow ing SAFETY instru ctions could resu lt in serious

injury or death to the operator or other persons. The owner of the machine must understand these instructions

and must allow only persons who understand these instructions to operate machine. Each person operating the

machine must be of sound mind and body and must not be under the influence of any substance, which might

impair vision, dexterity or judgment. If you have any questions pertaining to your machine which your dealer

cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough,

Georgia 30253. Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. KEEP children out of the mowing area and

under the watchful care of a responsible adult.

2. DO NOT allow children in yard w hen machine is

operated and turn machine OFF if anyone

enters the area.

3. DO NOT allow pre-teenage children to operate

machine.

4. ALLOW only responsible adults & teenagers

with mature judgment under close adult

supervision to operate machine.

5. DO NOT pull mower backwards unless

absolutely necessary. LOOK and SEE behind

and down for children, pets and hazards before

and while backing.

6. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other object s that may

obscure vision.

SLOPE OPERATION

1. Slopes are a majo r factor related to slip and f all

accidents, which can result in severe injury. All

slopes require extra cau tion. If you feel uneasy

on a slope, DO NOT mow it.

2. Mow across slopes, never up-and-down.

Exercise extreme CAUTION when changing

directions on slopes. DO NOT mow steep

slopes or other areas where stability or traction

is in doubt.

3. Use extra care with crass catchers or other

attachments; these affect the handling and the

stability of the machine.

PREPARATION

1. Read, understand, and follow instructions and

warnings in this manual and on the mower,

engine and attachments. Know the controls and

the proper use of the mower before starting.

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

PREPARATION

(Continued From Previous Column)

3. Dat a indicates t hat operators age 60 an d above,

are involved in a large percentage of mowerrelated injuries. These operators should

evaluate their ability to operate the mower

safely enough to protect themselves and others

from serious injury.

4. Handle fuel wit h ext ra care. Fuels are flammabl e

and vapors are explosive. Use only an approved

fuel container. DO NOT remove fuel cap or add

fuel with engine running. Add fuel outdoors

only with engine stopped and cool. Clean

spilled fuel and oil from machine. DO NOT

smoke.

5. Check the area to be mowed and remove all

objects such as toys, wire, rocks, limbs and

other objects that could cause injury if thrown

by blade or interfere with mo win g. Also note the

location of holes, stumps, and other possible

hazards.

6. Keep people and pets out of the mowing area.

Immediately, STOP Blade, Stop engine and Stop

mower if anyone enters the area.

7. Check shields, deflectors, switches, blade

controls and other safety dev ices frequently for

proper operation and location.

8. Make sure all safety decals are clearly legible.

Replace if damaged.

9. Protect yourself when mow ing and wear safety

glasses, long pants and substantial footwear.

DO NOT mow barefooted or with sandals.

10. Know how to STOP blade and engine quickly in

preparation for emergencies.

11. Use extra care when loading or unloading the

machine into a trailer or truck.

12. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or torn spots.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

OPERATION

1. DO NOT put hands or feet near or under rotating

parts. Keep clear of discharg e area while engine is

running.

2. STOP engine when crossing gravel drives, walks, or

roads, and under any conditions where thrown

objects might be a hazard.

3. Mow only in daylight or good artificial light.

4. DO NOT operate mower while under the influence

of alcohol or drugs.

5. After striking a foreig n object or if mower vibrates

abnormally, STOP the engine, disconnect and

secure spark plug wire. Inspect t he mower for any

damage and repair the damage.

6. DO NOT mow near drop offs, ditches or

embankments. Operator could lose footing or

balance.

7. STAY ALERT for holes and other hidden

hazards. Tall grass can hide obstacles. Keep

away from ditches, washouts, culverts, fences

and protruding objects.

8. DO NOT mow on wet grass. Always be sure of

your footing. Keep a firm hold on the handle

and walk, never run. Slipping could cause

injury.

9. DO NOT leave the machine with the engine

running. STOP BLADE and STOP ENGINE

before leaving the operators position for any

reason.

10. Before cleaning, repairing or inspecting make

certain engine, blade and all moving parts have

STOPPED. Disconnect and secure spark plug

wire away from plug to prevent accidental

starting.

11. STOP engine and wait until the blade comes to

complete STOP before removing grass bag

and/or clearing grass.

12. DO NOT operate mower without the entire grass

catcher or guards in place. DO NOT point

discharge at people, passing cars, windows or

doors.

13. Slow down before turning.

14. Watch out for traffic when near or crossing

roadways.

15. DO NOT operate engine in enclosed areas.

Engine exhaust gases contain carbon

monoxide, a deadly poison.

MAINTENANCE AND STORAGE

1. DO NOT store mower or fuel container inside

where fumes may reach an open flame, spark or

pilot light such as in a water heater, furnace,

clothes dryer or other gas appliance. Allow

engine to cool before storing machine in an

enclosure. Store fuel container out of reach of

children in a well ventilated, unoccupied

building.

2. Keep mower and engi ne free of grass, leaves or

excess grease to reduce fire hazard and engine

overheating.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from

open flame.

4. Keep all bolts, especially blade bolts, nuts and

screws properly tight. Check that all cott er pins

are in proper position.

5. Always provide adequate ventilation when

running engine. Engine exhaust gases contain

carbon monoxide, a deadly poison.

6. Service engine and make adjustments only

when engine is stopped. Removed spark plug

wire from spark p lu g an d secu re w ire away from

spark plug to prevent accidental starting.

7. DO NOT change engine governor speed

settings or overspeed engine.

8. Check grass bag assembly frequently for wear

or deterioration to avoid thrown objects and

exposure to moving parts. Replace with new

bag if loose seams or tears are ev ident. Rep lace

slider or bag adapter if broken or cracked.

9. Mower blades are sharp and can cut. Wrap the

blades or wear heavy leather gloves and use

CAUTION when handling them.

10. DO NOT test for spark by grounding spark plug

next to spark plug hole; spark plug could ignite

gas exiting engine.

11. Have machine serviced by an authorized

SNAPPER dealer at least once a year and have

the dealer install any new safety devices.

12. Use only genuine SNAPPER replacement parts

to assure that original standards are

maintained.

3

Page 4

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS...............................................2&3

TABLE OF CONTENTS............................................................................4

SECTION 1 - FAMILIARIZATION..............................................................5

SECTION 2 - OPERATING INSTRUCTIONS.........................................6-9

Pre-start Checklist ............................................................................................... 6

Starting & Stopping Engine & Blade............................................................... 6-7

Starting & Stopping Wheel Drive ....................................................................... 7

Handle Height Adjustment.................................................................................. 7

Cutting Height Adjustment................................................................................ .8

Recycling Operation............................................................................................ 8

Baffle Adjustment................................................................................................ 8

Installation of Grass Catcher.............................................................................. 9

SECTION 3 - MAINTENANCE INSTRUCTIONS................................10-11

Change Engine Oil............................................................................................. 10

Check Transmission Grease........................................................................10-11

Check Mower Blade........................................................................................... 11

Check Engine Drive Belt ................................................................................... 11

Check Transmission Poly-V Belt...................................................................... 11

Service - Annually.............................................................................................. 11

Engine.............................................................................................................. 11

Air Filter........................................................................................................... 11

Engine Oil........................................................................................................ 11

Storage Procedure............................................................................................. 11

SECTION 4 - ADJUSTMENTS AND REPAIR....................................12-20

Mower Blade Replacement ............................................................................... 12

Blade Sharpening .........................................................................................12-13

Wheel Drive Control Adjustment...................................................................... 13

Driven and Drive Disc Service.......................................................................... 13

Cleaning Drive Disc and Driven Disc............................................................ 14

Drive Spring Repair/Replacement................................................................. 14

Driven Disc Adjustment............................................................................ 14-15

Driven Disc Replacement..........................................................................15-16

Driven Disc Bearing Replacement................................................................ 16

Hex Shaft Bearing Replacement ................................................................... 17

Belt Service ........................................................................................................ 17

Engine Drive Belt Replacement ...............................................................17-18

Transmission Poly-V Belt Replacement....................................................... 18

Battery Service.............................................................................................. 19-20

