Safety/nstructions& Operator'sManualfor

ZERO-TURNRIDINGMOWER

500Z Series

26HP Zero-Turn Riders

Mtg, No, Description

8900731 800ZB2648 Snapper 26HP 5OOZZero-Turn Rider with 48" Mower

00

5101453

Revision IR

Rev. Date: 1/2008

TP 100-7367-1R-ZT-N

Thankyoufor purchasingthis quality-built Snapperproduct. We'repleasedthat you've

placedyour confidencein the Snapperbrand. Whenoperatedand maintainedaccording

to the instructions in this manual,your Snapperproduct will providemanyyearsof

dependableservice.

This manual containssafetyinformationto makeyou awareof the hazardsand

risksassociatedwith this machineand howto avoidthem. Thismachineis designedand

intendedto beusedand maintainedaccordingto the manualfor finish cutting of

establishedlawnsand is not intendedfor any other purpose. It is importantthat you read

and understandtheseinstructionsthoroughly beforeattemptingto start or operatethis

equipment

Unit Model Number

MowerDeck ModelNumber

DealerName

EngineMake EngineModel

EngineType/Spec EngineCode/SerialNumber

SeeFeaturesand Controls for the location of Identification Numbers

DATEPURCHASED

Unit SERIALNumber

Mower DeckSERIALNumber

DatePurchased

,I WARNIN6

Engine exhaustfrom this productcontains chemicals

known, in certainquantities, to causecancer, birth

defests, or other reproductive hare].

Copyright (© 2008 Briggs & Stratton Corporation

Milwaukee, WI, USA, All rights reserved.

TheSnapperlogo is a trademark of Briggs & Stratton

Corporation Milwaukee,WI, USA.

Contact Information:

Snapper Products

535 Macon St.

McDonough, GA30253

www.snapper.com

Table of Contents

Operator Safety ..................................................... 2

SafetyRulesand Information...........................................2

SafetyDecals....................................................................8

SafetyInterlockSystem....................................................9

Features& Controls.............................................. 19

IdentificationNumbers ...................................................10

Control Functions ...........................................................11

Operation........................................................... 13

General...........................................................................13

ChecksBeforeStarting...................................................13

CheckingTire Pressures.................................................14

SeatAdjustment .............................................................14

Mowing Height Adjustment ............................................15

Foot PedalAdjustment....................................................15

Starting tbe Engine.........................................................16

Stoppingthe Rider..........................................................16

Pusbingtbe Riderby Hand.............................................16

Zero Turn Driving Practice..............................................17

Mowing...........................................................................19

Mowing Reccomendations.............................................19

Mowing Methods............................................................20

Attaching aTrailer...........................................................21

Regular Maintenance ............................................ 22

MaintenanceSchedule....................................................22

Checking/AddingFuel.....................................................23

FuelFilter........................................................................23

Oil & FilterChange..........................................................23

Lubrication......................................................................24

CheckTransmission Oil Level.........................................25

Transmission Oil Filter Cbange.......................................25

Servicingtbe Mower Blades...........................................26

Ground SpeedControl LeverAdjustment .......................28

SpeedBalancingAdjustment..........................................28

NeutralAdjustment .........................................................28

ParkingBrakeAdjustment ..............................................29

Returnto NeutralAdjustment.........................................30

DeckRodTiming Adjustment.........................................31

DeckLevelingAdjustment ..............................................31

Mower Belt Replacement................................................32

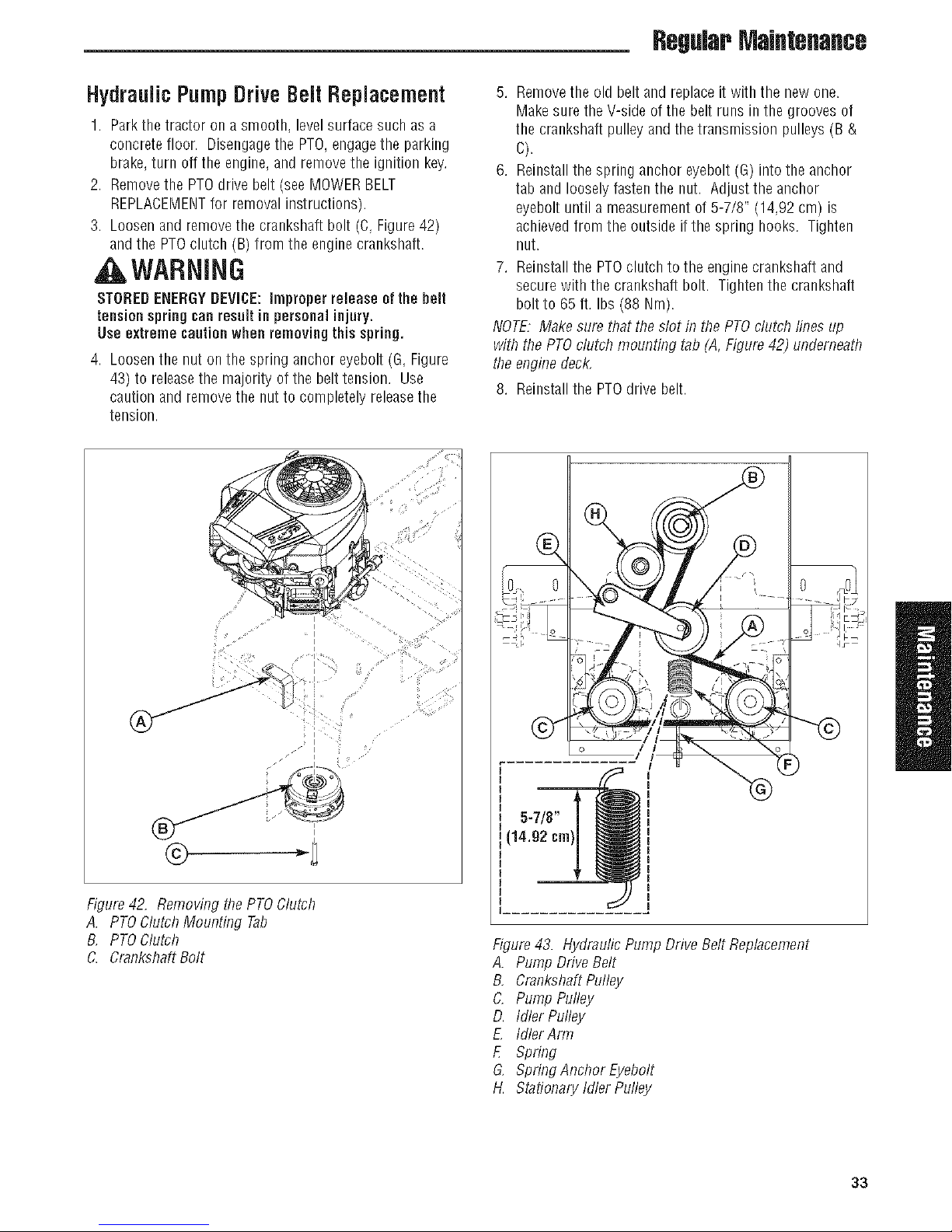

Hydraulic Pump Drive Belt Replacement........................33

Battery Maintenance.......................................................34

BatteryService...............................................................35

Storage...........................................................................37

Starting After Long Term Storage...................................37

Troubleshooting ................................................... 38

Troubleshootingthe Rider ..............................................38

Troubleshootingthe Mower............................................39

Troubleshooting Common Cutting Problems..................40

Specifications ...................................................... 41

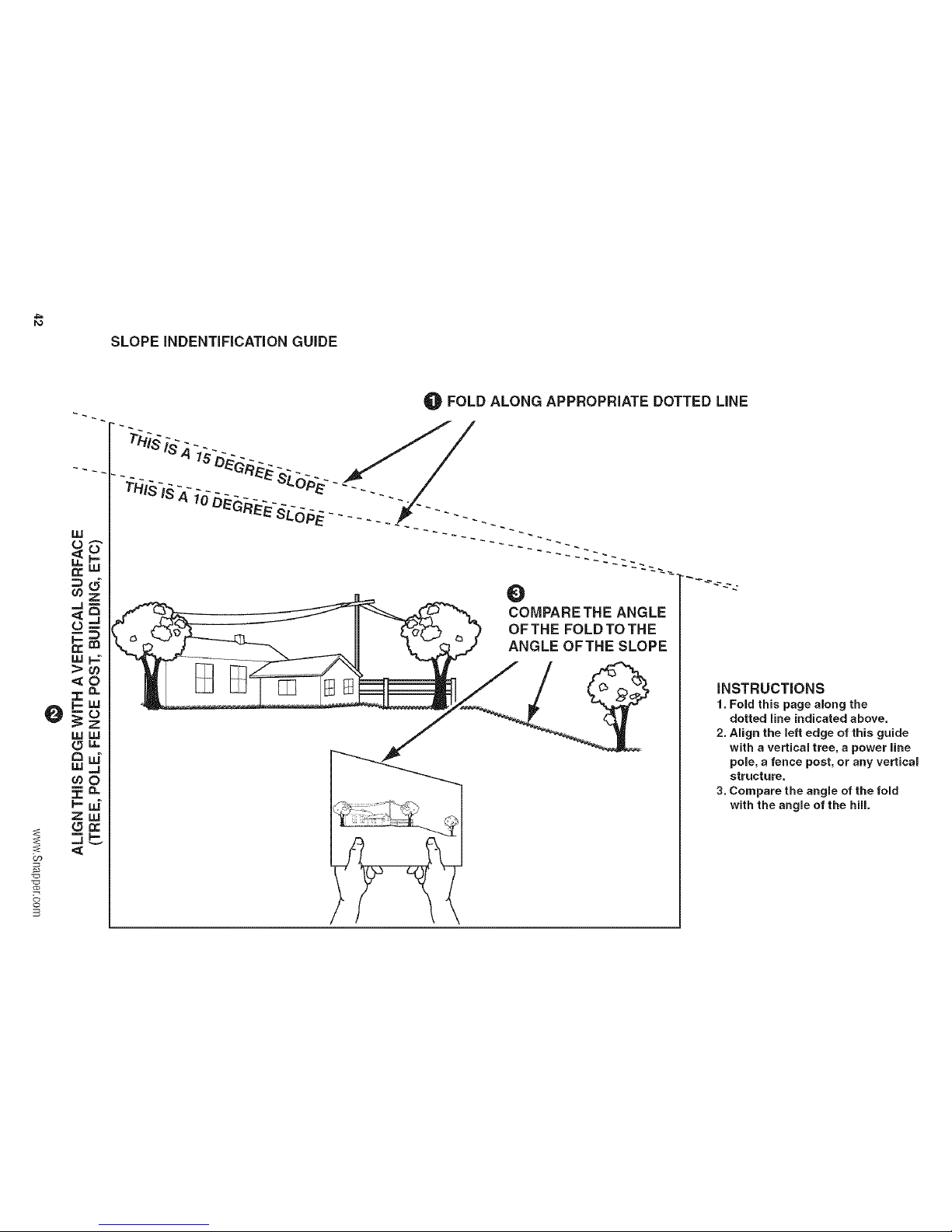

Slope identificationGuide....................................... 42

NOTE,"In this manual, "left" and "right" are referred to as seen

from the operatingposition.

OperatorSafety

OperatorSafety

SafetyRules and Information

Congratulationson pumhaeinga superior-qualitypieceoflawnand

gardenequipment.Ourproductsaredesignedandmanufacturedtomeet

orexceedallindustrystandardsforsafety.

Do notoperatethismachineunlessyouhavebeentrained.Readingand

understandingthisoperator'smanualisa way totrainyourself.

Power equipment is only as safe as the operator. If it is misused, or not

properly maintained,it can be dangerous! Remember,you are

responsible for your safety and that of those aroundyou.

Use common sense,andthink through what you are doing. If you are

not surethat the task you are about to perform can be safely done with

the equipment you havechosen ask a professional: contact your local

authorized dealer.

READ THE MANUAL

Theoperator's manualcontains important safety information

you needto be awareof BEFOREyou operateyour unit as

well as DURINGoperation.

Safeoperatingtechniques, anexplanationof the product's

features andcontrols, and maintenanceinformation is

included to helpyou get the most out of your equipment

investment.

OPERATINGSAFETY

Be sureto completely readthe Safety Rulesand Information

found on the following pages. Also completely readthe

Operationsection.

CHILDREN

Tragic accidents can occur with children. Do not

allowthem anywherenear the areaof operation.

Childrenareoften attractedto the unit and mowing

activity. Neverassume that children will remain

where you last saw them. Ifthere is a risk that

children may enterthe areawhere you are mowing,

haveanother responsibleadult watch them.

