Snapper NZMJ25611KH, NZMJ23521KH Owner’s Manual

Safety Instructions & Operator's Manual for

MID MOUNT Z-RIDER

ZERO TURNING

HYDRO DRIVE

SERIES 1

MODELS

NZMJ23521KH

NZMJ25611KH

MODEL NUMBER EXPLANATION

INI;

MODEL DESIGNATION ._1

DRIVE SYSTEM TYPE

MOWER ORIENTATION

ENGINE HP

N - Model Designation 23 - Engine Horse Power 1- Series Designation KH - Kohler Engine

Z -Zero Turning - Hydro Drive 25- Engine Horse Power

M - Mid Mount Mower 52 - 52" Mower Width

J - Joystick Control 61 - 61" Mower Width

Thank you for buying a SNAPPER Product! Before operating your machine, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 - 4. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

SNAPPER McOooouoh

COPYRIGHT © 2003

SNAPPER PRODUCTS INC

ALL RIGHTS RESERVED

: I_JI _31_zl , I KHI

I

POWER UNIT

GA., 30253 U.S.A.

MANUAL No. 7-5593 (Rev I, 8/5/03)

ENGINE TYPE

SERIES DESIGNATION

MOWER DECK SIZE

Section 1 - FAMILIARIZATION

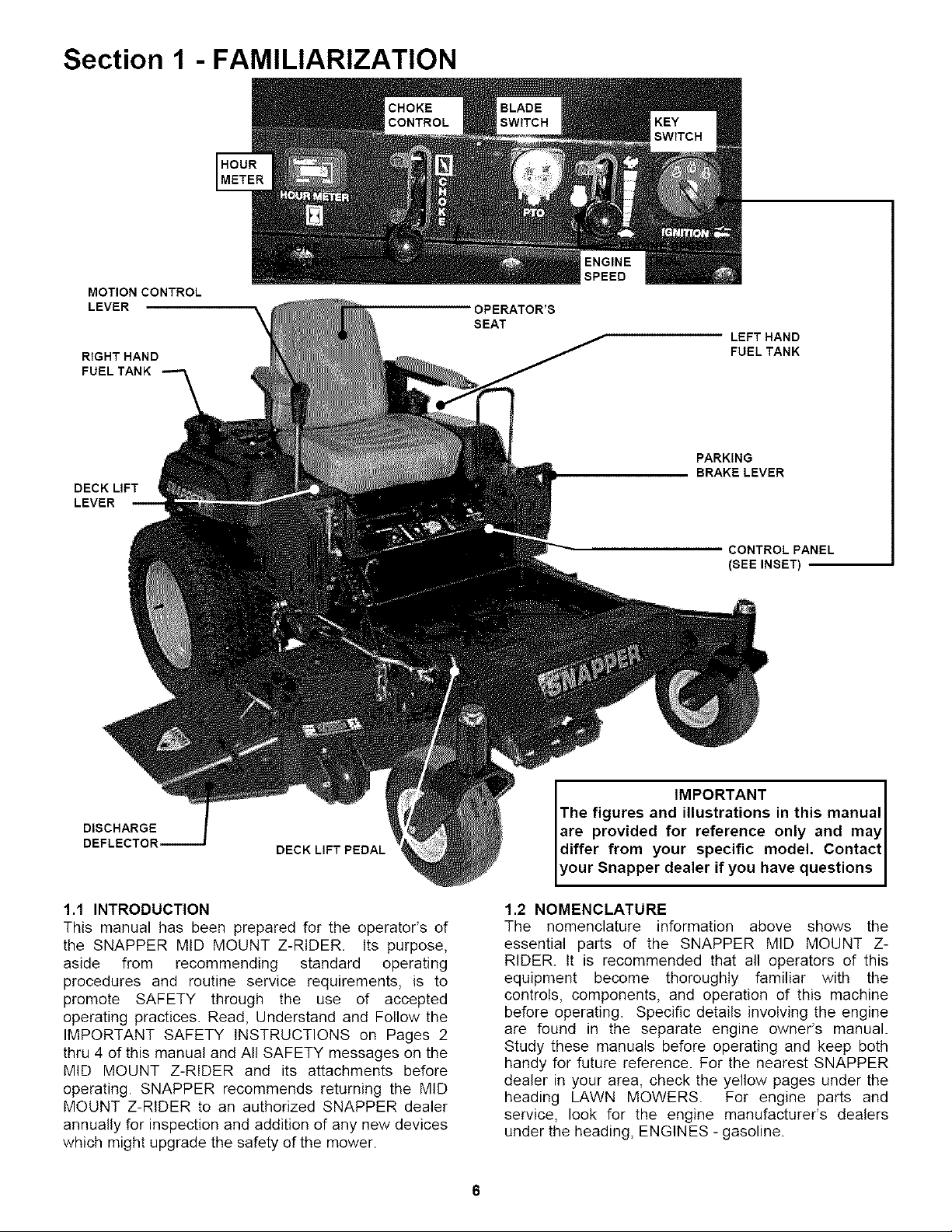

MOTION CONTROL

LEVER

\

RIGHT HAND

FUEL TANK

DECK LIFT

LEVER

ENGINE

SPEED

OPERATOR'S

SEAT

LEFT HAND

FUEL TANK

PARKING

BRAKE LEVER

DISCHARGE

DEFLECTOR,

DECK LIFT PEDAL

1.1 INTRODUCTION

This manual has been prepared for the operator's of

the SNAPPER MID MOUNT Z-RIDER Its purpose,

aside from recommending standard operating

procedures and routine service requirements, is to

promote SAFETY through the use of accepted

operating practices. Read, Understand and Follow the

IMPORTANT SAFETY INSTRUCTIONS on Pages 2

thru 4 of this manual and All SAFETY messages on the

MID MOUNT Z-RIDER and its attachments before

operating. SNAPPER recommends returning the MiD

MOUNT Z-RIDER to an authorized SNAPPER dealer

annually for inspection and addition of any new devices

which might upgrade the safety of the mower.

