Page 1

Safety Instructions & Operator's Manual for

,SNAPPER,

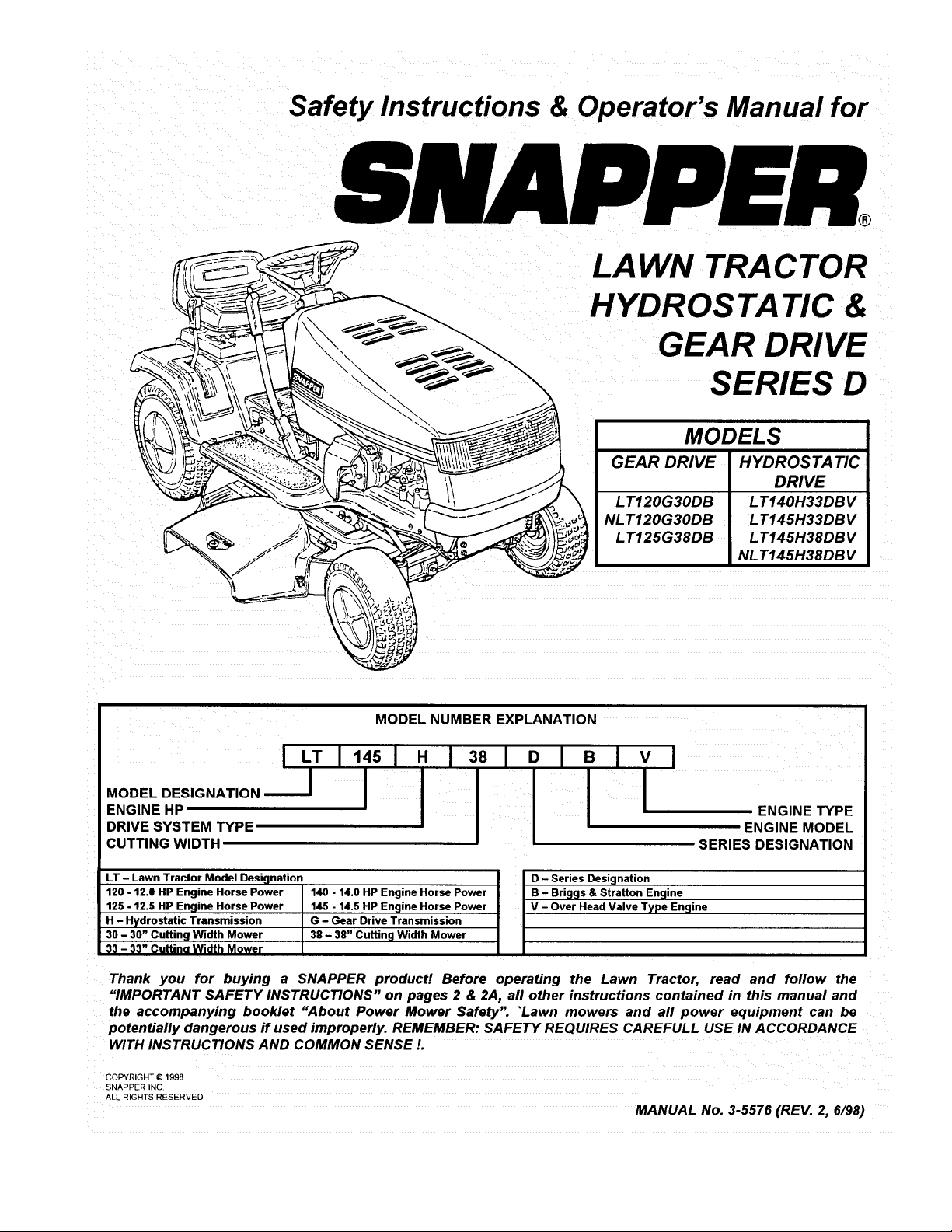

LAWN TRA CTOR

HYDROSTATIC &

GEAR DRIVE

SERIES D

MODELS

GEAR DRIVE HYDROSTATIC

DRIVE

LT120G30DB LT140H33DBV

NLT120G30DB LT145H33DBV

LT125G38DB LT145H38DBV

NLT145H38DBV

MODEL NUMBER EXPLANATION

I

LTI 145I H 1381 O I B I V I

MODEL DESIGNATION

ENGINE HP

DRIVE SYSTEM TYPE

CUTTING WIDTH

LT - Lawn Tractor Model Designation

120 - 12.0 HP Engine Horse Power

125 - 12,5 HP Engine Horse Power

H - Hydrostatic Transmission

30 - 30" Cutting Width Mower

33 - 33" Cuttino Width Mower

Thank you for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow the

"IMPORTANT SAFETY INSTRUCTIONS" on pages 2 & 2A, all other instructions contained in this manual and

the accompanying booklet "About Power Mower Safety". "Lawn mowers and all power equipment can be

potentially dangerous ff used improperly. REMEMBER: SAFETY REQUIRES CAREFULL USE IN ACCORDANCE

WITH INSTRUCTIONS AND COMMON SENSE/.

COPYRIGHT © 1998

SNAPPER NC

ALL RIGHTS RESERVED

140 - 14.0 HP Engine Horse Power

145 - 14.5 HP Engine Horse Power

G - Gear Drive Transmission

38 - 38" Cutting Width Mower

i ENGINE TYPE

; ENGINE MODEL

SERIES DESIGNATION

D - Series Designation

B - Briggs & Stratton Engine

V - Over Head Valve Type Engine

MANUAL No. 3-5576 (REV. 2, 6/98)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful cutting machine is capable of amputating hands and feet and can throw objects that

can cause injury and damage! Failure to comply with the following SAFETY instructions could result in

serious injury or death to the operator or other persons. The owner of the machine must understand these

instructions and must allow only persons who understand these instructions to operate machine. Each

person operating the machine must be of sound mind and body and must not be under the influence of any

substance which might impair vision, dexterity or judgment. If you have any questions pertaining to your

machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department

at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. KEEP children out of the mowing area and under

the watchful care of a responsible adult.

2. DO NOT allow children in yard when machine is

operated (even with the blade OFF).

3. DO NOT allow children or other passengers to

ride on machine or on attachments (even with the

blade OFF). They may fall and be seriously

injured.

4. DO NOT allow pre-teenage children to operate

machine.

5. ALLOW only responsible adults & teenagers with

mature judgment under close adult supervision to

operate machine.

6. BE SURE the area is clear of others before

mowing and turn machine OFF if anyone enters

the area.

7. DO NOT mow in reverse unless absolutely

necessary. LOOK BEHIND and down for small

children before and when backing.

8. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

PROTECTION AGAINST TIPOVERS

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra CAUTION. If

you cannot back up the slope or if you feel uneasy on

it, DO NOT mow it. Use extra care with grass catchers

or other attachments; these can change the stability

of the machine.

1. DO NOT operate machine on slopes exceeding 15

degrees (27% grade).

2. Exercise EXTREME CAUTION on slopes above 10

degrees (18% grade). Turn blade OFF when

traveling uphill. Use first speed and avoid sudden

or sharp turns.

3. DO NOT mow back and forth across face of

slopes. Mow up and down.

PROTECTION AGAINST TIPOVERS

(Continued From Previous Column)

4. AVOID uphill starts. If machine stops going uphill

or tires lose traction, turn blade OFF and back

slowly down the slope.

5. STAY ALERT for holes and other hidden hazards.

Tall grass can hide obstacles. Keep away from

ditches, washouts, culverts, fences and

protruding objects.

6. KEEP A SAFE DISTANCE (at least 3 feet) away

from edge of ditches and other drop offs. The

mower could turn over if an edge caves in.

7. Always begin forward motion in the #1 speed

position.

8. Use weights or a weighted load carrier in

accordance with instructions with a grass catcher

on slopes above 10 degrees (18% grade).

9. DO NOT put your foot on the ground to try to

stabilize the machine.

10. DO NOT mow on wet grass. Reduced traction

could cause sliding.

11. DO NOT mow under any condition where traction,

steering or stability is doubtful without first test

driving over the terrain with blade OFF.

PREPARATION

1. Read this manual, get to know where all controls

are located and practice how to use them before

starting for the first time, and at the beginning of

each season. Read and follow Warnings and

Instructions on engine and machine. Read and

follow operator's manual and instructions

furnished with attachments.

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

3. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved

fuel container. Never remove fuel cap or add fuel

with engine running. Add fuel outdoors only with

engine stopped and cool. Clean spilled fuel from

machine. DO NOT smoke.

4. Practice operation of machine with BLADE OFF to

learn controls and develop skills.

(Continued on Next Page}

Page 3

IMPORTANT SAFETY INSTRUCTIONS

PREPARATION

(Continued From Previous Page)

5. Check the area to be mowed and remove all

objects such as toys, wire, rocks, limbs and other

objects that could cause injury if thrown by blade

or interfere with mowing.

6. Keep people and pets a safe distance from

machine.

7. Check shields, deflectors, switches, blade

controls and other safety devices frequently for

proper operation and location.

8. Make sure all safety decals are clearly legible.

Replace if damaged.

9. Protect yourself when mowing and wear safety

glasses, long pants and substantial footwear.

10. Know how to STOP blade and engine quickly in

preparation for emergencies.

11. Use extra care when loading or unloading the

machine into a trailer or truck.

12. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or worn spots.

OPERATION

1. Mount and dismount machine from left side.

2. Start engine from operator's seat, if possible.

Make sure blade is OFF and parking brake is set.

3. STOP blade, STOP engine, set parking brake and

remove key when leaving machine.

4. DO NOT operate machine unless properly seated

with feet on feet rests or pedal(s).

5. STOP BLADE and ENGINE and make sure blade

has stopped before removing grass catcher or

unclogging mower to prevent loss of fingers or

hand.

6. Blade must be OFF except when cutting grass.

Set blade in highest position when mowing over

rough ground.

7. Keep hands and feet away from rotating blade

underneath deck. NEVER place foot on ground

while BLADE is ON or machine is in motion.

8. Deflector or entire grass catcher must be in place.

NEVER point discharge at people, passing cars,

windows or doors.

9, Slow down before turning.

10. Watch out for traffic when near or crossing

roadways.

11. STOP engine immediately after striking an

obstruction. Inspect machine and repair damage

before resuming operation.

12. Mow only in daylight or with good artificial light.

13. Move joystick (if equipped) SLOWLY to maintain

control during speed and directional changes.

14. Exercise CAUTION when pulling loads. Limit

loads to those you can safely control and attach

loads to hitch plate as specified with SNAPPER

attachment instructions.

MAINTENANCE

1. Never store machine or fuel container inside

where fumes may reach an open flame, spark or

pilot light such as in a water heater, furnace,

clothes dryer or other gas appliance. Allow

engine to cool before storing machine in an

enclosure. Store fuel container out of the reach of

children in a well ventilated, unoccupied building.

2. Keep engine free of grass, leaves or excess

grease to reduce fire hazard and engine

overheating.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from open

flame.

4. Check brakes frequently; adjust, repair or replace

as needed.

5. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

6. Always provide adequate ventilation when

running engine indoors. Exhaust gases contain

carbon monoxide, an odorless and deadly

poison.

7. Disconnect negative (black) cable from battery

before performing maintenance or service.

Cranking engine could cause injury.

8. Never work under machine without safety blocks.

9. Service engine and make adjustments only when

engine is stopped. Remove spark plug wire(s)

from spark plug(s) and secure wire(s) away from

spark plug(s).

10. DO NOT change engine governor speed settings

or overspeed engine.

11. Lubricate machine at intervals specified in

manual to prevent controls from binding.

12. Mower blades are sharp and can cut. Wrap the

blades or wear heavy leather gloves and use

CAUTION when handling them.

13. NEVER test for spark by grounding spark plug

next to spark plug hole; spark plug could ignite

gas exiting engine.

14. Have machine serviced by an authorized

SNAPPER dealer at least once a year and have the

dealer install any new safety devices.

15. Use only genuine SNAPPER replacement parts to

assure that original standards are maintained.

2A

Page 4

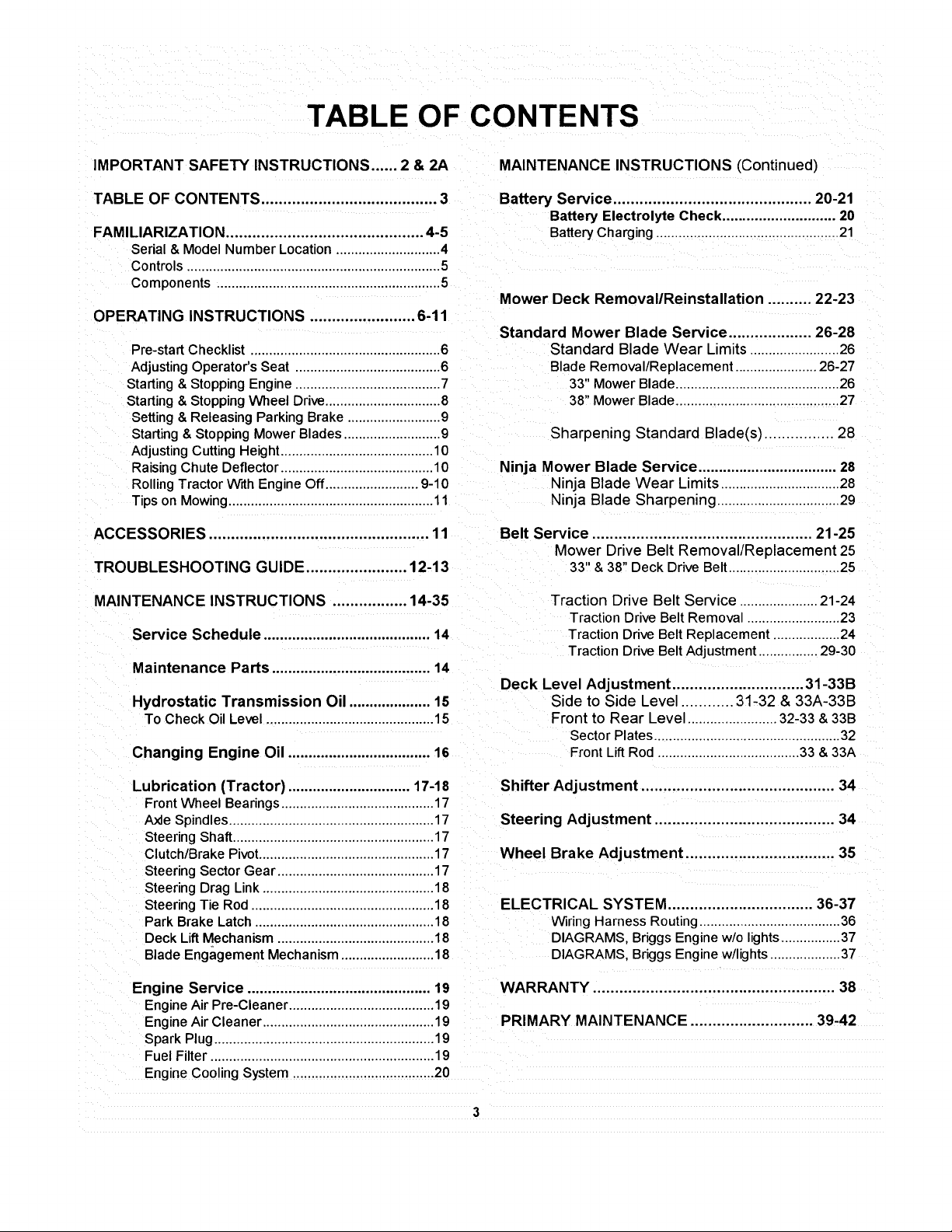

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ...... 2 & 2A

TABLE OF CONTENTS ........................................ 3

FAMILIARIZATION ............................................. 4-5

Serial & Model Number Location ........................... 4

Controls .................................................................... 5

Components ........................................................... 5

OPERATING INSTRUCTIONS ........................ 6-11

Pre-start Checklist ................................................... 6

Adjusting Operator's Seat ....................................... 6

Starting & Stopping Engine ....................................... 7

Starting & Stopping Wheel Drive ............................... 8

Setting & Releasing Parking Brake ..........................

Starting & Stopping Mower Blades .......................... 9

Adjusting Cutting Height ......................................... 10

Raising Chute Deflector ......................................... 10

Rolling Tractor W_h Engine Off ......................... 9-10

Tips on Mowing ....................................................... 11

ACCESSORIES .................................................. 11

TROUBLESHOOTING GUIDE ....................... 12-13

MAINTENANCE INSTRUCTIONS ................. 14-35

Service Schedule ......................................... 14

Maintenance Parts ....................................... 14

Hydrostatic Transmission Oil .................... 15

To CheckOilLevel...............................................

Changing Engine Oil ................................... 16

MAINTENANCE INSTRUCTIONS (Continued)

Battery Service ............................................. 20-21

Battery Electrolyte Check ............................ 20

Battery Charging ................................................ 21

Mower Deck Removal/Reinstallation .......... 22-23

Standard Mower Blade Service ................... 26-28

Standard Blade Wear Limits ....................... 26

Blade Removal/Replacement ...................... 26-27

33" Mower Blade............................................ 26

38" Mower Blade ............................................ 27

Sharpening Standard Blade(s) ................ 28

Ninja Mower Blade Service .................................. 28

Ninja Blade Wear Limits................................28

Ninja Blade Sharpening .................................29

Belt Service .................................................. 21-25

Mower Drive Belt Removal/Replacement 25

33" & 38" Deck Drive Belt.............................25

Traction Drive Belt Service .................... 21-24

Traction Drive Belt Removal ......................... 23

Traction Drive Belt Replacement .................. 24

Traction Drive Belt Adjustment ................ 29-30

Deck Level Adjustment .............................. 31-33B

Side to Side Level ............ 31-32 & 33A-33B

Front to Rear Level........................32-33& 33B

Sector Plates..................................................32

FrontLiftRod......................................33 &33A

Lubrication (Tractor] .............................. 17-18

Front Wheel Bearings ......................................... 17

Axle Spindles ....................................................... 17

Steering Shaft ...................................................... 17

Clutch/Brake Pivot............................................... 17

Steering Sector Gear .......................................... 17

Steering Drag Link .............................................. 18

Steering Tie Rod ................................................. 18

Park Brake Latch ................................................ 18

Deck Lift Mechanism .......................................... 18

Blade Engagement Mechanism ......................... 18

Engine Service ............................................. 19

Engine Air Pre-Cleaner ....................................... 19

Engine Air Cleaner .............................................. 19

Spark Plug ........................................................... 19

Fuel Filter ........................................................... 19

Engine Cooling System ...................................... 20

Shifter Adj ustment ............................................ 34

Steering Adjustment ......................................... 34

Wheel Brake Adjustment .................................. 35

ELECTRICAL SYSTEM ................................. 36-37

Wiring Harness Routing ...................................... 36

DIAGRAMS, Briggs Engine w/o lights................ 37

DIAGRAMS, Briggs Engine w/lights................... 37

WARRANTY ....................................................... 38

PRIMARY MAINTENANCE ............................ 39-42

Page 5

FAMILIARIZATION

H_.'t::1:! P"_IHE:I _v,(o]_] ::!mid_Ill Lv,I:1:1:1 Ko]).]P',_In/ (o]; •

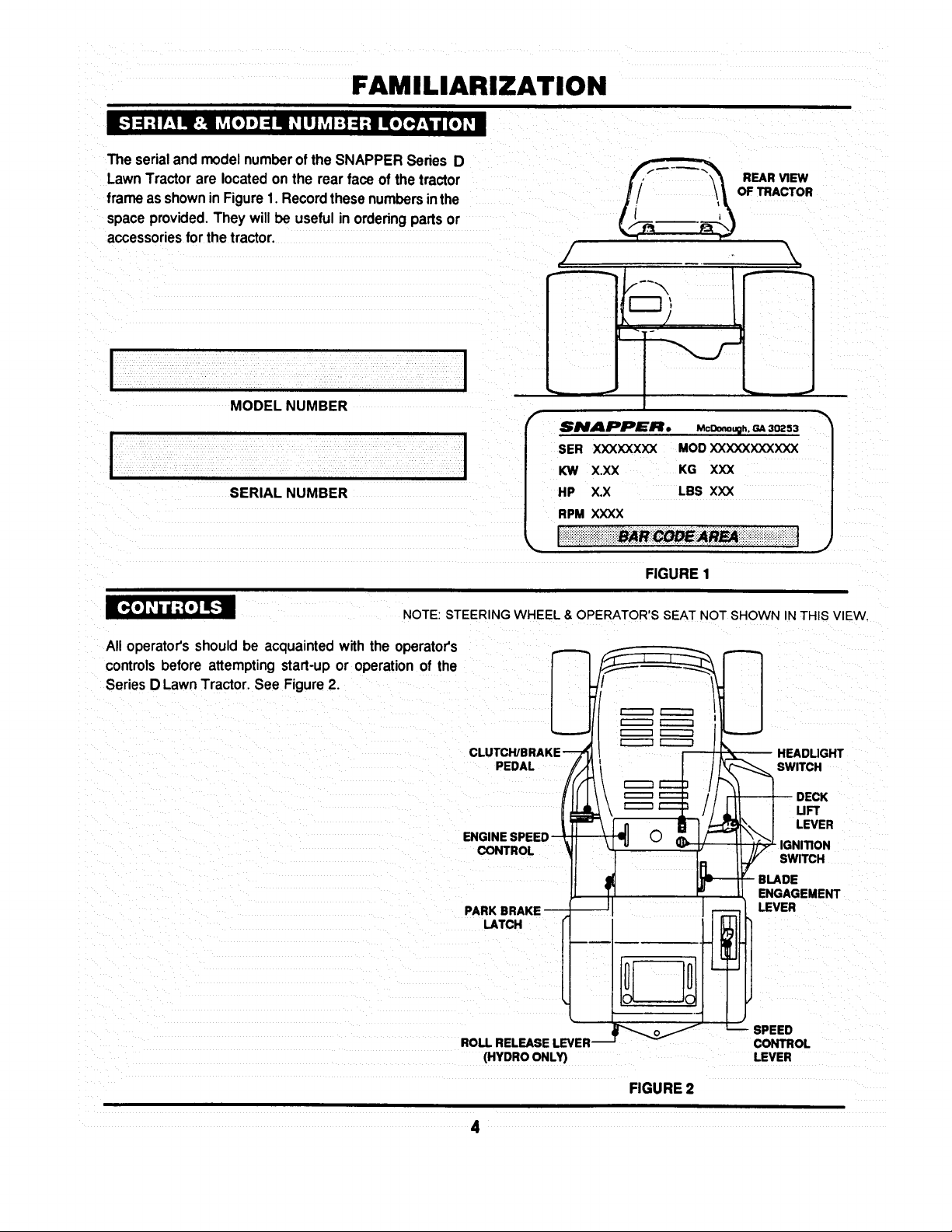

The serial and model number of the SNAPPER Series D

Lawn Tractor are located on the rear face of the tractor

frame as shown in Figure 1. Record these numbers inthe

space provided. They will be useful in ordering parts or

accessories for the tractor.

