Page 1

Model No. 130.288370

LT=125 Series Hydro Tractor

Mfg. No. Description

2690826 LT23420, 23HP & 42" Mower Deck

1737502

Revision

Rev. Date 02/2009

Page 2

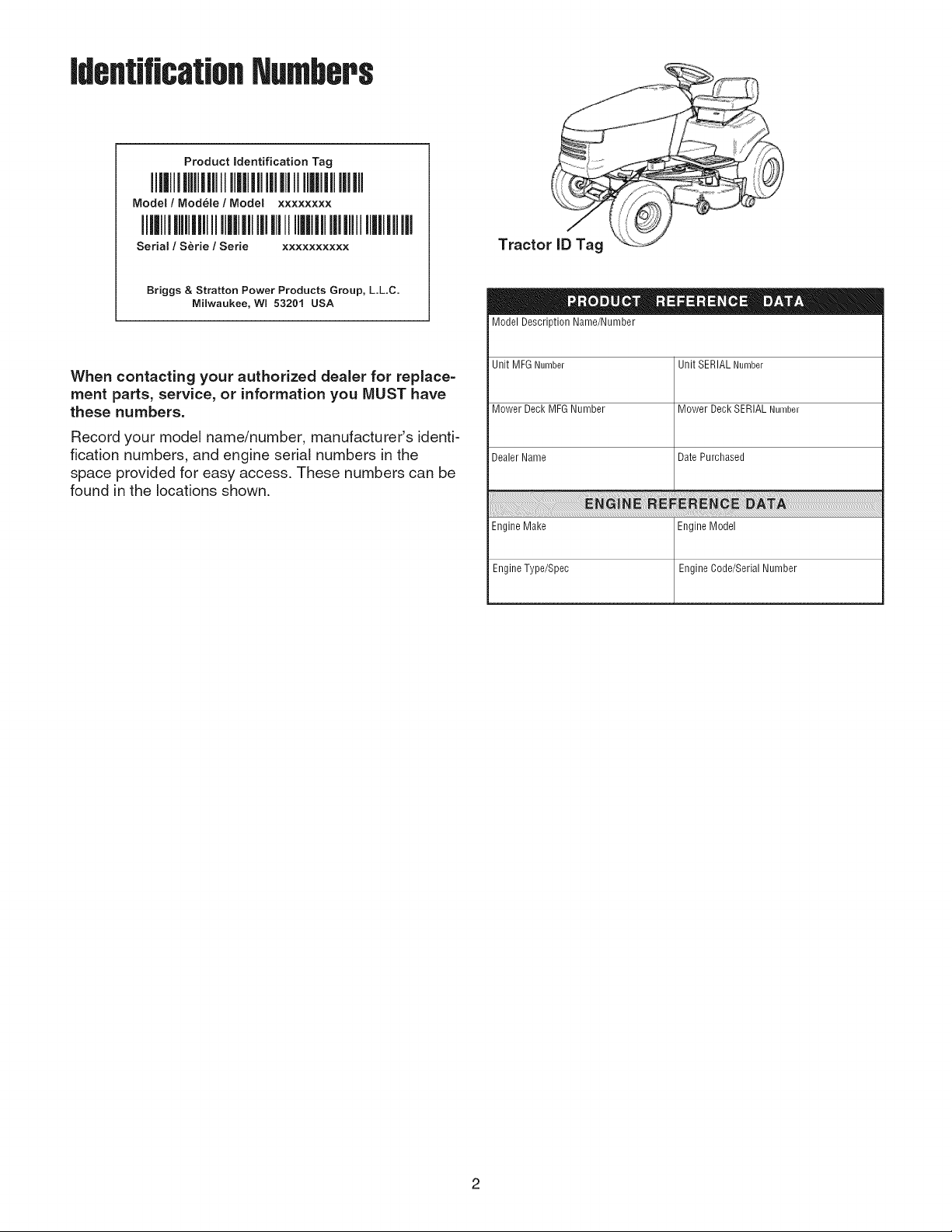

Product identification Tag

IIIIIIIIIIIIIlllIIII!11111IllIIIIIIIIIIIIIIIIIII

Model / ModUle / Model xxxxxxxx

lillilllilllllllIIIIIIIIIIIIIIIIIIlillilllIIIlilllllllllllIII

Serial / Serie / Serie xxxxxxxxxx

Briggs & Stratton Power Products Group, L.L.C.

Milwaukee, WI 53201 USA

When contacting your authorized dealer for replace-

ment parts, service, or information you MUST have

these numbers.

Record your model name/number, manufacturer's identi-

fication numbers, and engine serial numbers inthe

space provided for easy access. These numbers can be

found in the locations shown.

/!

Tractor ID Tag

Model Description Name/Number

Unit MFGNumber Unit SERIALNumber

Mower Deck MFG Number Mower Deck SERIALNumber

Dealer Name Date Purchased

Engine Make

EngineType/Spec

Engine Model

Engine Code/Serial Number

Page 3

(ableofContents

Operator Safety .................................................... 4

Features & Controls .......................................... 10

Control Functions .................................................. 10

Operation ........................................................... 12

General Operating Safety ..................................... 12

Check & Fill Engine Oil ......................................... 12

Adding Fuel ........................................................... 12

Starting the Engine ............................................... 12

Parking Brake Function ......................................... 13

Cruise Control Operation ...................................... 13

Seat Adjustment .................................................... 13

Stopping the Tractor & Engine .............................. 14

Driving the Tractor ................................................ 14

Mowing .................................................................. 14

Mowing in Reverse ............................................... 14

Attachment Operation in Reverse ......................... 14

Pushing the Tractor by Hand ................................ 14

Adjusting Mower Cutting Height ............................ 15

Attaching a Trailer ................................................. 15

Maintenance ....................................................... 16

Maintenance Schedule ......................................... 16

Check Tire Pressure ............................................. 16

Check Safety Interlock System ............................. 17

Check Blade Brake ............................................... 17

Engine Maintenance ............................................. 17

Battery Maintenance ............................................. 18

Lubrication ............................................................ 18

Servicing the Mower Blades ................................. 20

Mower Deck Removal & Installation ..................... 21

Oil Drain Valve Operation ..................................... 22

Change Engine Oil ................................................ 22

Change Engine Oil & Filter ................................... 22

Air Filter & Pre-Cleaner Service ............................ 23

Replace Spark Plug .............................................. 23

Battery Charging ................................................... 24

Brake Adjustment .................................................. 24

PTO Clutch Adjustment ........................................ 24

Fuse Replacement ................................................ 25

Mower Adjustments .............................................. 25

Gauge Wheels .............................................. 25

Leveling the Mower ....................................... 26

Mower Belt Replacement ...................................... 26

Storage ................................................................. 27

Troubleshooting ................................................ 28

Troubleshooting the Tractor .................................. 28

Troubleshooting the Mower .................................. 29

Specifications .................................................... 30

3

Page 4

perator

g

Congratulations on purchasing a superior-quality piece of lawn and

garden equipment. Our products are designed and manufactured to

meet or exceed all industry standards for safety.

Power equipment is only as safe as the operator. If it is misused, or

not properly maintained, it can be dangerous! Remember, you are

responsible for your safety and that of those around you.

Use common sense, and think through what you are doing. Ifyou

are not sure that the task you are about to perform can be safely

done with the equipment you have chosen, ask a

professional: contact your local authorized dealer.

RI

The operator's manual contains important safety information you need to be aware of

BEFORE you operate your unit as well as DURING operation.

Safe operating techniques, an explanation of the product's features and

controls, and maintenance information is included to help you get the

most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found on

the following pages. Also completely read the Operation section.

in

Tragic accidents can occur with children. Do not allow

them anywhere near the area of operation. Children are

often attracted to the unit and mowing activity. Never

assume that children will remain where you last saw them.

If there is a risk that children may enter the area where you

are mowing, have another responsible adult watch them.

DO NOT GIVE CHILDREN RIDES ON THIS UNIT! This

encourages them to come near the unit in the future while it

is running, and they could be seriously hurt. They may then

approach the unit for a ride when you are not expecting it,

and you may run over them.

RSVSP88

Do not mow in reverse unless

absolutely necessary. Always look

down and behind before and

while traveling in reverse

even with the mower

blades disengaged.

4

Page 5

,peOperation

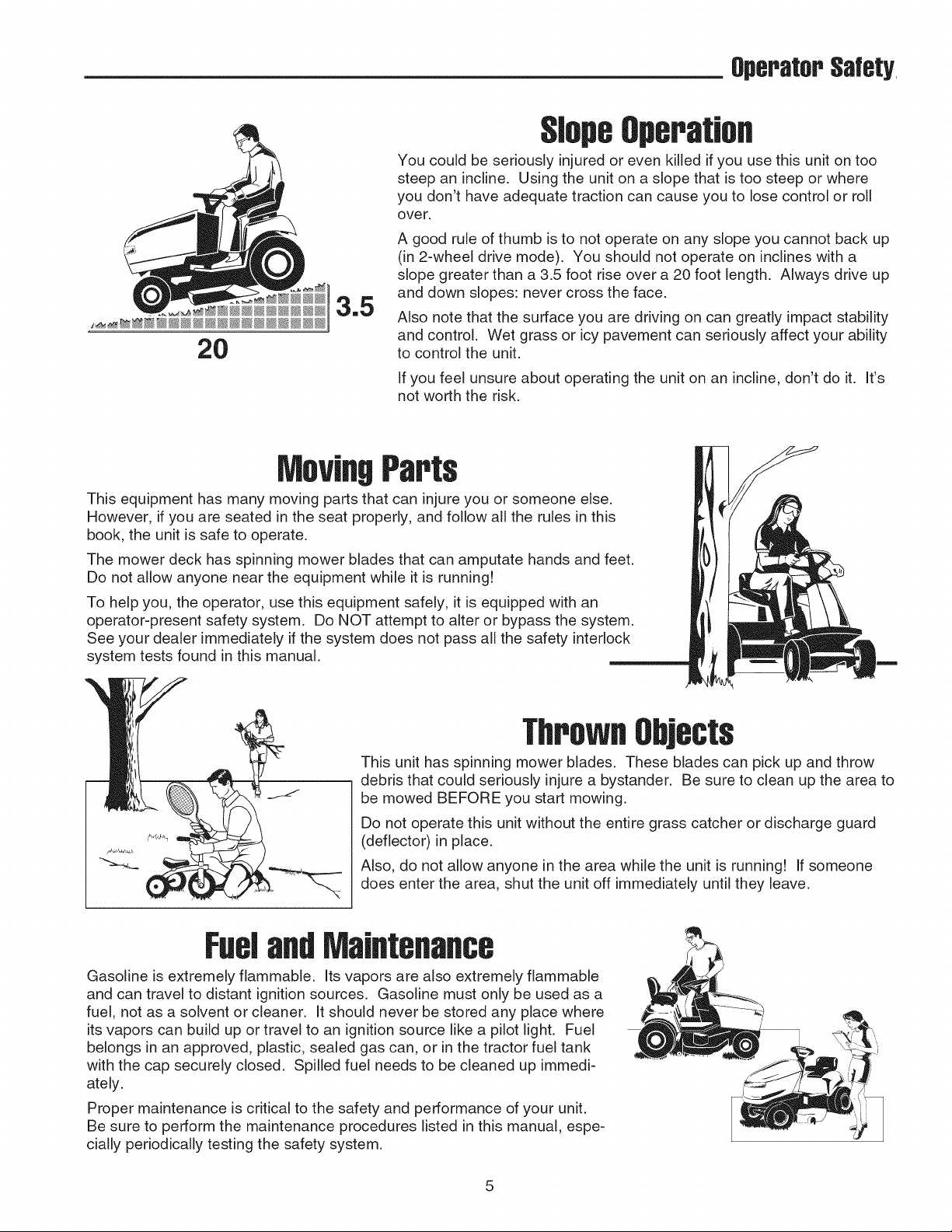

You could be seriously injured or even killed if you use this unit on too

steep an incline. Using the unit on a slope that is too steep or where

you don't have adequate traction can cause you to lose control or roll

over.

A good rule of thumb is to not operate on any slope you cannot back up

(in 2-wheel drive mode). You should not operate on inclines with a

slope greater than a 3.5 foot rise over a 20 foot length. Always drive up

3.5

2O

and down slopes: never cross the face.

Also note that the surface you are driving on can greatly impact stability

and control. Wet grass or icy pavement can seriously affect your ability

to control the unit.

If you feel unsure about operating the unit on an incline, don't do it. It's

not worth the risk.

Moving

This equipment has many moving parts that can injure you or someone else.

However, if you are seated inthe seat properly, and follow all the rules in this

book, the unit is safe to operate.

The mower deck has spinning mower blades that can amputate hands and feet.

Do not allow anyone near the equipment while it is running!

To help you, the operator, use this equipment safely, it is equipped with an

operator-present safety system. Do NOT attempt to alter or bypass the system.

See your dealer immediately if the system does not pass all the safety interlock

system tests found in this manual.

OperatorSafety,

Thrown ects

This unit has spinning mower blades. These blades can pick up and throw

debris that could seriously injure a bystander. Be sure to clean up the area to

be mowed BEFORE you start mowing.

Do not operate this unit without the entire grass catcher or discharge guard

(deflector) in place.

Also, do not allow anyone in the area while the unit is running! If someone

does enter the area, shut the unit off immediately until they leave.

Gasoline is extremely flammable. Its vapors are also extremely flammable

and can travel to distant ignition sources. Gasoline must only be used as a

fuel, not as a solvent or cleaner. It should never be stored any place where

its vapors can build up or travel to an ignition source like a pilot light. Fuel

belongs in an approved, plastic, sealed gas can, or in the tractor fuel tank

with the cap securely closed. Spilled fuel needs to be cleaned up immedi-

ately.

Proper maintenance is critical to the safety and performance of your unit.

Be sure to perform the maintenance procedures listed in this manual, espe-

cially periodically testing the safety system.

5

Page 6

OperatorSafety

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

This mowing deck is capable of amputating hands and feet and throwing objects.

The triangle _ in text signifies important cautions or warnings which must be followed.

GENERAL OPERATION

= Read, understand, and follow all instructions in the

manual and on the unit before starting.

Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at

all times.

= Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

= Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade(s).

= Be sure the area is clear of other people before mow-

ing. Stop the unit ifanyone enters the area.

= Never carry passengers.

= Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while travel-

ling in reverse.

= Never direct discharge material toward anyone.

Avoid discharging material against a wall or obstruc-

tion. Material may ricochet back toward the operator.

Stop the blade(s) when crossing gravel surfaces.

Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in place.

• Slow down before turning.

• Never leave a running unit unattended. Always disen-

gage the PTO, set parking brake, stop engine, and

remove keys before dismounting.

• Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete

stop before cleaning the machine, removing the grass

catcher, or unclogging the discharge guard.

• Operate the machine only in daylight or good artificial

light.

• Do not operate the unit while under the influence of

alcohol or drugs.

• Watch for traffic when operating near or crossing

roadways.

Use extra care when loading or unloading the unit

into a trailer or truck.

Always wear eye protection when operating this unit.

Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the equipment safely

enough to protect themselves and others from injury.

Follow the manufacturer's recommendations for

wheel weights or counterweights.

Keep in mind the operator is responsible for accidents

occurring to other people or property.

All drivers should seek and obtain professional and

practical instruction.

Always wear substantial footwear and trousers.

Never operate when barefoot or wearing sandals.

Before using, always visually check that the blades

and blade hardware are present, intact, and secure.

Replace worn or damaged parts.

Disengage attachments before: refueling, removing

an attachment, making adjustments (unless the

adjustment can be made from the operator's posi-

tion).

When the machine is parked, stored, or left unattend-

ed, lower the cutting means unless a positive

mechanical lock is used.

Before leaving the operator's position for any reason,

engage the parking brake (if equipped), disengage

the PTO, stop the engine, and remove the key.

To reduce fire hazard, keep the unit free of grass,

leaves, & excess oil. Do not stop or park over dry

leaves, grass, or combustible materials.

It is a violation of California Public Resource Code

Section 4442 to use or operate the engine on or near

any forest-covered, brush-covered, or grass-covered

land unless the exhaust system is equipped with a

spark arrester meeting any applicable local or state

laws. Other states or federal areas may have similar

laws.

TRANSPORTING AND STORAGE

= When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel. If

the unit is facing backwards, wind lift could damage

the unit.

Always observe safe refueling and fuel handling prac-

tices when refueling the unit after transportation or

storage.

Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an

ignition source (such as a furnace, water heater, etc.)

and cause an explosion. Fuel vapor is also toxic to

humans and animals.

Always follow the engine manual instructions for

storage preparations before storing the unit for both

short and long term periods.

Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

Never store the unit or fuel container inside where

there is an open flame or pilot light, such as in a

water heater. Allow unit to cool before storing.

Page 7

OperatorSalety

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip-

over accidents, which can result in severe injury or death.

Operation on all slopes requires extra caution. If you can-

not back up the slope or ifyou feel uneasy on it, do not

operate on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake.

