Page 1

SET-UP INSTRUCTIONS & PRE-OPERATION CHECKLIST

AS SHOWN

CABLE

For SNAPPER “W” SERIES REAR ENGINE RIDERS

INTRODUCTION: The SNAPPER “W” Series Rear Engine Riders are shipped fully assembled and require

minimal set-up. Complete each of the following steps carefully. Review and complete each item as instructed

on the Pre-Operation checklist. The Snapper Product Registration card must be filled out and sent to Customer

Service department at Snapper when completed.

BATTERY ACTIVATION and INSTALLATION

Snapper riders with a model prefix “ W ” are supplied with

wet batteries and do not require the addition of

electrolyte. All batteries require a slow charge before

being placed into service.

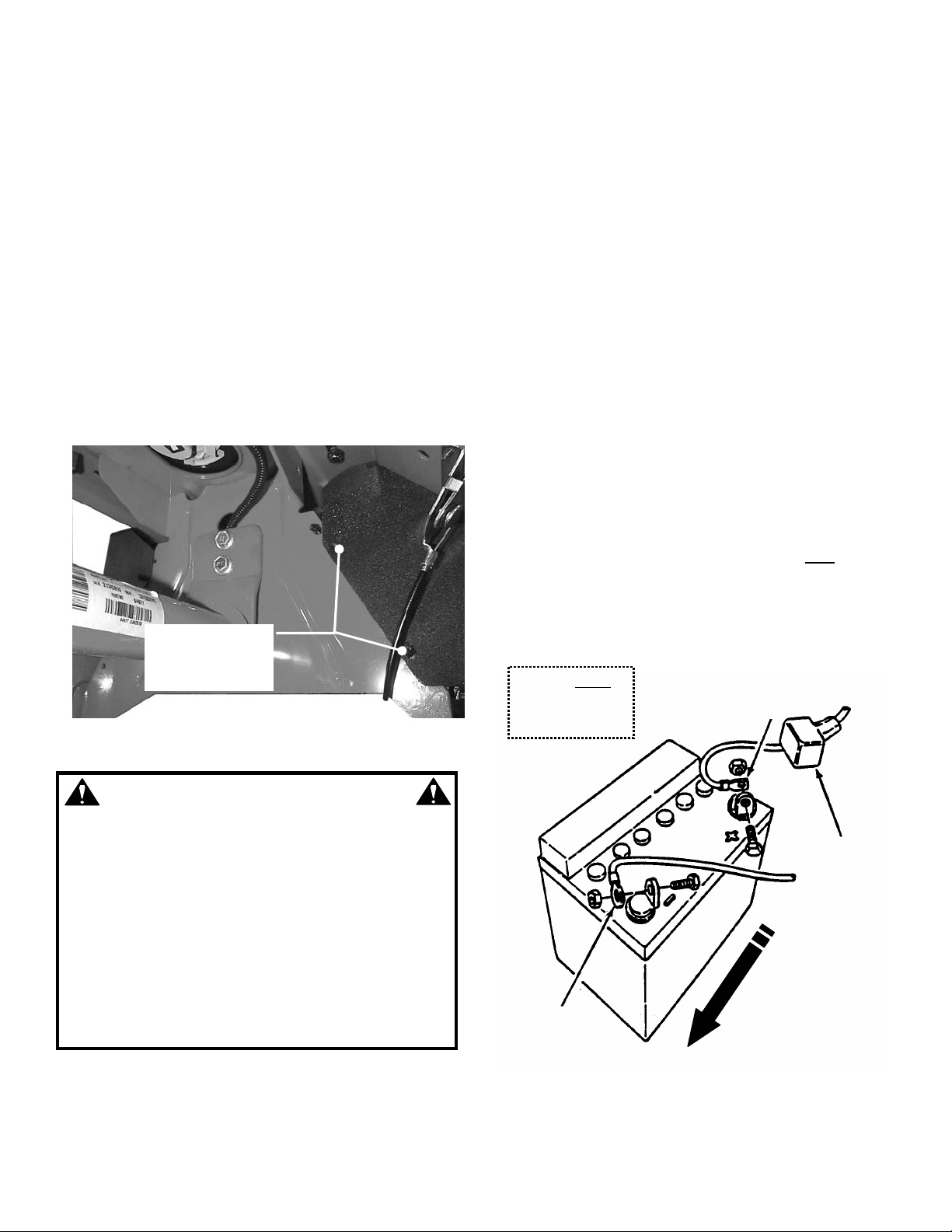

1. BATTERY REMOVAL

A. Remove battery cover by pulling each side away

from ratchet fasteners. See Figure 1.

B. Remove the hair pin and swivel f rom the deck

support to allow clearance for battery removal.

C. Remove battery from battery compartment.

PULL COVER AWAY

FROM RATCHET

FASTENERS ON

BOTH SIDES

FIGURE 1

2. BATTERY CHARGING

A. With all cell caps removed, connect an

automotive type battery charger to battery

terminals; RED to positive (+) and BLACK to

negative (-) terminal.

B. Slow charge at 2 to 6 amps for 30 minutes.

C. After charging, check level of electrolyte, add

water only if necessary, and tighten cell caps.