I

MODEL NUMBER

!

SERIAL NUMBER

REAR VIEW

_/. !_OF _ACTOR

/ \

/

SNAPPER. McOn.p. = 3o2ss

SER XXXXXXXX MOD XXXXXXXXXXX

KW X.XX KG XXX

HP X.X LBS XXX

RPM XXXX

_iiiii_ii_ii_iiiiiii_}iiii_ii!i!_!iii_i_!__e_n_iii!i!i!i_iii!_!i!iiii_!_i_ii_i!_i_i_!

m[o{o]: ind:To]_!

Alloperator'sshouldbe acquaintedwiththe operator's

controlsbefore attemptingstart-up or operationof the

SeriesD LawnTractor.See Figure2.

NOTE: STEERING WH EEL & OPERATOR'S SEAT NOT SHOWN IN THIS VIEW.

PEDAL

ENGINE SP

CONTROL

PARK BRAKE

LATCH

FIGURE 1

__W HEADLIGHT

ITCH

DECK

UFT

.°v°.

IGNITION

I_J/ SWITCH

-_ BLADE

! E_G_RGEMENT

(HYDRO ONLY)

4

SPEED

CONTROL

LEVER

FIGURE 2

Page 6

FAMILIARIZATION

[_o] Lv,I ".,To]_,1:1_,b u_

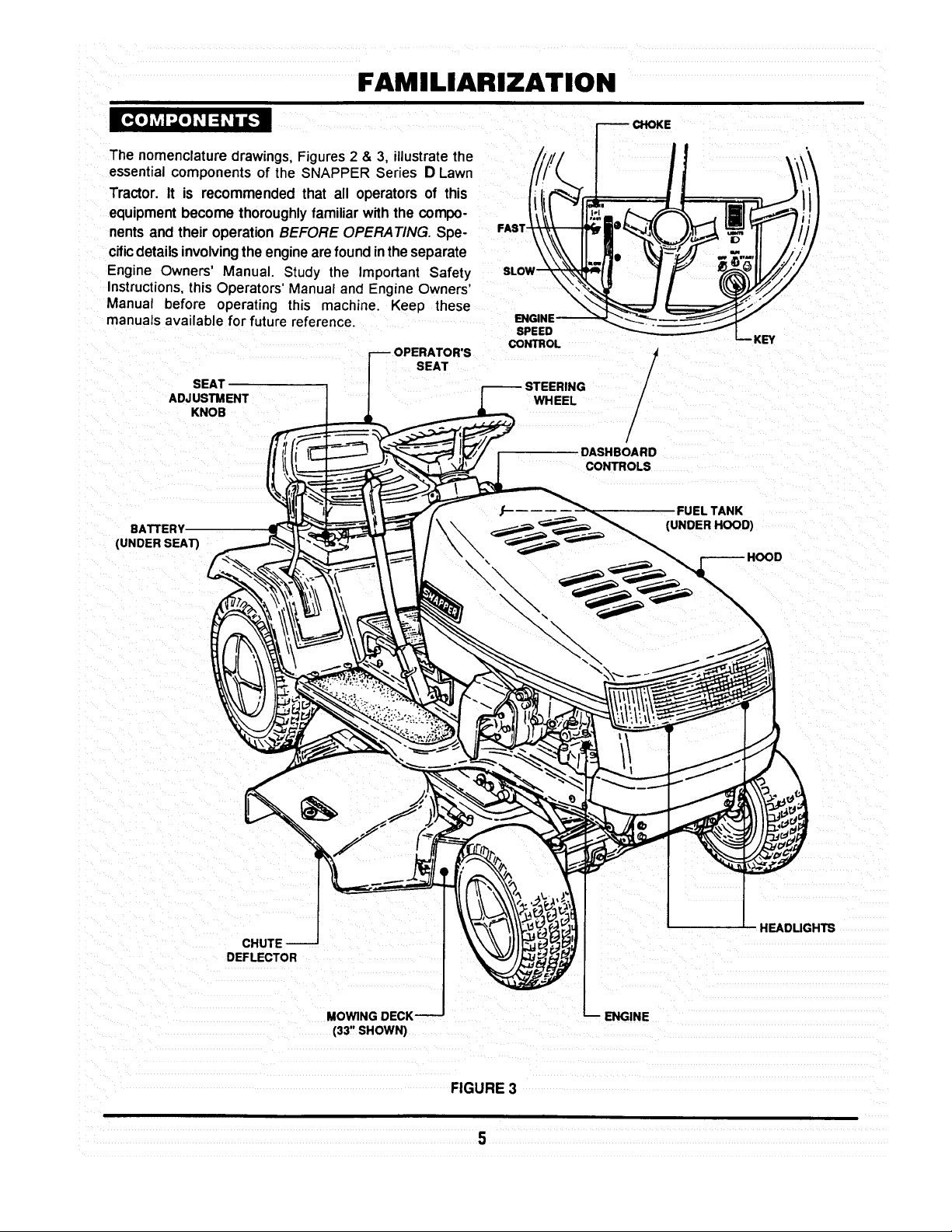

The nomenclature drawings, Figures 2 & 3, illustrate the

essential components of the SNAPPER Series D Lawn

Tractor. It is recommended that all operators of this

equipment become thoroughly familiar with the compo-

nents and their operation BEFORE OPERATING. Spe-

cific details involving the engine are found in the separate

Engine Owners' Manual. Study the Important Safety

Instructions, this Operators' Manual and Engine Owners'

Manual before operating this machine. Keep these

manuals avail able for future reference.

---OPERATOR'S

SEAT

ADJUSTMENT

KNOB

BATTERY

(UNOER SEAR

SEAT

_ CHOKE

FAST_i

SLOW-_

ENGINE-_-_

SPEED

CONTROL

!

/

WHEEL /

/

.DASHBOARD

CONTROLS

FUEL TANK

(UNDER HOOD)

CHUTE

DEFLECTOR

MOWING DECK

(33" SHOWN)

HEADUGHTS

ENGINE

FIGURE 3

Page 7

OPERATING INSTRUCTIONS

I d :! =5.'t if:! :_iI It.,].-I :(H ;I ii [..1,i

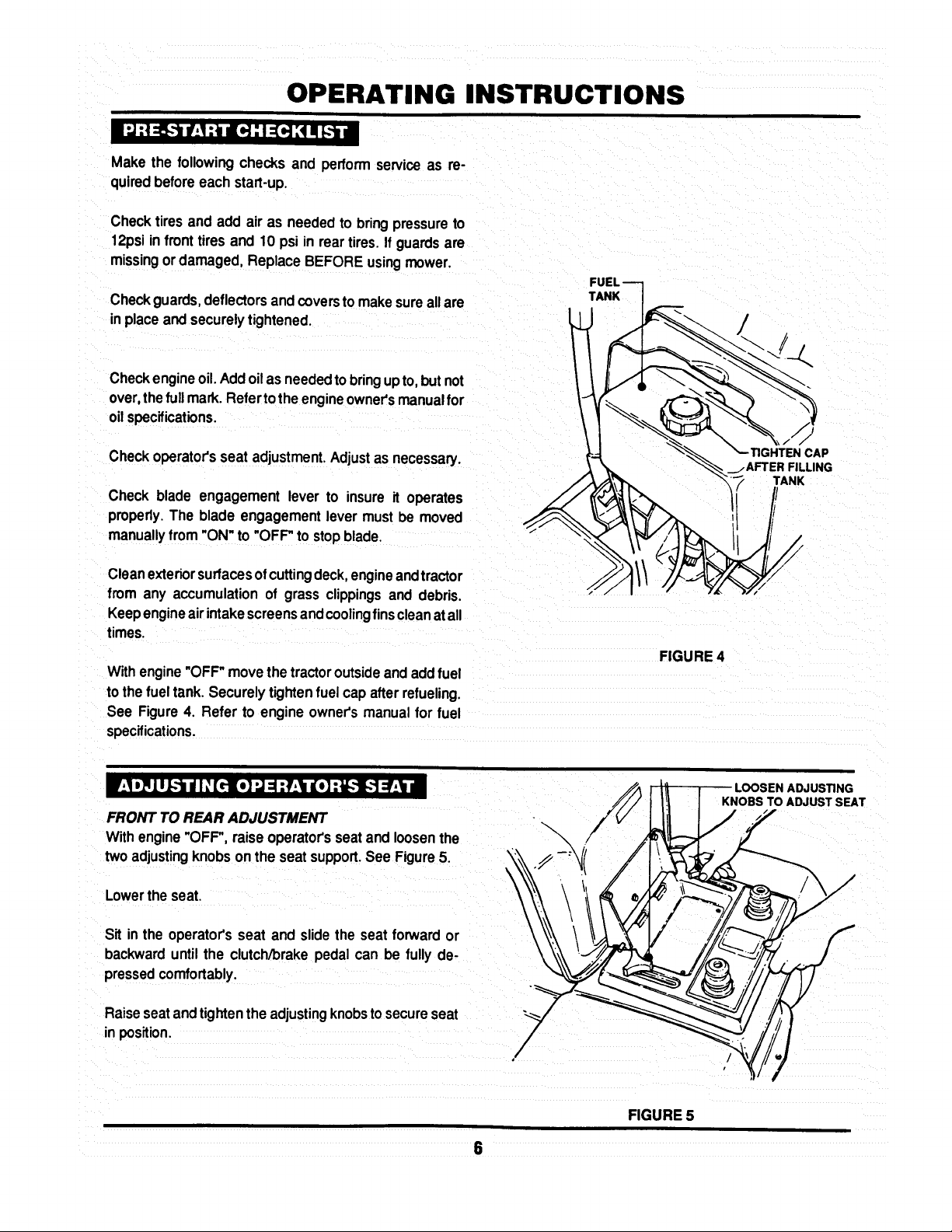

Make the followingchecks and perform serviceas re-

quiredbeforeeach start-up.

Checktires and add air as needed to bringpressureto

12psi infronttires and 10 psi in reartires. Ifguardsare

missingordamaged, Replace BEFORE usingmower.

Checkguards,deflectorsand coverstomakesureallare

inplaceand securelytightened.

Checkengineoil.Addoil asneededtobringupto,butnot

over,thefullmark.Refertotheengineowner'smanualfor

oilspecifications.

Checkoperator'sseat adjustment.Adjustasnecessary.

Check blade engagement lever to insure it operates

properly.The blade engagement lever mustbe moved

manuallyfrom "ON" to "OFF"to stopblade.

Cleanexteriorsurfacesofcuttingdeck,engineandtractor

from any accumulationof grass clippingsand debris.

Keepengineairintakescreensandcoolingfinscleanatall

times.

Withengine"OFF"movethe tractoroutsideand addfuel

tothe fueltank.Securely tightenfuelcapafterrefueling.

See Figure4. Refer to engine owner'smanual for fuel

specifications.

TANK

/

CAP

_.AFTER FILLING

TANK

FIGURE 4

FRONT TO REAR ADJUSTMENT

Withengine"OFF", raise operator'sseatand loosenthe

twoadjustingknobsonthe seat support.See Figure5.

Lowerthe seat.

Sit inthe operator'sseat and slide the seat forwardor

backwarduntilthe clutch/brakepedal can be fully de-

pressedcomfortably.

Raiseseatandtightentheadjustingknobstosecureseat

inposition.

LOOSEN ADJUSTING

KNOBS TO ADJUST SEAT

FIGURE 5

6

Page 8

OPERATING INSTRUCTIONS

:,In#,I :_idI: [rl:_..'t liD]"J"JI: [tl =1_[r] I: I =i

I _

STARTING ENGINE

Take a comfortablepositionin seat ofridingmower,look

aroundto make surethatthe area you aregoingto mow

is clear of people, children and pets. Take note of any

stationaryobstacles!

NOTE:

The interlocksystemwillpreventtheenginefromstarting

ifthe bladeengagementleverisinthe "ON" (up)position.

Ifthe interlocksystemeverfailsto work,DO NOTOPER-

ATE the tractoruntilthe interlockhas been repaired.

Pushbladeengagementleverdowntothe "OFF"position.

See Figure6.

Depressthe clutch/brakepedalfully. See Figure7.

PUSH BLADE ENGAGEMENT

TO START ENGINE

ENGAGEMENT

LEVER

\

\

FIGURE 6

NOTE:

The seat interlockwillshutoff the engine ifthe operator

getsofftheseatwithoutsetting theparkingbrakeleveror

ifthe bladeisrunning.Iftheinterlockeverfailstowork,DO

NOT OPERATE the tractoruntil the interlockhas been

repaired.

Choke enginefor coldstartingby moving enginespeed DOWN

controlto "CHOKE" position. Littleor no chokingwillbe '_',X _

needed when restarting a warm engine. See Figure 8.

Insertkey inswitch.

Turn key to "START" position to crank engine and hold

until engine starts, then release key.

NOTE:

DO NOT crank engine for more than five secondsat a

time. This will helppreventthe starterfrom overheating

an_or runningdownthe battery.Ifcrankingtime ismore

than five seconds, locate and correct cause of starting

problem.

\

L

FIGURE 7

CHOKE

After enginestarts,release key, move theenginespeed

controltothe"FAST"positionandallow enginetowarmup

before proceeding.See Figure8.

STOPPING ENGINE

Turn key to "STOP". See Figure8.

ENGINE -_-_-._ _. _--- _--_,,_

LKEy

FIGURE 8

Page 9

OPERATING INSTRUCTIONS

_._net :_unlI: [_lr:l-_ n[o]"J"JI _[riYl: 1:1=1nl ,] ;1Lvi=

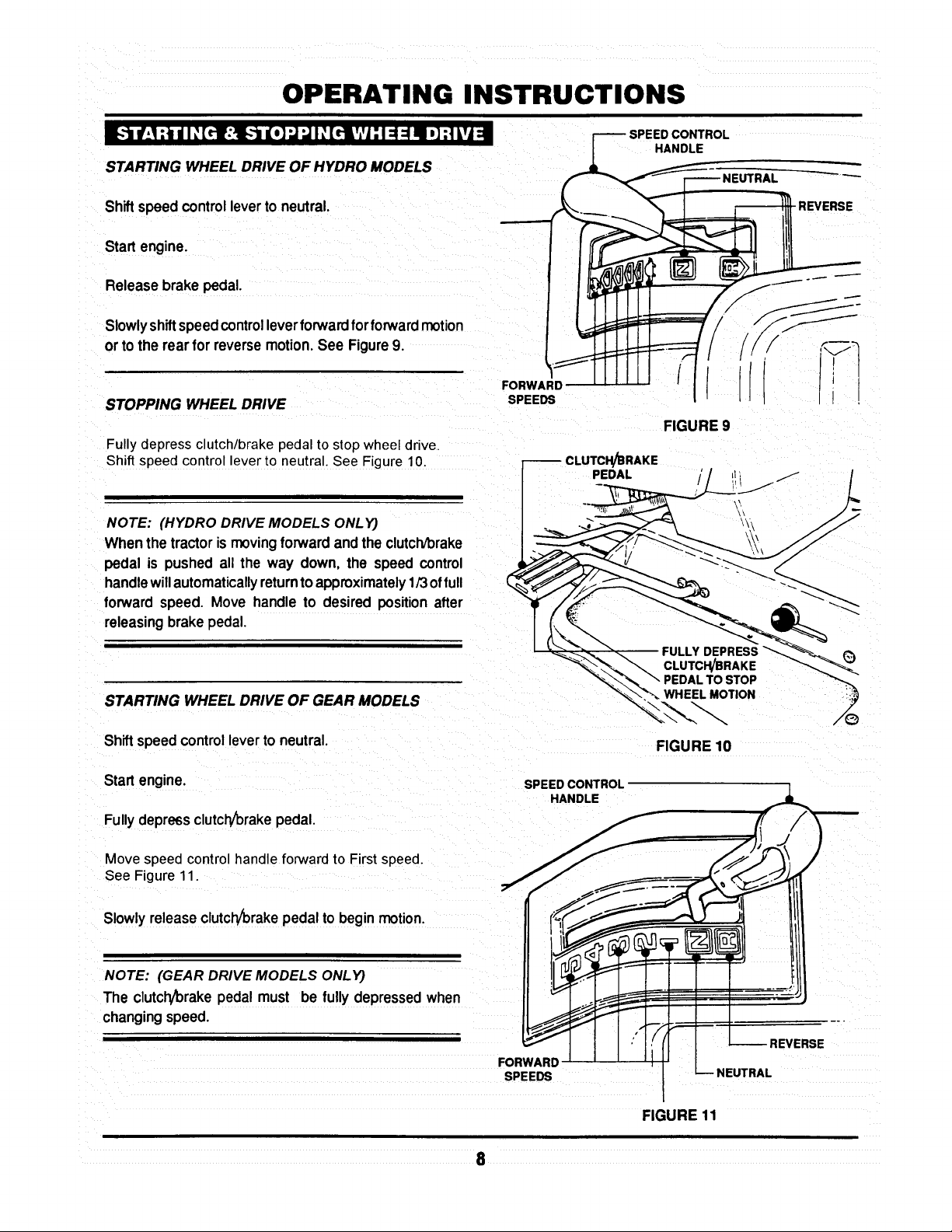

STARTING WHEEL DRIVE OF HYDRO MODELS

Shift speedcontrollevertoneutral.

Start engine.

Release brakepedal.

Slowlyshiftspeedcontrolleverforwardforforwardmotion

or tothe rear for reverse motion.See Figure9.

STOPPING WHEEL DRIVE

Fully depress clutch/brake pedal to stop wheel drive.

Shift speed control lever to neutral. See Figure 10.

NOTE: (HYDRO DRIVE MODELS ONLY)

When the tractor ismoving forwardand the clutch/brake

pedal is pushed all the way down, the speed control

handlewillautomaticallyreturnto approximately1/3offull

forward speed. Move handle to desired positionafter

releasingbrakepedal.

FORWARD

SPEEDS

HANDLE

REVERSE

I

FIGURE 9

CLUTCH/BRAKE

PEDAL

STARTING WHEEL DRIVE OF GEAR MODELS

Shiftspeed controlleverto neutral.

Startengine.

Fullydepressclutch/brakepedal.

Move speedcontrolhandle forward to Firstspeed.

See Figure11.

Slowlyrelease clutch/brakepedal to beginmotion.

NOTE: (GEAR DRIVE MODELS ONLY)

The clutch/brake pedal must be fully depressedwhen

changingspeed.

