Page 1

Safety Instructions & Operator’s Manual for

LAWN TRACTOR

HYDROSTATIC DRIVE

SERIES I

MODELS

LT150H33IBV

LT150H38IBV

WLT150H38IBV

WLT170H38IBV

MODEL NUMBER EXPLANATION

LT 150 H 38 I B V

MODEL DESIGNATION

ENGINE HP ENGINE TYPE

DRIVE SYSTEM TYPE ENGINE MODEL

CUTTING WIDTH SERIES DESIGNATION

LT – Lawn Tractor Model Designation 33 – 33” Cutting Width Mower

WLT – Lawn Tractor Model Designation 38 – 38” Cutting Width Mower

150 – 15.0 HP Engine Horse Power I – Series Designation

170 – 17.0 HP Engine Horse Power B – Briggs & Stratton

H – Hydrostatic Transmission V – Over Head Valve Type Engine

Thank you for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow the

“IMPORTANT SAFETY INSTRUCTIONS” on pages 2 & 3, all other instructions contained in this manual and the

accompanying booklet “About Power Mower Safety”. Lawn mowers and all power equipment can be potentially

dangerous if used improperly. REMEMBER: SAFETY REQUIRES CAREFULL USE IN ACCORDANCE WITH

INSTRUCTIONS AND COMMON SENSE!

COPYRIGHT © 2002

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 7-2343 (I.R. 6/28/02)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerf ul cutting machine is capab le of amputating hand s and feet and can throw objects that

can cause injury and damage! Failure to comply with the follow ing SAFETY instru ctions could resu lt in serious

injury or death to the operator or other persons. The owner of the machine must understand these instructions

and must allow only persons who understand these instructions to operate machine. Each person operating the

machine must be of sound mind and body and must not be under the influence of any substance, which might

impair vision, dexterity or judgment. If you have any questions pertaining to your machine which your dealer

cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough,

Georgia 30253. Phone: (1-800-935-2967).

PROTECTION FOR CHILDREN

Tragic accidents can occu r if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you last

saw them.

1. KEEP children out of the mowing area and under

the watchful care of a responsible adult.

2. DO NOT allow children in yard when machine is

operated (even with the blade OFF).

3. DO NOT allow children or others to ride on

machine or on attachments (even with the blades

OFF). They may fall and be seriously injured.

4. DO NOT allow pre-teenage children to operate

machine.

5. ALLOW only responsible adults & teenagers with

mature judgment under close adult supervision to

operate machine.

6. DO NOT operate blades in reverse. STO P BLADES.

LOOK and SEE behind an d down for children, pets

and hazards before and while backing.

7. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

PROTECTION AGAINST TIPOVERS

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra CAUTION. If

you cannot back up the slope or if you feel uneasy on

the slope, DO NOT mow it. Use extra care with grass

catchers or other attachments; these affect the

handling and the stability of the machine.

1. DO NOT operate machine on slopes exceeding 15

degrees (27% grade).

2. Exercise EXTREME CAUTION on slop es above 10

degrees (18% grade). Turn blades OFF when

traveling uphill. Use a slow speed and avoid

sudden or sharp turns.

3. DO NOT operate machine back and forth across

face of slopes. Operate up and down. Practice on

slopes with blades off.

4. AVOID uphill starts. If machine stops going uphill

or tires lose traction, turn blades OFF and back

slowly down the slope.

PROTECTION AGAINST TIPOVERS

(Continued From Previous Column)

5. STAY ALERT for holes and other hidden hazards.

Tall grass can hide obstacles. Keep away from

ditches, washouts, culverts, fences and

protruding objects.

6. KEEP A SAFE DISTANCE (at least 3 feet) away

from edge of ditches and other drop offs. The

machine could turn over if an edge caves in.

7. Always begin forward motion slowly and with

caution.

8. Use weights or a weighted load carrier in accordance

with instructions su pplied with a grass catcher. DO

NOT operate machine on slopes exceeding 10

degrees (18% grade) when equipped with grass

catcher.

9. DO NOT put your foot on the ground to try to

stabilize the machine.

10. DO NOT operate machine on wet grass. Reduced

traction could cause sliding.

11. DO NOT operate machine under any condition

where traction, steering or stability is doubtful.

PREPARATION

1. Read, understand, and follow instructions and

warnings in this manual and on the machine,

engine and attachments. Know the controls and

the proper use of the machine before starting.

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

3. Data indicates that operators age 60 and above,

are involved in a large percentage of mowerrelated injuries. These operators should evaluate

their ability to operate the mower safely enough to

protect themselves and others from serious injury.

4. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved

fuel container. DO NOT remove fuel cap or add

fuel with engine running. Add fuel outdoors only

with engine stopped and cool. Clean spilled fuel

from machine. DO NOT smoke.

5. Practice operation of machine with BLADES OFF

to learn controls and develop skills.

6. Check the area to be mowed and remove all

objects such as toys, wire, rocks, limb s and other

objects that could cau se injury if thrown by blade

or interfere with mowing.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

PREPARATION

(Continued From Previous Page)

7. Keep people and pets out of mowing area.

Immediately STOP blades, STOP engine, and

STOP machine if anyone enters the area.

8. Check shields, deflectors, switches, blade

controls and other safety dev ices frequently for

proper operation and location.

9. Make sure all safety decals are clearly legible.

Replace if damaged.

10. Protect yourself w hen mowing and wear safety

glasses, long pants and substantial footwear.

11. Know how to STOP blades and engine quickly

in preparation for emergencies.

12. Use extra care when loading or unloading the

machine into a trailer or truck.

13. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or worn spots.

OPERATION

1. Mount and dismount machine from left side.

2. Start engine from operator's seat, if possible.

Make sure blades are OFF and parking brake is

set.

3. DO NOT leave machine with engine running.

STOP engine, STOP blades, SET brake, and

Remove key before leaving operators position

of any reason.

4. DO NOT operate machine unless properly

seated with feet on feet rests or pedal(s).

5. STOP BLADES and ENGINE and make sure

blades have stopped before removing grass

catcher or unclogging mower to prevent loss of

fingers or hand.

6. Blades must be OFF except when cutting grass.

Set blades in highest position when mowing

over rough ground.

7. Keep hands an d feet away from rotating blades

underneath deck. DO NOT place foot on ground

while BLADES are ON or machine is in motion.

8. DO NOT operate machine without entire grass

catcher or guards in place. DO NOT point

discharge at people, passing cars, windows or

doors.

9. Slow down before turning.

10. Watch out for traffic when near or crossing

roadways.

11. STOP engine immediately after striking an

obstruction. Inspect machine and repair

damage before resuming operation.

12. Operate machine only in daylight or with good

artificial light.

13. Move joystick (if equipped) SLOWLY to

maintain control during speed and directional

changes.

OPERATION

(Continued From Previous Column)

14. Exercise CAUTION when pullin g loads. Limit loads

to those you can safely control and attach loads to

hitch plate as specified w ith SNAPPER attachment

instructions.

15. DO NOT operate engine in enclosed areas. Engine

exhaust gases contain carbon monoxide, a deadly

poison.

MAINTENANCE

1. DO NOT store machine or fuel container inside

where fumes may reach an open flame, spark or

pilot light such as in a water heater, furnace,

clothes dryer or other gas appliance. Allow

engine to cool before storing machine in an

enclosure. Store fuel container o ut of the reach

of children in a well ventilated, unoccupied

building.

2. Keep engine free of grass, leaves or excess

grease to reduce fire hazard and engine

overheating.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from

open flame.

4. Check brakes frequently; adjust, repair or

replace as needed.

5. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

6. Always provide adequate ventilation when

running engine. Exhaust gases contain carbon

monoxide, an odorless and deadly poison.

7. Disconnect negative (black) cable from battery

before performing maintenance or service.

Cranking engine could cause injury.

8. DO NOT work under machine without safety

blocks.

9. Service engine and make adjustments only

when engine is stopped. Remove spark plug

wire(s) from spark plug(s) and secure wire(s)

away from spark plug(s).

10. DO NOT change engine governor speed

settings or overspeed engine.

11. Lubricate machine at intervals specified in

manual to prevent controls from binding.

12. Mow er blades are sharp and can cut. Wrap the

blades or wear heavy leather gloves and use

CAUTION when handling them.

13. DO NOT test for spark by grounding spark plug

next to spark plug hole; spark plug could ignite

gas exiting engine.

14. Have machine serviced by an authorized

SNAPPER dealer at least once a year and have

the dealer install any new safety devices.

15. Use only genuine SNAPPER replacement parts to

assure that original standards are maintained.

16. If battery is removed, DO NOT operate engine

without insulating Positive + battery cable

terminal with electrical tape or sparking from

the battery cables can result.

3

Page 4

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS..........2 - 3

TABLE OF CONTENTS........................................4

SECTION 1 - FAMILIARIZATION.........................5

Components ........................................................5

Controls................................................................5

SECTION 2 -

OPERATING INSTRUCTIONS ........................6-11

Pre-start Checklist ..............................................6

Operator’s Seat Adjustment ..............................6

Starting & Stopping Engine................................7

Starting & Stopping Wheel Drive .......................8

Starting & Stopping Mower Blades................ 8-9

Parking Brake.......................................................9

Cutting Height Adjustment.................................9

Rolling Tractor With Engine Off .......................10

Reverse Lockout Mechanism ...........................11

SECTION 3 -

MAINTENANCE INSTRUCT IONS .................12-16

Service - After First 5 Hours........................12

Change Engine Oil..........................................12

Check Blade Brake.........................................12

Check Mower Blade.................................. 12-13

Check Deck Drive Belt ...................................13

Service – Every 25 Operating Hours.........13

Mower Components.......................................13

Check Blade Brake.........................................13

Lubrication (Tractor)................................ 14-15

Front Wheel Bearings ....................................14

Axle Spindles ..................................................14

Clutch/Brake Pivot..........................................14

Steering Sector Gear......................................14

Steering Shaft .................................................14

Steering Drag Link..........................................14

Steering Tie Rod.............................................15

Blade Engagement Mechanism.....................15

Park Brake Lever ............................................15

Deck Lift Mechanism......................................15

Service - Annually.....................................15-16

Engine .............................................................15

Fuel Filter................................................... 15-16

Spark Plug.......................................................16

Hydrostatic Transmission Oil........................16

The figures and illustrations in this manual are

provided for reference only and may differ from your

specific model. Contact your Snapper dealer if you

have questions.

IMPORTANT

SECTION 4 -

ADJUSTMENTS & REPAIR...........................17-32

Engine Adjustments & Repair..........................17

Mower Deck & Component Adjustments........17

Blade Brake Adjustment...................................17

33” Deck Blade Brake Adjustment ...............17

38” Deck Blade Brake Adjustment ...............17

Blade Belt Adjustment (33” Deck) ...................18

Blade Belt Adjustment (38” deck)....................18

Adjusting Mower Blade (33” Deck).............18-19

33” Side To Side ...........................................18-19

(Deck Level Adjustment)

33” Front To Rear Sector Plates ......................20

(Deck Level Adjustment)

33” Front To Rear Front Lift Rod .....................20

(Deck Level Adjustment)

38” Side To Side ................................................21

(Deck Level Adjustment)

38” Front To Rear..............................................22

(Deck Level Adjustment)

