Page 1

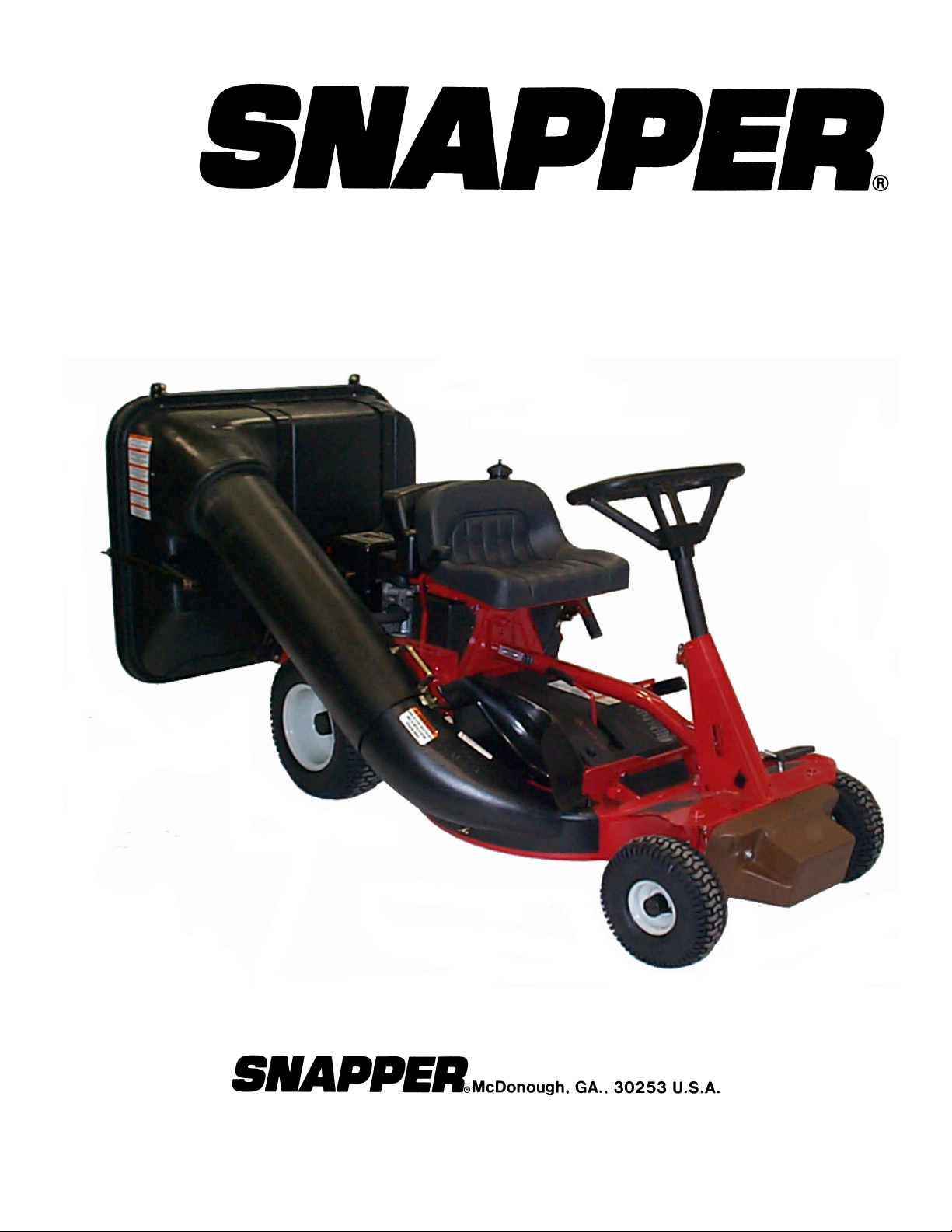

Safety Instructions, Installation & Operator’s Manual For

#6-3125 CLAMSHELL GRASS CATCHER KIT

For 28” & 33” REAR ENGINE RIDING MOWERS

28” REAR ENGINE RIDER WITH

CLAMSHELL BAGGER KIT SHOWN

COPYRIGHT © 2000

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 7-2887 (I.R. 01/24/00)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

All safety instructions and operating instructions in the manuals provided with the Snapper Rear Engine Rider

and this Grass Catcher attachment must be followed. Read, understand, and follow ALL instructions and

warnings in the Operator’s Manual provided with the machine, with this attachment, and ALL instructions and

warnings on the machine, engine and attachment. Failure to comply with ALL instructions and warnings can

result in damage, serious injury or death to the operator or other persons.