3. BATTERY INSTALLATION

A. Slide battery partially into box, with positive end to

inside and terminals to rear, to allow for cable

installations.

B. Battery cables MUST BE SECURED TO

BATTERY TERMINALS as shown in Figure 2,

using the 1/4” screws, that are mounted on

terminals, and lock nuts from the hardware bag.

C. Install positive (+) cable first. Place the positive

(+) terminal insulator over positive terminal and

cable. Install negative (-) cable last after

terminal insulator has been installed.

See Figure 2.

D. Slide battery into battery box and reinstall battery

cover.

E. Reinstall deck support swivel and hair pin.

CABLES MUST

BE MOUNTED

TO TERMINALS

RED POSITIVE (+)

positive

WARNING

The electrolyte (acid) produces a high ly explosive gas.

Keep all sparks, flame and fire away from area when

charging battery or when handling electrolyte or

battery. Electrolyte (acid) is a highly corrosive liquid.

Wear eye protection. Wash affected areas immed iately

after having eye or skin contact w ith electrolyte (acid).

Battery acid is corrosive. Rinse empty acid containers

with water and mutilate before discarding. If acid is

spilled on battery, bench, or clothing, etc., Flush with

clear water and neutralize with baking soda. DO NOT

attempt to charge battery while installed on the RIDER.

DO NOT use “BOOST” chargers on the battery. DO

NOT OVER FILL!

POSITIVE

TERMINAL

INSULATOR

TO OUTSIDE OF

MOWER

BLACK

NEGATIVE (-)

CABLE

FIGURE 2

INSTRUCTION No. 7-5122 (I.R. 6/28/02)

1

Page 2

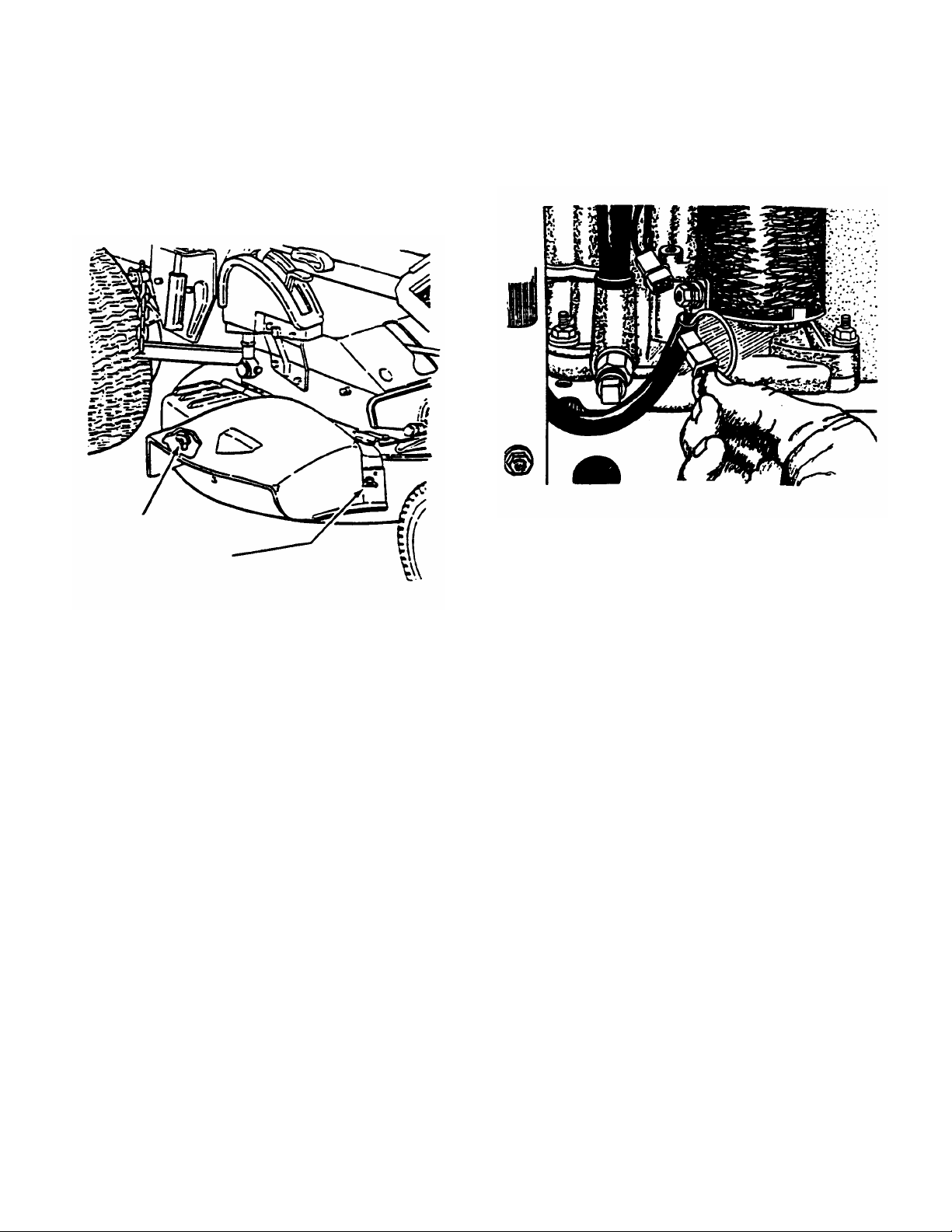

DISCHARGE DEFLECTOR

The discharge deflector is shipped in the “UP” position.

