Page 1

S_PER

0 PERATOR'S

MANUAL

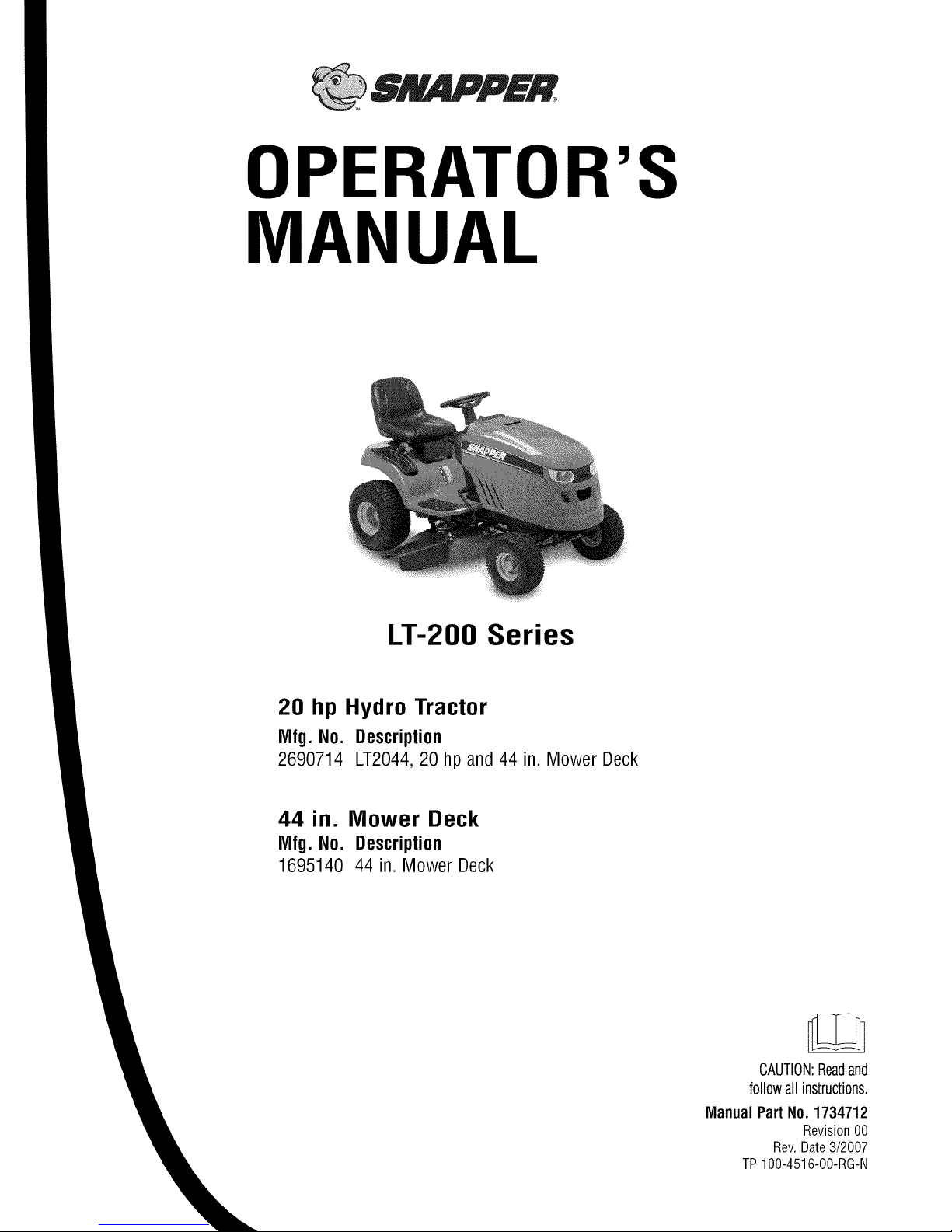

LT-200 Series

20 hp Hydro Tractor

IVlfg.No. Description

2690714 LT2044, 20 hp and 44 in. Mower Deck

44 in. Mower Deck

Mfg. No. Description

1695140 44 in. Mower Deck

CAUTION:Readand

followallinstructions.

ManualPartNo.1734712

RevisionO0

Rev.Date3/2007

TP 100-4516-O0-RG-N

Page 2

Thankyoufor purchasingthis quality-built Snapperproduct. We arepleasedthat you've placedyour confidence in the Snapper

brand. When operatedand maintainedaccording to the instructions in this manual,your Snapperproduct will provide many

years of dependableservice.

Thismanualcontainssafety information to makeyou awareof the hazardsand risks associatedwith lawn careand mowing

products andhow to avoidthem. Thistractor is designedand intended only for lawn careand is not intendedfor any other

purpose. It is important that you readand understand these instructions thoroughly before attempting to start or operate this

equipment. Savethese instructions for future reference.

Someunitsmay requirefinal assemblybeforeuse. Referto the Assemblysection of this manual for instructions on final

assembly procedures. Follow the instructions completely.

Where to Find Us

You can contact SnapperCustomer Service by phone at (888) 477-8650 or on the Internet at snapper.com.Tofind Briggs &

Stratton support and servicefor your engine,consult your Yellow Pages.There are over 30,000 Briggs & Stratton authorized

service dealersworldwide who provide quality service.

Model DescriptionName/Number

Unit Part Number Unit SERIALNumber

Mower DeckPartNumber Mower DeckSERIALNumber

DealerName DatePurchased

Engine Make EngineModel

EngineTypeiSpec EngineCode/SeriesNumber

Note: SeeIdentification Numbers in OperatorSafetysection to locatethis data.

SNAPPER@and SNAPPERPRO@aretrademarks of Briggs & Stratton Yard

Power Group,WI USA.

Snapper Products

535 Macon St.

McDonough, GA30253

Copyright © 2007 Briggs & Stratton Corporation

Milwaukee, WI USA.

All rights reserved.

Page 3

Tableof Contents

OperatorSafety .......................................... 2

Readthe Manual ............................................. 2

Safety Icons................................................. 2

Safety Risks................................................. 3

Safety Rulesand Information ................................... 4

Identification Numbers......................................... 8

Safety Decals................................................ 8

Assembly.............................................. 10

Add Engine Oil.............................................. 10

Add Fuel................................................... 10

Mower Deck Removaland Installation ........................... 10

Controlsand Features..................................... 12

Control Functions............................................ 12

Other Functions............................................. 14

Operation ............................................. 15

Safety InterlockSystem Tests.................................. 15

Adding Fuel................................................ 15

Starting the Engine .......................................... 16

Stopping the Tractor and Engine................................ 16

Driving the Tractor........................................... 16

Mowing ................................................... 16

Lawn Careand Mowing Information ............................. 17

Adjusting Mower Cutting Height ................................ 19

Pushing the Tractorby Hand................................... 19

Attaching aTrailer ........................................... 19

Maintenance ........................................... 21

MaintenanceSchedule........................................ 21

RegularChecks ............................................. 21

Battery Maintenance ......................................... 22

TransmissionMaintenance .................................... 23

Hood Removaland Installation ................................. 23

Tractorand Mower Maintenance................................ 24

Engine Maintenance.......................................... 27

Storage ................................................... 30

Troubleshooting,Adjustment,and Service....................... 31

Troubleshooting............................................. 31

Adjustments................................................ 34

Service.................................................... 35

Warranties............................................. 38

Tractorand Mower DeckWarranty .............................. 38

Parts and Accessories ..................................... 40

Parts ..................................................... 40

TechnicalManuals ........................................... 40

Specifications .................................... BackCover

Page 4

SAVETHESEINSTRUCTIONS

OperatorSafety

Congratulations on purchasinga

superior-quality pieceof lawnand

garden equipment. Our products

are designed and manufacturedto

meet or exceedall industry

standardsfor safety.

Power equipmentis only assafe

asthe operator.If it is misused,or

not properly maintained, it can be dangerous! Remember,

you are responsiblefor your safetyand that of those around

you.

Use common sense, andthink through what you aredoing.

If you are not sure that the task you are aboutto perform

can besafelydone with the equipment you havechosen, ask

a professional: contactyour local authorized dealer.

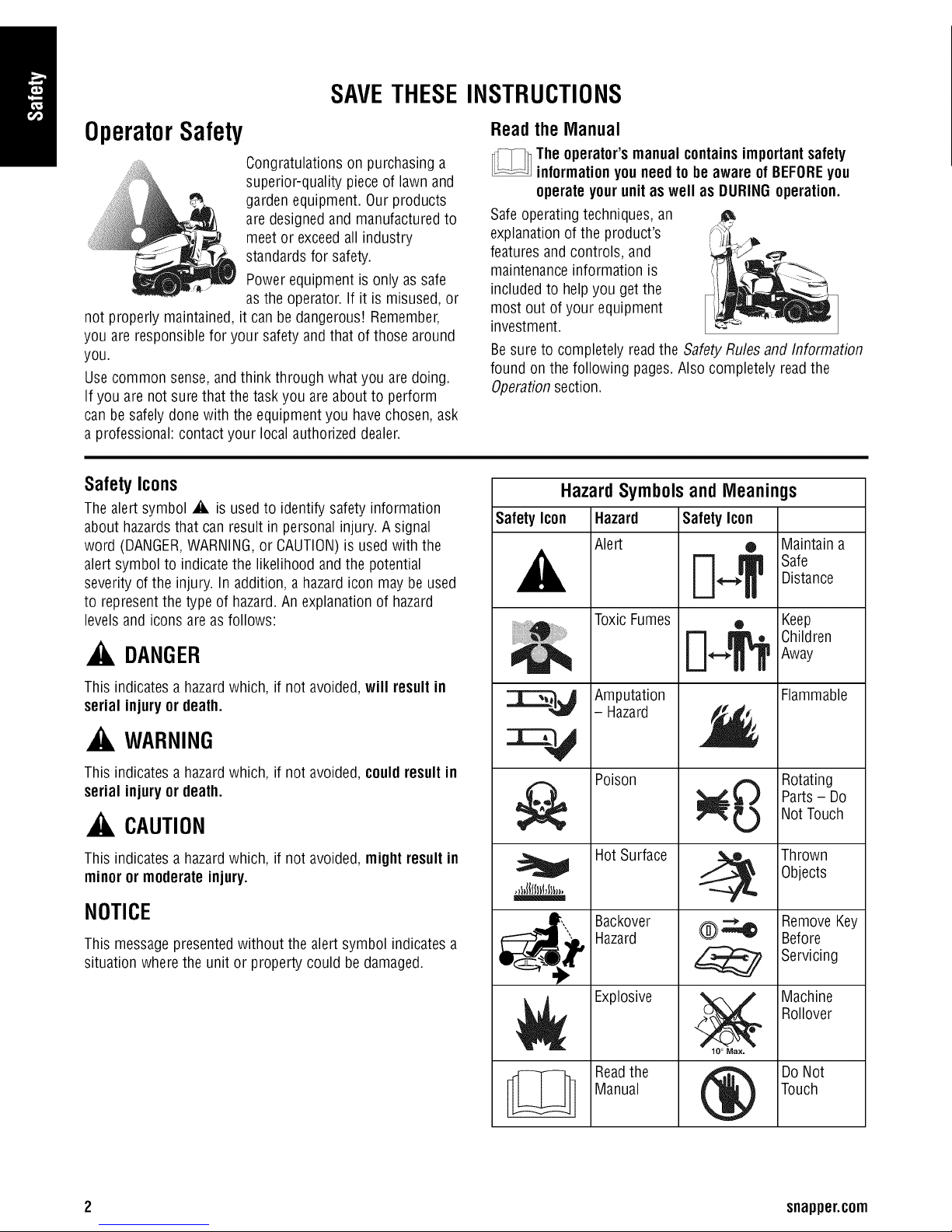

Safety Icons

Thealert symbol A isusedto identify safetyinformation

about hazardsthat can result in personalinjury. Asignal

word (DANGER,WARNING,or CAUTION)is used with the

alert symbol to indicate the likelihood and the potential

severity of the injury. In addition, a hazardicon maybe used

to representthe type of hazard.An explanationof hazard

levels and icons are as follows:

Read the Manual

The operator'smanual containsimportantsafety

informationyouneedto be aware ofBEFOREyou

operateyour unit as well as DURINGoperation.

Safeoperatingtechniques, an

explanation of the product's

featuresand controls, and

maintenanceinformation is

included to helpyou get the

most out of your equipment

investment.

Besureto completely readthe SafetyRules and Information

found onthe following pages.Also completely readthe

Operationsection.

Hazard Symbols and Meanings

Safety Icon Hazard Safety Icon

Alert ® Maintain a

A E] TS '0

ToxicFumes • Keep

Distance

_k, DANGER

This indicatesa hazardwhich, if not avoided,will result in

serial injuryor death.

, WARNING

This indicatesa hazardwhich, if not avoided, couldresult in

serial injuryor death.

_, CAUTION

This indicatesa hazardwhich, if not avoided, mightresult in

minor or moderateinjury.

NOTICE

This messagepresentedwithout the alert symbol indicatesa

situation where the unit or property could be damaged.

j'_ _.._1_ I ChildrenAway

Amputation Flammable

- Hazard

Poison

Hot Surface

Backover

Hazard

Explosive

Rotating

Parts- Do

Not Touch

Thrown

Objects

RemoveKey

Before

Servicing

Machine

Rollover

N

Readthe

Manual

®

DoNot

Touch

2 snapper.corn

Page 5

Safety Risks

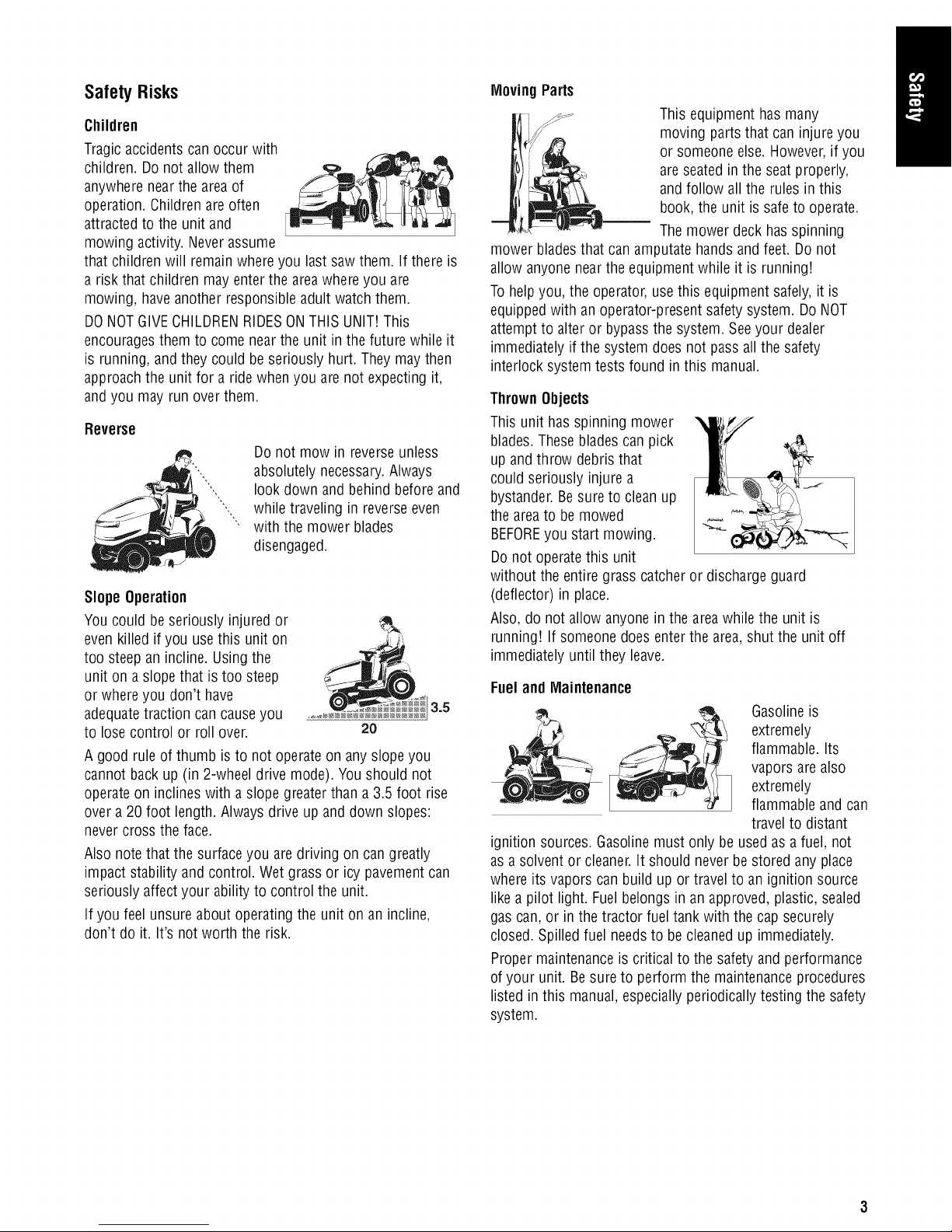

Children

Tragicaccidents can occur with

children. Do not allow them

anywhere nearthe area of

operation. Children are often

attracted to the unit and

mowing activity. Neverassume

that children will remainwhereyou last saw them. If there is

a risk that children mayenterthe areawhereyou are

mowing, haveanother responsible adult watch them.