1) DO NOT allow children or others in the yard

when the machine is operated (even with the

blades off).

2) DO NOT allow children or others to ride on the

machine or attachment (even with the blades

off).

3) DO NOT allow children to operate the machine.

4) DO NOT operate blades in reverse. STOP

blades. LOOK and SEE behind and down for

children, pets, and hazards before and while

backing.

5) FRONT WEIGHT must be installed before

operating machine with grass catcher.

6) DO NOT operate machine on slopes exceeding

10 degrees (18% grade) when equipped with

grass catcher.

7) Exercise EXTREME CAUTION on all slopes.

Turn blades off when traveling uphill. Use a

slow speed and avoid sudden or sharp turns.

8) DO NOT operate machine across face of slopes.

Operate up and down. Practice on slopes with

blades off.

9) AVOID uphill starts. If machine stops going up

hill or tires lose traction, turn blades OFF and

back slowly down the slope.

10) GRASS CATCHER COMPONENTS are subject to

deterioration during normal use. Inspect all

components frequently for signs of wear or

deterioration. Replace worn or damaged

components immediately.

11) DO NOT leave machine with engine running.

STOP engine, STOP blades, SET brake, and

REMOVE key before leaving operator’s position

for any reason.

12) DO NOT attempt to remove or unclog the grass

catcher with engine or blades running. Stop

engine and blades and make sure all rotating

components have come to a complete stop

before removing any catcher component or

attempting to unclog catcher or deck.

13) DO NOT operate machine with Clamshell

Catcher open. The catcher must be closed at all

times, unless dumping. Stop blades before

dumping grass catcher.

2

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ..............................................................2

TABLE OF CONTENTS........................................................................................3

SECTION 1 - ASSEMBLY INSTRUCTIONS..................................................... 3-9

Introduction.............................................................................................................................. 3

Right & Left Bumper Bracket Installation ............................................................................. 4

Hitch Plate & Heat Shield Installation.................................................................................... 5

Hinge Pivot Bolt Installation...................................................................................................5

Hinge Adjustment – Rear Cover............................................................................................. 6

Front Weight Installation .....................................................................................................6-7

Air Lift Kit, #6-0480 Installation ..............................................................................................7

Deck Adapter Installation .................................................................................................... 7-8

Grass Tube Installation........................................................................................................... 9

SECTION 2 – OPERATION & MAINTENANCE .................................................10

Introduction............................................................................................................................ 10

Grass Catcher Operation ...................................................................................................... 10

Emptying Grass Catcher....................................................................................................... 10

If The Grass Catcher Becomes Clogged?........................................................................... 10

Grass Catcher Maintenance ................................................................................................. 10

Before Each Use .................................................................................................................... 10

Clamshell Assembly Components.................................................................................. 11-12

3

Page 4

SECTION 1 – ASSEMBLY INSTRUCTIONS

INTRODUCTION

The 6-3125 Clamshell Grass Catcher kit fits Snapper Rear Engine Riding mowers equipped with 28” and 33”

decks. Use the following instructions to assemble the grass catcher components and prepare your machine for

collecting grass clippings and leaves. Follow and complete each step carefully.

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine running. STOP engine.

STOP blade. Engage parking brake. Remove key.

Remove spark plug wire from spark plug and

secure wire away from spark plug. Engine and

components are HOT. Avoid serious burns, allow all

parts to cool before working on machine.

STEP 1

RIGHT AND LEFT BUMPER BRACKET INSTALLATION

Riders equipped with 2-piece type rear bumpers,

See Figure 1.1, will require replacement to complete

installation. Replace with one-piece bumper,

P/ N 3-6367, purchased separately from your local

Snapper dealer. The Bumper and Bumper Brackets will

be attached to the Rider using bolts removed in the

following steps.

RIGHT REAR

BUMPER BOLTS

RIGHT BUMPER

SUPPORT BRACKET

RIGHT

FRAME

BOLT

FIGURE 1.2

B. Remove top left bolt from bumper and the left

frame bolt located at the top rear of the main

frame. See Figure 1.3. Align holes in left

bumper support bracket, bumper and frame.

Reinstall same bolts. Tighten the Bumper bolts

before tightening the frame bolt.

