Page 1

769-09211 / 01 11/13

Operator’s Manual

2-Cycle Backpack Blower

7800959-00

TABLE OF CONTENTS

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

All information, illustrations, and specifications in this manual are based

on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

Please do NOT return the machine to the retailer or dealer

without first contacting the Customer Support Department.

If you have difficulty assembling this product or have any questions

regarding the controls, operation, or maintenance of this machine,

you can seek help from the experts. Choose from the options below:

• Visit us on the web at www.snapper.com

• Call a Customer Support Represenative at (800) 317-7833

• Write to Briggs & Stratton Power Products Group, LLC • 12301

West Wirth St. • Wauwatosa • WI 53222

SAVE THESE INSTRUCTIONS

SERVICE

IMPORTANT: Read this manual thoroughly before using this product. Follow all instructions.

Briggs & Stratton Power Products Group, LLC • 12301 West Wirth St. • Wauwatosa • WI 53222

Page 2

SAFETY

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor. If it requires

replacement, contact your local service dealer to install the

appropriate muffler assembly.

Read the operator’s manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

SYMBOL MEANING

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

CALIFORNIA PROPOSITION 65

WARNING:Engine exhaust, some of its

constituents and certain finished components contain or

emit chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm. Wash

hands after handling.

2

WARNING:

Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in

serious injury to yourself or to others.

CAUTION:Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in

property damage or injury to yourself or to others.

DANGER:

Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in

serious injury or death to yourself or to others.

Page 3

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

• Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

• Children must not operate the unit. Teens must be accompanied

and guided by an adult.

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Be aware of risk of injury to the head, hands and feet.

• Carefully inspect the area before starting the unit. Remove

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments or

repairs before using the unit.

WHILE OPERATING

• Wear safety glasses or goggles that meet current ANSI Z87.1

standards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face mask or dust mask if the

operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• Adjust the handle to provide the best grip.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting and Stopping.

• Use the right tool. Only use this tool for its intended purpose.

• Always keep a firm grip on the handle when operating the unit.

• Do not overreach. Always keep proper footing and balance. Take

extra care when working on steep slopes or inclines.

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop moving parts.

• Do not touch the engine, gear housing or muffler. These parts get

extremely hot from operation, even after the unit is turned off.

• Do not operate the unit faster than the speed needed to do the job.

Do not run the unit at high speed when not in use.

• Do not force the unit. It will do a better, safer job when used at

the intended rate.

• Always stop the unit when operation is delayed or when walking

from one location to another.

• If you strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate the unit

before repairing damage. Do not operate the unit with loose or

damaged parts.

• Turn the engine to off and disconnect the spark plug for

maintenance or repair.

• Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit. These are available from your

authorized service dealer. Use of any other parts or accessories

could lead to serious injury to the user, or damage to the unit,

and void the warranty.

• Keep the unit clean. Carefully remove vegetation and other

debris that could block moving parts.

• To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

• If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

generally an indicator of trouble.

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

• Always mix and add fuel in a clean, well-ventilated outdoor area

where there are no sparks or flames. DO NOT smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

• IMPORTANT SAFETY INSTRUCTIONS •

WARNING:When using the unit, all safety

rules must be followed. Please read these instructions

before operating the unit in order to ensure the safety of

the operator and any bystanders. Please keep these

instructions for later use.

WARNING:Gasoline is highly flammable and

its vapors can explode if ignited. Take the following

precautions:

3

BLOWER SAFETY

• Do not insert anything into the air openings, blower tubes or

nozzle. Do not operate the unit if any of the air openings or

tubes are blocked. Keep the air openings free from dust, lint,

hair and anything else that may reduce airflow.

• Do not operate the unit without the blower tubes attached.

• Do not use the unit to spray liquids, especially flammable or

combustible liquids, such as gasoline. Do not use the unit in

areas where such liquids are present.

• Do not use the unit for spreading chemicals, fertilizer or any

other substance that may contain toxic materials.

Page 4

4

OTHER SAFETY WARNINGS

• All service, other than the maintenance procedures described in

this manual, should be performed by a qualified service dealer.

• Before inspecting, servicing, cleaning, storing, transporting or

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving parts have stopped.

3. Allow the unit to cool.

4. Disconnect the spark plug wire.

• Secure the unit while transporting.

• Never store the unit with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep the unit out of the reach of

children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean and free from debris. Clean the unit

after each use. Refer to Cleaning and Storage.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

SAVE THESE INSTRUCTIONS

• Do not set the unit down on any surface while the unit is

running. Debris can be picked up by the air intake and thrown

out the discharge opening, resulting in damage to the unit or

property or causing serious injury to bystanders or the operator.

• During operation, never point the unit in the direction of people,

animals, windows or automobiles. Always direct blowing debris

away from people, animals, windows or automobiles.

• Use extra caution when blowing debris near solid objects, such

trees, walls, fences, etc. When possible, blow away from such

objects, not toward them.

• Take care when working near valuable plants. The force of the

blown air could damage tender plants.

Page 5

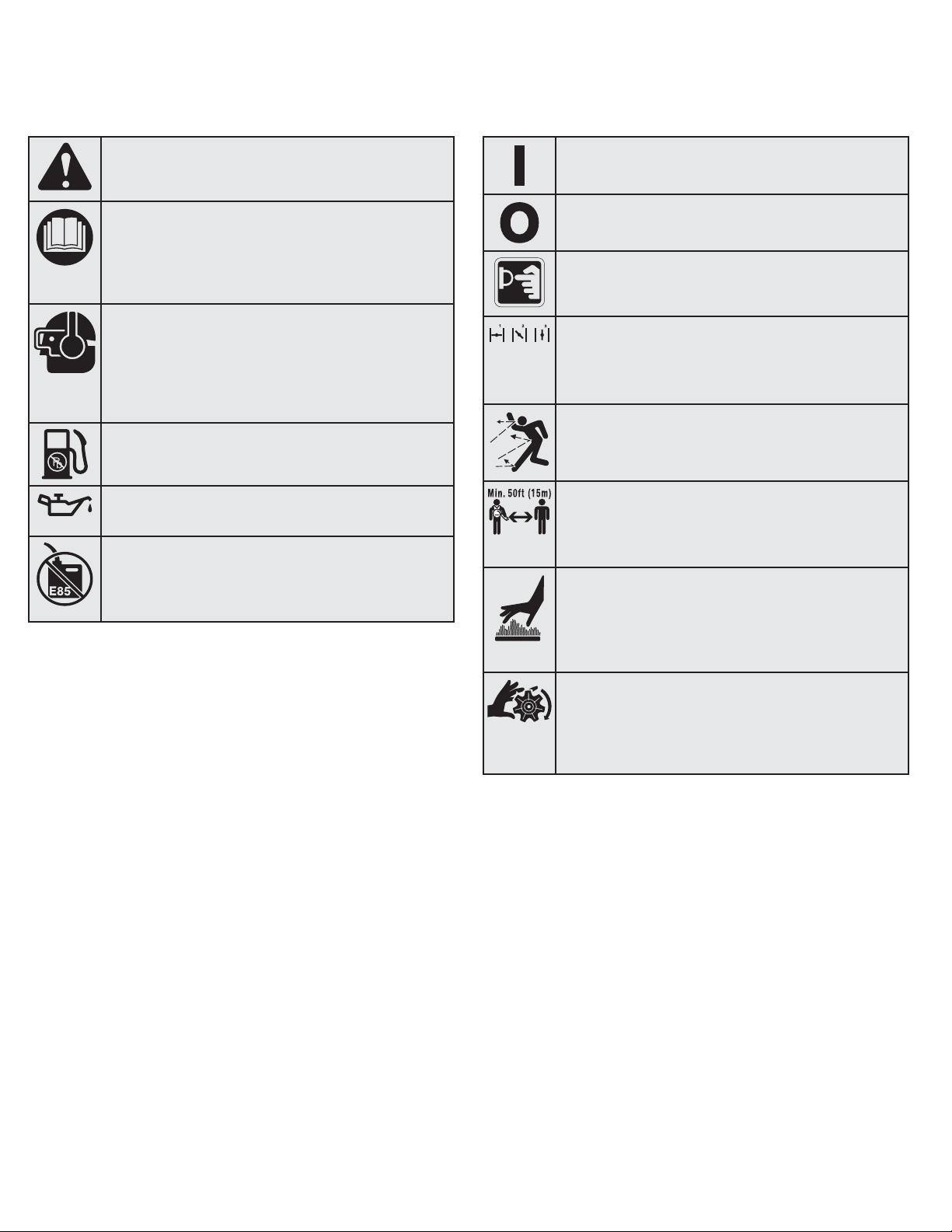

• SAFETY & INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

WARNING:

Read the operator’s

manual(s) and follow all warnings and safety

instructions. Failure to do so can result in serious

injury to the operator and/or bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING:

Thrown objects and loud

noise can cause severe eye injury and hearing loss.

Wear eye protection meeting current ANSI Z87.1

standards and ear protection when operating this unit.

Use a full face shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator’s manual for the proper type of oil.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING:

It has been proven that fuel

containing greater than 10% ethanol will likely

damage this engine and void the warranty.

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

• THROWN OBJECTS CAN CAUSE SEVERE INJURY

WARNING:

Small objects can be

propelled at high speed, causing injury.

• KEEP BYSTANDERS AWAY

WARNING:Keep all bystanders,

especially children and pets, at least 50 feet (15 m)

from the operating area.

• HOT SURFACE

WARNING:

Do not touch a hot muffler

or cylinder. You may get burned. These parts get

extremely hot from operation. When turned off they

remain hot for a short time.

• BLOWERS – ROTATING IMPELLER BLADES CAN

CAUSE SEVERE INJURY

WARNING:

Stop the engine and allow

the impeller to stop before changing tubes, cleaning

or performing any maintenance.

