Snapper RP2187519BVE (7800173), RP2187519BV (7800172), RP2167519BDV (7800066), RP216019KWV (7800199), P2187519BVE (7800178) Owner’s Manual

...

SafetyInstructions& Operator'sManual for

21" STEELDECK

WALKMOWERS

SERIES19

f

Models

RP2167519BDV(7800066)

RP2187519BV (7800172)

RP2187519BVE (7800173)

RP216019KWV (7800199)

2167519B

P2167519B

P2187519BV

P2187519BVE

P216019KWV

N2167519B

NP2167519B(7800134)

NP2187519BV (7800131)

(7800217)

(7800218)

(7800176)

(7800178)

(7800193)

(7800133)

J

NOTE:Specifications are correct attime of printing and are subjectto changewithout notice.

* Actualsustained engine power will likely helower due to operatinglimitations and environmentalfactors. Please refer to 'Engine Power Rating Information' for

further details.

Manual No. 7101587 (I.R. 9/25/2007)

TPlO0-5289-1R-WB-N

ThankYoufor purchasingthis quality-built Snapperproduct.We're pleasedthat you placedyour

confidenceinthe Snapperbrand.When operatedand maintainedaccordingto the instructions in this

manual,your Snapperproductwill providemanyyearsof dependableservice.

Thismanualcontainssafety information to makeyou awareof the hazardsand risks associatedwith the

machineandhow to avoidthem. This machineis designedand intendedonlyfor finish cutting of

establishedlawns and is not intendedfor any other purpose.It is importantthat you read and understand

theseinstructions thoroughly beforeattemptingto start or operatethis equipment.Savethese

instructions for future reference.

PRODUCT REGISTRATION

IMPORTANT: KEEPTHIS INFORMATION FORYOUR PERSONAL RECORDS

(Complete the following information on your Snapper purchase)

Date of Purchase

Retailer

Retailer'sPhoneNumber

Equipment

Model Number

Serial Number

Engine

Model .Type. Trim

It is veryimportantthatyouregisteryourpurchasewithSnappertoensurewarrantycoverage.Please

mail yourproductregistrationcardto:

Snapper at P.O. Box777, McDonough, Georgia 30253.

Oryou may registeronline at www.snapper.com.

Youcan contactusat ourwebsite,or if youwouldliketospeakwith a CustomerService

Representative,call usat theSnapperCustomerRelationsCenterat 1-800-935-2967. Forfaster

servicepleasehaveyourSerial NumberandModelNumberavailable.

SNAPPERis a trademarkof

SimplicityManufacturing,Inc.

PortWashington,WI, USA.

Briggs& StrattonYardPower Products Group

Copyright© 2007, Briggs& StrattonCorporation

Milwaukee, WI, USA. All RightsReserved.

Tableof Contents

Operator Safety ................................................ 2

Important OperatorSafety Instructions .................................. 2

Featuresand Controls ........................................... 4

CD

Operation .................................................... 5

Pre-Start Checklist .................................................. 5

Starting & Stopping Engine& Blades .................................... 5

Propelling Mower ................................................... 6

HandleHeightAdjustment ............................................ 6

Cutting HeightAdjustment ............................................ 7

Recycling Operation ................................................. 7

Removingthe RecyclingCover ......................................... 7

Installing the DischargeDeflector ....................................... 8

Installing the GrassBagAdapter ........................................ 8

Installing the GrassBag .............................................. 9

Maintenance ................................................. 10

ChangeEngine Oil .................................................. 10

CheckTransmission Grease .......................................... 10

CheckMower Blade ................................................ 11

CheckEngineDrive Belt ............................................. 11

CheckTransmission Belt ............................................. 11

Service - Periodic .................................................. 11

Engine ........................................................... 11

Air Filter ......................................................... 11

Engine Oil ........................................................ 11

Storage Procedure ................................................. 11

Mower BladeReplacement ........................................... 12

BladeSharpening .................................................. 12

Wheel DriveControl Adjustment ....................................... 13

Driven and DriveDisc Service ......................................... 14

Belt Service ....................................................... 17

Engine Drive Belt Replacement ........................................ 17

Transmission Belt Replacement ....................................... 18

Battery Service .................................................... 19

Service Schedule................................................... 20

"11

CD

CD

t_

,-1

t_

CD

mo

,-1

CD

,-1

,-1

CD

Troubleshooting............................................... 21

Warranty .................................................... 22

WARNING

Batteryposts,terminals and relatedaccessoriescontain

lead and lead compounds, chemicalsknownto the State of

Californiato cause cancer and birth defects or other

reproductiveharm. Wash handsafter handling.

WARNING

Engineexhaust, some of its constituents, and certain

vehicle components containor emit chemicals known to

the State of Californiato causecancer or other reproductive

harm.

,..z.

--z

CD

t_

,A

x,.,

ImportantOperatorSafetyInstructions

WARNING:This powerful cutting machineis capableof amputating handsandfeet andcanthrow objects

that can cause injury and damage! Failureto comply with the following SAFETYinstructions could result in

serious injury or deathto the operator or other persons. The owner of the machine must understandthese

instructions and must allow only personswho understandthese instructions to operate machine. Each

personoperating the machine must beof sound mind and body and must not be under the influence of any

substance,which might impair vision, dexterity or judgment. If you haveany questions pertaining to your

machinewhich your dealer cannot answer to your satisfaction, call or write the CustomerService

Departmentat SNAPPER,IVIcDonough,Georgia30253. Phone: (1-800-935-2967).

Protection for Children

Tragic accidents canoccur if the operator is not alert to the

presenceof children. Children areoftenattractedto the

machine andthe mowing activity. Neverassumethat

children will remain where you last saw them.

1. KEEPchildren out of the mowing area andunder the

watchful careof aresponsibleadult other than the operator.

2. DO NOTallow children inyard when machine is operated

andturn machineOFFif anyoneentersthe area.

3. DO NOTallow pre-teenagechildren to operate machine.

4. ALLOW only responsible adults & teenagerswith mature

judgment under close adult supervision to operate machine.

5. DO NOTpull mower backwardsunlessabsolutely

necessary.LOOKand SEEbehindanddown for children,

pets and hazards beforeandwhile backing.

6. USEEXTRACAREwhen approaching blind corners,

shrubs, trees, or other objects that may obscure vision.

SlopeOperation

1. Slopes are a major factor relatedto slip and fall acci-

dents,which can result in severeinjury.All slopes require

extra caution. If you feel uneasyon a slope, DONOTmow

it.

2. Mow across slopes, neverup-and-down. Exercise

extremeCAUTIONwhen changing directions on slopes. DO

NOTmow steep slopes or other areaswhere stability or

traction is in doubt. Referto the Slope Guideat the end of

this manual.

3. Useextra care with grass catchersor other attachments;

these affect the handling and the stability of themachine.

Preparation

1. Read,understand, and follow instructions and warnings

in this manualandon the mower, engine and attachments.

Knowthe controls and the proper useof the mower before

starting.

2. Only mature, responsible persons shall operatethe

machine and only after proper instruction.

3. Data indicates that operatorsage60 andabove,are

involved in alargepercentageof mower-related injuries.

Theseoperators should evaluatetheir ability to operatethe

mower safely enough to protect themselves and others

from serious injury.

Preparation

(ContinuedFromPrevious Column)

4. Handlefuel with extra care. Fuelsareflammable and

vapors areexplosive.Useonly an approvedfuel container.

DONOTremovefuel capor addfuel with engine running.

Add fuel outdoors only with engine stopped and cool. Clean

spilled fuel andoil from machine. DONOTsmoke.

5. Checkthe areato be mowed and removeall objects such

as toys, wire, rocks, limbs andother objects that could

cause injury if thrown by bladeor interfere with mowing.

Also notethe location of holes, stumps, and other possible

hazards.

6. Keeppeople and pets out of the mowing area.

Immediately,STOPBlade,Stop engineand Stop mower if

anyone entersthe area.

7. Checkshields, deflectors, switches, bladecontrols and

other safety devicesfrequently for proper operation and

location.

8. Make sureall safetydecalsareclearlylegible. Replaceif

damaged.

9. Protectyourself when mowing and wear safetyglasses, a

dust mask, long pants, and substantial footwear. DONOT

mow barefootedorwith sandals.

10. Know how to STOPbladeand engine quickly in

preparationfor emergencies.

11. Use extra care when loading or unloading the machine

into a trailer or truck.

12. Checkgrass catchercomponents frequently for signs of

wear or deterioration and replaceas neededto prevent

injury from thrown objects going through weak or torn

spots.

Safe Handling of Gasoline

Toavoid personal injury or property damage,useextreme

care in handling gasoline. Gasolineis extremely flammable

and the vapors are explosive.

1. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

2. Use only anapprovedfuel container.

3. DONOTremovefuel cap or addfuel with the engine

running. Allow the engineto cool before refueling.

4. DONOTrefuelthe machineindoors.

5. DONOTstore the machine or fuel container inside where

there is an open flame, spark or pilot light such as on a

water heateror other appliances.

2 www.snapper.com

ImportantOperatorSafetyInstructions(Continued)

Safe Handling of Gasoline

(ContinuedFromPrevious Page)

6. DO NOTfill fuel containers inside avehicleor on atruck

or trailer bed with a plastic liner. Always placethe contain-

erson the ground awayfrom the vehicle beforefilling.

7. Remove gas-poweredequipment from the vehicle or

trailer and refuelit onthe ground. If this is not possible,

then refuelequipment using a portablecontainer, rather

than a gasolinedispensernozzle.

8. DO NOTstart gas poweredequipment in enclosedvehi-

cles or trailers.

9. Keepthe nozzlein contact with the rim of the fuel tank or

container opening at all times until fueling is complete. DO

NOTuseanozzlelock-opendevice

10. If fuel is spilled on clothing, change clothing

immediately.

11. DO NOToverfill a fuel tank. Replacefuel cap andtighten

securely.

Operation

1. DO NOTput hands or feetnearor under rotating parts.

Keepclearof discharge areawhile engine is running.

2. STOPenginewhen crossing gravel drives, walks,or

roads, and under anyconditions where thrown objects

might bea hazard.

3. Mow only in daylight or good artificial light.

4. DONOToperatemower while underthe influence of

alcohol or drugs.

5.After striking a foreign object or if mower vibrates

abnormally,STOPthe engine, disconnect andsecurespark

plug wire. Inspect the mower for any damageand repair the

damagebeforestarting.

6. DO NOTmow near drop offs, ditches or embankments.

Operatorcould lose footing or balance.

7. STAYALERTfor holes andother hiddenhazards.Tall

grass can hide obstacles. Keepawayfrom ditches,

washouts, culverts, fencesand protruding objects.

8. DO NOTmow on wet grass. Always besure of your

footing. Keepafirm hold on the handleand walk, neverrun.

Slipping could cause injury.

9.ALWAYSstay behind handlewhen engine (motor) is

running.

10. DO NOTleavethe machinewith the enginerunning.

STOPBLADEand STOPENGINEbeforeleavingthe opera-

tors position for any reason.

11. Before cleaning, repairing or inspecting make certain

engine,bladeandall moving parts haveSTOPPED.

Disconnectandsecurespark plug wire awayfrom plug to

prevent accidentalstarting.

12. STOPengineand wait until the bladecomes to com-

pleteSTOPbefore removing grass bag and/or clearing

grass.

Operation

(ContinuedFromPrevious Column)

13. DO NOToperatemower without the entire grasscatch-

er, or guards in place discharge guard, rearguard or other

safety devicesin placeandworking. DONOTpoint dis-

charge at people,passing cars, windows or doors.

14. DO NOTdischarge material against a wall or obstruc-

tion. Material may ricochet back towards the operator.

15. Slow down beforeturning.

16. Watch out for traffic when nearor crossing roadways.

17. DO NOToperateenginein enclosedareas. Engine

exhaust gasescontain carbon monoxide, a deadly poison.

18. Only use accessories approvedby the manufacturer.

See manufacturer'sinstructions for proper operation and

installation of accessories.

MaintenanceandStorage

1. DO NOTstore mower or fuel container inside where

fumes may reachan openflame, spark or pilot light such as

in awater heater,furnace, clothes dryer or other gasappli-

ance. Allow engine to cool before storing machine in an

enclosure. Store fuel container out of reach of children in a

well ventilated, unoccupied building.

2. Keepmower and engine free of grass, leavesor excess

greaseto reducefire hazardand engine overheating.

3. Whendraining fuel tank, drain fuel into anapproved

container outdoors andawayfrom open flame.

4. Keepall bolts, especiallybladebolts, nuts and screws

properlytight. Checkthat all cotter pins arein proper

position.

5. Alwaysprovide adequateventilation when running

engine. Engineexhaust gasescontain carbon monoxide, a

deadly poison.

6. Serviceengine and makeadjustments only when engine

is stopped. Removedspark plug wire from spark plugand

secure wire awayfrom spark plug to prevent accidental

starting.

7. DONOTchangeenginegovernor speedsettings or

overspeed engine.

8. Checkgrass bagassemblyfrequently for wear or

deterioration to avoidthrown objects and exposure to

moving parts. Replacewith new bagif loose seamsor tears

are evident. Replaceslider or bag adapterif brokenor

cracked.

9. Mower bladesaresharp and can cut. Wrap the bladesor

wear heavy leather gloves and useCAUTIONwhen handling

them.

10. DO NOTtest for spark by grounding spark plug next to

spark plug hole; spark plug could ignite gas exitingengine.

11. Havemachineserviced by an authorized SNAPPER

dealer at least once ayear and havethe dealerinstall any

newsafetydevices.

12. Use only genuineSNAPPERreplacement parts to

assure that original standards are maintained.

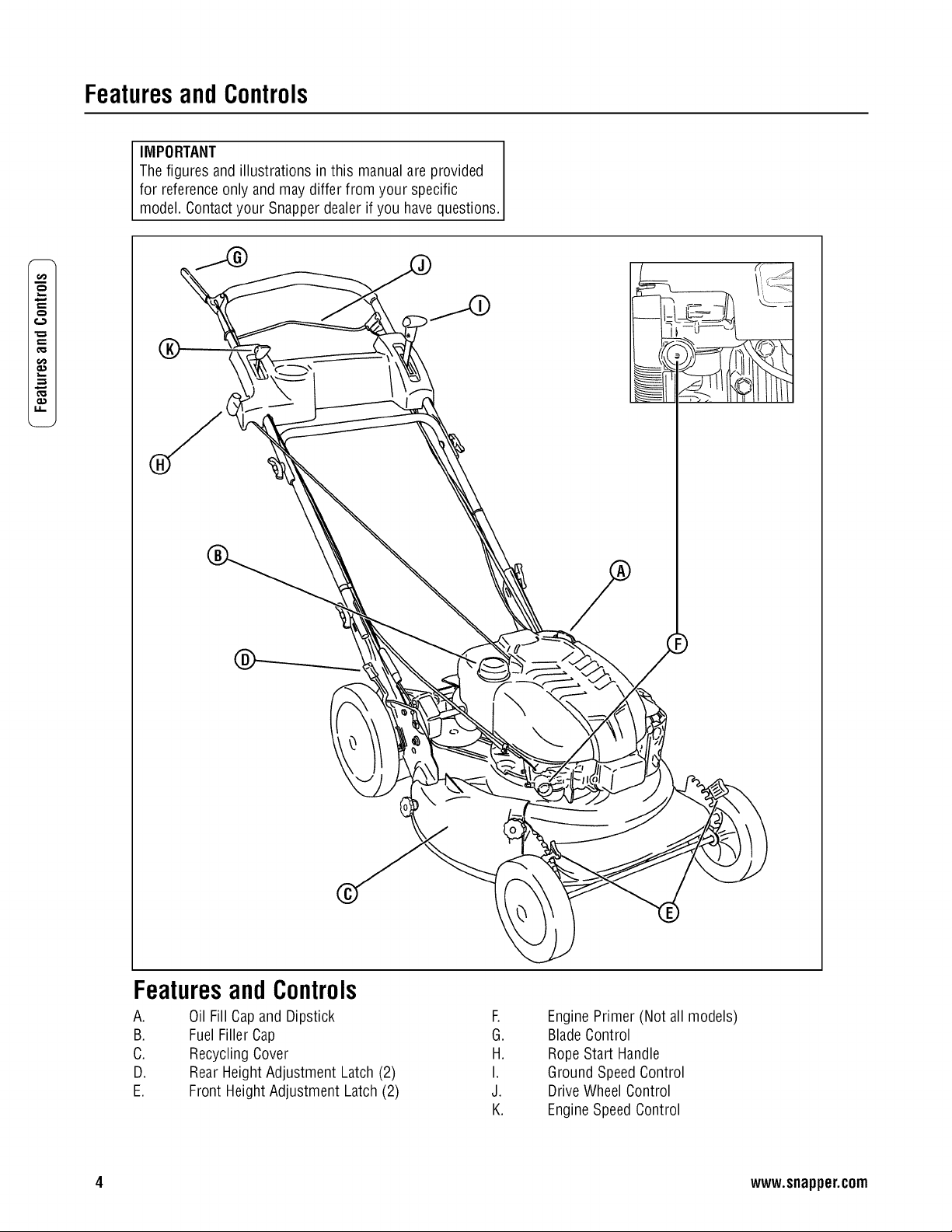

FeaturesandControls

IMPORTANT

The figures and illustrations in this manualare provided

for referenceonly and maydiffer from your specific

model. Contactyour Snapperdealer if you havequestions.

x,...