TWO PIECE

REAR BUMPER

FIGURE 1.1

A. Remove two right bumper bolts and the right

frame bolt located at the top rear of the main

frame. See Figure 1.2. Align holes in right

bumper support bracket, bumper and frame.

Reinstall same bolts. Tighten the two Bumper

bolts before tightening the frame bolt.

LEFT BUMPER

SUPPORT BRACKET

FIGURE 1.3

4

Page 5

SECTION 1 – ASSEMBLY INSTRUCTIONS

STEP 2

HITCH PLATE AND HEAT SHIELD INSTALLATION

A. Attach triangular shaped Hitch Plate to bottom

of Front Cover Assembly. Orientation of the

holes in the hitch plate is important, observe

picture carefully before assembling. Align holes

in Hitch Plate and Front Cover Frame. Insert (2)

5/16-18 x 5/8” Flange Lock hex bolts. Place

Heat Shield over bolts as shown and secure

with (2) 5/16-18 Flange Lock hex nuts.

Do not tighten at this time. See Figure 1.4.

HEAT SHIELD

HITCH PLATE

FRONT COVER

FIGURE 1.4

B. Place Front Cover Assembly over rear bumper

and secure in place with spring loaded latch.

See Figure 1.5.

D. Tighten hitch plate bolts that were left loose in

STEP 2, “A”.

E. Attach left end of baffle to Front Cover

Assembly. Place (1) 3/16” Flat Washer over

#10-24 x 3/4” Flange Lock Bolt and insert from

inside cover. Secure with (1) #10-24 Flange

Lock Nut. Tighten securely.

1/2” NUT &

LOCK

WASHER

FIGURE 1.6

STEP 3

HINGE PIVOT BOLT INSTALLATION

A. Place Rear Cover Assembly on Front Cover

Assembly aligning holes in hinge tabs. Place

one 3/8” flat washer between the two left Hinge

Tabs and insert 3/8-16 x 1” hex head bolt. See

Figure 1.7. Add 3/8” flat washer and secure with

3/8-16 Top Lock nut. Do not over tighten. Hinge

must pivot freely.

B. Repeat on right Hinge Tabs.

LATCH

FIGURE 1.5

C. Align hole in Hitch Plate with hole in Bumper

Support. Insert 1/2-13 x 1” hex bolt, with head on

inside of frame, through holes. Place one 1/2”

Internal Tooth lock washer and hex nut on bolt

(washer and nut on outside of frame) and tighten

securely. See Figure 1.6.

HINGE TAB

FIGURE 1.7

5

Page 6

SECTION 1 – ASSEMBLY INSTRUCTIONS

K

STEP 4

HINGE ADJUSTMENT – REAR COVER

The holes in the rear Hinge Plate are slotted and

adjustment may be required to insure a proper seal

between the front and rear Covers.

A. Insert hook on the right Rear Cover Assembly

into round hole in right Handle Link. Note: right

Handle Link is flat, no bend. See Figure 1.8.

RIGHT HANDLE LINK

HOOK

F. Actuate Catcher Handle. Catcher should open

and close smoothly with no binding. If the action

is not smooth, adjustment to the Hinge or

Handle Links may be required.

G. If hinge adjustment is required, loosen hinge

plate hardware. For a tighter seal, push top of

rear cover frame firmly against the Front Cover

Assembly. Tighten hinge plate hardware

securely. See Figure 1.10.

HINGE PLATE

HARDWARE

PUSH

FIGURE 1.8

B. Place one 3/8” flat washer over stud on right of

handle tube.

C. Insert stud into center hole of right Handle Link.

Add another 3/8” flat washer over stud and

secure with hair pin. See Figure 1.9.

NOTE: The right and left Handle Links contain 3

closely spaced holes to adjust the amount of

force required to close and latch the Grass

Catcher. To increase the closing force and

provide a tighter seal between the front and rear

covers, place stud in rear hole. To decrease the

force, place stud in front hole.

HANDLE

LIN

FIGURE 1.10

WARNING

DO NOT operate machine with Grass Catcher if

front weight has not been installed.

STEP 5

FRONT WEIGHT INSTALLATION

The weight of the Clamshell Grass Catcher and

contents affects the stability and handling of the

machine. The front weight must be installed prior to

operating the machine with the catcher installed. Failure

to install the weight could cause damage, serious injury

or death.