TROUBLESHOOTING ............................................................................ 21

SERVICE SCHEDULE ............................................................................ 22

WARRANTY............................................................................................ 23

PRIMARY MAINTENANCE................................................................24-27

4

Page 5

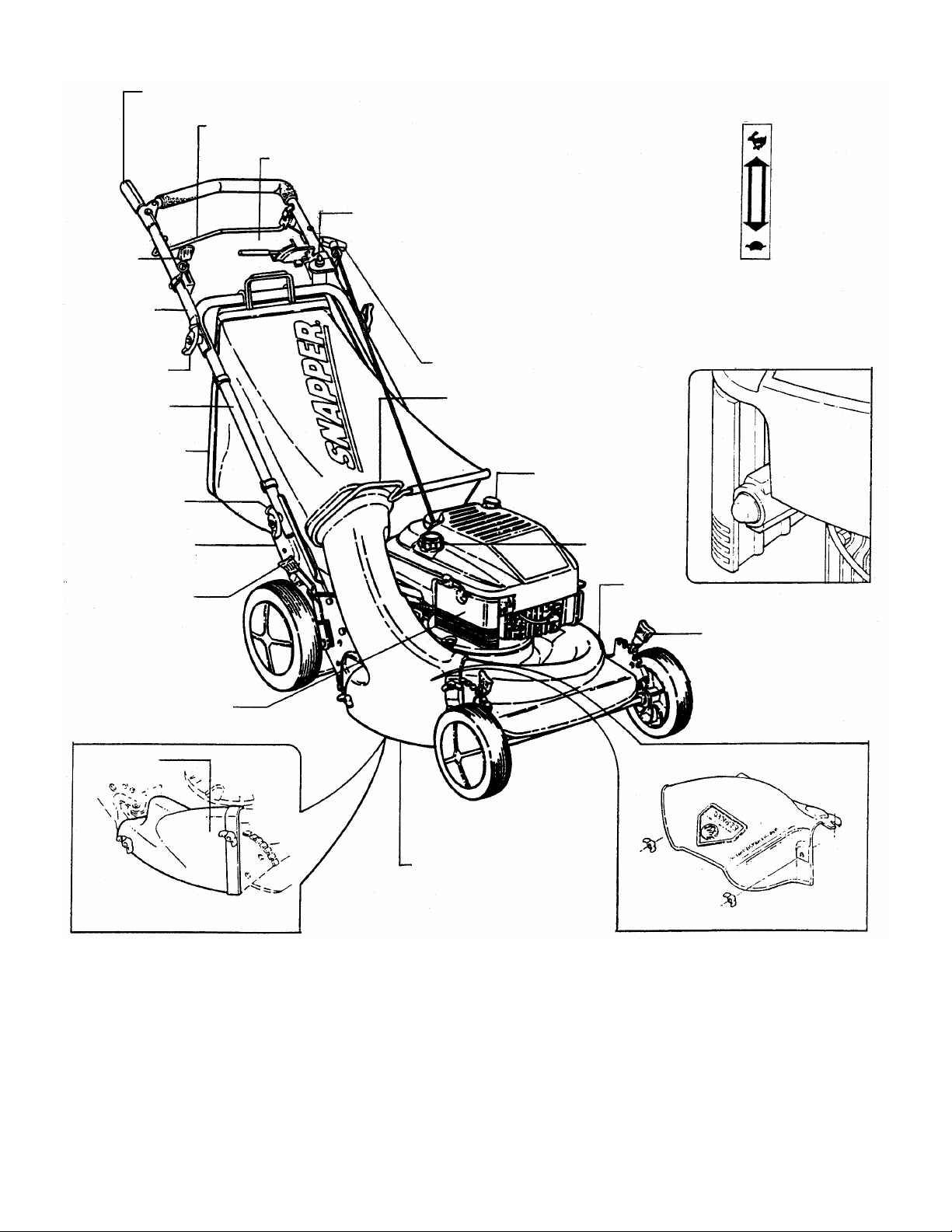

Section 1 - FAMILIARIZATION

BLADE CONTROL

GROUND SPEED CONTROL

FILLER CAP

DECK

OF HANDLE)

WHEEL DRIVE CONTROL

ELECTRIC START SWITCH

ENGINE SPEED CONTROL SYMBOLS

“FAST”

ENGINE

SPEED

CONTROL

UPPER

HANDLE

KNOB

MID

GRASS

BAG

KNOB

LOWER

HANDLE

REAR HEIGHT

ADJUSTMENT LATCH

ENGINE AIR

BREATHER COVER

ROPE START HANDLE

GRASS BAG CONNECTOR

OIL FILL CAP

AND DIPSTICK

“SLOW”

PRIMER

BULB

FUEL

MOWER

FRONT HEIGHT

ADJUSTMENT LATCH

CATCHER MODEL

SHOWN (ROPE START

MOUNTED ON LEFT SIDE

RECYCLING

DECK COVER

1.1 INTRODUCTION

This manual has been prepar ed for the operators of

the SNAPPER WALK BEHIND MOWERS. Its

purpose, aside from recommending operating and

routine service requirements, is to promote safety

through the use of accepted operating practices.

Read, Understand and Follow the “IMPORTANT

SAFETY INSTRUCTIONS” on Pages 2 & 3 of this

manual and all safety messages on the mower and

attachments before operating the mower.

BAG ADAPTOR

FIGURE 1.1

5

SIDE DISCHARGE DETAIL

1.2 NOMENCLATURE

The nomenclature drawing above, Figure 1.1, shows

the essential parts of the SNAPPER WALK BEHIND

MOWERS. It is recommended that all operators of

the mower become thoroughly familiar with the

controls, parts and operation of the mower before

operating. Specific details involving the engine are

found in the separate engine owner’s manual. Study

these manuals befor e operating and keep both handy

for future reference.

Page 6

Section 2 - OPERATING INSTRUCTIONS

SIDE OF HANDLE)

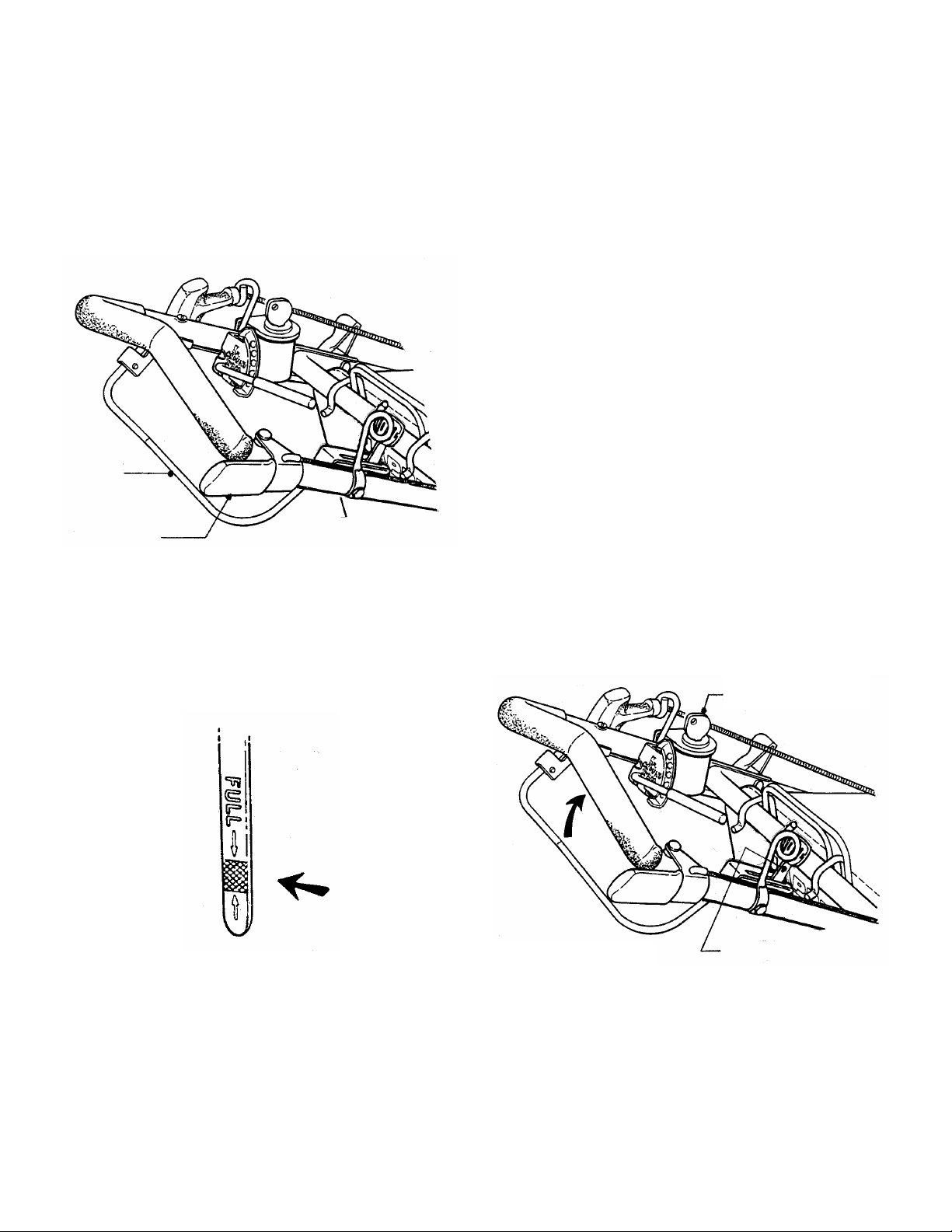

2.1 PRE-START CHECK LIST

Make the following checks and perform the service

required before each start-up.