Brake Adjustment - HYDRO DRIVE..................22

Steering Adjustment .........................................23

Shifter Adjustment ............................................23

Traction Drive Belt Adjustment........................24

Mower Blade Service ...................................25-26

Blade Wear Limits..........................................25

Mower Blade Sharpening ..............................25

Mower Blade Replacement.......................25-26

Traction Drive Belt Removal/Replace.........26-28

Blade Belt Removal & Replacement................29

33” Deck Drive Belt........................................29

38” Deck Drive Belt........................................29

Battery Service .............................................30-31

AVAILABLE ACCESSORIES..................................32

SECTION 5 -

ELECTRICAL SYSTEM...................................... 33

Schematic - Briggs & Stratton..........................33

TROUBLESHOOTING GUIDE ...................... 34-35

MAINTENANCE SCHEDULE ............................. 36

MAINTENANCE PARTS..................................... 36

WARRANTY .................................................... 37

PRIMARY MAINTENANCE............................38-41

PRODUCT REGISTRATION FORM................... 42

4

Page 5

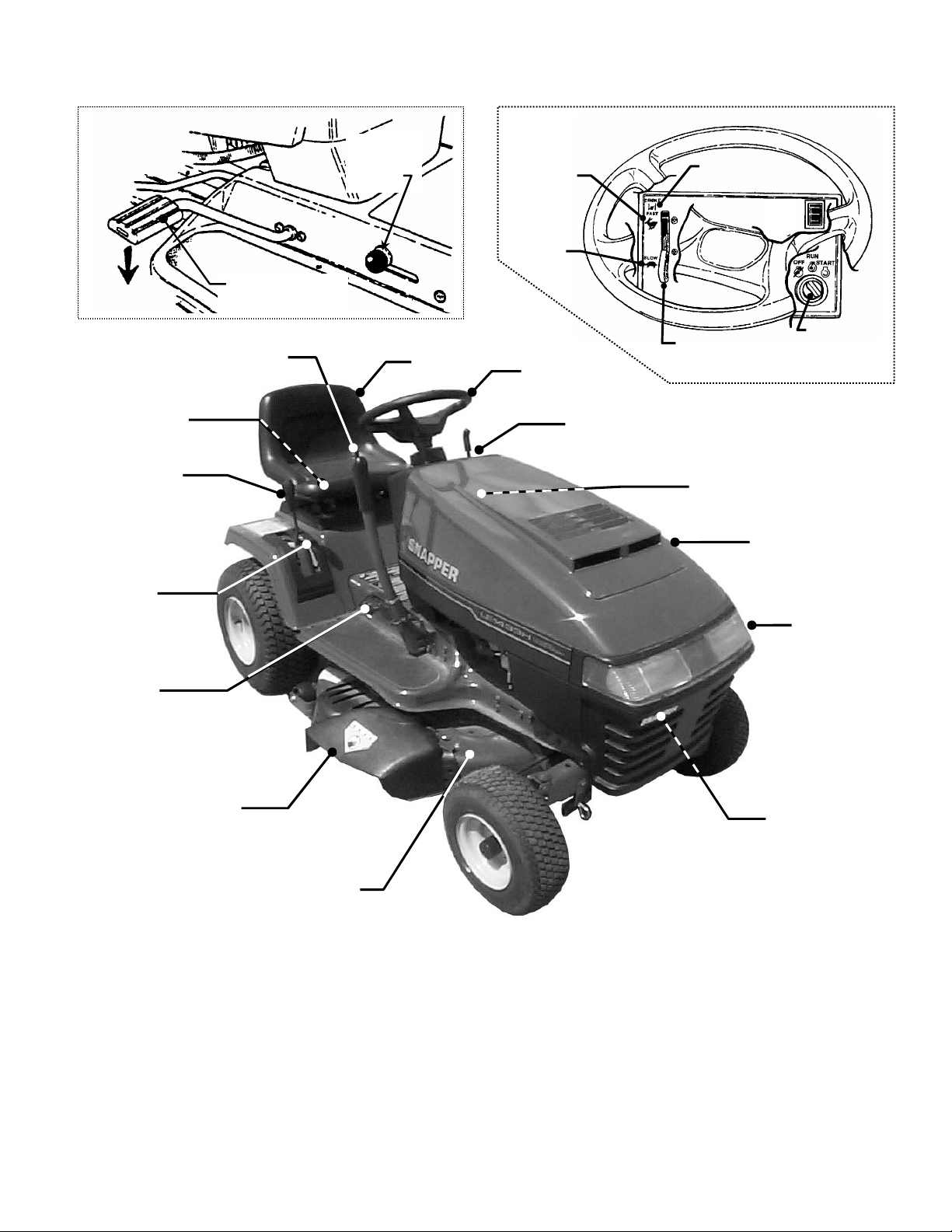

Section 1 - FAMILIARIZATION

(UNDER HOOD)

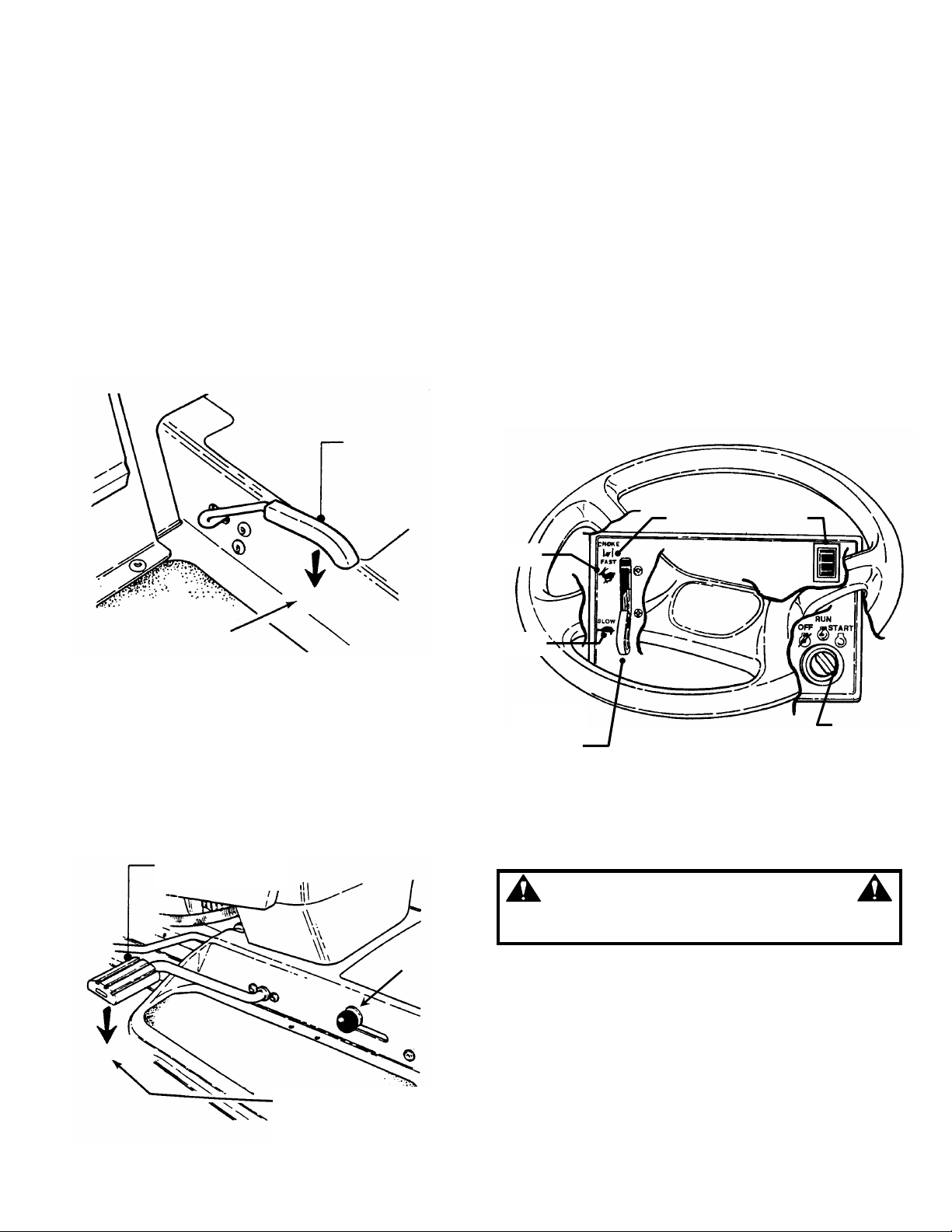

CONTROL PANEL

PEDAL

DOWN

CLUTCH/BRAKE

CUTTING HEIGHT

ADJUSTMENT LEVER

SEAT

ADJUSTMENT

KNOB

SPEED

CONTROL

LEVER

BATTERY

(UNDER SEAT)

OVERRIDE

LEVER

BLADE

ENGAGEMENT

LEVER

DISCHARGE

DEFLECTOR

MOWING DECK

(33” SHOWN)

COMPONENTS

The nomenclature drawings above, illustrate the

essential components of the SNAPPER Lawn Tractor. It

is recommended that all operators of this equipment

become thoroughly familiar with the components and

their operation BEFORE OPERATING.

Specific details involving the engine are found in the

separate Engine Owner’s Manual.

PARK

BRAKE

LEVER

OPERATOR’S

SEAT

FIGURE 1.1

FAST

SLOW

STEERING

WHEEL

DASHBOARD

CONTROLS

CHOKE

KEY

ENGINE SPEED

CONTROL

FUEL TANK

HOOD

HEADLIGHTS

ENGINE

Study the Important Safety Instructions, this Operator’s

Manual and Engine Owner’s Manual before operating

this machine. Keep these manuals available for future

reference.

CONTROLS

All operators should be acquainted with the operator’s

controls before attempting start-up or operation of the

Lawn Tractor. See the Control Panel drawing above.

6

Page 6

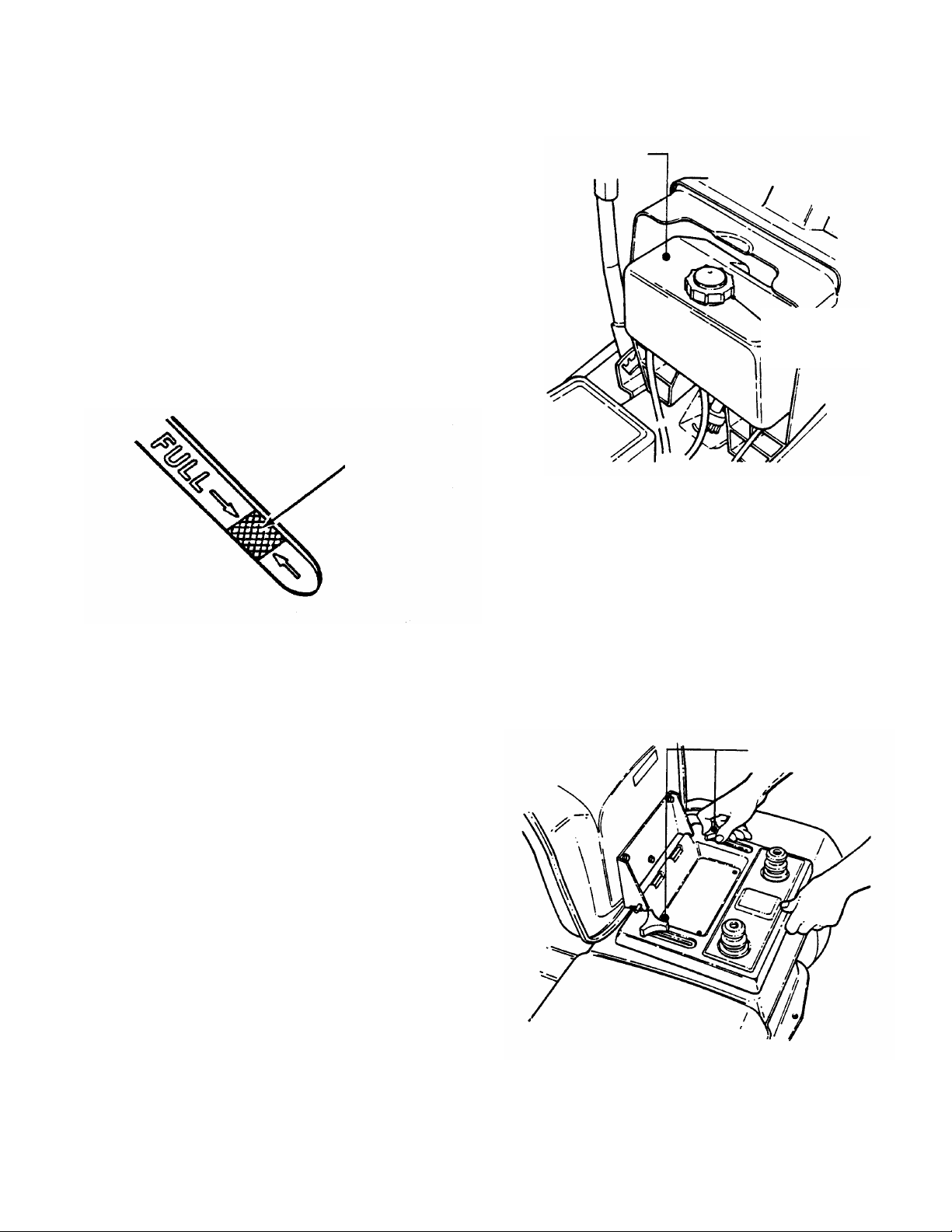

Section 2 - OPERATING INSTRUCTIONS

2.1 PRE-START CHECKLIST

Make the following checks and perform service as

required before each start-up.

2.1.1. Check tires and add air as needed to bring

pressure to 12 P.S.I. in front tires and 12 P.S.I. in

rear tires.

2.1.2. Check guards, deflector s and covers to make

sure all are in place and securely tightened. I f guards

are missing or damaged, replace BEFORE using

mower.

2.1.3. Check engine oil and add oil as needed to

bring level up to, but not over, the FULL mark . Ref er to

engine owner’s manual for oil specifications. See Figure

2.1.

SAFE

LEVEL

AREA

FIGURE 2.1

2.1.4. Check blade engagement lever to insure it

operates properly. The blade engagement lever

must be moved manually from “ON” to “OFF” to

stop blade.

2.1.5. Clean exterior surf aces of cutting deck , engine

and tractor of any accumulation of dirt, grass, oil, etc.

Keep engine air intake screens and cooling fins clean at

all times.

2.1.6. With engine “OFF” move the tractor outside

and add fuel to the fuel tank. Securely tighten fuel cap

after refueling. Refer to engine owner’s manual for fuel

specifications. See Figure 2.2.

2.1.7. Check Reverse Lockout Mechanism. With

engine “OFF”, rai se b l ade engagem ent lever to "ON".

