Page 1

®

O

A

TO

AL

Large Frame

Snowthrower

1428 Model

Mfg. No. Description

1695572 L1428E, Snowthrower, 130.887280

1736682

Revision 00

Rev. Date 07/2008

TP 191-4968-00-LW-SN

Page 2

TableofContents

CONTENTS:

Safety Rules & information

General ........................................................... 4

Training .......................................................... 6

Preparation ..................................................... 6

Operation ........................................................ 6

Children .......................................................... 7

Clearing a Clogged Discharge Chute ............. 7

Service, Maintenance and Storage ................ 7

Emissions ....................................................... 7

Decals ............................................................ 8

Safety Icons .................................................... 9

Identification Numbers .................................... 9

Assembly .......................................................... 10

Remove Packing Materials ........................... 11

Raise Handles and Check Cables ................ 11

Install Chute Rotator Control Handle ............ 11

Connect Shift Rod ........................................ 12

Assemble Chute and Rotator ....................... 12

Assemble Split Rod ...................................... 12

Connect Spout Rotator Brake Cable ............ 13

Remove Snowthrower from Crate ................ 13

Secure Cable and Final Checks ................... 14

Check Oil Level and Add Fuel ...................... 14

Read Manual Before Starting Engine ........... 14

Features, Controls, & Operation

Control Locations ......................................... 15

General Operation

Checks Before Each Start-Up ...................... 17

Starting Controls ........................................... 18

Starting the Engine ....................................... 19

Stopping the Engine ..................................... 20

Operating the Snowthrower .......................... 21

Clearing a Clogged Discharge Chute ........... 21

Ground Speed Selector ................................ 22

Engine Speed ............................................... 22

Deflector ....................................................... 22

Scraper Bar & Skid Shoes ............................ 22

Easy-Turn and Traction Drive Lock .............. 23

After Each Use ............................................. 24

Storage ......................................................... 24

Regular Maintenance

Schedule ...................................................... 25

Checking Tire Pressure ................................ 25

Auger Gear Case Lubrication ....................... 25

Lubrication .................................................... 26

Check/Lubricate Free-Hand Linkage .......... 27

Lubricate Auger Shaft Assembly .................. 27

Troubleshooting, Adjustments, & Service

Troubleshooting ............................................ 28

Auger Drive Cable Adjustment ..................... 30

Traction Drive Adjustment ............................ 30

Friction Disk Measurement .................................

31

Easy Turn Cable Adjustment ........................ 32

Belt Adjustment ............................................ 32

Shear Pin Replacement ............................... 33

Belt Guide Adjustment .................................. 33

Belt Replacement ......................................... 34

Specifications ................................................... 37

Parts & Accessories ....................................... 38

A WARNING

You must read, understand and comply with all

safety and operating instructions in this manual

before attempting to set-up and operate your

snowthrower.

Failure to comply with all safety and operating

instructions can result in loss of machine control,

serious personal injury to you and/or bystanders,

and risk of equipment and property damage. The

triangle in the text signifies important cautions or

warnings which must be followed.

A WARNING

Engine exhaust from this product contains chemi-

cals known, in certain quantities, to cause cancer,

birth defects, or other reproductive harm.

Page 3

tll

Congratulations on purchasing a superior-quality piece of lawn

and garden equipment. Our products are designed and manu-

factured to meet or exceed all industry standards for safety.

Power equipment is only as safe as the operator. If it is

misused, or not properly maintained, it can be dangerous!

Remember, you are responsible for your safety and that of

those around you.

Use common sense, and think through what you are doing. If

you are not sure that the task you are about to perform can be

safely done with the equipment you have chosen, ask a

professional: contact your local authorized dealer.

The operator's manual contains important safety information you

need to be aware of BEFORE you operate your unit as well as

DURING operation.

Safe operating techniques, an explanation of the product's features

and controls, and maintenance information is included to help you

get the most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found

on the following pages. Also completely read the Operation section.

g

DII

Tragic accidents can occur with children. Do not allow

them anywhere near the area of operation. Children

are often attracted to the unit and snowthrowing activ-

ity. Never assume that children will remain where you

last saw them. If there is a risk that children may enter

the area where you are operating the unit, have another

responsible adult watch them.

DO NOT ALLOW CHILDREN TO OPERATE THIS UNIT!

This encourages them to come near the unit in the

future while it is running, and they could be seriously

hurt. They may then approach the unit when you are not

expecting it, and you may run over them.

4

Page 4

SafetyRules&Infomati(m

M0vJflg

This equipment has many moving parts that can injure you or someone else.

However, if you are standing in the operator's position, and follow all the rules in

this book, the unit is safe to operate.

The auger and impeller have spinning parts that can amputate hands and feet.

Do not allow anyone near the equipment while it is running! DO NOT clear the

discharge chute by hand. If the chute becomes plugged, stop the engine, wait for

all moving parts to stop, and clear the blockage with a clean-out tool or piece of

wood.

To help you, the operator, use this equipment safely, it is equipped with an

operator-present safety system. Do NOT attempt to alter or bypass the system.

See your dealer immediately if the system does not pass all the safety interlock

system tests found in this manual.

Thrown 8C1$

This unit has a spinning auger and impeller. They

pick up and throw snow and ice. Thrown debris

could seriously injure a bystander. ALWAYS direct

the discharge chute away from bystanders and prop-

erty that could be damaged by flying debris. Be sure

to clean up the area to be cleared BEFORE you start.

Do not allow anyone in the area while the unit is run-

ning! If someone does enter the area, shut the unit

off immediately until they leave.

Gasoline is extremely flammable. Its vapors are also

extremely flammable and can travel to distant ignition

sources. Gasoline must only be used as a fuel, not as a

solvent or cleaner. It should never be stored any place

where its vapors can build up or travel to an ignition source

like a pilot light. Fuel belongs in an approved, plastic,

sealed gas can, or in the snowthrower fuel tank with the

cap securely closed. Spilled fuel needs to be cleaned up

immediately.

Proper maintenance is critical to the safety and perfor-

mance of your unit. Be sure to perform the maintenance

procedures listed in this manual, especially periodically test-

ing the safety system.

Page 5

SafetyRules& Informtm

This machine is capable of amputating hands and feet and throwing objects. Read these safety rules and

follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury

or death to you, or bystanders, or damage to property or equipment. The triangle _k in text signifies

important cautions or warnings which must be followed.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manuals before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment.

Never allow adults to operate the equipment without

proper instruction.

3. Keep the area of operation clear of all persons, par-

ticularly small children and pets.

4. Exercise caution to avoid slipping or falling especially

when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches before starting engine (motor).

3. Do not operate the equipment without wearing ade-

quate winter outer garments. Wear footwear that will

improve footing on slippery surfaces. Avoid loose fit-

ting clothing that can get caught in moving parts.

4. Handle fuel with care; it is highly flammable.

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors. Replace fuel cap securely and

wipe up spilled fuel.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place con-

tainers on the ground, away from your vehicle, before

filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground. If

this is not possible, then refuel such on a trailer with

a portable container, rather than from a gasoline dis-

penser nozzle.

(f) Keep nozzle in contact with the rim of the fuel tank

or container opening at all times, until refueling is

complete. Do not use a nozzle lock-open device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing imme-

diately.

5. Use extension cords and receptacles as specified

by the manufacturer for all units with electric drive

motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or

crushed rock surfaces.

7. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by the manufacturer).

8. Let engine (motor) and machine adjust to outdoor

temperatures before starting to clear snow.

9. Always wear safety glasses or eye shields dur-

ing operation or while performing an adjustment or

repair to protect eye from foreign objects that may be

thrown from the machine.

OPERATION

1. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect

the cord on electric motors, thoroughly inspect the

snowthrower for any damage, and repair the damage

before restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the

operating position, before unclogging the collector/

impeller housing or discharge guide, and when mak-

ing any repairs, adjustments, or inspections.

6. When cleaning, repairing, or inspecting make cer-

tain the collector/impeller and all moving parts have

stopped. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

7. Do not run the engine indoors except for starting the

engine or for transporting the snowthrower in or out of

the building. Open the outside doors; exhaust fumes

are dangerous.

8. Exercise extreme caution when operating on slopes.

Do not attempt to clear steep slopes.

9. Never operate the snowthrower without proper

guards plates, or other safety protective devices in

place and working.

