Page 1

DEALER SET-UP INSTRUCTIONS & PRE-SALE CHECKLIST for

EUROPEAN SNAPPER LT SERIES TRACTORS

INTRODUCTION: Snapper LT (One Piece Frame) Tractors are shipped with the steering wheel and seat

cushions removed. The following steps are required for set-up. Complete all items on the Dealer Pre-Sale

Checklist at time of purchase.

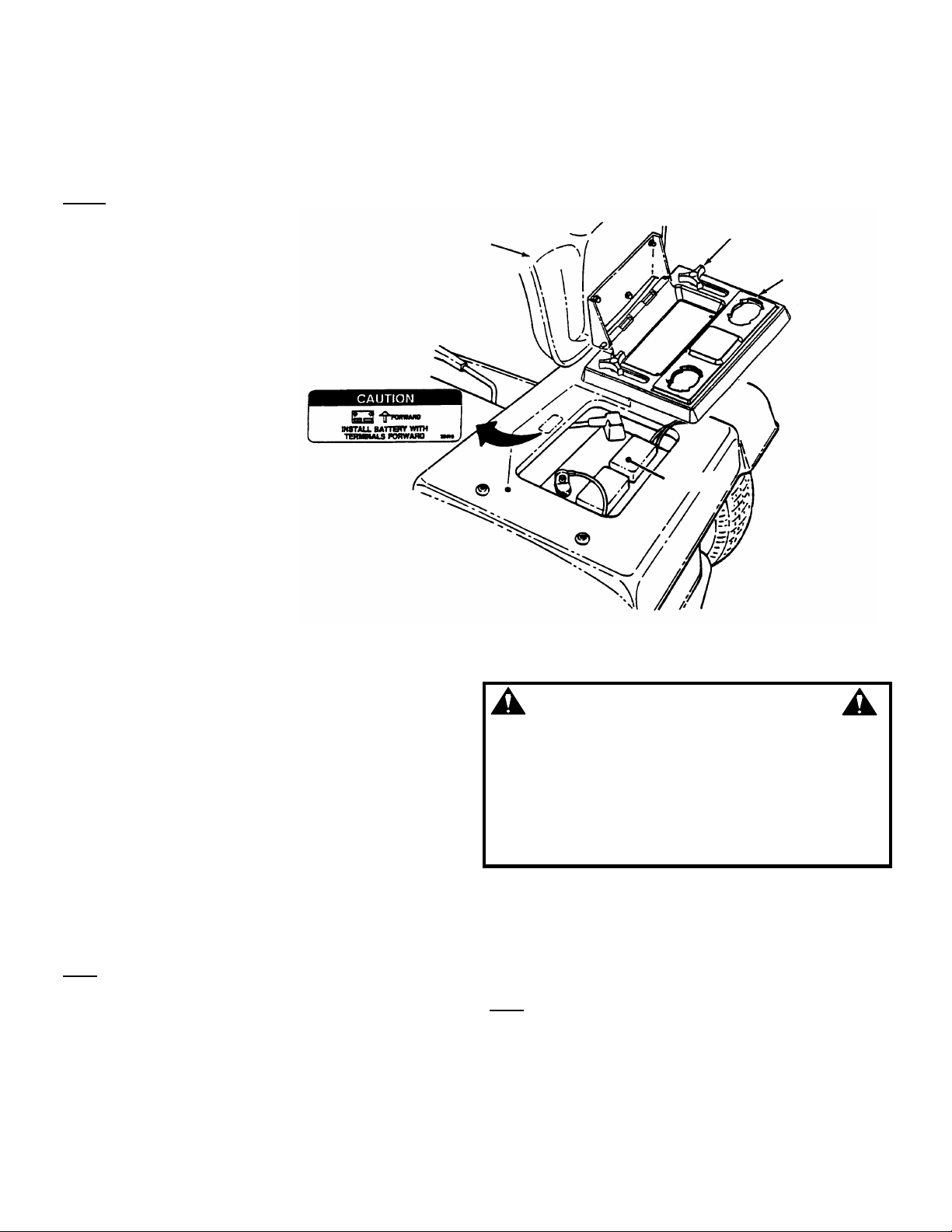

: Figure 1 shows the seat assembled to the seat

NOTE

pedestal assembly. Some models are shipped

with the seat loose and will require installation.

