Page 1

Mid Frame Snowthrower

Not for

Reproduction

Mfg. No. Description

1695678 Dual Stage Snowthrower, 13.5 TP, 24 Inch

1738329

Revision A

Page 2

Thank you for purchasing this quality-built Snapper snow thrower. We’re pleased that you’ve placed your confidence in the Snapper

Not for

Reproduction

brand. When operated and maintained according to the instructions in this manual, your Snapper product will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with snow throwers and how to avoid

them. This snow thrower is designed and intended only for snow throwing and is not intended for any other purpose. It is important that

you read and understand these instructions throroughly before attempting to start or operate this equipment. This snow thrower

requires final assembly before use. Refer to the Quck Start Guide for instructions on final assembly procedures. Follow the instructions

completely. Save these instructions for future reference.

Product Identification Tag

Product Identification Tag

Model / Modéle / Model xxxxxxxx

Serial / Sèrie / Serie xxxxxxxxxx

Briggs & Stratton Power Products Group, L.L.C.

Milwaukee, WI 53201 USA

When contacting your authorized dealer for replacement

parts, service, or information you MUST have these numbers.

Record your model name/number, manufacturer’s identification

numbers, and engine serial numbers in the space provided for

easy access. These numbers can be found in the locations

shown.

The Illustrated Parts List for this machine can be downloaded from www.snapper.com. Please provide model and serial number when

ordering replacement parts.

Model Description Name/Number

Unit MFG

Mower Deck MFG Number

Dealer Name

Engine Make

Engine Type/Spec

PRODUCT REFERENCE DATA

Number

ENGINE REFERENCE DATA

Unit SERIAL Number

Mower Deck SERIAL

Date Purchased

Engine Model

Engine Code/Serial Number

Number

Snapper Products

535 Macon St.

McDonough, GA 30253

1-800-317-7833

snapper.com

2

Page 3

TABLE OF CONTENTS

Not for

Reproduction

OPERATOR SAFETY.................................................................................... 4

FEATURES AND CONTROLS .......................................................................... 10

OPERATION ............................................................................................. 12

BEFORE OPERATING SNOW THROWER................................................................................. 12

OPERATE THE SNOW THROWER.............................................................................................................. 12

STOP THE SNOW THROWER.................................................................................................................... 13

TRACTION LOCK PINS ............................................................................................................................. 13

DISCHARGE CHUTE AND DEFLECTOR .................................................................................................... 14

CHECK THE OIL (BEFORE STARTING ENGINE) ........................................................................................ 15

FILL THE FUEL TANK................................................................................................................................ 15

START THE ENGINE .................................................................................................................................. 16

STOP THE ENGINE.................................................................................................................................... 17

CLEAR A CLOGGED DISCHARGE CHUTE.................................................................................................18

OPERATING TIPS...................................................................................................................................... 18

MAINTENANCE ......................................................................................... 20

SERVICE RECOMMENDATIONS ............................................................................................................... 20

LUBRICATE AUGER GEAR BOX................................................................................................................. 20

LUBRICATE AUGER SHAFT FITTINGS ...................................................................................................... 20

CHECK/LUBRICATE FREE-HAND LINKAGE.............................................................................................. 20

LUBRICATE CHUTE ROTATION GEAR ....................................................................................................... 20

ADUST THE DRAG ON THE CHUTE ROTATION......................................................................................... 20

ENGINE MAINTENANCE ........................................................................................................................... 20

CHANGE THE SPARK PLUG...................................................................................................................... 22

ADJUST SKID HEIGHT.............................................................................................................................. 23

BELT ADJUSTMENT.................................................................................................................................. 23

BELT GUIDE ADJUSTMENT ...................................................................................................................... 24

SPEED CONTROL ROD ADJUSTMENT ..................................................................................................... 25

CHECK AND ADJUST THE CABLES.......................................................................................................... 25

AUGER CONTROL CABLE ADJUSTMENT................................................................................................. 25

TRACTION CONTROL CABLE ADJUSTMENT ........................................................................................... 26

AUGER SHEAR PIN REPLACEMENT ......................................................................................................... 27

CHECK THE TIRES.................................................................................................................................... 27

STORAGE................................................................................................ 28

OFF SEASON STORAGE............................................................................................................................ 28

LUBRICATE HEX SHAFT AND CHAINS..................................................................................................... 28

REMOVE FROM STORAGE........................................................................................................................ 28

TROUBLESHOOTING................................................................................... 29

WARRANTIES........................................................................................... 31

SPECIFICATIONS ....................................................................................... 33

3

Page 4

product

OPERATOR SAFETY

Not for

Reproduction

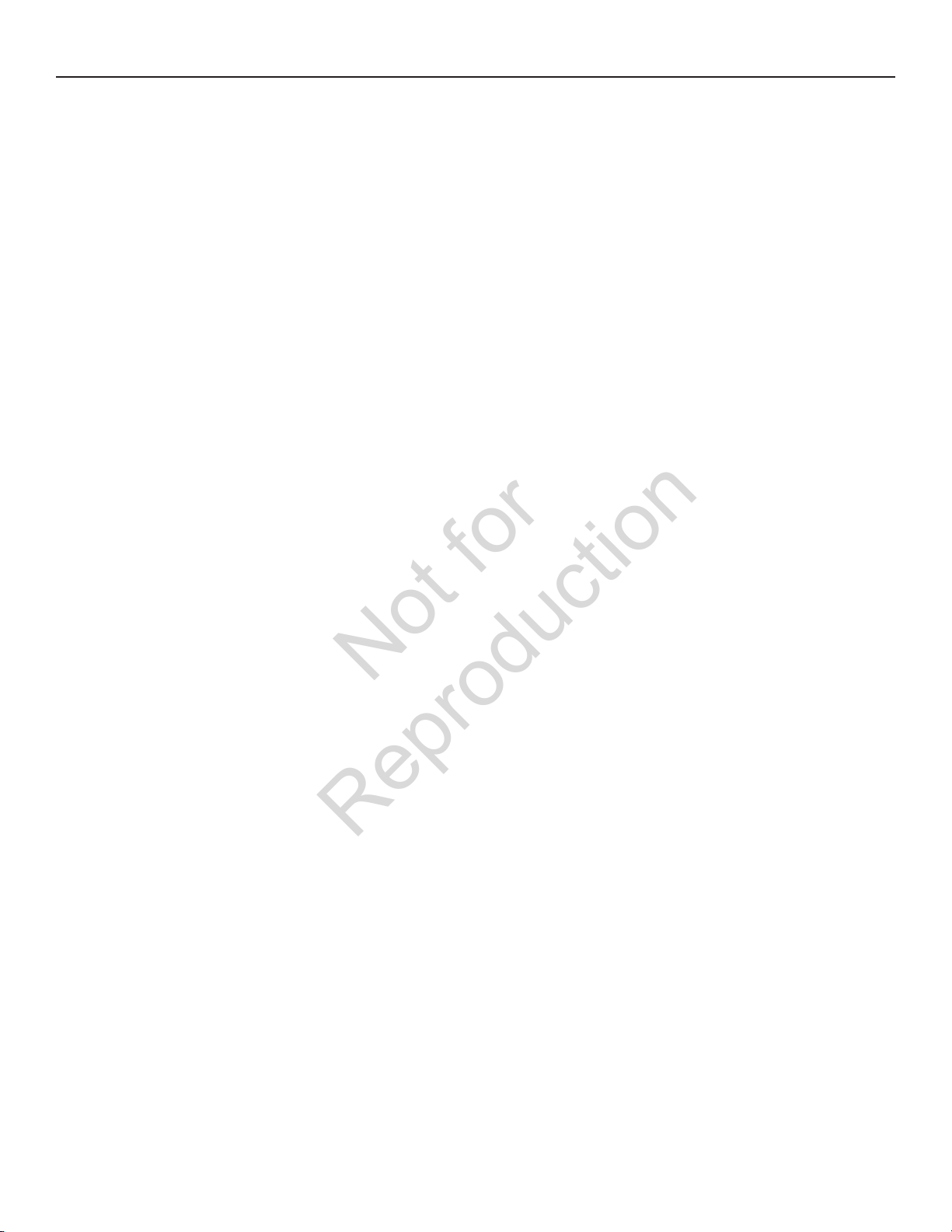

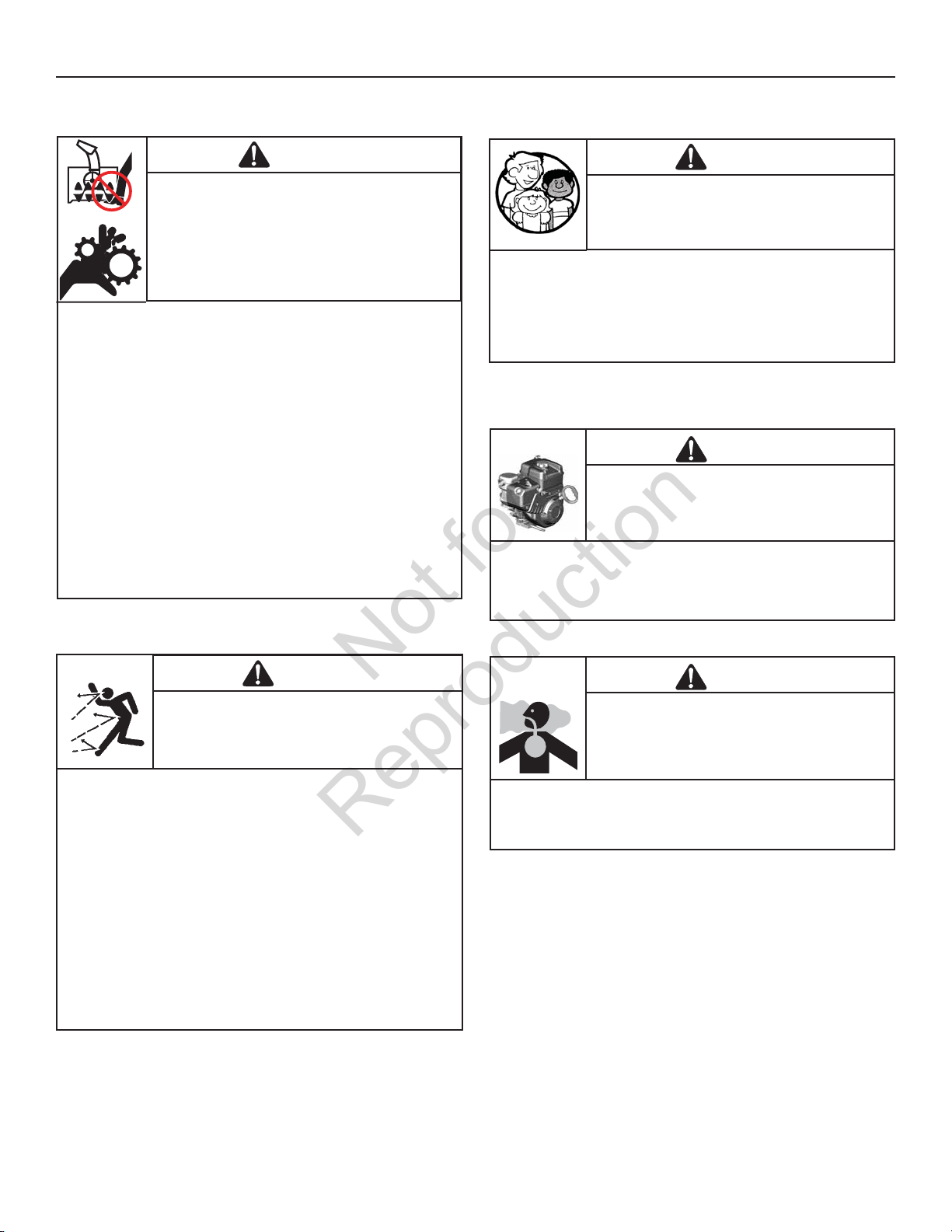

DANGER - Amputation Hazard

The discharge chute contains a rotating

impeller to throw snow. Never clear or unclog

the discharge chute with your hands. Fingers

can quickly become caught and traumatic

amputation or severe laceration will result.