2 www.Snapper.com

20

=154

Operator$alety

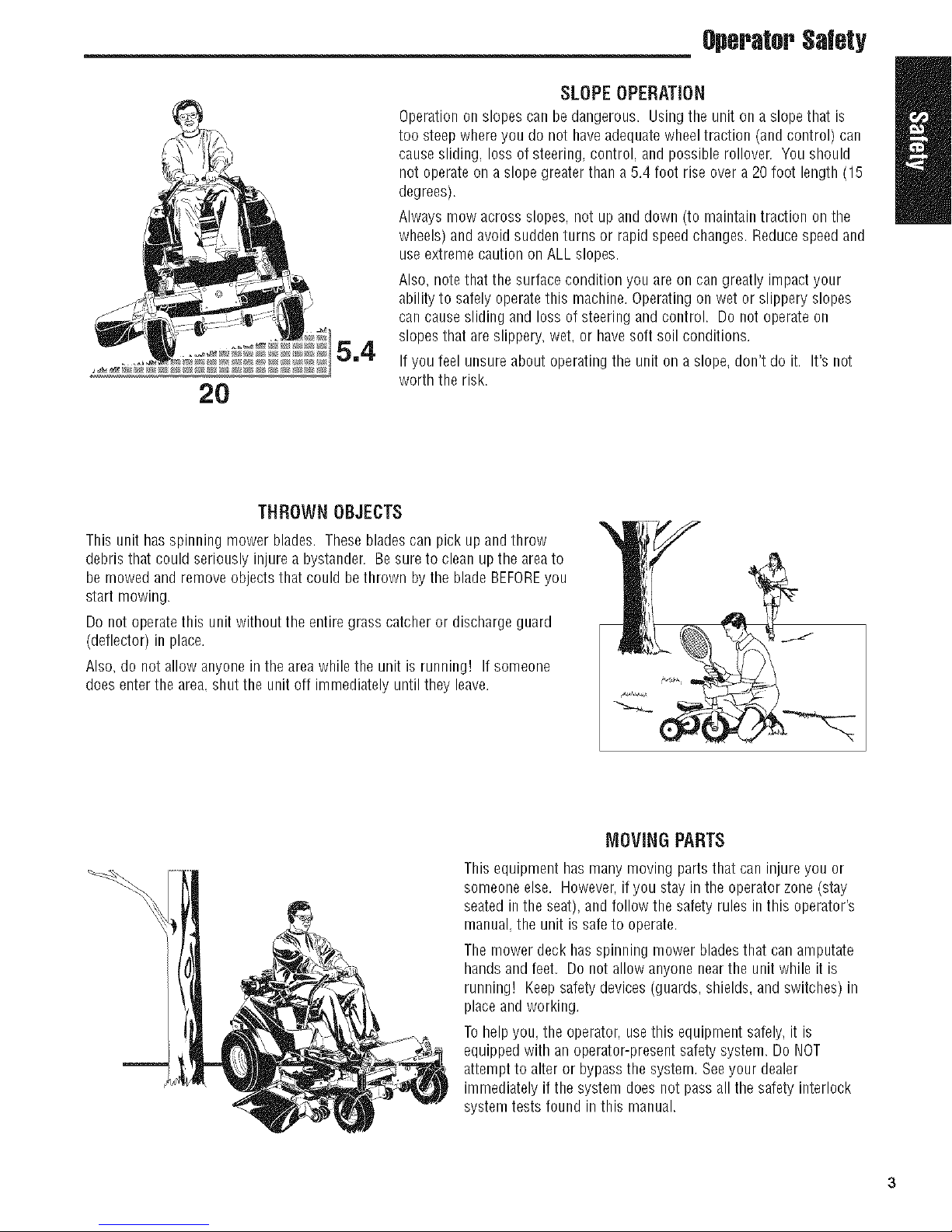

SLOPEOPERATION

Operationonslopescan be dangerous. Using theunit on a slopetbat is

too steepwhere you do not haveadequatewheel traction (and control) can

cause sliding, loss of steering, control, and possiblerollover. You should

not operate on a slope greater than a 5.4 foot rise over a 20 foot length (15

degrees).

Always mow across slopes, not up anddown (to maintaintraction on the

wheels) and avoid sudden turns or rapid speed changes. Reducespeed and

useextremecaution onALL slopes.

Also, notethat the surface condition you are on can greatly impact your

ability to safelyoperatethis machine.Operatingon wet or slippery slopes

can causesliding and loss of steering and control. Do not operate on

slopes that are slippery, wet, or havesoft soil conditions.

If you feel unsureabout operating the unit on a slope, don't do it. It's not

worth the risk.

THROWNOBJECTS

This unit has spinning mower blades. Theseblades can pick up and throw

debris that could seriously injure a bystander. Be sure to clean up the areato

be mowed and remove objects that could bethrown by the blade BEFOREyou

start mowing.

Do not operate this unit without the entiregrass catcher or discharge guard

(deflector) in place.

Also, do not allow anyonein the areawhile the unit is running! If someone

does enter the area.shut the unit off immediately until they leave.

This equipment has many moving parts that can injure you or

someone else. However,if you stay in the operator zone(stay

seated in the seat), and follow the safety rules in this operator's

manual, the unit is safe to operate.

The mower deck hasspinning mower bladesthat can amputate

hands and feet. Do not allow anyonenear the unit while it is

running! Keepsafetydevices (guards, shields, and switches) in

placeandworking.

Tohelpyou, the operator, usethis equipment safely, it is

equippedwith an operator-presentsafety system. Do NOT

attempt to alter or bypassthe system. Seeyour dealer

immediately if the system does not passall the safety interlock

system tests found in this manual.

IVIOVINGPARTS

OperatorSafety

RETAiNiNGWALLS,DROP-OFFS,ANDWATER

Retainingwalls anddrop-offs around stepsand water are a comrnon hazard.Giveyourself a rninimurn of two mower widths

of clearancearound thesehazardsandhand-trim with a walk behind moweror string trimmer. Wheelsdropping over

retainingwalls, edges, ditches, embankments,or intowater car/cause rollovers,which may resultin serious injury,death, or

drowning.

FUELANDIVlAINTENANCE

Always disengageall drives, shutoff the engine, and remove the

key beforedoing anycleaning, refueling, or servicing.

Gasolineandits vapors are extremely flammable. Do not smoke

while operating or refueling. Do not add fuel while engine is hot

or running. Allow engine to cool for at least 3 minutes prior to

adding fuel.

Do not add fuel indoors, in an enclosedtrailer, garage, or any

other enclosed areathat is not well ventilated. Gasolinespills

should be cleanedup promptly and beforeoperation begins.

Gasolineshould be stored only in sealedcontainers approvedfor

fuel.

Proper maintenanceis critical to the safety and performance of

your unit. Keepthe unit free of grass, leaves,and excess oil. Be

sureto perform the maintenance procedures listed in this

manual, especially periodicallytesting the safety system.

i i

ii [i

4 www.Snapper.com

ENCLOSEDAREAS

Only operatethis unit outdoors and away from

unventilatedareassuch as inside garagesor enclosed

trailers. The engine emits poisonous carbon

monoxide gas and prolonged exposure in an enclosed

area can result in serious injury or death.

Operator$a(ety

Readthese safety rules and follow them closely. Failureto obeythese rulescould result in loss of control of unit,

severe personal injury or deathto you, or bystanders, or damageto property or equipment.

This mowinq deck is capableof amputating handsand feet and throwingobjects. Thetriangle _ in text

signifies important cautions or warningswhich must be followed.

GENERAL OPERATION

1. Read,understand,and follow all instructions in the

manualandon the unit beforestarting.

2. Do not put hands or feet nearrotating parts or underthe

machine. Keepclear of the discharge opening at all

times.

3. Onlyallow responsible adults, who are familiar with the

instructions, to operatethe unit (local regulations can

restrict operator age).

4. Clearthe area of objects such as rocks, toys, wire, etc.,

which could be picked upand thrown by the blade(s).

5. Besure the area is clear of other peoplebeforemowing.

Stopthe unit if anyoneentersthe area.

6. Nevercarry I_assengers.

7. Do not mow in reverse unless absolutely necessary.

Always look down and behind beforeandwhile travelling

in reverse.

8. Neverdirect dischargematerial toward anyone. Avoid

discharging material against a wall or obstruction.

Materia/may ricochetback toward the operator. Stop

the blade(s)when crossing gravelsurfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in placeandoperational.

10. Slow down before turning.

11. Neverleavearunning unit unattended.Always disengage

the blades(PTO),set parking brake, stop engine,and

remove keysbefore dismounting.

12. Disengageblades(PTO)when not mowing. Shut off

engine and wait for all parts to come to a complete stop

beforecleaningthe machine,removing the grass

catcher, or unclogging the discharge guard.

13. Operatethe machine only in daylight or good artificial

light,

14. Do not operate the unit while underthe influence of

alcohol or drugs.

15 Watch for traffic when operatingnearor crossing

roadways.

16. Useextra carewhen loadingor unloadingthe unit into a

trailer or truck.

17. Always wear eyeprotection when operating this unit.

18. Dataindicatesthat operators, age60 years and above,

are involved in a large percentageof power equipment-

relatedinjuries. Theseoperators should evaluatetheir

ability to operatethe equipment safelyenoughto protect

themselves and others from injury.

19. Follow the manufacturer's recommendationsfor wheel

weights or counterweights.

20. Keepin mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seekand obtain professional and

practical instruction.

22. Always wear substantial footwear and trousers. Never

operatewhen barefoot or wearing sandals.

23. Beforeusing, always visually checkthat the bladesand

blade hardwarearepresent, intact, and secure. Replace

worn or damagedparts.

24. Disengageattachments before: refueling, removingan

attachment, making adjustments (unless the adjustment

can be madefrom the operator's position).

25. When the machine is parked,stored, or left unattended,

lowerthe cutting means unless a positive mechanical

lock is used.

26. Beforeleavingthe operator's position for any reason,

engagethe parking brake(if equipped), disengagethe

blades(PTO),stop the engine, andremove the key.

27. To reduce fire hazard,keepthe unit free of grass, leaves,

& excess oil. Do not stop or park over dry leaves,grass.

or combustible materials.

28. It is a violation of California Public ResourceCode

Section4442 to use or operatethe engine on or near

any forest-covered, brush-covered, or grass-covered

land unless the exhaustsystem is equipped with a spark

attester meeting any applicablelocal or state laws.

Otherstatesor federalareas may havesimilar laws.

29. OSHAregulations may require the use of hearing

protection when exposedto sound levelsgreaterthan 85

dBA for an 8 hour time period.

CAUTION

This machine produces sound levels in

excess of 85 dBAat the operator'sear and

cancausehearing lossthroughextended

periodsof exposure.

Wear hearing protectionwhenoperating this

machine.

TRANSPORTING AND STORAGE

1. When transportingthe unit on an open trailer, make sure

it isfacing forward, inthe direction oftravel. If the unit

is facing backwards, wind lift could damagethe unit.

2. Always observe safe refueling and fuel handling

practices when refuelingthe unit after transportation or

storage.

3. Neverstore the unit (with fuel) in an enclosed poorly

ventilated structure. Fuelvapors can travel to an ignition

source such as a furnace, water heater,etc. andcause

an explosion. Fuelvapor is alsotoxic to humans and

animals.

4. Always follow the engine manualinstructions for

storage preparations before storing the unit for both

short and long term periods.

5. Always follow the engine manualinstructions for proper

start-up procedureswhen returning the unitto service.

6. Neverstore the unit or fuel container inside where there

is an open flame or pilot light, such as in a waterheater.

Allow unit to cool before storing.

OperatorSa(ety

SLOPEOPERATION

Slopesare a majorfactor relatedto loss-of-control and tip-

overaccidents,which canresult in severeinjury or death.

Operationon all slopesrequiresextracaution.Ifyou cannot

backup the slopeor ifyou feel uneasyon it. do not operateon

it.

Control of awalk-behindor ride-on machinesliding on a slope

will not beregainedby theapplicationof the brake. Themain

reasonsfor loss of control are: insufficienttire grip onthe

ground,speedtoo fast, inadequatebraking,the type of

machineis unsuitablefor its task, lackof awarenessof the

ground conditions, incorrecthitchingandloaddistribution.

1. Mow across slopes, not up and down.

2. Watch for holes, ruts, or bumps. Uneventerrain could

overturn the unit. Tall grass can hide obstacles.

3. Choosea slow speedso that you will not have to stop or

changespeedswhile on the slope.

4. Do not mow on wet grass. Tires may loosetraction.

5. Avoid starting, stopping, or turning onaslope. If tires

losetraction (i.e. machine stops forward motion on a

slope), disengagethe blade(s) (PTO)anddrive slow off

the slope.

6. Keepall movementon slopes slow andgradual. Do not

makesudden changes in speed or direction, which could

cause the machine to rollover.

7. Useextra care while operating machines with grass

catchers or other attachments;they can affectthe

stability of the unit. Do not use on steepsslopes.

8. Do not try to stabilizethe machine by putting your foot

on the ground (ride-on units).

9. Do not mow near drop-offs, ditches, or embankments.

The mower could suddenly turn over if a wheel is over

the edgeof a cliff or ditch, or if an edgecavesin.

10. Do not use grass catchers on steepslopes.

11. Do not mow slopes if you cannot back up them.

12. Seeyour authorizeddealer/retailerfor recommendations

of wheel weights or counterweights to improve stability.