0.1

ii

FeaturesandControls

A. Oil Fill Capand Dipstick

B. FuelFillerCap

C. RecyclingCover

D. RearHeight Adjustment Latch (2)

E. Front Height Adjustment Latch (2)

4 www.snapper.com

F.

G.

H.

I.

J.

K.

Engine Primer (Not all models)

BladeControl

RopeStart Handle

Ground SpeedControl

Drive WheelControl

EngineSpeedControl

Operation

Pre-StartCheckList

Make the following checks and perform the service required

before each start-up.

1. Checkthe guards, deflectors, grass bag,adapter,and

covers to makesure all are in placeandsecurely

tightened.

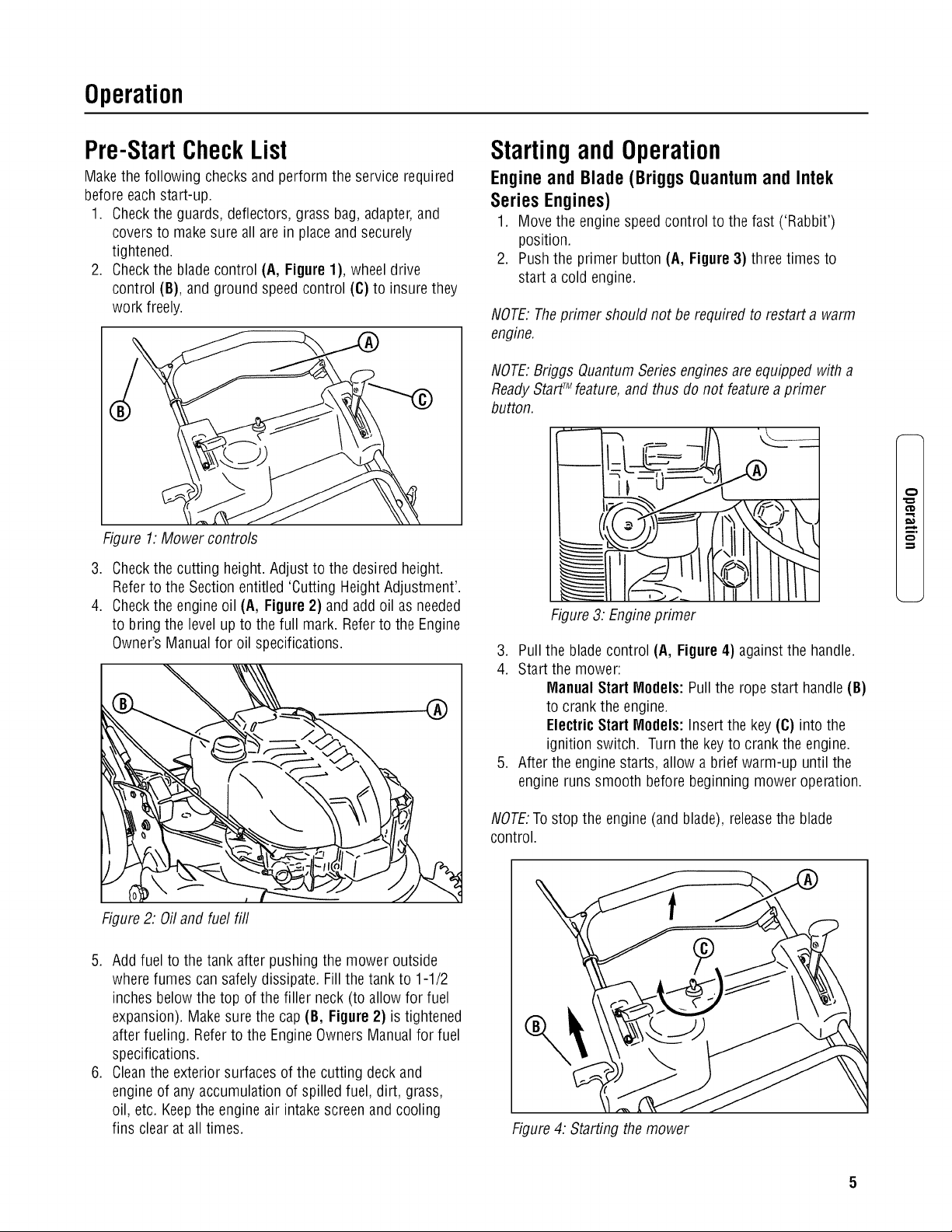

2. Checkthe blade control (A, Figure 1), wheel drive

control (B), and ground speedcontrol (C) to insurethey

work freely.

Figure 1. Mower controls

3. Checkthe cutting height. Adjust to the desired height.

Refer to the Section entitled'Cutting HeightAdjustment'.

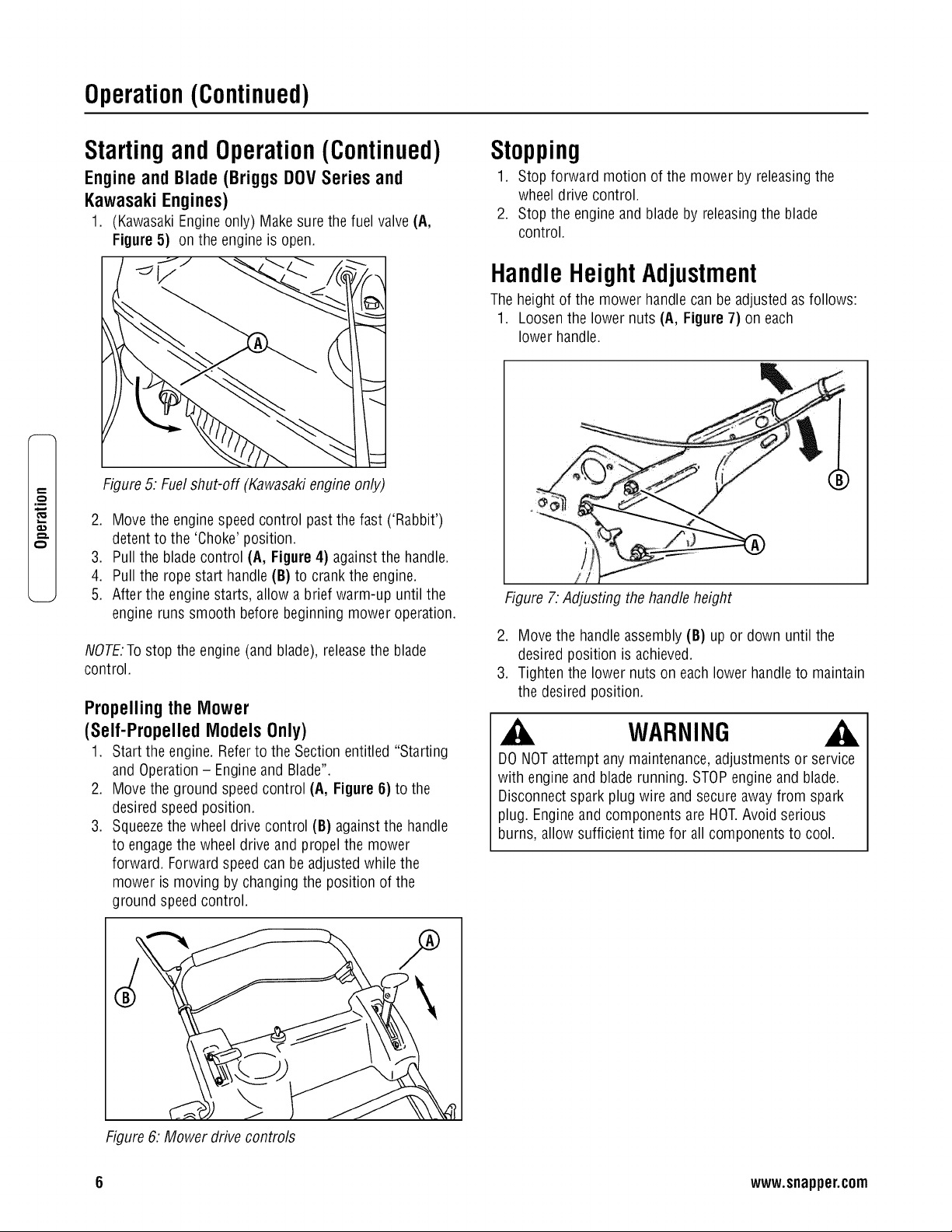

4. Checkthe engineoil (A, Figure 2) and add oil as needed

to bring the level upto the full mark. Referto the Engine

Owner's Manualfor oil specifications.

StartingandOperation

Engine and Blade (Briggs Quantum and Intek

SeriesEngines)

1. Move the enginespeedcontrol to the fast ('Rabbit')

position.

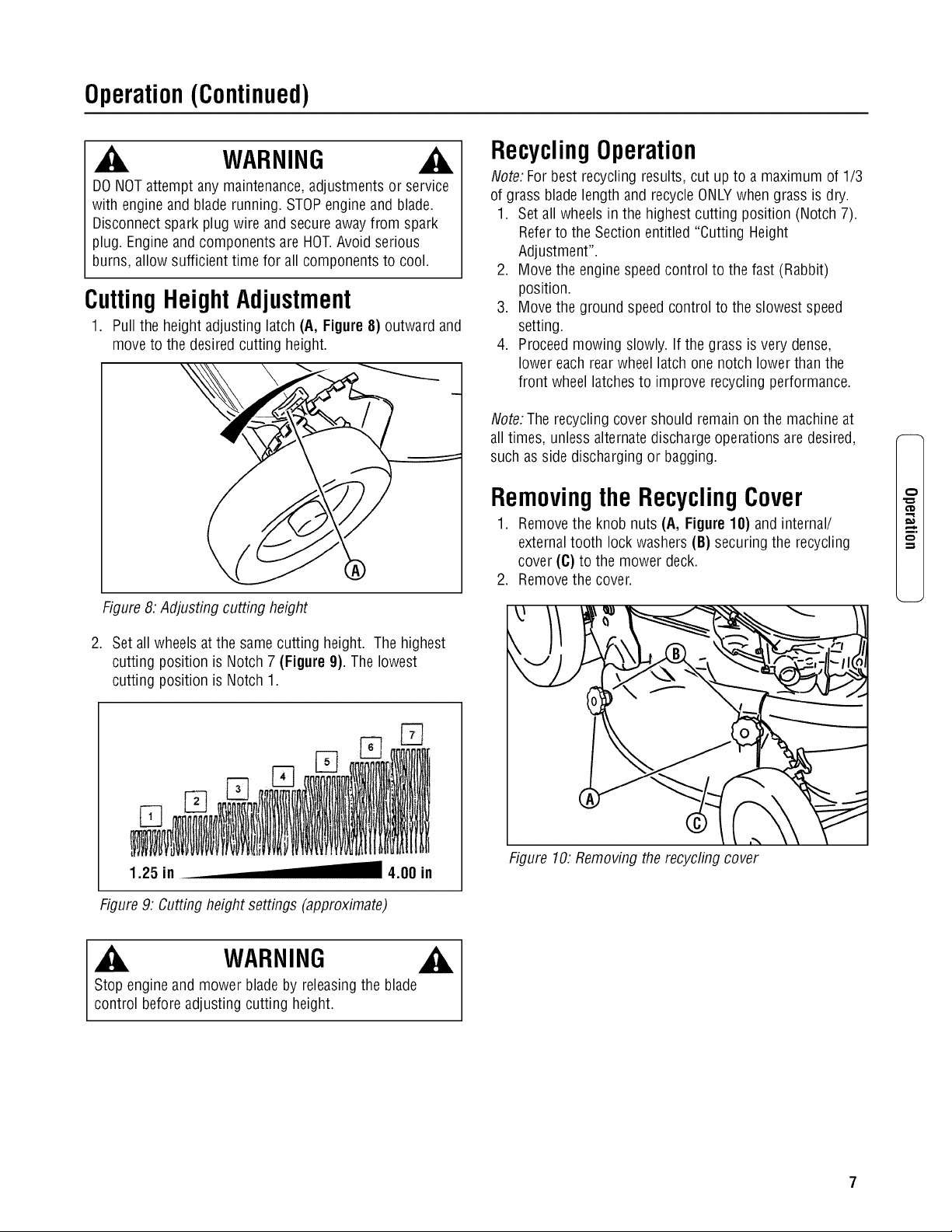

2. Pushthe primer button (A, Figure 3) three times to

start a cold engine.

NOTE:Theprimer should not berequired torestart a warm

engine.

NOTE:Briggs QuantumSeriesenginesare equipped with a

ReadyStartTMfeaturd and thus donot featurea primer

button.

