Page 1

SET-UP INSTRUCTIONS & PRE-OPERATION CHECKLIST for

SECURE UPPER

CUT WIRE TIE

CUT WIRE TIES

CHUTE

CHECK “Z” BEND END OF CABLE

CONTROL

CONTROL

CONTROL

CUT CABLE TIES

LOOSEN NUT

SNAPPER INTERMEDIATE FRAME SNOW THROWERS

INTRODUCTION: The SNAPPER Intermediate Frame Snow Throw ers are shipped almost fully assembled and

require minimal set-up. Setting up the machine will require the handles to be unfolded and secured, and the

attachment of the chute cran k rod. Some models may also require the inst allation of an elect ric start kit to the

engine. Complete each o f the following steps carefully. Review and complete each item as instructed on the

Pre-Operation checklist. The Snapper Product Registration card must be filled out and sent to Customer

Service department at Snapper when completed.

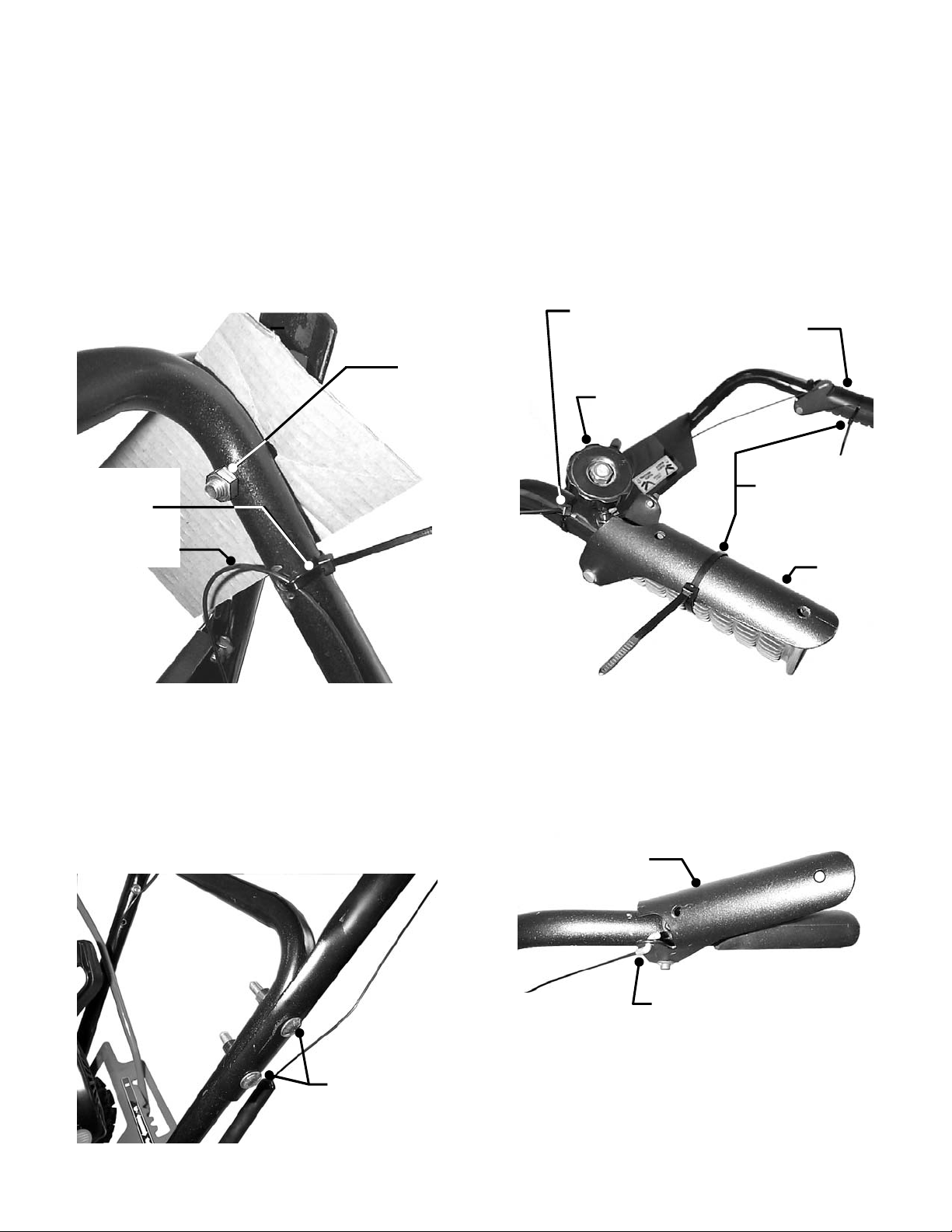

STEP 1: HANDLES: Cut both wire ties that secur e the

control cables to the handles. Be very careful and DO

NOT cut the control cables. See Figure 1.

REMOVE

CARDBOARD

ON BOTH

HANDLES

DO NOT CUT

CONTROL CABLE

FIGURE 1

STEP 2: HANDLES: Loosen handle nuts and rotate

handles up to the opera ting position. Remove ship ping

cardboard from in between handles. See Figure 1.

Insert bolts through both upper & lower handles and

secure with nuts. Make sure the square necks of the

bolts are recessed into the square holes of upper

handles. Tighten nuts securely. See Figure 2.

HANDLES WIT H

BOLTS AND NUTS

TIGHTEN SECURELY

FIGURE 2

STEP 3: HANDLES: Cut both wire ties that secure the

control levers to the handles. Cut the wire tie that

secures the chute crank to the handle. See Figure 3.

THAT SECURES

CHUTE CRANK

LEVER

CRANK

THAT SECURE THE

CONTROL LEVERS

TO THE HANDLES

LEVER

FIGURE 3

STEP 4: CABLES: Make sure that the “Z ” bend ends

of control cables are s ecured in t he holes on the c ontr ol

levers. Make sure cables are not kinked and have

freedom of movement when levers are engaged or

disengaged. See Figure 4.

LEVER

IS SECURELY INSERTED INTO

HOLE ON CONTROL LEVER

FIGURE 4

INSTRUCTIONS No. 7-4331 (Rev. 1, 4/08/02)