3/8” FLAT

WASHER

HAIR

PIN

FIGURE 1.9

D. Repeat procedure for left Handle Link.

E. Close catcher by pushing down on handle.

6

Page 7

SECTION 1 – ASSEMBLY INSTRUCTIONS

IMPORTANT – “M” SERIES RIDERS: Series 17, “M”

model riders will require the drilling of two holes in the

front frame to install the Front Weight. Series 19, “M”

model riders already have the holes drilled but are

covered by the SNAPPER decal. Holes can be located

by rubbing lightly over decal. If you have a Series 17

rider, use the dimensions on the illustration provided to

mark the locations for drilling the two holes. See Figure

1.11.

DRILL TWO 13/32”

DIAMETER HOLES

2-5/8”

3”

10”

FIGURE 1.11

A. Attach weight to the front frame of Rider using

(2) 3/8-16 x 3” hex head bolts and (4) heavy

3/8” flat washers. Place one washer on each

bolt.

B. Align holes in weight with holes in frame. Insert

bolt, with washer, through weight and frame.

See Figure 1.12.

STEP 6

AIR LIFT KIT, #6-0480 INSTALLATION

Some Rider models will not require the installation of

the Air Lift Kit included with the Grass Catcher. Inspect

the blade on your mower. If the blade does not have

mounting holes for the Air Lift Kit, the blade is a High Lift

version and does not require the kit. If the blade does

have the holes in the lift area of the blade, install the Lift

Kit. Installation instructions and the necessary hardware

are included with the Air Lifts.

WARNING

Blades are extremely sharp and can cause severe

injuries. Wear heavy gloves when working on or

handling blades. DO NOT use blades that show

signs of wear or damage.

WARNING

DO NOT operate machine without entire Grass

Catcher or guards in place.

STEP 7

DECK ADAPTER INSTALLATION

To install the deck adapter on certain 28” model riders,

the discharge deflector may have to be removed first.

Be careful to save the deflector and all hardware

removed for future use when not bagging.

A. Remove wing nuts, flat washers and bolts

securing deflector to side of deck. Save hardware.

See Figure 1.13.

3/8” FLATWASHER

FRONT WEIGHT3/8-16X3” BOLT &

FIGURE 1.12

C. Add washer to bolt on inside of frame and

secure with 3/8-16 Lock nut. Tighten securely.

WING NUTS &

FLAT WASHERS

FIGURE 1.13

B. Lift up, pivoting deflector on hinge, and

determine if there is sufficient room to install the

adapter. If there is not sufficient room, remove

deflector by removing Hinge nut, Spring, and Hinge

Pin. Save for future use. See Figure 1.14.

7

Page 8

SECTION 1 – ASSEMBLY INSTRUCTIONS

HINGE NUT

SPRING

HINGE PIN

FIGURE 1.14

C. Hold the adapter in front of the deck. Align the

adapter lugs with the lug retainers in the hinge.

Push or lightly tap front of adapter towards the rear

until tight against deck. See Figure 1.15.

LUG RETAINERS

D. Install one of the previously removed bolts into

the hole in the center of the discharge opening and

through the hole in the adapter. Secure the adapter

to the deck with a flat washer and wing nut. See

Figure 1.16.

FLAT WASHER &

WING NUT

FIGURE 1.16

E. Attach tube latch to deck adapter. Insert one

1/4-20 x 3/4” Carriage bolt from inside through

lower hole in adapter. Place Tube Latch over bolt,

followed by 1/4” Internal Tooth lock washer and

secure with 1/4-20 hex nut. Align Tube Latch as

shown and tighten securely. See Figure 1.17.

ADAPTER

ADAPTER

LUGS

DEFLECTOR

REMOVED

FIGURE 1.15A

TUBE

LATCH

FIGURE 1.17

DEFLECTOR

FIGURE 1.15B

8

Page 9

SECTION 1 – ASSEMBLY INSTRUCTIONS

STEP 8

GRASS TUBE INSTALLATION

A. Attach Tube Handle and Handle Base to Tube

before installing Tube to catcher. Insert (2)

1/4-20 x 3/4” Carriage bolts through Handle

Base and holes in Tube as shown. See Figure

1.18. Place Tube Handle over bolts followed by

1/4” Internal Tooth lock washers and secure

with (2) 1/4-20 hex nuts. Tighten securely. See

Figure 1.18.

HANDLE BASE

TUBE

HANDLE

FIGURE 1.18

B. Place deck in lowest cutting height setting.

C. Slide upper end of Grass Tube (end without

Handle) into opening in Front Cover Assembly.

