Page 1

Safety Instructions & Operator's Manual for

MID MOUNT Z-RIDER

ZERO TURNING

HYDRO DRIVE

SERIES 1

POWER UNIT MODEL S

MZM2301KH

MOWER UNIT MODEL S

ZM5202M ZM6102M

MZM5203M

MODEL NUMBER EXPLANATION

IMIZI_

MOOE'OES,GNAT,ON_I

DRIVE SYSTEM TYPE

MOWER ORIENTATION

M - Middle Market

Z - Zero Turning - Hydro Drive

M - Mid Mount Mower

Z - Zero Turninq - Hydro Drive

M - Mid Mount Mower

Thank you for buying a SNAPPER Product! Before operating your machine, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 - 4. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

23 - Engine Horse Power

52- Mower Cutting Width

61 - Mower Cutting Width

SNAPPER McDonough,

COPYRIGHT © 2002

SNAPPER INC

ALL RIGHTS RESERVED

_12

POWER UNIT

MOWER UNIT

310I lKHI

I

SERIES DESIGNATION

01 - Series Designation

I 02 - Series Designation I M - Mower Deck

03 -- Series Designation I

GA,, 30253 U.S.A.

MANUAL No. 7-5167 (I.R. 8/30/02)

ENGINE TYPE

ENGINE HP

KH - Kohler Engine

Page 2

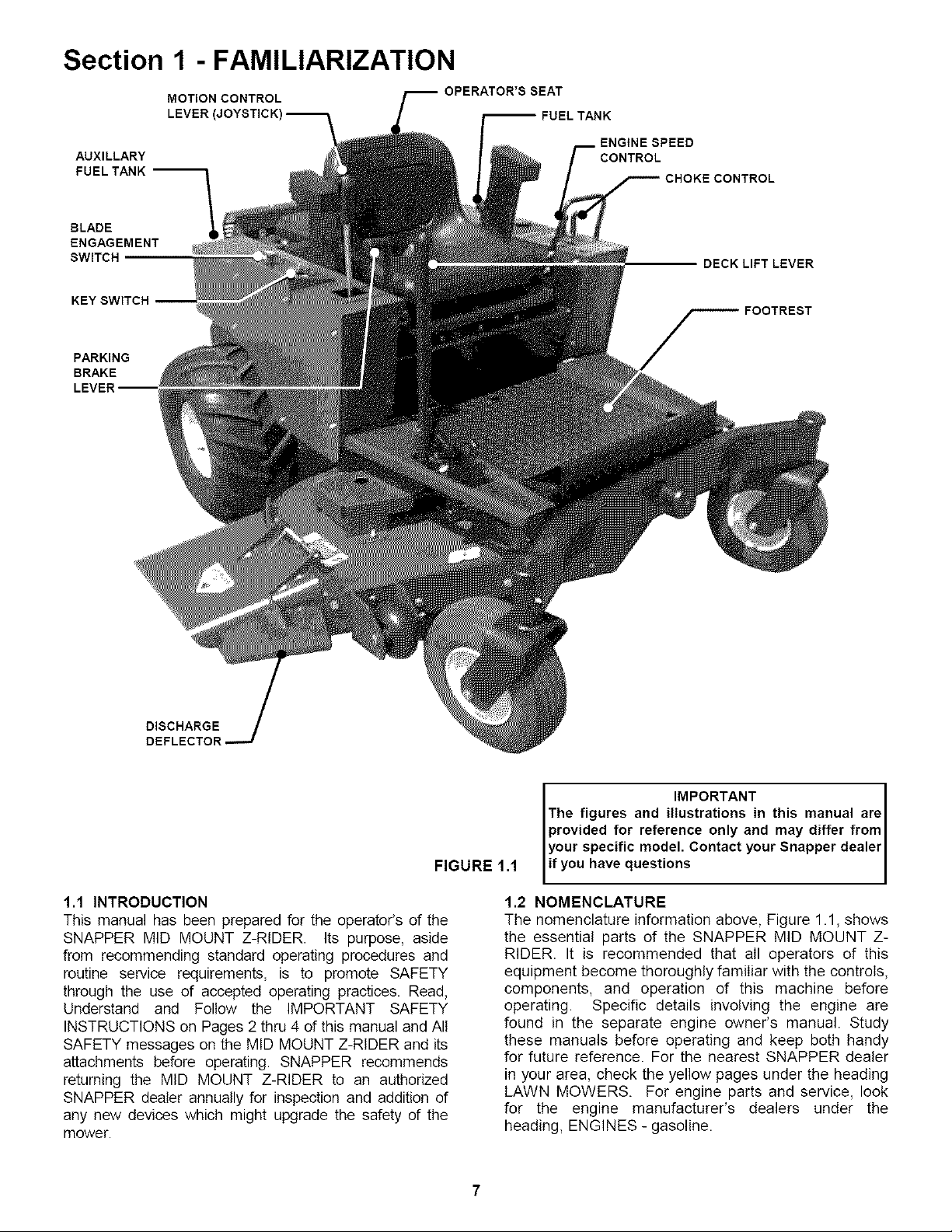

Section 1 - FAMILIARIZATION

AUXILLARY

FUEL TANK --

BLADE

ENGAGEMENT

SWITCH

PARKING

BRAKE

MOTION CONTROL

LEVER (JOYSTICK -- FUEL TANK

OPERATOR'S SEAT

ENGINE SPEED

CONTROL

DECK LIFT LEVER

FOOTREST

DISCHARGE

DEFLECTOR

FIGURE

1.1 INTRODUCTION

This manual has been prepared for the operator's of the

SNAPPER MID MOUNT Z-RIDER. Its purpose, aside

from recommending standard operating procedures and

routine service requirements, is to promote SAFETY

through the use of accepted operating practices. Read,

Understand and Follow the IMPORTANT SAFETY

INSTRUCTIONS on Pages 2 thru 4 of this manual and All