10. Never direct the discharge toward people or areas

where property damage can occur. Keep children

and others away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12. Never operate the machine at high transport speeds

on slippery surfaces. Look behind and use care

when operating in reverse.

13. Disengage power to the collector/impeller when

snowthrower is transported or not in use.

14. Use only attachments and accessories approved by

the manufacturer of the snowthrower (such as wheel

weights, counterweights, or cabs).

15. Never operate the snowthrower without good visibility

or light. Always be sure of your footing, and keep a

firm hold on the handles. Walk, never run.

16. Never touch a hot engine or muffler.

17. Never operate the snowthrower near glass enclo-

sures, automobiles, window wells, drop-offs, and the

like without proper adjustment of the discharge angle.

18. Never direct discharge at bystanders or allow anyone

in front of the unit.

19. Never leave a running unit unattended. Always dis-

engage the auger and traction controls, stop engine,

and remove keys.

20. Do not operate the unit while under the influence of

alcohol or drugs.

6

Page 6

Safety Rules & information

21. Keep in mind the operator is responsible for acci-

dents occurring to other people or property.

22. Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment=related injuries. These operators should

evaluate their ability to operate the unit safely enough

to protect themselves and others from injury.

23. DO NOT wear long scarves or loose clothing that

could become entangled in moving parts.

24. Snow can hide obstacles. Make sure to remove all

obstacles from the area to be cleared.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

unit and the operating activity. Never assume that children

will remain where you last saw them.

1. Keep children out of the area and under the watchful

care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Never allow children to operate the unit.

4. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

CLEARING A CLOGGED DISCHARGE

CHUTE

Hand contact with the rotating impeller inside the dis-

charge chute is the most common cause of injury associ-

ated with snowthrowers. Never use your hand to clean

out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

8. Always follow the engine manual instructions for stor-

age preparations before storing the unit for both short

and long term periods.

9. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

10. Keep nuts and bolts tight and keep equipment in

good condition.

11. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

12.Components are subject to wear, damage, and dete-

rioration. Frequently check components and replace

with manufacturer's recommended parts, when nec-

essary.

13.Check control operation frequently. Adjust and ser-

vice as required.

14. Use only factory authorized replacement parts when

making repairs.

15.Always comply with factory specifications on all set-

tings and adjustments.

16.Only authorized service locations should be utilized

for major service and repair requirements.

17. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper ser-

vice procedures can result in hazardous operation,

equipment damage and voiding of manufacturer's

warranty.

18.Check shear bolts and other bolts at frequent inter-

vals for proper tightness to be sure the equipment is

in safe working condition.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. If available, look for the relevant Emissions Durability

Period and Air Index information on the engine emis-

sions label.

SERVICE, MAINTENANCE, AND STORAGE

1. Check shear bolts and other bolts at frequent inter-

vals for proper tightness to be sure the equipment is

in safe working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water and spacer heaters, or clothes dry-

ers. Allow the engine to cool before storing in any

enclosure.

3. Always refer to the operator's manual for impor-

tant details if the snowthrower is to be stored for an

extended period.

4. Maintain or replace safety and instruction labels as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

6. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

7. Always observe safe refueling and fuel handling prac-

tices when refueling the unit after transportation or

storage.

IGNITION SYSTEM

1. This spark ignition system complies with Canadian

ICES-002.

Page 7

Decals

DECALS

This unit has been designed and manufactured to provide

you with the safety and reliability you would expect from an

industry leader in outdoor power equipment.

Although reading this manual and safety instructions it

contains will provide you with the necessary basic knowl-

edge to operate this equipment safely and effectively, we

have placed several safety labels on the unit to remind you

of this important information while you are operating your

unit.

All WARNING, CAUTION, and instructional messages on

your unit should be carefully read and obeyed. Personal

bodily injury can result when these instructions are not fol-

lowed. The information isfor your safety and it is important.

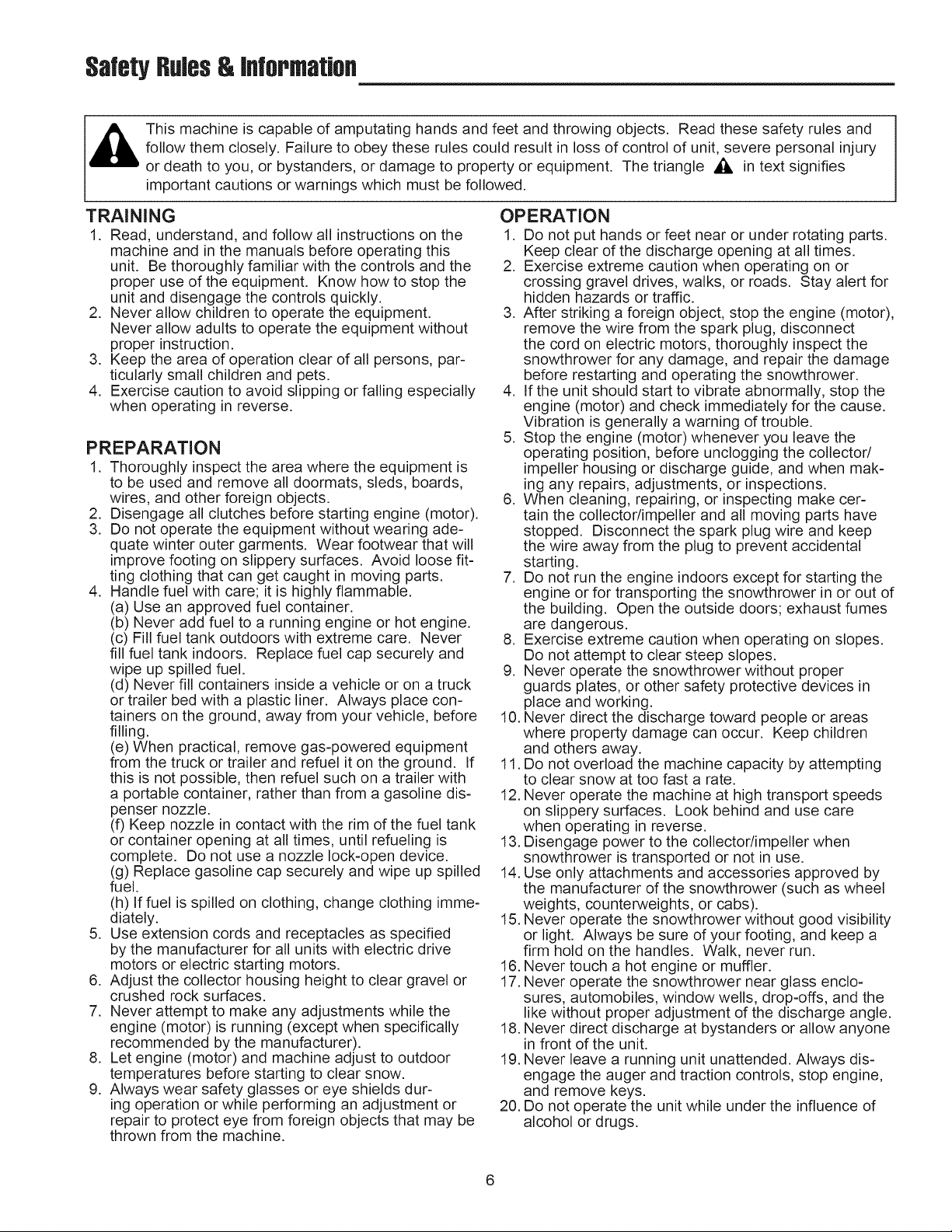

DECALS

Model L1228E Model L1428E

The safety decals below are on your unit.

If any of these decals are lost or damaged, replace them at

once. See your local dealer for replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the equip-

ment, to follow the safety instructions necessary for safe,

effective, operation,

NOTE: Engine operation and safety decals are supplied by

the engine manufacturer.

