Page 1

Safety Instruction & Operator's Manual

8NAPPER "HI.VAC

I

WALK BEHIND

MOWERS

MODELS:

21351

21351D

_21351PD

21401

21401S

21401P

21401PS

21401PD

214X1

214XIR

214XIR--2

214XIP

214XIPS

214XIPR

214XIPR---2

Thank you for buying a SNAPPER product! Before operating your mower, read this manual carefully

and pay particular attention to the Important Safety Instructions on page 2. Remember that mowers

and all power equipment can be dangerous if used improperly and keep in mind that safety requires

careful use in accordance with the instructions and .... common sense!

This manual covers all Snapper 21" design series I (last numeral in the five digit model designation)

walk behind mowers. Models without letter suffixes following the five digit designation are push

models equipped with Kwik-N-Ezy grass catcher. The letter suffix D indicates side discharge, P in-

dicates self-propelled, S indicates electric start, R indicates a premium engine and X in the fourth

digit indicates an extra tough version. The -2 suffix indicates the unit is powered by a 2-cycle engine.

Differences are pointed out wherever pertinent throughout the manual.

SNAPPER POWEREQUIPMENT[:_/-.-I..=;_. _:_:_i_i_i:i_____,""i:___"""ii::ii::iii!

McDonouqh GA 30253 / _oo-_J_o:o-,-::!::!::!::i::iiiREV_S_ON417/86)iiiiii!i:_

• ...:.:,:...:.:.,;:;:;:;:;.;t,;.;1.1...0.........,..-.-.-.-.-.........-.-

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Failure to comply with the following instructions may result in serious injury to the operator or other

persons. The owner of the mower must understand these instructions and, furthermore, must allow only persons

who understand these instructions to operate the mower. Each person operating the mower must be of sound

mind and body and must not be under the influence of any substance which might impair vision, dexterity, or

judgement. If you have any questions pertaining to your mower which your dealer cannot answer to your satisfac-

tion, call or write the Customer Service Department at SNAPPER POWER EQUIPMENT, McDonough

Georgia,30253. (Phone 404-957-9141).

TRAINING OPERATION

1.

Read this Manual carefully and question your dealer 1.

if something is not clear. Should the dealer be

unavailable or unable to answer to your satisfaction,

write or call our Customer Service Department at the 2.

factory. Be thoroughly familiar with the controls and

proper use of the equipment.

2. DO NOT allow children in yard when mower is

operated.

Do not change engine governor settings or overspeed

engine.

Do not put hands or feet near or under rotating parts.

Keep clear of discharge area while engine is running.

,

Stop engine when crossing gravel drives, walks, or

roads, and under any conditions where thrown ob.

jects might be a hazard.

3. DO NOT allow pre-teenager children to operate 4.

mower.

4,

Only responsible teenagers with mature judgement

shall be allowed to operate mower and only under

close supervision.

5,

Keep the area clear of all persons, particularly small

children, and pets.

PREPARATION 6.

1,

Never operate mower without proper guards, plates,

safety switches, or other safety protective devices in

place and properly connected. Inspect to determine

that these safety devices are installed properly, are

in good repair, and operate properly. If the condition

or operation of these devices are questionable, they

must be repaired or replaced before using the mower.

2.

Thoroughly inspect the area where the mower is to

be used and remove all stones, sticks, wire, bones

and other foreign objects. Also note the location of

holes, stumps, and other possible hazards.

3,

Do not operate mower when barefoot or wearing

open sandals. Always wear substantial footwear and

long pants.

4,

Fill gasoline tank before starting engine. Use approv-

ed gasoline container. Do not smoke near open

gasoline container. Do not fill gasoline tank indoors

or when engine is running. Allow engine to cool for at

least ten minutes before refilling. Wipe off any spill-

ed gasoline before starting engine. Do not run engine

indoors.

5, Make sure that the traction drive clutch control is

disengaged before starting engine.

6,

Never attempt to make a wheel height adjustment

while the engine is running.

After striking a foreign object or if mower vibrates ab-

normally, stop the engine, disconnect and secure

spark plug wire. Inspect the mower for any damage

and repair the damage.

5,

Stop engine whenever you leave the operating posi.

tion behind the handle for any reason, including emp.

tying grass bag and making any adjustments,

repairs, or inspections.

Before cleaning, repairing or inspecting, make cer-

tain blade and all moving parts have stopped.