13. Removeobstaclessuch as rocks, tree limbs, etc.

14. Useslow speed.Tiresmay losetraction on slopes even

though the brakes are functioning properly.

15. Do not turn on slopes unless necessary,andthen, turn

slowly and gradually uphill, if possible. Nevermow

down slopes.

TOWEDEQUIPMENT(RIDE-ONUNITS)

1. Tow only with a machinethat hasa hitch designedfor

towing. Do not attachtowed equipment except atthe

hitch point.

2. Follow the manufacturer's recommendationsfor weight

limit for towed equipmentandtowing on slopes. See

.WARNiNG

Never operate on slopes greater than 15° whichisa

rise of 5.4 feet (1,6 m) vertically in 20 feet (6 m)

hoNzontally.

Select slow ground speedbeforedriving onto slope.

Useextra cautionwhen operatingon slopeswith rear-

mounted grass catchers.

Mow across theface of slopes, not up and down,use

caution when changingdirections and DO NOTSTART

ORSTOPONSLOPE.

attaching a trailer under OPERATION.

3. Neverallow children or others in or ontowed

equipment.

4. Onslopes, the weight of the towed equipment may

cause loss of traction and lossof control.

5. Travelslowly and allow extra distanceto stop.

6. Do not shift to neutral and coast down hill.

CHILDREN

Tragicaccidentscanoccurif the operator is notalertto the

presenceof children.Childrenareoftenattractedto the unit

andthe mowing activity. Neverassumethat childrenwill

remainwhereyou lastsawthem.

1. Keepchildren out of the mowing areaandunderthe

watchful care of another responsible adult.

2. Bealert and turn unit off if children enter the area.

3. Beforeandduring reverseoperation, look behind and

down for small children.

4. Nevercarry children, evenwith the blade(s)off. They

may fall off and be seriously injured or interfere with

safe unit operation. Childrenwho havebeen given rides

in the past may suddenly appear in the mowing areafor

another ride and be run overor backedover by the

machine.

5. Neverallow children to operatethe unit.

6. Useextra care when approachingblind corners, shrubs.

trees, or other objectsthat may obscure vision.

EMISSIONS

1. Engineexhaustfrom this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Lookfor the relevant Emissions Durability Period and Air

Index information onthe engine emissions label.

IGNITIONSYSTEM

1. Thisspark ignitionsystem complies with Canadian

ICES-O02.

6 www.Snapper.com

OperatorSafety

SERVICEAND MAINTENANCE

Safe Handling ofGasoline

1. Extinguishall cigarettes,cigars, pipes, and other sources

of ignition.

2. Useonly approvedgasolinecontainers.

3. Neverremove the gas cap or add fuel with the engine

running. Allow the engineto cool before refueling.

4. Neverfuel the machine indoors.

5. Neverstore the machine or fuel container where there is

an open flame, spark, or pilot light such as near a water

heateror other appliance.

6. Neverfill containers insideavehicle or on atruck bed

with a plastic bed liner. Always placecontainers on the

ground away from your vehicle before filling.

7. Removegas-powered equipment from the truck or trailer

and refuel it on the ground. If this is not possible, then

refuelsuch equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

8. Keepnozzlein contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzlelock-opendevice.

9. If fuel is spilled on clothing, changeclothing

immediately.

10, Neverover-fill the fuel tank. Replacegas cap and tighten

securely.

11, Useextra care in handling gasoline and other fuels. They

are flammable and vapors are explosive.

12, If fuel is spilled, do not attempt to start the engine but

move the machine awayfrom the area of spillage and

avoid creating anysource of ignition until fuel vapors

havedissipated.

13, Replaceall fuel tank caps and fuel container caps

securely.

Service & Maintenance

1. Neverrun the unit in anenclosedareawhere carbon

monoxide fumes may collect.

2. Keepnuts andbolts, especially bladeattachment bolts.

tight and keepequipment ingood condition.

3. Nevertamper with safety devices. Checktheir proper

operation regularly and make necessaryrepairs if they

are not functioning properly.

4. Keepunit free of grass, leaves,or other debris build-up.

Cleanup oil or fuel spillage, and removeanyfuel-soaked

debris. Allow machineto cool before storage.

5. If you strike an object, stop andinspect the machine.

Repair,if necessary,before restarting.

6. Nevermake adjustments or repairs with the engine

running.

7. Checkgrass catchercomponents and the discharge

guard frequently and replacewith manufacturer's

recommendedparts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear

gloves, and useextracaution when servicing them.

9. Checkbrake operation frequently. Adjust and service as

required.

10. Maintain or replacesafety and instructions labels,as

necessary.

11. Do not remove the fuel filter whenthe engine is hot as

spilled gasoline may ignite. Do not spreadfuel line

clamps further than necessary. Ensureclamps grip

hosesfirmly over the filter after installation.

12. Do not use gasolinecontaining METHANOL,gasohol

containing more than 10% ETHANOL,gasolineadditives,

or white gas becauseengine/fuel system damagecould

result.

13. If the fuel tank must bedrained, it should be drained

outdoors.

14. Replacefaulty silencers/mufflers,

15. Maintain or replacesafety and instruction labelsas

necessary.

16. Useonly factory authorized replacementpartswhen

making repairs.

17. Always comply with factory specifications on all settings

and adjustments.

18. Onlyauthorizedservice locations should be utilized for

major service and repair requirements.

19. Neverattempt to make major repairs on this unit unless

you havebeenproperlytrained. Improper service

procedures canresult in hazardous operation, equipment

damageandvoiding of manufacturer's warranty.

20. On multiple blade mowers, take care as rotating one

bladecan cause other bladesto rotate.

21. Do not change engine governor settings or over-speed

the engine. Operatingthe engine at excessivespeedcan

increasethe hazardof personalinjury.

22. Disengagedrive attachments,stop the engine, remove

the key,and disconnectthe spark plug wire(s) before:

clearing attachment blockages and chutes, performing

service work, striking an object, or if the unit vibrates

abnormally. After striking an object, inspect the machine

for damageand make repairs before restarting and

operatingthe equipment.

23. Neverplace handsnearthe moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top of

the transaxle),

24. Units with hydraulic pumps, hoses,or motors:

WARNING:Hydraulicfluid escaping under pressure may

havesufficient force to penetrateskin and causeserious

injury. If foreign fluid is injected into the skin it must be

surgically removed within a few hours by a doctor

familiar with this form of injury or gangrenemay result.

Keepbody and hands awayfrom pin holes or nozzles

that eject hydraulicfluid under high pressure. Usepaper

or cardboard, and not hands,to search for leaks. Make

sure all hydraulic fluid connections are tight and all

hydraulic hoses and lines are in good condition before

applying pressureto the system. If leaks occur, havethe

unit serviced immediately byyour authorized dealer.

25. WARNING:Stored energydevice. Improper release of

springs can result inserious personal injury. Springs

should be removed by an authorizedtechnician.

26. Models equipped with an engine radiator: WARNING:

Storedenergy device. To prevent serious bodily injury

from hot coolant or steam blow-out, neverattempt to

removethe radiator capwhile the engine is running.

Stopthe engine andwait until it is cool. Eventhen. use

extreme care when removing the cap.

,OperstorSslety

Safety Decals

Thisunithasbeendesignedandmanufacturedto provide

youwiththesafetyandreliabilityyouwouldexpectfroman

industryleaderin outdoorpowerequipmentmanufacturing.

Although reading this manualand the safety instructions it

contains will provideyou with the necessary basic

knowledge to operatethis equipment safely and effectively,

we have placedseveralsafetylabelson the unit to remind

you of this important information while you are operating

your unit.

All DANGER,WARNING, CAUTIONand instructional

messageson your rider and mower should be carefully read

and obeyed. Personalbodily injury can result when these

instructions are not followed. The information is for your

safety and it is important! Thesafetydecalsbelow are on

your rider and mower.

If any of these decals are lost or damaged, replacethem at

once. Seeyour local dealerfor replacements.

Theselabelsare easilyapplied and will act as a constant

visual reminderto you, and others who mayusethe

equipment,to follow the safety instructions necessaryfor

safe,effective operation.

1

4

\

\

3

_5

4

5

8 www.Snapper.com

6 2

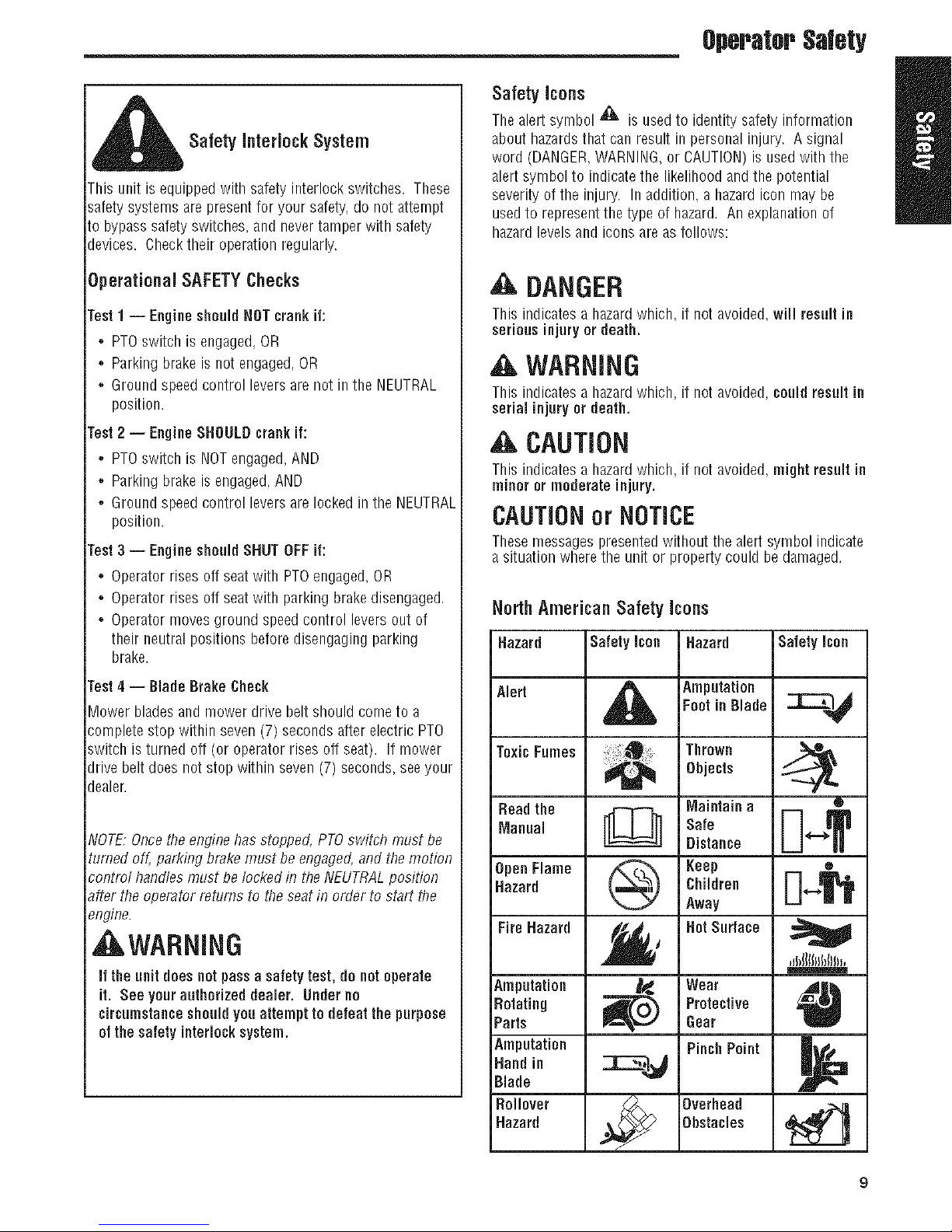

SafetyInterlockSystem

this unit isequippedwith safety interlockswitches. These

;afetysystems arepresentfor your safety,do not attempt

:o bypass safety switches, andnevertamper with safety

Jevices. Checktheir operation regularly.

Operator$alety

Safety icons

Thealert symbol '_ isusedto identitysafety inforrnation

about bazardsthatcan result in personalinjury. A signal

word (DANGER,WARNING,or CAUTION)is usedwitb tbe

alert symbol to indicatethe likelihood and the potential

severity of the injury. In addition, a hazardicon may be

usedto represent the type of hazard. An explanation of

hazardlevelsandicons are asfollows:

Operational SAFETYChecks

Fast1 -- Engine should NOTcrank if:

,, PTOswitch is engaged,OR

,, Parking brakeis not engaged,OR

,, Ground speed control levers are not in the NEUTRAL

position.

Fast2 -- EngineSHOULDcrankit:

,, PTOswitch is NOTengaged,AND

,, Parking brakeis engaged,AND

,, Ground speed control levers are locked in the NEUTRAL

position.

Fast3 -- Engineshould SHUTOFFif:

,, Operator rises off seatwith PTOengaged, OR

,, Operator rises off seatwith parking brake disengaged.

