Page 1

Safety Instructions & Operator’s Manual for

73” FINISHING MOWER

CATAGORY ONE

3 POINT HITCH

MODEL

FM7300

Thank you for buying a SNAPPER Product! Before operating your finishing mower, read this manual carefully

and pay particular attention to the “IMPORTANT SAFETY INSTRUCTIONS” on Pages 2 & 3. The “IMPORTANT

SAFETY INSTRUCTIONS” on pages 2 & 3 of this manual provide general saf e operating practices and w arnings

for operating powered lawn mowers. You must refer to your tractor manual for specific operating instructions

and warnings for your tractor. Remember that all power equipment can be dangerous if used improperly. Also

keep in mind that SAFETY requires careful use in accordance with the operating instructions and common

sense!

COPYRIGHT © 1998

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 7-2074 (I.R. 11/16/98)

Page 2

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This finishing mower is capable of amp ut atin g h ands an d f e et and can throw object s th at can cause

injury and damage! Failure to comply with the following SAFETY instructions could result in serious injury or

death to the operator or other persons. The owner of the finishing mower must understand these instructions

and must allow only persons who understand these instructions to operate the finishing mower. Each person

operating the finishing mower must be of sound mind and body and must not be under the influence of any

substance which might impair vision, dexterity or judgment. If you have any questions pertaining to the

finishing mower which your dealer cannot answer to your satisfaction, call or write the Customer Service

Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). Follow the SAFETY

instructions provided with your tractor and contact your dealer or the tractor manufacturer if you have any

questions pertaining to its safe use.

PROTECTION FOR CHILDREN

Tragic accidents can occu r if the operator is not alert

to the presence of children. Children are often

attracted to the mower and the mowing act ivity. Never

assume that children w ill remain where you last saw

them.

1. KEEP children out of the mowing area and under

the watchful care of a responsible adult.

2. DO NOT allow children in yard when mower is

operated (even with the blade OFF).

3. DO NOT allow children or ot her p assenge rs t o rid e

on mower (even with the blade OFF). They may fall

and be seriously injured.

4. DO NOT allow pre-teenage children to operate

mower.

5. ALLOW only adults or responsible teenagers with

mature judgment under close adult supervision to

operate mower.

6. BE SURE the area is clear of others before

mowing and turn mower OFF if anyone enters the

area.

7. DO NOT mow in reverse unless absolutely

necessary. LOOK BEHIND and down for small

children before and when backing.

8. USE EXTRA CARE when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

PROTECTION AGAINST TIPOVERS

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra CAUTION. If

you cannot back up the slope or if you feel uneasy on

it, DO NOT mow it. Use extra care when using the

finishing mower; it can change the stability of the

tractor.

1. DO NOT operate mower on slopes exceeding 15

degrees (27% grade).

2. Exercise EXT REME CAUTION on slopes abov e 10

degrees (18% grade). Turn blade OFF when

traveling uphill. Use first speed and avoid sudden

or sharp turns.

3. DO NOT mow back and forth across face of

slopes. Mow up and down.

PROTECTION AGAINST TIPOVERS

(Continued From Previous Column)

4. AVOID uphill starts. If you stop mowing while

going uphill or tires lose traction, turn bl ade OFF

and back slowly down the slope.

5. STAY ALERT for holes and other hidden hazards.

Tall grass can hide obstacles. Keep away from

ditches, washouts, culverts, fences and

protruding objects.

6. KEEP A SAFE DISTANCE (at least 3 feet) away

from edge of ditches and other drop offs. The

mower could turn over if an edge caves in.

7. Always begin forward motion slowly.

8. This mower attach ment can affect the handling a nd

stability of the tractor. Counter weights may be

required. Contact the tractor dealer or tractor

manufactur er for recom mend ed saf e pr actic e befo re

operating.

9. DO NOT mow on wet grass. Reduced traction

could cause sliding.

10. DO NOT mow under any condition where traction,

steering or stability is doubtful without first test

driving over the terrain with blade OFF.

11. Operator Protective Structure may be required

when this mower attachment is mounted to your

tractor. Contact the tractor dealer or tractor

manufacturer for Safe Operation instructions

before operating.

PREPARATION

1. Read this manual and tractor manual. Get to know

where all controls a re located and practice ho w to

use them before starting for the first time, and at

the beginning of each se ason. Read and follow all

Warnings and Instructions

2. Only mature, responsible persons shall operate

the machine and only after proper instruction.

3. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved

fuel container. Never re move fuel cap or add fuel

with engine running. Add fuel outdoors only with

engine stopped and cool. Clean spilled fuel from

machine. DO NOT smoke.

4. Practice operation of mower with BLADE OFF to

learn controls and develop skills.

(Continued on Next Page)

Page 3

3

IMPORTANT SAFETY INSTRUCTIONS

PREPARATION

(Continued From Previous Page)

5. Check the area to be mowed and remove all

objects such as to ys, wire, rocks, limb s and other

objects that could cause injur y if thrown by blade

or interfere with mowing.