Disconnect and secure spark plug wire away from

plug to prevent accidental starting.

7,

Stop engine and wait until the blade comes to com.

plete stop before removing grass bag andlor unclogg-

ing adapter.

8,

Mow across steep slopes, never up.and.down. Exer-

cise caution when changing directions on slopes. Do

not mow excessively steep slopes.

MAINTENANCE AND STORAGE

1,

Keep all nuts, bolts, and screws tight to be sure

mower, is in safe operating condition.

2,

Never store mower with gasoline in the tank inside of

a building where fumes may reach an open flame or

spark. Allow engine to cool before storing in any

enclosure.

3,

To reduce fire hazard, keep mower free of grass,

leaves or excessive grease.

4,

Check grass bag assembly frequently for wear or

deterioration. Replace with new bag if loose seams

or tears are evident. Replace slider or bag adapter if

broken or cracked.

7,

When mowing over rough ground or in tall grass,

mower must be set in highest cutting position.

8,

Mow only in daylight or in good artificial light.

.

Never operate mower in wet grass. Always be sure of

your footing; keep a firm hold on the handle and walk;

never run.

-2-

5.

Have your mower inspected and serviced each year

by an authorized Snapper dealer. Determine if any

additional devices are available which might upgrade

the safety of your mower.

,

Factory specified Snapper replacement parts must

be used to assure adequate protection against in-

jury.

Page 3

PRE-START CHECKS

Before each start-up, check the following and/or perform

the service specified as needed.

• CHECK guards, grass bag and adapter or side discharge

chute to make sure these items are in proper position and

securely tightened. NOTE: The tab on inside rear edge of

the adapter or side chute must push the interlock spring in

toward the center of the mower. If improperly installed, the

engine cannot be started.

oCLEAN surfaces to remove dust, dirt, clippings par-

ticularly from cooling air intake screen on engine to pre-

vent overheating.

• CHECK oil level in 4-cycle engine and add oil as needed

to bring the level up to, but not over, full mark.*

• CHECK cutting height and adjust, as needed, to suit

prevailing grass conditions before starting(Refer to height

adjusting procedure on page 4).