SPEED CONTROL

HANDLE

FORWARD

SPEEDS

CLUTCH/BRAKE

PEDAL TO STOP

WHEEL MOTION

FIGURE 10

REVERSE

NEUTRAL

FIGURE 11

8

Page 10

OPERATING INSTRUCTIONS

_-'lmmr.1:_mnlI_[rt::lE._m go]..J..JI_[it L',[olV,'J=1:l :| mF_,lp]=l

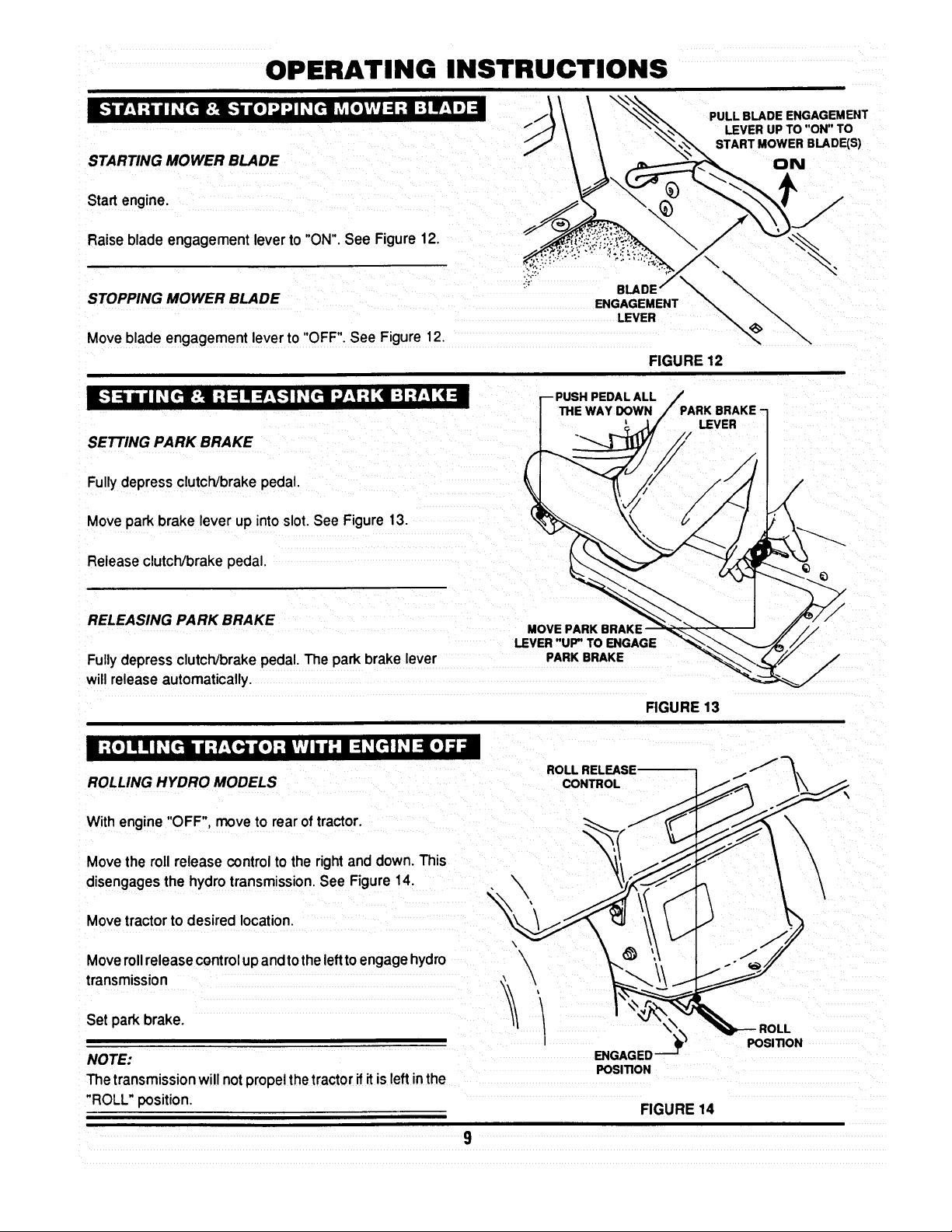

STARTING MOWER BLADE

Startengine.

Raise blade engagement leverto "ON". See Figure 12.

STOPPING MOWER BLADE

Move bladeengagement leverto "OFF". See Figure 12.

I_-.1:a / dI,_[rl:Ji :t :1al:f.!,.-] I_'[rll ".,/:I:t [1:1 ::El [4::1

SETTING PARK BRAKE

Fullydepress clutch/brake pedal.

Movepark brake lever up intoslot. See Figure13.

Release clutch/brakepedal.

PULL BLADE ENGAGEMENT

LEVER UP TO "ON" TO

START MOWER BLADE(S)

ON

ENGAGEMENT

LEVER

FIGURE 12

PEDALALL

PARK BRAKE

LEVER

RELEASING PARK BRAKE

Fully depress clutch/brake pedal. The park brake lever

will release automatically.

I :{o] ! q I _[ttl /; f-Till I[Ol:llV,'| 1111:I =1_[d I _I ::l[o]d =1

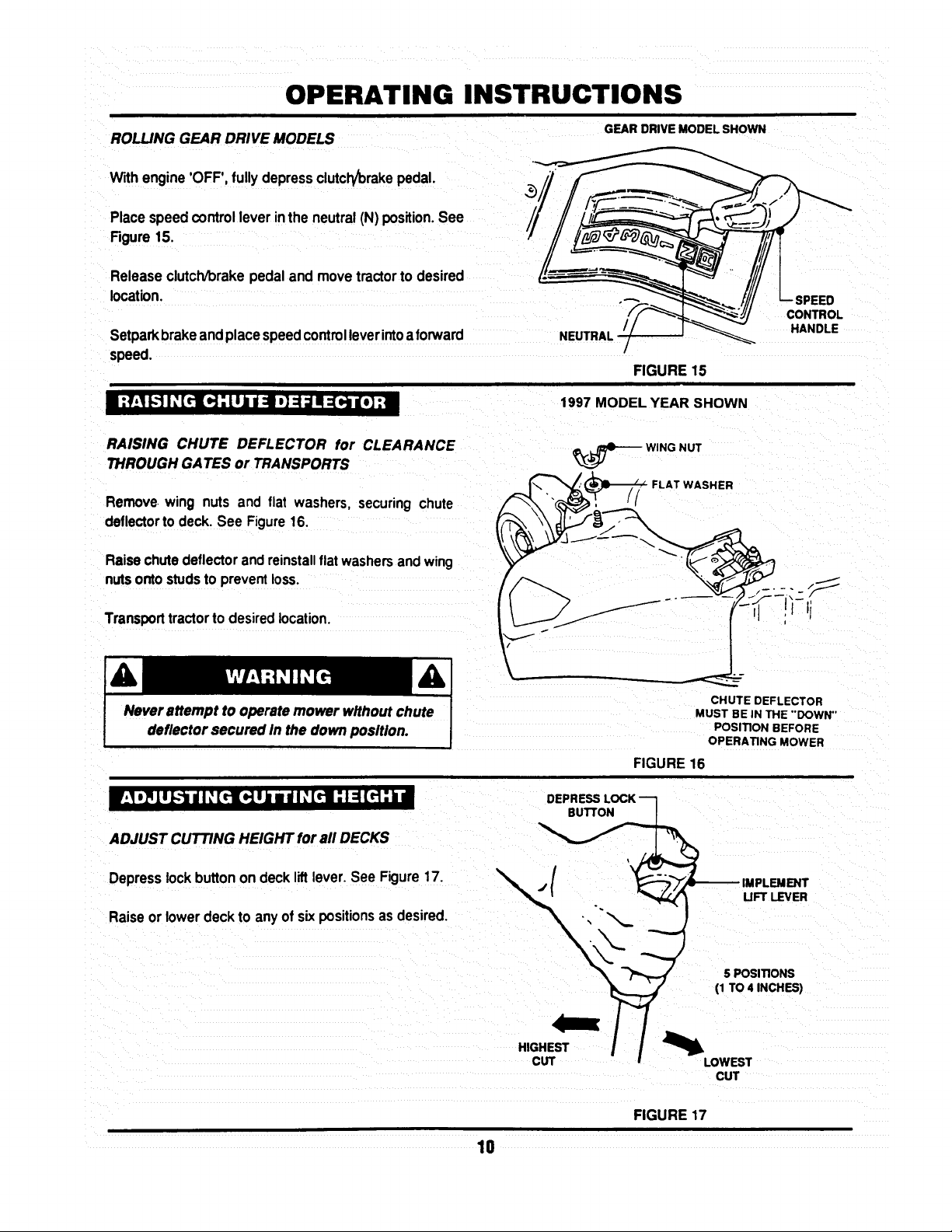

ROLLING HYDRO MODELS

Withengine "OFF", move to rearof tractor.

Movethe roll release control to the right and down. This

disengages the hydro transmission. See Figure 14.

Move tractorto desired location.

Moveroll release controlupandtothelefttoengage hydro

transmission

Set park brake.

NOTE:

Thetransmission will not propel thetractor ifit isleft inthe

"ROLL" position.

MOVE PARK

LEVER"UP"TOENGAGE

PARK BRAKE

FIGURE 13

ROLL RELEASE --

CONTROL

\

\

\

POSITION

ENGAGED

POSITION

FIGURE 14

Page 11

OPERATING INSTRUCTIONS

ROLLING GEAR DRIVE MODELS GEARDRIVEMODELSHOWN

Withengine'OFF', fullydepressclutcl_/brakepedal.

Placespeedcontrollever intheneutral(N)position.See

Figure15.

Release clutch/brakepedaland movetractortodesired

location.

Setparkbrakeandplacespeedcontrolleverintoaforward

speed.

/

FIGURE 15

-SPEED

CONTROL

HANDLE

m:_,_[_1I: [rl_]: t,J=i =1,]=1il_=[,,lo_ia=

RAISING CHUTE DEFLECTOR for CLEARANCE

THROUGH GATES or TRANSPORTS

Remove wing nuts and flat washers, securing chute

deflector to deck. See Figure 16.

Raise chute deflector and reinstall flat washers and wmg

nuts onto studs to prevent loss.

Transport tractor to desired location.

Never attempt to operatemower without chute

deflector secured In the down position.

i]I o_LuZ,,._dI _(_ub • dI_(_: I_ [_: b•

ADJUST CUTTING HEIGHT for all DECKS

1997 MODEL YEAR SHOWN

WING NUT

_,,._ FLAT WASHER

CHUTE DEFLECTOR

MUST BE IN THE "'DOWN"

POSITION BEFORE

OPERATING MOWER

FIGURE 16

DEPRESS LOCK ---I

Depresslockbuttonon deckliftlever.See Figure17.

Raiseor lowerdeckto anyof six positions as desired.

(15.I.oPO::_ON__s,

CUT

FIGURE 17

10

Page 12

OPERATING INSTRUCTIONS

I / I ",.Z.."_l] _I ;l [*;'i'l I_[rII

Forbest results,usethe followingtipswhen mowing.

Whenmowing,cutonly 1/3ofgrassheight.Cuttinggrass

deepercouldbe harmfulto yourlawn.

If cuttingextremelytall grass,make one cuttingwiththe

deck in its highestcuttingposition,then lowerdeck to

desiredposition and asecondcut.

Mow whenlawnis dry.

Mow often.Shortergrassclippingsdecomposequicker.

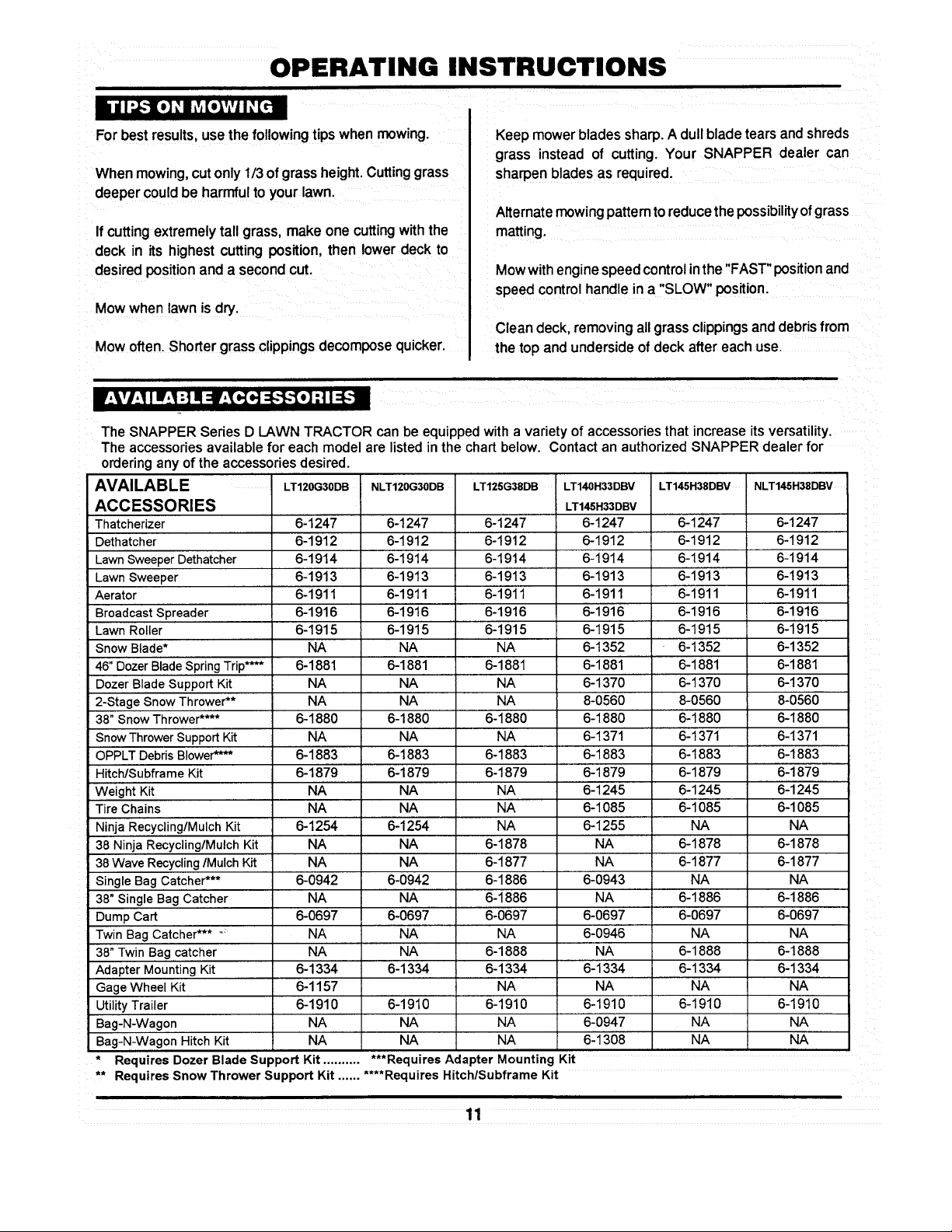

V'_ltl'_1!W_.!:] il =f;_*-[*4 =b'_._*]:! I $1

The SNAPPER Series D LAWN TRACTOR can be equipped with a variety of accessories that increase its versatility.

The accessories available for each model are listed in the chart below. Contact an authorized SNAPPER dealer for

ordering any of the accessories desired.

AVAILABLE

LT120G30DB

NLT120G30DB

ACCESSORIES

Thatcherizer

Dethatcher

Lawn SweeperDethatcher

Lawn Sweeper

Aerator

Broadcast Spreader

Lawn Roller

Snow Blade*

46" DozerBladeSpringTrip****

Dozer Blade Support Kit

2-Stage Snow Thrower**

38" Snow Thrower....

SnowThrowerSupport Kit

OPPLT DebrisBlower****

Hitch/Subframe Kit

Weight Kit

Tire Chains

Ninja Recycling/Mulch Kit

38 Ninja Recycling/Mulch Kit

38 Wave Recycling/Mulch Kit

Single Bag Catcher***

38" Single Bag Catcher

Dump Cart

Twin Bag Catcher......

38" Twin Bag catcher

Adapter Mounting Kit

Gage Wheel Kit

Utility Trailer

Bag-N-Wagon

Bag-N-Wagon Hitch Kit

* Requires Dozer Blade Su;_port Kit .......... ***Requires Adapter Mounting Kit

** Requires Snow Thrower Support Kit ...... ****Requires Hitch/Subframe Kit

6-1247

6-1912

6-1914

6-1913

6-1911

6-1916

6-1915

NA

6-1881

NA

NA

6-1880

NA

6-1883

6-1879

NA

NA

6-1254

NA

NA

6-0942

NA

6-0697

NA

NA

6-1334

6-1157

6-1910

NA

NA

6-1247

6-1912

6-1914

6-1913

6-1911

6-1916

6-1915

NA

6-1881

NA

NA

6-1880

NA

6-1883

6-1879

NA

NA

6-1254

NA

NA

6-0942

NA

6-0697

NA

NA

6-1334

6-1910

NA

NA

Keep mower blades sharp. Adull blade tearsandshreds

grass instead of cutting. Your SNAPPER dealer can

sharpen blades as required.

Alternate mowing pattern to reduce the possibility of grass

matting.

Mow withenginespeed controlinthe"FAST"positionand

speed controlhandlein a "SLOW" position.

Clean deck, removing all grass clippingsanddebris from

thetop and undersideofdeck after eachuse.

LT125G38DB

6-1247

6-1912

6-1914

6-1913

6-1911

6-1916

6-1915

NA

6-1881

NA

NA

6-1880

NA

6-1883

6-1879

NA

NA

NA

6-1878

6-1877

6-1886

6-1886

6-0697

NA

6-1888

6-1334

NA

6-1910

NA

NA

LT140H33DBV

LT145H33DBV

6-1247

6-1912

6-1914

6-1913

6-1911

6-1916

6-1915

6-1352

6-1881

6-1370

8-0560

6-1880

6-1371

6-1883

6-1879

6-1245

6-1085

6-1255

NA

NA

6-0943

NA

6-0697

6-0946

NA

6-1334

NA

6-1910

6-0947

6-1308

LT145H38DBV

6-1247

6-1912

6-1914

6-1913

6-1911

6-1916

6-1915

6-1352

6-1881

6-1370

8-0560

6-1880

6-1371

6-1883

6-1879

6-1245

6-1085

NA

6-1878

6-1877

NA

6-1886

6-0697

NA

6-1888

6-1334

NA

6-1910

NA

NA

NLT145H38DBV

6-1247

6-1912

6-1914

6-1913

6-1911

6-1916

6-1915

6-1352

6-1881

6-1370

8-0560

6-1880

6-1371

6-1883

6-1879

6-1245

6-1085

NA

6-1878

6-1877

NA

6-1886

6-0697

NA

6-1888

6-1334

NA

6-1910

NA

NA

11

Page 13

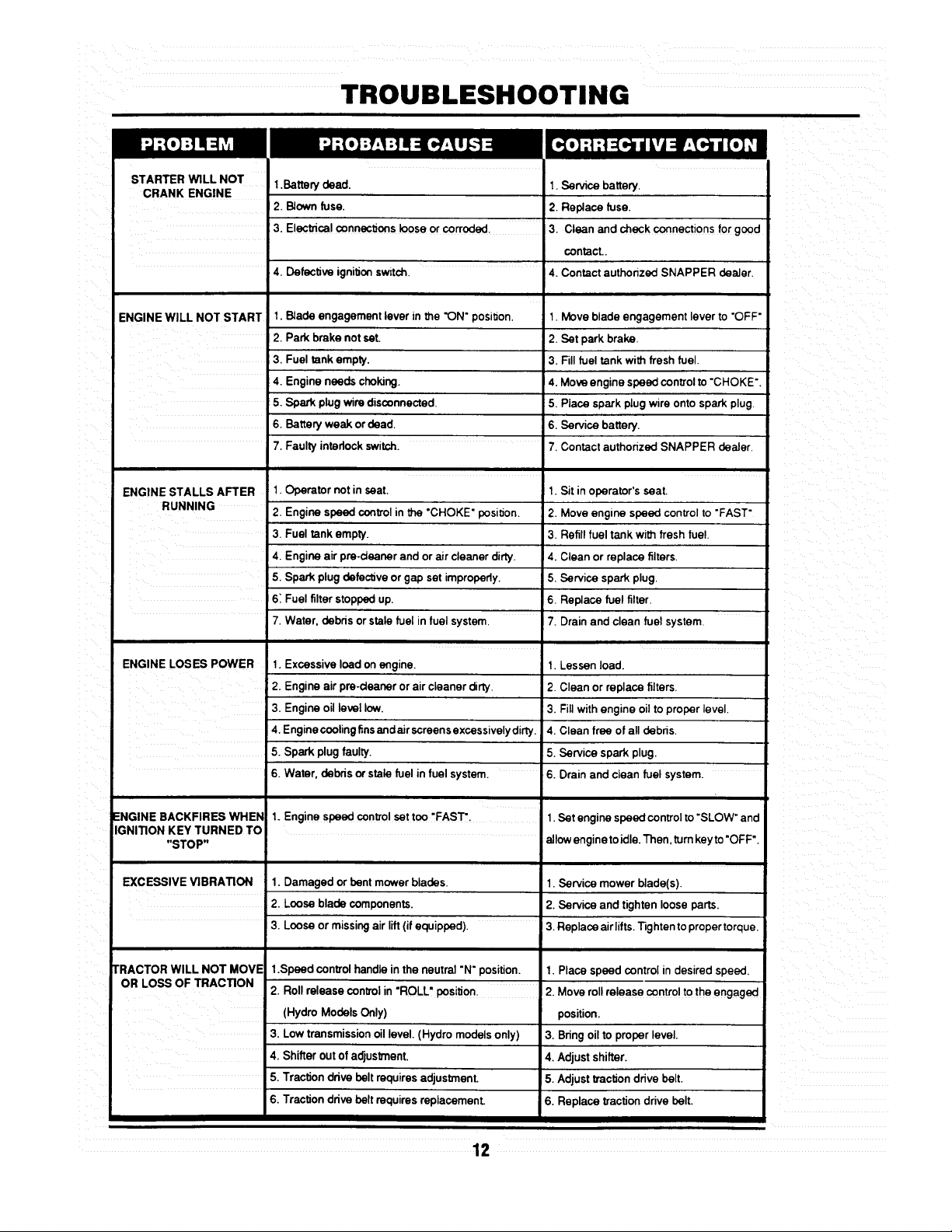

TROUBLESHOOTING

STARTER WiLL NOT

CRANK ENGINE

ENGINE WILL NOT START

ENGINE STALLS AFTER

RUNNING

1.Battery dead. 1. Service battery.

2. Blown fuse. 2. Replace fuse.

3. Electrical connections loose or corroded. 3. Clean end check connections for good

contact..

4. Defective ignition switch. 4. Contact authonzed SNAPPER dealer.

1. Bladeengagement lever inthe "ON" position.

I 2. Park brake not set.

3. Fuel tank empty.

4. Engine needs choking.

! 5. Spark plug wire disconnected.