5

Page 6

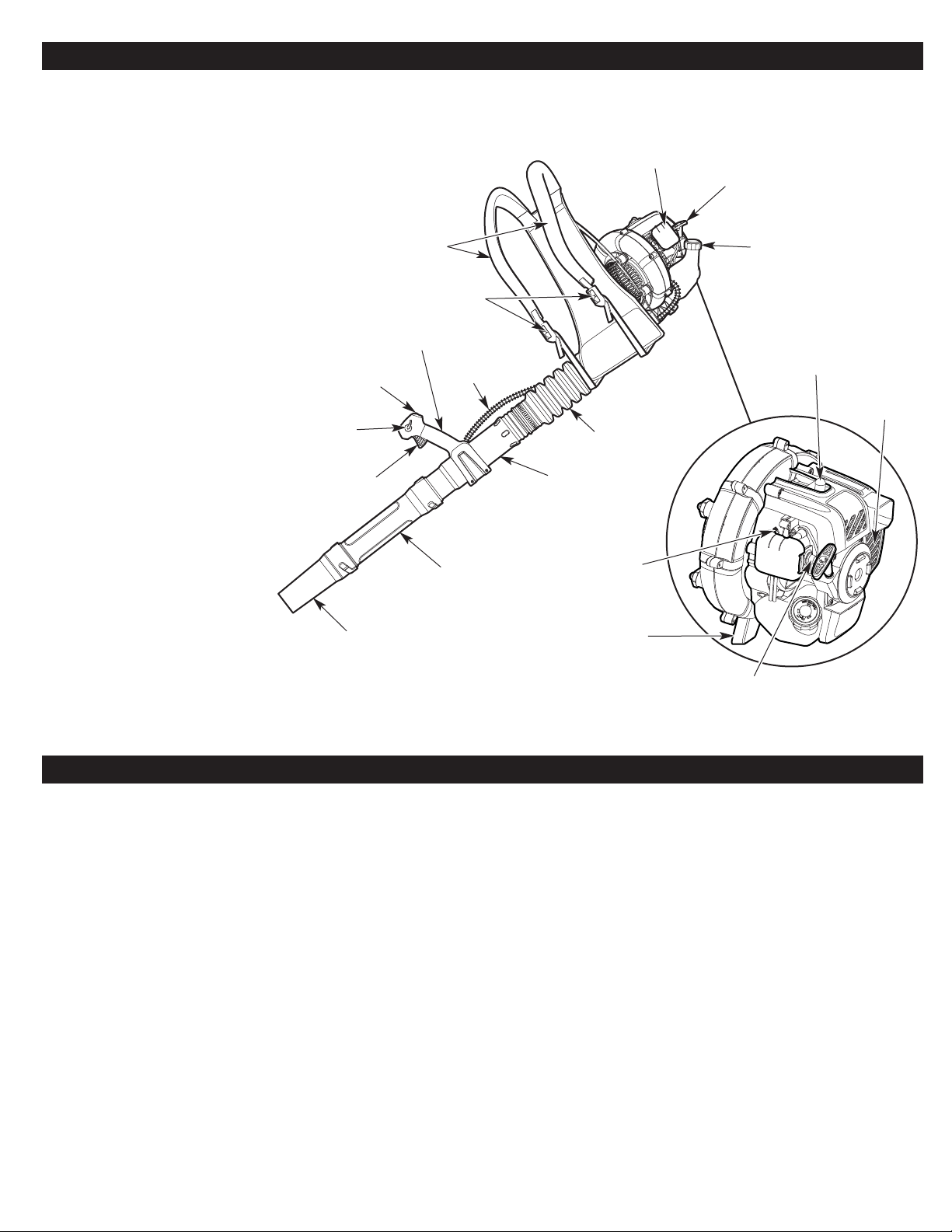

Fuel Cap

Starter

Rope Grip

Throttle Control

Spark Plug

Muffler

On/Off Switch

Primer Bulb

Choke Lever

Air Filter

Cover

Stand

Flex Tube

Upper

Blower Tube

Lower

Blower Tube

Nozzle

Cruise Control

Throttle Grip

Throttle

Cables

Shoulder Support

Buckles

Shoulder

Supports

6

KNOW YOUR UNIT

APPLICATIONS

• Cleaning yards, garages, driveways, porches, patios, around

walls, fences and more

SPECIFICATIONS*

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

Engine Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 2-Cycle

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 cc (1.64 cu. in.)

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RDJ7J or equivalent plug

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel/Oil Mixture

Fuel/Oil Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 oz. (591 ml)

Approximate Unit Weight (No fuel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 - 18 lbs. (7.7 - 8.2 kg)

Blower Air Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 445 cfm

Blower Air Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 145 mph

ASSEMBLY TOOLS REQUIRED:

• Flat-head Screwdriver

• T-20 Torx® Screwdriver

Page 7

ASSEMBLY

7

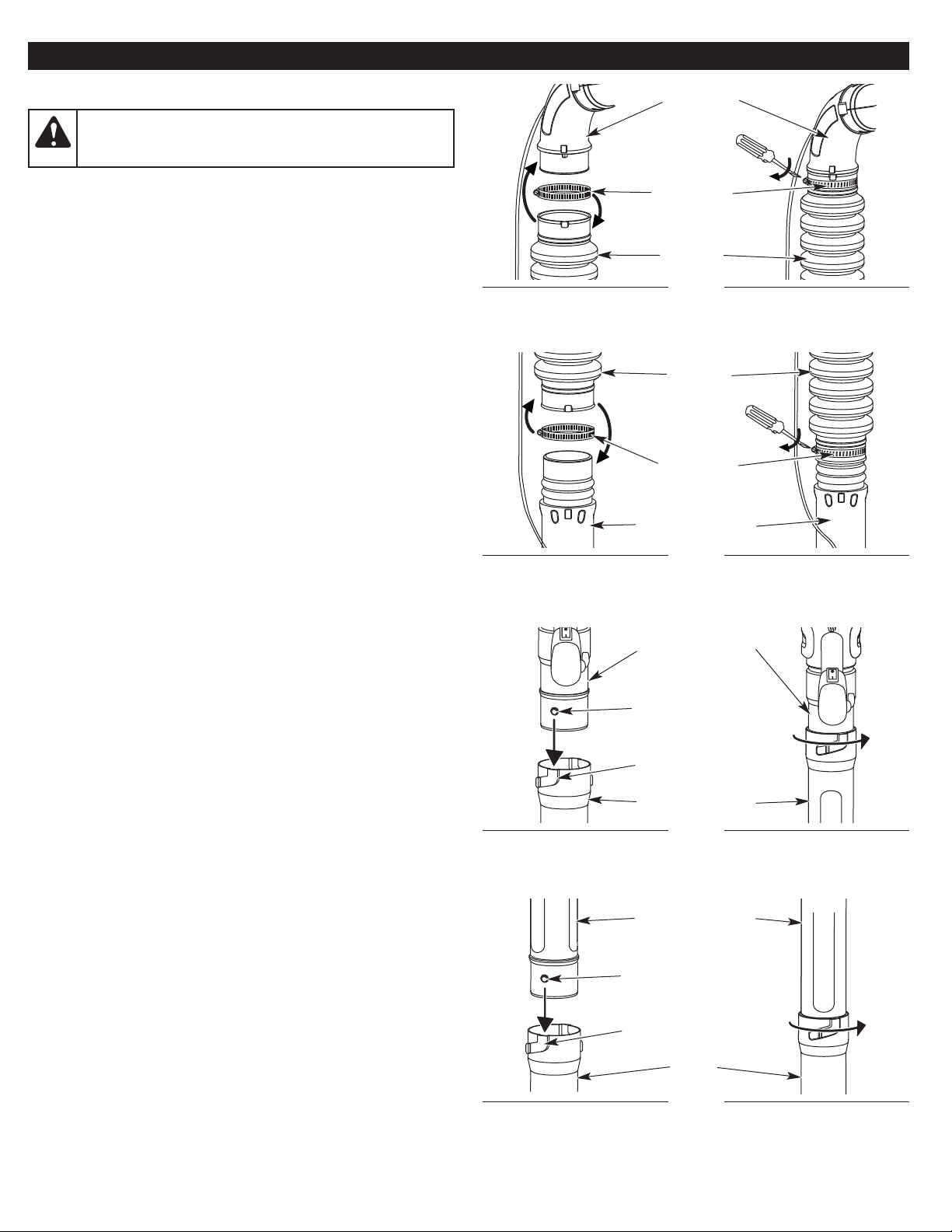

ASSEMBLING THE BLOWER TUBE

Installing the Flex Tube

1. Place a hose clamp around one end of the flex tube (Fig. 1).

2. Slide the flex tube and hose clamp onto the elbow tube (Fig. 1).

3. Tighten the screw on the hose clamp with a flat-head

screwdriver (Fig. 1).

Installing the Upper Blower Tube

1. Place a hose clamp around the other end of the flex tube (Fig. 2).

2. Slide the flex tube and hose clamp onto the upper end of the

upper blower tube (Fig. 2).

3. Tighten the screw on the hose clamp with a flat-head

screwdriver (Fig. 2).

Installing the Lower Blower Tube

1. Align the bump on the upper blower tube with the bump slot on

the lower blower tube (Fig. 3).

2. Insert the upper blower tube into the lower blower tube (Fig. 3).

3. While holding the upper blower tube, twist the lower blower tube

clockwise until it locks into place (Fig. 3).

Installing the Nozzle

1. Align the bump on the lower blower tube with the bump slot on

the nozzle (Fig. 4).

2. Insert the lower blower tube into the nozzle (Fig. 4).

3. While holding the lower blower tube, twist the nozzle clockwise

until it locks into place (Fig. 4).

Fig. 1

Hose Clamp

Flex Tube

Elbow Tube

Fig. 2

Fig. 3

Upper Blower Tube

Lower Blower Tube

Bump

Bump Slot

Fig. 4

WARNING:

To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing blower tubes or nozzles.

