Page 1

Safety Instructions & Operator's Manual for

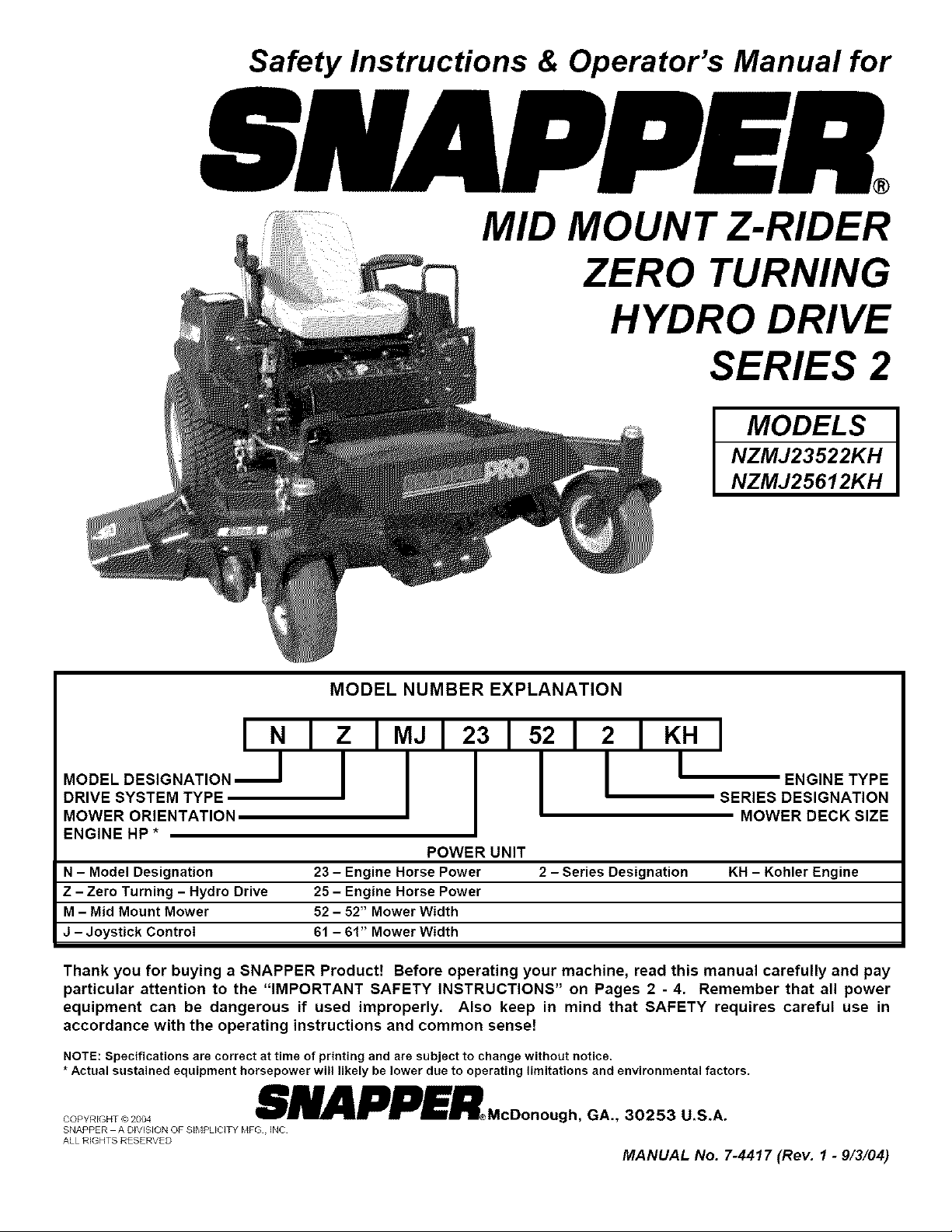

MID MOUNT Z-RIDER

ZERO TURNING

HYDRO DRIVE

SERIES 2

MODELS

NZMJ23522KH

NZMJ25612KH

MODEL NUMBER EXPLANATION

INI ;

MODEL DESIGNATION ._

DRIVE SYSTEM TYPE

MOWER ORIENTATION

ENGINE HP *

N - Model Designation 23 - Engine Horse Power 2 - Series Designation KH - Kohler Engine

Z -Zero Turning - Hydro Drive 25- Engine Horse Power

M - Mid Mount Mower 52 - 52" Mower Width

J - Joystick Control 61 - 61" Mower Width

Thank you for buying a SNAPPER Product! Before operating your machine, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 - 4. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

NOTE: Specifications are correct at time of printing and are subject to change without notice.