Always use a clean-out tool to clear or unclog

the discharge chute.

DANGER

• Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snow throwers.

• This snow thrower is capable of amputating hands and feet,

and throwing objects. Read and observe all the safety

instructions in this manual. Failure to do so will result in

death or serious injury.

Safety Alert Symbol and Signal Words

The safety alert symbol and signal word (DANGER,

WARNING, CAUTION, or NOTICE) is used to indicate the likelihood and potential severity of personal injury and/or damage to

the product. In addition, a hazard symbol may be used to

represent the type of hazard.

Hazard Symbols and Meanings

Safety Alert – Identifies safety information about

hazards that can result in personal injury.

Operator’s Manual – Read and understand before

performing any activity or running snow thrower.

Rotating Impeller

Rotating Auger Rotating Gears

Never Reach into

Rotating Parts

Fire Explosion

Shock Toxic Fumes

Keep a Safe

Distance from

Snow Thrower

Thrown Objects

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE indicates a situation that could result in damage

to the

.

WARNING

U.S.A. Models: Certain components in this product and its

related accessories contain chemicals known to the state of

California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

Recommended

Hot Surface

Shut off engine and remove spark plug connector

before performing maintenance or repair work.

Ear Protection for

Extended Use

WARNING

U.S.A. Models: The engine exhaust from this product contains chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

4

Page 5

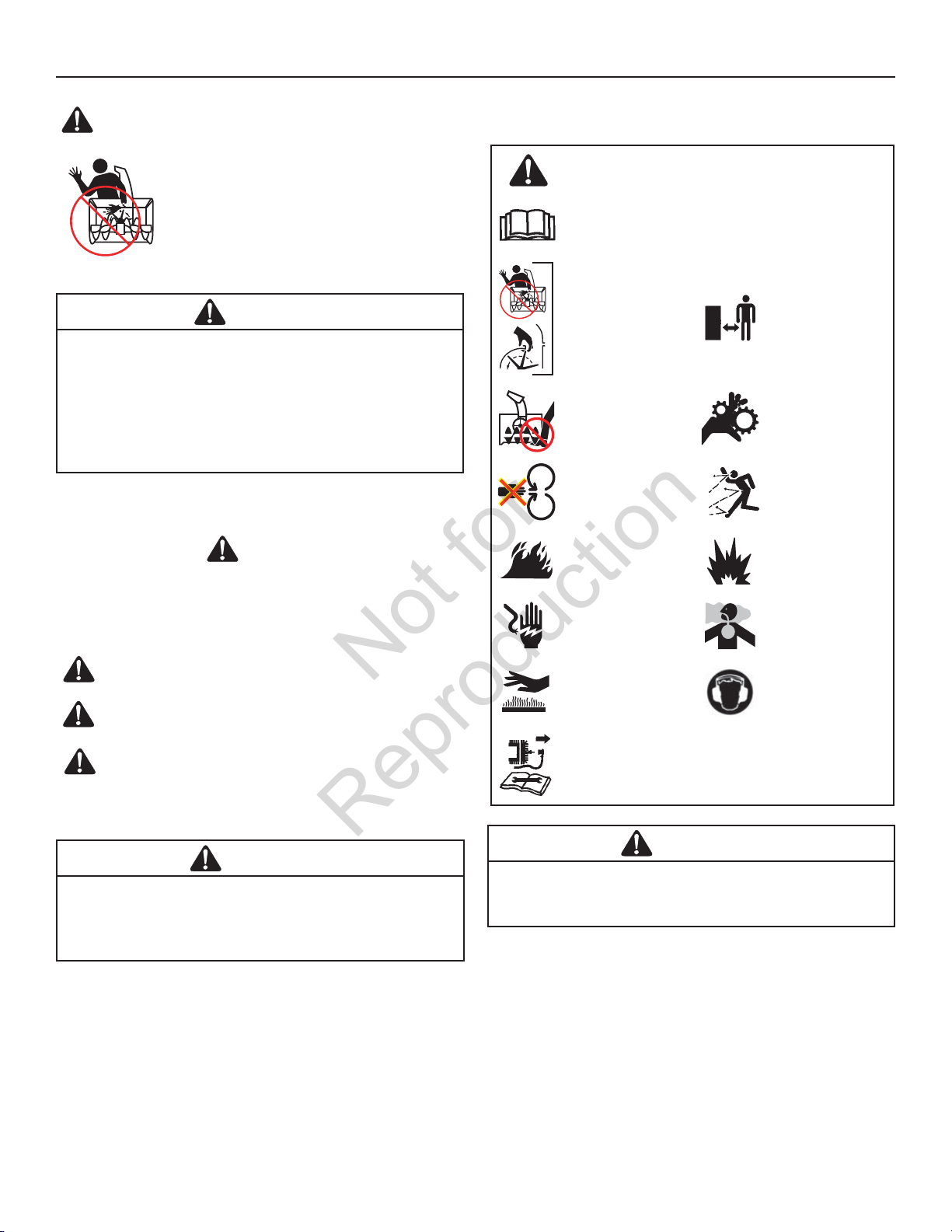

1

2

Free-Hand

TM

Control

Easy-Turn

TM

Traction Control

Read, understand, and follow all the instructions on the

snow thrower and in the operator’s manual before operating

this unit.

Failure to observe the safet y instructions in this manual will

result in death or serious injury.

DANGER: Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with snow

throwers. Never use your hands to clean out the discharge chute.

Discharge chute contains rotating impeller to throw snow.

Never clear or unclog the discharge chute with your hands.

Fingers can quickly become caught in the impeller. Always

use a clean-out tool.

Failure to observe these safety instructions will result in

traumatic amputation or severe laceration.

OPERATOR SAFETY

Not for

Reproduction

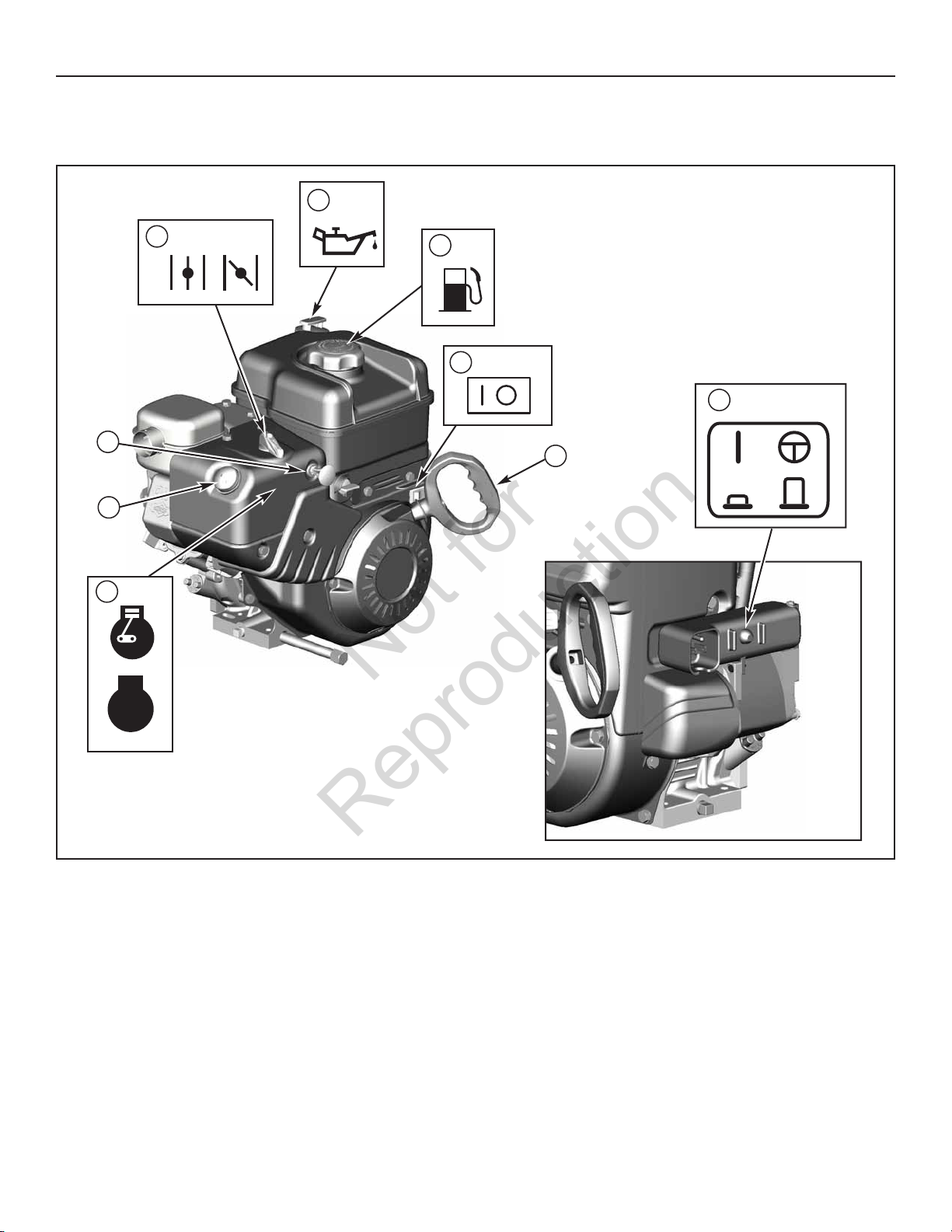

Control Symbols on Equipment

Oil

Fuel Forward

On Off Neutral

Choke Off Reverse

Choke On

Stop

Slow Engine - Run

Fast

STOP

Electric Start Engage (Down) &

Disengage (Up)

Engine - Stop

Read the Manual

DANGER

• Be thoroughly familiar with the controls and the proper use of the snow

thrower.

• Make sure you are properly trained before operating the snow thrower.

• Know how to stop the unit and disengage the controls quickly.

• Never allow anyone to operate the snow thrower without proper instruction.

• Always follow the instructions in the operator’s manual, if the snow thrower

will be stored for an extende d period.

• Maintain or replace safety and instruction labels as necessary.

• Never attempt to make major repairs on the snow thrower unless you have

been properly trained. Improper servicing of the snow thrower can result

in hazardous operation, equipment damage, and voiding of the product

warranty.

