Page 1

en

Not for

Reproduction

Operator’s Manual

da

Brugsanvisning

de

Bedienungsanleitung

Manuel d’utilisation

fr

Manuale per l’operatore

it

Gebruikershandleiding

nl

no

Bruksanvisning

GT600 Series (CE/Export)

Hydro Tractor & Mower Deck

Mfg. No. Description

2690634 ESGT27540D, Tractor, 4WD, 3P (CE)

2690667 ESGT27540D, Tractor, 4WD, 3P & 54” Mower (CE)

Mower Deck

Mfg. No. Description

1695204 54” Mower Deck

1738499

Revision: -

Rev. Date: 12/2010

1734110

Revision D

Page 2

CONTENTS

Not for

Reproduction

Front Cover ..........................................................................................................1

Operator Safety ...................................................................................................4

Features and Controls ...................................................................................... 12

Operation ...........................................................................................................17

Safety Interlock System Tests .......................................................................... 17

Maintenance ......................................................................................................27

Troubleshooting ................................................................................................ 31

.................................................................................................... 33

Warranty ............................................................................................................. 34

General Information

Thank you for purchasing this quality-built SNAPPER riding mower. We’re pleased that you’ve placed your confidence in the

SNAPPER brand. When operated and maintained according to the instructions in this manual, your SNAPPER product will

provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with riding mowers and

how to avoid them. This riding mower is designed and intended only for cutting grass and is not intended for any other purpose. It is important that you read and understand these instructions thoroughly before attempting to start or operate the

equipment. Save these original instructions for future reference.

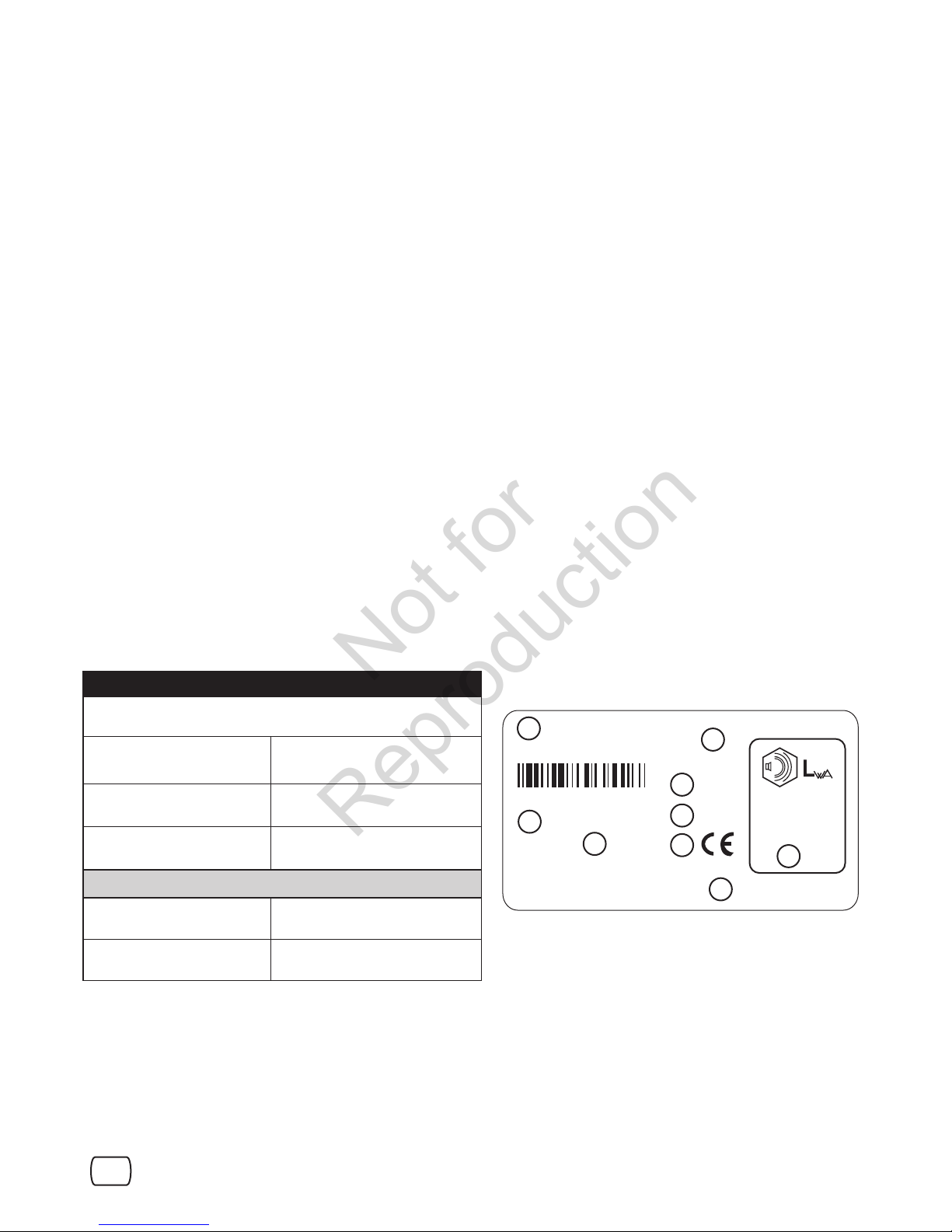

Product Reference Data

Record your model name/number, manufacturer’s identification numbers, and engine serial numbers in the space provided for easy access. These numbers can be found in the

locations shown.

When contacting your authorized dealer for replacement parts, service, or information you MUST have

these numbers.

PRODUCT REFERENCE DATA

Model Description Name/Number

Unit MFG Number Unit SERIAL Number

Mower Deck MFG Number Mower Deck SERIAL Number

Dealer Name Date Purchased

ENGINE REFERENCE DATA

Engine Make Engine Model

CE Identification Tag

A. Manufacturer’s Identification Number

B. Manufacturer’s Serial Number

C. Manufacturer’s Name and Address

D. Maximum Engine Speed in Rotations per Minute

E. Power Rating in Kilowatts

F. Mass of Unit in Kilograms

G. CE Compliance Logo

H. Year of Manufacture

I. Guaranteed Sound Power in Decibels

A

MODEL NO. xxxxxxx

SERIAL NO. xxxxxxxxxx

B

C

XXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXX

D

xxxx min

E

x.x kW

xxx kg

F

G

20xx

-1

H

xxx

I

dB

Engine Type/Spec Engine Code/Serial Number

For an Illustrated Parts List, Setup Instructions, or other

publications for this model, please visit www.snapper.com.

Copyright © 2012 Briggs & Stratton Power Products Group, LLC

Milwaukee, WI USA. All rights reserved.

en

3

“Vibration measurement uncertainty – machine vibration

was recorded using methods and procedures outlined in

the appropriate International Standards in eect at the time

of manufacture. The uncertainties due to the measurement

may result in a variance of up to 5% from the published value

shown in the Declaration of Conformity.”

Page 3

Operator Safety

Not for

Reproduction

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains im-

portant instructions that should be followed during the initial

set-up, the operation, and the maintenance of the equipment.

Save these original instructions for future reference.

Safety Symbols and Meanings

Fire

Toxic Fumes

Wear Eye

Protection

Read

Manual

Moving Parts Shock

Kickback

Chemical

Fast

Slow

Explosion

Hot SurfaceHazardous

Oil

Stop

Choke

Fuel

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE indicates a situation that could result in damage

to the product.

WARNING

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth

defects, or other reproductive harm.

WARNING

Certain components in this product and its related accessories contain chemicals known to the State of California

to cause cancer, birth defects, or other reproductive harm.

Wash hands after handling.

WARNING

Battery posts, terminals, and related accessories

contain lead and lead compounds - chemicals known to the

State of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

WARNING

Running engine gives o carbon monoxide, an odor-

less, colorless, poison gas.

Breathing carbon monoxide can cause headache, fa-

tigue, dizziness, vomiting, confusion, seizures, nausea,

fainting or death.

• Operate equipment ONLY outdoors.

• Keep exhaust gas from entering a conned area through

windows, doors, ventilation intakes, or other openings.