DONOTGIVECHILDRENRIDESONTHIS UNIT! This

encouragesthem to come near the unit inthe future while it

is running, and they could be seriously hurt. They may then

approachthe unit for a ride whenyou arenot expecting it,

and you may run over them.

Reverse

Do not mow in reverseunless

absolutely necessary.Always

look down andbehind beforeand

while traveling in reverseeven

with the mower blades

disengaged.

SlopeOperation

You could be seriously injured or

evenkilled if you usethis unit on

too steepan incline. Using the

unit ona slope that is too steep

or whereyou don't have

adequatetraction can causeyou

to losecontrol or roll over.

A good rule of thumb is to not operate on any slope you

cannot back up(in 2-wheeldrive mode).You should not

operateon inclines with aslope greaterthan a3.5 foot rise

over a20 foot length. Alwaysdrive upand down slopes:

nevercross the face.

Also note thatthe surfaceyou are driving on can greatly

impact stability and control. Wet grass or icy pavementcan

seriously affectyour ability to control the unit.

If you feel unsure about operating the unit on an incline,

don't do it. It's not worth the risk.

2O

MovingParts

This equipment has many

moving parts that can injureyou

or someone else.However,if you

are seated inthe seat properly,

and follow all the rules in this

book, the unit is safeto operate.

Themower deck has spinning

mower bladesthat can amputatehands and feet. Do not

allow anyone nearthe equipmentwhile it is running!

Tohelp you, the operator, usethis equipment safely, it is

equipped with anoperator-present safetysystem. Do NOT

attempt to alter or bypassthe system. Seeyour dealer

immediately if the system does not passall the safety

interlock systemtests found in this manual.

ThrownObjects

This unit has spinning mower

blades. Theseblades can pick

up andthrow debristhat

could seriously injure a

bystander. Besure to clean up

the areato bemowed

BEFOREyou start mowing.

Donot operatethis unit

without the entire grass catcheror discharge guard

(deflector) in place.

Also, do not allow anyonein the areawhile the unit is

running! If someone doesenter the area,shut the unit off

immediately until they leave.

Fueland Maintenance

Gasolineis

extremely

flammable. Its

vapors are also

extremely

flammable andcan

travel to distant

ignition sources.Gasolinemust only be used as afuel, not

as asolvent or cleaner.It should neverbe stored any place

where its vapors can build up or travel to an ignition source

like apilot light. Fuel belongs in an approved, plastic, sealed

gas can,or in the tractor fuel tank with the cap securely

closed. Spilledfuel needsto be cleaned up immediately.

Proper maintenanceis critical to the safety andperformance

of your unit. Besure to perform the maintenance procedures

listed in this manual,especiallyperiodically testing the safety

system.

Page 6

Safety Rules and Information

WARNING

Readthesesafetyrules andfollow themclosely.

Failureto obeytheserules couldresult in lossof

controlof unit, severepersonalinjuryor deathto

you,or bystanders,or damageto propertyor

equipment.

Thismowingdeckis capable of amputatinghands

andfeet and throwingobjects.

GeneralOperation

1. Read, understand,and follow all instructions in the

manual andon the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keepclearof the discharge opening at all

times.

3. Only allow responsibleadults, who arefamiliar with the

instructions, to operatethe unit (local regulations can

restrict operator age).

4. Clearthe areaof objects such as rocks, toys, wire, etc.,

which could be picked up andthrown bythe blade(s).

5. Be sure the areais clear of other peoplebefore

mowing. Stop the unit if anyoneenters the area.

6. Never carry passengers.

7. Do not mow in reverseunless absolutely necessary.

Always look down and behind before and while

travelling in reverse.

8. Never direct dischargematerialtoward anyone.Avoid

discharging material againsta wall or obstruction.

Material may ricochet backtoward the operator. Stop

the blade(s)when crossing gravel surfaces.

9. Do not operatethe machinewithout the entire grass

catcher,discharge guard (deflector), or other safety

devices inplace.

10. Slow down beforeturning.

11. Never leavea running unit unattended.Always

disengagethe PTO,set parking brake, stop engine,and

remove keys before dismounting.

12. Disengageblades(PTO)when not mowing. Shut off

engine and wait for all parts to come to a complete stop

before cleaningthe machine, removing the grass

catcher,or unclogging the discharge guard.

13. Operatethe machineonly in daylight or good artificial

light.

14.

Do not operatethe unit while underthe influenceof

alcohol or drugs.

15.

Watchfor traffic when operating near or crossing

roadways.

16.

Use extra carewhen loading or unloadingthe unit into

a trailer or truck.

17.

Alwayswear eyeprotection when operatingthis unit.

18.

Data indicates that operators, age 60years and above,

are involved ina large percentageof power equipment-

related injuries.These operatorsshould evaluatetheir

ability to operate the equipment safely enoughto

protect themselves andothers from injury.

19. Follow the manufacturer's recommendations for wheel

weights or counterweights.

20. Keepin mind the operator is responsiblefor accidents

occurring to other peopleor property.

21. All drivers should seek and obtain professional and

practical instruction.

22. Alwayswear substantial footwear and trousers. Never

operatewhen barefootor wearing sandals.

23. Before using, always visually checkthat the bladesand

blade hardware are present, intact, and secure. Replace

worn or damagedparts.

24. Disengageattachments before: refueling, removing an

attachment, making adjustments (unless the

adjustment can be made from the operator's position).

25. Whenthe machineis parked, stored, or left unattended,

lower the cutting meansunless a positive mechanical

lock is used.

26. Before leavingthe operator's position for any reason,

engagethe parking brake (if equipped),disengagethe

PTO,stop the engine,and removethe key.

27. Toreducefire hazard,keepthe unit free of grass,

leaves,and excessoil. Do not stop or parkover dry

leaves,grass, or combustible materials.

28. It is a violation of California Public ResourceCode

Section 4442 to useor operatethe engine on or near

anyforest-covered, brush-covered, or grass-covered

land unlessthe exhaustsystem is equippedwith a

spark arrester meetingany applicablelocal or state

laws. Other statesor federal areasmay have similar

laws.

4 snapper.corn

Page 7

TransportingandStorage

1. When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel. If the

unit is facing backwards,wind lift could damagethe

unit.

2. Always observesafe refueling andfuel handling

practices when refuelingthe unit after transportation or

storage.

3. Never store the unit (with fuel) in anenclosed poorly

ventilatedstructure. Fuelvapors can travel to an

ignition source (such as a furnace, water heater,etc.)

and cause anexplosion. Fuelvapor is also toxic to

humans and animals.

4. Alwaysfollow the engine manual instructions for

storage preparations beforestoring the unit for both

short and longterm periods.

5. Alwaysfollow the engine manual instructions for proper

start-up procedureswhen returning the unit to service.

6. Never store the unit or fuel container insidewhere there

is anopen flameor pilot light, such as in awater

heater.Allow unit to cool before storing.

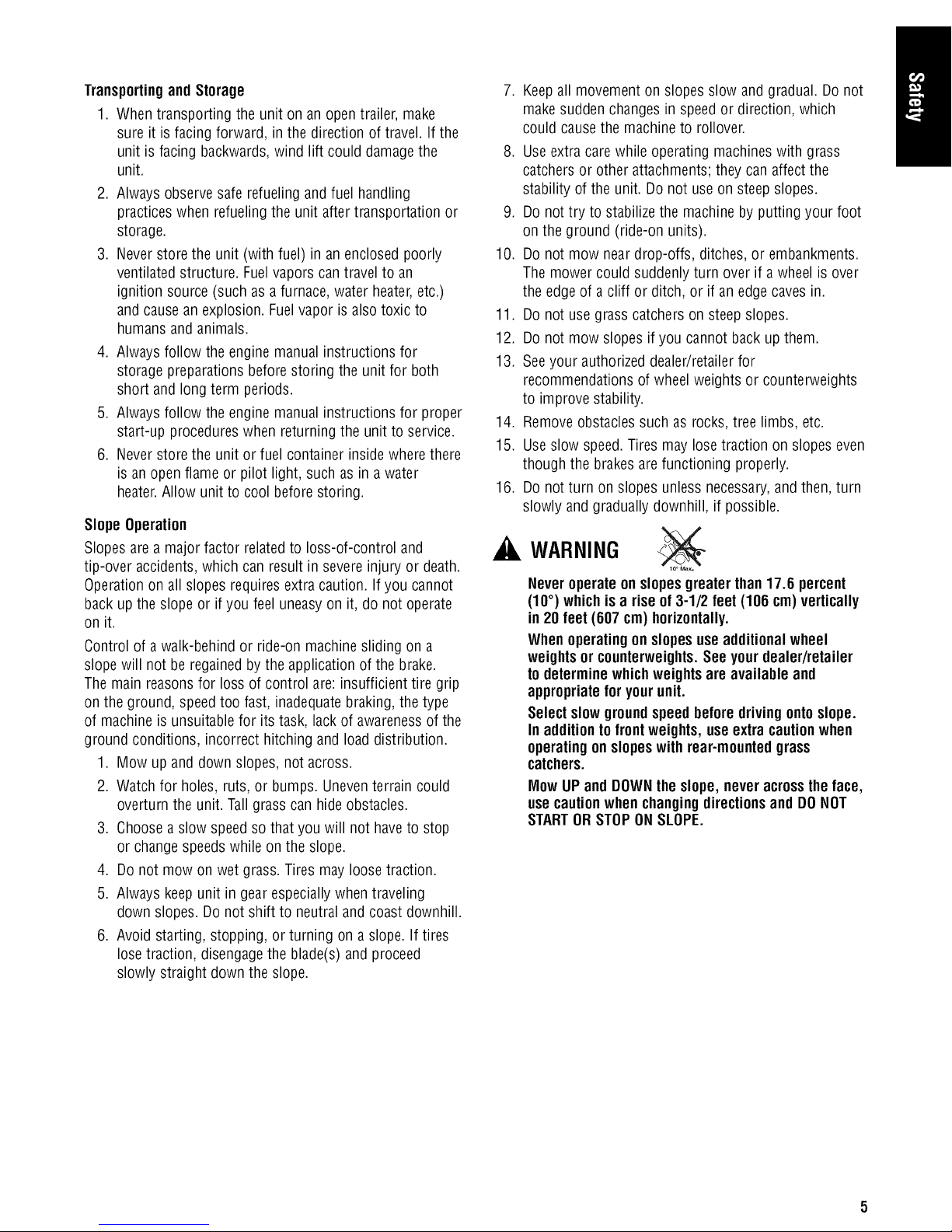

SlopeOperation

Slopes area major factor relatedto loss-of-control and

tip-over accidents, which can result insevere injury or death.

Operationon all slopesrequires extra caution. Ifyou cannot

back up the slope or if you feel uneasyon it, do not operate

on it.

Control of a walk-behind or ride-on machinesliding on a

slope will not be regainedby the application of the brake.

The main reasonsfor loss of control are: insufficient tire grip

on the ground, speedtoo fast, inadequatebraking, the type

of machineis unsuitablefor its task, lackof awareness of the

ground conditions, incorrect hitching and loaddistribution.

1. Mow up and down slopes, not across.

2. Watchfor holes, ruts, or bumps. Uneventerrain could

overturn the unit. Tall grass can hideobstacles.

3. Choosea slow speed so thatyou will not haveto stop

or changespeedswhile on the slope.

4. Do not mowon wet grass. Tires may loose traction.

5. Always keepunit in gear especiallywhen traveling

down slopes. Donot shift to neutral and coast downhill.

6. Avoid starting, stopping, or turning on a slope. If tires

lose traction, disengagethe blade(s) and proceed

slowly straight down the slope.

7. Keepall movement on slopes slow andgradual. Donot

make sudden changes in speedor direction, which

could causethe machine to rollover.

8. Use extra care while operating machineswith grass

catchers or other attachments; they can affect the

stability of the unit. Do not useon steepslopes.

9. Do not try to stabilize the machine by putting your foot

on the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embankments.

The mowercould suddenly turn over if awheel is over

the edgeof acliff or ditch, or if an edgecavesin.

11. Do not usegrass catchers onsteep slopes.

12. Do not mow slopes if you cannot back up them.

13. Seeyour authorizeddealer/retailerfor

recommendations of wheel weights or counterweights

to improvestability.

14. Remove obstacles suchas rocks, tree limbs, etc.

15. Use slow speed.Tires maylosetraction on slopes even

though the brakesare functioning properly.

16. Do not turn on slopes unlessnecessary,and then,turn

slowly andgradually downhill, if possible.

WARNING

Neveroperateonslopesgreaterthan17.6 percent

(10°) whichisa rise of3-1/2 feet (106 cm)vertically

in 20 feet(607 cm) horizontally.

Whenoperatingonslopesuseadditional wheel

weightsor counterweights.Seeyourdealer/retailer

todeterminewhichweightsare available and

appropriateforyourunit.

Selectslowgroundspeedbeforedrivingontoslope.

In additionto frontweights, useextra cautionwhen

operatingonslopeswith rear-mountedgrass

catchers.

Mow UP and DOWNtheslope, neveracrossthe face,

usecautionwhen changingdirectionsand DONOT

STARTORSTOPONSLOPE.

Page 8

TowedEquipment(Ride-On Units)

1. Tow only with a machinethat hasa hitch designedfor

towing. Do not attach towed equipment exceptat the

hitch point.

2. Follow the manufacturer's recommendations for weight

limit for towed equipment andtowing on slopes.

3. Never allow children or others in or on towed

equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travelslowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

Children

Tragicaccidents can occur if the operator is not alertto the

presenceof children. Childrenare often attractedto the unit

and the mowing activity. Neverassumethat children will

remain whereyou last saw them.

1. Keepchildren out of the mowing areaand underthe

watchful care of another responsible adult.

2. Be alert and turn unit off if children enterthe area.

.

Beforeand during reverseoperation, look behind and

down for small children.

4.

Never carry children, evenwith the blade(s) off. They

may fall off and beseriously injured or interfere with

safe unit operation. Children who havebeen given rides

in the past may suddenly appear inthe mowing areafor

another ride and be run over or backed over bythe

machine.

5. Never allow children to operatethe unit.

6. Use extra carewhen approaching blind corners, shrubs,

trees, or other objects that may obscurevision.

Emissions

1. Engineexhaust from this product contains chemicals

known, incertain quantities, to causecancer,birth

defects,or other reproductiveharm.

2. Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

IgnitionSystem

1. This spark ignition system complies with Canadian

ICES-O02.

Serviceand Maintenance

SafeHandling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, andother

sources of ignition.

2. Use only approved gasolinecontainers.

3. Never removethe gascap or addfuel with the engine

running. Allow the engine to cool before refueling.

4. Neverfuel the machineindoors.

5. Neverstore the machine or fuel container wherethere

is an openflame, spark, or pilot light suchas neara

water heateror other appliance.

6. Neverfill containers inside avehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground away from your vehiclebeforefilling.

7. Remove gas-powered equipmentfrom the truck or

trailer and refuel it on the ground. Ifthis is not

possible,then refuel such equipmenton atrailer with a

portable container, ratherthan from a gasoline

dispenser nozzle.

8. Keepnozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not usea nozzlelock-open device.

9. If fuel is spilled on clothing, changeclothing

immediately.

10. Neverover-fill the fuel tank. Replacegascap and

tighten securely.

11. Use extra care in handling gasolineand other fuels.

They areflammable and vapors are explosive.

12. If fuel is spilled, do not attemptto start the engine but

move the machineaway from the areaof spillage and

avoid creatingany source of ignition until fuel vapors

havedissipated.

13. Replaceall fuel tank capsand fuel containercaps

securely.

6 snapper.corn

Page 9

Service and Maintenance

1. Never run the unit inan enclosed areawhere carbon

monoxide fumes may collect.

2. Keepnuts and bolts, especiallyblade attachment bolts,

tight and keep equipment in good condition.

3. Nevertamper with safetydevices. Checktheir proper

operation regularly andmake necessary repairs if they

are not functioning properly.

4. Keepunit free of grass, leaves, or other debris build-up.

Cleanup oil or fuel spillageand remove anyfuel-soaked

debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspectthe machine.

Repair,if necessary,before restarting.

6. Never makeadjustments or repairswith the engine

running.

7. Checkgrass catcher components andthe discharge

guard frequently and replace with manufacturer's

recommendedparts,when necessary.

8. Mower blades are sharp.Wrap the bladeor wear

gloves, anduse extra caution when servicing them.

9. Checkbrakeoperation frequently.Adjust andservice as

required.

10. Maintain or replacesafety and instructions labels,as

necessary.

11. Do not removethe fuel filter when the engineis hot as

spilled gasoline mayignite. Donot spreadfuel line

clamps further than necessary.Ensureclamps grip

hoses firmly over the filter after installation.

12. Do not usegasolinecontaining METHANOL,gasohol

containing more than 10% ETHANOL,gasoline

additives, or white gas becauseengine/fuel system

damagecould result.

13. If the fuel tank must be drained, it should be drained

outdoors.

14. Replacefaulty silencers/mufflers.

15. Use only factory authorized replacement parts when

making repairs.