The speed control lever cannot be shifted into

“Reverse”.

FUEL TANK

2.2 OPERATOR’S SEAT ADJUSTMENT

2.2.1. FRONT TO REAR ADJUSTMENT

1. With the engine "OFF", raise operator's seat and

loosen the two adjusting knobs on the seat support.

Lower the seat. Sit in the operator's seat and slide the

seat forward or backward until the clutch/brake pedal

can be fully depressed comfortably. Raise seat and

tighten the adjusting knobs to secure seat in position.

See Figure 2.3.

TIGHTEN CAP

AFTER

FILLING TANK

FIGURE 2.2

LOOSEN ADJUSTING

KNOBS TO ADJUST

SEAT

FIGURE 2.3

7

Page 7

Section 2 - OPERATING INSTRUCTIONS

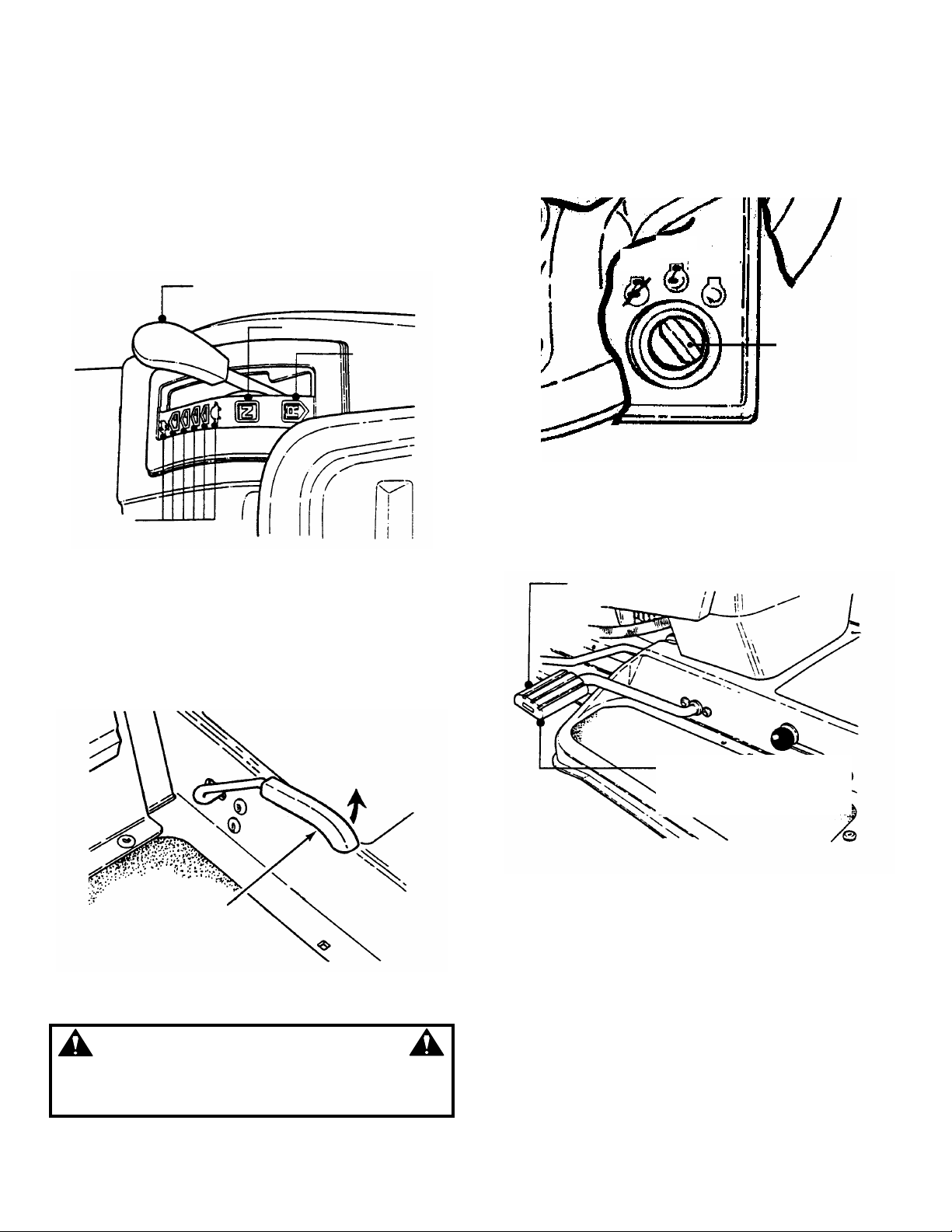

POSITION

SWITCH

2.3 STARTING & OPERATION

2.3.1. STARTING ENGINE

1. Take a comfortable position in seat of machine,

look around to make sure that the area you are going to

mow is clear of people, children and pets . Take note of

any stationary obstacles!

NOTE: The interlock system will prevent the engine from

starting if the blade engagement lever is in the "ON" (up)

position or if the c lutch/brak e pedal is not fully depressed. If

the interlock system ever f ails to work , DO NOT OPERAT E

the tractor until the interlock has been repaired.

2. Push blade engagement lever down to the "OFF"

position. See Figure 2.4.

BLADE

ENGAGEMENT

LEVER

5. Choke engine for cold s tarting by moving engine

speed control to "CHOKE" position. Little or no

choking will be needed when restarting a warm

engine. Insert key in switch. Turn key to "START"

position to crank engine and hold until engine starts,

then release key to “RUN” position. See Figure 2.6.

NOTE: DO NOT crank engine for more than five

seconds at a time. T his will help prevent the starter f rom

overheating and/or running down the battery. If cranking

time is more than f ive seconds, loc ate and correct cause

of starting problem.

6. After engine starts, release key, move the

engine speed control to "FAST" position and allow

engine to warm up before proceeding. See Figure

2.6.

OFF

PUSH BLADE

ENGAGEMENT LEVER

DOWN TO “OFF” TO

START ENGINE

FIGURE 2.4

3. Depress the clutch/brake pedal fully. See Figure 2.5.

4. Move speed control lever to neutral.

NOTE: T he seat interlock will shut off the engine if the

operator gets off the seat without setting the parking

brake or if the blade is running. If the interlock ever fails

to work, DO NOT OPERATE the tractor until the

interlock has been repaired.

CLUTCH/BRAKE

PARK BRAKE

LEVER

DOWN

PUSH PEDAL ALL THE

WAY DOWN TO START

ENGINE

FIGURE 2.5

CHOKE

FAST

SLOW

ENGINE

SPEED

CONTROL

LIGHT

KEY

FIGURE 2.6

WARNING

DO NOT leave machine with engine running. Stop

engine. Stop blade. Set parking brake. Remove key.

8

Page 8

Section 2 - OPERATING INSTRUCTIONS

MOWER BLADE(S)

KEY

2.3 STARTING & OPERATION (continued)

2.3.2. STARTING WHEEL DRIVE

1. Shift speed control lever to neutral.

2. Start engine. Refer to Section “STARTING

ENGINE”.

3. Release clutch/brake pedal.

4. Slowly shift speed control lever forward for

forward motion or to the rear f or revers e motion. See

Figure 2.7.

SPEED CONTROL LEVER

NEUTRAL

REVERSE

2.4 STOPPING ENGINE, BLADE, & WHEEL DRIVE

2.4.1. STOPPING ENGINE

1. Stop engine by turning key to the "OFF" position.

See Figure 2.9.

OFF

RUN

START

FORWARD

SPEEDS

FIGURE 2.7

2.3.3. STARTING MOWER BLADE

1. Start engine. Refer to Section “STARTING

ENGINE”.

2. Raise blade engagement lever to "ON". See

Figure 2.8.

PULL BLADE

ENGAGEMENT LEVER UP

TO “ON” TO START

ON

BLADE

ENGAGEMENT

LEVER

FIGURE 2.8

WARNING

DO NOT operate blades in reverse. STOP BLADES.

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

FIGURE 2.9

2.4.2. STOPPING WHEEL DRIVE

1. Fully depress clutch/brake pedal to stop wheel

drive. See Figure 2.10.

CLUTCH/BRAKE

PEDAL

FULLY DEPRESS

CLUTCH/BRAKE PEDAL TO

STOP WHEEL MOTION

FIGURE 2.10

9

Page 9

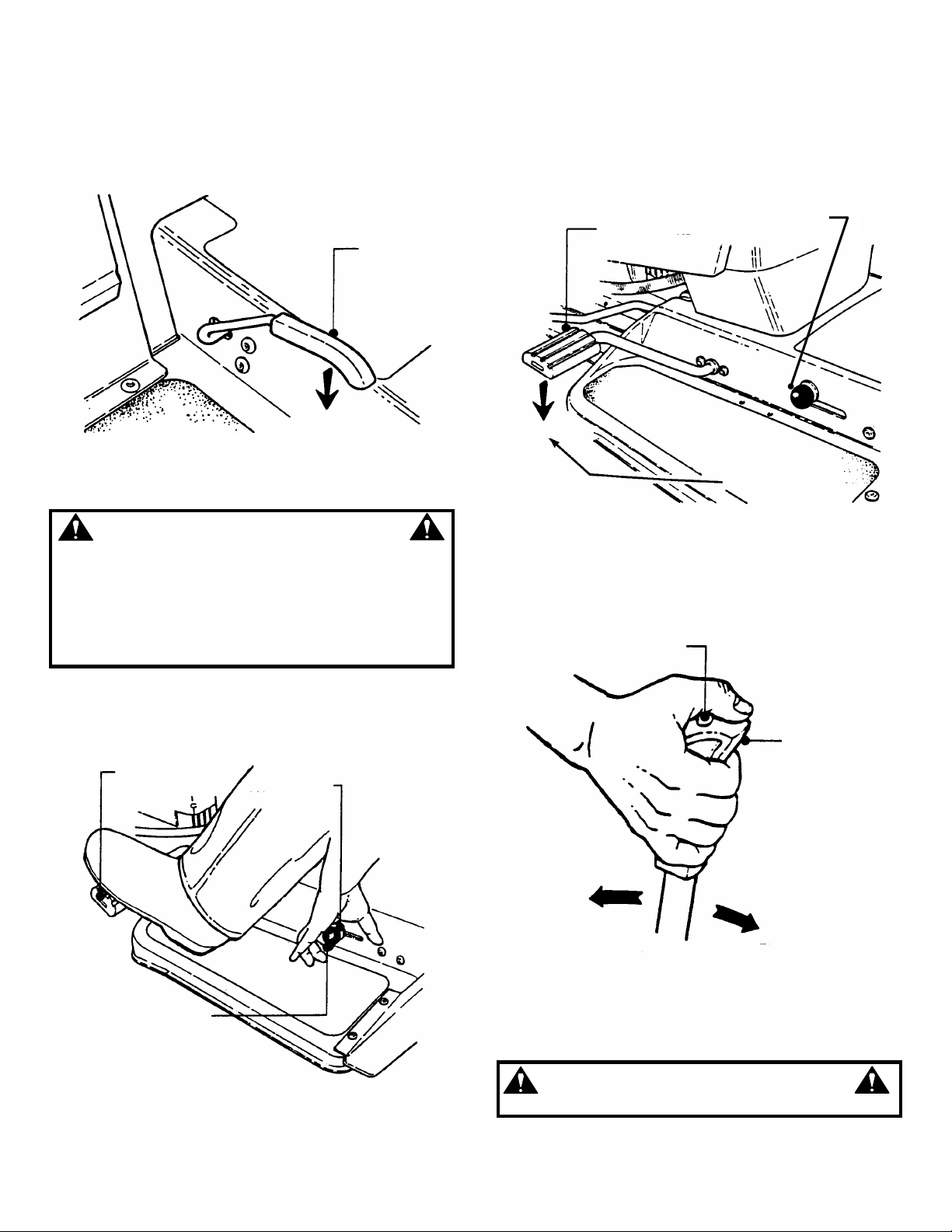

Section 2 - OPERATING INSTRUCTIONS

THE WAY DOWN

2.4 STOPPING

2.4.3. STOPPING MOWER BLADE

1. Stop mower blade by moving blade engagement

lever down to the "OFF" position. See Figure 2.11.

BLADE

ENGAGEMENT

LEVER

2.4.5. RELEASING PARK BRAKE

1. Fully depress clutch/brake pedal. Move park brake

lever “DOWN” to release park brake. Release

clutch/brake pedal. See Figure 2.13.

CLUTCH/BRAKE

PEDAL

PARK BRAKE

LEVER

OFF

FIGURE 2.11

WARNING

Once blade is disengaged, it should come to a

complete stop in 5 seconds or less. If the blade

continues to rotate after 5 seconds, the blade brake

must be adjusted. Refer to Section “BLADE BRAKE

ADJUSTMENT” for adjustment procedures or return

machine to dealer for adjustment. DO NO T CONTINUE

to operate mower until blade brake is properly adjusted.