Fuel

The safety alert symbol is used to identify safety information about hazards that can result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with

the alert symbol to indicate the likelihood and the potential

severity of injury. In addition, a hazard symbol may be used to

represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

Roll-Over

Hazard

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

4

Amputation

Hazard

WARNING

Running engines produce heat. Engine parts, espe-

cially muer, become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc.

can catch re.

Allo

•

w muer, engine cylinder and ns to cool before

touching.

• Remove accumulated debris from muer area and

cylinder ar

• It is a violation of California Public Resource Code,

Section 4442, to use or oper

covered, brush-covered, or grass-covered land unless

the e

dened in Section 4442, maintained in eectiv

order. Other states or federal jurisdictions may have

similar la

er, retailer, or dealer to obtain a spark arrester de-

tur

signed f

ea.

ate the engine on any forest-

xhaust system is equipped with a spark arrester, as

e working

ws. Contact the original equipment manufac-

or the exhaust system installed on this engine.

Page 4

Safe Operation Practices

Not for

Reproduction

Operating Safety

Power equipment is only as safe as the operator. If it is misused,

or not properly maintained, it can be dangerous! Remember, you are

responsible for your safety and that of those around you. Use common sense, and think through what you are doing. If you are not sure

that the task you are about to perform can be safely done with the

equipment you have chosen, ask a professional: contact your local

authorized dealer.

Read the Manual

The operator’s manual contains important safety information you

need to be aware of BEFORE you operate your unit as well as

DURING operation.

Safe operating techniques, an explanation of the product’s features

and controls, and maintenance information is included to help you get

the most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found on

the following pages. Also completely read the Operation section.

Children

Tragic accidents can occur with children. Do not allow

them anywhere near the area of operation. Children are

often attracted to the unit and mowing activity. Never

assume that children will remain where you last saw them.

If there is a risk that children may enter the area where

you are mowing, have another responsible adult watch

them.

DO NOT GIVE CHILDREN RIDES ON THIS UNIT! This

encourages them to come near the unit in the future while

it is running, and they could be seriously hurt. They may

then approach the unit for a ride when you are not expecting it, and you may run over them.

en

5

Reverse

Do not mow in reverse unless

absolutely necessary.

Always look down and

behind before and while

traveling in reverse even

with the mower blades disengaged.

Page 5

Slope Operation

Not for

Reproduction

You could be seriously injured or even killed if you use this unit on too

steep an incline. Using the unit on a slope that is too steep or where you

don’t have adequate traction can cause you to lose control or roll over.

A good rule of thumb is to not operate on any slope you cannot back up

(in 2-wheel drive mode). You should not operate on inclines with a slope

greater than a 3.5 foot rise over a 20 foot length. Always drive up and

down slopes: never cross the face.

3.5 ft

(1,5 m)

20.0 ft (6,0 m)

Also note that the surface you are driving on can greatly impact stability

and control. Wet grass or icy pavement can seriously affect your ability to

control the unit.

If you feel unsure about operating the unit on an incline, don’t do it. It’s

not worth the risk.

Moving Parts

This equipment has many moving parts that can injure you or someone

else. However, if you are seated in the seat properly and follow all the rules

in this book, the unit is safe to operate.

The mower deck has spinning mower blades that can amputate hands and

feet. Do not allow anyone near the equipment while it is running!

To help you, the operator, use this equipment safely, it is equipped with an

operator-present safety system. Do NOT attempt to alter or bypass the system. See your dealer immediately if the system does not pass all the safety

interlock system tests found in this manual.

Thrown Objects

This unit has spinning mower blades. These blades can pick up and throw

debris that could seriously injure a bystander. Be sure to clean up the area to

be mowed BEFORE you start mowing.

Do not operate this unit without the entire grass catcher or discharge guard

(deflector) in place.

Do not allow anyone in the mowing area while the unit is running! If someone

does enter the area, shut the unit off immediately until they leave.

Fuel and Maintenance

Gasoline is extremely flammable. Its vapors are also extremely flammable

and can travel to distant ignition sources. Gasoline must only be used as a

fuel, not as a solvent or cleaner. Fuel should never be stored any place where

its vapors can build up or travel to an ignition source like a pilot light. Fuel

belongs in an approved, plastic, sealed gas can, or in the tractor fuel tank with

the cap securely closed. Spilled fuel needs to be cleaned up immediately.

Proper maintenance is critical to the safety and performance of your unit. Be

sure to perform the maintenance procedures listed in this manual and be sure

to periodically test the safety system.

6

Page 6

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

Not for

Reproduction

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

This mowing deck is capable of amputating hands and feet and throwing objects.

The triangle in text signies important cautions or warnings which must be followed.

GENERAL OPERATION

1. Read, understand, and follow all instructions in the manual and on the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at all

times.

3. Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

4. Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown by the blade(s).

5. Be sure the area is clear of other people before mowing.

Stop the unit if anyone enters the area.

6. Never carry passengers.

7. Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while travelling

in reverse.

8. Never direct discharge material toward anyone. Avoid

discharging material against a wall or obstruction.

Material may ricochet back toward the operator. Stop the

blade(s) when crossing gravel surfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in place.

10. Slow down before turning.

11. Never leave a running unit unattended. Always disengage the PTO, set parking brake, stop engine, and

remove keys before dismounting.

12. Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete stop

before cleaning the machine, removing the grass catcher, or unclogging the discharge guard.

13. Operate the machine only in daylight or good artificial

light.

14. Do not operate the unit while under the influence of alcohol or drugs.

15. Watch for traffic when operating near or crossing roadways.

16. Use extra care when loading or unloading the unit into a

trailer or truck.

17. Always wear eye protection when operating this unit.

18. Data indicates that operators, age 60 years and above,

are involved in a large percentage of power equipmentrelated injuries. These operators should evaluate their

ability to operate the equipment safely enough to protect

themselves and others from injury.

19. Follow the manufacturer’s recommendations for wheel

weights or counterweights.

20. Keep in mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seek and obtain professional and practical instruction.

22. Always wear substantial footwear and trousers. Never

operate when barefoot or wearing sandals.

23. Before using, always visually check that the blades and

blade hardware are present, intact, and secure. Replace

worn or damaged parts.

24. Disengage attachments before: refueling, removing an

attachment, making adjustments (unless the adjustment

can be made from the operator’s position).

25. When the machine is parked, stored, or left unattended,

lower the cutting means unless a positive mechanical

lock is used.

26. Before leaving the operator’s position for any reason,

engage the parking brake (if equipped), disengage the

PTO, stop the engine, and remove the key.

27. To reduce fire hazard, keep the unit free of grass, leaves,

& excess oil. Do not stop or park over dry leaves, grass,

or combustible materials.

TRANSPORTING AND STORAGE

1. When transporting the unit on an open trailer, make sure

it is facing forward, in the direction of travel. If the unit is

facing backwards, wind lift could damage the unit.

2. Always observe safe refueling and fuel handling practices when refueling the unit after transportation or storage.

3. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an ignition

source (such as a furnace, water heater, etc.) and cause

an explosion. Fuel vapor is also toxic to humans and animals.

en

7

4. Always follow the engine manual instructions for storage preparations before storing the unit for both short

and long term periods.

5. Always follow the engine manual instructions for proper

start-up procedures when returning the unit to service.

6. Never store the unit or fuel container inside where there

is an open flame or pilot light, such as in a water heater.

Allow unit to cool before storing.

Page 7

SLOPE OPERATION

Not for

Reproduction

Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. Operation

on all slopes requires extra caution. If you cannot back up the

slope or if you feel uneasy on it, do not operate on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake. The

main reasons for loss of control are: insufficient tire grip on

the ground, speed too fast, inadequate braking, the type of

machine is unsuitable for its task, lack of awareness of the

ground conditions, incorrect hitching and load distribution.

1. Mow up and down slopes, not across.

2. Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

3. Choose a slow speed so that you will not have to stop or

change speeds while on the slope.

4. Do not mow on wet grass. Tires may loose traction.

5. Always keep unit in gear especially when traveling down

slopes. Do not shift to neutral and coast downhill.

6. Avoid starting, stopping, or turning on a slope. If tires

lose traction, disengage the blade(s) and proceed slowly

straight down the slope.