16. Always comply with factory specificationson all

settings and adjustments.

17. Only authorizedservice locations should be utilized for

major serviceand repairrequirements.

18. Neverattempt to make major repairson this unit unless

you havebeen properly trained. Improper service

procedures can result in hazardousoperation,

equipment damage and voiding of manufacturer's

warranty.

19. On multiple blade mowers, take care as rotating one

blade can causeother bladesto rotate.

20. Do not changeengine governor settings or over-speed

the engine.Operating the engine at excessive speed can

increasethe hazardof personal injury.

21. Disengagedrive attachments, stop the engine,remove

the key,and disconnectthe spark plug wire(s) before:

clearing attachment blockagesand chutes,performing

servicework, striking an object, or if the unit vibrates

abnormally.After striking an object, inspectthe

machine for damageand make repairs before restarting

and operating the equipment.

22. Never place hands nearthe moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans aretypically locatedon top

of the transaxle.)

23. Units with hydraulic pumps, hoses, or motors:

WARNING:Hydraulicfluid escapingunder pressure

may havesufficient force to penetrateskin andcause

serious injury. If foreign fluid is injected into the skin it

must besurgically removedwithin a few hours by a

doctor familiar with this form of injury or gangrene may

result. Keepbody and hands awayfrom pin holes or

nozzlesthat eject hydraulic fluid under high pressure.

Use paper or cardboard, and not hands,to searchfor

leaks.Make sure all hydraulic fluid connections are

tight and all hydraulichoses and linesare ingood

condition beforeapplying pressureto the system. If

leaks occur, havethe unit serviced immediately byyour

authorized dealer.

24. WARNING:Stored energydevice. Improper releaseof

springs can result in serious personalinjury. Springs

should beremoved by an authorizedtechnician.

25. Models equippedwith an engine radiator: WARNING:

Stored energydevice. To prevent seriousbodily injury

from hot coolant or steam blow-out, neverattempt to

remove the radiatorcap while the engineis running.

Stop the engineand wait until it is cool. Eventhen, use

extremecare when removingthe cap.

Page 10

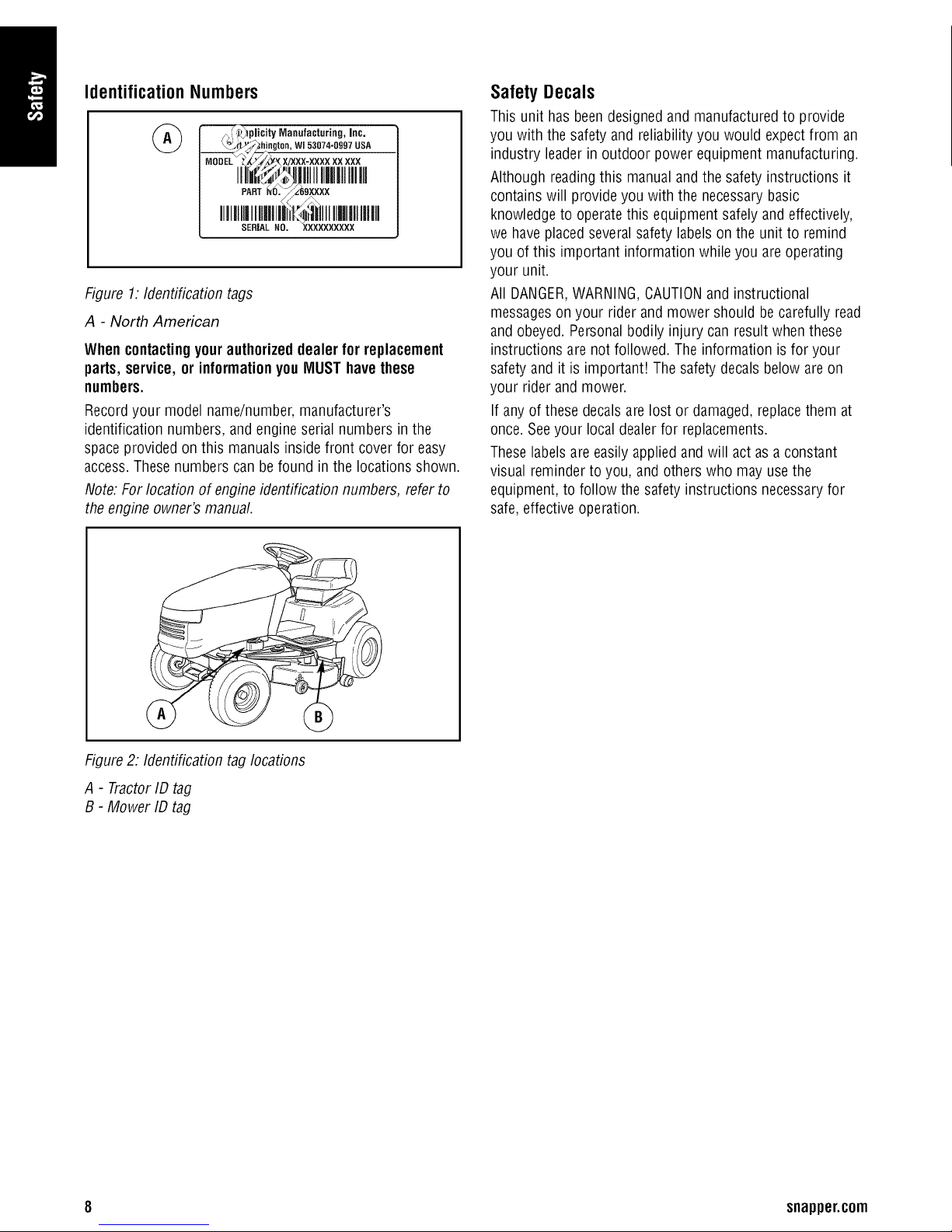

Identification Numbers

I \_._L_hi.g_°,,w153o74-og97usa

Figure 1:Identificationtags

A - North American

Whencontactingyourauthorizeddealer for replacement

parts,service, or informationyouMUSThavethese

numbers.

Recordyour model name/number,manufacturer's

identification numbers, and engineserial numbers in the

space provided on this manualsinside front cover for easy

access.Thesenumbers can befound in the locations shown.

Note: Forlocation of engine identification numbers, refer to

the engineowner's manual.

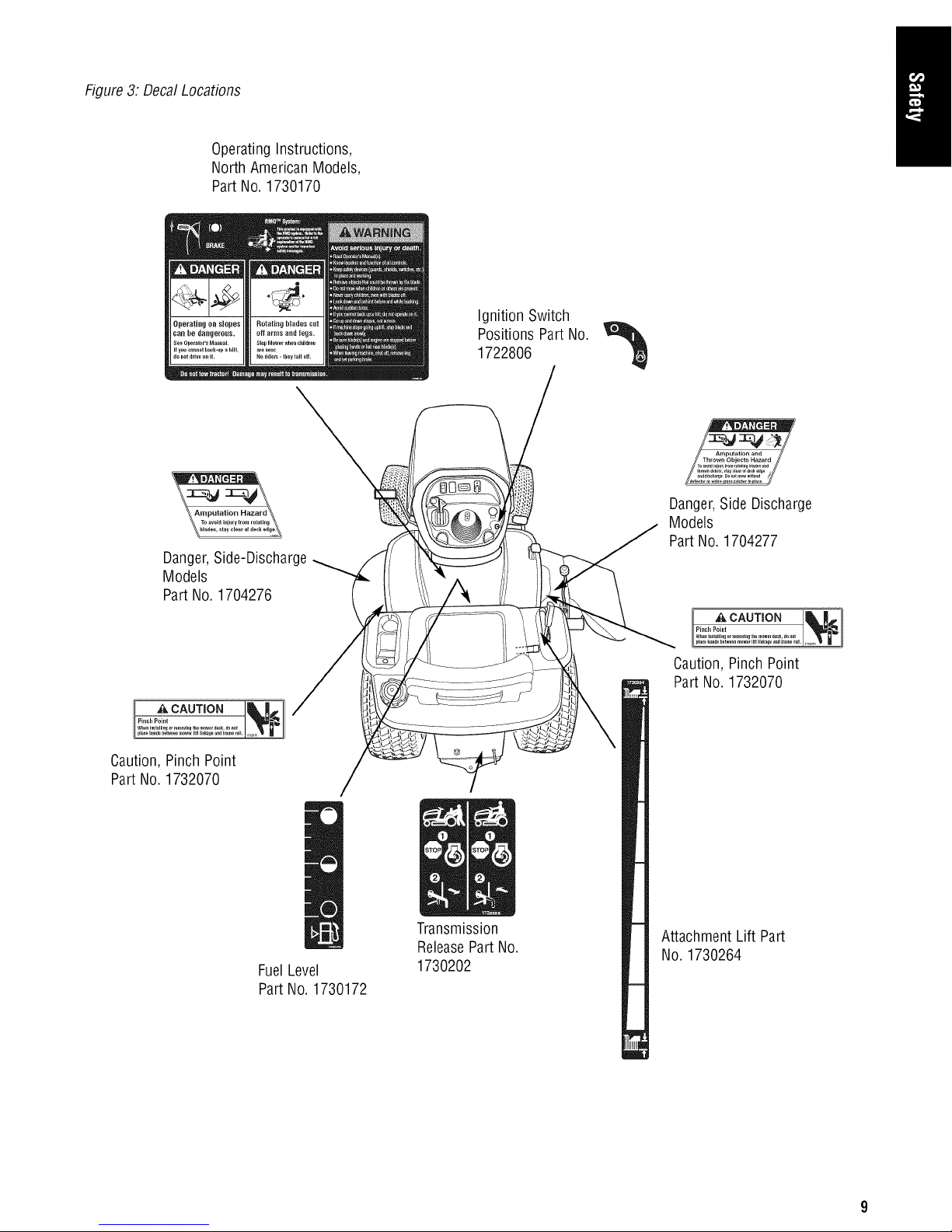

Safety Decals

This unit has beendesigned and manufactured to provide

you with the safety and reliability you would expectfrom an

industry leaderin outdoor power equipmentmanufacturing.

Although readingthis manualand the safety instructions it

contains will provide you with the necessarybasic

knowledge to operatethis equipment safely andeffectively,

we haveplaced several safetylabelson the unit to remind

you of this important information while you areoperating

your unit.

All DANGER,WARNING,CAUTIONand instructional

messageson your rider andmower should be carefully read

and obeyed. Personalbodily injury can result when these

instructions are not followed. The information is for your

safety and it is important! Thesafety decals below areon

your rider and mower.

If any of these decals are lost or damaged,replacethem at

once. Seeyour local dealerfor replacements.

Theselabelsare easily appliedand will act as aconstant

visual reminderto you, and others who mayusethe

equipment, to follow the safetyinstructions necessaryfor

safe,effective operation.

Figure2: Identification tag locations

A - TractorID tag

B - Mower IDtag

8 snapper.corn

Page 11

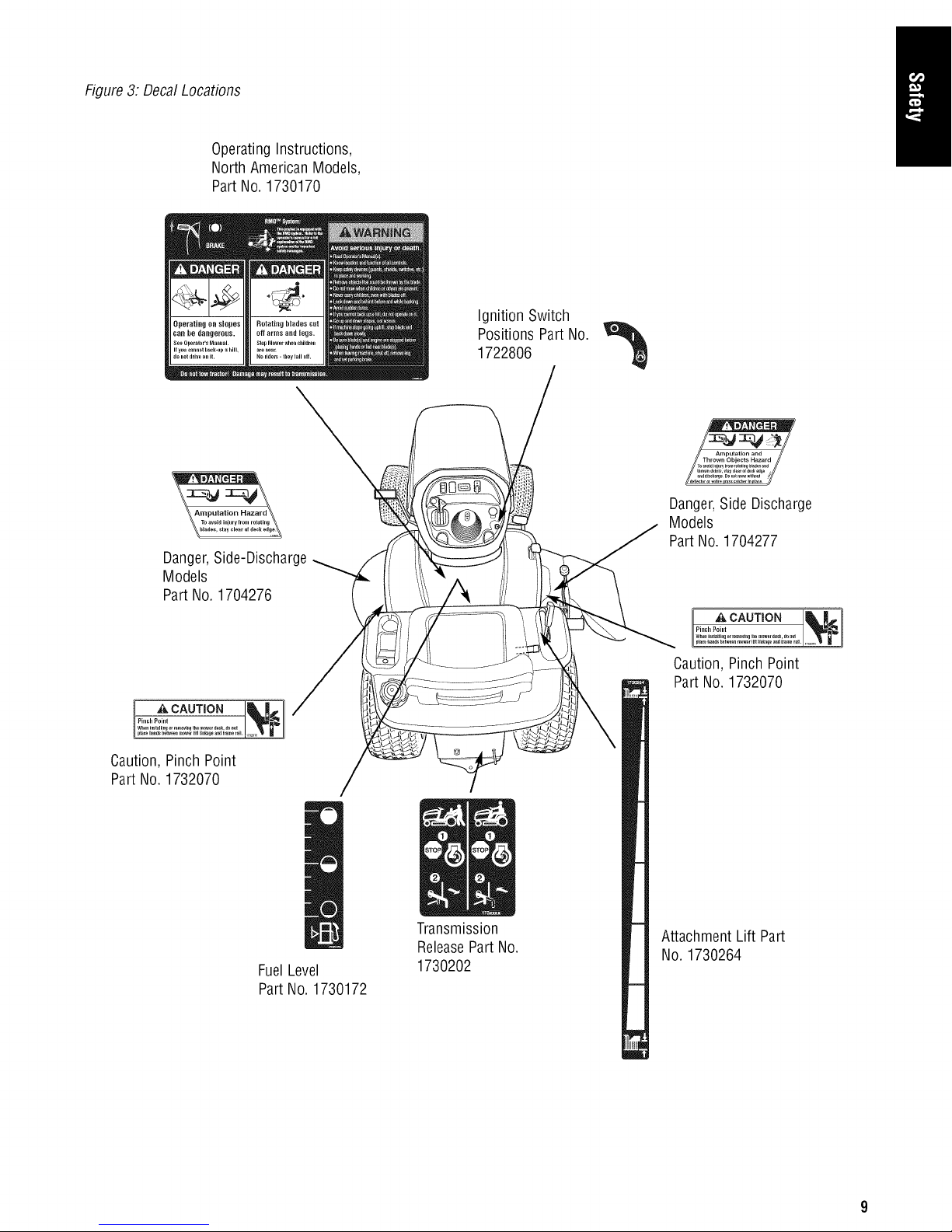

Figure3: DecalLocations

OperatingInstructions,

North American Models,

Part No.1730170

Danger,Side-Discharge

Models

Part No.1704276

Ignition Switch

Positions PartNo.

1722806

Danger,Side Discharge

Models

Part No.1704277

i ACAUTIONILR.]I

Pinch Point u_

I ACAUTIO._.!.

Caution, Pinch Point

Part No.1732070

FuelLevel

Part No.1730172

Transmission

ReleasePart No.

1730202

Caution,Pinch Point

Part No. 1732070

Attachment Lift Part

No. 1730264

Page 12

Assembly

NOTICE

DONOTattemptto start the engine beforeit has been

properlyservicedwith therecommendedoil. This

may result in anenginefailure.

Add Engine Oil

Refer to ChangeEngine Oilin the Maintenancesection for oil

type and fill procedures.

Add Fuel

Refer to Adding Fuelin the Operationsectionfor fuel

specifications andfilling procedures.

Mower Deck Removal and Installation

WARNING

Engageparkingbrake, disengagePTO, stopengine

and removekey beforeattemptingto install or

removethemower.

CAUTION

The mufflerand surroundingareas may be hot.

