Page 1

1

#7600023 & 7600024 TWIN BAG CATCHER KIT FOR

38 & 42” SNAPPER / SIMPLICITY RZT RIDING MOWERS

WARNING

DO NOT attempt any adjustments, maintenance, repairs, or service with engine running. Stop engine. Engage

parking brake. Remove key. Remove spark plug wire and secure wire away from spark plug. Engine, muffler and

surrounding areas are extremely hot. Avoid serious burns; allow components to cool down before installing kit.

Replace worn or damaged parts prior to operating. Use approved fuel container. DO NOT smoke near open fuel

container. DO NOT fill fuel tank indoors or when engine is running. Allow engine to cool for at least ten minutes

before refilling. Make sure that fuel cap is tightened securely. Wipe off any spilled fuel before starting engine.

!

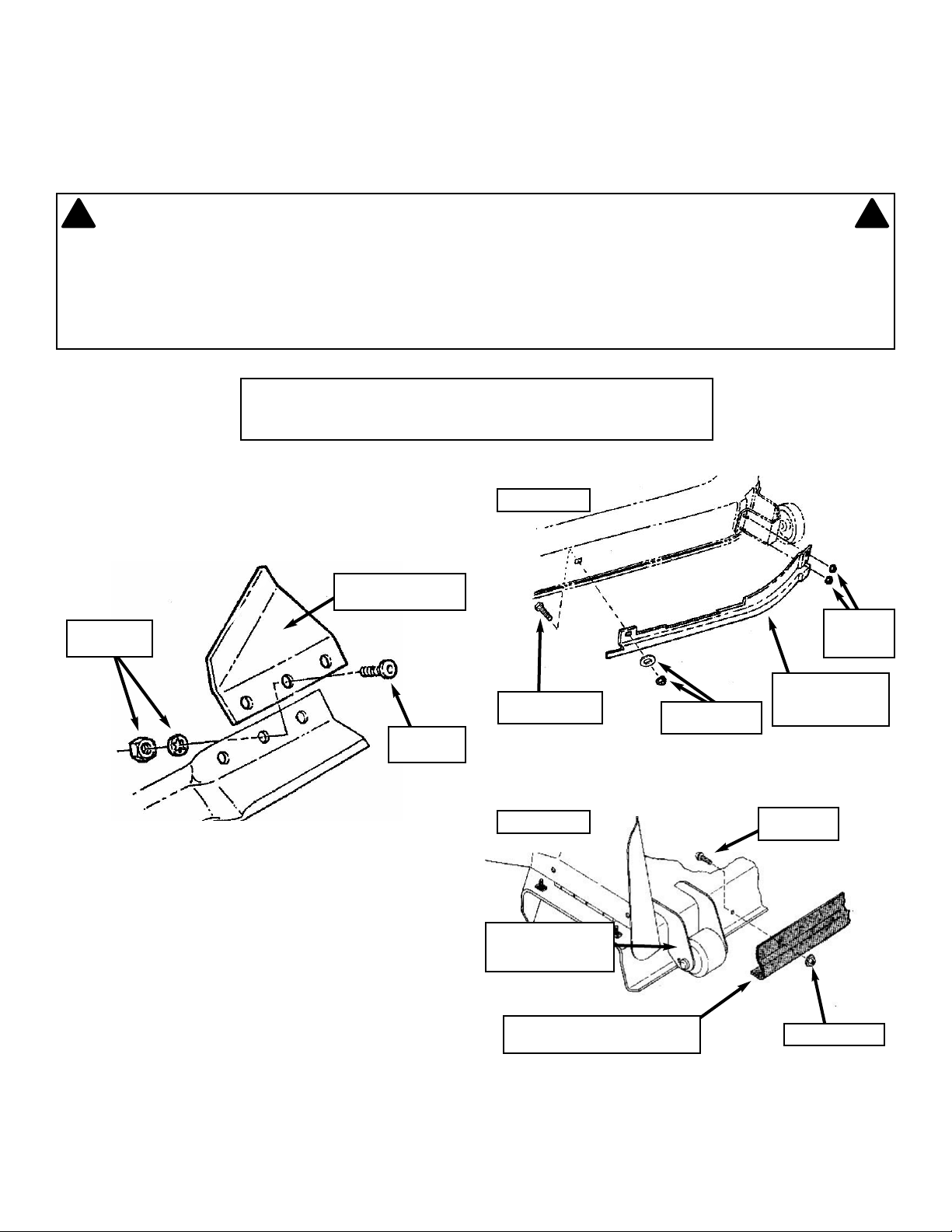

STEP 1 (38” Units Only): Install one air lift onto the topside

of each of the four blade tips, securing with three 5/16-24 x

5/8” oval head machine screws, internal tooth lock washers

and hex nuts. See Figure 1. Torque hardware to 12 ft-lbs.