2.1.1. Check guards, deflectors, grass bag, adapter

and covers to mak e sure all are in place and securely

tightened.

2.1.2. Check blade c ontr ol and wheel drive contr ol to

insure they work freely. See Figure 2.1.

BLADE

CONTROL

WHEEL

DRIVE

CONTROL

CATCHER MODEL

SHOWN (ROPE START

MOUNTED ON LEFT

FIGURE 2.1

2.1.3. Check cutting height. Adjust to desired height.

2.1.4. Check engine oil and add oil as needed to bring

level up to the full mark. Refer to Engine Owner’s

Manual for oil specifications. See Figure 2.2.

2.1.7. Clean exterior surfaces of cutting deck and

engine of any accumulation of spilled fuel, dirt, grass ,

oil, etc. Keep engine air intake screen and cooling

fins clear at all times.

2.2 STARTING & OPERATION

2.2.1. ENGINE & BLADE

(Primer Models) (Electric Start)

When the ignition key (Electric Start Switch) is turned to

“START”, the engine will not crank and will not start

unless the blade control is engaged!

1. Move engine speed control to the “Fast” (Rabbit)

position. See Figure 2.3.

2. Push primer button three times to start a cold

engine. NOTE: Do not use primer button to start

warm engine.

NOTE: Stop the engine (and blade) by releasing the

blade control.

3. Pull blade control against handle.

4. Turn key to the start position until engine starts.

See Figure 2.3.

NOTE: If after 5 seconds of cranking the engine does not

start, release the key and attempt starting again af ter waiting

for approximately 20 seconds.

5. After engine starts, allow a brief warm-up until

engine runs smooth.

TURN KEY SWITCH TO

START POSITION

2.1.5. The battery should be rem oved f r om its carton

and filled with electrolyte. See Section on Battery

Service for battery preparation.

2.1.6. Add fuel to tank after pushing the mower

outside where fumes can saf ely dissipate. Make sure

cap is tightened after refueling. Refer to Engine

Owners Manual for specifications.

FIGURE 2.2

PULL BLADE

CONTROL UP

AGAINST HANDLE

CATCHER MODEL SHOWN

(ROPE START MOUNTED

ON LEFT SIDE OF HANDLE)

ENGINE SPEED

CONTROL (SHOWN

IN FAST POSITION)

FIGURE 2.3

6

Page 7

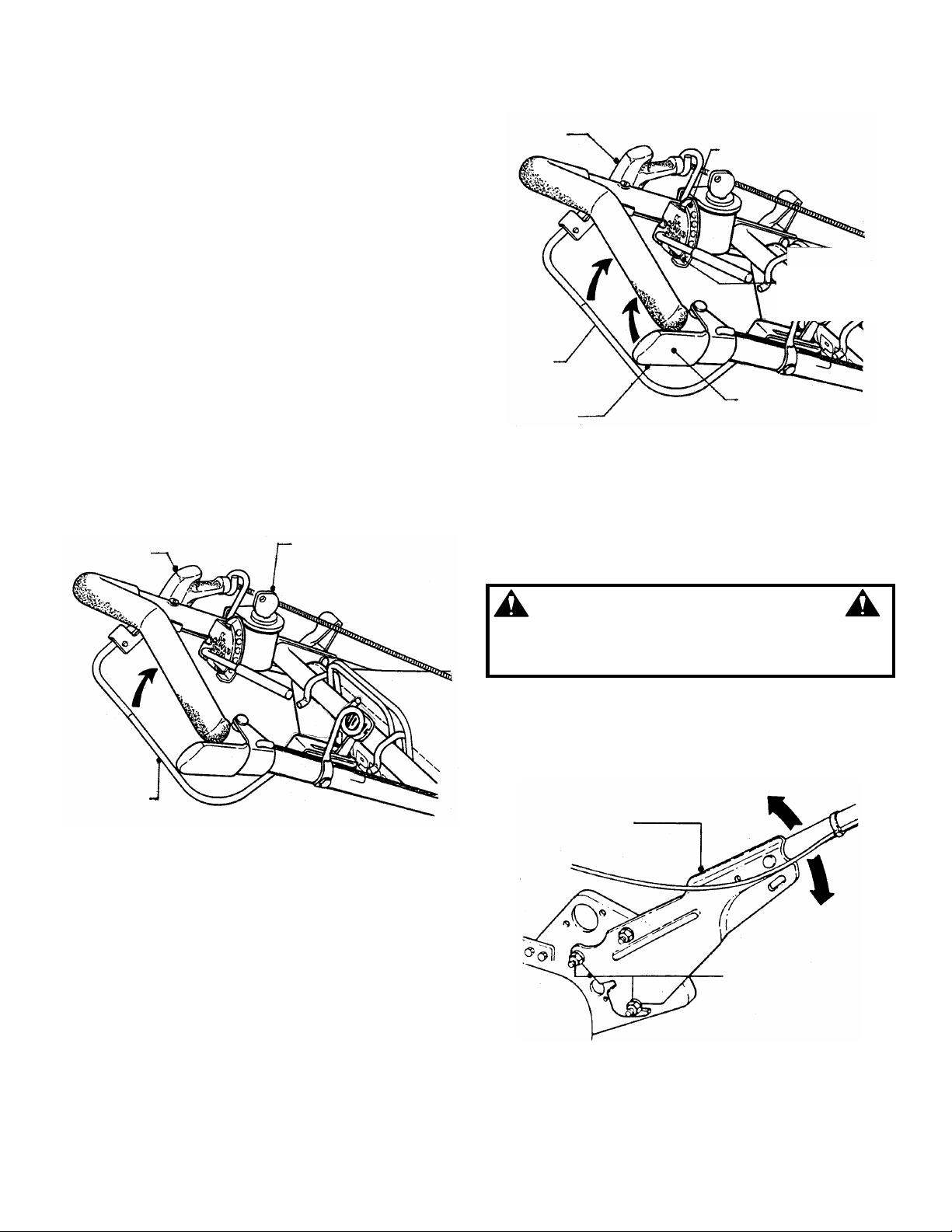

Section 2 - OPERATING INSTRUCTIONS

CONTROL

2.2 STARTING & OPERA TION (Continued)

2.2.2. ENGINE & BLADE

(Primer Models) (Recoil Start)

If the battery is dead or too weak to c rank engine use

the recoil backup. When using the recoil to start the

engine, leave the key switch in the “RUN” position and

pull the blade control up against the handle before

pulling the rope.

1. Move engine speed control to the “Fast” (Rabbit)

position. See Figure 2.4.

2. Push primer button three times to start a cold

engine. NOTE: Do not use primer button to start

warm engine.

NOTE: Stop the engine (and blade) by releasing the

blade control.

3. Pull blade control against handle.

4. Pull rope start handle until engine starts. See

Figure 2.4.

5. After engine starts, allow a brief warm-up until

engine runs smooth.

PULL ROPE START

HANDLE TO START

ENGINE

KEY SWITCH IN RUN

POSITION

MOVE GROUND

SPEED CONTROL

TO DESIRED

POSITION

BLADE

CONTROL

WHEEL

DRIVE

2.3 STOPPING

1. Stop engine and blade by releasing the blade

control. Stop forward motion by releasing the wheel

drive control.

CATCHER MODEL SHOWN (ROPE START

MOUNTED ON LEFT SIDE OF HANDLE)

(FAST) SIX SPEED

POSITION

(SLOW) ONE

SPEED

MOVE CONTROL

AGAINST HANDLE

TO ENGAGE WHEEL

DRIVE

FIGURE 2.5

BLADE

CONTROL

CATCHER MODEL SHOWN

(ROPE START MOUNTED ON

LEFT SIDE OF HANDLE)

FIGURE 2.4

2.2.3. PROPELLING MOWER

(Self Propelled Models)

1. Move ground speed control to the desired s peed

position. See Figure 2.5.