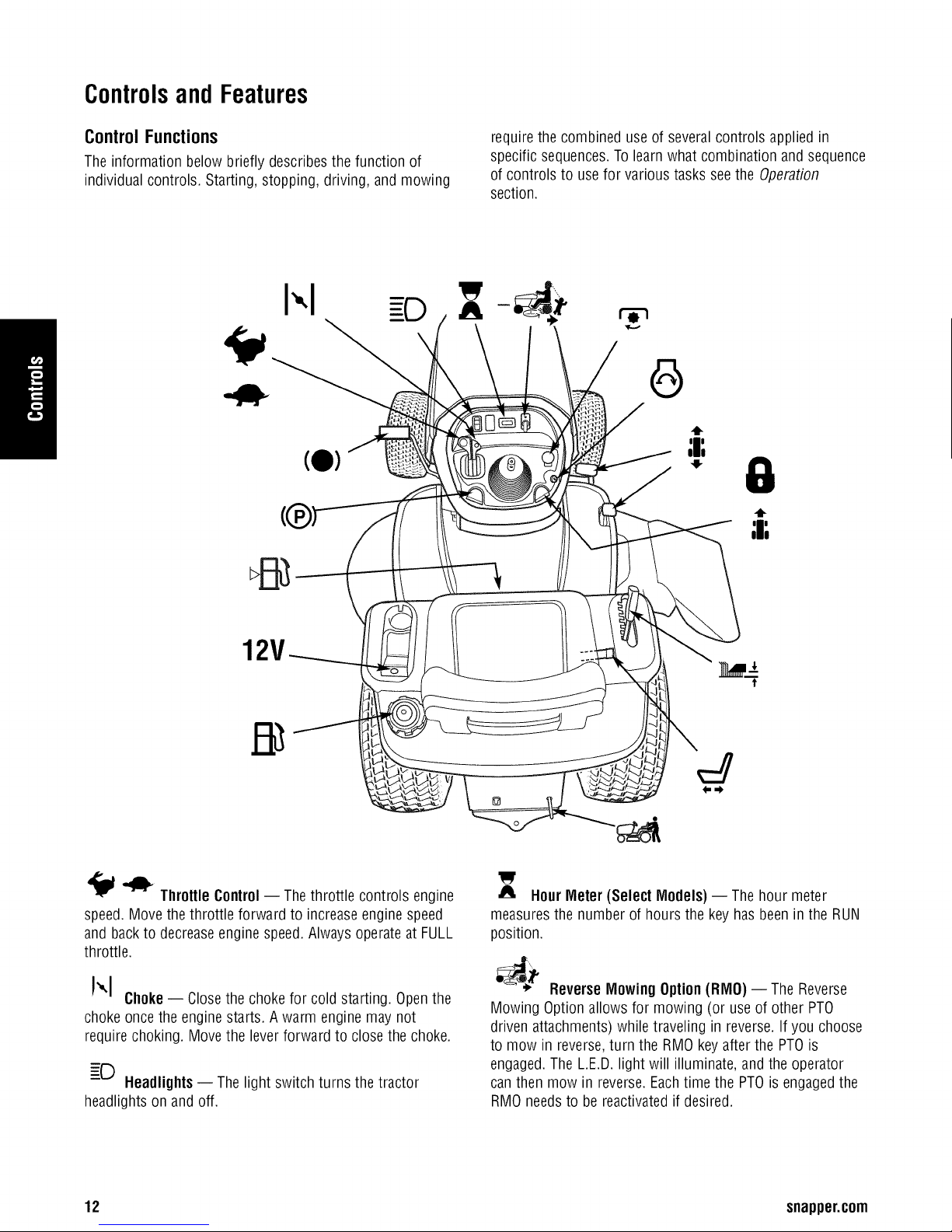

6. Turn wheels straight ahead.Support the mower hanger

(C). Removesafety clip (A, Figure6) and rod (B).

Lower the mower hanger (C).

7. Turn wheels fully left, andslide mower deck out right

side of tractor.

Installingthe MowerDeck

1. Park tractor, shut off PTOand engine, removethe key

and apply parking brake. Turn the wheels fully to the

left.

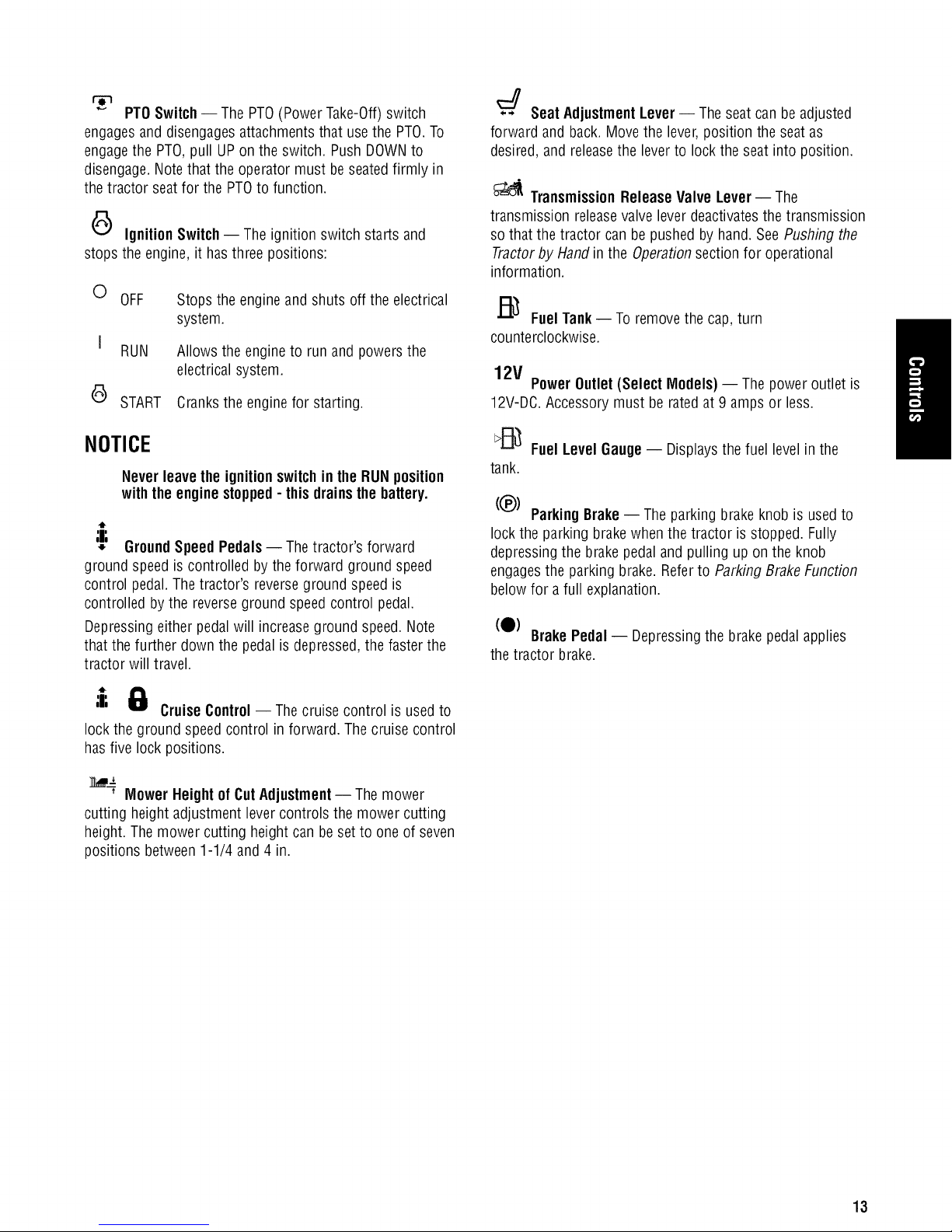

2. Placethe mower lift lever(A, Figure7) in the lowest

position. Slidemower deck under right sideof tractor

so that mower hitch is alignedwith the front tractor

hitch.

3. Turn wheels straight. Lift the mower hanger (C,

Figure6). Insert rod (B)through mower hanger (C) and

tractor brackets(D). Secure with safetyclip (A).

4. Re-install hair pins (D, Figure4) and washers (C) into

the mower lift plates (A) and the tractor lift arms (B).

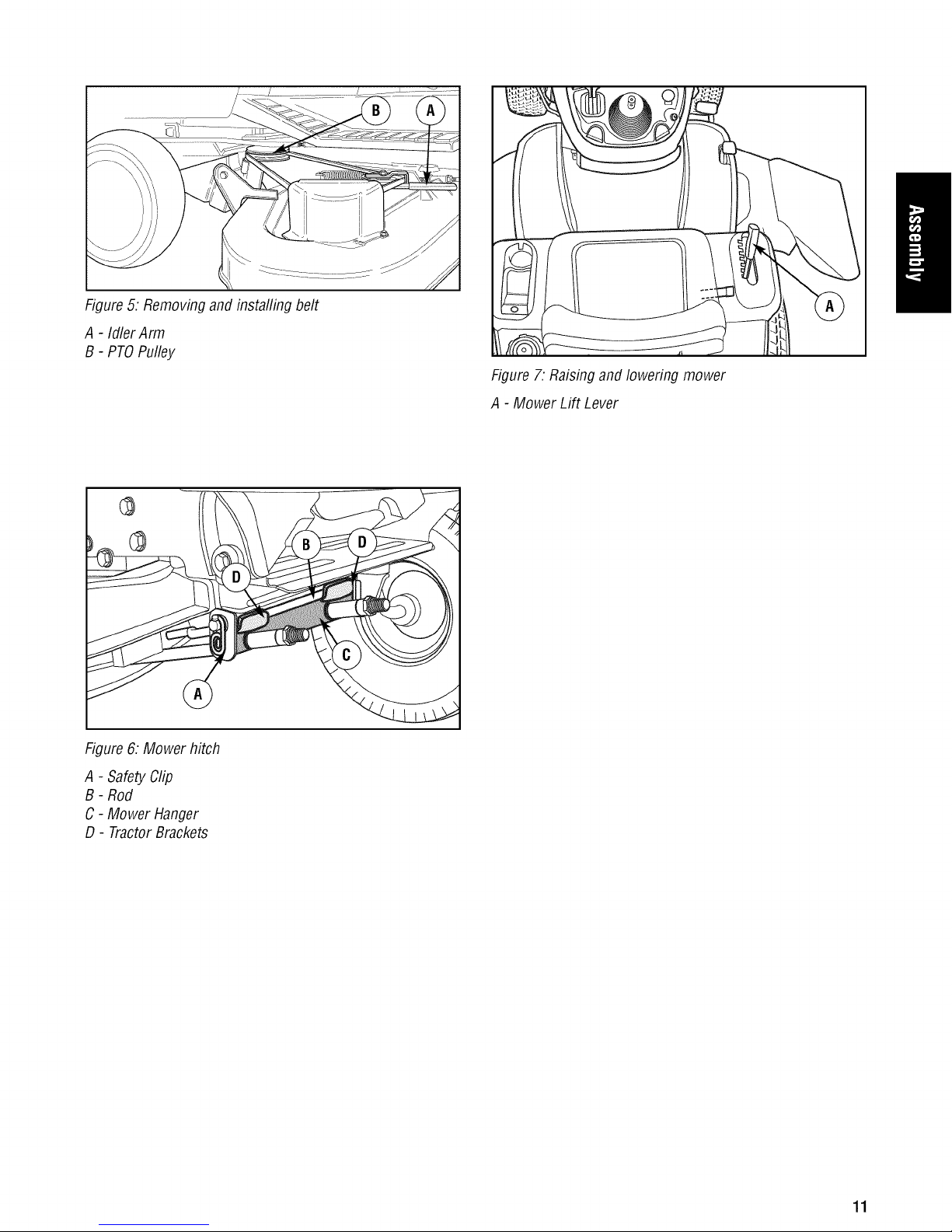

5. Move idlerarm (A, Figure5) to relievebelt tension.

Install belt onto the PTOpulley (B).

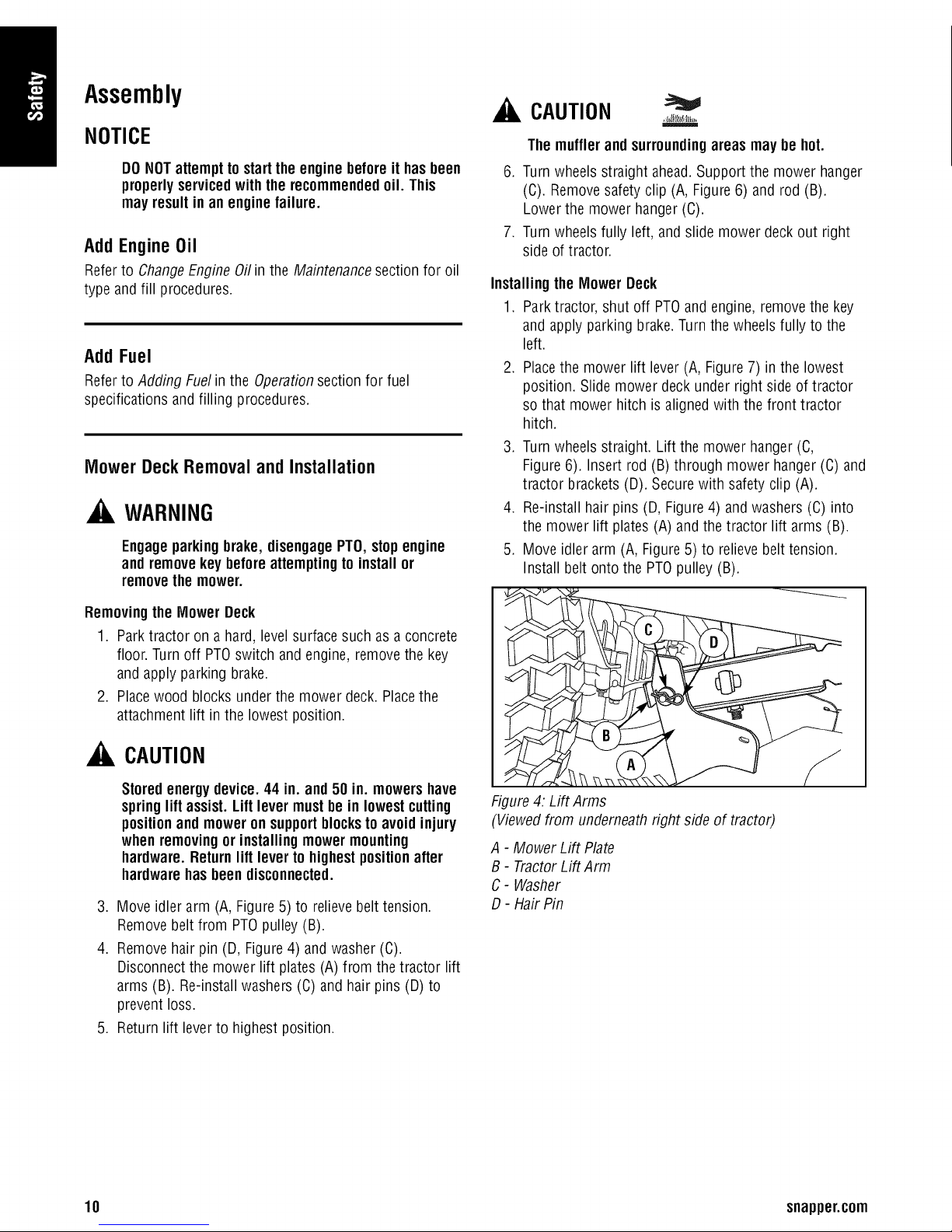

Removingthe Mower Deck

1. Park tractor on a hard, levelsurface such as a concrete

floor. Turnoff PTOswitch and engine, removethe key

and apply parking brake.

2. Placewood blocks underthe mower deck. Placethe

attachment lift in the lowest position.

CAUTION

Storedenergydevice.44 in. and50 in. mowershave

springlift assist. Lift levermustbe in lowestcutting

positionand moweronsupportblocksto avoidinjury

whenremovingor installingmowermounting

hardware.Returnlift lever tohighestpositionafter

hardwarehasbeendisconnected.

3. Move idler arm (A, Figure 5) to relieve belt tension.

Removebelt from PTOpulley (B).

4. Removehair pin (D, Figure4) and washer (C).

Disconnectthe mower lift plates (A) from the tractor lift

arms (B). Re-installwashers (C) andhair pins (D) to

prevent loss.

5. Return lift leverto highest position.

Figure4: Lift Arms

(Viewedfrom underneathright side of tractor)

A - Mower Lift Plate

B - TractorLift Arm

C- Washer

D- Hair Pin

10 snapper.corn

Page 13

Figure5: Removingand installing belt

A - Idler Arm

B- PTOPulley

Figure 6: Mower hitch

Figure 7. Raisingand lowering mower

A - Mower Lift Lever

A- SafetyClip

B - Rod

C - Mower Hanger

D - TractorBrackets

11

Page 14

ControlsandFeatures

Control Functions

The information below briefly describesthe function of

individual controls. Starting, stopping, driving, and mowing

I',1 -D ^

requirethe combined use of several controls applied in

specific sequences.To learn what combination andsequence

of controls to usefor various tasks seethe Operation

section.

W

Throttle Control-- Thethrottle controls engine

speed. Move thethrottle forward to increase enginespeed

and backto decreaseengine speed. Alwaysoperate at FULL

throttle.

!",1 Choke-- Closethe choke for cold starting. Openthe

choke once the enginestarts. Awarm engine may not

require choking. Move the leverforward to close the choke.

Headlights-- The light switch turns the tractor

headlights on andoff.

12 snapper.com

HourMeter (Select Models) -- The hour meter

measuresthe number of hours the key has been inthe RUN

position.

;_ ReverseMowing Option(RMO) -- The Reverse

Mowing Option allows for mowing (or useof other PTO

driven attachments)while traveling in reverse. If you choose

to mow in reverse,turn the RMO keyafter the PTOis

engaged.The L.E.D.light will illuminate, and the operator

canthen mow in reverse.Eachtime the PTOis engagedthe

RMOneedsto bereactivatedif desired.

Page 15

PTOSwitch- The PTO(PowerTake-Off)switch

engagesand disengagesattachments that usethe PTO.To

engagethe PTO,pull UPon the switch. Push DOWNto

disengage.Note that the operator must be seatedfirmly in

the tractor seatfor the PTOto function.

1_) Ignition Switch-- The ignition switch starts and

stops the engine, it hasthree positions:

©

0

OFF

RUN

START

Stops the engine andshuts offthe electrical

system.

Allows the engine to run andpowers the

electricalsystem.

Cranksthe enginefor starting.

J-- Seat AdjustmentLever-- The seat can beadjusted

forward and back. Movethe lever,position the seat as

desired, and releasethe leverto lockthe seatinto position.