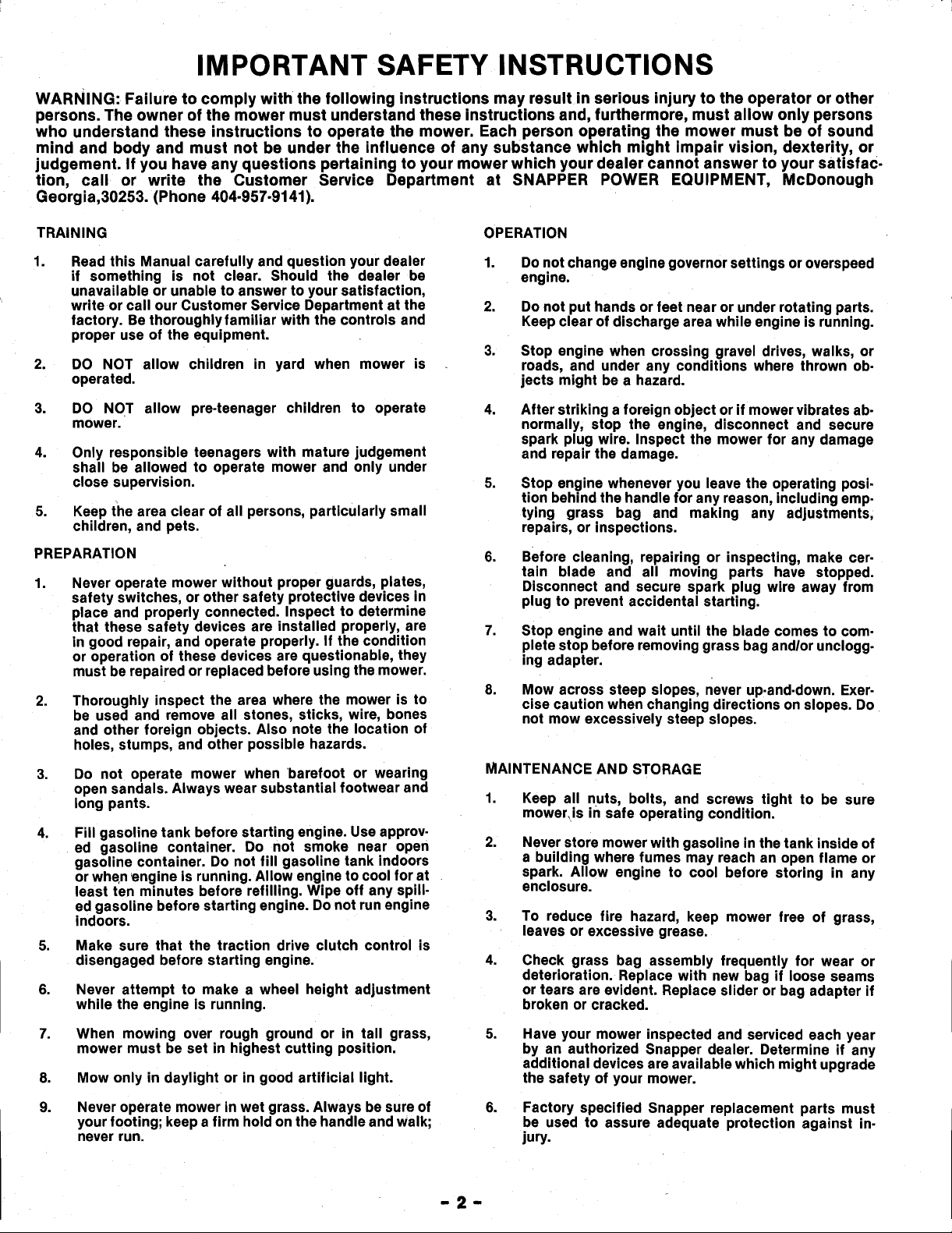

(_1. ENGINE CONTROL

2. BLADE CONTROL

3. WHEEL DRIVE CONTROL

4. GROUND SPEED CONTROL

5. ELECTRIC START KEYSWlTCH

FIGURE 1 - LOCATION OF CONTROLS

OPERATING PROCEDURE

Keep the important safety instructions in mind when

operating the mower. For easier starting, move the mower

to an area where the cutting blade can turn free of tall

grass. Know beforehand how to stop the mower in prepara-

tion for possible emergencies. The engine (and blade) is

stopped by releasing the BLADE CONTROL or by pulling

the ENGINE CONTROL rearward to STOP position. For-

ward motion of self.propelled models is stopped by releas-

ing the WHEEL DRIVE control. Refer to figure 1 for location

of these controls.

• FILL FUEL TANK after pushing mower outdoors where

fumes will be safely dissipated. On 2-cycle engine, use the

correct fuel to oil ratio.*

*See engine manual for fuel & oil specifications.

STARTING-STOPPING ENGINE

Stop engine (& blade) by releasing the BLADE CONTROL

or pulling the ENGINE CONTROL rearward to STOP posi-

tion.