The main reasons for loss of control are: insufficient tire

grip on the ground, speed too fast, inadequate braking, the

type of machine is unsuitable for its task, lack of awareness

of the ground conditions, incorrect hitching and load distrib-

ution.

Mow up and down slopes, not across.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

Choose a slow speed so that you will not have to

stop or change speeds while on the slope.

Do not mow on wet grass. Tires may loose traction.

Always keep unit in gear especially when traveling

down slopes. Do not shift to neutral and coast down-

hill.

Avoid starting, stopping, or turning on a slope. If tires

lose traction, disengage the blade(s) and proceed

slowly straight down the slope.

Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed or direction,

which could cause the machine to rollover.

Use extra care while operating machines with grass

catchers or other attachments; they can affect the

stability of the unit. Do not use on steeps slopes.

Do not try to stabilize the machine by putting your

foot on the ground (ride-on units).

Do not mow near drop-offs, ditches, or embank-

ments. The mower could suddenly turn over if a

wheel is over the edge of a cliff or ditch, or if an edge

caves in.

Do not use grass catchers on steep slopes.

Do not mow slopes you cannot back up them.

See your authorized dealer/retailer for recommenda-

tions of wheel weights or counterweights to improve

stability.

• Remove obstacles such as rocks, tree limbs, etc.

• Use slow speed. Tires may lose traction on slopes

even through the brakes are functioning properly.

• Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

When operating on slopes use additional wheel

weights or counterweights. See your dealer/retailer

to determine which weights are available and

appropriate for your unit.

Select slow ground speed before driving onto slope.

In addition to front weights, use extra caution when

operating on slopes with rear-mounted grass

catchers.

Mow UP and DOWN the slope, never across the

face, use caution when changing directions and DO

NOT START OR STOP ON SLOPE.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

unit and the mowing activity. Never assume that children

will remain where you last saw them.

Keep children out of the mowing area and under the

watchful care of another responsible adult.

Be alert and turn unit off if children enter the area.

Before and during reverse operation, look behind and

down for small children.

Never carry children, even with the blade(s) off. They

may fall off and be seriously injured or interfere with

safe unit operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over

by the machine.

Never allow children to operate the unit.

Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

EMISSIONS

Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

TOWED EQUIPMENT (RIDE-ON UNITS)

Tow only with a machine that has a hitch designed

for towing. Do not attach towed equipment except at

the hitch point.

Follow the manufacturer's recommendations for

weight limit for towed equipment and towing on

slopes.

Never allow children or others in or on towed equip-

ment.

On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

Travel slowly and allow extra distance to stop.

Do not shift to neutral and coast down hill.

IGNITION SYSTEM

= This spark ignition system complies with Canadian

standard ICES-O02.

7

Page 8

OperatorSafety

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

Use only approved gasoline containers.

Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

Never fuel the machine indoors.

Never store the machine or fuel container where

there is an open flame, spark, or pilot light such as

near a water heater or other appliance.

Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on

the ground away from your vehicle before filling.

Remove gas-powered equipment from the truck or

trailer and refuel it on the ground, if this is not possi-

ble, then refuel such equipment on a trailer with a

portable container, rather than from a gasoline dis-

penser nozzle.

Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is com-

plete. Do not use a nozzle lock-open device.

if fuel is spilled on clothing, change clothing immedi-

ately.

Never over-fill the fuel tank. Replace gas cap and

tighten securely.

Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

Replace all fuel tank caps and fuel container caps

securely.

Service & Maintenance

Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good condition.

Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

Keep unit free of grass, leaves, or other debris build-

up. Clean up oil or fuel spillage, and remove any fuel-

soaked debris. Allow machine to cool before storage.

If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

Never make adjustments or repairs with the engine

running.

Check grass catcher components and the discharge

guard frequently and replace with manufacturer's rec-

ommended parts, when necessary.

Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing them.

Check brake operation frequently. Adjust and service

as required.

Maintain or replace safety and instructions labels, as

necessary.

Do not remove the fuel filter when the engine is hot

as spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline addi-

tives, or white gas because engine/fuel system dam-

age could result.

If the fuel tank must be drained, it should be drained

outdoors.

Replace faulty silencers/mufflers.

Use only factory authorized replacement parts when

making repairs.

Always comply with factory specifications on all set-

tings and adjustments.

Only authorized service locations should be utilized

for major service and repair requirements.

Never attempt to make major repairs on this unit

unless you have been properly trained. Improper ser-

vice procedures can result in hazardous operation,

equipment damage and voiding of manufacturer's

warranty.

On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

Do not change engine governor settings or over-

speed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

Disengage drive attachments, stop the engine,

remove the key, and disconnect the spark plug

wire(s) before: clearing attachment blockages and

chutes, performing service work, striking an object, or

if the unit vibrates abnormally. After striking an

object, inspect the machine for damage and make

repairs before restarting and operating the equip-

ment.

Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top

of the transaxle).

Units with hydraulic pumps, hoses, or motors: WARN-

ING: Hydraulic fluid escaping under pressure may

have sufficient force to penetrate skin and cause seri-

ous injury. If foreign fluid is injected into the skin it

must be surgically removed within a few hours by a

doctor familiar with this form of injury or gangrene

may result. Keep body and hands away from pin

holes or nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, and not hands, to

search for leaks. Make sure all hydraulic fluid con-

nections are tight and all hydraulic hoses and lines

are in good condition before applying pressure to the

system. If leaks occur, have the unit serviced imme-

diately by your authorized dealer.

WARNING: Stored energy device. Improper release

of springs can result in serious personal injury.

Springs should be removed by an authorized techni-

cian.

• Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily

injury from hot coolant or steam blow-out, never

attempt to remove the radiator cap while the engine is

running. Stop the engine and wait until it is cool.

Even then, use extreme care when removing the cap.

Page 9

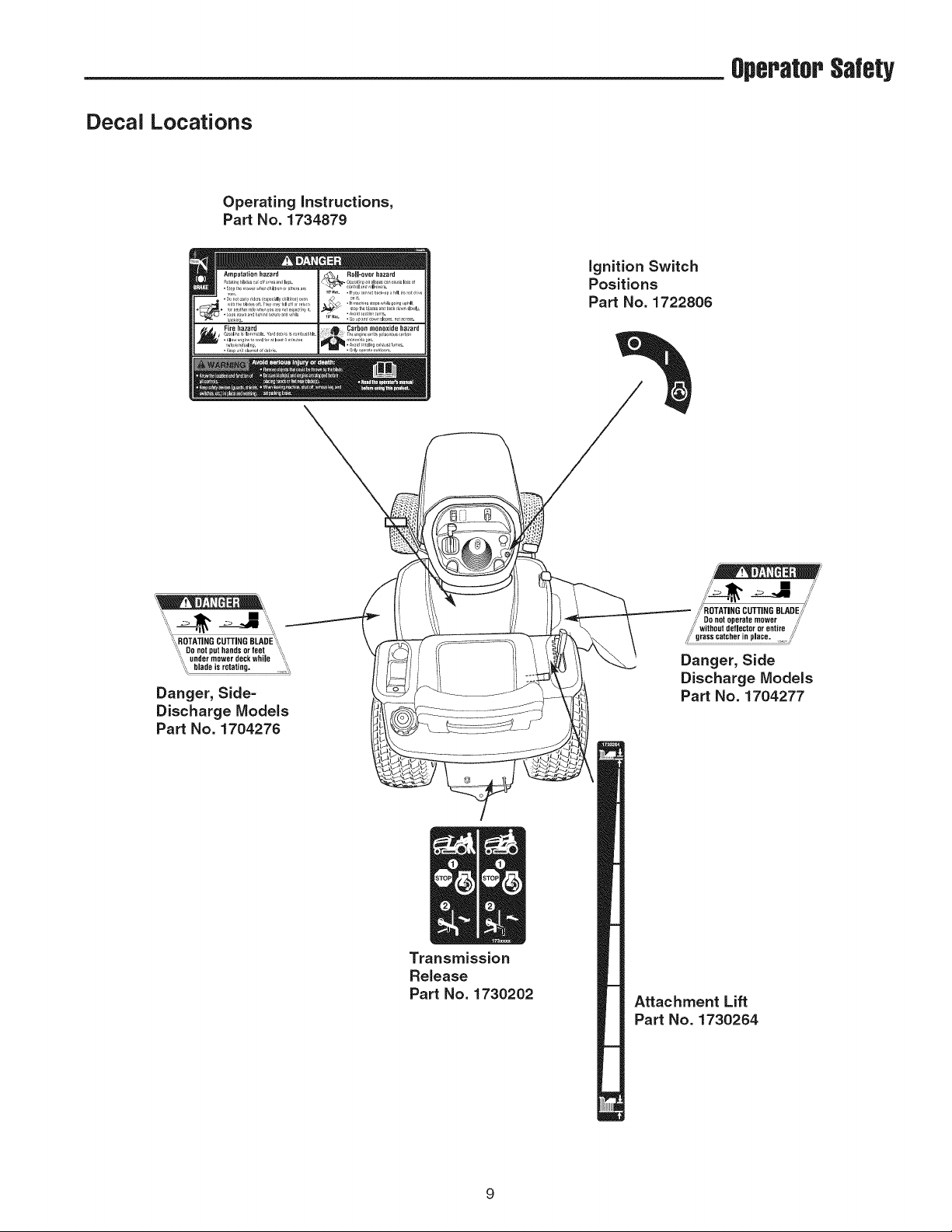

Decal Locations

Operating instructions,

Part No. 1734879

Fire hazard

OperatorSafety

ignition Switch

Positions

Part No. 1722806

",i_ _1_ .:> J "ii!i_,

",',_ROTATING CUTTING BLADE'S,

"_,',_Do not put hands or feet "_,

',',_ under mower deck while "_,

"'7 blade is rotating. ",_,_

Danger, Side-

Discharge Models

Part No. 1704276

Transmission

Release

Part No. 1730202

_, ROTATING CUTTING BLADE,i"

/_; Do not operate mower ,_'

/;' without deflector or entire o,//'

_' grass catcher n p ace ,_'

Danger, Side

Discharge Models

Part No. 1704277

Attachment Lift

Part No. 1730264

g

Page 10

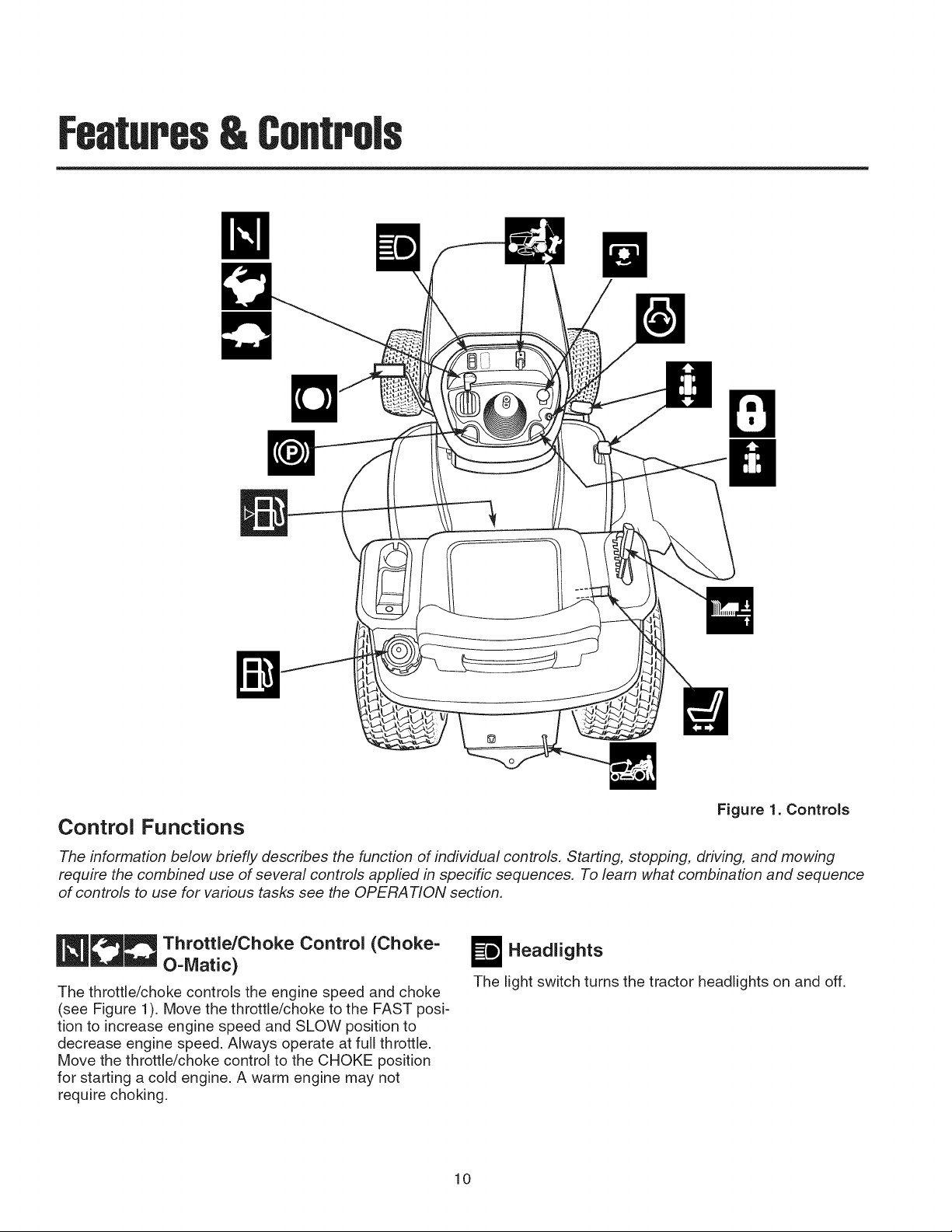

Features& Controls

Figure 1. Controls

Control Functions

The information below briefly describes the function of individual controls. Starting, stopping, driving, and mowing

require the combined use of several controls appfied in specific sequences. To learn what combination and sequence

of controls to use for various tasks see the OPERA T!ON section.

_]__ Throttle/Choke Control (Choke-

The throttle/choke controls the engine speed and choke

(see Figure 1). Move the throttle/choke to the FAST posi-

tion to increase engine speed and SLOW position to

decrease engine speed. Always operate at full throttle.

Move the throttle/choke control to the CHOKE position

for starting a cold engine. A warm engine may not

require choking.

O-iVlatic)

W Headlights

The light switch turns the tractor headlights on and off.

10

Page 11

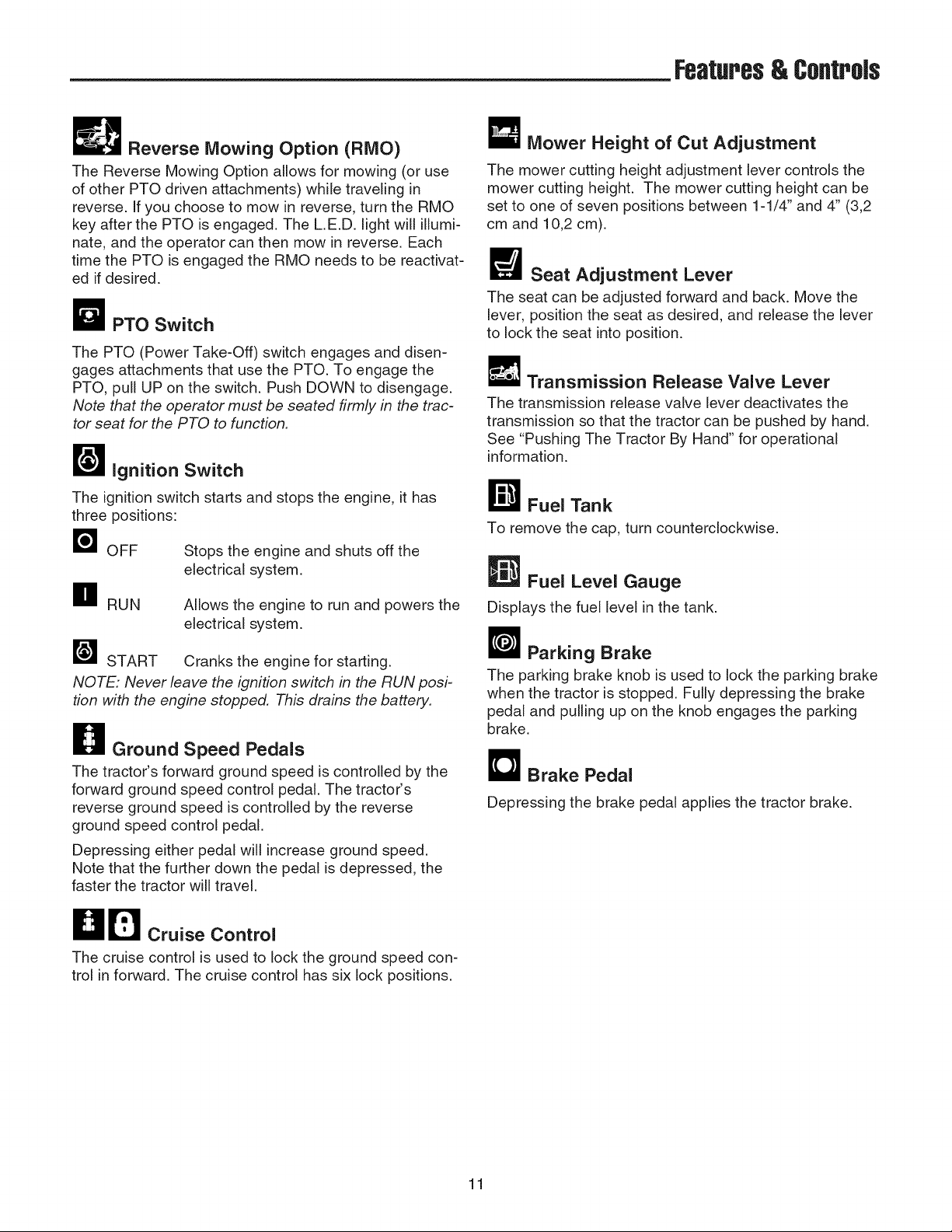

Features&Controls

_ Reverse Mowing Option (RMO)

The Reverse Mowing Option allows for mowing (or use

of other PTO driven attachments) while traveling in

reverse. If you choose to mow in reverse, turn the RMO

key after the PTO is engaged. The L.E.D. light will illumi-

nate, and the operator can then mow in reverse. Each

time the PTO is engaged the RMO needs to be reactivat-

ed ifdesired.