TransmissionReleaseValve Lever -- The

transmission releasevalve lever deactivatesthe transmission

so thatthe tractor can be pushed by hand. See Pushing the

Tractorby Handin the Operationsection for operational

information.

Pa

•-'_ Fuel Tank-- Toremove the cap, turn

counterclockwise.

12V

Power Outlet(Select Models) -- Thepower outlet is

12V-DC.Accessory must be ratedat 9 amps or less.

NOTICE

Never leave the ignition switchin the RUN position

withthe enginestopped- thisdrainsthe battery.

4_

;I;

* GroundSpeed Pedals-- Thetractor's forward

ground speedis controlled by the forward ground speed

control pedal.Thetractor's reverse ground speedis

controlled by the reverseground speedcontrol pedal.

Depressingeither pedalwill increaseground speed.Note

that thefurther down the pedalis depressed,the faster the

tractor will travel.

;_ CruiseControl-- Thecruise control is usedto

lock the ground speed control in forward. The cruise control

hasfive lock positions.

_e,4 Mower HeightofCutAdjustment-- The mower

cutting height adjustment levercontrols the mower cutting

height. Themower cutting height can be set to oneof seven

positions between1-1/4 and4 in.

'' Fuel LevelGauge -- Displaysthe fuel levelin the

tank.

ParkingBrake--The parking brake knob is usedto

lock the parking brakewhen the tractor is stopped. Fully

depressingthe brake pedaland pulling up on the knob

engagesthe parking brake. Referto Parking BrakeFunction

below for afull explanation.

(0)

BrakePedal- Depressingthe brake pedalapplies

the tractor brake.

13

Page 16

Other Functions

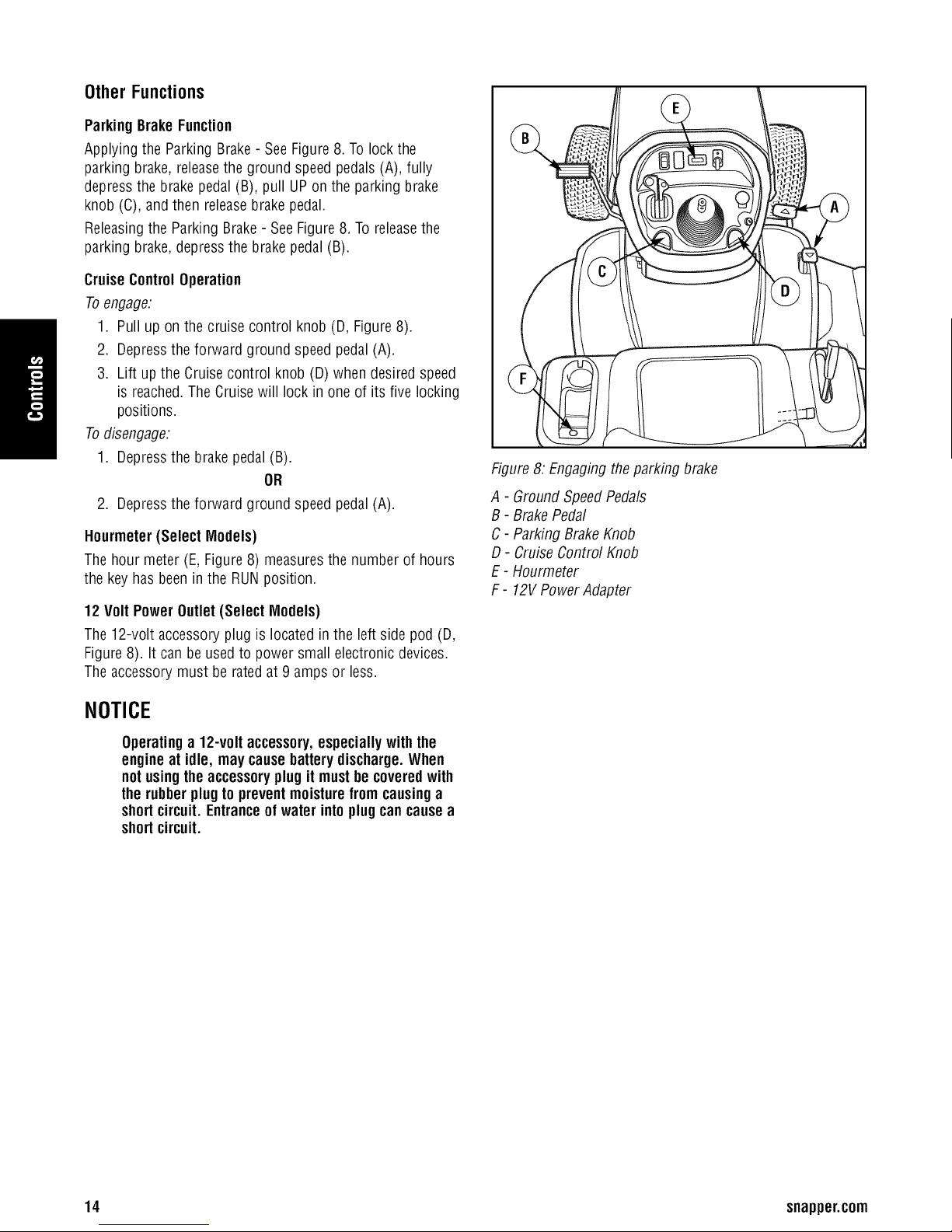

ParkingBrakeFunction

Applying the ParkingBrake- SeeFigure 8. To lock the

parking brake, releasethe ground speedpedals(A), fully

depress the brakepedal (B), pull UPon the parking brake

knob (C), and then release brake pedal.

Releasingthe Parking Brake- SeeFigure8. To releasethe

parking brake,depress the brake pedal (B).

CruiseControlOperation

Toengage:

1. Pull up on the cruise control knob (D, Figure8).

2. Depressthe forward ground speed pedal (A).

3. Lift up the Cruise control knob (D) when desired speed

is reached.The Cruisewill lock inone of its five locking

positions.

Todisengage:

1. Depressthe brake pedal(B).

OR

2. Depressthe forward ground speed pedal (A).

Hourmeter (Select Models)

The hourmeter (E, Figure8) measuresthe number of hours

the keyhas been in the RUNposition.

12 Volt Power Outlet(Select Models)

The 12-volt accessoryplug is located in the leftside pod(D,

Figure8). It can beusedto power small electronic devices.

Theaccessory must berated at 9 ampsor less.

Figure8: Engagingthe parking brake

A - GroundSpeedPedals

B - BrakePedal

C- Parking BrakeKnob

D- Cruise Control Knob

E- Hourmeter

F - 12VPowerAdapter

NOTICE

Operatinga 12-volt accessory,especiallywith the

engineat idle, may causebatterydischarge.When

notusingthe accessoryplug it mustbe coveredwith

therubberplugto preventmoisturefrom causinga

shortcircuit. Entranceofwater into plugcan causea

shortcircuit.

14 snapper.corn

Page 17

Operation

SafetyInterlockSystemTests

WARNING

Thisunitis equippedwithsafetyinterlockswitches

and othersafetydevices.Thesesafetysystemsare

presentforyoursafety:do notattemptto bypass

safetyswitches,andnevertamper withsafety

devices.Checktheir operationregularly.

Your unit is equippedwith a seatswitch safety system.

Checkthe seatswitch operation everyfall and spring with

the following tests.

TestI -- Engine

• PTOswitch

• Brakepedal

Test2 -- Engine

• PTOswitch

• Brakepedal

shouldNOTcrankif:

is ON,OR

is NOTfully depressed(parking brakeOFF),

SHOULDcrankif:

isOFF,AND

isfully depressed(parking brakeON)

, WARNING

Gasolineishighlyflammable andmustbe handled

with care. Neverfill the tank whenthe engineis still

hotfrom recentoperation.Do notallow openflame,

smokingor matchesin the area. Avoidover-filling

andwipe up anyspills.

NOTICE Q

Do notuse gasolinecontainingMETHANOL,gasohol

containingmorethan 10% ETHANOL,gasoline

additives,orwhite gas becauseengine/fuelsystem

damagecouldresult.

Adding Fuel

Toadd fuel:

1. Remove the fuel cap (A, Figure10).

2. Fill the tank. Do not overfill. Leaveroom inthe tank for

fuel expansion. Referto your engine manual for specific

fuel recommendations.

3. Install and hand tighten the fuel cap.

Test3 -- EngineshouldSHUTOFFif:

• Operator rises off seat with PTOengaged,OR

• Operator rises off seat with brakepedal NOTfully

depressed (parking brakeOFF).

Test4 -- Blade BrakeCheck

Mower bladesand mowerdrive belt should come to a

complete stop within five seconds after electric PTOswitch

is turned OFF(or operator risesoff seat). If mower drive belt

does not stop within five seconds, re-adjustthe PTOclutch

as describedin the ADJUSTMENTSsection or seeyour

dealer.

Test5 -- ReverseMow Option(RMO) Check

• Engineshould shut off if: PTOisengagedAND RMOis

not activatedAND reversepedal isdepressed.

• RMOlight should illuminate if: RMOis engagedAND

PTOswitch is activated.

Note: Oncethe engine has stopped, the PTOswitch must be

turned off after the operator returns to the seat in order to

start the engine,

WARNING

If the unitdoesnot passa safetytest, donotoperate

it. Seeyour authorizeddealer.Underno

circumstanceshouldyouattemptto defeat the

purposeofthesafety interlocksystem.

Besureto read all informationin the Operator

Safetyand Operationsectionsbefore attempting to

operatethis unit. Becomefamiliar withall ofthe controls

and howto stopthe unit.

15

Page 18

Starting the Engine

1. While sitting in the operator's seat,fully depress the

brake pedalor set the parking brake.

2. Make sure that your feet arenot depressingthe ground

speedcontrol pedalsand that the cruise control lever is

in neutral.

3. Disengagethe PTOclutch.

4. Setthe throttle to FULL.

5. Closethe choke.

Note:A warm engine maynot require choking.

6. Insert the ignition key andturn it to START.

7. After the enginestarts, move the engine throttle control

to half speed.Warm up the engine by running it for at

least 30 seconds.

8. Setthrottle to FULL.

Note: In theevent of an emergency the engine canbe

stopped by simply turning the ignition switch to STOP.Use

this method only in emergency situations. For normal engine

Tractorand Engine.

Stoppingthe Tractorand Engine

shut down follow theprocedure given inStopping the

1. Return the ground speedcontrol(s) to neutral.

2. Disengagethe PTOand wait for all moving parts to

stop.

3. Move the throttle control to SLOW position andturn the

ignition keyto OFF.Removethe key.

Driving the Tractor

1. Sit in the seat andadjust the seat so thatyou can

comfortably reachall the controls and see the

dashboarddisplay.

2. Engagethe parking brake.

3. Make surethe PTOswitch is disengaged.

4. Start the engine (seeStarting the Engine).

5. Disengagethe parking brakeand releasethe brake

pedal.

6. Depress the forward ground speedcontrol pedal to

travel forward. Releasethe pedalto stop. Notethat the

further down the pedalis depressedthe faster the

tractor will travel.

7. Stop the tractor by releasingthe ground speedcontrol

pedals, setting the parking brake,and stopping the

engine (see Stopping the Tractorand Engine).

Mowing

1. Set the mower cutting height to the desired leveland

set the gauge wheelsto the appropriate position (if

equipped).

2. Engagethe parking brake. Make surethe PTOswitch is

disengaged.

3. Start the engine (seeStarting the Engine).

4. Fully lower the mower using the attachment lift lever

and set cutting height.

5. Set the throttle to FULL.

6. Engagethe PTO(Mower Deck).

7. Begin mowing. SeeLawn Careand Mowing Information

tips on mowing patterns,lawn care,and

troubleshooting information.

8. When finished, shut off the PTOand raise the mower

using the attachment lift control lever.

9. Stop the engine (see Stopping the Tractorand Engine).

16 snapper.corn

Page 19

WARNING

The enginewill shutoffif the reversegroundspeed

pedalis depressedwhile the PTOis onandthe RMO

hasnotbeenactivated. The operatorshouldalways

turnthe PTOoffpriortodrivingacrosson roads,

pathsorany area thatmaybeusedbyothervehicles.

Suddenlossofdrivecouldcreatea hazard.

WARNING

Mowingin reversecan be hazardousto bystanders.

Tragicaccidentscanoccurif the operatoris notalert

tothe presenceof children.NeveractivateRMO if

childrenare present.Childrenare oftenattractedto

theunitand themowingactivity.

Mowingin Reverse

If an operator chooses to mow in reverse,the RMO system

can beused. Tousethe ReverseMowing Option (RMO) turn

the RMOkey afterthe PTOis engaged.The LED. light will

illuminate, andthe operator canthen mow in reverse.Each

time the PTOis engagedthe RMO needsto be reactivatedif

desired. The keyshould be removed to restrict accessto the

RMO feature.

AttachmentOperationin Reverse

If an operator chooses to operate a PTOdriven attachmentin

reverse,the RMOsystem can be used. Touse the Reverse

Mowing Option (RMO)turn the RMO keyafter the PTOis

engaged.The L.ED. light will illuminate, andthe operator

canthen operatethe attachment in reverse.Eachtime the

PTOis disengagedthe RMOneedsto bereactivated if

desired. The keyshould be removed to restrict accessto the

RMO feature.

LawnCareand MowingInformation

Howand When to Water, Fertilizeand Aerate

Most lawnsare watered too

often, but with too little

water.Howevertoo much

water can allow

developmentof diseases

with your lawn. It is best to

water the lawn only when

necessary,and then to

water it slowly, evenly,and

deeply- imitating a slow, soaking rain.

WhentoWater YourLawn- When the lawn beginsto wilt,

the grass'scolor dulls, or footprints stay compressed for

more than afew seconds, the lawn is beginning to dry out,

and needs additional moisture. The best time to water is

early morning to allow the water to soak deeply into the lawn

and reducethe amountthat evaporates in the hot afternoon

sun.

Howto Water YourLawn -The best method of watering a

lawn is to imitate a slow, soaking rain,applying about 1inch

of water.

Howto Fertilize YourLawn - Fertilizingwith a slow-release

fertilizer providesmissing nutrients which help create slow,

evengrowth. Rememberthat over-fertilizing can causeharm,

and that most fertilizing should be appliedin the spring so

that it will releaseinto the lawn through the summer.

AeratingYourLawn - Consider aeratingyour lawn in spring.

Using an aeratorto remove cores of soil from the lawn

increasesthe speedof clipping decomposition and

encouragesdeeper root growth by opening upthe soil and

permitting greater movement of water,fertilizer, and air.

How Highto Mow theGrass

Cutting the grasstoo short causesweak,thin grass plants,

which are easilydamagedby dry periods and pests.

Letting grass grow a bit longer - especiallywhen it is hot and

dry - reduces heat build-up, preservesneeded moisture and

protects the grass from heatdamageand other problems.

17

Page 20

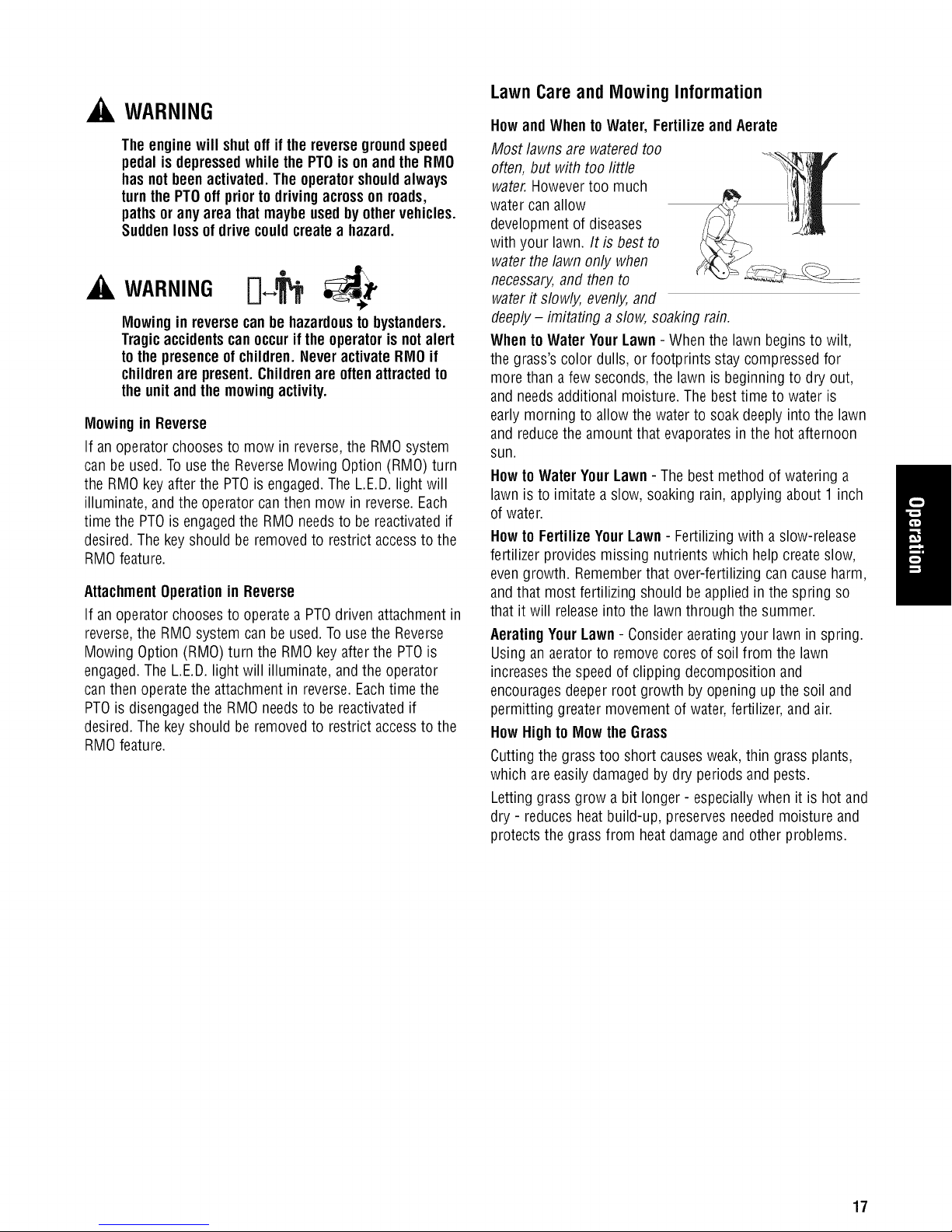

Cuttingofftoomuchatonetimeshockstheplant'sgrowth

systemandweakensthegrassplants.A good rule of thumb

is the 1/3 rule: to cut no more than one third of thegrass

height, and never more than 1inch at atime.