,, Operator movesground speedcontrol levers out of

their neutral positions before disengagingparking

brake.

rest4 -- Blade Brake Check

_ower bladesand mower drive belt should come to a

:;ompletestop within seven (7) seconds after electric PTO

;witch is turned off (or operator rises off seat). If mower

Jrive belt does not stop within seven (7) seconds,seeyour

Jealer.

_IOTE:Oncethe enginehas stopped, PTOswitch must be

turned off, parking brake must be engaged,and the motion

_ontml handlesmust be locked in the NEUTRALposition

_fter the operator returns to theseatin order to start the

9ngine.

,Ji WARNING

if theunit does notpassa safetytest, do notoperate

it. See yourauthorized dealer. Underno

circumstanceshould you attempt to defeat the purpose

of the safety interlocksystem.

DANGER

This indicatesa hazardwhich, if not avoided, will resultin

seriousinjury or death.

,A WARNING

This indicatesa hazardwhich, if not avoided, could resultin

serial injury or death.

CAUTION

This indicatesa hazardwhich, if not avoided, might result in

minor or moderate injury.

CAUTIONor NOTICE

Thesemessages presentedwithout tbe alert symbol indicate

a situation wherethe unit or property could be damaged.

NorthAmerican Safety Icons

Hazard

Alert

ToxicFumes

Read the

Manual

OpenFlame

Hazard

Fire Hazard

Amputation

Rotating

Parts

Amputation

Hand in

Blade

Rollover

Hazard

Safety icon

®

Hazard

Amputation

Foot in Blade

Thrown

Objects

Maintain a

Safe

Distance

Keep

Children

Away

Hot Surface

Wear

Protective

Gear

Pinch Point

Overhead

Obstacles

Safety icon

®

O

,JbIIIIId)()in,

O

9

.FeaturesandControls

Featuresand Controls

Identification Numbers

Whencontactingyourauthorized dealer for replacement

parts, service, or informationyou MUSThavethese

numbers.

Recordyour part number, serial number and engine serial

numbers in the space provided on the inside front cover for

easyaccess. These numbers can be found in the locations

shown in Figure1.

NOTE,Forlocationof engineidentification numbers, refer to

theengineowner's manual.

Figure 1. IdentificationNumbers

A. Identification Tag

10 www.Snapper.com

FesturesandCefltrols

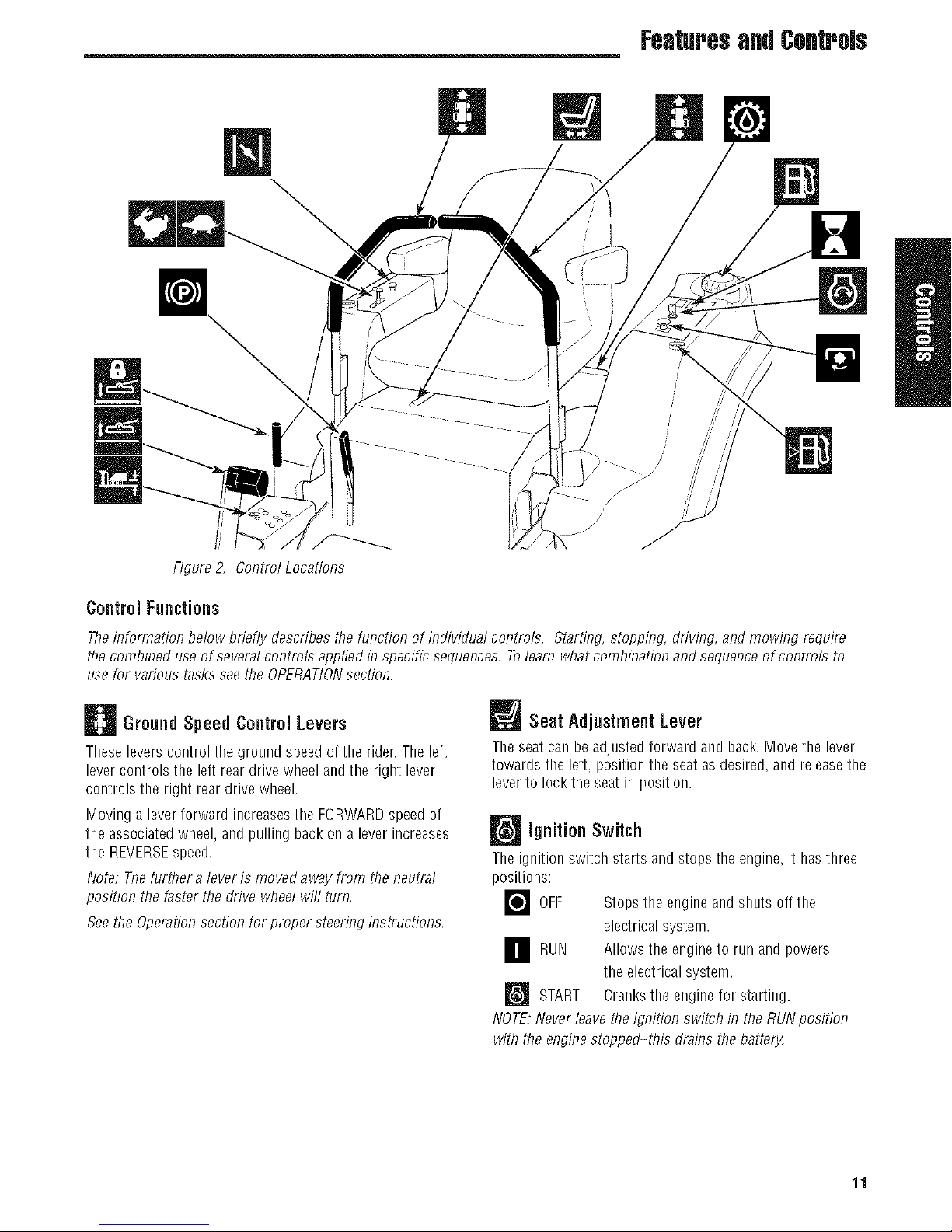

Figure2, Control Locations

Control Functions

Theinformation below briefly describes the timction of individual controls. Starting, stopping, driving, andmowing require

thecombined use of several controls applied in specific sequences. Tolearn whatcombination and sequenceof controls to

usefor various tasks seethe OPERATIONsection.

Ground Speed Control Levers

Theseleverscontrol the ground speed of the rider, The left

lever controls the left reardrive wheel andthe right lever

controls the right rear drive wheel.

Moving a leverforward increasesthe FORWARDspeed of

the associatedwheel,and pulling back on a lever increases

the REVERSEspeed.

Note: Thefurther alever is moved away from the neutral

position the faster the drive wheel will turn.

Seethe Operationsection for proper steering instructions.

Seat Adjustment Lever

Theseatcan be adjusted forward and back.Movethe lever

towards the left, position the seat as desired, and releasethe

leverto lock the seat in position.

ignition Switch

The ignition switch starts and stops the engine, it hasthree

positions:

r_OFF

RUN Allows the engineto run and

_'_ START Cranksthe enginefor starting.

NOTE.Neverleavethe ignition switch in the RUNposition

with the enginestopped-ttiis drains thebattery,

Stops the engineand shuts off the

electrical system.

powers

the electrical system.

11

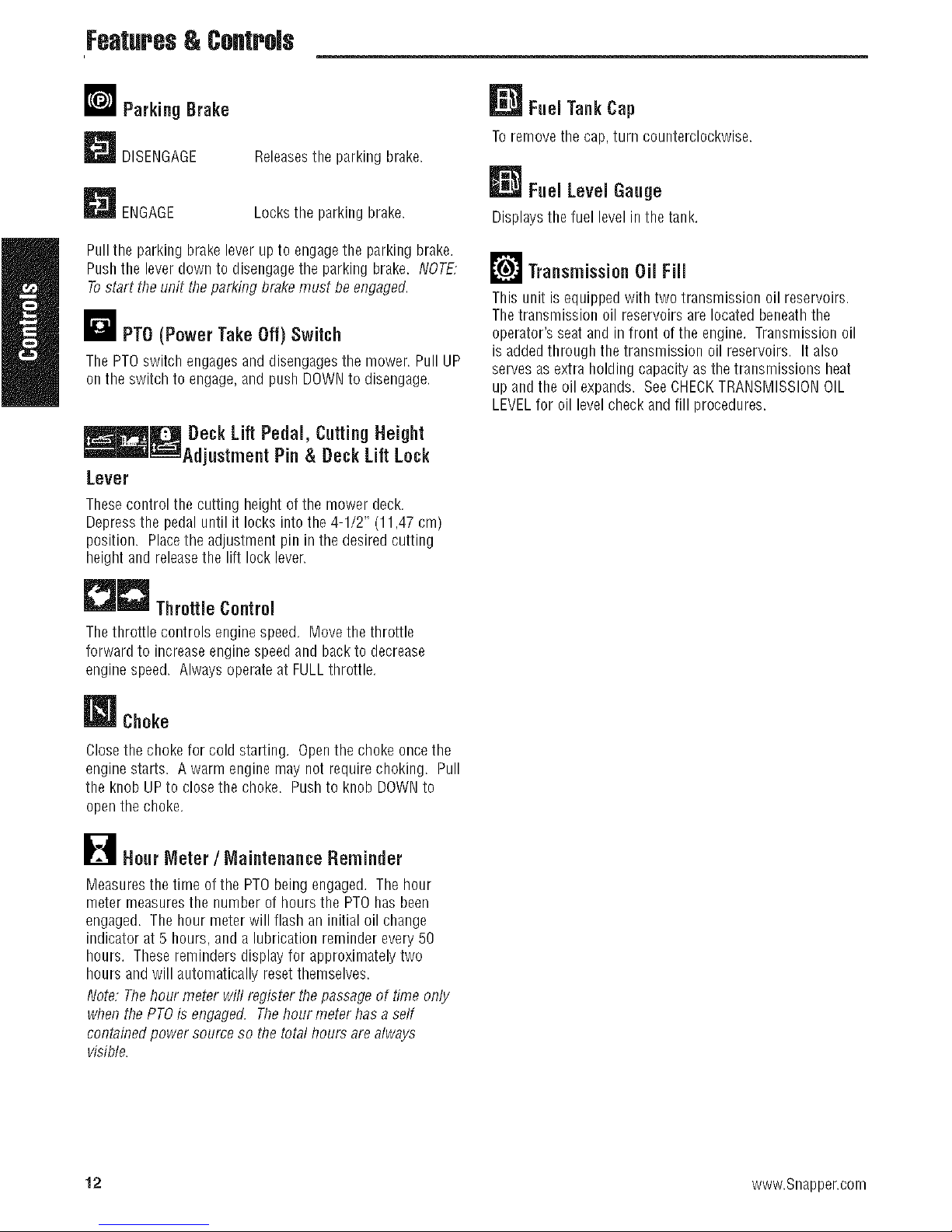

Features& Controls

ParkingBrake

DISENGAGE Releasesthe parking brake.

m ENGAGE Locks the parking brake.

Pullthe parking brake leverupto engagethe parking brake.

Pushthe lever down to disengage the parking brake. NOTE,

Tostart the unit theparking brakemust be engaged.

PTO (Power Take Off) Switch

The PTOswitch engagesand disengagesthe mower. Pull UP

on the switch to engage,and push DOWNto disengage.

m_ Deck Lift Pedal, Cutting Height

='='='_='-"_Adjustment Pin & Deck Lift Lock

Lever

Thesecontrol the cutting height of the mower deck.

Depressthe pedal until it locks into the 4-1/2" (11,47 cm)

position. Placethe adjustment pin in the desired cutting

height and releasethe lift lock lever.

Fuel Tank Cap

Toremovethe cap, turn counterclockwise.

Fuel LevelGauge

Displays the fuel level in the tank.

LL_JTransmission Oil Fill

This unit is equipped with two transmission oil reservoirs.

Thetransmission oil reservoirs arelocated beneaththe

operator's seat and in front of the engine. Transmission oil

is added through the transmission oil reservoirs. It also

servesas extra holding capacity as thetransmissions heat

up andthe oil expands. SeeCHECKTRANSMISSIONOIL

LEVELfor oil levelcheckandfill procedures.

Throttle Control

Thethrottle controls engine speed, Movethe throttle

forward to increaseenginespeedand backto decrease

engine speed. Always operateat FULLthrottle,

_ Choke

Closethe choke for cold starting. Openthe choke oncethe

engine starts. A warm engine may not requirechoking. Pull

the knob UP to close the choke. Pushto knob DOWNto

open the choke.

B Hour Meter / Maintenance Reminder

Measuresthe time of the PTObeing engaged, The hour

meter measuresthe number of hoursthe PTO hasbeen

engaged. The hour meter will flash an initialoil change

indicator at 5 hours, and a lubrication reminder every 50

hours. Thesereminders display for approximately two

hours andwill automatically reset themselves.

Note: Thehour meter will register the passageof time only

whenthe PTOis engaged. Thehour meter has a self

containedpower source so the total hours are always

visible.

