Page 1

Not for

Reproduction

80030025USCN

Revision: A

Page 2

Manual Contents:

Not for

Reproduction

Operator Safety.....................................................................2

indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Features and Controls..........................................................8

Operation...............................................................................8

Maintenance.........................................................................15

Troubleshooting..................................................................28

Warranties............................................................................29

Slope Guide.........................................................................34

Specifications......................................................................35

The images in this document are representative, and are meant

to complement the instructional copy they accompany. Your

unit may vary from the images displayed.

as seen from the operator's position.

Thank you for purchasing this quality-built Snapper Walkbehind

Mower. We’re pleased that you’ve placed your confidence in

the Snapper brand. When operated and maintained according

to the manuals, your Snapper product will provide many years

of dependable service.

The manuals contain safety information to make you aware of

the hazards and risks associated with the unit and how to avoid

them. This Walkbehind Mower was designed to be used as

described in operator's manual and is not intended for any other

purpose. It is important that you read and understand the

instructions thoroughly before attempting to start or operate this

equipment. Save these original instructions for future reference.

This product requires final assembly before use. Refer to the

setup guide for instructions on final assembly procedures. Follow

the instructions completely.

LEFT

and

RIGHT

are

Operator Safety

Safety Definitions

For your safety, the safety of others, and to protect the

performance of equipment, follow the precautions listed

throughout the manual before operation, during operation, and

during maintenance procedures.

indicates a potential personal injury hazard.

CAUTION

indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

indicates a situation which can cause damage to the equipment,

personal property and/or the environment, or cause the

equipment to operate improperly.

Safety Symbol Definitions

The following safety symbols may be found on the unit.

Read the operator’s manual before attempting to operate the

mower.

Mow across slopes, not up or down.

To avoid injury to others, do not mow when others, especially

children, are around.

To reduce the potential for fire, wait at least 2 minutes before

refueling.

To avoid serious injury or death, keep hands and feet away from

the mower deck at all times during operation.

To avoid injury from thrown objects, do not operate the mower

unless all mulching, discharge, or bagging components are in their

proper place.

California Spark Arrester Warning

WARNING

It is a violation of California Public Resource Code, Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federal jurisdictions may have similar laws. Contact the original

equipment manufacturer, retailer, or dealer to obtain a spark

arrester designed for the exhaust system installed on this

engine.

DANGER

indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

2 www.snapper.com

WARNING

Battery posts, terminals, and related accessories contain

lead and lead compounds, chemicals known to the State

of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

Page 3

California Proposition 65

3.5 ft

(1,5 m)

20.0 ft

(6,0 m)

Not for

Reproduction

This product can expose you to chemicals including gasoline

engine exhaust, which is known to the State of California to

cause cancer, and carbon monoxide, which is known to the

State of California to cause birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

Operating Safety

Tragic accidents can occur with children. Do not allow them

anywhere near the area of operation. Children are often attracted

to the unit and mowing activity. Never assume that children will

remain where you last saw them. If there is a risk that children

may enter the area where you are mowing, have another

responsible adult watch them.

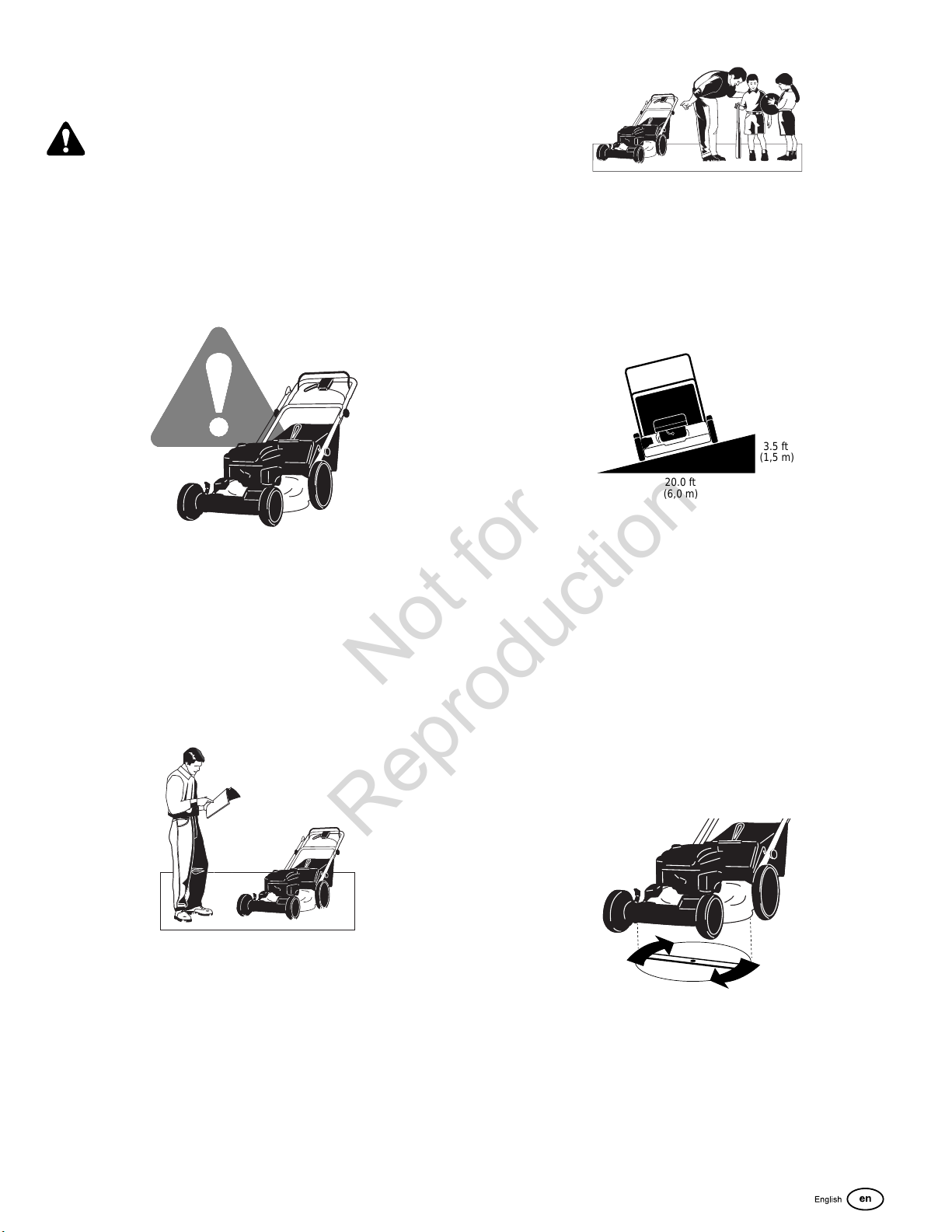

Slope Operation

Power equipment is only as safe as the operator. If it is misused,

or not properly maintained, it can be dangerous! Remember,

you are responsible for your safety and that of those around

you.

Use common sense, and think through what you are doing. If

you are not sure that the task you are about to perform can be

safely done with the equipment you have chosen, ask a

professional: contact your local authorized dealer.

Read the Manual

The operator’s manual contains important safety information

you need to be aware of BEFORE you operate your unit as well

as DURING operation.

Safe operating techniques, an explanation of the product’s

features and controls, and maintenance information is included

to help you get the most out of your equipment investment.

Be sure to completely read the Safety Rules and Information

found on the following pages. Also completely read the

Operation section.

You could be seriously injured or even killed if you use this unit

on too steep an incline. Using the unit on a slope that is too

steep or where you don’t have adequate footing or traction can

cause you to lose control or slip and fall.

You should not operate on inclines with a slope greater than 10

degrees, which is a 3.5 ft (1,5 m) rise over 20.0 ft (6,0 m).

Always mow across slopes, never up and down.

Also note that the surface you are mowing can greatly impact

control. Wet grass or leaves can seriously affect your footing

and traction on a slope.

If you feel about operating the unit on an incline, don’t do it. It’s

not worth the risk.

Moving Parts

This equipment has moving parts that can injure you or someone

else. However, if you stand behind the handle properly and

follow all the rules in this book, the unit is safe to operate.

The mower has a spinning mower blade that can amputate

hands and feet. Do not allow anyone near the equipment while

it is running!

Children

3

Page 4

To help you, the operator, use this equipment safely, it is

Not for

Reproduction

equipped with an operator present safety system. Do NOT

attempt to alter or bypass the system. See your dealer

immediately if the system does not pass all the safety interlock

system tests found in this manual.

Thrown Objects

This unit has a spinning mower blade. This blade can pick up

and throw debris that could seriously injure a bystander. Be

sure to clean up the area to be mowed BEFORE you start

mowing.

Do not operate this unit without the entire grass catcher or

discharge guard (deflector) in place.

Also, do not allow anyone in the area while the unit is running!

If someone does enter the area, turn the unit off immediately

until they leave.

Debris Accumulation

Proper maintenance is critical to the safety and performance of

your unit. Be sure to perform the maintenance procedures listed

in this manual, especially periodically testing the safety system.

General Safety Messages

WARNING

This powerful cutting machine is capable of amputating hands

and feet and can throw objects that can cause injury and

damage! Failure to comply with the following SAFETY

instructions could result in serious injury or death to the

operator or other persons. The owner of the machine must

understand these instructions and must allow only persons

who understand these instructions to operate machine. Each

person operating the machine must be of sound mind and

body and must not be under the influence of any substance,

which might impair vision, dexterity or judgment.

WARNING

Poisonous Gas Hazard

Engine exhaust contains carbon monoxide, a poisonous gas

that could kill you in minutes. You CANNOT see it, smell it,

or taste it. Even if you do not smell exhaust fumes, you could

still be exposed to carbon monoxide gas. If you start to feel

sick, dizzy, or weak while using this product, shut it off and

get to fresh air RIGHT AWAY. See a doctor. You may have

carbon monoxide poisoning.

Accumulation of grass and debris can result in a fire. Be sure

to clean any accumulation of grass and debris with a brush or

compressed air, before and after operation.

Fuel and Maintenance

Gasoline is extremely flammable. Its vapors are also extremely

flammable and can travel to distant ignition sources. Gasoline

must only be used as a fuel, not as a solvent or cleaner. It should

never be stored any place where its vapors can build up or travel

to an ignition source like a pilot light. Fuel belongs in an

approved, plastic, sealed gas can, or in the tractor fuel tank with

the cap securely closed. Spilled fuel needs to be cleaned up

immediately.

• Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in

carbon monoxide alarms with battery back-up according

to the manufacturer’s instructions. Smoke alarms cannot

detect carbon monoxide gas.

• DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other

partially-enclosed spaces even if using fans or opening

doors and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for hours,

even after this product has shut off.

• ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces.

Protection For Children

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the machine

and the mowing activity. Never assume that children will remain

where you last saw them.

1. KEEP children out of the mowing area and under the

watchful care of a responsible adult other than the operator.

2. DO NOT allow children in yard when machine is operated

and turn machine OFF if anyone enters the area.

3. DO NOT allow pre-teenage children to operate machine.

4 www.snapper.com

Page 5

4. ALLOW only responsible adults & teenagers with mature

Not for

Reproduction

judgment under close adult supervision to operate machine.

5. DO NOT pull mower backwards unless absolutely

necessary. LOOK and SEE behind and down for children,

pets and hazards before and while backing.

6. USE EXTRA CARE when approaching blind corners,

shrubs, trees, or other objects that may obscure vision.

Slope Operation

1. Slopes are a major factor related to slip and fall accidents,

which can result in severe injury. All slopes require extra

caution. If you feel uneasy on a slope, DO NOT mow it.

2. Mow across slopes, never up-and-down. Exercise extreme

CAUTION when changing directions on slopes. DO NOT

mow steep slopes or other areas where stability or traction

is in doubt. Refer to the Slope Guide at the back of this

manual.

3. Use extra care with grass catchers or other attachments;

these affect the handling and the stability of the machine.

Preparation

1. Read, understand, and follow instructions and warnings in

this manual and on the mower, engine and attachments.

Know the controls and the proper use of the mower before

starting.

2. Only mature, responsible persons shall operate the machine

and only after proper instruction.

3. Data indicates that operators age 60 and above, are

involved in a large percentage of mower-related injuries.

These operators should evaluate their ability to operate the

mower safely enough to protect themselves and others from

serious injury.

4. Handle fuel with extra care. Fuels are flammable and vapors

are explosive. Use only an approved fuel container. DO

NOT remove fuel cap or add fuel with engine running. Add

fuel outdoors only with engine stopped and cool. Clean

spilled fuel and oil from machine. DO NOT smoke.

5. Check the area to be mowed and remove all objects such

as toys, wire, rocks, limbs and other objects that could cause

injury if thrown by blade or interfere with mowing. Also note

the location of holes, stumps, and other possible hazards.

6. Keep people and pets out of the mowing area. Immediately,

STOP Blade, Stop engine and Stop mower if anyone enters

the area.

7. Check shields, deflectors, switches, blade controls and

other safety devices frequently for proper operation and

location.

8. Make sure all safety decals are clearly legible. Replace if

damaged.

9. Protect yourself when mowing and wear safety glasses,

long pants and substantial footwear. DO NOT mow

barefooted or with sandals.

10. Know how to STOP blade and engine quickly in preparation

for emergencies.

11. Use extra care when loading or unloading the machine into

a trailer or truck.

12. Check grass catcher components frequently for signs of

wear or deterioration and replace as needed to prevent

injury from thrown objects going through weak or torn spots.

Safe Handling Of Gasoline

To avoid personal injury or property damage, use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive.

1. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

2. Use only an approved fuel container.

3. DO NOT remove fuel cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. DO NOT refuel the machine indoors.

5. DO NOT store the machine or fuel container inside where

there is an open flame, spark or pilot light such as on a

water heater or other appliances.

6. DO NOT fill fuel containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place the containers

on the ground away from the vehicle before filling.

7. Remove gas-powered equipment from the vehicle or trailer

and refuel it on the ground. If this is not possible, then refuel

equipment using a portable container, rather than a gasoline

dispenser nozzle.

8. DO NOT start gas powered equipment in enclosed vehicles

or trailers.

9. Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. DO

NOT use a nozzle lock-open device.

10. If fuel is spilled on clothing, change clothing immediately.

11. DO NOT overfill a fuel tank. Replace fuel cap and tighten

securely.

Operation

1. DO NOT put hands or feet near or under rotating parts.

Keep clear of discharge area while engine is running.

2. STOP engine when crossing gravel drives, walks, or roads,

and under any conditions where thrown objects might be a

hazard.

3. Mow only in daylight or good artificial light.

4. DO NOT operate mower while under the influence of alcohol

or drugs.

5. After striking a foreign object or if mower vibrates

abnormally, STOP the engine, disconnect and secure spark

plug wire. Inspect the mower for any damage and repair

the damage before starting.

6. DO NOT mow near drop offs, ditches or embankments.

Operator could lose footing or balance.

7. STAY ALERT for holes and other hidden hazards. Tall grass

can hide obstacles. Keep away from ditches, washouts,

culverts, fences and protruding objects.

5

Page 6

8. DO NOT mow on wet grass. Always be sure of your footing.

Not for

Reproduction

Keep a firm hold on the handle and walk, never run. Slipping

could cause injury.

9. ALWAYS stay behind handle when engine (motor) is

running.

10. DO NOT leave the machine with the engine running. STOP

BLADE and STOP ENGINE before leaving the operators

position for any reason.

11. Before cleaning, repairing or inspecting make certain engine,

blade and all moving parts have STOPPED. Disconnect

and secure spark plug wire away from plug to prevent

accidental starting.

12. STOP engine and wait until the blade comes to complete

STOP before removing grass bag and/or clearing grass.

13. DO NOT operate mower without the entire grass catcher,

rear guard, or other safety devices in place and working.

DO NOT point discharge at people, passing cars, windows

or doors.

14. DO NOT discharge material against a wall or obstruction.

Material may ricochet back towards the operator.

15. Slow down before turning.

16. Watch out for traffic when near or crossing roadways.

17. DO NOT operate engine in enclosed areas. Engine exhaust

gases contain carbon monoxide, a deadly poison.

18. Only use accessories approved by the manufacturer. See

manufacturer’s instructions for proper operation and

installation of accessories.

Maintenance And Storage

moving parts. Replace with new bag if loose seams or tears

are evident. Replace slider or bag adapter if broken or

cracked.

9. Mower blades are sharp and can cut. Wrap the blades or

wear heavy leather gloves and use CAUTION when

handling them.

10. DO NOT test for spark by grounding spark plug next to

spark plug hole; spark plug could ignite gas exiting engine.

11. Have machine serviced by an authorized dealer at least

once a year and have the dealer install any new safety

devices.

12. Use only factory authorized replacement parts or like parts

when making repairs.