CutLessThan1/3

Optimalcutting

point at lessthan

1/3 fromtop of

grassblade

Cutting down to this

area contributes to

thatch problems

Tall GrassRequiresIncrementalCutting- Forextremelytall

grass, setthe cutting height at maximum for the first pass,

and then reset it to the desiredheight and mow asecond or

third time.

Don't cover the grass surfacewith a heavylayerof clippings.

CutHere On CutHere

FirstPass On

I_ if, IJ Is/ Pass

Second

Whenand How Oftento Mow

Thetime of dayand condition of the

grass greatly affectthe resultsyou'll

get when mowing. For the best

results, follow theseguidelines:

• Mow when the grass is

between 3-4 in. (7.5-10 cm)

high.

• Mow with sharp blades.Short

clippings of grass one inch or

shorter decompose more quickly than longer blades.

Sharp mower bladescut grass cleanlyand efficiently,

preventing frayed edgeswhich harmthe grass.

• Mow at time of day when the grass is cool and dry.

Lateafternoon or early evening often providethese

ideal mowing conditions.

• Avoid mowing after rainor even heavydew, and never

mulch when the grass is wet (moist grass does not

mulch well, andclumps beneaththe mowerdeck).

Note:Always operatetheengine at furlthrottle when

mowing.

ProperMowingSpeed

EngineSpeedand Ground

Speed- Always operate the

engine at full throttle when

mowing. If you hearthe

engine slowing down, you

are mowing too fast -

maintaining a slower ground

speedwill improve the

cutting efficiency of the

bladesand preventsmany common cutting problems.

Select an appropriate ground speedfor the thickness and

height of the grass you arecutting (3rd gearor slower for

manual gearmodels, or mid-range or slower for hydro

models). Ifyou hearthe engine slowing down you are

mowing too fast, usea slower ground speed.

How MuchGrassto Cut Off- Mow when the grass is 3-4 in.

(7.5-10 cm) long.Do not cut off more than 1 in.(2.5 cm) of

grass in a single pass.

18 snapper.corn

Page 21

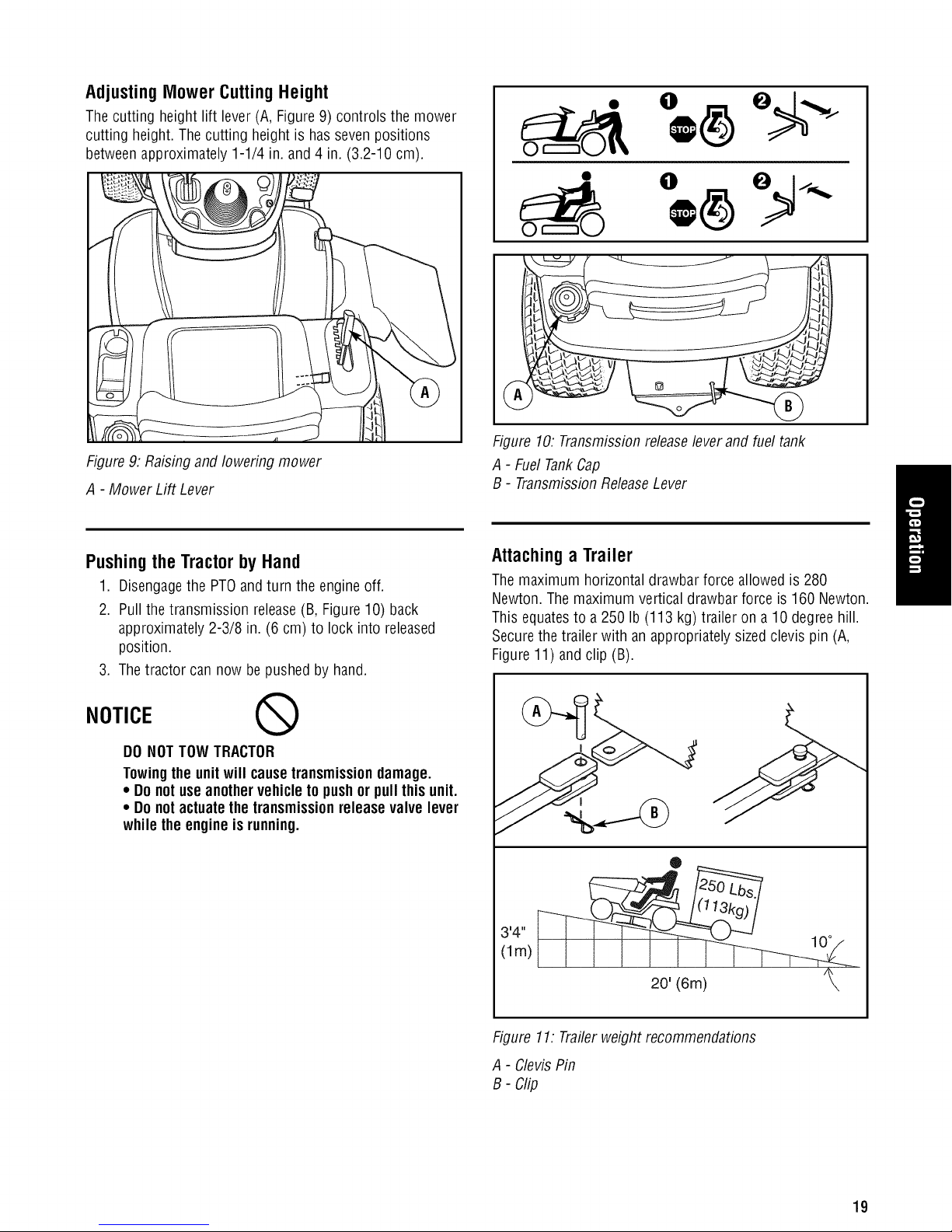

Adjusting Mower Cutting Height

Thecutting height lift lever (A, Figure9) controls the mower

cutting height.The cutting height is hasseven positions

betweenapproximately 1-1/4 in. and 4 in. 3.2-10 cm).

Figure 9: Raisingand lowering mower

A - Mower Lift Lever

\

JJJ, 7/

Figure 10. Transmissionreleaselever and fuel tank

A - FuelTankCap

B - TransmissionReleaseLever

Pushing the Tractor by Hand

1. Disengagethe PTOand turn the engine off.

2. Pull the transmission release(B, Figure10) back

approximately 2-3/8 in. (6 cm) to lock into released

position.

3. The tractor can now bepushed by hand.

NOTICE Q

DO NOTTOW TRACTOR

Towingthe unitwill causetransmissiondamage.

• Do notuse anothervehicle to pushor pull this unit.

• Do notactuatethe transmissionrelease valve lever

whilethe engineis running.

Attachinga Trailer

Themaximum horizontal drawbar force allowed is 280

Newton. The maximum vertical drawbar force is 160 Newton.

This equatesto a 250 Ib (113 kg) trailer on a 10 degree hill.

Securethe trailer with an appropriately sizedclevis pin (A,

Figure11) and clip (B).

I

1411

(lm)

J

®

10°

20' (6m)

Figure 11. Trailerweight recommendations

A - ClevisPin

B- Clip

19

Page 22

MaintenanceRecords

20 snapper.com

Page 23

Maintenance

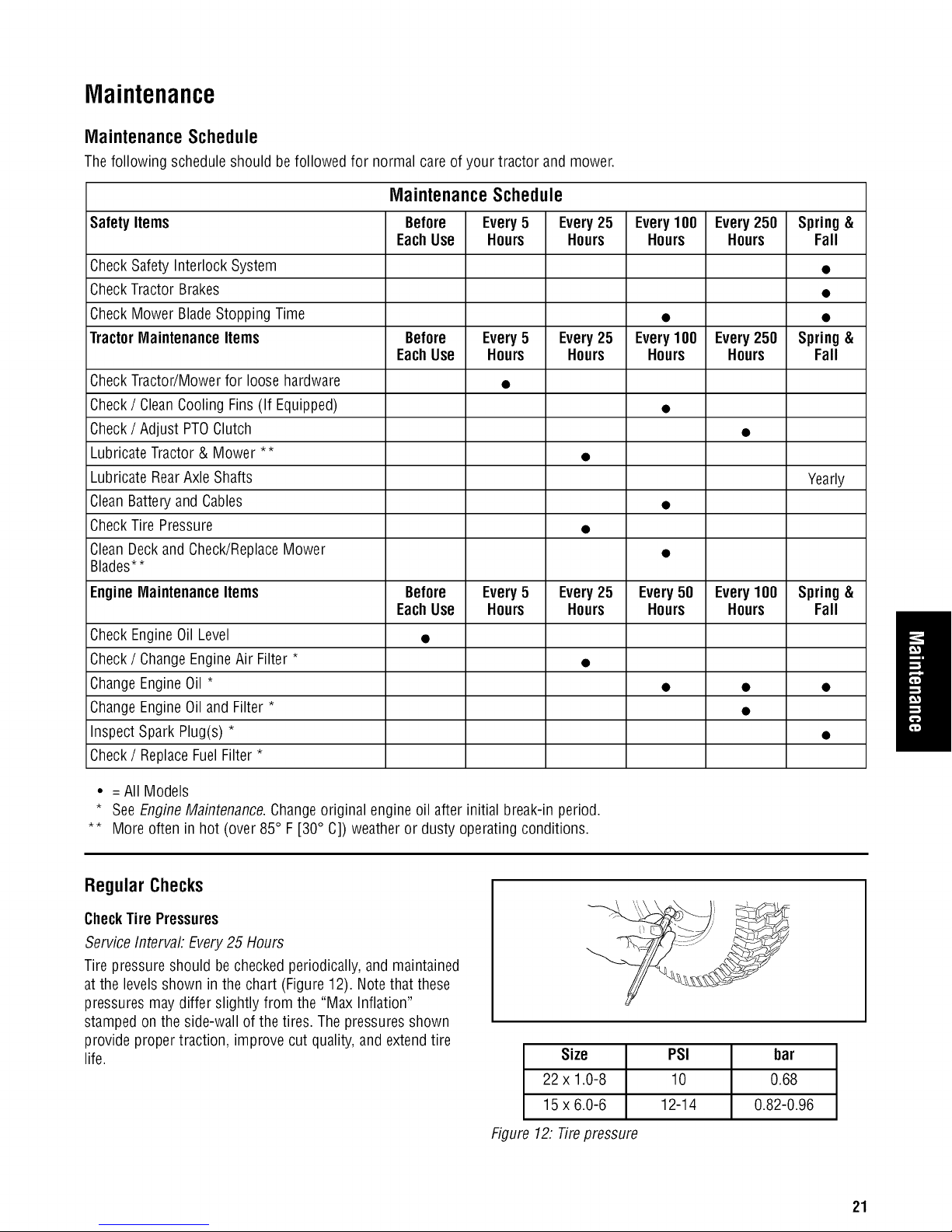

MaintenanceSchedule

Thefollowing schedule should be followed for normal careof your tractor andmower.

MaintenanceSchedule

SafetyItems Before Every5 Every25 Every100 Every250 Spring&

EachUse Hours Hours Hours Hours Fall

CheckSafety Interlock System •

CheckTractor Brakes •

CheckMower BladeStopping Time • •

TractorMaintenanceItems Before Every5 Every25 Every100 Every250 Spring&

CheckTractor/Mower for loose hardware •

Check/ CleanCooling Fins (If Equipped) •

Check/ Adjust PTOClutch •

Lubricate Tractor & Mower ** •

Lubricate Rear AxleShafts Yearly

CleanBattery and Cables •

CheckTire Pressure •

CleanDeck and Check/ReplaceMower •

Blades**

EachUse Hours Hours Hours Hours Fall

EngineMaintenanceItems Before Every5 Every25 Every50 Every100 Spring&

EachUse Hours Hours Hours Hours Fall

CheckEngine OilLevel •

Check/ ChangeEngineAir Filter * •

ChangeEngineOil * • • •

ChangeEngineOil and Filter * •

Inspect Spark Plug(s) * •

Check/ ReplaceFuelFilter *

• = All Models

* See EngineMaintenance.Changeoriginal engineoil after initial break-in period.

** More often in hot (over 85° F[30° C]) weather or dusty operating conditions.

Regular Checks

CheckTire Pressures

Service Intervah Every25 Hours

Tire pressureshould be checked periodically, and maintained

at the levelsshown in the chart (Figure12). Notethat these

pressures maydiffer slightly from the "Max Inflation"

stamped onthe side-wall of the tires. The pressuresshown

provide propertraction, improve cut quality, andextend tire

life.

Size

22 x 1.0-8

15 x 6.0-6

PSI bar

10 0.68

12-14 0.82-0.96

Figure 12: Tirepressure

21

Page 24

Safety InterlockSystemCheck

Service Interval: EveryFail and Spring

Checkthe function of the safety interlock system using the

test procedurefound inthe Operationsection of this manual.

If the tractor fails any of the tests, seeyour dealer.

BladeBrakeCheck

Service Interval: Every 100Hours or Failand Spring

Mower bladesand mowerdrive belt should come to a

complete stop within five seconds after the electric PTO

switch isturned off.

1. With tractor in neutral, PTOdisengagedand operator in

seat,start the engine.

2. Look over the left-hand footrest at the mower drive

belt. Engagethe PTOand wait severalseconds.

Disengagethe PTOand check the amount of time it

takesfor the mower drive belt to stop.

3. If mower drive belt doesnot stop within five seconds,

re-adjust the clutch or see your dealer.

PTOClutchAdjustmentCheck

Service Intervah Every250 Hrs.

Checkthe PTOclutch adjustment after every250 hours of

operation - or if the clutch startsslipping or will not engage.

Checkand adjust the clutch using the procedureoutlined in

the Troubleshooting,Adjustment, and Servicesection of this

manual.

4. Removethe battery (E).

5. Cleanthe battery compartment with a solution of

baking sodaand water.

6. Cleanthe batteryterminals and cable ends with awire

brush and batteryterminal cleaneruntil shiny.

7. Reinstall the battery (E) in the battery compartment.

Securewith the battery hold-down rod (C)and wingnut

and washer (D).

8. Re-attachthe battery cables, positive cables andcover

first (B) then the negativecables (A).

9. Coatthe cableendsand battery terminals with

petroleum jelly or non-conducting grease.