CONTROL PANEL

(SEE INSET)

IMPORTANT

The figures and illustrations in this manual

are provided for reference only and may

differ from your specific model. Contact

your Snapper dealer if you have questions

1.2 NOMENCLATURE

The nomenclature information above shows the

essential parts of the SNAPPER MID MOUNT Z-

RIDER. It is recommended that all operators of this

equipment become thoroughly familiar with the

controls, components, and operation of this machine

before operating. Specific details involving the engine

are found in the separate engine owner's manual.

Study these manuals before operating and keep both

handy for future reference. For the nearest SNAPPER

dealer in your area, check the yellow pages under the

heading LAWN MOWERS. For engine parts and

service, look for the engine manufacturer's dealers

under the heading, ENGINES - gasoline.

6

Section 2 - SAFETY MESSAGES AND SYMBOLS

DANGER ! ROTATING PARTS

KEEP AWAY FROM MOVING PARTS

MOTION CONTROLLEVER(JOYSTICK)

MULT-D RECT ONAL

REVERSE

I

I PARKING BRAKE LEVER OPERATION I

TO O_F._AT :

TO gT_z

I WARNING ! AVOID SERIOUS INJURY OR DEATH I

STARTING, OPERATION & STOPPING OF MACHINE

I WEARHEAR'NGPROTECT'ON I

-_ _ O_ %_ _ F_A_ DO_ _._ _ _E_E U_¸

I

I

Section 3 - OPERATING INSTRUCTIONS

3.1 PRE-START CHECK LIST

Make the following checks and perform the service

required before each start-up.

3.1.1. Check tires and add or release air as needed

to bring pressure to 12 psi in drive tires. Pressure in

front caster wheels should be 25 psi.

3.1.2. Check guards, deflectors and covers to make

sure all are in place and securely tightened.

3.1.3. Check engine oil and add oil as needed to

bring level up to the FULL mark. Refer to engine

owner's manual for oil specifications. See Figure 3.1.