6. Battery weak or dead

7. Faultyintedock switch.

1. Operator not inseat.

2. Engine speed controlinthe "CHOKE" position.

3. Fuel tank empty.

I

4. Engine airpra-deaner and orair cleaner dirty.

5. Spark plugdefective or gap set improperly.

6: Fuel filterstoppedup.

7. Water, debds or stalefuel in fuel system.

1. Move blade engagement lever to "OFF"

2. Set park brake.

3. Fill fuel tank with fresh fuel.

4. Move engine speed control to "CHOKE"

5. Place spark plug wire onto spark plug.

6. Service battery.

7. Contact authorized SNAPPER dealer.

1. Sit in operator's seat.

2. Move engine speed control to "FAST"

3. Refill fuel tank with fresh fue!.

14. Clean or replace filters.

5. Service spark plug.

6. Replace fuel filter.

7. Drain and clean fuel system.

ENGINE LOSES POWER

1. Excessiveload onengine.

2. Engine airpre-deaner or air cleanerdirty.

3. Engineoil level low.

4.Enginecoolingfinsendair screensexcessivelydirty.

5. Spark plug faulty.

6. Water, debds orstale fuel infuel system.

ENGINE BACKFIRES WHEN

1. Engine speed control set too "FAST". 1.Set engine speed control to "SLOW" and

IGNITION KEY TURNED TO

"STOP"

EXCESSIVE VIBRATION 1. Damaged or bent mower blades.

2. Loose blade components.

3. Loose or missing air lift (if equipped).

TRACTOR WILL NOT MOVE

OR LOSS OF TRACTION

.Speed control handle in the neutral "N" position. 1. Place speed control in desired speed,

2. Roll release control in "ROLL" Positio n . 2. Move roll release control to the engaged

(Hydro Models Only) position.

3. Lowtransmissionoillevel. (Hydro modelsonly)

4. Shifter outof adjustment.

5. Tractionddve beltrequiresadjustment.

6. Tractionddve beltrequires replacement.

t. Lessen load.

2. Clean or replace filters.

3. Fill with engine oil to proper level.

4. Clean free of all debns.

5. Service spark plug.

6. Drain and clean fuel system.

allow engine to idle. Then, turn key to "OFF".

1. Service mower blede(s).

2. Service and tighten loose parts.

3. Replace airlifts. Tighten to proper torque.

3. Bdngoil toproper level.

4. Adjustshifter.

5. Adjust_'action drivebelt.

6. Replace tractiondrive belt.

12

Page 14

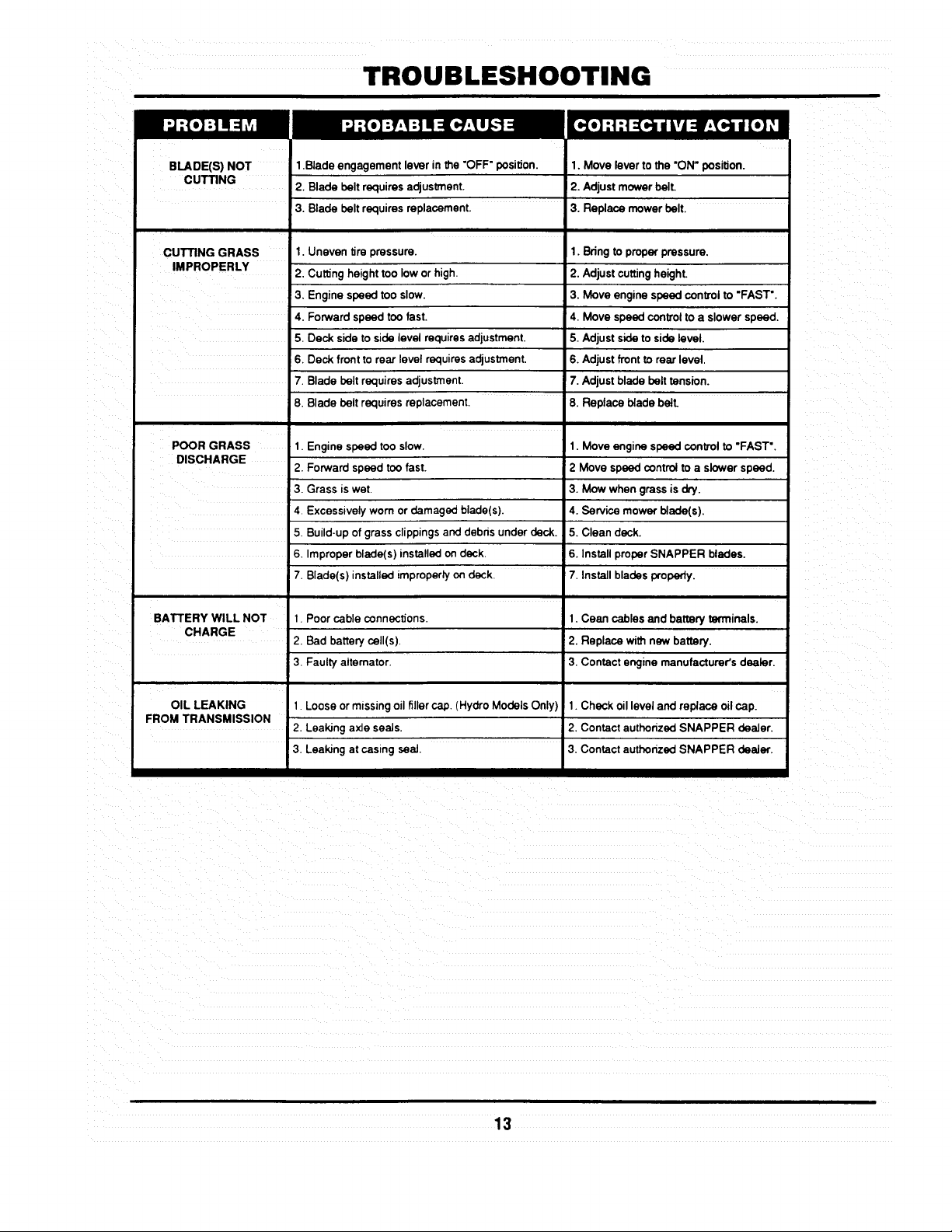

TROUBLESHOOTING

BLADE(S) NOT

CUllING

1.Bladeengagement leverin the "OFF"position.

2, Blade beltrequiresadjustment.

3. Blade belt requiresreplacement.

CUTTING GRASS 1.

IMPROPERLY

POOR GRASS 1.

DISCHARGE

BATTERY WILL NOT 1. Poor cable connections.

CHARGE

Uneven tire pressure.

2.

Cuing height too low or high.

3.

Engine speed too slow.

4.

Forward speed too fast.

5.

Deck side to side level requires adjustment.

6.

Deck front to rear level requires adjustment.

7,

Blade belt requires adjustment.

8.

Blade belt requires replacement.

Engine speed too slow.

2. Forward speed too fast.

3. Grass is wet.

4 Excessively worn or damaged blade(s).

5. Build-up of grass clippings and debns under deck.

6. Improper blade(s) installed on deck.

7. Blade(s) installed improperly on deck.

2. Bad battery cell(s).

3. Faulty alternator. 3. Contact engine manufacturer's dealer.

1. Move leverto the "ON"position.

2. Adjustmower belt.

3. Replace mowerbelt.

1. Bringto properpressure.

2. Adjustcuttingheight.

3. Move enginespeed oontrol to "FAST'.

4. Move speed controltoa slowerspeed.

5. Adjustsideto side level.

6. Adjustfront to rear level.

7. Adjustblade belt tension.

8, Replace bladebelt.

1. Move enginespeedoontrol to "FAST".

2 Move speed control to a slower speed.

3. Mow when grassis dry.

4.Servicemower blade(s).

5.Cleandeck.

6.InstallproperSNAPPER blades.

7.Installbladesproperly,

I.Cean cablesand batteryterminals.

2. Replace withnew battery.

OIL LEAKING

FROM TRANSMISSION

1. Loose or missing oil filler cap. (Hydro Models Only) 1. Check oil level and replace oil cap.

2. Leaking axle seals. 2. Contact authorized SNAPPER dealer.

3. Leaking at casing seal 3. Contact authorized SNAPPER dealer.

13

Page 15

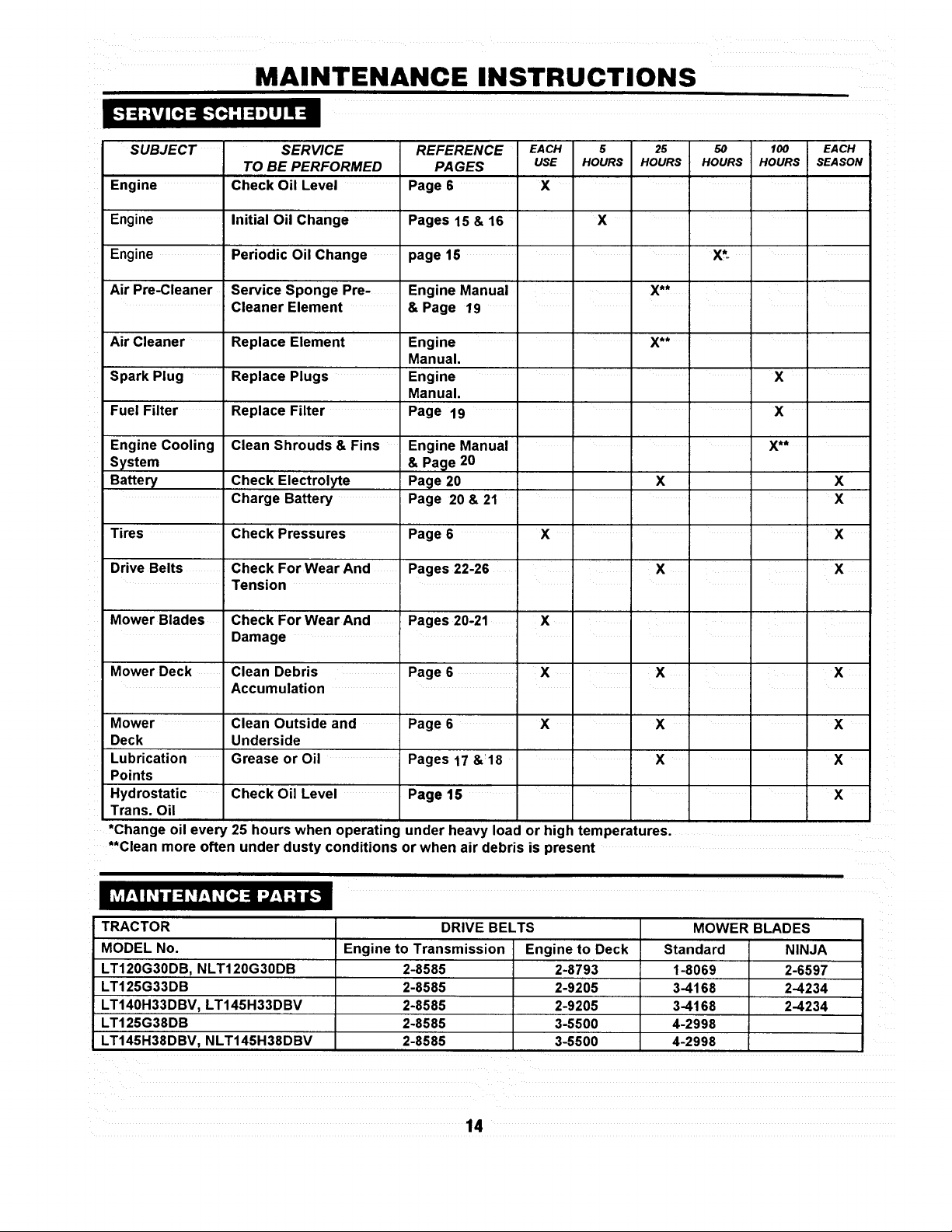

MAINTENANCE INSTRUCTIONS

SUBJECT

Engine

Engine

Engine

Air Pre-Cleaner

Air Cleaner

Spark Plug

Fuel Filter

Engine Cooling

System

Battery

Tires

Drive Belts

SERVICE

TO BE PERFORMED

Check Oil Level

Initial Oil Change

Periodic Oil Change

Service Sponge Pre-

Cleaner Element

Replace Element

Replace Plugs

Replace Filter

Clean Shrouds & Fins

Check Electrolyte

Charge Battery

Check Pressures

Check ForWear And

Tension

REFERENCE EACH 5 25 50 100 EACH

PAGES USE HOURS HOURS HOURS HOURS SEASON

Page 6 X

Pages 15 & 16 X

page 15 X*

Engine Manual X**

&Page 19

Engine X**

Manual.

Engine X

Manual.

Page 19 X

Engine Manual X**

& Page 20

Page 20 X X

Page 20 & 21 X

Page 6 X X

Pages 22-26 X X

Mower Blades

Mower Deck

Check ForWear And

Damage

Clean Debris

Pages 20-21 X

Page 6 X X X

i

Accumulation

Mower

Deck

Lubrication

Points

Hydrostatic

Trans. Oil

Clean Outside and

Underside

Grease or Oil

Check Oil Level

Page 6 X X X

Pages 17 &:18 X X

Page 15 X

*Change oil every 25 hours when operating under heavy load or high temperatures.

**Clean more often under dusty conditions or when air debris is present

TRACTOR

MODEL No.

LT120G30DB, NLT120G30DB

LTI25G33DB

LT140H33DBV, LT145H33DBV

LT125G38DB

LT145H38DBV, NLT145H38DBV

Engine to Transmission Engine to Deck Standard

DRIVE BELTS

2-8585 2-8793 1-8069

2-8585 2-9205 3-4168

2-8585 2-9205 3-4168

2-8585 3-5500 4-2998

2-8585 3-5500 4-2998

MOWER BLADES

NINJA

2-6597

2-4234

2-4234

14

Page 16

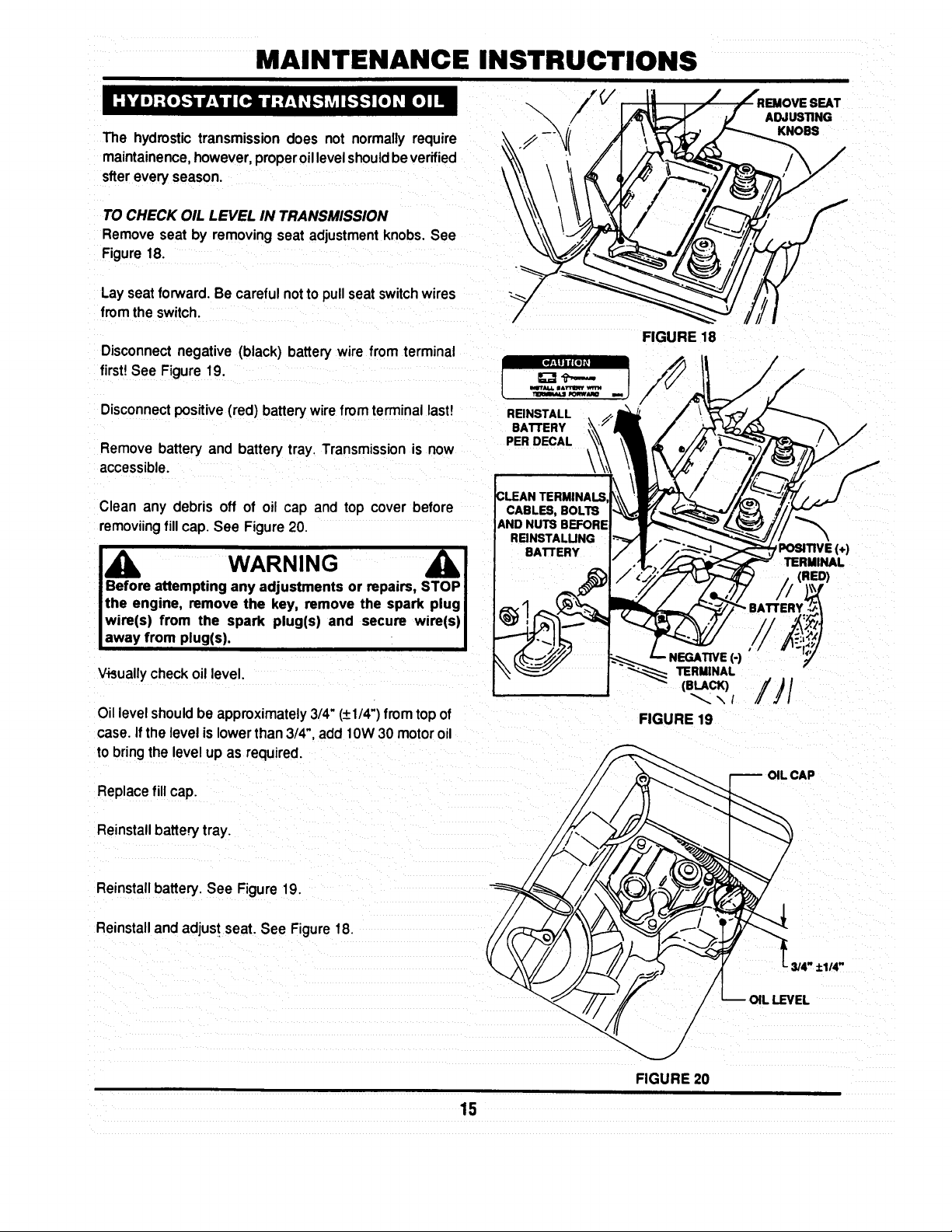

MAINTENANCE INSTRUCTIONS

The hydrostictransmissiondoes not normallyrequire

maintainence,however,properoillevelshouldbeverified

sftereveryseason.

TO CHECK OIL LEVEL IN TRANSMISSION

Remove seat by removing seat adjustment knobs, See

Figure 18.

Layseatforward. Becarefulnotto pullseatswitchwires

from the switch.

Disconnectnegative (black) batterywire from terminal

first!See Figure19.

Disconnectpositive(red) batterywirefromterminallast!

Remove batteryand battery tray. Transmissionis now

accessible.

Clean any debris off of oil cap and top cover before

removiing fill cap. See Figure 20.

Before attempting any adjustments or repairs, STOP

the engine, remove the key, remove the spark plug

wire(s) from the spark plug(s) and secure wire(s)

away from plug(s).

Visuallycheckoil level.

\

REINSTALL

BATTERY

PER DECAL

SEAT

ADJUSTING

KNOBS

FIGURE 18

\

POSITIVE(÷)

TERMINAL

(RED)

NEGATIVE (-)

TERMINAL

(BLACK)

Oillevelshouldbe approximately3/4" (+1/4")from topof

case. Ifthe levelislowerthan 3/4",add 10W30 motoroil

tobringthe levelup as required.

Replacefillcap.

Reinstallbatterytray.

Reinstall battery. See Figure 19.

Reinstallandadjust seat. See Figure18.

FIGURE 19

- 3/4" +1/4"

FIGURE 20

15

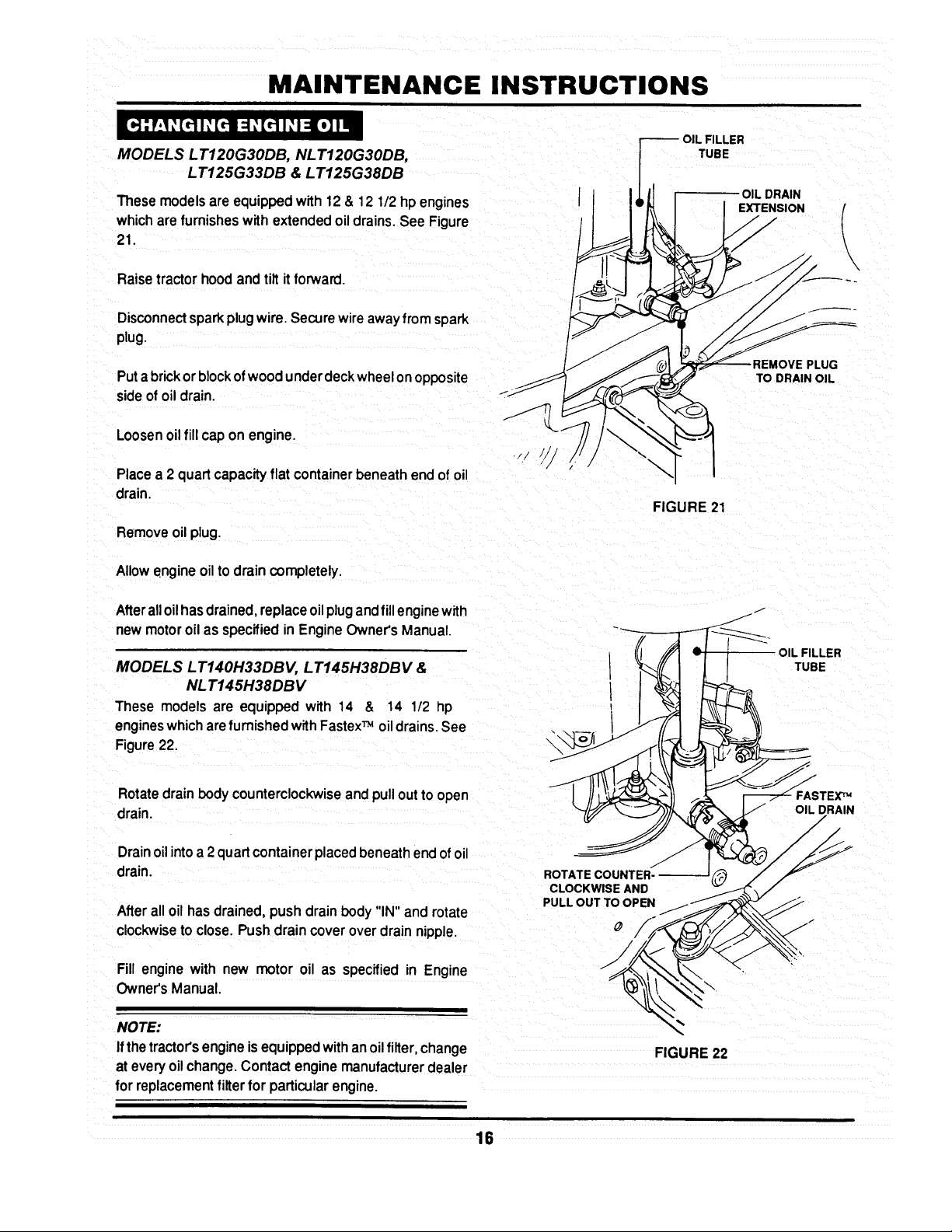

Page 17

MAINTENANCE INSTRUCTIONS

MODELS L T120G30DB, NL T120G30DB,

LT125G33DB & LT125G38DB

These models are equipped with 12 & 12 1/2 hp engines

which are furnishes with extended oil drains. See Figure

21.