O PTO Switch

The PTO (Power Take-Off) switch engages and disen-

gages attachments that use the PTO. To engage the

PTO, pull UP on the switch. Push DOWN to disengage.

Note that the operator must be seated firmly in the trac-

tor seat for the PTO to function.

_"_ Ignition Switch

The ignition switch starts and stops the engine, it has

three positions:

r_OFF Stops the engine and shuts off the

electrical system.

O RUN

[!_ START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN posi-

tion with the engine stopped. This drains the battery.

Allows the engine to run and powers the

electrical system.

H Ground Speed Pedals

The tractor's forward ground speed is controlled by the

forward ground speed control pedal. The tractor's

reverse ground speed is controlled by the reverse

ground speed control pedal.

Depressing either pedal will increase ground speed.

Note that the further down the pedal is depressed, the

faster the tractor will travel.

Mower Height of Cut Adjustment

The mower cutting height adjustment lever controls the

mower cutting height. The mower cutting height can be

set to one of seven positions between 1-1/4" and 4" (3,2

cm and 10,2 cm).

_Seat Adjustment Lever

The seat can be adjusted forward and back. Move the

lever, position the seat as desired, and release the lever

to lock the seat into position.

Transmission Release Valve Lever

The transmission release valve lever deactivates the

transmission so that the tractor can be pushed by hand.

See "Pushing The Tractor By Hand" for operational

information.

r_ Fuel Tank

To remove the cap, turn counterclockwise.

Fuel Level Gauge

Displays the fuel level in the tank.

_ Parking Brake

The parking brake knob is used to lock the parking brake

when the tractor is stopped. Fully depressing the brake

pedal and pulling up on the knob engages the parking

brake.

D Brake Pedal

Depressing the brake pedal applies the tractor brake.

O B Cruise Control

The cruise control is used to lock the ground speed con-

trol in forward. The cruise control has six lock positions.

11

Page 12

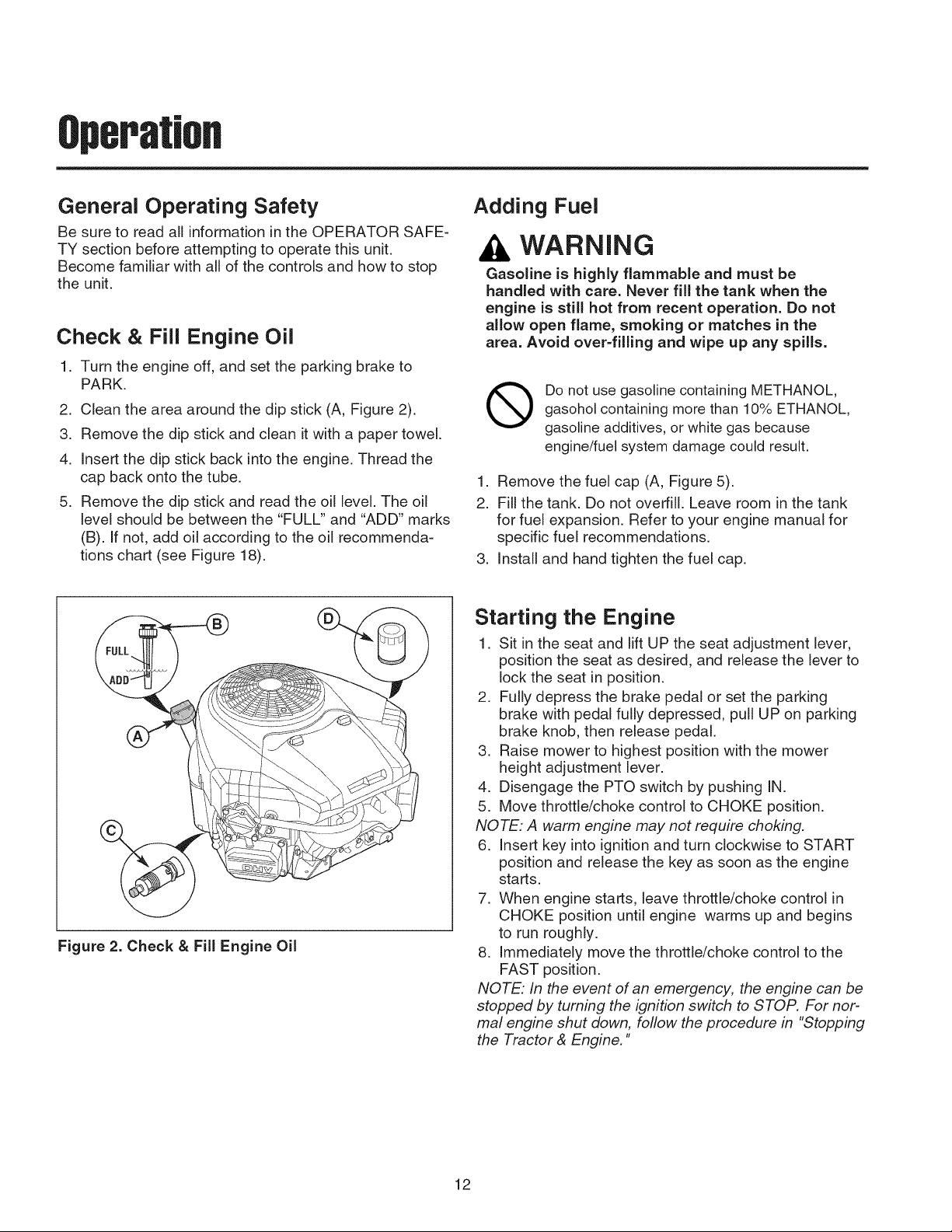

Operation

General Operating Safety

Be sure to read all information in the OPERATOR SAFE-

TY section before attempting to operate this unit.

Become familiar with all of the controls and how to stop

the unit.

Check & Fill Engine Oil

1. Turn the engine off, and set the parking brake to

PARK.

2. Clean the area around the dip stick (A, Figure 2).

3. Remove the dip stick and clean it with a paper towel.

4. Insert the dip stick back into the engine. Thread the

cap back onto the tube.

5. Remove the dip stick and read the oil level. The oil

level should be between the "FULL" and "ADD" marks

(B). If not, add oil according to the oil recommenda-

tions chart (see Figure 18).

Figure 2. Check & Fill Engine Oil

Adding Fuel

WARNING

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is still hot from recent operation. Do not

allow open flame, smoking or matches in the

area. Avoid over-filling and wipe up any spills.

Do not use gasoline containing METHANOL,

gasohol containing more than 10% ETHANOL,

gasoline additives, or white gas because

engine/fuel system damage could result.

1. Remove the fuel cap (A, Figure 5).

2. Fill the tank. Do not overfill. Leave room in the tank

for fuel expansion. Refer to your engine manual for

specific fuel recommendations.

3. Install and hand tighten the fuel cap.

Starting the Engine

1. Sit in the seat and lift UP the seat adjustment lever,

position the seat as desired, and release the lever to

lock the seat in position.

2. Fully depress the brake pedal or set the parking

brake with pedal fully depressed, pull UP on parking

brake knob, then release pedal.

3. Raise mower to highest position with the mower

height adjustment lever.

4. Disengage the PTO switch by pushing IN.

5. Move throttle/choke control to CHOKE position.

NOTE: A warm engine may not require choking.

6. Insert key into ignition and turn clockwise to START

position and release the key as soon as the engine

starts.

7. When engine starts, leave throttle/choke control in

CHOKE position until engine warms up and begins

to run roughly.

8. Immediately move the throttle/choke control to the

FAST position.

NOTE: In the event of an emergency, the engine can be

stopped by turning the ignition switch to STOP. For nor-

mal engine shut down, follow the procedure in "Stopping

the Tractor & Engine."

12

Page 13

Operatm,

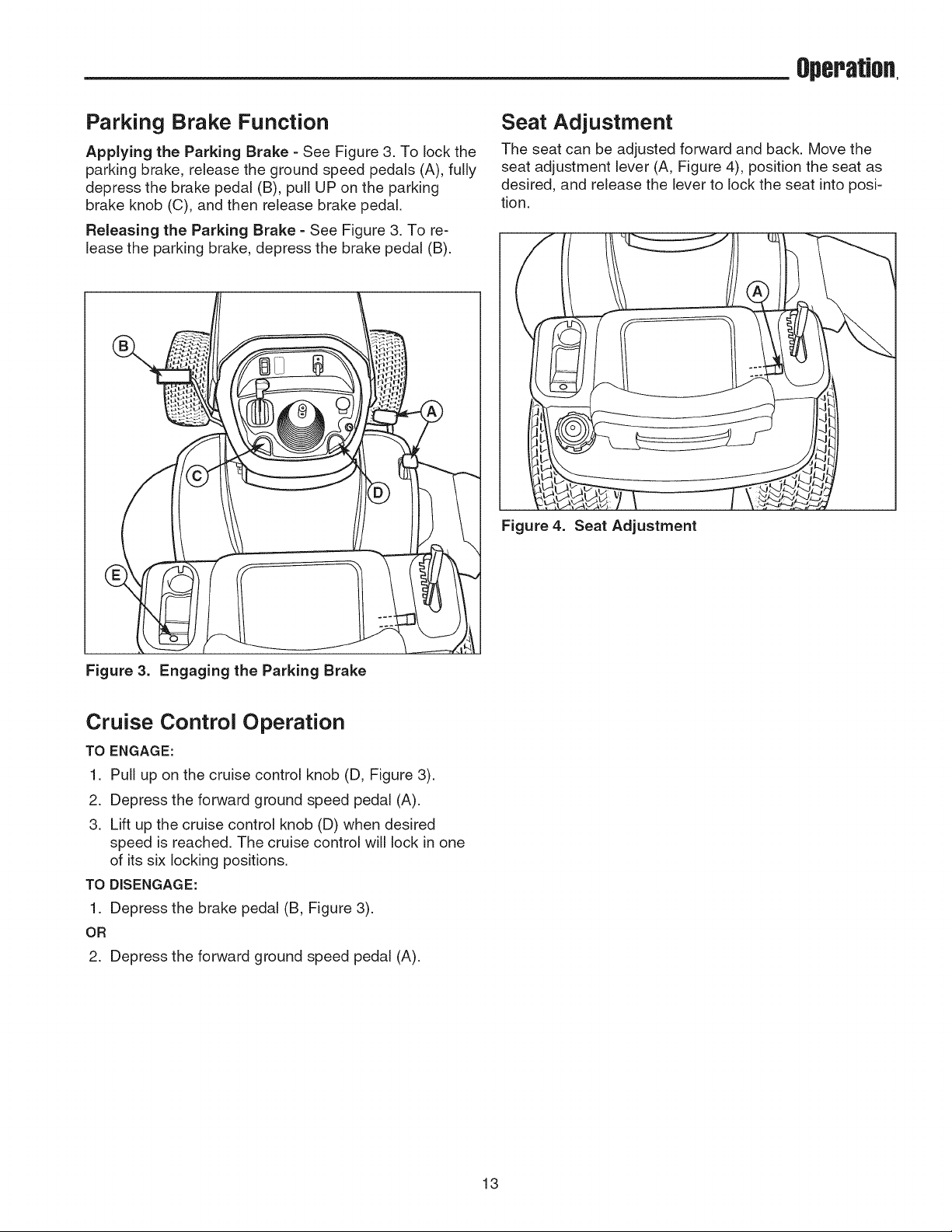

Parking Brake Function

Applying the Parking Brake =See Figure 3. To lock the

parking brake, release the ground speed pedals (A), fully

depress the brake pedal (B), pull UP on the parking

brake knob (C), and then release brake pedal.

Releasing the Parking Brake = See Figure 3. To re-

lease the parking brake, depress the brake pedal (B).

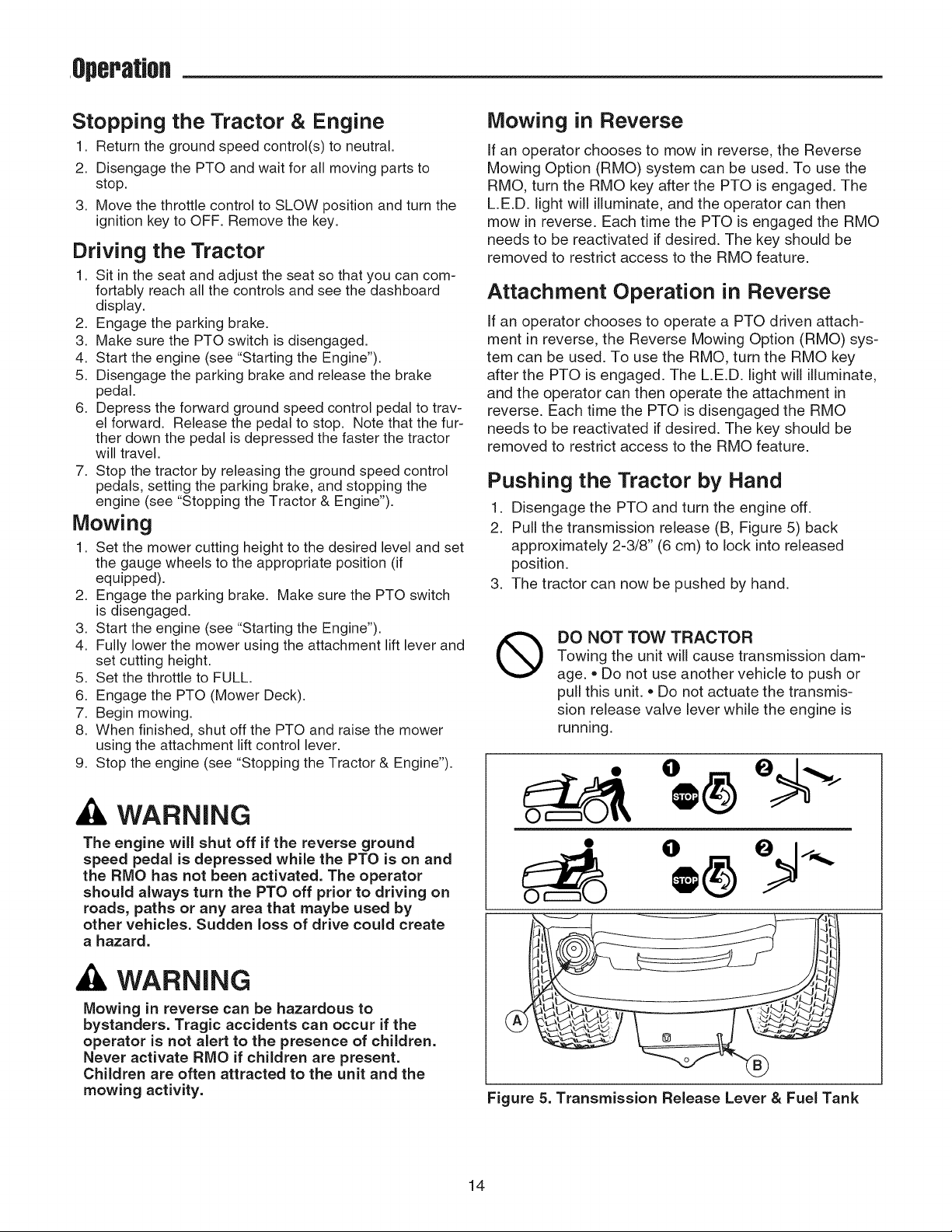

Seat Adjustment

The seat can be adjusted forward and back. Move the

seat adjustment lever (A, Figure 4), position the seat as

desired, and release the lever to lock the seat into posi-

tion.