12 www.Snapper.com

Operation

Operation

GeneralOperatingSafety

Beforefirst time operation:

,, Besure to read all information in the Safety and

Operationsections before attempting to operate this

tractor and mower.

,, Becomefamiliar with all of the controls and how to stop

the unit.

,, Drive in an open areawithout mowing to become

accustomedto the unit.

WARNING

Neverallow passengers to ride an the unit.

Beforeleavingthe operator'spositionfor any reason,

engage the parking brake, disengage the PTO,stopthe

engine and remave thekey.

Toreducefire hazard, keepthe engine, tractorand

mower free of grass, leavesand excessgrease. Donot

stopor park tractor over dry leaves, grass or

combustiblematerials.

Gasoline is highly flammable and must be handled

with care. Neverfill the tankwhen the engineis still

hotfrom recent operation.Donet allow open flame,

smokingor matches in the area. Avoid over-fillingand

wipe up any spills.

WARNING

AWARNING

Never operateon slopesgreater than (15°) whichisa

rise of5.4 feet (1,6 m) vertically in 20 feet (607 cm)

horizontally.

Select slow ground speedbeforedriving ontoa slope.

Useextracautionwhenoperatingonslopeswith a

rear-mountedgrass catcher.

Mow across theface ofslopes, net up anddown, use

cautionwhenchangingdirections and DO NOTSTART

ORSTOPONSLOPE.

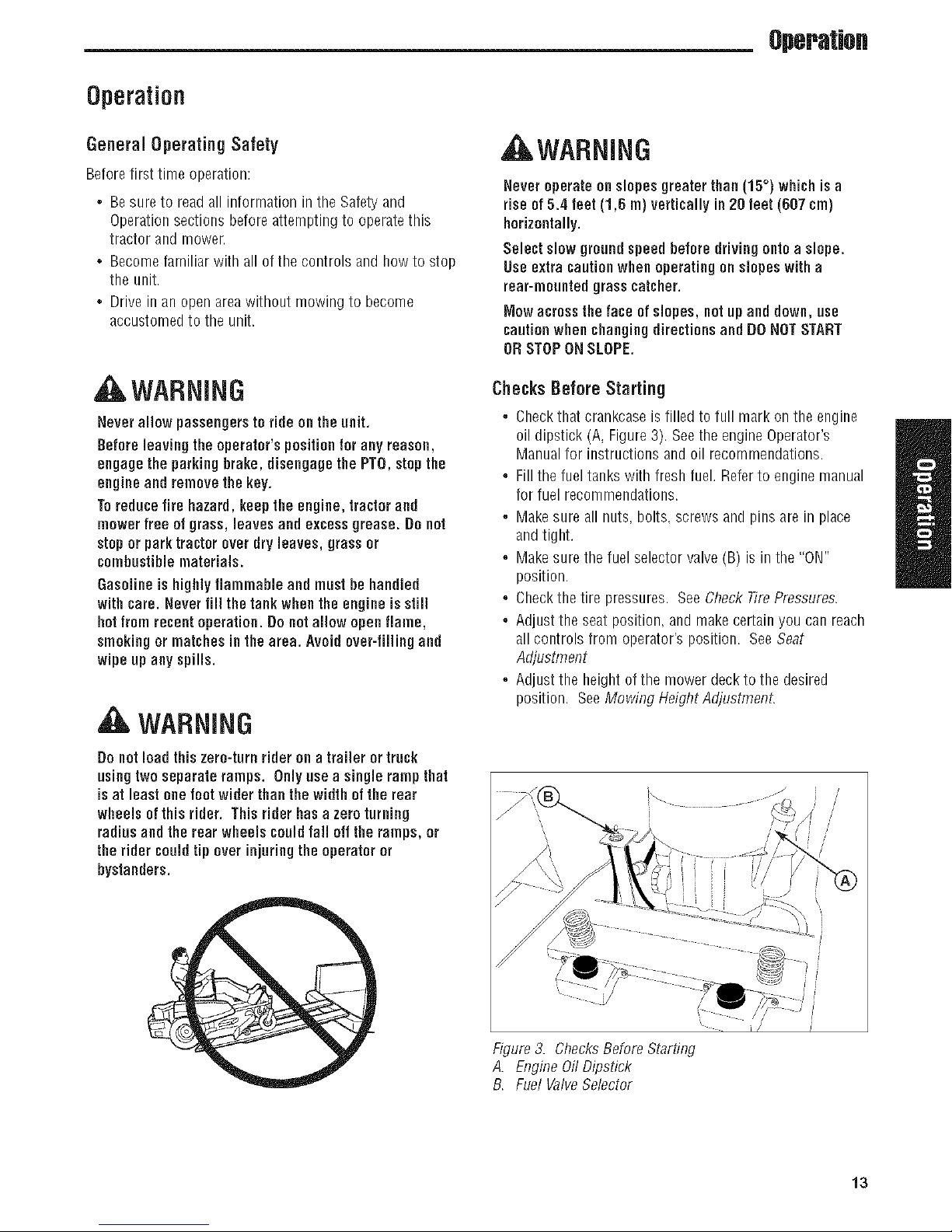

Checks Before Starting

,, Checkthat crankcaseis filled to full mark on the engine

oil dipstick (A, Figure3). Seethe engine Operator's

Manualfor instructions and oil recommendations.

,, Fill the fuel tanks with fresh fuel. Referto engine manual

for fuel recommendations.

,, Makesure all nuts, bolts, screws andpins are in place

and tight.

,, Makesure the fuel selector valve (B) is in the "ON"

position.

,, Checkthe tire pressures. See Check TirePressures.

,, Adjust the seat position, and make certain you canreach

all controls from operator's position. SeeSeat

Adjusflnent

,, Adjust the height ofthe mower deck to the desired

position. SeeMowing Height Adjustment.

Donotloadthis zero-turnrider on a trailer or truck

using two separateramps. Onlyuse a singlerampthat

isat least onefootwiderthan the width of the rear

wheels of this rider. Thisriderhasa zero turning

radius and therear wheels couldfail offthe ramps, or

the rider couldtip over injuringthe operatoror

bystanders.

®

Figure3. ChecksBefore Starting

A. Engine0il Dipstick

B. Fuel ValveSelector

13

Operation

CheckTire Pressures

Tire pressure should bechecked periodically,and

maintained at the levels shown in the chart. Note that these

pressures may differ slightly from the "Max Inflation"

stamped on the side-wall of the tires. The pressures shown

provide proper traction, improve cut quality, and extendtire

life.

Tire Pressure

Front 40 psi (276 bar)

Rear 15 psi (1,03 bar)

Seat Adjustment

See Figure5. The seat can be adjusted forward and

backward. Movethe lever towards the left, position the seat

asdesired, and releasethe lever to lock the seat into

position.

Figure4. Checking TirePressure

Figure5. SeatAdjustment

A. SeatAdjustment Lever

14 www.Snapper.com

Mowing HeightAdjustment

Thecutting height adjustment pin (A, Figure6) controls the

mower cutting height. Thecutting height is adjustable

between 1-1/2" (3,37 cm) and 4-1/2" (11,47 cm) in 1/4"

(0,64 cm) increments.

1. Depressthe deck lift foot pedal (B) until it locks into the

4-1/2" (11,47 cm) position.

2. Placethe cutting height adjustment pin in the desired

cutting height.

3. Depressthe deck lift foot pedalthen pushthe lock lever

(C)toward the right to releasethe lock.

4. Releasethe deck lift foot pedal until it comes to rest

against the cutting height adjustment pin.

Foot PedalAdjustment

OperaUofl

Figure 6, Mowing Height Adjustment

A. Cutting Height Adjustment Pin

B, Deck Lift Foot Pedal

C. Deck Lift Lock/ever

Thedecklift foot pedalcan be adjusted to accommodatethe

operator's height for optimal comfort.

Toadjust pedal position:

1. Removethe foot pedal (A, Figure7) from the pedal

mount tab (B).

2. Removethe pedal mount hardware(C) and rotate the

tab 180 degrees.

3. Reinstallthe pedal mount hardware andtighten securely.

4. Reinstallthe foot pedalon the pedal mount tab in the

proper orientation as shown in Figure7.

Figure 7. Foot PedalAdjustment

A. Deck Lift FootPedal

B, Pedal Mount Tab

C. PedalMount Hardware

D. Optional Position

15

Operation

Starting the Engine

AWARNING

ifyoude net understandhow a specificcontrol

functions, or havenotyetthoroughlyread the

FEATURES& CONTROLSsection, do sonow.

DoNOTattempt to operatethetractorwithoutfirst

becoming familiar with the locationand function ofALL

controls.

1. While sitting in the operator's seat,engagethe parking

brakeby pulling the parking brake lever up, make sure

the PTOswitch is disengaged (presseddown fully) and

the ground speedcontrol levers are locked in the

NEUTRALposition.

2. NOTE:A warm enginemay not require choking.

Setthe enginethrottle control to FULLthrottle position,

Thenfully close the choke by pulling the knob OUTfully.

3. Insert the key into the ignition switch andturn it to

START.

4. After the engine starts, gradually open the choke (push

knob down fully). Reduceto half throttle speedand

allow to warm up.

Warm up the engineby running it for at leasta minute

before engaging the PTOswitch or driving the riden

5. After warming the engine,ALWAYSoperate the unit at

FULLTHROTTLEwhen mowing.

In the eventof an emergencythe enginecan he stopped

hy simply turningthe ignition switch to STOP. Use this

method only in emergencysituations. Fornormal engine

shut down follow theprocedure given in STOPPINGTHE

RIDER,

Pushingthe Rider By Hand

NOTICE

DO NOT TOW BINDER

Towingthe units will causetransmissiondamage. De

notuse another vehicle to pushor pull this unit.

1. Disengagethe PTO,engagethe parking brake,turn the

ignition OFEand remove the key.

2. Locatethe transmission releaselevers(A, Figure 8)

located underneaththe front ofthe fuel tanks.

3. Pull both transmission releaseleversback and down so

that they lock in the disengaged (free-wheelposition)

(C).

4. Disengagethe parking brake.

Thetractor can now be pushed by hand.

5. After moving the tractor, re-engagethe transmissions by

pulling thetransmission releaseleversupand pushing

them forward to the engaged (drive) position (B).

Stopping the Rider

1. Returning the ground speedcontrol leversto the middle

position will stop rider movement. Pivot the levers

outward and lock them in NEUTRAL.

2. Disengagethe PTOby pushing down on the PTOswitch.

3. Engagethe parking brake by pulling the handleup until

it locks into position.

4. Move thethrottle control to mid-throttle position and

turn the ignition keyto OFE Removethe key.

16 www.Snapper.com

Figure8. Transmission ReleaseLevers (LH shown)

A. TransmissionReleaseLever

B, EngagedPosition (Drive Position)

C. DisengagedPosition (Free-wheelPosition)

Operatiofl

Zero Turn Driving Practice

The lever controls of the Zero Turn rider are responsive, and

learning to gain a smooth and efficient control of the rider's

forward, reverse,andturning movements will take some

practice.

Spending some time going through the maneuvers shown

and becoming familiar with how the unit accelerates,travels.

and steers -- beforeyou beginmowing --is absolutely

essentialto getting the most out of the Zero Turn rider.

Locatea smooth, fiat area ofyour lawn -- one with plenty

of room to maneuver. (Clearthe area of objects, peopleand

animals before you begin.) Operatethe unit at mid-throttle

during this practicesession (ALWAYSoperateat full throttle

when mowing), and turn slowly to preventtire slippage and

damageto your lawn.

Wesuggest you begin with the Smooth Travelprocedureto

the right, and then advancethrough the forward, reverse.

and turning maneuvers.

You must releasethe parking brake prior to moving the

ground speedcontrol levers inward.

Smooth Travel

The lever controls of the

ZeroTurn rider are

responsive.

The BESTmethod of

handling the ground

speedcontrol levers is in

three steps -- as shown

in Figure9.

FIRSTplaceyour hands

onto the levers as shown.

SECOND,to go forward

gradually push the levers

forward with your palms.

THIRD,to speedup move

the levers farther

forward. Toslow down

smoothly, slowly move

the levers toward neutral.

ForwardTravelPractice

Graduallymove both ground speedcontrol levers--evenly

FORWARDfrom neutral. Slow down and repeat.

NOTE:Straight forward travel takespractice, If necessad4

top speed canbe balance-adjusted-- seethe Speed

BalancingAdjusflnent in theAdjustments section near the

back of this manual.

Forward

Travel

Figure9. Move Control

Levers Gradually

Reverse Travel Practice

LOOKDOWN& BEHIND,then gradually move both ground

speedcontrol levers evenly BACKfrom neutral. Slow down

and repeat.

NOTE:Practicebacking upfor severalminutes before

attempting to do so near objects. Therider turns sharply in

reverseas well as forward, and backing up straight takes

practice.