¢D

m,

Figure3: Engineprimer

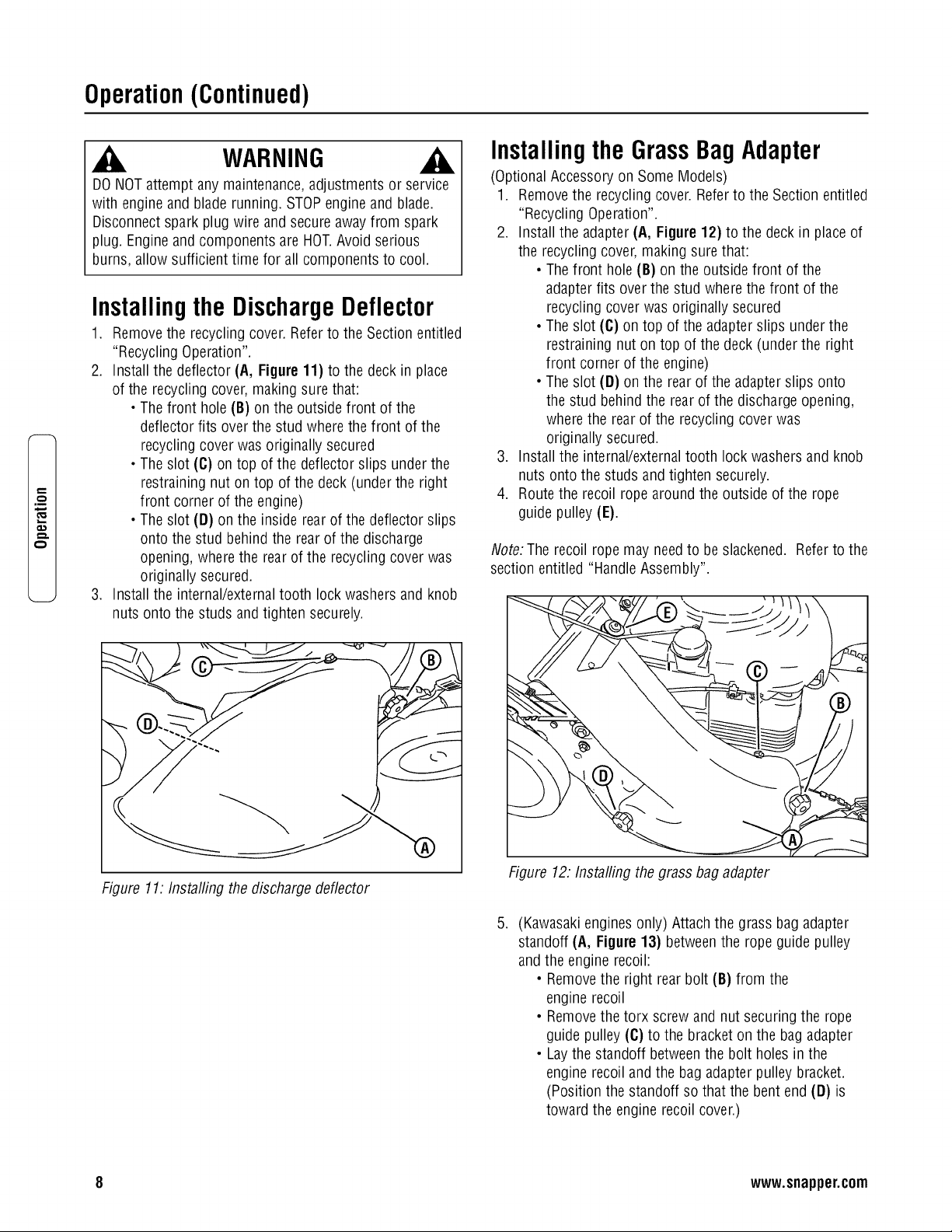

3. Pull the blade control (A, Figure 4) against the handle.

4. Start the mower:

Manual Start Models: Pullthe ropestart handle (B)

to crank the engine.

ElectricStart Models: Insertthe key(C) intothe

ignitionswitch, Turn the keyto crank the engine,

5. After the enginestarts, allow a brief warm-up until the

engine runs smooth before beginning mower operation.

Figure2: Oiland fuel fill

5. Add fuel to the tank after pushing the mower outside

wherefumes cansafely dissipate.Fill thetank to 1-1/2

inches belowthe top of the filler neck (to allowfor fuel

expansion). Makesure the cap (B, Figure2) is tightened

after fueling. Referto the EngineOwners Manualfor fuel

specifications.

6. Cleanthe exterior surfaces of the cutting deck and

engine of any accumulation of spilled fuel, dirt, grass,

oil, etc. Keepthe engineair intakescreenandcooling

fins clear at alltimes.

NOTE:Tostop the engine (and blade), releasethe blade

control.

Figure4: Starting the mower

Operation(Continued)

StartingandOperation(Continued)

Engine and Blade (Briggs DOV Series and

Kawasaki Engines)

1. (Kawasaki Engineonly) Make sure the fuel valve(A,

Figure5) on the engine is open.

Stopping

1. Stop forward motion of the mower by releasingthe

wheel drive control.

2. Stop the engineandbladeby releasingthe blade

control.

HandleHeightAdjustment

Theheight of the mower handle can beadjustedasfollows:

1. Loosen the lower nuts (A, Figure 7) on each

lower handle.

t::

€:)

,m

o.1

Figure5: Fuelshut-off (Kawasakiengineonly)

2. Move the enginespeedcontrol past the fast ('Rabbit')

detent to the 'Choke'position.

3. Pull the blade control (A, Figure 4) againstthe handle.

4. Pull the rope start handle(B) to crank the engine.

5. After the engine starts, allow a brief warm-up until the

engine runs smooth before beginning mower operation.

NOTE.Tostop the engine (and blade), releasethe blade

control.

Propelling the Mower

(Self-PropelledModels Only)

1. Start the engine. Referto the Section entitled "Starting

and Operation- Engineand Blade".

2. Move the ground speedcontrol (A, Figure 6) to the

desired speed position.

3. Squeezethe wheel drive control (B) againstthe handle

to engagethe wheeldrive and propel the mower

forward. Forward speedcan be adjusted while the

mower is moving by changingthe position of the

ground speedcontrol.

Figure 7: Adjusting the handleheight

2. Move the handleassembly (B) up or down until the

desired position is achieved.

3. Tighten the lower nuts on eachlower handleto maintain

the desired position.

WARNING

DONOTattempt anymaintenance,adjustmentsor service

with engineand bladerunning. STOPengine and blade.

Disconnectspark plug wire and secureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

Figure6: Mower drive controls

6 www.snapper.com

Operation(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engineand bladerunning. STOPengine and blade.

Disconnectsparkplug wire andsecureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

CuttingHeightAdjustment

1. Pull the height adjusting latch (A, Figure8) outward and

move to the desired cutting height.

RecyclingOperation

Note: For best recycling results, cut upto a maximum of 1/3

of grass blade length and recycle ONLYwhen grass is dry.

1. Set all wheelsin the highest cutting position (Notch 7).

Referto the Section entitled "Cutting Height

Adjustment".

2. Move the engine speed control to the fast (Rabbit)

position.

3. Move the ground speed control to the slowest speed

setting.

4. Proceedmowing slowly. If the grass is very dense,

lower each rearwheel latch one notch lower than the

front wheel latchesto improve recycling performance.

Note:The recycling cover should remain on the machineat

all times, unless alternatedischarge operations are desired,

such asside discharging or bagging.

Removingthe RecyclingCover

1. Removethe knob nuts (A, Figure 10) andinternal/

externaltooth lock washers(B) securing the recycling

cover (C) to the mower deck.

2. Removethe cover.

m.

Figure8:Adjusting cutting height

2. Set allwheelsatthe same cutting height. The highest

cutting position is Notch 7 (Figure 9). The lowest

cutting position is Notch 1.

1.25 in 4.00 in

Figure9: Cuttingheight settings (approximate)

WARNING

Stop engineand mower bladeby releasing the blade

control before adjusting cutting height.

Figure 10. Removingthe recycling cover

Operation(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engineand bladerunning. STOPengine and blade.

Disconnectsparkplug wire andsecureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

Installingthe DischargeDeflector

1. Remove the recycling cover. Referto the Section entitled

"Recycling Operation".

2. Install the deflector (A, Figure11)to the deck in place

of the recycling cover, making sure that:

• Thefront hole (B) on the outside front of the

deflector fits over the stud wherethe front of the

recycling cover was originally secured

• Theslot (C) on top of the deflector slips underthe

t_

,m

3. Install the internal/externaltooth lock washersand knob

restraining nut on top of the deck (underthe right

front corner of the engine)

• Theslot (D) on the inside rearof the deflector slips

onto the stud behindthe rear of the discharge

opening, where the rear of the recycling cover was

originally secured.

nuts onto the studs andtighten securely.

Installingthe GrassBagAdapter

(Optional Accessory on Some Models)

1. Removethe recycling cover. Referto the Sectionentitled

"Recycling Operation".

2. Install the adapter(A, Figure 12) to the deckin place of

the recycling cover, making surethat:

• Thefront hole (B) on the outside front of the

adapterfits over the stud where thefront of the

recycling cover was originally secured

• Theslot (C) on top of the adapterslips under the

restraining nut on top of the deck(under the right

front corner of the engine)

• Theslot (D) on the rear of the adapterslips onto

the stud behind the rear of the discharge opening,

wherethe rearof the recycling coverwas

originally secured.

3. Install the internal/externaltooth lock washersand knob

nuts onto the studs andtighten securely.

4. Route the recoil rope around the outside of the rope

guide pulley (E).

Note:The recoil rope may needto be slackened. Referto the

section entitled "HandleAssembly".

Figure 12. Installing the grassbagadapter

Figure 11: Installing the discharge deflector

.

(Kawasakienginesonly) Attach the grass bag adapter

standoff (A, Figure13) betweenthe rope guide pulley

and the engine recoil:

• Removethe right rearbolt (B) from the

engine recoil

• Removethe torx screwand nut securing the rope

guide pulley (C)to the bracket onthe bagadapter

• Laythe standoff betweenthe bolt holes in the

engine recoil and the bag adapterpulley bracket.

(Position the standoff so that the bent end(D) is

toward the engine recoil cover.)

8 www.snapper.com

Operation(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engineand bladerunning. STOPengine and blade.

Disconnectsparkplug wire andsecureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

InstallingtheGrassBagAdapter

(Continued)

• Flipthe pulley over sothat the bushing flange is

under the pulley. The bushing will act as awasher

betweenthe pulley andthe standoff.

• Reassemblethe pulleyto the bag adapter,and

install the supplied replacementbolt, fitted with the

thread sleeve, into the recoil cover. Tightenall

hardwaresecurely.

Figure 14.Installing the recycfing plug

Installingthe GrassBag

(Door Type Bag)

1. Install the grass bag adapter.Refer to the Section

entitled "Installing the Grass BagAdapter".

2. Install the grass bag by sliding the connector(A, Figure

15) over the adapterflange.

3. Attachthe grassbag hooks(B) over the middle handle

cross bar.

m.

Figure 13: Installing theadapterstandoff

(Kawasakiengines only)

WARNING

DONOToperatewithout entire GrassCatcheror guard in

place. GrassCatchercomponentsaresubject to

deterioration during normal use. Inspect frequently and

replaceworn or damagedcomponents immediately.

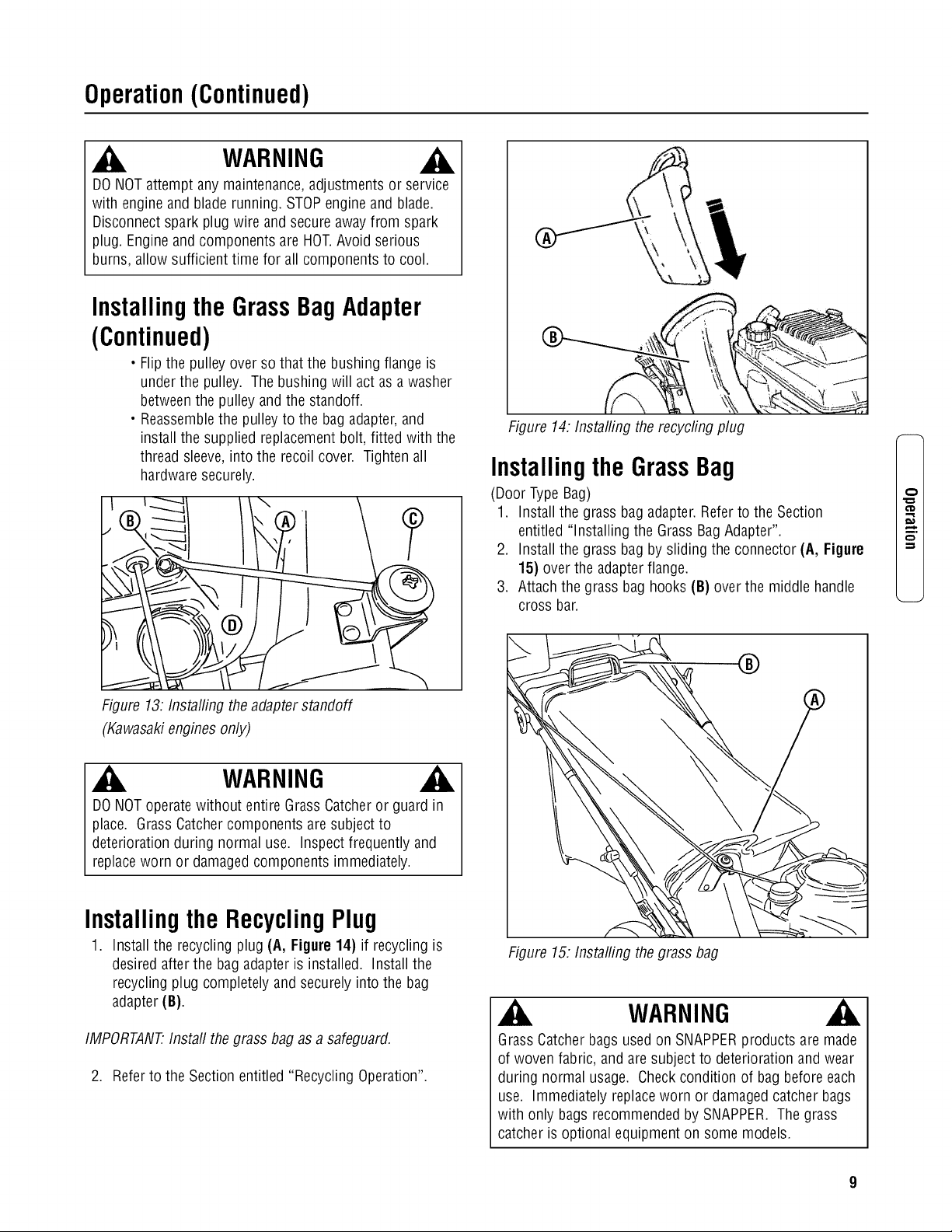

InstallingtheRecyclingPlug

1. Install the recycling plug (A, Figure 14) if recycling is

desired after the bagadapter is installed. Install the

recycling plug completely and securely into the bag

adapter(B).

IMPORTANT.Install the grass bagas a safeguard.

2. Referto the Section entitled "Recycling Operation".

®

Figure 15.Installing thegrass bag

WARNING

GrassCatcherbags usedon SNAPPERproducts are made

of woven fabric, andaresubject to deterioration andwear

during normal usage. Check condition of bag before each

use. Immediately replace worn or damagedcatcherbags

with only bags recommended by SNAPPER. The grass

catcher is optional equipment on somemodels.

Maintenance

p,,

q-.

.m

_E

Maintenance-Introduction

Toretain the quality of the mower,use genuineSNAPPER

replacementparts only. Contact a local SNAPPERdealer for

parts andservice assistance.For the correct part or

information for a particular mower, alwaysmentionthe

model and serial number.

WARNING

DONOTattempt any maintenance,adjustments or service

with engineand bladerunning. STOPengine and blade.

Disconnectsparkplug wire andsecureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

Wearheavyleathergloves when handling or working

around cutting blades.Bladesare extremely sharp andcan

causesevere injury.