Figure 4. Seat Adjustment

Figure 3. Engaging the Parking Brake

Cruise Control Operation

TO ENGAGE:

1. Pull up on the cruise control knob (D, Figure 3).

2. Depress the forward ground speed pedal (A).

3. Lift up the cruise control knob (D) when desired

speed is reached. The cruise control will lock in one

of its six lockingpositions.

TO DISENGAGE:

1. Depress the brake pedal (B, Figure 3).

OR

2. Depress the forward ground speed pedal (A).

13

Page 14

,Operation

Stopping the Tractor & Engine

1. Return the ground speed control(s) to neutral.

2. Disengage the PTO and wait for all moving parts to

stop.

3. Move the throttle control to SLOW position and turn the

ignition key to OFF. Remove the key.

Driving the Tractor

1. Sit in the seat and adjust the seat so that you can com-

fortably reach all the controls and see the dashboard

display.

2. Engage the parking brake.

3. Make sure the PTO switch is disengaged.

4. Start the engine (see "Starting the Engine").

5. Disengage the parking brake and release the brake

pedal.

6. Depress the forward ground speed control pedal to trav-

el forward. Release the pedal to stop. Note that the fur-

ther down the pedal is depressed the faster the tractor

will travel.

7. Stop the tractor by releasing the ground speed control

pedals, setting the parking brake, and stopping the

engine (see "Stopping the Tractor & Engine").

Mowing

1. Set the mower cutting height to the desired level and set

the gauge wheels to the appropriate position (if

equipped).

2. Engage the parking brake. Make sure the PTO switch

is disengaged.

3. Start the engine (see "Starting the Engine").

4. Fully lower the mower using the attachment lift lever and

set cutting height.

5. Set the throttle to FULL.

6. Engage the PTO (Mower Deck).

7. Begin mowing.

8. When finished, shut off the PTO and raise the mower

using the attachment lift control lever.

9. Stop the engine (see "Stopping the Tractor & Engine").

Mowing in Reverse

If an operator chooses to mow in reverse, the Reverse

Mowing Option (RMO) system can be used. To use the

RMO, turn the RMO key after the PTO is engaged. The

L.E.D. light will illuminate, and the operator can then

mow in reverse. Each time the PTO is engaged the RMO

needs to be reactivated if desired. The key should be

removed to restrict access to the RMO feature.

Attachment Operation in Reverse

If an operator chooses to operate a PTO driven attach-

ment in reverse, the Reverse Mowing Option (RMO) sys-

tem can be used. To use the RMO, turn the RMO key

after the PTO is engaged. The L.E.D. light will illuminate,

and the operator can then operate the attachment in

reverse. Each time the PTO is disengaged the RMO

needs to be reactivated if desired. The key should be

removed to restrict access to the RMO feature.

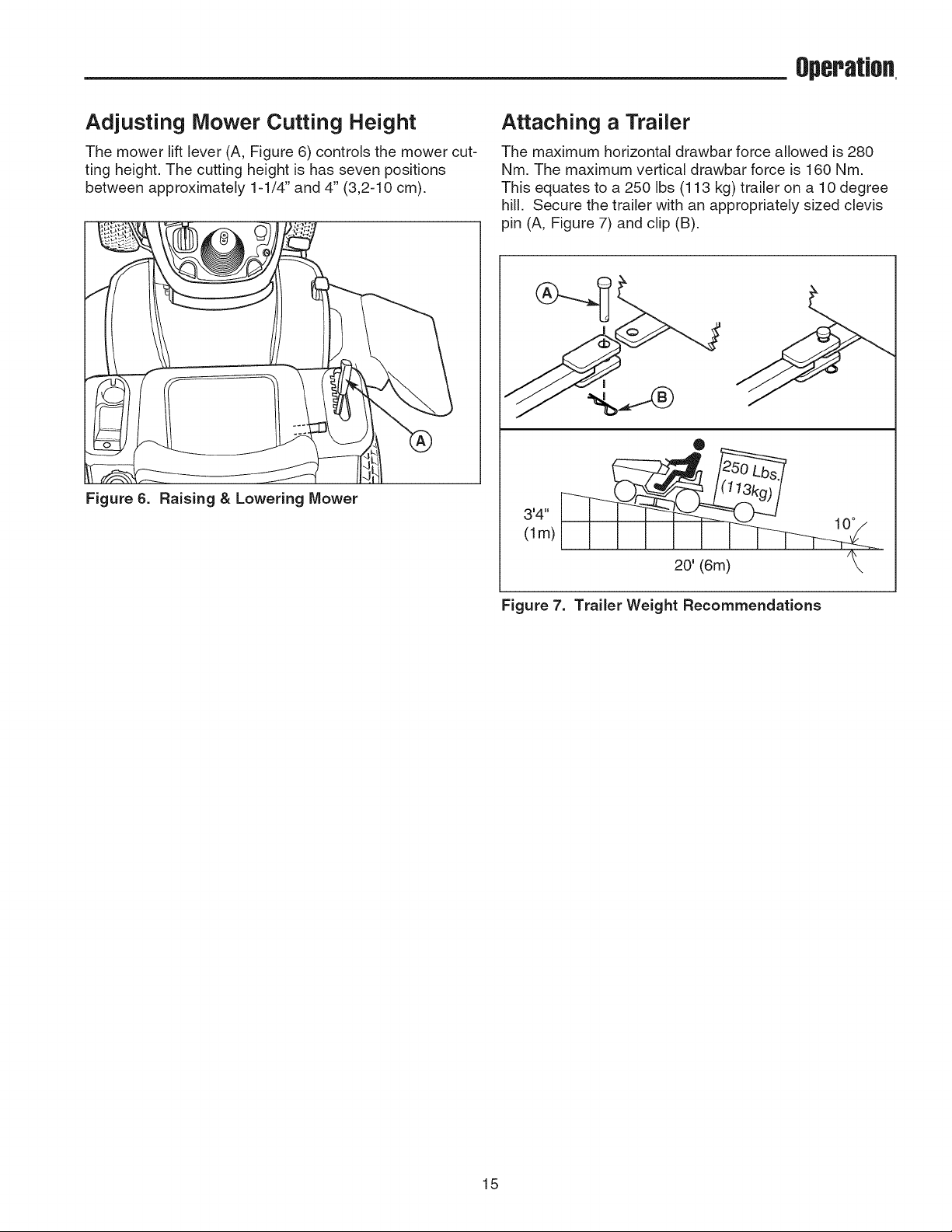

Pushing the Tractor by Hand

1. Disengage the PTO and turn the engine off.

2. Pull the transmission release (B, Figure 5) back

approximately 2-3/8" (6 cm) to lock into released

position.

3. The tractor can now be pushed by hand.

DO NOT TOW TRACTOR

®

Towing the unit will cause transmission dam-

age. • Do not use another vehicle to push or

pull this unit. • Do not actuate the transmis-

sion release valve lever while the engine is

running.

WARNING

The engine will shut off if the reverse ground

speed pedal is depressed while the PTO is on and

the RMO has not been activated. The operator

should always turn the PTO off prior to driving on

roads, paths or any area that maybe used by

other vehicles. Sudden loss of drive could create

a hazard.

WARNING

Mowing in reverse can be hazardous to

bystanders. Tragic accidents can occur if the

operator is not alert to the presence of children.

Never activate RMO if children are present.

Children are often attracted to the unit and the

mowing activity,

O

®

Figure 5. Transmission Release Lever & Fuel Tank

14

Page 15

Operation,

Adjusting Mower Cutting Height

The mower lift lever (A, Figure 6) controls the mower cut-

ring height. The cutting height is has seven positions

between approximately 1-1/4" and 4" (3,2-10 cm).

Figure 6. Raising & Lowering Mower

Attaching a Trailer

The maximum horizontal drawbar force allowed is 280

Nm. The maximum vertical drawbar force is 160 Nm.

This equates to a 250 Ibs (113 kg) trailer on a 10 degree

hill. Secure the trailer with an appropriately sized clevis

pin (A, Figure 7) and clip (B).

®

'4"

(lm)

20' (6m)

10°

Figure 7. Trailer Weight Recommendations

15

Page 16

Maintenance

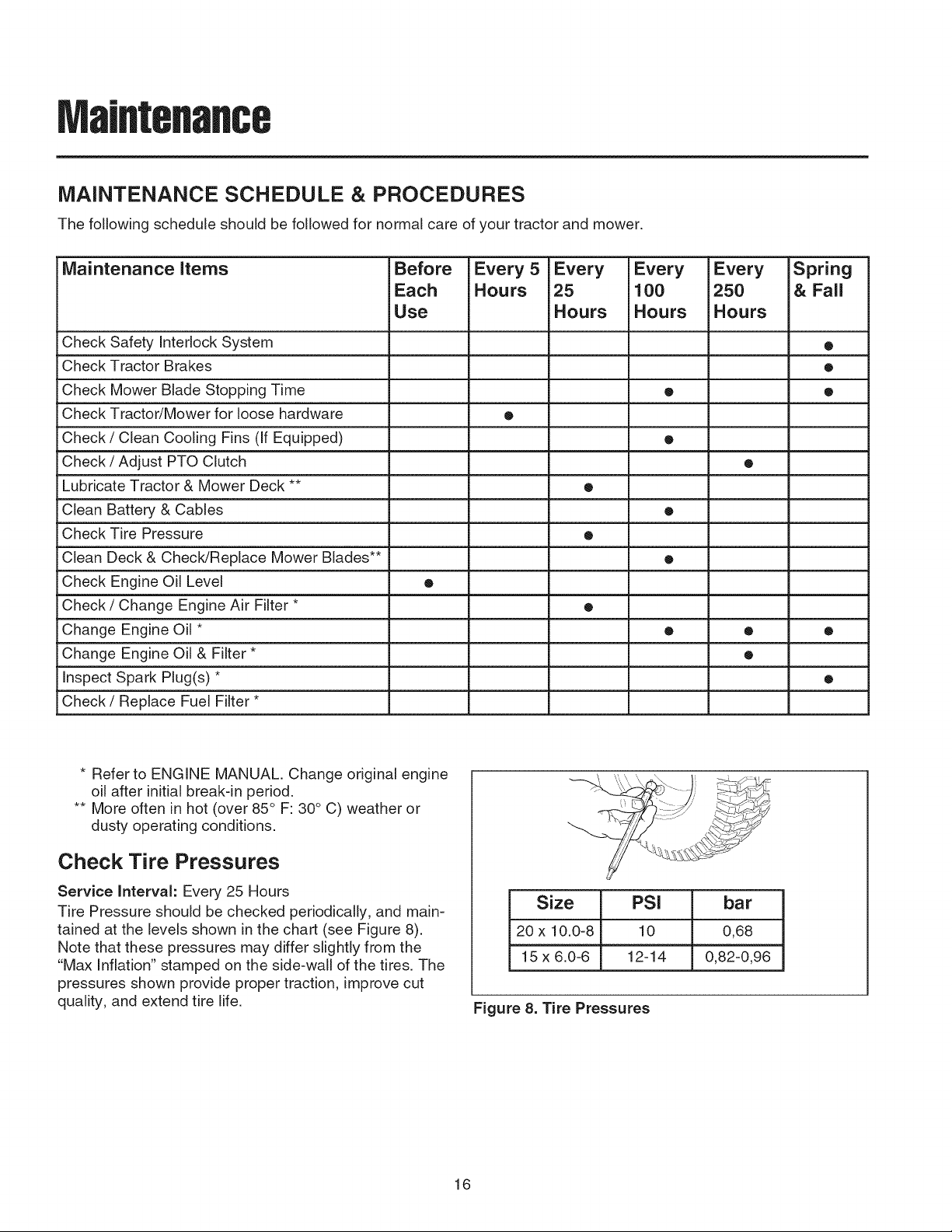

MAINTENANCE SCHEDULE & PROCEDURES

The following schedule should be followed for normal care of your tractor and mower,

Maintenance items Before Every 5 Every Every Every Spring

Each Hours 25 100 250 & Fall

Use Hours Hours Hours

Check Safety Interlock System •

Check Tractor Brakes •

Check Mower Blade Stopping Time • •

Check Tractor/Mower for loose hardware •

Check / Clean Cooling Fins (If Equipped) •

Check / Adjust PTO Clutch •

Lubricate Tractor & Mower Deck ** •

Clean Battery & Cables •

Check Tire Pressure •

Clean Deck & Check/Replace Mower Blades** •

Check Engine Oil Level •

Check / Change Engine Air Filter * •

Change Engine Oil * • • •

Change Engine Oil & Filter * •

Inspect Spark Plug(s) * •

Check/Replace Fuel Filter *

* Refer to ENGINE MANUAL. Change original engine

oil after initial break-in period.

** More often in hot (over 85° F: 30° C) weather or

dusty operating conditions.

Check Tire Pressures

Service Interval: Every 25 Hours

Tire Pressure should be checked periodically, and main-

tained at the levels shown in the chart (see Figure 8).

Note that these pressures may differ slightly from the

"Max Inflation" stamped on the side-wall of the tires. The

pressures shown provide proper traction, improve cut

quality, and extend tire life.

Size PSI bar

20 x 10.0-8 10 0,68

15 x 6.0-6 12-14 0,82-0,96

Figure 8. Tire Pressures

16

Page 17

MaJflteflaflce

Check Safety interlock System

Service interval: Every Fall & Spring

This unit is equipped with safety interlock switches and

other safety devices. These safety systems are present

for your safety: do not attempt to bypass safety switches,

and never tamper with safety devices.

Check the seat switch operation every fall and spring

with the following tests.

Test 1 -- Engine should NOT crank if:

• PTO switch is ON, OR

• Brake pedal is NOT fully depressed (parking brake

OFF),

Test 2 -- Engine SHOULD crank if:

• PTO switch is OFF, AND

• Brake pedal is fully depressed (parking brake ON),

AND

Test 3 -- Engine should SHUT OFF if:

* Operator rises off seat with PTO engaged, OR

* Operator rises off seat with brake pedal NOT fully

depressed (parking brake OFF).

Test 4 -- Blade Brake Check

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned OFF (or operator rises off seat). If

mower drive belt does not stop within five seconds, re

adjust the PTO clutch as described in the MAINTE-

NANCE section or see your dealer.

Test 5 -- Reverse Mow Option (RMO) Check

* Engine should shut off if: PTO is engaged AND RMO

is not activated AND reverse pedal is depressed.

* RMO light should illuminate if: RMO is engaged AND

PTO switch is activated.

NOTE: Once the engine has stopped, the PTO switch

must be turned off after the operator returns to the seat

in order to start the engine,

Check Blade Brake

Service Interval: Every 100 Hours or Fall & Spring

Mower blades and mower drive belt should come to a

complete stop within five seconds after the electric PTO

switch is turned off.

1. With tractor in neutral, PTO disengaged and operator

in seat, start the engine.

2. Look over the left-hand footrest at the mower drive

belt. Engage the PTO and wait several seconds.

Disengage the PTO and check the amount of time it

takes for the mower drive belt to stop.

3. If mower drive belt does not stop within five seconds,

re-adjust the clutch or see your dealer.

Engine Maintenance

Refer to the ENGINE MANUAL for all engine mainte-

nance procedures and recommendations.

WARNING

if the unit does not pass a safety test, do not

operate it. See your authorized dealer. Under no

circumstance should you attempt to defeat the

purpose of the safety interlock system.

17

Page 18

Maintenance

Battery Maintenance

Service interval: Every 100 Hours

WARNING

When removing or installing battery cables,

disconnect the negative cable FIRST and reconnect

it LAST. if not done in this order, the positive

terminal can be shorted to the frame by a tool.