STEP 2: Install the baffle to the front of the mower deck:

38” Decks - Secure the baffle with one 5/16 x 3/4” hex head

cap screw, flat washer and center lock nut on one end, and

the existing hardware on the other end. See Figure 2.

42” Decks - Secure the baffle with two 5/16 x 5/8” pan head

machine screws and flange lock nuts. See Figure 3.

NOTE: One or more holes may have to be drilled into the

deck in order to install the baffle. If so, install the baffle as

fully onto the deck as possible with the existing holes, then

drill the remaining holes with an 11/32” drill, using the baffle

hole(s) as a template.

FIGURE 1

INSTRUCTION No. 7100642 (Rev. 2, 12/14/2006)

TP 200-5173-R2-AT-SN

SECURE AIR LIFT

TO TOP OF BLADE

FIGURE 2

INSTALL BAFFLE

TO OUTSIDE

FRONT OF DECK

!

WASHER

AND NUT (3)

38” DECK

USE

EXISTING

NUTS

HEX HEAD CAP

SCREW

WASHER AND

LOCK NUT

(Components removed for clarity)

MACHINE

SCREW (3)

FIGURE 3

42” DECK

MACHINE

SCREW (2)

LOCK NUT (2)

INSTALL BAFFLE TO OUTSIDE

FRONT OF DECK

NOTE: CASTER

MAY DIFFER FROM

ONE SHOWN

NOTE: Refer to the parts lists at the end of this manual for

additional assistance with component identification.

