Snapper E95247 (1694854), E13387 (1694860), E115327 (1694858), E105287 (1694856) Owner’s Manual

Page 1

Bimplicilq

OPERATOR'S

MANUAl

Large Frame

Snowthrowers

9524 Models

Mfg. No. Description

1694853 95247E, 9.5HP Snowthrower

1694854 E95247, 9.5HP Snowthrower (CE)

9560 Models

Mfg. No. Description

1694867 9560E, 9.5HP Snowthrower

1694914 9560EX, 9.5HP Snowthrower (CE)

10528 Models

Mfg. No. Description

1694855 105287E, IO.5HP Snowthrower

1694856 E105287, IO.5HP Snowthrower (CE)

10560 Models

Mfg. No. Description

1694847 10560E, IO.5HP Snowthrower

1694848 10560EX, IO.5HP Snowthrower (CE)

11532 Models

Mfg. No. Description

1694857 115327E, 11.5HP Snowthrower

1694858 E115327, 11.5HP Snowthrower (CE)

11570 Models

Mfg. No. Description

1694849 11570E, 11.5HP Snowthrower

1694850 11570EX, 11.5HP Snowthrower (CE)

1338 Models

Mfg. No. Description

1694859 13387E, 13HP Snowthrower

1694860 E13387, 13HP Snowthrower (CE)

1380 Models

Mfg. No. Description

1694851 1380E, 13HP Snowthrower

1694852 1380EX, 13HP Snowthrower (CE)

1390 Models

Mfg. No. Description

1694872 1390E, 13HP Snowthrower

1694915 1390EX, 13HP Snowthrower (CE)

1731288

Revision 03

Rev. Date 11/2005

TP

100-4220-03-LW-SN

Page 2

TableofContents

CONTENTS:

Safety Rules & Information

Training ............................................................ 2

Preparation ...................................................... 2

Operation ......................................................... 2

Children ........................................................... 3

Clearing a Clogged Discharge Chute .............. 3

Service, Maintenance and Storage ................. 3

Emissions ........................................................ 3

Decals .............................................................. 5

Safety Icons ..................................................... 6

Identification Numbers ........................................ 7

Features, Controls, & Operation

Control Locations ............................................. 8

General Operation

Checks Before Each Start-Up ....................... 10

Starting the Engine ........................................ 11

Starting Controls ............................................ 11

Operating The Snowthrower .......................... 12

Clearing a Clogged Discharge Chute ............ 12

Ground Speed Selector ................................. 12

Engine Speed ................................................ 12

Deflector ........................................................ 13

Scraper Bar & Skid Shoes ............................. 13

Easy-Turn and Traction Drive Lock ................ 14

After Each Use .............................................. 15

Storage .......................................................... 15

Regular Maintenance

Schedule ........................................................ 16

Checking Tire Pressure ................................. 16

Auger Gear Case Lubrication ........................ 16

Lubrication ..................................................... 17

Check/Lubricate Free-Hand Linkage ........... 18

Lubricate the Auger Shaft & Assembly .......... 18

Troubleshooting, Adjustments, & Service

Troubleshooting ............................................. 20

Speed Selector Adjustment ........................... 22

Auger Drive Tension ...................................... 22

Traction Drive Tension ................................... 23

Manual Discharge Chute Adjustment ............ 24

Electric Discharge Chute Adjustment ............ 24

Easy Turn Cable Adjustment ......................... 25

Shear Pin Replacement ................................. 25

Belt Replacement .......................................... 26

Specifications .................................................... 28

Replacement Parts & Accessories ................. 29

WARNING

You must read, understand and comply with all

safety and operating instructions in this manual

before attempting to set-up and operate your

snowthrower.

Failure to comply with all safety and operating

instructions can result in loss of machine control,

serious personal injury to you and/or

bystanders, and risk of equipment and property

damage. The triangle in the text signifies

important cautions or warnings which must be

followed.

WARNING

Engine exhaust from this product contains

chemicals known, in certain quantities, to cause

cancer, birth defects, or other reproductive harm,

Page 3

SafetyRules& Information

_ his machine is capable to amputating hands and feet and throwing objects. Read these safety rules and

TRAINING

1. Read, understand, and follow all instructions on the

2. Never allow children to operate the equipment.

3. Keep the area of operation clear of all persons, partic-

4. Exercise caution to avoid slipping or falling especially

PREPARATION

1. Thoroughly inspect the area where the equipment is

2. Disengage all clutches and shift into neutral before

3. Do not operate the equipment without wearing ade-

4. Handle fuel with care; it is highly flammable.

5. Use extension cords and receptacles as specified by

6. Adjust the collector housing height to clear gravel or

7. Never attempt to make any adjustments while the

8. Let engine (motor) and machine adjust to outdoor

9. Always wear safety glasses or eye shields during

TP-600-3606-03-LW-UV

follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury

or death to you, or bystanders, or damage to property or equipment. The triangle ,_ in text signifies

important cautions or warnings which must be followed.

OPERATION

1. Do not put hands or feet near or under rotating parts.

machine and in the manuals before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

Never allow adults to operate the equipment without

proper instruction.

ularly small children and pets.

when operating in reverse.

to be used and remove all doormat, sleds, boards,

wires, and other foreign objects.

starting engine (motor).

quate winter outer garments. Wear footwear that will

improve footing on slippery surfaces. Avoid loose fit-

ting clothing that can get caught in moving parts.

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors. Replace fuel cap securely and

wipe up spilled fuel.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place con-

tainers on the ground, away from your vehicle, before

filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground. If

this is not possible, then refuel such on a trailer with a

portable container, rather than from a gasoline dis-

penser nozzle.

(f) Keep nozzle in contact with the rim of the fuel tank

or container opening at all times, until refueling is

complete. Do not use a nozzle lock-open device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing imme-

diately.

the manufacturer for all units with electric drive

motors or electric starting motors.

crushed rock surfaces.

engine (motor) is running (except when specifically

recommended by the manufacturer).

temperatures before starting to clear snow.

operation or while performing an adjustment or repair

to protect eye from foreign objects that may be

thrown from the machine.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the

snowthrower for any damage, and repair the damage

before restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the

operating position, before unclogging the

collector/impeller housing or discharge guide, and

when making any repairs, adjustments, or inspec-

tions.

6. When cleaning, repairing, or inspecting make certain

the collector/impeller and all moving parts have

stopped. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

7. Do not run the engine indoors except for starting the

engine or for transporting the snowthrower in or out of

the building. Open the outside doors; exhaust fumes

are dangerous.

8. Exercise extreme caution when operating on slopes.

Do not attempt to clear steep slopes.

9. Never operate the snowthrower without proper

guards plates, or other safety protective devices in

place and working.

10. Never direct the discharge toward people or areas

where property damage can occur. Keep children

and others away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12. Never operate the machine at high transport speeds

on slippery surfaces. Look behind and use care

when operating in reverse.

13. Disengage power to the collector/impeller when

snowthrower is transported or not in use.

14. Use only attachments and accessories approved by

the manufacturer of the snowthrower (such as wheel

weights, counterweights, or cabs).

15. Never operate the snowthrower without good visibility

or light. Always be sure of your footing, and keep a

firm hold on the handles. Walk, never run.

16. Never touch a hot engine or muffler.

17. Never operate the snowthrower near glass enclo-

sures, automobiles, window wells, drop-offs, and the

like without proper adjustment of the discharge angle.

18. Never direct discharge at bystanders or allow anyone

in front of the unit.

19. Never leave a running unit unattended. Always disen-

gage the auger and traction controls, stop engine,

and remove keys.

20. Do not operate the unit while under the influence of

alcohol or drugs.

Page 4

Safety Rules

21.Keepinmindtheoperatorisresponsibleforacci-

dentsoccurringtootherpeopleorproperty.

22.Dataindicatesthatoperators,age60yearsand

above,areinvolvedinalargepercentageofpower

equipment-relatedinjuries.Theseoperatorsshould

evaluatetheirabilitytooperatetheunitsafelyenough

toprotectthemselvesandothersfrominjury.

23.DONOTwearlongscarvesorlooseclothingthat

couldbecomeentangledinmovingparts.

24.Snowcanhideobstacles.Makesuretoremoveall

obstaclesfromtheareato becleared.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

unit and the operating activity. Never assume that children

will remain where you last saw them.

1. Keep children out of the area and under the watchful

care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Never allow children to operate the unit.

4. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

CLEARING A CLOGGED DISCHARGE

CHUTE

Hand contact with the rotating impeller inside the dis-

charge chute is the most common cause of injury associ-

ated with snowthrowers. Never use your hand to clean

out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

SERVICE, MAINTENANCE, AND STORAGE

1. Check shear bolts and other bolts at frequent inter-

vals for proper tightness to be sure the equipment is

in safe working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water and spacer heaters, or clothes dry-

ers. Allow the engine to cool before storing in any

enclosure.

3. Always refer to the operator's manual for important

details if the snowthrower is to be stored for an

extended period.

4. Maintain or replace safety and instruction labels as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

6. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

7. Always observe safe refueling and fuel handling prac-

tices when refueling the unit after transportation or

storage.

8. Always follow the engine manual instructions for stor-

age preparations before storing the unit for both short

and long term periods.

9. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

10. Maintain or replace safety and instruction labels as

necessary.

11. Keep nuts and bolts tight and keep equipment in

good condition.

12. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

13. Components are subject to wear, damage, and dete-

rioration. Frequently check components and replace

with manufacturer's recommended parts, when nec-

essary.

14. Check control operation frequently. Adjust and ser-

vice as required.

15. Use only factory authorized replacement parts when

making repairs.

16. Always comply with factory specifications on all set-

tings and adjustments.

17. Only authorized service locations should be utilized

for major service and repair requirements.

18. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper ser-

vice procedures can result in hazardous operation,

equipment damage and voiding of manufacturer's

warranty.

19. Check shear bolts and other bolts at frequent inter-

vals for proper tightness to be sure the equipment is

in safe working condition.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. If available, look for the relevant Emissions Durability

Period and Air Index information on the engine emis-

sions label.

3

Page 5

Page 6

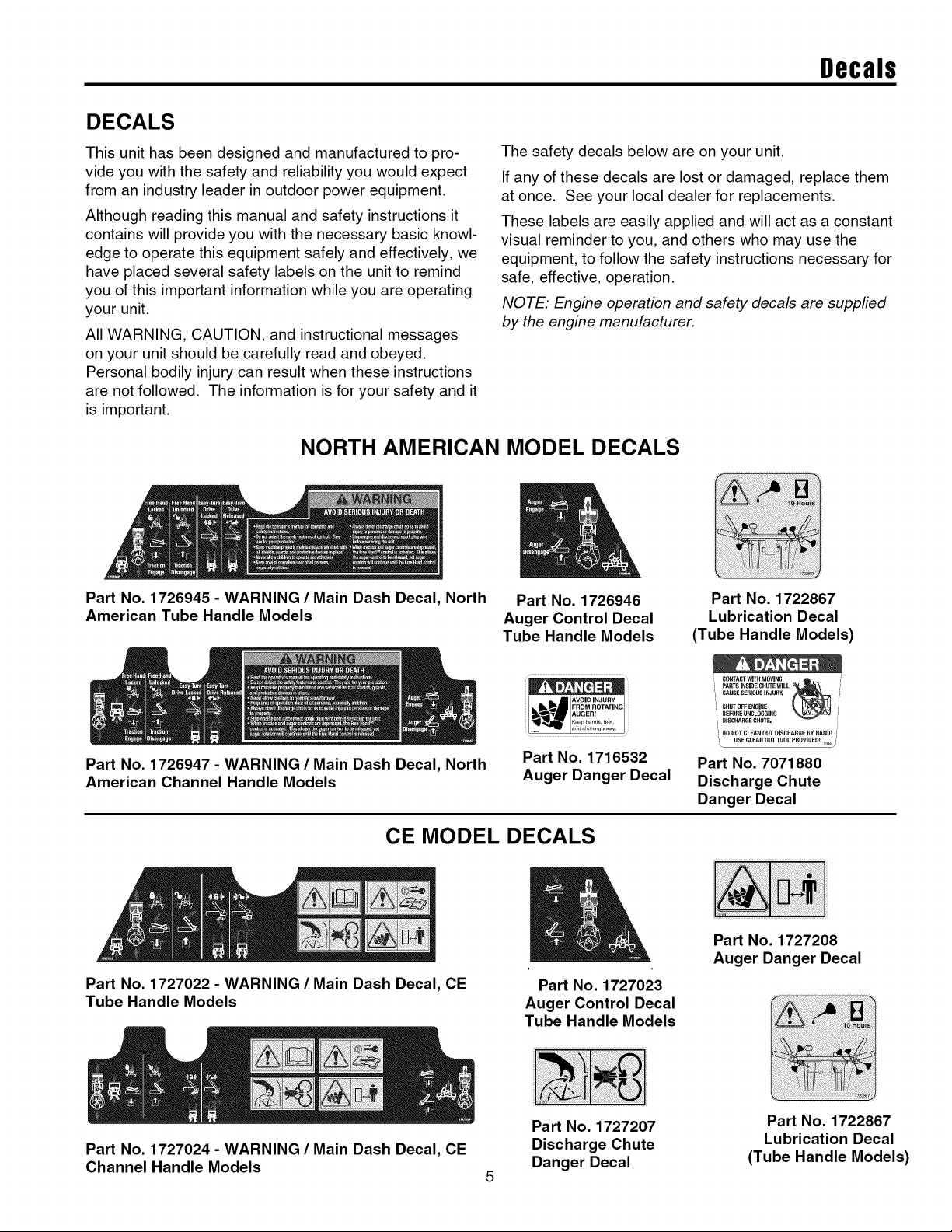

DECALS

Decals

This unit has been designed and manufactured to pro-

vide you with the safety and reliability you would expect

from an industry leader in outdoor power equipment.