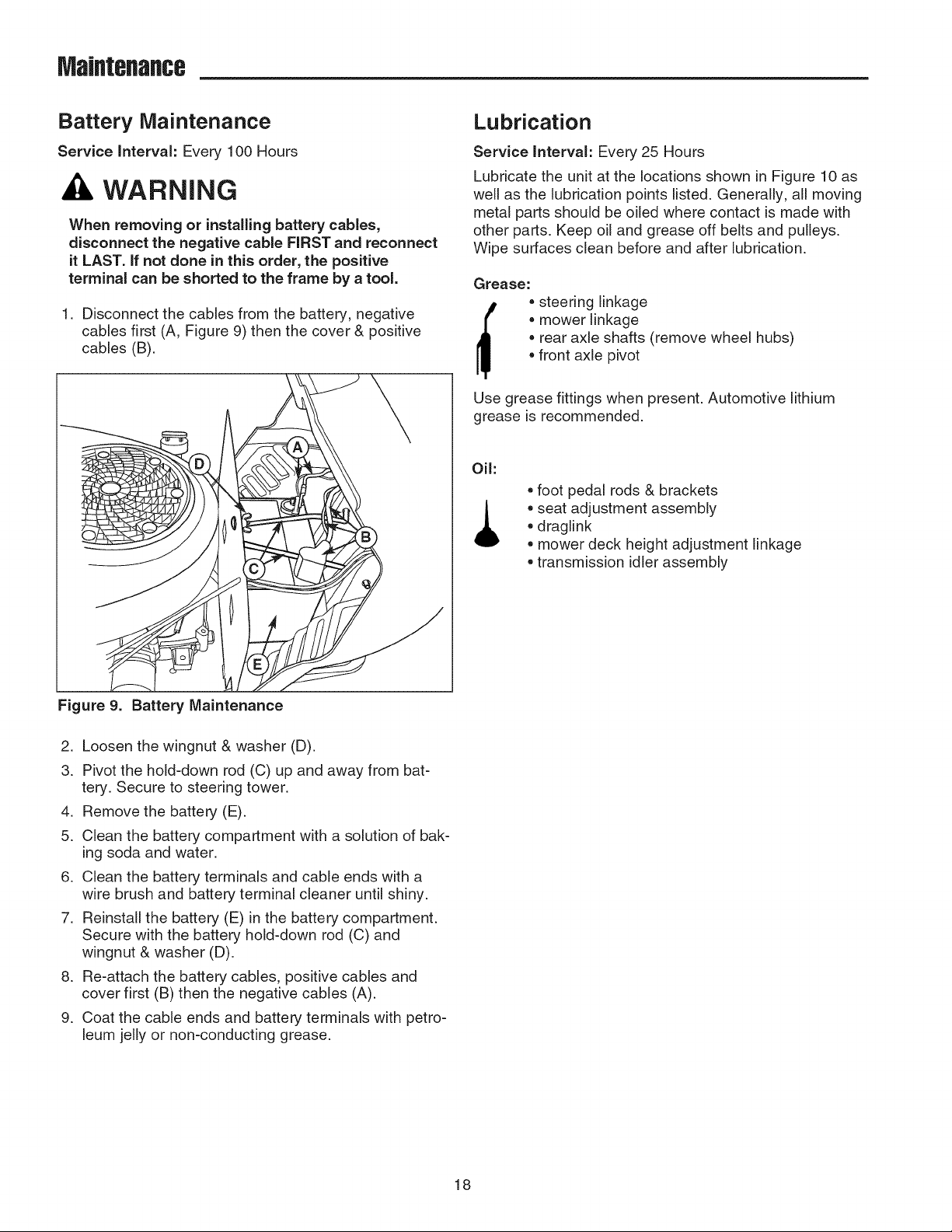

1. Disconnect the cables from the battery, negative

cables first (A, Figure 9) then the cover & positive

cables (B).

Lubrication

Service interval: Every 25 Hours

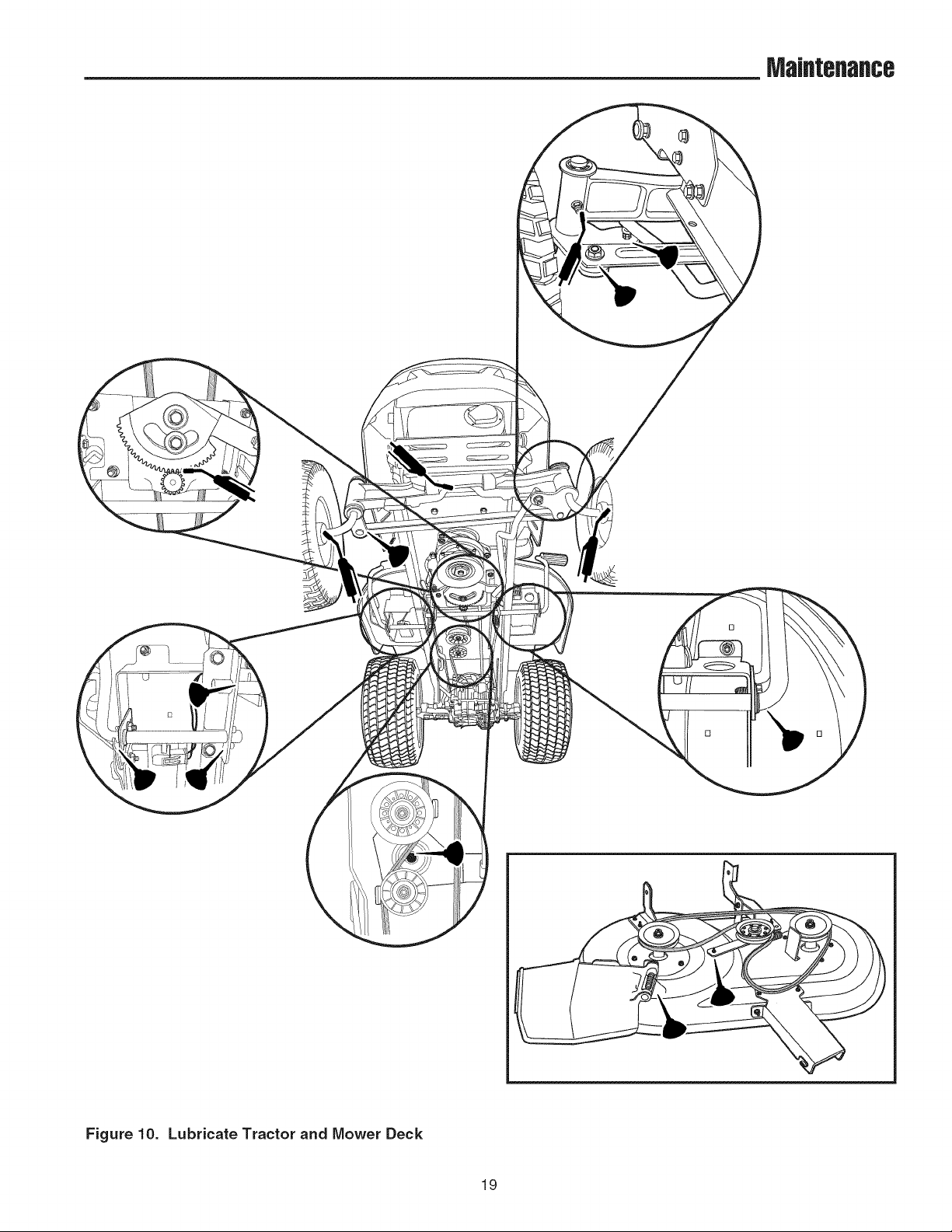

Lubricate the unit at the locations shown in Figure 10 as

well as the lubrication points listed. Generally, all moving

metal parts should be oiled where contact is made with

other parts. Keep oil and grease off belts and pulleys.

Wipe surfaces clean before and after lubrication.

Grease:

• mower linkage

• rear axle shafts (remove wheel hubs)

[_ * steering linkage

Use grease fittings when present. Automotive lithium

grease is recommended.

Oil:

• front axle pivot

* foot pedal rods & brackets

* draglink

* seat adjustment assembly

* mower deck height adjustment linkage

* transmission idler assembly

Figure 9. Battery Maintenance

2. Loosen the wingnut & washer (D).

3. Pivot the hold-down rod (C) up and away from bat-

tery. Secure to steering tower.

4. Remove the battery (E).

5. Clean the battery compartment with a solution of bak-

ing soda and water.

6. Clean the battery terminals and cable ends with a

wire brush and battery terminal cleaner until shiny.

7. Reinstall the battery (E) in the battery compartment.

Secure with the battery hold-down rod (C) and

wingnut & washer (D).

8. Re-attach the battery cables, positive cables and

cover first (B) then the negative cables (A).

9. Coat the cable ends and battery terminals with petro-

leum jelly or non-conducting grease.

18

Page 19

MaJflteflaflce

Figure 10. Lubricate Tractor and Mower Deck

19

Page 20

MaJflteflaflce

Servicing the Mower Blades

Service interval: Every 100 Hours or As Required

WARNING

For your personal safety, do not handle the sharp

mower blades with bare hands. Careless or

improper handling of blades may result in serious

injury.

WARNING

For your personal safety, blade mounting

capscrews must each be installed with two spring

washers or a he× washer and spring washer, then

securely tightened. Tighten blade mounting nut to

70=80 ft=lbs (95=108 Nm). Tighten blade mounting

capscrew to 45=55 ff-lbs (61=75 Nm).

1. Remove mower deck (see "Mower Deck Removal").

Nail

Figure 11. Balancing the Blade

2. To remove blade for sharpening, use a block of wood

to prevent blade rotation while loosening the cap-

screw (see Figure 12).

3. Remove the nut (C, Figure 13), or spring washers

(B), and blade.

4. Use a file to sharpen blade to a fine edge. If blade is

damaged, it must be replaced.

5. Balance the blade as shown in Figure 11. Center the

blade's hole on a nail lubricated with a drop of oil. A

balanced blade will remain level.

6. Reinstall the spring washers (B, Figure 13) and nut

(C). Use a wooden block (A) to prevent blade rotation

while tightening the nut (C) to 70-80 ft-lbs (95-108

Nm).

Loosen

Figure 12. Blade Removal

Figure 13. Blade Installation Mowers (42" Mowers)

20

Page 21

Mower Deck Removal & Installation

Service JntervaJ:As Required

WARNING

Engage parking brake, disengage PTO, stop

engine and remove key before attempting to

instalJ or remove the mower.

Removing the Mower Deck

1. Park tractor on a hard, level surface such as a con-

crete floor. Turn off PTO switch and engine, remove

the key and apply parking brake.

2. Place wood blocks under the mower deck. Place the

attachment lift in the lowest position.

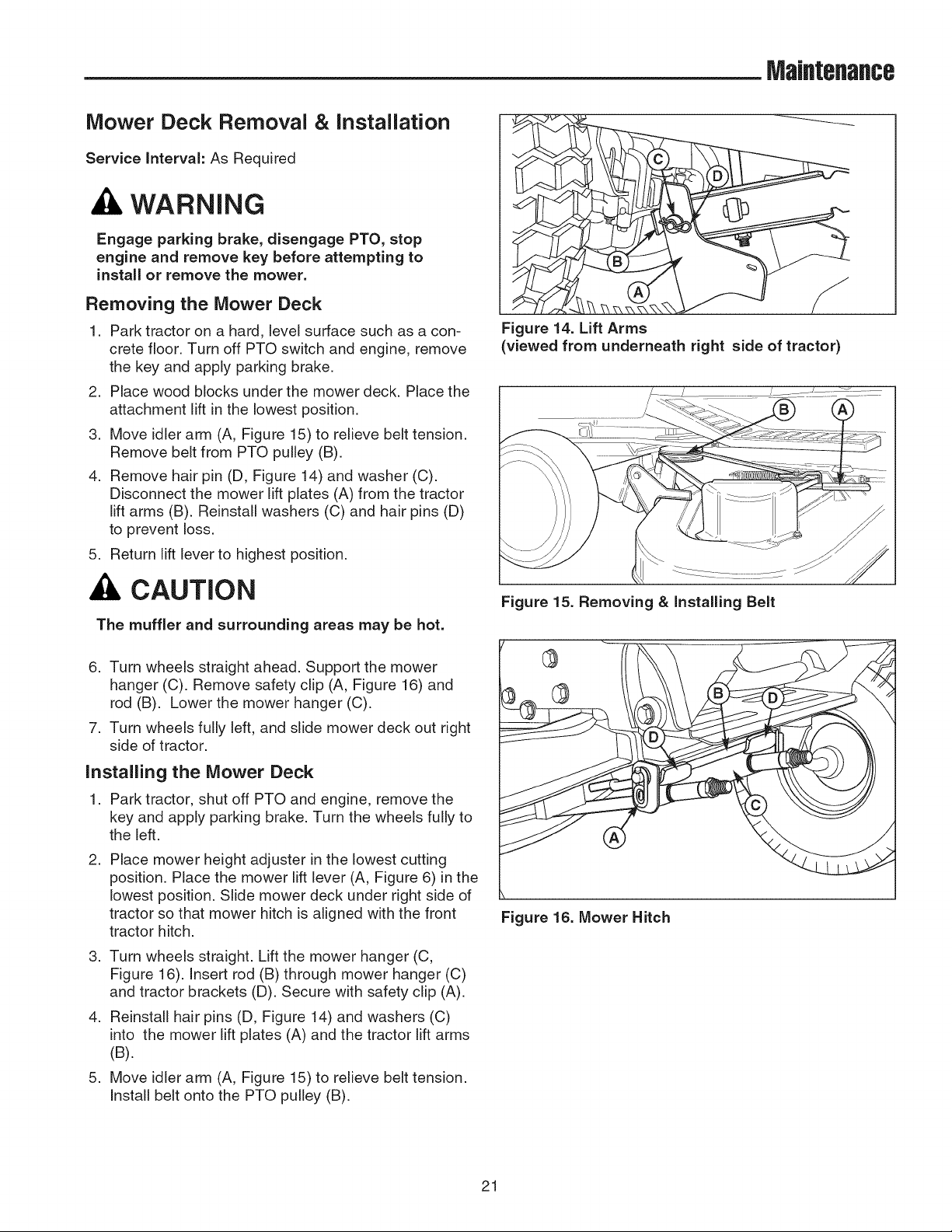

3. Move idler arm (A, Figure 15) to relieve belt tension.

Remove belt from PTO pulley (B).

4. Remove hair pin (D, Figure 14) and washer (C).

Disconnect the mower lift plates (A) from the tractor

lift arms (B). Reinstall washers (C) and hair pins (D)

to prevent loss.

5. Return lift lever to highest position.

MaJflteflaflce

Figure 14. Lift Arms

(viewed from underneath right side of tractor)

CAUTION

The muffler and surrounding areas may be hot.

6. Turn wheels straight ahead. Support the mower

hanger (C). Remove safety clip (A, Figure 16) and

rod (B). Lower the mower hanger (C).

7. Turn wheels fully left, and slide mower deck out right

side of tractor.

Installing the Mower Deck

1. Park tractor, shut off PTO and engine, remove the

key and apply parking brake. Turn the wheels fully to

the left.

,

Place mower height adjuster in the lowest cutting

position. Place the mower lift lever (A, Figure 6) in the

lowest position. Slide mower deck under right side of

tractor so that mower hitch is aligned with the front

tractor hitch.

3. Turn wheels straight. Lift the mower hanger (C,

Figure 16). Insert rod (B) through mower hanger (C)

and tractor brackets (D). Secure with safety clip (A).

4. Reinstall hair pins (D, Figure 14) and washers (C)

into the mower lift plates (A) and the tractor lift arms

(B).

5. Move idler arm (A, Figure 15) to relieve belt tension.

Install belt onto the PTO pulley (B).

Figure 15. Removing & Installing Belt

®

®

Figure 16. Mower Hitch

21

Page 22

Maintenance

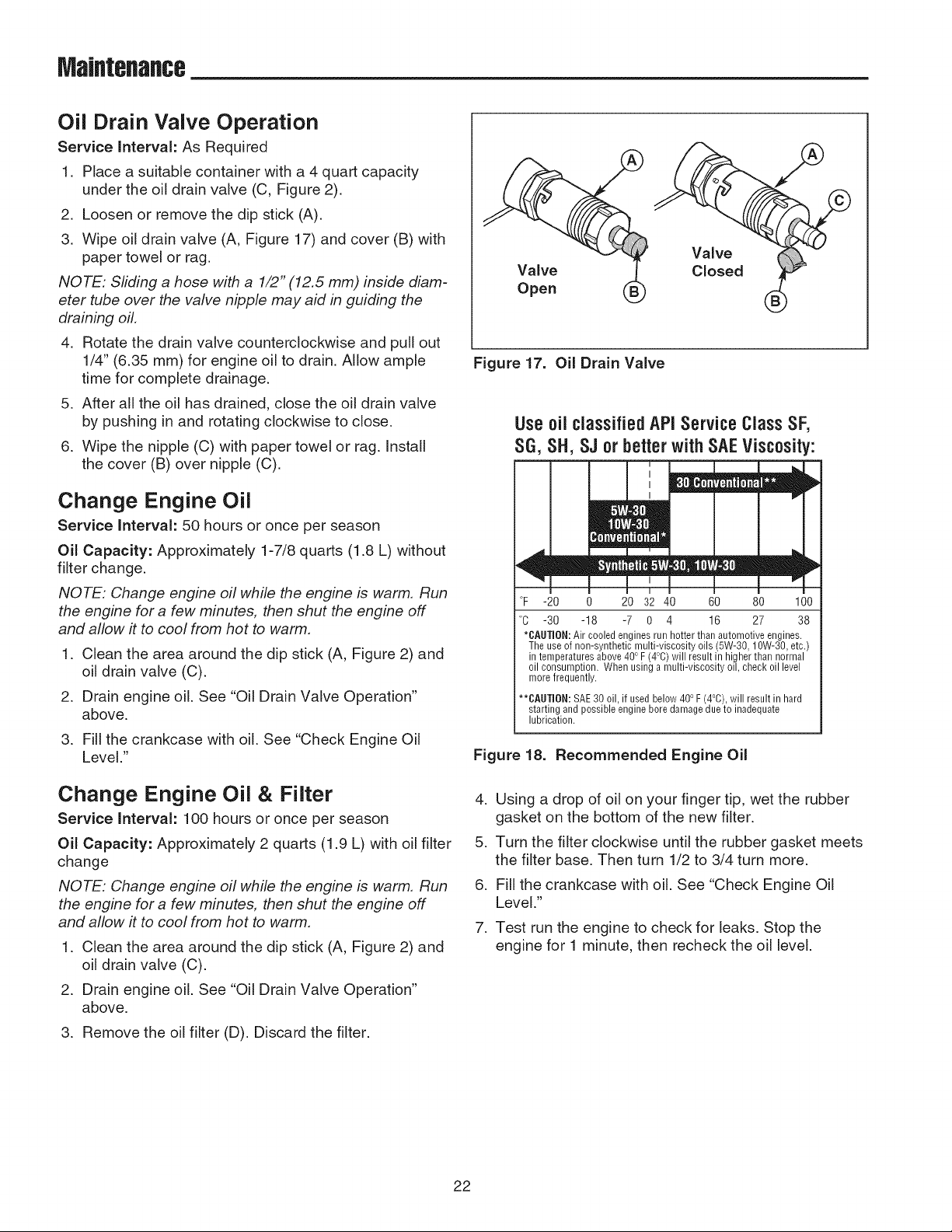

Oil Drain Valve Operation

Service interval: As Required

1. Place a suitable container with a 4 quart capacity

under the oil drain valve (C, Figure 2).