Service- AfterFirst5 Hours

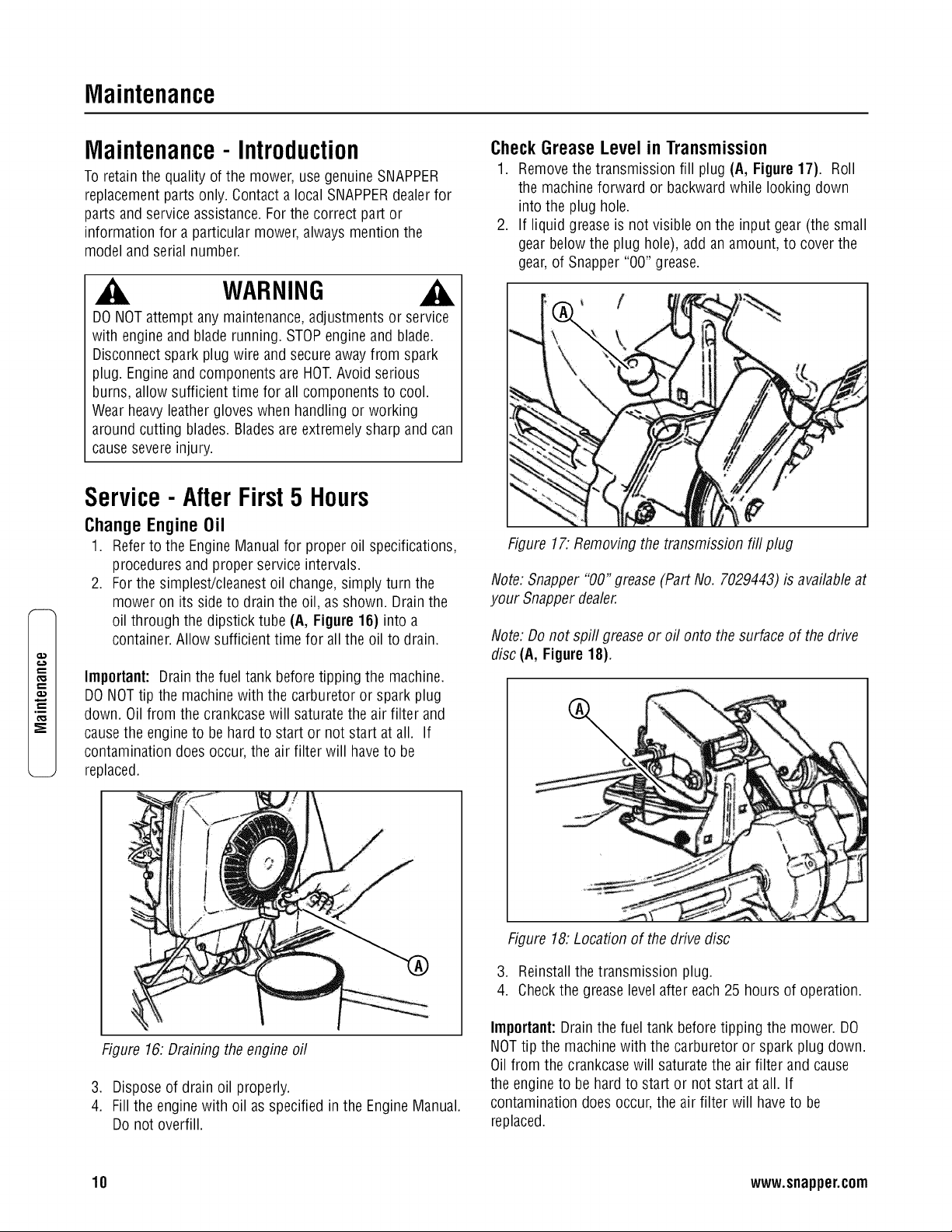

Change Engine Oil

1. Refer to the EngineManualfor proper oil specifications,

procedures and properservice intervals.

2. For the simplest/cleanest oil change,simply turn the

mower on its side to drain the oil, as shown. Drainthe

oil through the dipstick tube (A, Figure 16) into a

container.Allow sufficient time for all the oil to drain.

Important: Drainthe fuel tank before tipping the machine.

DONOTtip the machinewith the carburetor or spark plug

down. Oilfrom the crankcasewill saturatethe air filter and

causethe engineto behardto start or not start at all. If

contamination doesoccur, the air filter will haveto be

replaced.

CheckGreaseLevelinTransmission

1. Removethe transmission fill plug (A, Figure 17). Roll

the machine forward or backwardwhile looking down

into the plug hole.

2. If liquid greaseis not visible on the input gear (the small

gear belowthe plug hole), add an amount, to cover the

gear,of Snapper "00" grease.

Figure 17. Removingthe transmission fill plug

Note: Snapper "00" grease(Part No. 7029443)is availableat

your Snapper dealer.

Note: Do not spill grease or oil onto the surface of the drive

disc (A, Figure18).

%

Figure 18: Locationof the drive disc

3. Reinstallthe transmission plug.

4. Checkthe greaselevelafter each 25 hours of operation.

Important:Drain the fuel tank before tipping the mower. DO

Figure 16: Draining theengine oil

3. Dispose of drain oil properly.

4. Fillthe enginewith oil as specified inthe EngineManual.

Do not overfill.

10 www.snapper.com

NOTtip the machinewith the carburetor or spark plugdown.

Oil from the crankcasewill saturate the air filter and cause

the engine to be hard to start or not start at all. If

contamination does occur,the air filter will haveto be

replaced.

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engineand bladerunning. STOPengine and blade.

Disconnectsparkplug wire andsecureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

Wearheavyleathergloves when handling or working

around cutting blades.Bladesare extremely sharp andcan

causesevere injury.

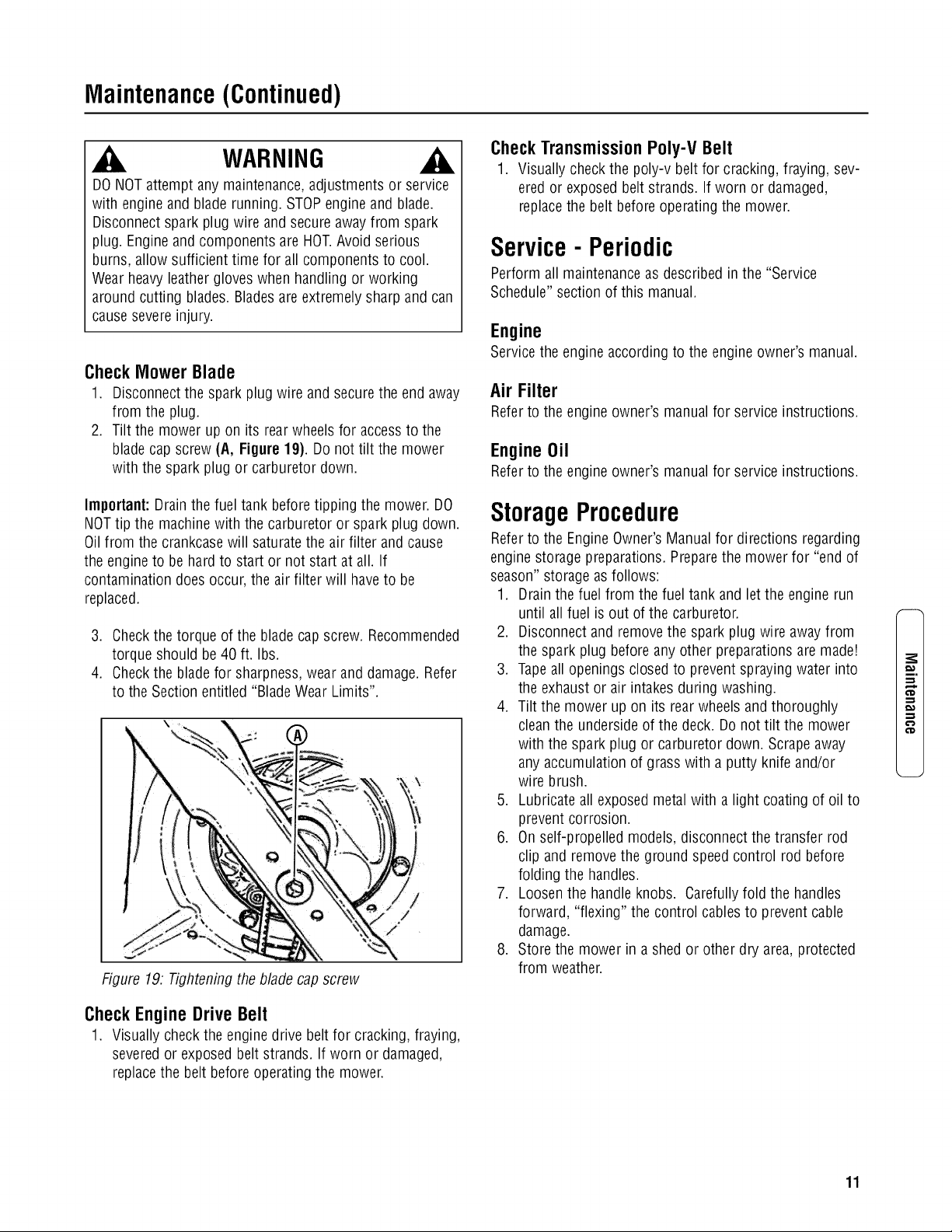

Check Mower Blade

1. Disconnect the spark plug wire and securethe end away

from the plug.

2. Tilt the mower up on its rearwheels for accessto the

blade cap screw (A, Figure19). Do not tilt the mower

with the spark plug or carburetor down.

Important:Drain the fuel tank before tipping the mower.DO

NOTtip the machinewith the carburetor or spark plug down.

Oil from the crankcasewill saturatethe air filter and cause

the engineto be hardto start or not start at all. If

contamination doesoccur, the air filter will haveto be

replaced.

3. Checkthe torque of the bladecapscrew. Recommended

torque should be 40 ft. Ibs.

4. Checkthe bladefor sharpness, wear anddamage.Refer

to the Section entitled "BladeWear Limits".

Figure 19. Tighteningthe blade capscrew

Check Transmission Poly-V Belt

1. Visually check the poly-v belt for cracking, fraying, sev-

ered or exposedbelt strands. If worn or damaged,

replacethe belt before operatingthe mower.

Service- Periodic

Perform all maintenanceas described in the "Service

Schedule" section of this manual.

Engine

Service the engine according to the engineowner's manual.

Air Filter

Referto the engine owner's manualfor service instructions.

EngineOil

Referto the engine owner's manualfor service instructions.

StorageProcedure

Referto the EngineOwner'sManual for directions regarding

engine storage preparations. Preparethe mower for "end of

season"storage asfollows:

1. Drain the fuel from the fuel tank and letthe engine run

until all fuel is out of the carburetor.

2. Disconnect and remove the sparkplug wire awayfrom

the spark plug beforeany other preparations are made!

3. Tapeall openingsclosedto preventspraying water into

the exhaust or air intakes during washing.

4. Tilt the mower up on its rearwheelsandthoroughly

cleanthe undersideof the deck. Do not tilt the mower

with the spark plug or carburetor down. Scrapeaway

any accumulation of grass with a putty knifeand/or

wire brush.

5. Lubricate all exposedmetalwith a light coating of oil to

prevent corrosion.

6. On self-propelled models, disconnect the transfer rod

clip and remove the ground speed control rod before

folding the handles.

7. Loosenthe handleknobs. Carefullyfold the handles

forward, "flexing" the control cablesto prevent cable

damage.

8. Store the mower in a shed or other dry area,protected

from weather.

m.

€'D

Check Engine Drive Belt

1. Visually check the enginedrive belt for cracking, fraying,

severedor exposed belt strands. If worn or damaged,

replacethe belt before operating the mower.

11

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engineand bladerunning. STOPengine and blade.

Disconnectsparkplug wire andsecureawayfrom spark

plug. Engineand components are HOT.Avoid serious

burns, allow sufficient time for all components to cool.

Wearheavyleathergloves when handling or working

around cutting blades.Bladesare extremely sharp andcan

causesevere injury.

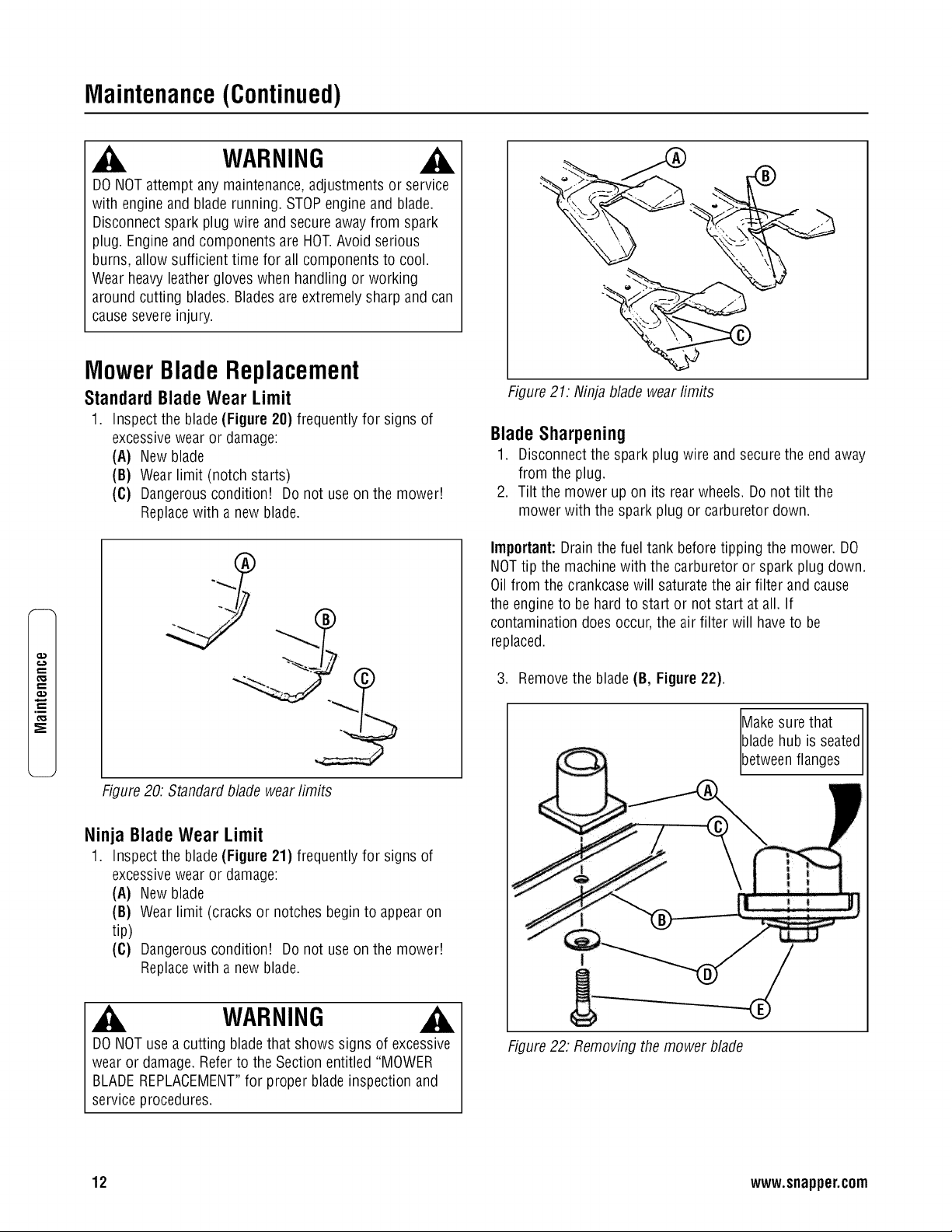

MowerBladeReplacement

Standard Blade Wear Limit

1. Inspect the blade(Figure20) frequently for signs of

excessivewear or damage:

(A) New blade

(B) Wear limit (notch starts)

(C) Dangerous condition! Do not useonthe mower!

Replacewith a newblade.

Figure21: Ninjablade wearfimits

BladeSharpening

1. Disconnect the spark plug wire and secure the endaway

from the plug.

2. Tilt the mower up on its rearwheels. Donot tilt the

mower with the spark plug or carburetor down.

Important:Drain the fueltank before tipping the mower.DO

NOTtip the machinewith the carburetor or spark plugdown.

Oil from the crankcasewill saturate the air filter and cause

the engineto be hard to start or not start at all. If

contamination does occur,the air filter will haveto be

replaced.

,m

_E

Figure20: Standardblade wear limits

Ninja Blade Wear Limit

1. Inspect the blade(Figure21) frequently for signs of

excessivewear or damage:

(A) New blade

(B) Wear limit (cracks or notches begin to appearon

tip)

(C) Dangerous condition! Do not useonthe mower!

Replacewith a newblade.

WARNING

DONOTuse a cutting bladethat shows signs of excessive

wear or damage.Refer to the Section entitled "MOWER

BLADEREPLACEMENT"for proper blade inspection and

service procedures.

3. Removethe blade (B, Figure22).

Makesure that

bladehub is seatedI

[betweenfanges J

i

Figure22: Removingthe mower blade

12 www.snapper.com

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engine and blade running. STOPengineand blade.