7. Keep all movement on slopes slow and gradual. Do not

make sudden changes in speed or direction, which could

cause the machine to rollover.

8. Use extra care while operating machines with grass

catchers or other attachments; they can affect the stability of the unit. Do not use on steep slopes.

9. Do not try to stabilize the machine by putting your foot on

the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embankments.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

11. Do not use grass catchers on steep slopes.

12. Do not mow slopes you cannot back up them.

13. See your authorized dealer/retailer for recommendations

of wheel weights or counterweights to improve stability.

14. Remove obstacles such as rocks, tree limbs, etc.

15. Use slow speed. Tires may lose traction on slopes even

through the brakes are functioning properly.

16. Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Follow the manufacturer’s recommendations for weight

limit for towed equipment and towing on slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

When operating on slopes use additional wheel

weights or counterweights. See your dealer/retailer

to determine which weights are available and

appropriate for your unit.

Select slow ground speed before driving onto

slope. In addition to front weights, use extra caution

when operating on slopes with rear-mounted grass

catchers.

Mow UP and DOWN the slope, never across the face,

use caution when changing directions and DO NOT

START OR STOP ON SLOPE.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the mowing activity. Never assume that children will

remain where you last saw them.

1. Keep children out of the mowing area and under the

watchful care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and during reverse operation, look behind and

down for small children.

4. Never carry children, even with the blade(s) off. They

may fall off and be seriously injured or interfere with safe

unit operation. Children who have been given rides

in the past may suddenly appear in the mowing area

for another ride and be run over or backed over by the

machine.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

IGNITION SYSTEM

1. This spark ignition system complies with Canadian

ICES-002.

8

Page 8

SERVICE AND MAINTENANCE

Not for

Reproduction

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other sources

of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there is

an open flame, spark, or pilot light such as near a water

heater or other appliance.

6. Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground away from your vehicle before filling.

7. Remove gas-powered equipment from the truck or trailer

and refuel it on the ground. If this is not possible, then

refuel such equipment on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

8. Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing immediately.

10. Never over-fill the fuel tank. Replace gas cap and tighten

securely.

11. Use extra care in handling gasoline and other fuels. They

are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

13. Replace all fuel tank caps and fuel container caps

securely.

Service & Maintenance

1. Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

2. Keep nuts and bolts, especially blade attachment bolts,

tight and keep equipment in good condition.

3. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if they

are not functioning properly.

4. Keep unit free of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage. and remove any fuel-soaked

debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

6. Never make adjustments or repairs with the engine running.

7. Check grass catcher components and the discharge

guard frequently and replace with manufacturer’s recommended parts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear gloves,

and use extra caution when servicing them.

9. Check brake operation frequently. Adjust and service as

required.

10. Maintain or replace safety and instructions labels, as

necessary.

11. Do not remove the fuel filter when the engine is hot as

spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

12. Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline additives, or white gas because engine/fuel system damage

could result.

13. If the fuel tank must be drained, it should be drained outdoors.

14. Replace faulty silencers/mufflers.

15. Use only factory authorized replacement parts when

making repairs.

16. Always comply with factory specifications on all settings

and adjustments.

17. Only authorized service locations should be utilized for

major service and repair requirements.

18. Never attempt to make major repairs on this unit unless

you have been properly trained. Improper service procedures can result in hazardous operation, equipment damage and voiding of manufacturer’s warranty.

19. On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

20. Do not change engine governor settings or over-speed

the engine. Operating the engine at excessive speed

can increase the hazard of personal injury.

21. Disengage drive attachments, stop the engine, remove

the key, and disconnect the spark plug wire(s) before:

clearing attachment blockages and chutes, performing

service work, striking an object, or if the unit vibrates

abnormally. After striking an object, inspect the machine

for damage and make repairs before restarting and operating the equipment.

22. Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top of

the transaxle).

23. Units with hydraulic pumps, hoses, or motors:

WARNING: Hydraulic fluid escaping under pressure may

have sufficient force to penetrate skin and cause serious

injury. If foreign fluid is injected into the skin it must be

surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result. Keep

body and hands away from pin holes or nozzles that eject

hydraulic fluid under high pressure. Use paper or cardboard, and not hands, to search for leaks. Make sure

all hydraulic fluid connections are tight and all hydraulic

hoses and lines are in good condition before applying

pressure to the system. If leaks occur, have the unit serviced immediately by your authorized dealer.

24. WARNING: Stored energy device. Improper release of

springs can result in serious personal injury. Springs

should be removed by an authorized technician.

25. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily injury

from hot coolant or steam blow-out, never attempt to

remove the radiator cap while the engine is running.

Stop the engine and wait until it is cool. Even then, use

extreme care when removing the cap.

en

9

Page 9

Safety Decals

5.25

Not for

Reproduction

All DANGER, WARNING, CAUTION and instructional

messages on your rider and mower should be carefully

read and obeyed. Personal bodily injury can result when

these instructions are not followed. The information is for

your safety and it is important! The safety decals below

are on your rider and mower.

If any of these decals are lost or damaged, replace them

at once. See an authorized dealer for replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective operation.

ANGLE

Decal - Transmission

Release

Part No. 1725776

1725776

Decal - Cutting

Height

Part No. 1717583

Decal - Ignition

Switch Positions

Part No. 1722806

Decal - Throttle

FLOAT

LOWER

LEFT

RAISE

Decal - Attachment

Lift Control

ANGLE

Part No. 1725603

RIGHT

1725603

Decal - Cutting

Height

Part No. 1721197

1725571

Positions

Part No.