2. Loosen or remove the dip stick (A).

3. Wipe oil drain valve (A, Figure 17) and cover (B) with

paper towel or rag.

NOTE: Sliding a hose with a 1/2" (12.5 mm) inside diam-

eter tube over the valve nipple may aid in guiding the

draining oil.

4. Rotate the drain valve counterclockwise and pull out

1/4" (6.35 ram) for engine oil to drain. Allow ample

time for complete drainage.

5. After all the oil has drained, close the oil drain valve

by pushing in and rotating clockwise to close.

6. Wipe the nipple (C) with paper towel or rag. Install

the cover (B) over nipple (C).

Change Engine Oil

Service Interval: 50 hours or once per season

Oil Capacity: Approximately 1-7/8 quarts (1.8 L) without

filter change.

NOTE: Change engine oil while the engine is warm. Run

the engine for a few minutes, then shut the engine off

and allow it to cool from hot to warm.

1. Clean the area around the dip stick (A, Figure 2) and

oil drain valve (C).

2. Drain engine oil. See "Oil Drain Valve Operation"

above.

3. Fill the crankcase with oil. See "Check Engine Oil

Level."

Figure 17. Oil Drain Valve

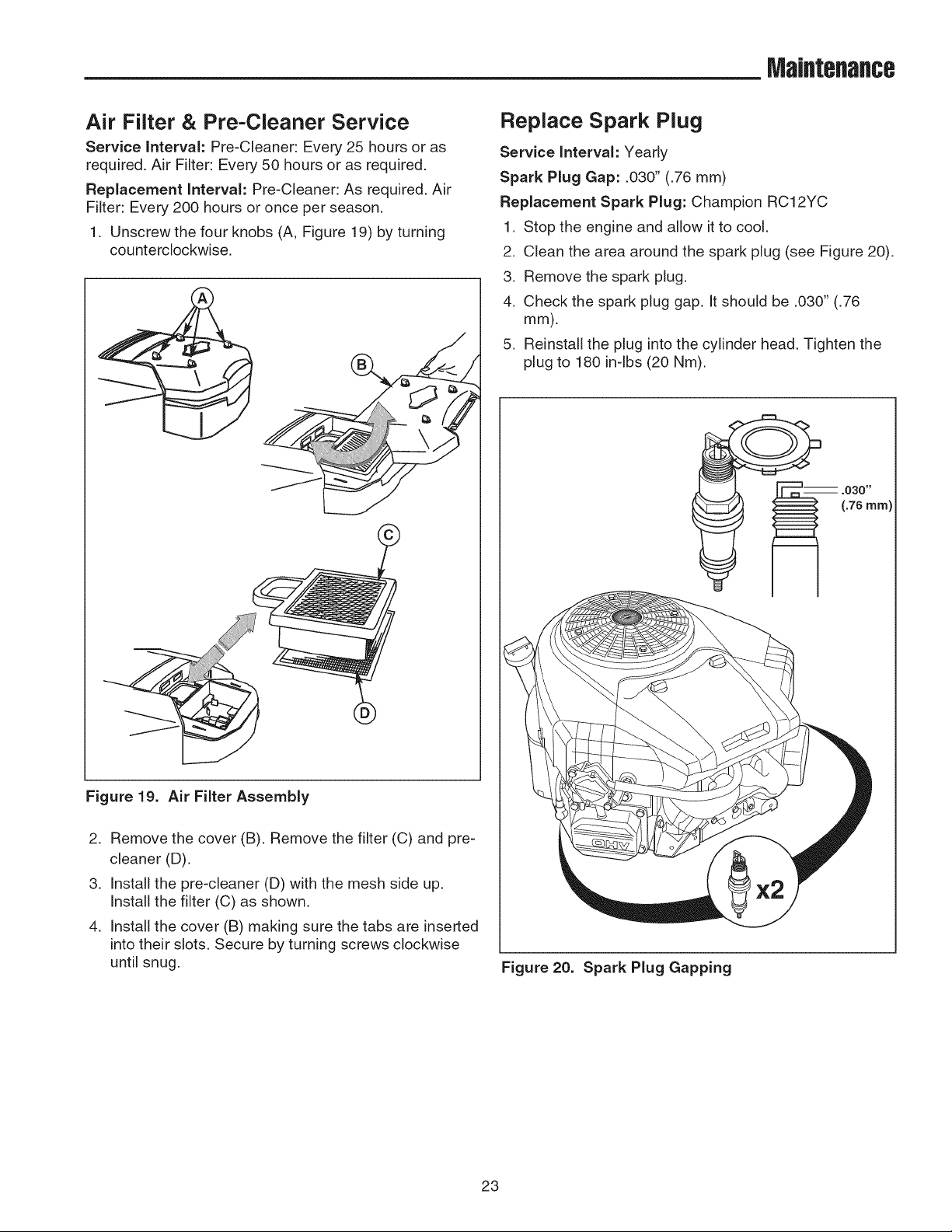

Useoil classifiedAPIService ClassSF,

SG,SH,SJ orbetterwith SAEViscosity:

II "

°F -20 0 20 32 40 60 80 100

°C -30 -18 -7 0 4 16 27 38

*CAUTION:Air cooled engines run hotter than automotive engines.

The use of non-synthetic multi-viscosity oils (5W-30, 10W-30, etc.)

in temperatures above 400F(4°C)will result in higher than normal

oil consumption. When using a multi-viscosity oil, check oil level

more frequently.

**CAUTION: SAE30 oil, if usedbelow 400F (4°C), will result in hard

starting andpossible engine bore damagedue to inadequate

lubrication.

Figure 18. Recommended Engine Oil

I I I! ! ,

Change Engine Oil & Filter 4.

Service Interval: 100 hours or once per season

Oil Capacity: Approximately 2 quarts (1.9 L) with oil filter 5.

change

NOTE: Change engine oil while the engine is warm. Run 6.

the engine for a few minutes, then shut the engine off

and allow it to cool from hot to warm. 7.

1. Clean the area around the dip stick (A, Figure 2) and

oil drain valve (C).

2. Drain engine oil. See "Oil Drain Valve Operation"

above.

3. Remove the oil filter (D). Discard the filter.

22

Using a drop of oil on your finger tip, wet the rubber

gasket on the bottom of the new filter.

Turn the filter clockwise until the rubber gasket meets

the filter base. Then turn 1/2 to 3/4 turn more.

Fill the crankcase with oil. See "Check Engine Oil

Level."

Test run the engine to check for leaks. Stop the

engine for 1 minute, then recheck the oil level.

Page 23

Maintenance

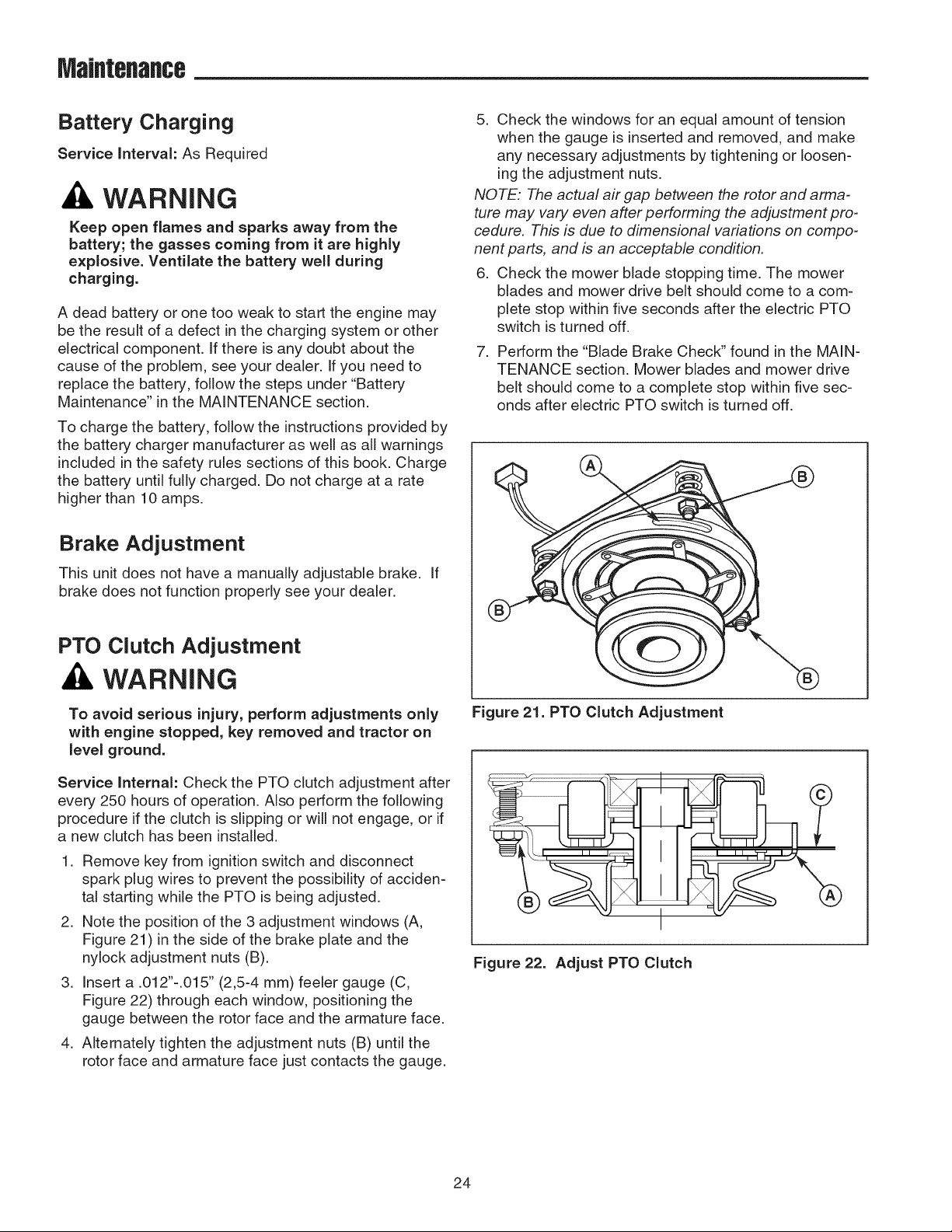

Air Filter & Pre-Cleaner Service

Service Interval: Pre-Cleaner: Every 25 hours or as

required. Air Filter: Every 50 hours or as required.

Replacement Interval: Pre-Cleaner: As required. Air

Filter: Every 200 hours or once per season.

1. Unscrew the four knobs (A, Figure 19) by turning

counterclockwise.

©

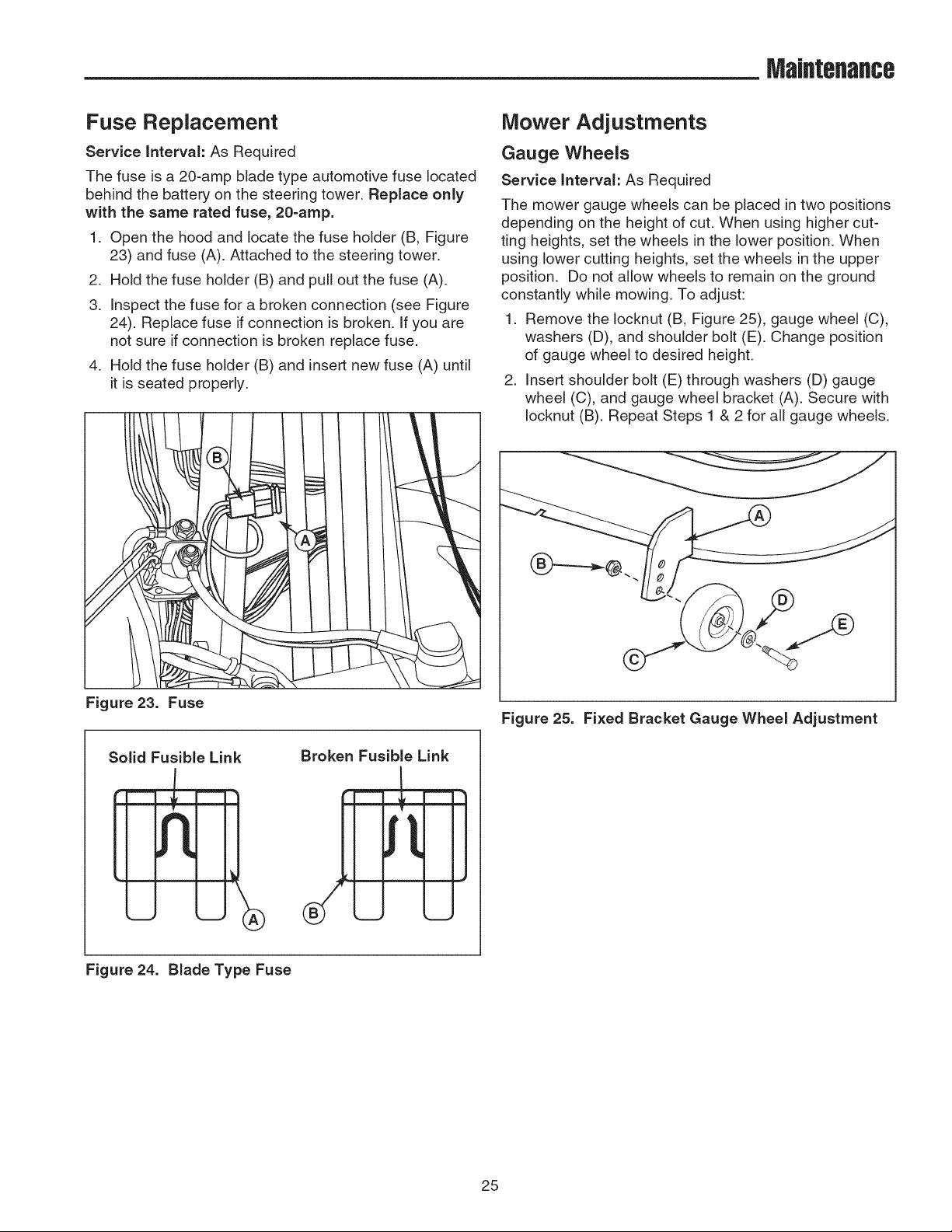

Replace Spark Plug

Service Interval: Yearly

Spark Plug Gap: .030" (.76 mm)

Replacement Spark Plug: Champion RC12YC

1. Stop the engine and allow it to cool.

2. Clean the area around the spark plug (see Figure 20).

3. Remove the spark plug.

4. Check the spark plug gap. It should be .030" (.76

mm).

5. Reinstall the plug into the cylinder head. Tighten the

plug to 180 in-lbs (20 Nm).

_ .030"

I _ _ ( 76 rnrn)

Figure 19. Air Filter Assembly

2. Remove the cover (B). Remove the filter (C) and pre-

cleaner (D).

3. Install the pre-cleaner (D) with the mesh side up.

Install the filter (C) as shown.

4. Install the cover (B) making sure the tabs are inserted

into their slots. Secure by turning screws clockwise

until snug.

Figure 20. Spark Plug Gapping

23

Page 24

Maintenance

Battery Charging

Service interval: As Required

WARNING

Keep open flames and sparks away from the

battery; the gasses coming from it are highly

explosive. Ventilate the battery well during

charging.

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the

cause of the problem, see your dealer. Ifyou need to

replace the battery, follow the steps under "Battery

Maintenance" in the MAINTENANCE section.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the safety rules sections of this book. Charge

the battery until fully charged. Do not charge at a rate

higher than 10 amps.

Brake Adjustment

5. Check the windows for an equal amount of tension

when the gauge is inserted and removed, and make

any necessary adjustments by tightening or loosen-

ing the adjustment nuts.