Although reading this manual and safety instructions it

contains will provide you with the necessary basic knowl-

edge to operate this equipment safely and effectively, we

have placed several safety labels on the unit to remind

The safety decals below are on your unit.

If any of these decals are lost or damaged, replace them

at once. See your local dealer for replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective, operation.

you of this important information while you are operating

your unit.

NOTE: Engine operation and safety decals are supplied

by the engine manufacturer.

All WARNING, CAUTION, and instructional messages

on your unit should be carefully read and obeyed.

Personal bodily injury can result when these instructions

are not followed. The information is for your safety and it

is important.

NORTH AMERICAN MODEL DECALS

Part No. 1726945 - WARNING / Main Dash Decal, North Part No. 1726946

American Tube Handle Models Auger Control Decal

Tube Handle Models

Part No. 1722867

Lubrication Decal

(Tube Handle Models)

Part No. 1726947 - WARNING / Main Dash Decal, North

American Channel Handle Models

CE MODEL DECALS

Part No. 1727022 - WARNING / Main Dash Decal, CE

Tube Handle Models

Part No. 1727024 - WARNING / Main Dash Decal, CE

Channel Handle Models 5

Part No. 1716532

Auger Danger Decal

Part No. 1727023

Auger Control Decal

Tube Handle Models

Part No. 1727207

Discharge Chute

Danger Decal

PARTS INSIDE CHUTE WILL

CAUSE SERIOUS iNJURY,

SHUT OFFENGINE

BEFORE UNCLOGGING

i [}JSCNARCE CHUTE=

DO NOT CLEAN OUT D SCHARGE NY HAND[

USE CLEAN OUT TOOL PROVIDED!

Part No. 7071880

Discharge Chute

Danger Decal

Part No. 1727208

Auger Danger Decal

Part No. 1722867

Lubrication Decal

(Tube Handle Models)

Page 7

Safety icons

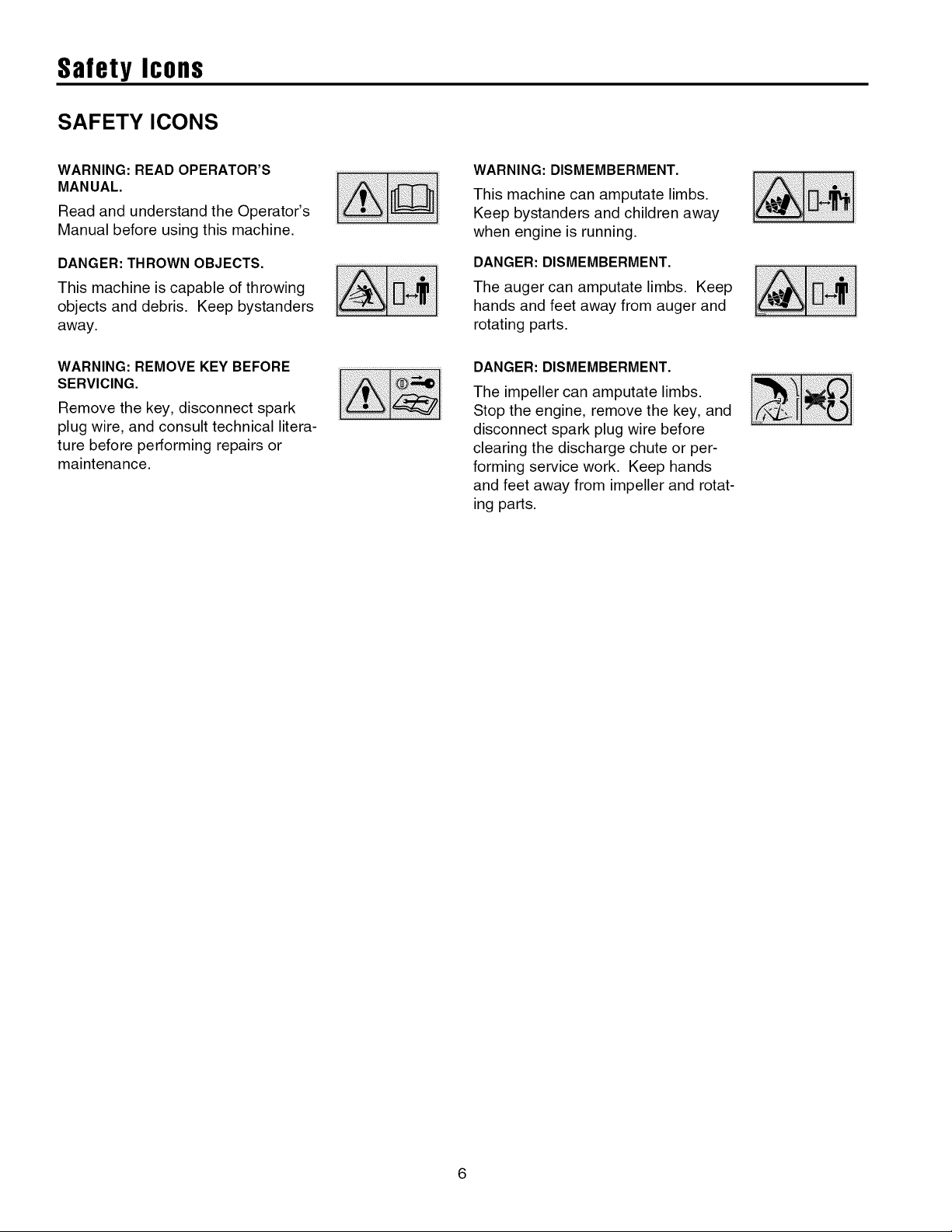

SAFETY ICONS

WARNING: READ OPERATOR'S

MANUAL.

Read and understand the Operator's

Manual before using this machine.

DANGER: THROWN OBJECTS.

This machine is capable of throwing

objects and debris. Keep bystanders

away.

WARNING: REMOVE KEY BEFORE

SERVICING.

Remove the key, disconnect spark

plug wire, and consult technical litera-

ture before performing repairs or

maintenance.

WARNING: DISMEMBERMENT.

This machine can amputate limbs.

Keep bystanders and children away

when engine is running.

DANGER: DISMEMBERMENT.

The auger can amputate limbs. Keep

hands and feet away from auger and

rotating parts.

DANGER: DISMEMBERMENT.

The impeller can amputate limbs.

Stop the engine, remove the key, and

disconnect spark plug wire before

clearing the discharge chute or per-

forming service work. Keep hands

and feet away from impeller and rotat-

ing parts.

Page 8

i_piicity Manufacturing, inc.

_,_ingt0n, WI 53074-0997 USA

North American /

CE Models

IllllilllliJlllJllJllr_lllJlJlJllJ

CE Models

(Only)

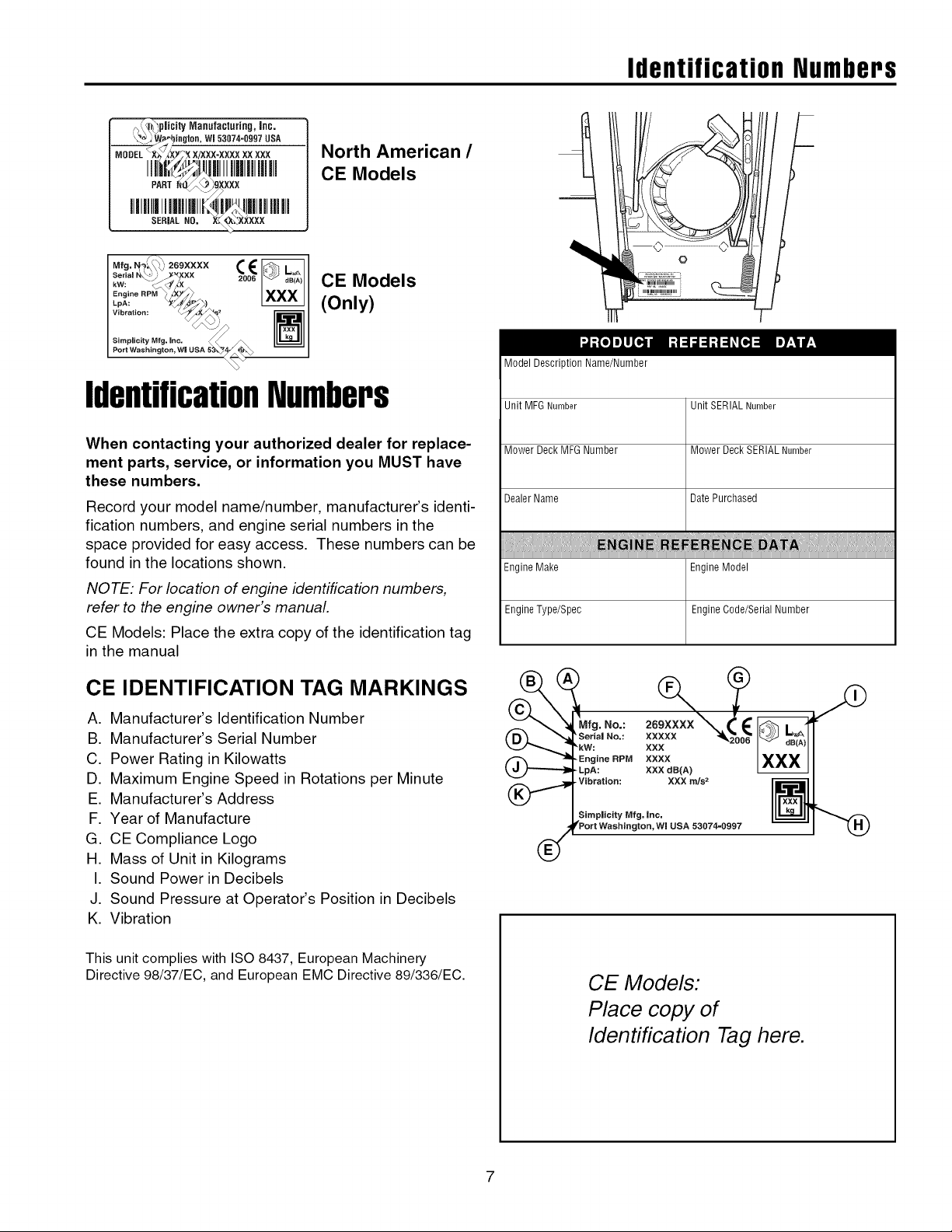

Identification Numbers

Model Description Name/Number

IdentificationNumbers

When contacting your authorized dealer for replace-

ment parts, service, or information you MUST have

these numbers.

Record your model name/number, manufacturer's identi-

fication numbers, and engine serial numbers in the

space provided for easy access. These numbers can be

found in the locations shown.

NOTE: For location of engine identification numbers,

refer to the engine owner's manual.

CE Models: Place the extra copy of the identification tag

in the manual

CE IDENTIFICATION TAG MARKINGS

A. Manufacturer's Identification Number

B. Manufacturer's Serial Number

C. Power Rating in Kilowatts

D. Maximum Engine Speed in Rotations per Minute

E. Manufacturer's Address

F. Year of Manufacture

G. CE Compliance Logo

H. Mass of Unit in Kilograms

I. Sound Power in Decibels

J. Sound Pressure at Operator's Position in Decibels

K. Vibration

Unit MFGNumber Unit SERIAL Number

Mower Deck MFG Number Mower Deck SERIALNumber

Dealer Name Date Purchased

EngineMake EngineModel

Engine Type/Spec Engine Code/Serial Number

Mfg..o.: x2xSxxx"_gg6k Serial No.:

_kW: XXX

= Engine RPM XXXX

LpA: XXX dB(A)

- Vibration: XXX m/s 2

Simplicity Mfg, Inc,

_'Port Washington, Wl USA 53074=0997

This unit complies with ISO 8437, European Machinery

Directive 98/37/EC, and European EMC Directive 89/336/EC.