* Actual sustained equipment horsepower will likely be lower due to operating limitations and environmental factors.

,dnm_ in IIIIll=lllnh

SNAPPER A DIVISION OF SIMPLIC]TY _']FG INC

ALL RIGHTS RESERVED

: I_JI _31_zl :! I KHI

I

POWER UNIT

MANUAL No. 7-4417 (Rev. I - 9/3/04)

ENGINE TYPE

SERIES DESIGNATION

MOWER DECK SIZE

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ........................................................................ 2-4

TABLE OF CONTENTS ..................................................................................................... 5

SECTION 1 - FAMILIARIZATION ...................................................................................... 6

SECTION 2 -SAFETY MESSAGES AND SYMBOLS .................................................... 7-8

SECTION 3 - OPERATING INSTRUCTIONS ............................................................... 9-13

Pre-start Checklist ................................................................................................. 9-10

Starting & Stopping Engine, Blades & Parking Brake ..................................... 10-11

Starting & Stopping Mower Blades ........................................................................ 11

Parking Brake ........................................................................................................... 11

Cutting Height Adjustment ...................................................................................... 12

Driving & Stopping Machine ............................................................................... 12-13

Safety Interlock System Check ............................................................................... 13

SECTION 4 - MAINTENANCE INSTRUCTIONS ....................................................... 14-18

Change Engine Oil .................................................................................................... 14

Check Mower Blade ................................................................................................. 14

Check Mower Drive Belt .......................................................................................... 16

Check Belt Tension .................................................................................................. 16

Service - After every 25 Hours (Engine Components) ......................................... 16

Service - After every 25 Hours (Mower Components) ......................................... 16

Lubrication ................................................................................................................ 16

Mower Blade Spindle Lubrication ...................................................................... 16

Mower Deck Linkage Lubrication ...................................................................... 16

Front Wheel Bearings Lubrication ..................................................................... 16

Hydro Pump Lubrication ..................................................................................... 16

Other Lubrication ................................................................................................. 16

Before Operating Machine ....................................................................................... 16

Annually - End of Season ................................................................................... 16-17

Engine Service .......................................................................................................... 16

Fuel Filter Replacement ........................................................................................... 17

Deck Removal ...................................................................................................... 17-18

Hydraulic Fluid Filters .............................................................................................. 18

SECTION 5 - ADJUSTMENTS AN D REPAIR ............................................................ 19-27

Neutral Position Adjustments ............................................................................ 19-20

Mower Deck Adjustment (Levelness) ................................................................ 20-21

Parking Brake Adjustment ...................................................................................... 21

Traction Belt Tension & Replacement .................................................................... 22

Blade Brake/Electric Clutch Adjustment ............................................................... 22

Tracking Adjustment ................................................................................................ 23

Mower Drive Belt Removal & Replacement ........................................................... 23

Engine Adjustments & Repair ................................................................................. 24

Mower Blade Replacement ...................................................................................... 24

Mower Blade Sharpening ........................................................................................ 24

Battery Removal ....................................................................................................... 25

Battery Installation ................................................................................................... 25

Battery Charging ...................................................................................................... 25

Battery Testing ......................................................................................................... 26

New Battery Preparation .......................................................................................... 26

Mower Spindle Bearing Replacement .................................................................... 27

Hydraulic System, Purging ...................................................................................... 28

TROUBLESHOOTING ................................................................................................ 29-30

SERVICE SCHEDULE ..................................................................................................... 31

WARRANTY ..................................................................................................................... 32

PRIMARY MAINTENANCE ......................................................................................... 33-36

PRODUCT REGISTRATION FORM ................................................................................ 37

MaintenancelReplacement Parts ....................................................................... 31

IMPORTANT

NOTICE: Operator Protective Structures are available as optional kits for the Mid-Mount and Out-Front Z-Rider

machines. These structures, when installed and used properly can offer additional security to the operator

against serious injury in the event of a tip over accident. Operator Protective Structures may be required by local

ordinances. Discuss your mowing application and ordinances with your local Snapper Dealer.