NOTE: The actual air gap between the rotor and arma-

ture may vary even after performing the adjustment pro-

cedure. This is due to dimensional variations on compo-

nent parts, and is an acceptable condition.

6. Check the mower blade stopping time. The mower

blades and mower drive belt should come to a com-

plete stop within five seconds after the electric PTO

switch is turned off.

, Perform the "Blade Brake Check" found in the MAIN-

TENANCE section. Mower blades and mower drive

belt should come to a complete stop within five sec-

onds after electric PTO switch is turned off.

This unit does not have a manually adjustable brake. If

brake does not function properly see your dealer.

PTO Clutch Adjustment

WARNING

To avoid serious injury, perform adjustments only

with engine stopped, key removed and tractor on

level ground.

Service Internal: Check the PTO clutch adjustment after

every 250 hours of operation. Also perform the following

procedure if the clutch is slipping or will not engage, or if

a new clutch has been installed.

1. Remove key from ignition switch and disconnect

spark plug wires to prevent the possibility of acciden-

tal starting while the PTO is being adjusted.

2. Note the position of the 3 adjustment windows (A,

Figure 21) in the side of the brake plate and the

nylock adjustment nuts (B).

3. Insert a .012"-.015" (2,5-4 mm) feeler gauge (C,

Figure 22) through each window, positioning the

gauge between the rotor face and the armature face.

4. Alternately tighten the adjustment nuts (B) until the

rotor face and armature face just contacts the gauge.

Figure 21. PTO Clutch Adjustment

I

Figure 22. Adjust PTO Clutch

24

Page 25

MaJflteflaflce

Fuse Replacement

Service Interval: As Required

The fuse is a 20-amp blade type automotive fuse located

behind the battery on the steering tower. Replace only

with the same rated fuse, 20=amp.

1. Open the hood and locate the fuse holder (B, Figure

23) and fuse (A). Attached to the steering tower.

2. Hold the fuse holder (B) and pull out the fuse (A).

3. Inspect the fuse for a broken connection (see Figure

24). Replace fuse if connection is broken. If you are

not sure if connection is broken replace fuse.

4. Hold the fuse holder (B) and insert new fuse (A) until

it is seated properly.

Mower Adjustments

Gauge Wheels

Service Interval: As Required

The mower gauge wheels can be placed in two positions

depending on the height of cut. When using higher cut-

ting heights, set the wheels in the lower position. When

using lower cutting heights, set the wheels in the upper

position. Do not allow wheels to remain on the ground

constantly while mowing. To adjust:

1. Remove the Iocknut (B, Figure 25), gauge wheel (C),

washers (D), and shoulder bolt (E). Change position

of gauge wheel to desired height.

2. Insert shoulder bolt (E) through washers (D) gauge

wheel (C), and gauge wheel bracket (A). Secure with

Iocknut (B). Repeat Steps 1 & 2 for all gauge wheels.

Figure 23. Fuse

Solid Fusible Link

Figure 24. Blade Type Fuse

Figure 25. Fixed Bracket Gauge Wheel Adjustment

Broken Fusible Link

======_=,%

--j

25

Page 26

MaJflteflaflce

WARNING

Before checking mower, shut off PTO and engine,

remove the key, and allow all moving parts to

stop.

Leveling The Mower

Service interval: As Required

If the cut is uneven, the mower may need leveling.

Unequal or improper tire pressure may also cause an

uneven cut. Make sure tire pressure is correct as speci-

fied in "Check Tire Pressures."

SIDE-TO=SIDE LEVELING

1. With the mower installed, place the tractor on a

smooth, level surface such as a concrete floor. Turn

the front wheels straight forward.

2. Check for bent blades and replace if necessary.

3. Place the mower in mid-cut position. Arrange the

outside mower blades so that they are pointing from

side-to-side.

4. Measure the distance between the outside tips of

each blade and the ground. If there is more than 1/8"

(3 mm) difference between the measurements on

each side, proceed to Step 5. If the difference is 1/8"

(3 mm) or less, proceed to Step 6.

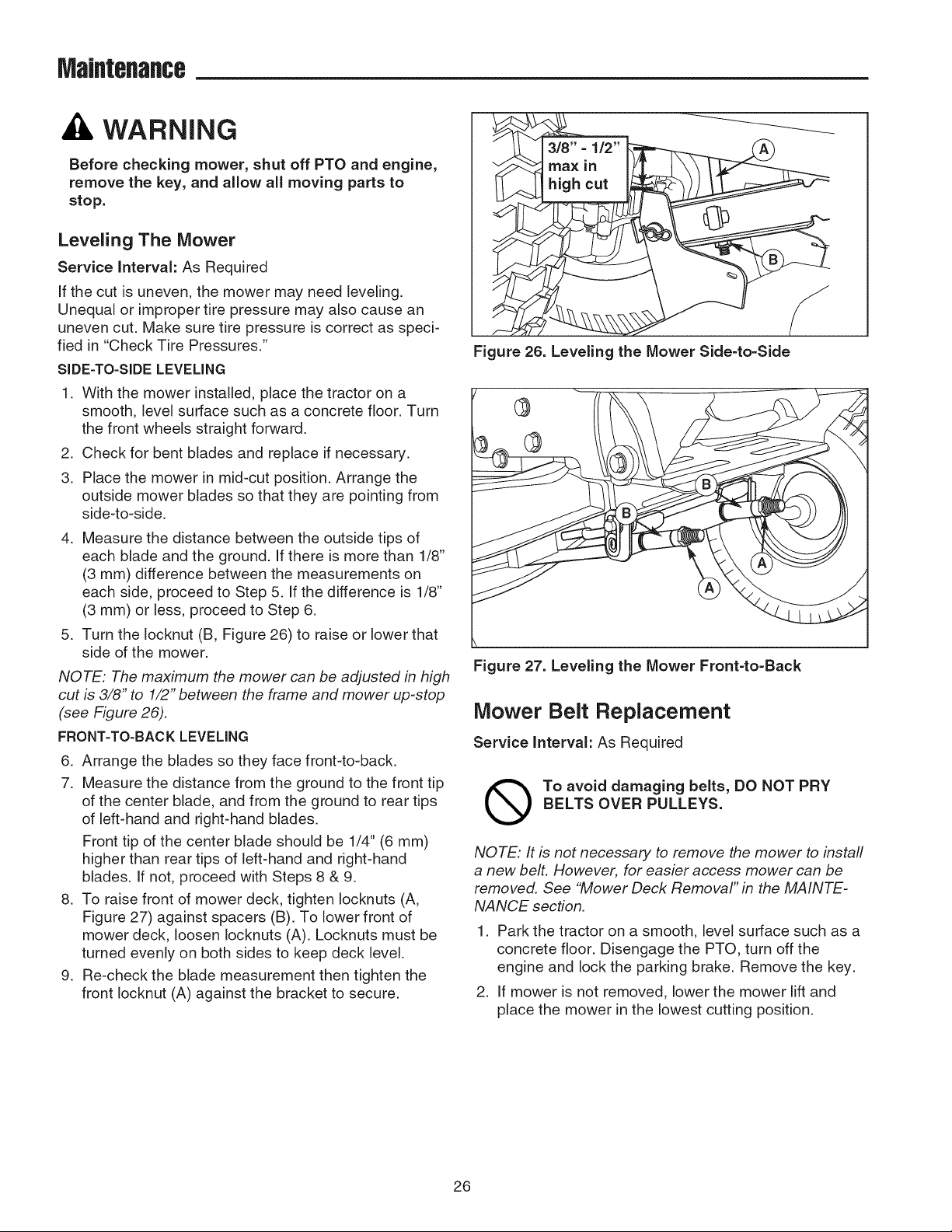

5. Turn the Iocknut (B, Figure 26) to raise or lower that

side of the mower.

NOTE: The maximum the mower can be adjusted in high

cut is 3/8" to 1/2" between the frame and mower up-stop

(see Figure 26).

FRONT=TO=BACKLEVELING

6. Arrange the blades so they face front-to-back.

7. Measure the distance from the ground to the front tip

of the center blade, and from the ground to rear tips

of left-hand and right-hand blades.

Front tip of the center blade should be 1/4" (6 mm)

higher than rear tips of left-hand and right-hand

blades. If not, proceed with Steps 8 & 9.

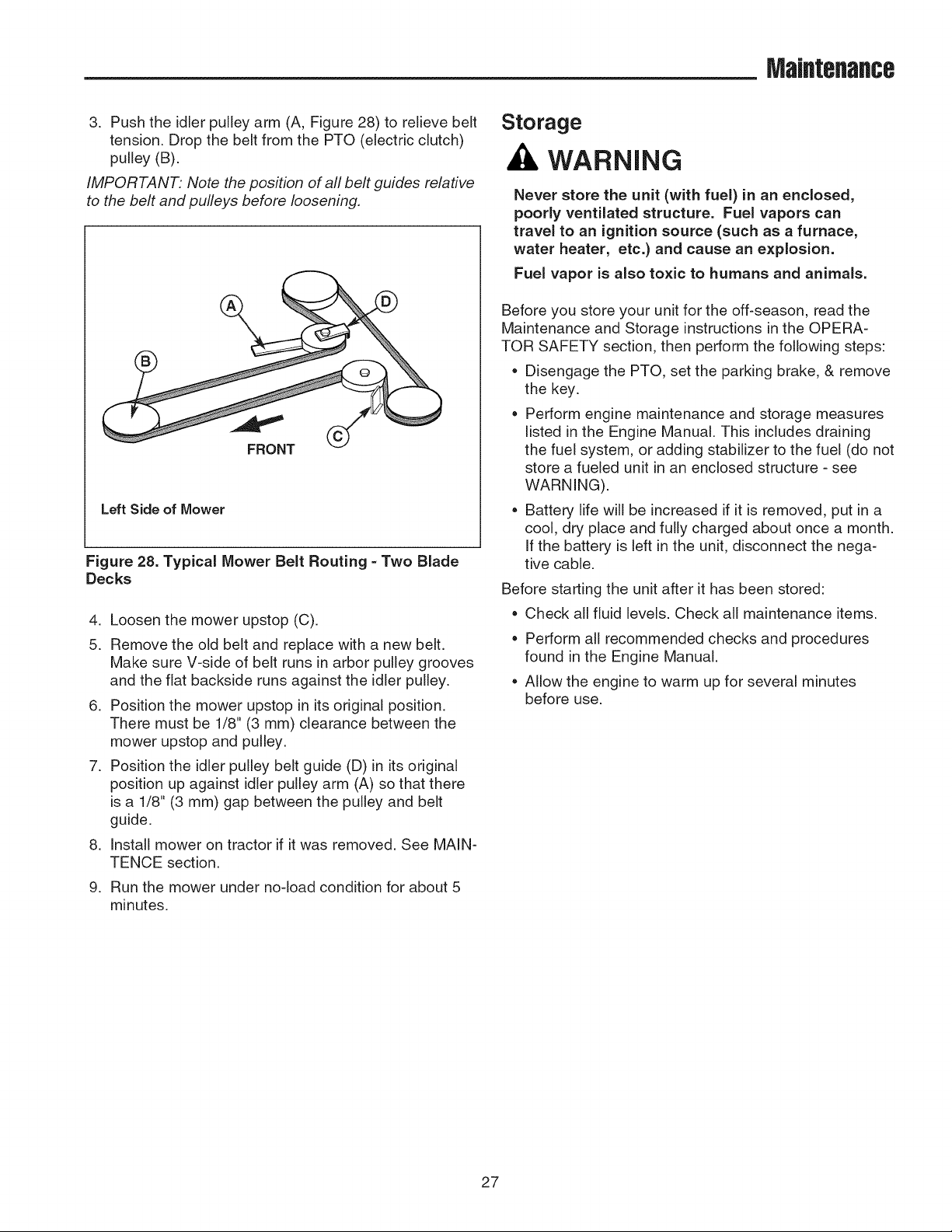

8. To raise front of mower deck, tighten Iocknuts (A,

Figure 27) against spacers (B). To lower front of

mower deck, loosen Iocknuts (A). Locknuts must be

turned evenly on both sides to keep deck level.

9. Re-check the blade measurement then tighten the

front Iocknut (A) against the bracket to secure.

Figure 26. Leveling the Mower Side=to=Side

Figure 27. Leveling the Mower Front-to=Back

Mower Belt Replacement

Service Interval: As Required

Q o avoid damaging belts, DO NOT PRY

NOTE: It is not necessary to remove the mower to instafl

a new belt. However, for easier access mower can be

removed. See "Mower Deck Removal" in the MAINTE-

NANCE section.

1. Park the tractor on a smooth, level surface such as a

2. If mower is not removed, lower the mower lift and

BELTS OVER PULLEYS.

concrete floor. Disengage the PTO, turn off the

engine and lock the parking brake. Remove the key.

place the mower in the lowest cutting position.

26

Page 27

MaJflteflaflce

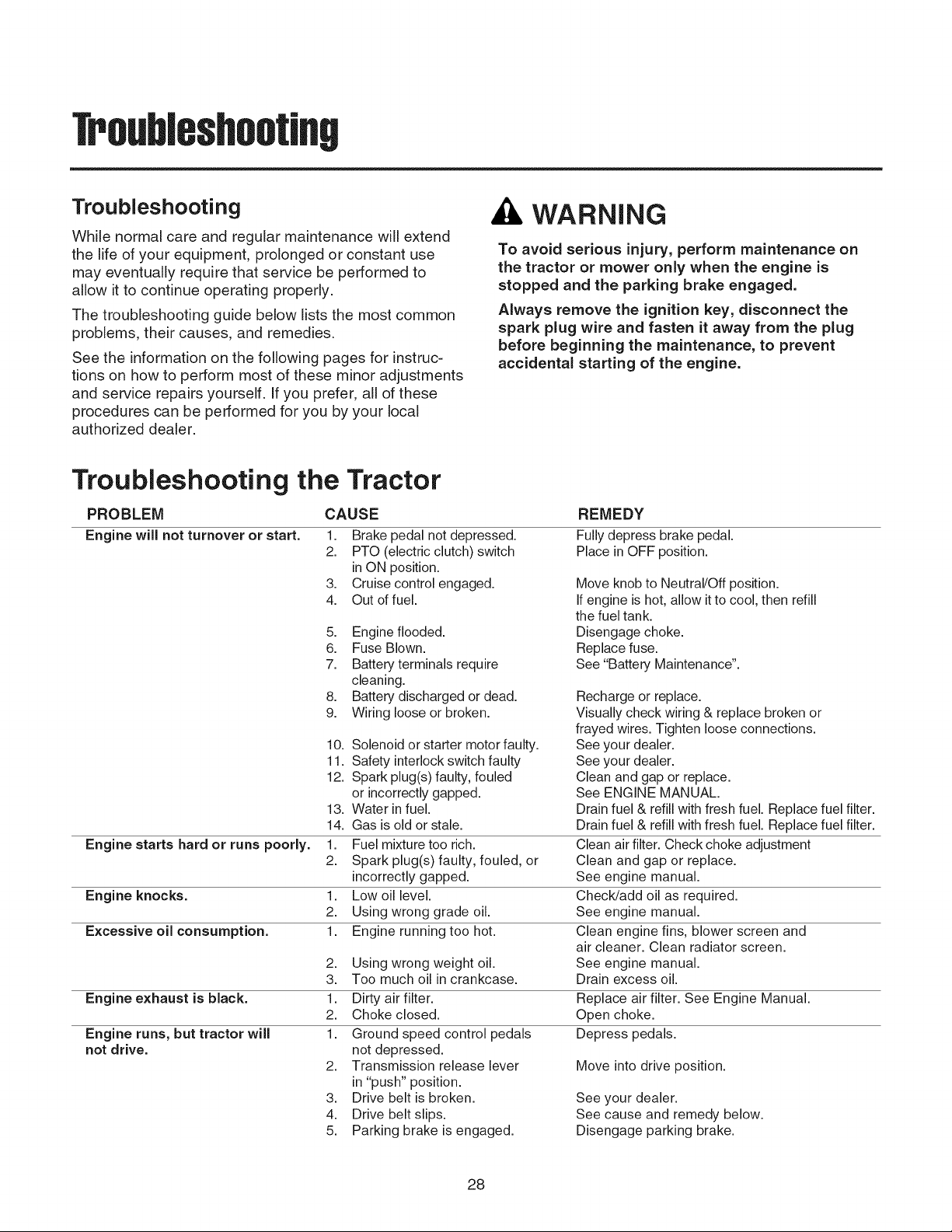

3. Push the idler pulley arm (A, Figure 28) to relieve belt

tension. Drop the belt from the PTO (electric clutch)

pulley (B).

IMPORTANT: Note the position of all belt guides relative

to the belt and pulleys before loosening,

Left Side of Mower

Figure 28. Typical Mower Belt Routing =Two Blade

Decks

4. Loosen the mower upstop (C).

5. Remove the old belt and replace with a new belt.

Make sure V-side of belt runs in arbor pulley grooves

and the fiat backside runs against the idler pulley.