Flex Tube

Hose Clamp

Upper Blower Tube

Lower Blower Tube

Bump

Bump Slot

Nozzle

Page 8

8

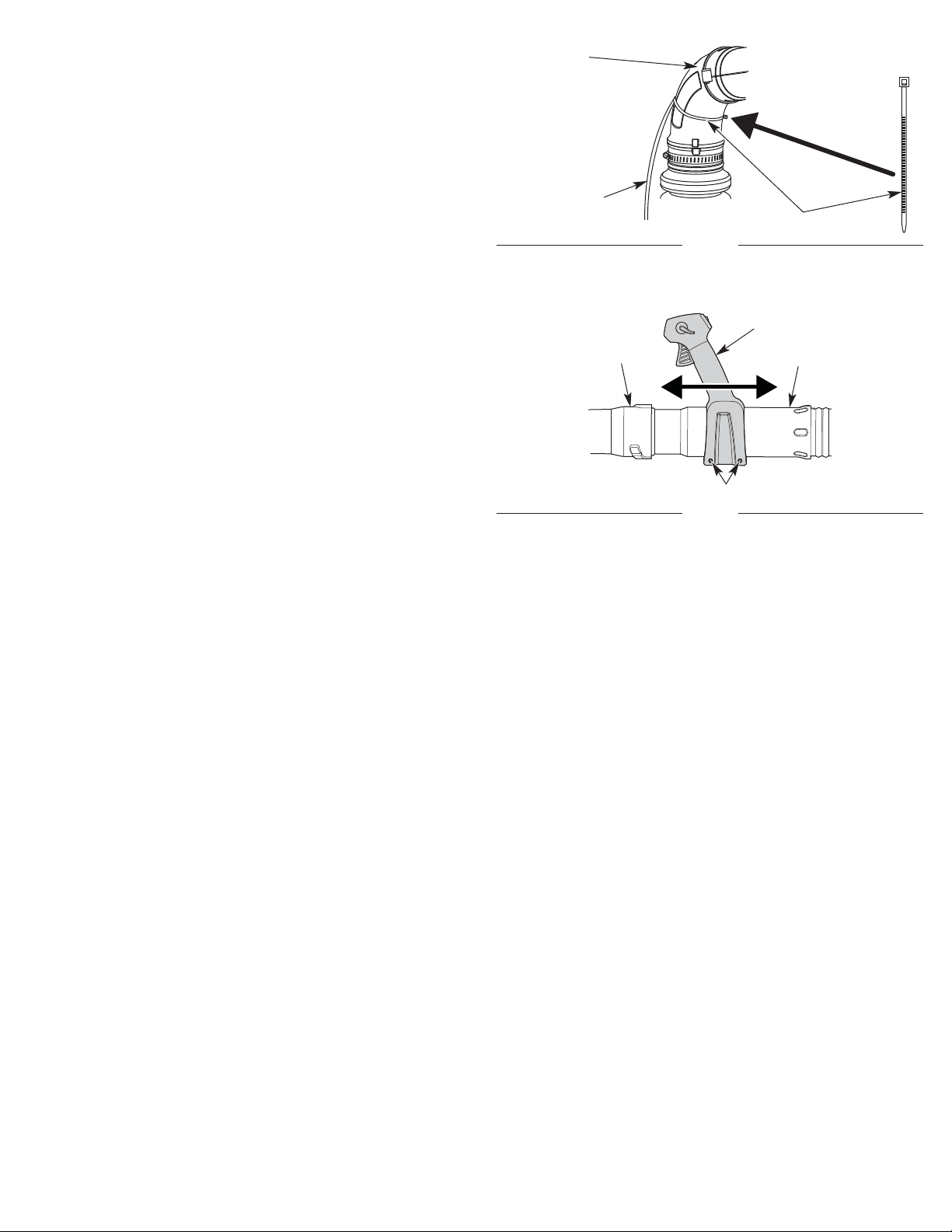

Securing the Throttle Cables

1. Wrap a zip tie around the elbow tube and the throttle cables (Fig. 5).

2. Carefully tighten the zip tie. Do not crimp the throttle cables.

Adjusting the Throttle Grip

1. Move the throttle grip to a location on the upper blower tube

that provides the best grip (Fig. 6).

2. Tighten the two screws on the throttle grip with a T-20 Torx®

screwdriver until the throttle grip is secure (Fig. 6).

Fig. 5

Throttle Cables

Elbow Tube

Zip Tie

Fig. 6

Upper Blower Tube

Screws

Throttle Grip

Lower Blower Tube

Page 9

9

OIL AND FUEL

FUELING THE UNIT

1. Position the unit with the fuel cap facing up.

2. Remove the fuel cap.

3. Place the fuel container spout into the fill hole on the fuel tank

and fill the tank.

NOTE: Do not overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and

the fueling site before starting the engine.

OIL AND FUEL MIXING INSTRUCTIONS

The use of old and/or improperly mixed fuel is the most common cause

of performance problems. Use only fresh, clean unleaded gasoline.

Follow the instructions carefully for the proper gasoline/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as 1% water in the fuel can make fuel and oil

separate, forming acids when stored. ALWAYS use fresh fuel (less

than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local

regulations.

Using Blended Fuels

If using a blended fuel:

• Always use the fresh fuel mix explained in your operator's manual

• Use Briggs & Stratton Advanced Formula Fuel Treatment and

Stabilizer or an equivalent

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil provided with this unit contains a fuel

additive to help inhibit corrosion and minimize gum deposits.

Always use the brand of 2-cycle oil that came with this unit. If this is

unavailable, use a 2-cycle oil designed for air-cooled engines and

mix it with a fuel additive, such as Briggs & Stratton Advanced

Formula Fuel Treatment and Stabilizer or an equivalent. Add 0.8 oz.

(23 ml) of fuel additive per gallon of fuel, according to the

instructions on the container. NEVER add fuel additives directly to

the unit's fuel tank.

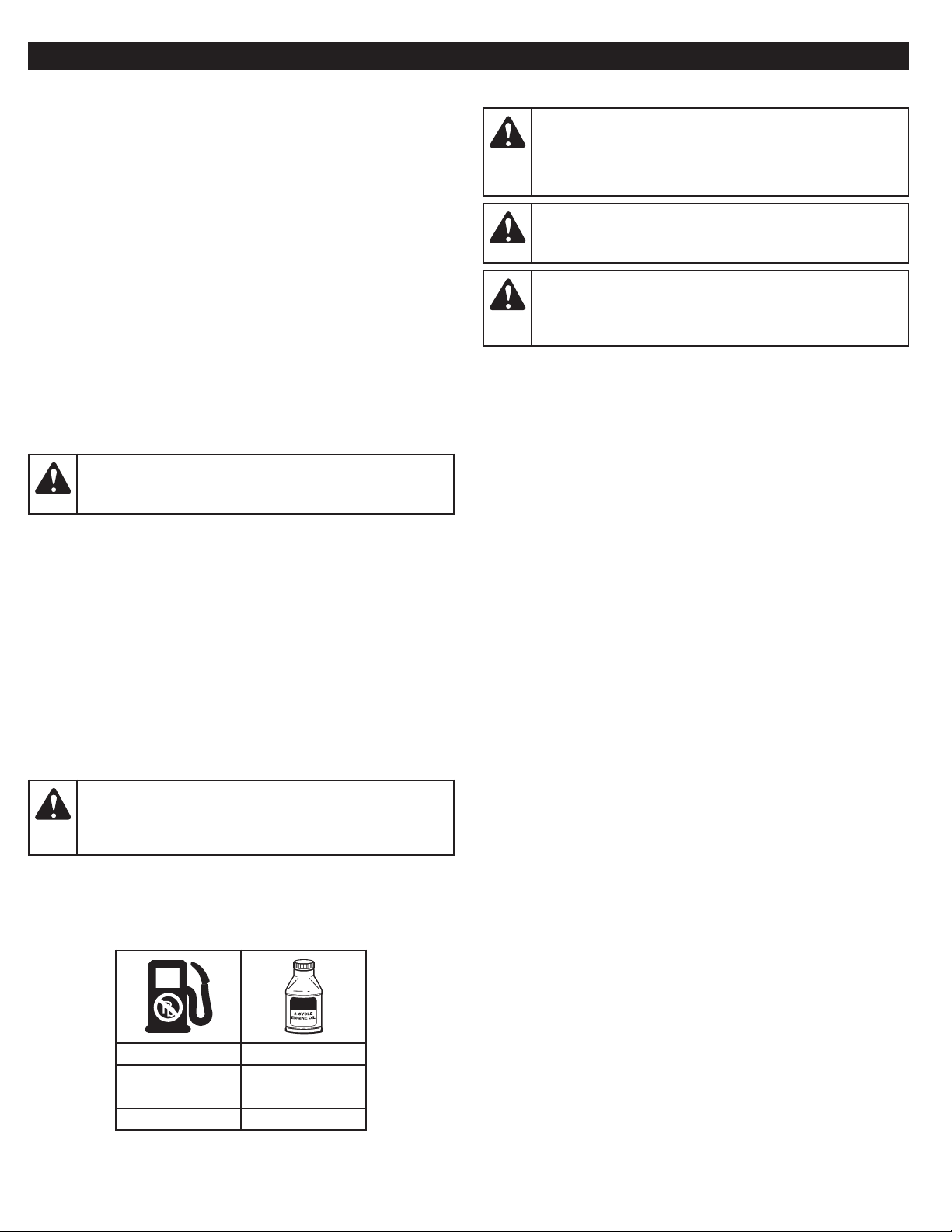

Mixing the Fuel

NOTE: This unit comes with a 3.2 oz. bottle of 2-cycle oil. To obtain

the correct fuel mixture described below, pour the entire bottle

into one gallon of unleaded gasoline.

Thoroughly mix the proper ratio of unleaded gasoline with 2-cycle

engine oil. Do not mix them directly in the unit’s fuel tank. Use a

separate fuel can. Use a 40:1 gasoline/oil ratio. See the table below

for specific gasoline and oil mixing ratios.