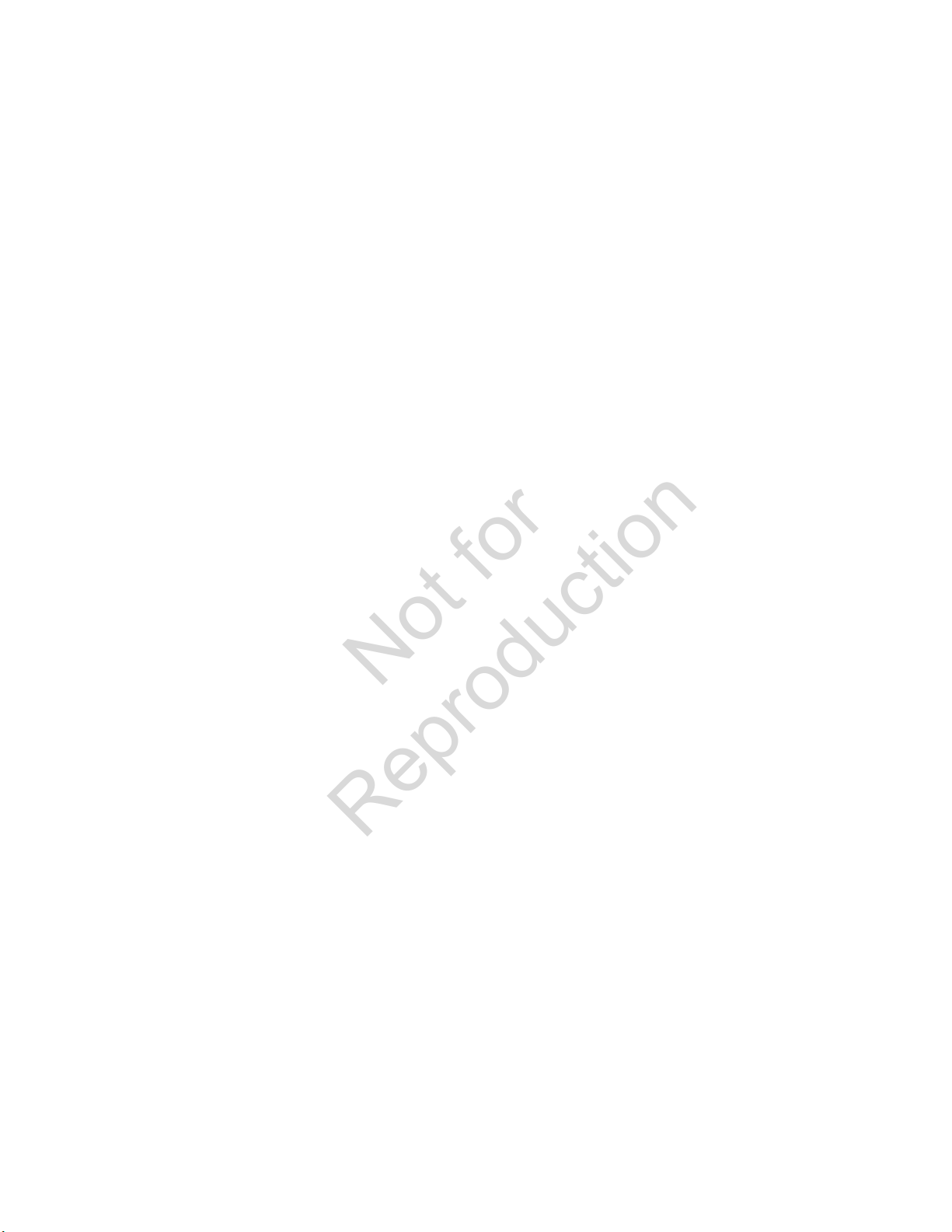

Safety and Operation Decals

Reading this manual and the safety instructions it contains will

provide the basic knowledge necessary to operate this mower

safely and effectively. However, several safety and operation

decals have also been placed on the mower as a reminder of

this important information during operation.

The decals noted below are located on the mower. The safety

warnings and operation instructions they contain should be

carefully read, understood, and followed. Not following these

important warnings and instructions can result in serious bodily

injury or death.

If any of these decals are lost or damaged, replace them

immediately. Contact your dealer for replacement decals.

Compare Figure 1 with the table following.

1. DO NOT store mower or fuel container inside where fumes

may reach an open flame, spark or pilot light such as in a

water heater, furnace, clothes dryer or other gas appliance.

Allow engine to cool before storing machine in an enclosure.

Store fuel container out of reach of children in a well

ventilated, unoccupied building.

2. Keep mower and engine free of grass, leaves or excess

grease to reduce fire hazard and engine overheating.

3. When draining fuel tank, drain fuel into an approved

container outdoors and away from open flame.

4. Keep all bolts, especially blade bolts, nuts and screws

properly tight. Check that all cotter pins are in proper

position.

5. Always provide adequate ventilation when running engine.

Engine exhaust gases contain carbon monoxide, a deadly

poison.

6. Service engine and make adjustments only when engine

is stopped. Removed spark plug wire from spark plug and

secure wire away from spark plug to prevent accidental

starting.

7. DO NOT change engine governor speed settings or

overspeed engine.

8. Check grass bag assembly frequently for wear or

deterioration to avoid thrown objects and exposure to

6 www.snapper.com

Page 7

1

Not for

Reproduction

D

WARNING: Spark

Arrestor may be

required.

E

F

G

G

A

Drive Control

• Squeeze drive

control against

handle to engage

wheel drive.

WARNING: Avoid

Serious Injury or Death

DANGER: Keep Hands

and Feet Away.

DANGER: Amputation

and Thrown Object

Hazard.

DANGER: Amputation

and Thrown Object

Hazard.

B

C

OPC (Blade Control)

• Squeeze blade

control to start

and run engine

and blade.

• Release blade

control to stop

engine and blade.

Ground Speed Control

• Move ground

speed control

toward Fast

(Rabbit) to

increase ground

speed.

• Move ground

speed control

toward Slow

(Turtle) to

decrease ground

speed.

H

WARNING: Cancer

and Reproductive

Harm.

7

Page 8

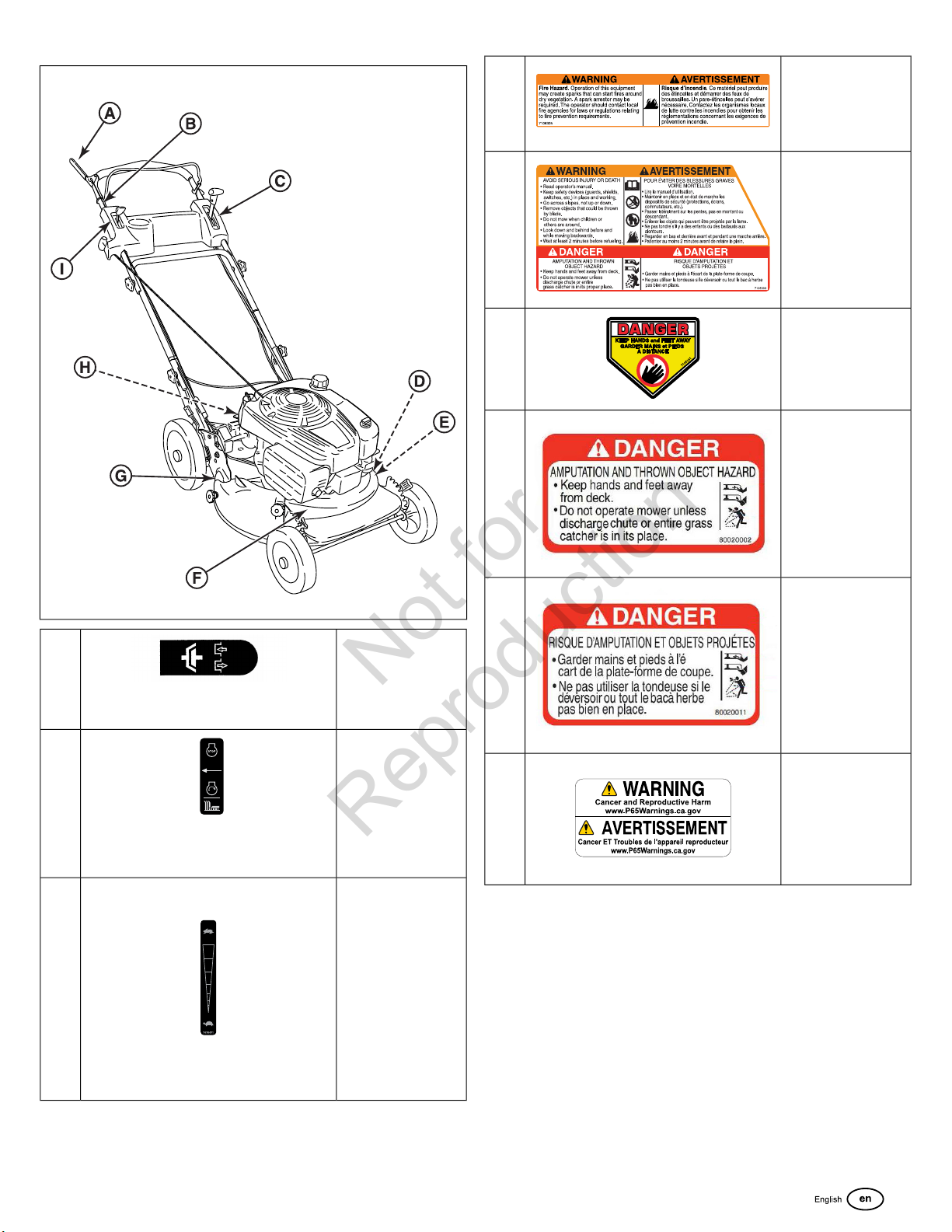

I

Not for

Reproduction

Engine Speed Control

• Move engine

speed control

lever toward Slow

(Turtle) to

decrease engine

speed.

• Move engine

speed control

lever toward Fast

(Rabbit) to

increase engine

speed.

• Move engine

speed control

lever past Fast

(Rabbit) to turn

on choke.

Engine Speed ControlE

Drive ControlF

Blade ControlG

Ground Speed ControlH

Fuel Filler CapI

Front Height Adjustment Latch (2)J

Operation

Before Starting

1. Check the guards, deflectors, grass bag, and covers to

make sure all are in place and securely tightened.

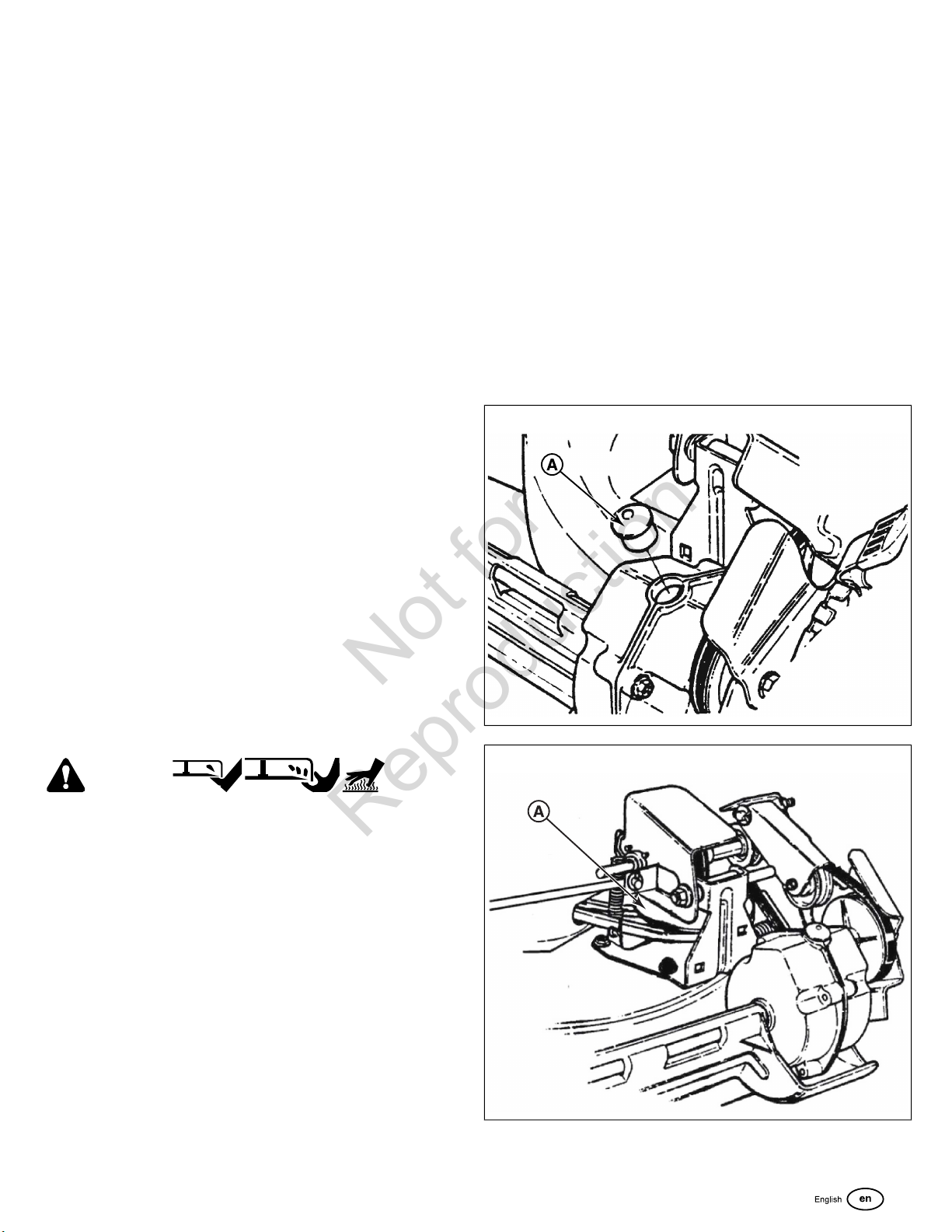

2. Check the blade control (A, Figure 3), drive control (B), and

ground speed control (C) to insure they work freely.

Features and Controls

Note:

The figures and illustrations in this manual are provided

for reference only and may differ from your specific model.

Contact your dealer if you have questions.

Compare Figure 2 with the table following.

2

3

3. Check the cutting height. Adjust to the desired height. See

Cutting Height Adjustment

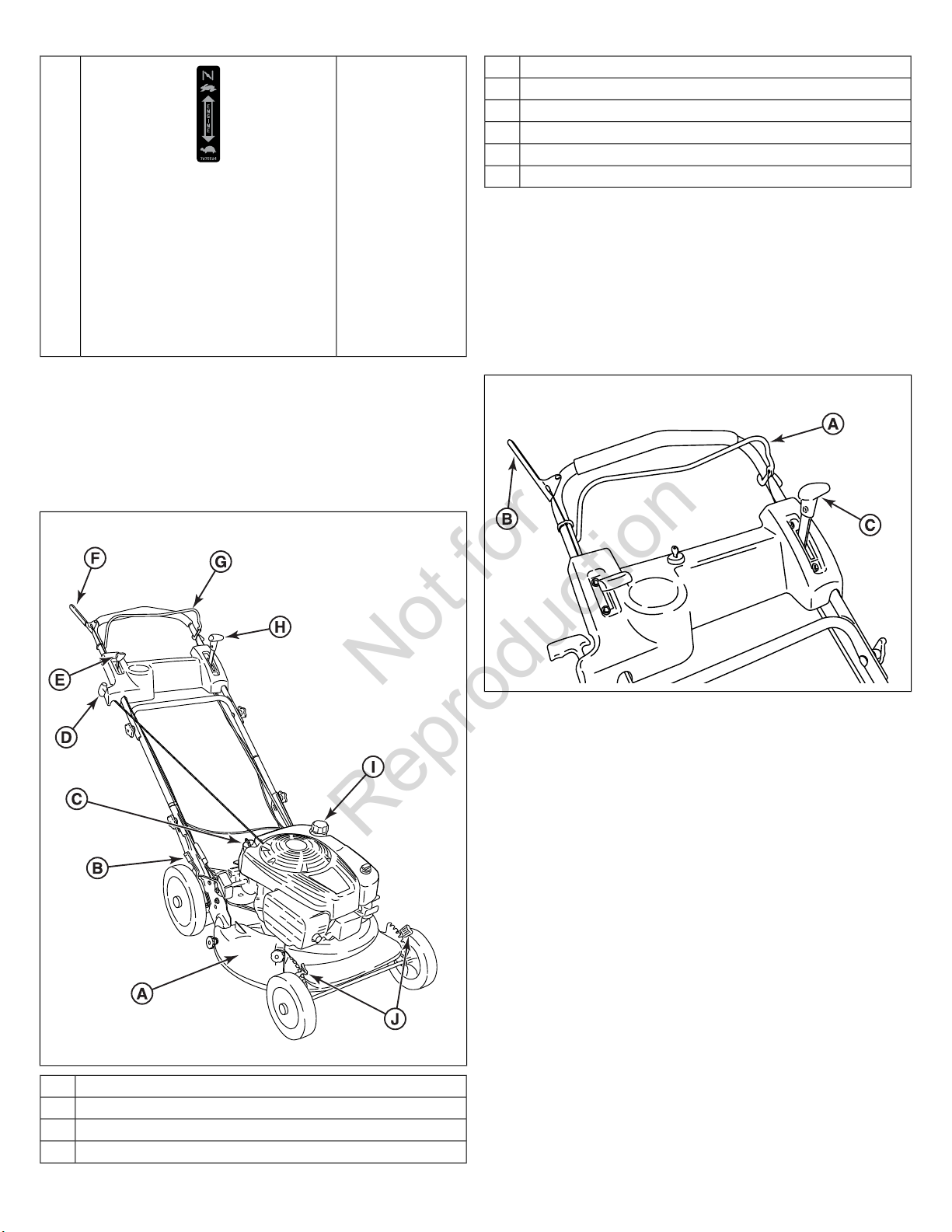

4. Check the engine oil:

• Make sure the mower is on a level surface.