Remove rubber band, lower discharge deflector and

secure to deck with carr iage bolt(s), flat washer(s) and

wing nut(s) furnished in the deck. See Figure 3.

ELECTRICAL CIRCUIT

The electrical connection at the engine is shipped

disconnected to protect the electrical system when the

battery is installed and MUST BE THE LAST STEP in

preparation.

A. Connect electrical circ uit at rear of the engine.

See Figure 4.

SECURE DISCHARGE

DEFLECTOR TO DECK

WITH CARRIAGE BOLTS,

FLAT WASHERS, AND

WING NUTS

FIGURE 3

FIGURE 4

LUBRICATION and FUEL

1. Engine

A. Perform normal engine service, oil and fuel,

according to engine manuf acturer’s recomm endations

found in the Engine Owner’s Manual.

PRE-OPERATION CHECKLIST

Complete all items on the Pre-Operation Checklist as

instructed.

2

Page 3

SERVICE NOTES

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

3

Page 4

PRE-OPERATION CHECKLIST

Snapper has completed initial adjustments and performed operational tests prior to shipping the machine. Due

to the possible effects of shipping, handling and storage, Snapper intends for all of the following items to be

verified and necessary final adjustments made at time of setup. It remains good practice and is strongly

recommended that all the items also be checked prior to placing the machine into service. It is very important

that setup is verified and all o perational t ests complet ed and result s are acceptable. After completing t his form,

sign and retain for future reference.

SET-UP CHECKLIST

_____ STEERING WHEEL and steering shaft assembled.

_____ TIE RODS connected.

_____ LUBRICATION of entire unit completed.

_____ OPERATOR’S SEAT installed and tightened and seat switch connected.

_____ FUEL TANK installed and fuel line connected.

_____ GRASS DEFLECTOR, MULCH COVER or CATCHER ADAPTER and assembly positioned, secured, checked.

_____ BATTERY activated and charged per instructions and installed into battery compartment on machine.

_____ TIRE inflated to proper Pounds per Square Inch (PSI). Front tire is 12 PSI and Rear tire is 12 PSI.

CUTTING BLADE & MOWER

_____ BLADE RETAINING hardware checked for proper tightness.

_____ BLADE TIP CLEARANCE inside lower edge of mower checked and corrected as needed.

_____ BLADE STRAIGHTNESS checked and adjusted as required.

_____ MOWER CUTTING HEIGHT settings checked and adjusted as needed (with tires properly inflated).

_____ MOWER SIDE TO SIDE level checked and adjusted as needed (with tires properly inflated).

_____ MOWER FRONT TO REAR setting checked and adjusted as needed (with tires properly inflated).

_____ BLADE LEVER checked and adjusted as required.

_____ BELT TENSION checked and adjusted as required.

_____ REVERSE LOCKOUT MECHANISM shifter will not go into reverse when blade pedals are depressed.

PRE-START CHECKS & SERVICES

_____ TIRES checked and inflated to correct pressures.

_____ ENGINE OIL level checked.

_____ DIFFERENTIAL check lubricant and add as needed.

_____ CHAIN CASE check lubricant and add as needed.

_____ YOKE ASSEMBLY checked for freedom of movement.

_____ FUEL added to tank and system checked for leaks. Refer to Engine’s Owner’s Manual for fuel specifications.

_____ BATTERY (not overfilled!) reinstalled and properly connected with red boot over positive terminal.

OPERATIONAL TESTS

_____ CHECK SEAT SWITCH for proper function

_____ INTERLOCK SYSTEMS checked to insure proper functioning.

_____ ENGINE STARTED and throttle control settings checked.

_____ IGNITION SWITCH checked to insure engine stops when turned to OFF position.

_____ PARKING BRAKE tested to insure proper operation.

_____ CLUTCH/BRAKE tested for proper operation and adjusted as required.

_____ BLADE STOPS in 3 seconds or less after releasing the blade pedal. Adjust blade brake as required.

_____ BLADE LEVER can be moved to OFF position with blade pedal depressed.

CONSUMER INFORMATION

SALE DATE

Retailer's Name

Address_________________________ City

MACHINE WILL BE USED COMMERCIALLY? YES _________ NO

Purchaser's Name

Address_________________________ City

IMPORTANT: This form is to be retained for future reference regarding Warranty, proof of purchase, traceability for product

recall or service, etc. Complete the Product Registration Card immediately and mail to: Customer Service Department at

SNAPPER, P.O. BOX 1379, McDonough, Georgia, 30253.

MACHINE MODEL SERIAL NO.

Signature

State Zip

Signature

State Zip

INSTRUCTION No. 7-5122 (I.R. 6/28/02)

4

Loading...

Loading...