Page 1

1

SETUP INSTRUCTIONS AND PRE-OPERATION CHECKLIST FOR

LUG NUTS

SNAPPER GROUNDS CRUISER UTILITY VEHICLE

INTRODUCTION: These instructions cov er the setup of the Snapper Grounds Cruiser utility vehicle. Complete

each step carefull y. A checklist h as been provid ed. It is v ery important to v erify and record each item on t he

list prior to placing the machine into service. The dry weight of the machine you are about to setup is 1,230 lb. It

is strongly recommended that you use an overhead hoist when lifting the machine. The capacity of the device

used for lifting must exceed the weight of the machine. DO NOT work on the machine until properly blocked

and secured to prevent it from falling. If an overhead hoist is not available, you may have to remove boards

from the crate bottom to gain access with floor type jacks.

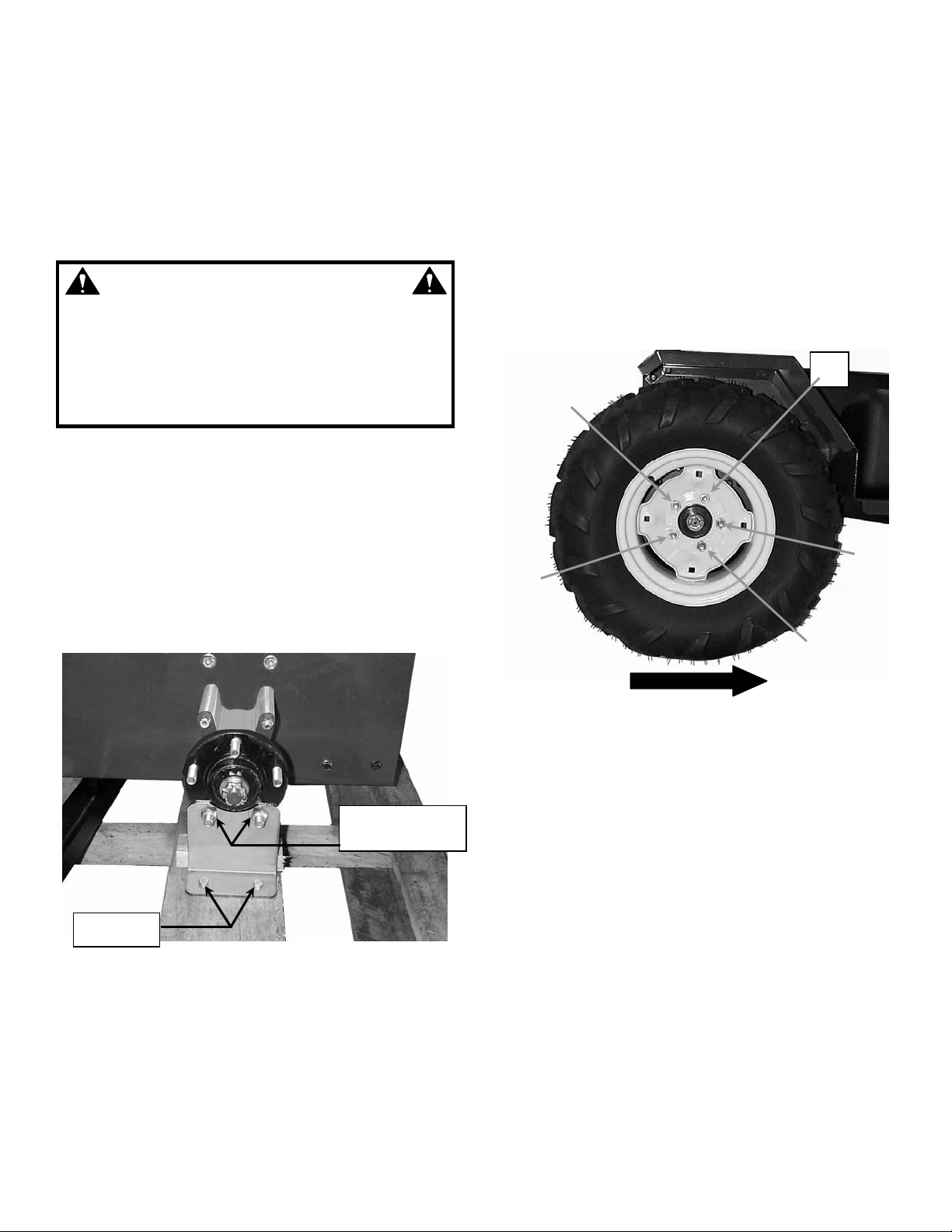

5. Install left and right rear tires and secure each with

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine running. STOP engine. Set