• Clean the oil fill area of any debris.

• Remove the dipstick (A, Figure 4) and wipe with a clean

cloth.

• Insert and tighten the dipstick.

• Remove the dipstick and check the oil level. It should

be at the top of the full indicator (B) on the dipstick.

• If low, add oil slowly into the engine oil fill. See

Recommendations

wait one minute and recheck the oil level.

• Replace and tighten the dipstick.

.

Oil

. Do not overfill. After adding oil,

Mulching CoverA

Rear Height Adjustment Latch (2)B

Oil Fill Cap and DipstickC

Rope Start HandleD

8 www.snapper.com

Page 9

4

Not for

Reproduction

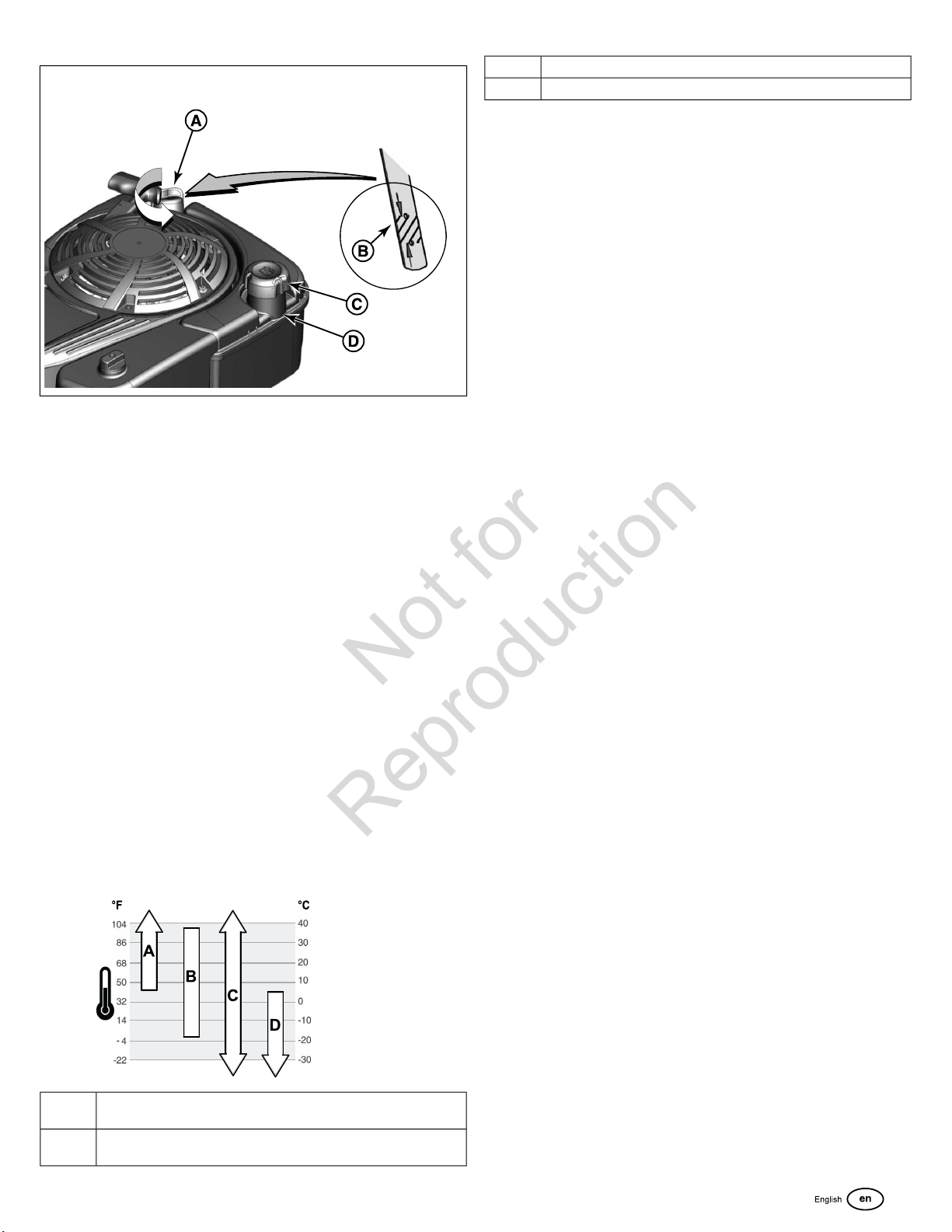

Synthetic 5W-30C.

5W-30D.

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane / 87 AKI (91 RON). For high altitude

use, see below.

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

5. Add fuel to the tank:

• Make sure the mower is outside, where fumes can

safely dissipate.

• Remove the fuel fill cap (C, Figure 4).

• Fill the tank with fuel. See

To allow for expansion of the fuel, do not fill above the

bottom of the filler neck (D).

• Reinstall the fuel fill cap.

6. Clean the exterior surfaces of the cutting deck and engine

of any accumulation of spilled fuel, dirt, grass, oil, etc. Keep

the engine air intake screen and cooling fins clear at all

times.

7. Charge the battery. See

Fuel Recommendations

Charging the Battery

.

.

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty Certified

oils for best performance. Other high-quality detergent oils are

acceptable if classified for service SF, SG, SH, SJ or higher.

Do not use special additives.

NOTICE

and E85. Do not mix oil in gasoline or modify the engine to

run on alternate fuels. Use of unapproved fuels will cause

damage to engine components, which will not be covered

under warranty.

To protect the fuel system from gum formation, mix a fuel

stabilizer into the fuel. See Storage. All fuel is not the same. If

starting or performance problems occur, change fuel providers

or change brands. This engine is certified to operate on gasoline.

The emissions control system for this engine is EM (Engine

Modifications).

Do not use unapproved gasolines, such as E15

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85

octane/85 AKI (89 RON) gasoline is acceptable.

For carbureted engines, high altitude adjustment is required to

maintain performance. Operation without this adjustment will

cause decreased performance, increased fuel consumption,

and increased emissions. Contact a Briggs & Stratton Authorized

Service Dealer for high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762

meters) with the high altitude adjustment is not recommended.

For Electronic Fuel Injection (EFI) engines, no high altitude

adjustment is necessary.

Outdoor temperatures determine the proper oil viscosity for the

engine. Use the chart to select the best viscosity for the outdoor

temperature range expected.

SAE 30 - Below 40°F (4°C) the use of SAE 30 will result in hard

A.

starting.

10W-30 - Above 80°F (27°C) the use of 10W-30 may cause

B.

increased oil consumption. Check oil level more frequently.

9

Page 10

Starting the Mower

Not for

Reproduction

WARNING

Poisonous Gas Hazard

Engine exhaust contains carbon monoxide, a poisonous gas

that could kill you in minutes. You CANNOT see it, smell it,

or taste it. Even if you do not smell exhaust fumes, you could

still be exposed to carbon monoxide gas. If you start to feel

sick, dizzy, or weak while using this product, shut it off and

get to fresh air RIGHT AWAY. See a doctor. You may have

carbon monoxide poisoning.

• Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or plug-in

carbon monoxide alarms with battery back-up according

to the manufacturer’s instructions. Smoke alarms cannot

detect carbon monoxide gas.

• DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other

partially-enclosed spaces even if using fans or opening

doors and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for hours,

even after this product has shut off.

• ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces.

5

Propelling the Mower

1. Start the mower.

2. Move the ground speed control (A, Figure 6) to the desired

speed position.

3. Squeeze the wheel drive control (B) against the handle to

engage the wheel drive and propel the mower forward.

Forward speed can be adjusted while the mower is moving

by changing the position of the ground speed control.

The engine on your mower is equipped with the Briggs &

Stratton Ready Start™ System. This features a

temperature-controlled automatic choke. No additional steps

are required to start a cold engine.

1. Move the engine speed control (A, Figure 5, if equipped)

to the fast (‘Rabbit’) position.

2. Squeeze the blade control (B) against the handle.

3. Start the mower:

• Manual Start Models: Pull the rope start handle (C) to

crank the engine.

• Electric Start Models: Insert the key (D) into the electric

start switch. Turn the key to crank the engine. Use short

starting cycles, five seconds maximum, and wait 1

minute between starting cycles.

4. To stop the engine (and blade), release the blade control.

5. After the engine starts, allow a brief warm-up until the engine

runs smooth before beginning mower operation.

6

Stopping the Mower

1. Stop forward motion of the mower by releasing the wheel

drive control.

2. Stop the engine and blade by releasing the blade control.

3. Electric Start Models: Remove the key from the electric start

switch.

10 www.snapper.com

Page 11

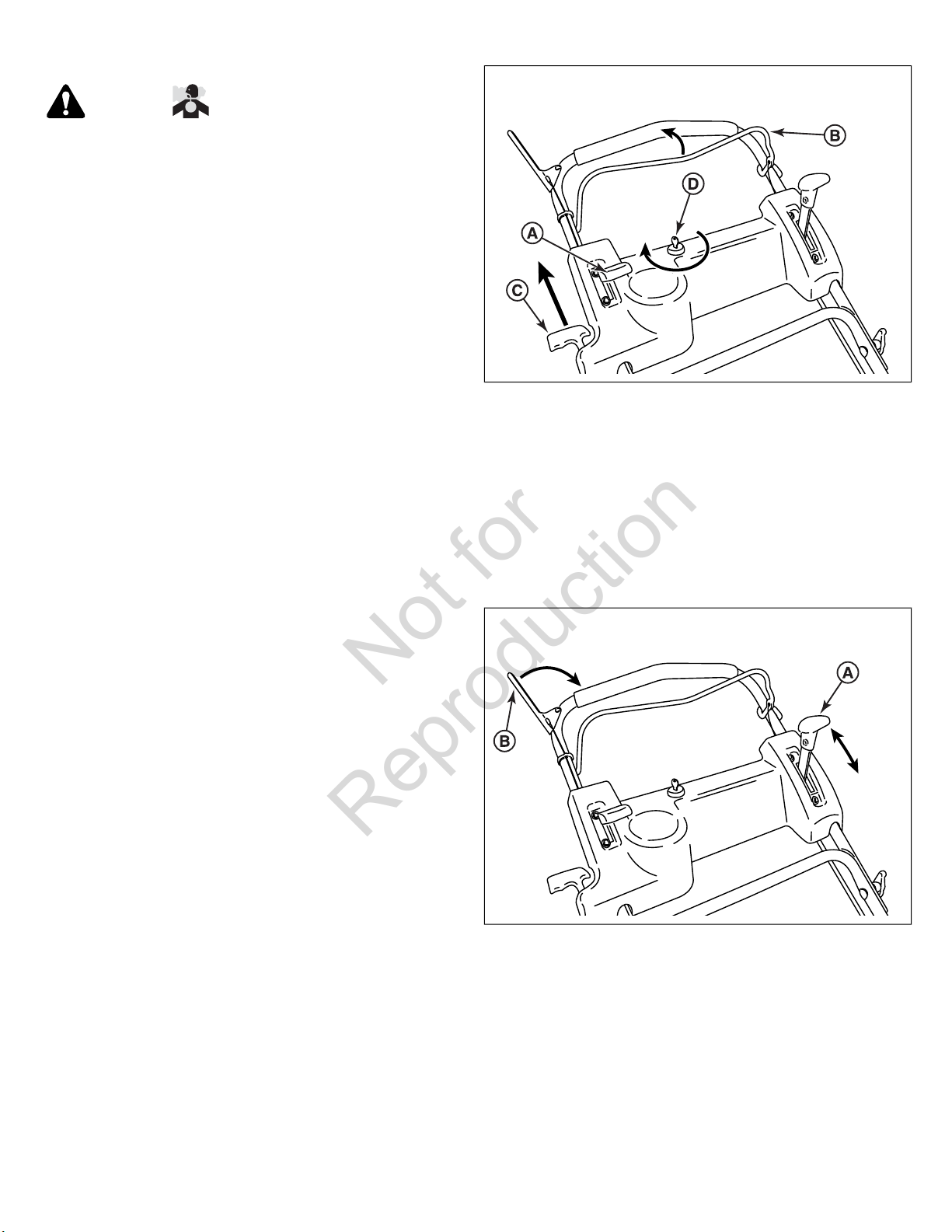

Handle Height Adjustment

Not for

Reproduction

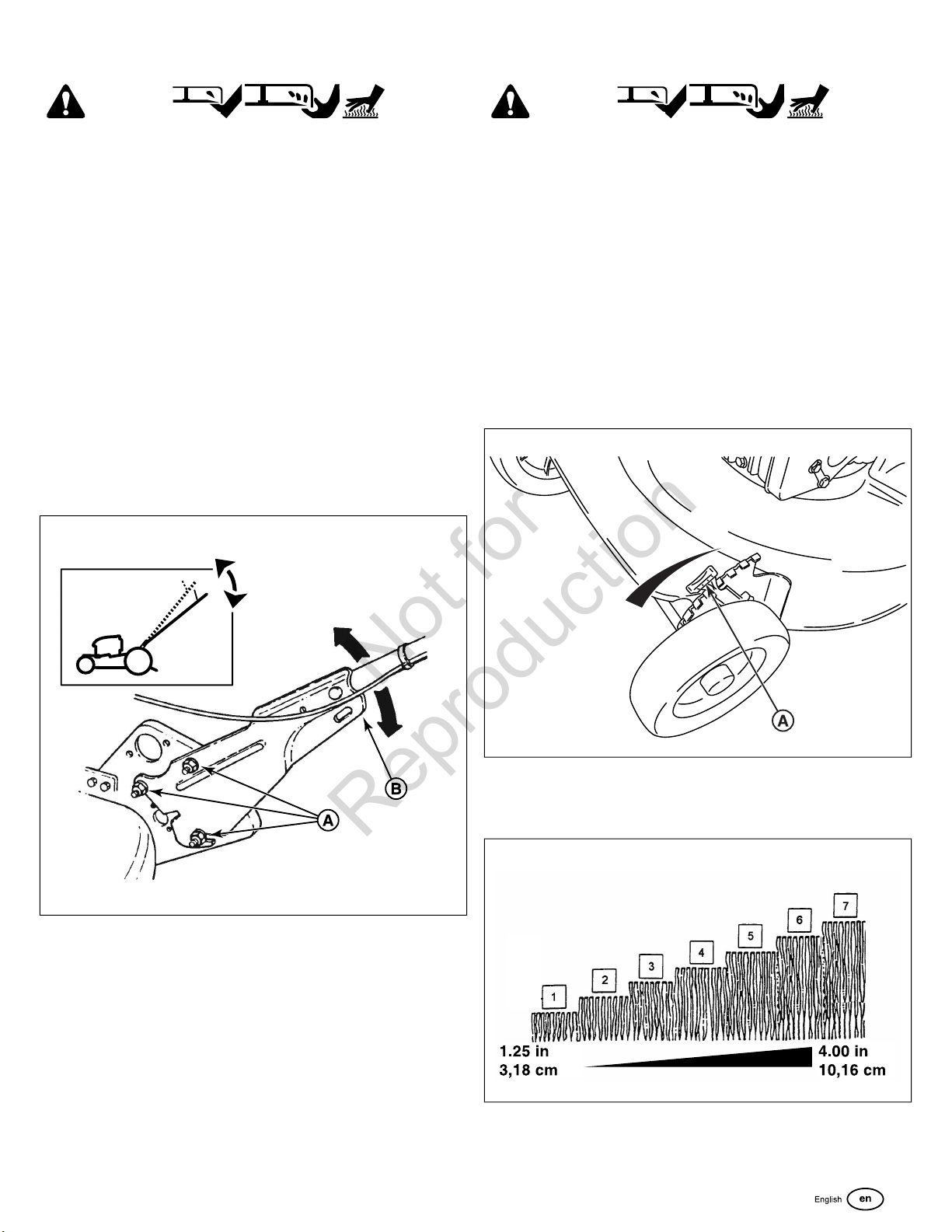

Cutting Height Adjustment

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

The height of the mower handle can be adjusted as follows:

1. Loosen the lower nuts (A, Figure 7) on each lower handle.

2. Move the handle assembly (B) up or down until the desired

position is achieved.