7600023 TWIN BAG CATCHER KIT FOR 38” SNAPPER / SIMPLICITY RZT RIDING MOWER

7600024 TWIN BAG CATCHER KIT FOR 42” SNAPPER / SIMPLICITY RZT RIDING MOWER

Page 2

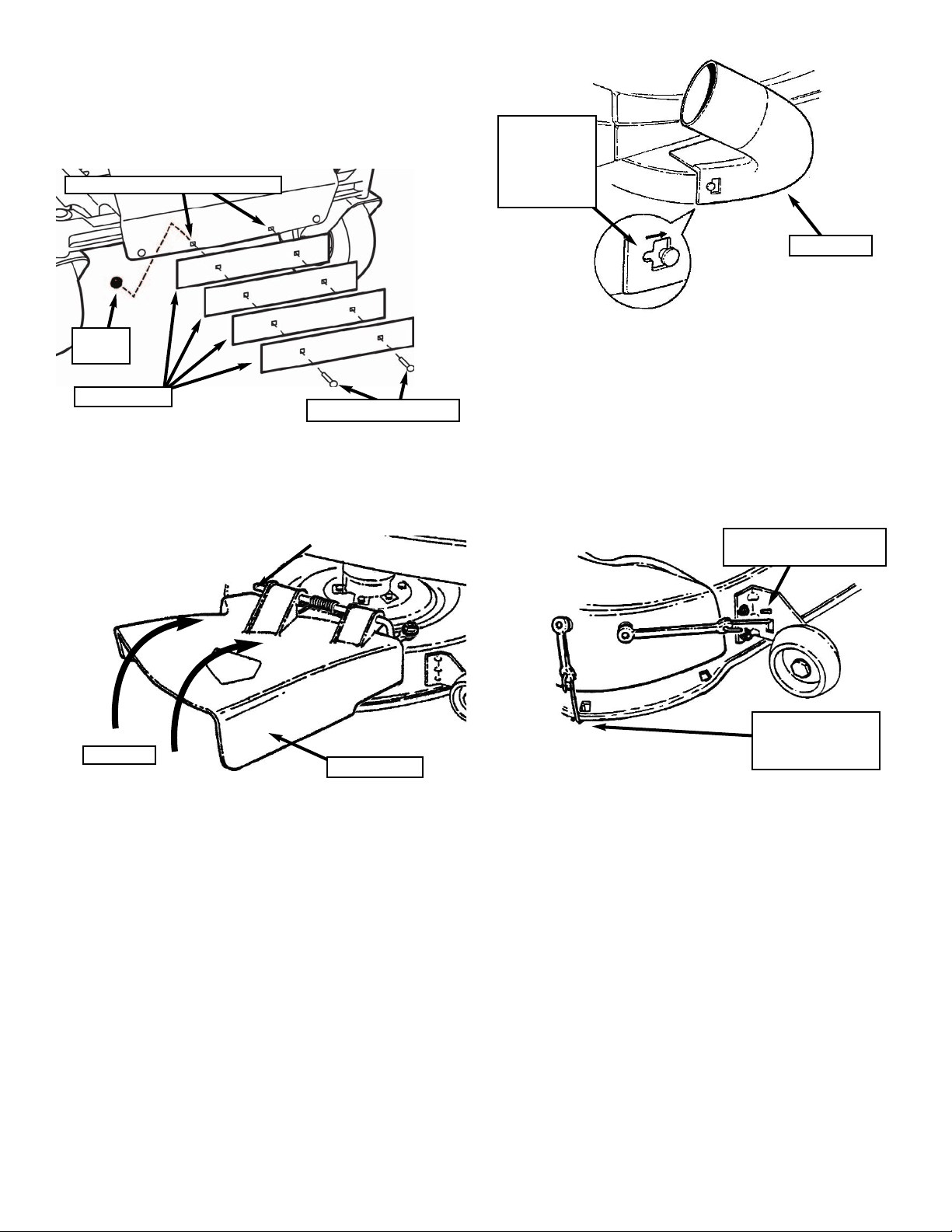

STEP 3: Remove the two innermost front carriage bolts

securing the unit footrest to the frame. Install the four

ballasts against the front of the machine, securing with the

supplied 5/16 x 1-3/4” carriage bolts and lock nuts in place

of those removed. Tighten hardware securely. See Figure 4.

STEP 4: Install the bag adapter (38” Deck):

a. Raise the discharge deflector. See Figure 5.

b. Use the existing tee nut for mounting the rear of the

adapter to the side of the deck. See Figure 6.

c. Secure the front adapter mounting strap to the slots in the

anti-scalp wheel bracket. Secure the other strap to the hole

in the deck flange. See Figure 7.

NOTE: Refer to Step 12 for instructions on installing the

adapter mounting straps.

FIGURE 4

REMOVE EXISTING HARDWARE

CARRIAGE BOLTS

BALLASTS (4)

FIGURE 5

DEFLECTOR

RAISE

FIGURE 6

ADAPTER

PLACE HOLE

OVER TEE NUT

AND SLIDE

ADAPTER

FORWARD

2

FIGURE 7

SECURE SECOND

STRAP TO HOLE IN

DECK FLANGE

SECURE FRONT STRAP

TO WHEEL BRACKET

LOCK

NUT (2)