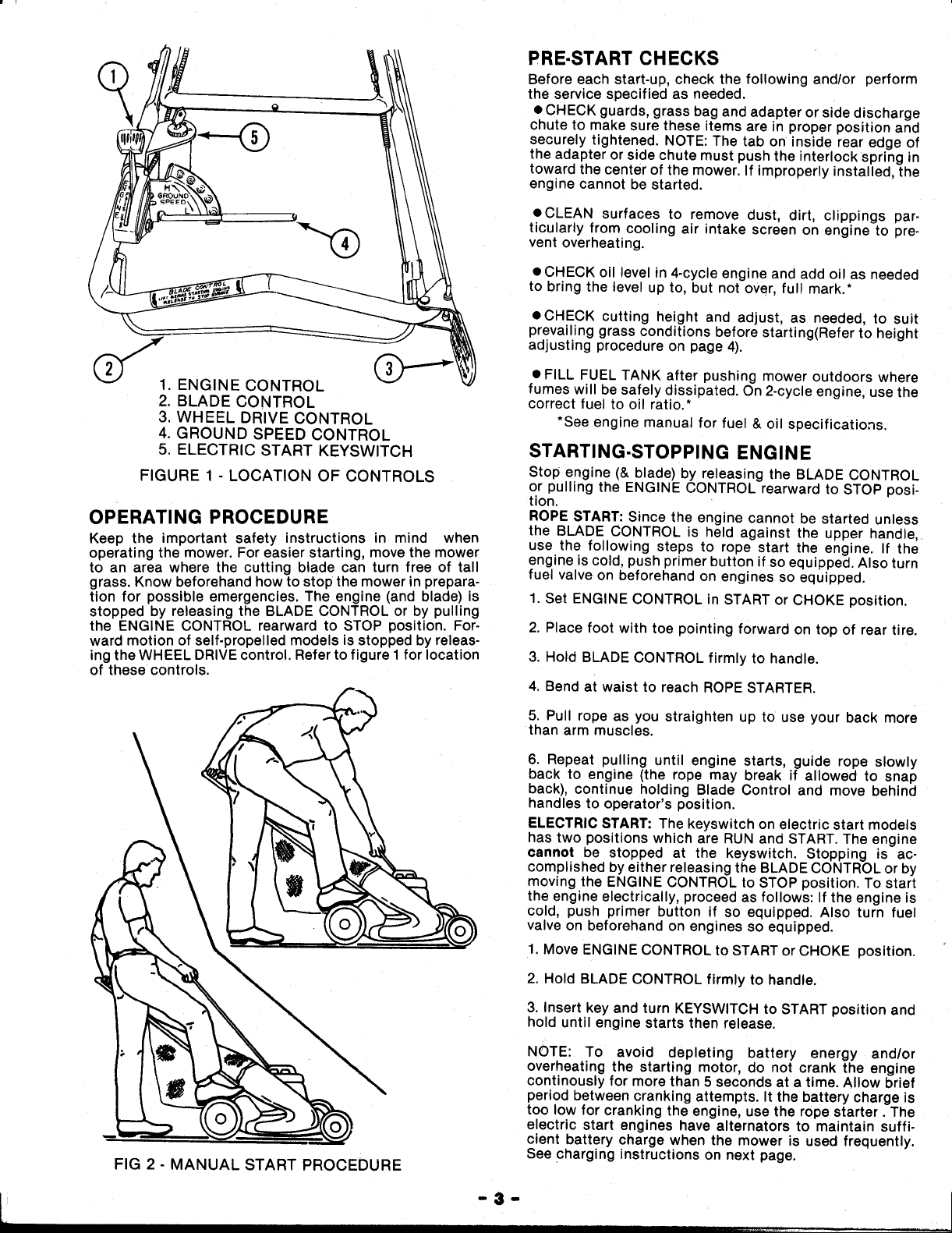

ROPE START: Since the engine cannot be started unless

the BLADE CONTROL is held against the upper handle,

use the following steps to rope start the engine. If the

engine is cold, push primer button if so equipped. Also turn

fuel valve on beforehand on engines so equipped.

1. Set ENGINE CONTROL in START or CHOKE position.

2. Place foot with toe pointing forward on top of rear tire.

3. Hold BLADE CONTROL firmly to handle.

4. Bend at waist to reach ROPE STARTER.

5. Pull rope as you straighten up to use your back more

than arm muscles.

6. Repeat pulling until engine starts, guide rope slowly

back to engine (the rope may break if allowed to snap

back), continue holding Blade Control and move behind

handles to operator's position.

ELECTRIC START: The keyswitch on electric start models

has two positions which are RUN and START. The engine

cannot be stopped at the keyswitch. Stopping is ac-

complished by either releasing the BLADE CONTROL or by

moving the ENGINE CONTROL to STOP position. To start

the engine electrically, proceed as follows: If the engine is

cold, push primer button if so equipped. Also turn fuel

valve on beforehand on engines so equipped.

1. Move ENGINE CONTROL to START or CHOKE position.

FIG 2 - MANUAL START PROCEDURE

2. Hold BLADE CONTROL firmly to handle.

3. Insert key and turn KEYSWITCH to START position and

hold until engine starts then release.

NOTE: To avoid depleting battery energy and/or

overheating the starting motor, do not crank the engine

continously for more than 5 seconds at a time. Allow brief

period between cranking attempts. It the battery charge is

too low for cranking the engine, use the rope starter. The

electric start engines have alternators to maintain suffi-

cient battery charge when the mower is used frequently.

See charging instructions on next page.

-3-

Page 4

BATTERY CHARGING:A plug in battery charger is provided

which operates off 120V/60hz household current. When

recharging, disconnect battery from wiring harness, install

charger in household outlet and connect battery to

charger. If battery is weak charge for 48 hours. Charge bat-

tery for 72 hours if completely discharged.

Note: Continuous Charging will not damage battery.