5

Page 3

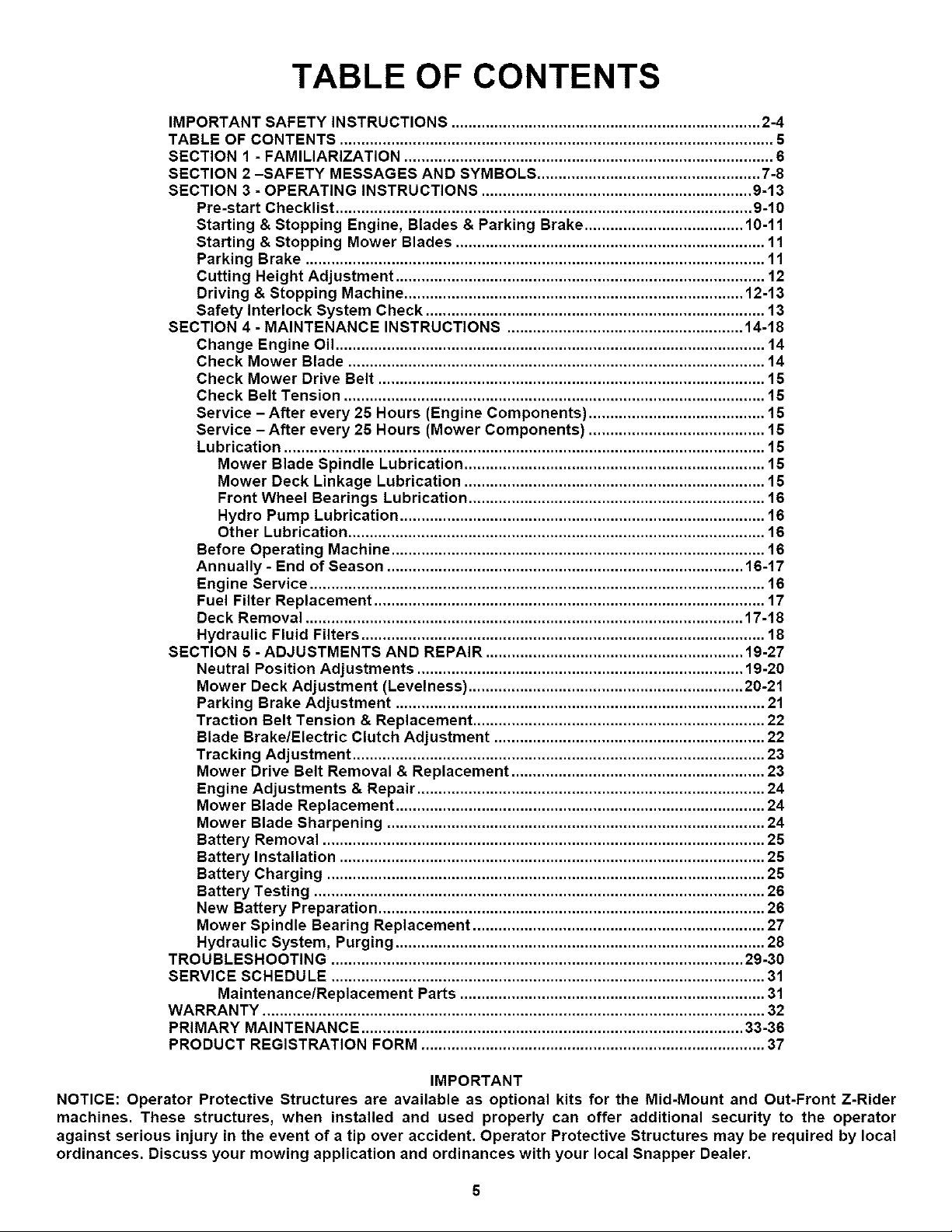

Section 2 - SAFETY MESSAGES AND SYMBOLS

RUN

HOUR METER DISENGAGE BLADES KEYSWITCH

1 I T I

I CONTROL PANEL IDENTIFICATION I

CHOKE

CONTROL

OFF/STOP

PULL SWITCH "UP" TO I1% l _

ENGAGE BLADES

PUSH SWITCH "DOWN" TO

ENGINE

SPEED

CONTROL

_ T _

SLOW

START

KEEP CHILDREN AND OTHERS OUT OF MOWING AREA

I DANGER! ROTATING BLADES I

I DANGER! ROTATING BLADES I

STOP RUN START

I IGNITION SWITCH I

Page 4

Section 3 - OPERATING INSTRUCTIONS

3.2.1. STARTING ENGINE

NOTE: If after 5 seconds of cranking the engine

does not start, release the key. Attempt starting

again after waiting for approximately 20 seconds.

7, After engine starts, move the choke control to

the "OFF" or no choke position. Allow a brief

warm-up until engine runs smooth.

3.2.2. STOPPING ENGINE

1, Stop engine by turning key to "STOP" position.