Part No. 1733033 - DANGER / WARNING

Main Dash Decal, North American, w/Easy Turn

. . before LlSing the unit after storage FailLire to hlbri_3te

.... T................................................[ 1with 30 weight oil every 10 hours of opeTation and

ina_causea rf]alfunctionof thesafety s#tem a

Part No. 1733526

Lubrication Decal

Part No. 728183

Important

Over Adjustment

Both Models

Part No. 1733772

Shift Decal

Part No. 1733056 - DANGER / WARNING

Main Dash Decal, North American, w/o Easy Turn

Amputationhazard

_L _J Lontaclv,iththeaugerw,__use

I" Shat off engine bef_e se[_lciag

Part No. 1716532

Auger Danger Decal

Part No. 1733057

Discharge Chute

Danger Decal

Part No. 725432

Belt Stretch &

Adjust

Part No. 1733443

Chute Release

Page 8

SAFETY iCONS

Safety icons

WARNING: READ OPERATOR'S MANUAL.

Read and understand the Operator's

Manual before using this machine.

DANGER: THROWN OBJECTS.

This machine is capable of throwing

objects and debris. Keep bystanders

away.

WARNING: REMOVE KEY BEFORE

SERVICING.

Remove the key, disconnect spark

plug wire, and consult technical lit-

erature before performing repairs or

maintenance.

WARNING: DISMEMBERMENT.

This machine can amputate limbs.

Keep bystanders and children away

when engine is running.

DANGER:DISMEMBERMENT.

The auger can amputate limbs. Keep

hands and feet away from auger and

rotating parts.

DANGER:DISMEMBERMENT.

The impeller can amputate limbs. Stop

the engine, remove the key, and discon-

nect spark plug wire before clearing the

discharge chute or performing service

work. Keep hands and feet away from

impeller and rotating parts.

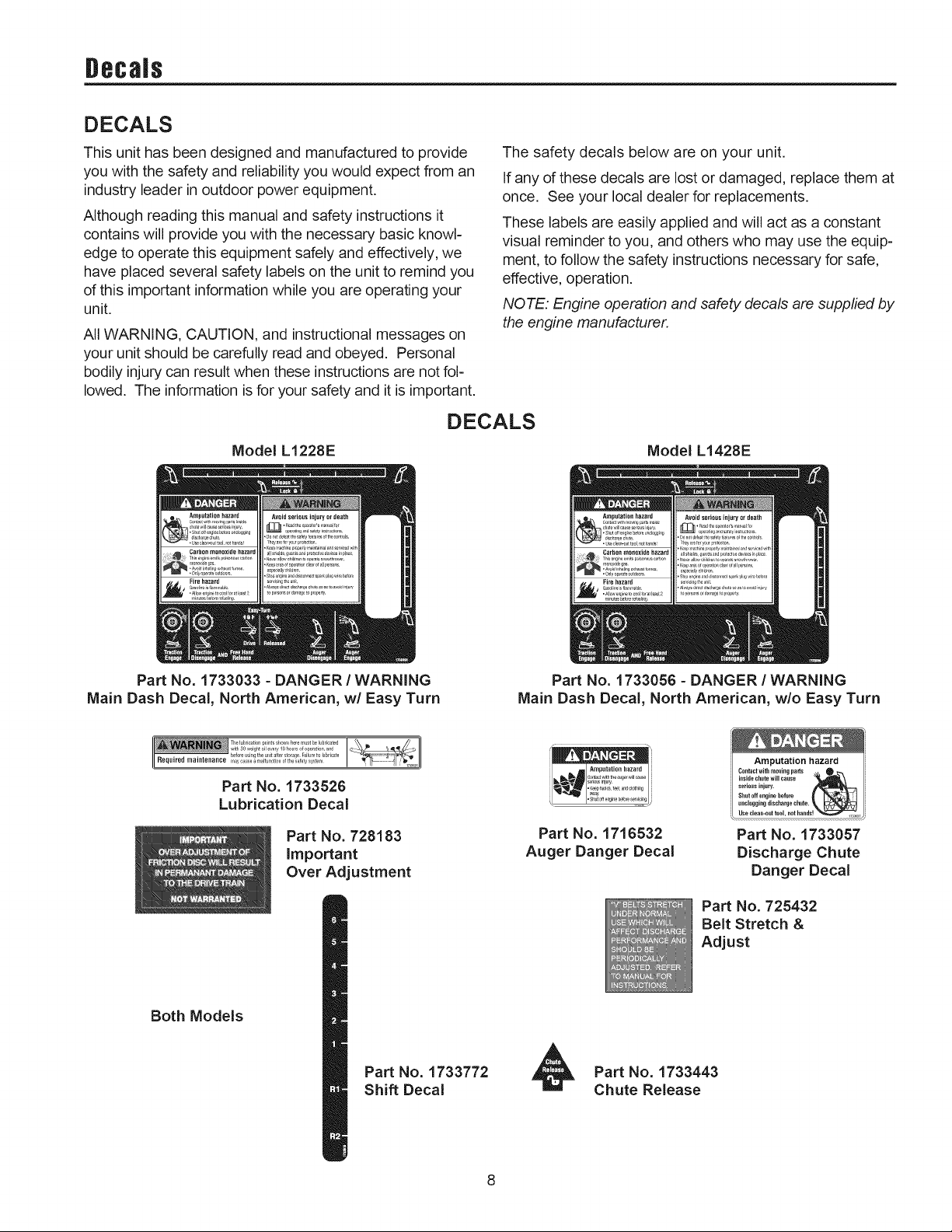

Identification Numbers

Mfg.Ne,:t;,26eXXXX C_'

se,i,I_o.5".'_ xxx _'oo_

Eogi.oRP#",,"x,_}

LpA: _)

Simplicity Mfg. lnc. _/ /\

Port Washington, WI USA 53_7_0997_,

When contacting your authorized dealer for replace=

ment parts, service, or information you MUST have

these numbers.

Record your model name/number, manufacturer's iden-

tification numbers, and engine serial numbers in the

space provided for easy access. These numbers can be

found in the locations shown.

NOTE: For location of engine identification numbers,

refer to the engine owner's manual.

Model Description Name/Number

Unit MFG Number Unit SERIAL Number

Mower Deck MFG Number Mower Deck SERIAL Number

Dealer Name Date Purchased

Engine Make _Engine Model

Engine Type/Spec Engine C0de/Serial Number

Page 9

AssemhJy

YOU WILL NEED:

• Utility knife

• Unleaded fuel

• Tire pressure gauge

• 1/2" deep socket wrench or combination

• 9/16" deep socket wrench or combination

• 7/16" wrench

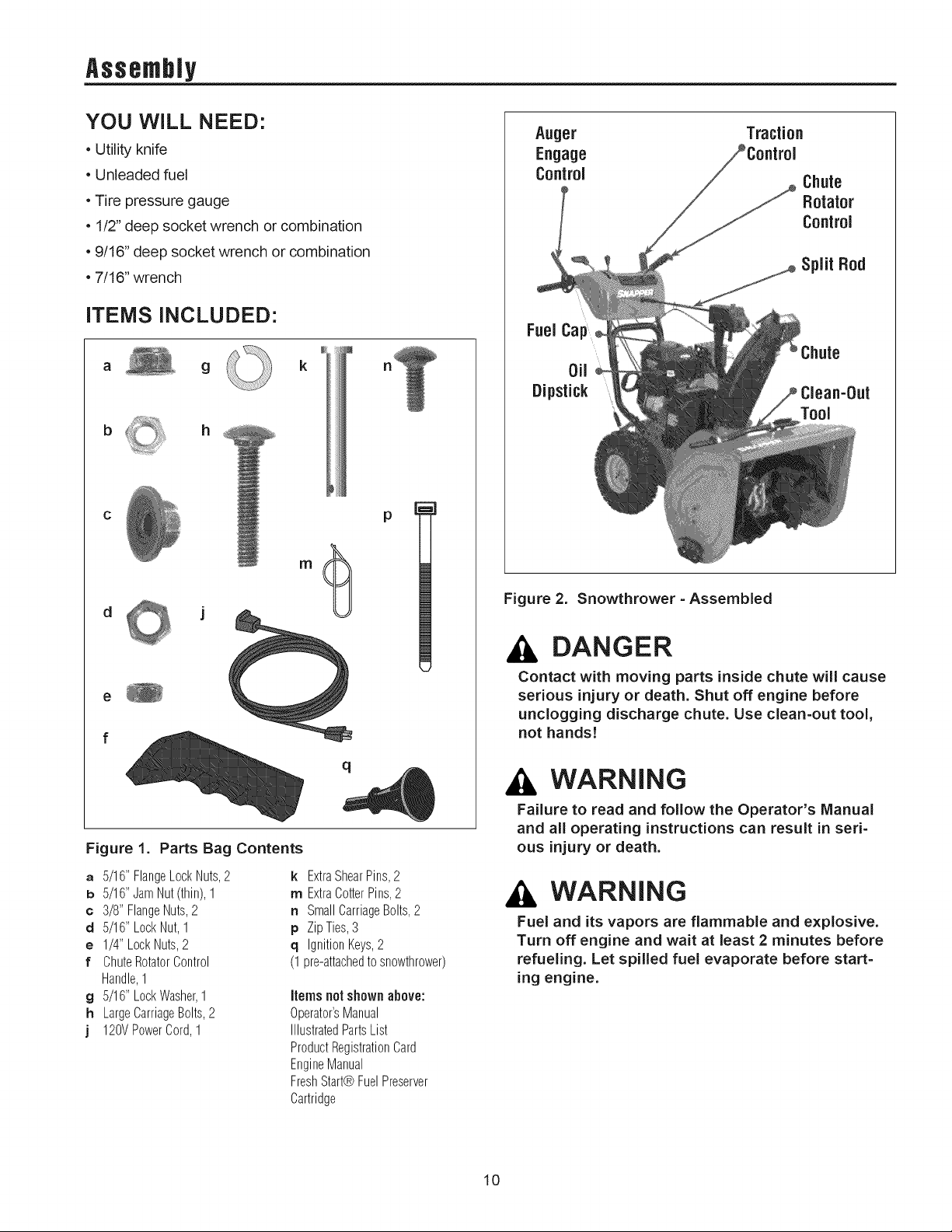

ITEMS INCLUDED:

a

b h

c

g k

Auger

Engage

Control

Traction

Chute

Rotator

Control

Split Rod

FuelCa

Chute

0il

Dipstick Clean-0ut

Tool

P

d

e

f

Figure 1. Parts Bag Contents

a 5/16" FlangeLockNuts,2

b 5/16"JamNut(thin),1

c 3/8" FlangeNuts,2

d 5/16" LockNut,1

e 1/4" LockNuts,2

f ChuteRotatorControl

Handle,1

g 5/16"LockWasher,1

h LargeCarriageBolts,2

j 120VPowerCord,1

q

k ExtraShearPins,2

m ExtraCotterPins,2

n SmallCarriageBolts,2

p ZipTies,3

q IgnitionKeys,2

(1 pre-attachedtosnowthrower)

Items not shown above:

Operator'sManual

IlhstratedPartsList

ProductRegistrationCard

EngineManual

FreshStart® FuelPreserver

Cartridge

Figure 2. Snowthrower - Assembled

DANGER

Contact with moving parts inside chute will cause

serious injury or death. Shut off engine before

unclogging discharge chute. Use clean=out tool,

not hands!

WARNING

Failure to read and follow the Operator's Manual

and all operating instructions can result in seri-

ous injury or death.

WARNING

Fuel and its vapors are flammable and explosive.

Turn off engine and wait at least 2 minutes before

refueling. Let spilled fuel evaporate before start-

ing engine.

10

Page 10

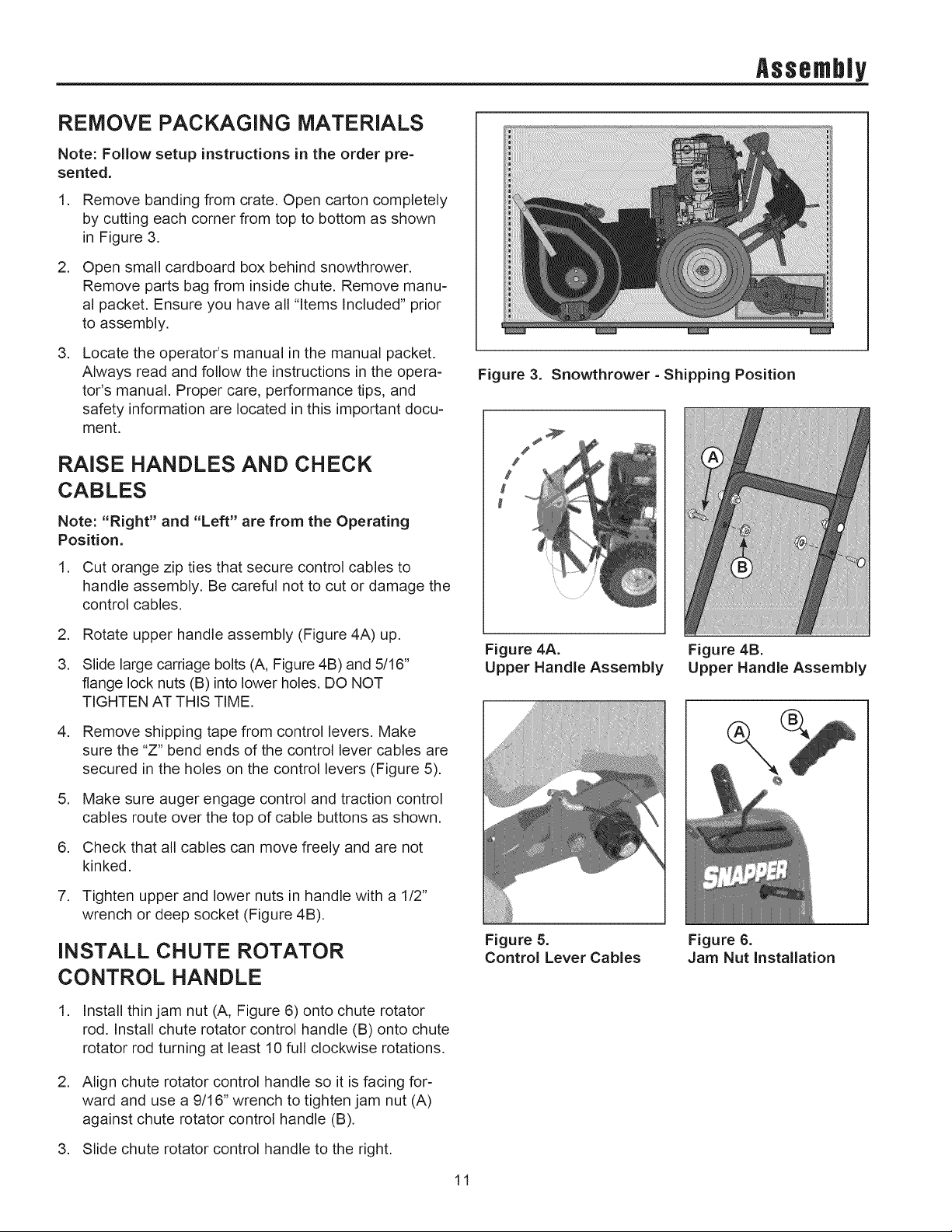

REMOVE PACKAGING MATERIALS

Note: Follow setup instructions in the order pre=

sented.

1. Remove banding from crate. Open carton completely

by cutting each corner from top to bottom as shown

in Figure 3.

,

Open small cardboard box behind snowthrower.

Remove parts bag from inside chute. Remove manu-

al packet. Ensure you have all "Items Included" prior

to assembly.

,

Locate the operator's manual in the manual packet.

Always read and follow the instructions in the opera-

tot's manual. Proper care, performance tips, and

safety information are located in this important docu-

ment.

RAISE HANDLES AND CHECK

CABLES

Note: "Right" and "Left" are from the Operating

Position.

AssemhJy

Figure 3. Snowthrower - Shipping Position

1. Cut orange zip ties that secure control cables to

handle assembly. Be careful not to cut or damage the

control cables.

,

Rotate upper handle assembly (Figure 4A) up.

3.

Slide large carriage bolts (A, Figure 4B) and 5/16"

flange lock nuts (B) into lower holes. DO NOT

TIGHTEN AT THIS TIME.

,

Remove shipping tape from control levers. Make

sure the "Z" bend ends of the control lever cables are

secured in the holes on the control levers (Figure 5).

,

Make sure auger engage control and traction control

cables route over the top of cable buttons as shown.

,

Check that all cables can move freely and are not

kinked.

7. Tighten upper and lower nuts in handle with a 1/2"

wrench or deep socket (Figure 4B).

INSTALL CHUTE ROTATOR

CONTROL HANDLE

1. Install thin jam nut (A, Figure 6) onto chute rotator

rod. Install chute rotator control handle (B) onto chute

rotator rod turning at least 10 full clockwise rotations.