park brake. Shift transmission to neutral and

remove key. Remove spark plug wire from spark

plug and secure wi re away from sp ark plug. Eng ine

and components are HOT. Avoid serious burns,

allow all parts to cool before working on machine.

STEP 1

INSTALL REAR TIRES

The machine is secur ely attached to the c rate bottom at

each wheel location. See Figure 1.1. The four steel

plates must be rem oved before lifting t he machine. The

device used to lift the machine must have a capacity

greater than 1230 lb. The c argo bed is attached to the

frame of the machine with plastic straps. Carefully

remove the straps and set the cargo bed aside for

installation later.

5 lug nuts. NOTE: The tir es are directional. Instal l

with valve stem out and the points of the chevron

treads pointing forward. See Figure 1.2.

3

1

5

4

2

(LOOSEN ONLY)

REMOVE

FIGURE 1.1

1. Loosen only, two lug nuts at left and right rear

wheel hubs.

2. Remove the four bolts securing the left and right

support plates to the crate bottom.

3. Lift machine, at t he rear hitch, onl y high enough to

allow tire installation. Block machine securely to

prevent it from falling. Remove support plates.

4. Check castle nuts to insure that the cotter pins have

been fully inserted and hav e at leas t o ne l eg be nt to

secure in place.

POINTS OF TREADS POINTING TOWARD FRONT OF VEHICLE.

FIGURE 1.2

6. Remove blocks and lower rear of machine.

7. Torque lug nuts to 75 f t-lb using sequence shown.

See Figure 1.2.

STEP 2

INSTALL FRONT BUMPER

The bolts used to attach the front bumper to the

machine are already installed in the front frame. The

bumper can be used t o lift the weight of the f ront of the

machine. The mounting hardware must be tightened

securely (30 ft-lb).

1. Place bumper over f our bolts at front of fram e. Note

orientation, flat side of side plates towards bottom

2. Attach using (4) 3/8-16 flange lock nuts.

3. Torque nuts to 30 ft-lb.

INSTRUCTION No. 7-4510 (I.R. 5/3/01)

Page 2

2

STEP 3

REPRESENTING

SEAT

MOUNT

7/16-20X2”

1/2”X1

-

1/4”

1/2”X1

-

1/4”

7/16-20

2-1/2”

INSTALL FRONT TIRES

The front bumper can be used to lift the front of the

machine. Block the machine to prevent it from falling.

NOTE: The front tires are directional. Install with valve

stems out and with the points of the chevron treads

pointing forward.

1. Loosen only, two lug nuts at left and right front

wheel hubs.

2. Remove the four bolts securing the left and right

support plates to the crate bottom.