CE Models:

Place copy of

Identification Tag here.

7

Page 9

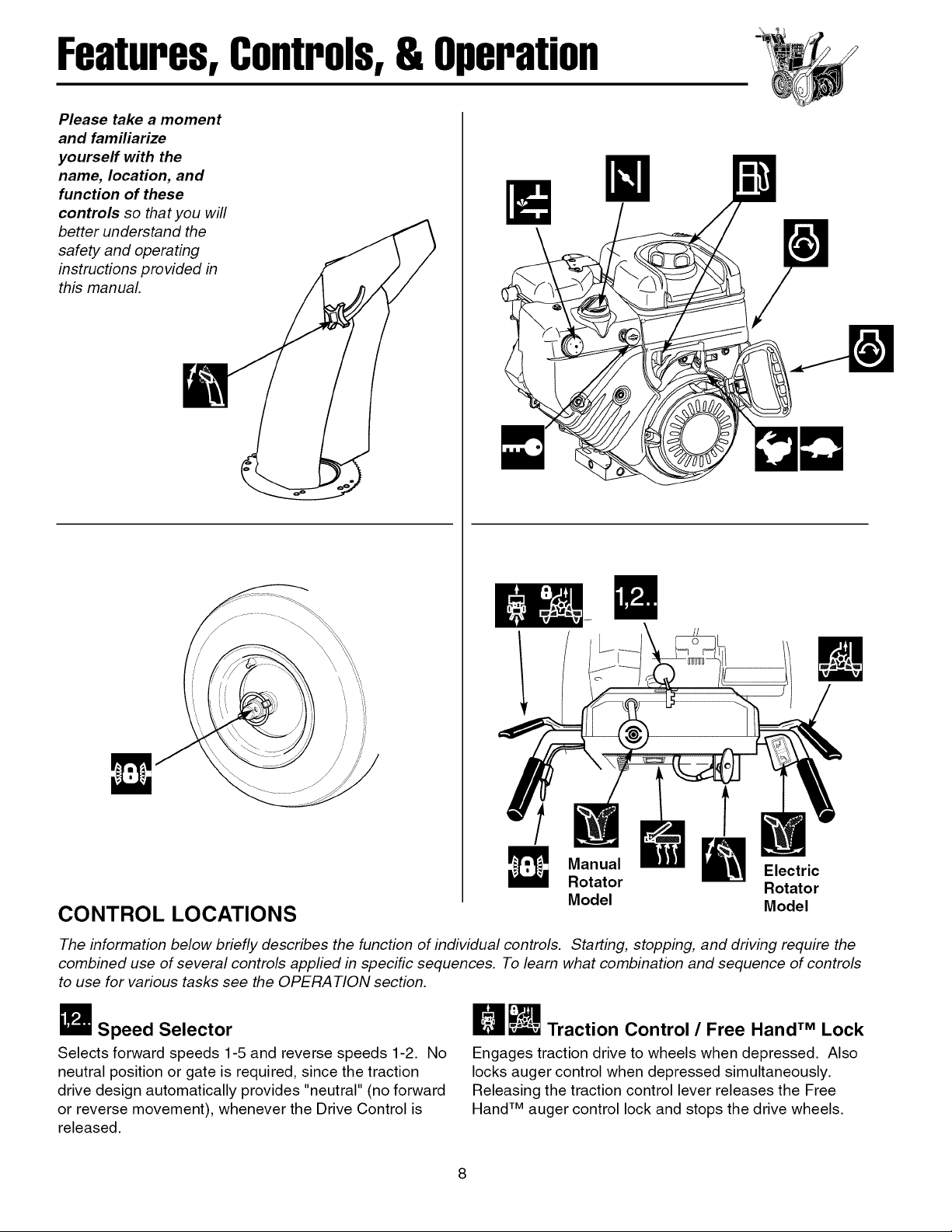

Features,Controls,& Operation

Please take a moment

and familiarize

yourself with the

name, location, and

function of these

controls so that you will

better understand the

safety and operating

instructions provided in

this manual

\

t

Manual

Rotator

Model

CONTROL LOCATIONS

The information below briefly describes the function of individual controls. Starting, stopping, and driving require the

combined use of several controls appfied in specific sequences. To learn what combination and sequence of controls

to use for various tasks see the OPERATION section.

a speed Selector

Selects forward speeds 1-5 and reverse speeds 1-2. No

neutral position or gate is required, since the traction

drive design automatically provides "neutral" (no forward

or reverse movement), whenever the Drive Control is

released.

Engages traction drive to wheels when depressed. Also

locks auger control when depressed simultaneously.

Releasing the traction control lever releases the Free

Hand TM auger control lock and stops the drive wheels.

Traction Control / Free Hand TM Lock

Electric

Rotator

Model

Page 10

Features & Controls

Auger Control

Engages the auger/impeller when depressed. Releasing

the control stops the auger/impeller.

Chute Direction Control

Models with Electric Chute Rotator: Depressing the

chute rotator switch rotates the chute left or right.

Models with Manual Chute Rotator: Turning the crank

rotates the discharge chute to desired position.

r_ Remote/Regular Deflector Control

Regular (Knob) Chute Deflector: Locks chute deflector in

desired position. Tilting the chute deflector UP provides

a higher stream and greater distance, while tilting the

deflector DOWN provides a lower stream and less dis-

tance.

Remote Chute Deflector: Twist the knob to unlock the

chute deflector. Pull or push the knob to change the

deflector angle. UP provides a higher stream and

greater distance, while tilting the deflector DOWN pro-

vides a lower stream and less distance.

Easy Turn TM Control

Easy Turn Control: Engaging the Easy Turn TM lever

releases the right wheel to allow easy turning in tight

areas. Releasing the control automatically engages both

drive wheels for full traction.

Traction Lock Pins: The right traction wheel can be

completely released using the locking pin (see Figure 7).

This allows the unit to be easily moved with the engine

off.

r_ Fuel

Fuel tank filler cap (see illustration). Note: The fuel shut

off valve is located under the fuel tank or on the front of

the engine. Close the valve when the snowthrower is not

in use. Open the valve before starting.

E Primer Button

When pressed, the primer button provides initial fuel to

help start a cold engine. Normally, pressing the primer

button twice will provide enough fuel to start a cold

engine.

_PJ!_I Throttle Lever

Controls engine speed. Move toward the hare icon for

faster engine speed, move toward the turtle icon for

slower engine speed. Move the throttle all the way to

STOP to stop the engine. Set throttle to FULL/FAST

(hare icon) for operation.

_ Engine Key

The engine key prevents the engine from being started.

The key must be fully inserted intothe key slot for the

unit to start. The key can also used to stop the engine by

pulling the key out of the key slot.

W Choke Knob

The choke knob adjusts the air/fuel mixture, and is used

to help start a cold engine by providing a richer mixture.

Once the engine is warm and running smoothly, the

choke knob should be set to the off position to provide a

normal air/fuel mix.

r_ Starter

Electric Start (If Equipped): Depressing the starter but-

ton activates the electric starter. The electric start button

operates on 120 Volts AC, which is provided by connec-

tion to the extension cord provided with units equipped

with this feature. Connect this extension cord ONLY to a

properly grounded 3 prong electrical outlet.

Recoil Starter (All Models): Pulling the recoil handle

cranks the engine.

Grip Warmers (Select Models)

The optional grip warmers are powered when the engine

is running and have three settings: low, off, and high.

Headlight (Select Models, Not Pictured)

For use in low sunlight - early morning and evening. The

headlight is on at all times when the engine is running.

9

Page 11

Operation

GENERAL OPERATION

CHECKS BEFORE EACH START-UP

1. Make sure all safety guards are in place and all nuts,

bolts and clips are secure.

2. Check to make sure that the clean-out is attached to

the handle on the machine. Do not operate the

machine without the clean-out tool properly stored on

the handle.

3. Check the engine oil level. See your engine owner's

manual for procedure and specifications.

4. Check to make sure spark plug wire is attached and

spark plug is tightened securely. If necessary, torque

spark plug to 15 ft. Ibs.

5. Check the fuel supply. Fill the tank no closer than 1/4

to 1/2 inch of top of tank to provide space for expan-

sion. See your engine owner's manual for fuel recom-

mendations.

6. Check the scraper bar to make sure it is set at the

desired height. Adjust the skid shoes if necessary.

7. Check the drive control (B, Figure 2), and auger con-

trol (C) for proper operation. If adjustment is required,

see the service section for procedures.

8. Check the chute direction control (D, Figure 2) for

proper operation. The discharge chute should rotate

freely in both directions. See the service section for

adjustment procedures and troubleshooting.

9. Check the chute deflector (E, Figure 2) for proper

operation. The deflector should pivot freely up and

down when the chute deflector knob is loosened.

10. Position the chute at the desired starting direction

and set the deflector at the desired angle.

11. Check the speed selector (A, Figure 2) for smooth

operation. The control must move freely into each

speed position gate and remain in position when

released. If the speed selector does not move freely

into all forward and reverse speed positions, contact

your local authorized dealer for assistance.

WARNING

This unit is a "two-stage" snowthrower.

The first stage is the auger, which feeds the snow

back into the impeller housing. The second stage

is the impeller, which throws the snow out the

discharge chute. If bodily contact is made with

the auger or impeller when they are rotating,

severe personal injury will occur.

To avoid injury, keep others and yourself away

from the auger and the discharge chute whenever

the engine is running. Read and follow all of the

safety rules and warnings in this manual.

DANGER

Do not clean out discharge chute with hands.

Contact with moving parts inside chute will

cause serious injury. Use clean out tool provided

with machine. Use the following procedure to

remove objects or clear the chute:

1. Stop the engine. Remove the key

2. Wait 10 seconds to be sure the auger/impeller

blades have stopped rotating.

3. Always use the clean-out tool. DO NOT use your

hands.

, WARNING

For your safety, operation on slopes should be in

an up and down direction only. If it becomes

necessary to move across the face of a slope, use

caution and do not blow snow. Be very careful

when changing direction on a slope.

Proper winter footwear is recommended for the

operator to help prevent slipping. Never attempt

to clean snow from excessively steep slopes. The

maximum slope for any operation is 17.7% (10°).

WARNING

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is hot or running. Always move outdoors

to fill the tank. Keep snowthrower and gasoline

away from open flame or spark.

10

Page 12

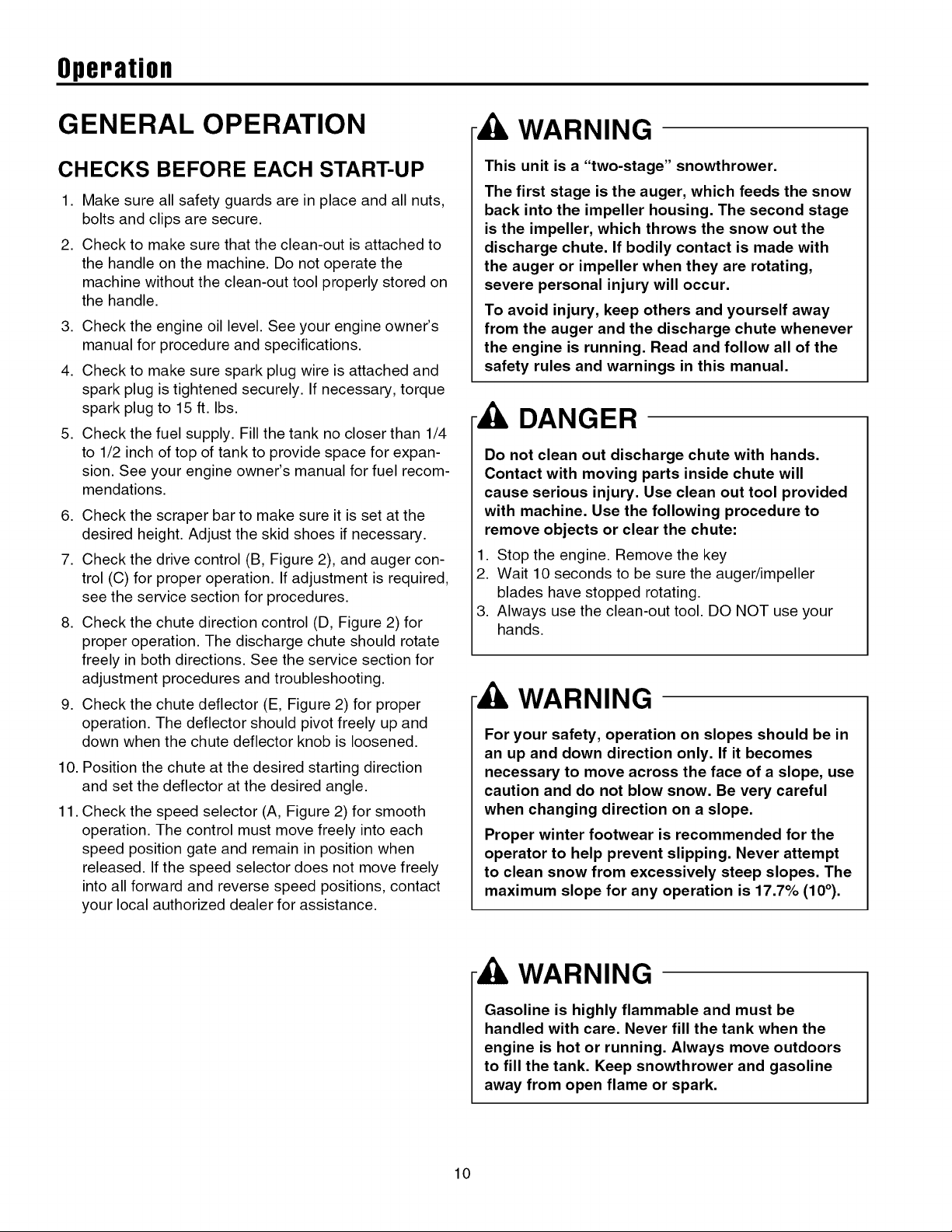

STARTING CONTROLS

See Figure 1for the following instructions.