Page 3

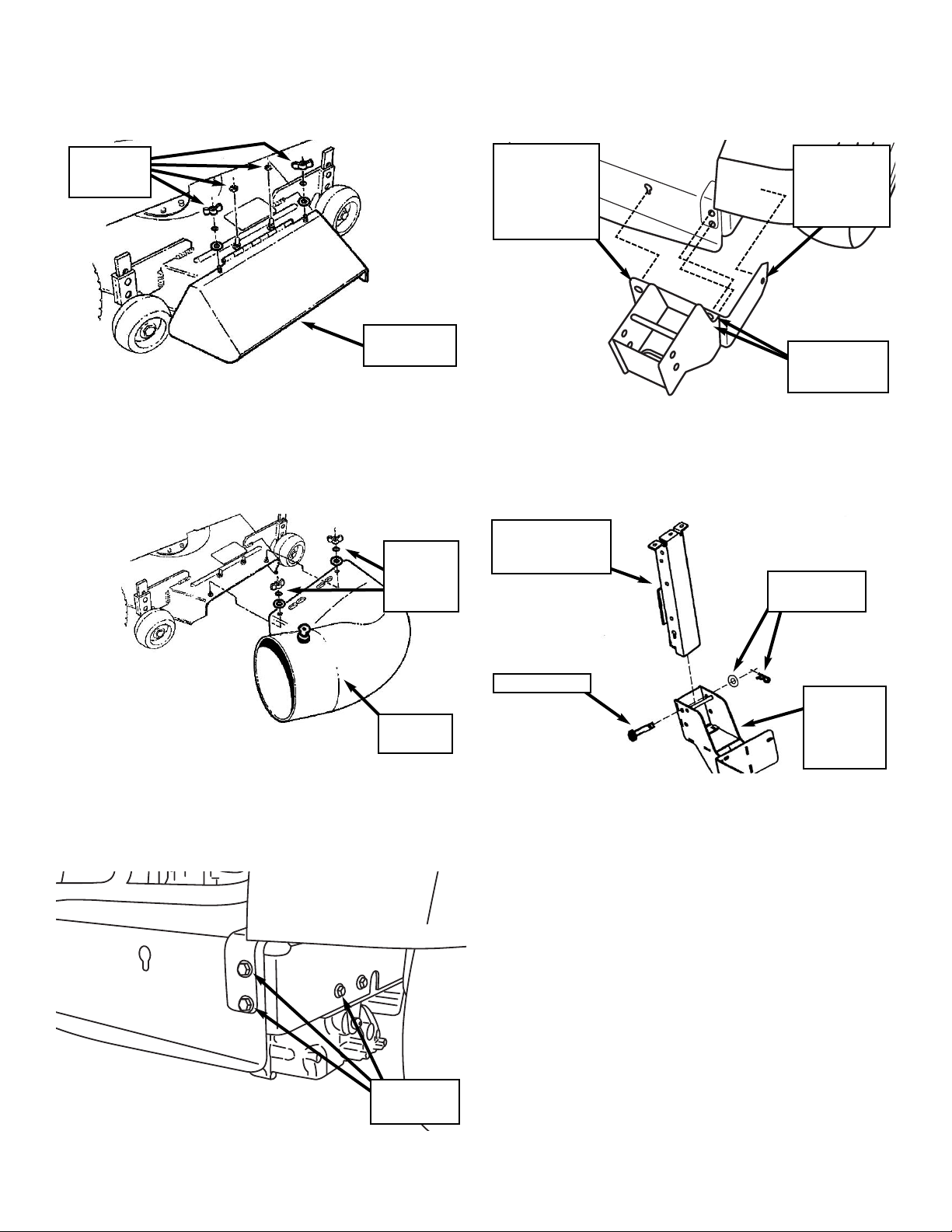

STEP 5: Install the bag adapter (42” Deck):

a. Remove the wing nuts, split lock washers, flat washers,

and hex nuts that secure the deflector to the deck, and

remove the deflector. See Figure 8.

b. Fit the two top holes in the adapter over the wing nut

studs. Secure the adapter with the flat washers, split lock

washers and wing nuts removed in Step 5a. Tighten

securely. See Figure 9.

STEP 6: Install the grass catcher support:

a. Remove the three noted bolts and nuts from the right rear

of the unit. See Figure 10.

b. Install the catcher support onto the unit, securing with the

hardware noted in Figure 11. Tighten all hardware securely.

NOTE: Be sure to reinstall any components that may have

been removed when removing the hardware in Step 6a.

STEP 7: Insert the bagger channel into the grass catcher

support, and secure with two 1/2 x 4-3/16” clevis pins,

washers, and hair pins. See Figure 12.

3

FIGURE 8

REMOVE

DEFLECTOR

FIGURE 9

INSTALL

ADAPTER

INSTALL

WASHERS

AND WING

NUTS

FIGURE 11

SECURE WITH

REMOVED

HARDWARE

SECURE WITH

SUPPLIED 5/16

x 3/4” HEX

WASHER HEAD

BOLT & FLANGE

LOCK NUT

SECURE WITH

SUPPLIED 5/16

x 3/4” HEX

WASHER

HEAD BOLT

FIGURE 12

INSERT CHANNEL

INTO CATCHER

SUPPORT

CATCHER

SUPPORT

(SHOWN

DETACHED

FROM UNIT)

WASHER &

HAIR PIN (2)

CLEVIS PIN (2)