Reverse

Travel

' / \

Figure 10. Forward Travel Figure 11. ReverseTravel

17

Operation

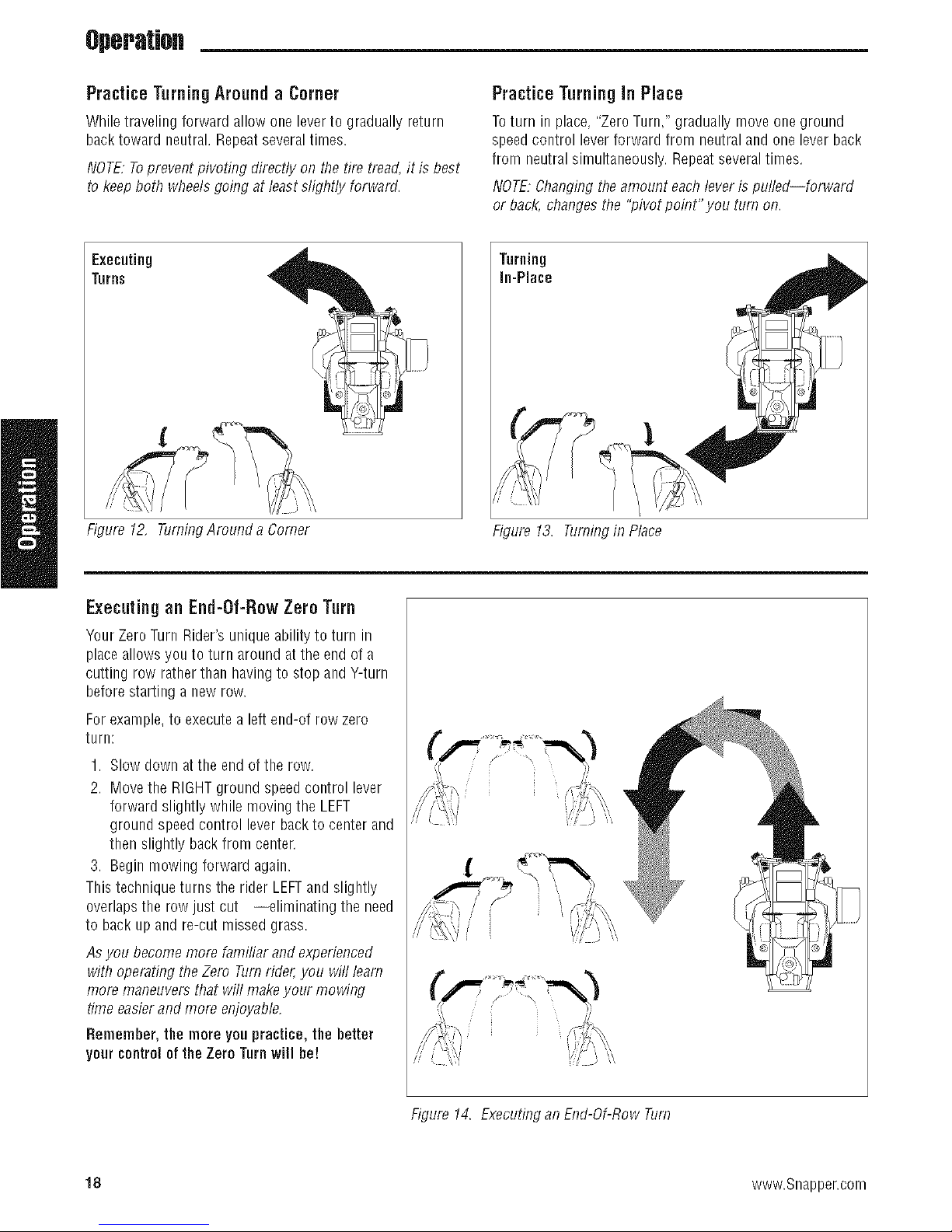

Practice Turning Around a Corner

WNletravelingfarwardallawanelevertograduallyreturn

backtowardneutral.Repeatseveraltimes.

NOTE,"Toprevent pivoting directly an the fire tread, it is best

to keep bath wheelsgoing at least slightly forward.

Executing

Turns

Figure 12, TurningAmund a Corner

PracticeTurningin Place

Toturn in place, "Zero Turn," gradually mave ane graund

speedcontrol leverforward from neutral and one lever back

from neutral simultaneously. Repeatseveraltimes.

NOTE:Changingtheamount eachleveris pulled--farward

ar back, changes the "pivot paint" yau turn an.

Turning

In-Place

Figure 13. Turningin Place

Executingan End-Of-RowZero Turn

Your ZeroTurn Rider'sunique ability to turn in

placeallows you to turn aroundat the end of a

cutting row ratherthan havingto stop and Y-turn

before starting a new row.

Forexample,to executea left end-of row zero

turn:

1. Slow down at the end of the row.

2. Move the RIGHTground speedcontrol lever

forward slightly while moving the LEFT

ground speed control leverbackto center and

then slightly backfrom center.

3. Begin mowing forward again.

This technique turns the rider LEFTand slightly

overlaps the row just cut --eliminating the need

to back up and re-cut missed grass.

Asyou become more familiar and experienced

with operating theZero Turnrider,you will learn

more maneuvers that will makeyour mowing

time easierandmore enjoyable.

Remember,the mare yau practice, the better

yourcontroloftheZero Turnwili be!

18 www.Snapper.com

Figure 14. Executingan End-Of-Raw Turn

Operatio.

Mowing

1. Engagethe parking brake. Make surethe PTOswitch is

disengaged,the ground speed control leversare locked

in the NEUTRALposition andthe operator is on the seat.

2. Start the engine (see Starting The Engine).

3. Setthe mower cutting height (see Mowing Height

Adjustment).

4. Setthe throttle to FULL.

5. Engagethe PTOby pulling up on the PTOswitch.

6. Begin mowing. See Mowing Recommendationsfor tips

on mowing patterns, lawn care, and trouble shooting

information.

7. When finished, shut off the PTOby pushingthe PTO

switch down completely..

8. Stopthe engine (see Stopping TheRiderand Engine).

Mowing Recommendations

Severalfactors canaffect how well your machine cuts grass,

Following proper mowing recommendationscan improve

the performance and life of your machine.

Heightof Grass

Often cutting height is a matter of personal preference.

Typically,you should mow the grass when it is is between

three and five inches high. The proper cutting height range

for a specific lawn will depend upon several factors,

including the type of grass,the amount of rainfall, the

prevailing temperature, and the lawn's overallcondition.

Cutting the grass too short causesweak,thin grass plants,

which are easily damaged by dry periods and pests. Cutting

too short is often more damaging than allowing the grass to

be slightly higher.

Letting grass grow a bit longer--especially when it is hot

and dry--reduces heat build-up, preservesneededmoisture

and protects the grass from heatdamageand other

problems. However,allowing grassto grow too high can

causethin turf and additional problems.

Cutting off too much at one time shocksthe plant's growth

system and weakensthe grass plants. A good rule of thumb

is the 1/3 role:to cut nomore thanonethirdof the grass

height, and nevermare than 1 inch at a time.

Theamount of grass you are ableto cut in one pass is also

effected by thetype of mowing system you are using (for

example,broadcasting with side discharge decks can

process a much larger volume of grassthan mulching

does).

I

Figure 15. Proper Cutting Height

Tall GrassRequires IncrementalCutting

Forextremelytall grass, set the cutting heightat maximum

for the first pass, andthen reset it to the desired height and

mow a second or third time.

Don't coverthe grass surface with a heavy layerof

clippings. Consider using a grass collection system and

starting a compost pile.

Cut HereOn

First Pass Cut Here

_j/, Pass

Figure 16. IncrementalCutting

__ On Second

19

Operation

WhenandHowOften to Mow

Thetime of day and condition of the grass greatly affect the

results you'll get when mowing. For the best results, follow

these guidelines:

1. Mow when the grass is betweenthree and five inches

high.

2. Mow with sharp blades. Short clippings of grass one

inch or shorter decompose more quickly than longer

blades.Sharp mower bladescutgrass cleanly and

efficiently, preventing frayed edgeswhich harmthe

grass.

3. Mow at time of day whenthe grassis cool and dry. Late

afternoon or early evening often providethese ideal

mowing conditions.

4. Avoid mowing after rain or even heavy dew,and never

mulch when the grass is wet (moist grass does not

mulch well, and clumps beneaththe mower deck).

Mowing Patterns

Always start mowing on a smooth, levelarea.

Thesizeandtype of areato be mowedwill determine the

best mowing patternto use.Obstructions such astrees,

fencesand buildings, and conditions such asslopes and

grades must also be considered.

1. Cut long straight strips overlapping slightly.

2. Where possible, changepatterns occasionallyto

eliminate matting, graining or a corrugated appearance.

3. Foratruly professional cut, mow across the lawn in one

direction, then recutthe lawn by mowing perpendicular

to the previous cut.

Note:Alwaysoperate the engine at full throttle when

mowing,

If you hearthe engine slowing down, you are mowing too

fast--using a slower ground speedwill improve the cutting

efficiency of the blades and prevents many common cutting

problems. Usean appropriate ground speed for the

thickness and height of the grass you arecutting (3rd gear

or slower for manualgear models). If you hearthe engine

slowing down you are mowing too fast. useaslower ground

speed.

Wherepossible, make one or two passes around the outside

of the areadischarging the grass INTOthe lawn to keep the

cut grass off fencesand walks.

Theremainderof the mowing should be done in the

opposite direction so that the clippings aredispersed OUT

onto the areaof lawn previously cut.

Mowing Methods

ProperBroadcastMowing

Broadcasting, or side-discharging, dispersesfine clippings

evenly overthe entire lawn. Many golf courses use this

method. Your mower has a deep dish deck to allow freer

circulation of clippings so they are broadcast evenlyover the

lawn.

Engine Speed & GroundSpeedfor Broadcasting

Always operatethe engine at full throttle when mowing. If

you hearthe engine slowing down, you are mowing too

fast--using a slower ground speedwill improve the cutting

efficiency of the blades and prevents many common cutting

problems.

ALWAYSusean appropriate ground speedfor the thickness

and height of the grass you arecutting (3rd gear or slower

for manualgear models). If you hearthe engine slowing

down you are mowing too fast, usea slower ground speed.

20 www.Snapper.com

How Much Grassto CotOff When Broadcasting

Mow when the grass is 3-5 inches long. Do not cut the

grass shorter than 2 to 2-1/2 inches. Do not cut off more

that 1 inch of grass in a single pass

Operatiofl

ProperMulching

Mulching consists of a mower deck which cuts and recuts

clippings into tiny particles and which then blowsthem

down INTOthe lawn. Thesetiny particles decomposerapidly

into by-products your lawn can use. UNDERPROPER

CONDITIONS,your mulching mower will virtually eliminate

noticeable clippings on the lawn surface.

NOTE:When mulching under heavycutting conditions, a

rumbling sound maybe presentand is normal.

Mulching RequiresEXCELLENTMowing Conditions

Mulching mowers cannot function properly if the grass is

wet, or ifthe grass is simply to high to cut, Evenmorethan

normal mowing, mulching requiresthat the grass be dry

and the the appropriate amount is cut.

Do not use the mower as a mulching mower during the first

two or three mowings in the spring. The long grass blades,

quick growth, and often wetter conditions are more suitable

for broadcasting (side-discharging) or grass bagging

operation.

EngineSpeed & GroundSpeedfor Mulching

Use full enginethrottle matched with a slow ground speed

so that clippings will befinely cut. Groundspeedwhile

mulching should be HALFof the speedthat would be used

when broadcasting (side discharging) undersimilar

conditions. Since mulching requires more horsepowerthan

broadcasting, using a slower ground speedis vitally

important for proper mulching operation.

Now Much Grassto Mulch

Attaching A Trailer

The maximum weight of atowedtrailersbould be lesstban

200 Ibs (91kg). Securethe trailer with a appropriately sized

clevis pin (A, Figure 18) and clip (B).

Excessivetowed loadscan cause loss of traction and loss of

control on slopes. Reducetowedweight when operating on

slopes. The surface being driven on greatly impactstraction

and stability. Wet or slippery surfaces can greatly reduce

traction and the ability to stop or turn. Carefullyevaluatethe

surface conditions before operatingthe unit and trailer, and

neveroperate on slopes greaterthan 10°. See SLOPE

OPERATIONand TOWEDEQUIPMENTin the safety section

of this manualfor additional safety information.

o/

®

The best mulching action typically results from cutting only

the top 1/2 inch to 3/4 inch of grass blade.This provides

short clippings which decompose properly (much more

quickly than longer clippings). The ideal cutting height will

vary with climate, time of year,and quality of your lawn.We

recommend that you experimentwith both the cutting height

and ground speed until you achievethe bestcut. Start with a

high cutting height and using progressively lower settings

until you find a cutting height that is matchedto your

mowing conditions and preferences.

Figure 17. Mulching Action

20' (6m)

Figure 18. TrailerWeightRecommendations

A. Clevis Pin

B. Clip

21

RegularMaintenance

RegularMaintenance

Maintenance Schedule

Thefollowing schedule should be followed for normal careof your rider and mower,Youwill needto keepa record of your

operating time. Determining operatingtime is easily accomplished by observing the elapsedtime recordedby the hour meter.

