Page 1

OPERATOR’S

Not for

Reproduction

MANUAL

Single Stage

Snowthrower

521E Models

Mfg. No. Description

1695702 521E, Snowthrower

1737682-A

Revision: A

07/2009

Page 2

Thank you for purchasing this quality-built Snapper snow thrower. We’re pleased that you’ve placed your confi dence in the Snapper

Not for

Reproduction

brand. When operated and maintained according to the instructions in this manual, your Snapper product will provide many years of

dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with snow throwers and how

to avoid them. This snow thrower is designed and intended only for snow throwing and is not intended for any other purpose. It is

important that you read and understand these instructions throroughly before attempting to start or operate this equipment. This snow

thrower requires fi nal assembly before use. Refer to the Quck Start Guide for instructions on fi nal assembly procedures. Follow

the instructions completely. Save these instructions for future reference.

Snow Thrower

Revision

Serial Number

Engine

Model Number

Model Number

Date Purchased

The Illustrated Parts List for this machine can be downloaded from www.snapper.com. Please provide model and serial number when

ordering replacement parts.

Snapper

Snapper Products

535 Macon St.

McDonough, GA 30253

1-800-317-7833

Snapper.com

Copyright © 2009 Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, All rights reserved.

Murray is a trademark of Briggs & Stratton Power Products

Group, LLC Milwaukee, WI USA.

Revision

Serial Number

2

Page 3

Table of Contents

Not for

Reproduction

Operator Safety .................................................................... 4

Assembly ............................................................................ 10

Remove Snowthrower from Carton ...................................................... 10

Handle Assembly .................................................................................. 10

Add Oil to the Engine ............................................................................ 11

Add Fuel to the Engine .......................................................................... 11

Before Operate the Snowthrower .......................................................... 12

Operation............................................................................ 13

Snowthrower and Engine Controls ....................................................... 13

Control Snow Discharge ....................................................................... 14

Snow Throwing ..................................................................................... 14

Stop Discharging Snow ........................................................................ 14

Move Forward ....................................................................................... 14

Before Starting the Engine .................................................................... 15

Stop the Engine .................................................................................... 15

Start the Engine .................................................................................... 15

Starting a Cold Engine .......................................................................... 15

Starting a Warm Engine ........................................................................ 16

Frozen Starter ....................................................................................... 16

Clear a Clogged Discharge Chute .......................................................... 16

Snow Throwing Tips ............................................................................. 16

Maintenance ....................................................................... 18

Customer Responsibilities .................................................................... 18

Emissions Control ................................................................................. 18

Engine Power Rating Information ......................................................... 18

After Each Use ...................................................................................... 19

Remove the Top Cover ......................................................................... 19

Lubricate Before Storage ...................................................................... 19

Adjust the Auger Control Cable ............................................................. 20

Remove the Belt Cover ......................................................................... 20

Replace the Auger Drive Belt ................................................................ 21

Replace the Auger ................................................................................. 22

Adjust the Brake Pad ............................................................................. 22

Replace the Spark Plug ......................................................................... 23

Prepare the Snowthrower for Storage .................................................. 23

Order Replacement Parts ...................................................................... 24

Trouble Shooting Chart ........................................................... 25

Warranty Statements .............................................................. 26

Specifi cations ...................................................................... 28

3

Page 4

Operator Safety

Not for

Reproduction

DANGER

AMPUTATION HAZARD

The discharge chute contains a rotating

impeller to throw snow. Never clear or

unclog thedischarge chute with

your hands. Fingers can quickly become

caught and traumatic amputation severe

laceration will result. Always use a

clean-out tool to clear or unclog the

discharge chute.

DANGER

Hand contact with the rotating impeller inside the •

discharge chute is the most common cause of injury

associated with snowthrowers.

This snowthrower is capable of amputating hands and •

feet, and throwing objects. Read and observe all the

safety instructions in this manual. Failure to do so will

result in death or serious injury.

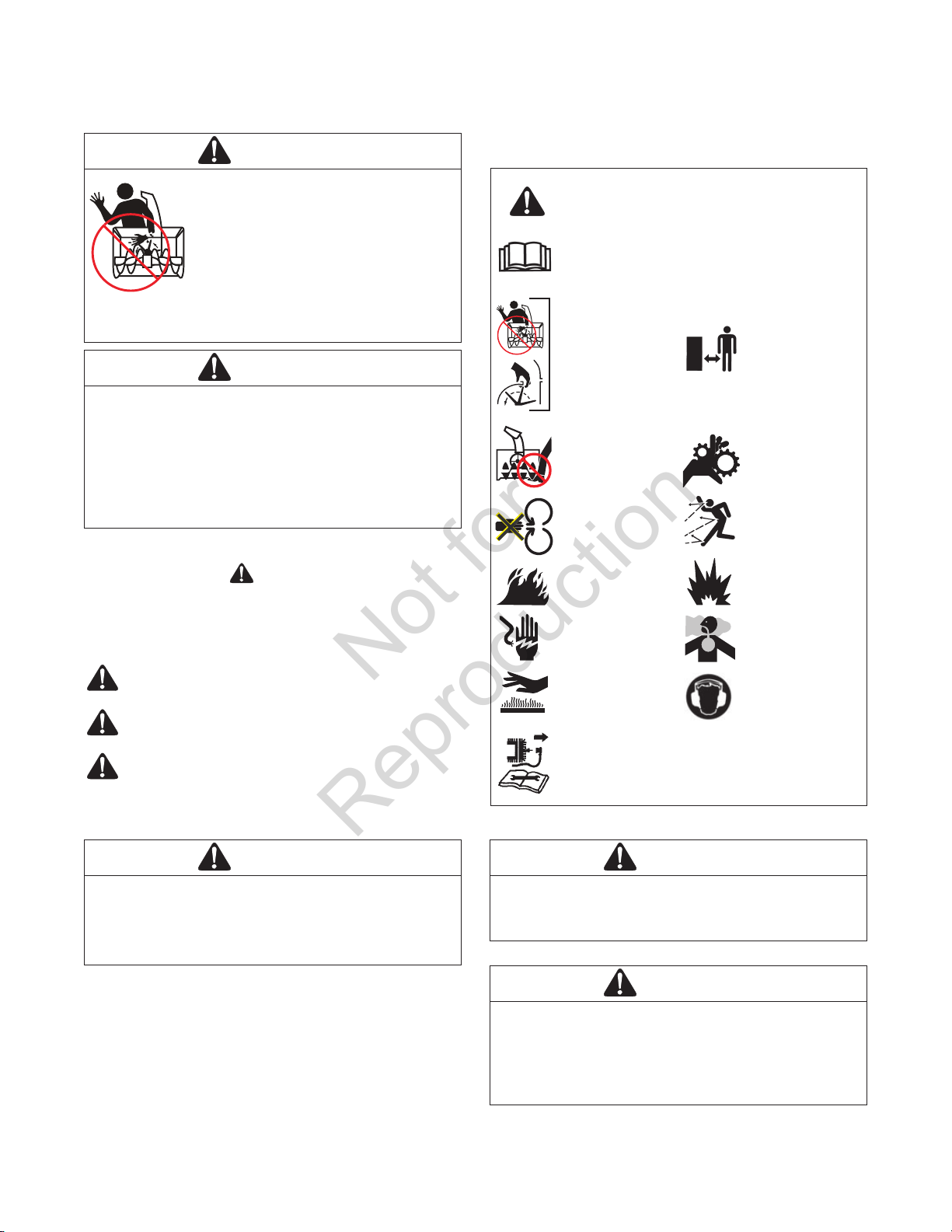

Safety Alert Symbol and Signal Words

The safety alert symbol and signal word (DANGER,

WARNING, CAUTION, or NOTICE) is used to indicate the

likeli- hood and potential severity of personal injury and/or

damage to the product. In addition, a hazard symbol may be

used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

Notice indicates a situation that could result in

damage to the product.

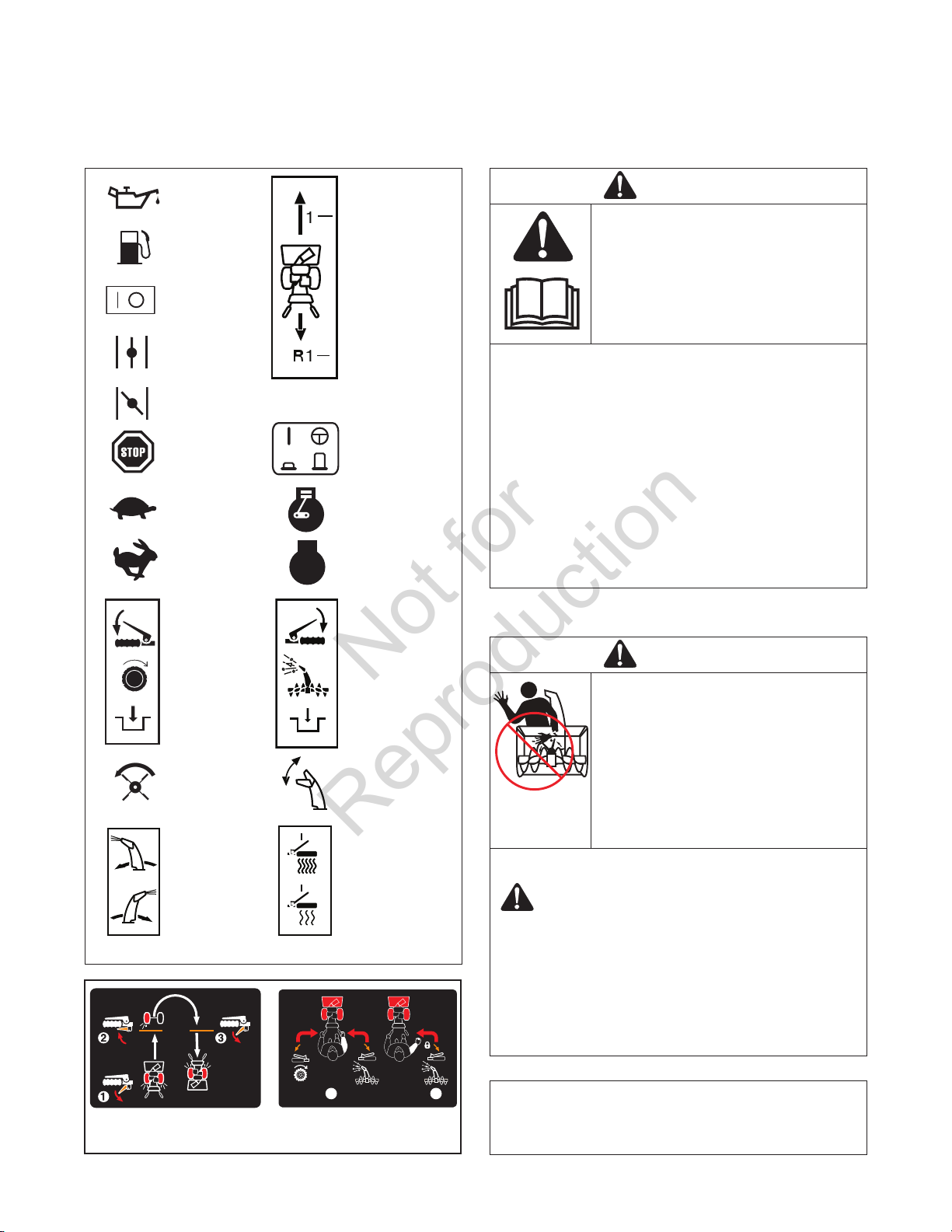

Hazard Symbols and Their Meanings

Safety Alert – Identifies safety information

about hazards that can result in personal injury.