MOWING PROCEDURE

Vary speed to suit grass conditions. Set the engine speed

high for tall, thick grass or lower for sparse grass. Push

hand propelled models at a speed that is comfortable but

will allow even cutting without stalling. On self propelled

models, set ground SPEED CONTROL lever in desired for-

ward speed setting, then grip the WHEEL DRIVE control

and hold against handle to engage clutch for forward mo-

tion. Releasing the WHEEL DRIVE control stops forward

motion. The mower can be hand pushed forward or in

reverse for trimming with the WHEEL DRIVE control

released. The ground speed can be changed to a new set-

ting at any time when in motion. Use low speed setting and

clutch for down-hill braking.

MOWINGIVACUUMING HINTS: The cutting deck should be

level under all conditions. As a general rule, never cut more

than 1/3 off the height of the grass. If for example, the

grass has grown to 4 inches tall, set the mower height lat-

ches in the lowest position which establishes the cutting

height at approximately 3" (see cutting height chart)

thereby, cutting about 718" off the grass and staying well

within the 1/3 off limit. If you want the grass shorter, wait a

few days then recut to the lower height. If cut too short, the

grass will expend more energy for development of new leaf

structures and less for a healthy root system and will be

more subject to burning. On the other hand, if allowed to

grow too long, the lower portion will be shaded and, as a

result will discolor. In dry periods, allow the grass to grow

longer than you normally would. NOTE: Do not mow across

an area where dry type fertilizer has just been spread as

most of the fertilizer will be vacuumed up.

Change your mowing pattern from time to time for a

smoother cut lawn. Finely chopped clippings add nutrients

to the soil to promote grass growth, however if the clipp-

ings become too heavy, they mat to form thatch which

prevents proper breathing and holds moisture. If thatch is

particularly heavy, the Thatcherizer accessory described

on the back page will do an effective job of dislodging the

decaying matter. To prevent grass disease from thatch,

vacuuming and bagging is recommended for most cut-

tings along with an occasional broadcasting of the clipp-

ings into the lawn for nutritive value. Your Snapper can be

quickly converted back and forth from bagging to side

discharge with the accessories.

EMPTYING GRASS CATCHER BAG

_ Highest

t

Cutting

Height

)

®

®

Position Q

®

ltll(l/

FIG. 3 - CUTTING HEIGHT SETTINGS

CUTTING HEIGHT ADJUSTMENT

Always stop the engine and wait until the mower blade

comes to a complete halt before readjusting the cutting

height! To readjust, move the height adjusting latch on

each wheel outward and slide each, one notch at a time, to

the position desired. Positioning the latches in the highest

notch sets the mower at the lowest cutting height while

the lowest notches sets it in the highest cutting position.

Refer to figure 3 for the approximate cutting height afford.

ed by each of the five latch positions: For best results, set

both latches on one side first, then go to the other side and

set these latches into corresponding notches. Before

resetting the rear latches into lower notches, lift the

weight of mower off'the rear wheels first by pulling up on

the handle, then reset.

To install the KWIK-N-EZY grass catcher on the mower,

slide the connector down over the adapter flange then

lower the support flame hooks onto the middle handle (see

figure 4). When the catcher becomes full, stop engine and

lift the support hooks up over the handle then lift the con-

nector off and continue lifting while moving the catcher

forward until the bagclears the mower. To empty the bag,

raise the connector end up and release the handle of the

door flap. Shake the catcher back and forth to dump the

clippings.

TO EMPTY IN TRASH BAG: Use the following procedure to empty

clippings in trash bag. After removing catcher from mower, place

connector erid on ground, open door flap, slip trash bag over the

catcher, turn catcher over so that large opening is down inside

bag, !ift catcher by connector and door handles and shake until

clippings are dUmped in the trash bag.

FIG. 4 - REMOVING GRASS CATCHER

m 4 _

Page 5

SERVICE PROCEDURE

The mower itself requires very little service, however, it is

important that the engine be serviced at the intervals

specified in the engine manual furnished with your mower.

When performing any services on the mower, always

disconnect the spark plug wire from the spark plug to pre-

vent unintentional starting. When tipping the mower to

work on the underside, always tilt with spark plug up to

prevent flooding the engine with gasoline and oil which

would cause hard starting after servicing. NOTE: On

Tecumseh powered units, comply with the following rules

to prevent oil from entering the air cleaner and ruining the

dry element (1) DO NOT keep engine in tilted position for

more than 5 minutes. (2) DO NOT crank engine or turn

blade while tilted (3) DO NOT tilt plug up more than 90

degrees.

