Page 1

SET-UP INSTRUCTIONS And PRE-OPERATION CHECKLIST FOR

SNAPPER LE MODEL SINGLE STAGE SNOW THROWERS

The Snapper LE snow throwers are shipped with the upper handle folded forward, and with the discharge chute

and chute control handle detached. These machines are designed for quick set-up. No special tools are

required. Carefully follow and complete each step. Review and complete each item as instructed on the PreOperation checklist. The Snapper Product Registration card must be filled out and sent to the Customer Service

department at SNAPPER when completed.

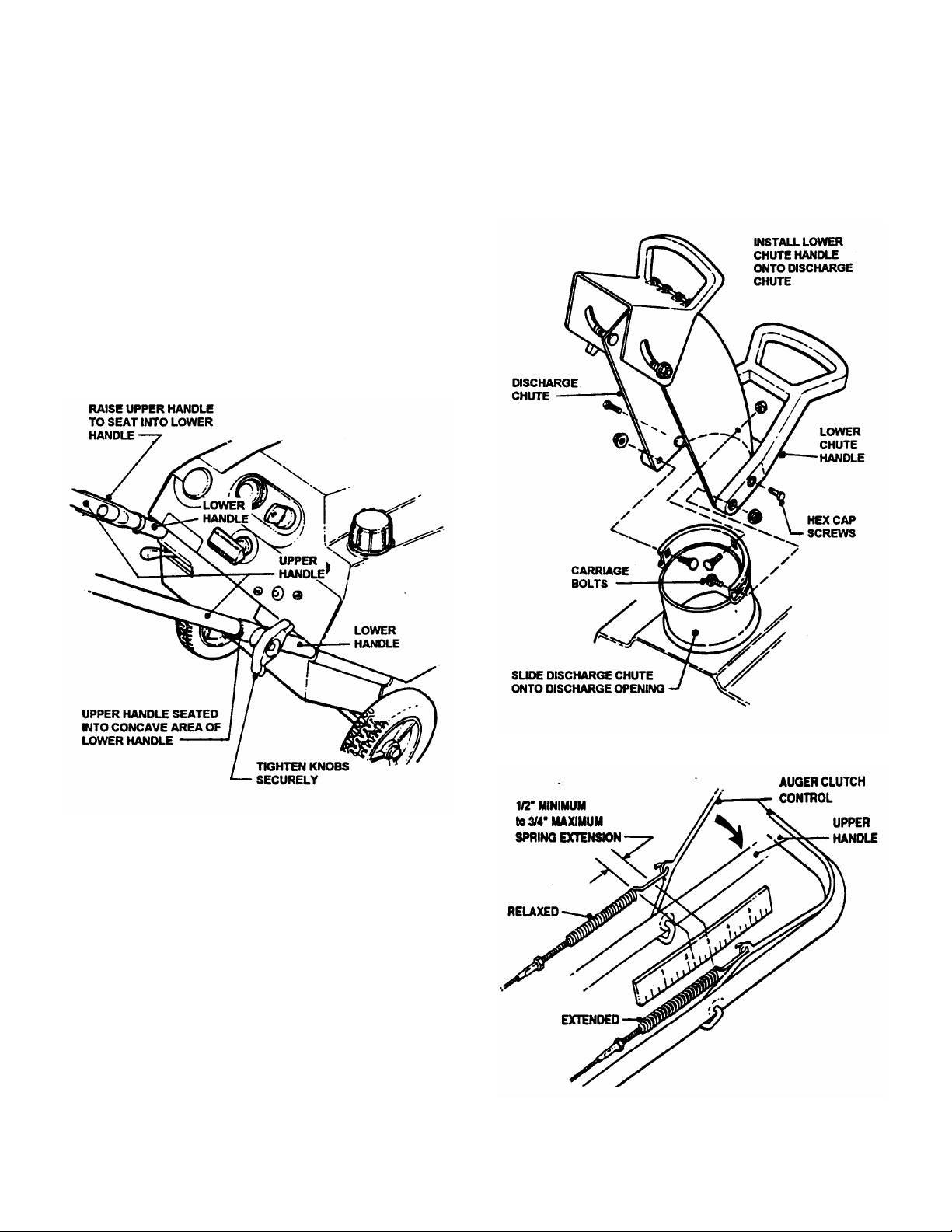

STEP 1: Remove machine from shipping carton. Machine is

shipped in carton with handles folded. Rem ove and discard

cardboard from between all handles. The right side of upper

handle is positioned on the outside of lower handle. The

upper handle should be moved to the inside of the lower

handle and bolt and knob reinstalled. Raise upper handle

until the lower ends seat into concave area of lower handle.

Securely tighten upper handle with knobs and curved head

bolts on both sides. See Figure 1.

FIGURE 1

STEP 2: Install lower chute handle onto chute with two

hex cap screws. Install chute/handle assembly onto

discharge opening and secure with three carriage bolts

and nuts. Tighten all nuts and bolts securely but, do not

overtighten. See Figure 2.

STEP 3: Measure auger clutch control cable extension from

a relaxed position to full extended position. Proper extension

should be between 1/2” minimum to 3/4”maximum

extension. NOTE: Meas ure from the top of spring (T he top

is in relation to where spring hooks into auger clutch

control). Loosen jam nut at the upper end of cable. Hold

threaded end of cable and then turn cable clockwise until

correct extension is achieved. Retighten jam nut.

IMPORTANT: DO NOT over tighten cable. T he cable m ust

have slack for the auger brake to function properly. See

Figure 3.

FIGURE 2

FIGURE 3

INSTRUCTION No. 7-5228 (I.R. 3/3/03)

1

Page 2

PRE-OPERATION CHECKLIST for SNAPPER

SINGLE STAGE SNOW THROWERS

Complete each of the follow ing items p rior to placin g the machin e into serv ice. It is very important that setup is

verified and all operational test s completed and results are accep table. Check (

After completing this form, sign and retain for future reference.

SET-UP (Details on Page 1 of this Instruction)

_____ UPPER HANDLE & LOWER HANDLE secured in place and hardware tightened securely.

_____ DISCHARGE CHUTE and DEFLECTOR ASSEMBLY installed on snow thrower.

LUBRICATION

_____ ENGINE OIL added to bring level up to full mark on 4-cycle engines (Refer to Engine Manual).

_____ OIL mixed with FUEL in specified ratio (2 Cycle Engines Only). (Refer to Engine Manual).

OPERATIONAL TEST

_____ AUGER checked to insure stopping within 5 seconds after clutch control is released.

_____ ENGINE started, engine control settings checked and adjusted as needed.

_____ FUEL SYSTEM checked for leaks around tank and connections.

_____ DISCHARGE CHUTE checked for free rotation.

_____ AUGER CONTROL CABLE adjusted per instructions in the Operator’s Manual supplied with machine.

CONSUMER INFORMATION

Purchase Date ___________________ Model _______________________ Serial No.________________________

Retailers Name ____________________________________ ______________________________________________

Address _____________________________________ City ____________________ State _______ Zip _______

MACHINE WILL BE USED COMMERCIALLY? _____ YES _____ NO

Purchaser’s Name _________________________________ Signature ____________________________________

Address ____________________________________ City _____________________ State _______ Zip _______

IMPORTANT: This fo rm is to be retained fo r future reference regarding W arranty, proof of purchase, traceability

for product recall or service, etc. Complete the Snapper Product Registration Card and Mail to Customer

Service Department at SNAPPER, P.O. BOX 1379, McDonough, Georgia, 30253.

2

✔) all items actually performed.

INSTRUCTION No. 7-5228 (I.R. 3/3/03)

Loading...

Loading...