Disconnectspark plug wire and secure awayfrom spark

plug. Engineandcomponents are HOT.Avoid serious

burns, allow sufficient time for all componentsto cool.

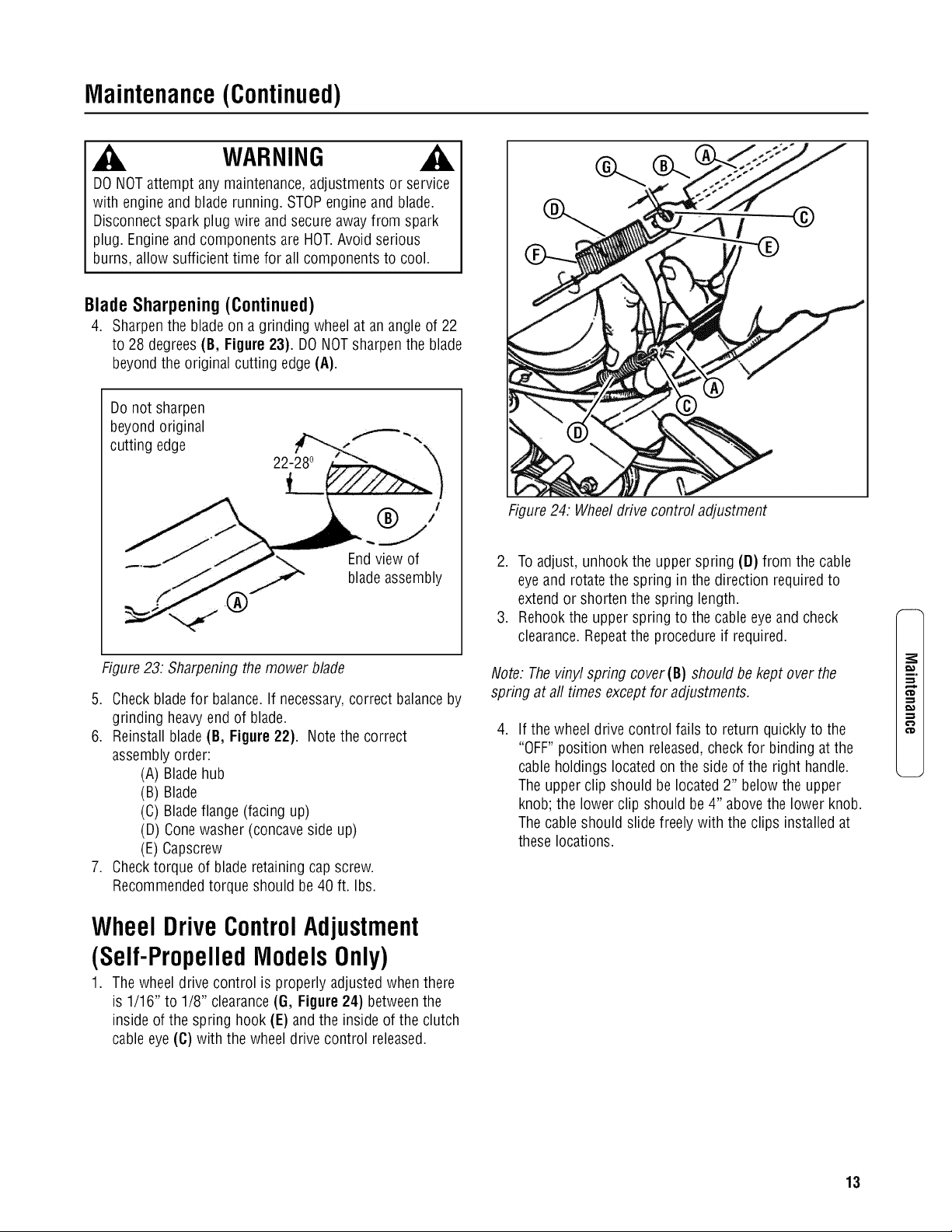

BladeSharpening(Continued)

4. Sharpenthe bladeon a grinding wheel at an angle of 22

to 28 degrees(B, Figure 23). DONOTsharpen the blade

beyondthe original cutting edge(A).

Do not sharpen

beyondoriginal

cutting edge

Figure24: Wheeldrive control adjustment

Endview of

bladeassembly

Figure23: Sharpeningthemower blade

5. Check bladefor balance.If necessary,correct balance by

grinding heavyend of blade.

6. Reinstall blade(B, Figure 22}. Notethe correct

assembly order:

(A) Bladehub

(B) Blade

(C) Bladeflange (facing up)

(D) Conewasher (concaveside up)

(E) Capscrew

7. Checktorque of blade retainingcap screw.

Recommendedtorque should be40ft. Ibs.

WheelDriveControlAdjustment

(Self-PropelledModelsOnly)

1. The wheel drive control is properly adjusted when there

is 1/16" to 1/8" clearance(G, Figure24) betweenthe

inside of the spring hook (E) andthe inside of the clutch

cableeye(C) with the wheeldrive control released.

2. Toadjust, unhook the upper spring (D) from the cable

eyeand rotatethe spring in the direction required to

extend or shortenthe spring length.

3. Rehook the upper spring to the cable eyeandcheck

clearance.Repeatthe procedure if required.

Note. Thevinyl spring cover(B) should be kept over the

spring at afttimes except for adjustments.

.

If the wheel drive control fails to return quickly to the

"OFF"position when released,checkfor binding at the

cable holdings locatedon the side of the right handle.

Theupper clip should be located 2" below the upper

knob; the lower clip should be 4" abovethe lower knob.

Thecableshould slide freelywith the clips installedat

these locations.

m.

€'D

13

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engine and blade running. STOPengineand blade.

Disconnectspark plug wire and secure awayfrom spark

plug. Engineandcomponents are HOT.Avoid serious

burns, allow sufficient time for all componentsto cool.

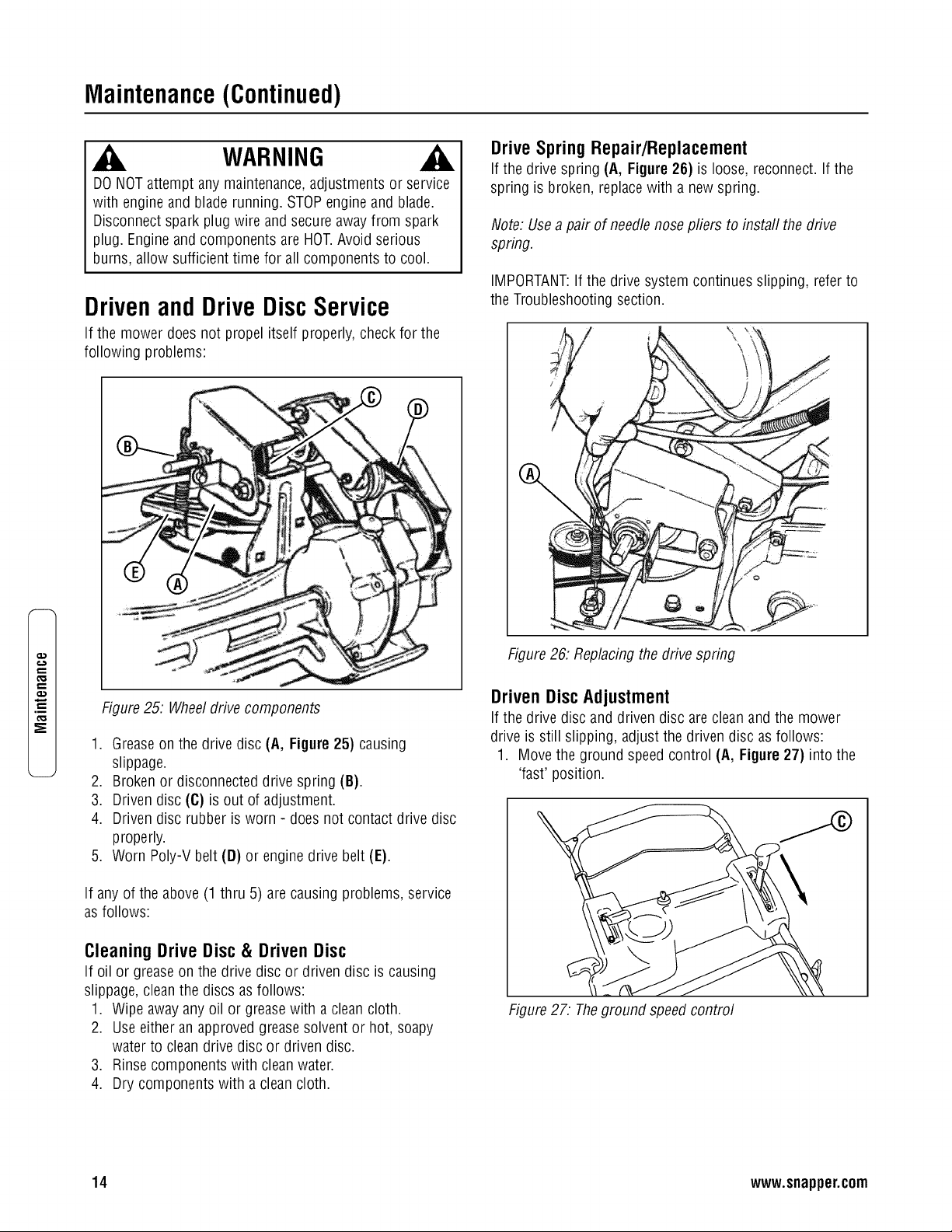

DrivenandDriveDiscService

If the mower does not propel itself properly, check for the

following problems:

DriveSpringRepair/Replacement

If the drive spring (A, Figure 26) is loose, reconnect. If the

spring is broken, replacewith a newspring.

Note: Usea pair of needlenose pliers to install the drive

spring.

IMPORTANT:If the drive system continues slipping, referto

the Troubleshooting section.

e,,,

t_

.m

_E

Figure25. Wheeldrive components

1. Greaseon the drive disc (A, Figure 25) causing

slippage.

2. Broken or disconnecteddrive spring (B).

3. Driven disc (C) is out of adjustment.

4. Driven disc rubber is worn - does not contact drive disc

properly.

5. Worn Poly-Vbelt (D) or engine drive belt (E).

If any of the above (1 thru 5) arecausing problems, service

asfollows:

Cleaning Drive Disc & Driven Disc

If oil or greaseon the drive disc or driven disc is causing

slippage, cleanthe discs asfollows:

1. Wipe awayany oil or greasewith a cleancloth.

2. Use either anapprovedgrease solvent or hot, soapy

water to cleandrive disc or driven disc.

3. Rinse components with clean water.

4. Dry componentswith a clean cloth.

Figure26: Replacingthe drive spring

Driven Disc Adjustment

If the drive disc anddriven disc areclean andthe mower

drive is still slipping, adjust the driven disc asfollows:

1. Move the ground speedcontrol (A, Figure 27) into the

'fast' position.

Figure27: Theground speed control

14 www.snapper.com

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engine and blade running. STOPengineand blade.

Disconnectspark plug wire and secure awayfrom spark

plug. Engineandcomponents are HOT.Avoid serious

burns, allow sufficient time for all componentsto cool.

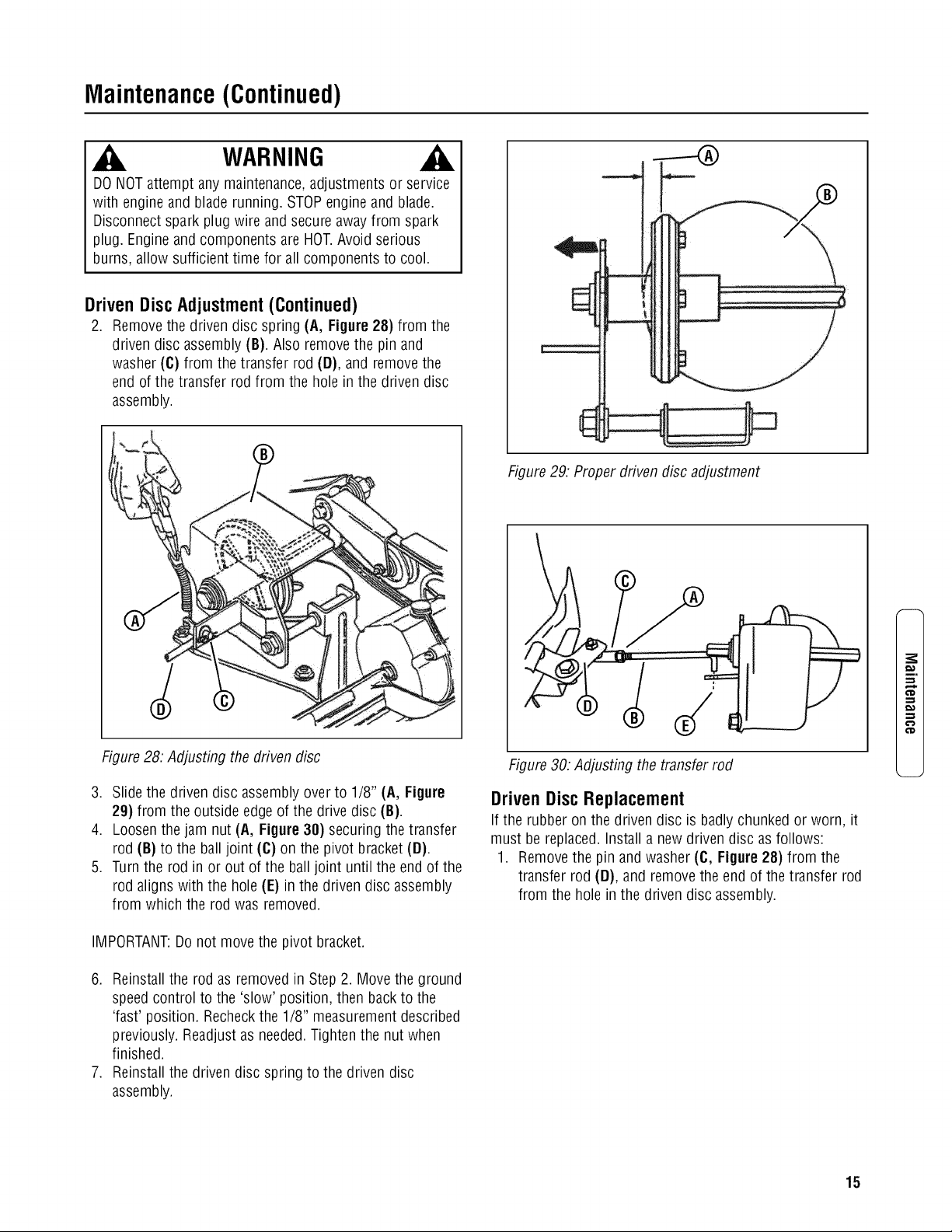

Driven Disc Adjustment (Continued)

2. Remove the driven disc spring (A, Figure 28) from the

driven disc assembly (B). Also removethe pin and

washer (C) from the transfer rod (D), and removethe

end of the transfer rod from the holein the driven disc

assembly.

Figure29: Properdriven disc adjustment

Figure28: Adjusting the driven disc

3. Slide the driven disc assembly over to 1/8" (A, Figure

29) from the outsideedgeof the drive disc (B).

4. Loosenthe jam nut (A, Figure 38) securing the transfer

rod (B) to the ball joint (C) on the pivot bracket (D).

5. Turn the rod in or out of the ball joint until the endof the

rod aligns with the hole (E) inthe driven disc assembly

from which the rodwas removed.

IMPORTANT:Donot move the pivot bracket.

6. Reinstall the rod as removed in Step 2. Move the ground

speedcontrol to the 'slow' position, then backto the

'fast' position. Recheckthe 1/8" measurement described

previously. Readjustas needed.Tightenthe nut when

finished.

7. Reinstall the driven disc spring to the driven disc

assembly.

m.