To retain the quality of your mower, use Genui'ne Snapper

Replacement Parts only. To obtain the correct part for your

particular mower, always specify model and serial number

as found on nameplate. Contact your local Snapper Dealer

for parts and service assistance. We recommend returning

your mower to an authorized Snapper Dealer on a yearly

basis for inspection and addition of any new devices which

might upgrade the safety of your mower. For the nearest

Snapper Dealer, check the yellow pages under the heading

LAWN MOWERS.

LUBRICATION SERVICES

ENGINE- Change oil every 25 hours as specified in engine

manual.

TRANSMISSION(Self.Propelled Models). Remove plug and

check every 25 hours of operation. If grease is not visible

on the input gear, add small amount of Snapper "00"

grease, CAUTION: Avoid over lubricating, capacity not to

exceed 2 ounces of grease. Snapper "OO" grease is

available in a convenient quart size container (Part No.

1-1050) at your Snapper dealer. Replace plug after servic-

ing transmission.

MOVING PARTS - Occasionally put a few drops of oil on

movable surfaces of components such as the height ad-

justing levers, wheel axles, shift levers, etc. Be careful not

to spill oil on surface of drive disc on self-propelled

models.

CHECK FOR

GREASE ON

INPUT GEAR

' Fi(3. 5- CHECKING TRANSMISSION

\

CUTTING BLADE SERVICE

CAUTION: Before checking or doing any work on the blade,

disconnect the spark plug wire and secure it away from the

plug to prevent unintentional starting.

CHECK at frequent intervals to make sure the blade is

securely tightened and that it is in good condition.

REPLACE blade if badly chipped, bent, out of balance or

as soon as a notch starts wearing in the tip between the

flat surface and upturned lift as depicted in View B, Figure

6. This type wear pattern occurs more rapidly under sandy

soil conditions. CAUTION: Never operate the mower with

blade worn to the extent shown in View C as the tip could

fly off causing personal injury or property damage.

SHARPEN blade when the cutting edges become dull if the

blade is in otherwise good condition. Sharpen blade on a

grinding wheel at a angle of 22 to 28 degrees. The cutting

surface should extend in.about 31/2" from the tips. Check

the blade after sharpening to determine that it is still

balanced. It will cause excessive vibration if unbalanced.

BE CAREFUL: AVOID CUTTING YOURSELF ON SHARP

BLADE! Protect your hands from cuts while handling

blade

INSTALL blade with components in sequence shown in

Figure 7. Make sure that the turned-up rims in the center of

the blade fit over the edges of the blade drive hub when in-

stalling. Do no substitute any components here. Tighten

the blade retaining capscrew 20 to 30 foot pounds torque

value.

-5-

FIG 6 - BLADE WEAR PATTERNS

1-_'_'1 _,_ -BLADE HUB

(ON E_GINE)

(_'_"_" S PEC IA L RETAINING

i

FIG 7- BLADI£ RETENTION DETAIL

CAPSCREW

DANGEROUS

Page 6

FIG 8 - cLuTcH LINKAGE ADJUSTMENT

1/8"-1/4

IN HIGHEST

SPEED SETTING

CO NNECTO R

NUT

i ll|

FIG 9 - DRIVEN DISC COMPONENTS

FIG 10 - UNHOOKING DRIVE SPRING

-\

INNER

SPRING

DRIVE

DISC

CLUTCH LIN KAG E (Self-Propelled)

Make sure the vinylcover remains over the spring(s)con-

necting the clutch pull rodto the clutch idler components

(see Figure 8). This not only keeps the spring clean but

preventsit from rubbing against and wearing a hole in the

grass bag on mowers so equipped.

ADJUSTMENTS: If excessive pressure is required to hold

the wheel drive clutch lever in the engaged or drive posi.

tion, the clutch pull rodsprings are probably out of adjust-

ment. This is checked with the engine stopped and the

clutch handle released. When properly adjusted there

should be 1/16" to 1/8" clearance between the inside hook

of the spring and inside eye of the push rod as shown in

Figure 8. To adjust, unhookand rotate the inner and outer

springs in opposite direction, rehookand check clearance.

Repeat this procedure until the clearance is correct. If the

wheel drive control does not snap back to disengage the

drive when the handle is released, check the clip holding

the pull rodto the handle bar for binding. Position this clip

about 5" from the upper handle and rotate to best position

to allow the rod to slide without interference.