Units with Optional Electric Start

A, Electric Start Button - The Electric Start Button

(A) activates an electric starter mounted to the

engine, eliminating the need to pull the starter han-

dle. The Electric Start Button operates on 120 Volts

AC, which is provided by connection to the extension

cord provided with units equipped with this feature.

Connect this extension cord ONLY to aproperly

grounded 3 prong electrical outlet.

Manual Start

B. Fuel Valve - The fuel valve (B) is located under the

fuel tank. It is used to turn the fuel supply off for out-

of-season storage.

C. Starter Handle - The starter handle (C) connects to a

starter cord to manually start the engine. Pulling

starter handle rapidly spins the engine crankshaft,

cycles the engine, and generates the spark neces-

sary for starting the engine.

D. Primer Button - When pressed, the primer button

(D) provides initial fuel to help start a cold engine.

Normally, pressing the primer button twice will pro-

vide enough fuel to start a cold engine.

E. Throttle Lever - The throttle lever (E) controls the

engine speed. For best overall performance, the

throttle lever should be set to the FAST position. Use

the SLOW position only for warming the engine, or to

help prevent snow/ice freeze-up when shutting the

unit down for the day.

F. Engine Key - The engine key (F) prevents the

engine from being started by unauthorized individu-

als. The key must be fully inserted into the key slot

for the unit to start. The key is also used to stop the

engine by pulling the key out of the key slot.

G. Choke Knob - The choke knob (G) adjusts the

air/fuel mixture, and is used to help start a cold

engine by providing a richer mixture. Once the engine

is warm and running smoothly, the choke knob

should be set to the off position to provide a normal

air/fuel mix.

STARTING THE ENGINE

1. Turn the fuel valve (located below the fuel tank) to

the ON position.

2. Insert the engine key (F, Figure 1) into the engine key

slot and push fully in to the RUN position.

3. Move the throttle lever (E) fully up to the FAST posi-

tion.

Operation

@-_

Figures 1. Engine Controls

A. Electric Start Button

B. Fuel Valve

C. Starter Handle

D. Primer Button

E. Throttle Lever

F. Engine Key

G. Choke Knob

4. Turn the choke knob (G) fully clockwise if engine is

cold. (Do not choke a warm engine.)

5. Push the primer button (D) two times if engine is cold.

(Do not prime a warm engine.)

6. Engine Mounted Electric Start: Press the starter

button to crank the engine.

Manual Start: Pull starter handle (C) rapidly to start

the engine. Do not allow the starter handle to snap

back--let the starter rope rewind slowly--while keep-

ing a firm grip on the starter handle.

7. As the engine starts and begins to operate evenly,

turn the choke knob (G) slowly counter-clockwise to

the OFF position, and set the Throttle Lever to

SLOW. If the engine falters, turn the choke knob

clockwise until the engine runs smoothly, and let it

run briefly before returning the choke to the OFF

position.

NOTE: Allow the engine to warm up at SLOW throttle for

a few minutes before operating the snowthrower at full

speed. The engine will not develop full power until it

reaches operating temperature. After warming up,

always operate at full throttle.

11

Page 13

Operation

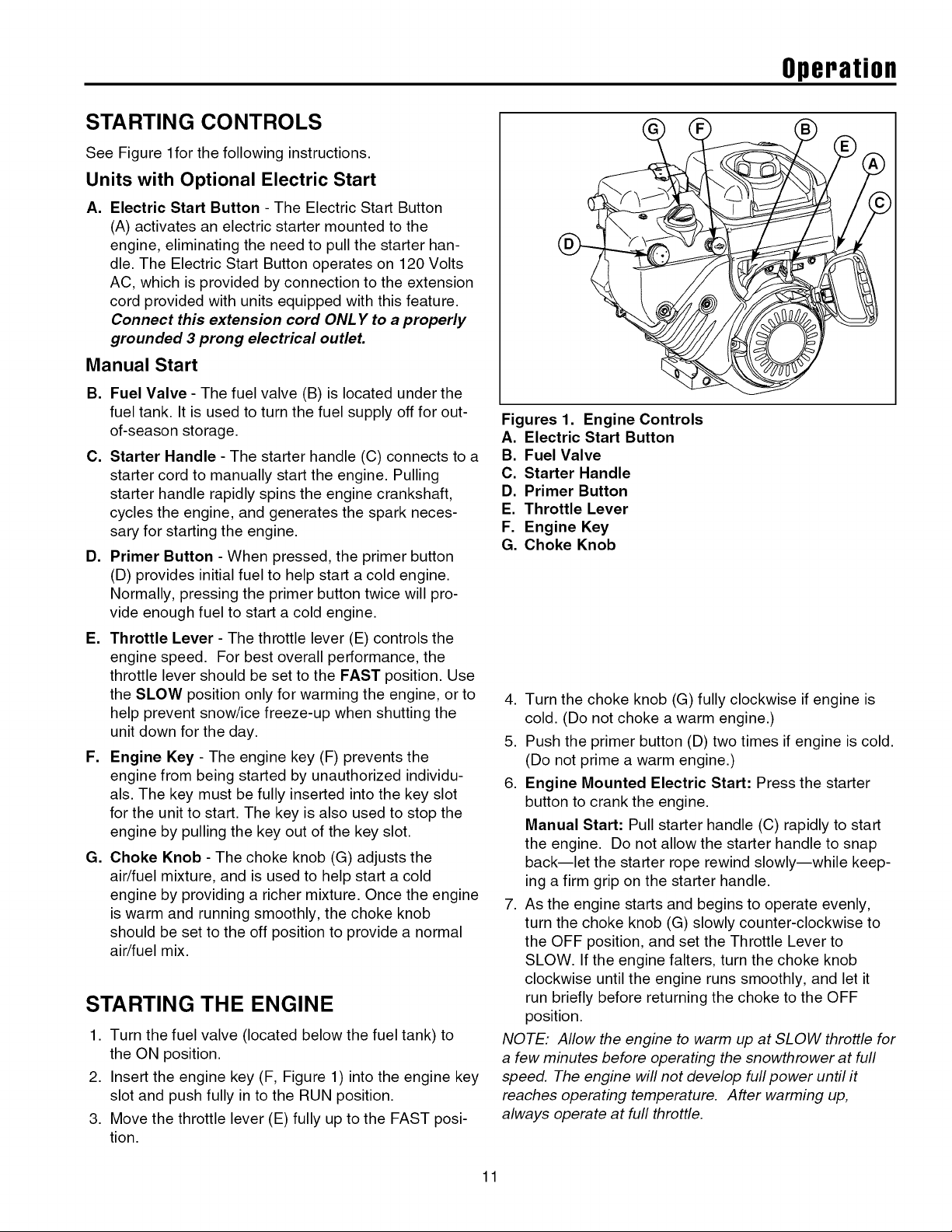

OPERATING THE SNOWTHROWER

1. Rotate the discharge chute to the desired direction.

2. Set the speed selector to the desired forward speed.

3. Fully press and hold the auger engage control (C,

Figure 2) on the right-hand grip to begin auger rota-

tion. Releasing the auger engage control will disen-

gage the auger --unless the Free-Hand TM Control

has been activated (See step 5 below).

4. Fully press and hold the traction & Free-Hand TM

Control lever (B, Figure 2) on the left-hand grip to

engage the traction drive and begin moving the

snowthrower. To disengage the traction drive, com-

pletely release the lever.

5. When BOTH levers are depressed, the Free-Hand TM

Control is activated. This allows Auger Engage

Control to be released -- YET AUGER ROTATION

WILL CONTINUE -- until the Free-Hand TM Control

is released.

6. Select forward or reverse speeds as needed using

the Speed Selector (A, Figure 2). Release both con-

trol levers before changing drive speeds.

WARNING

When BOTH levers are depressed, the Free-

Hand TM Control is activated. This allows Auger

Engage Control to be released -- YET AUGER

ROTATION WILL CONTINUE -- until the Free-

HandTM Control is released.

CLEARING A CLOGGED DISCHARGE

CHUTE

Hand contact with the rotating auger/impeller inside the

discharge chute is the most common cause of injury

associated with snowthrowers. DO NOT use your hand

to clean out the discharge chute. To clear the chute:

1. Stop the engine. Remove the key

2. Wait 10 seconds to be sure the auger/impeller blades

have stopped rotating.

3. Always use the clean-out tool. DO NOT use your

hands.

GROUND SPEED SELECTOR

Use the speed selector (A, Figure 2) to control the drive

speed of the snowthrower. There are five forward speeds

and two reverse speeds.

Use the lower speeds to blow deep or wet snow. Use the

higher speeds to blow light snow or to drive the snow-

thrower without blowing snow.

To change speeds, release both control levers (B, Figure

2), then move the speed selector to the desired setting.

Fully depress the control levers to resume.

Figure 2. Controls (from operator's position)

A. Speed Selector

B. Traction & Free-Hand TM Control

C. Auger Engage Control

D. Chute Direction Control Knob

E. Chute Direction Control Remote

F. Remote Deflector Control

ENGINE SPEED

Always run the snowthrower at full throttle.

12

Page 14

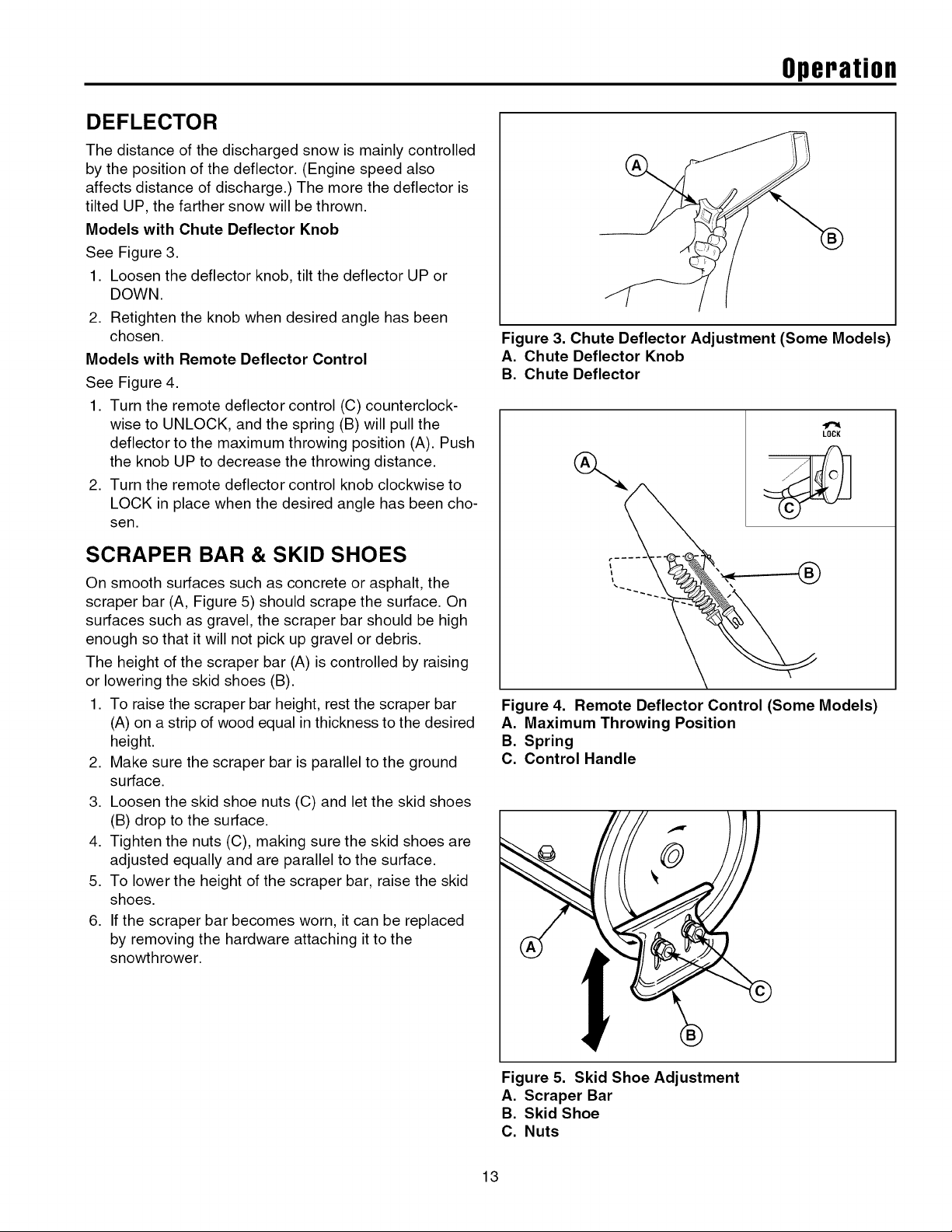

DEFLECTOR

The distance of the discharged snow is mainly controlled

by the position of the deflector. (Engine speed also

affects distance of discharge.) The more the deflector is

tilted UP, the farther snow will be thrown.