Operator’s Manual – Read and understand

before performing any activity or running

equipment.

Keep a Safe

Rotating Impeller

Rotating Auger

Never Reach into

Rotating Parts

Fire

Shock

Hot Surface

Shut off engine and remove spark plug

connector before performing maintenance or

repair work.

Ditance from

Snowthrower

Rotating Gears

Thrown

Objects

Explosion

Toxic Fumes

Recommended

Ear Protection

for Extended Use

WARNING

U.S.A. Models: Certain components in this product and

its related accessories contain chemicals known to the

state of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

Certifi cation: This equipment meets the requirements of

ANSI B71.3-2005 for snowthrowers.

U.S.A. Models: The engine exhaust from this product

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

U.S.A. Models: Battery posts, terminals, and related

accessories contain lead and lead components chemicals knownto the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

4

WARNING

WARNING

Page 5

Operator Safety

Not for

Reproduction

Operating Symbols and Their Meanings

Oil

Fuel

On Off

Choke Off

Choke On

Stop

Slow

Fast

STOP

Foward

Nuetral

Reverse

Electric Start Engage (Down)

& Disengage Up

Engine - Run

Engine - Stop

Read the Manual

DANGER

Read, understand, and follow all the

instructions on the snowthrower and in

the operator’s manual before operating

this unit.

Failure to observe the safet y instructions

in this manual will result in death or

serious injury.

Be thoroughly familiar with the controls and the proper use of the snow •

thrower.

Make sure you are properly trained before operating the snowthrower.•

Know how to stop the unit and disengage the controls quickly.•

Never allow anyone to operate the snowthrower without proper •

instruction.

Always follow the instructions in the operator’s manual, if the •

snowthrower will be stored for an extende d period.

Maintain or replace safety and instruction labels as necessary.•

Never attempt to make major repairs on the snowthrower unless you •

have been properly trained. Improper servicing of the snowthrower can

result in hazardous operation, equipment damage, and voiding of the

product warranty.

Traction Control

Engage (Down)

Auger Clutch

Discharge Chute

(Left and Right)

Auger Control

Engage (Down)

Chute Deflector

(Up and Down)

Heated Hand

Grips

(High and Low)

Discharge Chute

DANGER

Discharge chute contains rotating

impeller to throw snow. Never clear or

unclog the discharge chute with your

hands. Fingers can quickly become

caught in the impeller. Always use a

clean-out tool.

Failure to observe these safety

instructions will result in traumatic

amputation or severe laceration.

TO SAFELY CLEAR A CLOGGED DISCHARGE CHUTE

DANGER: Hand contact with the rotating impeller inside the

discharge chute is the most common cause of injury

associated with snow throwers. Never use your hands to clean

out the discharge chute.

FOLLOW THESE INSTRUCTIONS:

1. Shut OFF the engine.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean-out tool, not your hands.

Easy-Turn

Traction Control

TM

1

Free-Hand

Control

2

TM

NOTE: Not all control symbols shown on this page will

appear on your snowthrower. See FEATURES AND

CONTROLS section for the applicable symbols.

5

Page 6

Operator Safety

Not for

Reproduction

Operation and Equipment Safety

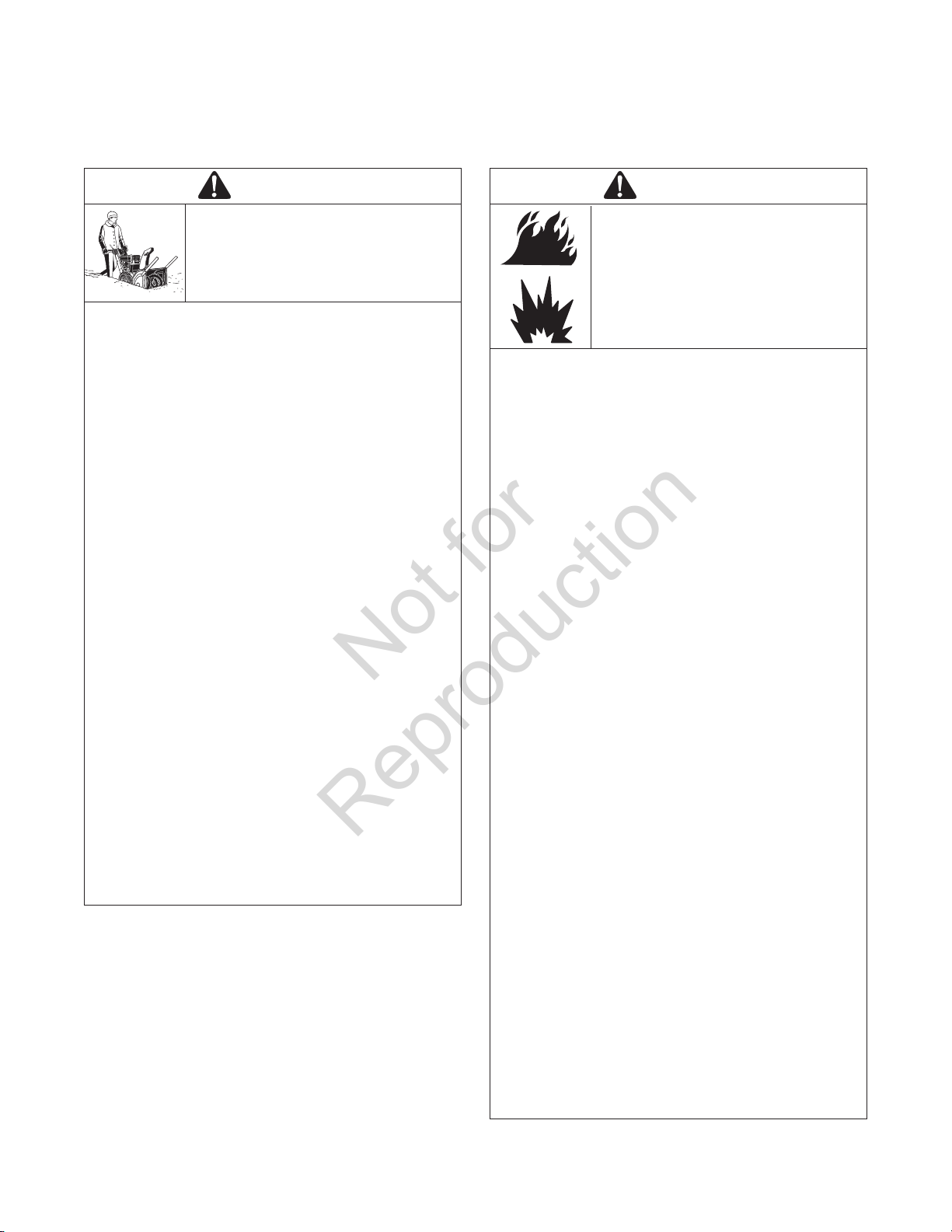

DANGER

This snowthrower is only as safe as the

operator. If it is misused, or not properly

maintained, it can be dangerous.

Remember you are responsible for your

safety and that of those around you.

Keep the area of operation clear of all persons, particularly small •

children and pets.

Thoroughly inspect the area where the snowthrower will be used and •

remove all doormats, sleds, boards, wires, and other foreign objects.

Do not operate the snowthrower without wearing adequate winter •

clothing.

Wear footwear that will improve footing on slippery surfaces.•

Use caution to avoid slipping or falling especially when operating the •

snowthrower in reverse.

Never operate the snowthrower without good visibility or light. Always •

be sure of your footing, and keep a fi rm hold on the handles.

Do not clear snow across the face of slopes. Use extreme caution when •

changing direction on slopes. Do not attempt to clear steep slopes.

Do not overload the machine capacity by attempting to clear snow too •

quickly.

Never operate the snowthrower at high transport speeds on slippery •

surfaces. Look behind the snowthrower and use care when operating in

reverse.

Do not use the snowthrower on surfaces above ground level such as •

roofs of residences, garages, porches, or other such structures or

buildings.

Operators should evaluate their ability to operate the snowthrower safely •

enough to protect themselves and others from injury.

The snowthrower is intended to remove snow only. Do not use the snow •

thrower for any other purpose.

Do not carry passengers.•

After striking a foreign object, shut OFF the engine, disconnect the cord •

on electric motors, thoroughly inspect the snowthrower for any damage,

and repair the damage before restarting and operating the snowthrower.

If the snowthrower vibrates abnormally, shut OFF the engine. Vibration •

is generally a warning of trouble. See an authorized dealer if necessary

for repairs.

For models equipped with electric starting motors, disconnect the power •

cord after the engine starts.

Fuel Handling

DANGER

Fuel and its vapors are extremely

fl ammable and explosive. Always handle

fuel with extreme care.

Failure to observe these safety

instructions can cause a fi re or

explosion which will result in severe

burns or death.