3. Tighten the lower nuts on each lower handle to maintain

the desired position.

7

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

1. Pull the height adjusting latch (A, Figure 8) outward and

move to the desired cutting height.

8

2. Set all wheels at the same cutting height. The highest cutting

position is Notch 7 (Figure 9). The lowest cutting position

is Notch 1.

9

11

Page 12

Mulching Operation

Not for

Reproduction

For best mulching results, cut up to a maximum of 1/3 of grass

blade length and recycle ONLY when grass is dry.

1. Set all wheels in the highest cutting position (Notch 7). See

Cutting Height Adjustment

2. Move the engine speed control to the fast (Rabbit) position.

3. Move the ground speed control to the slowest speed setting.

4. Proceed mowing slowly. If the grass is very dense, lower

each rear wheel latch one notch lower than the front wheel

latches to improve mulching performance.

.

Installing the Discharge Deflector

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

Note:

The mulching cover should remain on the machine at all

times, unless alternate discharge operations are desired, such

as side discharging or bagging.

Removing the Mulching Cover

(Optional Accessory on Some Models)

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

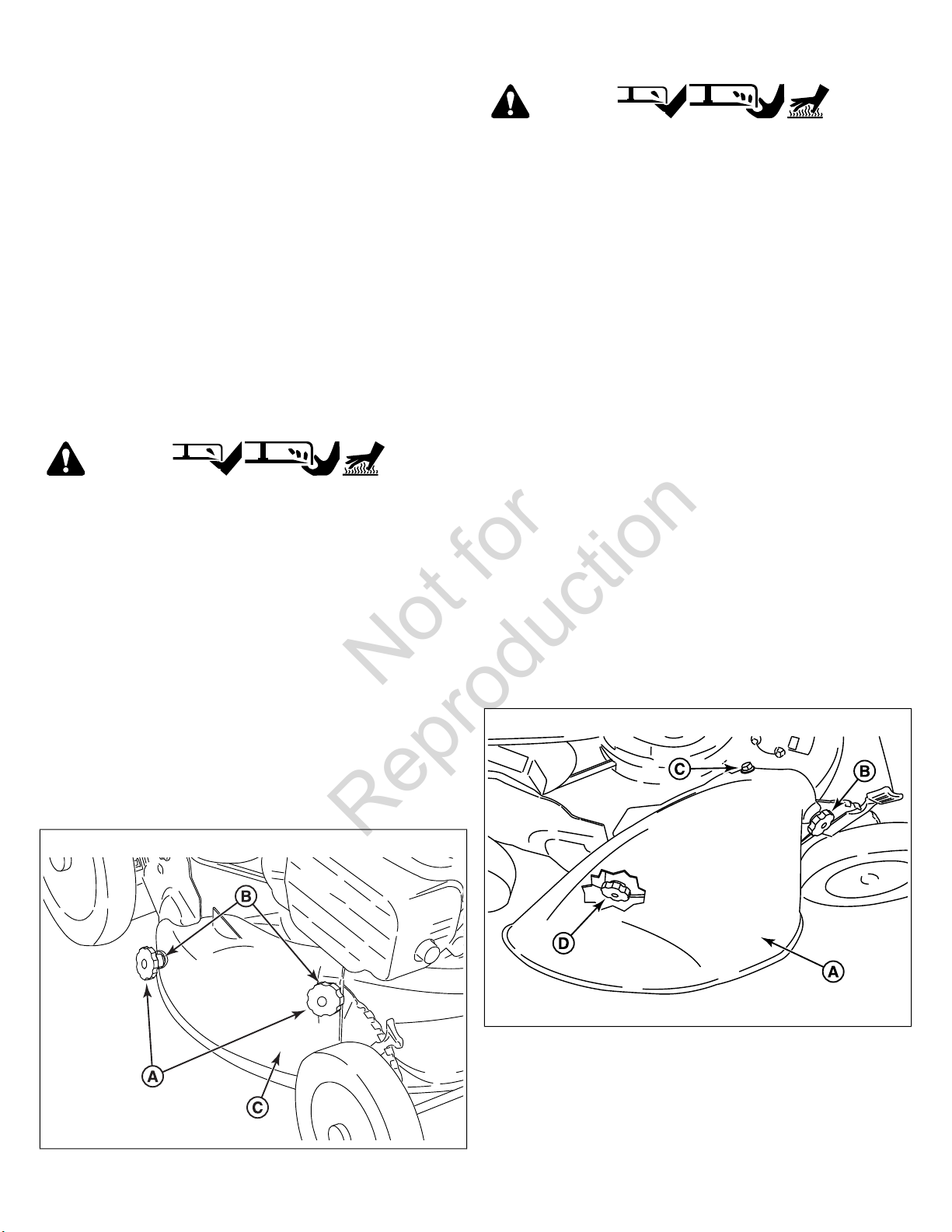

1. Remove the knob nuts (A, Figure 10) and internal/ external

tooth lock washers (B) securing the mulching cover (C) to

the mower deck.

2. Remove the cover.

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

1. Remove the mulching cover. See

2. Install the deflector (A, Figure 11) to the deck in place of

the mulching cover, making sure that:

• The front hole (B) on the outside front of the deflector

fits over the stud where the front of the mulching cover

was originally secured;

• The slot (C) on top of the deflector slips under the

restraining nut on top of the deck (under the right front

corner of the engine);

• The slot (D) on the inside rear of the deflector slips onto

the stud behind the rear of the discharge opening,

where the rear of the mulching cover was originally

secured.

3. Install the internal/external tooth lock washers and knob

nuts onto the studs and tighten securely.

Mulching Operation

11

.

10

12 www.snapper.com

Page 13

WARNING

Not for

Reproduction

Thrown Objects Hazard

DO NOT operate without entire Grass Catcher or guard in

place. Grass Catcher components are subject to deterioration

during normal use. Inspect frequently and replace worn or

damaged components immediately.

Installing the Grass Bag Adapter

(Optional Accessory on Some Models)

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

12

Installing the Mulching Plug

(Optional Accessory on Some Models)

1. Remove the mulching cover. See

Cover

.

2. Install the adapter (A, Figure 12) to the deck in place of the

mulching cover, making sure that:

• The front hole (B) on the outside front of the adapter

fits over the stud where the front of the mulching cover

was originally secured;

• The slot (C) on top of the adapter slips under the

restraining nut on top of the deck (under the right front

corner of the engine);

• The slot (D) on the rear of the adapter slips onto the

stud behind the rear of the discharge opening, where

the rear of the mulching cover was originally secured.

3. Install the internal/external tooth lock washers and knob

nuts onto the studs and tighten securely.

4. Route the recoil rope around the outside of the rope guide

pulley (E).

Note:

The recoil rope may need to be slackened. See

the Mower

.

Removing the Mulching

Starting

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

1. Install the mulching plug (A, Figure 13) if mulching is desired

after the bag adapter is installed. Install the mulching plug

completely and securely into the bag adapter (B).

2. Install the grass bag as a safeguard and to further secure

the mulching plug.

WARNING

Thrown Objects Hazard

Install the grass bag when using the mulching plug. Failure

to do so may result in personal injury or death.

3. See

Mulching Operation

.

13

Page 14

13

Not for

Reproduction

Installing the Grass Bag

(Optional Accessory on Some Models)

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

14

WARNING

Unsafe Operation Hazard

Grass Catcher bags are made of woven fabric, and are subject

to deterioration and wear during normal usage. Check

condition of bag before each use. Immediately replace worn

or damaged catcher bags with only genuine replacement

bags. The grass catcher is optional equipment on some

models.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

1. Install the grass bag adapter. See

Bag Adapter

2. Install the grass bag by sliding the connector (A, Figure 14)

over the adapter flange.

3. Attach the grass bag hooks (B) over the middle handle cross

bar.

.

Installing the Grass

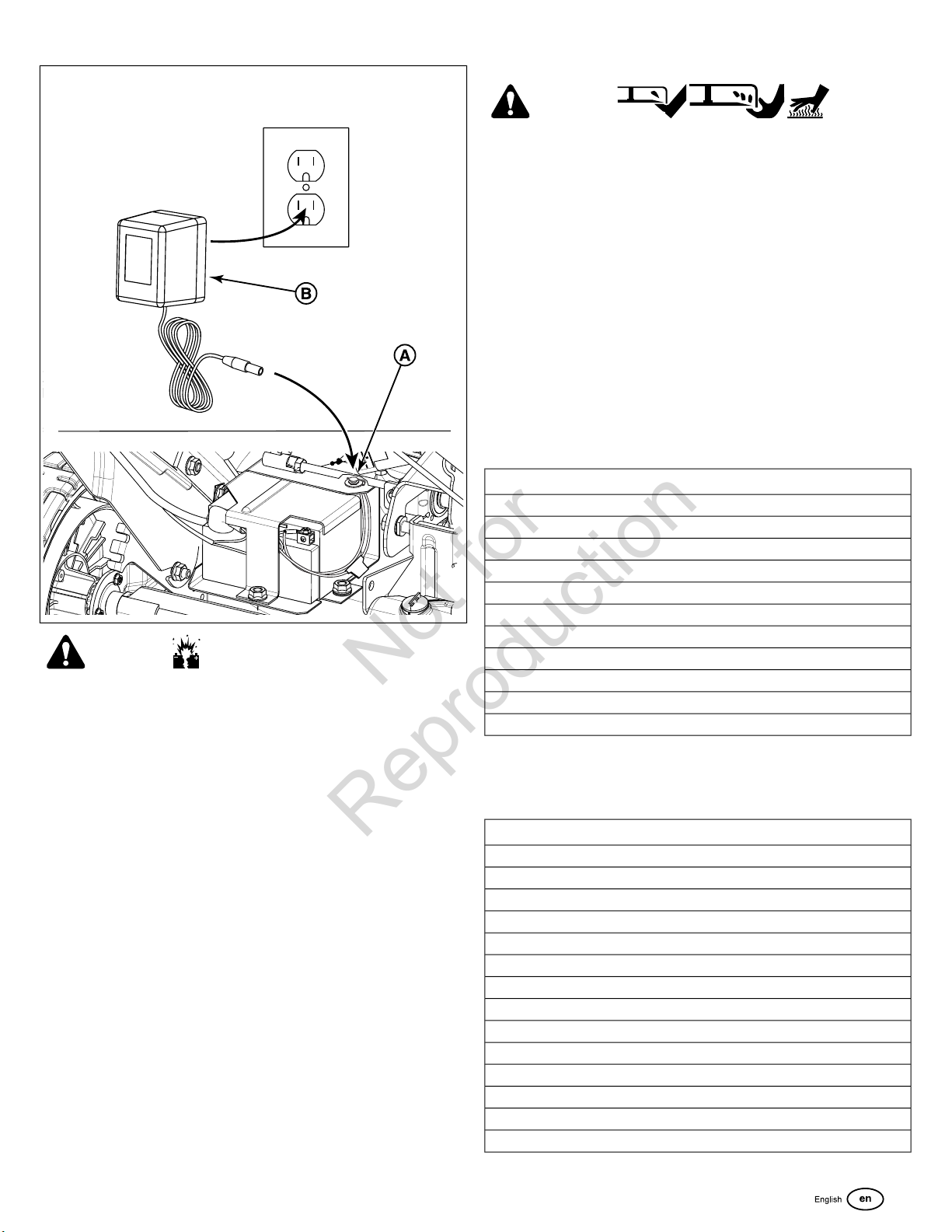

Charging the Battery

(Optional Accessory on Some Models)

The battery provided with your mower is sealed and

maintenance-free. It requires no special care other than keeping

it properly charged. Use only the charger provided with your

mower when charging the battery.

Charge the battery after each use, and if the battery has been

stored for longer than 30 days. The time required to charge the

battery varies, but typically 16 to 24 hours will be sufficient to

bring the battery to a fully charged condition.

1. Remove the dust cap from the charger jack (A, Figure 15).

2. Plug the battery charger (B) into the charger jack.

3. Plug the charger into a 120-volt wall outlet.

4. Charge the battery for a period of 16 to 24 hours. (Longer

periods will not damage the battery.)

5. Unplug the charger from the wall outlet.

6. Unplug the charger from the charger jack.

7. Replace the dust cap onto the charger jack.

14 www.snapper.com

Page 15

15

Not for

Reproduction

WARNING

Explosion Hazard

Avoid Serious Injury and Property Damage.

• DO NOT attempt to charge this battery with automotive

or ‘Boost’ chargers.

• DO NOT attempt to jump start a mower that has a dead

battery.

• Always use the charger supplied with this mower to charge

this battery.

Maintenance

Emissions Control Service

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by any

off-road engine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work must

be performed by a factory authorized dealer. See the Emissions

Control Statements.

Maintenance Chart

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

Laceration Hazard

• Wear heavy leather gloves when handling or working

around cutting blades.

• Blades are extremely sharp and can cause severe injury.

MOWER

Every 8 Hours or Daily

Check safety interlock system

Clean debris off mower

Every 25 Hours or Annually *

Check mower for loose hardware

See Dealer Annually to

Lubricate mower

Check mower blade **

Check mower blade stopping time

Check drive belt

Clean battery and cables

* Whichever comes first

** Check blade more often in regions with sandy soils or high

dust conditions

ENGINE

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Check engine oil level

Every 25 Hours or Annually *

Clean engine air filter and pre-cleaner (if equipped) **

Every 50 Hours or Annually *

Change engine oil

Replace oil filter (if equipped)

Annually

Replace air filter

Replace pre-cleaner (if equipped)

See Dealer Annually to

Inspect muffler and spark arrester (if equipped)

15

Page 16

ENGINE

Not for

Reproduction

Replace spark plug

Replace fuel filter (if equipped)

Clean engine air cooling system

* Whichever comes first

** Clean more often in dusty conditions or when airborne debris

is present

Change Engine Oil

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

Laceration Hazard

NOTICE

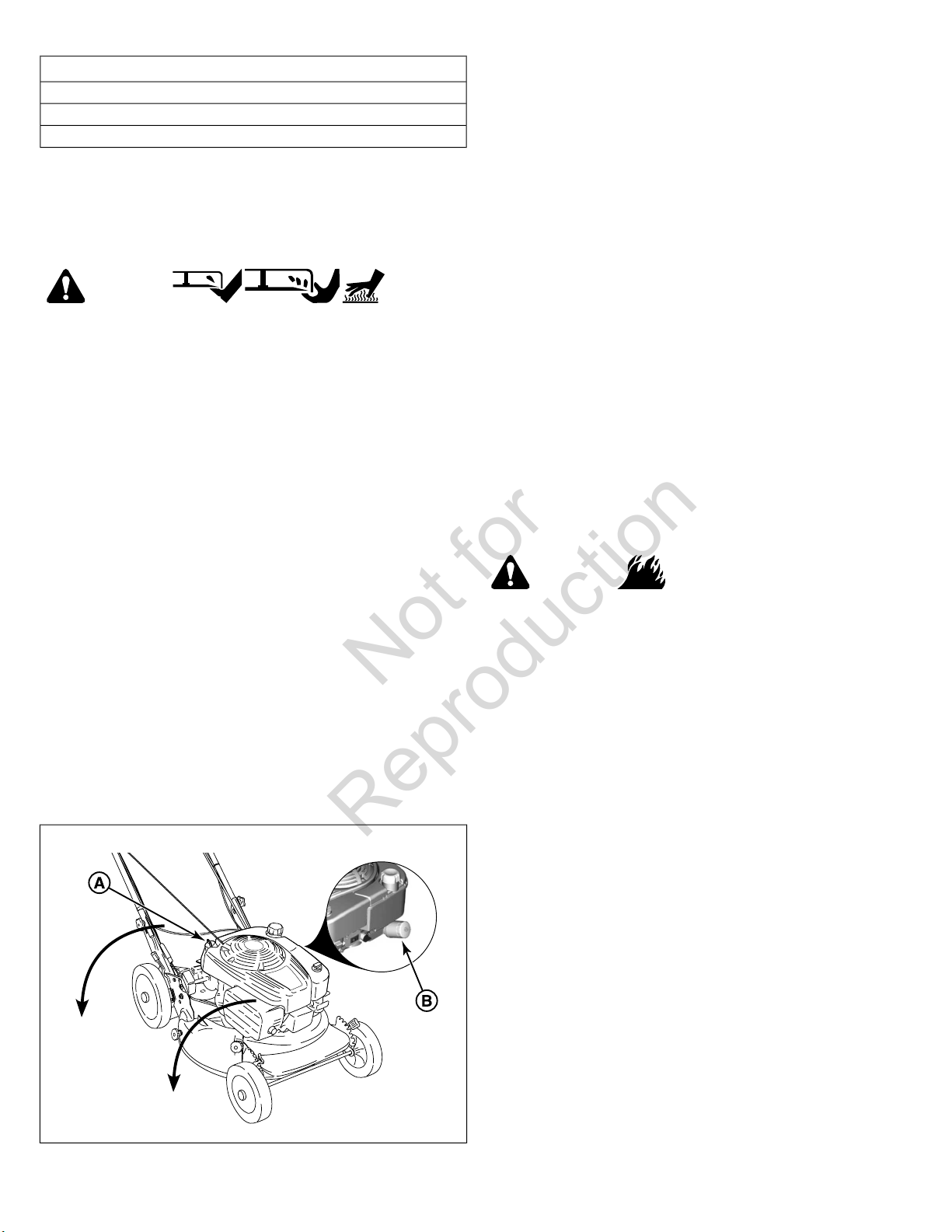

Drain the fuel tank before tipping the machine. DO NOT tip

the machine with the carburetor or spark plug down. Oil from

the crankcase will saturate the air filter and cause the engine

to be hard to start or not start at all. If contamination does

occur, the air filter will have to be replaced.