FIGURE 3.1

3.1.4. Check Blade Switch to insure it works freely.

1, Pull the Blade Switch up to the "ON" position to

engage or turn "ON" the mower blades.

2, Push Blade Switch down to the "OFF" position to

disengage or turn "OFF" the blades.

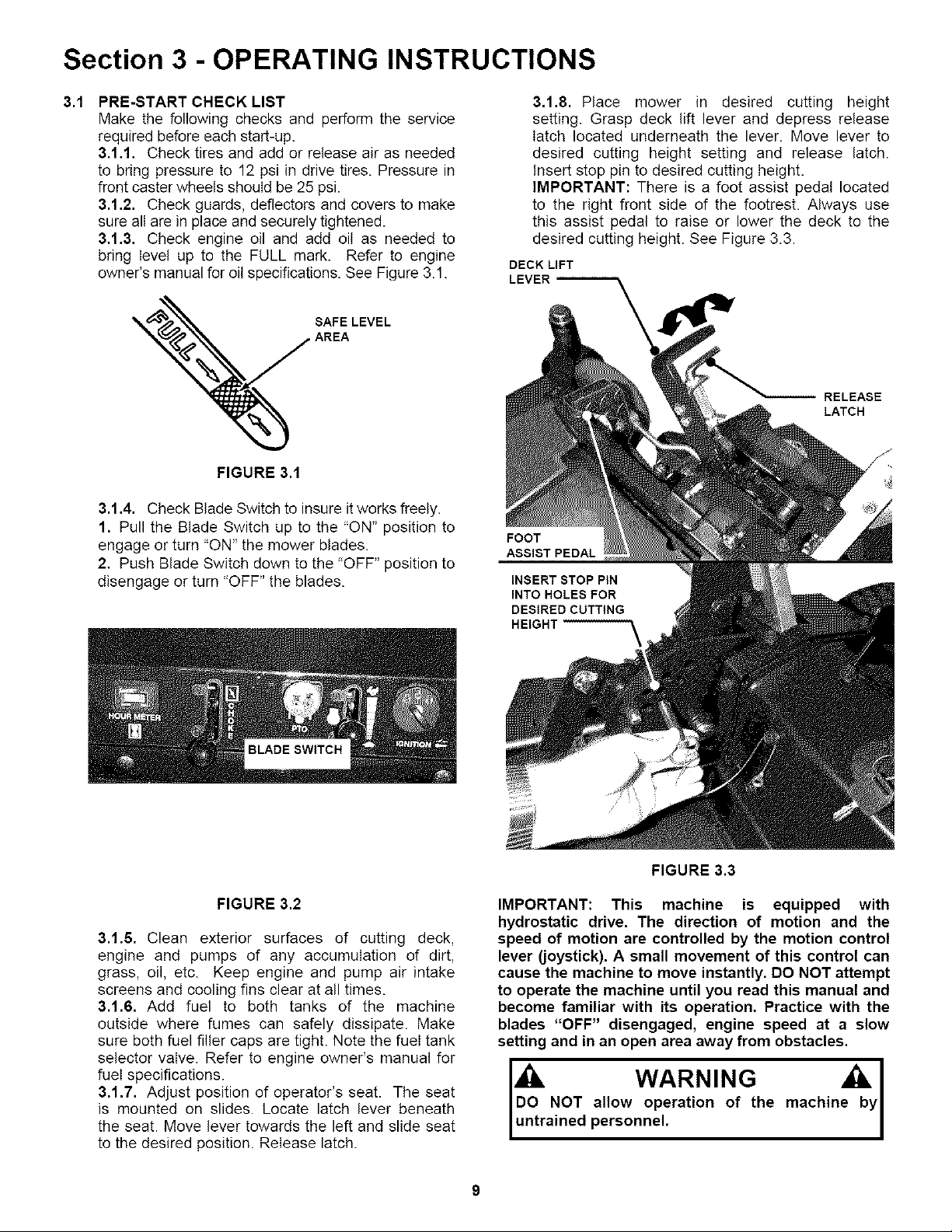

3,1,8. Place mower in desired cutting height

setting. Grasp deck lift lever and depress release

latch located underneath the lever. Move lever to

desired cutting height setting and release latch.