Figure30: Adjusting the transfer rod

Driven Disc Replacement

If the rubber on the driven disc isbadly chunked or worn, it

must be replaced. Install a new driven disc asfollows:

1. Removethe pin and washer (C, Figure 28) from the

transfer rod (D), and removethe end of thetransfer rod

from the hole in the driven disc assembly.

15

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engine and blade running. STOPengineand blade.

Disconnectspark plug wire and secure awayfrom spark

plug. Engineandcomponents are HOT.Avoid serious

burns, allow sufficient time for all componentsto cool.

Driven Disc Replacement (Continued)

2. Using needlenose pliers,unhook the drive spring (A,

Figure 31) and slide the driven disc assemblyoff the

hex shaft.

3. Remove the two snap rings (A, Figure 32) which secure

the rubber driven disc (B) to the driven disc assembly.

4. Install a new rubber driven disconto the driven disc

assembly,andsecurewith the retaining rings.

5. Reversethe above proceduresfor reassemblyand

installation ofthe driven disc assembly.

Driven Disc Bearing Replacement

IMPORTANT:Thebearingon thesemachinesis staked into

the thrust plate. The bearingwill haveto be driven out with a

mallet andalargepunch. Anew bearing with four retaining

screws will haveto be purchasedto replaceexisting bearing.

If the driven disc bearing requires replacement,replace the

bearing as follows:

1. Removethe driven disc assembly. Referto the Section

entitled "Driven Disc Replacement".

2. Removeboth snap rings (A, Figure 32) that securethe

rubber driven disc (B) to the thrust plate.

3. Slide the rubber driven disc hub out of the bearing.

4. Drive out the existing bearing (C).

5. Install a new bearingandsecureto the thrust platewith

four retaining screws. Tighten the screws securely.

6. Reassemblethe components in reverseorder.

NOTE:Besure to replacethe shim washer(D) when

reassembfingthe driven disc assembly.

e,,,

t_

.m

_E

Figure31. Removingthe driven disc assembly

Figure32: Replacing the driven disc

16 www.snapper.com

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engine and blade running. STOPengineand blade.

Disconnectspark plug wire and secure awayfrom spark

plug. Engineandcomponents are HOT.Avoid serious

burns, allow sufficient time for all componentsto cool.

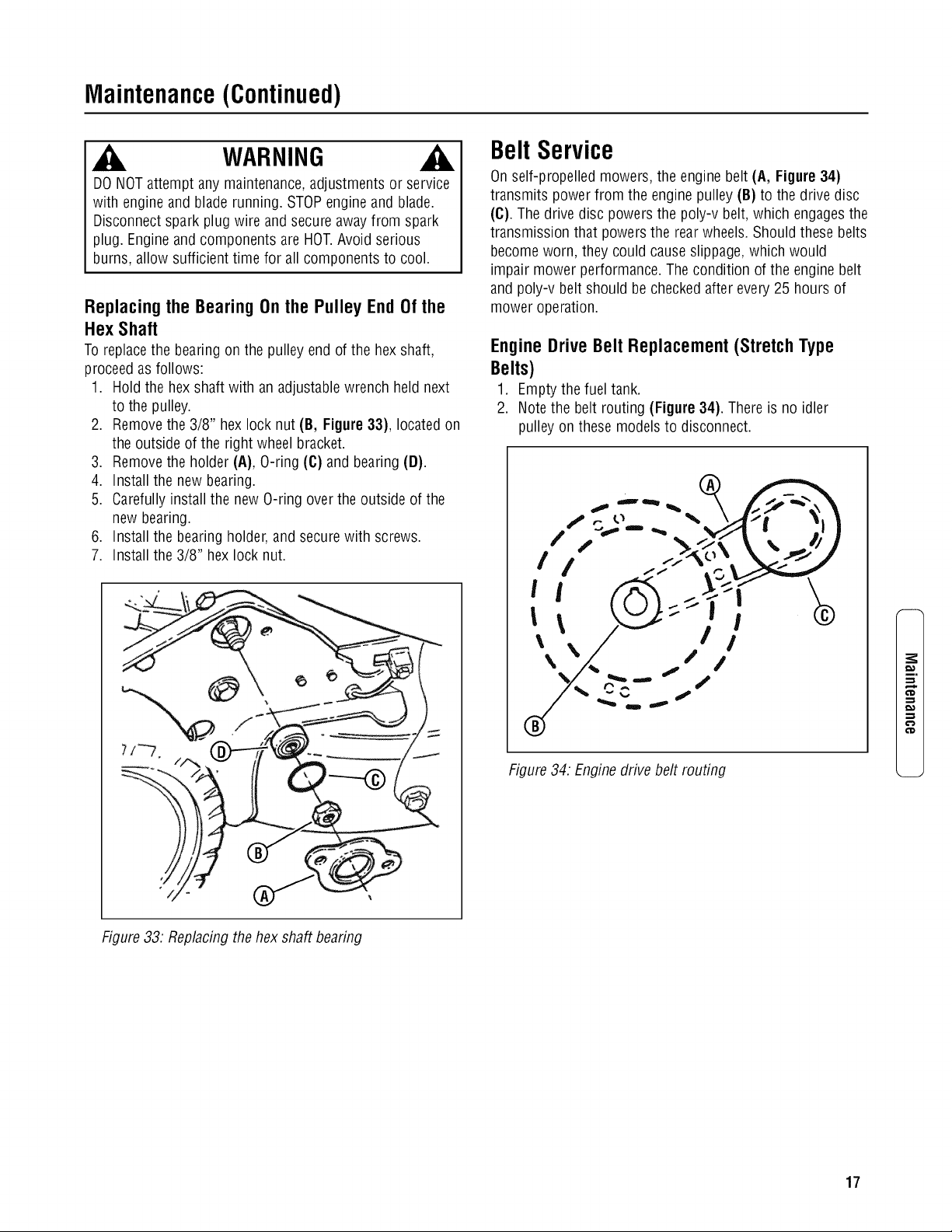

Replacing the Bearing On the Pulley End Of the

Hex Shaft

Toreplacethe bearingon the pulley end of the hexshaft,

proceedas follows:

1. Hold the hex shaft with an adjustablewrench held next

to the pulley.

2. Remove the 3/8" hexlock nut (B, Figure33), located on

the outside of the right wheel bracket.

3. Remove the holder (A), O-ring (C) and bearing (D).

4. Install the new bearing.

5. Carefully install the new O-ring over the outside of the

new bearing.

6. Install the bearingholder,andsecurewith screws.

7. Install the 3/8" hex lock nut.

BeltService

On self-propelled mowers,the engine belt (A, Figure 34)

transmits power from the engine pulley (B)to the drive disc

(C). The drive disc powersthe poly-v belt,which engages the

transmission that powers the rearwheels. Shouldthese belts

become worn, they could cause slippage,which would

impair mower performance. Thecondition of theenginebelt

and poly-v belt should becheckedafter every 25 hours of

mower operation.

Engine Drive Belt Replacement (Stretch Type

Belts)

1. Empty the fuel tank.

2. Note the belt routing (Figure 34). Thereis no idler

pulley on these models to disconnect.

f ,.. o "_ \//>_ "l,

Figure33. Replacingthe hex shaft bearing

\% \/ /I//

i.

€'D

€'D

Figure34. Engine drive belt routing

17

e,,,

t_

.m

_E

Maintenance(Continued)

WARNING

DONOTattempt any maintenance,adjustments or service

with engine and blade running. STOPengineand blade.

Disconnectspark plug wire and secure awayfrom spark

plug. Engineandcomponents are HOT.Avoid serious

burns, allow sufficient time for all componentsto cool.

EngineDriveBeltReplacement(StretchType

Belts- Continued)

IMPORTANT:Drainthe fuel tank before tipping the mower.

DONOTtip the machinewith the carburetor or spark plug

down. Oilfrom the crankcasewill saturatethe air filter and

causethe engineto behardto start or not start at all. If

contamination doesoccur, the air filter will haveto be

replaced.

3. Remove the driven disc. Referto the Sectionentitled

"Driven Disc Replacement"for driven disc removal

procedure.

4. Drain the fueltank before tipping the mower. Do not tilt

the mower with the spark plug or carburetor down. Tilt

the mower up on its rearwheels and removethe blade

and bladehub. Assistance from another person maybe

necessaryto hold the mower inthe tilted position.

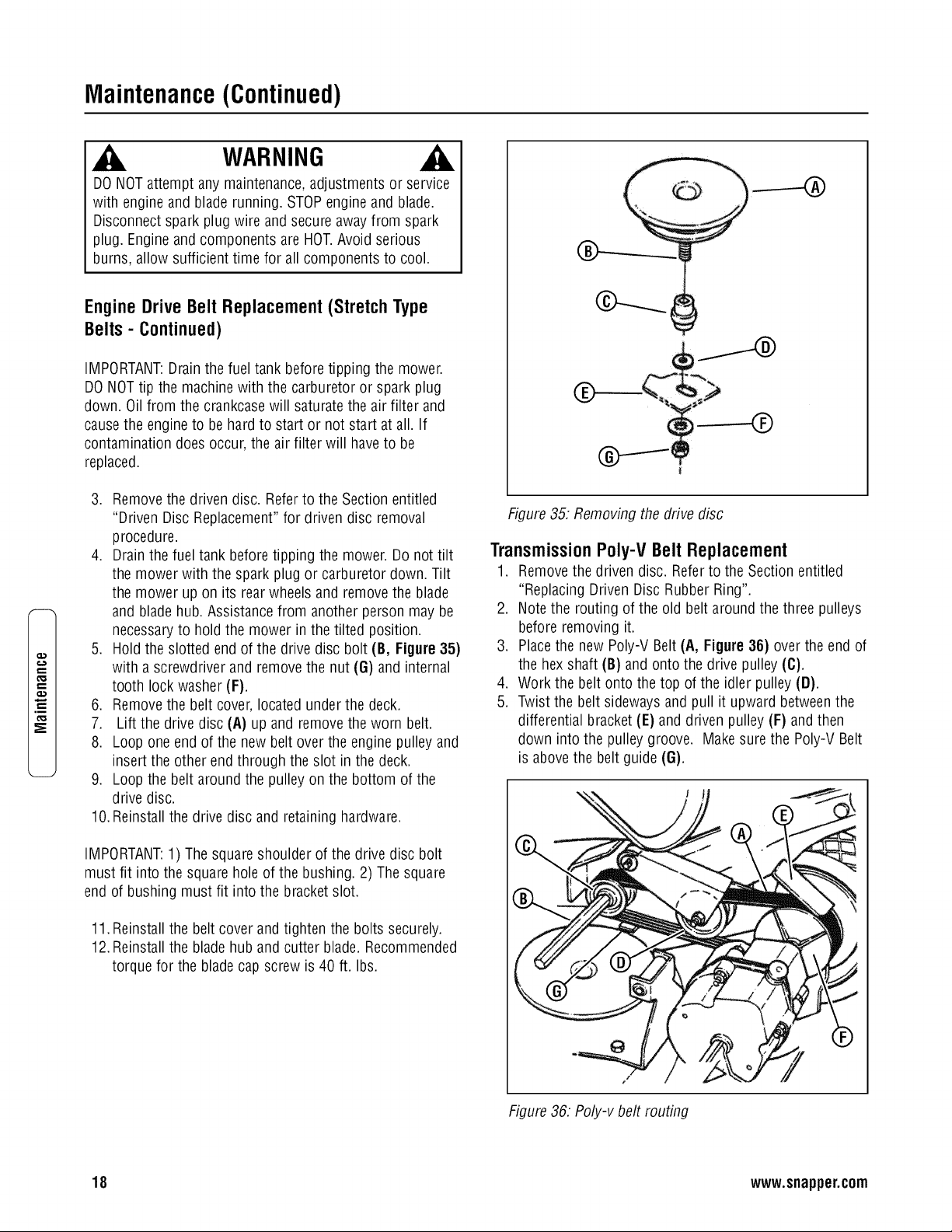

5. Hold the slotted end of the drive disc bolt (B, Figure 35)

with a screwdriverand remove the nut (G) and internal

tooth lock washer (F).

6. Remove the belt cover, located under the deck.

7. Lift the drivedisc (A) up and removethe worn belt.

8. Loop one end of the new belt over the engine pulley and

insert the other endthrough the slot in the deck.

9. Loop the beltaroundthe pulleyon the bottom of the

drive disc.

10.Reinstall the drive disc and retaining hardware.

------4b

)

Figure35. Removingthe drive disc

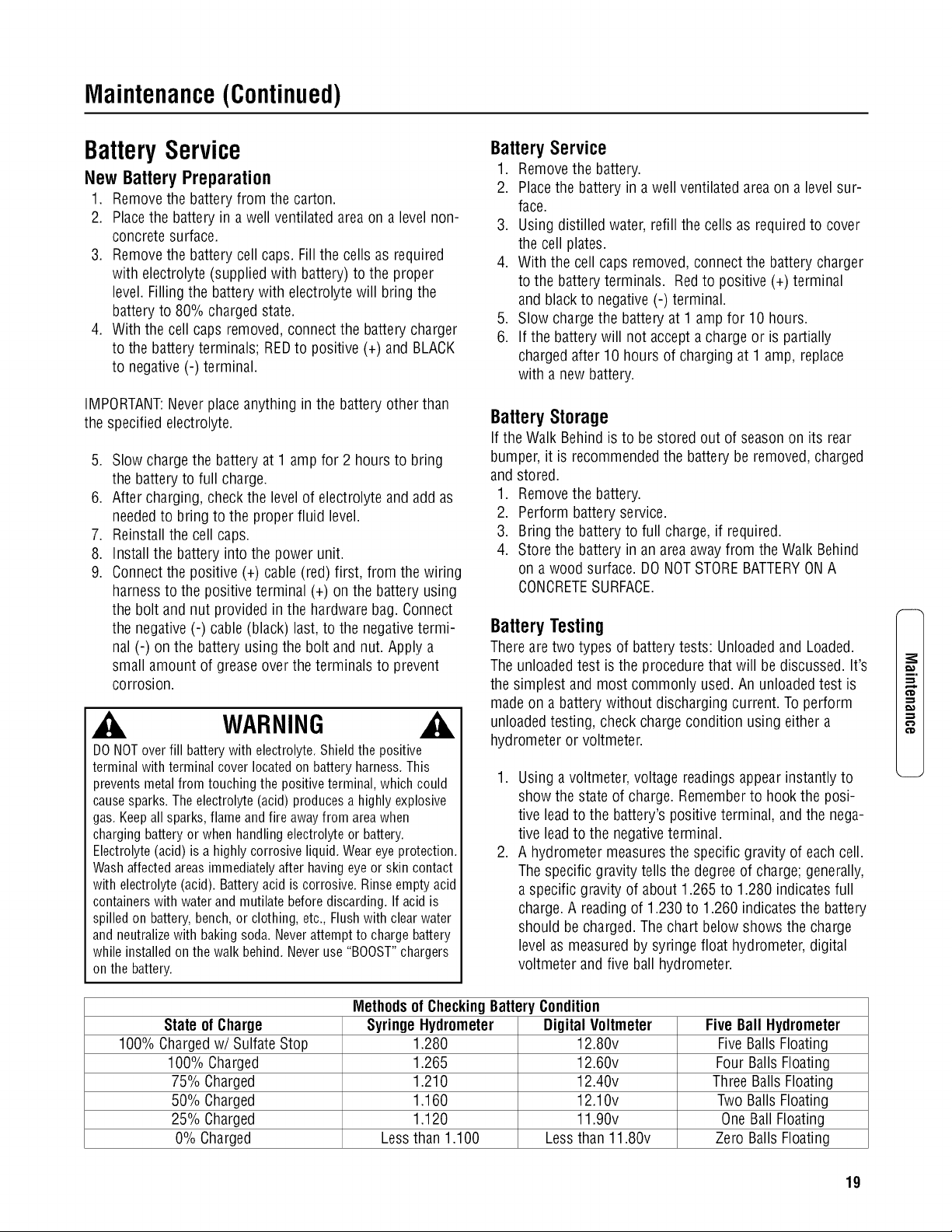

Transmission Poly-V Belt Replacement

1. Remove the driven disc. Referto the Sectionentitled

"Replacing DrivenDisc Rubber Ring".