Raisetractorhoodandtilt itforward.

Disconnectsparkplugwire.Securewireawayfrom soark

plug.

Putabrick or block ofwood under deck wheelon opposite

side ofoil drain.

Loosenoilfill cap on engine.

Placea 2 quart capacityflat containerbeneath endof oil

drain.

Removeoilplug.

FILLER

TUBE

OIL DRAIN

EXTENSION

\

PLUG

TO DRAIN OIL

FIGURE 21

Allowengineoilto drain completely.

After alloilhasdrained, replace oilplugand fillenginewith

new motor oil as specifiedin Engine Owner's Manual.

MODELS LT140H33DBV, LT145H38DBV &

NL T145H38DB V

These models are equipped with 14 & 14 1/2 hp

engineswhicharefurnished withFastexTM oildrains.See

Figure22.

Rotatedrain body counterclockwise and pullout to open

drain.

Drainoil into a 2quart container placed beneathend of oil

drain.

After all oil has drained, push drain body "IN" and rotate

clockwiseto close. Push drain cover over drain nipple.

Fill engine with new motor oil as specified in Engine

Owner's Manual.

L FILLER

TUBE

/

FASTEX'_

OIL DRAIN

ROTATE

CLOCKWISE AND

PULL OUT TO OPEN

NOTE:

Ifthetractor's engine isequipped withan oilfilter, change

at everyoilchange.Contactenginemanufacturerdealer

for replacementfilter for particularengine.

FIGURE 22

16

Page 18

MAINTENANCE INSTRUCTIONS

The followinglubricationpoints shouldbe servicedafter

each 25 operating hours to insure optimum performance

of the Series D Lawn Tractor.

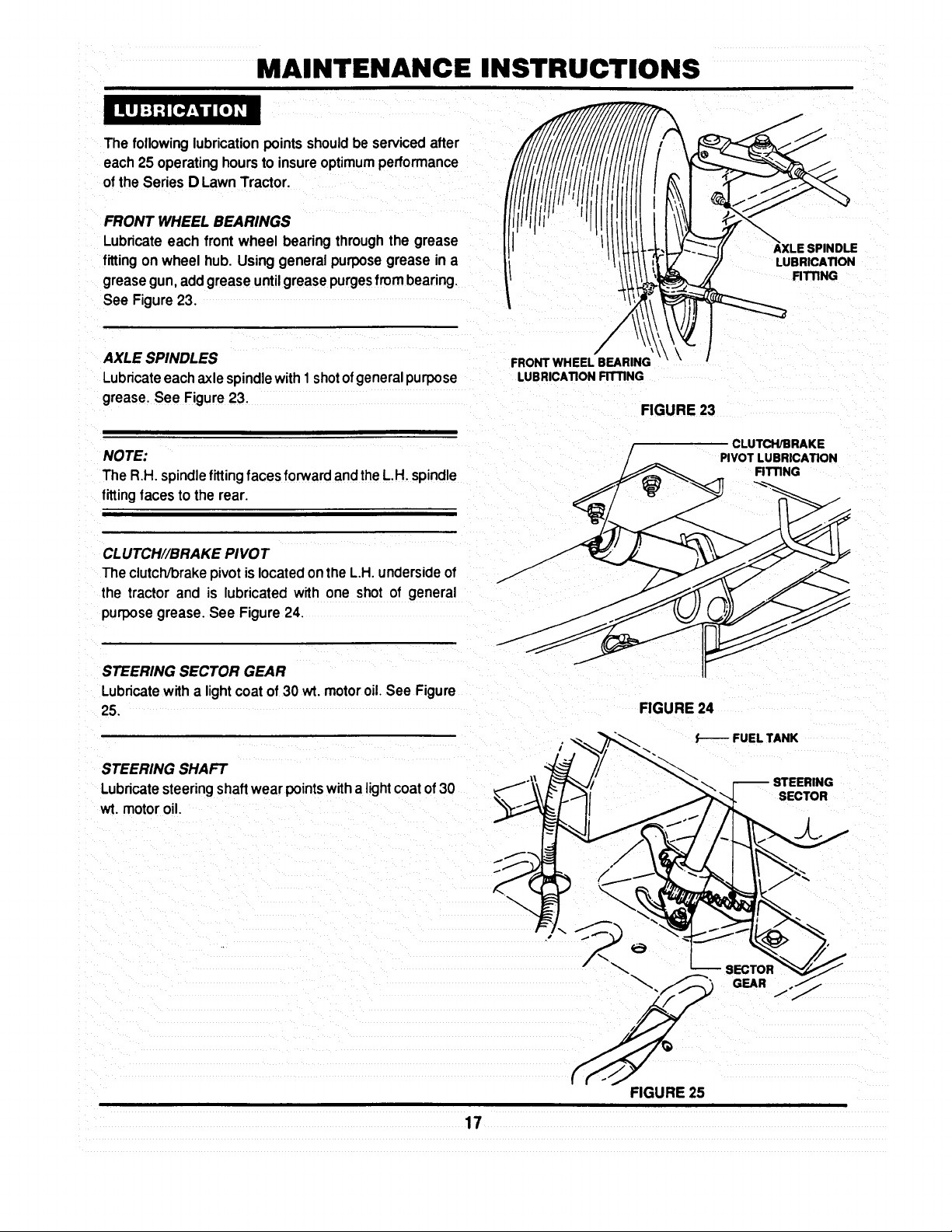

FRONT WHEEL BEARINGS

Lubricateeach front wheel bearing through the grease

fitting onwheel hub. Using generalpurposegrease in a

greasegun, addgreaseuntilgreasepurgesfrombearing.

See Figure23.

AXLE SPINDLE

LUB RICATION

FITTING

AXLE SPINDLES

Lubricateeach axlespindlewith1shot ofgeneral purpose

grease.See Figure 23.

NOTE:

The R.H. spindle fitting faces forward and the L,H. spindle

fitting faces to the rear.

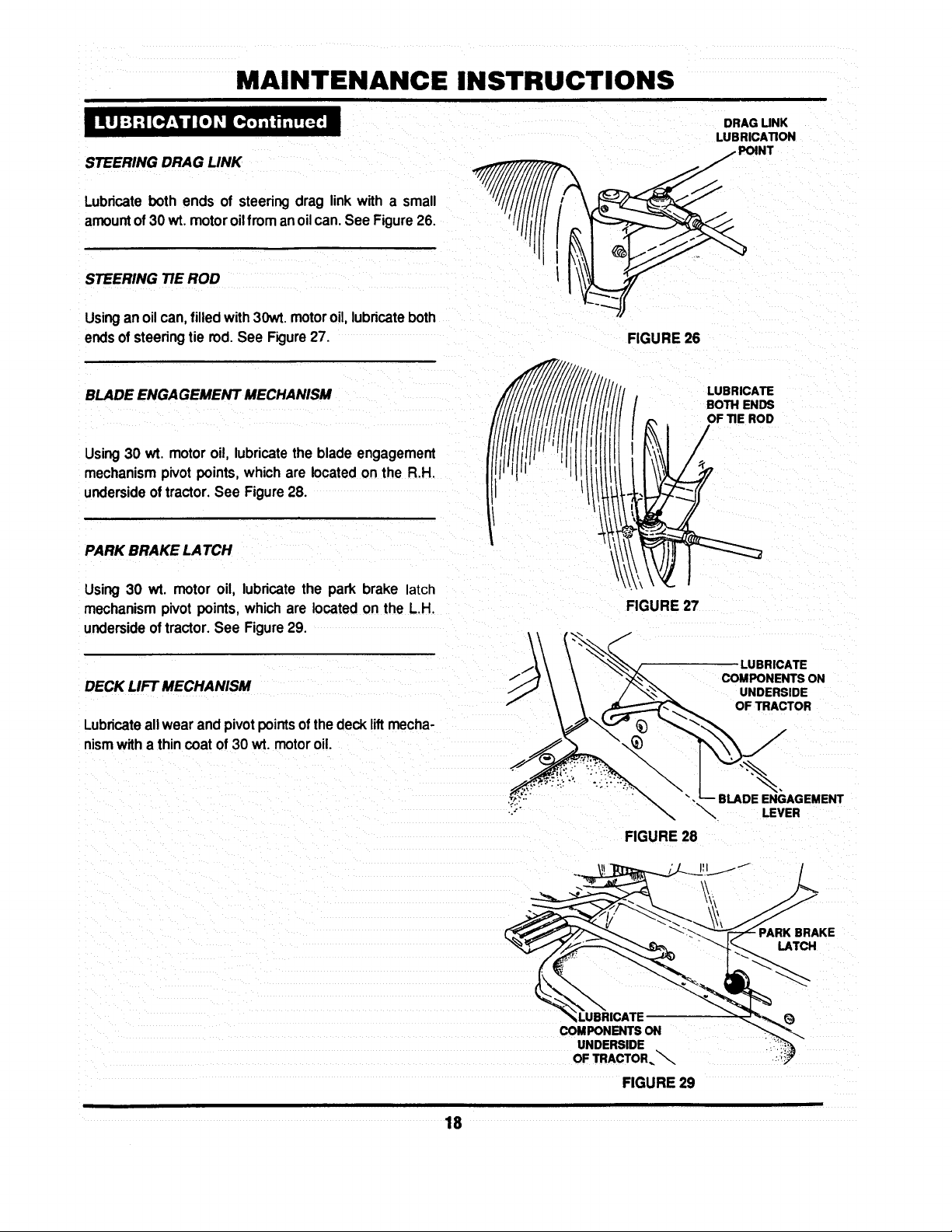

CLUTCH//BRAKE PIVOT

The clutch/brake pivot is located on the L.H. underside of

the tractor and is lubricated with one shot of general

purpose grease. See Figure 24.

STEERING SECTOR GEAR

Lubricatewitha lightcoat of30 wt.motoroil.See Figure

25.

STEERING SHAFT

Lubricatesteeringshaft wear pointswithalightcoatof 30

wt. motoroil.

FRONT WHEEL BEARING

LUBRICATION FITTING

FIGURE 23

CLUTCH/BRAKE

PIVOT LUBRICATION

RTTING

FIGURE 24

FUEL TANK

STEERING

SECTOR

17

FIGURE 25

SECTOR

GEAR

j"

Page 19

MAINTENANCE INSTRUCTIONS

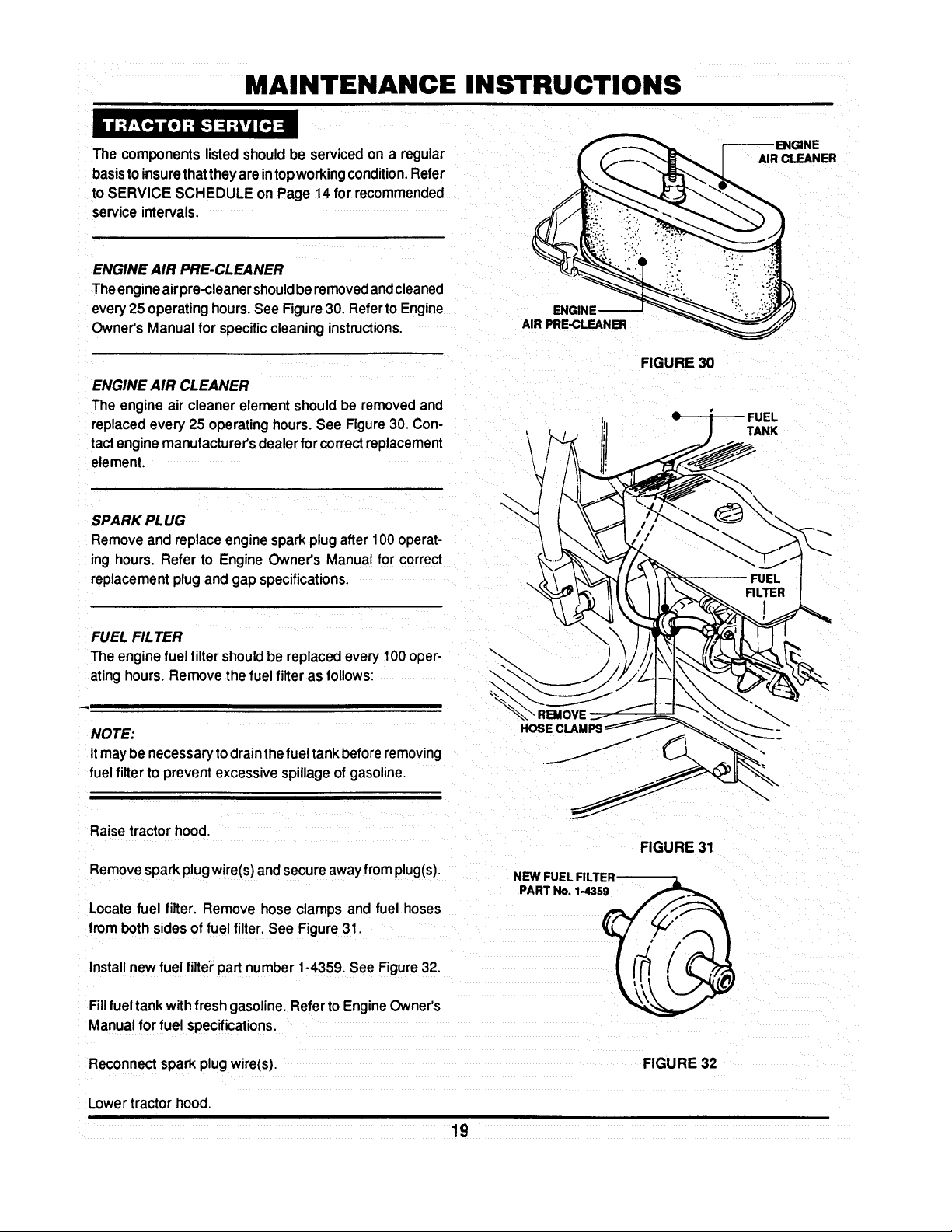

STEERING DRAG LINK

Lubricateboth ends of steering drag link with a small

amountof30 wt.motoroilfrom anoilcan.See Figure26.

STEERING TIE ROD

Usinganoil can,filledwith30wt.motoroil,lubricateboth

endsofsteeringtie rod.See Figure27.

BLADE ENGAGEMENT MECHANISM

Using30 wt. motoroil,lubricatethe blade engagement

mechanismpivotpoints,which are locatedonthe R.H.

undersideoftractor.See Figure28.

DRAG UNK

LUBRICATION

FIGURE 26

::::C'o:

PARK BRAKE LATCH

Using 30 wt. motor oil, lubricatethe park brake latch

mechanismpivotpoints, whichare located on the L.H

undersideoftractor.See Figure29.

DECK LIFT MECHANISM

Lubricateallwearandpivotpoints ofthedeckliftmecha-

nismwith athincoatof 30 wt. motor oil.

FIGURE 27

".BLADE ENGAGEMENT

FIGURE 28

LUBRICATE

COMPONENTS ON

UNDERSIDE

OF TRACTOR

\

PARK BRAKE

LEVER

LATCH

18

LUBRICATE

COMPONENTS ON

UNDERSIDE

OF TRACTOR._

FIGURE 29

Page 20

MAINTENANCE INSTRUCTIONS

The componentslistedshouldbe servicedon a regular

basistoinsurethattheyare intopworkingcondition.Refer

toSERVICE SCHEDULE on Page 14for recommended

serviceintervals.

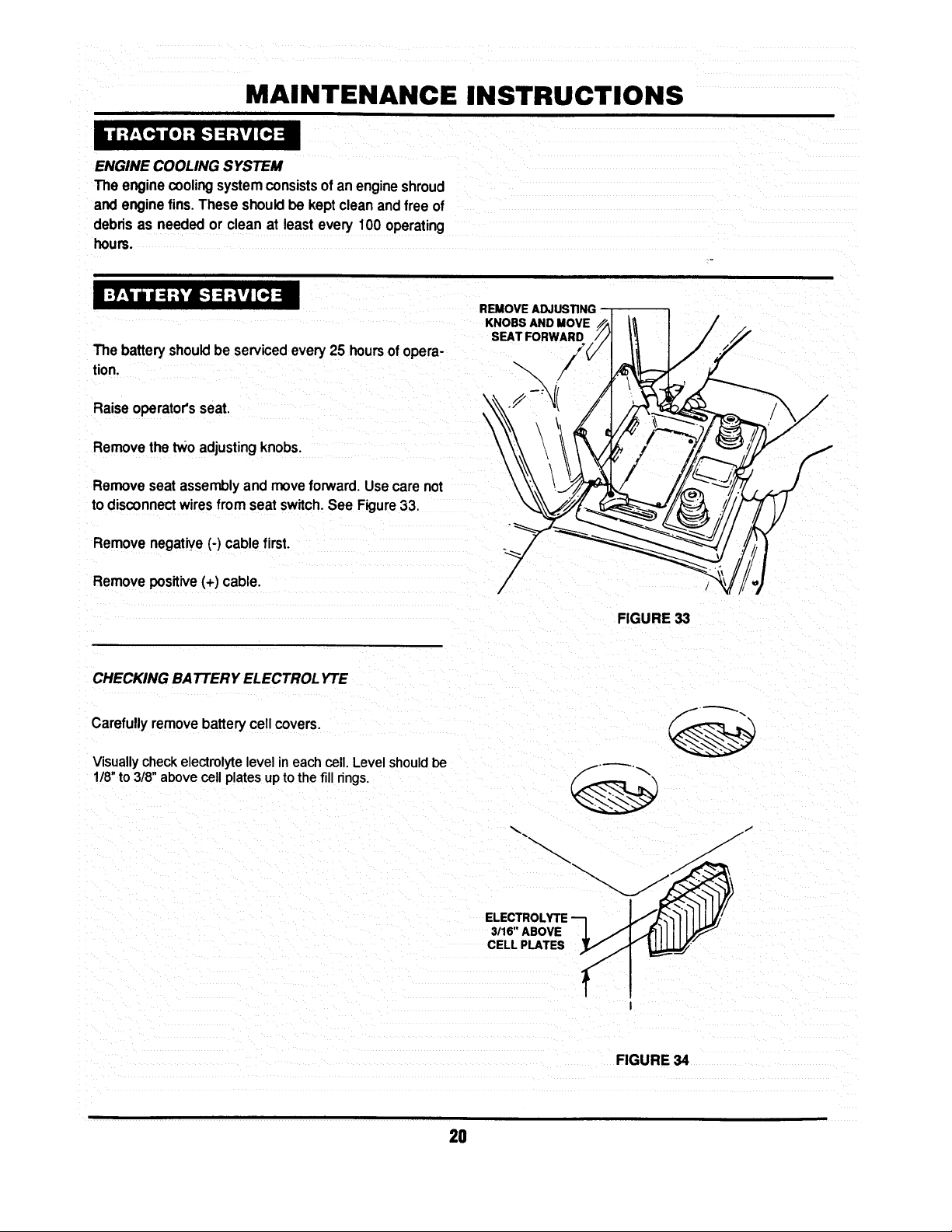

ENGINE AIR PRE-CLEANER

Theengineairpre-cleanershouldbe removedandcleaned

every25 operatinghours.SeeFigure30. Referto Engine

Owner'sManualfor specificcleaninginstructions.

ENGINE AIR CLEANER

The engine aircleaner elementshouldbe removedand

replacedevery25 operatinghours.See Figure30. Con-

tactenginemanufacturer'sdealerfor correctreplacement

element.

SPARK PLUG

Removeand replaceenginesparkplugafter100operat-

ing hours.Refer to EngineOwner's Manualfor correct

replacementplugand gapspecifications.

AIR CLEANER

ENGINE

AIR PRE.CLEANER

FIGURE 30

FUEL

TANK

\

\

FUEL FILTER

Theenginefuelfiltershouldbe replacedevery100oper-

atinghours.Remove thefuel filter as follows:

NOTE:

Itmaybe necessary to drainthefuel tankbefore removing

fuel filter to preventexcessivespillageof gasoline.

Raisetractorhood.

Removesparkplugwire(s)andsecureawayfrom plug(s).

Locate fuel filter. Remove hoseclamps and fuel hoses

from bothsidesof fuel filter. See Figure31.

Installnewfuelfiltei"part number1°4359. See Figure32,

Fillfueltankwithfreshgasoline.Referto EngineOwner's

Manualforfuel specifications.