Change Oil Filter

(If Equipped)

1. Drain the oil from the engine. See

2. Remove the oil filter (B, Figure 16) and dispose of properly.

3. Before you install the new oil filter, lightly lubricate the oil

filter gasket with fresh, clean oil.

4. Install the oil filter by hand until the gasket contacts the oil

filter adapter, then tighten the oil filter 1/2 to 3/4 turns.

5. Add oil. See

6. Start and run the engine. As the engine warms up, check

for oil leaks.

7. Stop the engine and check the oil level. It should be at the

top of the full indicator on the dipstick.

Change Engine Oil

Change Engine Oil

.

.

Service Air Filter

• Wear heavy leather gloves when handling or working

around cutting blades.

• Blades are extremely sharp and can cause severe injury.

1. Drain the fuel tank completely.

2. Remove the dipstick (A, Figure 16), then turn the mower

on its side. Allow the oil to drain from the oil fill tube into an

appropriate container. Dispose of used oil properly.

3. Place the mower upright, then fill the engine with engine oil

to the ‘full’ mark on the dipstick. Refer to the section entitled

‘Oil Recommendations’. Do not overfill.

16

WARNING

Fire Hazard

Never start or run the engine with the air cleaner assembly (if

equipped) or the air filter (if equipped) removed.

NOTICE

Do not use pressurized air or solvents to clean the filter.

Pressurized air can damage the filter and solvents will dissolve

the filter.

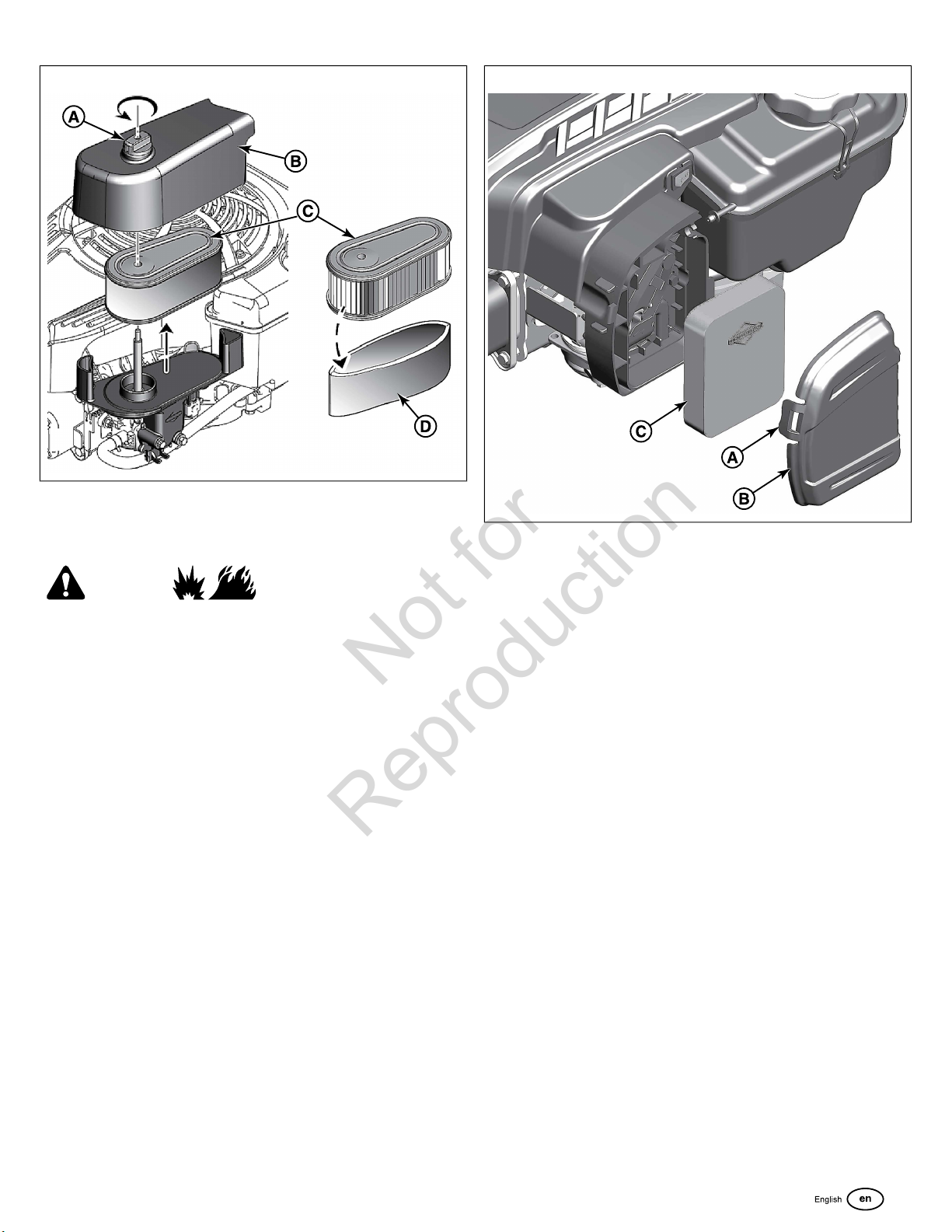

1. Remove the fastener (A, Figure 17) and the air filter cover

(B).

2. Remove the pre-cleaner (C) and the filter (D).

3. To loosen debris, gently tap the filter on a hard surface. If

the filter is excessively dirty, replace with a new filter.

4. Wash the pre-cleaner in liquid detergent and water. Then

allow it to thoroughly air dry. Do not oil the pre-cleaner.

5. Assemble the dry pre-cleaner to the filter.

6. Install the filter and pre-cleaner into the base (E). Make sure

filter fits securely in the base.

7. Install air filter cover and secure with fastener. Make sure

the fastener is tight.

16 www.snapper.com

Page 17

17

Not for

Reproduction

Service Air Filter

See Figure: 18, 19

WARNING

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or death.

• Never start and run the engine with the air cleaner assembly

(if equipped) or the air filter (if equipped) removed.

NOTICE

filter. Pressurized air can damage the filter and solvents will

dissolve the filter.

See the

Do not use pressurized air or solvents to clean the

Maintenance Schedule

for service requirements.

18

2. Remove the cover (B, Figure 18).

3. To prevent debris from falling into the carburetor, carefully

remove the foam element (C, Figure 18) from the air filter

base.

4. Wash the foam element (C, Figure 18) in liquid detergent

and water. Squeeze dry the foam element in a clean cloth.

5. Saturate the foam element (C, Figure 18) with clean engine

oil. To remove the excess engine oil, squeeze the foam

element in a clean cloth.

6. Install the foam element (C, Figure 18) onto the air filter

base.

7. Install the cover (B, Figure 18) and secure with fastener(s)

(A).

Various models use either a foam or a paper filter. Some models

may also have an optional pre-cleaner that can be washed and

reused. Compare the illustrations in this manual with the type

installed on your engine and service as follows.

Foam Air Filter

1. Open the fastener(s) (A, Figure 18).

Paper Air Filter

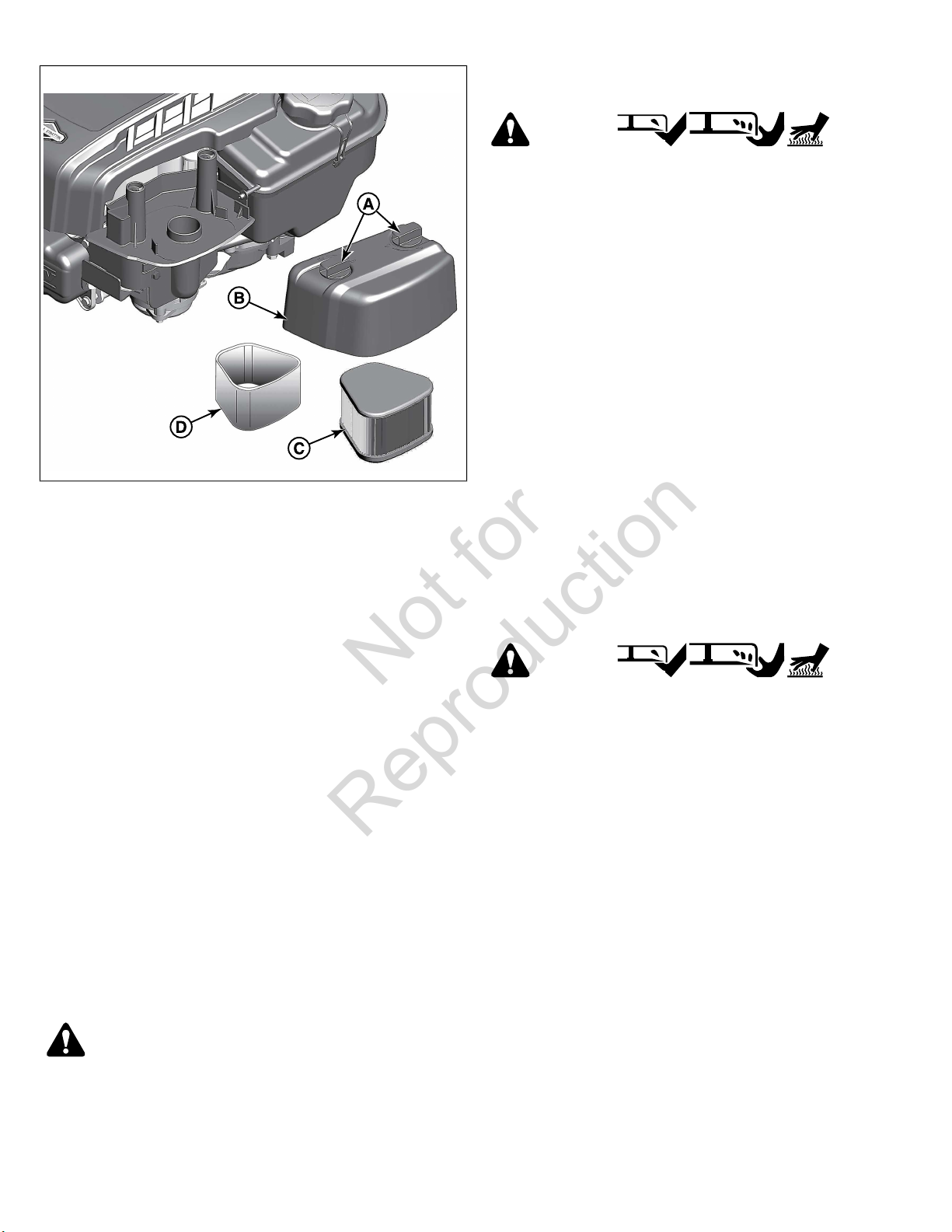

1. Loosen the fastener(s) (A, Figure 19).

17

Page 18

19

Not for

Reproduction

Clean Debris Off Mower

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

Laceration Hazard

• Wear heavy leather gloves when handling or working

around cutting blades.

• Blades are extremely sharp and can cause severe injury.

2. Remove the cover (B, Figure 19).

3. To prevent debris from falling into the carburetor, carefully

remove the pre-cleaner (D, Figure 19) and the filter (C) from

the air filter base.

4. Remove the pre-cleaner (D, Figure 19), if equipped, from

the filter (C).

5. To loosen debris, gently tap the filter (C, Figure 19) on a

hard surface. If the filter is excessively dirty, replace with a

new filter.

6. Wash the pre-cleaner (D, Figure 19), if equipped, in liquid

detergent and water. Allow the pre-cleaner to throughly air

dry. Do not oil the pre-cleaner.

7. Assemble the dry pre-cleaner (D, Figure 19), if equipped,

to the filter (C).

8. Install the filter (C, Figure 19) and the pre-cleaner (D), if

equipped, onto the air filter base. Make sure the filter fits

securely on the air filter base.

9. Install the cover (B, Figure 19) and secure with the

fastener(s) (A). Make sure the fastener(s) is tight.

Check Safety Interlock System

1. Start the mower.

2. Release the blade control. The engine must stop within 3

seconds.

1. Clean dirt and debris from the top of the mower deck.

2. Clean any debris buildup on or around the engine, etc.

While cleaning, check components for wear or damage. Replace

worn or damaged components immediately.

Storage Procedure

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

Laceration Hazard

• Wear heavy leather gloves when handling or working

around cutting blades.

• Blades are extremely sharp and can cause severe injury.

Prepare the mower for end-of-season storage as follows:

WARNING

Unsafe Operation Hazard

If the engine does not stop within 3 seconds, do not use the

mower. Bring the mower to an authorized dealer for service.

18 www.snapper.com

1. Disconnect the spark plug wire and secure away from the

spark plug.

2. Drain the fuel tank and let the engine run until all fuel is out

of the carburetor.

Page 19

Note:

Not for

Reproduction

If using a fuel stabilizer, there is no need to drain the fuel

tank. See

3. Use a brush or compressed air to remove loose debris, then

4. Tilt the mower up on its rear wheels and inspect the

5. Lubricate all exposed metal with a light coating of oil to

6. Carefully fold the handles, flexing the control cables to

7. Store the mower in a shed or other dry area, protected from

Fuel System

use a damp cloth to wipe down the unit.

underside of the deck. (Do not tilt the mower with the spark

plug or carburetor down.) Scrape away stubborn

accumulation of grass with a putty knife and/or wire brush.

prevent corrosion.

prevent cable damage.

weather.

.