Unleaded gasoline 2-cycle oil

1 gallon U.S.

(3.8 liters)

3.2 fl. oz.

(95 ml)

1 liter 25 ml

MIXING RATIO - 40:1

CAUTION:

For proper engine operation and maximum

reliability, pay strict attention to the gasoline and oil mixing

instructions on the 2-cycle oil bottle. Using improperly

mixed fuel can severely damage the engine.

WARNING:

Gasoline is extremely flammable. Ignited

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a distance

from the area.

WARNING:

Remove the fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING:

Add fuel in a clean, well ventilated outdoor

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilled fuel. Do not start the engine

until fuel vapors dissipate.

WARNING:

DO NOT USE E85 FUEL IN THIS UNIT. It

has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the warranty.

Page 10

10

STARTING AND STOPPING

WARNING:

Operate this unit only in a well-ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING:

Avoid accidentally starting the unit. To avoid

serious injury, the operator and the unit must be in a stable

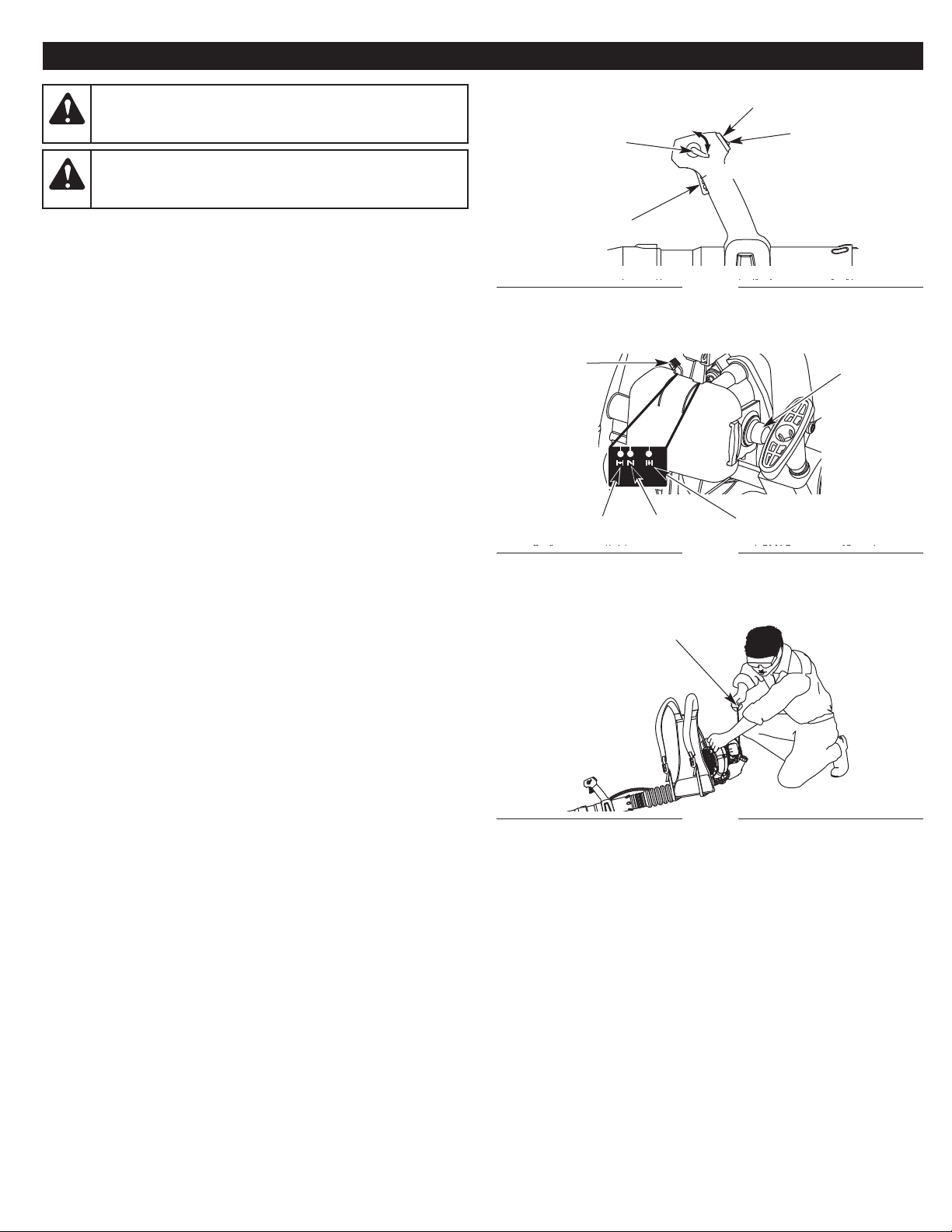

position when pulling the starter rope (Fig. 9).

STARTING INSTRUCTIONS

1. Mix gasoline with oil. Refer to Oil and Fuel Mixing Instructions.

2. Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in

the ON ( I ) position at all times (Fig. 7).

3. Slowly press and release the primer bulb 10 times (Fig. 8). If fuel

cannot be seen in the primer bulb, press and release the primer

bulb until fuel is visible.

4. Move the choke lever to Position 1 (Fig. 8).

5. Move the cruise control to the FAST position (Fig. 7).

NOTE: Keep the cruise control in the FAST position for ALL further

steps.

6. Crouch in the starting position (Fig. 9).

7. Pull the starter rope with a controlled and steady motion 5 times

(Fig. 9).

8. Move the choke lever to Position 2 (Fig. 8).

9. Pull the starter rope with a controlled and steady motion 3 to 5

times to start the engine.

10. Allow the engine to warm up for 30 to 60 seconds.

11. Move the choke lever to Position 3 (Fig. 8) and continue

warming the engine for an additional 60 seconds. The unit may

be used during this time.

NOTE: The engine is properly warmed up when it accelerates

without hesitation.

NOTE: Once the engine is properly warmed, the cruise control may

be adjusted and the throttle control can be used normally.

IF... the engine hesitates, return the choke lever to Position 2 (Fig. 8)

and continue the warm-up.

IF... the engine does not start, begin the starting procedure with

step 3.

IF... the engine fails to start after a few attempts, move the choke

lever to Position 3 and move the cruise control to the FAST

position. Pull the starter rope with a controlled and steady

motion 3 to 8 times. The engine should start. If it does not,

repeat this instruction.

IF... the engine is already warm, begin the starting procedure with

step 8.

STOPPING INSTRUCTIONS

1. Release the throttle control, or move the cruise control to the

SLOW position, and allow the engine to idle.

2. Press and hold the On/Off switch in the OFF (O) position until

the engine comes to a complete stop (Fig. 7).

Fig. 7

Fig. 9

On ( I ) / Start

Off (O) / Stop

Throttle Control

Starting

Position

Starter Rope Grip

1

2

3

Fig. 8

Primer Bulb

Position 3Position 2

Position 1

Choke Lever

Cruise Control

SLOW

FAST

Page 11

11

OPERATION

HOLDING THE UNIT

• Stand in the operating position (Fig. 12).

• Hold the throttle grip with the right hand. Keep the right arm

slightly bent.

• Make sure the unit is secure and comfortable on the operator’s

back.

WARNING: Always wear eye, hearing, hand, foot and body

protection to reduce the risk of injury when operating this unit.

Wear a face mask or dust mask if the operation is dusty.

Fig. 10

Fig. 11

Fig. 12

Shoulder Support

Buckles

PUTTING ON AND TAKING OFF THE UNIT

Putting On the Unit

1. Place the shoulder supports over both shoulders. The engine

should rest securely on the operator’s back.

2. Pull the shoulder support straps down to tighten the shoulder

supports (Fig. 10).

NOTE: Start the unit before putting it on. Refer to Starting and Stopping.

Taking Off the Unit

1. Pull the tabs on the bottom of the shoulder support buckles up

to loosen the shoulder supports (Fig. 11).

2. Remove the unit.

TIPS FOR BEST RESULTS

• Conserve water by using the blower instead of a hose to

perform many outdoor cleaning actions.

• Operate the unit only at reasonable hours, not early in the morning

or late at night when people might be disturbed. Comply with

times listed in local ordinances. Usual recommendations are 9:00

a.m. to 5:00 p.m., Monday through Saturday.

• To reduce noise levels, operate the unit at the lowest speed

needed to do the job. Limit the number of pieces of power

equipment used at any one time.

• Use rakes or brooms to loosen debris before blowing.

• In dusty conditions, slightly dampen surfaces.

• Watch out for children, pets, open windows and freshly washed

cars. Blow debris safely away. Never direct the unit toward

anyone while the unit is in operation.

• Use the nozzle to concentrate the air stream closer to the ground.

• Use the cruise control to make continuous operation easier (Fig. 7).

• Clean up after operation. Dispose of debris appropriately.

WARNING:

To prevent serious personal injury, never

operate the unit without the blower tubes firmly installed.

Shoulder Support

Straps

Shoulder Supports

Page 12

12

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures, take the unit to

an authorized service dealer.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by an authorized service

dealer.

NOTE: Please read the California/EPA statement that came with the

unit for a complete listing of terms and coverage for the emissions

control devices, such as the spark arrestor, muffler, carburetor, etc.

WARNING:

To prevent serious injury, never perform

maintenance or repairs while the unit is running. Always

allow the unit to cool before servicing or repairing the unit.

Disconnect the spark plug wire to prevent the unit from

starting accidentally.

MAINTENANCE

FREQUENCY MAINTENANCE REQUIRED

Every 10 hours • Clean and re-oil the air filter. Refer to

Maintaining the Air Filter.

Every 25 hours • Check the spark plug condition and gap.

Refer to Maintaining the Spark Plug.

MAINTAINING THE AIR FILTER

Failure to maintain the air filter can result in poor performance or can

cause permanent damage to the engine. Engine failure due to

improper air filter maintenance is not covered by the product warranty.

Cleaning the Air Filter

1. Open the air filter cover: press in the lock tab and swing the air

filter cover to the left (Fig. 13).