Reconnectsparkplugwire(s).

HOSE CLAMR

FIGURE 31

NEW FUEL FII

PART No. 1-4359

FIGURE 32

Lowertractor hood.

19

Page 21

MAINTENANCE INSTRUCTIONS

ENGINE COOLING SYSTEM

The enginecoolingsystemconsists ofanengineshroud

and enginefins.These shouldbe keptcleanandfree of

debrisas neededor clean at leastevery 100 operating

houm.

The batteryshouldbe servicedevery25 hours of opera-

tion.

Raiseoperator'sseat.

Removethetwo adjustingknobs.

Remove seatassemblyandmoveforward.Use carenot

to disconnectwiresfrom seat switch.See Figure33.

Removenegative(-) cable first.

REMOVE ADJUSTING

KNOBS AND MOVE _ / --

S ,TFO.WA.0, I / ,7

f

Removepositive(+) cable.

CHECKING BATTERY ELECTROLYTE

Carefully remove battery cell covers.

Visually check electrolyte level in each cell. Level shouldbe

1/8"to 3/8" above cell plates upto the fill rings.

FIGURE 33

ELECTROLYTE

3116"ABOVE

CELL PLATES

2O

FIGURE 34

Page 22

MAINTENANCE INSTRUCTIONS

Usingdistilledwater, fill cells as needed to 1/8" to 3/8"

abovecell plates.

Replace cell covers.

Charge battery if required.

Install positive(+) cable first.

Install negative(-) cable last.

Install seat assembly over battery and secure in position

with adjusting knobs. Leave knobs loose.

Lower operator's seat and adjust to desired position.

Raise seat and tighten adjusting knobs.

BATTERY CHARGING

The engine is equipped with a flywheel alternator to

charge the battery. If the tractor is not run regularly,

connectthe batteryto a charger monthlyto maintainthe

specific gravity at 1.250 or higher. If this reading falls

below1.175, the batteryliquidmayfreezewhentempera-

turesdropto aroundzerodegrees F. To charge, connect

perinstructionsfumishedwithcharger,If time allows, slow

charge at 1 amp for ten hours, or as an alternate, fast

chargeat 3 amps forfour hours.Observe allprecautions

whilecharging.

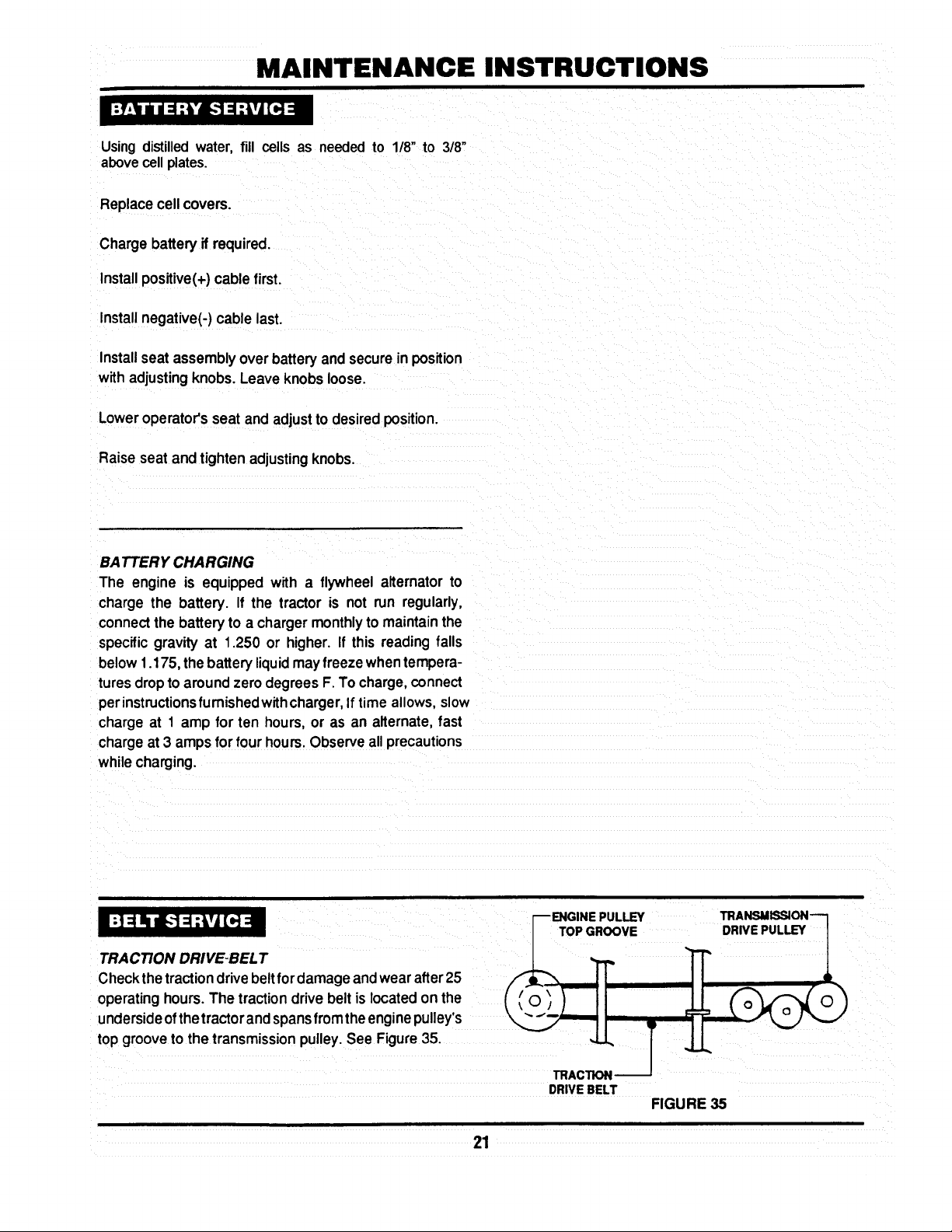

TRACTION DR!VE-BELT

Check thetractiondrivebeltfordamage andwear after25

operatinghours.The tractiondrive beltis locatedon the

undersideofthe tractorandspansfromtheenginepulley's

top grooveto the transmissionpulley. See Figure 35.

.LEY

21

TRACTION --

DRIVE BELT

FIGURE 35

Page 23

MAINTENANCE INSTRUCTIONS

Shouldthe tractiondrive belt show signsof excessive

wearor damage,replace.

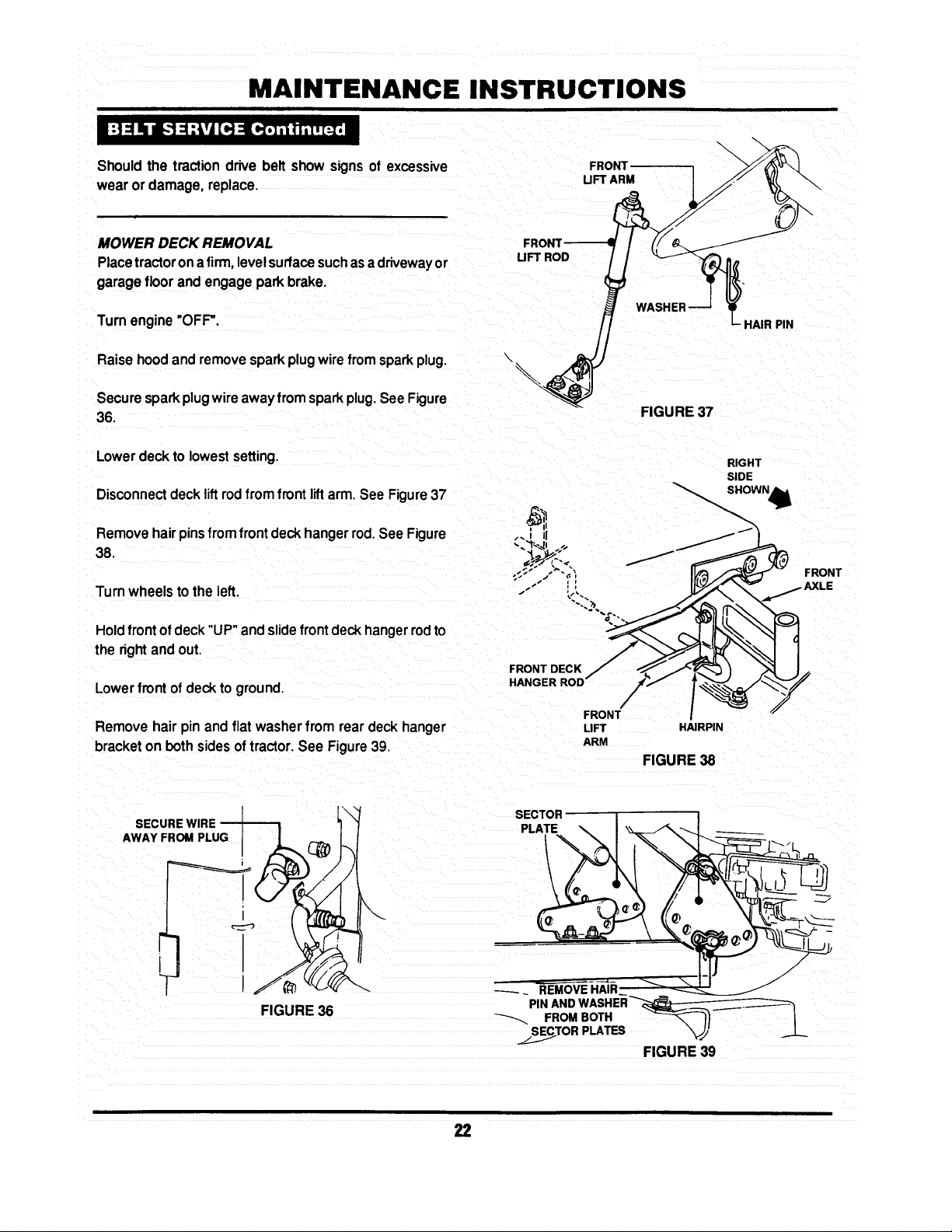

MOWER DECK REMOVAL

Placetractoronafirm,levelsurfacesuchasadrivewayor

UFT ROD

garagefloorandengage parkbrake.

Turnengine "OFF".

Raise hoodandremovesparkplugwirefromsparkplug.

\

Securesparkplugwireawayfromsparkplug.See Figure

36.

Lowerdeck tolowestsetting.

Disconnectdeckliftrodfromfrontliftarm. See Figure37

Removehairpinsfromfrontdeckhangerrod.See Figure

38.

Turnwheelstothe left, k'-,

FRONT

UFT ARM

HAIR PIN

FIGURE 37

RIGHT

SIDE

Hold front ofdeck"UP"andslidefrontdeckhangerrodto ""'_%_- "'_

the right and out. FRONT DECK /"f_ _.._/_/_

HANOERROO/

Lowerfront of decktoground. /

Remove hair pin and flatwasherfrom reardeckhanger LIFT HAIRPIN

bracket on bothsidesof tractor.See Figure39. ARM

SECURE WIRE

AWAYFROMPLUG ! t_

I

__.//_ SECTOR I

FRONT

FIGURE 38

S

FIGURE 38

PIN AND WASHER_ _. ,

FROM BOTH _ /

../_.._.TO R PLATES "_' _.__L_

FIGURE 39

LO;T

22

Page 24

MAINTENANCE INSTRUCTIONS

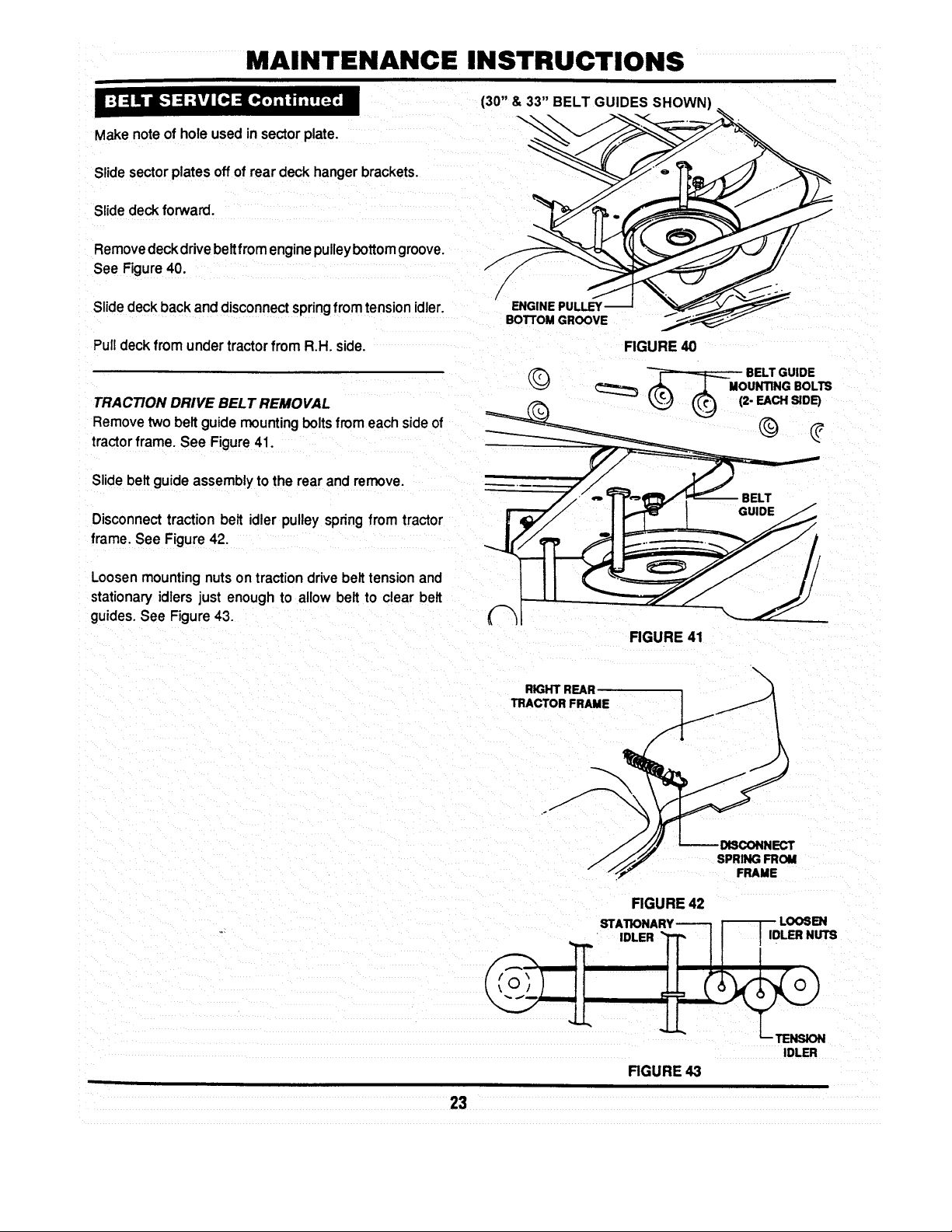

Make note of hole used in sector plate.

Slide sectorplates off of rear deck hanger brackets.

Slide deck forward.

Removedeckdrive beItfrom enginepulleybottom groove.

See Figure 40.

Slidedeck back and disconnect springfromtension idler.

(30" & 33" BELT GUIDES SHOWN)

Pull deckfrom under tractor from R.H. side.

TRACTION DRIVE BELT REMOVAL

Remove two belt guide mounting bolts from each side of

tractor frame. See Figure 41.

Slide belt guide assembly to the rear and remove.

Disconnect traction belt idler pulley spring from tractor

frame. See Figure 42.

Loosen mounting nuts on traction drive belt tension and

stationary idlers just enough to allow belt to clear belt

guides. See Figure 43.

FIGURE 40

FIGURE 41

RIGHT REAR

TRACTOR FRAME

23

FIGURE 42

_I'ATIONARY------1 I-_1 _ LOO6EN

II I

IDLER

FIGURE 43

Page 25

MAINTENANCE INSTRUCTIONS

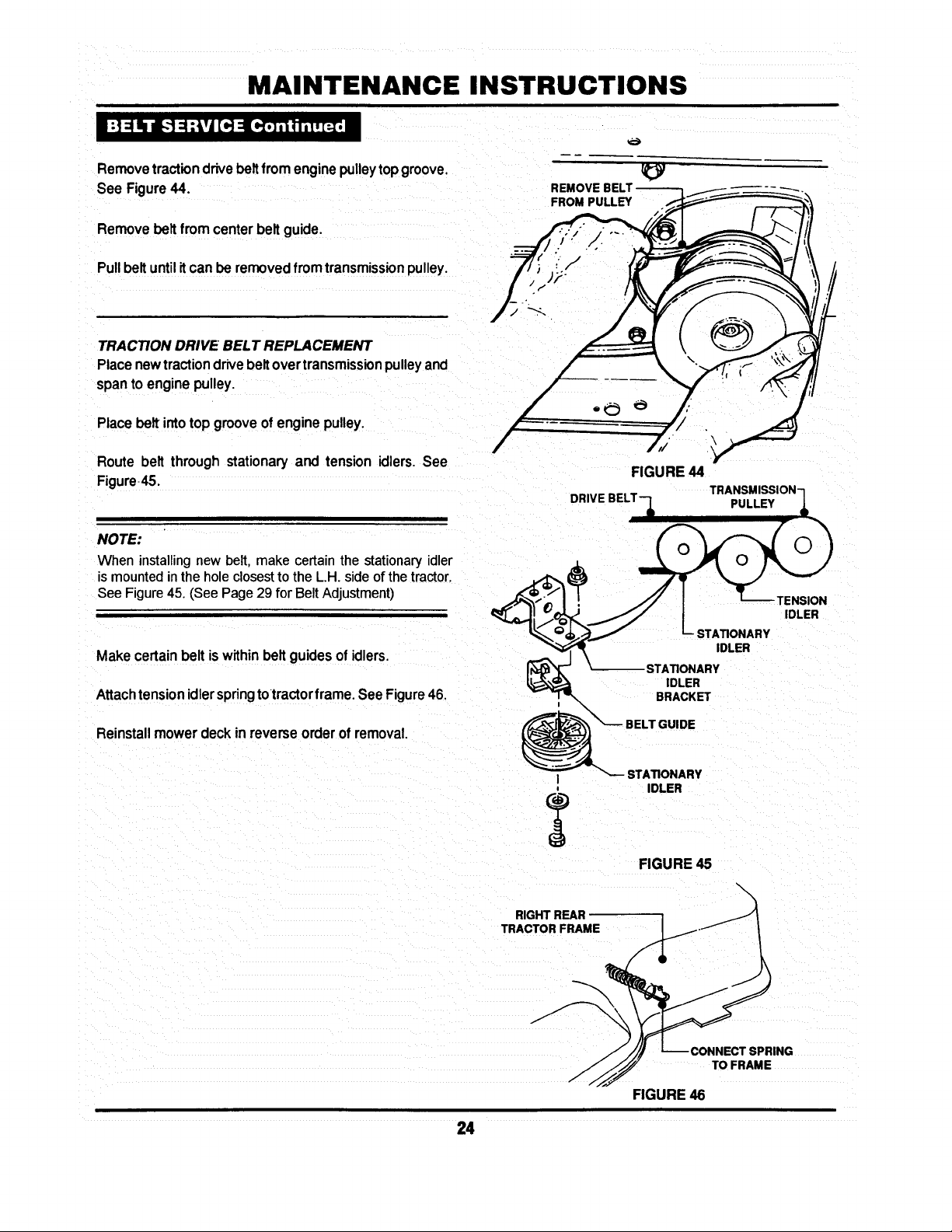

Removetractiondrivebeltfromenginepulleytopgroove.

See Figure44.

Removebelt from centerbeltguide.

Pullbeltuntilitcanbe removedfrom transmissionpulley.

TRACTION DRIVE BELT REPLACEMENT

Place new traction drive belt over transmission pulley and

span to engine pulley.

Placebelt intotopgrooveof enginepulley.

REMOVE

FROM PULLEY

Route belt through stationaryand tension idlers.See

Figure45.

NOTE:

When installingnew belt, make certain the stationary idler

is mounted in the hole closest to the L.H. side of the tractor.

See Figure 45. (See Page 29 for Belt Adjustment)

Makecertainbelt iswithinbeltguidesofidlers.

Attachtensionidlerspringtotractorframe. See Figure46,

Reinstall mower deck in reverse order of removal.