Discharge Chute

Traction Control Engage (Down)

Auger Clutch

Discharge Chute

(Left and Right)

Auger Control Engage (Down)

Chute Deflector

(Up and Down)

Heated Hand Grips

(High and Low)

DANGER

TO SAFELY CLEAR A CLOGGED DISCHARGE CHUTE

FOLLOW THESE INSTRUCTIONS:

1. Shut OFF the engine.

2. Wait 10 seconds to be sure the impeller blades have stopped rotating.

3. Always use a clean-out tool, not your hands.

NOTE: Not all control symbols shown on this page will appear

on your snow thrower. See FEATURES AND CONTROLS section

for the applicable symbols.

F

5

Page 6

Fuel and its vapors are extremely flammable and explosive.

Always handle fuel with extreme care.

Failure to observe these safety instructions can cause a fire

or explosion which will result in severe burns or death.

This snow thrower is only as safe as the operator. If it is

misused, or not properly maintained, it can be dangerous.

Remember you are responsible for your safety and that of

those around you.

OPERATOR SAFETY

Not for

Reproduction

Operation and Equipment Safety

DANGER

• Keep the area of operation clear of all persons, particularly small children

and pets.

• Thoroughly inspect the area where the snow thrower will be used and remove

all doormats, sleds, boards, wires, and other foreign objects.

• Do not operate the snow thrower without wearing adequate winter clothing.

• Wear footwear that will improve footing on slippery surfaces.

• Use caution to avoid slipping or falling especially when operating the

snow thrower in reverse.

• Never operate the snow thrower without good visibility or light. Always be

sure of your footing, and keep a firm hold on the handles.

• Do not clear snow across the face of slopes. Use extreme caution when

changing direction on slopes. Do not attempt to clear steep slopes.

• Do not overload the machine capacity by attempting to clear snow too

quickly.

• Never operate the snow thrower at high transport speeds on slippery

surfaces. Look behind the snow thrower and use care when operating in

reverse.

• Do not use the snow thrower on surfaces above ground level such as roofs of

residences, garages, porches, or other such structures or buildings.

• Operators should evaluate their ability to operate the snow thrower safely

enough to protect themselves and others from injury.

• The snow thrower is intended to remove snow only. Do not use the snow

thrower for any other purpose.

• Do not carry passengers.

• After striking a foreign object, shut OFF the engine, disconnect the cord on

electric motors, thoroughly inspect the snow thrower for any damage, and

repair the damage before restarting and operating the snow thrower.

• If the snow thrower vibrates abnormally, shut OFF the engine. Vibration is

generally a warning of trouble. See an authorized dealer if necessary for

repairs.

• For models equipped with electric starting motors, disconnect the power

cord after the engine starts.

Fuel Handling

DANGER

WHEN ADDING FUEL

• Turn off engine and let cool at least 2 minutes before removing the fuel

cap and adding fuel.

• Fill fuel tank outdoors or in a well ventilated area.

• Do not overfill the fuel tank. To allow for the expansion of gasoline, do not fill

above the bottom of the fuel tank neck.

• Keep fuel away from sparks, open flames, pilot lights, heat, and other

ignition sources.

• Check fuel lines, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• Use an approved fuel container.

• If fuel spills, wait until it evaporates before starting engine.

WHEN STARTING ENGINE

• Ensure that spark plug, muffler, fuel cap, and air cleaner (if equipped) are in

place and secured.

• Do not crank the engine with the spark plug removed.

• If fuel is spilled, do not attempt to start the engine, but move the snow

thrower away from the area of the spill, and avoid creating any source of

ignition, until the fuel vapors have dissipated.

• Do not over-prime the engine. Follow the engine starting instructions in this

manual.

• If the engine floods, set choke (if equipped) to OPEN/RUN position, move

throttle (if equipped) to FAST position and crank until engine starts.

WHEN OPERATING EQUIPMENT

• Do not tip the snow thrower at an angle which causes the fuel to spill.

• Do not choke the carburetor to stop the engine.

• Never run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

WHEN CHANGING OIL

• If you drain the oil from the top oil fill tube, the fuel tank must be empty or

fuel can leak out and result in a fire or explosion.

WHEN TRANSPORTING EQUIPMENT

• Transport with fuel tank EMPTY, or with fuel shut-off valve OFF.

WHEN STORING GASOLINE OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water heaters, or other appliances that have

pilot light or other ignition source because they can ignite fuel vapors.

6

Page 7

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the operating activity. Never assume that children will

remain where you last saw them.

Engines give off carbon monoxide, an odorless, colorless,

poison gas.

Breathing carbon monoxide can cause nausea, fainting,

or death.

Safe operation of the snow thrower requires the proper care

and maintenance of the engine. Failure to observe the safety

instructions in this manual will result in death or serious

injury.

Objects can be picked up by auger and thrown from chute.

Never discharge snow toward bystanders or allow anyone in

front of the snow thrower. Failure to observe these safety

instructions will result in death or serious injury.

Keep hands, feet, and clothing away from rotating parts.

Rotating parts can contact or entangle hands, feet, hair,

clothing, or accessories.

Failure to observe these safety instructions will result in

traumatic amputation or severe laceration.

OPERATOR SAFETY

Not for

Reproduction

Moving Parts

DANGER

• Whenever cleaning, repairing, or inspecting the snow thrower, make sure the

engine is OFF, spark plug wire is disconnected, and all moving parts have

stopped.

• Do not put hands or feet near or under rotating parts. Keep clear of the

discharge opening at all times.

• Never operate the snow thrower without proper guards, and other safety

devices in place and working.

• Never leave the snow thrower unattended while engine is running. Always

disengage the auger and traction controls, stop engine, and remove keys.

• Keep all loose clothing away from the front of the snow thrower and auger.

Scarves, mittens, dangling drawstrings, loose clothes, and pants can quickly

become caught in the rotating device and amputation will occur. Tie up

long hair and remove jewelry.

• Run the machine a few minutes after discharging snow to prevent freeze-up

of the collector/impeller.

• Disengage power to the collector/impeller when snow thrower is transported

or not in use.

Thrown Objects

Children

DANGER

• Keep children out of the area during operation. Children are often attracted to

the equipment. Be mindful of all persons present.

• Be alert and turn unit off if children enter the area.

• Never allow children to operate the unit.

• Use extra care when approaching blind corners, shrubs, trees, or other

objects that may obscure vision. Children may be present.

Engine Safety

DANGER

• Disengage all clutches and shift into neutral before starting the engine.

• Let the engine adjust to outdoor temperatures before starting to clear snow.

• Use a grounded three-wire plug-in for all snow throwers equipped with

electric drive motors or electric starting motors.

DANGER

• Always wear safety glasses or eye shields while during operation, and while

performing an adjustment or repair.

• Always be aware of the direction the snow is being thrown. Nearby

pedestrians, pets, or property may be harmed by objects being thrown.

• Be aware of your environment while operating the snow thrower. Running

over items such as, gravel, doormats, newspapers, toys, and rocks hidden

under snow, can all be thrown from the chute or jam in the auger.

• Use extreme caution when operating on or crossing gravel drives, walks, or

roads.

• Adjust the collector housing height to clear gravel or crushed rock surface.

• Never operate the snow thrower near glass enclosures, automobiles, window

wells, drop-offs, and the like without proper adjustment of the discharge

chute angle.

• Familiarize yourself with the area in which you plan to operate the snow

thrower. Mark off boundaries of walkways and driveways.

DANGER

• Start and run engine outdoors.

• Do not run the engine in an enclosed area, even if doors or windows are

open.

7

Page 8

This snow thrower must be properly maintained to ensure safe

operation and performance. Failure to observe the safety

instructions in this manual could result in death or serious

injury.

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

U.S.A. Models:

Running the engine produces heat. Engine parts, especially

muffler, become extremely hot.

Failure to observe these safety instructions could result in

severe thermal burns on contact.

OPERATOR SAFETY

Not for

Reproduction

Engine Safety (Continued)

WARNING

-

• If there is natural or LP gas leakage in area, do not start engine.

• Do not use pressurized starting fluids because vapors are flammable.

WARNING

• Never touch a hot engine or muffler. Allow muffler, engine cylinder, and fins

to cool before touching.

• Remove debris from muffler area and cylinder area.

• Install and maintain in working order a spark arrester before using equipment

on forest-covered, grass-covered, or brush-covered unimproved land.

•U

Section 4442 to use or operate the engine on or near any forest-covered,

brush-covered, or grass-covered land unless the exhaust system is equipped

with a spark arrester meeting any applicable local or state laws. Other states

or federal areas may have similar laws.

It is a violation of California Public Resource Code

Maintenance and Storage

WARNING

• When performing any maintenance or repairs on the snow thrower, shut OFF

the engine, disconnect spark plug wire, and keep the wire away from the

plug to prevent someone from accidently starting the engine.

• Check shear bolts and other hardware at frequent intervals for proper

tightness to be sure the snow thrower is in safe working condition.

• Keep nuts and bolts tight and keep snow thrower in good condition.

• Never tamper with safety devices. Check their proper operation regularly and

make necessary repairs if they are not functioning properly.

• Components are subject to wear, damage, and deterioration. Frequently

check components and replace with recommended parts, when necessary.

• Check control operation frequently. Adjust and service as required.

• Use only factory authorized replacement parts when making repairs.

• Always comply with factory specifications on all settings and adjustments.

• Only authorized service locations should be utilized for major service and

repair requirements.

• Use only attachments and accessories approved by the factory (such as

wheel weights, counterweights, or cabs).

• Never attempt to make any adjustments while the engine is running (except

when specifically recommended by the factory).