SAFETY messages on the MID MOUNT Z-RIDER and its

attachments before operating. SNAPPER recommends

returning the MID MOUNT Z-RIDER to an authorized

SNAPPER dealer annually for inspection and addition of

any new devices which might upgrade the safety of the

mower.

I IMPORTANT 1

The figures and illustrations in this manual areI

provided for reference only and may differ from I

your specific model. Contact your Snapper dealerI

1.1

if you havequestions I

1.2 NOMENCLATURE

The nomenclature information above, Figure 1.1, shows

the essential parts of the SNAPPER MID MOUNT Z-

RIDER. It is recommended that all operators of this

equipment become thoroughly familiar with the controls,

components, and operation of this machine before

operating. Specific details involving the engine are

found in the separate engine owner's manual. Study

these manuals before operating and keep both handy

for future reference. For the nearest SNAPPER dealer

in your area, check the yellow pages under the heading

LAWN MOWERS. For engine parts and service, look

for the engine manufacturer's dealers under the

heading, ENGINES - gasoline.

I

7

Page 3

Section 2 - SAFETY MESSAGES AND SYMBOLS

I BLAOBSENGAGBO"ON"I BLAOBSDISENGAGED"OFF"I

"START"

MOTION CONTROL

MULTI-DIRECTIONAL

BEFORE OPERATING

I READ OPERATOR'S MANUAL I

MACHINE

KEEP CHILDREN AND OTHERS OUT OF MOWING AREA

I DANGER! ROTATING BLADES

DANGER! ROTATING BLADES

9

Page 4

Section 4 - MAINTENANCE

4.3.3.

OIL FILL

LINE

RIDING MOWER - LUBRICATION

1. Front Wheel Bearings

Lubricate with Kendall NLGI No. 2 lithium

grease or equivalent, from a grease gun.

See Fi( 4.5.