2. Note the routing of the old belt around the three pulleys

before removing it.

3. Placethe new Poly-V Belt(A, Figure 36) over the end of

the hex shaft (B) and onto the drive pulley (C).

4. Work the belt onto the top of the idler pulley(D).

5. Twist the belt sidewaysandpull it upward betweenthe

differential bracket(E)and driven pulley (F) andthen

down into the pulley groove. Makesure the Poly-V Belt

is above the belt guide(G).

IMPORTANT:1) Thesquareshoulder of the drive disc bolt

must fit into the square hole of the bushing. 2) Thesquare

end of bushing must fit into the bracket slot.

11.Reinstall the belt coverandtighten the bolts securely.

12.Reinstall the blade hub and cutter blade. Recommended

torque for the blade cap screw is 40 ft. Ibs.

J

Figure36. Poly-v belt routing

18 www.snapper.com

Maintenance(Continued)

BatteryService

New BatteryPreparation

1. Remove the battery from the carton.

2. Placethe battery in awell ventilated areaon a levelnon-

concrete surface.

3. Remove the battery cell caps. Fillthe cells as required

with electrolyte (supplied with battery) to the proper

level. Fillingthe battery with electrolyte will bring the

battery to 80% chargedstate.

4. With the cell caps removed, connectthe battery charger

to the batteryterminals; REDto positive (+) andBLACK

to negative(-) terminal.

IMPORTANT:Neverplace anything in thebattery other than

the specified electrolyte.

5. Slow chargethe battery at 1amp for 2 hours to bring

the battery to full charge.

6. After charging, check the levelof electrolyteandaddas

neededto bring to the proper fluid level.

7. Reinstall the cell caps.

8. Install the battery into the power unit.

9. Connect the positive (+) cable(red) first, from the wiring

harness to the positiveterminal (+) on the battery using

the bolt and nut provided inthe hardwarebag. Connect

the negative (-) cable (black) last, to the negativetermi-

nal (-) onthe battery using the bolt and nut.Apply a

small amount of greaseover the terminals to prevent

corrosion.

WARNING

DONOToverfill batterywithelectrolyte.Shieldthepositive

terminalwithterminalcoverlocatedonbatteryharness.This

preventsmetalfromtouchingthe positiveterminal,whichcould

causesparks.Theelectrolyte(acid)producesa highlyexplosive

gas.Keepallsparks,flameandfireawayfromareawhen

chargingbatteryorwhenhandlingelectrolyteor battery.

Electrolyte(acid)isahighlycorrosiveliquid.Weareyeprotection.

Washaffectedareasimmediatelyafterhavingeyeor skincontact

with electrolyte(acid).Batteryacidiscorrosive.Rinseemptyacid

containerswithwaterandmutilatebeforediscarding.Ifacidis

spilledonbattery,bench,or clothing,etc.,Flushwith clearwater

andneutralizewith bakingsoda.Neverattemptto chargebattery

whileinstalledonthe walkbehind.Neveruse"BOOST"chargers

onthebattery.

BatteryService

1. Removethe battery.

2. Placethe battery in a well ventilated areaon a level sur-

face.

3. Using distilledwater, refill the cellsas requiredto cover

the cell plates.

4. With the cell caps removed, connectthe battery charger

to the batteryterminals. Redto positive (+) terminal

and black to negative (-) terminal.

5. Slow charge the battery at 1 amp for 10 hours.

6. If the battery will not accept a charge or is partially

chargedafter 10 hours of charging at 1 amp, replace

with a new battery.

BatteryStorage

If the Walk Behindis to be stored out of season on its rear

bumper, it is recommendedthe battery beremoved,charged

and stored.

1. Removethe battery.

2. Perform battery service.

3. Bring the battery to full charge, if required.

4. Storethe battery in an area awayfrom the Walk Behind

on awood surface. DONOTSTOREBATTERYONA

CONCRETESURFACE.

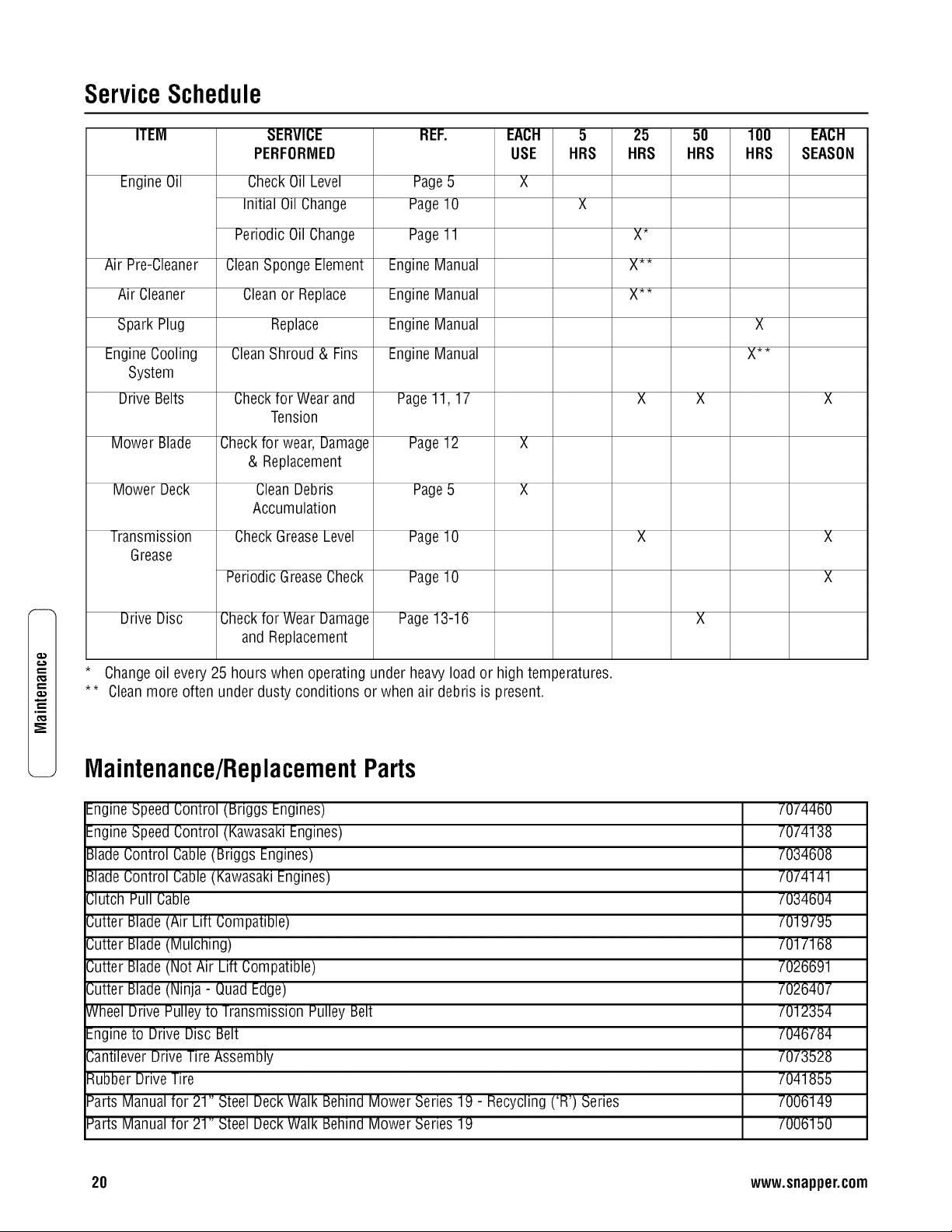

Battery Testing

Therearetwo types of batterytests: Unloadedand Loaded.

Theunloadedtest isthe procedurethat will be discussed. It's

the simplest and most commonly used. An unloadedtest is

madeon a batterywithout discharging current. To perform

unloaded testing, checkcharge condition usingeither a

hydrometer or voltmeter.

.

Using avoltmeter,voltage readingsappearinstantlyto

show the stateof charge. Rememberto hookthe posi-

tive leadto the battery's positiveterminal, andthe nega-

tive leadto the negativeterminal.

.

A hydrometer measuresthe specific gravity of eachcell.

Thespecific gravity tells the degreeof charge; generally,

a specific gravity of about 1.265 to 1.280 indicatesfull

charge. A readingof 1.230 to 1.260 indicatesthe battery

should be charged.The chart belowshows the charge

level as measured by syringe float hydrometer, digital

voltmeter andfive ball hydrometer.

m,

¢D

€'D

Methodsof CheckingBatteryCondition

State of Charge SyringeHydrometer Digital Voltmeter Five BallHydrometer

100% Chargedw/Sulfate Stop 1.280 12.80v FiveBallsFloating

100% Charged 1.265 12.60v Four Balls Floating

75% Charged 1.210 12.40v ThreeBalls Floating

50% Charged 1.160 12.10v Two Balls Floating

25% Charged 1.120 11.90v OneBallFloating

0% Charged Lessthan 1.100 Lessthan 11.80v Zero Balls Floating

19

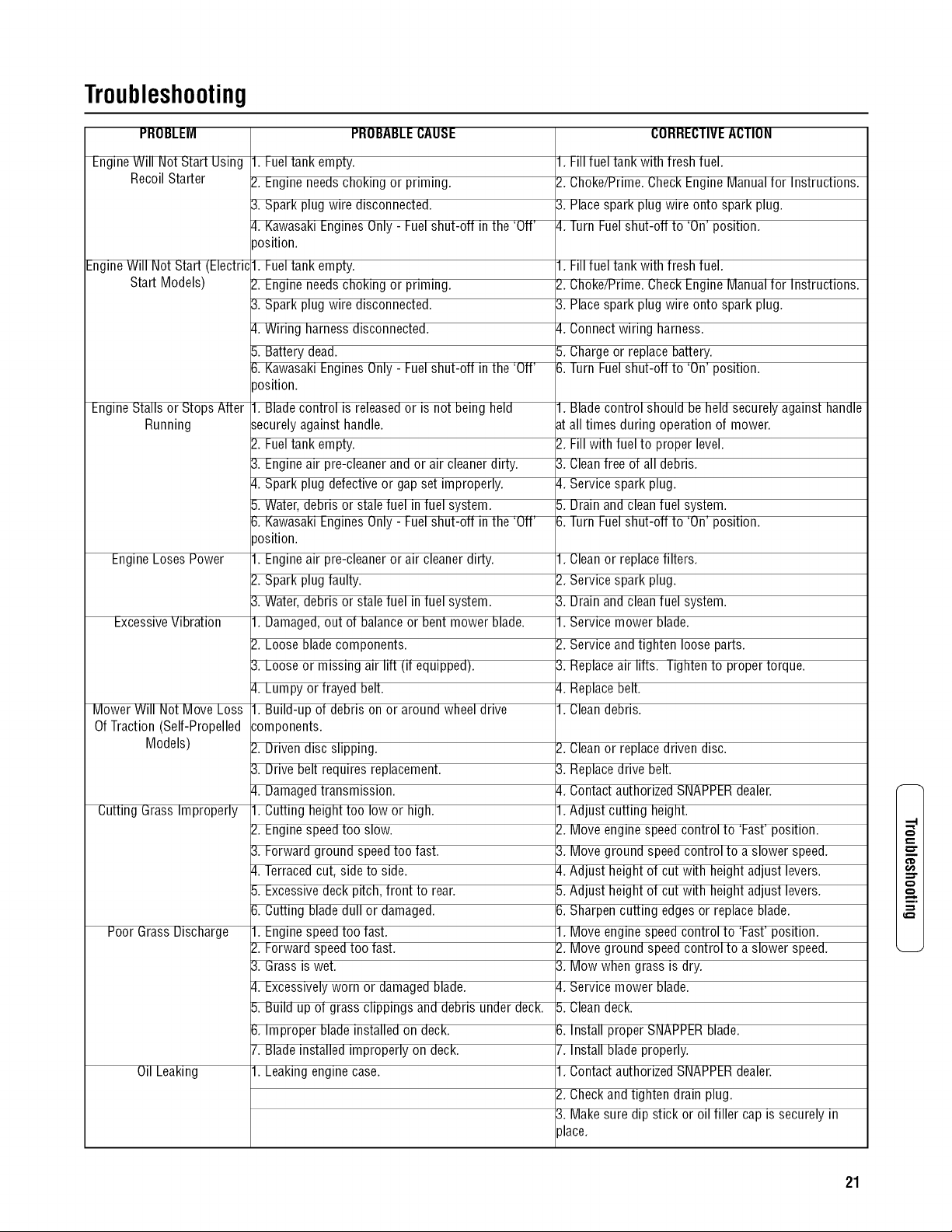

ServiceSchedule

ITEM

Engine Oil

Air Pre-Cleaner

Air Cleaner

Spark Plug

EngineCooling

System

Drive Belts

Mower Blade

Mower Deck

Transmission

Grease

SERVICE

PERFORMED

CheckOilLevel

Initial OilChange

Periodic Oil Change

CleanSponge Element

Cleanor Replace

Replace

CleanShroud & Fins

Checktor Wearand

Tension

Checkfor wear, Damage

& Replacement

CleanDebris

Accumulation

CheckGrease Level

Periodic GreaseCheck

REF.

Page5

Page10

Page11

EngineManual

EngineManual

EngineManual

EngineManual

Page11, 17

Page12 X

Page5 X

Page10

Page10

EACH

USE5HRS

X

25

HRS

X_

X**

X**

5O

HRS

lOO

HRS

X

X**

EACH

SEASON

X

X

X

Drive Disc

Checkfor WearDamage

Page13-16

and Replacement

* Changeoil every 25 hours when operating under heavyload or high temperatures.

** Cleanmore often underdusty conditions or when air debris is present.

,m

Maintenance/ReplacementParts

EngineSpeed Control (Briggs Engines)

EngineSpeed Control (KawasakiEngines)

BladeControl Cable(Briggs Engines)

BladeControl Cable(KawasakiEngines)

Clutch Pull Cable

Cutter Blade(Air Lift Compatible)

Cutter Blade(Mulching)

Cutter Blade(Not Air Lift Compatible)

Cutter Blade(Ninja - QuadEdge)

Wheel Drive Pulley to Transmission Pulley Belt

Engineto DriveDisc Belt

CantileverDriveTireAssembly

Rubber Drive Tire

Parts Manual for 21" Steel DeckWalkBehindMower Series 19 - Recycling('R') Series

Parts Manual for 21" Steel DeckWalkBehindMower Series 19

7074460

7074138

7034608

7074141

7034604

7019795

7017168

7026691

7026407

7012354

7046784

7073528

7041855

7006149

7006150

20 www.snapper.com

Troubleshooting

PROBLEM

EngineWill Not Start Using

Recoil Starter

EngineWill Not Start (Electri(

Start Models)

EngineStalls or Stops After

Running

EngineLoses Power

Excessive Vibration

IVlowerWill Not IVloveLoss

OfTraction(Self-Propelled

Models)

Cutting GrassImproperly

Poor Grass Discharge

Oil Leaking

PROBABLECAUSE

1. Fuel tankempty. 1.

2. Engine needschoking or priming. 2.

3. Spark plug wire disconnected. 3.

4. Kawasaki EnginesOnly - Fuelshut-oft in the 'Off' 4.

)osition.

1. Fuel tankempty. 1.

2. Engine needschoking or priming. 2.

3. Spark plug wire disconnected. 3.

4. Wiring harness disconnected. 4.

5. Battery dead. 5.

6. Kawasaki EnginesOnly - Fuelshut-off in the 'Off' 6.

)osition.