D. Slide lower end of Grass Tube over adapter

and rotate towards mower to secure Handle

Base under Latch. See Figure 1.19.

E. Adjust deck to desired cutting height.

ROTATE GRASS TUBE

TOWARDS MOWER

FIGURE 1.19

9

Page 10

SECTION 2– OPERATION & MAINTENANCE

INTRODUCTION

Follow operation and maintenance instructions in

the Operator’s Manual provided with the Snapper

Rear Engine Rider.

2.1 GRASS CATCHER OPERATION

A. Select desired cutting height. Choose a setting that

will not attempt to cut off too much at once,

overloading the machine.

B. After starting engine and allowing a brief warm up

period, move engine speed control to highest

setting.

C. Drive machine to cutting area. Engage blades.

D. Select a slow forward ground speed until familiar

with conditions. Do not select a speed that is too

fast, causing the machine to become overloaded.

E. The weight of the grass catcher and contents will

affect the stability and handling of the machine.

Avoid sudden starts and sharp turns. Reduce speed

on slopes, and DO NOT operate machine on slopes

exceeding 10 degrees (18% grade). Operate

machine up and down slopes. DO NOT operate

machine across the face of slopes. Turn blades off

when traveling up slope.

F. Empty grass catcher often to minimize effect on

stability and handling. Over filling the catcher will

reduce performance and cause clogging of the

tube, adapter and deck.

G. Do not operate the machine with the Grass Catcher

open. The entire Grass Catcher must be installed,

the catcher closed and latched properly before

operating.

2.2 EMPTYING GRASS CATCHER

A. Empty Grass Catcher often to avoid overfilling.

Overfilling reduces performance and causes

clogging of tube, adapter and deck.

B. Turn blades off. Drive machine to location the

clippings are to be dumped. DO NOT operate

blades in reverse. If you must back machine to

dump clippings in desired location, LOOK and SEE

behind and down for children, pets and hazards

before and while backing.

C. Shift transmission to Neutral (N). Engage Park

Brake. Stop engine. Remove key.

D. Lift up on handle sufficiently to allow all clippings to

exit catcher. If the dumped pile is too high to allow

the catcher to close, you may be required to use a

rake or similar implement to distribute the clippings.

E. After dumping, to maintain peak performance,

check the catcher screen located on the inside of

the Rear Cover Assembly to make sure it is clean

and free of any build up. Clean as required with

brush or broom.

F. Close catcher. Push down firmly on handle to

ensure it is properly latched.

G. Re-start engine and drive machine to cutting area.

Set engine speed to highest setting, engage blades

and resume operation.

DO NOT attempt to remove any clogs from deck,

adapter, or tube with engine or blade running.

STOP engine. STOP blade. Engage parking brake.

Remove key. Make sure blade and all rotating

components have come to a complete stop before

removing or unclogging any catcher component.

2.3 IF THE GRASS CATCHER BECOMES CLOGGED?

The grass catcher may become plugged if the

conditions are too severe, the catcher is overfilled, or

the machine is used improperly. If plugging does occur,

attempt the following:

1. Empty catcher more often.

2. Clean screen on Rear Cover Assembly.

3. Ground speed too fast – cut at slower speed.

4. Removing too much grass – raise cutting height, cut

partial width, and cut lawn more frequently.

5. Grass is too wet from rain or dew – allow grass to

dry.

6. Blades are dull or worn – inspect blades and

replace as necessary. Use only genuine SNAPPER

replacement blades.

7. Mower equipped with incorrect blade. Catcher

operation requires high lift blade. Contact your local

SNAPPER dealer for assistance in choosing the

correct blade for your application.

8. Deck, adapter, or tube has clipping build up – clean

all clippings from all internal surfaces.

2.4 GRASS CATCHER MAINTENANCE

Grass Catcher components are subject to wear and

deterioration during normal usage. Inspect all

components frequently for signs of wear and

deterioration. Replace worn or damaged components

immediately.

BEFORE EACH USE

A. Inspect all Catcher components. Replace all worn

or damaged parts.

B. Clean grass build up from deck, adapter, grass

tube, covers and rear cover screen. To maintain

peak performance make sure screen is clean at

each dumping.

C. Inspect blade for wear or damage. Replace as

needed.

D. Perform pre-start check list and maintenance as

instructed in the SNAPPER Rear Engine Rider

Operator’s Manual and Engine Owner’s Manual

included with the machine.