6. Keep people and pets a safe distance from

machine.

7. Check shields, deflectors, switches, blade

controls and other safety devices frequently for

proper operation and location.

8. Make sure all safety decals are clearly legible.

Replace if damaged.

9. Protect yourself when mowing and wear safety

glasses, long pants and substantial footwear.

10. Know how to STOP blade and engine quickly in

preparation for emergencies.

11. Use extra care when loading or unloading the

mowing equipment into a trailer or truck.

12. Check grass catcher components frequently, if

applicable, for signs of wear or deterioration and

replace as needed to prevent injury from thrown

objects going through weak or worn spots.

13. Attach mower to tractor hitch using proper hitch

pins and retainers. If mower separates from

tractor during operation, serious injury or death

can result.

14. Adjust stabilizer bars on tractor hitch to prevent

driveline contact with tires during turns and keep

mower in proper position behind tractor.

15. Mower caster wheels mu st be on the ground and

support mower before turning blades on. DO NOT

operate mower at any time with casters off the

ground. Blades must stop rotating before lifting or

transporting mower to avoid dangerous driveline

condition.

OPERATION

1. Follow Tractor Manual Instructions for proper

tractor operation.

2. STOP BLADE and ENGINE and make sure blade

has stopped before removing grass catcher, if

applicable, or unclogging mower to prevent loss

of fingers or hand.

3. Blade must be OFF except wh en cu tt ing grass. Set

blade in highest position when mowing over

rough ground.

4. Keep hands and feet away from rotating blade

underneath deck. NEVER place foot on ground

while BLADE is ON or machine is in motion.

5. Deflector or entire grass catcher, if applicable,

must be in place. NEVER point discharge at

people, passing cars, windows or doors.

6. Slow down before turning.

7. Watch out for traffic when near or crossing

roadways.

8. STOP engine immediately after striking an

obstruction. Inspect mower and repair damage

before resuming operation.

9. Mow only in daylight or with good artificial light.

OPERATION

(Continued From Previous Column)

9. DO NOT pull loads when mower is attached to

tractor.

10. This mower attachment can affect the handling

and stability of the tractor it is mounted on. Refer

to your tractor manual or contact your tractor

dealer or tractor manufacturer for SAFETY

information and requirements for counter weights.

11. DO NOT operate mow er unless all guards, sh ields

and defectors are in place.

12. Rotating driveline contact can cause injury or

death. DO NOT operate mower without all driveline

& mower shields in place and functioning

properly.

13. DO NOT operate mower if driveline shielding is

damaged or does not rotate freely.

14. Make sure all motion has stopped (traction,

blades, etc.) and mower is parked in position to

prevent movement before approaching mower for

any reason.

15. DO NOT transport mower with mower blades

rotating.

16. DO NOT exceed the recommended operating

speed of mower driveline.

17. DO NOT stand on mower or driveline.

18. DO NOT exceed the safe working angle of the

driveline. Make sure blades have stopped rotating

before lifting mower.

19. DO NOT ent er th e area be t ween the tractor and the

mower until all rotating parts have stopped. STOP

tractor. STOP engine. STOP blades. Set brake.

Remove key.

20. DO NOT allow children or others to stand sit or

ride on finishing mower.

21. DO NOT lift people or objects with the finishing

mower.

MAINTENANCE

1. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

2. Lubricate mower at intervals specified in manual.

3. Mower blades are sharp and can cut. Wrap the

blades or wear heavy leather gloves and use

CAUTION when handling them.

4. Have mower serv iced by an authorized SNAPPER

dealer at least once a year and have the dealer

install any new safety devices.

5. Use only genuine SNAPPER replacement parts on

finishing mower to assure that original safety

standards are maintained.

6. DO NOT work under the mower when lifted unless

it has been securel y blo c ked t o p r ev ent th e mower

from falling or moving. Disconnect driveline from

tractor before doing any work on mower.

Page 4

4

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS................................................2-3

TABLE OF CONTENTS............................................................................4

SECTION 1 - FAMILIARIZATION............................................................. 5

SECTION 2 - SET-UP INSTRUCTIONS.................................................6-7

SECTION 3 - OPERATING INSTRUCTIONS.........................................8-9

Mower Preparation ........................................................................................................ 8

Tractor Preparation ....................................................................................................... 8

Mower Attachment ........................................................................................................ 8

Setting Cutting Height................................................................................................ 8-9

Starting & Stopping Mower .......................................................................................... 9

SECTION 4 - MAINTENANCE INSTRUCTIONS ................................... 10

Service - After First 5 Hours.......................................................................................10

Checking Mower Blade......................................................................................... 10

Checking Mower Drive Shaft ............................................................................... 10

Lubricating Mower Components................................................................................ 10

Mower Gear Box Lubrication ............................................................................... 10

Service - Every 25 Hours ............................................................................................ 10

Service - Annually ....................................................................................................... 10

SECTION 5- ADJUSTMENTS AND REPAIR.....................................11-13

Mower Belt Replacement ............................................................................................ 11

Mower Blade Replacement/Sharpening .................................................................... 11

Mower Spindles Bearing Replacement ..................................................................... 12

Driveline Repair ...................................................................................................... 12-13

WARRANTY............................................................................................ 14

IMPORTANT

The IMPORTANT SAFETY INSTRUCTIONS on pages 2 & 3 of this manual provide

safe operating instructions and warnings for powered lawn mowers. You must

refer to your tractor manual for safe operating instructions and warnings for your

tractor.