WHEN ADDING FUEL

Turn off engine and let cool at least 2 minutes before removing the fuel •

cap and adding fuel.

Fill fuel tank outdoors or in a well ventilated area.•

Do not overfi ll the fuel tank. To allow for the expansion of gasoline, do •

not fi ll above the bottom of the fuel tank neck.

Keep fuel away from sparks, open fl ames, pilot lights, heat, and other •

ignition sources.

Check fuel lines, cap, and fi ttings frequently for cracks or leaks. Replace •

if necessary.

Use an approved fuel container.•

If fuel spills, wait until it evaporates before starting engine.•

WHEN STARTING ENGINE

Ensure that spark plug, muffl er, fuel cap, and air cleaner (if equipped) •

are in place and secured.

Do not crank the engine with the spark plug removed.•

If fuel is spilled, do not attempt to start the engine, but move the snow •

thrower away from the area of the spill, and avoid creating any source of

ignition, until the fuel vapors have dissipated.

Do not over-prime the engine. Follow the engine starting instructions in •

this manual.

If the engine fl oods, set choke (if equipped) to OPEN/RUN position, •

move throttle (if equipped) to FAST position and crank until engine

starts.

WHEN OPERATING EQUIPMENT

Do not tip the snowthrower at an angle which causes the fuel to spill.•

Do not choke the carburetor to stop the engine. •

Never run the engine with the air cleaner assembly (if equipped) or the •

air fi lter (if equipped) removed.

WHEN CHANGING OIL

If you drain the oil from the top oil fi ll tube, the fuel tank must be empty •

or fuel can leak out and result in a fi re or explosion.

WHEN TRANSPORTING EQUIPMENT

Transport with fuel tank EMPTY, or with fuel shut-off valve OFF.•

WHEN STORING GASOLINE OR EQUIPMENT WITH FUEL

IN TANK

Store away from furnaces, stoves, water heaters, or other appliances •

that have pilot light or other ignition source because they can ignite fuel

vapors.

For models equipped with electric starting motors, disconnect the power •

cord after the engine starts.

6

Page 7

Operator SafetyOperator Safety

Not for

Reproduction

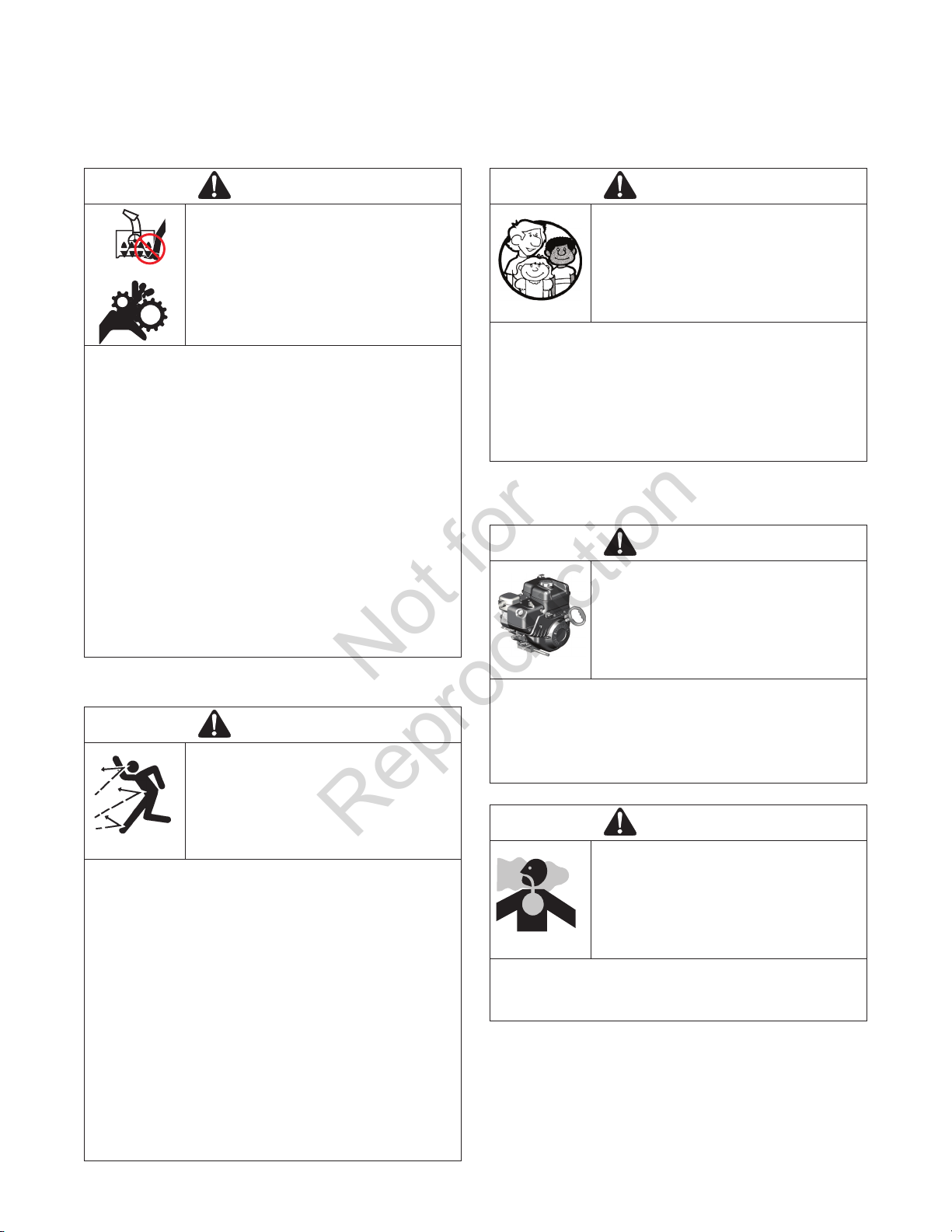

Moving Parts

DANGER

Keep hands, feet, and clothing away

from rotating parts.Rotating parts can

contact or entangle hands, feet, hair,

clothing, or accessories.

Failure to observe these safety

instructions will result in traumatic

amputation or severe laceration.

Whenever cleaning, repairing, or inspecting the snowthrower, make sure •

the engine is OFF, spark plug wire is disconnected, and all moving parts

have stopped.

Do not put hands or feet near or under rotating parts. Keep clear of the •

discharge opening at all times.

Never operate the snowthrower without proper guards, and other safety •

devices in place and working.

Never leave the snowthrower unattended while engine is running. •

Always disengage the auger and traction controls, stop engine, and

remove keys.

Keep all loose clothing away from the front of the snowthrower and •

auger. Scarves, mittens, dangling drawstrings, loose clothes, and pants

can quickly become caught in the rotating device and amputation will

occur. Tie up long hair and remove jewelry.

Run the machine a few minutes after discharging snow to prevent •

freeze-up of the collector/impeller.

Disengage power to the collector/impeller when snowthrower is •

transported or not in use.

Thrown Objects

DANGER

Objects can be picked up by auger and

thrown from chute. Never discharge

snow toward bystanders or allow anyone

in front of the snowthrower. Failure to

observe these safetyinstructions will

result in death or serious injury.

Always wear safety glasses or eye shields while during operation, and •

while performing an adjustment or repair.

Always be aware of the direction the snow is being thrown. Nearby •

pedestrians, pets, or property may be harmed by objects being thrown.

Be aware of your environment while operating the snowthrower. •

Running over items such as, gravel, doormats, newspapers, toys, and

rocks hidden under snow, can all be thrown from the chute or jam in the

auger.

Use extreme caution when operating on or crossing gravel drives, •

walks, or roads.

Adjust the collector housing height to clear gravel or crushed rock •

surface.

Never operate the snowthrower near glass enclosures, automobiles, •

window wells, drop-offs, and the like without proper adjustment of the

dischargechute angle.

Familiarize yourself with the area in which you plan to operate the snow •

thrower. Mark off boundaries of walkways and driveways.

Children

DANGER

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the unit

and the operating activity. Never assume

that children will remain where you last

saw them.

Keep children out of the area during operation. Children are often •

attracted to the equipment. Be mindful of all persons present.

Be alert and turn unit off if children enter the area.•

Never allow children to operate the unit.•

Use extra care when approaching blind corners, shrubs, trees, or other •

objects that may obscure vision. Children may be present.

Engine Safety

DANGER

Safe operation of the snowthrower

requires the proper care and

maintenance of the engine. Failure to

observe the safety instructions in this

manual will result in death or serious

injury.

Disengage all clutches and shift into neutral before starting the engine.•

Let the engine adjust to outdoor temperatures before starting to clear •

snow.

Use a grounded three-wire plug-in for all snowthrowers equipped with •

electric drive motors or electric starting motors.

DANGER

Safe operation of the snowthrower

requires the proper care and

maintenance of the engine. Failure to

observe the safety instructions in this

manual will result in death or serious

injury.

Start and run engine outdoors. •

Do not run the engine in an enclosed area, even if doors or windows are •

open.