ACTIVATE BATTERY

The battery is not installed and is shipped dry. Allow

sufficient time for charging and installing the battery

before operating the tractor. Pay close attention to the

precautionary statements on the battery and in these

instructions. Electrolyte must be purchased separately

from your local dealer or retailer. You will also need an

automotive type battery charger to activate the battery for

use.

STEP 1: SEAT/PEDESTAL ASEMBLY REMOVAL

1. Remove the s eat/pedes tal as sembly by removing the

two seat knobs that secure it to rear fender. See

Figure 1.

: The seat switch wires are still connected, so be

Note

careful.

2. Move the seat/pedestal assembly forward and out of

the way.

STEP 2: ACTIVATING AND CHARGING BATTERY

1. Remove battery from carton.

2. Place battery in a well ventilated area on a level

surface.

INSTRUCTION No. 7-4375 (I.R. 2/15/01)

SEAT

BATTERY

FIGURE 1

SEAT KNOB

SEAT/PEDESTAL

ASSEMBLY

WARNING

The electrolyte (acid) produces a highly explosive

gas. Keep all sparks, flame and fire away from area

when charging battery or when handling electrolyte

or battery. Electrolyte (acid) is a highly corrosive

liquid. Wear eye protection. Wash affected areas

immediately after having eye or skin contact with

elec tr ol yte ( ac id) . Flush w ith clear water and neutralize

with baking soda. DO NOT OVER FILL!

3. Remove battery cell caps. Fill c ells as required with

electrolyte (purchased separately) to proper level.

Fill to 3/16” above cell plates. Filling battery with

electrolyte will bring the battery to 80% charged

state.

: 3/16” above cell plates is the recomm ended level.

Note

DO NOT place anything in battery other than

specified electrolyte.

(OVER)

1

Page 2

4. With cell c aps removed, connect battery charger to

battery terminals; RED to positive (+) and BLACK to

negative (-) terminal.

5. If tim e allows, slow charge at 1 amp for 10 hours, or

as an alternative, fast charge at not more than 2.5

amps for 4 hours to bring the battery to full charge.

NOTE: Slow charging is recomm ended and extends

battery life.

6. Af ter charging, check level of electrolyte and add as

needed to bring level to 3/16” above cell plates.

7. Reinstall cell caps.

WARNING

Keep sparks and flames away from battery at all times!

Battery acid is corrosive. Rinse empty acid containers

with water and mutilate before discarding. If acid is

spilled on battery, bench, or clothing, etc., flush with clear

water and neutralize with baking soda or ammonia

solution.

STEP 3: BATTERY INSTALLATION

1. Carefully place the charged battery, with terminals

toward front of tractor as shown on decal, in the

tractor battery compartment. See Figure 1.

2. Retrieve plastic bag from under the hood, on top of

gas tank. Remove nuts and bolts from plastic

hardware bag.

3. Connect positive (+) cable (red) from wiring harness

to the positive term inal (+) on battery using bolt and

nut provided in hardware bag.

4. Connect negative (-) cable (black) to negative

terminal (-) on battery using bolt and nut.

: Shield the positive terminal with terminal cover

Note

located on battery harness. This prevents metal

from touching the positive terminal which could

cause sparks.

5. Reinstall seat/pedestal assembly and tighten seat

knobs securely. DO NOT operate tractor without the

seat/pedestal assembly installed properly because it

serves as the battery hold down.