Page 5

5

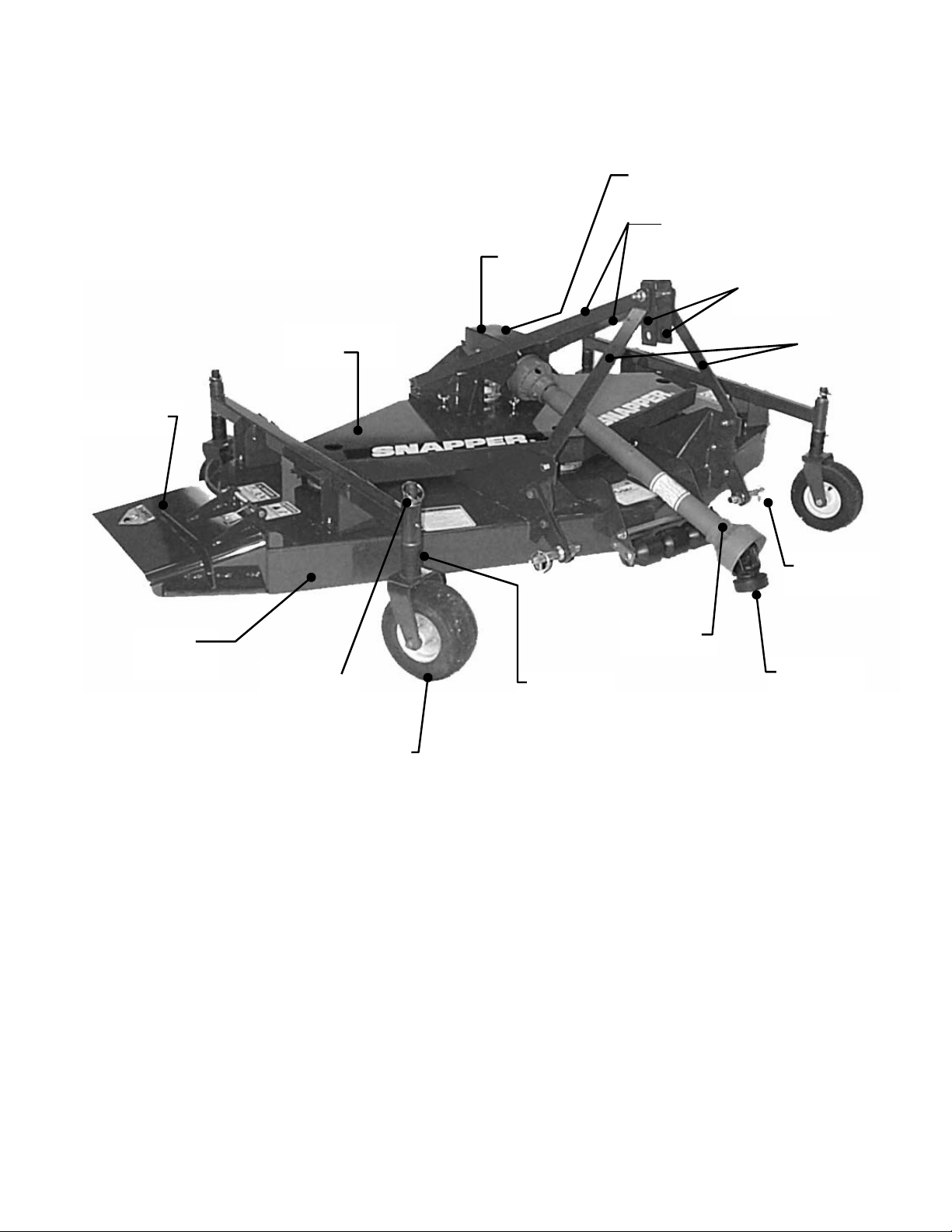

SECTION 1 - FAMILIARIZATION

BELT/SPINDLE

TOP HITCH

PIVOTING

COUPLING

CUTTING

CASTER

MOWER

FRONT HITCH

DEFLECTOR

DECK

1.1 INTRODUCTION

This manual has been prepar ed for the operator s of the

SNAPPER 73” Finishing Mower. Its purpose, aside

from recommending s tand a rd oper at ing procedures and

routine service requirements, is to promote SAFETY

through the use of accepted operat ing practices. Read,

Understand and Follow the IMPORTANT SAFETY

INSTRUCTIONS on Pages 2 and 3 of this m anual, ALL

Safety messages on the 73” Finishing Mower and all

Safety messages which accompany and are attached

to your tractor.