3. Lift front of machine on ly hi gh en oug h to ins t al l f r ont

tires. Block machine securely to prevent it from

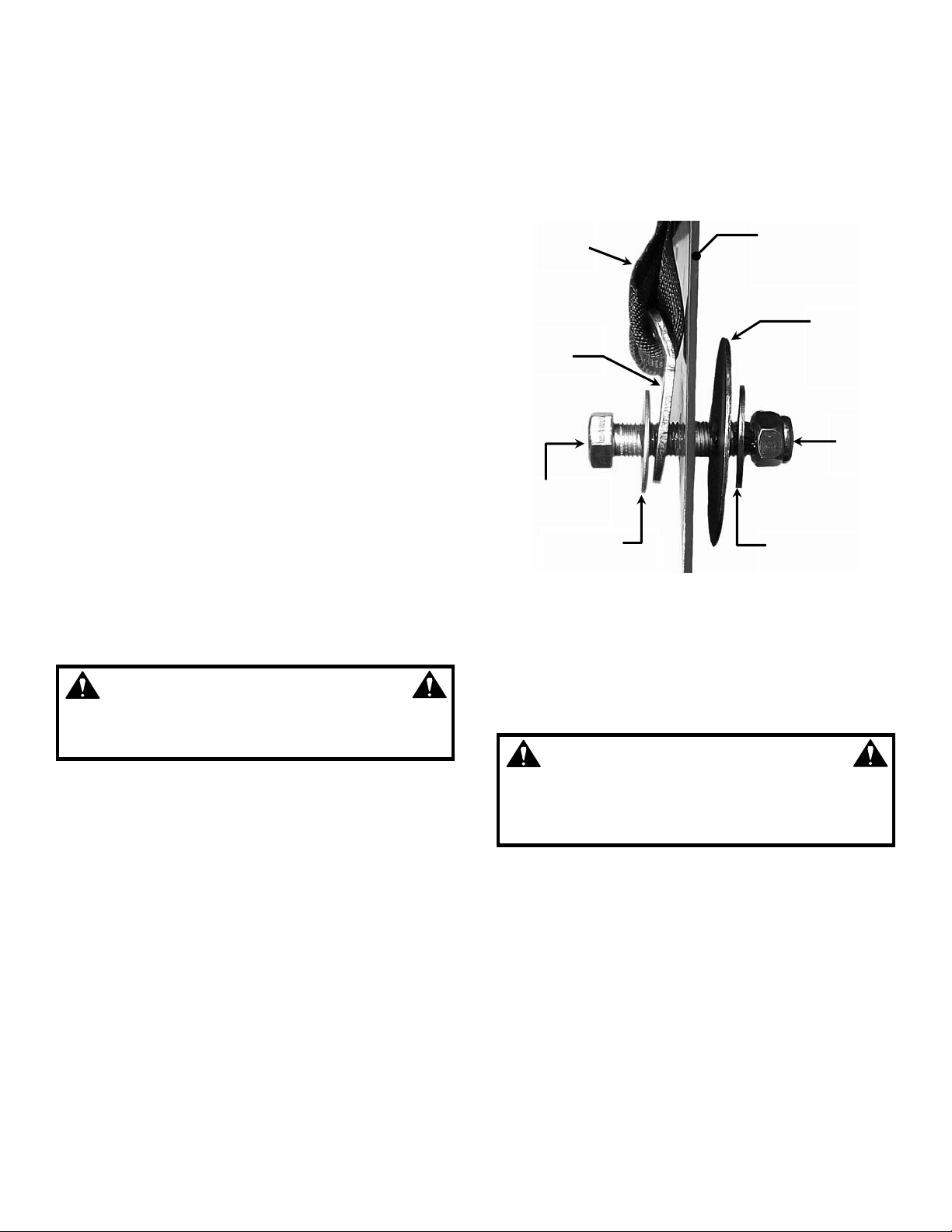

3. Place (1) 1/2” x 1 1/4“ d iameter flat washer on (1)

7/16-20 x 2” bolt. Inser t bolt with washer into seat

belt mounting plate. See Figure 1.3.

4. Insert bolt into hole in seat support. Place large

2 1/2” diameter flat washer over bolt against inside

surface of seat support.

5. Place (1) 1/2” x 1 1/4” flat washer on bolt. Install (1)

7/16-20 top lock nut.

BELT

SEAT SUPPORT

STRUCTURE

falling. Remove support plates.

4. REMOVE OPERATOR PROTECTIVE STRUCTURE

FROM CRATE B OTTOM A T TH IS TI ME.

5. Check front wheel hubs to insure that they rotate fr eely ,

the castle nuts are tight and the cotter pins are inserted

PLATE

DIAMETER

FLAT

WASHER

fully and have at least one leg bent to secure in pla ce.

6. Install left and right f ront tires and s ecure each with

5 lug nuts.

7. Remove blocks and lower machine.

8. Torque lug nuts to 75 f t-lb using sequence shown.

NYLOC

NUT

See Figure 1.2.

9. Install dust caps onto wheel hubs

HEX BOLT

STEP 4

ADJUST TIRE PRESSURE

IMPORTANT! C orr ect tir e i nflatio n pres sur e is cr itic al to

the proper handling and braking of the machine.

1. Using a low-pressure tire gauge, check tire

pressure.