Page 2

2

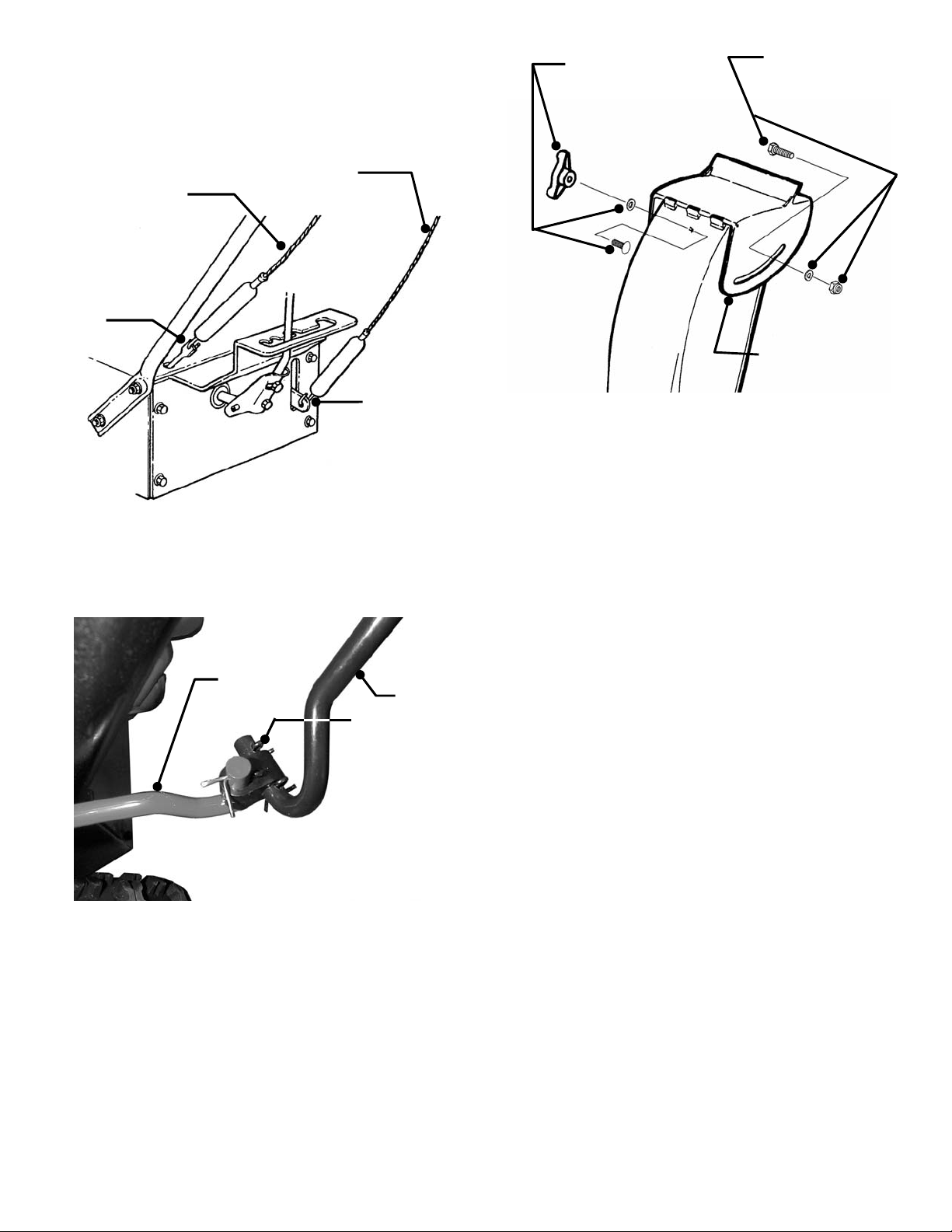

STEP 5: CABLES: Make sure that the cables are

BLOWER

TRACTION

TRACTION

BLOWER

CHUTE

SECURE WITH

WORM

INSTALL WING

DEFLECTOR MUST

INSTALL CAP

connected to the traction clutch rod and blower clutch

bracket. IMPORTANT: Cables should ha ve some slack

and should not be under tension. See Figure 5.

CLUTCH

CABLE

(LEFT SIDE)

CLUTCH

CABLE

(RIGHT SIDE)

CLUTCH

ROD

CLUTCH

BRACKET

FIGURE 5

STEP 6: CHUTE CRANK: Connect chute crank to worm

gear shaft and secure with cotter pin. See Figure 6.

GEAR

SHAFT

CRANK

COTTER PIN

FIGURE 6

STEP 7: DISCHARGE CHUTE DEFLECT OR: Secure

the deflector to the discharge chute using hardware

supplied in hardware bag. Tighten the cap screw,

washer and nut but allow deflector to rotate freely.

Install the carriage bolt, washer and wing nut. Tighten

securely. Use wing nut to securely lock deflector into

desired position. See Figur e 7.

NUT, WASHER

AND WING NUT

SCREW, WASH ER

AND NUT BUT DO

NOT OVER TIGHTEN

ROTATE FREELY

FIGURE 7

NOTE: After set-up the hardware bag will contain:

two shear bolts and two nuts and a cotter pin.

IMPORTANT: All necessary initial adjustments are

made to the machine at the factory. The following

cable adjustments and lu brication are provided for

reference only. Complete all items on the PreOperation Checklist as instructed.