1725571

Decal - PTO Selector

Positions

Part No. 1725574

1725618

1725574

Decal - Operating Instructions, CE

Models, Part No. 1723175

10

Decal - Danger,

1723175

Rotating Blades

Part No. 1720389

Decal - Danger, Rotating Parts,

540 PTO Models

Part No. 1725618

1726086

Decal - Danger, Rotating Fan,

CE, Diesel Models

Part No. 1726086

Page 10

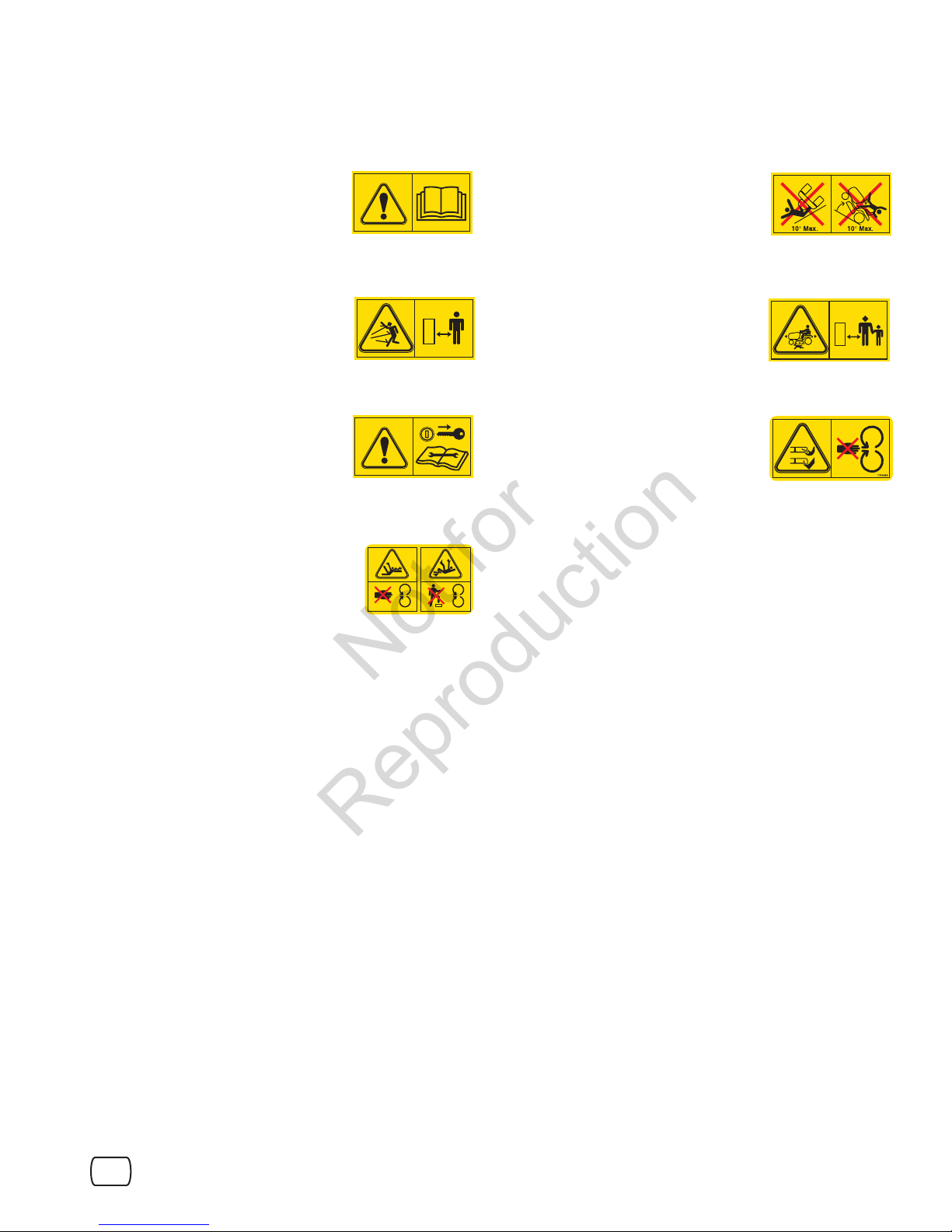

Safety Icons

Not for

Reproduction

Warning: Read Operator’s

Manual.

Read and understand the

Operator’s Manual before using

this machine.

Danger: Thrown Objects.

This machine is capable of throwing

objects and debris. Keep bystanders away.

Warning: Remove Key Before

Servicing.

Remove the key and consult technical literature before performing

repairs or maintenance.

Warning: Rotating Shaft Can

Cause Injury or Death.

Keep hands and feet clear.

Danger: Machine Rollover.

Do not use this machine on slopes

greater than 10°.

Danger: Dismemberment.

This machine can amputate limbs.

Keep bystanders and children away

when engine is running.

Danger: Dismemberment.

This mower deck can amputate

limbs. Keep hands and feet away

from blades.

1725618

en

11

Page 11

Features and Controls

2WD

4WD

Not for

Reproduction

12V

Choke (Select Models)

Close the choke for cold starting. Open the choke once

the engine starts. A warm engine may not require choking. Pull the choke control out to close the choke.

Throttle Control

The throttle controls engine speed. Move the throttle

forward to increase engine speed and back to decrease

engine speed. Always operate at FULL throttle.

The light switch turns the tractor headlights on and off.

12

Headlights

Figure 1. Controls

Front Axle Oil Level Plug

(4WD Models Only)

The front axle oil check plug/dipstick is used to check

the front axle oil level and to add oil to the axle. See

FRONT AXLE MAINTENANCE for oil level check and

fill procedures.

Transmission Oil Level Check Plug

Transmission oil check plug/dipstick is used to check

transmission oil level and to add oil to the transmission.

See TRANSMISSION MAINTENANCE for oil level

check and fill procedures.

Page 12

Attachment Lift Control Lever

4WD

Not for

Reproduction

When using the mower deck, lift the deck off the ground

while transporting to and from the job site. DO NOT cut

with the mower in the raised, transport position.

The attachment lift control lever raises and lowers attachments that utilize the tractor’s hydraulic lift cylinder. This

lever also controls attachments that use the tractor’s auxiliary hydraulics via the quick couplers on the front left and

right sides of the frame.

When using a mower deck (Front / Rear Hydraulic selector switch must be in REAR position), pulling the lever

back raises the attachment lift. Pushing the lever forward

to the first detent lowers the attachment lift. Pushing the

lever forward to the second detent locks the control in

“float” position, allowing the lift mechanism to float up and

down. Float is the recommended position when mowing.

For a complete explanation on this control, see

HYDRAULIC SYSTEM FUNCTIONS.

Cutting Height Adjustment

The cutting height adjustment switch controls the mower

cutting height. This same switch also controls the spout

rotator motor when a snowthrower is installed. The

arrows on the switch correspond to the direction of

adjustment (UP arrow raises cutting height, RIGHT arrow

rotates the spout right, etc). The mower cutting height is

infinitely adjustable between 1” to 4-13/32” (2,5 cm-11,2

cm). When the adjustment indicator has reached the end

of its travel, release the switch; holding the switch down

will damage the motor.

Ignition Switch

The ignition switch starts and stops the engine, it has

three positions:

OFF Stops the engine and shuts off the

electrical system.

RUN Allows the engine to run and powers the

electrical system. Activates the glow

plugs on diesel models

START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN position with the engine stopped–this drains the battery.

Ground Speed Pedals

The tractor’s forward ground speed is controlled by

the forward ground speed control pedal. The tractor’s

reverse ground speed is controlled by the reverse ground

speed control pedal. Note that the further down the pedal

is depressed, the faster the tractor will travel.

Parking Brake

This locks the parking brake when the tractor is

stopped. See Parking Brake section.

Steering Tilt Adjust (Select Models)

Use the tilt knob located on the bellows to release the

pivot mechanism and pivot the wheel to the desired position. Release the tilt knob to lock in position.

Seat Adjustment Lever

The seat can be adjusted forward and back. Move the

lever, position the seat as desired, and release the lever

to lock the seat into position.

Cruise Control

The cruise control is used to lock the ground speed control in forward. Move the lever forward until the desired

ground speed is reached. To disengage the cruise control move the lever back. In the event you need to stop

quickly, depressing the brake pedal will also return the

cruise control to neutral.

2WD

2-Wheel / 4-Wheel Drive Selector (Select

Models)

The 2-wheel / 4-wheel drive selector disengages the front

wheels in the 2-wheel drive position and drives all four

wheels in 4-wheel drive position. Engage / disengage

the 4-wheel drive control only when stopped or at slow

speeds.

Transmission Release Valve Lever

The transmission release valve lever deactivates the

transmission so that the tractor can be pushed by hand.

See PUSHING THE TRACTOR BY HAND for operational

information.

Brake Pedal

Depressing the brake pedal applies the tractor brake.

Depressing the brake pedal will also return the cruise

control lever to neutral.

en

13

Fuel Tank

To remove the cap, turn counterclockwise.

Page 13

Transmission Oil Level Check Plug

Not for

Reproduction

Transmission oil check plug/dipstick is used to check

transmission oil level and to add oil to the transmission.

See TRANSMISSION MAINTENANCE for oil level check

and fill procedures.

Mid / Rear PTO Selector

The mid / rear PTO selector lever selects which PTO or

combination of PTOs is activated by the PTO switch. The

selector has three positions (from front to back:) mid PTO

active only, mid and rear PTO active, rear PTO active

only. Disengage the PTO switch before altering this control’s setting.

Front / Rear Hydraulics Selector

The front / rear hydraulics selector switches which

hydraulic circuit is controlled by the forward and backward movement of the attachment lift lever.

When the switch is in the forward position, the attachment

lift control lever affects attachments connected to the two

front left quick couplers. When the switch is in the rear

position the attachment lift control affects the tractor’s

hydraulic cylinder.

12V

Power Outlet

The power outlet is 12V-DC. Accessory must be rated at

14 amps or less.

Differential Lock Pedal

Depressing this pedal locks the transmission differential,

locking both rear wheels into “drive”.

Use this feature if the tractor is stuck because one wheel

is slipping. Engage the differential lock at slow

ground speeds only.

PTO Switch

The PTO (Power Take-Off) switch, in conjunction with the

mid / rear PTO selector, engages and disengages attachments connected to the tractor’s mid or rear PTO shafts.

To engage the PTO, pull UP on the switch. Push DOWN

to disengage. Be sure to check the position of the mid /

rear PTO selector lever before engaging the PTO. DO

NOT engage a PTO that is not connected to an attachment as the rotating shaft is a safety hazard. Note that

the operator must be seated firmly in the tractor seat for

the PTO to function.