Figure 4A.

Upper Handle Assembly

Figure 5.

Control Lever Cables

Figure 4B.

Upper Handle Assembly

\

Figure 6.

Jam Nut Installation

,

Align chute rotator control handle so it is facing for-

ward and use a 9/16" wrench to tighten jam nut (A)

against chute rotator control handle (B).

3. Slide chute rotator control handle to the right.

11

Page 11

AssemhJy

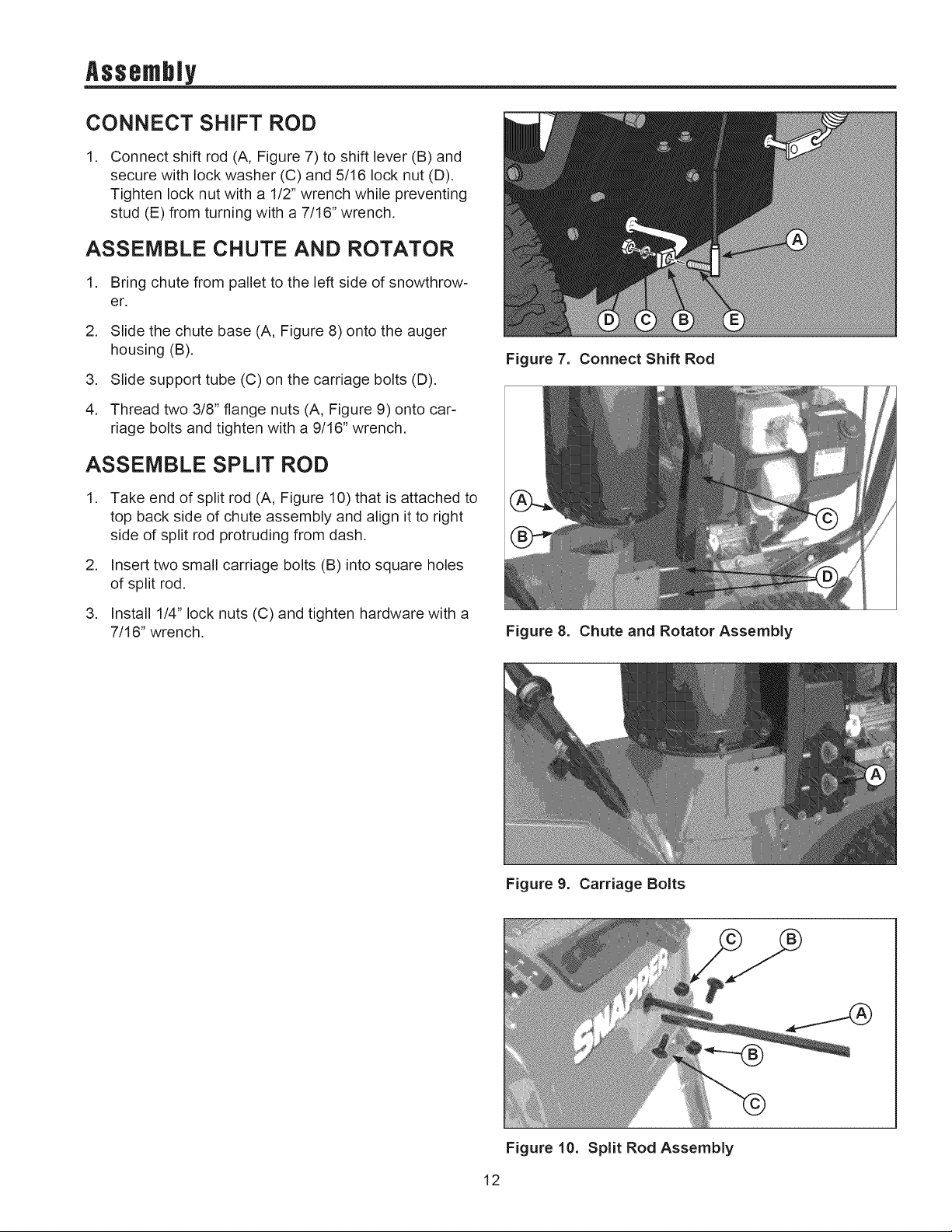

CONNECT SHIFT ROD

,

Connect shift rod (A, Figure 7) to shift lever (B) and

secure with lock washer (C) and 5/16 lock nut (D).

Tighten lock nut with a 1/2" wrench while preventing

stud (E) from turning with a 7/16" wrench.

ASSEMBLE CHUTE AND ROTATOR

1. Bring chute from pallet to the left side of snowthrow-

er.

2. Slide the chute base (A, Figure 8) onto the auger

housing (B).

3. Slide support tube (C) on the carriage bolts (D).

4. Thread two 3/8" flange nuts (A, Figure 9) onto car-

riage bolts and tighten with a 9/16" wrench.

ASSEMBLE SPLIT ROD

,

Take end of split rod (A, Figure 10) that is attached to

top back side of chute assembly and align it to right

side of split rod protruding from dash.

,

Insert two small carriage bolts (B) into square holes

of split rod.

,

Install 1/4" lock nuts (C) and tighten hardware with a

7/16" wrench.

Figure 7.

Figure 8.

Connect Shift Rod

Chute and Rotator Assembly

Figure 9. Carriage Bolts

Figure 10. Split Rod Assembly

12

Page 12

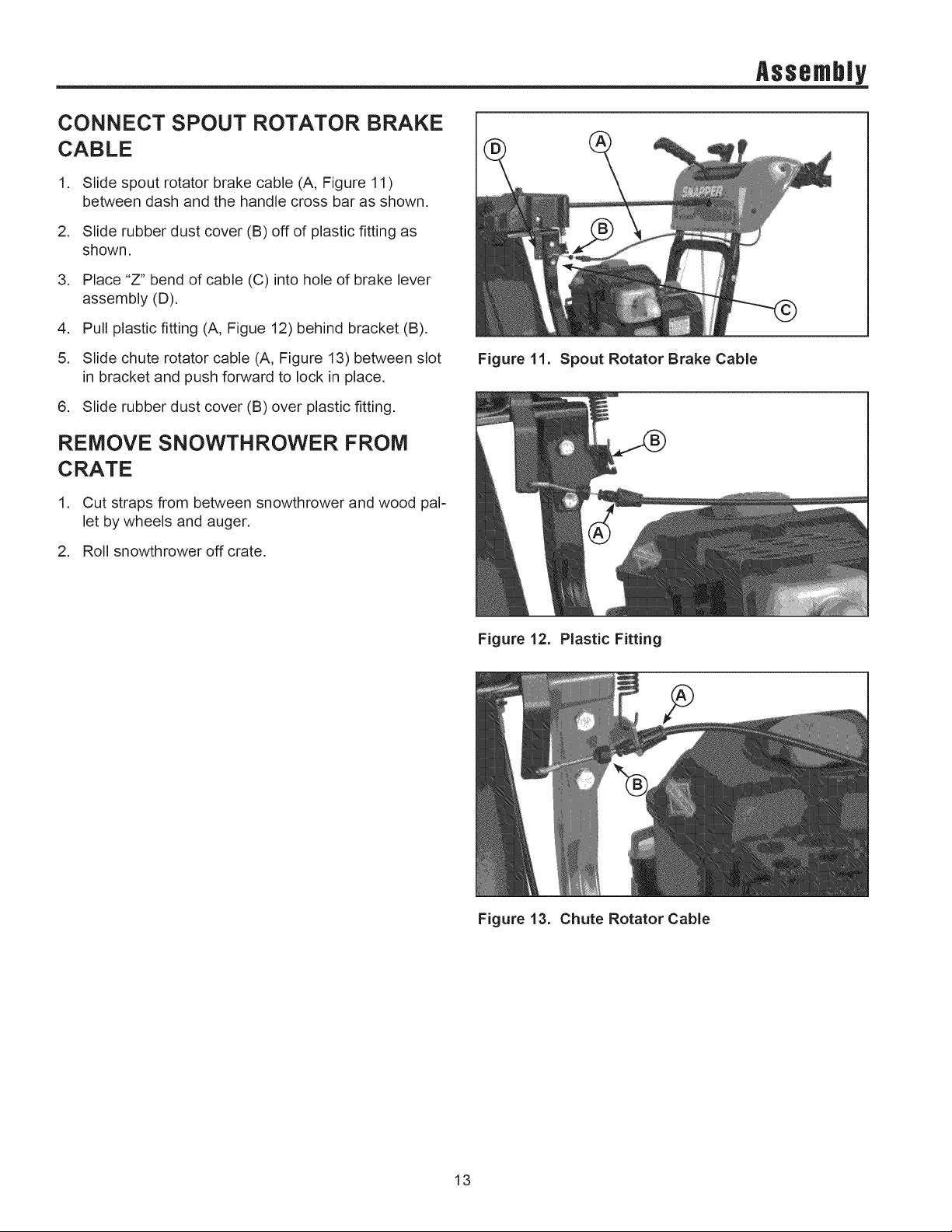

CONNECT SPOUT ROTATOR BRAKE

CABLE

1. Slide spout rotator brake cable (A, Figure 11)

between dash and the handle cross bar as shown.