DRIVEN DISC SERVICE

If the mower does not pull properly with the wheel drive

clutch engaged, check for the following: Grease on drive

disc causing slippage, broken or disconnected driven

assembly spring (see Figure 10), driven disc too worn to

contact the drive disc properly, driven disc out rof adjust-

merit.This condition could also be caused byworn belts. If

the belts are in good condition and the clutch is properly

adjusted, service the drive system as follows:

DRIVEN DISC ADJUSTMENT: With the engine stopped and

the speed lever shifted into highest speed setting, the

driven disc should be 1/8" to 1/4" from the center of the

drive disc as illustrated in Figure 9. Readjust with engine

stopped as follows: Shift the speed selector into the

highest speed setting, loosen the connector hex nut and

slide the driven disc assembly inward or outward until the

center is 1/8" to 1/4" from the edge of the drive disc.

Retighten connector nut to lock at new setting.

DRIVEN DISC REPLACEMENT: If the rubberof driven disc

is badlychunked or worn downto within 1/16" of the metal

rim, remove the driven, disc assembly and replace the

driven disc as follows: Remove the clip and detach the

transfer rod from the speed control lever(Figure 10),Using

a pair of needle nose pliers, unhook the drive spring and

slide the driven disc assembly off as shown in Figure 11 .

Remove the five machine screws securing the rubber

driven disc and separate the worn disc from the hub.

Reversethis procedureto install the replacement disc and

to reconnect the drivecomponents.

BEARING REPLACEMENT: If the bearing fails, remove the

driven disc assembly as described above and replace the

bearing as follows: Remove the snap ring using special

snap ring pliers. Slide the driven ring, hub and bushing out

of the bearing. Remove the four screws and bearing.

Reverse this procedure to install the replacement bearing

and reconnect the drive components.

BELT SERVICE

Slippage of worn belts will cause self-propelled models to

pull poorly. On these the engine belt transmits this power

to the poly-V-belt which, in turn, engages the clutch to

drive the transmission and rear drive wheels.

ENGINE BELT REPLACEMENT: Disconnect the spark plug

wire and empty the fuel tank or tape the vents in the filler

cap to prevent fuel spillage then proceed as follows:

Unhook the idler arm spring from the right rear wheel

bracket and remove the driven dic assembly as described

under DRIVEN DISC service. Tilt the mower up on its right

wheels and removethe cutting blade and hub,then remove

the drive disc retaining nut and internal tooth Iockwasher.

Lift the drive disc-idler assembly off the deck and remove

faulty belt. Loopend of replacement belt over engine drive

-6-

Page 7

FIGURE 11 - SLIDING DRIVEN DISC ASSEMBLY OFF

POLY V-BELT

pulley and insert other end through deck opening. Loop

belt around driven pulley then push the drive, disc-idler

assembly down into position on the deck. Install the inter-

nal tooth Iockwasher and disc retaining nut on the drive

disc stud and securely tighten these. Test to make sure the

idler arm is free to pivot without interference then reinstall

the cutting blade components (refer to BLADE SERVICE),

driven disc assembly, then using a stiff wire(Hint: coat

hanger) with hooked end, pull the hooked end of the idler

arm spring through the larger hole in the right wheel

bracket and hook the end through the smaller hole.

POLY V-BELT REPLACEMENT:This belt can be replaced

after removing the driven disc assembly as described

earlier. Note the arrangement of old belt around pulleys

before cutting and removing it. Slip the replacement belt

over the end of hex shaft pulley and work over idler pulley.

Twist the belt sideways and pull it upward between the dif-

ferential bracket and transmission pulley. Slip belt over

grooves in the hex shaft, clutch idler and transmission

pulleys. Note: When properly installed, the lower span of

the Poly V-Belt will be above the belt guide.

RIGHT REAR \

WHEEL BRACKE'f

IDLER

IDLER

STORAGE PROCEDURE

Prepare your mower for Storage at the end of the mowing

season as follows. (Refer to the engine manual for direc-

tions for preserving engine). With the spark plug wire

disconnected, turn the mower on its side and thorougly

clean underside of deck. Scrape away grass with putty

knife and/or wire brush then wash down with water from a

hose. WARNING: Tape openings closed to prevent spray-

ing water into exhaust or air intake while washing. Clean

external surfaces of mower and allow to dry, then lubricate

all exposed metal with a light coating of oil to prevent cor-

rosion. Make sure grass bag is completely emptied to pre-

vent decay and formation of mold while in storage. The

grass bag may be washed in detergent but allow it to dry

thoroughly. Store mower during off season in a storage sh-

ed or dry area protected from weather. Handles on push

models can be tilted forward for storage by loosening

wingnuts--do not kink cables!