2.4.4. SETTING PARK BRAKE

1. Fully depress clutch/brake pedal.

2. Move park brake lever up into slot. See Figure 2.12.

PUSH PEDAL ALL

PARK BRAKE

LEVER

FULLY DEPRESS

CLUTCH/BRAKE

PEDAL

FIGURE 2.13

2.5. CUTTING HEIGHT ADJUSTMENT

1. Depress lock button on c utting height adjustm ent

lever. See Figure 2.14.

DEPRESS

LOCK BUTTON

CUTTING

HEIGHT

ADJUSTMENT

MOVE PARK BRAKE

LEVER “UP” TO

ENGAGE PARK BRAKE

FIGURE 2.12

HIGHEST CUT

LOWEST CUT

FIGURE 2.14

2. Raise or lower deck to any of six positions as

desired. Release lock button.

WARNING

DO NOT park machine on slopes.

10

Page 10

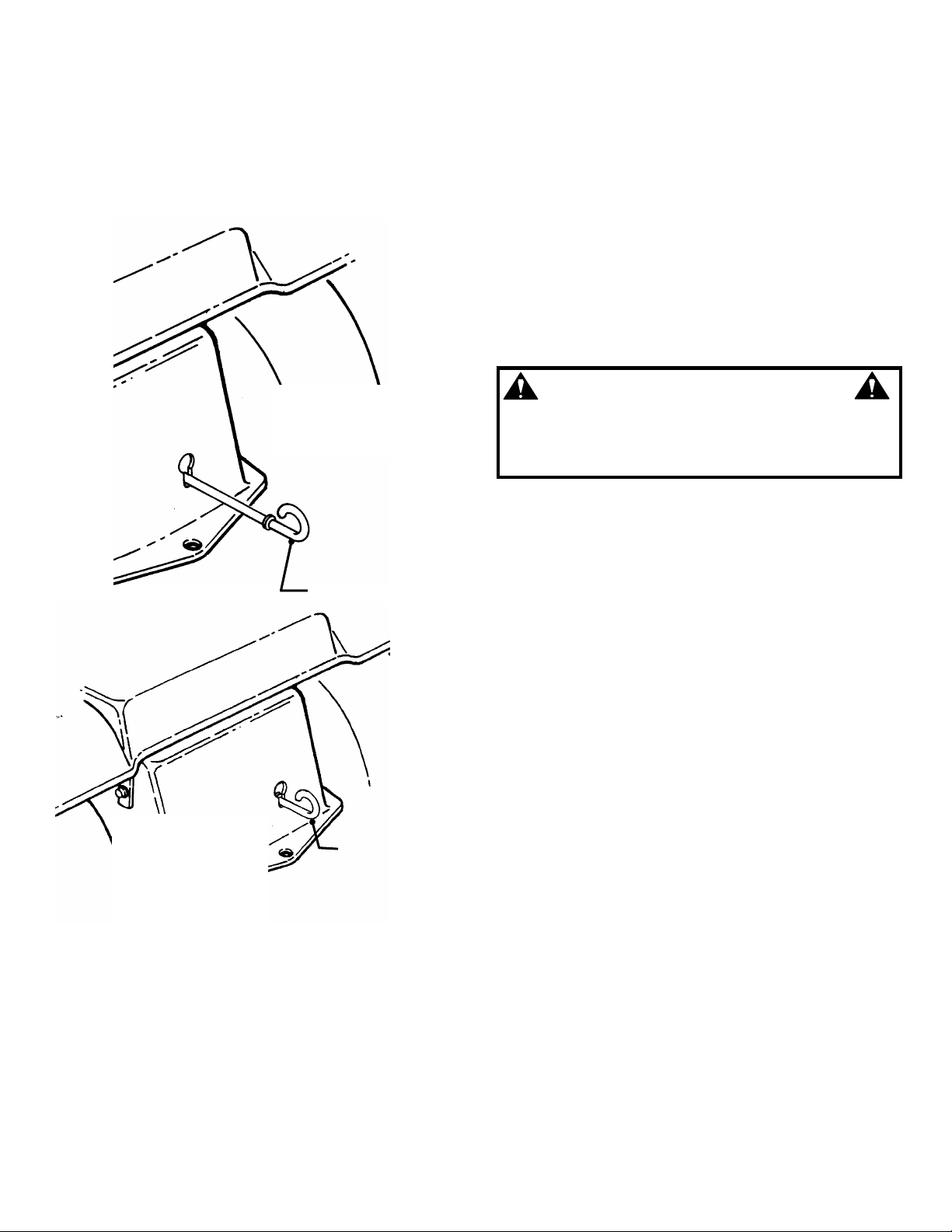

Section 2 - OPERATING INSTRUCTIONS

2.6. ROLLING TRACTOR WITH ENGINE OFF

2.6.1. Rolling Hydro Models

1. With engine "OFF", move to rear of tractor.

2. Pull the roll release control all the way out to

disengage the hydro transmission. See Figure 2.15.

PULL ROLL RELEASE

CONTROL ALL THE WAY

OUT TO DISENGAGE

HYDRO TRANSMISSION

PUSH ROLL RELEASE

CONTROL ALL THE WAY

IN TO ENGAGE HYDRO

TRANSMISSION

ROLL RELEASE

CONTROL

ROLL RELEASE

CONTROL

FIGURE 2.15

3. Move tractor to desired location.

4. Push roll release control all the way in to engage

hydro transmission. See Figure 2.15.

5. Set park brake.

NOTE: The transmission will not propel the tractor if it is

left in the "ROLL" position.

WARNING

DO NOT disengage the hydro transmission and coast

down slopes. DO NOT use Roll Release Control to

disengage the hydro transmission unless machine

motion can be controlled and engine is off.

11

Page 11

Section 2 - OPERATING INSTRUCTIONS

2.7. REVERSE LOCKOUT MECHANISM

Data indicates that tragic back-over accidents occur

each year. These accidents usually involve unsupervised

children. Many times these children have been given

rides on the mac hine and have been trained to view this

potentially dangerous piece of machinery as fun rather

than being taught how to avoid danger.

This riding mower has a Reverse Lockout Mechanism.

This mechanis m prevents the mower from being shifted

into reverse with the blades running. To shif t into reverse

you must first s top the blades and then s hif t to rever s e. It

is our recommendation that this mechanism remain

functional and the operator of this equipment develop the

habit of never backing up with the blades running. As the

Safety Instructions Indicate, DO NOT operate blades in

reverse. STOP BLADES, LOOK AND SEE BEHIND

AND DOWN for children, pets and hazards before

and while backing.

We realize that this could cause a change to your

previous mowing method but we encourage you to adjust

to this new system. Do not defeat the Reverse Lockout

Mechanism.

If you operate your mower near roadways or use

attachments that require quicker shifting to reverse,

there is an override lever provided. This lever can be

pushed and held before star ting the blades and will allow

reverse operation until the blade engagement lever is

moved to the “OFF” position, at which time the system

will return to its Reverse Lockout mode. This feature

should never be selected unless you are absolutely sure

that no children or others are present in the mowing area

and that all children are away and supervised by a

responsible adult.

2.7.1. Reverse Lockout Mechanism Override

1. Stop machine. Stop blades.

2. Depress and hold Override Lever.

3. Raise blade engagement lever to "ON".

4. Release override lever.

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

IMPORTANT! DO NOT use the Reverse Lockout

Mechanism Override as the nor mal operating mode. To

return to the Reverse Lockout Mechanis m mode, move

the blade engagement lever down to the “OFF” position.

The Override will reset to Reverse Lockout.

2.7.2. Check the Reverse Lockout Mechanism

Before each use, check the Reverse Lockout

Mechanism for proper function. Perform the following

check with the engine “OFF”.

1. With engine “OFF”, raise blade engagement

lever to "ON".

2. The Reverse Lockout Mechanism must

prevent the speed control lever from going into

reverse.

DO NOT operate machine if Reverse Lockout

Mechanism is not functioning properly. Contact your

SNAPPER dealer immediately for assistance.

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

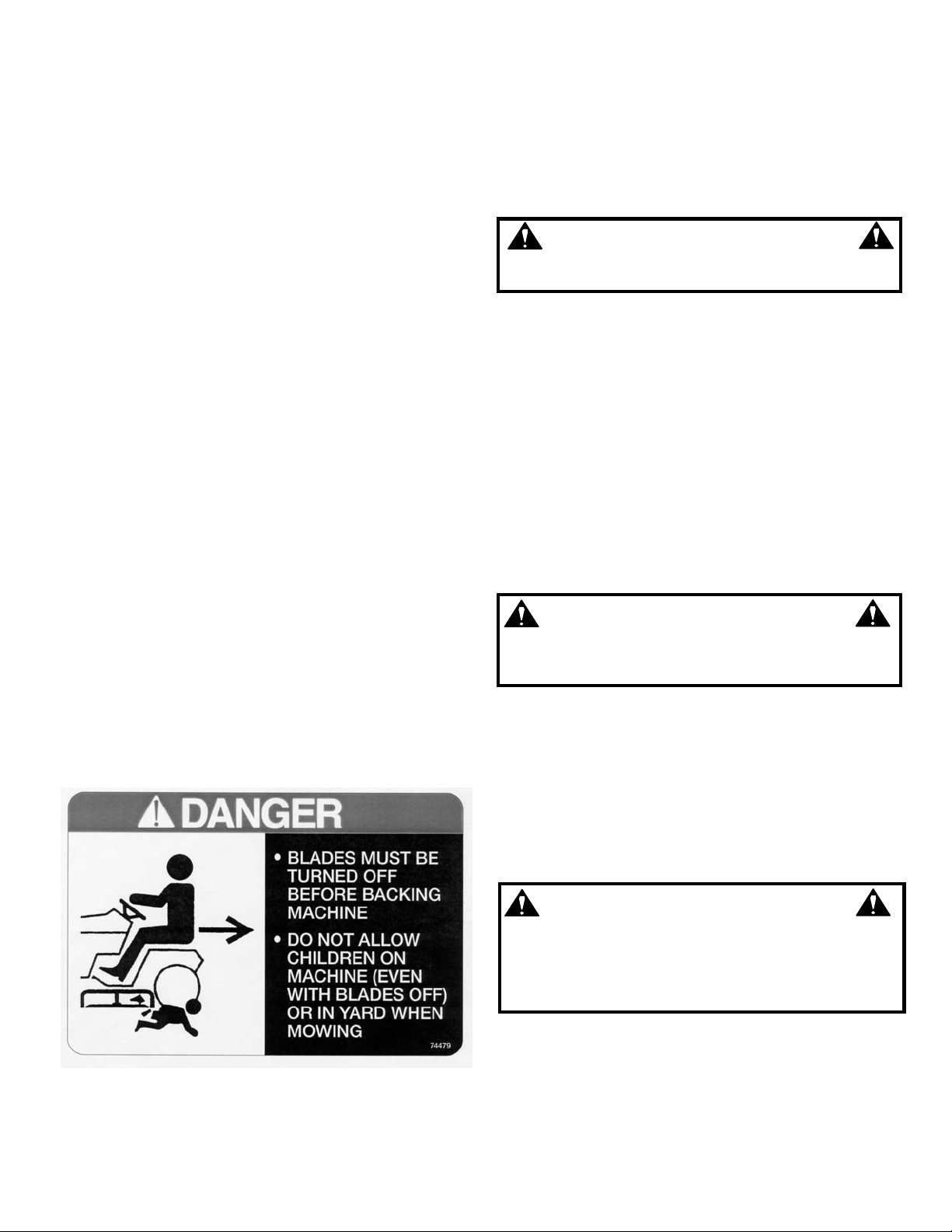

BLADES must be turned off before backing machine.

DO NOT allow children on machine (even with

blades off) or in yard when mowing.

WARNING

WARNING

DANGER

12

Page 12

Section 3 - MAINTENANCE

PICTURED

3.1 INTRODUCTION

To retain the quality of the Tractor, use genuine

SNAPPER replacement parts only. Contact a local

SNAPPER dealer for parts and ser vice assistance. For

the correct part or inform ation for a particular Tractor,

always mention the model and serial number.

SNAPPER recommends returning the Tractor to an

authorized SNAPPER dealer annually for inspection

and addition of any new devices, which might upgrade

the safety of the Tractor. For the nearest SNAPPER

dealer in your area, check the yellow pages under the

heading LAWN MOWERS. For engine parts and

service, look for the engine manufacturer’s dealers

under the heading, ENGINES - gasoline.

3.2 SERVICE - AFTER FIRST 5 HOURS

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blades running. STOP blades.

STOP engine. Set park brake. Remove key. Remove

spark plug wire from spark plug and secure wire away

from spark plug. Engine and components can be

extremely hot. Avoid burns by allowing engine and

components sufficient time to cool.

3.2.1. CHANGE ENGINE OIL

The engine is equipped with a Fastex™ oil drain.