8

Page 9

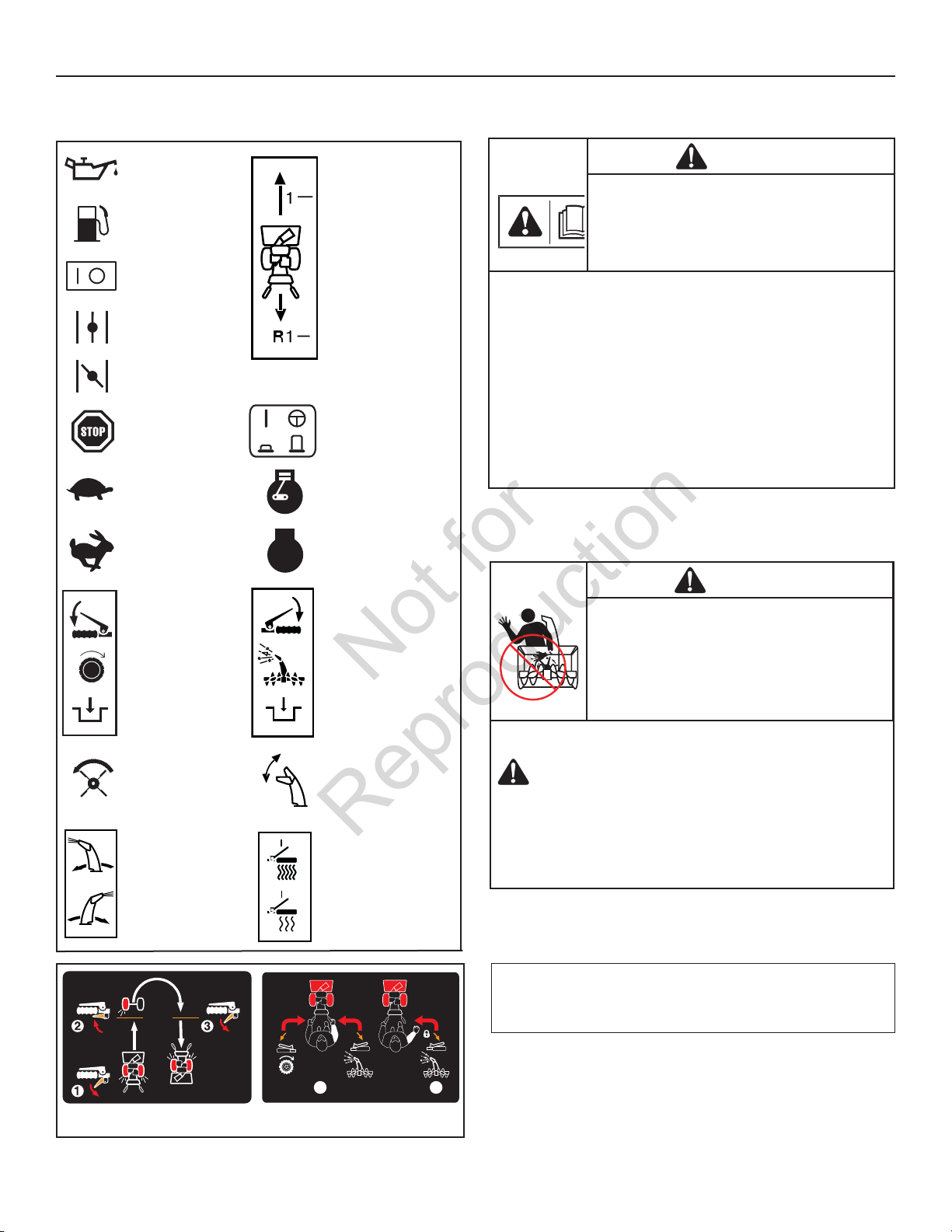

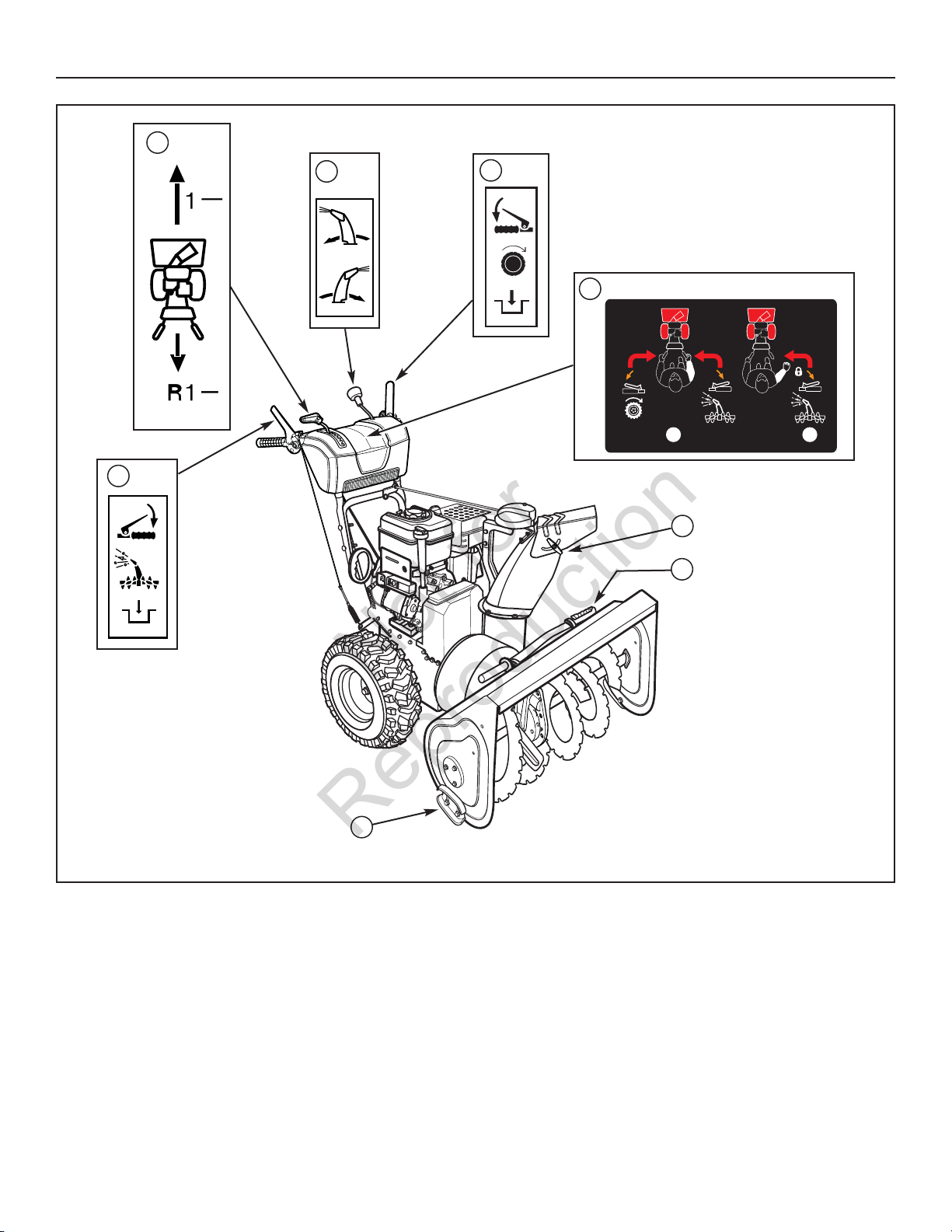

If any safety decals become worn or damaged and

cannot be read, order replacement decals from your local dealer.

OPERATOR SAFETY

Not for

Reproduction

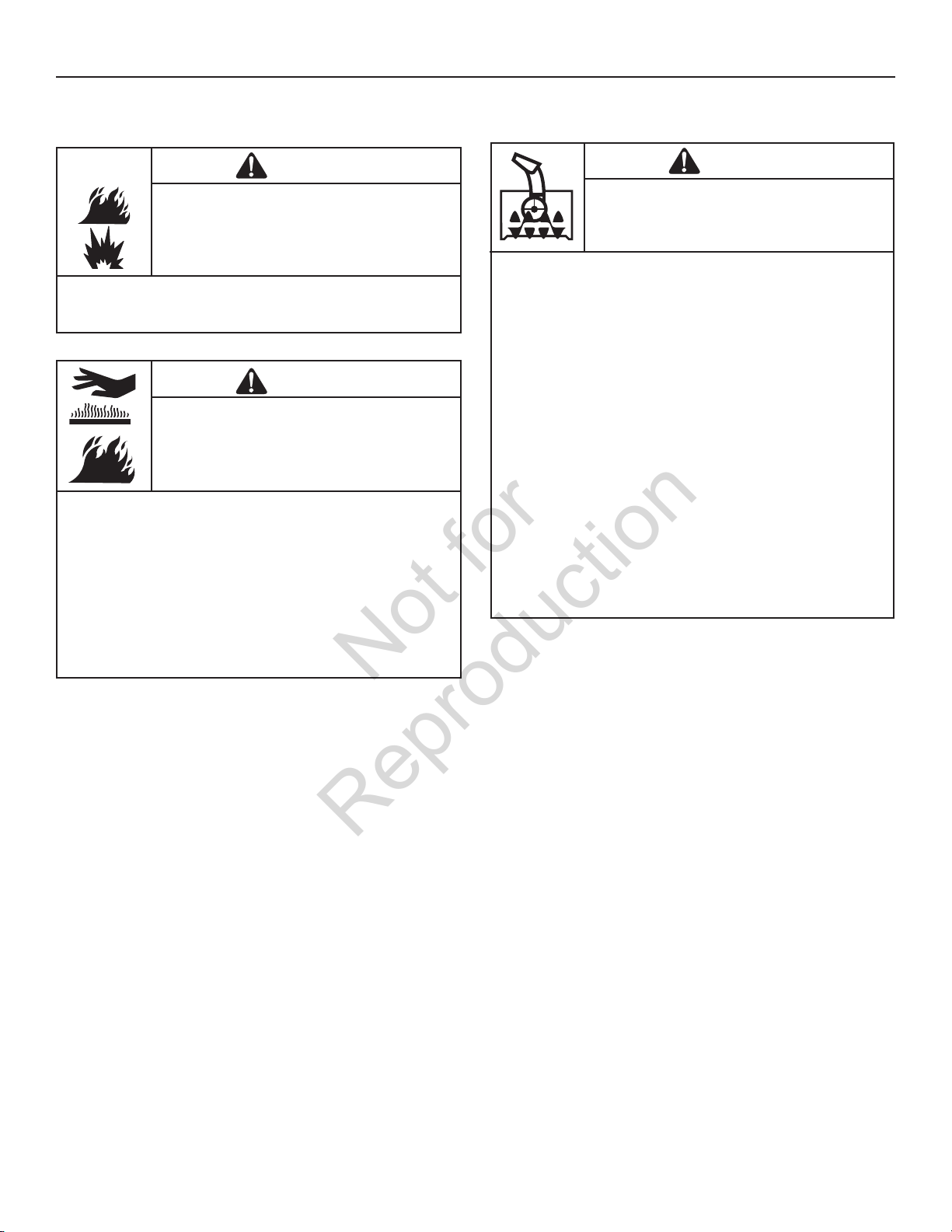

Look for this symbol to indicate important safety

pre cautions. This symbol indicates: “Attention! Become

Alert! Your Safety Is At Risk.”

Before operating your snow thrower, read the safety decals

as shown on your snow thrower. The cautions and warnings

are for your safety. To avoid a personal injury or damage to

your snow thrower, understand and follow all the safety decals.