Page 3

3

STEP 8: ADJUSTMENT: Adjust cable lengths s o that

SPRING SHOULD

TO ADJUST, LOOSEN JAM NUT

JAM

GEAR CASE

CHECK PLUG

each spring stretches 3/8” when the clutch lever is

depressed. When released, both clutch cables should

be slack. See Figure 8.

STRETCH 3/8”

WHEN HANDLE IS

DEPRESSED

CONNECTOR

NUT

AND TURN CONNECTOR TO

SHORTEN O R LENGTHEN

CABLE AS NEEDED TO ATTAIN

THE 3/8” EX TENSION. TIGHTEN

JAM NUT AFTER ADJUSTING.

FIGURE 8

STEP 9: LUBRICATION: Remove check plug to

check grease level i n auger gear case. If gr ease is not

visible from check plug hole, pump BENELENE 900

grease, SNAPPER Part No. 2-9577, into fill plug on

case until grease is visible. Reinstall check plug. See

Figure 9.

GREASE FITTING

FIGURE 9

STEP 10: CHECKLIST: Complete all item s on the Pre-

Operation Checklist as instructed.

Page 4

4

PRE-OPERATION CHECKLIST for

SNAPPER INTERMEDIATE FRAME SNOW THROWERS

Snapper has completed initial adjustments and performed operational tests prior to shipping the machine. Due

to the possible effects of shipping, handling and storage, Snapper intends for all of the following items to be

verified and necessary final adjustments made at time of setup. It remains good practice and is strongly

recommended that all t he items also be che cked prior to pla cing the machine in to service. It is v ery important

that setup is verified and all operational test s completed and results ar e ac cept able. After completin g t his f orm,

sign and retain for future reference.

LUBRICATION

_____ ENGINE OIL added to bring level up to full mark on 4-cycle engines (Refer to Engine Manual).

_____ GEAR CASE grease level check ed, add Benale ne 90 0 grease ( Sn app er Part No. 2-957 7) if needed .

OPERATIONAL TEST

_____ AUGER DRIVE CONTROL check ed for proper engag em ent and disengagem ent to insure auger s tops within 5

seconds after auger clutch control is released.

_____ WHEEL DRIVE CONTROL checked for proper engagement and disengagement of wheel drive.

_____ ENGINE started, engine speed control settings checked and adjusted as needed.

_____ IGNITION SWITCH checked to insure engine stops when turned to OFF position.

_____ ENGINE ELECTRIC STARTER checked for proper operation.

_____ FUEL SYSTEM checked for leaks around tank and connections.

______DISCHARGE CHUTE CRANK checked for proper operation and free rotation.

______AUGER and WHEEL DRIVE CONTROL CABLES checked and adjusted per instructions in the Operator’s Manual.

_____ GROUND SPEED CONTROL checked and adjusted per instructions in the Operator’s Manual.

_____ CHOKE CONTROL checked for proper operation during start up.

_____ TIRE PRESSURE checked. 15 to 20 PSI if chains are to be installed or 12 PSI if chains are not being used.

CONSUMER INFORMATION

Purchase Date __________________ Model_______________________ Serial No. _______________________

Retailers Name ___________________________________ ______________________________________________

Address _____________________________________ City ____________________ State _______ Zip ______

MACHINE WILL BE USED COMMERCIALLY? _____ YES _____ NO

Purchaser’s Name ________________________________ Signature ____________________________________

Address ____________________________________ City _____________________ State _______ Zip _______

IMPORTANT: Th is fo rm is to be ret ained fo r fu tu re r eferen c e reg ard ing W ar ra nt y, proof o f p urch as e, tr aceab i lity

for product recall or service, etc. Complete the Snapper Product Registration Card and Mail to Customer

Service Department at SNAPPER, P.O. Box 1379, McDonough, Georgia, 30253.

INSTRUCTION No. 7-4331 (Rev. 1, 4/08/02) Printed in U.S.A.

Loading...

Loading...