2. Move wheel drive control against handle to

engage wheel drive and propel mower forward.

Forward speed can be adjusted while the mower is

moving by changing position of the ground speed

control. See Figure 2.5.

WARNING

STOP engine and mow er b lade b y releasing the blade

control before adjusting cutting height or handle

height.

2.4 HANDLE HEIGHT ADJUSTMENT

The height of the mo wer handle can be adjusted as

follows:

1. Loosen the lower nuts on each lower handle as

shown in Figure 2.6.

LOWER

HANDLE

FIGURE 2.6

2. Move upper mower handle up or down until the

desired position is achieved.

3. Tighten the lower nuts on each lower handle to

maintain desired position.

7

HIGHER

LOWER

LOOSEN LOWER

NUTS ON EACH

LOWER HANDLE

Page 8

Section 2 - OPERATING INSTRUCTIONS

HEIGHT

1

POSITIONS

NUTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

2.5 CUTTING HEIGHT ADJUSTMENT

1. Pull the height adjusting latch outward and move

to desired cutting height. See Figure 2.7.

LOWEST

CUTTING

FIGURE 2.7

2. Set all wheels at the same cutting height. The

highest cutting position is Notch 6. The lowest

cutting position is Notch 1. See Figure 2.8.

LATCH

HIGHEST

CUTTING

HEIGHT

6

2. Move engine speed control to “FAST” (Rabbit)

position.

3. Move ground speed control to slowest speed

setting.

4. Proceed mowing slowly. If grass is very dense,

lower each rear wheel latch one notch lower than the

front wheel latches to improve recycling performance.

2.7 ADJUSTING FRONT DECK BAFFLE

(Models with an “F” prefix in model number)

(Example: F

The front of the cutting deck on these m odels has

been cut out. This allows the blade to have more

direct contact with the grass and allows more air

flow into deck chamber. The adjustable baffle

should be secured in the lowest position when using

a grass bag. The baffle should be secured in the

highest position when mulching grass. NOTE: Under

certain conditions, when mulching, some grass may

blow out from under front of baffle. This is normal but,

the amount of grass blowing out can be reduced.

Lower baffle down slightly until the smallest amount of

grass blow out is present.

1. Stop engine.

2. Loosen wing nuts that secure front deck baffle.

See Figure 2.9.

3. Lower the adjustable baffle to the lowest position

when using a grass bag. Raise the baffle to its

highest position when mulching grass. Take care to

keep the baffle’s lower edge par allel to the bottom of

the deck. See Figure 2.9.

4. Retighten wing nuts securely.

RP216012)

LATCH

CUTTING HEIGHT SETTINGS

FIGURE 2.8

2.6 RECYCLING OPERATION

NOTE: For best recycling results, cut up to a m axim um of

1/3 of grass blade length and recycle ONLY when grass is

dry.

1. Set all wheels in the highest cutting position

(Notch 6).

HOLE DESIGNATES TOP

OF BAFFLE (ALWAYS

KEEP HOLE IN UP

POSITION)

FRONT DECK

BAFFLE (SHOWN

IN HIGHEST

POSITION)

FRONT CUTOUT OF DECK

8

FRONT

DECK

BAFFLE

WING

MOVE BAFFLE UP

FOR MULCHING

GRASS

MOVE BAFLE DOWN

FOR GRASS

BAGGING

FIGURE 2.9

Page 9

Section 2 - OPERATING INSTRUCTIONS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

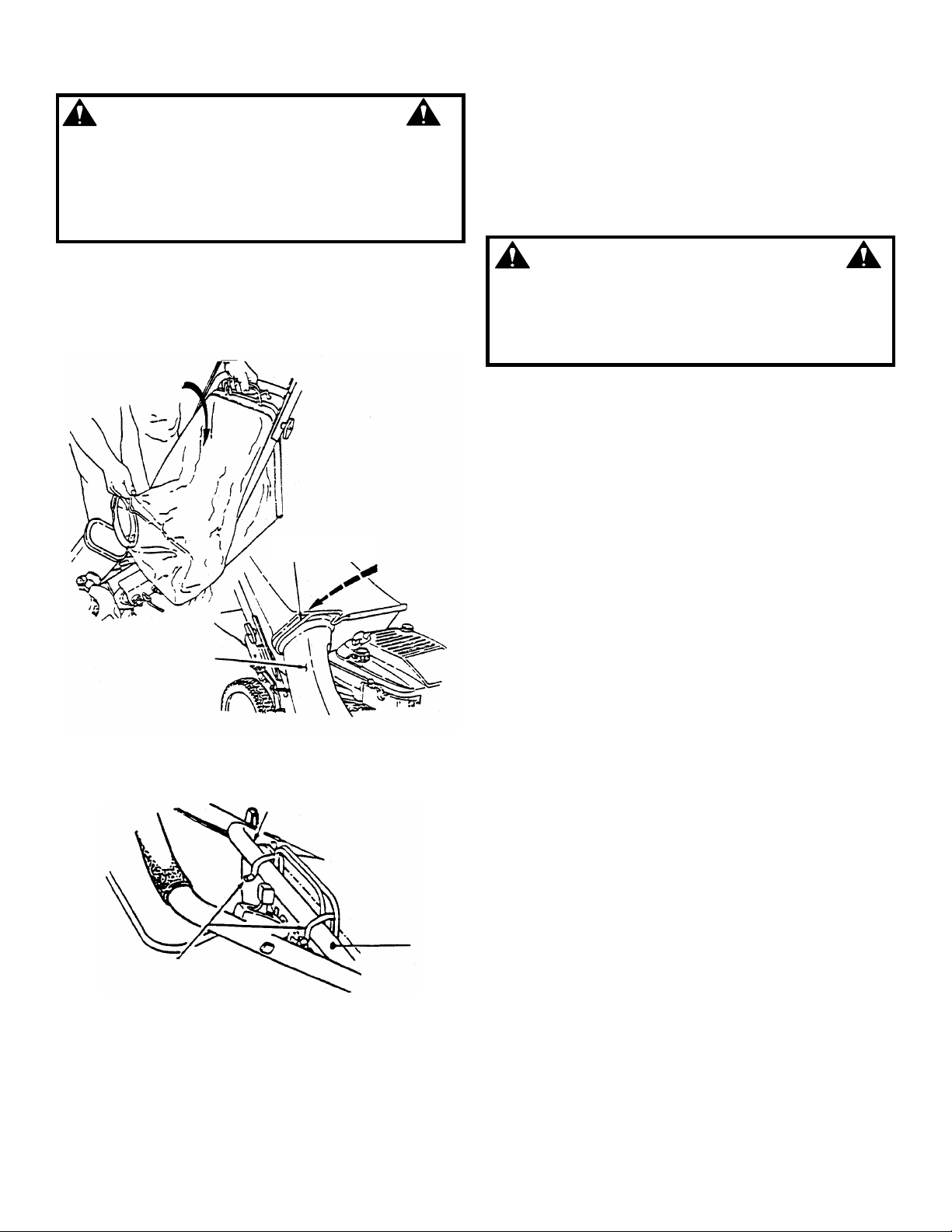

2.8 INSTALLATION of GRASS CATCHER

Install grass catcher by sliding connector over f lange

of adapter. See Figure 2.10. Attach grass bag hook s

over middle handle cross bar. See Figure 2.11.

POSITION BAG

BAG ADAPTER

ATTACH BAG HOOKS

OVER MIDDLE

HANDLE CROSS BAR

CONNECTOR

FIGURE 2.10

MIDDLE HANDLE

CROSS BAR

FIGURE 2.11

SLIDE CONNECTOR DOWN

OVER BAG ADAPTER

FLANGE

MIDDLE

HANDLE

CROSS BAR

DO NOT operate without entire Grass Catcher or

guard in place. Grass Catcher components are

subject to deterioration during normal use. Inspect

frequently and replace worn or damaged components

immediately.

9

WARNING

Page 10

Section 3 - MAINTENANCE

3.1 INTRODUCTION

To retain the quality of the mower, use genuine

SNAPPER replacement parts only. Contact a local

SNAPPER dealer for parts and service assistance.

For the correct part or information for a particular

mower, always mention model and serial number.