Models with Chute Deflector Knob

See Figure 3.

1. Loosen the deflector knob, tilt the deflector UP or

DOWN.

2. Retighten the knob when desired angle has been

chosen.

Models with Remote Deflector Control

See Figure 4.

1. Turn the remote deflector control (C) counterclock-

wise to UNLOCK, and the spring (B) will pull the

deflector to the maximum throwing position (A). Push

the knob UP to decrease the throwing distance.

2. Turn the remote deflector control knob clockwise to

LOCK in place when the desired angle has been cho-

sen.

Operation

Figure 3. Chute Deflector Adjustment (Some Models)

A. Chute Deflector Knob

B. Chute Deflector

LOCK

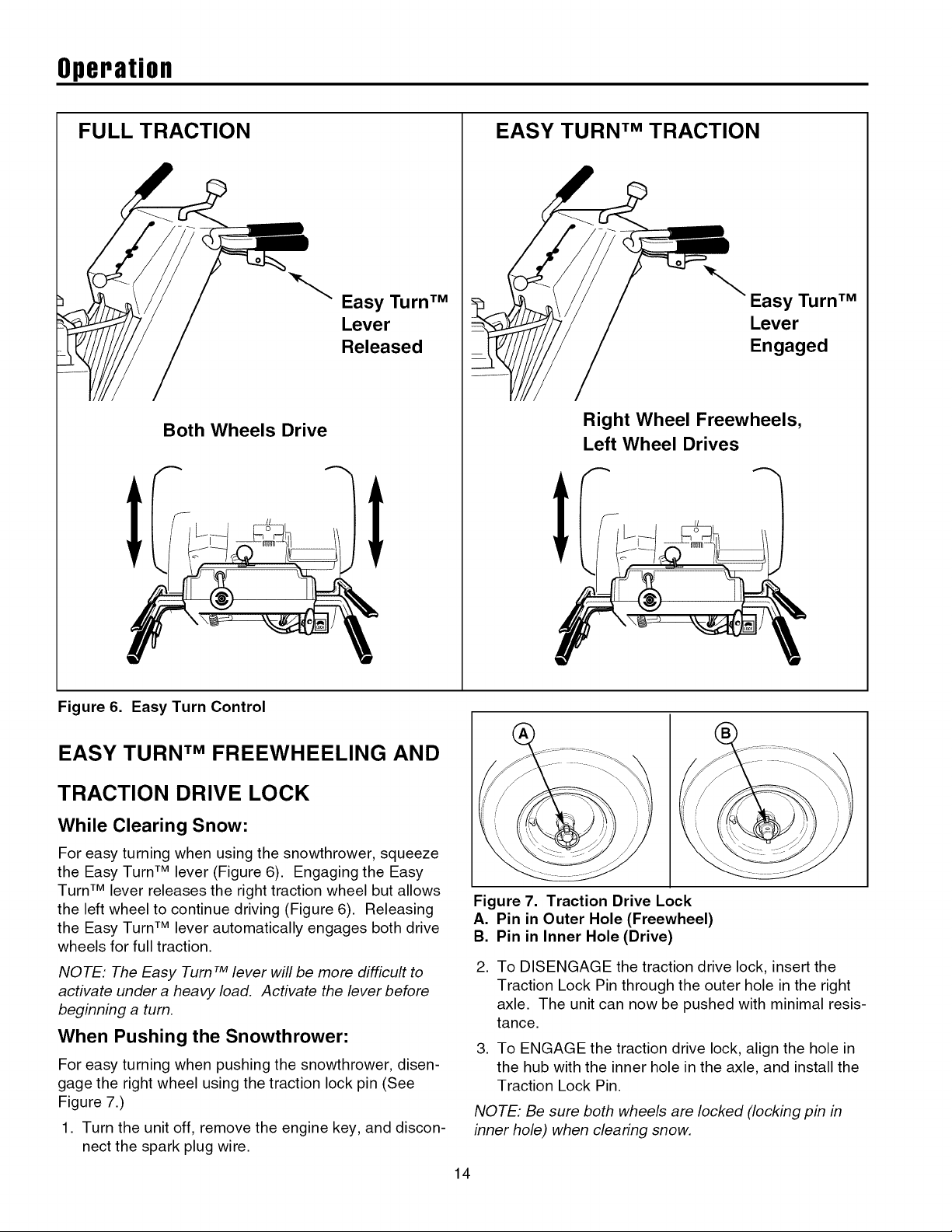

SCRAPER BAR & SKID SHOES

On smooth surfaces such as concrete or asphalt, the

scraper bar (A, Figure 5) should scrape the surface. On

surfaces such as gravel, the scraper bar should be high

enough so that it will not pick up gravel or debris.

The height of the scraper bar (A) is controlled by raising

or lowering the skid shoes (B).

1. To raise the scraper bar height, rest the scraper bar

(A) on a strip of wood equal in thickness to the desired

height.

2. Make sure the scraper bar is parallel to the ground

surface.

3. Loosen the skid shoe nuts (C) and let the skid shoes

(B) drop to the surface.

4. Tighten the nuts (C), making sure the skid shoes are

adjusted equally and are parallel to the surface.

5. To lower the height of the scraper bar, raise the skid

shoes.

6. If the scraper bar becomes worn, it can be replaced

by removing the hardware attaching it to the

snowthrower.

Figure 4. Remote Deflector Control (Some Models)

A. Maximum Throwing Position

B. Spring

C. Control Handle

©

®

Figure 5. Skid Shoe Adjustment

A. Scraper Bar

B. Skid Shoe

C. Nuts

13

Page 15

Operation

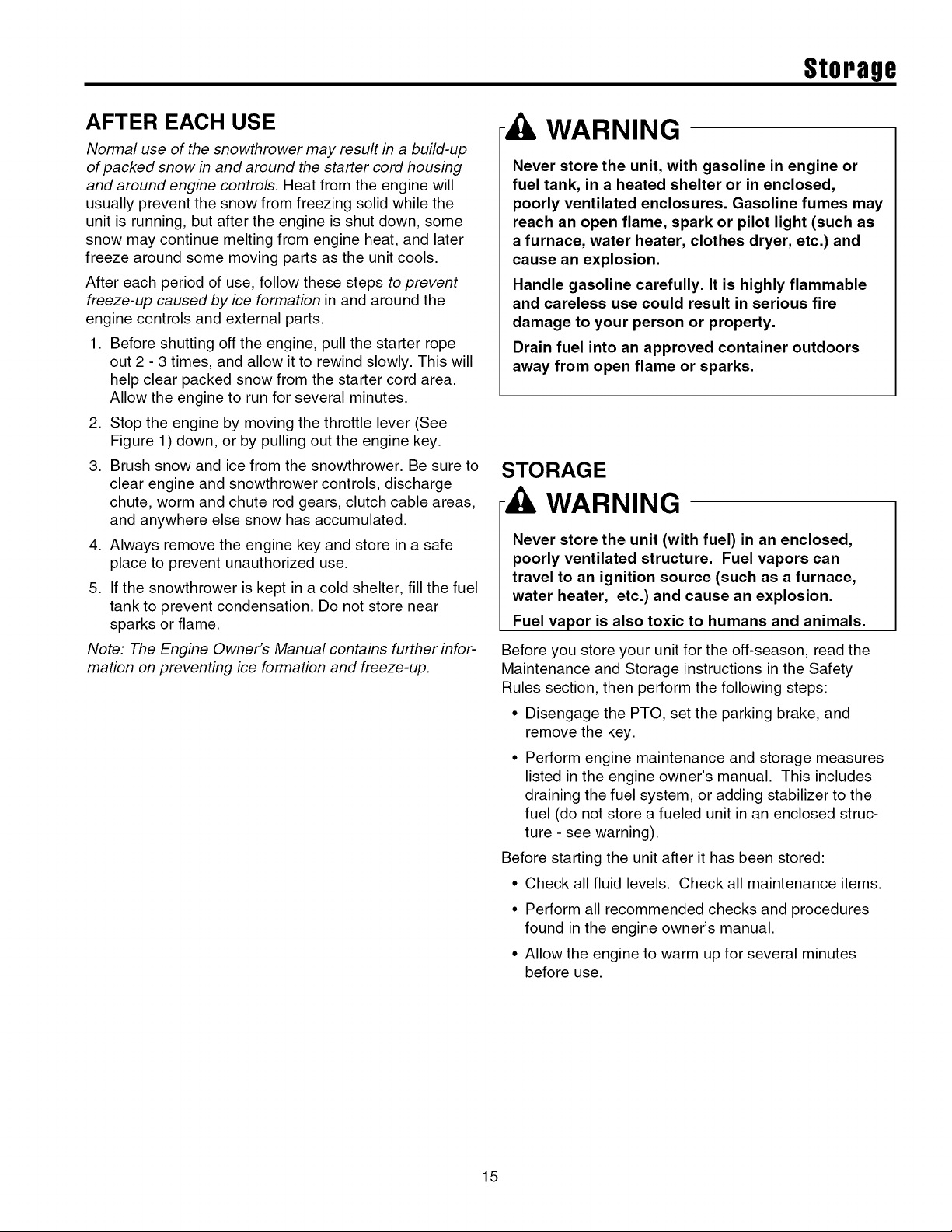

FULL TRACTION

Both Wheels Drive

i

_r'_ Easy TurnTM

Lever

Released

EASY TURN TM TRACTION

"_EasyTurn TM

Lever

Engaged

Right Wheel Freewheels,

Left Wheel Drives

Figure 6. Easy Turn Control

EASY TURN TM FREEWHEELING AND

TRACTION DRIVE LOCK

While Clearing Snow:

For easy turning when using the snowthrower, squeeze

the Easy Turn TM lever (Figure 6). Engaging the Easy

Turn TM lever releases the right traction wheel but allows

the left wheel to continue driving (Figure 6). Releasing

the Easy Turn TM lever automatically engages both drive

wheels for full traction.

NOTE: The Easy TurnTM lever will be more difficult to

activate under a heavy load. Activate the lever before

beginning a turn.

When Pushing the Snowthrower:

For easy turning when pushing the snowthrower, disen-

gage the right wheel using the traction lock pin (See

Figure 7.)

1. Turn the unit off, remove the engine key, and discon-

nect the spark plug wire.

Figure 7. Traction Drive Lock

A. Pin in Outer Hole (Freewheel)

B. Pin in Inner Hole (Drive)

2. To DISENGAGE the traction drive lock, insert the

Traction Lock Pin through the outer hole in the right

axle. The unit can now be pushed with minimal resis-

tance.

3. To ENGAGE the traction drive lock, align the hole in

the hub with the inner hole in the axle, and install the

Traction Lock Pin.

NOTE: Be sure both wheels are locked (locking pin in

inner hole) when clearing snow.

14

Page 16

Storage

AFTER EACH USE

Normal use of the snowthrower may result in a build-up

of packed snow in and around the starter cord housing

and around engine controls. Heat from the engine will

usually prevent the snow from freezing solid while the

unit is running, but after the engine is shut down, some

snow may continue melting from engine heat, and later

freeze around some moving parts as the unit cools.

After each period of use, follow these steps to prevent

freeze-up caused by ice formation in and around the

engine controls and external parts.

1. Before shutting off the engine, pull the starter rope

out 2 - 3 times, and allow it to rewind slowly. This will

help clear packed snow from the starter cord area.

Allow the engine to run for several minutes.

2. Stop the engine by moving the throttle lever (See

Figure 1) down, or by pulling out the engine key.