1. Rotate drain body counterclockwise and pull out to

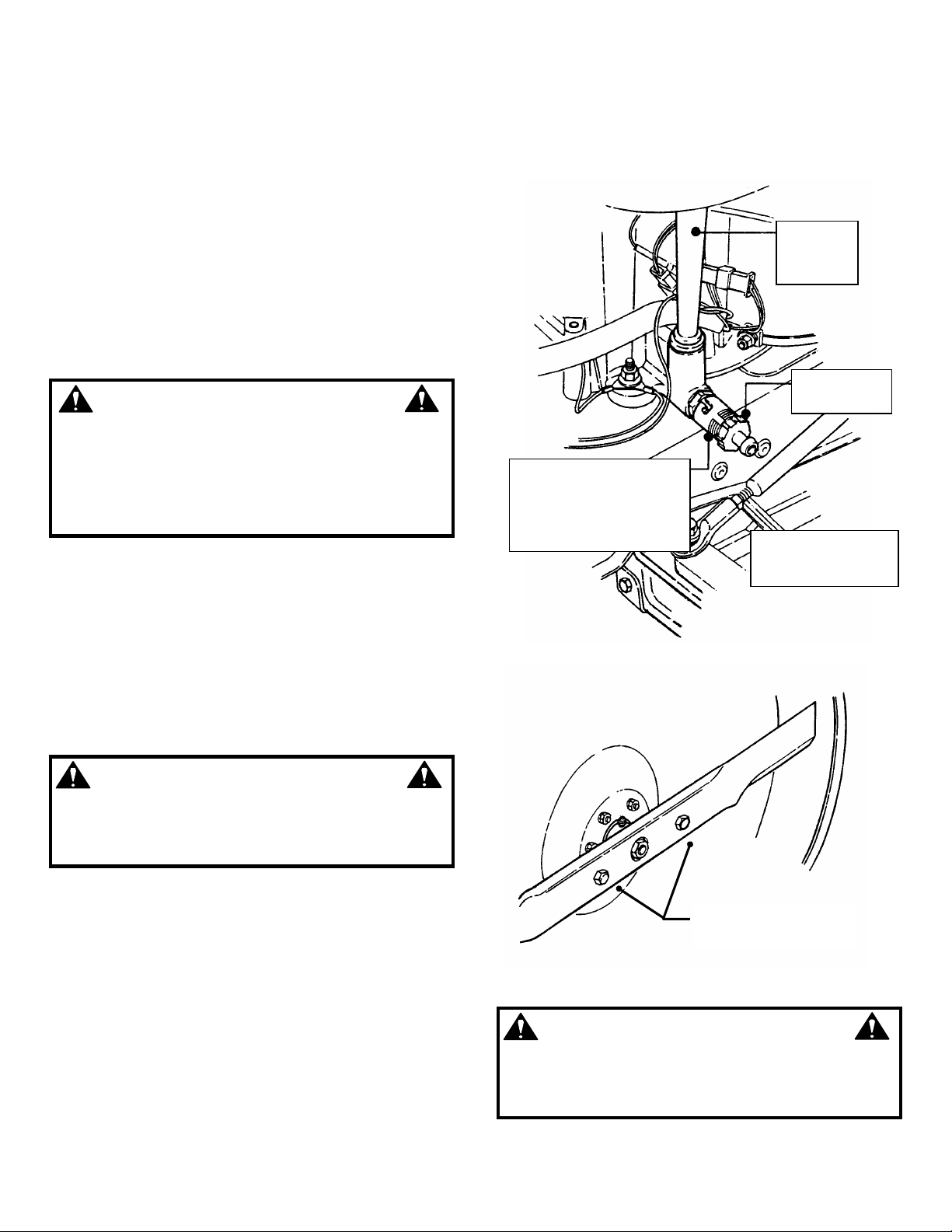

open drain. See Figure 3.1.

2. Drain oil into a 2 quart container placed beneath

end of oil drain.

3. After all oil has dr ained, push drain body "IN" and

rotate clockwise to close.

4. Fill engine with new motor oil as specified in engine

owner's manual.

“ADJUSTING MOWER BLADE”.

5. Check torque of blade mounting bolts. Torque to:

33” deck – 30 to 40 ft. lbs. See Figure 3.2.

38” deck – 70 to 80 ft. lbs. See Figure 3.3.

OIL

FILLER

TUBE

FASTEX™

OIL DRAIN

ROTATE COUNTERCLOCKWISE AND PULL

OUT TO OPEN.

PUSH IN AND ROTATE

CLOCKWISE TO CLOSE .

NOTE: BRIGGS &

STRATTON ENGINE

FIGURE 3.1

WARNING

The following procedure requires the engine and

blades to be operated. Exercise ext reme caution. Clear

area of loose parts & tools first. Only operate blades

when seated in the operator’s seat.

3.2.2. CHECK BLADE BRA KE

1. Check blade brake for proper function. Blades

should stop rotating in 5 seconds or less after moving

the blade engagement lever down to the OFF position.

2. If blades continue to rotate longer than 5 seconds

do not operate machine. Refer to Section “BLADE

BRAKE ADJUSTMENT” or contact your SNAPPER

dealer for assistance.

3.2.3. CHECK MOWER BLADE

1. Remove deck from tractor.

2. Carefully position deck to access blade.

3. Check blade for sharpness, wear and damage.

Refer to Section “BLADE WEAR LIMITS”.

4. Check blade for straightness. Refer to Section

TORQUE 33” BLADE TO

30 TO 40 FT. LBS.

FIGURE 3.2

WARNING

Blades must stop rotating in 5 seconds or less after

blades have been turned off . DO NOT operate machine

until blade brake has been adjusted and functioning

properly. Contact your SNAPPER dealer for assistance.

13

Page 13

Section 3 - MAINTENANCE

3.2.3. CHECK MOWER BLADE (Continued)

TORQUE 38” BLADES TO

70 TO 80 FT. LBS.

FIGURE 3.3

3.2.4. CHECK 33" DECK DRIVE BELT

1. With engine "OFF", move blade engagement

lever to "ON".

2. Measure blade cable extension spring. Spring

should extend 1" +/-1/8" for proper belt tension. See

Figure 3.4.

BLADE CABLE

EXTENSION SPRING

3. To adjust tension, Refer to Section “BLADE

BELT ADJUSTMENT”.

3.2.5. CHECK 38” DECK DRIVE BELT

1. On 38" m odel, check belt for excessive wear or

damage and replace if necessary, there are no

adjustments on this model.

3.3 SERVICE - EVERY 25 OPERATING HOURS

3.3.1. CHECK ENGINE

1. Change engine oil. Refer to Section “CHANGE

ENGINE OIL”. Refer to engine owner's m anual for oil

specification.

X

X + 1” +/- 1/8”

FIGURE 3.4

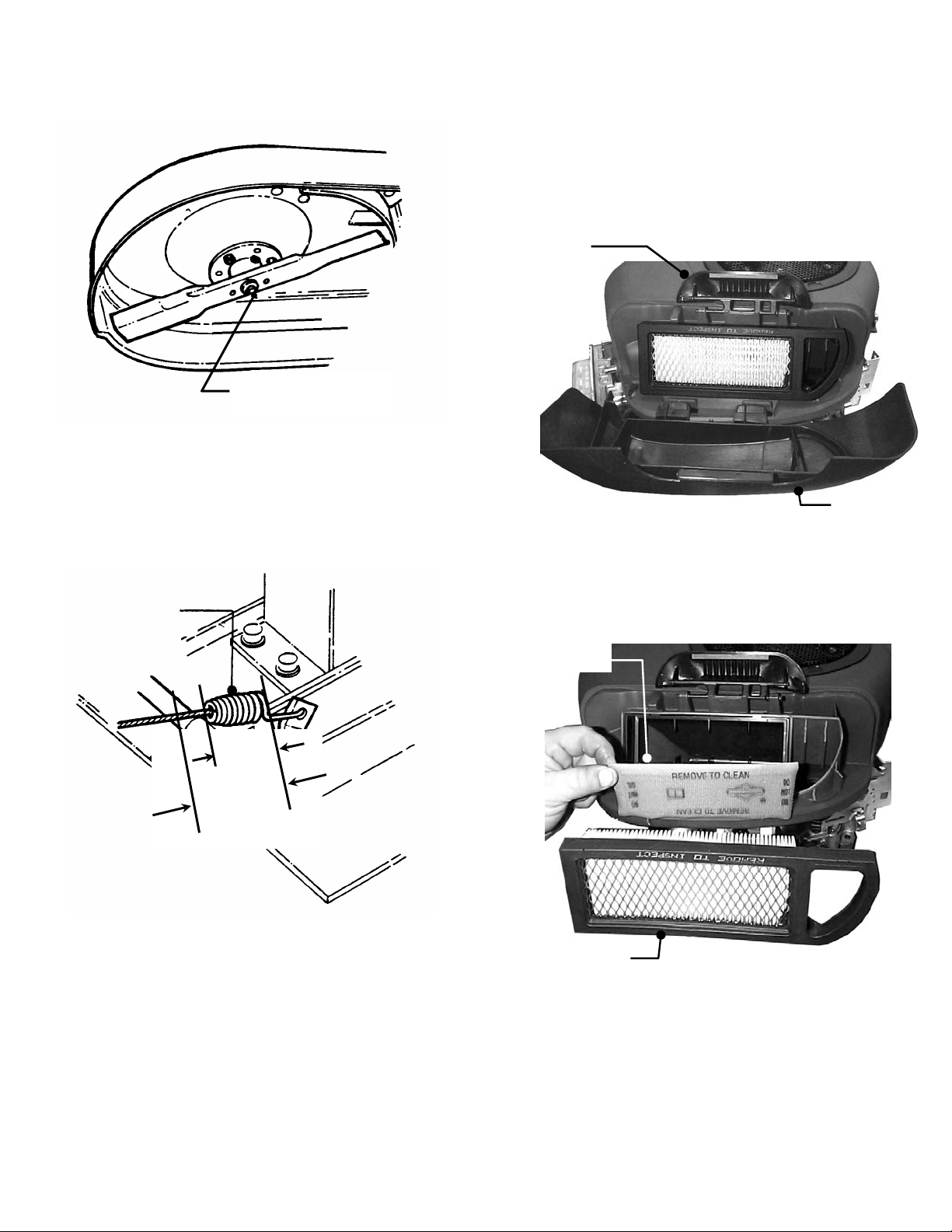

2. Change air filter. Pull up and rotate the air cleaner

latch to remove cleaner cover. See Figure 3.5.

IMPORTANT: When cover is removed, you are

viewing the carburetor side of the air filter, which will

appear clean. Remove filter and pre-cleaner for

inspection.

AIR CLEANER

LATCH

AIR CLEANER

COVER

FIGURE 3.5

2. Refer to engine owner's manual for cleaning and

service instructions. Remove and clean engine air

pre-cleaner. Remove and replace engine air cleaner.

See Figure 3.6. Install pre-cleaner and air cleaner

per engine owner’s manual.

AIR PRECLEANER

AIR CLEANER

FIGURE 3.6

3. Reinstall air cleaner cover. Insert tabs located at

the bottom of the cover into corresponding slots in

engine cover. Position cover and engage latch over

cover and rotate and push down to lock.

14

Page 14

Section 3 - MAINTENANCE

FUEL TANK

GEAR

3.3.2. MOWER COMPONENTS

1. Check deck drive belt for proper tension. Refer

to Section “CHECK DECK DRIVE BELT”.

2. Check blades for sharpness, wear, damage and

torque. Refer to Section “MOWER BLADE

REPLACEMENT”.

3. Check mower deck for proper levelness. Refer

to Section “MOWER DECK ADJUSTMENT LEVELNESS”.

4. Clean mower deck.

a. Remove key from ignition switch.

b. Remove deck.

c. Clean underside of mower deck, removing all

accumulation of grass clippings and debris.

d. Clean top of deck, removing all grass clippings

and debris.

5. 33" and 38” blade spindle lubrication.

a. Lubricate spindle with 1 to 3 shots of general

purpose grease from grease gun.

6. Lubricate all mower deck linkage pivot points

with a light coat of motor oil.