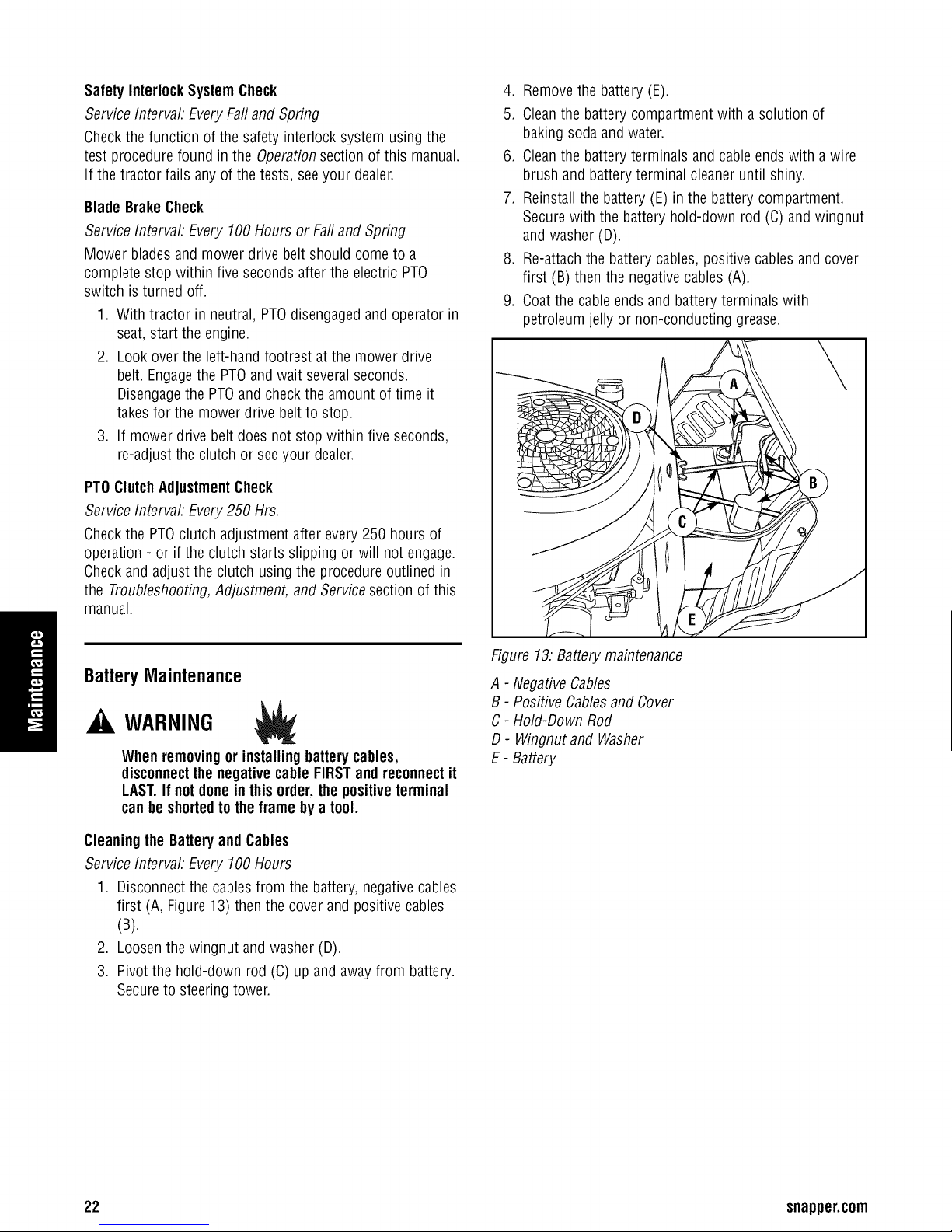

BatteryMaintenance

WARNING

Whenremovingor installingbatterycables,

disconnectthe negative cable FIRSTand reconnectit

LAST.If notdonein this order,the positiveterminal

canheshortedto the frame by a tool.

Cleaningthe Batteryand Cables

Service Intervah Every 100Hours

1. Disconnect the cablesfrom the battery, negativecables

first (A, Figure 13) then the cover and positivecables

(B).

2. Loosenthe wingnut and washer (D).

3. Pivot the hold-down rod (C) up and awayfrom battery.

Secureto steering tower.

Figure 13:Batterymaintenance

A - NegativeCables

B - Positive Cablesand Cover

C- Hold-Down Rod

D- Wingnut and Washer

E- Battery

22 snapper.com

Page 25

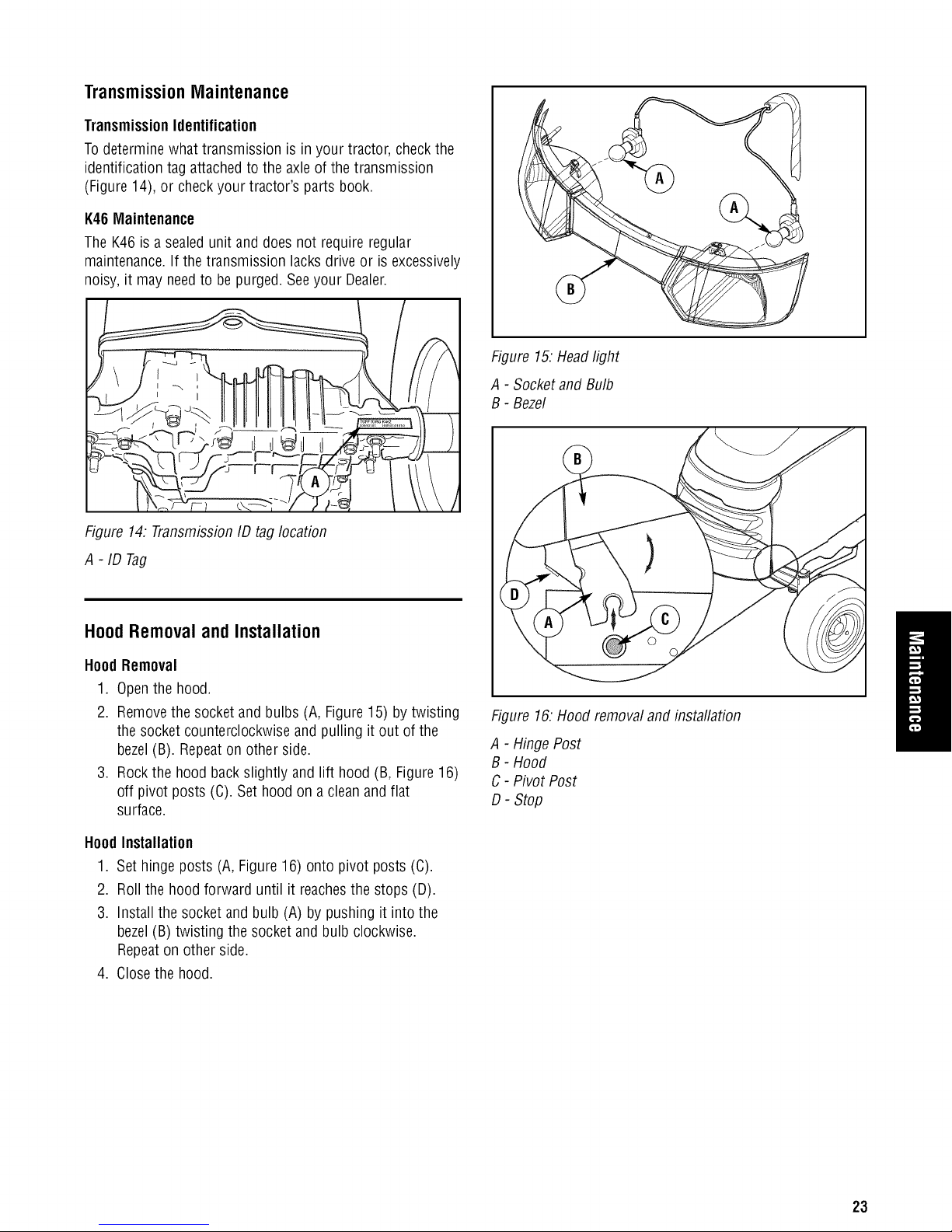

TransmissionMaintenance

TransmissionIdentification

Todetermine what transmission is in your tractor, checkthe

identification tag attachedto the axleof the transmission

(Figure 14), or checkyour tractor's parts book.

K46Maintenance

The K46is a sealed unit and does not require regular

maintenance. If the transmission lacks drive or is excessively

noisy, it mayneedto bepurged. Seeyour Dealer.

Figure 14: TransmissionID tag location

Figure 15.Headlight

A - Socketand Bulb

B - Bezel

A - ID Tag

Hood Removal and Installation

HoodRemoval

1. Openthe hood.

2. Removethe socketand bulbs (A, Figure15) by twisting

the socketcounterclockwise and pulling it out of the

bezel(B). Repeaton other side.

3. Rockthe hood backslightly and lift hood (B, Figure16)

off pivot posts (C). Set hood ona clean and flat

surface.

HoodInstallation

1. Set hinge posts (A, Figure16) onto pivot posts (C).

2. Roll the hood forward until it reachesthe stops (D).

3. Install the socketand bulb (A) by pushing it into the

bezel(B) twisting the socket andbulb clockwise.

Repeaton other side.

4. Closethe hood.

Figure 16.Hood removal and installation

A - HingePost

B - Hood

C- Pivot Post

D- Stop

23

Page 26

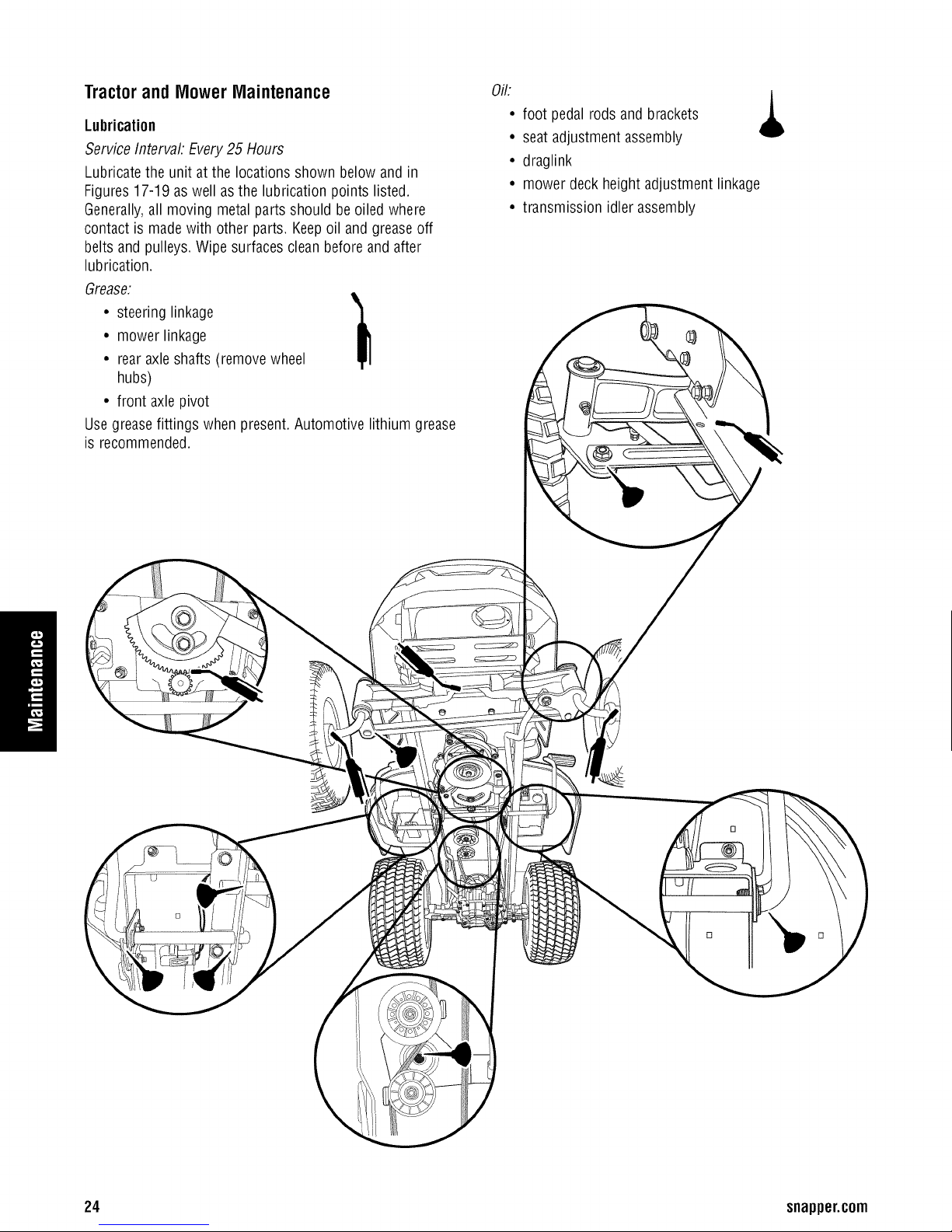

Tractorand MowerMaintenance

Lubrication

Service Intervah Every25 Hours

Lubricate the unit at the locations shown below and in

Figures 17-19 aswell asthe lubrication points listed

Generally,all moving metal partsshould beoiled where

contact is madewith other parts Keepoil andgreaseoff

belts and pulleys Wipe surfaces clean before and after

lubrication

Grease:

• steering linkage

• mower linkage

• rearaxle shafts (remove wheel

hubs)

• front axle pivot

Use greasefittings when present Automotive lithium grease

is recommended

Oil:

• foot pedal rods andbrackets ,_

• seat adjustment assembly

• draglink

• mower deckheight adjustment linkage

• transmission idler assembly

1

Q

24 snapper.com

D

Page 27

/

/

/

Figure 18:Lubricate decklinkage (38 in. shown)

Figure 17.Arbor lubrication points

LubricateRear Axle Shafts

Service Interval: Yearly

We recommend removingthe rearwheel hubs and

lubricating the axle shafts yearly. This preventsthe wheel

hubs from seizing onto the axleshaft andmakesfuture

service easier.

1. Turn off the ignition, turn off the PTO,engagethe

parking brake,and block the front tires.

2. Using ajack or chain hoist positioned atthe center of

the rearframe, carefully jack the unit up until the rear

tires are approximately1-2 in. (2.5-5 cm) off the

ground.

Note: For overallunit stability during service, donot jack rear

end higher than required for wheel removal

3. Support the rearof the unit onjackstands positioned

under the rearframe.

Note: Youraxle assembly may differ slightly from the

assembly pictured: the quantity of washers is adjusted to

allow a smaflamount of axleend-play.

4. Removethe hardware retaining the wheel assembly to

the axleand lubricatethe axleshaft using anti-seize

compound or lithium grease.

5. Reinstallthe components in reverseorder of

disassemblyand lower the unit. Besure the key (A,

Figure19) is in placein the axle keyway.

"

Figure 19:Rearaxle hardware

A - Key

B- Spacer

C - Wheeland Hub

D- Special Washer

E- Small Washer

F- E-Clip

G- Axle Cap

H- Large Washer

25

Page 28

: 3d

WARNING

Foryourpersonalsafety,do not handlethe sharp

mowerbladeswith barehands. Carelessor improper

handlingof blades may resultinseriousinjury.

WARNING

Foryour personalsafety,blade mountingcapscrews

musteachbe installedwithtwo springwashersora

hexwasherand springwasher,then securely

tightened.Torqueblade mountingnutto 70-80 ft-lb

(95-108 Nm). Torqueblademountingcapscrewto 45-

55 ft-lb (61-75 Nm).

Servicingthe Mower Blades

Service Intervah Every 100Hours orAs Required

1. Remove mower deck(see Mower DeckRemovaland

Installation in the Assembly section).

2. SeeFigure21. To remove bladefor sharpening, usea

block of wood to prevent blade rotation while loosening

the capscrew.

3. Rremovethe capscrew (D, Figure22), hexwasher (B),

spring washer (C), and blade.

4. Use a file to sharpen bladeto a fine edge. If bladeis

damaged, it must be replaced.

5. Balancethe bladeas shown in Figure20. Centerthe

blade'shole on anail lubricated with a drop of oil. A

balancedbladewill remain level.

.

Reinstallthe blade(Figures22) with thetabs pointing

up toward the mower deckasshown.

7.

Reinstallthe hexwasher (B, Figure 22), spring washer

(C) andcapscew (D). Use awooden block (A) to

prevent blade rotationwhile tightening the nut (D) to

45-55 ft-lb (61-75 Nm).

Figure20: Balancingthe blade

A - Workbench

B - Nail

Figure21: Bladeremoval - follow arrow to loosen

26 snapper.com

Figure22: Bladeinstallation

A - 4x4 WoodBlock

B - HexWasher

C- Spring Washer

D- Blade Capscrew

Page 29

EngineMaintenance

Checkand Fill EngineOil

Service Interval. BeforeEachUse,and Every 8 Hours

1. Turn the engine off, and set the parking braketo PARK.

2. Cleanthe areaaround the dip stick (C,Figure23).

3. Removethe dip stick (C) and clean it with a paper

towel.

4. Insert the dip stick (C) back into the engine. Threadthe

cap backonto the tube.

5. Removethe dip stick and readthe oil level.Theoil level

should bebetweenthe FULLand ADDmarks (D). If not,

add oil according to the oil recommendations chart

(Figure 23).

Figure23: Briggs & Stratton two cylinder models

A - OilDrain Valve

B - OilFilter

C - Dip Stick

D -CheckingOil Level

27

Page 30

Oil DrainValve Operation

1. Place a suitable container with a4 quart capacity under

the oil drain valve (A, Figure23 or 24).

2. Loosen or removethe dip stick (C,Figure23).

3. Wipe oil drain valve (B, Figure24) and cover (C)with

paper towel or rag.

Note: Sliding a hose with a 1/2 in. (12.5 ram) inside diameter

tube over the valvenipple may aidin guiding the draining oil.

4. Rotatethe drain valve (B) counter clockwise and pull

out 1/4 in. (6.35 mm) for engineoil to drain. Allow

ampletime for complete drainage.

5. After all the oil hasdrained, close the oil drain valve (B)

by pushing in androtating clockwise to close.

6. Wipethe nipple (D) with paper towel or rag. Install the

cover (C)over nipple (D).

ChangeEngineOil

Service Intervah 50 Hours or Onceper Season

Oil Capacity: Approximately 1-7/8 quarts (1.8 L) without filter

change.

Note: Changeengine oil whilethe engine is warm. Run the

engine for a few minutes, then shut the engine off and allow

it to cool from hot to warm.