2. Slide rubber dust cover (B) off of plastic fitting as

shown.

3. Place "Z" bend of cable (C) into hole of brake lever

assembly (D).

4. Pull plastic fitting (A, Figue 12) behind bracket (B).

AssembJy

5. Slide chute rotator cable (A, Figure 13) between slot

in bracket and push forward to lock in place.

6. Slide rubber dust cover (B) over plastic fitting.

REMOVE SNOWTHROWER FROM

CRATE

1. Cut straps from between snowthrower and wood pal-

let by wheels and auger.

2. Roll snowthrower off crate.

Figure 11. Spout Rotator Brake Cable

Figure 12. Plastic Fitting

Figure 13. Chute Rotator Cable

13

Page 13

AssembJy

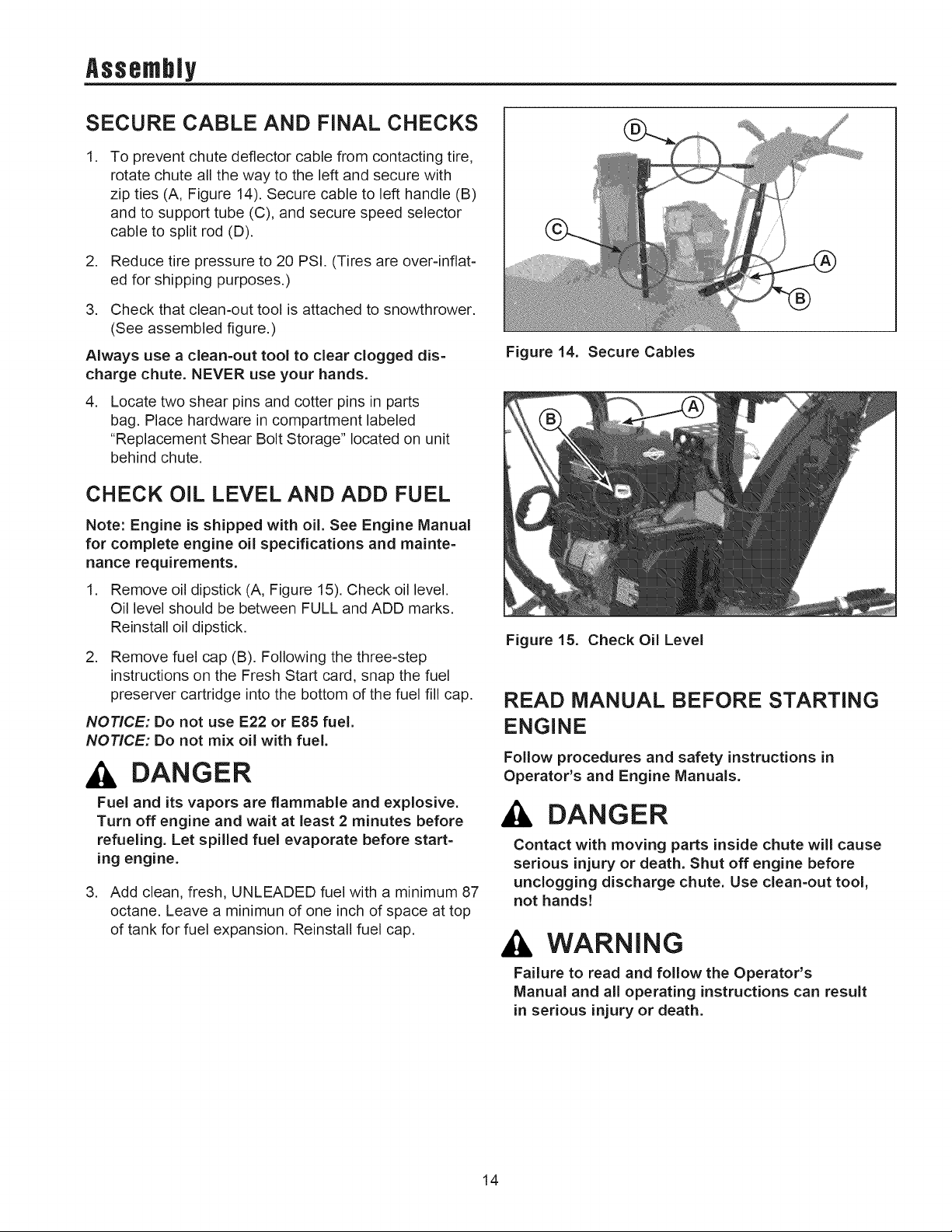

SECURE CABLE AND FINAL CHECKS

,

To prevent chute deflector cable from contacting tire,

rotate chute all the way to the left and secure with

zip ties (A, Figure 14). Secure cable to left handle (B)

and to support tube (C), and secure speed selector

cable to split rod (D).

2. Reduce tire pressure to 20 PSI. (Tires are over-inflat-

ed for shipping purposes.)

3. Check that clean-out tool is attached to snowthrower.

(See assembled figure.)

Always use a clean=out tool to clear clogged dis=

charge chute. NEVER use your hands.

,

Locate two shear pins and cotter pins in parts

bag. Place hardware in compartment labeled

"Replacement Shear Bolt Storage" located on unit

behind chute.