3.2 SERVICE - AFTER FIRST 5 HOURS

3.2.1. CHANGE ENGINE OIL

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

1. Refer to Engine Manual for proper oil

specifications and procedures.

2. For simplest/cleanest oil change, loosen lower

handle wing nuts and stand mower up on lower

handle as shown in Figure 3.1. Drain oil through

dipstick tube into a container.

FIGURE 3.1

3.2.2. CHECK GREASE LEVEL IN TRANSMISSION

1. Remove transmission fill plug. Roll machine

forward or backward while looking down into plug

hole.

2. If liquid

(the small gear below the plug hole), add an

amount, to cover gear, of Snapper “ 00” grease. See

Figure 3.2.

FILL PLUG

NOTE: Snapper “00” Grease (Part No. 2-9443) is available

at your SNAPPER dealer.

grease IS NOT visible on the input gear

FIGURE 3.2

(Continued on Next Page)

10

Page 11

Section 3 - MAINTENANCE

3.2.2. CHECK GREA SE LEVEL IN TRANSMISSION

NOTE: Do not spill gr ease or oil on s urface of drive

disc. See Figure 3.3.

3. Reinstall transmission plug.

4. Check grease level after each 25 hours of

operation.

KEEP DRIVE DISC CLEAN !

3.2.4 CHECK ENGINE DRIVE BELT

1. Visually check engine drive belt for cracking,

fraying, severed or belt strands exposed. If worn or

damaged, replace belt before operating mower.

3.2.5 CHECK TRANSMISSION POLY-V BELT

1. Visually check poly-v belt for cracking, fraying,

severed or belt strands exposed. If worn or damaged,

replace belt before operating mower.

RECOMMENDED BLADE

RETAINING CAP SCREW

TORQUE VALUE SHOULD

BE 30 TO 40 FT. LBS.

FIGURE 3.3

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for

all components to cool. Wear heavy leather gloves

when handling or working around cutting blades.

Blades are extremely sharp and can cause severe

injury.

IMPORTANT: DO NOT tip machine with carburetor or

spark plug down. Oil f rom crankcase will saturate the air

filter and cause the engine to be hard to start or not start

at all. If contamination does occ ur, the air f ilter will have to

be replaced.

3.2.3 CHECK MOWER BLADE

1. Disconnect spark plug wire and secure end away

from plug.

2. Tilt mower up on its rear wheels for access to

the blade cap screw. Do not tilt mower with spark

plug or carburetor down. See Figure 3.4.

3. Check torque of blade retaining cap screw.

Recommended torque should be 30 to 40 ft. lbs.

See Figure 3.4.

4. Check blade for sharpness, wear and damage.

Refer to Section “Blade Wear Limits”.

FIGURE 3.4

3.3 SERVICE - ANNUALLY

Perform all maintenance as described in the “Service

Schedule” section of this manual.

3.3.1. Engine

Service engine according to engine owner’s manual.

3.3.2. Air Filter

Refer to engine owner’s manual for service instructions.

3.3.3. Engine Oil

Refer to engine owner’s manual for service

instructions.

3.4 STORAGE PROCEDURE

Refer to the Engine Owner’s Manual for directions

regarding engine storage preparations. Prepare the

mower for “end of season” storage as follows:

1. Drain fuel from f uel tank and let engine run until

all fuel is out of the carburetor.

2. Disconnect and remove the spark plug wire

away from spark plug before any other

preparations are made!

3. Tape all openings closed to prevent spraying

water into exhaust or air intakes during washing.

4. Tilt m ower up on its rear wheels and thoroughly

clean the underside of the deck . Do not tilt mower

with spark plug or carburetor down. Scrape away

any accumulation of grass with a putty knife and or

wire brush.

5. Lubricate all exposed metal with a light coating

of oil to prevent corrosion.

6. On self-propelled models, loosen wing nuts on

ground speed control rod before folding handles.

7. Loos en handle knobs. Car efully fold the handles

forward, “flexing” the c ontro l cables to pr event cable

damage.

8. Store the mower in a shed or other dry area,

protected from weather.

11

Page 12

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool. Wear heavy leather gloves when

handling or working around cutting blades. Blades

are extremely sharp and can cause severe injury.

4.1 MOWER BLADE REPAIR/REPLACEMENT

4.1.1. STANDARD BLADE WEAR LIMIT

1. Inspect blade frequently for signs of excessive wear

or damage. See Figure 4.1.

NEW

BLADE

WEAR

LIMIT

DANGEROUS ! DO NOT USE A

BLADE IN THIS CONDITION !

FIGURE 4.1

4.1.1A. NINJA BLADE WEAR LIMIT

1A. Inspec t blade frequently for signs of excessive

wear or damage. See Figure 4.2.

NEW

BLADE

NOTCH OR CRACK

IN TIP - REPLACE

BLADE

DEEP NOTCH

IN TIP

WEAR LIMIT

CRACKS OR

NOTCHES BEGIN TO

APPEAR ON TIP

2. Replace the blade if it is badly chipped, bent,

noticeably out of balance or has cracks or notch in

either tip. See Figure 4.1. Replace with new blade.

DO NOT use a cutting blade that shows signs of

excessive wear or damage. Refer to Section

“MOWER BLADE REPLACEMENT” for proper blade

inspection and service procedures.

4.1.2. BLADE SHARPENING

1. Dis connect spark plug wire and secure end away

from plug.

IMPORTANT: DO NOT tip machine with carburetor or

spark plug down. Oil from crankcase will saturate the air

filter and cause the engine to be hard to start or not start at

all. If contamination does occ ur, the air f ilter will have to be

replaced.

2. Tilt mower up on its rear wheels. Do not tilt

mower with spark plug or carburetor down.

3. Remove blade. See Figure 4.3.

WARNING

BLADE HUB

FLANGE

BLADE

CONE WASHER

(Concave Side Up)

MAKE SURE THAT

BLADE HUB IS

SEATED BETWEEN

FLANGES

CAPSCREW

FIGURE 4.3

REPLACE

BLADE

DANGEROUS ! DO

NOT USE A BLADE IN

THIS CONDITION !

FIGURE 4.2

12

Page 13

Section 4 - REPAIR & ADJUSTMENTS

VINYL SPRING COVER

CABLE

CLUTCH CABLE EYE

BLADE TIP

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

4. Sharpen blade on a grinding wheel at an angle of

22 to 28 degrees. DO NOT sharpen blade beyond

original cutting edge. See Figure 4.4.

DO NOT SHARPEN

BEYOND ORIGINAL

CUTTING EDGE

END VIEW OF

BLADE ASSEMBLY

ORIGINAL CUTTING EDGE

FIGURE 4.4

5. Check blade for balance. If necessary, correct

balance by grinding heavy end of blade.

6. Reinstall blade. See Figure 4.1. Check torque of

blade retaining cap screw. Recommended torque

should be 30 to 40 ft. lbs.

NOTE: The following sections 4.2 through

4.4 are for self-propelled models.