1. Cleanthe area around the dip stick (C, Figure23) and

oil drain valve(A).

2. Drain engine oil. See OilDrain ValveOperationabove.

Figure24: Oildrain valve -closed (left view), open (right

view)

A - EngineBlock/Valve Base

B - OilDrain Valve

C- Cover

D- Nipple

Useoil classifiedAPI Service ClassSF,

SG,SH,SJ or better withSAEViscosity:

I r

NN

Change EngineOil and Filter

Service Interval: 100 Hours or Onceper Season

3. Fillthe crankcasewith oil. See CheckEngine Oil Level

Oil Capacity: Approximately 2 quarts (1.9 L) with oil filter

change.

Note. Changeengine oil whilethe engine is warm. Run the

engine for a few minutes, then shut the engine off and allow

it to cool from hot to warm.

1. Cleanthe area around the dip stick (C, Figure23) and

oil drain valve(A).

2. Drain engine oil. See OilDrain ValveOperationabove.

3. Removethe oil filter (B). Discardthefilter.

4. Using a drop of oil on your finger tip, wet the rubber

gasketon the bottom of the new filter.

°F -20 0 20 32 40 60 80 100

°C -30 -18 -7 O 4 16 27 38

*CAUTION:Air cooled engines run hotter than automotive engines.

The use of non-synthetic multi-viscosity oils (5W-30, 1OW-3O,etc,)

in temperatures above 400F (4°C)will result inhigher than normal

oil consumption. When using a multi-viscosity oil, check oil level

more frequently.

**CAUTION: SAE30 oil, if used below 40oF(4°C),will result in hard

starting and possibleengine bore damagedue to inadequate

lubrication.

Figure25. Recommendedengine oil - Briggs & Stratton

models

5. Turn the filter clockwise until the rubber gasketmeets

the filter base.Thenturn 1/2 to 3/4 turn more.

6. Fill the crankcasewith oil. See CheckEngine Oil Level

7. Test run the engineto checkfor leaks.Stopthe engine

for 1 minute, then recheckthe oil level.

28 snapper.com

Page 31

Air Filter and Pre-Cleaner Service

Service Intervah Every25 hours or as required.

1. Loosen the air filter cover screws (A, Figure 26) and

removethe air filter cover.

2. Locatethe air filter cartridge (A, Figure 27). Pull up on

the front edgeof the cartridge until it snaps out of

place.

3. Inspect the cartridge for dirt or damage.

If the thin foam sleevesurrounding the filter is

damaged, replacethe filer. DONOToil the foam sleave

or cartridge. If there is oil of heavy dirt onthe

cartridge, replaceit.

DONOTusepressurized air or solvents to cleanthe

filter cartridge.

Removeany dirt from the air filter housing.

4. Replacethe cartridge by aligning the hole of the

cartridge with the air vent (A, Figure28).

5. Pushthe cartridge in toward the engine until it snaps

into place.

6. Reinstallthe air filter cover andtighten the screws (A,

Figure26).

Figure27. Air Filter Removal

A - FilterCartridge

Figure26. Air Filter Cover

A - Air FilterCover Screws

Figure28. Air Filter Installation

A - FilterCartridge

29

Page 32

ReplaceSpark Plug

Service Intervah Yearly

Spark PlugGap:.030 in. (.76 mm)

ReplacementSpark Plug: ResistorSpark Plug,Champion

RC12YC

1. Stop the engine andallow it to cool.

2. SeeFigures 29. Cleanthe area around the spark plug.

3. Removethe spark plug.

4. Checkthe sparkplug gap. It should be .030 in. (see

Figure29).

5. Reinstallthe plug into the cylinder head.Torquethe

plug to 180 in-lb (20 Nm).

=

030'

Storage

Beforeyou store your unit for the off-season, readthe

WARNING

Neverstorethe unit(withfuel) inan enclosed,poorly

ventilatedstructure.Fuelvaporscantravel to an

ignitionsource(suchas a furnace,water heater,etc.)

and causean explosion.

Fuelvaporis also toxictohumansandanimals.

Maintenanceand Storage rulesand information in the

OperatorSafety section, then perform the following steps:

• Disengagethe PTO,set the parking brake,and remove

the key.

• Perform enginemaintenanceand storage measures

listed in the engine owner's manual. This includes

draining the fuel system, or addingstabilizerto the fuel

(do not store a fueled unit in anenclosed structure -

seewarning).

• Battery life will be increasedif it is removed, put in a

cool, dry placeand fully charged about once a month.

If the battery is left in the unit, disconnectthe negative

cable.

Beforestarting the unit after it has beenstored:

• Check all fluid levels. Checkall maintenance items.

• Perform all recommendedchecks and procedures

found the Operationsection.

• Allow the engine to warm up for several minutes before

use.

Figure29: Sparkplug gapping

30 snapper.com

Page 33

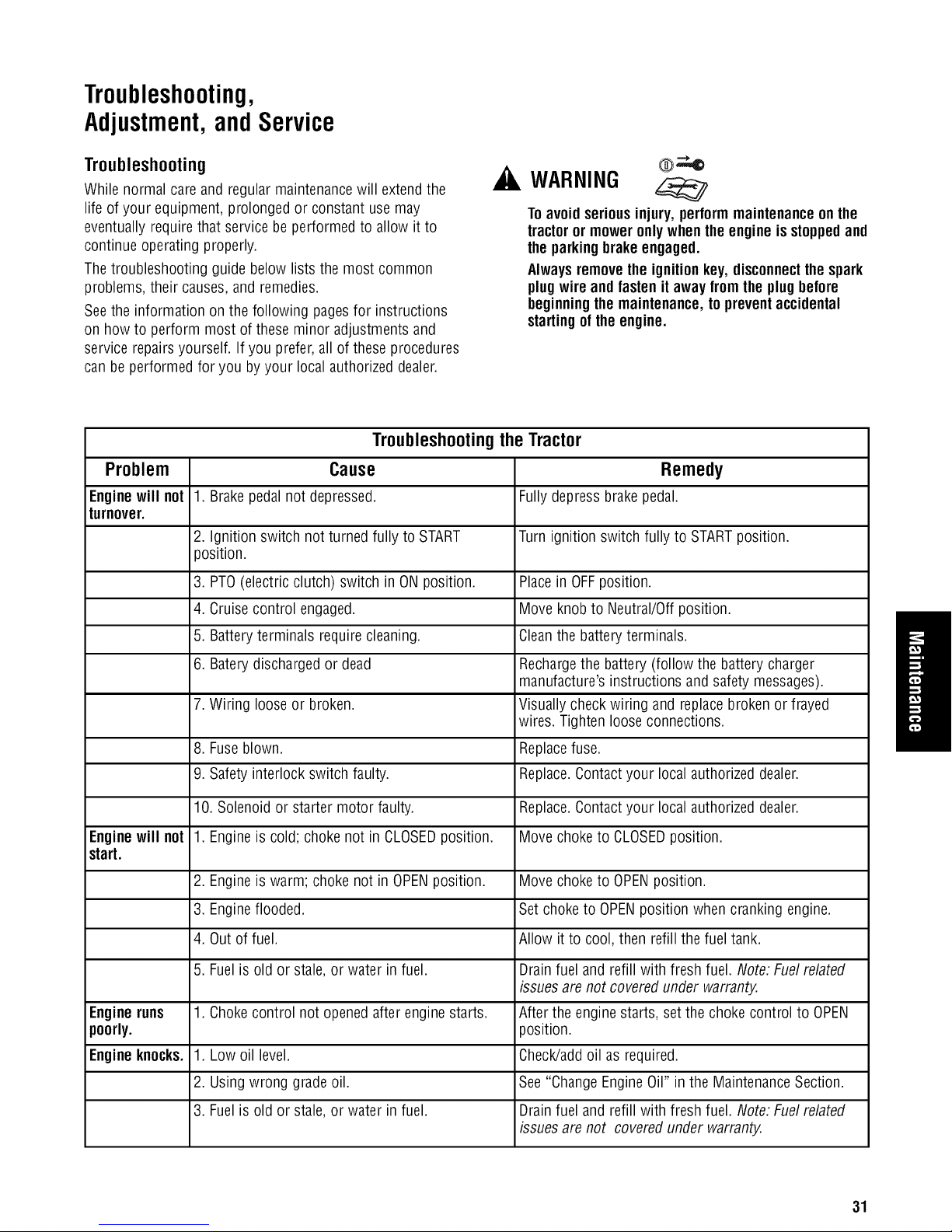

Troubleshooting,

Adjustment,andService

Troubleshooting

While normal care and regular maintenancewill extendthe

life of your equipment, prolonged or constant use may

eventually requirethat service be performed to allow it to

continue operating properly.

Thetroubleshooting guide below lists the most common

problems, their causes,and remedies.

Seethe information on the following pagesfor instructions

on how to perform most of these minor adjustmentsand

service repairsyourself. If you prefer, all of theseprocedures

can beperformed for you by your local authorized dealer.

TroubleshootingtheTractor

Problem Cause Remedy

Enginewill not 1. Brakepedal not depressed. Fullydepress brake pedal.

turnover.

2. Ignition switch not turned fully to START Turn ignition switch fully to STARTposition.

position.

WARNING

Toavoidseriousinjury, performmaintenanceonthe

tractoror moweronlywhentheengine is stoppedand

theparkingbrakeengaged.

Alwaysremovethe ignitionkey, disconnectthespark

plugwire and fastenitaway fromthe plugbefore

beginningthemaintenance,to preventaccidental

startingof theengine.

3. PTO(electric clutch) switch in ONposition. Placein OFFposition.

4. Cruisecontrol engaged. Move knob to Neutral/Offposition.

5. Batteryterminals require cleaning. Cleanthe battery terminals.

6. Baterydischarged or dead Rechargethe battery (follow the battery charger

manufacture'sinstructions andsafety messages).

7. Wiring loose or broken. Visuallycheck wiring and replacebroken orfrayed

wires. Tightenlooseconnections.

8. Fuseblown. Replacefuse.

9. Safetyinterlock switch faulty. Replace.Contactyour local authorized dealer.

10. Solenoidor starter motor faulty. Replace.Contactyour local authorized dealer.

Enginewill not 1. Engineis cold; choke not in CLOSEDposition. Movechoke to CLOSEDposition.

start.

2. Engineis warm; choke not in OPENposition. Move choketo OPENposition.

3. Engineflooded. Set choketo OPENposition when cranking engine.

4. Outof fuel. Allow it to cool,then refill the fueltank.

5. Fuelis old or stale,or water in fuel. Drainfuel and refill with fresh fuel. Note:Fuel related

issuesare not covered under warranty.

Engine runs 1. Chokecontrol not opened after enginestarts. After the engine starts, set the chokecontrol to OPEN

poorly, position.

Engineknocks. 1. Low oil level. Check/addoil as required.

2. Usingwrong gradeoil. See "ChangeEngineOil" in the MaintenanceSection.

3. Fuelis old or stale,or water in fuel. Drainfuel and refill with fresh fuel. Note:Fuel related

issuesare not covered under warranty.

31

Page 34

Troubleshootingthe Tractor(Continued)

Problem Cause

Excessiveoil consumption. 1. Engine running too hot.

2. Too much oil in crankcase.

3. Using wrong weight oil.

Engineexhaustis black.

Engineruns,but tractorwill not

drive.

.

Chokeset to CLOSEwhen engine

is running.

.

oo much oil in crank case.

1.

Parking brakeis engaged.

2.

Ground speed control pedals not

depressed.

Transmission releaselever in

3.

"push" position.

.

Drive belt slips.

Drive belt is broken

5.

Remedy

Cleanengine fins, blower screen andair

cleaner.Cleanradiator screen.

Checkthe oil level, drainexcess oil as

required.

See"Change EngineOil" in the

MaintenanceSection of operator's manual

for complete oil specifications.

Setchoke to OPENas soon as engine

starts.

Checkthe oil level, drainexcess oil as

required.

Disengageparking brake.

Depress3edals.

Stop engmeand move into drive

position.Seeyour Dealer.

Seecause and remedy below.

Seeyour Dealer

Tractordrivebelt slips.

Brakewill nothold.

Tractorsteershardor handles

poorly.

1.

Pulleys or belt greasy or oily.

Belt stretchedor worn.

2.

3.

Idler pulley pivot bracket "frozen"

in declutched position.

Internal brakeworn.

1. Seeyour dealer.

1.

Improper tire inflation

Cleanas required.

Seeyour Dealer.

Removeidler pulley bracket, cleanand

lubricate.

Checkand correct.Checkandtighten any

loose connections. SeeSteeringGear

Adjustment.

2. Front wheel spindle bearingsdry.

GearAdjustment.Greasespindles. See

Tractorand Mower Maintenancein the

Maintenancesection.

3. Steering linkage is loose.

Checkand correct.Checkandtighten any

loose connections.

32 snapper.com

Page 35

Troubleshootingthe Mower

Problem Remedy

Mower will not raise. 1. Attachor repair.

Mower cut is uneven.

Mower cut is rough looking.

Enginestalls easilywith mower

engaged.

Excessivemower vibration.

Lift linkagenot properly attached

or damaged.

,

Mower not leveledproperly.

2.

Tractortires not inflated equally or

properly.

.

Engine speedtoo slow.

2.

Ground speed too fast.

Bladesare dull.

3.

.

Mower drive belt slipping because

it is oily or worn.

5.

CheckPTO(Electric Clutch)

Adjustment.

6.

Bladesnot properly fastened to

arbors.

1.

Engine speedtoo slow.

2.

Ground speed too fast.

3.

Dirty or cloggedair filter.

4.

Cutting height settoo low.

5.

Dischargechute jamming with cut

grass.

6.

Engine not up to operating

temperature.

7.

Starting mower intall grass.

1.

Blade mounting screws are loose.

2.

Mower blades, arbors,or pulleys

are bent.

3.

Mower bladesare out of balance.

Cause

See Leveling the Mower in this section.

See Regular Checksin the Maintenance

section.

Setto full throttle.

Slow down.

Sharpen or replaceblades.See Tractorand

Mower Maintenancein the Maintenance

section.

Cleanor replace belt as necessary.

SeeAdjustments section.

See Tractor and Mower Maintenancein the

Maintenancesection.

Setto full throttle.

Slow down.

SeeEngine Maintenancein the

Maintenancesection.

Cut tall grass at maximum cutting height

during first pass.

Cut grass with discharge pointing toward

previously cut area.

Runenginefor severalminutes to warm-

up.

Start the mower in aclearedarea.

Tighten to 45-55 ft-lb (61-75 Nm).

Checkand replaceas necessary.

Remove,sharpen,and balanceblades. See

Tractorand Mower Maintenancein the

Maintenancesection.

Excessivebelt wear or breakage.

Mower drive belt slips or fails to

drive.

4. Belt installed incorrectly.

1. Bent or rough pulleys.

2. Using incorrect belt.

1. Idler pulley spring brokenor not

properly attached.

2. Belt stops out of adjustment.

3. Mower drive belt broken.

4. PTOclutch out of adjustment.

Reinstallcorrectly.

Repairor replace.

Replacewith correct belt.

Repairor replaceas needed.

Checkbelt stops.

Replacedrive belt.

Adjust PTOclutch.

33

Page 36

Adjustments

PTOClutchAdjustment

Seat Adjustment

Theseat can be adjustedforward and back.Move the lever

(A, Figure30), position the seat as desired,and releasethe

leverto lock the seatinto position.

Figure30: Seatadjustment

A - SeatAdjustment Lever

BatteryCharging

WARNING

Keepopenflames andsparksaway fromthe battery;

thegassescomingfrom it are highlyexplosive.

Ventilatethe batterywell duringcharging.

A dead battery or one too weakto start the engine may be

the result of a defect in the charging system or other

electrical component. If there is anydoubt about the cause

of the problem, seeyour dealer.If you needto replacethe

battery, follow the steps under Battery Maintenance in the

Maintenancesection.

Tochargethe battery,follow the instructions provided bythe

battery charger manufactureras well as allwarnings

included in the safety rules sections of this book. Chargethe

battery until fully charged.Donot chargeat a rate higher

than 10 amps.

WARNING

Toavoidseriousinjury, performadjustmentsonly

with enginestopped,keyremovedandtractor on

level ground.

Checkthe PTOclutch adjustment after every250 hours of

operation. Also perform the following procedure if the clutch

is slipping or will not engage,or if a newclutch has been

installed.

1. Remove key from ignition switch and disconnect spark

plug wires to prevent the possibility of accidental

starting while the PTOis beingadjusted.

2. See Figure31. Notethe position of the 3adjustment

windows (A) in the sideof the brake plateand the

nylock adjustment nuts (B).

3. Insert a .012 in.-.015 in. (2,5-4 mm) feeler gauge(C)

through eachwindow, positioning the gauge between

the rotor faceandthe armature face as shown in

Figure32.

4. Alternatelytighten the adjustment nuts (B, Figure31)

until the rotor face andarmature face just contactsthe

gauge.

5. Checkthe windows for an equal amount of tension

when the gaugeis inserted and removed,and makeany

necessaryadjustments bytightening or loosening the

adjustment nuts.

Note: Theactual air gapbetween the rotor and armature may