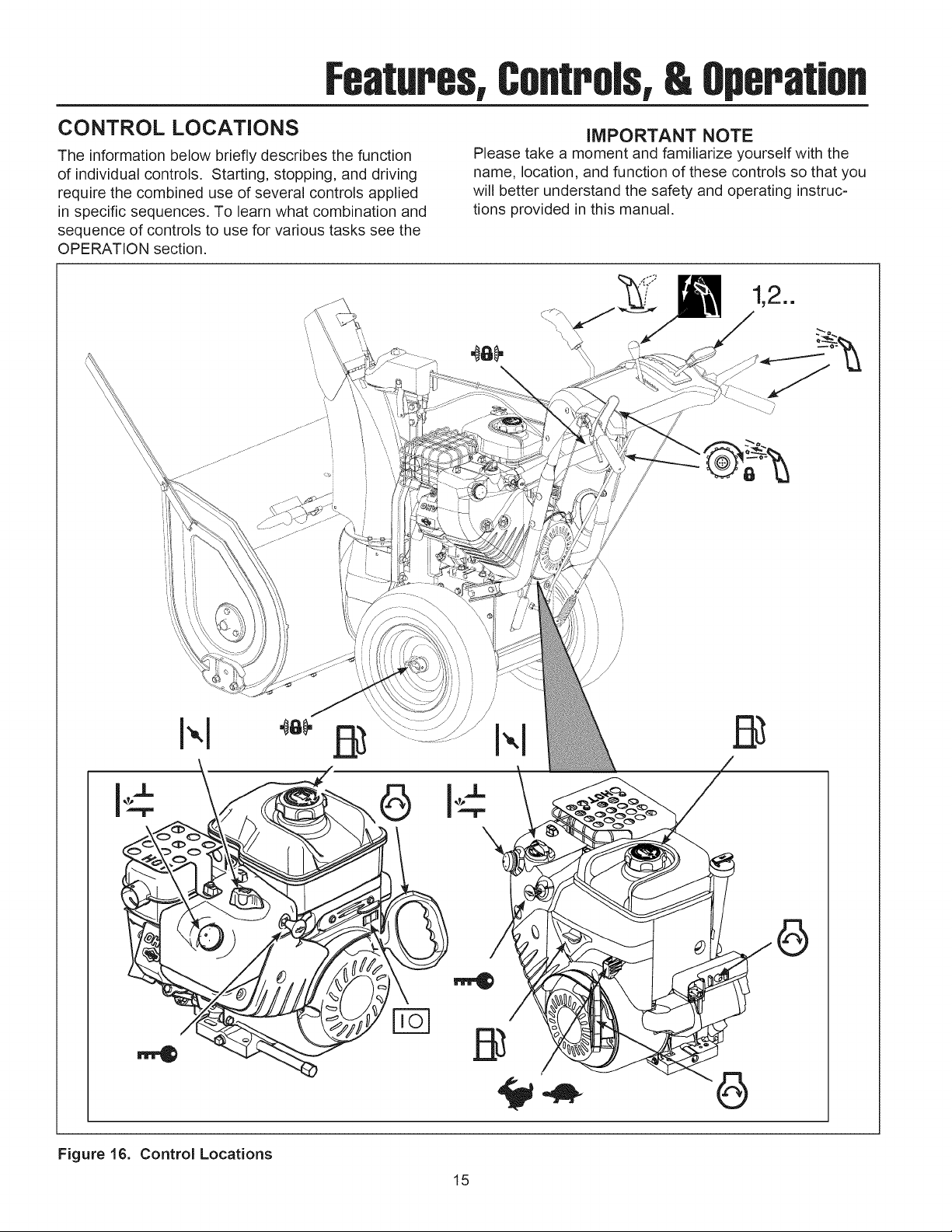

CHECK OIL LEVEL AND ADD FUEL

Figure 14. Secure Cables

Note: Engine is shipped with oil. See Engine Manual

for complete engine oil specifications and mainte=

nance requirements.

1. Remove oil dipstick (A, Figure 15). Check oil level.

Oil level should be between FULL and ADD marks.

Reinstall oil dipstick.

2. Remove fuel cap (B). Following the three-step

instructions on the Fresh Start card, snap the fuel

preserver cartridge into the bottom of the fuel fill cap.

NOTICE: Do not use E22 or E85 fuel.

NOTICE: Do not mix oil with fuel.

DANGER

Fuel and its vapors are flammable and explosive.

Turn off engine and wait at least 2 minutes before

refueling. Let spilled fuel evaporate before start-

ing engine.

3. Add clean, fresh, UNLEADED fuel with a minimum 87

octane. Leave a minimun of one inch of space at top

of tank for fuel expansion. Reinstall fuel cap.

Figure 15. Check Oil Level

READ MANUAL BEFORE STARTING

ENGINE

Follow procedures and safety instructions in

Operator's and Engine Manuals.

DANGER

Contact with moving parts inside chute will cause

serious injury or death. Shut off engine before

unclogging discharge chute. Use clean=out tool,

not hands!

WARNING

Failure to read and follow the Operator's

Manual and all operating instructions can result

in serious injury or death.

14

Page 14

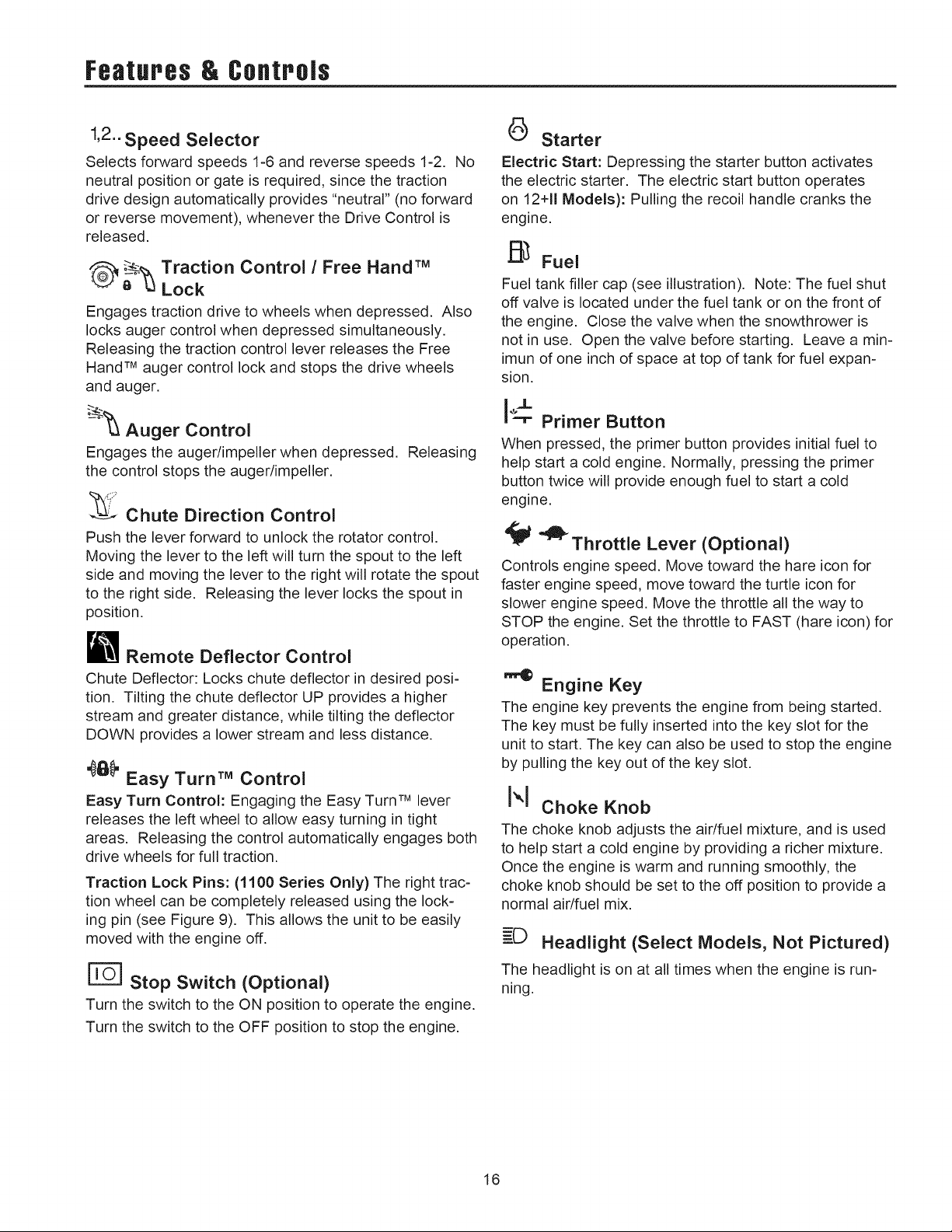

Features,Controls,&Operation

CONTROL LOCATIONS

The information below briefly describes the function

of individual controls. Starting, stopping, and driving

require the combined use of several controls applied

in specific sequences. To learn what combination and

sequence of controls to use for various tasks see the

OPERATION section.

IMPORTANT NOTE

Please take a moment and familiarize yourself with the

name, location, and function of these controls so that you

will better understand the safety and operating instruc-

tions provided in this manual,

\

/

Figure 16. Control Locations

15

Page 15

Features & Controls

1,2.. Speed Selector

Selects forward speeds 1-6 and reverse speeds 1-2. No

neutral position or gate is required, since the traction

drive design automatically provides "neutral" (no forward

or reverse movement), whenever the Drive Control is

released.

_'_ Traction Control / Free Hand TM

Engages traction drive to wheels when depressed. Also

locks auger control when depressed simultaneously.

Releasing the traction control lever releases the Free

Hand TM auger control lock and stops the drive wheels

and auger.

Lock

_ Auger Control

Engages the auger/impeller when depressed. Releasing

the control stops the auger/impeller.

_ Chute Direction Control

Push the lever forward to unlock the rotator control.

Moving the lever to the left will turn the spout to the left

side and moving the lever to the right will rotate the spout

to the right side. Releasing the lever locks the spout in

position.

M Remote Deflector Control

(_) Starter

Electric Start: Depressing the starter button activates

the electric starter. The electric start button operates

on 12+11Models): Pulling the recoil handle cranks the

engine.

J_ Fuel

Fuel tank filler cap (see illustration). Note: The fuel shut

off valve is located under the fuel tank or on the front of

the engine, Close the valve when the snowthrower is

not in use. Open the valve before starting, Leave a min-

imun of one inch of space at top of tank for fuel expan-

sion.