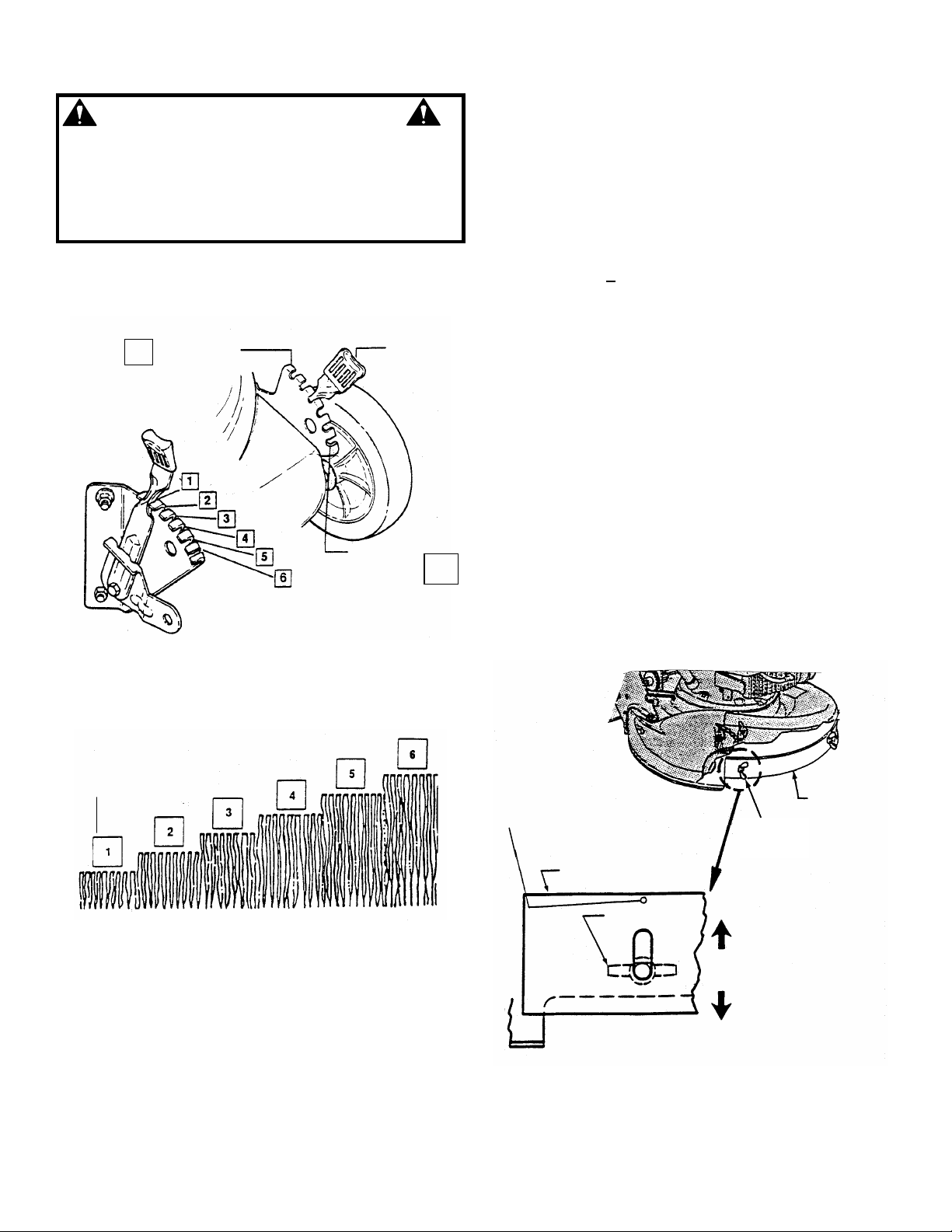

4.2 WHEEL DRIVE CONTROL ADJUSTMENT

1. The wheel drive control is properly adjusted when

there is 1/16” to 1/8” clearance between the inside of

the spring hook and the inside of the clutch cable

eye with the wheel drive control released. See

Figure 4.5.

CLUTCH CABLE

1/16” TO 1/8”

UPPER

SPRING

LOWER

SPRING

CLUTCH CABLE

EYE

SPRING HOOK

FIGURE 4.5

2. To adjust, unhook upper spring from cable eye

and rotate spring in direction required to extend

or shorten spring length.

3. Rehook upper spring to cable eye and check

clearance. Repeat procedure if required.

NOTE: The vinyl spring cover should be kept over the

spring at all times except for adjustments.

4. If the wheel drive control fails to return quick ly to

the “OFF” position when released, check for binding

at the cable holdings located on the side of the right

handle. The upper clip should be loc ated 2” below

the upper knob; the lower clip should be 4” above

the lower knob. The cable should slide freely with

the clips installed at these locations.

13

Page 14

Section 4 - REPAIR & ADJUSTMENTS

FIRST

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

4.3 DRIVEN DISC SERVICE

If the mower does not propel itself properly, See

Figure 4.6. Check for the following problems:

DRIVEN DISC &

RUBBER RING

DRIVE

SPRING

POLY-V-BELT

USE NEEDLE

NOSE PLIERS

TO INSTALL

DRIVE SPRING

DRIVE

SPRING

ENGINE

DRIVE BELT

FIGURE 4.6

1. Grease on drive disc causing slippage.

2. Broken or disconnected drive spring.

3. Driven disc is out of adjustment.

4. Driven disc rubber ring is worn - does not contact

drive disc properly.

5. Worn Poly-V Belt or engine drive belt.

NOTE: If any of the above (1 thru 5) are causing

problems, service as follows:

4.3.1. Cleaning Drive Disc & Driven Disc.

If oil or grease on the drive disc or driven disc is

causing slippage, clean discs as follows:

1. Wipe away any oil or grease with a clean cloth.

2. Use either an approved grease solvent or hot,

soapy water to clean drive disc or driven disc.

3. Rinse components with clean water.

4. Dry components with a clean cloth.

4.3.2. Drive Spring Repair/Replacement

If drive spring is loose, reconnect as shown in Figure

4.7. If spring is broken, replace with new spring.

IMPORTANT: If machine drive system continues

slipping see Trouble Shooting section.

FIGURE 4.7

4.3.3. DRIVEN DISC ADJUSTMENT

If the drive disc and driven disc are clean and the

mower drive is still slipping, adj ust the driven dis c as

follows:

1. Place shift rod in the sixth speed position. See

Figure 4.8.

MOVE GROUND

SPEED CONTROL

TO SIXTH SPEED

POSITION

SIXTH

FIRST SPEED

POSITION

FIGURE 4.8

14

Page 15

Section 4 - REPAIR & ADJUSTMENTS

EDGE

EDGE

SPRING

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for

all components to cool.

4.3.3. DRIVEN DISC ADJUSTMENT

(Continued From Previous Page)

2. Remove driven disc spring from driven disc

assembly. Loosen connector hex nut. See Figure 4.9.

SLIDE DRIVEN DISC

ASSEMBLY

TOWARD OUTSIDE

TRANSFER

ROD

1/8” MEASUREMENT TO

OUTSIDE EDGE OF DRIVE DISC

DRIVE

DISC

DRIVEN DISC ASSEMBLY

DRIVEN

DISC

TRANSFER

ROD

CONNECTOR

CONNECTOR

HEX NUT

FIGURE 4.9

3. Slide driven disc assembly over to 1/8” from outside

edge of drive disc. Maintaining the 1/8” measurem ent,

remove any looseness from the linkage. This can be

done by holding the transfer rod and applying pressure

to the left (as viewed from operators position). Then

retighten the connector hex nut secur ely. See Figure

4.10. Move ground speed control to the first speed

position, then back to the sixth speed position.

Recheck the 1/8” meas urement described previously.

Reinstall driven disc spring to driven disc assembly.

DRIVE DISC

CONNECTOR HEX NUT

CONNECTOR

OUTSIDE

FIGURE 4.10

4.3.4. Replacing Driven Disc Rubber Ring

If the rubber r ing is badly chunked or worn down to

within 1/16” of the metal rim of the driven disc hub,

it must be replaced. Install new rubber ring as

follows:

1. Using a small flat blade screwdriver, free the clip

from the transf er rod. Then rem ove the transfer r od

from the clip and the speed control rod. See Figure

4.11.

CONNECTOR

CLIP

TRANSFER ROD

SPEED

CONTROL

ROD

FIGURE 4.11

15

Page 16

Section 4 - REPAIR & ADJUSTMENTS

PLATE

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for

all components to cool.

4.3.4. Replacing Driven Disc Rubber Ring

(Continued From Previous Page)

2. Using needle nose pliers, unhook the drive

spring and slide the driven disc assembly off the hex

shaft. See Figure 4.12.

3. Remove the five machine screws and plate

which secure the rubber ring to the driven disc hub.

See Figure 4.13.

4. Install new rubber ring.

5. Reverse above procedures for reassembly and

installation.

DRIVEN DISC

ASSEMBLY

FIGURE 4.12

DRIVEN DISC HUB

MACHINE

SCREWS

RUBBER

RING

PLATE

FIGURE 4.13

4.3.5. Replacing Bearing In Driven Disc Assembly

If the driven disc bearing fails, remove the driven

disc assembly and replace bearing as follows:

1. Remove snap ring. See Figure 4.14.

THRUST PLATE

BEARING

REMOVE FOUR

MACHINE SCREWS

DRIVEN

DISC

2. Slide the hub assembly out of the bearing.

3. Remove the four screws.

4. Remove bearing and replace with new bearing.

5. Reassemble components in reverse order.

FIGURE 4.14

SNAP

RING

SHIM

WASHER

DRIVEN DISC

HUB

RUBBER DISC

16

Page 17

Section 4 - REPAIR & ADJUSTMENTS

RING

HOLDER

IDLER ARM

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

4.3.6. Replacement Of Bearing On Pulley End Of Hex

Shaft

To replace the bearing on the pulley end of the hex

shaft, proceed as follows:

1. Hold the hex shaft with an adjustable wrench

held next to the pulley.