Move engine speed to the Turtle "SLOW" position

and turn key to "STOP". See Figure 3.6.

SHOWN FROM OPERATOR'S VIEW POINT

FIGURE 3.6

3.2.5. PARKING BRAKE

1, Engage parking brake by pulling the parking brake

lever back to the engaged position.See Figure 3.7.

NOTE: To engage the parking brake, the joystick

control must first be placed in the center neutral

position.

2 Release parking brake by pushing parking brake

leverforward to the released position.See Figure3.8.

WARNING

DO NOT operate blades in reverse. STOP blades. I

LOOK and SEE behind and down for children, pets,

and hazards before and while backing. I

3.2.3. STARTING MOWER BLADES

1. Start engine and set engine speed control to

the Rabbit "FAST" position. See Figure 3.5.

2, Pull the Blade Switch up to the "ON" position to

engage or turn "ON" the mower blades.

See Figure 3.2.

3.2.4. STOPPING MOWER BLADES

1. Push Blade Switch down to "OFF" position to

disengage or turn "OFF" the blades.

2, Move engine speed control to the Turtle

"SLOW" position. Turn key to "STOP" position.

blades are disengaged, they should come to a

complete stop in 7 seconds. If the blades continue

to rotate after 7 seconds, the electric clutch should

be checked. Adjustment or replacement of electric

clutch may be necessary. Return the machine to an

authorized Snapper dealer for replacement. DO

NOT CONTINUE to operate mower if blades fail to

stop in 7 seconds.

WARNING

FIGURE 3.7

PARKING BRAKE

LEVERIN RELEASED

"OFF'POSITION

FIGURE 3.8

DO NOT park the machine on slopes. DO NOT I

machine with engine running. Stop engine.

blades. Engage parking brake. Remove key.

11

Page 5

Section 5 - ADJUSTMENTS & REPAIR

5.1 NEUTRAL POSITION ADJUSTMENTS 5.2

(Continued From Previous Page)

12, Move motion control lever to the neutral position

and engage the parking brake, See Figure 3.7, hold

connecting rod up to the activation assembly and

check length of rod. Tie rod end bolt must align with

the activation assembly. If bolt is not aligned with the

activation assembly, adjust tie rod. Loosen jam nut

that secures tie rod. Rotate tie rod in or out to align

with hole in activation assembly. Repeat step for

other hydro pump. See Figure 5.4.

HYDRO PUMP _,

ACTIVATION PUMP

ASSEMBLY .....

in HYDRO

LOOSEN NUT AND

ROTATE TIE ROD END

TIE ROD END

IN OR OUT TO ALIGN

WITH ACTIVATION

MOWER DECK & COMPONENT ADJUSTMENTS

The leveling procedures for the 61 deck differ from

the 48 and 52 decks. The 61 deck replaces the two

rear eyebolts with slotted brackets_ and uses 1 1/4"

leveling blocks in place of the 1" blocks. Follow and

complete each step carefully.

5,2.1, MOWER DECK ADJUSTMENT (LEVELNESS)

SIDE to SIDE and FRONT to REAR

Before making deck leveling adjustments, inflate rear

tires to 12 PSI and front tires to 25 PSI. When

adjusted correctly, the deck will be level side to side

within 1/8", have a low cut setting of approximately 1"

(1 1/4" for 61 deck) and the blades pitched

approximately 3/16" higher at the rear.

1. Place machine on a smooth level surface.

2. Check side to side level by rotating blades until

tips are pointing to the sides of the deck. Check the

measurement of outside blade tips to the ground on

both blades. The measurement of each of the outside

blade tips should be within 1/8" of each other. If

measurement of the blade tips is not within 1/8",

adjustment should be made.

3. Move deck lift lever and set the mower deck to the

highest cutting position.

4. Relive tension on deck lift assist spring by

loosening nut on eyebolt. Refer to Section

"Removing Deck".

5. Place 1" blocks (1 1/4" for 61 deck) under the front

and rear edge of the mower deck.

6. Move deck lift lever and set the mower deck to the

lowest cutting position.

6. Loosen the nuts and bolts that secure both front

deck support chains. Adjust chains until tight and

retighten bolts and nuts. Torque to 70 ft. Ibs. See

Figure 5.5.

BOLT IS SHOWN

ALIGNED WITH

HOLE

FIGURE 5,4

13. Once tie rod end bolt is aligned with activation

assembly insert into hole and reinstatI washers and

nut that secure bolt to assembly. Tighten securely.