3. Brush snow and ice from the snowthrower. Be sure to

clear engine and snowthrower controls, discharge

chute, worm and chute rod gears, clutch cable areas,

and anywhere else snow has accumulated.

4. Always remove the engine key and store in a safe

place to prevent unauthorized use.

5. If the snowthrower is kept in a cold shelter, fill the fuel

tank to prevent condensation. Do not store near

sparks or flame.

Note: The Engine Owner's Manual contains further infor-

mation on preventing ice formation and freeze-up.

WARNING

Never store the unit, with gasoline in engine or

fuel tank, in a heated shelter or in enclosed,

poorly ventilated enclosures. Gasoline fumes may

reach an open flame, spark or pilot light (such as

a furnace, water heater, clothes dryer, etc.) and

cause an explosion.

Handle gasoline carefully. It is highly flammable

and careless use could result in serious fire

damage to your person or property.

Drain fuel into an approved container outdoors

away from open flame or sparks.

STORAGE

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can

travel to an ignition source (such as a furnace,

water heater, etc.) and cause an explosion.

Fuel vapor is also toxic to humans and animals.

Before you store your unit for the off-season, read the

Maintenance and Storage instructions in the Safety

Rules section, then perform the following steps:

• Disengage the PTO, set the parking brake, and

remove the key.

• Perform engine maintenance and storage measures

listed in the engine owner's manual. This includes

draining the fuel system, or adding stabilizer to the

fuel (do not store a fueled unit in an enclosed struc-

ture - see warning).

Before starting the unit after it has been stored:

• Check all fluid levels. Check all maintenance items.

• Perform all recommended checks and procedures

found in the engine owner's manual.

• Allow the engine to warm up for several minutes

before use.

15

Page 17

RegularMaintenance

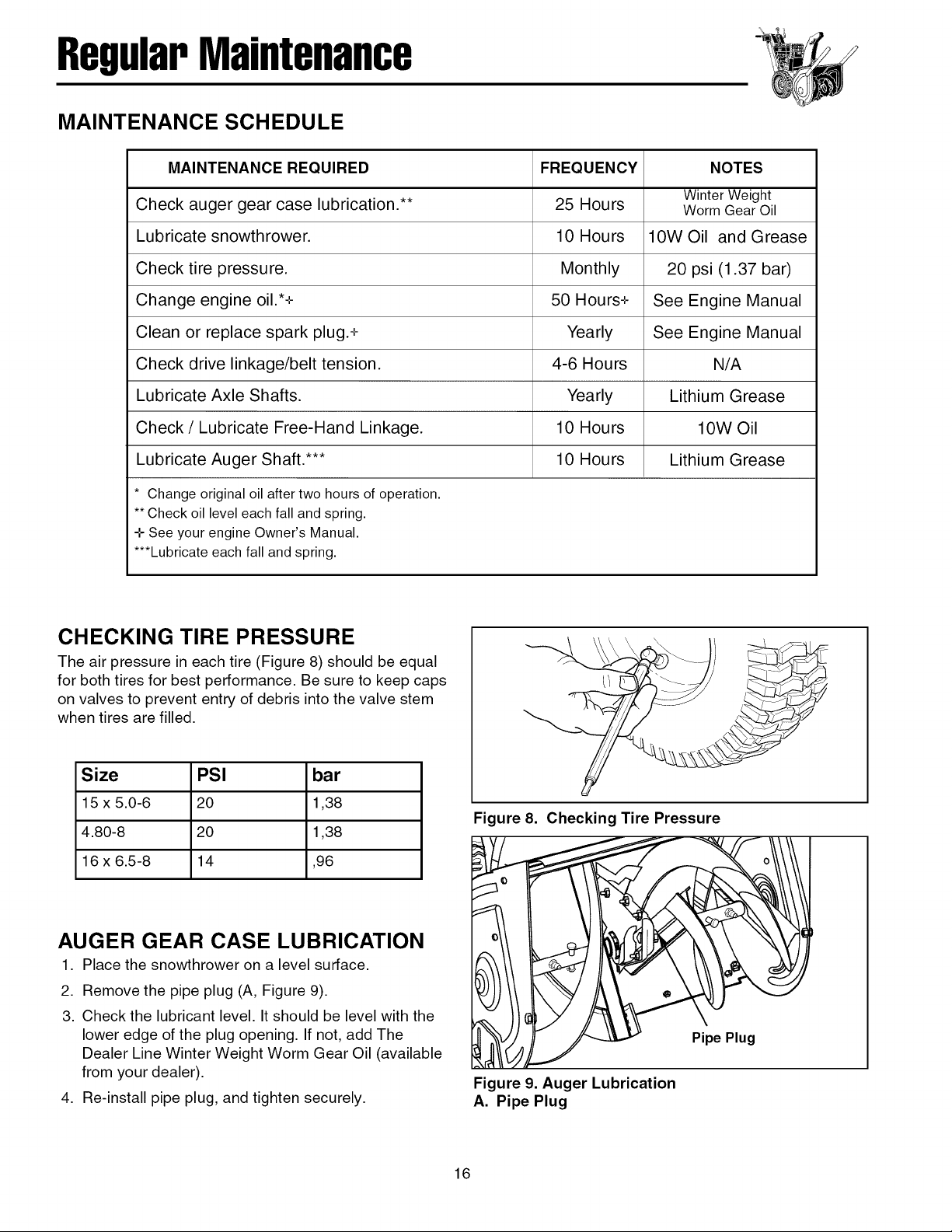

MAINTENANCE SCHEDULE

MAINTENANCE REQUIRED FREQUENCY NOTES

Check auger gear case lubrication.**

Lubricate snowthrower.

Check tire pressure.

Change engine oil.*+

Clean or replace spark plug.+

Check drive linkage/belt tension.

Lubricate Axle Shafts.

Check / Lubricate Free-Hand Linkage.

Lubricate Auger Shaft.***

* Change original oil aftertwo hours of operation.

** Check oil level each fall and spring.

4-See your engine Owner's Manual.

***Lubricate each fall and spring.

CHECKING TIRE PRESSURE

The air pressure in each tire (Figure 8) should be equal

for both tires for best performance. Be sure to keep caps

on valves to prevent entry of debris into the valve stem

when tires are filled.

25 Hours Worm Gear Oil

10 Hours 10W Oil and Grease

Monthly 20 psi (1.37 bar)

50 Hours+ See Engine Manual

Yearly See Engine Manual

4-6 Hours N/A

Yearly Lithium Grease

10 Hours 10W Oil

10 Hours Lithium Grease

Winter Weight

Size PSI bar

15 x 5.0-6 20 1,38

4.80-8 20 1,38

16 x 6.5-8 14 ,96

AUGER GEAR CASE LUBRICATION

1. Place the snowthrower on a level surface.

2. Remove the pipe plug (A, Figure 9).

3. Check the lubricant level. Itshould be level with the

lower edge of the plug opening. If not, add The

Dealer Line Winter Weight Worm Gear Oil (available

from your dealer).

4. Re-install pipe plug, and tighten securely.

Figure 8. Checking Tire Pressure

Figure 9. Auger Lubrication

A. Pipe Plug

16

Page 18

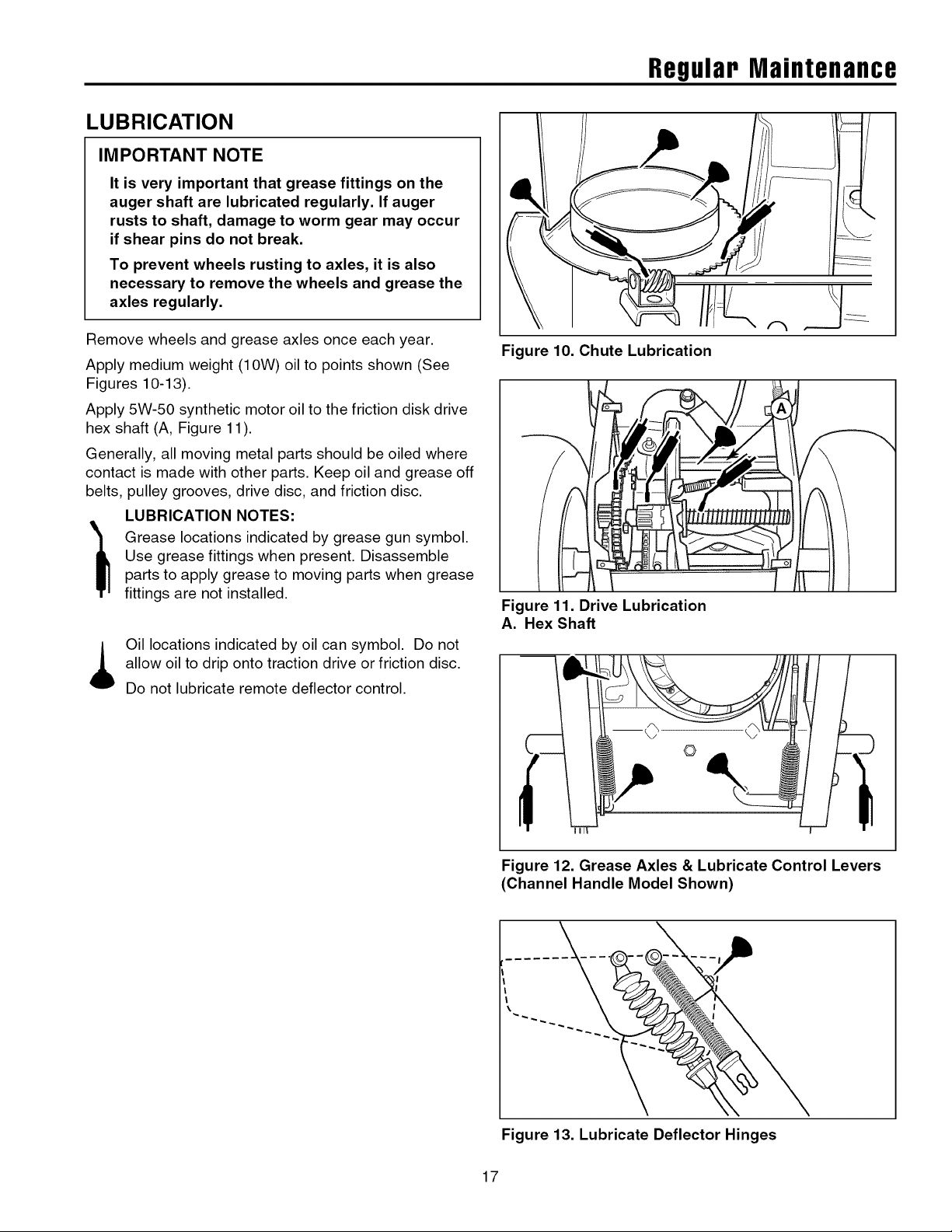

LUBRICATION

IMPORTANT NOTE

It is very important that grease fittings on the

auger shaft are lubricated regularly. If auger

rusts to shaft, damage to worm gear may occur

if shear pins do not break.

To prevent wheels rusting to axles, it is also

necessary to remove the wheels and grease the

axles regularly.

Regular Maintenance

Remove wheels and grease axles once each year.

Apply medium weight (10W) oil to points shown (See

Figures 10-13).

Apply 5W-50 synthetic motor oil to the friction disk drive

hex shaft (A, Figure 11).

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts, pulley grooves, drive disc, and friction disc.

LUBRICATION NOTES:

Use grease fittings when present. Disassemble

Grease locations indicated by grease gun symbol.

parts to apply grease to moving parts when grease

fittings are not installed.

allow oil to drip onto traction drive or friction disc.

Oil locations indicated by oil can symbol. Do not

Do not lubricate remote deflector control.

Figure 10. Chute Lubrication

Figure 11. Drive Lubrication

A. Hex Shaft

©

Figure 12. Grease Axles & Lubricate Control Levers

(Channel Handle Model Shown)

\

Figure 13. Lubricate Deflector Hinges

17

Page 19

RegularMaintenance

CHECK / LUBRICATE FREE-HAND

LINKAGE

Check the function of the Free-Hand controls: the con-

trols should function as described in the CONTROLS

section. It is critical for the safe operation of the unit

that the controls disengage when released.

If the controls do not function properly, lubricate them. If

lubrication does not rectify the problem, see your dealer.

Under no circumstances should the unit be used if the

controls are not functioning properly.

Figure 14. Lubricate Free-Hand TM Control Linkage

A. DO NOT Lubricate Deflector Control

IMPORTANT NOTE

It is very important that grease fittings on the auger shaft

are lubricated regularly. If auger rusts to shaft, damage to

worm gear may occur if shear pins do not break.

LUBRICATING THE AUGER SHAFT &

ASSEMBLY

1. Remove cotter pin (C, Figure 16) and shear pin (B).

2. Use a grease gun and squirt several shots of grease

into grease fitting (A).

3. Rotate auger assembly (D) several times to distribute

the grease evenly. Repeat step 2.