Part No. 1738344

Free-Hand

Part No. 1736616

Shift Decal

Part No. 1737869

Auger Control Decal

TM

Control Decal

1

WARNING:

Traction Control Decal

2

Part No. 1737870

Part No. 1738348

Chute Rotation Crank Decal

Part No. 278297

Engine Decal

Part No. 1737866

Auger Danger Decal

Part No. 1737865

Chute Danger Decal

Safety Decals Figure 1

9

Page 10

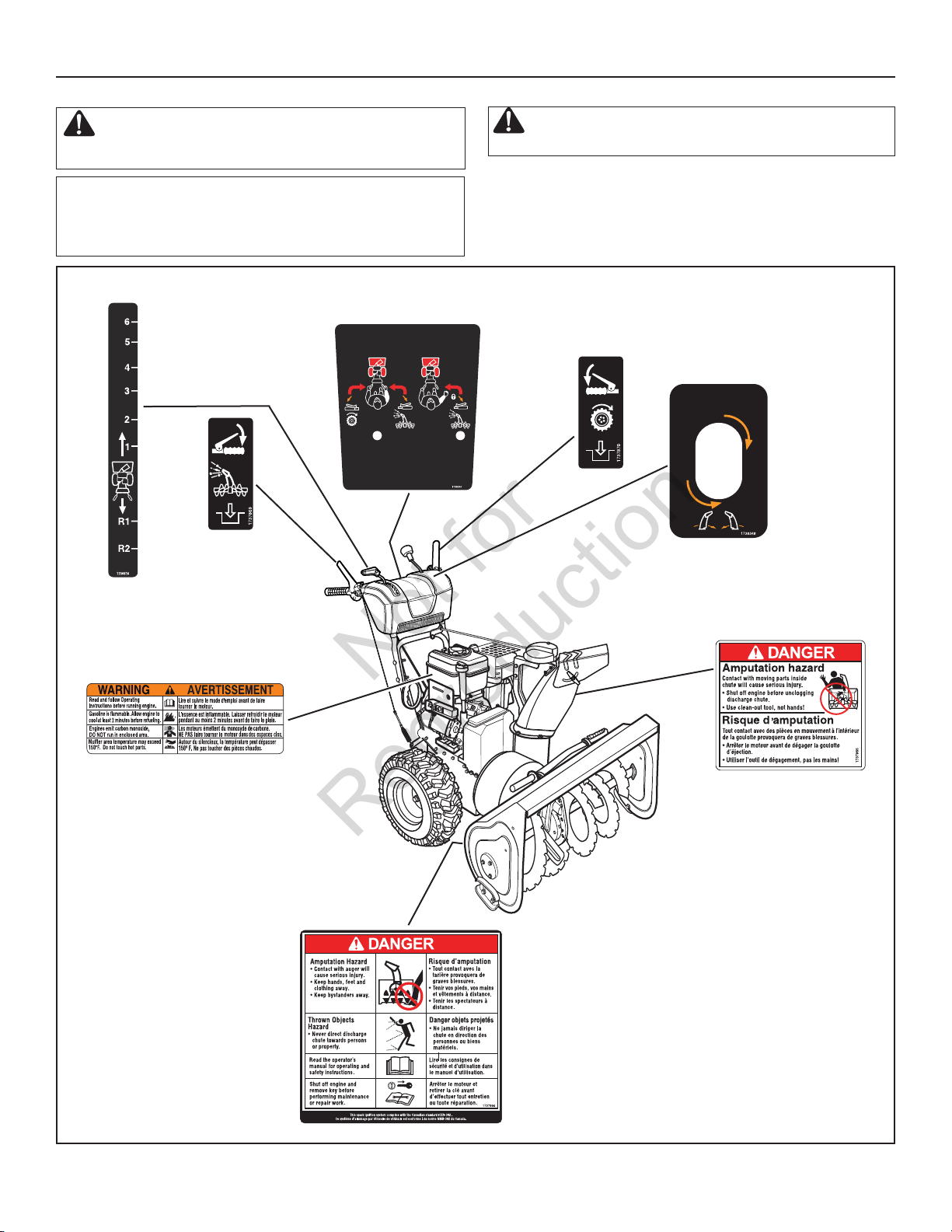

FEATURES AND CONTROLS

Not for

Reproduction

NOTICE: Read this OPERATOR’S MANUAL and OPERATOR SAFETY before operating your snow thrower. Compare the illustrations with your

SNOW THROWER to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference.

H

A

D

C

I

G

F

B

E

STOP

Engine Controls Figure 2

ENGINE AND SNOW THROWER CONTROLS

ENGINE CONTROLS

A. Choke Control Knob — Used to start a cold engine (see Figure 2).

B. Electric Start Button — Used to start the engine using the electric

starter.

C. Primer Button — Used to inject fuel directly into the carburetor

manifold to ensure fast starts in cool weather.

D. Safety Key — Must be inserted to start engine. Pull out to stop. Do

not turn safety key.

E. Starter Cord Handle — Used to start the engine manually.

F. ON/OFF Switch — Used to start and stop the engine.

G. Fuel Tank and Cap — Fill the fuel tank to approximately 1-1/2 in.

(38 mm) below the top of the neck to allow for fuel expansion.

H. Oil Fill Cap (Extended Dipstick)

SNOW THROWER CONTROLS

A. Speed Select Lever — Allows the operator to use one of six (6)

forward and two (2) reverse speeds (see Figure 3). To shift, move

speed select lever to desired position.

NOTICE: Do not move speed select lever while Traction

Drive Clutch is engaged. This may result in severe damage

to drive system.

10

Page 11

FEATURES AND CONTROLS

1

2

Not for

Reproduction

A

C

B

F

E

D

H

G

Snow Thrower Controls Figure 3

B. Auger Control Lever — Used to engage and disengage the

auger and impeller. To engage push down, to disengage release.

C. Chute Rotation Crank — Used to rotate the discharge chute to the

left or right.

D. Chute Deflector Knob — Used to control the angle of the chute

deflector (up or down).

TM

E. Free-Hand

hand) and auger control (right hand), allows the operator to

release the auger control lever to use the other controls.

Control — After engaging the traction control (left

F. Traction Drive Clutch Lever — Used to propel snow thrower for-

ward or reverse. Push down to engage, release to disengage.

G. Skid Shoe — Used to adjust ground clearance of auger housing.

H. Clean-Out Tool — Used to remove snow and debris from the dis-

charge chute and the auger housing.

11

Page 12

1

2

Free-Hand

TM

Control

OPERATION

■ Check the fasteners. Make sure all fasteners are tight.

■ On electric start models, the unit was shipped with the starter cord

plugged into the engine. Before operating, unplug the starter cord from the

engine.

C

C

A

Not for

Reproduction

BEFORE OPERATING SNOW THROWER

■

■

WARNING: The operation of any snow thrower can result in foreign objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety glasses or eye shields before beginning snow thrower operation. We recommend

standard safety glasses or Wide Vision Safety Mask over spectacles.

OPERATE THE SNOW THROWER

CAUTION: Operation with a Snow Cab. Wind may blow

exhaust gasses back towards the operator. If you notice

the smell of exhaust, change direction of operation.

NOTICE: Do not throw snow toward a building as hidden objects

could be thrown with sufficient force to cause damage.

1. Start the engine. See “To Start Engine” in this section.

2. Turn the chute rotation crank (A

right) of the discharge chute. See “Discharge Chute and Deflector” in

this section.

3. Loosen the wing nut on the side of the discharge chute to set angle

(up or down) the snow is thrown. See “Discharge Chute and Deflector”

in this section.

, Figure 4) to set the direction (left or

NOTE: This snow thrower was shipped WITH OIL in the

engine. See “Before Starting Engine” instructions in the

OPERATION section of this manual before starting engine.

CAUTION: Before operating, make sure the area in

front of the snow thrower is clear of bystanders or

obstacles.

4. Fully press and hold the auger control lever (BBto engage auger

rotation. Releasing the auger control lever will disengage the auger unless the Free-Hand™ control has been activated.

5. Fully press and hold the traction and Free-Hand™ control lever (C

engage the traction drive and begin moving the snow thrower. To disengage the traction drive, completely release the lever.

6. When BOTH levers are depressed, the Free-Hand™ control is activated. This allows auger control lever to be released - YET AUGER

ROTATION WILL CONTINUE - until the Free-Hand™ control is released.

) to

A

C

D

B

Control Levers Figure 4

NOTE: Always release the traction control lever before moving

the speed select lever.

7. Use the speed select lever (DD) to select the forward drive speed. Set

the speed select lever to one of the following positions as determined

by snow conditions:

1-2 Wet, Heavy, Slushy, Extra Deep

3 Moderate

4-5 Very Light

6 Transport

NOTE: When clearing wet, heavy, snow, it is recommended

that the ground speed of the unit be reduced, maintained full

throttle and do not attempt to clear the full width of the unit.

8. To stop moving forward, release the traction control lever (C

9. To move the snow thrower backwards, move the speed select lever into

either first or second reverse position and engage the traction control

lever.

).

12

Page 13

OPERATION

C

A

A

Not for

Reproduction

STOP THE SNOW THROWER

1. Release the auger control lever (BB,Figure 4).

2. Release the traction control lever (C

3. Push the ON/OFF switch (A

out the safety key (BB).

WARNING: Never run engine indoors or in an enclosed,

poor ventilated area. Engine exhaust contains CARBON

MONOXIDE, an ODORLESS and DEADLY GAS.

• Keep hands, feet, hair, and loose clothing away

from any moving parts on engine and snow

thrower.

• Temperature of muffler and nearby areas can

exceed 150°F (66°C). Avoid these areas.

• DO NOT allow children or young teenagers to

operate or be near snow thrower while it is

operating.

).

, Figure 13) to the OFF position and pull

TRACTION LOCK PINS

The right traction wheel can be completely released using the locking pin

(A

, Figure 5). This allows the unit to be easily moved with the engine off.

WARNING: Read Operator’s Manual before operating

machine. This machine can be dangerous if used

carelessly.

• Never operate the snow thrower without all guards,

covers, shields in place.

• Never direct discharge towards windows or allow

bystanders near machine while engine is

running.

• Stop the engine whenever leaving the operating

position.

• Disconnect spark plug before unclogging the

impeller housing or the discharge chute and

before making repairs or adjustments.

• When leaving the machine, remove the safety key.

To reduce the risk of fire, keep the machine clean

and free from spilled gas, oil, and debris.

A

Traction Lock Pins Figure 5

13

Page 14

B

OPERATION

Not for

Reproduction

DISCHARGE CHUTE AND DEFLECTOR

Discharge Chute Rotation (Left/Right)

1. Turn the chute rotation crank (AA, Figure 6) clockwise to turn chute to

the right. Turn crank counterclockwise to turn chute to the left.

2. After the desired position is obtained, release the crank.

Chute Deflector (Up/ Down)

1. Loosen the wing nut (AA, Figure 6) on the side of the discharge

chute (B

).

2. Raise the deflector to provide a higher stream and greater distance. Or,

lower the deflector to provide a lower stream and less distance.

3. After the desired angle is obatained, tighten the wing nut.

A

A

B

Setting the Chute Deflector Angle Figure 7

Setting the Discharge Chute Rotation Figure 6

14

Page 15

DO NOT

CHECK THE OIL (BEFORE STARTING ENGINE)

A

FULL

Not for

Reproduction

NOTE: The engine was shipped from the factory filled with oil.

Check the level of the oil. Add oil as needed.

1. Make sure the unit is level. Use a high quality detergent oil classified

“For Service SG, SH, SJ, SL, or higher”.

2. Remove the oil fill cap/dipstick (A

3. Insert the oil fill cap/dipstick and turn clockwise to tighten.

4. Remove the oil fill cap/dipstick and check the oil.

NOTE: Do not check the level of the oil while the engine runs.

5. If necessary, add oil until the oil reaches the FULL mark on the oil fill

cap/dipstick. Do not add too much oil.

6. Tighten the oil fill cap/dipstick securely each time you check the oil

level.

NOTE: Synthetic 5W30 motor oil is acceptable for all temperatures. DO NOT mix oil with gasoline. See Chart for oil recommendations.

, Figure 8) and wipe with a clean cloth.

OPERATION

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil consumption. Check

oil level more frequently.

FULL

FILL THE FUEL TANK

This engine is certified to operate on gasoline. Exhaust Emission Control

System: EM (Engine Modifications).

Fill the fuel tank with fresh, clean, unleaded regular, unleaded premium, or reformulated automotive gasoline with a minimum of 85 octane along with a

fuel stabilizer (follow instructions on fuel stabilizer package). D

leaded gasoline. We recommend that fuel stabilizer be added to the fuel

each time that gasoline is added to the fuel tank.

NOTE: Winter grade gasoline has higher volatility to improve

starting. Be certain container is clean and free from rust or

other foreign particles. Never use gasoline that may be stale

from long periods of storage in the container.