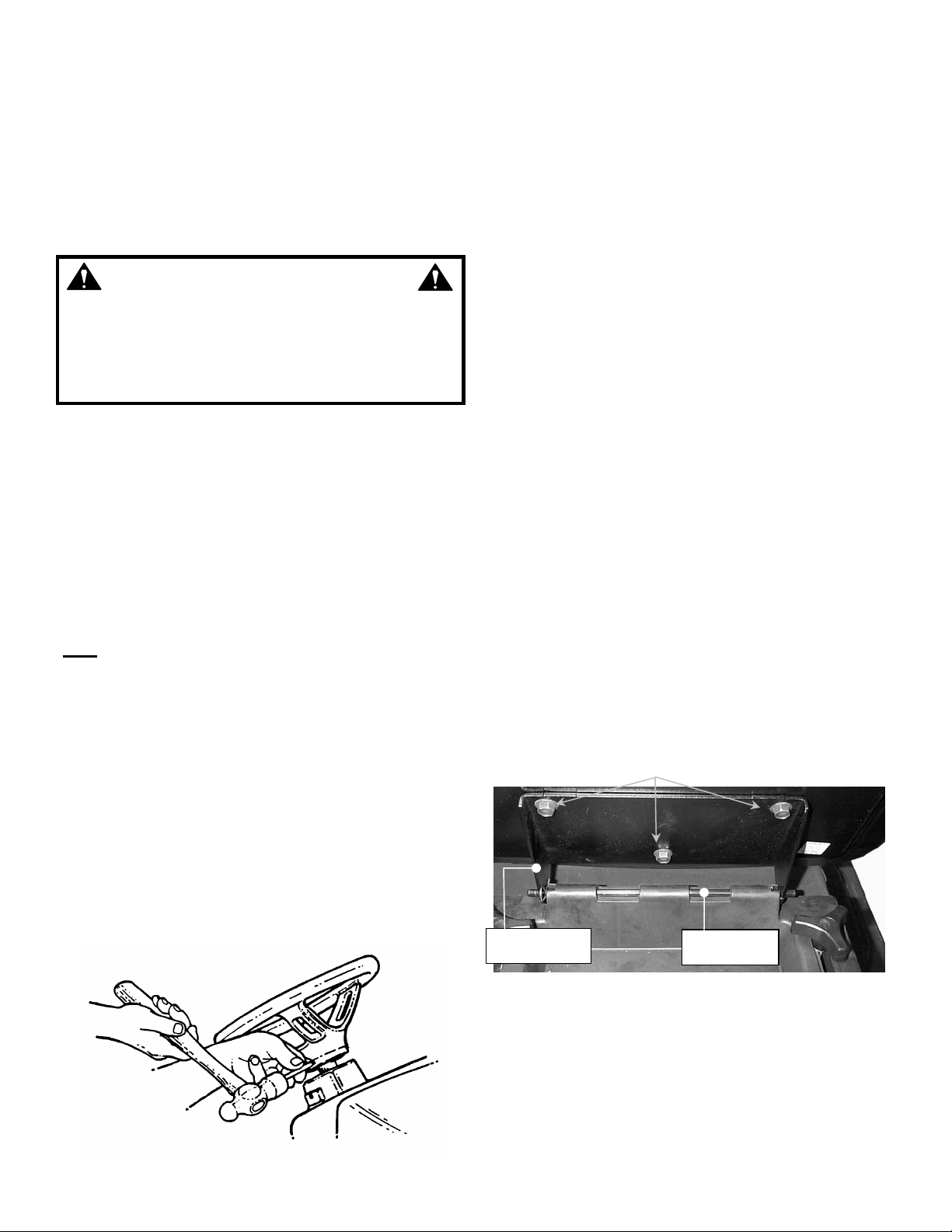

STEP 4: STEERING WHEEL INSTALLATION

1. Place steering wheel over steering s haft located on

tractor. Align hole in steering shaft with holes in

steering wheel and insert roll pin. Tap roll pin with

hammer gently through steering wheel and shaft until

roll pin is centered on the shaft. Do not use

excessive force! (See Figure 2)

Step 5: REDUCE TIRE PRESSURE

1. The tires are over-inflated for shipping. Reduce tire

pressure in front tires to 12 PSI and in rear tires to 12

PSI.

STEP 6: INSTALL OPERATOR’S SEAT

Some models are shipped with the seat, hinge rod and

hair pin already installed. On those models verify all seat

hardware is tight and that the hair pin is inserted fully into

the hinge rod and is between the hinge plate and seat

pedestal. See Figure 4. All models will require the

installation of the two seat cushions.

IMPORTANT: THE LOCATION OF THE HAIR PIN IN

THE HINGE ROD IS CRITICAL. TO PROPERLY

RETAIN THE HINGE ROD, THE HAIR PIN MUST BE

BETWEEN THE HINGE PLATE AND THE SEAT

PEDESTAL AND INSERTED FULLY INTO THE HINGE

ROD.

1. To install the seat, remove hair pin from hinge rod

and slide hinge rod from seat pedestal. See Figure 3.

2. Check seat bolts to insure hinge plate is tightened

securely to the bottom of the seat. See Figure 3.

3. Align hinge plate with the seat pedestal assembly

and insert hinge rod. See Figure 3.

IMPORTANT: Hinge rod m ust protrude past both sides

of the hinge plate and be positively retained by the

hair pin.

4. Insert hair pin fully into hinge rod. The hair pin must

be between the hinge plate and the seat pedestal.