COVER

LYNCH PIN

WHEEL

DRIVESHAFT GUARD

REAR HITCH BARS

GEAR BOX

LINKS

BARS

HITCH

DRIVELINE

HEIGHT

SPACERS

RING

1.2 NOMENCLATURE

The nomenclature information above, shows specific

components of the SNA PP ER 73” Fin is hing Mo wer. It is

recommended that all operators of this equipment

become thoroughly familiar with the controls,

components, and operation of the mowing equipment

before operating the mower. Driveline information is

also found in the separate driveline owner’s manual.

Study all equipment manuals before operating the

mower and keep all manuals handy for future

reference.

Page 6

6

SECTION 2 - SET-UP INSTRUCTIONS FOR SNAPPER 73” FINISHING MOWER

GREASE

IDLER ARM

IDLER

SPINDLE

DRIVESHAFT

GEAR BOX

REMOVE BREATHER/FILLER

FRONT

BARS

Set-Up Instructions

The following instruc tions cover the initial set up of the

SNAPPER 73” Finishing M ower. Read and follow each

step carefully.

PLUG TO CHECK FLUID LEVEL

WARNING

Read entire manual before attempting to set up or

operate this mower.

This mower is designed for a Category 1 hitch and

540 rpm Power Take Off (PTO). Only attach this

mower to tractors compatible with Category 1 hitch

requirements.

DO NOT modify mower attachment in any way.

STOP tractor. STOP engine. SET Brake. REMOVE key.

Allow all moving parts t o stop before attempting an y

adjustments, maintenance or service to the mower.

STEP 1: Remove the m ower and components fr om the

shipping carton.

STEP 2: Assem ble front & rear hitc h bars and hitch link

as shown in Figure 1. Tighten all hardware securely.

NOTE: When assembled properly, hitch link should

pivot on hitch bolt sleeve.

REAR HITCH BARS

TOP HITCH LINKS

HITCH

GUARD (SERVICE

POSITION)

FIGURE 2

WARNING

Driveshaft guard must be down and securely attached

before operating mower.

B. Mower Spindle Housings. Locate the grease

fitting on the front of each of the three spindle

housings. Add grease ( Kendall NLGI No. 2 Lithium

grease) using grease gun u ntil gr eas e p urges ou t of

spindle housing vent. NOTE: The spindle housing

vent is located on the housing below the mower

deck surface. See Figure 3.

C. Idler Arm Pivot. Locate grease fitting on idler

arm. Add 1 to 3 shots of grease as needed fr om the

grease gun. See Figure 3.

STEP 3: Check all lubric ation points and gear box fluid

level.

A. Gear Box Fluid. The gear box holds 20 fluid

ounces of SAE 90 EP ge ar lubricant. To chec k the

level, remove th e breather/filler plug located o n the

top of the gear box. If lubricant is needed, the

driveshaft guard co vering the gear box will have to

be removed. Add fluid as needed to fill. Install

breather/filler plu g and dri veshaf t guard. See F igure

2.

FIGURE 1

PIVOT

HOUSING

FITTING

ARM

FIGURE 3

Page 7

7

SECTION 2 - SET-UP INSTRUCTIONS FOR SNAPPER 73” FINISHING MOWER

CASTER

CASTER

HUB

FITTING

TWIST COUPLING

DRIVESHAFT GUARD NOT SHOWN

D. Caster Bushings & Wheel Bearings. Locate

the four caster bushin g grease fittings. Add 1 to 3

shots of grease as needed from the grease gun.

Locate grease fittings in hub of caster wheels. Add

1 to 3 shots of grease as needed from the grease

gun. See Figure 4.

BUSHING

GREASE

FITTING

GEAR BOX

COUPLING RING

WHEEL

GREASE

FIGURE 4

STEP 4. Remove driveline from shipping carton.

Carefully inspect dr iveline for an y signs of dam age.

Driveline shields must turn freely.

The driveline is s upplied with a n Operator’s and Safety

Instruction Manual. Read this manual carefully.

Lubricate U-joint bear ings, shield bearings, teles coping

tubes, and locking collars as described in driveline

manual before attaching to mower.

STEP 5. Attach driveline to mower gear box.

A. Twist the knurled coupling ring on the U-joint.

See Figure 5.

RING & SLIDE ONTO

GEAR BOX SHAFT

DRIVELINE

FIGURE 5

IMPORTANT: The tractor end of the driveline is

identified on the driveline shield. DO NOT install

tractor end of driveline to mower.

B. With the coupling ring twisted, slide the drive-

line onto the gear box shaft. Release coupling ring.

C. Tug aggressively on drive line to insure it is fully

seated and securely locked onto gear box shaft.