CAUTION: DO NOT use gasoline containing any

amount of alcohol as it can cause serious damage to

the engine or significantly reduce the performance.

use

A

Checking the Oil

WARNING: Gasoline is flammable. Always use

caution when handling or storing gasoline. Turn

engine off and let engine cool at least two minutes before

removing the gas cap. Do not add gasoline to the fuel tank

while snow thrower is running, hot, or when snow thrower

is in an enclosed area. Keep away from open flame,

electrical sparks and DO NOT SMOKE while filling the fuel

tank. Never fill the fuel tank completely; but fill the fuel

tank to within 1-1/2 inches (3.8 mm) from the top to

provide space for the expansion of the fuel. Always fill fuel

tank outdoors and use a funnel or spout to prevent spilling.

Make sure to wipe up any spilled fuel before starting the

engine.

Store gasoline in a clean, approved container, and keep

the cap in place on the container. Keep gasoline in a cool

well ventilated place; never in the house. Never buy more

than a 30 day supply of gasoline to assure volatility.

Gasoline is intended to be used as a fuel for internal

combustion engines; therefore, do not use gasoline for any

other purpose. Since many children like the smell of

gasoline, keep it out of their reach because the fumes are

dangerous to inhale, as well as being explosive.

Figure 8

15

Page 16

OPERATION

A

A

B

C)

A

Not for

Reproduction

START THE ENGINE

Be sure that engine oil is at FULL mark on the oil fill cap/dipstick. The snow

thrower engine is equipped with an A.C. electric starter and recoil starter. Before

starting the engine, be certain that you have read the following information.

If engine floods, set the choke to the OPEN/RUN position and crank until the engine starts.

WARNING: The electric starter is equipped with a

three−wire power cord and plug designed to operate on AC

house hold current. The power cord must be properly

grounded at all times to avoid the possibility of electric shock

which can cause injury to the operator. Follow all instructions

carefully as set forth:

Make sure your house has a three−wire grounded system.

If you are not sure, ask a licensed electrician. If your house does

not have a three−wire grounded system, do not use this electric

starter under any condition.

If your house has a three−wire grounded system but a three-hole

receptacle is not available to connect the electric starter, have a

three−hole receptacle installed by a licensed electrician.

WARNING: To connect power cord, always connect the

power cord first to the switch box located on the

engine and then plug the other end into a three−hole

grounded receptacle.

WARNING: To disconnect the power cord, always

unplug the end connected to the three−hole grounded

receptacle first.

Start the engine as follows:

1. Check the oil level. See the “Check/Add Oil” section in the ENGINE

MANUAL.

2. Make sure equipment drive controls are disengaged.

3. Push the ON /OFF switch (A

, Figure 9) to the ON position.

4. Insert the safety key (A

fully in to the RUN position.

5. Turn the choke knob (B

NOTE: Do not use the choke to start a warm engine.

6. Push the primer button (C

NOTE: Do not use the primer to start a warm engine.

NOTE: Ensure that electric extension cord is removed from the

power receptacle.

C

B

A

Inserting Safety Key Figure 10

7. Rewind Start: Firmly hold the starter cord handle (A

the starter cord handle slowly until resistance is felt, then pull rapidly.

WARNING: Rapid retraction of the starter cord (kickback)

will pull your hand and arm toward the engine faster

than you can let go. Broken bones, fractures, bruises,

or sprains could result. When starting engine, pull the

starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

NOTE: If the engine does not start after three attempts, see the

Engine Manual Troubleshooting section.

8. Electric Start: First connect the extension cord to the power cord

receptacle and then into a wall receptacle. If additional extension cord is

required, make sure it is three-wire.

, Figure 10) into the safety key slot and push

) fully clockwise if engine is cold.

two times.

, Figure 11). Pull

A

Starting the Engine Figure 9

WARNING: If the extension cord is damaged, it must

be replaced by the manufacturer (or its service agent)

or a similarly qualified person to avoid a hazard.

16

Page 17

A

9. Electric Start: Depress the starter push button (AA, Figure 12). After you

B

Not for

Reproduction

start the engine, first disconnect the extension cord from the wall receptacle

and then from the power cord receptacle (B

A

).

OPERATION

A

B

Starting with Electric Start Figure 12

Starting with Cord Handle Figure 11

STOP THE ENGINE

Before stopping the engine for a few minutes to help dry off any moisture

on the engine.

WARNING: Gasoline and vapors are extremely

flammable and explosive. Fire or explosion can

cause severe burns or death. DO NOT choke the

carburetor to stop the engine.

1. Push the ON/OFF switch (A

2. Remove the safety key (BB). Keep the safety key out of the reach of

children.

, Figure 13) to the OFF position.

IMPORTANT: To extend the life of the starter, use short

starting cycles (five seconds maximum). Wait one minute

between starting cycles.

NOTE: If the engine does not start after three attempts, see the

Engine Manual Troubleshooting section.

NOTE: Do not lose the safety key. Keep the safety key in a safe

place. The engine will not start without the safety/ignition key.

B

A

Stopping the Engine Figure 13

17

Page 18

• SHUT OFF THE ENGINE!

• Wait 10 seconds to be sure that the impeller blades have stopped

rotating.

• Always use a clean-out tool, not your hands.

OPERATION

Not for

Reproduction

CLEAR A CLOGGED DISCHARGE CHUTE

DANGER: Hand contact with the rotating impeller inside

the discharge chute is the most common cause of injury

associated with snow throwers. Never clear or unclog

discharge chute with your hands, or while engine is

running. Fingers can quickly become caught and

traumatic amputation or severe laceration can result.

A clean-out tool (AA, Figure 14) is attached to either the handle or the top of the

auger housing. Use the clean-out tool to remove snow from the auger housing.

A

OPERATING TIPS

1. Most efficient snowthrowing is accomplished when snow is removed

immediately after it falls.

2. For complete snow removal, slightly overlap each swath previously taken.

3. Snow should be discharged downwind whenever possible.

4. For normal usage, set the skids 1/8 inch (3 mm) below the scraper

bar. For extremely hard-packed snow surfaces, the skids may be adjusted upward to ensure cleaning efficiency.

5. On gravel or crushed rock surfaces, the skids should be set at 1-1/4

inch (32 mm) below the scraper bar (see “Adjust Skid Height” in the

MAINTENANCE section of this manual). Rocks and gravel must not

be picked up and thrown by the machine.

6. After the snowthrowing job has been completed, allow the engine to

idle for a few minutes, to melt snow and ice accumulated on the

engine.

7. Clean the snow thrower thoroughly after each use.

8. Remove ice and snow accumulation and all debris from the entire

snow thrower, and flush with water (if possible) to remove all salt or

other chemicals. Wipe snow thrower dry.

9. Before starting snow thrower, always inspect augers and impeller for

ice accumulation and/or debris, which could result in snow thrower

damage.

10. Check oil level before every start. Make sure the oil is at the FULL

mark on the oil fill cap/dipstick.

Clean-Out Tool Figure 14

1818

Page 19

SERVICE RECOMMENDATIONS

Not for

Reproduction

MAINTENANCE

PROCEDURE

SAFETY

SNOW THROWER

Check to Make Sure

Auger Blade Stops Within

5 Seconds After Right

Control Lever is Released

Lubricate Control Levers

and Linkages

Check Snow Thrower for

Loose Hardware

Lubricate Hex Shaft and

Chains

Lubricate Auger Shaft

Fittings

Lubricate Chute Rotation

Gear and Deflector

Mechanism

Remove All Snow and

Slush off Snow Thrower to

Prevent Freezing of Auger

or Controls

FIRST

HOURS

BEFORE

2

✓ ✓ ✓

EACH

USE

✓

AFTER

EACH

USE

✓

EVERY

5

HOURS

✓ ✓

EVERY

10

HOURS

✓ ✓

EVERY

25

HOURS

✓

BEGINNING

EACH

SEASON

✓ ✓

BEFORE

STORAGE

Check Tire Pressure

Oil, Check

ENGINE

Oil, Change

Check and Replace

Spark Plug

NOTE: The warranty on this snow thrower does not cover items

that have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

snow thrower as instructed in this manual.

✓ ✓ ✓

✓ ✓ ✓

✓

✓

The above Service Recom mendations are supplied to assist the opera-

tor to properly maintain the snow thrower.

19

Page 20

C

MAINTENANCE

B

lubricate the controls

Not for

Reproduction

LUBRICATE AUGER GEAR BOX

The auger gear box is lubricated at the factory and should not require

additional lubrication. If for some reason the lubricant should leak out,

or if the auger gear box has been serviced, add Lubriplate GR132 Grease or

equivalent. Maximum 3- 1/4 ounces, (92 grams) should be used.

Remove filler plug (AA, Figure 15), once a year. If grease is visible, do not

add. If grease is not visible, use a piece of fine wire, like a dipstick to check

if there is grease in the gear box. Mobilux EP1 and Shell Alvania EP1 are

suitable equivalents.

B

B

C

Lubricating Auger Gear Box Figure 15

A

LUBRICATE AUGER SHAFT FITTINGS

1. Using a hand grease gun, lubricate the auger shaft fittings (BB, Figure

15) every ten (10) operating hours. Each time a shear pin is replaced,

the auger shaft (CC) MUST be greased. (See “Auger Shear Pin Replacement” section.)

2. For storage or when replacing shear pins, remove shear pins and

lubricate auger shaft fittings (B

shaft and reinstall the shear pins.

). Rotate augers several times on the

A

Lubricating Control Lever Linkage Figure 16

C

B

LUBRICATE CHUTE ROTATION GEAR

Lubricate the chute rotation gear (AA, Figure 17) and shaft (BB) with automotive type oil every twenty-five (25) operating hours .

ADJUST THE DRAG ON THE CHUTE ROTATION

NOTE: After repeated use, the chute rotation gear may loosen,

causing the chute to move back to the center position.

Adjust the drag by tightening the nut (C

limit the chute from moving without the operator turning the chute rotation

crank.

, Figure 17). Tightening the nut will

B

CHECK/LUBRICATE FREE-HAND LINKAGE

Check the function of the Free-Hand controls. The controls should function

as described in the OPERATION section.

WARNING: It is critical for the safe operation of the

unit that the controls disengage when released.

If the controls do not function properly, l

Figure 16).

NOTICE: Under no circumstances should the unit be used if the

controls do not function properly.

(see

A

C

Lubricating Chute Rotation Gear Figure 17

20

Page 21

MAINTENANCE

A

A

Not for

Reproduction

ENGINE MAINTENANCE

Check Crankcase Oil Level - Before starting engine and after each 8

hours of continuous use. Add the recommended motor oil as required.

NOTE: Over filling the engine can affect performance. Tighten

the oil fill cap securely to prevent leakage.

Change Oil - Every 50 hours of operation or at least once a year, even if

the snow thrower is not used for fifty hours. Use a clean, high quality

detergent oil. Fill the crankcase to FULL line on dipstick (A

sure original container is marked: A.P.I. service “SF” or higher. Do not use

SAE10W40 oil (as it may not provide proper lubrication). See Chart for

oil recommendations.

Drain Oil – Position snow thrower so that the oil drain plug (A

18) is lowest point on engine. When the engine is warm, remove oil drain

plug and oil fill cap and drain oil into a suitable container.