REMOVE

NUTS AND

WASHERS

FIGURE 10

REMOVE

HARDWARE

Page 4

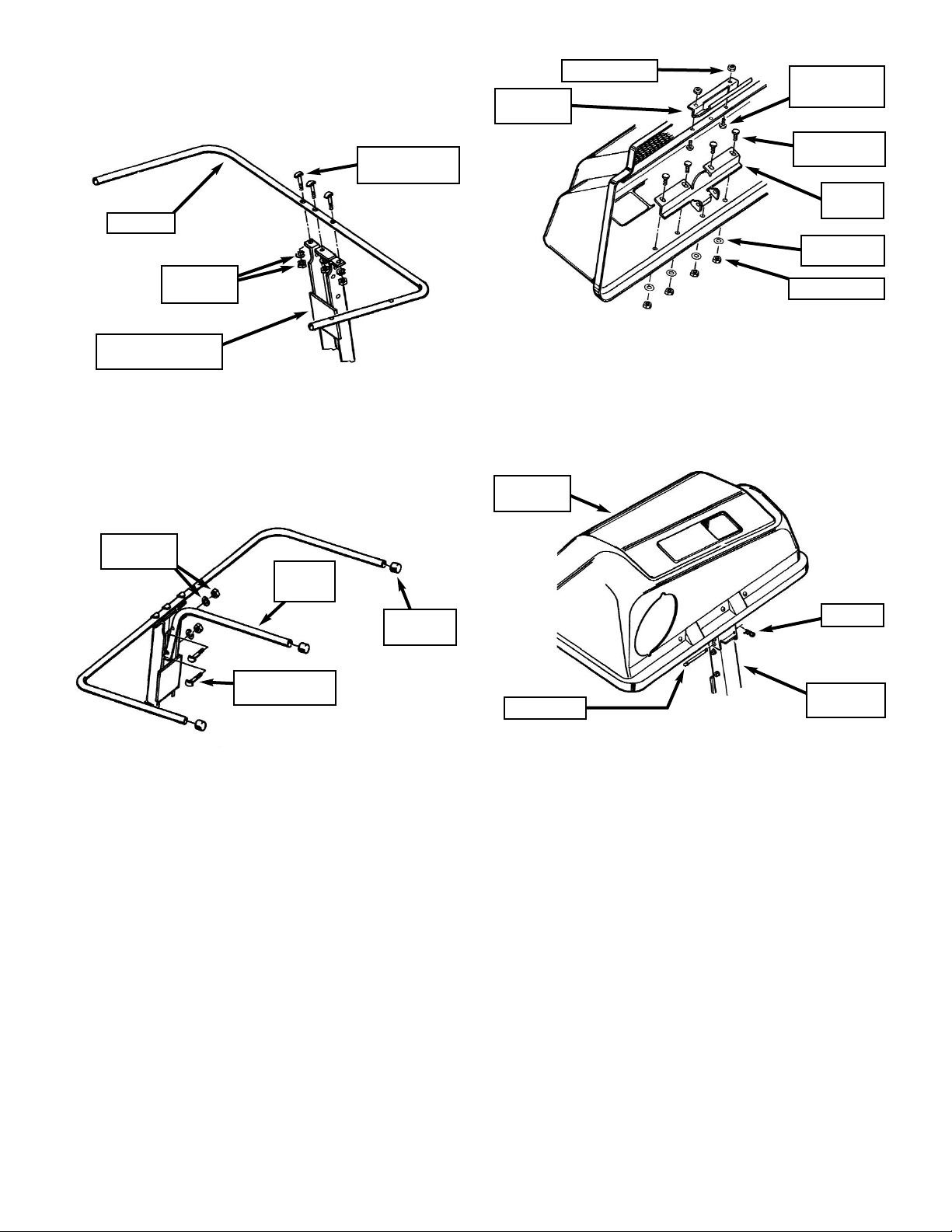

STEP 8: Install the U-tube onto the top of the bagger chan-

nel, securing with three 5/16-24 x 1-5/8” curved head bolts,

split lock washers, and hex nuts. See Figure 13. Tighten

hardware securely.

STEP 9: Install the center tube into the center of the bagger

channel, securing with two 5/16-24 x 1-5/8” curved head

bolts, split lock washers, and hex nuts. Tighten hardware

securely. Also insert one tube end cap into each of the three

open tube ends. See Figure 14.

STEP 10: Install the cover hinge to the inside back of the

cover assembly, securing with four 1/4 x 3/4” carriage bolts,

flat washers, and lock nuts. Also, install the cover handle

onto the screen support bar, behind the front of the cover

assembly, securing with two pan head screws and lock nuts.

See Figure 15.

NOTE: On some units, the cover handle has been preassembled onto the cover assembly.

STEP 11: Attach the cover assembly to the bagger channel

by aligning the holes in the cover hinge with the top set of

holes in the bagger channel. Insert the hinge pin through

the holes, and secure with a hair pin. See Figure 16.

4

FIGURE 13

U-TUBE

BACK OF BAGGER

CHANNEL

CURVED HEAD

BOLT (3)

WASHER &

NUT (3)

FIGURE 14

CENTER

TUBE

CURVED HEAD

BOLT (2)

WASHER &

NUT (2)

TUBE END

CAP (3)

FIGURE 15

CARRIAGE

BOLT (4)

COVER

HANDLE

COVER

HINGE

LOCK NUT (2)

PAN HEAD

SCREW (2)

FIGURE 16

BAGGER

CHANNEL

COVER

ASSEMBLY

HAIR PIN

HINGE PIN

LOCK NUT (4)

FLAT

WASHER (4)