4. Reinstall shear pin (B) and cotter pin (C).

5. Repeat procedure for other side.

Figure 15. Lubricate Free Hand Control

®

Figure 16. Lubricating the Auger Shaft Assembly

A. Grease Fittings C. Cotter Pins

B. Shear Pins D. Auger Assembly

18

Page 20

19

Page 21

Troubleshooting,Adjustments,Service

TROUBLESHOOTING

This section provides troubleshooting and service

instructions• Locate the problem and check the possible

cause/remedy in the order listed•

Also, refer to the engine manufacturer's Owner's Manual

for additional information•

For problems not covered here, contact your local deal-

er.

PROBLEM REMEDY

Engine fails to start. 1. Push key in to the ON position•

2. Failure to prime cold engine

3. Fuel valve is in CLOSED position.

4. Out of fuel.

5. Choke OFF - cold engine.

6. Engine flooded.

POSSIBLE CAUSE

• Key is OFF.

WARNING

Before performing any adjustment or service to

snowthrower, stop the engine and wait for

moving parts to stop. Remove the key. To prevent

accidental starting, disconnect the spark plug

wire and fasten away from the plug.

2. Press primer button twice and

restart.

3. Turn valve to OPEN position.

4. Fill fuel tank.

5. Turn choke to ON, set throttle to

FAST.

6. Turn choke to OFF; try starting.

Engine starts hard or runs poorly.

Scraper bar does not clean hard

surface.

Auger does not rotate.

7. No spark.

8. Water in fuel, or old fuel.

• Fuel mixture too rich.

2. Carburetor adjusted incorrectly•

3. Spark plug faulty, fouled, or gapped

improperly•

4. Fuel cap vent is blocked•

• Skid shoes improperly adjusted•

1. Skid shoes improperly adjusted•

•Auger control not engaged•

2. Foreign matter blocking auger•

3. Auger drive clutch rod slack. 3. Tighten to remove slack. See auger

4. Auger drive belt slipping. 4. Check auger drive belt adjustment.

7. Check gap. Gap plug, clean elec-

trode, or replace plug as necessary.

8. Drain tank (Dispose of fuel at an

authorized hazardous waste facility).

Fill with fresh fuel.

1. Move choke to OFF position•

2. See your dealer for adjustments•

3. Clean and gap, or replace•

4.Clear vent.

1. RAISE skid shoes (this lowers the

scraper bar).

1. LOWER skid shoes (this raises the

scraper bar.)

1. Engage auger control•

2. STOP engine and REMOVE the

key. DISCONNECT the spark plug

wire. Clear auger using clean-out

tool. See warning in SAFETY

RULES•

clutch rod adjustment.

5. Broken belt. 5. Replace belt.

6. Shear pin broken. 6. Replace shear pin.

20

Page 22

Troubleshooting

PROBLEM

Auger rotates, but snow is not

thrown far enough

Poor traction

Auger does not stop when auger

lever is released

Snowthrower does not stop when

drive lever is released

POSSIBLE CAUSE

1. Chute deflector too low.

2. Engine speed too slow•

3. Ground speed too fast•

4. Snowthrower discharge chute

clogged•

5. Auger belt loose or worn•

1. Tires slipping•

1. Free-Hand TM control is ACTIVE•

2. Auger clutch rod too tight or bent•

3. Auger drive belt out of adjustment•

4. Auger belt guide out of adjustment•

1. Traction drive clutch rod bent or too

tight•

1. Traction drive clutch rod loose•

2. Drive belt loose, broken, or

stretched•

3. Drive roller chain damaged•

REMEDY

1. Adjust deflector as necessary.

2. Set speed to full throttle•

3. Use slower speed selector setting•

4..STOP engine and REMOVE the

key. DISCONNECT the spark plug

wire. Clear auger using clean-out

tool. See warning in SAFETY

RULES•

5. Check auger drive belt adjustment

1. Check tire pressure and tread•

1. Release BOTH auger engage

Control AND Free-Hand TM Control

to stop auger•

2. Loosen or straighten clutch rod.

3. Adjust auger belt.

4..Adjust auger belt guide•

1. Loosen rod to remove slack or

replace• See adjustment procedure•

1. Tighten to remove slack• See

adjustment procedure•

2. Replace drive belt.

3. Replace chain•

4. Traction lock pins in free-Wheeling

position (OUTER hole)•

5. Friction disc worn.

Discharge control is difficult to

operate.

Snowthrower veers to one side.

Excessive vibration.

Drive fails to move snowthrower 1. Traction drive out of adjustment• 1. Readjust drive, or shift speed selec-

at slow speeds, tot setting up one speed faster•

Speed selector difficult to move or 1. Hex shaft needs lubrication• 1. Lubricate hex shaft with 5W-50 syn-

frozen in place, thetic motor oil (see Maintenance)•

1. Gearing needs lubrication

2. Worm gear not adjusted properly•

3. Control rod gears misaligned.

1. Tire pressure not equal•

2. One wheel is set in free-wheeling

mode. (Traction Lock Pin is in the

OUTER hole)•

1. Loose parts or damaged auger•

4..Change traction lock pins to INNER

hole to engage traction drive•

5. Replace disc (see your dealer)•

1. Oil or grease as required•

2. Adjust worm gear. See adjustment

procedure•

3. Adjust gear bracket• See adjust-

ment procedure•

1. Check tire pressure•

2. Make certain the left traction lock

pin is in the INNER holes (to

engage traction drive)•

• STOP engine and REMOVE the

key. DISCONNECT the spark plug

wire. Tighten all hardware• Replace

auger if necessary. If vibration con-

tinues, see your dealer•

21

Page 23

Adjustments

SPEED SELECTOR ADJUSTMENT

1. Loosen the two nuts (C, Figure 17).

2. Place the shift lever in 5th gear.

3. Push the lower rod into the housing and tighten the

two nuts (C). Do not lift up or down on rods while

tightening. Make sure the shoulders of the carriage

bolts (B) are in the slots.

4. Always check traction drive tension and auger drive

tension after adjusting speed selector.

AUGER DRIVE TENSION

WARNING

Do not over-tighten, as this may lift the lever and

cause auger drive to be engaged without

depressing the Auger Control,

1. With the drive lever released, the hook (B, Figure 18)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32" clearance as shown.

2. To adjust, loosen nut (D, Figure 20) by holding the

adjusting flats (A)and turning nut (D). Turn adjust-

ment flats and hold screw. The adjustment screw is

a phillips screw and the head can be held or turned

by inserting a screwdriver through the spring.

3. Hold adjusting flats (A) and tighten nut (D).

4. Start unit and check auger, auger must not be

engaged unless auger control is depressed.

5. With engine running, fully depress auger control, the

auger should engage and run normally.

6. Release auger control. Auger must stop within 5

seconds.

7. If auger does not operate properly, stop engine and

recheck drive linkage adjustments.

8. If drive linkage is properly adjusted, auger drive belt

tension may require adjustment. See "Adjusting

Auger Drive Belt".

Figure 17. Speed Selector Linkage

A. Shift Rod

B. Carriage Bolts

C. Nuts

Figure 18. Auger Drive Adjustment

A. Adjusting Flats

B. Spring Hook

C. Lever

D. Nut

E. Adjustment Screw

22

Page 24

TRACTION DRIVE TENSION

Initial Adjustment

1.With the drive lever released there should be no slack

in the cable when moved slightly from side to side,

but bellcrank arm remains in fully down position.

1. To adjust tension on the cable loosen adjustment hex

nut (D, Figure 19) by holding the adjusting flats (A).

Turn the adjustment screw. The adjustment screw is

a phillips screw and the head can be held or turned

by inserting a screwdriver through the traction drive

clutch cable spring

3. Engage the drive lever to check the adjustment.

When correct, tighten hex nut securely. The unit

should able to be pushed forward and back freely.

WARNING

Do not over-tighten, as this may cause traction

drive to engage without depressing the traction

drive control (bellcrank arm must remain in down

position).

Verify that the cables are not over-tightened: With

speed selector in position 1 and traction drive

control fully released, push snowthrower forward.

The unit should move forward freely.

If unit does not move forward freely, the cable has

been over-tightened. To remedy, loosen tension

on clutch cable slightly, and recheck.

Adjustments

O

Figure 19. Traction Drive Adjustment

A. Adjusting Flats

B. Spring Hook

C. Bellcrank Arm

D. Nut

E. Adjustment Screw

Run-In Adjustment

ALL MODELS

,

After 5 hours of use, check for proper adjustment.

Readjust clutch cable if necessary by increasing ten-

sion on cable. A small amount of bellcrank arm

movement is permissible if unit passes operating

checks described in the Caution above.

23

Page 25

Adjustments

MANUAL DISCHARGE CHUTE

CONTROL LINKAGE ADJUSTMENT

Pinion Gear Adjustment

If the discharge chute is difficult to operate, first lubricate

the pinion gear (A, Figure 20) and ring gear (F). If it is

still difficult to operate, adjust as follows:

NOTE: If the discharge chute will not stay in position,

adjust the pinion gear (,4) closer to the ring gear (F).

1. Loosen the nut (G, Figure 20) which holds the pinion

gear bracket in the slotted hole.

2. If the pinion gear is too tight against the ring gear,

move it away slightly and then retighten the nut.

3. Check the operation again

Figure 20. Discharge Control

A. Pinion Gear

B. Control Rod

C. Carriage Bolt

D. Slotted Bracket

E. U-shaped Bracket

F. Ring Gear

G. Nut

Gear Bracket Adjustment

If the discharge chute becomes difficult to rotate or

begins to operate erratically, the chute direction control

rod gears may require adjustment:

1. Loosen the gear bracket mounting nuts (Figure 21).

2. Slide the gear bracket into the position that provides

the best engagement between the gears.

3. Tighten the bracket mounting hardware, and check

for smooth operation.

4. Readjust if necessary.

5. Lubricate the chute direction control rod gears with a

medium weight (10W) oil

ELECTRIC DISCHARGE CHUTE

ROTATOR MOTOR ADJUSTMENT

If the electric chute rotator does not function properly,

check the electrical connections and then perform the

procedure below.

1. Remove the rotator motor cover.

2. Lubricate the chute ring gear.

3. Loosen the screws (A, Figure 22) securing the rotator

motor and adjust so that the motor gear and chute

ring gear mesh. Tighten the capscrews.

4. Reinstall the rotator motor cover.

Figure 21. Gear Bracket Adjustment

A. Mounting Hardware

Figure 22. Chute Rotator Motor Adjustment

A. Screws

24

Page 26

EASY TURN TM CABLE ADJUSTMENT

If the Easy Turn TM cable has stretched, the gears will not

disengage when the control lever is activated. Adjust the

cable using the following procedure.

1. Turn the engine off and disconnect the spark plug

wire.

2. Loosen the jam nut (B, Figure 23).

3. Turn the adjustment nut (A) to lengthen or shorten

the cable. The cable should be tightened just until all

slack is removed from the lever, however it must not

engage the Easy Turn TM release without depressing

the control lever.

4. Tighten the jam nut.

Adjustments & Service

SHEAR PIN REPLACEMENT

WARNING

Do not go near the discharge chute or auger

when the engine is running. Do not run the engine

with any cover or guard removed.

Under most circumstances, if the auger strikes an object

which could cause damage to the unit, the shear pin will

break. (This protects the gear box and other parts from

damage.)

The shear pins are located on the auger shaft as shown

in Figure 24. To replace the shear pins, tap out the bro-

ken pin with a pin punch, and install a new shear pin and

cotter pin. Spread the legs of the new cotter pin fully. Do

NOT replace shear pins with anything other than the

correct grade replacement shear pin. (Use of bolts,

screws or a harder shear pin will lead to damaged equip-

ment.)

Figure 23. Cable Adjustment

A. Adjustment Nut

B. Jam Nut

Figure 24. Shear Pins

A. Shear Pins

B. Cotter Pins

25

Page 27

Adjustments & Service

BELT REPLACEMENT

1. Turn off the engine, remove the spark plug wire, and

wait for all moving parts to stop. Rotate the spout full

right. Loosen the two screws (B, Figure 25) securing

the belt cover.

2. Tilt the cover forward and work it off the snowthrower.

3. Move the belt guides (B, Figure 26) by loosening the

two capscrews (A).

4. Remove the auger drive belt as follows:

a. Slip the auger drive belt (D, Figure 26) from the

idler pulley by pushing it away from the pulley and

then toward the rear.

b. Remove the belt from the engine pulley. Slip the

belt from under the brake pad.

c. Remove two capscrews from bottom cover to

snowthrower frame. Loosen nuts (A, Figure 27) on

each side to release auger pulley belt stops (B).

Move belt stops and remove belt from pulley (C).

d. Remove the two bolts (D, Figure 27) from the gear

assembly.

e. Loosen the set collar and slide the axle shaft right.

f. Belt can be removed from top or bottom. For more

clearance to remove the belt, engage the traction

drive lever.