Tighten tie rod jam nut securely.

14. Start engine, disengage parking brake, and

check rotation of the rear wheels.

15. Reinstall both hydro pump fans. Reinstall

washer and bolt. Tighten bolt securely.

16. Reinstall screen and tighten retaining hardware

securely.

FRONT

LIFT ARM

DECK HANGER

BRACKET

LOOSEN BOLT AND NUT,

TIGHTEN CHAIN. SECURE

BOLTS AND NUTS

FIGURE 5.5

20

Page 6

Section 5 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine running. STOP engine. STOP

blades. Set brake. Remove key. Remove spark plug

wires and secure away from spark plugs. Engine

and components are HOT. Avoid serious burns,

allow sufficient time for all parts to cool.

5.3 TRACTION BELT TENSION

The traction drive belt tension does not require

adjustment. If the belts are slipping, they will have to be

replaced.

J-BOLT

FIGURE 5.9

5.4 TRACTION BELT REPLACEMENT

1. Remove clutch to deck belt. See Figure 5.10

2. Turn lock nut out to the end of J-Bolt, reducing

spring tension. Unhook traction idler spring from bolt

in frame. See Figure 5.9

3. Remove anti-rotation bracket. See Figure 5.10

4. Disconnect the electric clutch from main wire

harness.

5, Remove traction belts from around engine pulley

and hydro pumps.

6, Install new belts and route around engine pulley

and hydro pump pulleys.

7, Reconnect electric clutch to main wire harness.

8, Reinstall anti-rotation bracket and tighten nuts

securely.

9, Reattach traction idler spring. Run lock nut all

the way to the end of the threads on the J-Bolt.

Tighten jam nut securely. See Figure 5.10.

10. Reinstall electric clutch to deck belt.

UNHOOK TRACTION

DRIVE IDLER SPRING

!IREMOVECLUTCH

REMOVEANTI-

ROTATION BRACKET

FIGURE 5.10

5.5 BLADE BRAKE/ELECTRIC CLUTCH ADJUSTMENT

The blade switch engages the electric clutch when

pulled out to the "ON" position. When the blade

switch is in the "ON_' position the cutting blade(s)

are engaged. The blade switch disengages the

electric clutch when the blade switch is pushed in

to the "OFF" position. When the blade switch is in

the "OFF" position the cutting blade(s) are

disengaged. The electric clutch is adjustable. The

blades should stop rotation in 7 seconds or less. If

the electric clutch fails to stop the blades rotation in

7 seconds, adjustment is necessary.

1. Insert a feeler gauge into the three slots on the

electric clutch.

2. Check gap through all three slots in the side of

the clutch. The gap should be set at .015.

3. If gap is incorrect rotate nuts in or out to achieve

the correct gap. See Figure 5.11.

NOTE: Electric Clutch is shown removed from the

machine. Removal is not necessary for adjustment.

INSERT FEELER GAUGE.

GAP SHOULD BE .015

S'