2. Remove the air filter (Fig. 13).

3. Wash the air filter in detergent and water. Rinse the air filter

thoroughly and allow it to dry.

4. Lightly coat the air filter with clean SAE 30 oil.

5. Squeeze the air filter to spread and remove excess oil.

6. Reinstall the air filter (Fig. 13).

NOTE: Operating the unit without the air filter and air filter cover will

VOID the warranty.

7. Close the air filter cover: insert the tabs on the air filter cover into

the slots on the backplate. Swing the air filter cover to the right

and press it closed until the lock tab snaps into place (Fig. 13).

WARNING:

To avoid serious personal injury, always stop

the engine and allow it to cool before cleaning or maintaining

the unit.

Fig. 13

Air Filter

Air Filter

Cover

Lock Tab

Backplate

Ta bs

Slots

Page 13

13

ADJUSTING THE IDLE SPEED

NOTE: Careless adjustments can seriously damage the unit. A qualified

service dealer should make carburetor adjustments.

If, after checking the fuel and cleaning the air filter, the engine still

will not idle, adjust the idle speed screw as follows:

1. Start the engine. Refer to Starting and Stopping.

2. Move the cruise control to the SLOW position and let the engine

idle. If the engine stops, use a small Phillips screwdriver to turn

the idle speed screw clockwise, 1/8 of a turn at a time (as

needed) until the engine idles smoothly (Fig. 14).

3. If the engine is idling too quickly, turn the idle speed screw

counterclockwise, 1/8 of a turn at a time (as needed) to reduce the

idle speed (Fig. 14).

Checking the fuel, cleaning the air filter, and adjusting the idle speed

should solve most engine problems. If not, and any of the following

conditions are true, take the unit to a qualified service dealer:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

WARNING:

Wear protective clothing and observe all

safety instructions to prevent serious personal injury.

Fig. 15

0.025 in.

(0.635 mm)

MAINTAINING THE SPARK PLUG

1. Stop the engine and allow it to cool. Grasp the spark plug boot

firmly and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug from the

cylinder head with a 5/8-inch socket, turning counterclockwise.

3. Inspect the spark plug. If the spark plug is cracked, fouled or dirty,

replace it with a Champion RDJ7J or an equivalent spark plug.

4. Use a feeler gauge to set the air gap at 0.025 in. (0.635 mm)

(Fig. 15).

5. Install the spark plug in the cylinder head. Tighten the spark plug

with a 5/8-inch socket, turning it clockwise until snug.

NOTE: If using a torque wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m). Do not over tighten.

6. Reattach the spark plug boot.

WARNING:

Do not sand blast, scrape or clean spark plug

electrodes. Grit in the engine could damage the cylinder.

Fig. 14

Idle Speed Screw

Page 14

14

CLEANING AND STORAGE

CLEANING

Use a small brush to clean the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as

pine and lemon, and solvents such as kerosene, can damage

plastic. Wipe off any moisture with a soft cloth.

STORAGE

• Never store a fueled unit where fumes may reach an open flame

or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

Long-term Storage

1. Remove the fuel cap, tip the unit and drain the fuel into an

approved container. Reinstall the fuel cap.

2. Start the engine and allow it to run until it stalls. This ensures

that all fuel has been drained from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5

drops of any high quality motor oil or 2-cycle oil into the cylinder.

Pull the starter rope slowly to distribute the oil. Reinstall the

spark plug.

4. Thoroughly clean the unit and inspect it for any loose or

damaged parts. Repair or replace damaged parts and tighten

loose screws, nuts or bolts.

Preparing the Unit for Use after Long-term Storage

1. Remove the spark plug and drain all of the oil from the cylinder.

NOTE: Do not use fuel that has been stored for more than 30 days.

Dispose of old fuel according to federal, state and local regulations.

WARNING:

To avoid serious personal injury, always stop

the engine and allow it to cool before cleaning or maintaining

the unit.

Page 15

15

If further assistance is required, contact an authorized service dealer.

The fuel tank is empty Fill the fuel tank with properly mixed fuel

The primer bulb was not pressed enough Press the primer bulb 10 times or until fuel is visible

The engine is flooded

Move the choke lever to Position 3, squeeze the throttle control and

pull the starter rope

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

The spark plug is fouled Replace the spark plug

TROUBLESHOOTING

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

The air filter is dirty Clean or replace the air filter

PROBLEM SOLUTION

The air filter is dirty Clean or replace the air filter

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

The idle speed is incorrect Adjust the idle speed

The fuel is old (over 30 days) and/or improperly mixed Drain the fuel tank and add fresh, properly mixed fuel

The air filter is dirty Clean or replace the air filter

The spark plug is fouled Replace the spark plug

THE ENGINE WILL NOT START

THE ENGINE WILL NOT IDLE

THE ENGINE WILL NOT ACCELERATE

THE ENGINE LACKS POWER OR STALLS

Page 16

16

BRIGGS & STRATTON PRODUCTS WARRANTY POLICY

WARRANTY PERIOD

ABOUT YOUR WARRANTY

Equipment 2 years 90 days

LIMITED WARRANTY

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or replace, free of charge, any part that is

defective in material or workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty

must be borne by purchaser. This warranty is effective for and is subject to the time periods and conditions stated below. For warranty

service, find the nearest Authorized Service Dealer in our dealer locator map at www.snapper.com. The purchaser must contact the

Authorized Service Dealer, and then make the product available to the Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose,

are limited to one year from purchase, or to the extent permitted by law. All other implied warranties are excluded. Liability for

incidental or consequential damages are excluded to the extent exclusion is permitted by law. Some states or countries do not

allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state or country to country.**

** In Australia - Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure. For

warranty service, find the nearest Authorized Service Dealer in our dealer locator map at BRIGGSandSTRATTON.COM, or by calling 1300

274 447, or by emailing or writing to salesenquires@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1 Moorebank Avenue,

NSW, Australia, 2170.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time

stated in the table above.

“Consumer use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for

commercial, income producing or rental purposes. Once a product has experienced commercial use, it shall thereafter be considered as a

commercial use product for purposes of this warranty.

No warranty registration is necessary to obtain warranty on Briggs & Stratton products. Save your proof of purchase receipt. If you

do not provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the product will

be used to determine the warranty period.

We welcome warranty repair and apologize to you for being inconvenienced. Warranty service is available only through Snapper Authorized

Service Dealers. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. This

warranty only covers defects in materials or workmanship. It does not cover damage caused by improper use or abuse, improper

maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using the product in a way not

described in the Operator’s Manual or using the product after it has been damaged will void your warranty. Warranty is not allowed if the

serial number on the product has been removed or the product has been altered or modified in any way, or if the product has evidence of

abuse such as impact damage, or water/chemical corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the Operator’s

Manual, and serviced or repaired using genuine Briggs & Stratton parts or equivalent. Damage caused by lack of maintenance or use of nonoriginal parts is not covered by warranty.

Normal Wear - Like all mechanical devices, your unit is subject to wear even when properly maintained. This warranty does not cover repairs

when normal use has exhausted the life of a part or the equipment. Maintenance and wear items such as filters, belts, cutting blades, and

brake pads (except engine brake pads) are not covered by warranty due to wear characteristics alone, unless the cause is due to defects in

material or workmanship.

Stale Fuel - In order to function correctly, this product requires fresh fuel that conforms to the criteria specified in the Operator’s Manual.

Damage caused by stale fuel (carburetor leaks, clogged fuel tubes, sticking valves, etc) is not covered by warranty.

Other Exclusions - This warranty excludes damage due to accident, abuse, modifications, alterations, improper servicing, freezing or

chemical deterioration. Attachments or accessories that were not originally packaged with the product are also excluded. There is no

warranty coverage on equipment used for primary power in place of utility power or on equipment used in life support applications. This

warranty also excludes failures due to acts of God and other force majeure events beyond the manufacturer’s control.

80007282EN Rev C

Item Consumer Use Commercial Use

AUGUST 2013

Page 17

Manual del Operador

ÍNDICE

Reparación y mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Conozca su unidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Aceite y combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Arranque y detención . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Limpieza y almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Solución de Problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Toda la información, las ilustraciones y las especificaciones que se

incluyen en el presente manual se basan en la información más

reciente sobre el producto disponible al momento de la impresión.

Nos reservamos el derecho a realizar cambios en cualquier

momento sin previo aviso.

Por favor, NO devuelva la unidad al minorista o distribuidor sin

ponerse en contacto primero con el Departamento de

Asistencia al Cliente.

En caso de tener problemas para montar este producto o de tener

dudas con respecto a los controles, funcionamiento o mantenimiento

del mismo, puede solicitar la ayuda de expertos. Elija entre las

opciones que se presentan a continuación:

• Visite nuestro sitio web en www.snapper.com

• Llame a un representante de Asistencia al Cliente al (800) 317-7833

• Escríbanos a Briggs & Stratton Power Products Group, LLC •

12301 West Wirth St. • Wauwatosa • WI 53222

GUARDE ESTAS

INSTRUCCIONES

REPARACIÓN Y MANTENIMIENTO

Sopladora Mochila de 2 tiempos

7800959-00

769-09211 / 01 11/13

IMPORTANTE: Lea este manual por completo antes de utilizar este producto. Siga todas las instrucciones.

Briggs & Stratton Power Products Group, LLC • 12301 West Wirth St. • Wauwatosa • WI 53222

Page 18

18

SEGURIDAD

NOTA SOBRE EL AMORTIGUADOR DE CHISPAS

NOTA: Para usuarios de los territorios de bosques de EE. UU. y

de los estados de California, Maine, Oregon y Washington.

Todos los territorios de bosques de EE. UU. y los estados de

California (Códigos de Recursos Públicos 4442 y 4443), Oregon y

Washington exigen por ley, que determinados motores de

combustión interna que se operan en zonas cubiertas por malezas

de bosque y/o hierbas cuenten con un amortiguador de chispas

que se deberá mantener en condiciones de uso adecuadas o que el

motor se diseñe, equipe y mantenga para prevenir incendios.