Safety items Before Every 5 Every25 Every100 Every250 Spring &

EachUse Hours Hours Hours Hours Fall

CheckSafetyInterlock System • •

CheckRider Brakes • •

CheckMower BladeStopping Time • •

Rider Maintenance Before Every 5 Every25 Every100 Every250 Spring &

EachUse Hours Hours Hours Hours Fall

CheckRider/ Mower for loose hardware • •

CleanDeck& Check/ReplaceMowerBlades** •

Lubricate Rider& Mower ** •

CleanBattery & Cables •

CheckTire Pressure •

CheckTransmission Oil • •

ChangeTransmission Oil Filter ** ®

EngineMaintenance Before Every 5 Every25 Every100 Every250 Spring &

EachUse Hours Hours Hours Hours Fall

ICheck EngineOil Level •

Check/Clean Cooling Fins& Intake ** •

ServiceAir Filter *

ChangeOil & Filter *

Check/ ReplaceSpark Plugs *

Check/Replace FuelFilter *

* Referto engine owner's manual. Changeoriginal engineoil after initial break-in period.

** More often in hot (over 85° F:30° C)weather or dusty operating conditions.

22 www.Snapper.com

RegularMaintenance

Checking/Adding Fuel

Toadd fuel:

1. Removethe fuel cap.

2. Fillthetankto about 1-1/2" (3,81 crn) of the bottom of

theTillerneck, Thiswill allow for fuel expansion.

NOTE. Do not overfill, Refertoyour enginemanual for

specific fuel recommendations.

3. Install and handtighten the fuel cap.

Fuel Filter

Thefuel filter is located in the fuel linebetweenthe fuel tank

and the carburetor, nearthe fuel pump. If filter is dirty or

clogged, replaceas follows:

1. Disconnectthe negative battery cable.

2. Placea container below the filter to catch any spilled

fuel.

3. Using pliers, open and slide the hose clamps from the

fuel filter (D, Figure19).

4. Removethe hosesfrom the fuel filter.

5. Install the new fuel filter in the proper flow direction in

the fuel line.

6. Securewith the hoseclamps.

7. Reconnectthe negative batterycablewhen finished.

Change OiJ & FiJter

1. Warm engine by running for a few ndnutes. (Referto

the engineoperator's manualfor oil andfilter

replacementinstructions.)

2. Briggs& Straiten Models: Locatethe oil drain hose A,

Fgure19 on the eft s de of the eng ne and route the o

drain hose over the rear of the enginedeck.

3. Placea small pan under the oil drain hoseto catchthe

oil. Using the appropriate tools, removethe cap (B)

from the oil drain hose (A) and drain the engineoil into

the pan,

4. After draining, replacethe capandwipe up any spilled

oil. Route the oil drain towards the front of the machine

facing so the oil drain hose is retained during normal

operation.

5. Placean absorbent shop cloth underthe engine oil filter.

Removethe engine oil filter and replace with a new one.

6. Briggs& Straiten Models: Removethe engine oil

dipstick F)that is located on the left side of the engine

and ref wth new o Referto the eng ne operators

manualfor oil recommendations.)

7. Removethe shop cloth and wipe up any spilled oil,

EngineMaintenance

WARNING

Gasolineis highly flammable and must be handled

with care. Neverfill thetankwhen the engineis still

hotfrom recent operation. Do notallow openflame,

smokingor matchesin thearea. Avoid over-fillingand

wipe up any spills.

Donotremove fuel filter when engineis hot, as spilled

gasoline may ignite. DONOTspreadhoseclamps

further than necessary.Ensureclampsgrip hoses

firmly everfilter after installation.

NOTICE

Donat use gasoline containingMETHANOL,gasohol

containingmore than 10% ethanol, gasoline additives,

premium gasoline, or white gas because engine/fuel

systemdamage couldresult.

/

/

Figure 19. EngineOil Drain(Briggs &Stratton shown)

A. Oil Drain Hose

B, Cap

C. OilFilter

D, FuelFilter

E, Fuel TankSelection Valve

E Oil Dipstick

Referto the engine owner's manualfor allengine

rnaintenanceprocedures and recommendations.

23

.RegularMaintenance

Lubrication

Lubricate the unit at the locationsshown in Figures20

through 28 as well as the following lubricationpoints.

Grease:

,.deck lift pivot blocks

f ,.front casterwheel axles & yokes

Use greasefittings when present. Disassemble parts to

apply greaseto moving parts when greasefittings are not

installed.

Not all greases arecompatible. RedGrease(p/n 5022285)

is recommended,automotive-type high-temperature, lithium

greasemay be usedwhenthis is not available.

Oil:

,.mower deckspindles

,.mower deck idler arm

,.control handle pivots

Figure20. Deck Lubrication

_lb . seat plate pivots

,.deck lift pivots

,.discharge chute hinge

Generally,all moving metal parts should be oiled where

contact is madewith other parts. Keepoil and greaseoff

belts and pulleys. Rememberto wipe fittings and surfaces

clean both before and after lubrication.

LubricatingtheFront Casters:

NOTE,Frontcastersshould be lubricated annuallj_

1. Removethe 1/4-28 bolt (A, Figure23) screwedinto the

front caster and install a1/4-28 greasefitting.

2. Greasethe front caster.

3. Removethe 1/4-28 greasefitting and reinstall the 1/4-28

bolt.

4. Repeatprocessfor the other side of the machine.

/ /

/

Figure21. Control HandlePivots & SeatPlatePivots

[

Figure22, Deck Lift Linkage Pivots

/

/

24 www.Snapper.com

\

Figure23. Front Caster& Wheel

A. 1/4-28Bolt

Check/ FiiiTransmission Oil

Oil Type: 20W-50 conventional detergent motor oil.

1. Checkthe oil levelwhenthe unit is cold. Locatethe

transmissionoil reservoirs (A, Figure24) locatedon the

seat support plate. The oil sbould be up to tbe "FULL

COLD"mark (B). Ifthe oil isbelowthis level,proceed

to step 2.

2. Beforeremovingthe reservoir caps, makesure the area

around the reservoir cap andfill neckof the reservoir is

free of dust. dirt. or other debris. Removethe reservoir

cap.

3. Add oil up to the "FULLCOLD"mark (B).

4. Reinstallthe reservoir caps.

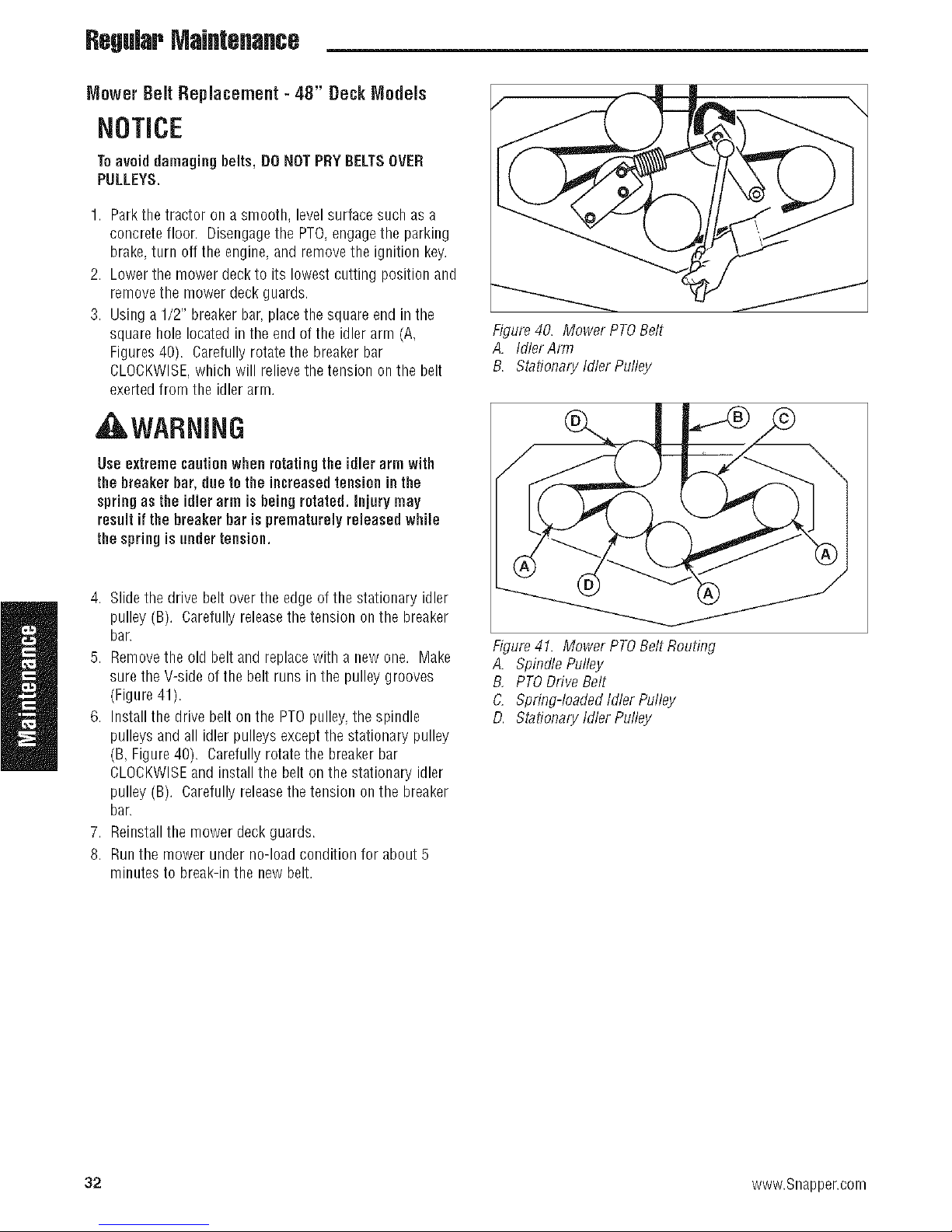

Transmission Oil Filter Change

ChangeInterval: Every200 Hours

Replacement Filter Number:5101026X1

1. Locatethe transmission oil filters (A, Figure25)

underneaththe rear of the machine on the

transmissions.

RegularMaintenance

Figure24. Checking TransmissionOilLevel

A. TransmissionOilReservoirs

B. "FULLCOLD"mark

2. Removethe three 1/4" filter guard screws (C) and the

filter guard (B).

3. Cleanthe areaaroundthe filter baseand removethe

filter.

4. Apply a film of new oil to the gasket of the new

replacementfilter. After the oil hasdrained,thread the

newfilter onto the filter baseuntil the gasketmakes

contact, then tighten 3/4 of aturn more.

5. Reinstallthe filter guard with the three 1/4" filter guard

screws

6. Using a hex bit swivel socket or a modified allenwrench

removethe top port plug from the transmissions.

7. Removethe transmission reservoir cap and fill with oil

until oil appearsat the bottom of the transmission's top

port (approximately 2 qts (1,89L).

8. Reinstallthe top port plug and tighten to 15ft Ibs (20.38

Nm).

9. Continueto add oil to the transmission oil reservoirs

until the oil levelreachesthe "FULL COLD"mark.

Reinstallthe oil reservoir cap.

10. Repeatthis processfor the other side ofthe machine.

11. Runthe unit for several minutes and checkthe

transmission oil level.

Figure25. Transmission (Left Side Shown.)