HANDLE HEIGHT ADJUSTMENT

To raise or lower handle, loosen tl_e adjusting Iocknuts on

both sides as shown below, reset handle to desired posi-

tion and retighten the Iocknuts.

LOOSEN

PUSH MODELS

ONLY

ON LOCKNUTS

\\

LEFT ,,,,

SIDE , ,_,....., ,

SHOWN ' / ' "

/t

/ POINT

/

CARRIAGE

__ X PIVOT

\ /

\ /

BOLTS FLAT WASHER

FIG. 13- HANDLE HEIGHT ADJUSTMENT

- 7 - (OVER) ,

Page 8

SNAPPER 21" HI-VAC WALK MOWERS

POPULAR ACCESSORIES

Depending on how your mower is originally equipped, it MULCHERIZER

can I_e converted to perform other lawn care duties with KIT #6-0420

the kits described below.

SNAPPERIZER KIT: Converts mower into an outdoor

vacuum and shredder to broadcast shredded clippings and

leaves with side discharge chute or for bagging with the

grass catcher. Specify model mower when ordering.

SNAPPERIZER

KIT #6-0440

MULCHERIZER KIT: Converts mower into effective mower

/mulcher to cut and chop the grass before blowing clipp-

ings directly into the lawn as nutritive mulch. Specify

model when ordering.

THATCHERIZER KIT: Attaches to front of self*propelled

models to dislodge thatch for vacuuming into grass cat-

cher. One kit fits all. 21" models.

GRASS CATCHER BAG KIT: If your mower is equipped

with side discharge chute, it can be converted for bagging

operation whenever desired with a grass bag kit. Specify

model when ordering.

SIDE CHUTE KIT: If your mower is equipped with the grass

catcher, it can be quickly converted to side discharge with

a side chute kit to broadcast clippings and eliminate bagg-

ing whenever desired, and to quickly convert back to bagg-

ing operation. Specify model when ordering.

THATCHERIZER

KIT #6-0476

'MANUFACTURER'S 2 YEAR LIMITED WARRANTY

For two (2) Years from purchase date for the original purchaser's residential, non-commercial use

[ninety (90) days from purchase date for the original purchaser's commercial, rental, or other non-

residential use], SNAPPER POWER EQUIPMENT, through any SNAPPER dealer will replace, free of

charge, any part or parts found upon examination by the factory at McDonough, Georgia, to be

defective in material or workmanship or both.

All transportation cost incurred by the purchaser in submitting material to a SNAPPER dealer for

replacement under this warranty must be borne by the purchaser.

This warranty does not apply to engines and their components, as these items are warranted

separately by their manufacturers, and does not apply to batteries which are covered separately.

This warranty does not apply to parts that have been damaged by accident, alteration, abuse,

improper lubrication, normal wear, or other cause beyond our control.

There is no other express warranty.

Implied warranties, including those of merchantability and fitness for a particular purpose, are

limite d to two (2) years from purchase date for the original pu_'chaser's residential, non-commercial

use [ninety (90) days from purchase for the original purchaser's commercial, rental or other non-

residential use], and to the extent permitted by law any and all implied warranties are excluded. This

is the exclusive remedy. Liabilities for consequential damages, under any and all warranties are

excluded.

Some states do not allow limitations on how long an implied warranty lasts,or do not allow the ex-

clusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

WARNING: THE USE OF REPLACEMENT PARTS OTHER THAN GENUINE SNAPPER PARTS MAY

IMPAIR THE SAFETY OF SNAPPER PRODUCTS AND WILL VOID ANY LIABILITY AND

WARRANTY BY SNAPPER ASSOCIATED WITH THE USE OF SUCH PARTS,

IMPORTANT: Please fill out the attached SNAPPER Product Registration Card immediately and

mail to:

SNAPPER POWEREQUIPMENT

MANUAL 1-4322 REV. 4 (7/86) McDonough, Georgia 30253 Printed in U.S.A.

Loading...

Loading...