7

Page 8

Operator Safety

Not for

Reproduction

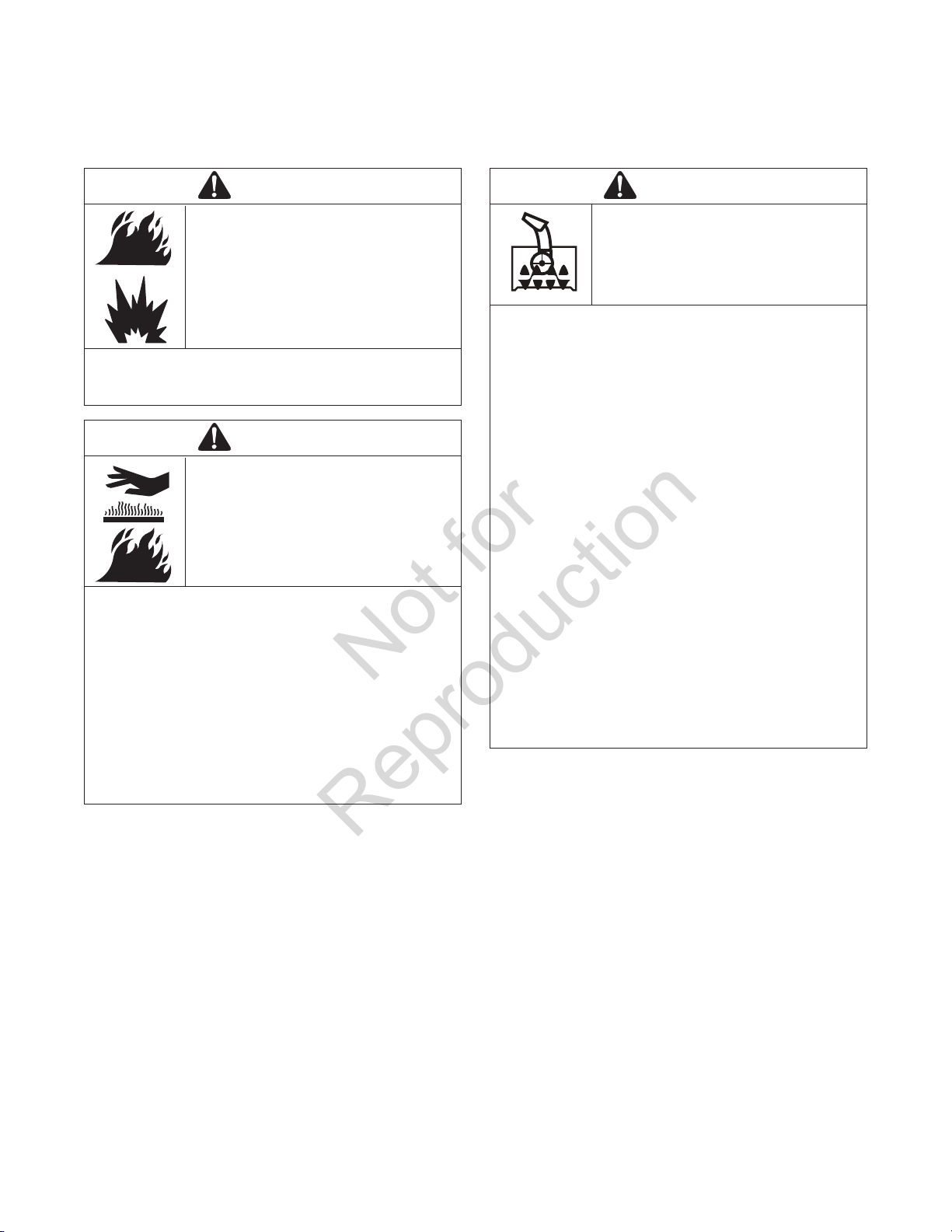

Engine Safety (Continued)

WARNING

Starting engine creates sparking.

Sparking can ignite nearby fl ammable

gases.

Explosion and fi re could result.

If there is natural or LP gas leakage in area, do not start engine.•

Do not use pressurized starting fl uids because vapors are fl ammable.•

WARNING

Running the engine produces heat.

Engine parts, especially muffl er, become

extremely hot.

Failure to observe these safety

instructions could result in severe

thermal burns on contact.

Never touch a hot engine or muffl er. Allow muffl er, engine cylinder, and •

fi ns to cool before touching.

Remove debris from muffl er area and cylinder area.•

Install and maintain in working order a spark arrester before using •

equipment on forest-covered, grass-covered, or brush-covered

unimproved land.

• U.S.A. Models: It is a violation of California Public Resource Code

Section 4442 to use or operate the engine on or near any forestcovered, brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester meeting any applicable local or

state laws. Other states or federal areas may have similar laws.

Maintenance and Storage

WARNING

This snowthrower must be properly

maintained to ensure safe operation

and performance. Failure to observe the

safety instructions in this manual could

result in death or serious injury.

When performing any maintenance or repairs on the snowthrower, shut •

OFF the engine, disconnect spark plug wire, and keep the wire away

from the plug to prevent someone from accidently starting the engine.

Check shear bolts and other hardware at frequent intervals for proper •

tightness to be sure the snowthrower is in safe working condition.

Keep nuts and bolts tight and keep snowthrower in good condition.•

Never tamper with safety devices. Check their proper operation regularly •

and make necessary repairs if they are not functioning properly.

Components are subject to wear, damage, and deterioration. Frequently •

check components and replace with recommended parts, when

necessary.

Check control operation frequently. Adjust and service as required.•

Use only factory authorized replacement parts when making repairs.•

Always comply with factory specifi cations on all settings and •

adjustments.

Only authorized service locations should be utilized for major service •

and repair requirements.

Use only attachments and accessories approved by the factory (such as •

wheel weights, counterweights, or cabs).

Never attempt to make any adjustments while the engine is running •

(except when specifi cally recommended by the factory).

Do not allow grease or oil to contact the rubber friction wheel or the disc •

drive plate. If the disc drive plate or friction wheel come in contact with

grease or oil, damage to the rubber friction wheel will result.

8

Page 9

Safety Decals

Not for

Reproduction

This unit has been designed and manufactured to provide

you with the safety and reliability you would expect from an

industry leader in outdoor power equipment.

Although reading this manual and safety instructions it

contains will provide you with the necessary basic knowledge

to operate this equipment safely and effectively, we have

placed several safety labels on the unit to remind you of this

important information while you are operating your unit.

All WARNING, CAUTION, and instructional messages on your unit

should be carefully read and obeyed. Personal bodily injury can

result when these instructions are not followed. The information is

for your safety and it is important.

8

5

The safety decals below are on your unit. If any of these

decals are lost or damaged, replace them at once. See your

local dealer for replacements. These labels are easily applied

and will act as a constant visual reminder to you, and others

who may use the equipment, to follow the safety instructions

necessary for safe, effective, operation.

Note: Not all control symbols shown on this page will appear

on your snowthrower. See FEATURES AND CONTROLS

section for the applicable symbols.

7

3

4

9

6

REF NO. PART NO. DESCRIPTION

1 - - - - - - *Decal, EPA, Mass

2 728046 Decal, Electric Start (EN/FR)

3 1742294 Decal, Dash Panel (EN/FR)

4 276063 Decal, Briggs & Stratton Logo

5 1737831 Decal, 521E

6 723023 Decal, Warning Hot Muffl er

7 723710 Decal, Auger Control

8 728042 Decal, Danger Chute

9 728043 Decal, Danger Auger, Foot

VIEW FROM REAR

2

1

9

Page 10

ASSEMBLY

Not for

Reproduction

Read and follow the assembly and adjustment

instructions for your snowthrower. All fasteners are in the parts bag. Do not discard any

parts or material until the unit is assembled.

WARNING: Before doing any assembly

or maintenance to the snowthrower,

remove the wire from the spark plug.

NOTE: In this instruction book, left and right

describe the location of a part from the operator’s

position behind the unit.

NOTE: Torque is measured in foot pounds (metric

Nm). This measurement describes how tight a nut

or bolt must be. The torque is measured with a

torque wrench.

PARTS BAG CONTENTS

1 - Electric Start Cord (Not Shown)

1 - Owner’s Manual

1 - Fuel Stabilizer

1 - Container Oil 5W30

4. Cut down all four corners of the carton and lay the

side panels flat.

5. Cut off the plastic bag that covers the snowthrower.

6. Hold onto the lower handle and pull the snowthrower

off the carton.

CAUTION: DO NOT back over cables.

7. Remove the packing material from the handle as sembly.

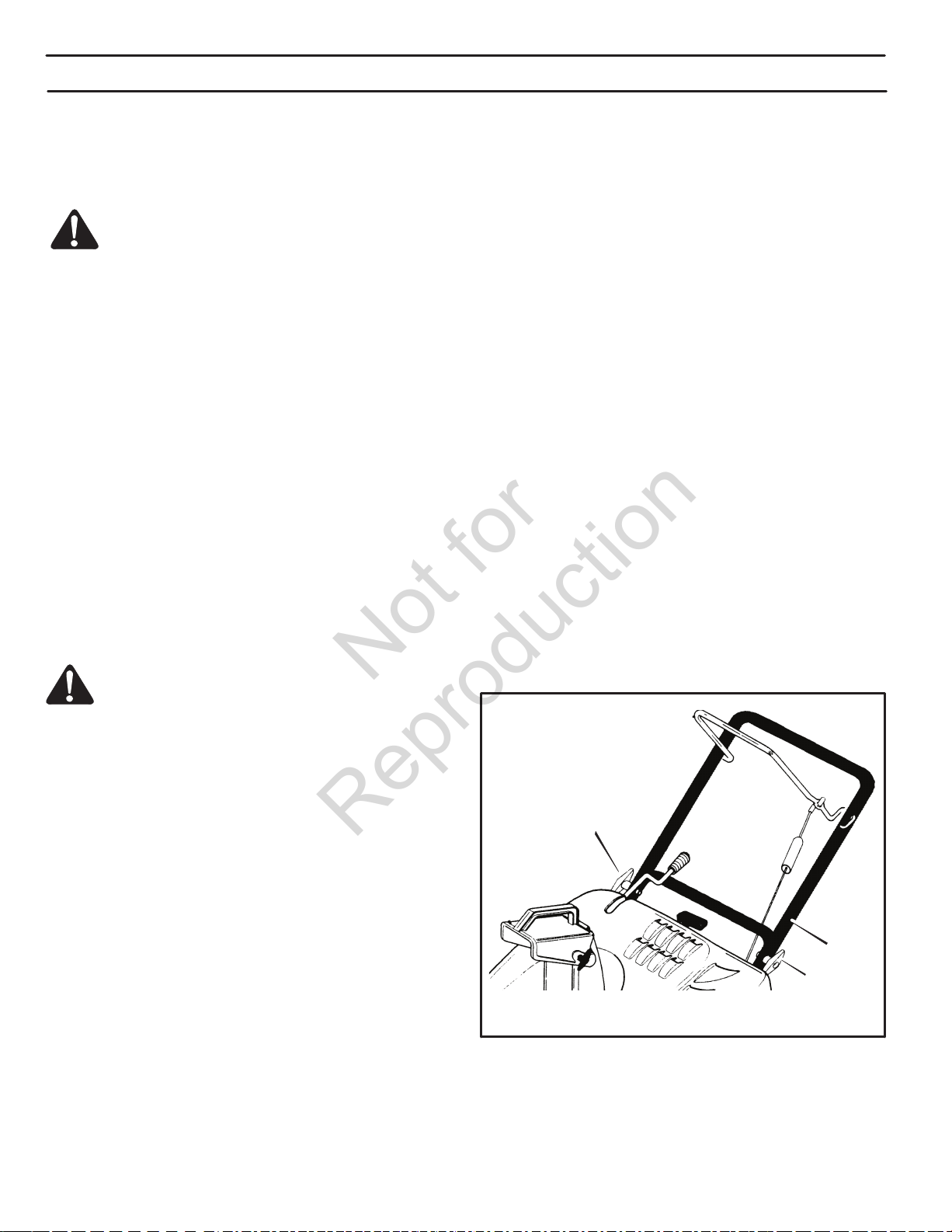

HOW TO ASSEMBLE THE HANDLE

1. Remove the packing material from the upper and

lower handles.