Corrobore con las autoridades estatales o locales cuáles son las

normativas correspondientes a dichas exigencias. El

incumplimiento de dichos requerimientos podría generarle una

responsabilidad o una multa. La presente unidad se equipa en la

fábrica con un amortiguador de chispas. Si requiere reemplazo,

póngase en contacto con su representante local de servicio para

instalar el conjunto de silenciador adecuado.

Lea el manual del operador y siga todas las advertencias e

instrucciones de seguridad. Si no lo hace, el operador y/o los

observadores pueden sufrir lesiones graves.

SÍMBOLOS SIGNIFICADO

ADVERTENCIA:

Indica un peligro

GRAVE.

Si no se cumple una ADVERTENCIA de seguridad usted

mismo u otras personas PUEDEN sufrir lesiones graves.

PRECAUCIÓN:Indica un peligro de

GRAVEDAD MODERADA.

Si no se cumple una señal de seguridad de PRECAUCIÓN

usted mismo o a otras personas PUEDEN sufrir lesiones o

se PUEDEN producir daños materiales.

El objetivo de los símbolos de seguridad es dirigir su atención hacia

posibles peligros. Los símbolos de seguridad, así como sus

explicaciones, necesitan su atención y comprensión completas. Las

advertencias de seguridad no eliminan por sí mismas ningún

peligro. Las instrucciones o advertencias que contienen no

reemplazan a las medidas adecuadas de prevención de accidentes.

NOTA: Proporciona información o instrucciones de vital importancia

para el funcionamiento o el mantenimiento del equipo.

PELIGRO:Indica un peligro EXTREMO.

Si no se cumple una advertencia de seguridad de

PELIGRO usted mismo u otras personas sufrirán lesiones

graves o la muerte.

PROPOSICIÓN 65 DE CALIFORNIA

ADVERTENCIA:

El escape del motor

de este producto, algunos de sus componentes y algunos

componentes terminados contienen o liberan sustancias

químicas que el estado de California considera que

pueden producir cáncer, defectos de nacimiento u otros

problemas reproductivos. Lávese las manos después de

estar en contacto con estos componentes.

Page 19

19

LEA TODAS LAS INSTRUCCIONES ANTES DE USAR LA

UNIDAD

• Lea las instrucciones con atención. Debe familiarizarse con los

controles y con el uso apropiado de la unidad.

• No opere esta unidad si está cansado, enfermo o bajo la

influencia de alcohol, drogas o medicamentos.

• La unidad no debe ser utilizada por niños. Los adolescentes

deben contar con la compañía y guía de un adulto.

• Se deben instalar correctamente todos los protectores y

accesorios de seguridad antes de operar la unidad.

• Inspeccione la unidad antes de usarla. Reemplace las piezas

dañadas. Compruebe si hay pérdidas de combustible.

Compruebe que todas las sujeciones estén en su lugar y bien

ajustadas. Reemplace las piezas que estén agrietadas,

astilladas o dañadas de cualquier manera. No utilice la unidad si

hay piezas sueltas o dañadas.

• Tenga en cuenta el riesgo de lesiones en la cabeza, las manos y

los pies.

• Inspeccione el área con atención antes de arrancar la unidad.

Extraiga las rocas, los vidrios rotos, los clavos, los cables,

cordeles y demás objetos que podrían ser arrojados o enredarse

en la unidad.

• Despeje la zona de niños, observadores y mascotas;

manténgalos fuera de un radio de 50 pies (15 m), como mínimo.

Incluso a esa distancia, sigue el riesgo de ser alcanzados por

los objetos arrojados por el aire. Sugiérales a los observadores

que usen protección ocular. Si alguien se le aproxima, detenga

la unidad de inmediato.

• Apriete el control del acelerador y verifique que vuelva

automáticamente a la posición de ralentí. Realice todos los

ajustes o las reparaciones antes de usar la unidad.

DURANTE LA OPERACIÓN

• Utilice anteojos o antiparras de seguridad que cumplan con las

normas ANSI Z87.1 vigentes y que tengan la identificación

correspondiente. Utilice una protección auditiva al operar esta

unidad. Utilice una máscara facial o para polvos si la máquina

levanta polvo durante su funcionamiento.

• Use pantalones largos y gruesos, botas, guantes y camisa de

mangas largas. No use ropa holgada, alhajas, pantalones

cortos, sandalias ni ande descalzo. Sujétese el cabello a nivel de

los hombros.

• Ajuste la manija para que brinde el mejor agarre.

• Use la unidad solamente con luz de día o con una buena luz artificial.

• Evite arranques accidentales. Permanezca en la posición de

arranque siempre que tire de la cuerda de arranque. El operador

y la unidad deben estar en una posición estable durante el

arranque. Consulte Arranque y Parada

• Utilice la herramienta apropiada. Use esta herramienta sólo para

el propósito para el que fue diseñada.

• Siempre sujete con firmeza la manija mientras utiliza la unidad.

• No se extienda demasiado. Siempre debe estar bien afirmado y

mantener el equilibrio adecuado. Tenga cuidado al trabajar en

pendientes o inclinaciones empinadas.

• Mantenga las manos, el rostro y los pies alejados de todas las

piezas móviles. No toque ni intente detener las piezas móviles.

• No toque el motor, el alojamiento del engranaje ni el silenciador.

Estas partes se ponen extremadamente calientes por el

funcionamiento, incluso después de que se apaga la unidad.

• No opere la unidad a una velocidad mayor a la necesaria para la

tarea. No haga funcionar la unidad a alta velocidad cuando no

está en uso.

• No exija demasiado a la unidad. Si se usa a la velocidad para la

que fue diseñada, realizará un trabajo más eficiente y seguro.

• Detenga siempre la unidad cuando la operación esté demorada

o cuando camine de un lugar a otro.

• Si golpea un objeto extraño o si éste se engancha en la unidad,

deténgala de inmediato y controle si se produjeron daños. No

utilice la unidad hasta haber reparado el daño. No utilice la

unidad si hay piezas sueltas o dañadas.

• Apague el motor y desconecte la bujía para realizar tareas de

mantenimiento o reparación.

• Use sólo piezas de reemplazo y accesorios del fabricante del

equipo original (OEM) para esta unidad. Los puede adquirir al

distribuidor de servicio autorizado. Si usa cualquier otra pieza o

accesorio, el usuario podría lesionarse gravemente o la unidad

podría dañarse y se anularía la garantía.

• Mantenga limpia la unidad. Quite con cuidado cualquier resto de

vegetación u otros residuos que puedan bloquear las piezas móviles.

• A fin de reducir el riesgo de incendio, reemplace el silenciador y

el amortiguador de chispas si están averiados. Mantenga el

motor y el silenciador libres de hierbas, hojas y de la

acumulación excesiva de grasa o de carbono.

ADVERTENCIAS DE SEGURIDAD PARA LAS UNIDADES

A GASOLINA

• Almacene el combustible únicamente en recipientes diseñados

específicamente y aprobados para el almacenamiento de dichos

materiales.

• Detenga siempre el motor y déjelo enfriar antes de llenar el

depósito. Nunca retire la tapa del depósito de combustible ni

agregue combustible cuando el motor esté caliente. Afloje siempre

lentamente la tapa del depósito de combustible para descargar la

presión que haya en el depósito antes de recargar combustible.

• Mezcle y agregue siempre combustible en una zona al aire libre,

limpia y bien ventilada, en la que no haya chispas ni llamas. NO

fume.

• Nunca opere la unidad si la tapa del combustible no está bien

sujeta en su lugar.

• INSTRUCCIONES DE SEGURIDAD IMPORTANTES •

ADVERTENCIA:

Se deben respetar

todas las normas de seguridad al usar la unidad. Por favor,

lea estas instrucciones antes de utilizar la unidad para

garantizar la seguridad del operador y los observadores.

Por favor, guarde estas instrucciones para su uso

posterior.

ADVERTENCIA:

La gasolina es

sumamente inflamable y sus vapores pueden explotar si se

encienden. Adopte las siguientes precauciones:

• Evite que se genere una fuente de encendido para el

combustible derramado. Limpie de inmediato el combustible

derramado de la unidad, antes de encenderla. Mueva la unidad

al menos 30 pies (9.1m) de la fuente de combustible y del sitio

antes de arrancar el motor. NO fume.

• Nunca arranque ni use la unidad dentro de una habitación o de

una construcción cerrada. La inhalación de humos de escape

puede ser mortal. Opere esta unidad únicamente en una zona

bien ventilada, al aire libre.

Page 20

20

OTRAS ADVERTENCIAS DE SEGURIDAD

• Todas las tareas de reparación, con excepción de los

procedimientos de mantenimiento que se describen en este manual,

deben ser realizados por un distribuidor de servicio calificado.

• Antes de inspeccionar, limpiar, guardar o transportar la unidad, o

de hacer tareas de reparación o mantenimiento o reemplazar

alguna de sus piezas:

1. Detenga la unidad.

2. Asegúrese de que se hayan detenido todas las piezas móviles.

3. Deje que la unidad se enfríe.

4. Desconecte el cable de la bujía.

• Sujete la unidad durante el transporte.

• Nunca almacene la unidad con combustible en el depósito, en el

interior de una construcción donde las emanaciones puedan

alcanzar una llama abierta (luces piloto, etc.) o chispas

(interruptores, motores eléctricos, etc.).

• Almacene la unidad en un lugar seco, asegurada o a una altura

que evite que se la use sin autorización o se la dañe. Mantenga

la unidad lejos del alcance de los niños.

• Nunca rocíe ni arroje chorros de agua ni de ningún otro líquido a la

unidad. Mantenga las manijas secas, limpias y sin residuos. Limpie

la unidad luego de cada uso. Consulte Limpieza y almacenamiento.

• Guarde estas instrucciones. Consúltelas con frecuencia y úselas

para capacitar a otros usuarios. Si le presta esta unidad a otras

personas, también debe prestarles estas instrucciones.