Reverse Mowing Option (RMO)

The Reverse Mowing Option allows for mowing (or use of

other PTO driven attachments) while traveling in reverse.

If you choose to mow or operate another attachment in

reverse, turn the RMO key after the PTO is engaged. The

L.E.D. light will illuminate, and the operator can then mow

in reverse. Each time the PTO is disengaged the RMO

needs to be reactivated if desired.

14

Page 14

Parking Brake Function

Not for

Reproduction

Applying the Parking Brake - See Figure 2. To lock the

parking brake, release the ground speed pedals (A), fully

depress the brake pedal (B), pull the parking brake knob

(C) out, and then release brake pedal.

Releasing the Parking Brake - See Figure 2. To

release the parking brake, fully depress the brake pedal

(B) and push in the parking brake knob (C).

Automatic Controlled Traction

What is Automatic Controlled Traction?

Automatic Controlled Traction (ACT) is an exclusive

feature of our transmissions that provides improved traction. ACT applies a preset amount of torque to both rear

wheels even if one starts slipping (a transmission without

ACT will lose traction completely if one rear wheel starts

slipping). This preset torque is just enough to provide

additional traction, and still allow the wheels to turn at different speeds in a tight turn without damaging the lawn.

What to Expect from Your ACT Tractor

For the most part, while using your tractor you will not

notice ACT working, and you will simply become accustomed to increased traction an ACT transmission provides.

C

Figure 2. Engaging the Parking Brake

Under certain circumstances the ACT system limit can

be exceeded, and one of the rear wheels may slip (for

instance if trying to turn up a hill while accelerating). This

is normal. If you start to lose traction, do not speed up.

Instead, slow to a stop, straighten the steering wheel, and

slowly accelerate. Stopping the tractor allows the transmission to regain more traction.

B

A

en

15

Page 15

Dashboard Display Functions

Not for

Reproduction

The dashboard display (Figure 3) shows a variety of

engine operation and control status information, as

explained in the descriptions below.

A. Irregular Voltage

Indicates that the voltage being produced by the charging

system and battery is higher or lower than normal levels.

B. Rear PTO Light

Indicates that the optional rear PTO is engaged.

C. Mid (Front) PTO Light

Indicates that the mid PTO is engaged.

D. Hour Meter/Clock

Displays number of hours the unit has been operated.

E. Cruise Control Light

Indicates that the cruise control is engaged.

F. Low Oil Pressure Light

Indicates that the engine oil pressure is low. If this indicator lights, shut the engine off immediately and contact

your dealer.

G. 4 Wheel Drive Light (4WD Models Only)

Indicates that 4 wheel drive is engaged.

H. Fuel Separator Full Light

Indicates that the fuel separator is full and must be emptied.

I. Fuel Gauge

The fuel gauge shows the level of fuel in the fuel tank.

J. Tachometer

Displays the engine RPM. Normal operating speed is

3400 RPM. Do not operate at less than 3000 RPM during

normal use.

K. Coolant Temperature

Shows the engine coolant temperature.

L. Glow Plug Light

Indicates that the glow plugs are heating. Leave the key

in the run position until the light goes out, then turn the

key to start.

B D FE

A

L

Figure 3. Dashboard Display

C

K

G

IJ

H

16

Page 16

Operation

Not for

Reproduction

Safety Interlock System Tests

This unit is equipped with safety interlock switches and

other safety devices. These safety systems are present for

your safety: do not attempt to bypass safety switches, and

never tamper with safety devices.

WARNING

If the unit does not pass a safety test, do not oper-

ate it. See an authorized dealer.

Test 1 — Engine should NOT crank if:

• PTO is engaged, OR

• Brake pedal is NOT fully depressed (parking brake

OFF), OR

Test 2 — Engine SHOULD crank and start if:

• Operator is sitting in seat, AND

• PTO is disengaged, AND

• Brake pedal is fully depressed (parking brake ON),

AND

Test 3 — Engine should SHUT OFF if:

• Operator rises off seat.

Test 4 — Check Mower Blade Stopping Time

Mower blades and mower drive belt should come to a

complete stop within five seconds after PTO is disengaged. If mower drive belt does not stop within five seconds, see an authorized dealer.

Test 5 — Check Reverse Mow Option (RMO)

• Engine should shut off if reverse travel is attempted if

the PTO is engaged and RMO has not been activated.

• RMO light should illuminate when RMO has been activated.

Adding Fuel

To add fuel:

1. Remove the fuel cap (A, Figure 4).

2. Fill the tank. Do not overfill. Leave room in the tank for

fuel expansion. Refer to your engine manual for specific fuel recommendations.

3. Install and hand tighten the fuel cap.

Starting the Engine

1. While sitting in the operator’s seat, fully depress the

brake pedal or set the parking brake.

2. Set the cruise control lever in neutral and make sure

that your feet are not depressing the ground speed

control pedals.

3. Disengage the PTO.

4. Set the throttle to middle position (set throttle to FULL

when starting in cold weather).

5. Turn the key to the RUN position to activate the glow

plugs; the glow plug light in the dashboard display will

light.

6. Wait for the glow plug light to turn off, then turn the key

to START. If the engine does not start immediately,

move the throttle to FULL.

7. After the engine starts, move the engine throttle control to SLOW. Warm up the engine by running it for at

least a minute.

8. Move the throttle to FULL before engaging the PTO

switch or driving the tractor.

NOTE: In the event of an emergency the engine can be

stopped by simply turning the ignition switch to STOP.

Use this method only in emergency situations. For

normal engine shut down follow the procedure given i

STOPPING THE TRACTOR.

WARNING

Mowing in reverse can be hazardous to bystanders. Tragic accidents can occur if the operator is not alert

to the presence of children. Never activate the RMO if

children are present. Children are often attracted to the

unit and the mowing activity.

en

17

Page 17

Stopping the Tractor & Engine

Not for

Reproduction

1. Return the ground speed control(s) to neutral and

engage the parking brake.

2. Disengage the PTO and wait for all moving parts to

stop.

3. Place the throttle control in the position specified in

the engine owner’s manual provided in the operator’s

packet shipped with your tractor. Follow any recommended stopping procedures.

4. Turn the ignition switch to OFF. Remove the key.

Mowing in Reverse

WARNING

The engine will shut off if the reverse ground

speed pedal is depressed while the PTO is

on and the RMO has not been activated. The

operator should always turn the PTO off prior to

driving across on roads, paths or any area that

maybe used by other vehicles. Sudden loss of

drive could create a hazard.

Driving the Tractor

1. Sit in the seat and adjust the seat so that you can

comfortably reach all the controls and see the dashboard display.

2. Engage the parking brake.

3. Make sure the PTO switch is disengaged.

4. Start the engine (see STARTING THE ENGINE).

5. Disengage the parking brake and release the brake

pedal.

6. Depress the forward ground speed control pedal to

travel forward. Release the pedal to stop. Note that

the further down the pedal is depressed the faster the

tractor will travel.

7. Stop the tractor by releasing the ground speed control pedals, setting the parking brake, and stopping

the engine (see STOPPING THE TRACTOR AND

ENGINE).

Mowing

1. Engage the parking brake. Make sure the PTO switch

is disengaged.

2. Start the engine (see STARTING THE ENGINE).

3. Set the hydraulic selector switch to REAR. Fully lower

the mower using the attachment lift lever.

4. Set the mower cutting height to the desired level.

5. Set the throttle to FULL.

6. Set the PTO selector to MID PTO ONLY. Engage the

PTO switch.

7. Begin mowing.

8. When finished, shut off the PTO and raise the mower

using the attachment lift control lever.

9. Stop the engine (see STOPPING THE TRACTOR

AND ENGINE).

WARNING

Mowing in reverse can be hazardous to

bystanders. Tragic accidents can occur if the

operator is not alert to the presence of children.

Never activate RMO if children are present.

Children are often attracted to the unit and the

mowing activity.

If an operator chooses to mow in reverse, the RMO system can be used. To use the Reverse Mowing Option

(RMO) turn the RMO key after the PTO is engaged. The

L.E.D. light will illuminate, and the operator can then mow

in reverse. Each time the PTO is disengaged the RMO

needs to be reactivated if desired. The key should be

removed to restrict access to the RMO feature.