FRONT

WHEE

FIGURE 4.5

2. Transaxle

Check the level of fluid in both of the fluid

reservoirs. Wipe away all dirt and debris from

around reservoir cap before removing. Oil

must remain absolutely clean! Check with

machine on a level surface with engine

"OFF". Fill reservoir as needed to bring

level up to 1-1/2 inches below the top of the

filler neck. Use clean, fresh premium

hydraulic oil having a viscosity equivalent to

SAE 20W20, SAE 30 or SAE40. The fluid

should be chemically stable, incorporating rust

and oxidation inhibitors. Make sure funnels,

pouring spouts and oil can are completely

clean. Reinstall reservoir cap. See Figure 3.6.

IMPORTANT: DO NOT remove or service

the transaxle fluid filters. This service should

be made periodically by an authorized

SNAPPER dealer. See the service schedule

to determine the recommended change

interval.

3. Power Transfer Shaft

Lubricate power transfer shaft with Kendall

NLGI No. 2 lithium grease or equivalent,

from a grease gun. See Figure 4.7.

VIEW IS SHOWN WITH

PARTS REMOVED FOR

CLEAR VIEW OF SHAFT

LUBRICATE

POWER

TRANSFER

FIGURE 4.7

4. Other Lubrication Points

Lubricate machine caster wheel shafts,

traction drive shaft and mower deck idler

arm with Kendall NLGI No. 2 lithium grease

or equivalent, from a grease gun.

4.4

BEFORE OPERATING MACHINE

1, Clean all dirt and debris from around the two

hydraulic fluid reservoirs. Especially around the top

and cap area.

2, Clean all dirt and debris from the cooling fins on

the engine and from both hydraulic pumps.

4.5

ANNUALLY (END OF EACH SEASON)

Perform aII maintenance as described in Section

"AFTER EVERY 25 OPERATING HOURS".

4.5.1. ENGINE

Service engine according to engine owner's manual.

HYDRAULIC OIL

RESERVOIR

(Continued on next Page)

IMPORTANT: FLUID LEVEL MUST

BE ABOVE TOP OF BAFFLE.

RESERVOIR CAPACITY IS ONE (1)

GALLON. DO NOT OVERFILL.

FIGURE 4.6

16

Page 5

Section 5 - ADJUSTMENTS & REPAIR

5.5.2. BLADE SHARPENING

1. Remove blade. See Figure 5.5.

®

BEVELED WASHER

FIGURE 5.5

BLADE

BLADE MOUNTING

BOLT

5.6 MOWER DRIVE BELT REPLACEMENT

Inspect mower drive belt. Replace belt if it shows

signs of excessive wear, damage and/or is broken.

5.6.1. BELT REMOVAL

1. Remove power unit foot rest.

2, Remove old belt.

5.6.2. BELT REPLACEMENT

1. Route belt around blade pulleys and idler

pulley in same the position as old belt was

removed. It may be necessary to use a pry

bar to pull idler pulley back to install belt.

See Figure 5.7.

2, Reinstall power unit foot rest.

2. Inspect condition of blade. See Figure 4.4.

3. If blade is in good condition, sharpen at 22

to 28 degrees. DO NOT sharpen beyond

original cutting edge. See Figure 5.6.

BLADE

22° TO 28°

ORIGINAL CUTTING EDGE

FIGURE 5.6

4. Check blade balance after sharpening.

If necessary, correct blade balance by

grinding the heavy end of blade.

IMPORTANT: Blade balancing should be performed by a

qualified dealer.

FRONT OFDECK

BELT

ROUTING

FIGURE 5.7

5. Reinstall blade. See Figure 5.5. Torque

blade mounting bolts to recommended

range of 70 to 80 ft. Ibs.

22

Page 6

Section 5 - ADJUSTMENTS & REPAIR

WARNING

Shield the positive terminal with terminal cover

located on battery harness. This prevents metal from

touching the positive terminal, which could cause

sparks. Cables must be connected to battery

terminals in the proper position. RED (Positive) cable

must go to the ( + ) terminal. BLACK (Negative) cable

must go to the ( - ) terminal.

5.7 BATTERY

5.7.1. BATTERY REMOVAL

1. Remove battery retainer.

2. Slide terminal cover away from positive

terminal.