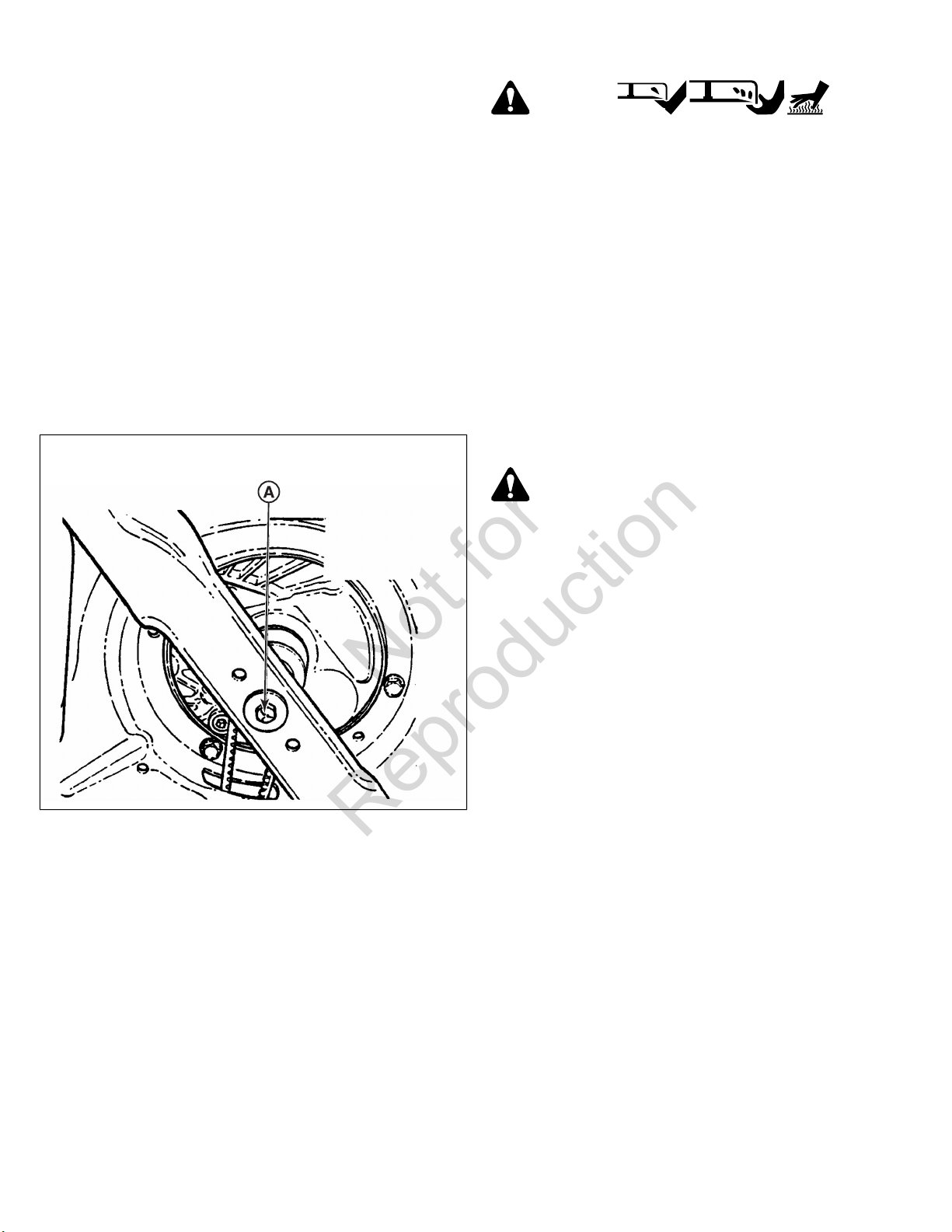

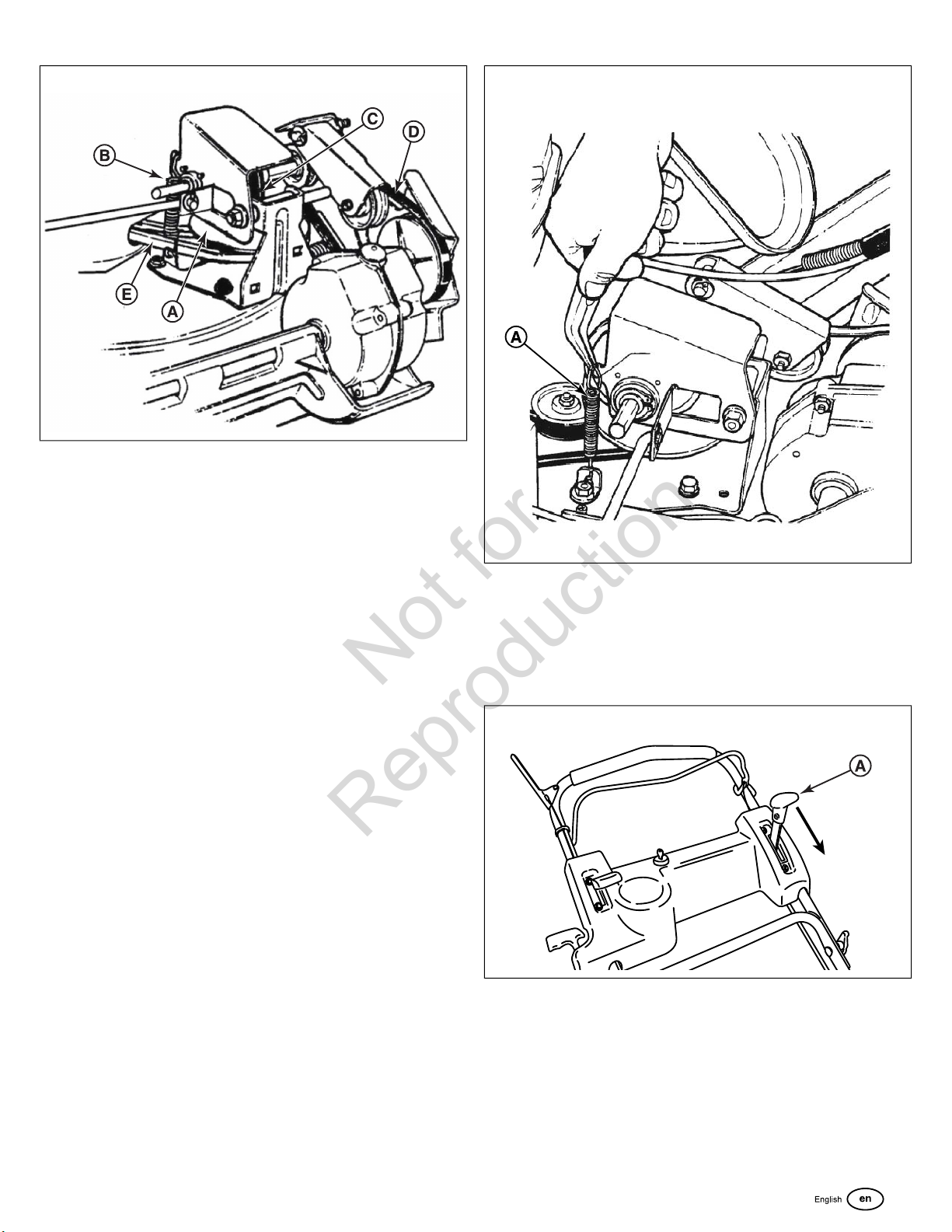

Check Grease Level in Transmission

1. Remove the transmission fill plug (A, Figure 20). Roll the

machine forward or backward while looking down into the

plug hole.

2. If liquid grease is not visible on the input gear (the small

gear below the plug hole), add an amount, to cover the

gear, of Snapper “00” grease.

Note:

Snapper “00” grease (Part No. 7029443) is available at

your dealer.

Note:

Do not spill grease or oil onto the surface of the drive disc

(A, Figure 21).

3. Reinstall the transmission plug.

4. Check the grease level after each 25 hours of operation.

Fuel System

Fuel can become stale when stored over 30 days. Stale fuel

causes acid and gum deposits to form in the fuel system or on

essential carburetor parts. To keep fuel fresh, use Briggs &

Stratton Advanced Formula Fuel Treatment & Stabilizer,

available wherever Briggs & Stratton genuine service parts are

sold.

There is no need to drain gasoline from the engine if a fuel

stabilizer is added according to instructions. Run the engine for

two (2) minutes to circulate the stabilizer throughout the fuel

system before storage.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container. Run

the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to maintain

freshness.

Service

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

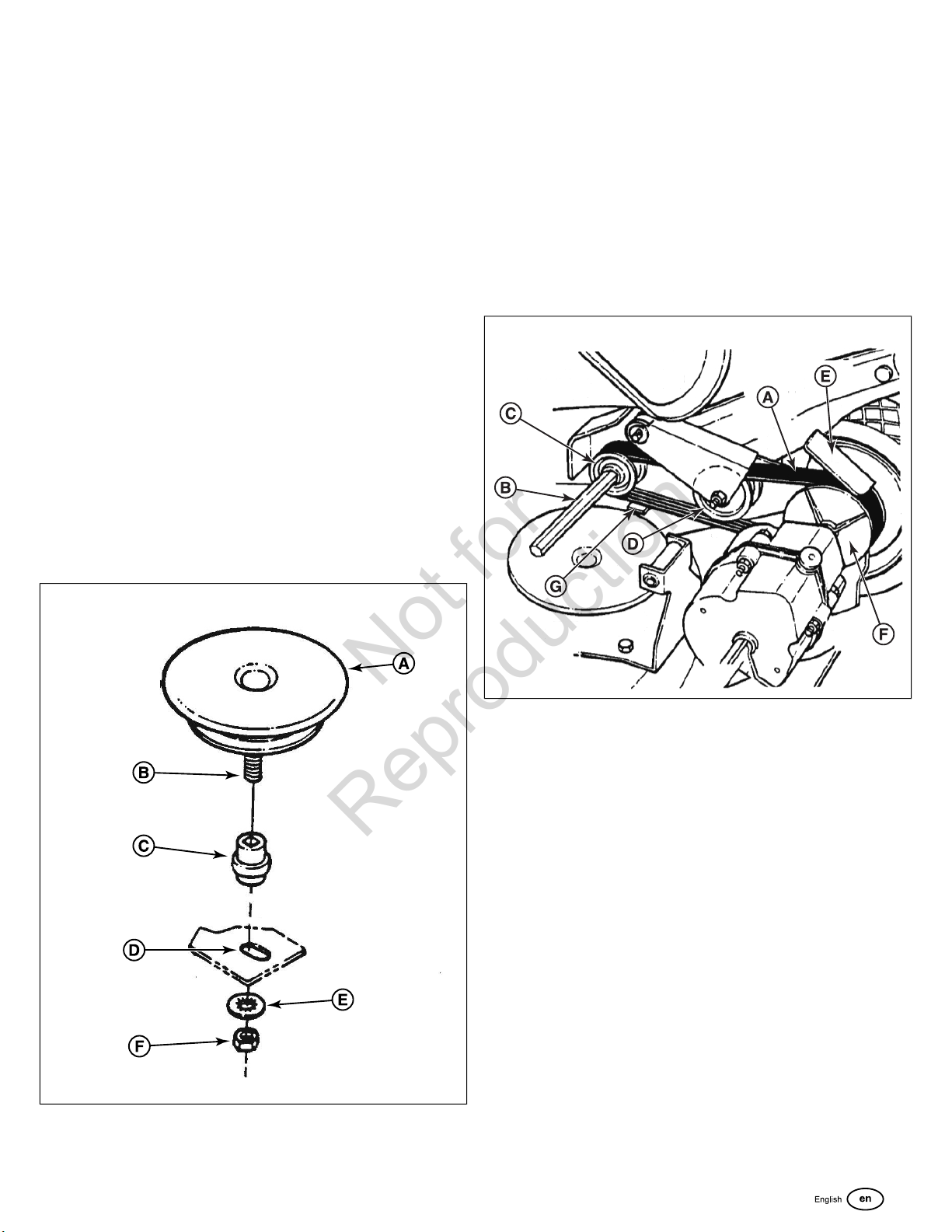

20

21

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

Laceration Hazard

• Wear heavy leather gloves when handling or working

around cutting blades.

• Blades are extremely sharp and can cause severe injury.

19

Page 20

Check Mower Blade

Not for

Reproduction

Mower Blade Replacement

1. Disconnect the spark plug wire and secure the end away

from the plug.

2. Tilt the mower up on its rear wheels for access to the blade

cap screw (A, Figure 22). Do not tilt the mower with the

spark plug or carburetor down.

NOTICE

Drain the fuel tank before tipping the mower. DO NOT tip the

machine with the carburetor or spark plug down. Oil from the

crankcase will saturate the air filter and cause the engine to

be hard to start or not start at all. If contamination does occur,

the air filter will have to be replaced.

3. Check the torque of the blade cap screw. Recommended

torque: 40 lb-ft (54 Nm).

4. Check the blade for sharpness, wear and damage. See

Blade Wear Limits

.

22

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

Laceration Hazard

• Wear heavy leather gloves when handling or working

around cutting blades.

• Blades are extremely sharp and can cause severe injury.

WARNING

Unsafe Operation Hazard

Check Engine Drive Belt

• Visually check the engine drive belt for cracking, fraying,

severed or exposed belt strands. If worn or damaged,

replace the belt before operating the mower.

Check Transmission Drive Belt

• Visually check the poly-v belt for cracking, fraying, severed

or exposed belt strands. If worn or damaged, replace the

belt before operating the mower.

DO NOT use a cutting blade that shows signs of excessive wear

or damage.

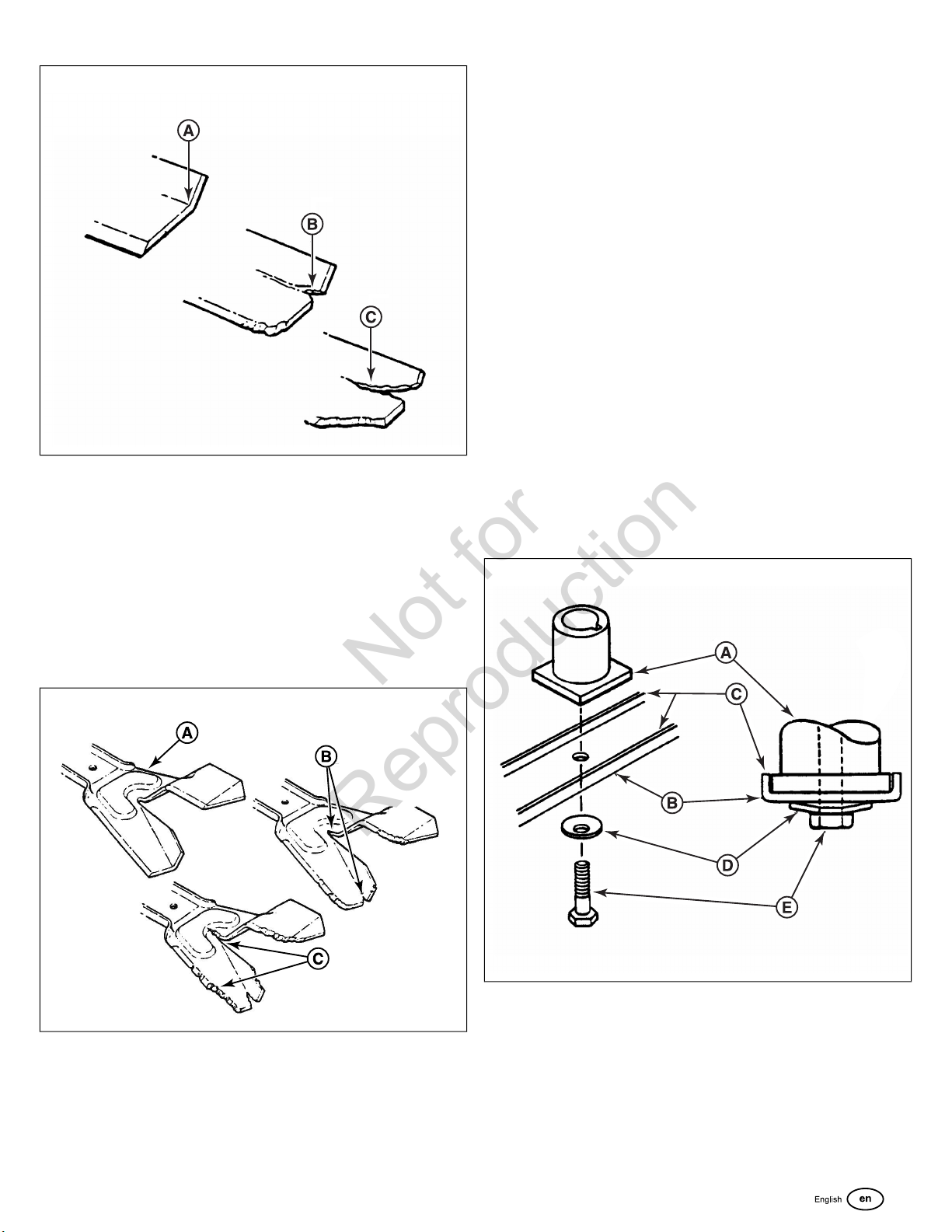

Standard Blade Wear Limit

1. Inspect the blade (Figure 23) frequently for signs of

excessive wear or damage:

• (A) New blade

• (B) Wear limit (notch starts)

• (C) Dangerous condition! Do not use on the mower!

Replace with a new blade.

20 www.snapper.com

Page 21

23

Not for

Reproduction

Ninja Blade Wear Limit

1. Inspect the blade (Figure 24) frequently for signs of

excessive wear or damage:

NOTICE

Drain the fuel tank before tipping the mower. DO NOT tip the

machine with the carburetor or spark plug down. Oil from the

crankcase will saturate the air filter and cause the engine to

be hard to start or not start at all. If contamination does occur,

the air filter will have to be replaced.

3. Remove the blade (B, Figure 25).

4. Sharpen the blade on a grinding wheel at an angle of 22 to

28 degrees (B, Figure 26). DO NOT sharpen the blade

beyond the original cutting edge (A).

5. Check blade for balance. If necessary, correct balance by

grinding heavy end of blade.

6. Reinstall blade (B, Figure 25). Note the correct assembly

order:

• (A) Blade hub

• (B) Blade

• (C) Blade flange (facing up)

• (D) Cone washer (concave side up)

• (E) Capscrew

7. Check torque of blade retaining cap screw. Recommended

torque: 40 lb-ft (54 Nm).

• (A) New blade

• (B) Wear limit (cracks or notches begin to appear on

tip)

• (C) Dangerous condition! Do not use on the mower!

Replace with a new blade.

24

25

Blade Sharpening

1. Disconnect the spark plug wire and secure the end away

from the plug.

2. Tilt the mower up on its rear wheels. Do not tilt the mower

with the spark plug or carburetor down.