STEP 6. Inspect the mower to insure that all guards

and shields have been installed. Check all

hardware to insure that it has been securely

tightened. The discharge deflector must be

attached and in the down or closed position before

operating.

WARNING

DO NOT attempt to operate driveline without all

guards and shields in pl ace and functioning p roperly

on tractor, driveline & mower.

Page 8

8

SECTION 3 - OPERATING INSTRUCTIONS

The operator m ust be familiar with the contents of this

manual before attempting to attach or operate this

mower. There may be specific operating and safety

instructions with the trac tor that are not covered in this

manual. Read and fol low the Instr uctions a nd W arnings

in the tractor manual before operating mower.

2.1 MOWER PREPARATION

Read and follow mower set up instructions and

inspect mower to insure mower has been

properly set up.

2.1.1. Check guards, shields, covers and

deflectors to mak e sure all are in place, sec urely

tightened and functioning properly.

2.1.2. Check lubrication points and gear box

fluid level for proper lubrication.

2.1.3. Inspect driveline. Driveline must be

securely attached to the mower gear box. All

driveline shields must be in place and rotate

freely.

2.1.4. Inspect mower blades for damage and

wear. Replace damaged or worn blades before

operating.

2.1.5. Verify that the discharge deflector is

attached and in the down/closed operating

position.

2.2 TRACTOR PREPARATION

The following are general guidelines.

Refer to the tractor manual or the tractor

manufacturer for specific instructions about the

preparation and operation of the tractor.

WARNING

The tractor may require counter weights and the

addition of an Oper a tor Pro tec t i ve Str uct ure whe n this

mower is attached. Follow the Safety Instructions

provided by the tractor manufacturer.

2.2.1. Remove tractor drawbar , if necessary, to

prevent interference and damage to the driveline.

2.3 ATTACHING MOWER TO TRACTOR

This mower is designed to attach to a tractor

equipped with a standard Category 1 three (3)

point hitch and 540 rpm Power Take Off (PTO).

2.3.1. Place tractor and mower on level s ur f ac e.

Lower tractor 3 point hitch.

2.3.2. STOP tractor. STO P engine. Set parking

brake. REMOVE key.

WARNING

DO NOT get between the tractor and mower when

the engine is running. STOP tractor. STOP engine.

Set Brake. REMOVE ke y. Allow all moving parts to

stop before leaving the operators position.

2.3.3. Attach lower tractor h itch arms to the pins

on the mower pivoting hitch. Secure with Lynch

pins.

2.3.4. Attach the top hitch link to the top hitch

link on the mower. Adjust the length of the link

and insert the pin. Secure pin with Lynch pin.

Tighten locking device on top hitch link.

2.3.5. Adjust stabilizer bars on lower hitch arms.

Refer to tractor manual for proper adjustment

procedure.

2.3.6. Attach driveline to trac tor Power T ake Off

(PTO). Twist coupling ring and slide driveline onto

tractor PTO shaft. Tug aggressively on driveline

yoke and insure that it is securely locked into

position.

Tractor Power Take Off (PTO) shield must be in place

before operating mower. Driveline must be securely

locked to tractor and mower to prevent dangerous

disconnect condition.

2.3.7. Verify the minimum and maximum

working lengths of the driveline. The telescoping

tubes must overlap at least 1/3 of the length whi le

in use. The driveline must not bottom out or

disengage during tr ans port . Verify drivelin e length

before engaging Power Take Off (PTO).

DO NOT attempt any adjustments, maintenance or

service to mower with engine running. STOP tractor.

STOP engine. Set Brake. REMOVE key. Allow all

moving parts to stop before approaching mower.

2.4 SETTING THE CUTTING HEIGHT.

2.4.1. Use tractor hitch to lift mower until all f our

casters are off the ground.

2.4.2. STOP engine. Remove key. Make sure

all moving parts have stopped. Support mower

securely to prevent it from falling.

2.4.3. Adjust cutting height by moving the

spacers located on the mower casters. Placing

more spacers on the bottom will increase the

cutting height. Removing spacers from the bottom

will lower the cutting height. Each caster has a

total of 6 (1/2”) slotted spacers to adjust the

height of the deck. There must always be 6

spacers installed.

A. To rem ove spacers, first remove th e Lynch

pin and washer from the top of the caster.

B. Raise cutting height b y sliding spacer(s) off

of top and installing on bottom. Align slotted

end of spacer with the two flats on the caster

shaft. Slide spacer across flats. Repeat as

needed to raise height.

WARNING

WARNING

Page 9

9

SECTION 3 - OPERATING INSTRUCTIONS

C. Push up on caster t o remove slac k between

spacers. Install washer and Lynch pin.

D. Reverse procedure to lower cutting height.

NOTE: All casters should have the same

number of spacers instal led below the caster

tube when the cutting height adjustment is

completed.

2.5 STARTING & OPERATING THE MOWER

Refer to the tractor Operator’s Man ual for star ting

and operating instructions for the tractor. Be

familiar with all controls. Know how to stop the

tractor & mower quickly in case of an emergency.