Attachment Operation in Reverse

If an operator chooses to operate a PTO driven attachment in reverse, the RMO system can be used. To use

the Reverse Mowing Option (RMO) turn the RMO key

after the PTO is engaged. The L.E.D. light will illuminate, and the operator can then operate the attachment

in reverse. Each time the PTO is disengaged the RMO

needs to be reactivated if desired. The key should be

removed to restrict access to the RMO feature.

4-Wheel Drive Operation

When operating in 4WD without a mower deck installed

on the tractor, it is recommended you install rear wheel

weights to increase stability.

18

Page 18

WARNING

Not for

Reproduction

If you cannot back up a hill in 2WD, Do not

operate on it. Use extra caution on slopes. To

increase traction and provide four-wheel braking,

engage mechanical front wheel drive (4WD)

when driving on slopes. Be aware that 4WD can

improve access to dangerously sloped terrain,

thereby increasing the possibility of tipover.

Pushing the Tractor By Hand

DO NOT TOW TRACTOR

Towing the unit will cause transmission damage.

Do not use another vehicle to push or pull this

unit. Do not actuate the transmission release

valve lever while the engine is running.

1. Disengage the PTO and turn the engine off.

2. Push the transmission release (B, Figure 4) forward

and down to lock into the released position. The tractor can now be pushed by hand.

3. Move the lever rearward and up to engage the transmission.

A

B

Figure 4. Transmission Release Lever & Fuel Tank

en

19

Page 19

Hydraulic System Functions

Not for

Reproduction

General

All of the inboard and auxiliary hydraulics are controlled

by the attachment lift control lever. The attachment lift

control lever raises and lowers attachments that utilize

the tractor’s hydraulic lift cylinder. This lever also controls

attachments that use the tractor’s auxiliary hydraulics via

the quick couplers on the front left and right sides of the

frame.

The rate of hydraulic fluid flow and pressure that are available when using the auxiliary hydraulic quick couplers is

listed in the chart in Figure 5.

The lever has five positions: left, right, back, forward (first

detent) and float (pushed forward to second detent).

Using Inboard Hydraulics

The inboard hydraulics control the tractor’s belly attachment lift (mower deck) and three point hitch lift (if

equipped). The front / rear hydraulic selector switch must

be in the REAR position.

Pulling the lever back raises the attachment lift (A, Figure

6). Pushing the lever forward to the first detent lowers the

attachment lift (B, Figure 6). Pushing the lever forward

to the second detent locks the control in “float” position,

allowing the lift mechanism to float up and down.

A.

B.

Implement Flow @ 3600 RPM

7

6

5

4

Implement Flow — gpm

3

0 100 200 300 400

Pressure — psi

Figure 5. Hydraulic System Pressure / Flow

Figure 6. Inboard Hydraulics

20

Page 20

A.

Not for

Reproduction

Figure 7. Auxiliary Hydraulics

B.

Using Auxiliary Hydraulics

The attachment lift control is also used to control attachments that use the tractor’s auxiliary hydraulic couplers

located on the right and left front frame rails. The left set

of quick couplers is activated when the front / rear hydraulic switch is turned to the FRONT position (this disables

the inboard hydraulic cylinder).

Moving the control lever to the left (A, Figure 7) angles

the attachment left. Moving the lever right (B) angles the

attachment right.

Pulling the lever back raises the attachment lift (A, Figure

8). Pushing the lever forward to the first detent lowers the

attachment lift (B, Figure 8). Pushing the lever forward

to the second detent locks the control in “float” position,

allowing the lift mechanism to float up and down.

Many approved attachments have color coded quick couplers to aid in installation. Match the tractor quick coupler

with the like colored attachment quick coupler.

A.

B.

en

21

Figure 8. Auxiliary Hydraulics

Page 21

Optional 3-Point Hitch

Not for

Reproduction

Operation (Select Models)

Attachment Weight Limit

The maximum allowable attachment weight is determined

by the gross weight of the attachment verses the distance

from the end of the tractor hitch arm to the attachment’s

center of gravity (Figure 10). The further an attachment’s

center of gravity is from the tractor, the more leverage is

required to raise it.

Measure the distance from the end of the hitch arms to

the attachment’s center of gravity (Figure 10) and use

the graph in Figure 9 to determine if an attachment is too

heavy to be used with your tractor.

Always use a front weight carrier and 50 lbs. suitcase

weights when using a rear-mounted attachment. Remove

the front weights when the rear attachment is removed.

CAUTION

Avoid injury! A machine with a 3-point hitch

attachment installed may become unstable when

the attachment is raised. Always drive slower

over uneven ground and when turning with the

attachment raised.

Max. Attachment Weight

600

400

200

0

Max. Attachment Weight (Lbs.)

Figure 9. Attachment Weight Limit

Distance from End of Hitch Arm

to Attachment Center of Gravity (Feet " ")

Approved

Weight Range

1'0'

Distance from End of Hitch Arm

to Attachment Center of Gravity

2'

X'

3'

Attachment

4'

X'

Locking the Hitch

The 3-point hitch can be locked in the raised position.

When a rear attachment is locked in the raised position,

the tractor’s on-board hydraulic cylinder can be used to lift

mid mounted attachments without having to remove the

rear attachment. For example, if a tractor equipped with

a tiller is to be used for mowing, the tiller can be locked in

the raised position allowing the mower to be installed and

used.

To lock the 3-point hitch in the raised position:

1. Raise the attachment lift.

2. Remove the locking rod from its storage position (A,

Figure 11) and insert it below the hitch arms in the

locking position (B).

3. Secure with a hair pin clip.

End of Hitch Arm

Figure 10. Attachment Weight Limit

Figure 11. Hitch Rod Positions

Attachment's Center

of Gravity

A

B

22

Page 22

E

Not for

Reproduction

D

E

B

C

D

F

F

A

A

B

C

Figure 12. Install Sway Arms

B

Hitch Arms Installation

1. Attach the upper lift link (D, Figure 12) to the hitch

using a clevis pin (F) and safety clip (E).

2. Attach the sway arms (A, Figure 12) to the hitch

assembly using clevis pins (C) and hair pin clips (B).

The arms should angle out, away from center.

3. Attach the sway chains (D, Figure 13) to the back of

the sway arms (A, E) using 3/8 x 1-1/2 capscrews

(C) and 3/8 locknuts. Cross the chains and secure

to front of the sway arms with clevis pins and hair pin

clips (B).

4. Attach the adjustable link (E, Figure 14) and lift link

assembly (C) using clevis pins (B) and hair pin clips.

NOTE: The adjustable lower lift link (E, Figure 14) goes

on the right side.

C

A

Figure 13. Install Chains

Figure 14. Install Lift Links

B

E

B

D

C

B

C

B

E

B

C

B

A

en

23

Page 23

540 Rear PTO Operation (Select Models)

ABC

Not for

Reproduction

Checks Before Starting

Refer to the Maintenance & Adjustments sections of this

manual and perform any needed service.

Connecting a Drive Shaft

1. Disengage the PTO, set the parking brake, stop the

engine, and wait for all moving parts to stop.

2. Pull back on the locking collar (A, Figure 15) and slide

the connector on the PTO shaft as far as it will go.

3. Pull back on the drive shaft until the locking collar snaps into place. Check that the connection is

secure.

Starting & Stopping the PTO

1. Stop the engine and remove the key. Set the parking

brake.

2. See Attachment Operator’s Manual or Installation

Instructions to properly install/connect the attachment

to be used. If connecting to a stationary attachment,

set the parking brake during attachment operation.

3. Start the tractor engine. Allow the engine to warm-up

for several minutes before engaging the PTO.

4. Set engine throttle to FULL

5. Place the PTO selector lever in the rear position (A,

Figure 16) if only a rear attachment is being used. If

a mid and rear attachment are being used simultaneously, place the lever in the mid position (B). If only a

mid or front attachment is being used, place the control in position (C).

6. Pull UP on the PTO switch to engage the PTO.

7. When finished, move the throttle control to IDLE and

push the PTO switch DOWN to disengage. Wait for

all moving parts to stop.