Insert stop pin to desired cutting height.

IMPORTANT: There is a foot assist pedal located

to the right front side of the footrest. Always use

this assist pedal to raise or lower the deck to the

desired cutting height. See Figure 3.3.

DECK LIFT

LEVER

RELEASE

LATCH

FOOT

ASSIST PEDAL

INSERT STOP PIN

INTO HOLES FOR

DESIRED CUTTING

HEIGHT

FIGURE 3.2

3.1.6. Clean exterior surfaces of cutting deck,

engine and pumps of any accumulation of dirt,

grass, oil, etc. Keep engine and pump air intake

screens and cooling fins clear at all times.

3.1.6. Add fuel to both tanks of the machine

outside where fumes can safely dissipate. Make

sure both fuel filler caps are tight. Note the fuel tank

selector valve. Refer to engine owner's manual for

fuel specifications.

3.1.7. Adjust position of operator's seat. The seat

is mounted on slides. Locate latch lever beneath

the seat. Move lever towards the left and slide seat

to the desired position. Release latch.

FIGURE 3.3

IMPORTANT: This machine is equipped with

hydrostatic drive. The direction of motion and the

speed of motion are controlled by the motion control

lever (joystick). A small movement of this control can

cause the machine to move instantly. DO NOT attempt

to operate the machine until you read this manual and

become familiar with its operation. Practice with the

blades "OFF" disengaged, engine speed at a slow

setting and in an open area away from obstacles.

allow operation of the machin

personnel.

Section 3 - OPERATING INSTRUCTIONS

ROLL RELEASE: To roll the machine without the

engine running, pressure within the hydraulic pumps

must be released, There is a hydraulic pressure relief

valve on the upper side of each pump that is used to

release the pressure. Use awrench to rotate both relief

valves counter clockwise two full turns to open, After

rolling machine, both relief valves must be rotated

clockwise to close valves and tighten securely before

operating machine, Machine will not move if relief

valves are open, See Figure 3.3.

3.2 STARTING & STOPPING - ENGINE, BLADES,

PARKING BRAKE

This machine is equipped with dual hydraulic pumps and

wheel drive motors. Each pump is controlled by a single

motion control lever or joystick. This single control lever

(joystick) controls the direction of motion, Forward and

Reverse, and the speed of motion. Move the joystick

forward to propel the machine forward. Move the control

rearward to propel the machine in reverse. The speed of

motion is continuously variable from neutral (zero) to

maximum. Moving the joystick farther from the neutral

position will cause the speed of motion to increase. To

turn, move the joystick towards the side you want to turn

to. DO NOT make sudden changes in speed or

direction. Always slow machine motion before turning.

To stop the motion of the machine, bring the joystick

back to the neutral position. Engage parking brake.

3.2.1. STARTING ENGINE

When the ignition key is turned the engine will not

start or turn over unless, the blade switch is pushed

in to the "OFF" position, the motion control lever is

in the neutral position with the parking brake

engaged.

1, Complete pre-start checklist.

2, Sit in operator's seat.

3, Push blade switch in to "OFF", blades

disengaged position and engage parking brake.

See Figures 3.2 and 3.7.

4, Move choke control forward to choke position to

start a cold engine. See Figure 3.5.

5, Move engine speed control to the Rabbit "FAST"

position. See Figure 3.5.

6, Turn key to the start position until engine starts.

See Figure 3.6.

WARNING

DO NOT disengage the hydro transmission and coast

down slopes. DO NOT use Roll Release Control to

disengage the hydro transmission unless machine

motion can be controlled and engine is off.

CHOKE SPEED

SHOWN FROM OPERATOR'S VIEW POINT

10

ENGINE

KEY

SWITCH

FIGURE 3.5

Loading...

Loading...