A. TransmissionOilFilter

B, Filter Guard

C. 1/4" Filter Guard Screws

D. TopPort Plug

IMPORTANTNOTE:Use caution after changing the filter, air

in the hydraulic system may affect the responsiveness of the

ground speed control levers. Repeatstep 11until theair is

out of the system,

25

RegularMaintenance

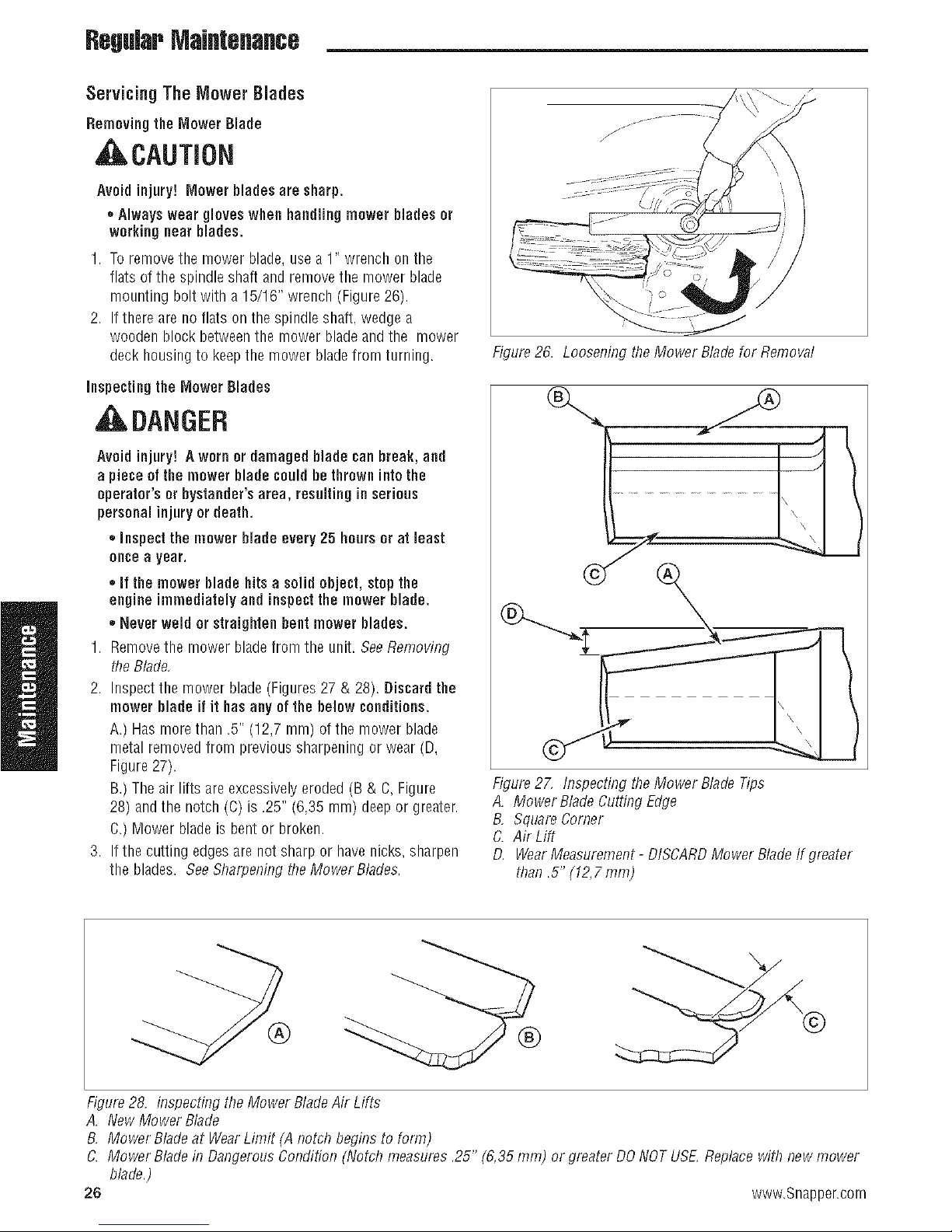

Servicing The Mower Blades

Removing theMower Blade

, ,CAUTION

Avoid injury! Mower blades are sharp.

* Always wear gloves when handling mower blades or

working near blades.

1. To removethe mower blade,use a 1" wrench on the

flats of the spindle shaft and remove the mower blade

mounting bolt with a 15/16" wrench (Figure 26).

2. If there are no flats on the spindle shaft, wedge a

wooden block betweenthe mower bladeand the mower

deck housing to keepthe mower bladefrom turning.

inspecting the Mower Blades

, ILDANGER

Avoid injury! Aworn or damaged blade can break, and

a piece of the mower blade couldbe thrown into the

operator's or bystander's area, resulting in serious

personal injury ordeath.

,, inspect the mower blade every 25 hours or at least

oncea year.

,,if the mower blade hitsa solid object, stop the

engine immediatelyand inspectthe mower blade.

,, Never weld or straighten bent mower blades.

1. Removethe mower bladefrom the unit. BeeRemoving

the Blade,

2. Inspect the mower blade (Figures 27 & 28). Discardthe

mower blade if it hasany ofthe below conditions.

A.) Has morethan .5" (12,7 mm) of the mower blade

metal removed from previous sharpening or wear (D,

Figure27).

B,)The air lifts are excessivelyeroded(B & C, Figure

28) andthe notch (C) is .25" (6,35 mm) deep or greater.

C.) Mower blade is bent or broken.

3. If the cutting edgesarenot sharp or have nicks, sharpen

the blades. See Sharpening the Mower Blades.

Figure26. Loosening the Mower Bladefor Removal

\

Figure27, Inspecting theMower BladeTips

A. Mower BladeCutting Edge

B, Square Corner

C. Air Lift

D. WearMeasurement- DISCARDMower Bladelf greater

than .5" (12,7 ram)

®

Figure28. inspecfing the Mower BladeAir Lifts

A. New Mower Blade

B, Mower Bladeat WearLimit (A notch begins to form)

C. Mower Bladein Dangerous Condition (Notch measures.25" (6,35 ram) or greater DO NOTUSE,Replacewith newmower

blade.)

26 www.Snapper.com

Sharpening the Mower Blade

, CAUTION

Avoid injury! Mower blades are sharp.

,, Alwayswear gloves when handling the mower

blades.

,, Alwayswear safety eye protectionwhen grinding.

RegularMaintenance

t

®

1. Sharpenthe mower blades with grinder, handfile. or

electric blade sharpener.

2. Sharpenthe mower blade by removing an equal amount

of material from each end of the mower blade.

3. Keepthe original bevel(A, Figure29) when grinding. DO

NOTchangethe mower blade bevel.

4. The mower bladeshould have a maximum 1/64" (0,40

ram) cutting edge (B) or less.

5. Balancethe mower bladesbefore installing.

Balancing the Mower Blades

, CAUTION

Avoidinjury! Keepmower blades balanced.

• An unbalanced mower blade can create excessive

vibrationand damage the unit or cause mower blade

failure.

1. Cleanthe mower bladeto remove any dried grass or

other debris.

2. SeeFigure30. Put the mower blade on a nail in a vise

and turn the mower bladeto the horizontal position.

3. Checkthe balanceof the mower blade. Ifeither end of

the mower blade moves downward, sharpen the heavy

end until the mower blade is balanced. SeeSharpening

the Mower Bladesfor proper sharpening instructions.

4. Repeatthe process until the mower blade remains in the

horizontal position.

Figure2! Sharpening BleMower Blade

A. Mower BladeBevel

B. Mower BladeCutting Edge

Figure30. Balancingthe Mower Blade

A. Nail

Reinstallingthe Mower Blades

1. Reinstalleachmower bladewith the air lifts pointing up

towards the mower deck asshown in Figure 31.

48" Models: Securewith the mower blade mounting

bolt and flat washer (A& B,Figure31) andtorque to 70

ft. Ibs (94 Nm).

2. If there are no flats on the spindle shaft, wedge a

wooden block betweenthe mower bladeand the mower

deck housing to keepthe mower bladefrom turning.

Figure31, Tighteningthe Mower Bladefor Installation

A. Mower Blade Mounting Bolt

B, Flat Washer

C. Mower BladeAir Lift (Points Up For Installation)

D. 4X4 WoodenBlock

27

RegularMaintenance

GroundSpeed Control Lever Adjustment

Thecontrol leverscan be adjusted inthree ways, The

alignment of the control levers,the placement of the levers

(how close the ends areto one another) and the height of

the levers can be adjusted.

ToAdjust the Handle Alignment

Loosenthe mount bolts (A, Figure32) and pivot the lever(s)

(B) to align with eachother.

ToAdjust the Handle Placement

Loosenthe jam nuts and adjust the placementbolt (C,

Figure33) in or out to properly adjust the leverend spacing.

ToAdjust the Handle Height

Removethe mounting hardwareandreposition the handle

either up or down from its original position. You will need

to readjust the handle alignment as described above.

Speed Balancing Adjustment

Ifthe rider veers to the right or leftwhenthe ground speed

control leversare in the maximum forward position, the top

speedof each of these levers can be balancedby turning the

adjustment bolt(s) (A, Figure33). Only adjust the speedof

the wheel that is traveling faster.

ToReduce the Speed of the FasterWheel

1. Loosenthe securing nut.

2. Turn thetop speed adjustment bolt COUNTER-

CLOCKWISEto reduce the speed.

3. Retightenthe securing nut when adjustment is

complete.

, WARNING

DONOTadjust the tractorfor a faster overallspeed

forward or reverse thanit was designed for.

Figure32. Contml LeverAdjustment

A. PlacementHardware

B. Ground 5 JeedControl Lever

Figure33. Top SpeedAdjustment

A. TopSpeedAdjusfinent Bolt

B. Contml Lever Base

C. Alignment Hardware

Neutral Adjustment

If the tractor "creeps" while the ground speedcontrol levers

are locked in their NEUTRALpositions, seeyour dealer.

28 www.Snapper.com

ParkingBrakeAdjustment

1. Disengagethe PTO,stop tile engine,engagetile parking

brake,and removethe key from the ignition.

2. Raisethe seat plateto gainaccessto the parking brake

components.

3. Measurethe distancefrom the top of the brakespring

rod (C, Figure 34) to the top of the lock nut (D) on both

sides of the unit. The measurementshould be .50"

(1,27 cm). If not, adjust the Iocknut to achievethe

measurementof .50" (t ,27 cm)

4. Measurethe distance betweenthe bottom of the brake

shaft weldment (G) and the top of the set collar (F). The

measurementshould be .375" (0,95 cm). If not,

position the set collar until the measurementequals

.375" (0,95 cm).

if this does notcorrectthe brakingproblem,seeyour

Snapper Prodealer.

RegularMaintenance

Figure34, Parking BrakeAdjustment

A. Brake Spring

B, First Measurement- .50" (1,27 cm)

C. Brake Spring Rod

D. LockNut

E, SecondMeasurement - .375" (0,95 cm)

F. Set Collar

G, Brake Shaft Weldment

29

RegWr Maintenance

Return-to-NeutraJAdjustment

Todetermine if it is necessaryto adjust the neutral return,

perform the following steps.

1. Disengagethe PTO,engagethe parking brakeandturn

off the engine.

2. Move the ground speed control levers into the operating

position, pull the levers rearward and release.

3. Move the ground speed control levers out towards the

neutral position. If the leversdo not align with the

notches in the neutral lock plate, it is necessaryto

adjust the neutralreturn rod (B, Figure35).

Adjustment

,II WARNING

Toavoid seriousinjury, perform adjustments only with

the enginestopped, the key removed andthe tractoron

level ground.

1. Disengagethe PTO,engagethe parking brakeandturn

off the engine.

2. Therearethree jam nuts (A, Figure 35) on the linkage

rod (B). The first two are usedtogetherto turn the rod

and the third (towards the front of the machine) is used

to lock the rod in place. Loosenthe jam nutthat locks

against the ball joint and turn the linkage rod to adjust.

If the machine creepsforward, turn the linkagerod

CLOCKWISE(while standing atthe rear of the machine,

facing forward). If the machine creeps backward,turn

the rod COUNTER-CLOCKWISE.

3. Lock the jam nut (A) againstthe ball joint when neutral

is achieved.

4. Pull the ground speed control lever rearwardand release

to check position again. Adjust as necessaryto align

the ground speedcontrol levers with the notches in the

neutral lock plate.

NOTE.+ This adjustment should not be performed while the

machine is running,

©

Figure35. Retum-to-Neutral Adjustment

A. Jam Nuts

B. Neutral Return Rod

30 www.Snapper.com

Deck Rod Timing Adjustment

1. Parkthe machine on aflat, levelsurface, Disengagethe

PTO,engagethe parking brake,turn off the engine,and

removethe ignitionkey. Reartires must be inflatedto

15 psi (1,03 bar);front tires to 40 psi (2,76 bar).

2. Tocheck the lift rod timing, measureandrecord the

distance betweenthe liftpivots and the rod pivots.

Repeatfor other side of unit, SeeFigure36.

3. If the measurementsfor the rods are equal, no further

adjustment is required, If the measurementsare NOT

equal (greaterthan 1/8" (3,17 ram) difference),

adjustment is required continue with Step4.

4. Lock the deck lift pedal in the 4-1/2" (11,47 cm)

position. Removethe cutting height adjustment pin and

lower the mower deck.

5. Toensurethat the deck is in the lowest position, push

the pedal by handtowards the rear of the unit and install

the height adjustment pin in the 3" (7,6 cm) position to

hold in place.

6. Block up the mower deck until all hanger chains are

slack. Referto Figure38.

7. SeeFigure37. To adjust the lift rod, loosen thejam nut

on the front clevis then removethe 1/2" clevis pin

fastening the clevis to the lift pivot arm. Turnthe clevis

clockwise to shorten the distance betweenthe rod pivots

or counterclockwiseto lengthenthe distance between

the rod pivots. Reinstallthe clevis on the lift pivot arm

and securewith the 1/2" clevis pin previously removed.

Tighten the jam nut against the clevis.

8. Removethe blocks from the underthe mower deck.

9. Removethe cutting height adjustment pin from in front

of the deck lift pedal arm. Lift mower deckand reinstall

adjustment pin in desired mowing height.

RegularMaintenance

I

Figure36. CheckLift Rod Timing

Adjust

Here

Figure37. Adjust Lift Rod Timing

Deck LevelingAdjustment

NOTE:Beforeadjusting the deck leveL the deck lift rod

timing must be checked and/or adjusted,

1. Parkthe machine on aflat. levelsurface. Disengagethe

PTO,stop the engine and engagethe parking brake.

Reartires must be inflated to 15 psi (1,03 bar); front

tires to 40 psi (2,76 bar).

2. Lock the deck lift pedal in the 4-1/2" (11,47 cm)