8. When disconnecting the attachment, stop the engine,

remove the key, and set the parking brake. Wait for

all moving parts to stop.

A

Figure 15. Typical Drive Shaft

Figure 16. PTO Selector Lever

Engine Speed Selection

When engaging the rear PTO, set the throttle to FULL.

When disengaging the rear PTO, set the throttle to IDLE

and allow the attachment to slow down.

While using an attachment, always set the throttle to

FULL.

24

Page 24

540 Attachment Recommendations

Not for

Reproduction

GENERAL

This rear PTO was designed and tested with the 540

RPM rear tiller sold by Simplicity Manufacturing. There

are a wide variety of other 540 attachments available

from numerous manufacturers. It is impossible for us to

test every one of them. There are a few basic, commonsense criteria that can be used to determine whether

these attachments are suitable for use with your tractor.

In general, any attachment that:

• stalls the engine,

• requires the clutch to be toggled on and off while start-

ing, or

• takes longer than 3 seconds to reach operating speed

is too large.

PTO BOX OUTPUT SPEED & HORSEPOWER

OUTPUT

This rear PTO box is designed to output a maximum of

18 horsepower at 540 RPM. Therefore it should only be

used to run 540 RPM attachments that require 18 HP or

less.

Using this PTO box to run attachments that require

more than 18 HP or an input shaft speed other than

540 could result in poor performance, shortened

equipment life, or equipment damage, and will void

the tractor warranty. Improper use can also create

an unsafe condition resulting in injury.

This PTO can be used with direct drive attachments

that have small start-up and stopping loads like tillers or

mower decks.

DO NOT use this PTO box with attachments that require

a large amount of torque to start: for example, attachments such as direct drive chipper/shredders and large

silo blowers cannot be used because their starting and

stopping loads may damage the PTO clutch.

Large attachments that have their own clutching mechanism to lessen the load on the PTO box during starting

and stopping may be used provided they do not exceed

the 18 horsepower limit.

OVERLOAD PROTECTION

Any attachment used with this PTO box MUST have

shear pin(s), shear bolt(s), a slip clutch, or some other

device to prevent PTO box damage if the attachment

should jam.

en

25

Page 25

Attaching a Trailer

Not for

Reproduction

The maximum weight of a towed trailer should be less

than 800 lbs (363 kg). Secure the trailer with an appropriately sized clevis pin (A, Figure 17) and clip (B).

Excessive towed loads can cause loss of traction and

loss of control on slopes. Reduce towed weight when

operating on slopes. The surface being driven on greatly

impacts traction and stability. Wet or slippery surfaces

can greatly reduce traction and the ability to stop or turn.

Carefully evaluate the surface conditions before operating the tractor and trailer, and never operate on slopes

greater than 10°. See SLOPE OPERATION and TOWED

EQUIPMENT in the safety section of this manual for additional safety information.

Storage

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can

travel to an ignition source (such as a furnace,

water heater, etc.) and cause an explosion.

Fuel vapor is also toxic to humans and animals.

Before you store your unit for the off-season, read the

Maintenance and Storage instructions in the Safety

Rules section, then perform the following steps:

• Disengage the PTO, set the parking brake, and

remove the key.

• Perform engine maintenance and storage measures

listed in the engine owner’s manual. This includes

draining the fuel system, or adding stabilizer to the

fuel (do not store a fueled unit in an enclosed structure - see warning).

• Battery life will be increased if it is removed, put in

a cool, dry place and fully charged about once a

month. If the battery is left in the unit, disconnect the

negative cable.

Before starting the unit after it has been stored:

• Check all fluid levels. Check all maintenance items.

• Perform all recommended checks and procedures

found in the engine owner’s manual.

• Allow the engine to warm up for several minutes

before use.

A

B

800 Lbs.

(363kg)

3'4"

(1m)

20' (6m)

Figure 17. Trailer Weight Recommendations

10˚

12 Volt Power Outlet

The 12-volt accessory outlet is located in the left side

pod. It can be used to power small electronic devices.

The accessory must be rated at 14 amps or less.

NOTE: Operating a 12-volt accessory, especially with

the engine at idle, may cause battery discharge. When

not using the accessory outlet it must be covered with

the rubber plug to prevent moisture from causing a short

circuit. Entrance of water into outlet can cause a short

circuit.

26

Page 26

Maintenance Chart

Not for

Reproduction

Maintenance

TRACTOR AND MOWER

Every 8 Hours or Daily

Check safety interlock system

Clean debris o tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually *

Check tire pressure

Check mower blade stopping time

Check tractor and mower for loose hardware

Every 50 Hours or Annually *

Clean battery and cables

Check tractor brakes

See Dealer Annually to

Lubricate tractor and mower

Check mower blades **

* Whichever comes rst

** Check blades more often in regions with sandy soils or

high dust conditions.

ENGINE

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Check engine oil level

Every 25 Hours or Annually *

Clean engine air lter and pre-cleaner **

Every 50 Hours or Annually *

Change engine oil

Replace oil lter

Annually

Replace air lter

Replace pre-cleaner

See Dealer Annually to

Inspect muer and spark arrester

Replace spark plug

Replace fuel lter

Clean engine air cooling system

Engine Maintenance

Refer to the engine owner’s manual for all engine maintenance procedures and recommendations.

Check the Tire Pressure

Tires should be checked periodically to provide the

optimum traction and to guarantee the best cut (see

Figure 18).

NOTE: These pressures may differ slightly from the

“Maximum Inflation” stamped on the side walls of the tires.

* Whichever comes rst

** Clean more often in dusty conditions or when airborne

debris is present.

Size Tread PSI bar

26 x 12-12 Turf 12-15 0,83-1,03

18 x 8.5-8 Turf 20-22 1,38-1,52

26 x 12-12 Field 10-12 0,69-0,83

18 x 8.5-10 Field 20-22 1,38-1,52

Figure 18. Tire Pressure

en

27

Page 27

Check Transmission Oil Level

Not for

Reproduction

Do not allow dirt, water, or other debris to

enter the expansion chamber or transmission.

Even a small amount of dirt can damage the

transmission

Service Interval: Every 25 Hours

Oil Type: Type F Automatic Transmission Fluid

1. Clean the area around the transmission dip stick (A,

Figure 19).

2. Remove the dip stick (A) from the transmission and

wipe it clean.

3. Insert the dip stick into the transmission without

threading it in. Remove the dip stick and read the oil

level. The oil level should be even with the top of the

hash mark area when the transmission is cold.

Cleaning the Battery and Cables

WARNING

When removing or installing battery cables,

disconnect the negative cable FIRST and

reconnect it LAST. If not done in this order, the

positive terminal can be shorted to the frame by a

tool.

A

Figure 19. Transmission Fluid Check

A

B

C

D

1. Disconnect the cables from the battery, negative

cable first (C, Figure 20).

2. Remove the battery clamp (B) and battery. On diesel

models the battery clamp is secured with bolts to both

frame rails (D).

3. Clean the battery compartment with a solution of baking soda and water.

4. Clean the battery terminals and cable ends with a wire

brush and battery terminal cleaner until shiny.

5. Reinstall the battery in the battery compartment, and

secure with the battery clamp (B).

6. Reattach the battery cables, positive cable first (A).

7. Coat the cable ends and battery terminals with petroleum jelly or non-conducting grease.

28

Figure 20. Battery - Diesel Models

Page 28

Battery Charging

Not for

Reproduction

WARNING

Keep open flames and sparks away from the

battery; the gasses coming from it are highly

explosive. Ventilate the battery well during

charging.

A dead battery or one too weak to start the engine may be

the result of a defect in the charging system or other electrical component. If there is any doubt about the cause of

the problem, see your dealer. If you need to replace the

battery, see the Clean the Battery and Cables section.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the Operator Safety section of this manual.

Charge the battery until fully charged. Do not charge at a

rate higher than 10 amps.

Check Mower Blade Stopping Time

The mower should come to a complete stop within five

seconds after PTO switch is turned off.

1. With tractor in neutral, PTO disengaged and operator

in seat, start the engine. Make sure the area is clear

of bystanders.