WARNING

DO NOT operate mower in transport position. All

mower caster wheels must be in contact with the

ground before blades are engaged.

2.5.1. Transport tractor & m ower with blades of f

to area to be cut.

2.5.2. Lower m ower until all four caster wheels

are on the ground.

2.5.3. Select a slow ground speed until you

become familiar with the operation of the mower.

Adjust forward speed, if desired, within safe

cutting conditions.

2.5.4. Engage tractor Power Take Off (PTO)

slowly to engage mower blades. 540 rpm Power

Take Off (PTO) speed is required.

WARNING

DO NOT exceed 540 RPM Power Take Off (PTO)

speed.

2.6 STOPPING MOWER

Refer to tractor manual for details on the

operation of the PTO.

2.6.1. Stop tractor. Bring engine to idle.

2.6.2. Disengage tractor PTO.

WARNING

DO NOT leave machine with engine running. STOP

engine. STO P blades. Set brake. REM OVE key. Allow

all moving parts to stop before leaving operator’s

position. Place mower on ground. DO NOT leave in

transport position.

2.6.3. Stop engine. Set tractor brake. Remove

key. Allow all machinery to stop before leaving

the operators position.

WARNING

DO NOT park mowing equipment on slopes.

Page 10

10

SECTION 4 - MAINTENANCE

WARNING

DO NOT attempt any maintenance, adjustments, or

service with the engine or blades running. STOP

engine. STOP b lades . SET br ake. REM OVE ke y. Allo w

all machinery to stop before leaving operators

position or approaching mower.

3.1 INTRODUCTION

Proper maintenance is extremely important.

Failure to perf orm the following maintenance ca n

adversely affect the performance of the mower,

decrease the life of the mower, and can cause

the mower to be unsaf e to operate. Perform the

following steps at the recommended intervals.

Inspect the mower frequently for loose, missing,

damaged and worn components. Fix or replace

those components immediately. To retain the

original quality of the FM7300 Finishing Mower,

use only genuine SNAPPER replacement parts.

Contact a local SNAPPER Dealer for parts &

service assistance. SNAPPER recommends

returning the mower to an author ized SNAPPER

Dealer annually for ins pec tion a nd add ition of any

new devices which might upgrade the safety of

the mower.

3.2 SERVICE - AFTER FIRST 5 HOURS

3.2.1. Inspect mower. Carefully inspect entire

mower for loose, missing, damaged and worn

components. All guards, shields and deflectors

must be in place. Repair and replace as required.

3.2.2. Inspect mower blades. Check blades

for flatness, sharpness, wear and damage. See

section “Mower Blade Repair/Replacement” for

blade wear limits, sharpening and replacement

instructions.

3.2.3. Inspect mower belt. The mower belt

does not require adjustment. Visually check belt

for signs of deterioration. Replace as required.

See section "Mower Belt Replacement” for

instructions.

3.2.4. Inspect and lubricate driveline.

WARNING

Contact with rotating driveline can cause death. A

high percentage of driveline injuries occur when

safety shielding is missing or not functioning

properly. Frequent inspections and proper

maintenance is essential for the safet y o f t he operator

and others. STOP engine. STOP blades. REMOVE key.

Allow all machi nery to stop be fore ap proach ing.

3.2.4.1. Inspect driveline, tractor and mower

shields. All shielding must be in place and

functioning properly. Be sure the driveline

shielding is not dam aged and that shields rotate

freely on the driveline. See section “Driveline

Repair” for instructions.

3.2.4.2. Lubricate U-joint bearings. Rotate

flexible cone shield to align access hole with

grease fitting. Apply 2 to 3 shots of General

Purpose grease from a grease gun.

3.2.4.3. Lubricate driveline shield bearings.

Locate grease fitting on flexible cone shield.

Apply 2 to 3 shots of General Purpose grease

from a grease gun.

3.2.4.4. Lubricate driveline telescoping tubes.

Slide driveline apart. Wipe male surface of tube

with grease. Carefully insert tubes, making sure

that the driveline shields are aligned and not

binding.

3.2.5. LUBRICATE MOWER COMPONENTS

3.2.5.1. Mower spindle housings. Apply 2 to 3

shots of grease (Kendall NLGI No. 2 Lithium

grease).

NOTE: The spindle housings are equipp ed with a

grease purge valve. The valve is located on the

housing below the dec k. The spin dle housing h as

been properly lubricated when grease exits the

purge valve.

3.2.5.2. Mower Caster Bushings. Apply 1 to 2

shots at each of the four locations.

3.2.5.3. Mower Caster Wheel Bearing. Apply 1

to 2 shots at each of the four locations.

3.2.5.4. Mower Belt Idler Arm. Apply 1 to 2

shots of grease at idler arm pivot.