3.3.3. CHECK BLADE BRAKE

1. Refer to Section “CHECK BLADE BRAKE”.

3.3.4. TRACTOR LUBRICATION

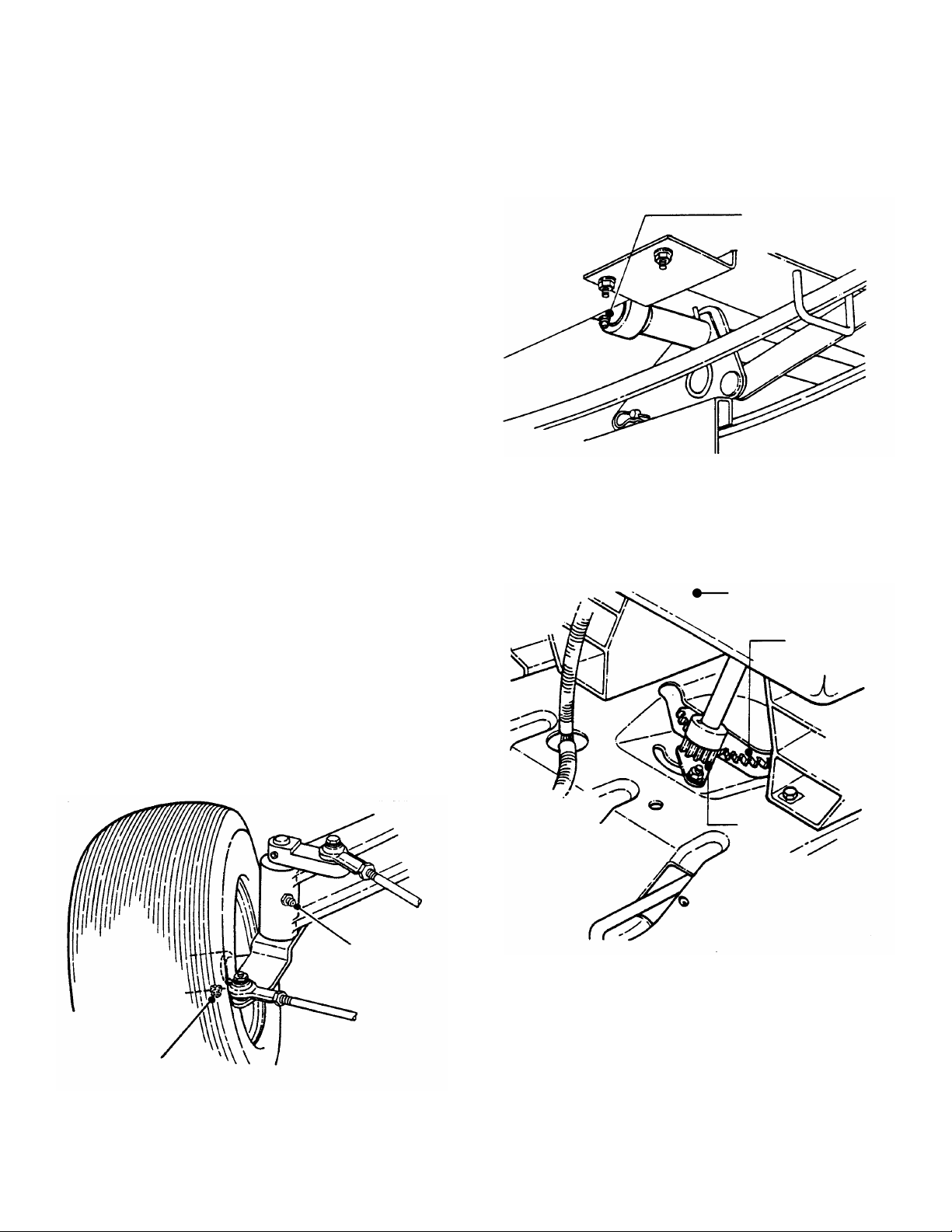

1. Front Wheel Bearings

Lubricate each front wheel bearing through the

grease fitting on wheel hub. Using general purpose

grease in a grease gun, add grease until grease

purges from bearing. See Figure 3.7.

2. Axle Spindles

Lubricate each axle spindle with 1 to 3 shots of

general purpose grease. See Figure 3.7.

NOTE: T he right hand spindle fitting faces forward and

the left hand spindle fitting faces to the rear.

3. Clutch/Brake Pivot

The clutch/brake pivot is located on the left hand

underside of the tractor and is lubricated with one

shot of general purpose grease. See Figure 3.8.

CLUTCH/BRAKE

PIVOT LUBRICATION

FITTING

FIGURE 3.8

4. Steering Sector Gear

Lubricate with a light coat of general purpose grease.

See Figure 3.9.

STEERING

SECTOR

FRONT WHEEL

BEARING LUBRICATION

FITTING

FIGURE 3.7

AXLE SPINDLE

LUBRICATION

FITTING

SECTOR

FIGURE 3.9

5. Steering Shaft

Lubricate steering shaft wear points with a light coat

of SAE30 oil.

15

Page 15

Section 3 - MAINTENANCE

POINT

6. Steering Drag Link

Lubricate both ends of steering drag link with a sm all

amount of SAE30 oil. See Figure 3.10.

DRAG LINK

LUBRICATION

LUBRICATE

COMPONENTS ON

UNDERSIDE OF

TRACTOR

BLADE

ENGAGEMENT

LEVER

FIGURE 3.10

3.3.4. TRACTOR LUBRICATION

(Continued From Previous Page)

7. Steering Tie Rod

Lubricate both ends of steering tie rod with a small

amount of SAE30 oil. See Figure 3.11.

LUBRICATE

BOTH ENDS

OF TIE ROD

FIGURE 3.11

8. Blade Engagement Mechanism

Using SAE30 oil, lubricate the blade engagement

mechanism pivot points, which are located on the

R.H. underside of tractor. See Figure 3.12.

FIGURE 3.12

9. Park Brake Lever

Using general purpose grease, lubricate the park

brake lever mechanism pivot points, which are

located on the left hand underside of tractor. See

Figure 3.13. Mechanism with a thin coat of 30 wt.

motor oil.

PARK BRAKE

LEVER

LUBRICATE COMPONENTS

ON UNDERSIDE OF TRACTOR

FIGURE 3.13

10. Deck Lift Mechanism

Lubricate all wear and pivot points of the deck lift

3.4 SERVICE - ANNUALLY

Perform all maintenance as described in Section

“SERVICE - EVERY 25 OPERAT ING HOUR S”. Also

see service schedule.

3.4.1. ENGINE

1. Service engine according to engine owner's

manual.

16

Page 16

Section 3 - MAINTENANCE

3.4 SERVICE - ANNUALLY

3.4.2. FUEL FILTER

1. Service fuel filter as ins tructed below, on COLD

ENGINE ONLY!

NOTE: It m ay be necessary to drain the fuel tank bef ore

removing fuel filter to prevent spillage of gasoline.

2. Locate fuel filter. Remove hose clamps and fuel

hoses from both sides of fuel filter. See Figure 3.14.

FUEL TANK

FUEL FILTER

REMOVE

HOSE CLAMPS

FIGURE 3.14

3.4 SERVICE - ANNUALLY

3.4.2. FUEL FILTER

(Continued From Previous Page)

3. Install new fuel filter part number 1-4359. See

Figure 3.15.

NEW FUEL FILTER

PART NUMBER 1-4359

FIGURE 3.15

4. Fill fuel tank with fresh gasoline. Ref er to engine

owner's manual for fuel specifications.

3.4.3. SPARK PLUG

Remove and replace engine spark plug. Refer to

engine owner's manual for corr ect replacement plug

and gap specifications.

3.4.4. HYDROSTATIC TRANSMISSION OIL

The hydrostatic transmission does not require

maintenance. If any problems arise return

immediately to an authorized Snapper dealer.

17

Page 17

Section 4 - ADJUSTMENT & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.1 ENGINE ADJUSTMENTS & REPAIR

Refer to the engine owner's manual for those

adjustments and/or repairs that can be made by the

owner.

4.2 MOWER DECK & COMPONENT ADJUSTMENTS

The following mower deck and component adjustments

and repairs can be made by the owner. However, if there

is difficulty in achieving these adjustments and repairs, it

is recommended that these repairs be made by an

authorized SNAPPER dealer.

WARNING

Blades must stop rotating in 5 seconds or less after

blades have been turned off. DO NOT operate

machine until blade brake has been adjusted and

functioning properly. Contact your SNAPPER dealer

for assistance.

4.2.1. BLADE BRAKE ADJUSTMENT

The blade brake when properly adjusted will stop

blade rotation in 5 seconds or less when the blade

engagement lever is moved to the OFF position.

33” DECK BLADE BRA KE A DJUS TMENT

1. Blade brake adjustment is made by turning the

adjustment nut on the thr eaded brake rod. The brak e

is initially set with 1-3/16” of thread exposed beyond

the nut. See Figure 4.1. Verify this setting before

attempting any adjustments. To tighten the brake

(stop blade rotation quicker) turn the adjustment nut

clockwise – ONE TURN ONLY.

IMPORTANT: DO NOT over-tighten blade brake.

Tighten one turn and check f unction of brak e. If blade

stop time remains over 5 seconds, turn adjustment

nut 1 to 2 turns clockwise. If blade stop tim e remains

over 5 seconds, DO NOT OPERATE machine.

Contact your SNAPPER dealer for assistance.

38” DECK BLADE BRA KE A DJUS TMENT

The 38” deck requires no blade brake adjustment.

Blades must stop in 5 sec onds or les s af ter blades have

been turned off. If blades c ontinue to r otate, contac t your

authorized SNPPER dealer for assistance.

DO NOT operate machine unt il blade brake has been

repaired and functioning properly. If blade stop time

can not be achieved with the adjustment procedure

described above, take machine immediately to an

authorized SNAPPER dealer.

1-3/16”

FIGURE 4.1

WARNING

18

Page 18

Section 4 - ADJUSTMENT & REPAIR

SPRING

LEAST TENSION

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remove key. Remove spark

plug wire from spark plug and secure wire away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool. If deck f ront to rear level is not

correct, this could cause blade belt problems.

4.2.2. BLADE BELT ADJUSTMENT – 33” DECK

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Move blade engagement lever down to "OFF". See

Figure 4.2.

4. Place deck in mid cutting position.

5. Check front to rear level. Ref er to Section “33 DECK

LEVEL ADJUSTMENT (FRONT TO REAR)”.

MOVE BLADE

ENGAGEMENT

LEVER TO “OFF”

8. (33" Deck) T o adjust tension, rem ove extension rod

mounting bolt and nut. See Figure 4.4.

9. Move extension rod to next hole towards rear of

deck and secure with mounting bolt and nut.

10. Measure extension spring with blade engagement

lever in the "ON" and "OFF" positions. See Figure 4.3.

Continue adjustment until tension is correct.

IMPORTANT: Blade brake function must be verified

after performing blade belt adjustment.

11. Check blade brake. Refer to Section “CHECK

BLADE BRAKE”. Blades must stop rotating in 5

seconds or less when turned off.

MOST TENSION

FIGURE 4.2

IMPORTANT: If deck f r ont to rear level is not cor r ect, this

could cause blade belt problems.

6. Move blade engagement lever to "ON".

7. Measure blade cable extension spring. The length of

the spring (x) should increase by 1” (+/-1/8”). See Figure

4.3.

BLADE CABLE

EXTENSION

X

X + 1” +/- 1/8”

FIGURE 4.3

EXTENSION

ROD

MOUNTING

NUT & BOLT

FIGURE 4.4

4.2.3. BLADE BELT ADJUSTMENT – 38” DECK

The blade belt on the 38” deck requires no tension

adjustment. If the belt becom es worn or damaged it mus t

be replaced. Refer to Section “BLADE BELT REMOVAL &

REPLACEMENT”.

4.2.4. ADJUSTING MOWER BLADE – 33” DECK

(33" Decks Only; no adjustment for 38")

1. Select a point on the deck and mark for reference.

2. Mark blade tips as “A” and “B”.

3. Rotate blade until blade tip “A” is at deck

reference mark

4. Measure the distance between deck lip and

blade tip. Note the measurement. See Figure 4.5.

(Continued on next page)

19

Page 19

Section 4 - ADJUSTMENT & REPAIR

LOOSEN PIVOT BOLT

BOLT

BLADE TIP

JAM

NUT

JACK SCREW

4.2.4. ADJUSTING MOWER BLADE – 33” DECK

(Continued from previous page)

MEASURE THE DISTANCE

BETWEEN DECK LIP AND

4.2.5. 33" DECK LEVEL ADJUSTMENT (SIDE TO SIDE)

NOTE: Adjust tire pressure, 12 P.S.I. front and rear,

before adjusting deck.

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Place a piece of angle iron under center rear of deck.

4. Remove hair pins and washers sec uring rear of dec k

to sector plates. See Figure 4.7.

5. Slide sector of f of pins and carefully lower deck onto

angle iron.

6. Rotate blade(s) until blade tips are at each side of

deck.

7. Measure distanc e from blade tip to f loor on each s ide

of deck. Blade tips should be within 1/8" of eac h other for

the deck to be considered level. See Figure 4.8.

SECTOR PLATE

FIGURE 4.5

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

NOTE: On 33” decks, the measurement between the blade

tip and deck lip should be 5/16".

5. Repeat steps 2 and 3 with blade tip “B”.

6. If measurement between blade tips and deck are

different and there is m ore than 1/16” difference between

blade tip measurements, adjust blade as follows:

a. Loosen jam-nuts on blade bar.

b. Adjust jack screws “IN” or “OUT” until blade

tip measurements are within 1/16” of each other.

See Figure 4.6.

c. Tighten jam-nuts.

LOOSEN JAM NUTS, ADJUST

JACK SCREWS “IN” OR

“OUT” TO LEVEL BLADE WITH

SIDE VIEW OF DECK

FIGURE 4.6

8. If measurement differs more than 1/8", adjust as

follows:

a. Loosen front lift arm pivot bolt on front of right side rail.

See Figure 4.9.