Replace oil drain plug and tighten securely. Refill crankcase with the recommended motor oil.

, Figure 17). Be

, Figure

A

Full

Checking Crankcase Oil Level Figure 18

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil consumption. Check

oil level more frequently.

A

Oil Drain Plug Figure 19

21

Page 22

A

A

MAINTENANCE

Not for

Reproduction

CHANGE THE SPARK PLUG

Remove the Snow Hood

1. Remove the choke control knob (AA, Figure 20).

2. Remove the safety key (BB).

3. Remove the mounting screws (A

4. Slowly remove the snow hood (BB) Make sure that the primer button

hose (CC) and the ignition wire (DD) are not disconnected.

5. The spark plug (EE) can now be accessed.

6. To install the snow hood, first make sure that the primer button hose

and the ignition wire are connected.

7. Mount the snow hood to the engine and secure with the mounting

screws.

8. Connect the choke control knob (A

on the carburetor (BB). Make sure the choke control knob is properly

installed. If the choke control knob is not installed correctly, the choke

will not operate.

9. Install the safety key (CC).

A

, Figure 21).

, Figure 22) with the choke shaft

B

D

E

Removing the Snow Hood Figure 21

A

A

C

B

C

B

Snow Thrower Engine Figure 20

Connecting Choke Control Knob Figure 22

22

Page 23

A

Check and Replace Spark Plug

.030 in.

(.76 mm)

Not for

Reproduction

Check the spark plug every twenty-five (25) hours. Replace the spark plug

(Figure 23) if the electrodes are pitted or burned or if the porcelain is

cracked.

1. Remove snow hood (see “Remove the Snow Hood” section).

2. Clean spark plug and reset gap periodically.

3. Clean area around spark plug base before removal, to prevent dirt

from entering engine.

4. Replace spark plug if electrodes are pitted or burned or if porcelain is

cracked.

5. Clean spark plug by carefully scraping electrodes (do not sandblast

or use wire brush).

6. Be sure spark plug is clean and free of foreign material. Check electrodes gap with a wire feeler gauge and reset gap to 0.030" (0.76 mm)

if necessary.

7. Before installing spark plug, coat threads lightly with graphite grease

to insure easy removal.

8. Tighten plug firmly into engine. If torque wrench is available, tighten

plug to 18-23 ft-lbs (24.4-31.2 Nm).

MAINTENANCE

Replacing Spark Plug Figure 23

WARNING: Always turn unit off, remove ignition key,

and disconnect the spark plug wire before making any

repairs or adjustments.

ADJUST SKID HEIGHT

This snow thrower is equipped with two height adjust skids, secured to the

outside of the auger housing. These elevate the front of the snow thrower.

When removing snow from a hard surface area such as a paved driveway

or walk, adjust the skids up to bring the front of the snow thrower down.

When removing snow from rock or uneven construction, raise the front of

the snow thrower by moving the skids down. This will help to prevent

rocks and other debris from being picked up and thrown by the augers.

To adjust skids, proceed as follows:

1. Place a block (equal to height from ground desired) under scraper bar

near but not under skid.

2. Loosen skid mounting nuts (A

(BB) until it touches the ground. Retighten mounting nuts.

3. Set skid on other side at same height.

NOTE: Make sure that snow thrower is set at same height on

both sides.

, Figure 24) and push the skid down

WARNING: Be certain to maintain proper ground

clearance for your particular area to be cleared.

Objects such as gravel, rocks, or other debris, if

struck by the impeller, may be thrown with sufficient

force to cause personal injury, property damage, or

damage to the snow thrower.

A

B

Adjusting Skid Height Figure 24

23

Page 24

A

B

Screw

A

B

The auger must stop within five

(5) seconds.

MAINTENANCE

Not for

Reproduction

BELT ADJUSTMENT

Traction Drive Belt

The traction drive belt has constant spring pressure and does not require

an adjustment. If the traction drive belt is slipping, replace the belt. See authorized dealer.

Auger Drive Belt

If your snow thrower will not discharge snow, check the control cable adjustment. If it is correct, then check the condition of the auger drive belt. If it is

damaged or loose, replace it (see authorized dealer).

1. Disconnect spark plug wire.

2. Remove screw (A

3. Loosen nut on idler drive pulley (AA, Figure 26) and move idler drive

pulley towards belt about 1/8 inch (3 mm).

, Figure 25) from belt cover (BB). Remove belt cover.

A

WARNING: Do not over-tighten, as this may lift the

lever and cause the auger drive to be engaged without

depressing the auger control.

4. Tighten nut.

5. With the aid of an assistant, engage the auger drive clutch. Check tension on belt which is opposite idler pulley (B

deflect about 1/2 inch (12.5 mm) with moderate pressure. You may

have to move idler pulley more than once to obtain the correct tension.

6. Release the auger drive control lever. T

7. If auger does not operate properly, stop engine and recheck drive

linkage adjustments.

8. Reinstall belt cover (BB, Figure 25). Tighten screw (AA).

9. Whenever belts are adjusted or replaced, the cables will need to be

adjusted (see “Check and Adjust the Cables” section).

10. Attach the spark plug wire.

, Figure 26). Belt should

B

Adjusting Auger Drive Belt Figure 25

3

A

B

Checking Tension on Auger Drive Belt Figure 26

8

1/2” (12.5mm)

Deflection

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

2. Have someone engage the auger drive. This will engage auger idler

pulley (A

3. Measure the distance between the belt guide (B

distance should be about 1/8 inch (3 mm).

4. If adjustment is necessary, loosen belt guide mounting bolt. Move

belt guide to the correct position. Tighten mounting bolt.

5. Install belt cover.

6. Connect spark plug wire.

, Figure 26).

) and belt (CC). The

1/8” (3mm)

A

Adjusting Belt Drive Figure 27

24

B

C

Page 25

C

The auger must stop within 5

seconds.

1/32”

(0.8mm)

SPEED CONTROL ROD ADJUSTMENT

Not for

Reproduction

If the speed control rod (AA, Figure 28) requires adjustment, see an authorized dealer for assistance.

CHECK AND ADJUST THE CABLES

The cables are adjusted at the factory and no adjustment should be necessary. If the cables have become stretched or are sagging adjustment will be

necessary.

Whenever belts are adjusted or replaced, the cables will need to be adjusted.

AUGER CONTROL CABLE ADJUSTMENT

WARNING: Do not over-tighten, as this may lift the

lever and cause the auger drive to be engaged without depressing the auger drive control.

MAINTENANCE

A

Adjusting Speed Control Rod Figure 28

1. With the auger drive control lever released, the hook (AA, Figure 29)

should barely touch the lever (BB) without raising it. There can be a

maximum of 1/32" (0.8 mm) clearance.

2. To adjust, loosen the nut (C

turning the nut. Then, turn the adjusting flats and hold the adjustment screw (EE). The adjustment screw is a phillips screw and the

head can be held or turned by inserting a screwdriver through the

spring (FF).

3. Hold the adjusting flats and tighten the nut.

4. Start the engine and check the auger. The auger must not be engaged

unless the auger drive control lever is depressed.

5. With the engine running, fully depress the auger drive control lever.

The auger should engage and run normally.

6. Release the auger drive control lever. T

7. If the auger does not operate properly, stop the engine and recheck

the auger drive cable adjustment.

8. If the drive linkage is properly adjusted, the tension of the auger drive

belt may require an adjustment (see “Belt Adjustment” section).

) by holding the adjusting flats (DD) and

D

C

E

A

B

Adjusting Auger Control Cable Figure 29

F

25

Page 26

MAINTENANCE

A

B

A

B

“A”

Not for

Reproduction

TRACTION CONTROL CABLE ADJUSTMENT

1. Remove the gas from the gas tank. Stand the snow thrower up on the

front end of the auger housing.

WARNING: Drain the gasoline outdoors, away from fire

or flame.

A

C

2. Loosen the bolts (A

3. Remove the bottom panel.

4. Slide the cable boot (AA, Figure 31) off the cable adjustment bracket

(B

).

5. Push the bottom of the traction drive cable (CC) through the cable

adjustment bracket until the “Z” hook (DD) can be removed.

6. Remove the “Z” hook from the cable adjustment bracket. Move the “Z”

hook down to the next adjustment hole.

7. Pull the traction drive cable up through the cable adjustment bracket.

8. Put the cable boot over the cable adjustment bracket.

9. To check the adjustment, depress the drive lever and check the length

of the drive spring (A

of the drive spring is a minimum 3 inches (76 mm) and a maximum

3-3/8 inches (85 mm).

10. Install the bottom panel (B

11. Tighten the bolts (AA) on each side of the bottom panel.

, Figure 30) on each side of the bottom panel (BB).

, Figure 32). In correct adjustment, the length

, Figure 30).

A

D

B

Traction Drive Cable Figure 31

B

Adjusting Traction Drive Cable Figure 30

A

Checking Adjustment of Traction Drive Cable Figure 32

26

Page 27

AUGER SHEAR PIN REPLACEMENT

A

Not for

Reproduction

The augers are secured to the auger shaft with special shear pins that are

designed to break if an object becomes lodged in the auger housing. Use

of a harder grade shear pin will reduce the protection provided by the

shear pin.

WARNING: Do not go near the discharge chute or auger

when the engine is running. Do not run the engine if

any cover or guard is removed.

Under most circumstances, if the auger strikes an object which could

cause damage to the unit, the shear pin will break. This protects the gear

box and other parts from damage.

The shear pins (A

broken shear pin as follows.

1. Tap out the broken shear pin with a pin punch.

2. Install a new shear pin and cotter pin. Bend the ends of the cotter pin

down.

IMPORTANT: Do not replace shear pins with anything other

than the correct grade replacement shear pin. Use of bolts,

screws, or harder grade shear pins can result in equipment

damage.

, Figure 33) are located on the auger shaft. Replace a

MAINTENANCE

A

A

Replacing Broken Shear Pin Figure 33

CHECK THE TIRES

Check tires for damage. Check the air pressure in the tires with an

accurate gauge (see Figure 34).

CAUTION: Avoid Injury! Explosive separation of tire

and rim parts is possible when they are serviced

incorrectly.

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Do not inflate the tires above the recommended pressure.

• Do not weld or heat a wheel and tire assembly. Heat can

cause an increase in air pressure resulting in an

explosion. Welding can structurally weaken or deform the

wheel.

• Do not stand in front or over the tire assembly when

inflating. Use appropriate tool that allows you to stand to

one side.

NOTICE: Check side of tire for maximum tire pressure. DO

NOT exceed maximum.

Checking Tire Air Pressure Figure 34

27

Page 28

D

A

STORAGE

Not for

Reproduction

OFF SEASON STORAGE

WARNING: Never store the engine, with fuel in the tank,

indoors or in a poor ventilated enclosure where fuel

fumes could reach an open flame, spark or pilot light

as on a furnace, water heater, clothes dryer, etc.

Handle gasoline carefully. It is highly flammable and

careless use could result in serious fire damage to your

person and/or property.

Drain fuel into approved containers outdoors, away from

open flame.

If the snow thrower will be stored for thirty (30) days or more at the end of

the snow season, the following steps are recommended to prepare your

snowthrower for storage.

NOTE: Gasoline must be removed or treated to prevent gum

deposits from forming in the tank, filter, hose, and carburetor

during storage.