Page 5

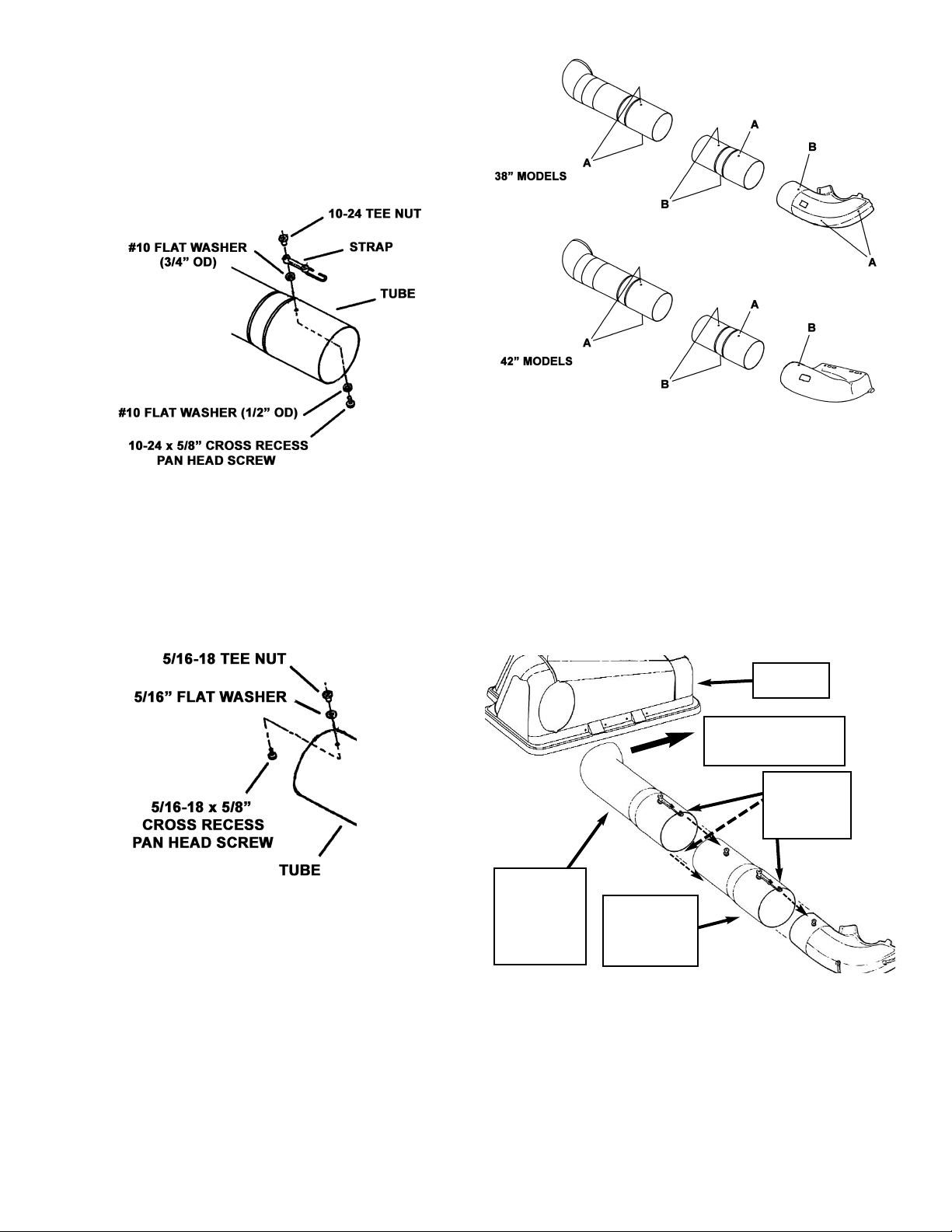

STEP 12: Assemble the discharge tubes:

a. Install one strap assembly to each of the locations

marked ‘A’ in Figure 19. Insert one #10-24 x 5/8” pan head

screw, fitted with one #10 x 1/2” OD flat washer, out through

the hole in the tube or adapter. Secure with one #10 x 3/4”

OD flat washer, strap, and #10-24 tee nut, tightening

securely. See Figure 17.

b. Install one tee nut assembly to each of the locations

marked ‘B’ in Figure 19. Insert one 5/16 x 5/8” pan head

screw out through the hole in the tube or adapter. Secure

with one 5/16” flat washer and 5/16-18 tee nut, tightening

securely. See Figure 18.

c. Install the large end of the lower tube (short, straight tube)

onto the end of the adapter, and secure the strap on the

tube to the tee nut on the adapter. See Figure 20.

d. Intall the curved end of the upper tube into the hole in the

cover assembly, making sure the discharge faces toward

the left of the unit. Install the bottom of the upper tube onto

the top of the lower tube, and secure the two straps on the

upper tube to the two tee nuts on the lower tube. See

Figure 20.

5

FIGURE 17

ATTACH TO ALL

‘A’ LOCATIONS

(SEE FIGURE 19)

FIGURE 18

ATTACH TO ALL

‘B’ LOCATIONS

(SEE FIGURE 19)

FIGURE 19

FIGURE 20

COVER

ASSEMBLY

INSTALL

UPPER TUBE

INTO COVER

ASSEMBLY,

THEN OVER

LOWER TUBE

DISCHARGE SHOULD

FACE TOWARD LEFT

SIDE OF UNIT

INSTALL

LOWER TUBE

OVER

ADAPTER

SECURE

STRAPS TO

‘T’ NUTS

(3 PLACES)

Page 6

STEP 13: Assemble the grass containers:

a. Match the numbers on the side of each container

segment with its corresponding segment. ‘1’s and ‘2’s

designate the first container, ‘3’s and ‘4’s designate the

second. See Figure 21.

b. With the matched numbers aligned, insert the bottom

segment of each container through the middle segment, and

the middle segment through the top segment, until the tabs

around the top of each segment lock the segment in place.

See Figure 21.

c. With the containers assembled, firmly insert one plastic

fastener out through the aligned holes in all four sides where

the top and middle segments meet. See Figure 22.

STEP 14: Flip open the cover assembly, then slide each

container fully onto the U-tube assembly. See Figure 23.