LOOSEN SHOULDER

20

REMOVE

HAIRPIN &

WASHER

33” DECK SHOWN

SIDE TO SIDE VIEW

MEASURE

FROM BLADE

TIPS TO F LOOR

FIGURE 4.7

ANGLE IRON

FIGURE 4.8

TURN ECCENTRIC

FIGURE 4.9

Page 20

Section 4 - ADJUSTMENT & REPAIR

WASHER

FRONT

TIPS TO F LOOR

NUT

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.2.5. 33" DECK LEVEL ADJUSTMENT

(SIDE TO SIDE)

(Continued from previous page)

b. Loosen eccentric shoulder bolt.

c. Turn eccentric "UP" or "DO W N" as required to level

deck. See Figure 4.9.

d. Tighten eccentr ic bolt. Plac e s ec tor plates bac k onto

rear lift arms and secure with washers and hairpins.

4.2.6. 33" DECK LEVEL ADJUSTMENT

FRONT TO REAR - SECTOR PLATES

1. Remove hair pins and washers securing sector

plates to rear lift arms. See Figure 4.10.

SECTOR PLATES

33” DECK SHOWN

REAR

X + 1/4”

MEASURE FROM BLADE

FIGURE 4.11

4.2.7. 33" DECK LEVEL ADJUSTMENT

FRONT TO REAR - FRONT LIFT ROD

If the sector plates are in their lowest setting and proper

level cannot be obtained, adjust the front lift rod as

follows:

1. Move deck lift lever to #5 position.

2. Place a 2 x 4 wooden block on edge under front

center of deck.

3. Place a 3 x 3 wooden block under rear center of

deck.

4. Remove hair pins and washers securing sector

plates. Lower rear of deck onto 3 x 3 block.

5. Remove hair pin and washer sec uring f r ont lif t rod

to front lift arm. See Figure 4.12.

HIGHEST

DECK

SETTING

REMOVE HAIR PIN &

LOWEST DECK

SETTING

FIGURE 4.10

2. Move sector plate as required to raise or lower deck.

NOTE: The deck should be set so that the rear of the deck

is 1/4" lower than the front. See Figure 4.11.

JAM

HAIR PIN

WASHER

FRONT LIFT ROD

FIGURE 4.12

6. Remove front lift rod and c arefully rest front of deck

onto 2 x 4 block.

7. Loosen jam nut on front lift rod. See Figure 4.12.

8. Turn front lift rod hanger block until it can be

reinstalled into front lift arm without lifting deck.

9. Secure lift rod to lift arm with washer and hair pin.

10. Place sector plates onto r ear hanger br ackets and

secure with washers and hair pins.

11. Raise deck and remove wooden blocks.

12. Repeat steps for f ront to rear level until levelness

is acquired.

21

Page 21

Section 4 - ADJUSTMENT & REPAIR

SIDE TO SIDE LEVEL CHECK POINTS

ROD

ADJUSTER NUT

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.2.8. 38" DECK LEVEL ADJUSTMENT

(SIDE TO SIDE)

NOTE: Before adjusting deck, bring tire pressure to

proper P.S.I.; front 12 P.S.I., rear 12 P.S.I..

1. Move tractor to a firm, level surface.

2. Turn engine “OFF”. Remove key.

3. Place a 2-1/2” tall block under the f ront of the deck

centered between the front lift arms. See Figure 4.13.

FRONT OF TRACTOR

38” DECK

JAM NUT

WASHER

FRONT LIFT

HAIR PIN

FIGURE 4.14

9. If the differ ence is less than 1/8", go to nex t section,

Front to rear level. If the difference is more than 1/8",

adjust as described in the following steps.

10. Loosen the f ront adjuster nut until adjus ter moves

freely. Then tighten the nut until the adjuster moves only

when moderate forc e is applied to one side of the dec k.

See Figure 4.15.

2-1/2” TALL BLOCK

1-3/4” TALL

BLOCK

FIGURE 4.13

4. Place a 1-3/4" tall block under the rear of the deck in

the center. See Figure 4.13.

5. Position blades as shown and lower deck onto

blocks. See Figure 4.13.

6. Disconnect the front lift rod and the rear hanger

plates. See Figure 4.14.

7. Put the lift lever in the 3rd position from low cut.

8. Measure the distance from each blade tip to the

floor. The measur ements should be within 1/8" of each

other. (Factory setting)

FRONT OF TRACTOR

11. Adjust the side to side level of the blade tips by

moving one side of the deck up or down as needed to

obtain 1/8" or less side to side deck level.

12. After leveling deck, retighten the adjuster nut using

30 to 40 ft. lbs.

13. Attach the rear hanger plates to the hole that most

closely aligns with the pin on the deck lift bracket. Secure

with washer and hair pin.

14. Adjust the swivel on the front lift rod until it lines up

with the hole in the front lift bracket. (Mak e sure the lift

rod is at the top of the slot in the deck bracket) Sec ure

with hair pin.

FIGURE 4.15

22

Page 22

Section 4 - ADJUSTMENT & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.2.9. 38" DECK LEVEL ADJUSTMENT

(FRONT TO REAR)

1. Position the blades as shown. See Figure 4.16.

FRONT OF TRACTOR

LEFT FRONT

BLADE TIP

X

4.3 TRACTOR DRIVE COMPONENTS

4.3.1. BRAKE ADJUSTMENT

When adjusted properly, the brake should stop the

tractor in approximately 6 feet or less from top speed.

Drive the machine at maximum forward speed and

apply the brake. If s topping distance is greater than 6

feet, brake adjustment is required.

1. Turn engine “OFF”. Remove key.

2. Locate brake adjustment nut underneath the left side

at the rear of tractor. See Figure 4.18.

3. Turn nut 1 turn clockwise to increase braking

action. DO NOT over tighten brake adjustment.

4. Start engine and test brake.

5. Continue adjustment as described above until

proper brake function is achieved.

REAR TO FRONT VIEW OF DECK

ANGLE IRON

FIGURE 4.17

X - 1/8”

RIGHT REAR BLADE TIP

FIGURE 4.16

2. Measure the distanc e from the left front blade tip to

the ground and from the right rear blade tip to the ground.

The front left blade tip s hould be between 1/8" and 3/8"

higher than the right rear (factory setting). If it is between

1/8" and 3/8" you are finished with adjustment.

3. If it is not within specifications, adjust by raising or

lowering the front of the deck using the s wivel on the front

lift rod. Turning the swivel clock wise will raise the front of

the deck. Turning the swivel counterclockwise will lower

the front of the deck.

NOTE: The deck should be set so that the rear of the deck

is 1/4" lower than the front. See Figure 4.17.

ROTATE ADJUSTING NUT CLOCKWISE TO

INCREASE BRAKING OR COUNTER

CLOCKWISE TO DECREASE BRAKING

FIGURE 4.18

23

Page 23

Section 4 - ADJUSTMENT & REPAIR

REDUCE FORWARD CREEP

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.3.2. STEERING ADJUSTMENT

Should excessive “Play” be noted in the steering,

adjust as follows:

1. Turn engine “OFF”. Remove key.

2. From left s ide of trac tor , locate the s teer ing s ector

below fuel tank. See Figure 4.19.

FUEL TANK

ROTATE TO

REDUCE “PLAY”

ECCENTRIC

MOUNTING NUT

4. Turn the neutral adjustment nut 1/4 turn clockwise

to reduce FORW ARD creep. T urn the adjustm ent nut

1/4 turn counter cloc kwise to reduce Reverse creep.

Only turn the adjustment nut in 1/4 turn increments.

5. Check for creep in neutral. Start engine. Move

speed control lever to rear edge of the neutral detent.

Machine should not move. If further adjustment is

required, stop engine and repeat Step 4.

NEUTRAL

ADJUSTMENT

NUT

TURN NUT CLOCKWISE TO

FIGURE 4.20

FIGURE 4.19

3. Loosen the eccentric m ounting nut and rotate the

eccentric clockwise until steering “Play” is reduced.

See Figure 4.19.

4. Tighten eccentric mounting nut.

4.3.3. SHIFTER ADJUSTMENT

The shift linkage is set at the factory and should not

require further adjustment. The shifter is adjusted

properly when the speed control lever can be placed

at rear edge of the neutral detent and the tractor

remains absolutely stationary. If motion is detected,

neutral adjustment will be required. DO NOT operate

a machine that creeps when shifted to neutral.

1. Stop engine. Remove key.

2. Move speed control lever to rear edge of neutral

detent and hold firmly.

3. Locate neutral adjustment nut underneath the

right rear of the tractor. See Figure 4.20

WARNING

DO NOT adjust shift linkage with engine running. The

adjustment requires hands to be close to rotating

parts. STOP engine. REMOVE key.

24

Page 24

Section 4 - ADJUSTMENT & REPAIR

4.3.4. TRACTION DRIVE BELT ADJUSTMENT

Should a gradual loss of traction be noticed, it m ay be

necessary to adjust the traction drive belt tension.

Adjust as follows:

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Remove mowing deck.

4. Remove the traction drive belt stationary idler

mounting bolt. See Figure 4.21.

5. Move the stationary idler one hole towards left side

of tractor for more belt tension.

NOTE: Note the orientation of belt guide and make certain

it remains in the same orientation after moving idler.

NOTE: Should less tension be required move stationary

idler towards right side of tractor. See Figure 4.21.

6. Secure stationary idler with mounting bolt.

7. Place spark plug wire onto spark plug. Set park

brake. Start engine.

8. Visually inspect traction drive belt for movement.

When properly adjusted, the traction drive belt should

not have any movement or rotation with the engine

running and park brake engaged.

9. Should movement be present, readjust traction

drive belt to release belt tension as described in

previous instructions.

BELT GUIDE

STATIONARY IDLER

STATIONARY IDLER

MOUNTING BOLT

MORE TENSION

LESS TENSION

MOUNTING BRACKET

MOUNTING

BOLT

MOUNTING

BRACKET

MORE

TENSION

LESS

TENSION

BELT GUIDE - MAKE CERTAIN

BELT GUIDE ORIENTATION IS

MAINTAINED.

STATIONARY IDLER

FIGURE 4.21

25

Page 25

Section 4 - ADJUSTMENT & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool. Wear heavy leather gloves

when handling or working around cutting blades.

Blades are extremely sharp and can cause severe

injury.

4.4 MOWER BLADE SERVICE

4.4.1. (STANDARD) BLADE WEAR LIMITS

All mower blades should be check ed for excessive wear

and damage before each use. See Figure 4.22.

4.4.3. (STANDARD) BLADE SHA RPENING

Blades should be kept sharp at all times. When the

blades are dull, cut grass will be ragged and lawn will

usually turn brown. Sharpen standard blades as follows:

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Remove mowing deck from tractor.

4. Remove mower blade(s).

5. If a blade is in good condition, sharpen cutting edge

at an angle of 22 to 28 degrees. DO NOT sharpen

beyond existing cutting edge. Replace blades not in good

condition. See Figure 4.24.

STANDARD BLADE

22º TO 28º

NOTCH FORMING

WEAR LIMIT.

CUTTING EDGE

WORN.

DANGEROUS CONDITION! DO

NOT USE ON MOWER!

NEW

BLADE

FIGURE 4.22

4.4.2. (NINJA) BLADE WEA R LIMITS

The ninja recycling blade requires m ore frequent ser vice

intervals than standard blades. Check for excessive wear

and damage before each use. See Figure 4.23.

NEW

BLADE

WEAR LIMIT. (CRACKS

OR NOTCHES BEGIN

TO APPEAR)

ORIGINAL CUTTING EDGE

FIGURE 4.24

4.4.4. (NINJA) BLADE SHA RPENING

The Ninja recycling blades requires more frequent

service intervals than standard blades. When the blades

are dull, cut grass will be ragged and lawn will usually

turn brown. Sharpen standard blades as follows:

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Remove mowing deck from tractor.

4. Remove mower blade(s).

5. Sharpen all cutting edges of the Ninja recycling

blade at an angle of 22 to 28 degrees for optimum

performance. See Figure 4.25.

NINJA BLADE

22º TO 28º

DANGEROUS CONDITION!

DO NOT USE ON MOWER!

BLADE TIP

FIGURE 4.23

26

FIGURE 4.25

Page 26

Section 4 - ADJUSTMENT & REPAIR

BAR

WASHERS

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool. Wear heavy leather gloves

when handling or working around cutting blades.

Blades are extremely sharp and can cause severe

injury.

4.4.5. 33" MOWER BLADE REPLACEMENT

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Remove mowing deck from tractor.

4. Position deck on its left side to access blade.

5. Rem ove blade mounting bolts, nuts and washers.

See Figure 4.26.

BLADE

(2 REQUIRED)

SPINDLE

ASSEMBLY

BLADE

SPACER

CONE

MOUNTING

NUT

LOCK WASHER

BLADE

BLADE

BLADE MOUNTING

BOLTS

FIGURE 4.26

6. Install new blade onto blade mounting bar.

7. Torque 30 to 40 ft lbs.

4.4.6. 38" MOWER BLADE REPLACEMENT

1. Move tractor to a firm, level surface.

2. Turn engine "OFF". Remove key.

3. Remove mowing deck from tractor.

4. Position deck to access blade.

5. Remove blade mounting nut and cone washer from

each blade. See Figure 4.27.