I

RIGHT REAR

TRACTOR FRAME

FIGURE 44

STATIONARY

IDLER

BRACKET

DE

STATIONARY

IDLER

FIGURE 45

PULLEY

STATIONARY

IDLER

\

\

TENSION

IDLER

24

!CTSPRING

TO FRAME

FIGURE 46

Page 26

MAINTENANCE INSTRUCTIONS

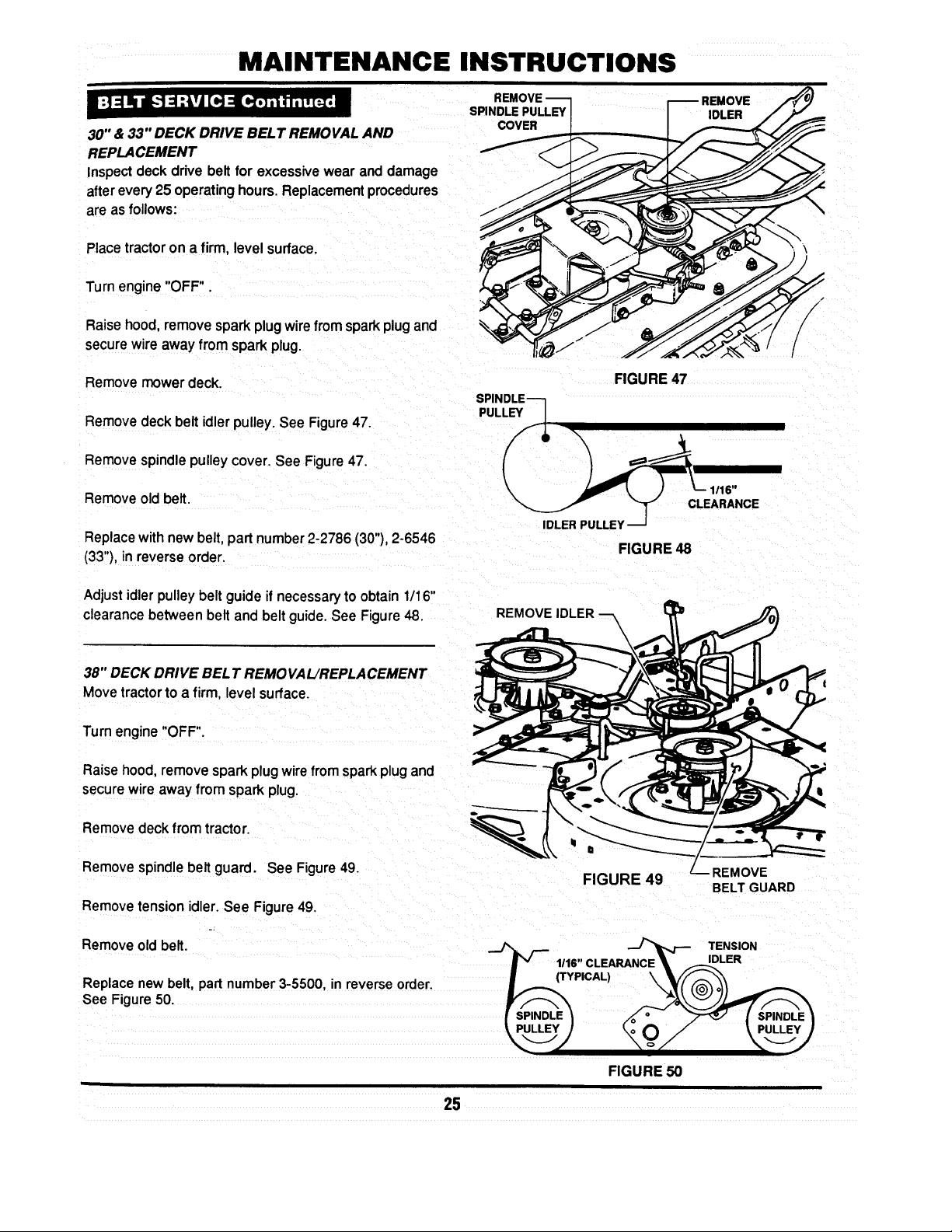

30" & 33" DECK DRIVE BELT REMOVAL AND

REPLACEMENT

Inspect deck drive belt for excessive wear and damage

after every 25 operating hours. Replacement procedures

are as follows:

Place tractorona firm, level surface.

Turn engine "OFF".

Raise hood, remove spark plug wire from spark plug and

secure wire away from spark plug.

Remove mower deck.

Remove deck belt idler pulley. See Figure 47.

Remove spindle pulley cover. See Figure47.

Remove old belt.

Replace with new belt, part number 2-2786 (30"), 2-6546

(33"), in reverse order.

SPINDLE PULLEY

COVER

SPINDLE----]

PULLEYFq L

IDLERPULLEY

FIGURE 47

FIGURE 48

REMOVE

IDLER

/

/

Adjustidler pulley belt guide if necessary to obtain 1/16"

clearance between belt and belt guide. See Figure 48.

REMOVE IDLER ---_

38" DECK DRIVE BEL TREMOVAL/REPLACEMENT

Movetractorto a firm, levelsurface.

Turn engine "OFF".

Raise hood, remove spark plug wire from spark plug and

secure wnreaway from spark plug.

Remove deck from tractor.

Remove spindle belt guard. See Figure49.

FIGURE 49

BELT GUARD

Removetension idler. See Figure 49.

Remove old belt. _ ,__ . _ TENSION

Replace new belt, part number 3-5500, in reverse order. I.,_ (TYP'cAL) k_y(F_-'_o_

See Fngure 50 _pupl_ _ __._

p' 1,1,c,E, .cE\

25

FIGURE 50

Page 27

MAINTENANCE INSTRUCTIONS

" W.ARNING " A I

Blades are extremely sharp and can cause severe I

injury. Wear heavy leather gloves when handling or I

working around blades. DO NOT use a blade that is I

excessively worn or damaged. I

_Ib WARNING --_

I Never use a cutting blade that shows signs oq

excessive wear or damage. Refer to Figure 4.5. Wear I

heavy leather gloves when handling or working I

around cutting blades. Blades are extremely sharPl

and can cause severe injury. I

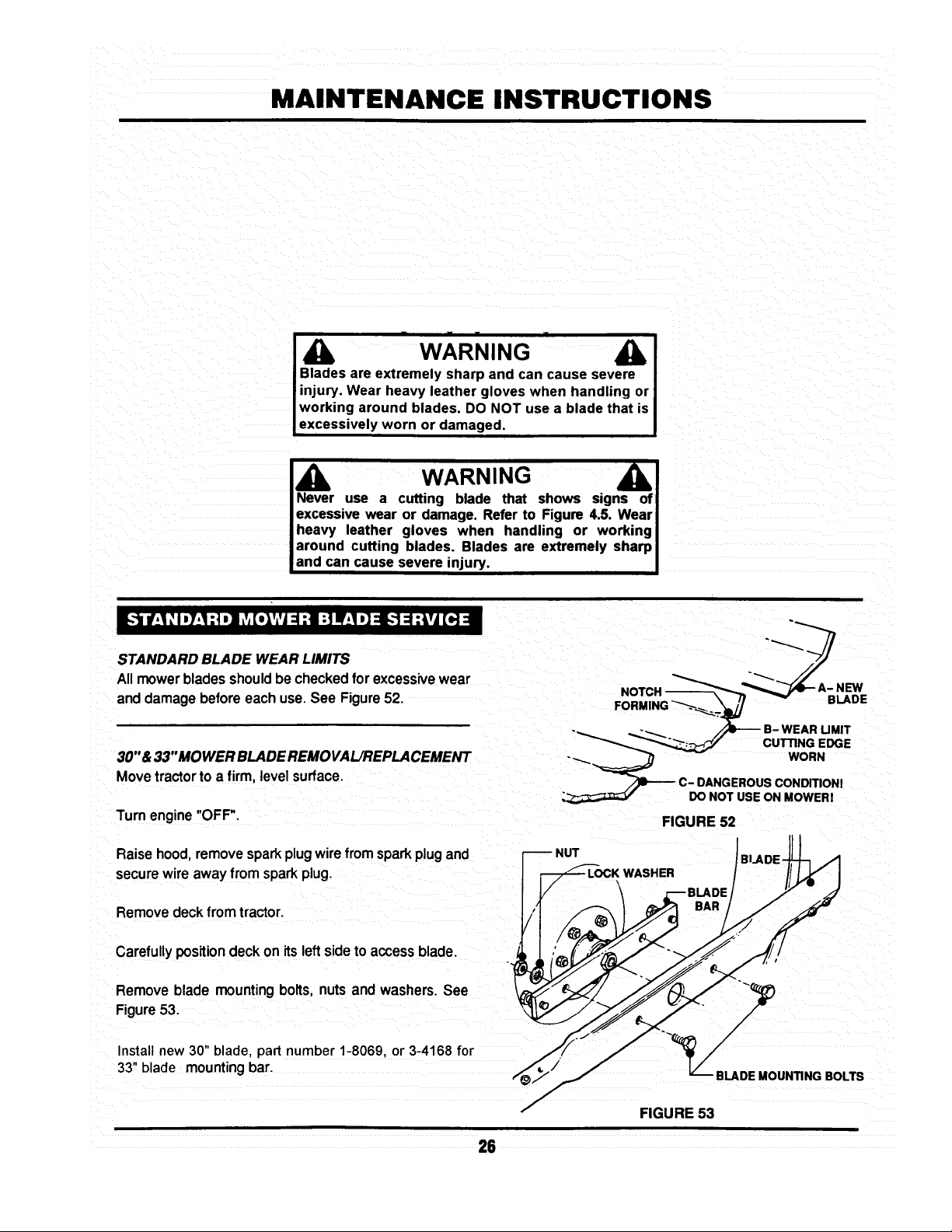

STANDARD BLADE WEAR LIMITS

Allmowerblades shouldbecheckedfor excessivewear

anddamage beforeeach use.See Figure52.

-_ -_ _ B- WEARUMIT

30"&33"MOWER BLADEREMOVAL/REPLACEMENT

Movetractorto a firm, levelsurface.

Turn engine "OFF".

Raise hood, remove spark plug wire from spark plug and r-_ NUT BLADE-JJ-_ ./1

secure wire away from spark plug. 1 _-FF-'-LOCK WASHER I/I _ I

__ CUTTINGEDGE

-_.._ WORN

_--- C- DANGEROUSCONDITIONI

DONOTUSEON MOWERI

FIGURE 52

I11

e ove eo ,ro traOor.

Install new 30" blade, pad number 1-8069, or 3-4168 for _J/ "_/

33" blade mounting bar. v__

BLADEMOUNTINGBOLTS

28

FIGURE 53

Page 28

MAINTENANCE INSTRUCTIONS

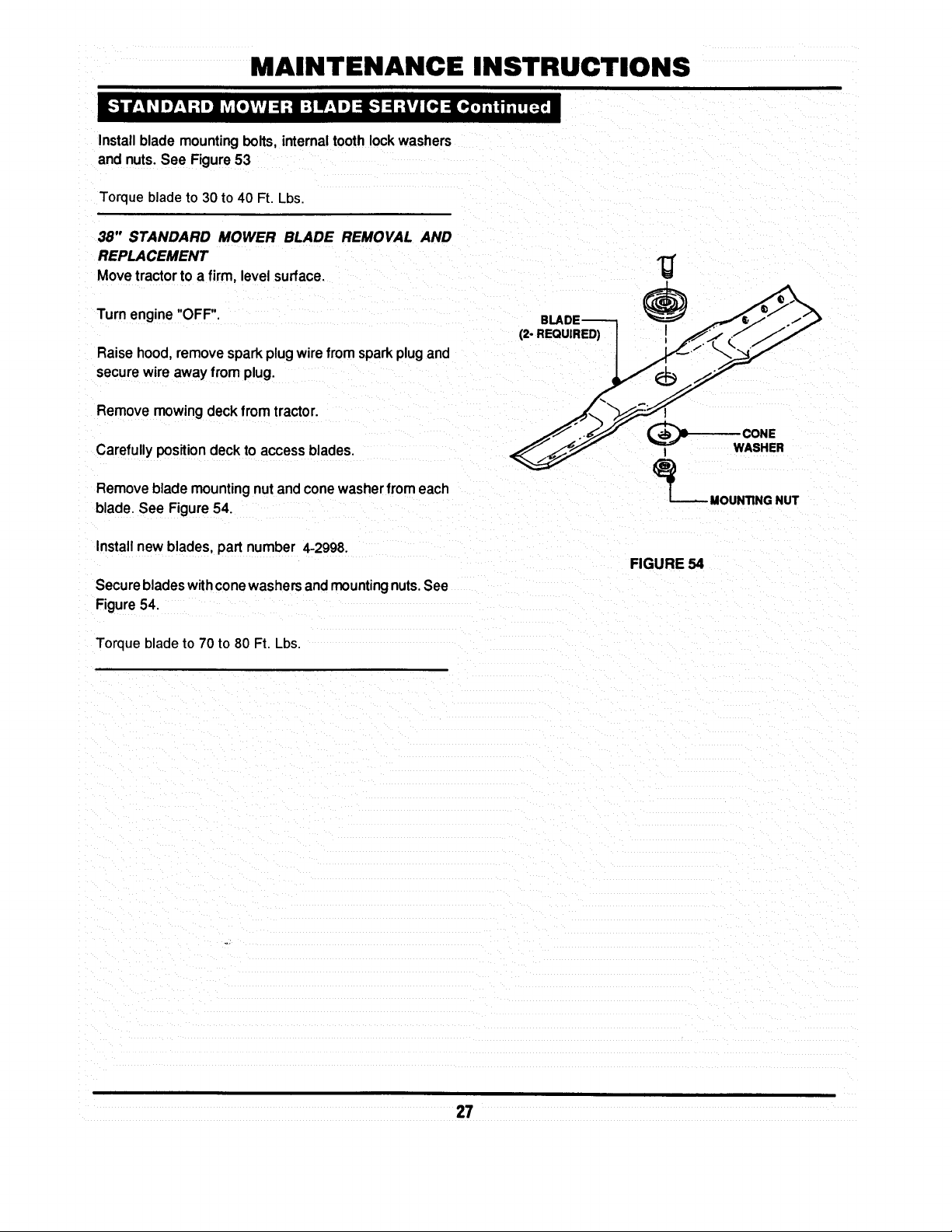

Install blade mounting bolts, internal tooth lockwashers

and nuts. See Figure 53

Torque blade to 30 to 40 Ft, Lbs.

38" STANDARD MOWER BLADE REMOVAL AND

REPLACEMENT

Move tractor to a firm, level surface.

Turn engine "OFF".

Raise hood, remove spark plug wire from spark plug and

secure wire away from plug.

Remove mowing deck from tractor.

Carefully position deck to access blades.

(2- REQUIRED)

CONE

I WASHER

Remove blade mounting nut and cone washer from each

blade. See Figure 54.

Install new blades, part number 4-2998.

Secure blades with cone washers and mounting nuts. See

Figure 54.

Torque blade to 70 to 80 Ft Lbs.

_ MOUNTING NUT

FIGURE 54

27

Page 29

MAINTENANCE INSTRUCTIONS

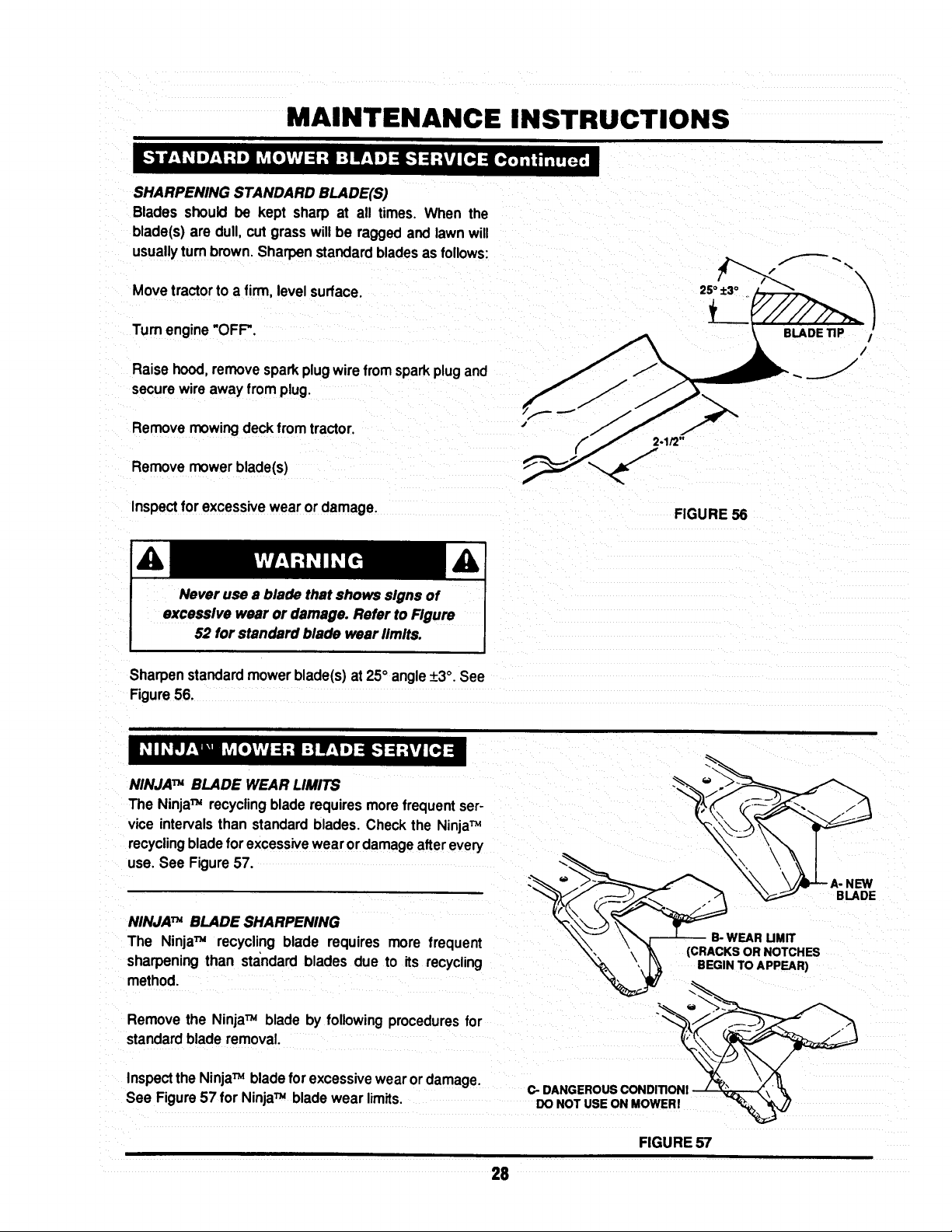

SHARPENING STANDARD BLADE(S)

Blades should be kept sharp at all times. When the

blade(s) are dull, cut grasswillbe ragged and lawn will

usuallyturnbrown.Sharpen standardbladesas follows:

Movetractorto a firm, levelsurface.

Tum engine "OFF'.

Raise hood,removesparkplugwirefromsparkplugand

securewire awayfromplug.

Remove mowing deck fromtractor.

Remove mower blade(s)

Inspectfor excessivewearor damage.

Never use a blade that shows signs of

exceaslve wear or damage. Refer to Figure

52 for standard blade wear limits.

Sharpenstandardmowerblade(s)at 25° angle+3°.See

Figure56.

NINJATM BLADE WEAR LIMITS

The NinjaTM recyclingbladerequiresmorefrequentser-

vice intervalsthan standardblades. Check the NinjaTM

recyclingbladeforexcessivewearor damageafterevery

use. See Figure 57.

NINJATM BLADE SHARPENING

The NinjaTM recycling blade requires more frequent

sharpening than standard blades due to its recycling

method.

FIGURE 56

B- WEAR UMIT

(CRACKS OR NOTCHES

BEGIN TO APPEAR)

Remove the NinjaTM blade by followingproceduresfor

standardbladeremoval.

Inspectthe NinjaTM bladeforexcessivewearordamage.

See Figure57 for NinjaTM bladewear limits,

_ DANGEROUS CONDITIONI / _2._ ._,' 'It

DO NOT USE ON MOWERI "_ "_ _

FIGURE 57

28

Page 30

MAINTENANCE INSTRUCTIONS

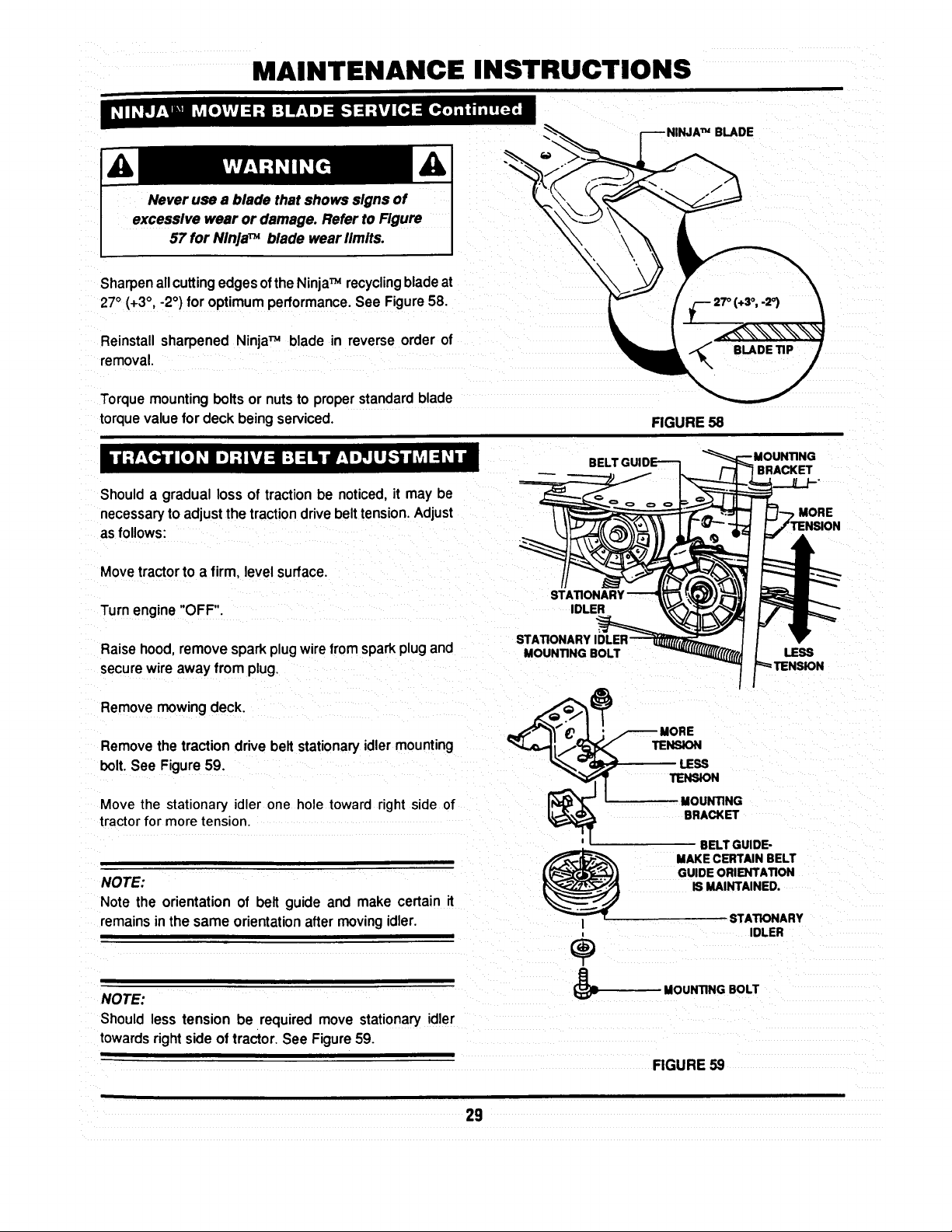

Never use a blade that shows signs of

excessive wear or damage. Refer to Figure

57 for NinJaTM blade wear limits.