3. Observe and note cable positions on

battery. See Figure 5.8.

4. Disconnect cables from battery terminals,

disconnecting BLACK (Negative) cable first,

then disconnect RED (Positive) last. Retain

mounting bolts and nuts.

RED (POSITIVE) CABLE

\

TERMINAL COVER

4. With celt caps removed, connect battery

charger to battery terminals. RED to positive

(+) terminal and BLACK to negative (-)

terminal.

5. Slow charge battery at 1 amp for 10

hours. An alternative fast charge should be

no more than 2.5 amps for four hours.

6. If battery will not accept charge or is

partially charged after 10 hours of charging

at 1 amp, replace with new battery.

CABLE

TERMINAL

COVER MUST

SHIELD

POSITIVE

TERMINAL

AFTER

INSTALLATION

5.7.2.

5.7.3.

BLACK (NEGATIVE)

CABLE

\

FIGURE 5.8

BATTERY INSTALLATION

1. Position battery into battery compartment.

2, Connect cables to battery terminals.

Connect RED (Positive) cable first. Connect

BLACK (Negative) cable last.

3, Reinstall battery retainer and positive

terminal cover. See Figure 5.9

BATTERY SERVICE

1. Remove battery.

2, Place battery in a well ventilated area on

a level surface.

3. Using distilled water, refill ceils as

required to cover ceil plates.

FIGURE 5.9

WARNING

The electrolyte (acid) produces a highly explosive

gas. Keep all sparks, flame and fire away from area

when charging battery or when handling electrolyte

or battery. Electrolyte (acid) is a highly corrosive

liquid. Wear eye protection. Wash affected areas

immediately after having eye or skin contact with

electrolyte (acid). Battery acid is corrosive. Rinse

empty acid containers with water and mutilate before

discarding. If acid is spilled on battery, bench, or

clothing, etc., Flush with clear water and neutralize

with baking soda.

23

Page 7

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Starter Will Not Crank 1. Battery dead. 1. Service battery.

Engine 2. Blown fuse. 2. Replace fuse.

3. Electrical connections loose or corroded. 3. Clean and check connections for good contact.

4. Defective ignition switch. 4. Contact authorized SNAPPER dealer.

Engine Will Not Start 1. Blade engagement switch in the 'ON" position. I. Move blade engagement switch to 'OFF".

2. Park brake not set. 2. Set park brake.

3. Fuel tank empty. 3. Fill fuel tank with fresh fuel.

4. Engine needs choking. 4. Move choke control to 'CHOKE" position.

5. Spark plug wire disconnected. 5. Place spark plug wire onto spark plug.

6. Battery weak or dead. 6. Service battery.

7. Faulty parking brake, blade or ignitionswitch. 7. Contact authorized SNAPPER dealer.

Engine Stalls After 1. Operator not in seat. 1. Sit in operator's seat.

Running 2. Choke control in the "CHOKE" position. 2. Move choke control to 'OFF" position.

3. Fuel tank empty. 3. Fill with fuel to proper level.

4. Engine air pre-cleaner and or air cleaner dirty. 4. Clean free of all debris.

5. Spark plug defective or gap set improperly. 5. Service spark plug.

6. Fuel filter stopped up. 6. Replace fuel filter.

7. Water, debris or stale fuel in fuel system. 7. Drain and clean fuel system.

Engine Loses Power 1. Excessive load on engine. 1. Lessen toad.

2. Engine air pre-cleaner or air cleaner dirty. 2. Clean or replace filters.

3. Engine eli level low. 3. Fitl with engine oil to proper level

4. Engine cooling fins & air intakescreen excessively dirty. 4. Clean cooling fins, air intakescreen of all debris.

5. Spark plug faulty. 5. Service spark plug.

6. Water, debris or stale fuel in fuel system. 6. Drain and clean fuel system.

Engine Backfires When 1. Throttle control set too 'FAST". 1. Set throttle control to "SLOW" and atlow engine to

Turned To "STOP" idle. Then, turn keyto "OFF".