2. (Figure 1) Loosen the knobs (1) on each side of

the handle (2).

3. Raise the upper handle (2) to the operating posi tion. Hold the upper handle (2) apart to prevent

scratching the lower handle.

TOOLS REQUIRED FOR ASSEMBLY

1 − Knife

WARNING: Always wear safety glasses

or eye shields while assembling the

snowthrower.

Figure 3 shows the snowthrower in the operating

position.

References to the right or left hand side of the snow

thrower are from the viewpoint of the operator’s

position behind the unit.

HOW TO REMOVE THE SNOWTHROWER

FROM THE CARTON

1. Locate and remove the container of oil.

2. Locate all parts that are packed separately and

remove from the carton.

NOTE: Make sure the cables are not caught

between the upper and lower handle.

4. Tighten the knobs.

1

2

1

Figure 1

3. Remove and discard the packing material from

around the snowthrower.

10

Page 11

ASSEMBLY

Not for

Reproduction

ADD OIL TO THE ENGINE

NOTE: Engine may already contain some

residual oil. Check frequently when filling the

crankcase. DO NOT overfill.

The snow thrower was shipped with a container

of 5W30 motor oil. This oil must be added to the

engine before operating.

OIl Fill Cap/Dipstick

Figure 2

1. Make sure the unit is level.

ADD FUEL TO THE ENGINE

This engine is certied to operate on gasoline or

petrol. The emissions control system for this engine is

EM (Engine Modications).

WARNING: Alcohol blended fuels (called

gasohol or those using ethanol or methanol)

can attract moisture which leads to separation and

formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage.

NOTE: To avoid engine problems, the fuel system must

be emptied before storage for 30 days or longer. Start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See the Storage section

in this manual for additional information.

Fill the fuel tank only with fresh, clean, unleaded regular,

unleaded premium, or reformulated automotive fuel with

a minimum of 85 octane. DO NOT use leaded gasoline

or petrol. Make sure that the container you pour the fuel

is free from rust or foreign particles. Never use fuel that

may be stale from long periods of storage in the container.

2. Remove the oil fill cap/dipstick and fill

the crankcase to “FULL” line on dipstick.

DO NOT overfill.

3. Pour the oil slowly into the engine oil fill.

DO NOT overfill. After adding oil, wait one

minute and then recheck the oil level.

4. Tighten the oil fill cap/dipstick securely each

time you check the oil level.

NOTE: Synthetic oil can assist with starting in

extreme cold temperatures. Synthetic 5W30 is

acceptable for all temperatures. Do NOT mix oil

with unleaded gasoline.

1. Stop the engine. Before you remove fuel

cap, let the engine cool at least 2 minutes.

2. Remove the fuel cap. Fill the fuel tank to

approximately 1-1/2 inches (38 mm) below

top of neck to allow for fuel expansion. Be

careful not to overfill.

3. Replace the fuel cap before starting the engine.

WARNING: Gasoline and petrol and its vapors

are extremely flammable and explosive. Fire or

explosion can cause severe burns or death.

• Turn engine off and let engine cool at least 2 minutes

removing the gas cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Keep gasoline away from sparks, open flames, pilot

lights, head, and other ignition sources.

• If fuel spills, wait until it evaporates before starting

engine.

11

Page 12

ASSEMBLY

Not for

Reproduction

BEFORE YOU OPERATE

Before you operate your new snow thrower,

please review the following checklist:

• Make sure all assembly instructions have been

completed.

• Make sure the discharge chute rotates freely.

• Make sure that no loose parts remain in the

carton.

As you learn how to properly use the snow

thrower, pay extra attention to the following

important items:

• Make sure the engine oil is at the proper

level. For the type engine oil to use, see the

Engine Manufacturer’s manual.

• Make sure the fuel tank is filled with clean,

fresh, unleaded gasoline or petrol with a

minimum of 85 octane.

.

• Become familar with the location of all

controls and understand their function.

• Before starting the engine, make sure all

controls operate correctly.

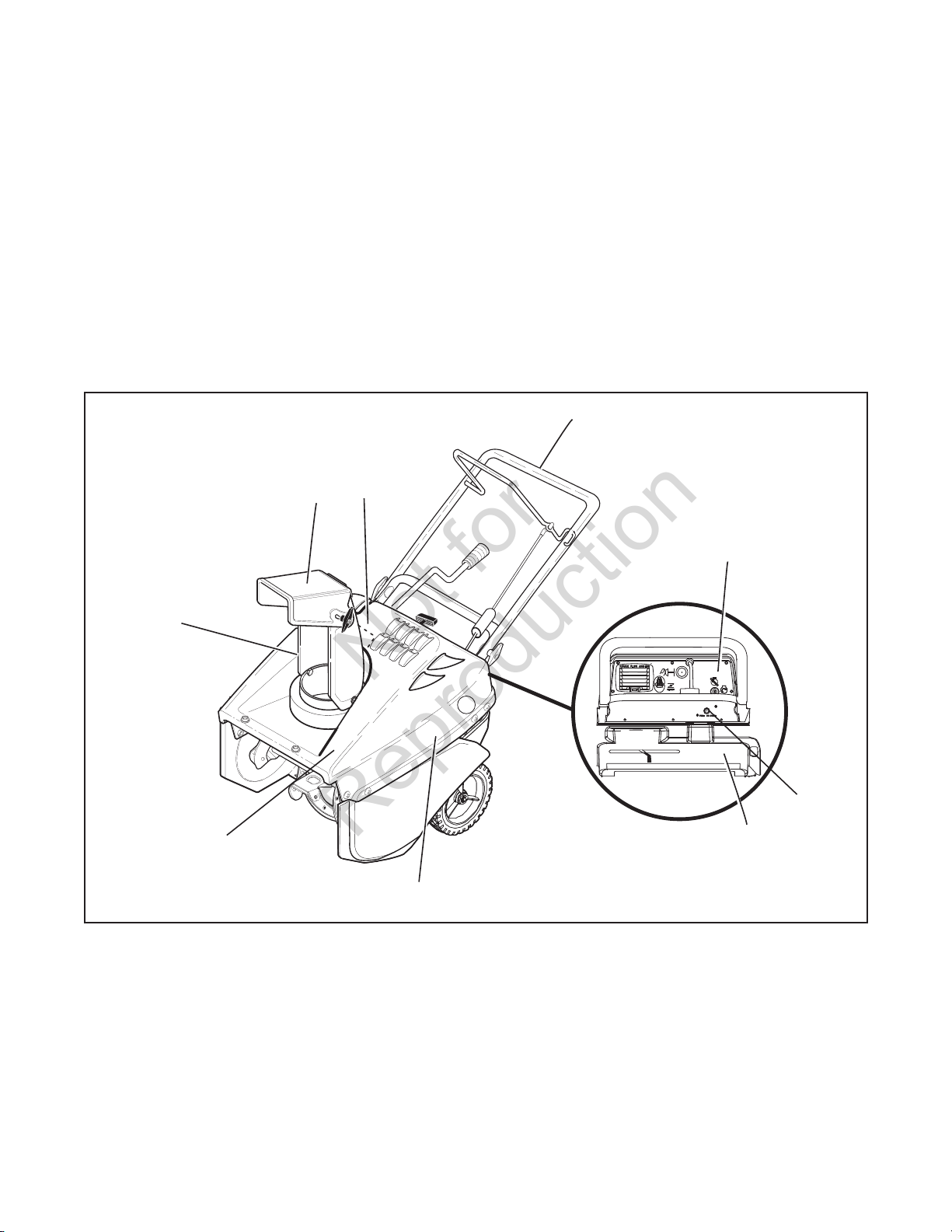

KNOW YOUR SNOWTHROWER

Read this Instruction Book and safety rules before

operating the snow thrower. Compare the illustration

with your snow thrower to familiarize yourself with

the location of various controls and adjustments.

12

Page 13

OPERATION

Not for

Reproduction

4

2

3

5

1

7

11

12

8

10

6

9

Figure 3

Control and Equipment Features (Figure 3)

Crank Assembly (1) - Changes the direction of

the discharge chute.

Chute Deflector (2) - Changes the distance the

snow is thrown.

Discharge Chute (3) - Changes the direction the

snow is thrown.

Auger Drive Lever (4) - Starts and stops the auger

which propels the snow thrower.

Auger Blades (5) - Cuts through the snow.

Engine Features (Figure 3)

Stop Switch (6) - If equipped, move to the ON position

to start the engine.

Ignition Key (6) - If equipped, insert and turn to the

ON position to start the engine.

Primer Button (7) - Injects fuel directly into the

carburetor for fast starts in cold weather.

Engine Start Button (8) - On electric start models,

used to start the engine.

Switch Box (9) - On electric start models, used to

attach electrical power cord.

Recoil Starter Handle (10) - Used to manually

start the engine.

Choke Control (11) - Used to start a cold engine.

Spark Plug Access Panel (12) - Remove to access

the spark plug.

13

Page 14

OPERATION

Not for

Reproduction

HOW TO CONTROL DISCHARGE

OF SNOW

WARNING: Never direct the discharge of snow toward bystanders.

WARNING: Always stop the engine

before unclogging the discharge chute

or the auger housing and before leaving the

snow thrower.

1. (Figure 3) Turn the crank assembly (1) to

change the discharge direction of the snow.