3.2.5.5. Mower Gear Box. Check fluid level in

gear box. Remove br eather/filler plug located on

top of gear box. T he ge ar box holds 20 ounces of

SAE 90 EP gear lube. Reinstall plug. DO NOT

over tighten.

3.3 SERVICE - EVERY 25 HOURS

Perform all inspections, and lubr icate all item s as

specified in the section “Service - After First 5

Hours”. The 25 hour service interval is the

maximum interval recommended between

services. Certain applications will require more

frequent service intervals. Inspect mower before

each use.

3.4 SERVICE - ANNUALLY

In addition to the regular maintenance the

following components of the finishing mower

should be carefully inspected for wear or

damage. Replace worn or damaged parts with

genuine SNAPPER replacement parts available

from an authorized SNAPPER Dealer.

3.4.1. Caster Bushings

3.4.2. Caster wheel bearings.

3.4.3. Mower spindle housing bearings.

3.4.4. Driveline U-joint bearing.

3.4.5. Driveline rotating shield bearings.

Page 11

11

SECTION 5 - ADJUSTMENTS & REPAIR

FOUR

BLADE

BLADE

DANGEROUS CONDITION!

WEAR LIMIT

WARNING

DO NOT attempt any maintenance, adjustments, or

service with the engine or blades running. STOP

engine. STOP b lades . SET br ake. REM OVE ke y. Allo w

all machinery to stop before leaving operators

position or approaching mower.

4.1 MOWER BELT REPLACEMENT

1. Remove belt cover from mower.

NOTE: Belt routing diagram is located on the deck.

2. Carefully roll belt out of groove and of f left spindle

pulley.

3. Remove old belt.

WARNING

Use CAUTION removing old belt. Belt is under spring

tension.

4. Route new belt as shown in Figur e 4.1, l eaving b elt

off of left spindle pulley.

5. Remove all slack from belt and pull towards left

pulley. At sam e time, rotate clock wise allowin g belt

to roll onto the groove on the pulley.

FIGURE 4.1

4.2 MOWER BLADE SHARPENING &

REPLACEMENT

4.2.1. Blade Wear Limits

1. Inspect blades before each use for signs of

excessive wear or damage. See Figure 4.2.

WARNING

DO NOT use a blade that has worn beyon d the wear

limit. Blad es are sharp and c an cause severe in jury.

Wear heavy gloves when handling or working around

blades.

NEW BLADE

(NOTCH STARTS)

DO NOT USE ON MOWER!

REPLACE WITH NEW BLADE.

FIGURE 4.2

4.2.2 Blade Sharpening.

1. Inspect blades. If the blade has not been

damaged and it has not worn beyond the wear

limit it may be sharpened. See Figure 4.2.

2. Remove blade by removing the nut from

the blade bolt. Allow the blade bolt, blade

washer, blade and four blade spacers to drop

down out of the spindle housing. See Figure

4.3.

BLADE

SPACERS

3. Remove bolt, washer and spacers from

blade. Sharpen existing c utting edge onl y at an

angle of 22 to 28 degrees. DO NOT sharpen

beyond existing cutting edge. See Figure 4.4.

4. Check the balance of the blade after

sharpening. Correct as required by removing

material from the e nd (not cutting edge) of the

blade.

5. Install blade paying close attention to the

assembly sequence shown in Figure 4.3.

6. Torque blade bolt and nut to 60 to 75 ft. lbs.

4.2.3. MOWER BLADE REPLACEMENT

1. If blades are worn beyond the lim it or have

been damaged, they must be replaced. See

Figure 4.2.

2. Remove blade as instructed in “Mower

Blade Sharpening” abov e.

3. Install new blade following assembly

sequence carefully. See Figure 4.3.

4. Torque blade bolt and nut to 60 to 75 ft. lbs.

WASHER

BOLT

FIGURE 4.3

22º - 28º

ORIGINAL CUTTING EDGE

FIGURE 4.4

Page 12

12

SECTION 5 - ADJUSTMENTS & REPAIR

REMOVE BLADE

REMOVE BELT

PULLEY

BEARING

SPINDLE

BEARING

SPINDLE

BE

ARING

SEAL UP

BEARING SEAL

DOWN

3 LOCKING TABS

FLEXIBLE

TRACTOR

4.3 MOWER SPINDLES (Field Serviceable

Spindles) BEARING REPLACEMENT

In the event that a spindle bearing requires

replacement, the SNAPPER Field Serviceable

Spindles have been designed so that no special

tools or presses are required.

1. Remove belt. Loosen blade nut and remove.

Allow blade bolt, washer, blade and four spacers

to drop down out of the spindle housing. See

Figure 4.5.

REMOVE NUT

FROM SPINDLE

BOLT

FIGURE 4.5

2. Remove spindle pulley from spindle shaft.

3. Locate circul ar retaining r ing on spindl e shaft at

top bearing. Rem ove retaining ring. Allow spindle

shaft to drop out of housing.

4. Top and bottom bearings are now removable.

Pull out on inner race to slide bearing from

housing. See Figure 4.6.