j_

ROTATE NUTS

IN OR OUT

TO ACHIEVE

CORRECTGAP

22

FIGURE 5.11

Page 7

Section 5 - ADJUSTMENTS & REPAIR

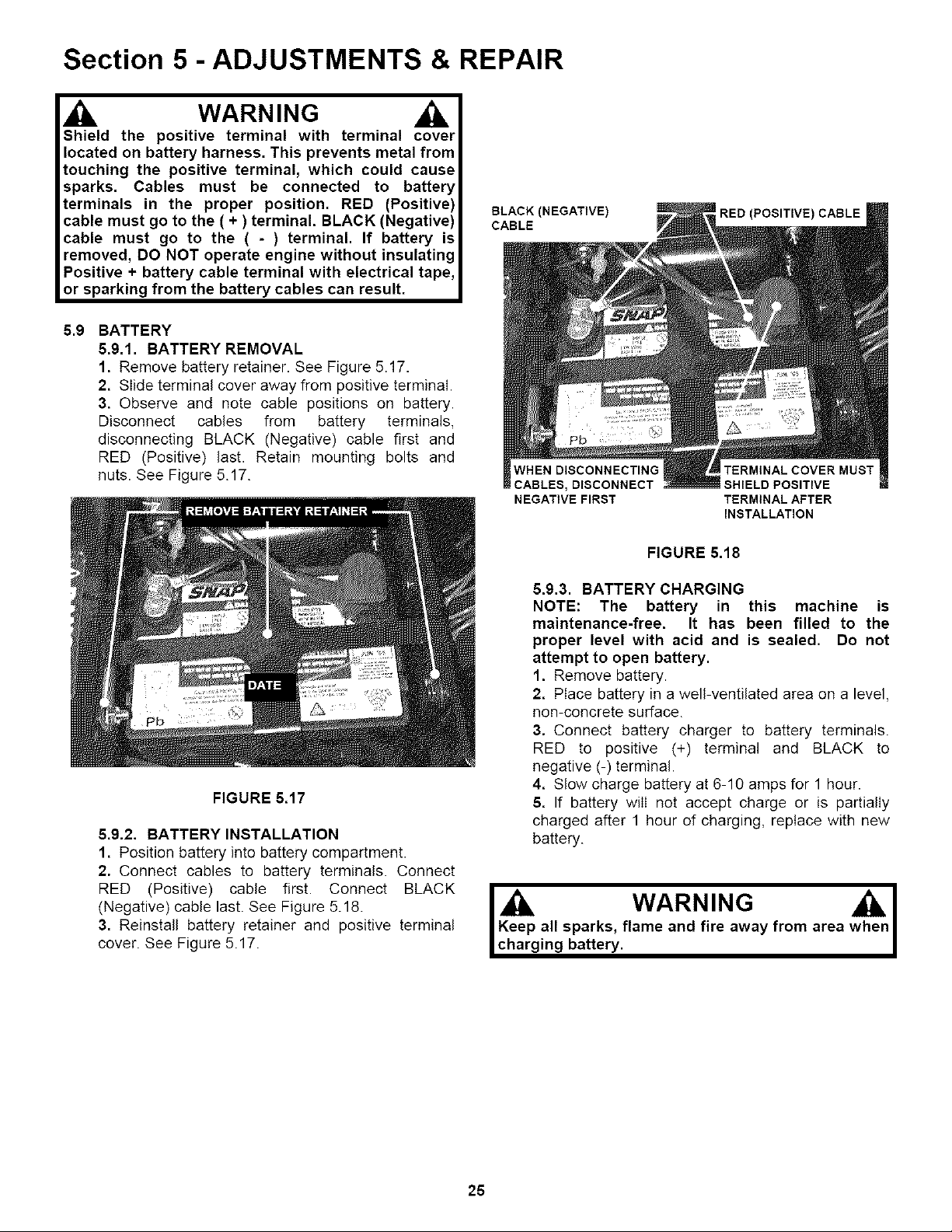

WARNING

Shield the positive terminal with terminal cover

located on battery harness. This prevents metal from

touching the positive terminal, which could cause

sparks. Cables must be connected to battery

terminals in the proper position. RED (Positive)

cable must go to the ( + ) terminal. BLACK (Negative)

cable must go to the ( - ) terminal. If battery is

removed, DO NOT operate engine without insulating

Positive + battery cable terminal with electrical tape,

or sparking from the battery cables can result.

5.9 BATTERY

5.9.1. BATTERY REMOVAL

1, Remove battery retainer. See Figure 5.17.

2. Slide terminal cover away from positive terminal.

3. Observe and note cable positions on battery.

Disconnect cables from battery terminals,

disconnecting BLACK (Negative) cable first and

RED (Positive) last. Retain mounting bolts and

nuts. See Figure 5.17.

BLACK (NEGATIVE)

CABLE

WHEN DISCONNECTING

CABLES, DISCONNECT

NEGATIVE FIRST

RED (POSITIVE) CABLE

SHIELD POSITIVE

TERMINAL AFTER

INSTALLATION

FIGURE 5.17

5.9.2. BATTERY INSTALLATION

1. Position battery into battery compartment.

2. Connect cables to battery terminals. Connect

RED (Positive) cable first. Connect BLACK

(Negative) cable last. See Figure 5.18.

3. Reinstall battery retainer and positive terminal

cover. See Figure 5.17.

FIGURE 5.18

5.9.3. BATTERY CHARGING

NOTE: The battery in this machine is

maintenance-free. It has been filled to the

proper level with acid and is sealed. Do not

attempt to open battery.

1. Remove battery.

2. Place battery in a well-ventilated area on a level,

non-concrete surface.

3. Connect battery charger to battery terminals.

RED to positive (+) terminal and BLACK to

negative (-) terminal.

4. Slow charge battery at 6-10 amps for 1 hour.

5. If battery wilI not accept charge or is partially

charged after 1 hour of charging, replace with new

battery.

Keep all sparks, flame and fire away from area

charging battery.

WARNING w I

25

Loading...

Loading...