2. Remove the 3/8” hex lock nut which is loc ated on

the outside of the right wheel bracket. See Figure

4.15.

3. Remove holder, O-ring and bearing.

4. Install new bearing.

5. Carefully install new O-ring over the outside of the

new bearing.

6. Install bearing holder and secure with screws.

7. Install 3/8” hex lock nut.

4.4. BELT SERVICE

On these mowers, the engine belt transmits power

from engine to drive disc. The drive disc powers the

poly-v belt which engages the transmission that powers

the rear wheels. Should these belts become worn, they

could cause slippage which would impair mower

performance. The condition of the engine belt and polyv belt should be checked after every 25 hours of mower

operation.

4.4.1. Engine Drive Belt Replacement

1. Empty the fuel tank.

2. Unhook the idler spring from the right rear wheel

bracket. See Figures 4.16.

RIGHT REAR

WHEEL BRACKET

SLOT IN

DECK

IDLER

SPRING

DRIVE DISC

DRIVE BELT

ENGINE DRIVE PULLEY

TOP VIEW OF ENGINE BELT ROUTING

BALL BEARING

“O”

IMPORTANT: DO NOT tip machine with carburetor or

FIGURE 4.16

spark plug down. Oil from crankcase will saturate the air

filter and cause the engine to be hard to start or not start at

3/8”

LOCK

NUT

BALL

BEARING

FIGURE 4.15

all. If contamination does occ ur, the air f ilter will have to be

replaced.

3. Remove the driven disc. Refer to Section

“Replacing Driven Disc Rubber Ring” for driven disc

removal procedure.

4. Do not tilt mower with spark plug or car buretor down.

Tilt mower up on its rear wheels and rem ove blade and

blade hub. Assistance from another person may be

necessary to hold mower in the tilted position.

(Continued On Next Page)

17

Page 18

Section 4 - REPAIR & ADJUSTMENTS

BRACKET

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

4.4.1. Engine Drive Belt Replacement

(Continued from Previous Page)

RIGHT

WHEEL

BRACKET

IDLER

SPRING

DRIVE

DISC

SLOT IN END

OF DRIVE

DISC BOLT

BUSHING

IDLER

ARM

IDLER

SPRING

DECK BRACKET

(PARTIALLY

SHOWN)

POSITION

SCRAPER TO

CLEAR “V” OF

BOLT

RETAINER

INTERNAL TOOTH

LOCKWASHER

NUT

FIGURE 4.17

5. Hold the slotted end of the drive disc bolt with a

screwdriver and rem ove the nut and internal tooth lock

washer. See Figure 4.17.

6. Lift the drive disc off the idler arm and rem ove worn

belt.

7. Loop one end of new belt over engine pulley and

insert the other end through slot in deck. See Figure

4.17.

8. Loop the belt around the pulley on the bottom of the

drive disc.

9. Reinstall drive disc and retaining hardware.

10. Reinstall blade hub and cutter blade. Recom-

mended torque for blade cap screw is 30 to 40 ft. lbs.

11. Use a stiff wire, such as a coat hanger, with a hook

fashioned on one end to pull the hooked end of the idler

spring through the large hole in the right wheel brack et.

See Figure 4.18.

12. Reinstall the driven disc assembly.

PULL SPRING

THROUGH LARGE

HOLE & HOOK

INTO SMALL HOLE

FIGURE 4.18

4.4.2. Transmission Poly-V Belt Replacement

1. Remove the driven disc. Refer to Section

“Replacing Driven Disc Rubber Ring” for procedure.

2. Note the routing of the old belt around the three

pulleys before removing it. See Figure 4.19.

3. Place new Poly-V Belt over end of hex shaft and

onto driven pulley.

4. Work belt onto top of idler pulley.

5. Twist belt sideways and pull it upward between

the differential bracket and drive pulley and then

down into the pulley groove. Make sure the Poly-V

Belt is above belt guide. See Figure 4.19.

IDLER

PULLEY

DRIVE

PULLEY

HEX

SHAFT

BELT

GUIDE

ROUTING OF POLY-V BELT

DIFFERENTIAL

POLY-V

BELT

DRIVEN

PULLEY

FIGURE 4.19

18

Page 19

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

4.5. BATTERY SERVICE

4.5.1. NEW BATTERY PREPARATION

1. Remove battery from carton.

2. Place battery in a well ventilated area on a level

non-concrete surface.

3. Remove battery cell caps. Fill cells as required

with electrolyte (purchased separately) to proper

level. Fill to 3/16” above cell plates. Filling battery

with electrolyte will bring the battery to 80% charged

state.

4. With cell caps r emoved, connect battery charger

to battery terminals; RED to positive (+) and BLACK

to negative (-) terminal.

IMPORTANT: 3/16” above cell plates is the

recommended level. Never place anything in battery

other than specified electrolyte.

5. Slow charge the battery at 1 amp f or 2 hours to

bring the battery to full charge.

6. After charging, check level of electrolyte and add

as needed to bring level to 3/16” above cell plates.

7. Reinstall cell caps.

8. Install battery into power unit.

9. Connect positive (+) cable (red) firs t, from wiring

harness to the positive terminal ( +) on battery using

bolt and nut provided in hardware bag. Connect

negative (-) cable (black) last, to negative terminal () on battery using bolt and nut. Apply a small

amount of grease over terminals to prevent

corrosion.

WARNING

DO NOT over fill battery w ith electrolyte. Shield the

positive terminal with terminal cover located on

battery harness. This prevents metal from touching

the positive terminal w hich could cause sparks. The

electrolyte (acid) produces a highly explosive gas.

Keep all sparks, flame and fire away from area w hen

charging battery or when handling electrolyte or

battery. Electrolyte (acid) is a highly corrosive liquid.

Wear eye protection. Wash affected areas

immediately after having eye or skin contact with

electrolyte (acid). Battery acid is corrosive. Rinse

empty acid containers with water and mutilate before

discarding. If acid is spilled on battery, bench, or

clothing, etc., Flush with clear water and neutralize

with baking so da. DO NOT attempt to charg e battery

while installed on the walk behind. DO NOT use

“BOOST” chargers on the battery.

19

4.5.2. BATTERY SERVICE

1. Remove battery.

2. Place battery in a well ventilated area on a level

surface.

3. Using distilled water, refill cells as required to

cover cell plates of which can also be visualized

through the plastic battery case.

4. W ith cell caps removed, connect battery charger

to battery terminals. Red to positive (+) terminal and

black to negative (-) terminal.

5. Slow charge battery at 1 amp for 10 hours.

6. If battery will not accept charge or is partially

charged after 10 hours of charging at 1 amp,

replace with new battery.

4.5.3. BATTERY STORAGE

If W alk Behind is to be stored out of season on its

rear bumper, it is recommended the battery be

removed, charged and stored.

1. Remove battery.

2. Perform battery service.

3. Bring battery to full charge, if required.

4. Store battery in an area away from the Walk

Behind on a wood surface. DO NOT STORE

BATTERY ON A CONCRETE SURFACE.

4.5.4. BATTERY TESTING

There are two types of battery tests: Unloaded and

Loaded. The unloaded test is the procedure that will

be discussed. It’s the sim plest and most commonly

used. An unloaded test is m ade on a battery without

discharging current. To perform unloaded testing,

check charge condition us ing either a hydrometer or

voltmeter.

1. Using a voltmeter, voltage readings appear

instantly to show the state of charge. Remember to

hook the positive lead to the battery’s positive

terminal, and the negative lead to the negative

terminal.

2. A hydrometer measures the specific gravity of

each cell. The specific gravity tells the degree of

charge; generally, a specific gravity of about 1.265

to 1.280 indicates full charge. A reading of 1.230 to

1.260 indicates the battery should be charged. The

chart on the next page shows the charge level as

measured by syringe float hydrometer, digital

voltmeter and five ball hydrometer.

Page 20

Section 4 - REPAIR & ADJUSTMENTS

Battery Condit

ion Chart

4.5.4. BATTERY TESTING

State of Charge Syringe Hydrometer Digital Voltmeter Five Ball Hydrometer

100% Charged w/ Sulfate Stop 1.280 12.80v Five Balls Floating

100% Charged 1.265 12.60v Four Balls Floating

75% Charged 1.210 12.40v Three Balls Floating

50% Charged 1.160 12.10v Two Balls Floating

25% Charged 1.120 11.90v One Ball Floating

0% Charged Less than 1.100 Less than 11.80v Zero Balls Floating

20

Page 21

TROUBLESHOOTING

Mower Will Not Move

SNAPPER

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Engine Will Not Start 1. Battery is dead. 1. Charge or replace battery.