6. Install new blades.

7. Torque 70 to 90 ft lbs.

FIGURE 4.27

4.4.7. TRACTION DRIVE BELT REPLACEMENT

Mower Deck Removal

It is necessary to remove deck in order to replace

belts. Remove deck as follows:

1. Place tractor on a firm , level surface such as

a driveway or garage floor and set the park brake.

2. Turn engine “OFF”. Remove key.

3. Lower the deck to lowest setting.

4. Disconnect the deck lif t rod from the front lift

arm. See Figure 4.28.

FRONT LIFT

ARM

FRONT LIFT

ROD

WASHER

HAIR PIN

FIGURE 4.28

27

Page 27

Section 4 - ADJUSTMENT & REPAIR

FRAME

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.4.7. TRACTION DRIVE BELT REPLACEMENT

Mower Deck Removal

(Continued from previous page)

5. Remove hair pins from the front deck hanger

rod. See Figure 4.29.

RIGHT

SIDE

SHOWN

FRONT

AXLE

11. Slide deck back and disconnect spring from

tension idler.

12. Pull deck from under tractor from R.H. side.

Traction drive belt removal

1. Remove two belt guide m ounting bolts from each

side of tractor frame. See Figure 4.31.

30” & 33” BELT GUIDES SHOWN

ENGINE PULLEY

BOTTOM GROOVE

FIGURE 4.30

BELT GUIDE

MOUNTING

BOLTS (2 EACH

FRONT DECK

HANGER ROD

FRONT

LIFT ARM

HAIR PIN

FIGURE 4.29

6. Hold front of deck "UP" and slide the front deck

hanger rod to the right and out then lower the front of

deck to the ground.

7. Remove hair pin and flat washer f rom rear deck

hanger bracket on both sides of tractor.

8. Make note of hole used in sector plates.

9. Slide sector plates off of rear deck hanger

brackets.

10. Slide deck forward.

Remove deck drive belt from engine pulley bottom

groove. See Figure 4.30.

BELT

GUIDE

FIGURE 4.31

2. Slide belt guide assembly to the rear and remove.

3. Disconnect traction belt idler pulley spring from

tractor frame. See Figure 4.32.

RIGHT REAR

TRACTOR

DISCONNECT

SPRING FROM

FIGURE 4.32

28

Page 28

Section 4 - ADJUSTMENT & REPAIR

STATIONARY IDLER

PULLEYS

PULLEYS

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.4.7. TRACTION DRIVE BELT REPLACEMENT

(Continued from previous page)

4. Remove mounting nuts that secure the traction

drive belt idler tension pulley and stationary idler

pulleys. See Figure 4.33.

STATIONARY

IDLER

TRANSMISSION

PULLEY

Traction drive belt replacement

1. Place new traction drive belt over transmission

pulley and span to engine pulley.

2. Place belt into top groove of engine pulley.

3. Route belt through stationary and tension idlers.

See Figure 4.36.

DRIVE BELT

TRANSMISSION

PULLEY

TENSION

IDLER

STATIONARY

IDLER

STATIONARY

BELT GUIDE

ENGINE

PULLEY

REMOVE

ALL

TENSION

IDLER

PULLEY

VIEW FROM UNDERNEATH TRACTOR

FIGURE 4.33

5. Remove traction drive belt fr om engine pulley top

groove. See Figure 4.34.

REMOVE BELT

FIGURE 4.35

NOTE: When installing a new belt, make certain the

stationary idler is mounted in the hole closest to the L.H.

side of the tractor. See Figure 4.35.

4. Make certain belt is within belt guides of idlers.

5. Attach tension idler spring to tractor frame. See

Figure 4.36.

6. Reinstall mower deck in reverse order of removal.

RIGHT REAR

TRACTOR FRAME

CONNECT SPRING

TO FRAME

6. Remove belt from center belt guide.

7. Pull belt until it can be removed from trans mission

pulley.

FIGURE 4.34

FIGURE 4.36

29

Page 29

Section 4 - ADJUSTMENT & REPAIR

PULLEY

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blade running. STOP blade.

STOP engine. Set brake. Remov e key. Remove spark

plug wire from spark plu g and secure wi re away from

spark plug. Engine and components can be extremely

hot. Avoid burns by allowing engine and components

sufficient time to cool.

4.4.8. BLADE BELT REMOVAL & REPLACEMENT

33" Deck Drive Belt

1. Place tractor on a firm level surface.

2. Turn engine "OFF". Remove key.

3. Remove mower d e c k.

4. Remove deck belt idler pulley and spindle pulley

cover. See Figure 4.37.

38" Deck Drive Belt

1. Place tractor on a firm level surface.

2. Turn engine "OFF". Remove key.

3. Remove mower d e c k.

4. Remove spindle belt guard and tension idler. See

Figure 4.39.

REMOVE IDLE R

REMOVE

SPINDLE

PULLEY

COVER

REMOVE

IDLER

FIGURE 4.37

5. Remove old belt.

6. Replace with new belt in reverse order.

7. Adjus t idler pulley belt guide if necessary to obtain

1/16" clearance between belt and belt guide. See

Figure 4.38.

SPINDLE PULLEY

1/16”

CLEARANCE

IDLER PULLEY

FIGURE 4.38

REMOVE BELT

GUARD

FIGURE 4.39

5. Remove old belt.

6. Replace with new belt in reverse order.

7. Adjus t idler pulley belt guide if necessary to obtain

1/16" clearance between belt and belt guide. See

Figure 4.40.

1/16”

SPINDLE

PULLEY

CLEARANCE

(TYPICAL)

TENSION

IDLER

SPINDLE

FIGURE 4.40

30

Page 30

Section 4 - ADJUSTMENT & REPAIR

4.5 BATTERY

4.5.1. BATTERY REMOVAL

1. Raise operator's seat.

2. Remove the two adjusting knobs.

3. Remove seat assembly and move forward. Use

care not to disconnect wires from seat switch. See

Figure 4.41.

REMOVE ADJUSTING

KNOBS AND MOVE

SEAT FORWARD

FIGURE 4.41

4. Remove negative ( - ) cable first.

5. Remove positive ( + ) cable last.

6. Remove battery. See Figure 4.42.

WARNING

Cables must be connected to batt ery terminals in the

proper position as shown. DO NOT attempt to charge

battery while installed on tractor. DO NOT use

"BOOST" chargers on the battery. If battery is

removed, DO NOT operate engine without insulating

Positive + battery cable terminal w ith electrical tape,

or sparking from battery cables can result.

REMOVE POSITIVE

(+) CABLE LAST

4.5.2. BATTERY INSTALLATION

1. Slide battery into battery housing.

2. Connect positive (+) cable first.

3. Connect negative (-) cable last.

4. Reinstall seat assembly. Use care not to

disconnect wires from seat switch.

5. Reinstall the two adjusting knobs.

6. Lower operator's seat.

The electrolyte (acid) produces a highly explosive

gas. Keep all sparks, flame and fire away from area

when charging battery or when handling electrolyte

or battery. Electrolyte (acid) is a highly corrosive

liquid. Wear eye protection. Wash affected areas

immediately after having eye or skin contact with

electrolyte (acid). Battery acid is corrosive. Rinse

empty acid containers with water and mutilate before

discarding. If acid is spilled on battery, bench, or

clothing, etc., Flush with clear water and neutralize

with baking soda.

4.5.3. BATTERY SERVICE

1. Remove battery. See Section on Battery Removal.

2. Place battery in a well ventilated area on a level

surface.

3. Using distilled water, refill cells as required to

cover cell plates of which can also be visualized

through the plastic battery case.

4. W ith cell caps removed, connect battery charger

to battery terminals. Red to positive (+) terminal and

black to negative (-) terminal.

5. Slow charge battery at 1 amp for 10 hours.

6. If battery will not accept charge or is partially

charged after 10 hours of c harging at 1 amp, replace

with new battery.

4.5.4. BATTERY STORAGE

When out of season, it is recommended the battery

be removed, charged and stored.

1. Remove battery. (Refer to Section “BATTERY

REMOVAL”).

2. Perform battery service.

3. Bring battery to full charge, if required.

4. Store battery in an area away from the RIDER on a

wood surface. DO NOT STORE BATTERY ON A

CONCRETE SURFACE.

WARNING

WARNING

DO NOT attempt to charge battery while installed on the

machine. DO NOT use “BOOST” chargers on the

REMOVE NEGATIVE (-)

CABLE FIRST

FIGURE 4.42

battery. DO NOT OVERFILL!

31

Page 31

Section 4 - ADJUSTMENT & REPAIR

WARNING

DO NOT OVERFILL! DO NOT attempt to service or

charge the battery while it is installed on the machine.

DO NOT use “BOOST” chargers on the battery.

4.5.5. BATTERY TESTING

There are two types of battery tests: Unloaded and

Loaded. The unloaded test is the procedure that will

be discussed. It’s the simplest and most commonly

used. An unloaded test is m ade on a battery without

discharging current. To perform unloaded testing,

check charge condition using either a hydrometer or

voltmeter.

1. Using a voltmeter, voltage readings appear

instantly to show the state of charge. Remember to

hook the positive lead to the battery’s positive

terminal, and the negative lead to the negative

terminal.

2. A hydrometer measures the specific gravity of

each cell. The specific gravity tells the degree of

charge; generally, a specific gravity of about 1.265 to

1.280 indicates full charge. A reading of 1.230 to

1.260 indicates the battery should be charged. The

Battery Condition chart below shows the charge level

as measured by syringe float hydrometer, digital

voltmeter and five ball hydrometer.

4.5.6 NEW BATTERY PREPARA TION

1. Remove battery from carton.

2. Place battery in a well ventilated area on a level non-

concrete surface.

3. Remove battery cell caps. Fill cells as required

with electrolyte (purchased separately) to proper level.

Fill to 3/16” above cell plates. Filling battery with

electrolyte will bring the battery to 80% charged state.

4. With cell c aps removed, connect battery charger to

battery terminals; RED to positive (+) and BLACK to

negative (-) terminal.

Battery Condition Chart

State of Charge Syringe Hydrometer Digital Voltmeter Five Ball Hydrometer

100% Charged w/ Sulfate Stop 1.280 12.80v Five Balls Floating

100% Charged 1.265 12.60v Four Balls Floating

75% Charged 1.210 12.40v Three Balls Floating

50% Charged 1.160 12.10v Two Balls Floating

25% Charged 1.120 11.90v One Ball Floating

0% Charged Less than 1.100 Less than 11.80v Zero Balls Floating

IMPORTANT: 3/16” above cell plates is the recommended

level. However do not try to meas ure this dimens ion. Never

place anything in battery other than specified electrolyte.

5. Slow charge the battery at 1 amp for 2 hours to

bring the battery to full charge.

6. After charging, check level of electrolyte and add

as needed to bring level to 3/16” above cell plates.

7. Reinstall cell caps.

8. Slide battery partially into battery housing.

9. Connect positive (+) cable (red) first, from wiring

harness to the positive terminal ( +) on battery using bolt

and nut provided in hardware bag. Connect negative (-)

cable (black) last, to negative terminal (-) on battery

using bolt and nut. Apply a small am ount of gr eas e over

terminals to prevent corrosion.

10. Insert battery completely into battery housing.

11. Reinstall seat assembly.

WARNING

Shield the positive terminal with terminal cover

located on battery harness. This preven ts metal from

touching the positive terminal, which could cause

sparks. Cables must be connected to battery

terminals in the proper position. RED (Positive) cable

must go to the ( + ) terminal. BLACK (Negative) cable

must go to the ( - ) terminal.

32

Page 32

Section 4 - ADJUSTMENT & REPAIR

AVAILABLE ACCESSORIES

The SNAPPER Series H LAWN TRACTOR can be equipped with a variety of accessories that increase its versatility. The

accessories available for each model are listed in the chart below. Contact an authorized SNAPPER dealer for ordering

any of the accessories desired.

AVAILABLE

ACCESSORIES

Thatcherizer 6-1247 6-1247

Dethatcher 6-1912 6-1912

Lawn Sweeper Dethatcher 6-1914 6-1914

Lawn Sweeper 6-1913 6-1913

Aerator 6-1911 6-1911

Broadcast Spreader 6-1916 6-1916

Lawn Roller 6-1915 6-1915

42” Snow Blade* 6-1352 6-1352

44” Dozer Blade Spring Trip**** 6-1881 6-1881

Dozer Blade Support Kit 6-1370 6-1370

40” Snow Thrower**** 6-1880 6-1880

Debris Blower**** 6-1883 6-1883

RAD Quick Hitch/Subframe Kit 6-1879 6-1879

Weight Kit 6-1245 6-1245

Tire Chains 6-1085 6-1085

Ninja Recycling/Mulch Kit 6-1255 6-1878