5. Remove the traction drive belt as follows:

a. Pull the idler pulley (I, Figure 26) away from the

belt and slip the belt from the pulley.

b. Slip the belt off the traction pulley and then the

engine pulley. The arm for the front idler pulley (G,

Figure 26) may have to be pivoted to provide clear-

ance for removing the belt from the traction pulley.

c. Pull the belt out between the auger pulley (F,

Figure 26) and traction pulley.

Figure 25. Belt Cover

A. Belt Cover

B. Screws

Figure 26. Belts and Pulleys

A. Capscrews

B. Belt Guides

C. Traction Drive Belt

D. Auger Drive Belt

E. Engine Pulley

F. Auger Pulley

G. Idler Pulley, Auger

H. Traction Pulley

I. Idler Pulley, Traction

26

Page 28

6. Reverse the procedure to install the belts. Be sure

there are no twists and the belts are properly seated

in the grooves. Adjust the belt stops so there is 1/8"

(3mm) clearance between belt and stop. The pattern

for both belts is shown in Figure 28. Slide the right

axle left fully before tightening the set collar (E,

Figure 27).

7. Check the traction drive tension and auger drive ten-

sion. Follow the procedures under AUGER/TRAC-

TION DRIVE TENSION.

,

Make sure the auger stops when the auger drive

lever is released. Make sure traction drive stops

when the traction drive lever is released. If not, check

the drive tension. If a problem exists, see your dealer.

Service

Figure 27. Auger Pulley Belt Stops

(shown with bottom cover removed)

A. Nuts

B. Belt Stops

C. Auger Pulley

D. Gear Assembly. Bolts

E. Set Collar

I I

4// I""f

Figure 28. Belt Pattern (viewed from front)

A. Engine Pulley

B. Drive Belt

C. Idler Pulley

D. Driven Pulley

E. Engine Belt Stops

F. Auger Pulley Belt Stops (Power Boost Units Only)

27

Page 29

Specifications

NOTE: Specifications are correct at time of printing and are subject to change without notice.

* Actual sustained equipment horsepower will likely be lower due to operating limitations and environmental factors.

CHASSIS:

ENGINE: Wheels

- 9524, 9560,10560,

9.5 HP* Briggs & Stratton 10528,11570

Make Briggs & Stratton - 11532, 1380,

Model Intek Snow 113387, 1390

Horsepower 9,5 @ 3600 rpm Spout Rotation

Displacement 18,6 Cu, in (305 cc) Impeller

Oil Capacity 28 oz. (,84 L)

10.5 HP* Briggs & Stratton

Make Briggs & Stratton

Model Intek Snow

Horsepower 10.5 @ 3600 rpm

Displacement 18.6 Cu. in (305 cc)

Oil Capacity 28 oz, (,84 L)

11.5 HP* Briggs & Stratton

Make Briggs & Stratton

Model Intek Snow

Horsepower 11.5 @ 3600 rpm

Displacement 18,6 Cu. in (305 cc)

Oil Capacity 28 oz. (,84 L)

12.5 HP* Briggs & Stratton

Make Briggs & Stratton

Model Intek Snow

Horsepower 12.5 @ 3600 rpm

Displacement 18.6 Cu, in (305 cc)

Oil Capacity 28 oz. (,84 L)

13 HP* Briggs & Stratton

Make Briggs & Stratton

Model Intek Snow

Horsepower 13 @ 3600 rpm

Displacement 20.8 Cu. in (341 cc)

Oil Capacity 28 oz, (,84 L)

Auger Opening Height 19" (47.5 cm)

Drive System Friction Disc, 5 Forward Speeds, 2 Reverse

DIMENSIONS

Effective Clearing Width

-9524 24" (60cm)

-9560 24" (60cm)

-10560 24" (60cm)

-10528 28" (70cm)

-11570 28" (70cm)

-11532 32" (80cm)

-1380 32" (80cm)

-13387 38" (97cm)

-1390 38" (97cm)

Length

-960 57"(142cm)

-9560 57"(142cm)

-10560 57"(142cm)

-10528 57"(142cm)

-11570 57"(142cm)

-11532 57"(142cm)

-1380 57"(142cm)

-1290 57"(142cm)

-1390 57"(142cm)

Height

-9524 38" (93cm)

-9560 38" (93cm)

-10560 38"(93cm)

-10528 38"(93cm)

-11570 38"(93cm)

-11532 38"(93cm)

-1380 38"(93cm)

-13387 38"(93cm)

-1390 38"(93cm)

Tire Size: 16 x 4.8

Inflation Pressure: 20 psi (1,37 bar)

Tire Size: 16 x 6,5

Inflation Pressure: 14 psi (,96 bar)

210 Depress

12" (30cm) 4 Blade Ribbon Flighted Steel

Weight

-9524 255 Ibs (115kg)

-9560 255 Ibs (115kg)

-10560 245 Ibs (111 kg)

-10528 245 Ibs (111 kg)

-11570 270 Ibs (122kg)

-11532 265 Ibs (120kg)

-1380 275 Ibs (125kg)

-13387 275 Ibs (125kg)

-1390 300 Ibs (136kg)

28

Page 30

Parts& Accessories

REPLACEMENT PARTS

Replacement parts are available from your authorized

dealer. Always use genuine Simplicity / Snapper Service

Parts.

MAINTENANCE ITEMS

Many convenient and helpful service and maintenance

items are available from you authorized dealer. Some of

these items include:

Engine Oil

Touch-Up Paint

Grease Gun Kit

8 oz. Grease Tube

Tire Sealant

Degrimer/Degreaser

Gas Stabilizer

TECHNICAL MANUALS

Additional copies of this manual are available, as well as

fully illustrated parts lists. These manuals show all of the

product's components in exploded views (3D illustrations

which show the relationship of parts and how they go

together) as well as part numbers and quantities used.

Important assembly notes and torque values are also

included.

For applicable manuals currently available for your

model, contact our Customer Publications Department at

262-284-8519 (Simplicity) 1-866-313-6682 (Snapper)

Have the information listed in the box below available

when phoning in your request. Technical manuals can

be downloaded from

www.simplicitymfg.com

www.snapper.com

Model:

Mfg. No.:

Your Name:

Address:

City, State, Zip:

Visa/Mastercard No.:

Card Expiration Date:

29

Page 31

30

Page 32

Bimplicilq

MANUFACTURING, INC.

500 N Spring Street / PO Box 997

Port Washington, Wl 53074-0997

www.simplicitymfg.com, snapper.com

© Copyright 2005, Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

Page 33

Bimplicilq

OPERATOR'S

MANUAl

Large Frame

Snowthrowers

9524 Models

Mfg. No. Description

1694853 95247E, 9.5HP Snowthrower

1694854 E95247, 9.5HP Snowthrower (CE)

9560 Models

Mfg. No. Description

1694867 9560E, 9.5HP Snowthrower

1694914 9560EX, 9.5HP Snowthrower (CE)

10528 Models

Mfg. No. Description

1694855 105287E, IO.5HP Snowthrower

1694856 E105287, IO.5HP Snowthrower (CE)

10560 Models

Mfg. No. Description

1694847 10560E, IO.5HP Snowthrower

1694848 10560EX, IO.5HP Snowthrower (CE)

11532 Models

Mfg. No. Description

1694857 115327E, 11.5HP Snowthrower

1694858 E115327, 11.5HP Snowthrower (CE)

11570 Models

Mfg. No. Description

1694849 11570E, 11.5HP Snowthrower

1694850 11570EX, 11.5HP Snowthrower (CE)

1338 Models

Mfg. No. Description

1694859 13387E, 13HP Snowthrower

1694860 E13387, 13HP Snowthrower (CE)

1380 Models

Mfg. No. Description

1694851 1380E, 13HP Snowthrower

1694852 1380EX, 13HP Snowthrower (CE)

1390 Models

Mfg. No. Description

1694872 1390E, 13HP Snowthrower

1694915 1390EX, 13HP Snowthrower (CE)

1731288

Revision 03

Rev. Date 11/2005

TP

100-4220-03-LW-SN

Page 34

TableofContents

CONTENTS:

Safety Rules & Information

Training ............................................................ 2

Preparation ...................................................... 2

Operation ......................................................... 2

Children ........................................................... 3

Clearing a Clogged Discharge Chute .............. 3

Service, Maintenance and Storage ................. 3

Emissions ........................................................ 3

Decals .............................................................. 5

Safety Icons ..................................................... 6

Identification Numbers ........................................ 7

Features, Controls, & Operation

Control Locations ............................................. 8

General Operation

Checks Before Each Start-Up ....................... 10

Starting the Engine ........................................ 11

Starting Controls ............................................ 11

Operating The Snowthrower .......................... 12

Clearing a Clogged Discharge Chute ............ 12

Ground Speed Selector ................................. 12

Engine Speed ................................................ 12

Deflector ........................................................ 13

Scraper Bar & Skid Shoes ............................. 13

Easy-Turn and Traction Drive Lock ................ 14

After Each Use .............................................. 15

Storage .......................................................... 15

Regular Maintenance

Schedule ........................................................ 16

Checking Tire Pressure ................................. 16

Auger Gear Case Lubrication ........................ 16

Lubrication ..................................................... 17

Check/Lubricate Free-Hand Linkage ........... 18

Lubricate the Auger Shaft & Assembly .......... 18

Troubleshooting, Adjustments, & Service

Troubleshooting ............................................. 20

Speed Selector Adjustment ........................... 22

Auger Drive Tension ...................................... 22

Traction Drive Tension ................................... 23

Manual Discharge Chute Adjustment ............ 24

Electric Discharge Chute Adjustment ............ 24

Easy Turn Cable Adjustment ......................... 25

Shear Pin Replacement ................................. 25

Belt Replacement .......................................... 26

Specifications .................................................... 28

Replacement Parts & Accessories ................. 29

WARNING

You must read, understand and comply with all

safety and operating instructions in this manual

before attempting to set-up and operate your

snowthrower.

Failure to comply with all safety and operating

instructions can result in loss of machine control,

serious personal injury to you and/or

bystanders, and risk of equipment and property

damage. The triangle in the text signifies

important cautions or warnings which must be

followed.

WARNING

Engine exhaust from this product contains

chemicals known, in certain quantities, to cause

cancer, birth defects, or other reproductive harm,

Page 35

SafetyRules& Information

_ his machine is capable to amputating hands and feet and throwing objects. Read these safety rules and

TRAINING

1. Read, understand, and follow all instructions on the

2. Never allow children to operate the equipment.

3. Keep the area of operation clear of all persons, partic-

4. Exercise caution to avoid slipping or falling especially

PREPARATION

1. Thoroughly inspect the area where the equipment is

2. Disengage all clutches and shift into neutral before

3. Do not operate the equipment without wearing ade-

4. Handle fuel with care; it is highly flammable.

5. Use extension cords and receptacles as specified by

6. Adjust the collector housing height to clear gravel or

7. Never attempt to make any adjustments while the

8. Let engine (motor) and machine adjust to outdoor

9. Always wear safety glasses or eye shields during

TP-600-3606-03-LW-UV

follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury

or death to you, or bystanders, or damage to property or equipment. The triangle ,_ in text signifies

important cautions or warnings which must be followed.

OPERATION

1. Do not put hands or feet near or under rotating parts.

machine and in the manuals before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

Never allow adults to operate the equipment without

proper instruction.

ularly small children and pets.

when operating in reverse.

to be used and remove all doormat, sleds, boards,

wires, and other foreign objects.

starting engine (motor).

quate winter outer garments. Wear footwear that will

improve footing on slippery surfaces. Avoid loose fit-

ting clothing that can get caught in moving parts.

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors. Replace fuel cap securely and

wipe up spilled fuel.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place con-

tainers on the ground, away from your vehicle, before

filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground. If

this is not possible, then refuel such on a trailer with a

portable container, rather than from a gasoline dis-

penser nozzle.

(f) Keep nozzle in contact with the rim of the fuel tank

or container opening at all times, until refueling is

complete. Do not use a nozzle lock-open device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing imme-

diately.

the manufacturer for all units with electric drive

motors or electric starting motors.

crushed rock surfaces.

engine (motor) is running (except when specifically

recommended by the manufacturer).

temperatures before starting to clear snow.

operation or while performing an adjustment or repair

to protect eye from foreign objects that may be

thrown from the machine.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the

snowthrower for any damage, and repair the damage

before restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the

operating position, before unclogging the

collector/impeller housing or discharge guide, and

when making any repairs, adjustments, or inspec-

tions.

6. When cleaning, repairing, or inspecting make certain

the collector/impeller and all moving parts have

stopped. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

7. Do not run the engine indoors except for starting the

engine or for transporting the snowthrower in or out of