GUARDE ESTAS

INSTRUCCIONES

• Si la unidad comienza a vibrar en forma anormal, deténgala de

inmediato. Inspeccione la unidad para determinar la causa de la

vibración. La vibración por lo general indica que hay algún problema.

SEGURIDAD DE LA SOPLADORA

• No inserte nada en los pasos de aire, los tubos o la boquilla de

la sopladora. No utilice la unidad si uno de los pasos de aire o

tubos está tapado. Mantenga los pasos de aire libres de polvo,

pelusa, pelo y cualquier cosa que pueda reducir el flujo de aire.

• No utilice la unidad si no están instalados los tubos de la sopladora.

• No use la unidad para rociar líquidos, especialmente líquidos

inflamables o combustibles, como la gasolina. No use la unidad

en lugares donde esos líquidos están presentes.

• No use la unidad para rociar sustancias químicas, fertilizantes u

otras substancias que puedan contener materiales tóxicos.

• No apoye la unidad sobre ninguna superficie mientras está

funcionando. La toma de aire puede levantar residuos y

expulsarlos por el escape, dañando la unidad u otros bienes o

causando lesiones graves a los observadores o al operador.

• Durante la operación, no apunte nunca la unidad en dirección a

las personas, animales, ventanas o automóviles. Dirija siempre

los residuos soplados lejos de las personas, animales, ventanas

y automóviles.

• Tenga aún más cuidado al soplar residuos cerca de objetos

sólidos como árboles, muros, vallas, etc. Siempre que pueda,

sople en dirección opuesta a esos objetos y no hacia ellos.

• Tenga cuidado cuando trabaja cerca de plantas valiosas. La

fuerza del aire soplado puede dañar las plantas tiernas.

Page 21

21

• SÍMBOLOS INTERNACIONALES Y DE SEGURIDAD •

Este manual del operador describe símbolos de seguridad e internacionales, así como pictogramas, que pueden aparecer en este producto.

Lea el manual del operador para obtener información completa sobre seguridad, montaje, funcionamiento, mantenimiento y reparaciones.

SÍMBOLOS SIGNIFICADO SÍMBOLOS SIGNIFICADO

• SÍMBOLO DE ALERTA DE SEGURIDAD

Indica peligro, advertencia o precaución. Puede

utilizarse junto con otros símbolos o pictogramas.

• LEA EL MANUAL DEL OPERADOR

ADVERTENCIA :Lea el (los)

manual(es) del operador y cumpla todas las

advertencias e instrucciones de seguridad. Si no lo

hace, el operador y/o los observadores pueden sufrir

lesiones graves.

• UTILICE PROTECCIÓN OCULAR Y AUDITIVA

ADVERTENCIA:Los objetos que

son arrojados por el aire y los ruidos fuertes pueden

provocar graves lesiones oculares y pérdidas de

audición. Cuando opere esta unidad, utilice

protección ocular que cumpla con las normas ANSI

Z87.1 vigentes y protectores auditivos. Utilice una

máscara que cubra todo el rostro si es necesario.

• COMBUSTIBLE SIN PLOMO

Utilice siempre combustible limpio, nuevo y sin plomo.

• ACEITE

Consulte el manual del operador para conocer el tipo

adecuado de aceite.

• NO UTILICE COMBUSTIBLE E85 EN ESTA UNIDAD

ADVERTENCIA:

Se ha

demostrado que el combustible que contiene más de

un 10% de etanol es probable que dañe este motor y

anule la garantía.

• APAGADO/ENCENDIDO DE CONTROL DE PARADA

ENCENDIDO / ARRANQUE / MARCHA

• APAGADO/ENCENDIDO DE CONTROL DE PARADA

APAGADO o PARADA

• BULBO DEL CEBADOR

Presione por completo el bulbo del cebador

lentamente 10 veces.

• CONTROL DEL ESTRANGULADOR

1. • Posición FULL (máximo) del estrangulador.

2. • Posición PARTIAL (parcial) del estrangulador.

3. • Posición RUN (funcionamiento) del estrangulador

• LOS OBJETOS ARROJADOS PUEDEN PROVOCAR

LESIONES GRAVES

ADVERTENCIA:Es posible que

objetos pequeños sean despedidos a gran velocidad,

lo cual puede provocar lesiones.

• MANTENGA ALEJADOS A LOS OBSERVADORES

ADVERTENCIA:

Mantenga a

todos los observadores, especialmente a los niños y

las mascotas, al menos a 50 pies (15 m) de la zona de

trabajo.

• SUPERFICIE CALIENTE

ADVERTENCIA:

No toque el

silenciador o el cilindro cuando estén calientes. Puede

quemarse. Estas piezas se calientan extremadamente

durante el funcionamiento. Una vez apagadas,

continúan calientes durante un período breve.

• SOPLADORAS – LAS CUCHILLAS DEL ROTOR EN

MOVIMIENTO PUEDEN OCASIONAR LESIONES

GRAVES

ADVERTENCIA:Detenga el

motor y deje que el rotor se detenga antes de cambiar

los tubos, limpiar o realizar cualquier mantenimiento.

Page 22

Apoyo

Tubo

flexible

Tubo superior

de sopladora

Tubo inferior

de sopladora

Boquilla

Control de velocidad

Empuñadura del regulador

Cables del

regulador

Hebillas de soportes

de hombro

Soportes

de hombro

Tapa de

combustible

Empuñadura

cuerda de arranque

Control del acelerador

Bujía de encendido

Silenciador

Interruptor encendido / apagado

Bulbo del cebador

Palanca del

cebador

Tapa del

filtro de aire

22

CONOZCA SU UNIDAD

APLICACIONES

• Limpieza de jardines, garajes, caminos de acceso, porches,

patios, alrededor de muros, vallas y más

ESPECIFICACIONES*

* Todas las especificaciones están basadas se basan en la información más reciente sobre el producto disponible al momento de la

impresión. Nos reservamos el derecho a realizar cambios en cualquier momento sin previo aviso.

Tipo de motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refrigerado por aire, de 2 ciclos

Desplazamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 cc (1.64 pulgadas cúbicas)

Separación de las bujías. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 pulgadas (0.635 mm)

Bujía de encendido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RDJ7J o bujía equivalente

Lubricación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mezcla de combustible y aceite

Relación combustible/aceite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Capacidad del depósito de combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 onzas (591 ml)

Peso aproximado de la unidad (sin combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 - 18 libras (7.7 - 8.2 kg)

Caudal de aire de la sopladora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hasta 445 pies3/min

Velocidad de aire de la sopladora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hasta 145 mph

HERRAMIENTAS DE ENSAMBLADO

REQUERIDAS:

• Destornillador de cabeza plana

• Destornillador T-20 Torx®

Page 23

23

MONTAJE

MONTAJE DEL TUBO DE LA SOPLADORA

Instalación del tubo flexible

1. Coloque una abrazadera de manguera alrededor de un extremo

del tubo flexible (Fig. 1).

2. Deslice el tubo y la abrazadera sobre el tubo en codo (Fig. 1).

3. Ajuste el tornillo de la abrazadera de la manguera con un

destornillador de cabeza plana (Fig. 1).

Instalación del tubo superior de la sopladora

1. Coloque una abrazadera de manguera alrededor del otro

extremo del tubo flexible (Fig. 2).

2. Deslice el tubo y la abrazadera sobre el extremo superior del

tubo superior de la sopladora (Fig. 2).

3. Ajuste el tornillo de la abrazadera de la manguera con un

destornillador de cabeza plana (Fig. 2).

Instalación del tubo inferior de la sopladora

1. Alinee el tope del tubo superior de la sopladora con la ranura de

tope del tubo inferior (Fig. 3).

2. Inserte el tubo superior de la sopladora en el tubo inferior (Fig. 3).

3. Mientras sostiene el tubo superior, gire el tubo inferior de la

sopladora en el sentido de las agujas del reloj hasta que calce

en su lugar (Fig. 3).

Instalación de la boquilla

1. Alinee el tope del tubo inferior de la sopladora con la ranura de

tope de la boquilla (Fig. 4).

2. Inserte el tubo inferior de la sopladora en la boquilla (Fig. 4).

3. Mientras sostiene el tubo inferior, gire la boquilla en el sentido

de las agujas del reloj hasta que calce en su lugar (Fig. 4).

Fig. 1

Abrazadera de

la manguera

Tubo flexible

Tubo en codo

Fig. 2

Fig. 3

Tubo superior

de sopladora

Tubo inferior

de sopladora

Tope

Ranura de tope

Fig. 4

ADVERTENCIA:

A fin de evitar lesiones personales

graves y daños a la unidad, apáguela antes de extraer o

instalar los tubos o boquillas de la sopladora.

Tubo flexible

Abrazadera de

la manguera

Tubo superior

de sopladora

Tubo inferior

de sopladora

Tope

Ranura de tope

Boquilla

Page 24

24

Sujeción de los cables del regulador

1. Envuelva un sujetacables alrededor del tubo en codo y los

cables del regulador (Fig. 5).

2. Con cuidado ajuste el sujetacables. No doble los cables del

regulador.

Ajuste de la empuñadura del regulador

1. Mueva la empuñadura del regulador a la ubicación del tubo

superior de la sopladora que ofrezca el mejor agarre (Fig. 6).

2. Ajuste los dos tornillos de la empuñadura del regulador con un

destornillador T-20 Torx® hasta que la empuñadura esté fija (Fig. 6).

Fig. 5

Cables del

regulador

Tubo en codo

Sujetacables

Fig. 6

Tubo superior

de sopladora

Tornillos

Empuñadura del regulador

Tubo inferior

de sopladora

Page 25

25

ACEITE Y COMBUSTIBLE

CARGA DE COMBUSTIBLE EN LA UNIDAD

1. Ubique la unidad con la tapa del combustible orientada hacia arriba.

2. Extraiga la tapa de combustible.

3. Ubique el pico del recipiente de combustible dentro del orificio

de llenado del depósito de combustible y llene el depósito.