2. (Figure 4) Loosen the wing knob (1) on the

chute deflector (2).

2

2

WARNING: The operation of any snow

thrower can result in foreign objects

being thrown into the eyes, which can result

in severe eye damage. Always wear safety

glasses or eye shields while operating the

snow thrower. We recommend standard

safety glasses or use a wide vision safety

mask over your glasses.

HOW TO STOP DISCHARGING SNOW

1. (Figure 3) To stop discharging snow, release

the auger drive lever (4).

2. To stop the engine, turn the ignition key (5)

to the OFF position.

HOW TO MOVE FORWARD

1. (Figure 3) Hold the auger drive lever (4)

against the handle (10). The auger will begin

rotating.

1

3. Move the chute deector (2) up for more distance or

down for less distance.

4. Tighten the wing knob (1).

HOW TO THROW SNOW

1. (Figure 3) Engage the auger drive lever (4).

2. To stop throwing snow, release the

auger drive lever.

1

Figure 4

2. To go forward, raise the handle (10) to allow

the rubber auger blades (5) to contact the

ground. Maintain a firm hold on the handle

(10) as the snow thrower starts to move for ward. Guide the snowthrower by moving the

handle (10) either left or right. Do not attempt

to push the snowthrower.

3. To stop, release the auger drive lever (4).

NOTE: If the auger continues to rotate, see

“How To Adjust The Auger Control Cable” in

the Maintenance section.

14

Page 15

OPERATION

Not for

Reproduction

BEFORE STARTING THE ENGINE

1. Before you service or start the engine,

familiarize yourself with the snow thrower. Be

sure you understand the function and location

of all controls.

2. Make sure that all fasteners are tight.

3. Make sure the fuel tank is filled with fresh,

clean fuel.

4. Before starting the engine, make sure all

controls operate correctly.

HOW TO STOP THE ENGINE

To stop the engine, turn the ignition key to

the OFF position. Keep the ignition key in a

safe place. The engine will not start without

the ignition key.

HOW TO START A COLD ENGINE

1. Fill the fuel tank with fresh, clean fuel. See “Add

Fuel To The Engine” in the Assembly section.

2. Move the choke control to FULL position.

3. (Figure 3) Make sure the auger drive lever (4) is

in the disengaged (released) position.

4. Insert the ignition key (6) and turn to the ON

position.

5. Move the choke control (11) to the full choke

position.

6. (Electric Start) Connect the power cord to the

switch box (9) located on the engine.

7. (Electric Start) Plug the other end of the power

cord into a three-hole, grounded AC receptacle.

(See the WARNING in this section.)

HOW TO START THE ENGINE

NOTE: An electric starter kit can be added

to recoil start engines. Electric starter kits are

available from your nearest authorized service

center.

WARNING: The starter is equipped with

a three-wire power cord and plug and is

designed to operate on AC household current.

Carefully follow all instructions in the “How To

Start The Engine” section. Make sure that your

house wiring is a three-wire grounded system.

To connect an AC power cord, always connect

the power cord to the switch box on the engine

first. Then, plug the other end into the three-hole

grounded receptacle. When disconnecting the

power cord, always unplug the end from the

three-hole grounded receptacle first.

8. Push the primer button (7) two times. Every time

you push the primer button (7), wait two seconds.

9. (Electric Start) Push on the electric start button

(8) until the engine starts. Do not crank for more

than 10 seconds at a time.The electric starter is

thermally protected. If the electric starter over heats, it will automatically stop and can be re started when it has cooled to a safe temperature.

A wait of about 5 to 10 minutes is required to

allow the electric starter to cool.

10. (Recoil Start) Rapidly pull the recoil starter

handle (10). Do not allow the recoil starter han dle (10) to snap back. Slowly return the recoil

starter handle (10).

11. If the engine does not start in 5 or 6 tries, see the

“Troubleshooting Chart” instructions.

12. (Electric Start) When the engine starts, release

the electric start button (8) and move the choke

control (14) to 1/2 choke position. When the en gine runs smoothly, move the choke control (11)

to the OFF position.

15

Page 16

OPERATION

Not for

Reproduction

13. (Electric Start) First disconnect the power

cord from the three-hole receptacle. Then,

disconnect the power cord from the switch

box (11).

NOTE: In temperatures below 0° F (-18° C), allow

the engine to warm up for several minutes before

blowing snow.

WARNING: Never run the engine indoors

or in enclosed, poorly ventilated areas.

Engine exhaust contains carbon monoxide, an

odorless and colorless deadly gas. Keep hands,

feet, hair, and loose clothing away from any moving parts located on the engine or the snow thrower. The temperature of muffler and nearby areas

may exceed 150° F (65° C). Avoid these areas.

HOW TO START A WARM ENGINE

(Figure 3) If an engine has been running and is

still warm, leave the choke control (11) in the OFF

position and do not push the primer button (7). If

the engine fails to start, follow the instructions “How

To Start A Cold Engine.”

NOTE: Do not use the primer button (7) to start

a warm engine.

HOW TO START A WARM ENGINE WITH A

FROZEN STARTER

If the electric starter is frozen and will not turn

the engine, follow the instructions below.

1. With the engine running, quickly pull the re coil starter handle (10) three or four times with

a continuous full arm stroke. This will produce a

loud clattering sound that is not harmful to the

engine or starter.

2. Stop the engine. Wipe all snow and moisture

from the carburetor cover, control levers, and

cables. Also move the choke control (11) and

recoil starter handle (10) several times.

HOW CLEAR A CLOGGED DISCHARGE CHUTE

WARNING: Hand contact with the rotating

impeller inside the discharge chute is the

most common cause of injury associated with

snow blowing. Never use your hand to clean out

the discharge chute.

To Clear The Chute:

• Shut off the engine

• Wait 10 seconds to be sure that the impeller blades

have stop rotating.

• Always use a clean-out tool, not your hands.

How To Use A Clean-Out Tool:

• Release the auger drive lever.

• Pull out or remove the safety/ignition key.

• Disconnect the spark plug wire.

• Do not place your hands in the auger or dis-

charge chute. Use a clean-out tool to remove

snow or debris.

SNOW THROWING TIPS

1. (Figure 3) Pull out the recoil starter handle (10)

as far as possible.

2. Quickly release the recoil starter handle (10)

to snap back against the recoil starter.

If the engine still fails to start, repeat the two previous steps until the engine starts. Then, continue

with the directions “How To Start A Cold Engine.”

To help prevent the possible freeze-up of the

recoil starter and of the engine controls, proceed

as follows after each snow removal job.

1. This snow thrower will propel itself forward when

the handle is raised enough to cause the auger

blades to contact the ground. The auger should

stop when auger control bar is released. If it does

not stop, see “How To Adjust The Auger Control

Cable” in the Maintenance section.

2. Most efficient snow throwing is accomplished when

the snow if removed immediately after it falls.

16

Page 17

OPERATION

Not for

Reproduction

3. For complete snow removal, slightly overlap

leach previous path.

4. When possible, discharge the snow down wind.

5. The distance the snow will be discharged can

be adjusted by moving the discharge chute

deflector. Raise the deflector for more distance

or lower the deflector for less distance.

6. In windy conditions, lower the chute deflector

to direct the discharged snow close to the

ground where it is less likely to blow into un wanted areas.

7. For safety and to prevent damage to the snow

thrower, keep the area to be cleared free of

stones, toys, and other foreign objects.

8. Do not use the auger propelling feature when

clearing gravel or crushed rock driveways. Move

the handle down to slightly raise the auger.

Dry and Average Snow

1. Snow up to eight inches deep can be removed

rapidly and easily by walking at a moderate

rate. For snow drifts of a greater depth, slow

your pace to allow the discharge chute to dis pose of the snow as rapidly as the auger receives

the snow.

2. Plan to have the snow discharged in the direction

the wind is blowing.

Wet Packed Snow

Move slowly into wet, packed snow. It the wet,

packed now causes the auger to slow down or

the discharge chute begins to clog, back off and

begin a series of short back and forth jabs into

the snow. These short back and forth jabs, four

to six inches, will “belch” the snow from the chute.

9. The forward speed of the snowthrower is depen dent on the depth and weight of the snow. Exper ience will establish the most effective method of

using the snow thrower under different conditions.

10. After each snow throwing job, allow the engine to

run for a few minutes. The snow and accumulated

ice will melt off the engine.

11. Clean the snowthrower after each use.

12. Remove ice, snow, and debris from the entire

snow thrower. Flush with water to remove all

salt or other chemicals. Wipe snow thrower dry.

Snow Banks And Drifts

In snow of great depth than the unit, use the

same “jabbing” technique described above. Turn

the discharge chute away from the snow bank.

More time will be required to remove snow of this

type than level snow.

17

Page 18

CUSTOMER RESPONSIBILITIES

Not for

Reproduction

SERVICE RECORDS

Fill in dates as you

complete regular

service.

MAINTENANCE

Before

Each

Use

First

2

Hours

Every

5

Hours

Every

10

Hours

Every

25

Hours

Each

Season

Before

Storage

SERVICE DATES

Check And Tighten All Screws and Nuts

Check Spark Plug

Check Drive Belt

Check Fuel

Drain Fuel

Lubricate Chute Control Flange

Check Adjustment of Auger Control Cable

Auger Drive Belt

√ √

√

NOTE: Use the following maintenance section

to keep your unit in good operating condition.

All the maintenance for the engine is in the engine

manufacturer’s instructions. Before you start the

engine, read this book.

WARNING: Before you make an inspection, adjustment (except carburetor), or

repair, disconnect the wire from the spark plug.

EMISSIONS CONTROL

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by

any non-road engine repair establishment or indivHowever, to obtain a “no charge” emissions control

service, the work must be performed by a factory authorized dealer. See the Emissions Warranty.

GENERAL RECOMMENDATIONS

The warranty on this snowthrower does not cover items

that have been subjected to operator abuse or negligence.

To receive full value from the warranty, the operator must

maintain the snow thrower as instructed in this manual.

√ √

√

√

√

√

√

ENGINE POWER RATING INFORMATION

The gross power rating for individual gas engine models

is labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque Rating

Procedure), and rating performance has been obtained and

corrected in accordance with SAE J1995 (Revision 2002-05).