WARNING

10

Page 11

CLAMSHELL ASSEMBLY COMPONENTS

30

12

18

15

5

17

41

12

14

10

4

7

5

11

43

12

30

40

6

48

19

33

29

9

30

13

31

49

53

42

38

55

24

47

23

51

32

1

35

34

50

22

28

25

21

39

36

44

3

52

54

34

37

26

27

11

Page 12

CLAMSHELL ASSEMBLY COMPONENTS

ITEM PART NO. DESCRIPTION

1 1-4517 TUBE, Grass

2 2-8700 DECAL, Read Manual (Not Shown)

3 1-1870 GRIP

4 1-6314 WASHER, 11/32 Flat (9)

5 3-6422 WASHER, 3/16 Flat (30)

6 5-8615 WELDMENT, Front Cover Brace

7 7-2873 COVER, Front

8 7-2874 DEFLECTOR (Not Shown)

9 7-2950 GASKET, Chute

10 9-0307 SCREW, #10-24 x 1/2” Self-Tapping (3)

11 9-0999 SCREW, 1/4-20 x 5/8” Pan Head Self-Tapping (9)

12 9-1079 NUT, #10-24 Hex Flange Lock (22)

13 7-2951 END CAP, Tube

14 5-8600 WELDMENT, Rear Cover Brace

15 7-2872 COVER, Rear

16 7-2876 GRILL, Rear Cover (Not Shown)

17 7-3145 BOLT, #10-24 x 1-1/2” Oval Head (13)

18 7-3179 HINGE, Rear Cover

19 9-1265 SCREW, #10-24 x 1-1/2 Machine (5)

20 7-2964 DECAL, Warning (Not Shown)

21 3-1951 LATCH, Chute/Tube

22 3-1952 BASE, Handle

23 3-7745 HANDLE, Tube

24 9-1303 BOLT, 5/16-18 x 1” Carriage

25 9-1314 WASHER, 1/4 Internal Tooth Lock (3)

26 9-1530 BOLT, 1/4-20 x 3/4” Carriage (3)

27 9-1537 NUT, 5/16-18 Wing

28 9-1576 NUT, 1/4-20 Hex (3)

29 9-1593 PIN, 3/8 Self Lock Cotter (2)

30 9-1514 WASHER, 3/8 Lock (8)

31 9-1601 NUT, 5/16-18 Flange Lock (2)

32 9-1811 BOLT, 5/16-18 x 5/8” Hex Flange Lock (2)

33 3-1954 SUPPORT, Bumper

34 2-1746 WASHER, 3/8 Flat (4)

35 9-0499 NUT, 3/8-16 Hex Top Lock (2)

36 9-0509 WASHER, 1/2 Internal Tooth Lock

37 9-0590 BOLT, 3/8-16 x 3” Hex Cap Gr. 5 (2)

38 9-0646 BOLT, 1/2-13 x 1” Hex Cap Gr. 5

39 9-1316 NUT, 1/2-13 Hex Gr. B

40 9-1299 NUT, 3/8-16 Hex Lock (2)

41 9-1304 SCREW, 3/8-16 x 1” Hex Cap (2)

42 5-8745 BRACE, Bumper

43 9-0624 BOLT, #10-24 x 3/4” Flange Lock

44 5-8641 ASSEMBLY, Chute

45 2-9784 DECAL, International Warning (Not Shown)

46 4-6720 DECAL, Chute/Deflector (Not Shown)

47 7-3172 LINK, Handle (Right Hand)

48 7-3173 LINK, Handle (Left Hand)

49 7-3171 PLATE, Hitch

50 7-3271 WEIGHT (46 lb.)

51 5-8902 SHIELD, Heat

-- 6-0480 KIT, Air Lift (Includes Items 50 thru 53)

52 3-7723 Air Lift (2)

53 9-0223 NUT, 5/16-24 Hex (6)

54 9-0228 SCREW, 5/16-24 x 5/8” Oval Head Machine (6)

55 9-0391 WASHER, 5/16 Internal Tooth Lock (6)

12

Page 13

Safety Instructions, Installation & Operator’s Manual For

#6-3125 CLAMSHELL GRASS CATCHER KIT

For 28” & 33” REAR ENGINE RIDING MOWERS

COPYRIGHT © 2000

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 7-2887 (I.R. 01/24/00)

13

Loading...

Loading...