RETAINING RING

HOUSING

INNER RACE

NOTE: The bearing is s ealed/shi elded o n one side

only. The bottom bearing must be installed with

the sealed/shielded side DOWN.

7. Insert spindle shaft up through the bottom

bearing. Slide spacer down over spindle shaft.

8. Install new top bearing. Install the top bearing

with the seal/shield UP.

9. Slide circular retaining ring down spindle shaft

until it fully locks into groove on shaft.

10. Place spindle pulley and spacer on top of

spindle shaft.

11. Reinstall blade bolt, washer, blade and four

spacers.

12. Torque blade bolt and nut to 60 to 75 ft. lbs.

IMPORTANT: Spindle housing must be filled

with grease before oper ating mow er. Failure to

fill housing will cause premature bearing

failure.

13. Pump grease into spindle hous ing until grease

purges from vent on housing.

14. After the first 5 hours of operation, grease

spindle housing to insure it is full, then every 25

hours.

4.4 DRIVELINE REPAIR

The driveline shielding system is critical to the

safety of the operator and others. Inspect the

driveline shield and mower shield. If the driveline

guard does not rotate freely from the shaft,

displays signs of deterioration or damage, or the

safety signs are m issing or illegib le, parts m ust be

repaired or replaced.

4.4.1. Driveline Shield.

The driveline shields will have to be removed to

replace shield com ponents, shield bearings, or Ujoint bearings.

1. Disconnect driveline from tractor and mower.

Slide driveline apart. Work on one end at a time.

NOTE: Tractor end flexible cone, shield bearings

and plastic tubes are different from those on the

mower end.

2. Locate three l oc king tabs in flexibl e c o ne. While

pushing down on cone, pr ess in the three locking

tabs. Slide cone down on plastic tube when

unlocked. See Figure 4.7.

SHIELD BEARING

PLASTIC TUBE

LOCATED AROUND

SMALL END OF CONE

5. Thoroughly clean all parts removing all old

6. Install new bottom bearing first.

SHAFT

FIGURE 4.6

contaminated grease.

END

FIGURE 4.7

CONE

(Continued on next page)

Page 13

13

SECTION 5 - ADJUSTMENTS & REPAIR

4.4 DRIVELINE REPAIR

(Continued from previous page)

3. Remove cone, tube, and the shield bearing

from the yoke. Discard worn or damaged

components. Replace with new genuine

SNAPPER replacement parts.

4. Apply liberal amount of grease to the shield

bearing and place in groove on yoke.

5. Slide plastic tu be over drive shaf t. Align slots in

plastic tube with tabs on plastic bearing.

6. Slide flexible cone onto plastic tube. Carefully

align cone with plastic bearing while keeping

bearing in yoke groove and be aring tabs in plastic

tube slots.

7. Pull up and tap on cone until all three locking

tabs have locked.

8. Verify that locking tabs are fully seated and

locked.

9. The shield should rotate freely from shaft.

IMPORTANT: When replacing a driveline guard,

make sure that it has the “DANGER ROTATING

DRIVELINE” safety label in place before operating.

See Figure 4.8.

10. Lubricate after re-assembly.

FIGURE 4.8

Page 14

14

1 YEAR LIMITED WARRANTY

For one (1) year from purchase date for the original purchaser's commercial or other non-residential use,

SNAPPER, through any SNAPPER dealer will replac e, free of charge (exc ept for taxes where app licable), any

part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or

workmanship or both.

All transportation costs incurred by the purchaser in submitting material to a SNAPPER dealer under this

warranty must be paid by the purchaser.

This warranty does not cover any mower or component part that has been dam aged as a result of accident,

alteration, abuse, im proper lubr ication, norm al wear, or any other cause be yond the contr ol of SNAPPER. This

warranty does not cover any machine or component that has been altered or modified, changing safety,

performance, or durability.

There is no other express warranty.

DISCLAIMER OF WARRANTY

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to

one (1) year from pu rchase date for the o riginal pu rchaser's use, and up to t he extent perm itted b y law

and all implied warranties are excluded. This is the exclusive remedy. Liabilities for consequential

damages, under any and all warranties are excluded.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY

IMPAIR THE S AFETY OF SNAPPER PROD UCTS AND WILL VOI D ANY LIABILITY AND WARRANTY BY

SNAPPER ASSOCIATED WITH THE USE OF SUCH PARTS.

IMPORTANT: Please fill out the attached SNAPPER Product Registration Card immediately and mail to:

Snapper ’s P r od uct Regis tra t i on C e n te r, P.O. Box 777, McDonough, Georgia. 30253

Page 15

15

Safety Instructions & Operator’s Manual for

73” FINISHING MOWER

CATEGORY ONE

3 POINT HITCH

WARNING:

The engine exhaust from this product contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm.

COPYRIGHT © 1998

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 7-2074 (I.R. 11/16/98)

Loading...

Loading...