Torque values are derived at 3060 RPM; horsepower values

are derived at 3600 RPM. Actual gross engine power will be

lower and is aected by, among other things, ambient operating conditions and engine-to-engine variability. Given

both the wide array of products on which engines are

placed and the variety of environmental issues applicable

to operating the equipment, the gas engine will not develop

the rated gross power when used in a given piece of power

equipment (actual "on-site" or net power). This dierence

to due to a variety of factors including, but not limited to,

accessories (air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and

engine-to-engine variability. Due to manufacturing and

capacity limitations, Briggs & Stratton may substitute

an engine of higher rated power for this Series engine.

18

Page 19

MAINTENANCE

Not for

Reproduction

AFTER EACH USE

• Check for any loose or damaged parts.

• Tighten any loose fasteners.

• Check and maintain the auger.

• Check controls to make sure they are

functioning properly.

• If any parts are worn or damaged, replace

immediately.

• Check all safety and instruction decals

and labels. Replace any decals or labels

that are missing or cannot be clearly read.

HOW TO REMOVE THE TOP COVER

1. (Figure 5) Remove the discharge chute (1).

2. Remove the fuel cap.

3. Remove the two nuts and bolts (2) from the

front of the top cover (3).

7. Carefully pull the rear of the top cover (4) up and

over the gas tank.

8. To install the top cover (4), reverse the above

steps.

LUBRICATION BEFORE STORAGE

(Figure 5) Lubricate the chute control ange (7). Apply

a clinging type of grease such as Lubriplate.

3

2

6

4. Remove the two bolts (4) from the left and right

of the top cover (3).

5. Remove the eight screws (5) on the left and

right side of the top cover.

6. Remove the three screws (6) from the top

portion of the control panel.

4

1

7

5

Figure 5

19

Page 20

MAINTENANCE

Not for

Reproduction

HOW TO ADJUST THE AUGER CONTROL

CABLE

The auger control is adjusted at the factory. During

normal use, the auger control cable can become

stretched and the auger drive lever will not properly engage or disengage the auger.

1. (Figure 6) Remove the “Z” hook (1) from the

auger drive lever (2).

2

1

7. (Figure 6) Install the “Z” hook (1) to the

auger drive lever (2).

8. To check the adjustment, start the snowthrower.

Make sure the auger does not rotate when the

auger drive is released.

1

2

2

3

4

Figure 6

2. (Figure 7)

cable adjustment bracket (2).

3. Push the bottom of the auger control cable (3)

through the cable adjustment bracket (2) until

the “Z” hook (6) can be removed.

4. Remove the “Z” hook (4) from the cable adjust ment bracket (2). Move the “Z” hook (4) down to

the next adjustment hole.

5. Pull the auger control cable (3) up through the

cable adjustment bracket (2).

6. Put the cable boot (1) over the cable adjustment

bracket (2).

Figure 7

HOW TO REMOVE THE BELT COVER

1. (Figure 8) If equipped, remove the heat shield (1)

from the rear of the belt cover (2).

2. Remove the four bolts and nuts (3) holding

the belt cover (2) to the auger housing.

3. Remove the one screw (4) holding the belt

cover (2) to the bottom cover (5).

4. To remove, hold the bottom portion of the

belt cover (2) and pull down and out.

5. To install the belt cover (2), reverse the above

steps.

20

Page 21

MAINTENANCE

Not for

Reproduction

3. Move the belt guide (4) away from the drive

belt (1).

5

6

3

3

3

3

1

4. To reduce pressure on the drive belt (1), move

2

6

4

the idler pulley (2) away from the drive belt (1).

Remove the drive belt (1) from between the

brake pad (3) and the roller (5).

5. Remove the old drive belt (1).

6. To install the new drive belt (1), reverse the

above steps.

Figure 8

HOW TO REPLACE THE AUGER DRIVE BELT

The drive belt is of special construction and must be

replaced with original factory replacement belt available from your nearest authorized service center.

1. Remove the belt cover. See “How To Remove The

Belt Cover.”

2. (Figure 9) Remove the drive belt (1) from the idler

pulley (2).

2

3

7. Make sure the drive belt (1) is seated properly

on the pulleys.

8. (Figure 10) Set the belt guide (1) to 3/32”

clearance.

NOTE: When the auger control lever is en-

gaged, the belt guide (1) must be 3/32” (2 mm)

from the drive belt (2).

9. Install the belt cover. See “How To Remove

The Belt Cover.”

4

5

1

Figure 9

21

2

3/32”

1

Figure 10

Page 22

MAINTENANCE

Not for

Reproduction

HOW TO REPLACE THE AUGER

1. Remove the belt cover. See “How To Remove

The Belt Cover.”

2. Remove the drive belt. See “How To Replace

The Drive Belt.”

3

6

4

2

5

1

Figure 11

HOW TO ADJUST THE BRAKE PAD

IMPORTANT: An adjustment is only necessary

if the brake pad has become loose or has been

removed. To adjust, proceed as follows:

1. Remove the top cover. See “How To Remove

The Top Cover.”

2. Remove the belt cover. See “How To Remove

The Belt Cover.”

3. Tie the auger drive lever to the handle. This

will engage the drive system.

4. (Figure 12) Loosen the screw and nut that

secure the brake pad arm (1).

5. Set the clearance between the brake pad

(2) and the drive belt (3) to 1/8 inch (3 mm).

6. Tighten the screw and nut that secure the

brake pad arm (1).

7. Connect the wire to the spark plug.

3. (Figure 11) Remove the auger pulley (1) from

the auger shaft (threads are left hand; turn clock wise to remove).

4. To keep the auger (2) from rotating, set a

2” x 4” piece of wood (3) on the center pad dle (4) to secure the auger (2).

5. Remove the fasteners from the bearing as sembly (4). Remove the bearing assembly

(4) from the auger housing (5).

6. Slide the auger (2) out the bearing assem bly on the right side of the snow thrower.

7. Tip the auger (2) enough to allow the auger

(2) to slide out of the auger housing (6).

8. To install auger (2), reverse the above steps.

1

3

2

Figure 12

22

Page 23

MAINTENANCE

Not for

Reproduction

HOW TO REPLACE THE SPARK PLUG

NOTE: This spark plug ignition system meets

all requirements of the Canadian IntereferenceCausing Equipment Regulations (ICES-002).

NOTE: This engine complies with all current

Australian and New Zealand limitations electromagnetic interconference.

The spark plug is housed in the engine compartment under the top cover and cannot be seen

under normal conditions.

1. (Figure 13) Open the spark plug access

door (1) on the control panel.

2. The spark plug and wire are now visible.

3. Remove the spark plug wire.

4. Clean the area around the spark plug base

to prevent dirt from entering the engine when

the spark plug is removed.

5. Remove the spark plug.

6. Check the spark plug. If the spark plug is

cracked, fouled, or dirty, it must be replaced.

7. (Figure 14) Set the gap between the elec trodes of the new spark plug at .030 inch.

Next, install the spark plug in the cylinder

head and firmly tighten. Recommended

torque is 18 to 20 ft-lbs.

Figure 14

HOW TO PREPARE THE SNOWTHROWER

FOR STORAGE

repair, disconnect the wire from the spark plug.

WARNING: Before you make an inspection, adjustment (except carburetor), or

1

Figure 13

1. Drain the fuel tank.

2. Let the engine run until it is out of gasoline or

petrol.

3. Remove the spark plug from the cylinder.

a. Pour one ounce of oil into the cylinder.

b. Slow pull the recoil-start grip so that the oil

will protect the cylinder.

c. Install a new spark plug in the cylinder.

4. Thorougly clean the snow thrower.

5. Lubricate all lubrication points. See the Mainten ance section.

23

Page 24

MAINTENANCE

Not for

Reproduction

6. Be sure that all nuts, bolts, and screws are

securely fastened. Inspect all visible moving

parts for damage, breakage, and wear. Replace

if necessary.

7. Cover the bare metal parts of the blower

housing and auger with spray rust pre ventative lubricant.

8. Put the unit in a building that has good

ventilation.

9. If the machine must be stored outdoors,

block up the snow thrower to be sure the

entire machine is o the ground.

10. Cover the snow thrower with a suitable

protective cover that does not retain

moisture. Do not use plastic.

HOW TO ORDER REPLACEMENT PARTS

Use only manufacturer’s authorized or approved

replacement parts. Do not use attachments

or accessories not specically recommended for

this unit. In order to obtain proper replacement you

must supply the model number (see nameplate).

Warranty service is available only through Authorized

Service Dealers.

24

Page 25

TROUBLESHOOTING CHART

Not for

Reproduction

Trouble Cause Correction

Difficulty starting Defective spark plug. Replace spark plug.

Water or dirt in fuel system. Use carburetor bowl drain to flush and

refill with fresh fuel.

Engine runs erratic Blocked fuel line, empty gas tank,

or stale gasoline/petrol.

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Engine runs erratic; loss of

power

Excessive vibration Loose parts; damaged impeller. Stop engine immediately and disconnect

Unit fails to propel itself Drive belt loose or damaged. Replace drive belt.

Unit fails to discharge snow

Water or dirt in fuel system. Use carburetor bowl drain to flush and

Auger drive belt loose or damaged. Adjust auger drive belt; replaced if dam-

Auger control cable not adjusted

correctly.

Discharge chute clogged. Stop engine immediately and disconnect

Foreign object lodged in auger. Stop engine immediately and disconnect

Clean fuel line; check fuel supply; add

fresh fuel.

refill with fresh fuel.

spark plug wire. Tighten all bolts and

make all necessary repairs. If vibration

continues, have the unit serviced by a

competent repairman.

aged.

Adjust auger control cable.

spark plug. Clean discharge chute and

inside of auger housing.

spark plug wire. Remove object from

auger.

25

Page 26

BRIGGS & STRATTON POWER PRODUCTS GROUP, L.L.C. OWNER WARRANTY POLICY

Not for

Reproduction

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair and/or replace, free of charge, any part(s) of the equipment that is

defective in material or workmanship or both. Briggs & Stratton Corporation will repair and/or replace, free of charge, any

part(s) of the Briggs and Stratton engine* (if equipped) that is defective in material or workmanship or both. Transportation

charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is

effective for the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized

Service Dealer using our dealer locator at www.BriggsandStratton.com or www.SimplicityMfg.com.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular

purpose, are limited to one year from purchase or to the extent permitted by law. Liability for incidental or consequential

damages are excluded to the extent exclusion is permitted by law.

Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not

apply to you. This warranty gives you specific legal rights and you may also have other rights which vary from state to state

or country to country.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for

WARRANTY PERIOD

Item Consumer Use Commercial Use:

Equipment 2 Years 90 Days

Engine* 2 Years 90 Days

Battery 1 Year 1 Year

the period of time stated above. “Consumer use” means personal residential household use by a retail consumer. “Commercial

use” means all other uses, including use for commercial, income producing or rental purposes. Once product has experienced

commercial use, it shall thereafter be considered as commercial use for purposes of this warranty.

No warranty registration is necessary to obtain warranty on Briggs & Stratton products. Save your proof of purchase receipt. If you

do not provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the product will

be used to determine warranty eligibility.

We welcome warranty repair and apologize to you for being inconvenienced. Warranty service is available only through servicing

ABOUT YOUR WARRANTY

dealers authorized by Briggs & Stratton or BSPPG, LLC.

Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. This warranty

only covers defects in materials or workmanship. It does not cover damage caused by improper use or abuse, improper

maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using the product in

a way not described in the Operator’s Manual or using the product after it has been damaged will void your warranty. Warranty is

not allowed if the serial number on the product has been removed or the product has been altered or modified in any way, or if the

product has evidence of abuse such as impact damage, or water/chemical corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the

Operator’s Manual, and serviced or repaired using genuine Briggs & Stratton parts. Damage caused by lack of maintenance or use

of non-original parts is not covered by warranty.

Normal Wear - Like all mechanical devices, your unit is subject to wear even when properly maintained. This warranty does not

cover repairs when normal use has exhausted the life of a part or the equipment. Maintenance and wear items such as filters,

belts, cutting blades, and brake pads (engine brake pads are covered) are not covered by warranty due to wear characteristics

alone, unless the cause is due to defects in material or workmanship.

Stale Fuel - In order to function correctly, this product requires fresh fuel that conforms to the criteria specified in the Operator’s

Manual. Damage caused by stale fuel (carburetor leaks, clogged fuel tubes, sticking valves, etc) is not covered by warranty.

* Applies to Briggs and Stratton engines only. Warranty coverage of non-Briggs and Stratton engines is provided by the engine manufacturer.

26

Page 27

CALIFORNIA, U.S. EPA, AND BRIGGS & STRATTON CORPORATION EMISSIONS CONTROL WARRANTY STATEMENT

Not for

Reproduction

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Effective November 2008

The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S)

are pleased to explain the emissions control system warranty on your Model

Year 2008 and later engine/equipment. In California, new small off-road engines

must be designed, built, and equipped to meet the State’s stringent anti-smog

standards. B&S must warrant the emissions control system on your engine/

equipment for the periods of time listed below provided there has been no abuse,

neglect, or improper maintenance of your small off-road engine.

Your emissions control system may include parts such as the carburetor or

fuel injection system, fuel tank, ignition system, and catalytic converter. Also

included may be hoses, belts, connectors, sensors, and other emissions-related

assemblies. Where a warrantable condition exists, B&S will repair your engine/

equipment at no cost to you including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage:

Small off-road engines are warranted for two years. If any emissions-related part

on your engine/equipment is defective, the part will be repaired or replaced by

B&S.

Owner’s Warranty Responsibilities:

• As the small engine/equipment owner, you are responsible for the performance

of the required maintenance listed in your owner’s manual. B&S recommends that

you retain all receipts covering maintenance on your engine/equipment, but B&S

cannot deny warranty solely for the lack of receipts or your failure to ensure the

performance of all scheduled maintenance.

• As the engine/equipment owner, you should however be aware that B&S may

deny you warranty coverage if your engine/equipment or a part has failed due to

abuse, neglect, improper maintenance, or unapproved modifications.

• You are responsible for presenting your engine/equipment to a B&S distribution

center, servicing dealer, or other equivalent entity, as applicable, as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days. If you have any questions regarding your warranty

rights and responsibilities, you should contact B&S at (414) 259-5262.

BRIGGS & STRATTON EMISSIONS CONTROL WARRANTY PROVISIONS

The following are specific provisions relative to your Emissions Control Warranty

Coverage. It is in addition to the B&S engine warranty for non-regulated engines

found in the Operator’s Manual.

1. Warranted Emissions Parts

Coverage under this warranty extends only to the parts listed below (the

emissions control systems parts) to the extent these parts were present on

the engine purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel pump

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and

switches

• Connectors and assemblies

2. Length of Coverage

For a period of two years from date of original purchase, B&S warrants to

the original purchaser and each subsequent purchaser that the engine is

designed, built, and equipped so as to conform with all applicable regulations

adopted by the Air Resources Board; that it is free from defects in material

and workmanship that could cause the failure of a warranted part; and

that it is identical in all material respects to the engine described in the

manufacturer’s application for certification. The warranty period begins on the

date the engine is originally purchased.

The warranty on emissions-related parts is as follows:

• Any warranted part that is not scheduled for replacement as required

maintenance in the owner’s manual supplied, is warranted for the

warranty period stated above. If any such part fails during the period

of warranty coverage, the part will be repaired or replaced by B&S at

no charge to the owner. Any such part repaired or replaced under the

warranty will be warranted for the remaining warranty period.

• Any warranted part that is scheduled only for regular inspection in the

owner’s manual supplied, is warranted for the warranty period stated

above. Any such part repaired or replaced under warranty will be

warranted for the remaining warranty period.

• Any warranted part that is scheduled for replacement as required

maintenance in the owner’s manual supplied, is warranted for the

period of time prior to the first scheduled replacement point for that

part. If the part fails prior to the first scheduled replacement, the part

will be repaired or replaced by B&S at no charge to the owner. Any

such part repaired or replaced under warranty will be warranted for the

remainder of the period prior to the first scheduled replacement point

for the part.

• Add on or modified parts that are not exempted by the Air Resources

Board may not be used. The use of any non exempted add on or

modified parts by the owner will be grounds for disallowing a warranty

claim. The manufacturer will not be liable to warrant failures of

warranted parts caused by the use of a non exempted add on or

modified part.

3. Consequential Coverage

Coverage shall extend to the failure of any engine components caused by

the failure of any warranted emissions parts.

4. Claims and Coverage Exclusions

Warranty claims shall be filed according to the provisions of the B&S engine

warranty policy. Warranty coverage does not apply to failures of emissions

parts that are not original equipment B&S parts or to parts that fail due to

abuse, neglect, or improper maintenance as set forth in the B&S engine

warranty policy. B&S is not liable for warranty coverage of failures of

emissions parts caused by the use of add-on or modified parts.

LOOK FOR RELEVANT EMISSIONS DURABILITY PERIOD AND AIR INDEX INFORMATION ON YOUR ENGINE

EMISSIONS LABEL

Engines that are certified to meet the California Air Resources Board (CARB)

Emissions Standard must display information regarding the Emissions Durability

Period and the Air Index. Briggs & Stratton makes this information available to

the consumer on our emissions labels. The engine emissions label will indicate

certification information.

The Emissions Durability Period describes the number of hours of actual

running time for which the engine is certified to be emissions compliant, assuming

proper maintenance in accordance with the Operating & Maintenance Instructions.

The following categories are used:

Moderate:

Engine is certified to be emissions compliant

for 125 hours of actual engine running time.

Intermediate:

Engine is certified to be emissions compliant

for 250 hours of actual engine running time.

Extended:

Engine is certified to be emissions compliant

2

for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year.

Therefore, the Emissions Durability Period of an engine with an intermediate

rating would equate to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental

Protection Agency (USEPA) Phase 2 emissions standards. For Phase 2 certified

engines, the Emissions Compliance Period referred to on the Emissions

Compliance label indicates the number of operating hours for which the engine

has been shown to meet Federal emissions requirements.

For engines less than 225 cc displacement:

Category C = 125 hours

Category B = 250 hours

Category A = 500 hours

For engines of 225 cc or more displacement:

Category C = 250 hours

Category B = 500 hours

Category A = 1000 hours

27

Page 28

Specifi cations

Not for

Reproduction

ENGINE:

Brand Briggs & Stratton

Model Series 525 Snow Series

Gross Torque* 5.25 TP

Type 4-Cycle

Displacement 9.02 cu in.

Starting System 110V Electric, Recoil

Oil Capacity 20 oz (0,59 liters)

Engine Oil Synthetic 5W30

Fuel Tank Volume 2 qts (1,90 liters)

Spark Plug Gap 0.030 in. (0,76 mm)

Resistor Spark Plug 802592

Long Life Platinium Spark Plug 5062

AUGER:

Clearing Width 21 in. (53,3 cm)

Intake Height 10.25 in. (16 cm)

Auger Diameter 7 in. (18 cm)

CHUTE:

Chute Defl ector Manual

Chute Rotation Manual

DRIVE SYSTEM:

Drive Type Auger Propelled

Tire Size 7 x 1.5 in. (17.78 x 3.81 cm)

*Ignition System This spark plug ignition system complies with Canadian standard ICES-002.

Engine Power Rating Information

*The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive Engineers)

code J1940 (Small Engine Power & Torque Rating Procedure), and rating performance has been obtained and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower values are derived at 3600

RPM. Actual gross engine power will be lower and is affected by, among other things, ambient operating conditions and engineto-engine variability. Given both the wide array of products on which engines are placed and the variety of environmental issues

applicable to operating the equipment, the gas engine will not develop the rated gross power when used in a given piece of power

equipment (actual “on-site” or net power). This difference is due to a variety of factors including, but not limited to, accessories

(air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton

may substitute an engine of higher rated power for this Series engine.

28

3

Page 29

Not for

Reproduction

29

Page 30

Not for

Reproduction

30

Page 31

Not for

Reproduction

31

Page 32

Not for

Reproduction

Snapper Products

535 Macon St.

McDonough, GA 30253

1-800-317-7833

Snapper.com

Loading...

Loading...