2. Adjust tire pressure to 15 psi.

6. Tighten nut to a snug rotating fit. When properly

WARNING

Operator Protectiv e Structure and Seat Belts must

be installed and all mounting hardware tightened

securely before starting or operating machine.

STEP 5

INSTALL SEAT BELTS

Mounting of seat belts is very important. Assemble

carefully using the sequ ence shown. The seat belt wi th

the latch plate is typically attached at the outside

mounting hole. The seat belt with th e buc k le is attac h e d

at the inside or m iddle mounting hole. T ighte n hard w ar e

to a snug rotating fit as described below.

IMPORTANT! The la rge 2 1/2” diameter f lat w ashers

must be installed on the in side surface of the seat

support structure. See Figure 1.3.

1. Remove the top t wo bolts from the fuel tank straps

and slide tank out. This will allow clearance to

install the bolt used to mount the right seat belt.

See Figure 1.4.

NOTE: tank straps r em ain loos e unti l ST EP 6, O perato r

Protective Structure installation has been completed.

2. Locate seat belts and hardware bag.

7. Repeat for remaining three belts.

Safe operation of machin e limits total occupants to

(2), one operator and one passenger. Seat belts

must be securely latched and adjusted to a snug fit

before starting or operating the machine.

FLAT WASHER

FLAT WASHER

FIGURE 1.3

tightened the mounting bracket should be able to

rotate with some resistance to align properly with

seat position and size of operator, but not rattle.

WARNING

Page 3

3

STEP 6

FUEL TANK

REMOVE TOP

HEAT

INSTALL OPERATOR PROTECTIVE

STRUCTURE (OPS)

The installation of the Operator Protective Structure

requires two people. The mounting hardware for the

OPS and seat belts must be properly torqued. Do Not

modify the OPS in an y way. Install the OPS with the

“WARNING” sign on the ri ght (passenger’s) side of the

machine.

SHIELD

STRAPS

1. Locate the mounting hardware – (12) 3/8-16 x 1”

round head carriage bolts and (12) 3/8-16 Nyloc

nuts. Place 6 of each in the left and right seat

support tray for easy access when attaching OPS

to frame.

2. Raise OPS to vertical pos ition and ori entate so that

the “WARNING” decal located on the side of the

OPS is on the passenger’s side of the mac hine.

3. Align holes in OPS with holes in frame. Get (1)

carriage bolt started on each side. NOTE: insert

bolts with head to wards outs ide of fram e as sho wn.

Secure with 3/8-16 Nyloc n ut. Do not tight en at this

time.

4. Install remainder of the bolts and secure eac h with

a Nyloc nut.

5. Torque ALL OPS mounting hardware to 30-35 ft-lb.

6. Reattach fuel tank straps. Tighten hardware

securely.

7. Attach heat shield to OPS using (2) 5/16-18 selftapping bolts. Do Not tighten at this time.

8. Attach heat shield to left and right f rame rails usin g

(2) 5/16-18 x 7/8” bolts and (2) 5/16-18 NyLoc nuts.

9. Tighten all heat shield hardware securely.

10. Reattach fuel tank straps. Tighten hardware

securely.

TWO BOLTS

FIGURE 1.4

STEP 7

ENGINE OIL AND TRANSMISSION FLUID

The engine oil an d transmission fluid m ust be checked

before operation.

1. Fill engine crankcase to proper level. Refer to

Engine Owner’s Manual for capacity and oil

specifications. Check with dipstick unthreaded.

2. Check transmis sion fluid leve l. Bring to f ull level as

necessary using MOBILFLUID 424 or equivalent.

Check with dipstick fully threaded.

STEP 8

ACTIVATE BATTERY

Battery is located under the operator’s seat. Remove

battery from com partm ent before acti vatin g or char gin g.

Activate and charge t he battery in well ventilated area

away from sparks and flame. Do Not smoke.

1. Remove battery from the battery compartment

before charging.

2. Place battery in a well ventilated area on a level

non-concrete surface.

WARNING

The electrolyte (acid) produces a highly explosive gas.

Keep all sparks, flame and fire away from area when

charging battery or when handling electrolyte or

battery. Electrolyte (acid) is a highly corrosiv e liquid.