1. Remove gasoline, by running engine until tank is empty and engine

stops. If you do not want to remove the gasoline, add fuel stabilizer

to any gasoline left in the tank to minimize gum deposits and acids.

If the tank is almost empty, mix stabilizer with fresh gasoline in a

separate container and add some of the mixture to the tank. ALWAYS

FOLLOW INSTRUCTIONS ON STABILIZER CONTAINER. THEN RUN

ENGINE AT LEAST 10 MINUTES AFTER STABILIZER IS ADDED TO

ALLOW MIXTURE TO REACH CARBURETOR. STORE SNOW

THROWER IN SAFE PLACE.

2. You can help keep your engine (4-cycles only) in good operating

condition by changing oil before storage.

3. Lubricate the piston/cylinder area. This can be done by first removing

the spark plug and squirting clean engine oil into the spark plug hole.

Then cover the spark plug hole with a rag to absorb oil spray. Next,

rotate the engine by pulling the starter two or three times. Finally,

reinstall spark plug and attach spark plug wire.

4. Thoroughly clean the snow thrower.

5. Lubricate all lubrication points (see “Lubrication” topics in the

MAINTENANCE section).

6. Make sure all nuts, bolts, and screws are securely fastened. Inspect

all visible moving parts for damage, breakage, and wear. Replace if

necessary.

7. Touch up all rusted or chipped paint surfaces; sand lightly before

painting.

8. Cover the bare metal parts of the snow thrower housing auger, and the

impeller with rust preventative.

9. If possible, store your snow thrower indoors and cover it to give

protection from dust and dirt.

10. On models with folding handles, loosen the knobs that secure the

upper handle. Rotate the upper handle back.

11. If the machine must be stored outdoors, block up the snow thrower

and ensure the entire machine is off the ground. Cover the snow

thrower with a heavy tarpaulin.

LUBRICATE HEX SHAFT AND CHAINS

CAUTION: Do not allow grease or oil to contact the rubber friction wheel or the disc drive plate. If the disc

drive plate or friction wheel come in contact with

grease or oil damage to rubber friction wheel will

result.

NOTICE: If grease or oil comes into contact with the disc drive

plate or friction wheel, make sure to clean plate and wheel

thoroughly with an alcohol base solvent.

1. Position speed select lever (D

2. Drain fuel to an approved container.

3. Stand the snow thrower up on the auger housing end.

NOTE: When the crankcase is filled with oil, do not leave

the snow thrower standing up on the auger housing for an

extended period of time.

4. Remove the bottom panel.

5. Lubricate the chains (A

6. Wipe the hex shaft (BB) and sprockets (CC) with 5W30 motor oil, before

storage and at the beginning of each season.

7. Install the bottom panel.

C

Lubricate Hex Shaft and Chains Figure 35

, Figure 4) in first forward gear.

, Figure 35) with a chain type lubricant.

A

B

REMOVE FROM STORAGE

1. Put the upper handle in the operating position, tighten the knobs that

secure the upper handle.

2. Fill the fuel tank with a fresh fuel.

3. Check the spark plug. Make sure the gap is correct. If the spark plug

is worn or damaged, replace before using.

4. Make sure all fasteners are tight.

5. Make sure all guards, shields, and covers are in place.

6. Make sure all adjustments are correct.

28

Page 29

PROBLEM LOOK FOR REMEDY

Not for

Reproduction

Auger does not stop within

5 seconds after right

control lever is released.

TROUBLESHOOTING

Free-HandTMcontrol is ACTIVE. Release both auger control and Free-HandTMcontrol to stop auger.

Auger drive belt out of

adjustment.

Adjust auger belt.

Discharge chute or

deflector does not work

(electric).

Discharge chute or

deflector does not work

(remote-manual).

Drive fails to move snow

thrower at slow speeds.

Engine fails to start.

Auger belt guide out of

adjustment.

Electrical failure. See authorized dealer.

Discharge chute or deflector out

of adjustment or needs

lubrication.

Traction control out of

adjustment.

Key is off. Push key in to the ON position.

Failure to prime a cold engine. Press primer button twice and restart.

Fuel shut-off valve is in CLOSED

position.

Out of fuel. Fill fuel tank.

Choke OFF - cold engine. Turn choke ON, set throttle to FAST.

Engine flooded. Turn choke to OFF; try starting.

No spark. Check gap. Gap spark plug, clean electrode, or replace plug as necesary.

Water in fuel, or old fuel. Drain tank. (Dispose of fuel at an authorized hazardous waste facility.) Fill with

Adjust auger belt guide.

Adjust and/or lubricate control linkage.

Readjust drive, or select speed lever setting one speed faster.

Turn valve to OPEN position.

fresh fuel.

Engine starts hard or runs

poorly.

Excessive vibration.

Snow thrower does not

stop when traction control

lever is released.

Snow thrower veers to

one side.

Fuel mixture too rich. Move choke to OFF position.

Spark plug faulty, fouled, or

gapped improperly.

Fuel cap vent is blocked. Clear vent.

Loose parts or damaged

impeller.

Traction control out of

adjustment.

Tire pressure not equal. Check tire pressure.

One wheel is set in freewheeling mode. (Traction lock

pin is in the OUTER hole.)

Clean and gap spark plug, or replace.

Stop engine immediately. Tighten all hardware. If vibration continues, have the unit

serviced by an authorized dealer.

Adjust traction control linkage.

Make sure the left traction lock pin is in the INNER holes (to engage the traction

drive).

29

Page 30

TROUBLESHOOTING

Not for

Reproduction

PROBLEM LOOK FOR REMEDY

Scraper bar does not clean

hard surface.

Unit fails to propel itself.

Unit fails to discharge

snow.

Skid shoes improperly adjusted. Raise or lower skid shoes.

Drive belt loose or damaged. Replace drive belt. See authorized dealer.

Incorrect adjustment of traction

drive cable.

Worn or damaged friction disc. Replace friction disc. See authorized dealer.

Auger drive belt loose or

damaged.

Auger control cable not adjusted

correctly.

Broken shear pin. Replace shear pin. Refer to “Auger Shear Pin Replacement” in the MAINTENANCE

Discharge chute clogged. Stop engine immediately. Always use the clean-out tool to clear a clogged

Foreign object lodged in auger. Stop engine immediately. Always use the clean-out tool to clear a clogged chute,

Adjust traction drive cable. Refer to “Cable Adjustment” in the MAINTENANCE

section of this manual.

Replace or adjust auger drive belt. Refer to “Drive Belt Adjustment” in the

MAINTENANCE section of this manual, or see authorized dealer.

Adjust auger control cable. Refer to “Cable Adjustment” in the MAINTENANCE

section of this manual.

section of this manual.

discharge chute, not your hands. Clean discharge chute and inside of auger

housing. Refer to WARNINGS in OPERATOR SAFETY section.

not your hands. Remove object from auger. Refer to WARNINGS in OPERATOR

SAFETY section.

30

Page 31

WARRANTIES

Not for

Reproduction

BRIGGS AND STRATTON POWER PRODUCTS GROUP, L.L.C. OWNER WARRANTY POLICY

Effective January 1, 2008 replaces all undated Warranties and all Warranties dated before January 1, 2008

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the product that is defective in material or workmanship or

both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for

the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at

www.brutepower.com.

THERE IS NO OTHER EXPRESS WARRANTY, IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED WARRANTIES

ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY

LAW. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights

and you may also have other rights which vary from state to state or country to country.

Consumer Commercial

Brand / Unit U se U se

Dual Stage Snow Thrower . . . . . . . . . . . . . . . . . . . . . . . . . . 2 years . . . . . . . . . . . . . . . . . . . . . . . . 90 Days

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated above.

“Consumer use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once product has experienced commercial use, it shall thereafter be considered as commercial use for purposes of

this warranty.

No warranty registration is necessary to obtain warranty on BRUTE branded products. Save your proof of purchase receipt. If you do not provide proof

of the initial purchase date at the time warranty service is requested, the manufacturing date of the product will be used to determine the warranty.

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply to the

product if damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the warranty is void if the serial number on the product has been removed or the product has been altered or modified.

LIMITED WARRANTY

W

ARRANTY TERMS

A

BOUT YOUR WARRANTY

This warranty covers product related defective material and/or workmanship only. To avoid misunderstanding which might occur between the customer and

the Dealer, listed below are some of the causes of product failure that the warranty does not cover.

•N

ormal Wear: Small Engine Powered Equipment, like all mechanical devices, needs periodic parts and service to perform well. Warranty does not

cover repair when normal use has exhausted the life of the product or part.

•I

nstallation: This warranty does not apply to product that has been subjected to improper or unauthorized installation, alteration or modification. Nor

installations that prevent starting cause unsatisfactory engine performance.

mproper Maintenance: The life of this product depends upon the conditions under which it operates, and the care it receives. Recommended mainte-

•I

nance and adjustment intervals are stated in the Operator’s Manual. Often product, such as tillers, edgers, rotary mowers, are used in dusty or dirty

conditions, which can cause what appears to be premature wear. Such wear, when caused by dirt, dust, or other abrasive material entering the product because of improper maintenance is not covered by warranty. The warranty will not cover repairs due to problems caused by replacement parts

that are not original manufactured part(s).

•I

ncorrect and/or Insufficient Fuel or Lubrication: This warranty does not cover damage caused by the use of stale fuel, or altered gasoline. Damage to

engine or engine components i.e., combustion chamber, valves, valve seats, valve guides, burned starter motor windings caused by use of alternate

fuels such as liquefied petroleum, natural gas, are not covered unless engine is certified for this operation. Parts which are scored or broken because

product was operated with insufficient, contaminated or incorrect grade of lubricating oil as well as product components damaged due to lack of lubrication are not covered.

•O

perational Misuse: Proper operation of the product is stated in the Operator’s Manual. Product damaged by overspeeding, overheating, or operation

in a confined area without sufficient ventilation. Product broken by excessive vibration caused by a loose engine mounting, loose or unbalanced

blades, impellers, overspeeding, or bent crankshaft due to striking of solid object. Damage or malfunctions resulting from accidents, abuse, or improper servicing or freezing or chemical deterioration, as well as operating in excess of recommended capacities as outlined in the Operator’s Manual

are not covered.

•Routine Tune-Up, Wear Items, or Adjustments: This warranty excludes wear items such as oil, belts, blades, o-rings, filters, etc.

•Other Exclusions: Repair or adjustments for part(s) that are not manufactured by Briggs & Stratton Corporation, are not covered, see warranty for respective manufacturers. This warranty excludes failures due to acts of God and other major forceful events beyond the manufacturer’s control.

Also excluded are used, reconditioned, and demonstration products.

Warranty service is available only through Authorized Service Dealers. Locate your nearest dealer in our locator map at www.brutepower.com.

31

Page 32

California, U.S. EPA, and Briggs & Stratton Corporation Emissions Control Warranty Statement

Not for

Reproduction

Your Warranty Rights And Obligations

November 2008

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2008 and later

engine/equipment. In California, new small off-road engines must be designed, built, and

equipped to meet the State’s stringent anti-smog standards. B&S must warrant the

emissions control system on your engine/equipment for the periods of time listed below

provided there has been no abuse, neglect, or improper maintenance of your small

off-road engine.

Your emissions control system may include parts such as the carburetor or fuel injection