NOTA: No llene en exceso el depósito de combustible.

4. Limpie el combustible que se pueda haber derramado.

5. Vuelva a colocar la tapa del combustible.

6. Mueva la unidad al menos 30 pies (9.1m) del recipiente de

combustible y del sitio de carga de combustible antes de

arrancar el motor.

INSTRUCCIONES PARA LA MEZCLA DEL ACEITE Y EL

COMBUSTIBLE

El uso de combustible viejo y/o mal mezclado es la causa más

frecuente de los problemas de rendimiento. Sólo se debe utilizar

gasolina nueva, limpia y sin plomo. Siga atentamente las

instrucciones para que la mezcla de gasolina/aceite sea adecuada.

Definición de combustibles mezclados

Actualmente los combustibles con frecuencia son una mezcla de

gasolina y oxigenatos como etanol, metanol o éter (éter metílico

terciario-butílico, MTBE). Los combustibles con mezcla de alcohol

absorben el agua. Con tan solo un 1% de agua en el combustible

es posible que el combustible y el aceite se separen, formando

ácidos cuando se almacenan. SIEMPRE debe usar combustible

nuevo (con menos de 30 días de antigüedad).

NOTA: Deseche el combustible usado de acuerdo con las

normativas federales, estatales y locales.

Uso de combustibles mezclados

Si utiliza un combustible mezclado:

• Utilice siempre la mezcla de combustible nueva según se

explica en el manual del operador

• Utilice Briggs & Stratton Advanced Formula Fuel Treatment and

Stabilizer o un equivalente

• Agite siempre la mezcla de combustible antes de recargar

combustible en la unidad

• Drene el depósito y ponga en marcha el motor en seco antes de

almacenar la unidad

Uso de aditivos para el combustible

La botella de aceite de 2 ciclos que se suministra con esta unidad

contiene un aditivo para combustible que ayuda a inhibir la

corrosión y minimiza la formación de depósitos de goma. Utilice

siempre la marca de aceite de 2 ciclos que vino con esta unidad. Si

no está disponible, utilice un aceite de 2 tiempos que esté

diseñado para motores enfriados por aire y mézclelo con un aditivo

para combustible, como Briggs & Stratton Advanced Formula Fuel

Treatment and Stabilizer u otro equivalente. Agregue 0.8 onzas (23

ml) de aditivo para combustible por galón de combustible según las

instrucciones del recipiente. NUNCA agregue aditivos para el

combustible directamente al depósito de combustible de la unidad.

Gasolina sin plomo Aceite de 2 ciclos

1 galón EE. UU.

(3.8 litros)

3.2 onzas líquidas

(95 ml)

1 liter 25 ml

PROPORCIÓN DE LA MEZCLA - 40:1

ADVERTENCIA:

La gasolina es extremadamente

inflamable. Los vapores encendidos pueden explotar.

Detenga siempre el motor y déjelo enfriar antes de llenar el

depósito de combustible. No fume mientras llena el

depósito. Mantenga las chispas y llamas abiertas a una

distancia de la zona.

ADVERTENCIA:

Retire la tapa del combustible

lentamente a fin de evitar lesiones ocasionadas por

salpicaduras de combustible. Nunca opere la unidad si la

tapa del combustible no está bien sujeta en su lugar.

ADVERTENCIA: Agregue combustible en una zona al

aire libre, limpia y bien ventilada. Limpie de inmediato la

gasolina que se haya derramado. Evite que se genere una

fuente de encendido para el combustible derramado. No

arranque el motor hasta que se hayan disipado los

vapores del combustible.

ADVERTENCIA:

NO UTILICE COMBUSTIBLE E85 EN

ESTA UNIDAD. Se ha demostrado que el combustible que

contiene más de un 10% de etanol es probable que dañe

este motor y anule la garantía.

Mezcla del combustible

NOTA: La presente unidad viene con una botella de 3.2 onzas de

aceite de 2 ciclos. Para obtener la mezcla de combustible

correcta que se describe a continuación, vierta toda la botella

dentro de un galón de gasolina sin plomo.

Mezcle completamente la proporción adecuada de gasolina sin

plomo con el aceite para motor de 2 ciclos. No los mezcle

directamente en el depósito de combustible de la unidad. Use una

lata de combustible separada. Utilice una proporción de 40:1 de

gasolina/aceite. Consulte la tabla a continuación para conocer las

proporciones específicas para mezclar la gasolina y el aceite.

PRECAUCIÓN:

Para el funcionamiento correcto del

motor y la máxima confiabilidad, preste mucha atención y

siga estrictamente las instrucciones para la mezcla de la

gasolina y el aceite que figuran en la botella de aceite de 2

ciclos. El uso de combustible que se mezcló

incorrectamente puede dañar gravemente el motor.

Page 26

26

ARRANQUE Y PARADA

ADVERTENCIA:

Opere esta unidad únicamente en una

zona bien ventilada, al aire libre. Los humos de escape de

monóxido de carbono pueden ser mortales en un lugar

cerrado.

ADVERTENCIA:

Se debe evitar arrancar accidentalmente

la unidad. A fin de evitar que se produzcan lesiones graves, el

operador y la unidad deben estar en una posición estable

cuando se jala la cuerda de arranque (Fig. 9).

INSTRUCCIONES DE ARRANQUE

1. Mezcle gasolina con aceite. Consulte las instrucciones para la

mezcla de aceite y combustible.

2. Cargue el depósito de combustible. Consulte Carga de

combustible en la unidad.

NOTA: No es necesario encender la unidad. El interruptor de

encendido/apagado está en la posición ON ( I ) (encendido) en

todo momento (Fig. 7).

3. Presione y luego suelte el bulbo del cebador lentamente

10 veces (Fig. 8). Si no puede ver combustible en el bulbo del

cebador, oprima y suelte el bulbo del cebador hasta que se vea

combustible.

4. Coloque la palanca del estrangulador en la Posición 1 (Fig. 8).

5. Mueva el control de velocidad a la posición FAST (Fig. 7).

NOTA: Mantenga el control de velocidad en la posición FAST

durante TODOS los pasos siguientes.

6. Agacharse en la posición de arranque (Fig. 9).

7. Tire de la cuerda de arranque con un movimiento firme y

controlado 5 veces (Fig. 9).

8. Coloque la palanca del estrangulador en la Posición 2 (Fig. 8).

9. Tire de la cuerda de arranque con un movimiento controlado y

firme entre 3 y 5 veces para que arranque el motor.

10. Deje que el motor se caliente durante 30 a 60 segundos.

11. Pase la palanca del estrangulador a la Posición 3 (Fig. 8) y siga

calentando el motor durante 60 segundos más. Se puede usar

la unidad durante este período.

NOTA: El motor se calentó adecuadamente cuando acelera sin

problemas.

NOTA: Cuando el motor se ha calentado correctamente, el control

de velocidad puede ajustarse y el control del regulador se puede

usar normalmente.

SI... el motor no funciona de manera uniforme, regrese la palanca

del estrangulador a la Posición 2 (Fig. 8) y siga calentándolo.

SI... el motor no arranca, comience el procedimiento de arranque

con el paso 3.

SI... el motor no arranca al cabo de unos pocos intentos, pase la

palanca del cebador a la Posición 3 y mueva el control de

velocidad a la posición FAST. Tire de la cuerda de arranque con

un movimiento controlado y firme entre 3 y 8 veces. El motor

debe arrancar. Si no lo hace, repita esta instrucción.

SI... el motor ya está caliente, comience el procedimiento de

arranque con el paso 8.

INSTRUCCIONES DE DETENCIÓN

1. Suelte el control del regulador, o mueva el control de velocidad a

la posición SLOW, y deje que el motor funcione en ralentí.

2. Oprima y mantenga apretado el interruptor de

encendido/apagado en la posición OFF (O) (apagado) hasta

que el motor se pare por completo (Fig. 7).

Fig. 7

Fig. 9

On ( I ) / Arranque

Off (O) / Parada

Control del

acelerador

Posición de

arranque

Empuñadura cuerda

de arranque

1

2

3

Fig. 8

Bulbo del

cebador

Posición 3Posición 2

Posición 1

Palanca del

estrangulador

Control de

velocidad

SLOW

(LENTA)

FAST (RÁPIDA)

Page 27

27

FUNCIONAMIENTO

CÓMO SOSTENER LA UNIDAD

• Párese en la posición de arranque (Fig. 12).

• Sujete la empuñadura del regulador con la mano derecha.

Mantenga el brazo derecho ligeramente doblado.

• Compruebe que la unidad está cómodamente asegurada sobre

la espalda del operador.

ADVERTENCIA:

Utilice siempre protección ocular,

auditiva, de manos, pies y corporal para reducir el riesgo

de sufrir lesiones durante la operación de esta unidad.

Utilice una máscara facial o para polvos si la máquina

levanta polvo durante su funcionamiento.

Fig. 10

Fig. 11

Fig. 12

Hebillas de soportes

de hombro

CÓMO COLOCARSE Y SACARSE LA UNIDAD

Para colocarse la unidad

1. Póngase los soportes de hombro sobre ambos hombros. El

motor debe quedar bien apoyado contra la espalda del operador.

2. Tire hacia abajo de las correas de los soportes de hombro para

ajustarlas (Fig. 10).

NOTA: Encienda la unidad antes de colocársela. Consulte Arranque

y Parada.

Para sacarse la unidad

1. Tire hacia arriba de las lengüetas de las hebillas de los soportes

de hombro para aflojar los soportes (Fig. 11).

2. Retire la unidad.

CONSEJOS PARA OBTENER LOS MEJORES RESULTADOS

• Conserve agua utilizando la sopladora en lugar de una

manguera para realizar muchas tareas de limpieza en exteriores.

• Opere la unidad sólo en horarios razonables, ni temprano de

mañana ni a la noche tarde cuando se puede molestar a la gente.