Using Electric Starter 2. Wiring harness to battery disconnected. 2. Connect wiring harness and tighten securely.

3. Spark plug wire disconnected. 3. Place spark plug wire onto spark plug.

Engine Will Not Start 1. Fuel tank empty. 1. Fill fuel tank with fresh fuel.

Using Recoil Starter 2. Engine needs choking or priming. 2. Choke/Prime engine. Check Engine Manual for

3. Spark plug wire disconnected. 3. Place spark plug wire onto spark plug.

4. Key switch is not in the “RUN” pos ition. 4. Turn key switch to the “RUN” position.

Engine Stalls or Stops

After Running

2. Fuel tank empty. 2. Fill with fuel to proper level.

3. Engine air pre-cleaner and or air cleaner dirty. 3. Clean free of all debris.

4. Spark plug defective or gap set improperly. 4. Service spark plug.

5. Water, debris or stale fuel in fuel system. 5. Drain and clean fuel system.

Engine Loses Power 1. Engine air pre-cleaner or air cleaner dirty 1. Clean or replace filters.

2. Spark plug faulty. 2. Service spark plug.

3. Water, debris or stale fuel in fuel system. 3. Drain and clean fuel system.

Excessive Vibration 1. Damaged, out of balance or bent mower blade. 1. Service mower blade.

2. Loose blade components. 2. Service and tighten loose parts.

3. Loose or missing air lift (if equipped). 3. Replace air lifts. Tighten to proper torque.

4. Lumpy or frayed belt. 4. Replace belt.

5. Bent Idler pulley. 5. Replace pulley.

Loss Of Traction

(Self-Propelled Models)

Cutting Grass

Improperly

Poor Grass Discharge

Oil Leaking

1. Blade control is released or is not being held

securely against handle.

1. Damaged transmission.

2. Traction drive belt requires replacement. 2. Replace traction drive belt.

3. Driven disc slipping. 3. Clean or replace driven disc.

1. Cutting height too low or high. 1. Adjust cutting height.

2. Engine speed too slow. 2. Move engine speed control to “FAST” position.

3. Forward ground speed too fast. 3. Move ground speed control to a slower speed.

4. Terraced cut, side to side. 4. Adjust height of cut with height adjust levers.

5. Excessive deck pitch, front to rear. 5. Adjust height of cut with height adjust levers.

6. Cutting blade dull or damaged. 6. Sharpen cutting edges or replace blade.

1. Engine speed too slow. 1. Move engine speed control to “FAST” position.

2. Forward speed too fast. 2. Move ground speed control to a slower speed.

3. Grass is wet. 3. Mow when grass is dry.

4. Excessively worn or damaged blade. 4. Service mower blade.

5. Build up of grass clippings and debris under deck. 5. Clean deck.

6. Improper blade installed on deck.

7. Blade installed improperly on deck. 7. Install blade properly.

1. Leaking engine case.

instructions.

1. Blade control should be held securely against

handle at all times during operation of mower.

1. Contact authorized

6. Install proper SNAPPER blade.

1. Contact authorized SNAPPER dealer.

2. Check and tighten drain plug.

3. Make sure dip stick or oil filler cap is securely in

place.

dealer.

21

Page 22

ITEM SERVICE PERFORMED

Engine Oil

Check Oil Level Page 6

SERVICE SCHEDULE

REF. EACH

USE 5 HRS

X

25

HRS

50

HRS

100

HRS

EACH

SEASON

Air Pre-Cleaner

Air Cleaner

Spark Plug

Engine Cooling

System

Drive Belts

Mower Blades

Mower Deck

Transmission

Grease

Drive Disc

Battery

Initial Oil Change Page 10

Periodic Oil Change Page 11

Clean Sponge Element Engine Manual

Clean or Replace Engine Manual.

Replace Engine Manual.

Clean Shroud & Fins Engine Manual

& Page 6

Check For Wear And

Tension

Check For Wear, Damage

& Replacement

Clean Debris

Accumulation

Check Grease Level Pages 10-11

Periodic Grease Check Pages 11

Check for Wear Damage

& Replacement

Check Electrolyte Pages 19

Page 11

Page 12-13

Page 6 & 11

Page 13-16

X

X*

X**

X**

X

X**

X X X

X

X

X X

X

X

X X

* Change oil every 25 hours when operating under heavy load or high temperatures.

**Clean more often under dusty conditions or when air debris is present

4.6. MAINTENANCE/REPLACEMENT PARTS

Charge Battery Pages 19

Testing Battery Pages 19-20

X

X

MAINTENANCE PARTS

Engine Speed Control (Briggs Engines) 2-4136

Engine Speed Control (California Briggs Engines) 2-9036

Blade Control Cable 2-5036

Clutch Pull Cable 2-5013

Cutter Blade (Air Lift Compatible) 1-9795

Cutter Blade (Mulching) 1-7168

Cutter Blade (Not Air Lift Compatible) 2-6691

Cutter Blade (Ninja - Quad Edge) 2-6407

Wheel Drive Pulley to Transmission Pulley Belt 1-2354

Engine to Drive Disc Belt 1-2353

Rubber Drive Tire 2-3364

Parts Manual for 21” Steel Deck Electric Start Model

Walk Behind Mower Series 12

06060

22

Page 23

3 YEAR LIMITED WARRANTY

For three (3) years from pur chase date f or the original pur chaser 's res idential, non-com m erc ial use, SNAPPER, through

any authorized SNAPPER dealer will replace, free of charge (except for taxes where applic able), any part or parts found

upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

For ninety (90) days from purchase date for the or iginal purchaser's commercial, rental, or other non-residential use,

SNAPPER, through any authorized SNAPPER dealer will replace, free of charge, any part or parts found upon

examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

All transportation costs incurred by the purchaser in submitting material to an authorized SNAPPER dealer for

replacement under this warranty must be paid by the purchaser.

This warranty does not apply to engines and their components , and batteries, as these item s are warranted separately.

This warranty does not apply to parts that have been damaged by accident, alteration, abuse, improper lubrication,

normal wear, or other cause beyond the control of SNAPPER. This warranty does not cover any machine or com ponent

part that has been altered or modified changing safety, performance, or durability.

Batteries have a one (1) year prorated warranty period with free replacement if requir ed during the first ninety (90) days

from the original purchas e date. SNAPPER will not be responsible for any installation cost incurred. T he battery warranty

only covers original equipment batteries and does not cover dam age to the battery or machine caused by neglect or

abuse, destruction by fire, explosion, freezing, overcharging, improper maintenance, or use of improper electrolyte.

There is no other express warranty.

DISCLAIMER OF WARRANTY

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to three

(3) years from purchase date for the original purchaser's residential or other non-commercial use, and ninety

(90) days from purchase for the original purchaser's commercial, rental or other non-residential use, and to the

extent permitted by law, any and all implied warranties are excluded. This is the exclusive remedy. Liabilities for

consequential damages, under any and all warranties are excluded.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARNING: THE USE OF REPL ACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY IMPAIR THE

SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND WARRANTY BY SNAPPER

ASSOCIATED WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill out the attached SNAPPER Product Registration Card immediately and mail to:

Snapper’s Product Registration Ce nter, P.O. Box 1379, McDonough, Georgia 30253

23

Page 24

PRIMARY MAINTENANCE

24

Page 25

PRIMARY MAINTENANCE

25

Page 26

PRIMARY MAINTENANCE

26

Page 27

PRIMARY MAINTENANCE

27

Page 28

Safety Instructions & Operator’s Manual for

21” STEEL DECK

WALK MOWERS

ELECTRIC START

SERIES 12

IMPORTANT

Snapper products are built using engines that meet or exceed all applicable emissions requirements on

the date manufactured. The labels on those engines contain very important emissions information and

critical safety warnings. Read, Understand , and Follow all warnings and instructions in this manual, the

engine manual, and on the machine, engine and attachments. If you have any questions about your

Snapper product, contact your local authorized Snapper dealer or contact Snapper Customer Service at

Snapper, McDonough, GA. 30253. Phone: (1-800-935-2967).

WARNING:

COPYRIGHT © 1999

SNAPPER INC.

ALL RIGHTS RESERVED

The engine exhaust from this product contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm.

MANUAL No. 3-5769 (REV. 1, 9/2/99)

28

Loading...

Loading...