Wear eye protection. Wash affected areas immediately

after hav ing e ye o r skin c ont act with e lect rol yte ( aci d).

Battery acid is corrosive. Rinse empty acid containers

with water and mutilate before discarding. If acid is

spilled on battery, bench, or clothing, etc., Fl ush with

clear water and neutralize with baking soda.

3. Remove battery ce ll c aps . Fill c e lls as r e quired with

electrolyte (purchased separately) to proper level.

Fill to 3/16” above cell plates. Filling battery with

electrolyte will bring the battery to 80% of full

charged state.

IMPORTANT: 3/16” above cell plates is the

recommend ed leve l. Never p lace an ything in ba tter y other

than specified electrolyte.

WARNING

DO NOT OVERFILL!

4. With cell caps removed, c onnect battery charger to

battery terminals; RED to positive (+) and BLACK

to negative (-) terminal.

5. Slow charge the batter y at 4 to 6 amps f or 2 hours

to bring the battery to full charge.

6. After charging, check level of electrolyte and add as

needed to bring level to 3/16” above cell plates.

7. Reinstall cell caps. Tighten securely to prevent

leakage.

Page 4

4

RETAINING

POSITIVE (+) CABLES

NEGATIVE (

-

)

STEP 8 (Continued)

ACTIVATE BATTERY

8. Thoroughly clean any spilled acid from battery.

Neutralize with Baking Soda and flush with large

quantity of water. Dry off battery.

9. Install battery into power unit. Place battery into

battery tray and secure i n place with retaining rod.

See Figure 1.5.

ROD

FIGURE 1.5

10. Attach battery cables to t erminals on the batt ery as

shown. See Figure 1.6. Co nnect positive ( +) cables

(red) first, from wiring harness to the positive

terminal (+) on battery and secure wit h nu t pro vi ded

in hardware bag. Connect negative (-) cables

(black) last, to negative ter minal (-) on battery and

secure. Apply a small amount of grease over

terminals to prevent corrosion. See Figure 1.6.

(RED) WITH TERMINAL

COVER

CABLES (BLACK)

FIGURE 1.6

WARNING

Shield the positive terminal with Terminal Cover

located on Positive Battery Cable. This prevents

metal from touching the positive terminal, which

could cause sparks.

STEP 9

INSTALL STEERING WHEEL

Make sure that the front tires are aligned perfectly

straight before installing the steer in g whee l.

1. Make sure that front tires are pointing straight

forward.

2. Slide foam cover over steering shaft.

3. Remove plastic cover from center of steering

wheel.

4. Orientate the steering wheel so that spokes are

horizontal and align splines.

5. Place washer and nu t on steer ing shaft. T orque nut

to 50-70 ft-lb.

6. Install plastic cover in center of steering wheel.

STEP 10

INSTALL O PERATOR ’S A ND PASS ENGER’ S

SEAT

Carefully complete the following steps to install the

seats.

1. Check seat bolts to insure hinge p late is tightened

securely to the bottom of the seat. See Figure 1.7.

2. Align hinge plate with seat/pedestal assem bly and

insert hinge rod.

IMPORTANT: Hinge rod must protrude past both

sides of the hinge plate and be positively retained

by the hair pin.

3. Insert hair pin full y into hinge rod. Hairpin mus t be

between hinge plate and s eat/pedest al to reta in rod

properly. See Figure 1.7.

4. Check for 5/16” flat washer under head of seat

knobs. Install washer, if missing, and tighten knobs

securely.

Page 5

5

1/2-13 X 3”

1/2-13 X 3 3/4”

NYLOC NUT

STRIKER

STEP 10 (Continued)

INSTALL O PERATOR ’S A ND PASS ENGER’ S

SEAT

(3) SEAT BOLTS

BOLT & 1/2-13

NYLOC NUT

HINGE ROD

HAIRPIN

FIGURE 1.7

STEP 11

ATTACH CARGO BED

Attach bed to pivots at rear of frame. A prop rod is

provided to support an empty cargo bed onl y in a rais e d

position.

1. Align brackets on bottom rear of car go bed with left

and right pivots loc ate d at rear of f r am e. See Fig ur e

1.8.