21

Page 22

26

Not for

Reproduction

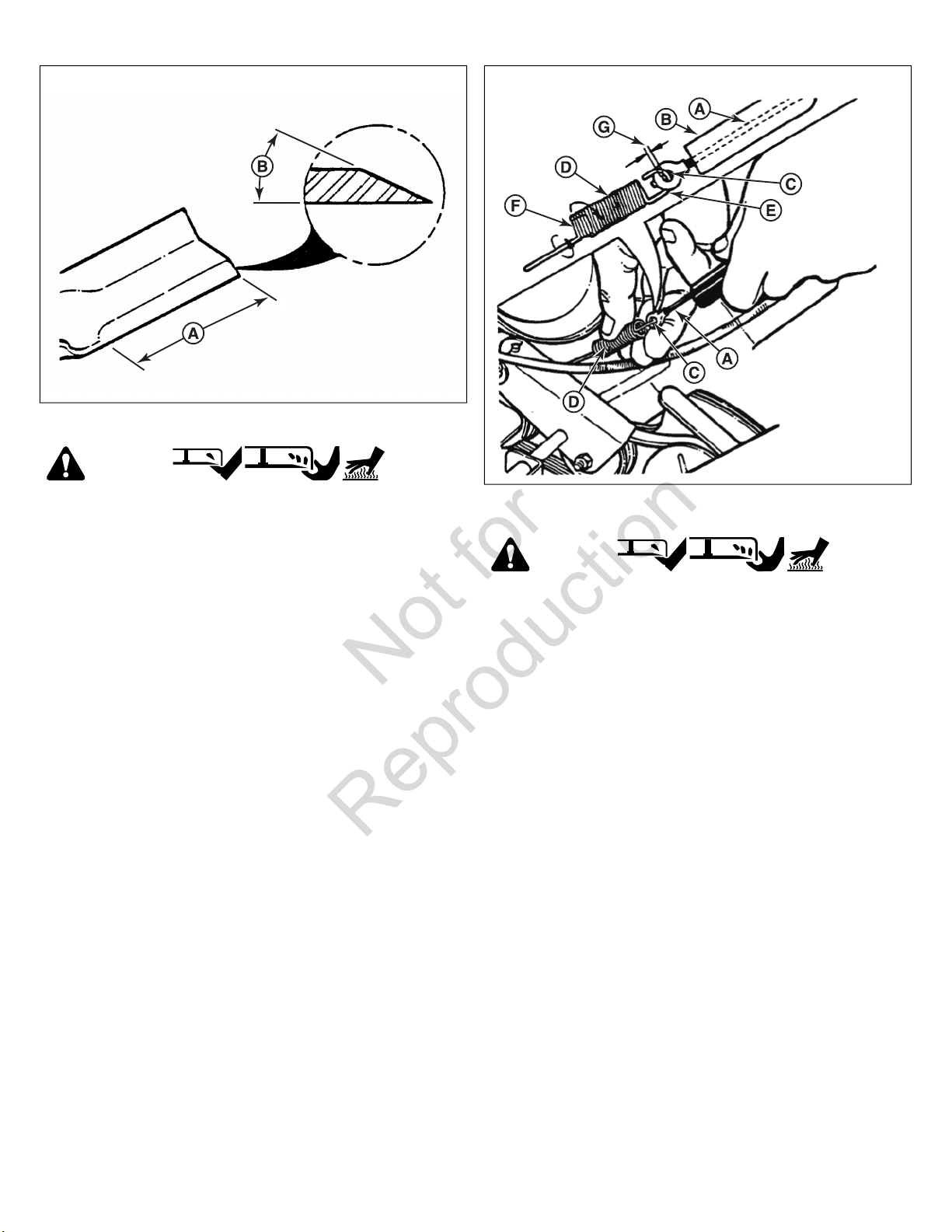

Wheel Drive Control Adjustment

WARNING

Amputation Hazard

27

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

1. The wheel drive control is properly adjusted when there is

1/16” to 1/8” (1.6 - 3.2 mm) clearance (G, Figure 27)

between the inside of the spring hook (E) and the inside of

the clutch cable eye (C) with the wheel drive control

released.

2. To adjust, unhook the upper spring (D) from the cable eye

and rotate the spring in the direction required to extend or

shorten the spring length.

3. Rehook the upper spring to the cable eye and check

clearance. Repeat the procedure if required.

Note:

The vinyl spring cover (B) should be kept over the spring

at all times except for adjustments.

4. If the wheel drive control fails to return quickly to the OFF

position when released, check for binding at the cable

holdings located on the side of the right handle. The upper

clip should be located 2” (5 cm) below the upper knob; the

lower clip should be 4” (10 cm) above the lower knob. The

cable should slide freely with the clips installed at these

locations.

Driven and Drive Disc Service

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

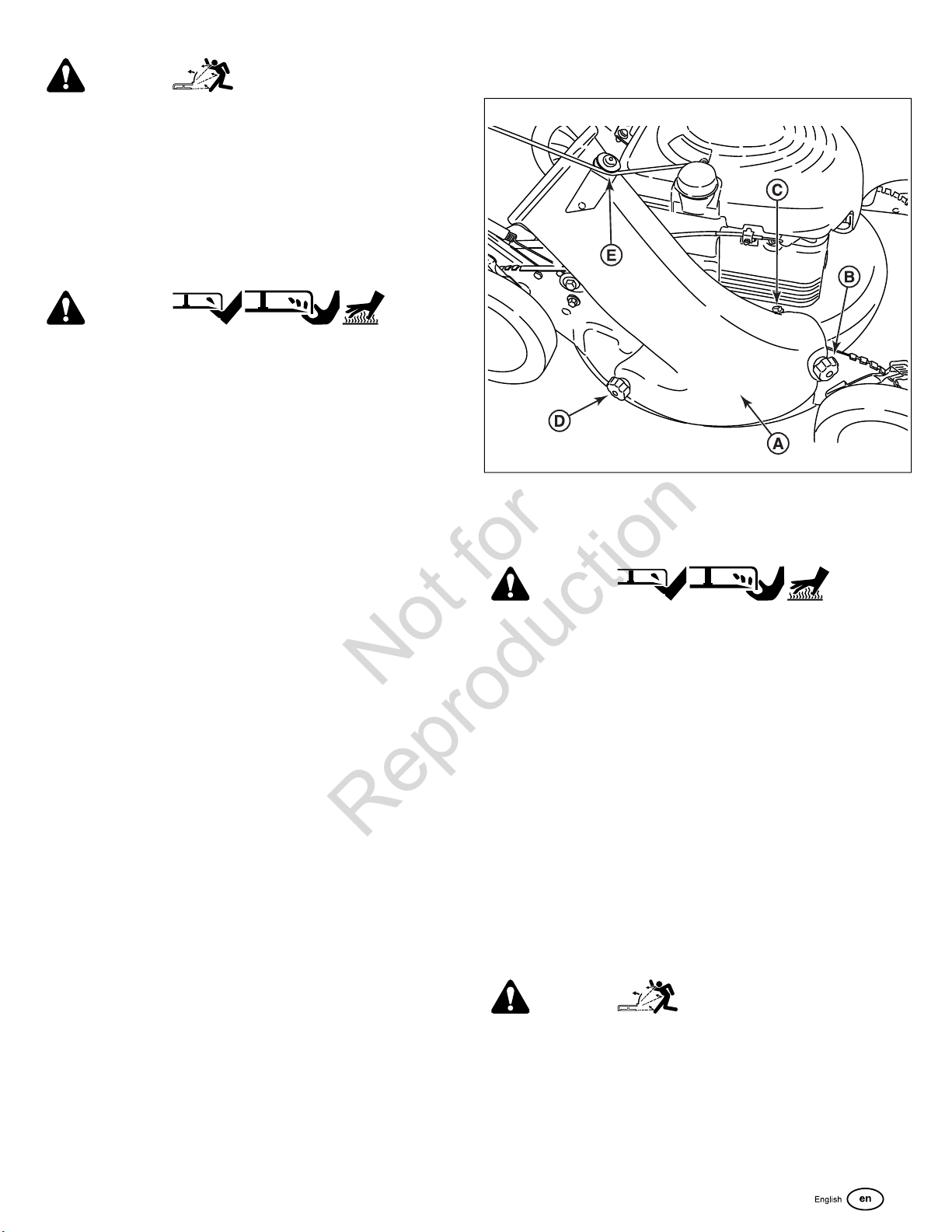

If the mower does not propel itself properly, check for the

following problems:

1. Grease on the drive disc (A, Figure 28) causing slippage.

2. Broken or disconnected drive spring (B).

3. Driven disc (C) is out of adjustment.

4. Driven disc rubber is worn - does not contact drive disc

properly.

5. Worn Poly-V belt (D) or engine drive belt (E).

22 www.snapper.com

Page 23

28

Not for

Reproduction

If any of the above (1 thru 5) are causing problems, service as

follows:

Cleaning Drive Disc and Driven Disc

If oil or grease on the drive disc or driven disc is causing

slippage, clean the discs as follows:

29

1. Wipe away any oil or grease with a clean cloth.

2. Use either an approved grease solvent or hot, soapy water

to clean drive disc or driven disc.

3. Rinse components with clean water.

4. Dry components with a clean cloth.

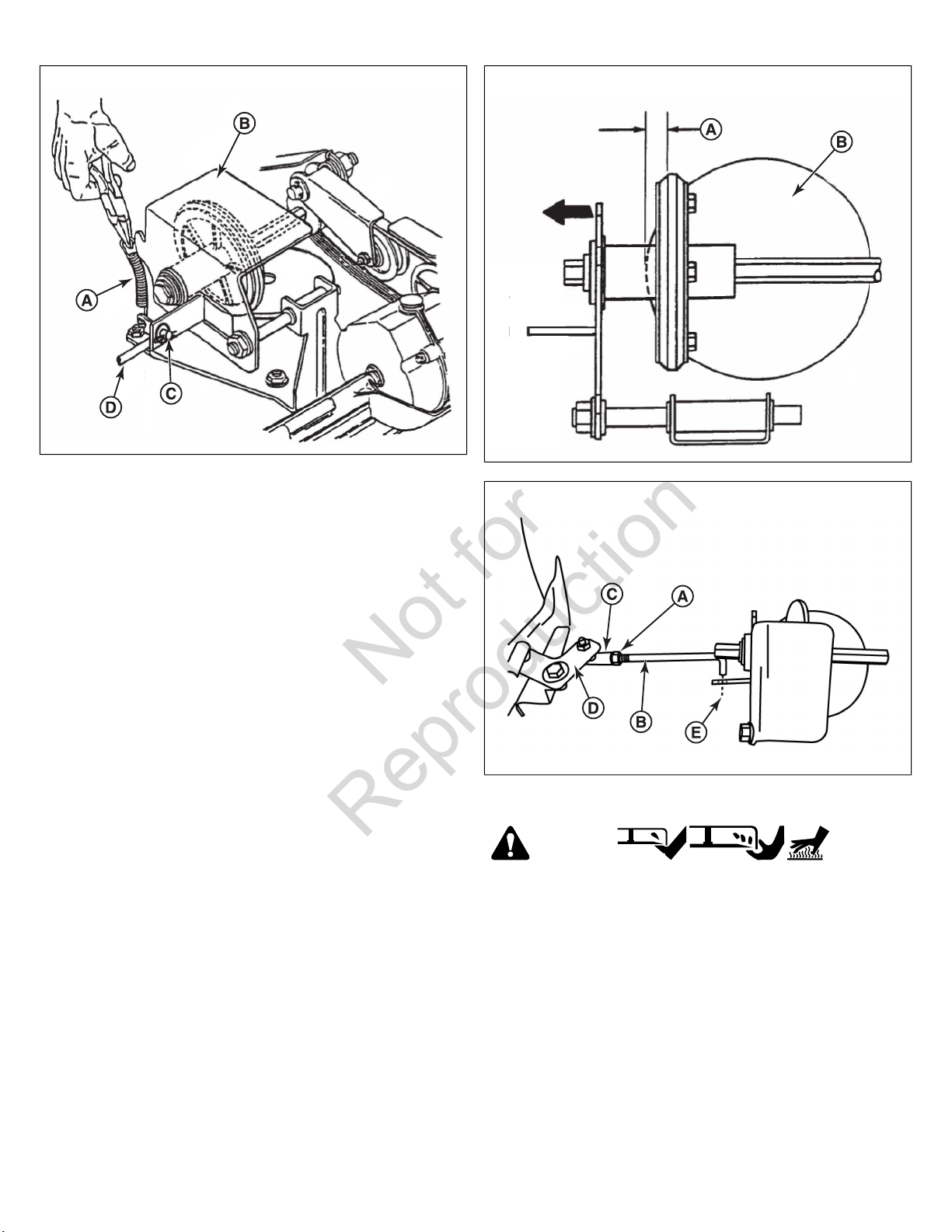

Drive Spring Repair / Replacement

If the drive spring (A, Figure 29) is loose, reconnect. If the spring

is broken, replace with a new spring.

Note:

Use a pair of needle nose pliers to install the drive spring.

If the drive system continues slipping, see

Troubleshooting

Driven Disc Adjustment

If the drive disc and driven disc are clean and the mower drive

is still slipping, adjust the driven disc as follows:

1. Move the ground speed control (A, Figure 30) into the FAST

position.

30

.

2. Remove the driven disc spring (A, Figure 31) from the driven

disc assembly (B). Also remove the pin and washer (C)

from the transfer rod (D), and remove the end of the transfer

rod from the hole in the driven disc assembly.

23

Page 24

31

Not for

Reproduction

3. Slide the driven disc assembly over to 1/8” (3.2 mm) (A,

Figure 32) from the outside edge of the drive disc (B).

4. Loosen the jam nut (A, Figure 33) securing the transfer rod

(B) to the ball joint (C) on the pivot bracket (D).

5. Turn the rod in or out of the ball joint until the end of the rod

aligns with the hole (E) in the driven disc assembly from

which the rod was removed.

32

33

Note:

Do not move the pivot bracket.

6. Reinstall the rod as removed in Step 2. Move the ground

speed control to the SLOW position, then back to the FAST

position. Recheck the 1/8” (3.2 mm) measurement described

previously. Readjust as needed. Tighten the nut when

finished.

7. Reinstall the driven disc spring to the driven disc assembly.

Driven Disc Replacement

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

If the rubber on the driven disc is badly chunked or worn, it must

be replaced. Install a new driven disc as follows:

24 www.snapper.com

Page 25

1. Remove the pin and washer (C, Figure 31) from the transfer

Not for

Reproduction

rod (D), and remove the end of the transfer rod from the

hole in the driven disc assembly.

2. Using needle nose pliers, unhook the drive spring (A, Figure

34) and slide the driven disc assembly off the hex shaft.

3. Remove the two snap rings (A, Figure 35) which secure the

rubber driven disc (B) to the driven disc assembly.

4. Install a new rubber driven disc onto the driven disc

assembly, and secure with the retaining rings.

5. Reverse the above procedures for reassembly and

installation of the driven disc assembly.

34

punch. A new bearing with four retaining screws will have to be

purchased to replace existing bearing.

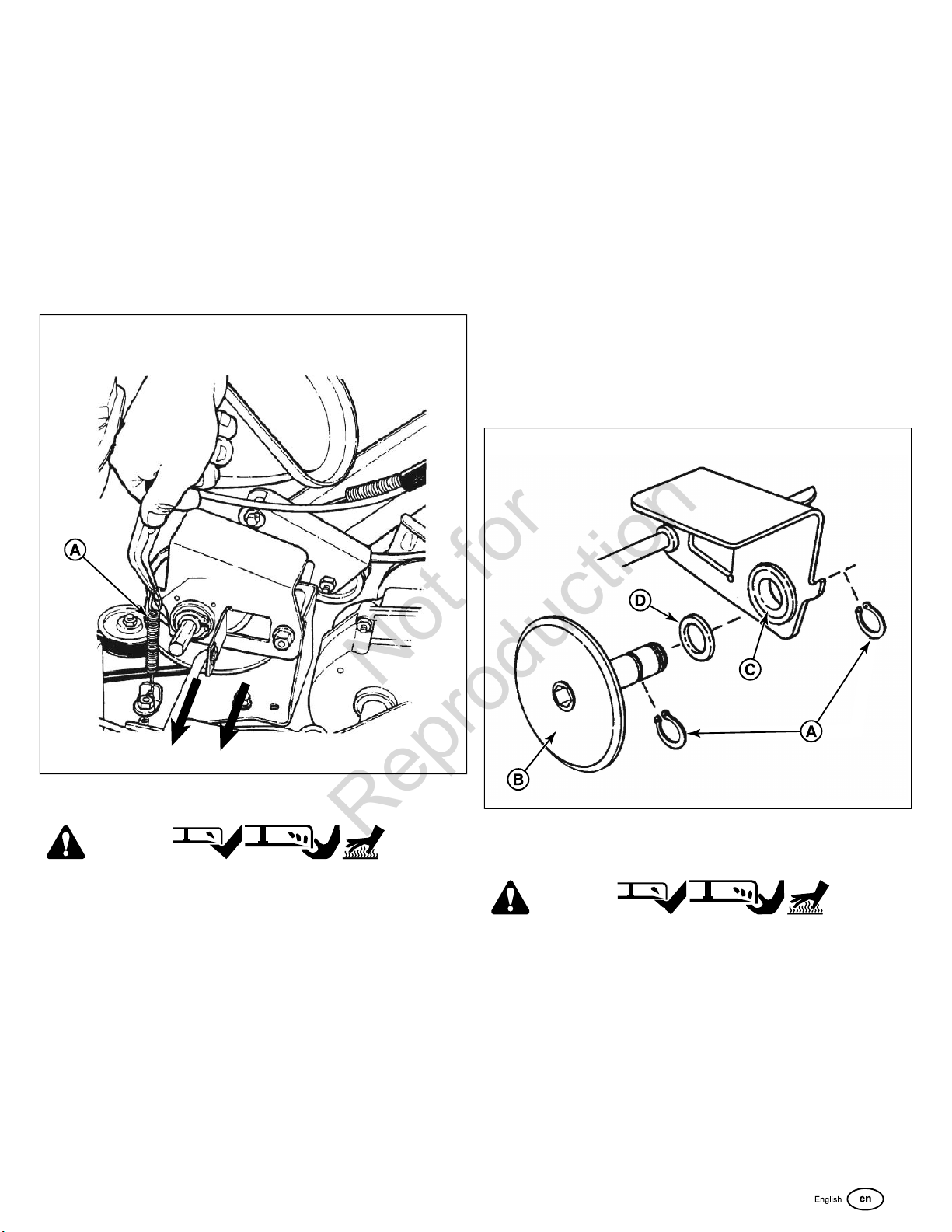

If the driven disc bearing requires replacement, replace the

bearing as follows:

1. Remove the driven disc assembly. See

Replacement

2. Remove both snap rings (A, Figure 35) that secure the

rubber driven disc (B) to the thrust plate.