NOTE: Make sure that the warning label on the side of each

container is facing out.

When closing the cover, make sure that the cover handle

locks under the lips of the containers.

Assembly is complete.

6

FIGURE 21

MATCH &

ALIGN

NUMBERS

TABS

FIGURE 22

INSERT FASTENERS

(4 PER CONTAINER)

FIGURE 23

WARNING

LABELS

FACING

OUT

COVER HANDLE

SHOULD LOCK ONTO

CONTAINERS WHEN

COVER IS CLOSED

SLIDE CONTAINERS

ONTO U-TUBES

Page 7

Operation:

To use the bagger:

-Start the engine.

-Move the throttle control to the fast position.

-To fill the containers, always operate at a slow ground

speed.

To check and clean the discharge tubes:

-Stop machine motion, turn off the blades, stop the engine.

-Disconnect the straps securing the discharge tubes, and

remove the tubes.

-If needed, clear the discharge tubes of clogged debris,

and clean with soap and water.

-Replace the discharge tubes.

To empty the containers:

-Stop machine motion, turn off the blades, stop the engine.

-Pull the cover handle back and raise the cover.

-Remove the containers and empty as needed.

NOTE: For easy removal of grass, use a 33 gallon plastic

lawn bag inside each container.

7

WARNING

To prevent injury or damage, always follow the

operating instructions supplied with your machine

when operating the bagger.

! !

Page 8

8

TWIN BAG CATCHER COMPONENTS - 38” RZT / JAVELIN

Page 9

9

TWIN BAG CATCHER COMPONENTS - 38” RZT / JAVELIN

ITEM NO. PART NO. QTY DESCRIPTION

1 7100658 1 ASSY., TWIN COVER - 38/42

7100659 1 COVER, TWIN - 38/42

1673320 4 RIVET, LARGE FLANGE - .188 X .617

1910531 4 WASHER, RIVET.188 (.20IDX.50OD)

1732490 4 FASTENER - PUSH DIA .25 X .70

1732488 1 SCREEN, TWIN COVER

1732489 1 SUPPORT, SCREEN - TWIN COVER

1732819 1 DECAL, WARNING

2 720524 1 HINGE, COVER

3 7091530 4 CARRIAGE BOLT, 1/4-20 X 3/4

3a 7091294 4 WASHER, SAE, 1/4

4 7091603 4 HEX CENTER LOCK NUT, 1/4-20

5 720525 1 PIN, COVER HINGE

6 7091503 3 PIN, HAIR, 3/32 X 1.5

7 720537 1 HANDLE, COVER

8 7036415 7 CROSS RECESS PAN HEAD, 10-24 X 5/8

9 7091290 2 HEX LOCK NUT, 10-24 UNC-2B, W/NYLON INSERT

10 1732867 1 WELD, CHANNEL SUPPORT

11 720529 1 TUBE, U

12 720530 1 TUBE, CENTER

13 720079 5 CURVED HEAD BOLT, 5/16-24 X 1.625

14 7091315 5 SPLIT LOCK WASHER, .32 X .58 X .08

15 7091297 11 HEX NUT, 5/16-24 GR5

16 720339 3 CAP, TUBE END

17 720553 1 ASSEMBLY, NESTABLE CONTAINER - TWIN BAG (SET OF 2)

18 7016704 8 PANEL FASTENER

19 7400094 1 WELDMENT, GRASS CATCHER SUPPORT - RZT

20 7091541 2 HEX WASHER HEAD SELF TAPPING BOLT, 5/16-18 X 3/4

21 7091601 1 FLANGE LOCK NUT, 5/16-18

22 7900034 2 PIN, CLEVIS - 1/2" X 4.160

23 7090250 2 SAE WASHER, 1/2

25 7100618 1 TUBE, UPPER - TWIN BAG - 38" & 42" RZT

26 7091575 3 HEX CENTER LOCK NUT, 5/16-18

27 7091552 5 FLAT WASHER, .219X.500X.049 BL

28 7036422 5 WASHER, FLAT- .190 I.D. X .75 O.D.