Sharpen allcuttingedgesoftheNinjaTM recycling blade at

27° (+3°,-2°) for optimum performance. See Figure 58.

Reinstall sharpened NinjaTM blade in reverse order of

removal.

Torque mounting bolts or nuts to proper standard blade

torque value for deck being serviced.

BLADE

FIGURE 58

Should a gradual loss of traction be noticed, it may be

necessary to adjust the traction drive belt tension. Adjust

as follows:

Movetractor to a firm, level surface.

Turn engine "OFF".

Raise hood remove spark plug wire from spark plug and

secure wire away from plug.

Remove mowing deck.

Remove the traction drive belt stationary idler mounting

bolt. See Figure 59.

Move the stationary idler one hole toward right side of

tractor for more tension.

NOTE:

Note the orientationof belt guide and make certain it

remainsinthe same orientationaftermoving idler.

BELT

IDLER

STATIONARY

MOUNTING BOLT

I

÷

BRACKET

MORE

LESS

BELT GUIDE-

GUIDE ORIENTATION

IS MAINTAINED.

MAKE CERTAIN BELT

STATIONARY

IDLER

NOTE:

Should less tension be required move stationaryidler

towardsrightsideof tractor.See Figure59.

|

MOUNTING BOLT

FIGURE 59

29

Page 31

MAINTENANCE INSTRUCTIONS

Securestationaryidlerwith mountingbolt.

Placesparkplugwire ontosparkplug.

Setpark brake.

StartEngine.

Visuallyinspecttractiondrivebeltfor movement.

Whenproperlyadjusted,thetractiondrivebelt shouldnot

haveany movement or rotationwith the enginerunning

and parkbrakeengaged.

Shouldmovement be present,readjusttractiondrivebelt

toreleasebeittension asdescribedinpreviousinstructions.

Movetractorto afirm,levelsurface. /

Turn engine"OFF'.

Raisehood,removesparkplugwirefrom sparkplugand

securewire awayfromplug.

Movebladeengagementleverdownto"OFF".See Figure ._._:

60. -::

Lower deckto lowestcutting position

Checkfrontto rear level.

EXTENSION SPRING

If deck front torear level isnot correct,

thiscouldcauseblade beltproblems.

30" &33" DECKS

Measure length of blade cable extensionspring. See

Figure61.

ENGAGEMENT

E

TO "OFF"

FIGURE 60

Movebladeengagementleverto "ON".

Measure blade cable extension spring.Spring should

extend1"+_1/8"for properbelttension.See Figure61.

FIGURE 61

3O

Page 32

MAINTENANCE INSTRUCTIONS

To adjusttension,remove extension rod mountingbolt

and nut.See Figure62.

Move extension rodto next hole towards rearof deck and

securewith mountingbolt andnut. MOUNTING-

NUT & BOLT

Measure extension spring with blade engagement lever in

the "ON" and "OFF" positions. See Figure 61. Continue

adjustment until tension is correct.

I

• _L / MOSTTENSlON

"-_ //

-_LEAST TENSION/d

FIGURE 62

NOTE:

Beforeadjusting deck, bring tire pressuretoproperpsi.

Front12 psi, Rear 10 psi.

SIDE TOSIDE LEVEL

Movetractorto a firm, level surface.

Turn engine"OFF".

Raisehood,removesparkplugwirefrom sparkplug and

securewire awayfrom plug.

Move blade engagementleverto "OFF".

Place a piece of angleironundercenterrearof deck.

Remove hair pins and washers securing rear of deck to

sector plates. See Figure 65.

SECTOR

PLATE

__ REMOV_ _

FIGURE 65

31

Page 33

MAINTENANCE INSTRUCTIONS

Slidesectoroffofpinsandcarefullylowerdeckontoangle

iron.

Rotate.blade(s) untilblade tipsare at eachsideof deck.

•Measuredistancefrom bladetiptoflooron each sideof LMEASUREFROM

deck. BLADE TIPS

TO FLOOR

Bladetipsshouldbewithin1/8"ofeachotherfor thedeck

to be consideredlevel. See Figure66.

Ifmeasurementdiffersmorethan 1/8",adjustasfollows:

Loosenfrontliftarmpivotboltonfrontofrightsiderail.See

Figure67.

LOOSEN

SHOULDER BOLT

PIVOT BOLT

NOTE:

The 38"deck doesnotincorporatea pivotbolt.

Looseneccentricshoulderbolt. See Figure67.

Turneccentric"UP"or'DOWN" as requiredtoleveldeck.

See Figure67.

J

Tighteneccentricshoulderbolt.

33" DECK SHOWN

_-_ ANGLE IRON

FIGURE 66

AS REQUIRED

f

ECCENTRIC

Tighten pivotbolt.

FIGURE 67

Placesectorplates back onto rearliftarms and secure

withwashersand hairpins. SECTORPLATES

holeson eachsideforproper frontto rearlevel.

Make certainsectorplatesare mountedin thesame _---_,,, ,,__ _;¢__ ________

FRONT TO REAR LEVEL-SECTOR PLATES --_-- "_-_

Removehairpinsand washerssecuringsectorplatesto

LOWEST OE

DECK

rearliftarms.See Figure68. _ ~ _DECI(-S'_ING _ -------_-SETTING

Movesectorplate asrequiredto raiseorlowerdeck. ___.-__ .)_1--'_ I_11_1_

REMOVE'

HAIR PIN & WASHER

FIGURE 68

32

Page 34

MAINTENANCE INSTRUCTIONS

NOTE:

Thedeckshouldbe set sothat therearofthedeckis1/4"

lowerthanthe front.See Figure69.

FRONT

33" DECK SHOWN

P'/////;! REAR

X • 1/4"

FRONT TO REAR LEVEL- FRONT LIFT ROD

Ifthe sector plates are in their lowest setting and proper L__ MEASUREFROM

level cannot be obtained, adjust the front liftrod asfollows: BLADETIPSTOFLOOR

Movedeck lift leverto #5 position.

Placea 2X4 woodenblockonedgeunderfrontcenterof

deck.

Placea 3X3 wooden blockunderrearcenterof deck.

Remove hair pinsand washers securingsectorplates.

Lowerrear ofdeck onto3X3 block.See Figure68.

Removehairpinandwasher securingfrontliftrodtofront

liftarm. See Figure 70.

Removefrontliftrod andcarefullyrestfrontofdeckonto

2X4 block.

Loosenjam nuton frontliftrod.See Figure70.

NUT

_ FRONT UFT ROD

FIGURE 69

/

/

FIGURE 70

x

f

30" & 33" DECK

•HAIR PIN

Turnfrontliftrodhangerblockuntilitcanbe reinstalledinto

frontliftarm withoutliftingdeck. See Figure70.

Secure lift rodto liftarm withwasher and hairpin.

Placesectorplatesonto rearhangerbracketsandsecure

withwashers andhairpins.

Raisedeck and removewooden blocks.

Repeat stepsfor frontto rear level adjustment.Referto

FRONT TO REAR LEVEL- SECTOR PLATESo

Make certainsectorplatesare mountedinthesame I

holes on each sideforproper front to rear level. I

33

Page 35

MAINTENANCE INSTRUCTIONS

NOTE:

Beforeadjusting deck, bring tire pressuretoproper psi.

Front 12psi, Rear 10 psi.

SIDE TO SIDE LEVEL

Move tractor to a firm, level surface.

Turn engine "OFF".

Raise hood, remove spark plug wire from spark

plug and secure wire away from plug.

Move blade engagement lever to "OFF".

FRONT OF TRACTOR

BLOCK

Place a 2-112" tall block under the front of the deck

centered between the front lift arms. See Fig 70a.

Place a 1-3/4" tall block under the rear of the

deck in the center. See Fig 70a.

Position the blades as shown in Fig 70a and lower

the deck onto the blocks.

Disconnect the front lift rod and the rear hanger

plates. See Fig 68 on page 32 and Fig 70b.

Put the lift lever in the 3rd position from low cut.

Measure the distance from each blade tip to the

floor. The measurements should be within 1/8"

of each other. (Factory setting)

If the difference is less than 1/8", go to next

section, Front-to-rear level.

If the difference is more than 1/8", adjust as

described in the following steps.

Loosen the front adjuster nut until adjuster

moves freely. Then, tighten the nut until the

adjuster moves only when moderate force is

applied to one side of the deck. See Fig. 70c.

1-3/4"TALLBLOCK_--_

FIGURE 70a

BLADESORIENTATEDFORSIDE-TO-SIDELEVELCHECK

38" DECK

NUT

FRONT UFT

FIGURE 70b

Adjust the side-to-side level of the blade tips by

moving one side of the deck up or down as

needed to obtain 118"or less side-to-side deck

level.

After leveling deck, re-tighten the adjuster nut

to from 30 to 40 ft-lbs.

33A

FIGURE 70c

\

_ADJUSTER

NUT

Page 36

MAINTENANCE INSTRUCTIONS

Attach the rear hanger plates to the hole that

most closely aligns with the pin on the deck lift

bracket. Secure with washer and hair pin.

FRONT OF TRACTOR

/h[ i !! !!ii! iiiii!i i ii! !i!!!i! !i Iiiiic i! !i ! Ni i ii!i Mii iii iii ii i i i i i i iiiiiiiiiiiiiii!j/hi

Makecertain sectorplatesare mountedin thesame I

holes on each sideforproper fronttorear level J

Adjust the swivel on the front lift rod until it

lines upwith the hole in the front lift bracket.

(make sure the lift rod is at the top of the slot in

the deck bracket) Secure with hair pin.

FRONT TO REAR LEVEL

Position the blades as shown in Fig. 70d.

Measure the distance from the left front blade

tip to the ground and from the right rear blade

tip to the ground. The front left blade tip should

be between 1/8" and 3/8" higher than the right

rear (factory setting). If it is between 1/8" and

3/8" you are finished with adjustment.

If it is not within specifications, adjust by raising

or lowering the front of the deck using the

the swivel on the front lift rod. Turning the swivel

clockwise will raise the front of the deck. Turning

the swivel counter-clockwise will lower the front of

the deck.

RIGHT REAR BLADE TIP

BLADESORIENTATEDFORFRONT-TO-REAR

LEVELCHECK

BLADE TIP

\

\

FIGURE 70d

NOTE:

The deck should be set sothat the rearofthe deckis 1/4"

lowerthan the front. See Fig. 70e.

33B

33" DECK SHOWN

FRONT

JL MEASURE FROM

BLADE TIPS TO FLOOR

REAR

X

f

FIGURE 70e

Page 37

MAINTENANCE INSTRUCTIONS

STEERING SECTOR

Should excessive "PLAY" be present in the steering,

adjustas follows:

Tum Engine"OFF"and raisetractorhood.

Removespark plugwirefromsparkplugandsecurewire

away fromplug.

Fromleftside oftractor,locatethe steeringsectorbelow

fuel tank.See Figure 71.

Looseneccentricmounting nut.

Rotate eccentricclockwiseuntil steering "PLAY"is re-

duced.See Figure71.

Tighteneccentricmounting nut.

Replacespark plugwire ontosparkplugand lowerhood.

If movement of tractor does not correspond with the

selectedspeedonshiftquadrant,adjustthespeedcontrol

lever asfollows:

Withengine running,drivetractorandmoveshiftleverto

locateneutral.

Turn engine"OFF".

Raise hood,remove sparkplugwire fromsparkplugand

securewire away fromplug.

Locate speedcontrollever mountbehind rightrear tire.

See Figure72.

Loosenmountingnuts.

Movethespeed controlleveruntilit isindirectrelationto

the neutral"N"position on quadrant.See Figure73.

FIGURE 71

SPEED CONTROL

LEVER MOUNT

MOUNTING (_

NUTS

FIGURE 72

SPEED CONTROL LEVER

ED

CONTROL

LEVER

®

Tightenmounting nuts.

MOVE TO NEUTRAL

(N) POSITION

FIGURE 73

34

Page 38

MAINTENANCE INSTRUCTIONS

HYDRO DRIVE MODELS

To beproperlyadjusted,thebrake shouldstopthetractor

inapproximately6 feet fromtopspeedwhen the clutch/

brake pedal isfully depressed.

Adjustbrake when necessaryas follows:

Turnengine "OFF'.

Raise hood,remove sparkplugwire fromsparkplugand

securewire awayfrom plug.

Locatebrake adjustmentonrightsideoftractorinfrontof

andbehind rightrear wheel. See Figure74.

Turn nut clockwiseto increase brakingactionor, coun-

terclockwiseto decrease brakingaction.See Figure 74.

Replacespark plugwire, startengine andtestbrake.

Continue adjustment as described above until proper

adjustmentis achieved.

\

BRAKE

FIGURE 74

GEAR DRIVE MODELS

Tobe properlyadjusted,thebrakeshouldstopthetractor

inapproximately6 feet fromtop speedwhenthe clutch/

brakepedal isfullydepressed.

Adjustbrake when necessaryas follows:

Turn engine"OFF".

Raisehood,remove sparkplugwire fromsparkplugand

securewire away fromplug.

Locatebrake adjustmenton rightsideoftractorinbackof

and behindrightrear wheel. See Figure75.

Turn nutclockwiseto increase brakingactionor, coun-

terclockwiseto decrease brakingaction.See Figure75.

Replacespark plugwire, startengine andtestbrake.

Continue adjustment as described above until proper

adjustmentisachieved.

ADJUSTMENT

FIGURE 75

35

Page 39

ELECTRICAL

Figure 76 illustratestypical hamess mutingon all the

Series D Lawn Tractors.Use thiswhen locatingvarious

electricalcomponents.

_---- O BATI1ERY

NEGATIVE (-)

-TO BATTERY

PosmvF.(+)

TERMINAL

SWITCH

D

(UNDER SEAT)

R,H°

HEADLIGHT

HEADUGHT

SWITCH

BRAKE

SWITCH

20 AMP-

FUSE

HEAD

HARNESS

HARNESS

BLADE ENGAGEMENT

LEVER SWITCH

GROUND

TO ENGINE

FIGURE 76

36

Page 40

ELECTRICAL

The schematics below, Figure 77 & Figure 78 represent

models with and without headlights.

BRIGGS & STRA TTON WITHOUT LIGHTS

PEDAL SWITCH

INoj. I

"EDI

ENGINE /GROUND

/-IGNITION

RED

BLACK

I

GREENI IN_ I II

I

RED

I I BLACK

I

SEAT

SWITCH

IN_ I

I" Tl

STARTER k

'_--ALTERNATOR

BLACK RED

BATTERY

BRIGGS & STRA TTON WITH LIGHTS

ANTI-AFTER FIRE

SOLENOID --_

\

\

ENGINE

STARTER

BLACK

BAI"rlERY

IGNmON GROUND

AC OUTPUT

RED

ALTERNATOR

RED

SOLENOID

PINK

RED

RED

FIGURE 77

SWITCH

RED

BLACK

BLACK

B_ YELLOW

BLUE

BLACK

PEDAL

_mTION

KEYswrrc_

PTO

SWITCH

RED

UGHT

SWITCH

YEllOW

HEAD

UGHTS

r

SEAT

SWITCH

GREEN

PURPLE

FIGURE 78

37

Page 41

!

3 YEAR LIMITED WARRANTY

For three (3) years from purchase date for the original purchaser's residential, non-commercial use, SNAPPER, through

any SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part.or parts found upon

examination bythe factory at McDonough, Georgia, to be defective in material or workmanship or both.

For ninety (90) days from purchase date for the odginal purchaser's commercial, rental, or other non-residential use

SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by th=

factory at McDonough, Georgia, to be defective in material or workmanship or both.

All transportation costs incurred by the purchaser in submitting material to a SNAPPER dealer for replacement under

this warranty must be paid by the purchaser.

This warranty does not apply to engines and their components, hydro transmissions, gear drive transmissions and

batteries, as these items are warranted separately. This warranty does not apply to parts that have been damaged by

accident, alteration, abuse, improper lubrication, normal wear, or other cause beyond the control of SNAPPER. This

warranty does not cover any machine or component part that has been altered or modified changing safety,

performance, or durability.

There is no other express warranty.

DISCLAIMER OF WARRANTY

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to three

(3) years from purchase date for the original purchaser's residential or other non-commercial use, and ninety

(90) days from purchase for the original purchaser's commercial, rental or other non-residential use, and to the

extent permitted by law, any and all implied warranties are excluded. This is the exclusive remedy. Liabilities

for consequential damages, under any and all warranties are excluded.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY IMPAIR THE

SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND WARRANTY BY SNAPPER

ASSOCIATED WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill outthe attachedSNAPPER ProductRegistrationCard immediatelyand mail to:

Snapper's Product Registration Center, P.O. Box777, McDonough, Georgia 30253

Page 42

SERVICE NOTES

Page 43

SERVICE NOTES

Page 44

Safety Instructions & Operator's Manual for

8NAPPER

LAWN TRA CTOR

HYDROSTA TIC &

GEAR DRIVE

SERIES D

IA WARNING: The engine exhaust from this product contains chemicals known to the State I

COPYRIGHT © 1998

SNAPPER INC

ALL RIGHTS RESERVED

of Califomia to cause cancer, birth defects or other reproductive harm.

MANUAL No. 3-5576 (REV. 2, 6/98)

I

Page 45

Safety Instructions & Operator's Manual for

,SNAPPER,

LAWN TRA CTOR

HYDROSTATIC &

GEAR DRIVE

SERIES D

MODELS

GEAR DRIVE HYDROSTATIC

DRIVE

LT120G30DB LT140H33DBV

NLT120G30DB LT145H33DBV

LT125G38DB LT145H38DBV

NLT145H38DBV

MODEL NUMBER EXPLANATION

I

LTI 145I H 1381 O I B I V I

MODEL DESIGNATION

ENGINE HP

DRIVE SYSTEM TYPE

CUTTING WIDTH

LT - Lawn Tractor Model Designation

120 - 12.0 HP Engine Horse Power

125 - 12,5 HP Engine Horse Power

H - Hydrostatic Transmission

30 - 30" Cutting Width Mower

33 - 33" Cuttino Width Mower

Thank you for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow the

"IMPORTANT SAFETY INSTRUCTIONS" on pages 2 & 2A, all other instructions contained in this manual and

the accompanying booklet "About Power Mower Safety". "Lawn mowers and all power equipment can be

potentially dangerous ff used improperly. REMEMBER: SAFETY REQUIRES CAREFULL USE IN ACCORDANCE

WITH INSTRUCTIONS AND COMMON SENSE/.

COPYRIGHT © 1998

SNAPPER NC

ALL RIGHTS RESERVED

140 - 14.0 HP Engine Horse Power

145 - 14.5 HP Engine Horse Power

G - Gear Drive Transmission

38 - 38" Cutting Width Mower

i ENGINE TYPE

; ENGINE MODEL

SERIES DESIGNATION

D - Series Designation

B - Briggs & Stratton Engine

V - Over Head Valve Type Engine

MANUAL No. 3-5576 (REV. 2, 6/98)

Page 46

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful cutting machine is capable of amputating hands and feet and can throw objects that

can cause injury and damage! Failure to comply with the following SAFETY instructions could result in

serious injury or death to the operator or other persons. The owner of the machine must understand these

instructions and must allow only persons who understand these instructions to operate machine. Each

person operating the machine must be of sound mind and body and must not be under the influence of any

substance which might impair vision, dexterity or judgment. If you have any questions pertaining to your

machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department

at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. KEEP children out of the mowing area and under

the watchful care of a responsible adult.

2. DO NOT allow children in yard when machine is

operated (even with the blade OFF).

3. DO NOT allow children or other passengers to

ride on machine or on attachments (even with the

blade OFF). They may fall and be seriously

injured.

4. DO NOT allow pre-teenage children to operate

machine.

5. ALLOW only responsible adults & teenagers with

mature judgment under close adult supervision to

operate machine.

6. BE SURE the area is clear of others before

mowing and turn machine OFF if anyone enters

the area.

7. DO NOT mow in reverse unless absolutely

necessary. LOOK BEHIND and down for small

children before and when backing.

8. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

PROTECTION AGAINST TIPOVERS

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra CAUTION. If