2. Insert (1) 1/2-13 x 3 3/4” b olt in to eac h left an d right

pivot and secure with 1/2-13 NyLoc nuts. Tighten

securely.

3. Attach prop rod t o bracket on bottom of cargo bed

using (1) 1/2-13 x 3” bolt a nd (1) 1/2-13 N yLoc nut.

Tighten to a snug rotating fit.

BOLT & 1/2-13

PROP ROD

FIGURE 1.8

STEP 12

ALIGN CARGO BED LATCH

Lower the Cargo bed slowl y until the latch contacts the

striker pin. The head of the striker pin s hould be inside

of the latch as shown in figure 1.9. If it is not aligned

correctly, loosen the bolts that attach the left and right

bed pivot brackets. Then, position the latch over the

striker pin as show n in figur e 1.9 and re- tighten th e bed

pivot bracket bolts.

PIN

FIGURE 1.9

LATCH ASSEMBLY

Page 6

6

PRE-OPERATION CHECKLIST FOR

SNAPPER GROUNDS CRUISER

Snapper has completed initial adjustments and performed operational tests prior to shipping the machine. Due

to the possible effects of shipping, handling and storage, Snapper intends for all of the following items to be

verified and necessary final adjustments made at time of setup. It remains good practice and is strongly

recommended that all t he items also be che cked prior to pla cing the machine in to service. It is v ery important

that setup is verified and all operational test s completed and results ar e ac cept able. After completing th is fo rm,

sign and retain for future reference.

SET-UP

_____ GEN E R A L I N SPECTI ON for loose, missing or damaged components. Rep aired as necessary.

_____ WHEEL LUG NUTS checked and torqued to 75 ft-lb.

_____ FRONT & REAR AXLE NUTS checked, castle nuts installed and secured with cotter pins.

_____ TIRE PRESSURE, FRONT AND REAR, adjusted to 15 PSI.

_____ SEAT BELTS installed, hardware tightened, and function of buckles verified.

_____ OPER ATOR P R OTECTI V E STR U C T U R E ins t a l led an d har d w are torqued to 5 0-70 f t - l b.

_____ BATTERY activated, charged and installed properly.

_____ STEERING WHEEL installed, alignment checked and nut torqued to 50-70 ft-lb.

_____ CA R GO B E D A N D P R O P R O D i n s t a l l e d and hardware tightened according to instructions.

_____ CARGO BED LATCH function verified.

_____ OPERATOR CONTROLS checked for binding and damage.

LUBRICATION AND FUEL

_____ ENGINE OIL added to bring level up to full mark (Refer to Engine Manual).

_____ TRANSMISSION FLUID checked and adjusted to full mark. (MOBILFLUID 424)

_____ AX L E C O U P L I N GS A N D S T E E R I N G KI N G P I N S g r e a se d . ( R e f e r t o O p e r a t o r ’ s manual).

_____ FUEL added to tank and system checked for leaks. (Refer to Engine Manual for fuel specifications).

OPERATIONAL TEST

_____ ENGINE started, engine idles without dieing and runs smoothly.

_____ SAFETY INTERLOCKS checked and all function correctly. (Refer to Operator’s manual).

_____ TRANSMISSION shifts into forward and reverse without excessive grinding of gears.

_____ CLUTCH engages and accelerates smoothly and does not drag at idle.

_____ STEERING checked and functions properly.

_____ SE R V I C E B R AKE AND PARK BRAKE checked and both function properly. (Refer to Operator’s manual).

CONSUMER INFORMATION

Purchase Date ________________ Model_____________________ Serial No. ____________________

Retailer’s Name _______________________________ Signature ________________________________

Address _________________________________ City _________________ State ______ Zip _____

MACHINE WILL BE USED COMMERCIALLY? _ YES ____ NO

Purchaser’s Name _____________________________ Signature ________________________________

Address _________________________________ City __________________ State______ Zip ______

IMPORTANT: This form is to be retained for future reference regarding Warranty, proof of

purchase, traceability for product recall or service, etc. Complete the Product Registration

Card and Mail to Customer Service Department at SNAPPER, P.O. BOX 1379, McDonough,

Georgia, 30253.

INSTRUCTION No. 7-4510 (I.R. 5/3/01)

Loading...

Loading...