See Figure 4.

5. Check for 5/16” flat washer under head of each seat

knob. Install washer, if missing, and tighten

securely. See Figure 5.

6. Install seat cushions by pushing into receptacles

located in seat pedestal. Seat must move freely on

hinge and depress cushions. See Figure 5.

HINGE PLATE

SEAT BOLTS

HINGE ROD

FIGURE 3

FIGURE 2

2

Page 3

INSERT HAIR PIN

INTO HINGE ROD

BETWEEN HINGE

PLATE AND SEAT

PEDESTA L.

SEAT KNOB

SEAT/PEDESTAL

ASSEMBLY

FIGURE 4

FIGURE 5

HINGE PLATE

SEAT PEDESTAL

SEAT

SEAT SUPPORT

BRACKET

CUSHION

Step 7: CHECK INTERLOCK SYSTEM

The interlock system includes a seat switch, a clutch

switch and a mower blade (PTO) switch. The system

functions in the following way:

A. ENGINE MUST NOT START IF:

1. The blade lever is in the ON position.

2. Clutch pedal is not completely depressed.

3. Operator is not seated on tractor.

B. ENGINE MUST START ONLY WHEN:

1. Blade lever is shifted into OFF position.

2. Parking brake is set.

3. Clutch pedal is completely depressed.

4. Operator is seated in tractor seat in operator's

position.

C. ENGINE WILL STOP WHEN:

1. The operator vacates the seat with the blade lever

in the ON position and/or with the clutch engaged

(when clutch pedal is not depressed).

2. The operator is not seated on tractor and the blade

is shifted into the ON position or engages the clutch

(clutch pedal is not depressed or is released).

D. ENGINE WILL CONTINUE RUNNING IF:

1. The operator vacates the seat with the parking

brake set and with the blade lever shifted in the

OFF position.

3

Page 4

DEALER PRE-SALE CHECKLIST

The following mu st b e accomp lished p rior sale. Ref er to pages 1 - 3 for detailed set-up instruct ion s. Review this

list with purchaser. Check (

✓) items actually performed and signed on this page.

CUTTING BLADE & MOWER

_____ BLADE RETAINING hardware checked for proper tightness.

_____ BLADE TIP CLEARANCE inside lower edge of mower checked and corrected as needed.

_____ MOWER CUTTING HEIGHT settings checked and adjusted as needed (with tires properly inflated).

_____ MOWER SIDE TO SIDE level checked and adjusted as needed (with tires properly inflated).

_____ MOWER FRONT TO REAR setting checked and adjusted as needed (with tires properly inflated).

PRE-START CHECKS & SERVICES

_____ TIRES checked and inflated to correct pressures.

_____ ENGINE OIL level checked.

_____ FUEL added to tank and system checked for leaks.

_____ BATTERY (not overfilled!) reinstalled and properly connected with red boot over positive terminal.

OPERATIONAL TESTS

_____ CHECK SEAT SWITCH for proper function.

_____ INTERLOCK SYSTEMS checked for proper function.

_____ ENGINE STARTED and throttle control settings checked.

_____ ALL OPERATIONS as listed on console checked.

_____ IGNITION SWITCH checked to insure engine stops when turned to OFF position.

_____ PARKING BRAKE tested to insure proper operation.

_____ BLADE BRAKE function verified. Blade rotation stops in 5 seconds or less.

DEMONSTRATION & INSTRUCTION

_____ DEMONSTRATED proper operation of mower to purchaser.

_____ INSTRUCTED purchaser to read and follow instructions in Operator's Manual.

_____ PER S O N A L L Y H A N D E D O p e r a t o r' s M anual to purchaser.

_____ ASSISTED purchaser in completing Product Registration cards.

DEALER'S RECORDS

SALE DATE TRACTOR MODEL SERIAL NO.

Dealer's Name

Address_________________________ City

TRACTOR WILL BE USED COMMERCIALLY? YES _________ NO

Purchaser's Name

Address_________________________ City

IMPORTANT: This form is to be retained by the Dealer for future reference regarding Warranty, proof of

purchase, traceability for product recall or service, etc. Complete the SNAPPER Product Registration Card

immediately and mail to: Snapper’s Product Registration Center, P.O. Box 1379, McDonough, Georgia 30253.

Signature

State Zip

Signature

State Zip

INSTRUCTION No. 7-4375 (I.R. 2/15/01)

4

Loading...

Loading...