1. Blade control is releasedor is not being held

securely against handle.

2. Fuel tankempty.

3. Engineair pre-cleaner and or air cleanerdirty.

4. Spark plug detective or gapset improperly.

5. Water, debris orstale fuel infuel system. 5.

6. Kawasaki EnginesOnly - Fuelshut-oft in the 'Ott' 6.

)osition.

1. Engineair pre-cleaner or air cleanerdirty. 1.

2. Spark plug faulty. 2.

3. Water, debris orstale fuel infuel system. 3.

1. Damaged,out of balanceor bent mower blade. 1.

2. Loose blade components. 2.

3. Loose or missing air Iitt (it equipped). 3.

4. Lumpy or trayed belt. 4.

1. Build-up of debris on or around wheel drive 1.

components.

2. Driven disc slipping.

3. Drive belt requires replacement.

4. Damagedtransmission.

1. Cutting height too low or high.

2. Engine speedtoo slow.

3. Forward ground speedtoo fast.

4. lerraced cut, sideto side.

5. Excessivedeck pitch, front to rear.

6. Cutting blade dull or damaged.

1. Engine speedtoo fast. 1.

2. Forward speedtoo tast. 2.

3. Grass is wet. 3.

4. Excessivelyworn or damagedblade. 4.

5. Build up of grass clippings and debris under deck. 5.

6. Improper bladeinstalled on deck. 6.

7. Blade installed improperly on deck. 7.

1. Leaking engine case. 1.

CORRECTIVEACTION

Fill tuel tankwith tresh fuel.

Choke/Prime.Check EngineIVlanualfor Instructions.

Place spark plug wire onto spark plug.

lurn Fuel shut-oft to 'On' position.

Fill tuel tankwith tresh tuel.

Choke/Prime.Check EngineManual for Instructions.

Place spark plug wire onto spark plug.

Connectwiring harness.

Charge or replacebattery.

lurn Fuel shut-off to 'On' position.

1. Blade control should be held securelyagainst handle

at all times during operation of mower.

2. Fill with fuel to proper level.

3. Cleantreeof all debris.

4. Service spark plug.

Drain andclean fuel system.

lurn Fuel shut-oft to 'On' position.

Cleanor replace tilters.

Service spark plug.

Drain andclean fuel system.

Service mower blade.

Service and tighten loose parts.

Replaceair lifts, lighten to proper torque.

Replacebelt.

Cleandebris.

2. Cleanor replace driven disc.

3. Replace drive belt.

4. Contact authorizedSNAPPERdealer.

1. Adjust cutting height.

2. Move enginespeed control to 'Fast' position.

3. Move ground speed control to a slower speed.

4. Adjust height of cut with height adjust levers.

5. Adjust height of cut with height adjust levers.

6. Sharpen cutting edges or replace blade.

Move engine speed control to 'Fast' position.

IVloveground speed control to a slower speed.

IVlowwhen grass is dry.

Service mower blade.

Cleandeck.

Install proper SNAPPEHblade.

Install blade properly.

Contact authorized SNAPPERdealer.

2.

Checkand tighten drain plug.

3. IVlakesure dip stick or oil tiller cap is securely in

)lace.

=3"

m.

21

2 YEAR LIMITED WARRANTY

Fortwo (2) years from purchase datefor the original purchaser's residential,non-commercial use, SNAPPER,through any

authorizedSNAPPERdealerwill replace,free of charge (except for taxes where applicable), any part or partsfound upon

_xaminationby the factory at McDonough, Georgia,to be defective in material or workmanship or both.

Forninety (90) days from purchasedate for the original purchaser's commercial, rental,or other non-residential use, SNAP-

PER,through any authorizedSNAPPERdealerwill replace,free of charge,any part or parts found upon examination by the

[actory at McDonough, Georgia,to be defective in material or workmanship or both.

&ll transportation costs incurred by the purchaser in submitting material to an authorized SNAPPERdealerfor replacement

underthis warranty must bepaid bythe purchaser.

This warranty does not apply to certaintransmissions, to engines andtheir components, and batteries, astheseitems arewar-

rantedseparately. This warranty does not apply to partsthat havebeen damagedby accident, alteration, abuse,improper

lubrication, normal wear,or other causebeyond the control of SNAPPER.This warranty doesnot cover anymachineor com-

ponent part that hasbeenalteredor modified changing safety, performance,or durability.

Batterieshavea one (1) year warranty period with free replacementif required for one (1) year from the original purchase

date.SNAPPERwill not be responsiblefor any installation cost incurred. Thebattery warranty only covers original equipment

batteriesanddoes not cover damageto the battery or machinecausedby neglect or abuse,destruction by fire, explosion,

[reezing,overcharging, improper maintenance, or useof improper electrolyte.

Thereis no other expresswarranty.

DISCLAIMMEROFWARRANTY

Implied warranties, includingthoseof merchantabilityandfitnessfor a particularpurpose,are limited to two (2) years

[rom purchasedatefor the originalpurchaser'sresidential or othernon-commercialuse, and ninety(90) daysfrom pur-

chase for theoriginal purchaser'scommercial,rental or othernon-residentialuse, and tothe extentpermittedby law, any

andall implied warrantiesare excluded. This is the exclusiveremedy. Liabilitiesfor consequentialdamages,underany

andall warrantiesare excluded.

Somestates donotallow limitations onhow longan implied warranty lasts, or do notallow the exclusionor limitation of

incidentalor consequentialdamages,so the abovelimitationorexclusionmay notapplyto you.

Thiswarranty givesyou specific legal rights, andyou mayalso haveother rights which varyfrom stateto state.

WARNING:THE USEOF REPLACEMENTPARTSOTHERTHANGENUINESNAPPERPARTSMAY IMPAIRTHESAFETYOF

SNAPPERPRODUCTSAND WILL VOIDANY LIABILITYANDWARRANTYBYSNAPPERASSOCIATEDWITH THE USEOF

SUCHPARTS.

t_

,m

IMPORTANT:

Pleasefill out the attachedSNAPPERProduct Registration Cardimmediately and mail to:

Snapper'sProductRegistrationCenter,P.O.Box1379, IVlcDonough,Georgia30253

22 www.snapper.com

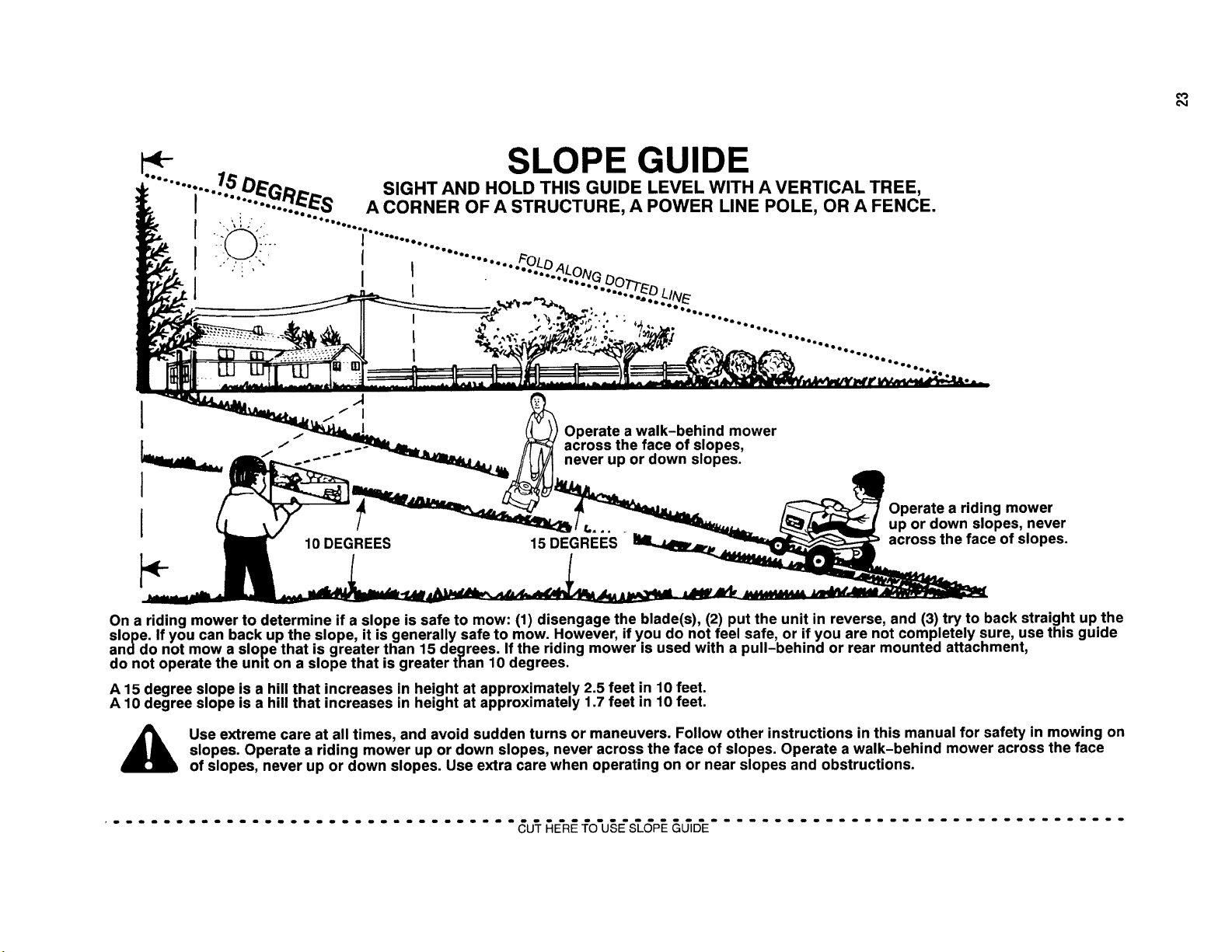

4- SLOPE GUIDE

........ :..../.b" DE_D_... SIGHT AND HOLD THIS GUIDE LEVEL WITH A VERTICAL TREE,

I ".... -'..'.._S A CORNER OF A STRUCTURE, A POWER LINE POLE, OR A FENCE.

...... .....................

j ........................

04

!

Operate a walk-behind mower

across the face of slopes,

never up or down slopes.

I

Operate a riding mower

I

10 DEGREES 15 DEGREES

On a riding mower to determine if a slope is safe to mow: (1) disengage the blade(s), (2) put the unit in reverse, and (3) try to back straight up the

slope. If you can back up the slope, it is generally safe to mow. However, if you do not feel safe, or if you are not completely sure, use this guide

anddo not mow a slope that is greater than 15 degrees. If the riding mower is used with a pull-behind or rear mounted attachment,

do not operate the und on a slope that is greater than 10 degrees.

A 15 degree slope is a hill that increases in height at approximately 2.5 feet in 10 feet.

A 10 degree slope is a hill that increases in height at approximately 1.7 feet in 10 feet.

slopes. Operate a riding mower up or down slopes, never across the face of slopes. Operate a walk-behind mower across the face

Use extreme care at all times, and avoid sudden turns or maneuvers. Follow other instructions in this manual for safety in mowing on

of slopes, never up or down slopes. Use extra care when operating on or near slopes and obstructions.

................................. _U'T_E'R_fO'U§E'_GP__&_D'E.................................

up or down slopes, never

across the face of slopes.

Notes

24 www.snapper.com

Notes

25

21" STEELDECK

WALKMOWERS

SERIES19

Product Specifications

Deck Size

Height of Cut

Transmission Type(Self-Propelled Models)

Ground Speed (Self-Propelled Models)

Engine Power- Briggs Quantum / DOV

Engine Power- Briggs Intek

Engine Power- Kawasaki

Engine Displacement- Briggs DOV

Engine Displacement- Briggs Quantum/ Intek

Engine Displacement- Kawasaki

FuelTankCapacity- Briggs (all)

FuelTankCapacity- Kawasaki

EnginePower RatingInformation:The gross power rating for individual gasenginemodels islabeledin accordancewith

SAE(Societyof Automotive Engineers)code J1940 (Small Engine Power& Torque RatingProcedure),and rating perform-

ancehasbeen obtainedand corrected in accordancewith SAEJ1995 (Revision 2002-05). Torquevaluesarederived at 3060

RPM;horsepowervaluesarederived at 3600 RPM.Actualgross enginepower will be lower and is affected by, among other

things, ambient operatingconditions andengine-to-engine variability. Givenboth the wide array of products on which engines

are placedandthe variety of environmental issues applicableto operating the equipment, the gas enginewill not developthe

ratedgross power when used in a given pieceof power equipment (actual "on-site"or net power). This difference is dueto a

variety of factors including, but not limited to, accessories (air cleaner,exhaust, charging, cooling, carburetor,fuel pump,

etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability.

Dueto manufacturingandcapacity limitations, Briggs & Stratton may substitute an engine of higher ratedpower for this

Seriesengine.

21 in

1,25- 4 in

Gear

1 -4 mph

6.50ft-lbs (gross)

8.75ft-lbs (gross)

6.0hp(gross)

160cc

190cc

180cc

1.6qt

2,1qt

CommonServiceParts

Cutter Blade(Ninja - Quad)

Drive Belt(Engine)

Drive Belt(Transmission)

Parts Manual(Recycling)

Parts Manual

Part Number

7026407

7046784

7012354

7006149

7006150

26

SnapperProducts

535 Macon Street

McDonough, GA30253

1-000-935-2967

www.snapper.com

SafetyInstructions& Operator'sManual for

21" STEELDECK

WALKMOWERS

SERIES19

f

Models

RP2167519BDV(7800066)

RP2187519BV (7800172)

RP2187519BVE (7800173)

RP216019KWV (7800199)

2167519B

P2167519B

P2187519BV

P2187519BVE

P216019KWV

N2167519B

NP2167519B(7800134)

NP2187519BV (7800131)

(7800217)

(7800218)

(7800176)

(7800178)

(7800193)

(7800133)

J

NOTE:Specifications are correct attime of printing and are subjectto changewithout notice.

* Actualsustained engine power will likely helower due to operatinglimitations and environmentalfactors. Please refer to 'Engine Power Rating Information' for

further details.

Manual No. 7101587 (I.R. 9/25/2007)

TPlO0-5289-1R-WB-N

ThankYoufor purchasingthis quality-built Snapperproduct.We're pleasedthat you placedyour

confidenceinthe Snapperbrand.When operatedand maintainedaccordingto the instructions in this

manual,your Snapperproductwill providemanyyearsof dependableservice.

Thismanualcontainssafety information to makeyou awareof the hazardsand risks associatedwith the

machineandhow to avoidthem. This machineis designedand intendedonlyfor finish cutting of

establishedlawns and is not intendedfor any other purpose.It is importantthat you read and understand

theseinstructions thoroughly beforeattemptingto start or operatethis equipment.Savethese

instructions for future reference.

PRODUCT REGISTRATION

IMPORTANT: KEEPTHIS INFORMATION FORYOUR PERSONAL RECORDS

(Complete the following information on your Snapper purchase)

Date of Purchase

Retailer

Retailer'sPhoneNumber

Equipment

Model Number

Serial Number

Engine

Model .Type. Trim

It is veryimportantthatyouregisteryourpurchasewithSnappertoensurewarrantycoverage.Please

mail yourproductregistrationcardto:

Snapper at P.O. Box777, McDonough, Georgia 30253.

Oryou may registeronline at www.snapper.com.

Youcan contactusat ourwebsite,or if youwouldliketospeakwith a CustomerService

Representative,call usat theSnapperCustomerRelationsCenterat 1-800-935-2967. Forfaster

servicepleasehaveyourSerial NumberandModelNumberavailable.

SNAPPERis a trademarkof

SimplicityManufacturing,Inc.

PortWashington,WI, USA.

Briggs& StrattonYardPower Products Group

Copyright© 2007, Briggs& StrattonCorporation

Milwaukee, WI, USA. All RightsReserved.

Loading...

Loading...