Excessive Vibration 1. Damaged or bent mower blades. I. Service mower blade(s).

2. Loose blade components. 2. Service and tighten loose parts.

3. Loose or missing air lift (if equipped). 3. Replace air lifts. Tighten to proper torque.

(Trouble Shooting Continued on Next Page)

26

Page 8

PRIMARY MAINTENANCE

Air Is also needed to keep

your engine coot. Dirt, dust

& debris build up to restrict

and clog cooling air Intake

screens and fins. Clean

screens and fins at frequent

Intervals. The engine blower

housing and shrouds should

be removed at least once

each season or more often

under dry, dusty conditions

/h

Generally, wash foam-type filters _

In a dlshwashlng detergent and I_-'_3 1 P Failure to keep external

water solution. Rinse and wring ( . '_ surfaces clean not only

dry, then saturate with oll and _ j presents fire hazards, but

squeeze out excess. Failure to "_,_// causes overheating and

re-oil this type _ter will ruin the _ resulting engine damages

engine. /f/_l_ SUChas:

V// I _\ \_ 1. distorted valve guides

Clean paper elements by tapplng ,._ _L_ \o 2. aticklngvalves

lightly. Blowlngwlthalrwlll ,r(_ T_, _ J o..3. scuffad, ecoredcyl

rupture paper elements, i_._._"_-:_ _,_ walls

Use a flashlight to detect clogged _@I_'._L--_.._ _'-_ r_ / 5. loss of power .

or torn paper elements - replace If I _ _ uLv'v':_I b. complete lailure or

damaged In any way. __ /_ engine.

_::_'_'___ __._ Oj_ 4. overspesdlng

J) fins.

for a thorough cleaning of

Dirt can also be introduced

into an engine In dirty fuel

from a contaminated

container. Always use clean

fresh fuel from a clean

container to guard against

dirt, sludge and water

contamination.

Be aware that fuel breaks

down In storage and forms

will block carburetor pass-

ages. Never use fuel more

than 3 months old. Drain

tank then run the engine out

of fuel before storing during

the off-season.

An engine must also have proper lubrication.

All engines use some oil On 4-cycle engines,

CHECK OIL LEVEL BEFORE EACH START-UP.

Wipe area clean around the oll check plug or

dipstick opening to keep dirt from falling Into

the engine when checking the oil Always

check with the machine on a level surface.

On engines with dipstick, keep the level up to,

but not over, the FULL mark. When adding oil,

allow time for all of the oll to flow down the fill

tube to prevent afalse full reading when the

level could actually be low and result In engine

damage.

32

Page 9

Safety Instructions & Operator's Manual for

MID MOUNT Z-RIDER

ZERO TURNING

HYDRO DRIVE

SERIES 1

IMPORTANT

Snapper products are built using engines that meet or exceed all applicable emissions requirements on the

date manufactured. The labels on those engines contain very important emissions information and critical

safety warnings. Read, Understand, and Follow all warnings and instructions in this manual, the engine

manual, and on the machine, engine and attachments. If you have any questions about your Snapper product,

contact your local authorized Snapper dealer or contact Snapper Customer Service at Snapper, McDonough,

GA. 30253. Phone: (1-800-935-2967).

_l_ WARNING

BATTERY POSTS, TERMINALS AND RELATED ACCESSORIES CONTAIN LEAD AND LEAD COMPOUNDS,

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER AND BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM. WASH HANDS AFTER HANDLING.

WARNING

ENGINE EXHAUST, SOME OF ITS CONSTITUENTS, AND CERTAIN VEHICLE COMPONENTS CONTAIN OR

EMIT CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER OR OTHER

REPRODUCTIVE HARM.

SNAPPERMcDonough,GA. 30253 U.S.A.

COPYRIGHT © 2002

SNAPPER INC

ALL RIGHTS RESERVED

MANUAL No. 7-5167 (I.R. 8/30/02)

37

Loading...

Loading...