3. Slide the rubber driven disc hub out of the bearing.

4. Drive out the existing bearing (C).

5. Install a new bearing and secure to the thrust plate with four

retaining screws. Tighten the screws securely.

6. Reassemble the components in reverse order.

Note:

Be sure to replace the shim washer (D) when

reassembling the driven disc assembly.

.

Driven Disc

35

Driven Disc Bearing Replacement

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

The bearing on these machines is staked into the thrust plate.

The bearing will have to be driven out with a mallet and a large

Replacing the Bearing on the Pulley End of the Hex

Shaft

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

25

Page 26

The bearing on these machines is staked into the thrust plate.

Not for

Reproduction

The bearing will have to be driven out with a mallet and a large

punch. A new bearing with four retaining screws will have to be

purchased to replace existing bearing.

To replace the bearing on the pulley end of the hex shaft:

1. Hold the hex shaft with an adjustable wrench held next to

the pulley.

2. Remove the 3/8” hex lock nut (B, Figure 36), located on the

outside of the right wheel bracket.

3. Remove the holder (A), O-ring (C) and bearing (D).

4. Install the new bearing.

5. Carefully install the new O-ring over the outside of the new

bearing.

6. Install the bearing holder, and secure with screws.

7. Install the 3/8” hex lock nut.

36

Belt Service

WARNING

Amputation Hazard

• DO NOT attempt any maintenance, adjustments or service

with engine and blade running.

• STOP engine and blade.

• Disconnect spark plug wire and secure away from spark

plug.

Burn Hazard

• Engine and components are HOT.

• Avoid serious burns, allow sufficient time for all

components to cool.

On self-propelled mowers, the engine belt (A, Figure 37)

transmits power from the engine pulley (B) to the drive disc (C).

The drive disc powers the poly-v belt, which engages the

transmission that powers the rear wheels. Should these belts

become worn, they could cause slippage, which would impair

mower performance. The condition of the engine belt and poly-v

belt should be checked after every 25 hours of mower operation.

Engine Drive Belt Replacement (Stretch Type Belts)

1. Empty the fuel tank.

2. Note the belt routing (Figure 37). There is no idler pulley on

these models to disconnect.

NOTICE

Drain the fuel tank before tipping the mower. DO NOT tip the

machine with the carburetor or spark plug down. Oil from the

crankcase will saturate the air filter and cause the engine to

be hard to start or not start at all. If contamination does occur,

the air filter will have to be replaced.

37

26 www.snapper.com

Page 27

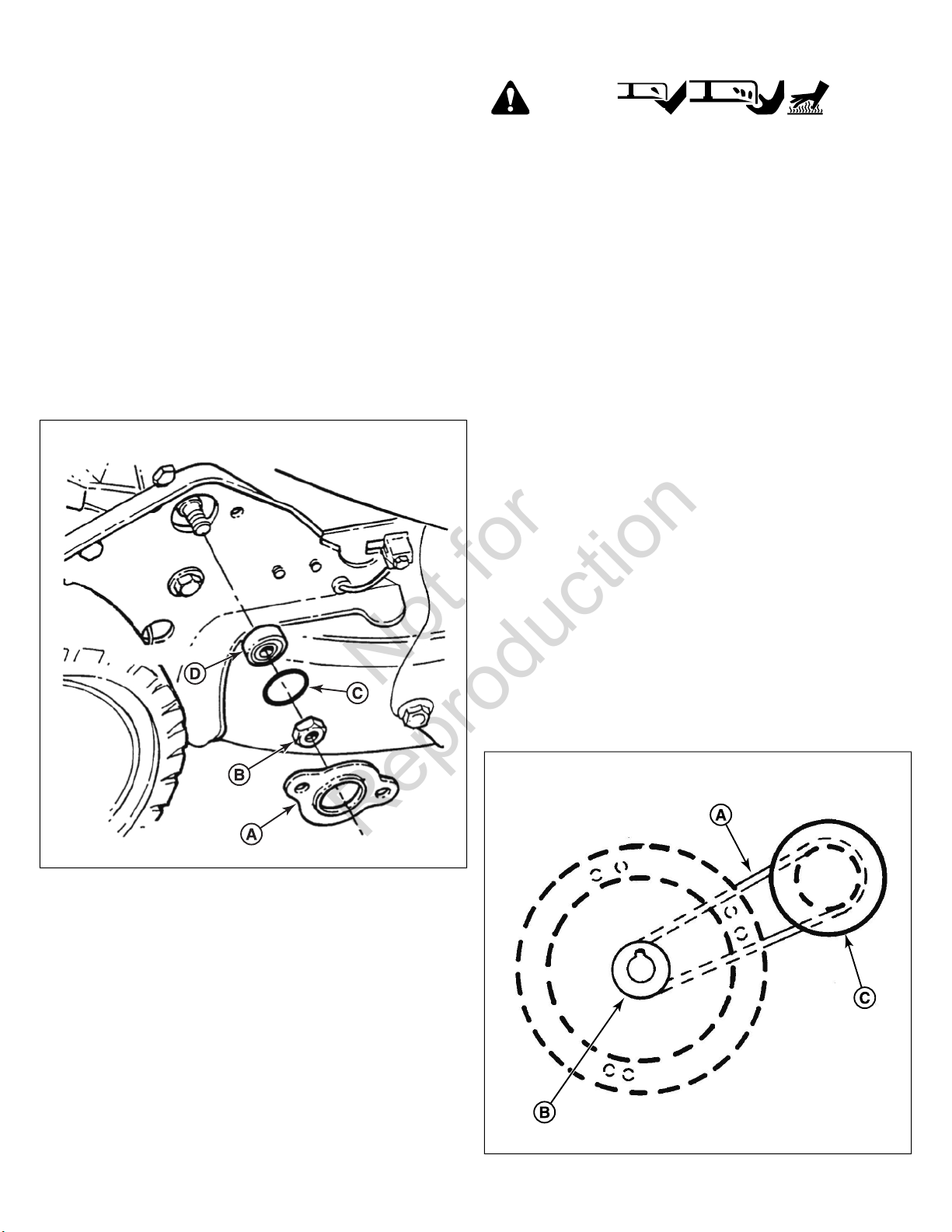

3. Remove the driven disc. See

Not for

Reproduction

for driven disc removal procedure.

4. Drain the fuel tank before tipping the mower. Do not tilt the

mower with the spark plug or carburetor down. Tilt the

mower up on its rear wheels and remove the blade and

blade hub. Assistance from another person may be

necessary to hold the mower in the tilted position.

5. Hold the slotted end of the drive disc bolt (B, Figure 38) with

a screwdriver and remove the nut (F) and internal tooth lock

washer (E).

6. Remove the belt cover, located under the deck.

7. Lift the drive disc (A) up and remove the worn belt.

8. Loop one end of the new belt over the engine pulley and

insert the other end through the slot in the deck.

9. Loop the belt around the pulley on the bottom of the drive

disc.

10. Reinstall the drive disc and retaining hardware.

Note:

1) The square shoulder of the drive disc bolt must fit into

the square hole of the bushing (C). 2) The square end of the

bushing must fit into the bracket slot (D).

11. Reinstall the belt cover and tighten the bolts securely.

12. Reinstall the blade hub and cutter blade. Recommended

torque for the blade cap screw is 40 lb-ft (54 Nm).

Driven Disc Replacement

Transmission Poly-V Belt Replacement

1. Remove the driven disc. See

2. Note the routing of the old belt around the three pulleys

before removing it.

3. Place the new Poly-V Belt (A, Figure 39) over the end of

the hex shaft (B) and onto the drive pulley (C).

4. Work the belt onto the top of the idler pulley (D).

5. Twist the belt sideways and pull it upward between the

differential bracket (E) and driven pulley (F) and then down

into the pulley groove. Make sure the Poly-V Belt is above

the belt guide (G).

Driven Disc Replacement

39

.

38

27

Page 28

Troubleshooting

Not for

Reproduction

Starter

Models)

Engine Stalls or Stops After Running

Loss Of Traction

1. Blade control is released or is not being held securely

against handle.

Corrective ActionProbable CauseProblem

1. Fill fuel tank with fresh fuel.1. Fuel tank empty.Engine Will Not Start Using Recoil

2. Place spark plug wire onto spark plug.2. Spark plug wire disconnected.

1. Fill fuel tank with fresh fuel.1. Fuel tank empty.Engine Will Not Start (Electric Start

2. Place spark plug wire onto spark plug.2. Spark plug wire disconnected.

3. Connect wiring harness.3. Wiring harness disconnected.

4. Charge or replace battery.4. Battery dead.

1. Blade control should be held securely against handle at

all times during operation of mower.

2. Fill with fuel to proper level.2. Fuel tank empty.

3. Clean free of all debris.3. Engine air pre-cleaner and or air cleaner dirty.

4. Service spark plug.4. Spark plug defective or gap set improperly.

5. Drain and clean fuel system.5. Water, debris or stale fuel in fuel system.

1. Clean or replace filters.1. Engine air pre-cleaner or air cleaner dirty.Engine Loses Power

2. Service spark plug.2. Spark plug faulty.

3. Drain and clean fuel system.3. Water, debris or stale fuel in fuel system.

1. Service mower blade.1. Damaged, out of balance or bent mower blade.Excessive Vibration

2. Service and tighten loose parts.2. Loose blade components.

3. Replace air lifts. Tighten to proper torque.3. Loose or missing air lift (if equipped).

4. Replace belt.4. Lumpy or frayed belt.

1. Clean debris.1. Build-up of debris on or around wheel drive components.Mower Will Not Move

2. Clean or replace driven disc.2. Driven disc slipping.

3. Replace drive belt.3. Drive belt requires replacement.

4. Contact authorized dealer.4. Damaged transmission.

1. Adjust cutting height.1. Cutting height too low or high.Cutting Grass Improperly

2. Move engine speed control to ‘Fast’ position.2. Engine speed too slow.

3. Move ground speed control to a slower speed.3. Forward ground speed too fast.

4. Adjust height of cut with height adjust levers.4. Terraced cut, side to side.

5. Adjust height of cut with height adjust levers.5. Excessive deck pitch, front to rear.

6. Sharpen cutting edges or replace blade.6. Cutting blade dull or damaged.

1. Move engine speed control to ‘Fast’ position.1. Engine speed too fast.Poor Grass Discharge

2. Move ground speed control to a slower speed.2. Forward speed too fast.

3. Mow when grass is dry.3. Grass is wet.

4. Service mower blade.4. Excessively worn or damaged blade.

5. Clean deck.5. Build up of grass clippings and debris under deck.

6. Install proper blade.6. Improper blade installed on deck.

7. Install blade properly.7. Blade installed improperly on deck.

1. Contact authorized dealer.1. Leaking engine case.Oil Leaking

2. Check and tighten drain plug.2. Loose drain plug.

3. Make sure dip stick or oil filler cap is securely in place.3. Dip stick or oil filler cap loose.

28 www.snapper.com

Page 29

Warranties

Not for

Reproduction

Warranty Statement

BRIGGS & STRATTON WARRANTY POLICY (January 2014)

LIMITED WARRANTY

Briggs & Stratton warrants that, during the warranty period

specified below, it will repair or replace, free of charge, any part

that is defective in material or workmanship or both.

Transportation charges on product submitted for repair or

replacement under this warranty must be borne by purchaser.

This warranty is effective for and is subject to the time periods

and conditions stated below. For warranty service, find the

nearest Authorized Service Dealer in our dealer locator map at

www.snapper.com

Service Dealer, and then make the product available to the

Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties,

including those of merchantability and fitness for a

particular purpose, are limited to the warranty period listed

below, or to the extent permitted by law. Liability for

incidental or consequential damages are excluded to the

extent exclusion is permitted by law. Some states or countries

do not allow limitations on how long an implied warranty lasts,

and some states or countries do not allow the exclusion or

limitation of incidental or consequential damages, so the above

limitation and exclusion may not apply to you. This warranty

gives you specific legal rights and you may also have other

rights which vary from state to state or country to country.**

. The purchaser must contact the Authorized

WARRANTY PERIOD

Commercial UseConsumer UseItem

3 months36 monthsEquipment

3 months36 monthsEngine*

12 months12 monthsBattery (if equipped)

commercial use, it shall thereafter be considered as a

commercial use product for purposes of this warranty.

To ensure prompt and complete warranty coverage, register

your product at the website shown above or at

www.onlineproductregistration.com, or mail the completed

registration card (if provided), or call 1-800-743-4115 (in USA).

Save your proof of purchase receipt. If you do not provide proof

of the initial purchase date at the time warranty service is

requested, the manufacturing date of the product will be used

to determine the warranty period. Product registration is not

required to obtain warranty service on Briggs & Stratton

products.

ABOUT YOUR WARRANTY

Warranty service is available only through

Service Dealers. This warranty covers only defects in materials

or workmanship. It does not cover damage caused by improper

use or abuse, improper maintenance or repair, normal wear

and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this

product is described in the Operator’s Manual. Using the product

in a way not described in the Operator’s Manual or using the

product after it has been damaged will not be covered under

this warranty. Warranty coverage will also not be provided if the

serial number on the product has been removed or the product

has been altered or modified in any way, or if the product has

evidence of abuse such as impact damage or water/chemical

corrosion damage.

Improper Maintenance or Repair - This product must be

maintained according to the procedures and schedules provided

in the Operator’s Manual, and serviced or repaired using genuine

Briggs & Stratton parts or equivalent. Damage caused by lack

of maintenance or use of non-original parts is not covered by

warranty.

Snapper

Authorized

* Applies to Briggs & Stratton engines only. Warranty coverage

of non-Briggs & Stratton engines is provided by that engine

manufacturer. Emissions-related components are covered by

the Emissions Warranty Statement.

** In Australia - Our goods come with guarantees that cannot

be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for

compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure. For warranty service,

find the nearest Authorized Service Dealer in our dealer locator

map at BRIGGSandSTRATTON.COM, or by calling 1300 274

447, or by emailing or writing to

salesenquires@briggsandstratton.com.au, Briggs & Stratton

Australia Pty Ltd, 1 Moorebank Avenue, NSW, Australia, 2170.

The warranty period begins on the date of purchase by the first

retail or commercial consumer. “Consumer use” means personal

residential household use by a retail consumer. “Commercial

use” means all other uses, including use for commercial, income

producing or rental purposes. Once a product has experienced

Normal Wear and Tear - Like most mechanical devices, your

unit is subject to wear even when properly maintained. This

warranty does not cover repairs when normal use has exhausted

the life of a part or the equipment. Maintenance and wear items

such as filters, belts, cutting blades, and brake pads (except

engine brake pads) are not covered by warranty due to wear

characteristics alone, unless the cause is due to defects in

material or workmanship.

Stale or Unapproved Fuel - In order to function correctly, this

product requires fresh fuel that conforms to the criteria specified

in the Operator’s Manual. Engine or equipment damage caused

by stale fuel or the use of unapproved fuels (such as E15 or

E85 ethanol blends) is not covered by warranty.

Other Exclusions - This warranty excludes damage due to

accident, abuse, modifications, alterations, improper servicing,

freezing or chemical deterioration. Attachments or accessories

that were not originally packaged with the product are also

excluded. There is no warranty coverage on equipment used

for primary power in place of utility power or on equipment used