6. Position the mower upstop in its original position.

There must be 1/8" (3 mm) clearance between the

mower upstop and pulley.

7. Position the idler pulley belt guide (D) in its original

position up against idler pulley arm (A) so that there

is a 1/8" (3 mm) gap between the pulley and belt

guide.

,

Install mower on tractor if it was removed. See MAIN-

TENCE section.

9.

Run the mower under no-load condition for about 5

minutes.

Storage

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can

travel to an ignition source (such as a furnace,

water heater, etc.) and cause an explosion.

Fuel vapor is also toxic to humans and animals.

Before you store your unit for the off-season, read the

Maintenance and Storage instructions in the OPERA-

TOR SAFETY section, then perform the following steps:

* Disengage the PTO, set the parking brake, & remove

the key.

Perform engine maintenance and storage measures

listed in the Engine Manual. This includes draining

the fuel system, or adding stabilizer to the fuel (do not

store a fueled unit in an enclosed structure - see

WARNING).

* Battery life will be increased if it is removed, put in a

cool, dry place and fully charged about once a month.

If the battery is left in the unit, disconnect the nega-

tive cable.

Before starting the unit after it has been stored:

Check all fluid levels. Check all maintenance items.

Perform all recommended checks and procedures

found in the Engine Manual.

Allow the engine to warm up for several minutes

before use.

27

Page 28

Troubleshootiflg

Troubleshooting

While normal care and regular maintenance will extend

the life of your equipment, prolonged or constant use

may eventually require that service be performed to

allow it to continue operating properly.

The troubleshooting guide below lists the most common

problems, their causes, and remedies.

See the information on the following pages for instruc-

tions on how to perform most of these minor adjustments

and service repairs yourself. If you prefer, all of these

procedures can be performed for you by your local

authorized dealer.

Troubleshooting the Tractor

PROBLEM

Engine will not turnover or start.

Engine starts hard or runs poorly. 1.

Engine knocks. 1.

Excessive oil consumption. 1.

Engine exhaust is black. 1.

Engine runs, but tractor will 1.

not drive.

CAUSE

1. Brake pedal not depressed.

2. PTO (electric clutch) switch

in ON position.

3. Cruise control engaged.

4. Out of fuel.

5. Engine flooded.

6. Fuse Blown.

7. Battery terminals require

cleaning.

8. Battery discharged or dead.

9. Wiring loose or broken.

10.

Solenoid or starter motor faulty.

11.

Safety interlock switch faulty

12.

Spark plug(s) faulty, fouled

or incorrectly gapped.

13.

Water in fuel.

14.

Gas is old or stale.

Fuel mixture too rich.

2.

Spark plug(s) faulty, fouled, or

incorrectly gapped.

Low oil level.

2.

Using wrong grade oil.

Engine running too hot.

2.

Using wrong weight oil.

3.

Too much oil in crankcase.

Dirty air filter.

2.

Choke closed.

Ground speed control pedals

not depressed.

2.

Transmission release lever

in "push" position.

3.

Drive belt is broken.

4.

Drive belt slips.

5.

Parking brake is engaged.

WARNING

To avoid serious injury, perform maintenance on

the tractor or mower only when the engine is

stopped and the parking brake engaged.

Always remove the ignition key, disconnect the

spark plug wire and fasten it away from the plug

before beginning the maintenance, to prevent

accidental starting of the engine.

REMEDY

Fully depress brake pedal.

Place in OFF position.

Move knob to Neutral/Off position.

If engine is hot, allow it to cool, then refill

the fuel tank.

Disengage choke.

Replace fuse.

See "Battery Maintenance".

Recharge or replace.

Visually check wiring & replace broken or

frayed wires. Tighten loose connections.

See your dealer.

See your dealer.

Clean and gap or replace.

See ENGINE MANUAL.

Drain fuel & refill with fresh fuel. Replace fuel filter.

Drain fuel & refill with fresh fuel. Replace fuel filter.

Clean air filter. Check choke adjustment

Clean and gap or replace.

See engine manual.

Check/add oil as required.

See engine manual.

Clean engine fins, blower screen and

air cleaner. Clean radiator screen.

See engine manual.

Drain excess oil.

Replace air filter. See Engine Manual.

Open choke.

Depress pedals.

Move into drive position.

See your dealer.

See cause and remedy below.

Disengage parking brake.

28

Page 29

TrouhJeshootJflg

Tractor Troubleshooting Cont.

Tractor drive belt slips. 1. Pulleys or belt greasy or oily. Clean as required.

2. Belt stretched or worn. See your dealer.

3. Idler pulley pivot bracket Remove idler pulley bracket, clean and lubricate.

'_rozen" in declutched position.

Brake will not hold. 1. Internal brake worn. See your dealer.

Tractor steers hard or 1. Steering linkage is loose. Check and tighten any loose connections.

handles poorly. 2. Improper tire inflation. Check and correct.

3. Front wheel spindle Grease spindles. See "Lubricating the

bearings dry. Tractor."

Troubleshooting the Mower

PROBLEM CAUSE REMEDY

Mower will not raise. 1. Lift linkage not properly attached Attach or repair.

or damaged.

Mower cut is uneven. 1. Mower not leveled properly. See "Mower Adjustment."

Mower cut is rough looking. 1. Engine speed too slow. Set to full throttle.

Engine stalls easily with

mower engaged.

Excessive mower vibration.

Excessive belt wear or breakage.

Mower drive belt slips

or fails to drive.

2. Tractor tires not inflated See "Check Tire Pressures."

equally or properly.

2. Ground speed too fast. Slow down.

3. Blades are dull. Sharpen or replace blades.

4. Mower drive belt slipping

because it is oily or worn.

5. Check PTO (Electric Clutch)

Adjustment.

6. Blades not properly fastened

to arbors.

1. Engine speed too slow.

2. Ground speed too fast.

3. Dirty or Clogged air filter.

4. Cutting height set too low.

5. Discharge chute jamming

with cut grass.

6. Engine not up to operating

temperature.

7. Starting mower in tall grass.

1. Blade mounting screws

are loose.

2. Mower blades, arbors,

or pulleys are bent.

3. Mower blades are out

of balance.

4. Belt installed incorrectly.

1. Bent or rough pulleys.

2. Using incorrect belt.

1. Idler pulley spring broken or not

properly attached.

2. Belt stops out of adjustment.

3. Mower drive belt broken.

4. PTO clutch out of adjustment.

See "Mower Blade Service."

Clean or replace belt as necessary.

See MAINTENANCE Section.

See "Servicing the Mower Blades."

Set to full throttle.

Slow down.

See Engine Manual.

Cut tall grass at maximum cutting

height during first pass.

Cut grass with discharge pointing toward

previously cut area.

Run engine for several minutes to warm-up.

Start the mower in a cleared area.

Tighten to 45-55 ft-lbs (61-75 Nm).

Check and replace as necessary.

Remove, sharpen, and balance blades.

See "Servicing the Mower Blades."

Reinstall correctly.

Repair or replace.

Replace with correct belt.

Repair or replace as needed.

Check belt stops.

Replace drive belt.

Adjust PTO clutch.

29

Page 30

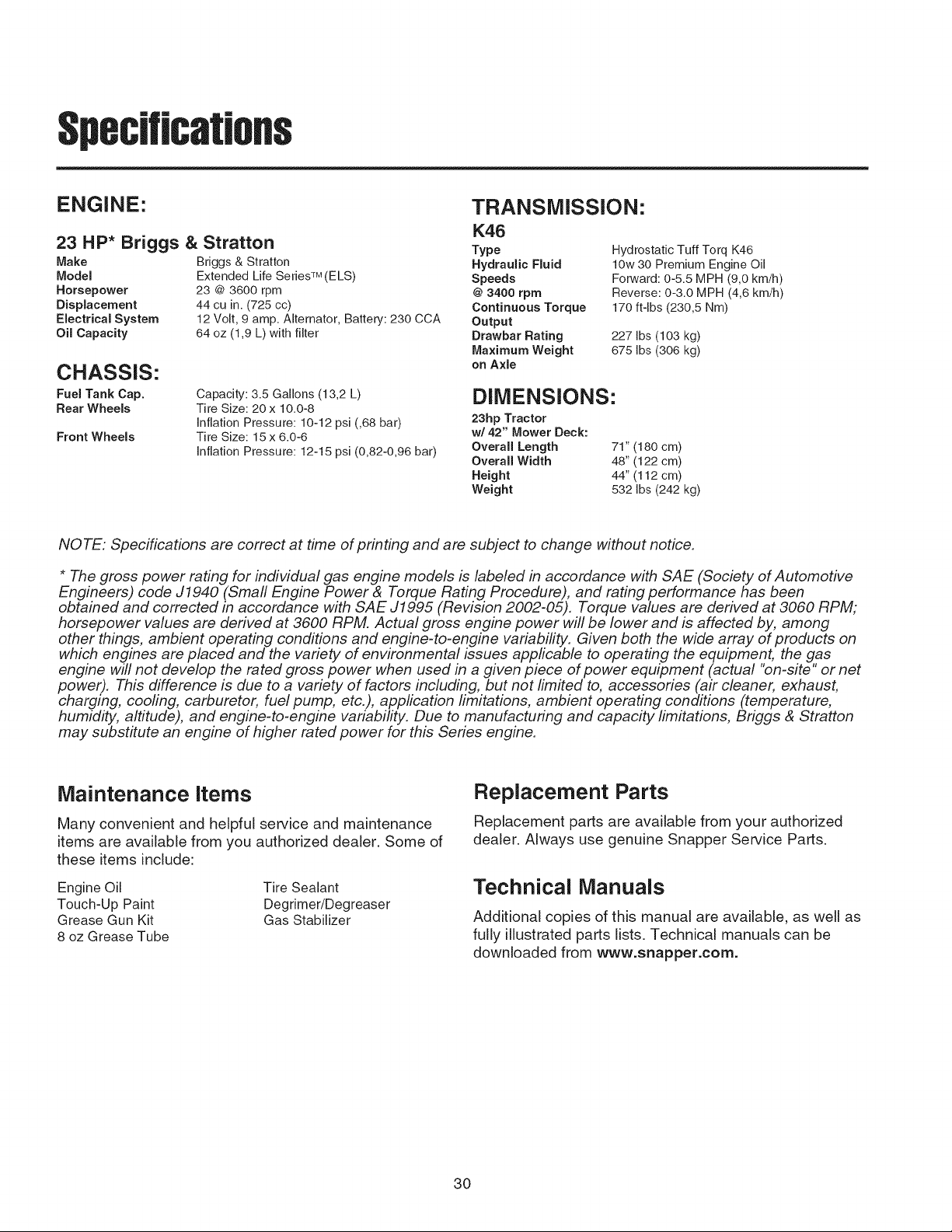

ENGINE:

TRANSMISSION:

K46

23 HP* Briggs & Stratton

Make Briggs & Stratton

Model Extended Life Series TM (ELS)

Horsepower 23 @ 3600 rpm

Displacement 44 cu in. (725 cc)

Electrical System 12 Volt, 9 amp. Alternator, Battery: 230 CCA

Oil Capacity 64 oz (1,9 L) with filter

CHASSIS:

Fuel Tank Cap.

Rear Wheels

Front Wheels

NOTE: Specifications are correct at time of printing and are subject to change without notice.

* The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque Rating Procedure), and rating performance has been

obtained and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM;

horsepower values are derived at 3600 RPM. Actual gross engine power will be lower and is affected by, among

other things, ambient operating conditions and engine-to-engine variability. Given both the wide array of products on

which engines are placed and the variety of environmental issues applicable to operating the equipment, the gas

engine will not develop the rated gross power when used in a given piece of power equipment (actual "on-site" or net

power). This difference is due to a variety of factors including, but not limited to, accessories (air cleaner, exhaust,

charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature,

humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton

may substitute an engine of higher rated power for this Series engine.

Capacity: 3.5 Gallons (13,2 L)

Tire Size: 20x 10.0-8

Inflation Pressure: 10-12 psi (,68 bar)

Tire Size: 15x 6.0-6

Inflation Pressure: 12-15 psi (0,82-0,96 bar)

Type

Hydraulic Fluid

Speeds

@ 3400 rpm

Continuous Torque

Output

Drawbar Rating

Maximum Weight

on Axle

Hydrostatic Tuff Torq K46

lOw 30 Premium Engine Oil

Forward: 0-5.5 MPH (9,0 kin/h)

Reverse: 0-3.0 MPH (4,6 kin/h)

170 ft-lbs (230,5 Nm)

227 Ibs (103 kg)

675 Ibs (306 kg)

DIMENSIONS:

23hp Tractor

w/42" Mower Deck:

Overall Length 71" (180 cm)

Overall Width 48" (122 cm)

Height 44" (112 cm)

Weight 532 Ibs (242 kg)

Maintenance Items

Many convenient and helpful service and maintenance

items are available from you authorized dealer. Some of

these items include:

Engine Oil

Touch-Up Paint

Grease Gun Kit

8 oz Grease Tube

Tire Sealant

Degrimer/Degreaser

Gas Stabilizer

Replacement Parts

Replacement parts are available from your authorized

dealer. Always use genuine Snapper Service Parts.

Technical Manuals

Additional copies of this manual are available, as well as

fully illustrated parts lists. Technical manuals can be

downloaded from www.snapper.com.

3O

Page 31

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased

to explain the emissions control system warranty on your Model Year 2008 and later

engine/equipment. In California, new small off-road engines must be designed, built, and

equipped to meet the State's stringent anti-smog standards. B&S must warrant the

emissions control system on your engine/equipment for the periods of time listed below

provided there has been no abuse, neglect, or improper maintenance of your small

off-road engine.

Your emissions control system may include parts such as the carburetor or fuel injection

system, fuel tank, ignition system, and catalytic converter. Also included may be hoses,

belts, connectors, sensors, and other emissions-related assemblies.

Where a warrantable condition exists, B&S will repair your engine/equipment at no cost

to you including diagnosis, parts, and labor.

Manufacturer's Warranty Coverage:

Small off-road engines are warranted for two years. If any emissions-related part on your

engine/equipment is defective, the part will be repaired or replaced by B&S.

The following are specific provisions relative to your Emissions Control Warranty Coverage. It is in addition to the B&S engine warranty for non-regulated engines found in the

Operator's Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the engine

purchased.

a. Fuel Metering System

Cold start enrichment system (soft choke)

Carburetor and internal parts

Fuel pump

Fuel line, fuel line fittings, clamps

Fuel tank, cap and tether

Carbon canister

b. Air Induction System

Air cleaner

Intake manifold

Purge and vent line

c. Ignition System

Spark plug(s)

Magneto ignition system

d. Catalyst System

Catalytic converter

Exhaust manifold

Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

Vacuum, temperature, position, time sensitive valves and switches

2. Length of Coverage

Connectors and assemblies

For a period of two years from date of original purchase, B&S warrants to the original

purchaser and each subsequent purchaser that the engine is designed, built, and

equipped so as to conform with all applicable regulations adopted by the Air

Resources Board; that it is free from defects in material and workmanship that could

cause the failure of a warranted part; and that it is identical in all material respects to

the engine described in the manufacturer's application for certification. The warranty

period begins on the date the engine is originally purchased.

Owner's Warranty Responsibilities:

As the small engine/equipment owner, you are responsible for the performance of

the required maintenance listed in your owner's manual. B&S recommends that you

retain all receipts covering maintenance on your engine/equipment, but B&S cannot

deny warranty solely for the lack of receipts or your failure to ensure the performance

of all scheduled maintenance.

As the engine/equipment owner, you should however be aware that B&S may deny

you warranty coverage if your engine/equipment or a part has failed due to abuse,

neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your engine/equipment to a B&S distribution

center, servicing dealer, or other equivalent entity, as applicable, as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of

time, not to exceed 30 days. If you have any questions regarding your warranty

rights and responsibilities, you should contact B&S at (414) 259-5262.

The warranty on emissions-related parts is as follows:

Any warranted part that is not scheduled for replacement as required

maintenance in the owner's manual supplied, is warranted for the warranty

period stated above. If any such part fails during the period of warranty

coverage, the part will be repaired or replaced by B&S at no charge to the

owner. Any such part repaired or replaced under the warranty will be warranted

for the remaining warranty period.

Any warranted part that is scheduled only for regular inspection in the owner's

manual supplied, is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining

warranty period.

Any warranted part that is scheduled for replacement as required maintenance

in the owner's manual supplied, is warranted for the period of time prior to the

first scheduled replacement point for that part. If the part fails prior to the first

scheduled replacement, the part will be repaired or replaced by B&S at no

charge to the owner. Any such part repaired or replaced under warranty will be

warranted for the remainder of the period prior to the first scheduled

replacement point for the part.

Add on or modified parts that are not exempted by the Air Resources Board

may not be used. The use of any non exempted add on or modified parts by the

owner will be grounds for disallowing a warranty claim. The manufacturer will

not be liable to warrant failures of warranted parts caused by the use of a non

exempted add on or modified part.

Consequential Coverage

Coverage shall extend to the failure of any engine components caused by the