2. Engage the PTO and wait several seconds.

Disengage the PTO and check the amount of time it

takes for the mower to stop.

3. If the mower does not stop within five seconds, see

your dealer.

Seat Adjustment

The seat can be adjusted forward and back. Move the

lever (A, Figure 21), position the seat as desired, and

release the lever to lock the seat into position.

A

Figure 21. Seat Adjustment

en

29

Page 29

Headlight Replacement

Not for

Reproduction

1. Open the hood (Figure 22).

2. Remove the forward heat shield.

3. Remove the light bulb socket from the bezel by twisting it counterclockwise and pulling it out.

4. Use a rag or gloves to remove and replace the light

bulb with an identical halogen bulb. DO NOT TOUCH

THE BULB WITH YOUR BARE HANDS.

5. Reinstall the socket into the bezel.

Taillight & Dash Light Replacement

1. Twist the socket counterclockwise and pull out to

remove it from the taillight or dashboard display

(Figure 23).

2. Remove and replace the old bulb with a new identical

bulb.

3. Reinstall the socket into the taillight bezel or dashboard display.

Figure 22. Headlight Replacement

Gauge Wheel Adjustment

The mower gauge wheels can be placed in two positions

depending on the height of cut. When using higher cutting heights, set the wheels in the lower position. When

using lower cutting heights, set the wheels in the upper

position. To adjust:

1. Remove the hair pin clip (A, B, Figure 24).

2. For upper position, install the pin (A) through the

spindle above the bracket (C). For the lower position,

push down on the top of the spindle, and install the

hair pin clip (B) below the top of the bracket (C).

Figure 23. Taillight Replacement

A

B

C

Figure 24. Gauge Wheel Adjustment

30

Page 30

Troubleshooting the Tractor

Not for

Reproduction

PROBLEM LOOK FOR REMEDY

Brake pedal is not

depressed.

PTO is engaged. Disengage the PTO.

Out of fuel. If engine is hot, allow it to cool, then rell the fuel tank.

Engine ooded. Disengage the choke.

Fuse is blown. See authorized dealer.

Troubleshooting

Fully depress the brake pedal.

Engine will not

turnover or start.

Engine starts hard or

runs poorly.

Engine knocks.

Excessive oil

consumption.

Engine exhaust is

black.

Battery terminals require

cleaning.

Battery discharged or

dead.

Wiring loose or broken. Visually check wiring. If wires are frayed or broken, see

Solenoid or starter motor

faulty.

Safety interlock switch

faulty.

Water in fuel. See authorized dealer.

Gas is old or stale. See authorized dealer.

Fuel mixture too rich. Clean air lter.

Engine has other

problem.

Low oil level. Check or add oil as required.

Using wrong grade oil. See engine manual.

Engine running too hot. See authorized dealer.

Using wrong grade oil. See engine manual.

Too much oil in

crankcase.

Dirty air lter. See engine manual.

Choke closed. Open choke.

See Clean the Battery and Cables section.

Recharge or replace battery.

authorized dealer.

See authorized dealer.

See authorized dealer.

See authorized dealer.

Drain excess oil.

Ground speed control

pedals not depressed.

Transmission release

Engine runs, but tractor

will not drive.

en

31

lever in PUSH position.

Parking brake is engaged. Disengage the parking brake.

Traction drive belt is

broken or slipping.

Depress pedals.

Move transmission release lever to DRIVE position.

See authorized dealer.

Page 31

Troubleshooting the Tractor (Continued)

Not for

Reproduction

PROBLEM LOOK FOR REMEDY

Brake will not hold.

Internal brake worn. See authorized dealer.

Steering linkage is loose. See authorized dealer.

Tractor steers hard or

handles poorly.

Improper tire ination. See Check the Tire Pressure section.

Front wheel spindle

bearings dry.

Troubleshooting the Mower

PROBLEM LOOK FOR REMEDY

Lift linkage not properly

Mower will not raise.

Mower cut is uneven.

Mower cut is rough

looking.

attached or damaged.

Mower not leveled

properly.

Blades are damaged. See authorized dealer.

Tractor tires not properly

inated.

Engine speed too slow. Set to full throttle.

Ground speed too fast. Slow down.

Blades need sharpening. See authorized dealer.

Mower has other problem. See authorized dealer.

See authorized dealer.

See authorized dealer.

See authorized dealer.

See Check the Tire Pressure section.

Engine stalls easily

with mower engaged.

Excessive mower

vibration.

Engine runs and tractor

drives, but mower will

not drive.

Catcher full alarm

does not sound when

catcher is full.

Engine speed too slow. Set to full throttle.

Ground speed to fast. Slow down.

Dirty or clogged air lter. See engine manual.

Cutting height set too low. Cut tall grass at maximum cutting height during rst pass.

Engine not up to

operating temperature.

Starting mower in tall

grass.

Catcher assembly not

closing properly.

Mower has other problem. See authorized dealer.

PTO not engaged. Engage the PTO.

Mower has other problem. See authorized dealer.

Grass buildup around

lever.

Alarm has other problem. See authorized dealer.

Run engine for several minutes to warm-up.

Start the mower in a cleared area.

Close catcher until latches are engaged. If still not closing

properly, see authorized dealer.

Clean area around lever.

32

Page 32

Specifications

Not for

Reproduction

ENGINE:

Briggs & Stratton

Make Briggs & Stratton

Model DM 950 D - Model 582447

Displacement 58.1 cu in (952 cc)

Electrical System Alternator: 40 amp

Battery: 12 Volt, 500 CCA

Oil Capacity 3.2 qt (3,0 L)

CHASSIS:

Fuel Tank Cap. 5.5 gal (20,8 L)

Rear Wheels:

Turf Tires Tire Size: 26x12-12

Inflation Pressure: 12-15 psi (0,83-1,03 bar)

HD Field Tires Tire Size: 26x12-12

Inflation Pressure: 10-12 psi (0,69-0,83 bar)

Front Wheels:

Turf Tires Tire Size: 18x8.5-8

Inflation Pressure.: 20-22 psi (1,38-1,52 bar)

HD Field Tires Tire Size: 18x8.5-10

Inflation Pressure.: 20-22 psi (1,38-1,52 bar)

TRANSAXLE:

Make Tuff Torq

Type K92 Integrated Hydrostatic Pump & Transaxle

Hydraulic Fluid Type F Automatic Transmission Fluid

Capacity 4WD-540: 9.5 qt /9,0 L

Speeds Forward: 0-9.0 mph (0-14,5 kph)

@ 3400 rpm Reverse: 0-5.5 mph (0-8,8 kph)

Continuous Torque 1200 ft-lbs (166 kg-m)

Output

Make Shibaura

Lubrication 80W-90 Gear Lube

Capacity 1.6 qt (1,5 L)

DIMENSIONS:

Overall Length 81” (206 cm)

Overall Width 44.9” (114 cm) (4WD)

Height 51,2” (130 cm)

Weight (approx.)

4WD Tractor, B&S Diesel 1131 lbs (513 kg)

54” Mower Deck 230 lbs (104 kg)

Power rating

The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque Rating Procedure), and rating performance has been obtained

and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower

values are derived at 3600 RPM. The gross power curves can be viewed at www.BRIGGSandSTRATTON.COM. Net

power values are taken with exhaust and air cleaner installed whereas gross power values are collected without these

attachments. Actual gross engine power will be higher than net engine power and is aected by, among other things,

ambient operating conditions and engine-to-engine variability. Given the wide array of products on which engines

are placed, the gas engine may not develop the rated gross power when used in a given piece of power equipment.

This dierence is due to a variety of factors including, but not limited to, the variety of engine components (air cleaner,

exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for this Series engine.

Parts and accessories

Contact an authorized dealer for details.

en

33

Page 33

BRIGGS & STRATTON POWER PRODUCTS GROUP, L.L.C. OWNER WARRANTY POLICY

Not for

Reproduction

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair and/or replace, free of charge, any part(s) of the equipment that is

defective in material or workmanship or both. Briggs & Stratton Corporation will repair and/or replace, free of charge, any part(s)

of the Briggs & Stratton engine* (if equipped) that is defective in material or workmanship or both. Transportation charges on