29 7036433 5 STRAP, MOUNTING BAG ADAPTER/TUBE

30 7036404 5 NUT, WELD-10/24 THREAD

31 7091833 3 CROSS RECESSED PAN HEAD SCREW, 5/16-18 X 5/8

32 7090188 4 FLAT WASHER, .34X.69X.08

33 7036543 3 TEENUT, 5/16-18 THREAD

34 7100645 1 TUBE, LOWER - TWIN BAG - 38" RZT

35 7500211 1 ASSY., BAGGER/DECAL 38" RZT

7100608 1 DISCHARGE, CHUTE - 8.25 O.D. BAGGER 38" RZT

36 7046720 1 DECAL, CHUTE/DEFLECTOR

Page 10

10

TWIN BAG CATCHER COMPONENTS - 38” RZT / JAVELIN

Page 11

11

TWIN BAG CATCHER COMPONENTS - 38” RZT / JAVELIN

ITEM NO. PART NO. QTY DESCRIPTION

37 7091318 1 HEX HEAD CAP SCREW, 5/16 X 3/4 GR5

38 7300369 1 BAFFLE, 38" DECK - RZT

39 7060480 2 AIR LIFT KIT - COMPLETE

40 7037723 4 AIR LIFT

41 7090228 6 OVAL HEAD MACHINE SCREW, 5/16-24 X .656

42 7090391 6 INTERNAL TOOTH LOCK WASHER 5/16

43 7300367 4 BALLAST-TWIN BAG CATCHER - RZT

44 7900039 2 CARRIAGE BOLT, 5/16-18 X 1.75 GR5

Page 12

12

TWIN BAG CATCHER COMPONENTS - 42” RZT / JAVELIN

Page 13

13

TWIN BAG CATCHER COMPONENTS - 42” RZT / JAVELIN

ITEM NO. PART NO. QTY DESCRIPTION

1 7100658 1 ASSY., TWIN COVER - 38/42

7100659 1 COVER, TWIN - 38/42

1673320 4 RIVET, LARGE FLANGE - .188 X .617

1910531 4 WASHER, RIVET.188 (.20IDX.50OD)

1732490 4 FASTENER - PUSH DIA .25 X .70

1732488 1 SCREEN, TWIN COVER

1732489 1 SUPPORT, SCREEN - TWIN COVER

1732819 1 DECAL, WARNING

2 720524 1 HINGE, COVER

3 7091530 4 CARRIAGE BOLT, 1/4-20 X 1/2

3a 7091294 4 WASHER, SAE, 1/4

4 7091603 4 HEX CENTER LOCK NUT, 1/4-20

5 720525 1 PIN, COVER HINGE

6 7091503 3 PIN, HAIR, 3/32 X 1.5

7 720537 1 HANDLE, COVER

8 7036415 5 CROSS RECESS PAN HEAD SCREW, 10-24 X 5/8

9 7091290 2 HEX LOCK NUT, 10-24 UNC-2B W/NYLON INSERT

10 1732867 1 WELD, CHANNEL SUPPORT

11 720529 1 TUBE, U

12 720530 1 TUBE, CENTER

13 720079 5 CURVED HEAD BOLT, 5/16-24 X 1.625

14 7091315 5 SPLIT LOCK WASHER, .32 X .58 X .08

15 7091297 5 HEX NUT, 5/16-24 GR5

16 720339 3 CAP, TUBE END

17 720553 1 ASSEMBLY, NESTABLE CONTAINER - TWIN CATCHER (SET OF 2)

18 7016704 8 PANEL FASTENER

19 7400094 1 WELDMENT, GRASS CATCHER SUPPORT - RZT

20 7091541 2 HEX WASHER SELF TAPPING BOLT, 5/16-18 X 3/4

21 7091601 3 FLANGE LOCK NUT, 5/16-18

22 7900034 2 PIN, CLEVIS - 1/2" X 4.160

23 7090250 2 SAE WASHER, 1/2

24 7046720 1 DECAL, CHUTE/DEFLECTOR

25 7100618 1 TUBE, UPPER - TWIN BAG - 38" & 42" RZT

26 7091575 2 HEX CENTER LOCK NUT, 5/16-18

27 7091552 3 FLAT WASHER, .219X.500X.049 BL

28 7036422 3 WASHER, FLAT- .190 I.D. X .75 O.D.

29 7036433 3 STRAP, MOUNTING BAG ADAPTER/TUBE

30 7036404 3 NUT, WELD, 10/24 THREAD

31 7091833 3 CROSS RECESSED PAN HEAD SCREW, 5/16-18 X 5/8

32 7090188 3 FLAT WASHER, .34X.69X.08

33 7036543 3 TEENUT, 5/16-18 THREAD

34 7100617 1 TUBE, LOWER - TWIN BAG - 42" RZT

35 7051663 1 CHUTE ASSY

Page 14

14

TWIN BAG CATCHER COMPONENTS - 42” RZT / JAVELIN

Page 15

15

TWIN BAG CATCHER COMPONENTS - 42” RZT / JAVELIN

ITEM NO. PART NO. QTY DESCRIPTION

36 7091613 2 PAN HEAD MACHINE SCREW, 5/16-18 X 3/4

37 7300386 1 BAFFLE, 42" DECK - RZT

38 7300367 4 BALLAST-TWIN BAG CATCHER - RZT

39 7900039 2 CARRIAGE BOLT, 5/16-18 X 1.75 GR5

Page 16

16

INSTRUCTION No. 7100642 (Rev. 2, 12/14/2006)

TP 200-5173-R2-AT-SN

Loading...

Loading...