I":-_--Primer Button

When pressed, the primer button provides initial fuel to

help start a cold engine. Normally, pressing the primer

button twice will provide enough fuel to start a cold

engine.

'_ "lliFThrottle Lever (Optional)

Controls engine speed. Move toward the hare icon for

faster engine speed, move toward the turtle icon for

slower engine speed. Move the throttle all the way to

STOP the engine. Set the throttle to FAST (hare icon) for

operation.

Chute Deflector: Locks chute deflector in desired posi-

tion. Tilting the chute deflector UP provides a higher

stream and greater distance, while tilting the deflector

DOWN provides a lower stream and less distance.

•_O_' Easy Turn TM Control

Easy Turn Control: Engaging the Easy Turn TM lever

releases the left wheel to allow easy turning in tight

areas. Releasing the control automatically engages both

drive wheels for full traction.

Traction Lock Pins: (1100 Series Only) The right trac-

tion wheel can be completely released using the lock-

ing pin (see Figure 9). This allows the unit to be easily

moved with the engine off.

Stop Switch (Optional)

Turn the switch to the ON position to operate the engine,

Turn the switch to the OFF position to stop the engine,

Engine Key

The engine key prevents the engine from being started.

The key must be fully inserted into the key slot for the

unit to start, The key can also be used to stop the engine

by pulling the key out of the key slot.

I",1 Choke Knob

The choke knob adjusts the air/fuel mixture, and is used

to help start a cold engine by providing a richer mixture.

Once the engine is warm and running smoothly, the

choke knob should be set to the off position to provide a

normal air/fuel mix.

=D Headlight (Select Models, Not Pictured)

The headlight is on at all times when the engine is run-

ning.

16

Page 16

OperstJon

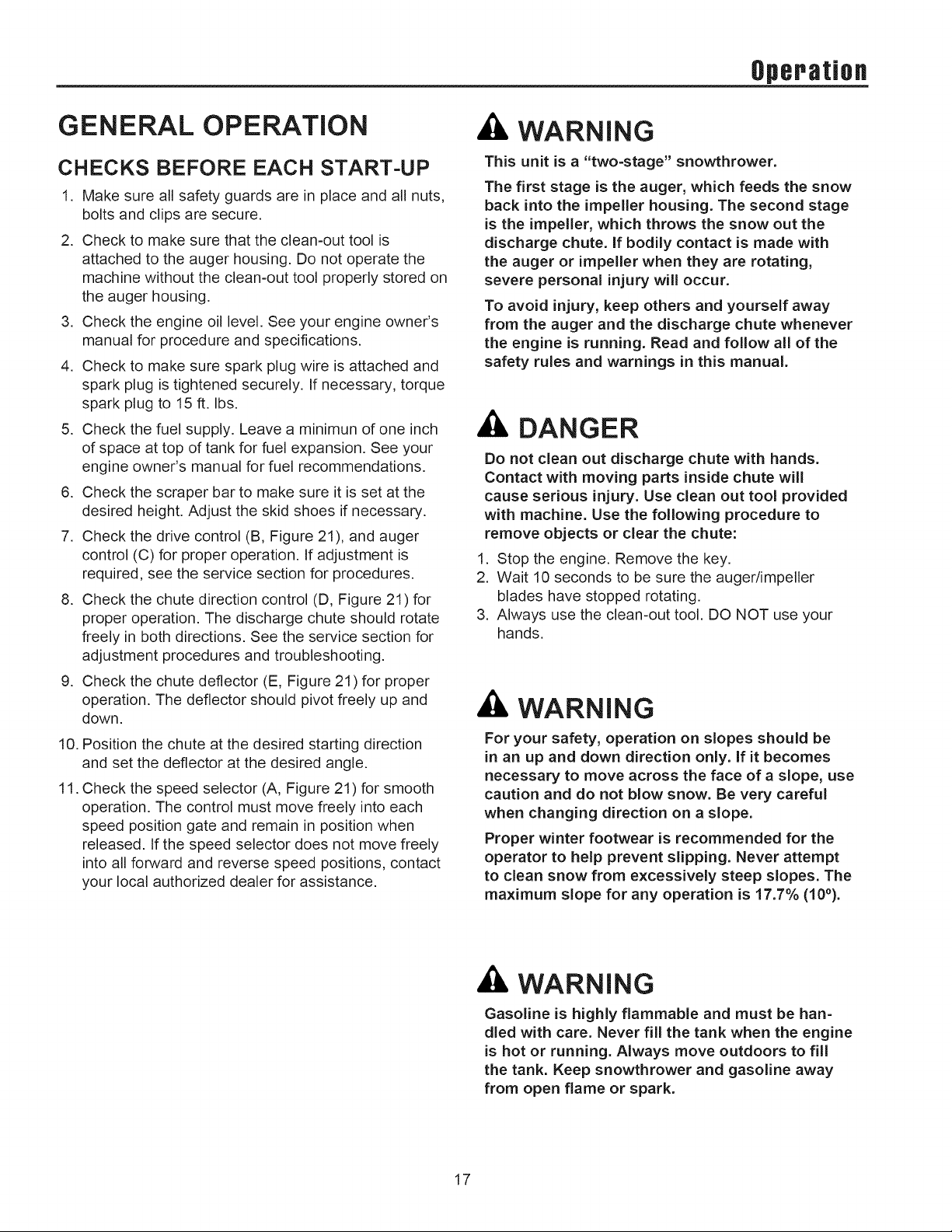

GENERAL OPERATION

CHECKS BEFORE EACH START=UP

1. Make sure all safety guards are in place and all nuts,

bolts and clips are secure.

2. Check to make sure that the clean-out tool is

attached to the auger housing. Do not operate the

machine without the clean-out tool properly stored on

the auger housing.

3. Check the engine oil level. See your engine owner's

manual for procedure and specifications.

4. Check to make sure spark plug wire is attached and

spark plug is tightened securely. If necessary, torque

spark plug to 15 ft. Ibs.

5. Check the fuel supply. Leave a minimun of one inch

of space at top of tank for fuel expansion. See your

engine owner's manual for fuel recommendations.

6. Check the scraper bar to make sure it is set at the

desired height. Adjust the skid shoes if necessary.

7. Check the drive control (B, Figure 21), and auger

control (C) for proper operation. If adjustment is

required, see the service section for procedures.

8. Check the chute direction control (D, Figure 21) for

proper operation. The discharge chute should rotate

freely in both directions. See the service section for

adjustment procedures and troubleshooting.

9. Check the chute deflector (E, Figure 21) for proper

operation. The deflector should pivot freely up and

down.

10. Position the chute at the desired starting direction

and set the deflector at the desired angle.

11. Check the speed selector (A, Figure 21) for smooth

operation. The control must move freely into each

speed position gate and remain in position when

released. If the speed selector does not move freely

into all forward and reverse speed positions, contact

your local authorized dealer for assistance.

WARNING

This unit is a "two=stage" snowthrower.

The first stage is the auger, which feeds the snow

back into the impeller housing. The second stage

is the impeller, which throws the snow out the

discharge chute. If bodily contact is made with

the auger or impeller when they are rotating,

severe personal injury will occur.

To avoid injury, keep others and yourself away

from the auger and the discharge chute whenever

the engine is running. Read and follow all of the

safety rules and warnings in this manual.

DANGER

Do not clean out discharge chute with hands.

Contact with moving parts inside chute will

cause serious injury. Use clean out tool provided

with machine. Use the following procedure to

remove objects or clear the chute:

1. Stop the engine. Remove the key.

2. Wait 10 seconds to be sure the auger/impeller

blades have stopped rotating.

3. Always use the clean-out tool. DO NOT use your

hands.

WARNING

For your safety, operation on slopes should be

in an up and down direction only. If it becomes

necessary to move across the face of a slope, use

caution and do not blow snow. Be very careful

when changing direction on a slope.

Proper winter footwear is recommended for the

operator to help prevent slipping. Never attempt

to clean snow from excessively steep slopes. The

maximum slope for any operation is 17.7% (10°).

WARNING

Gasoline is highly flammable and must be hart=

died with care. Never fill the tank when the engine

is hot or running. Always move outdoors to fill

the tank. Keep snowthrower and gasoline away

from open flame or spark.

17

Page 17

OperstJon

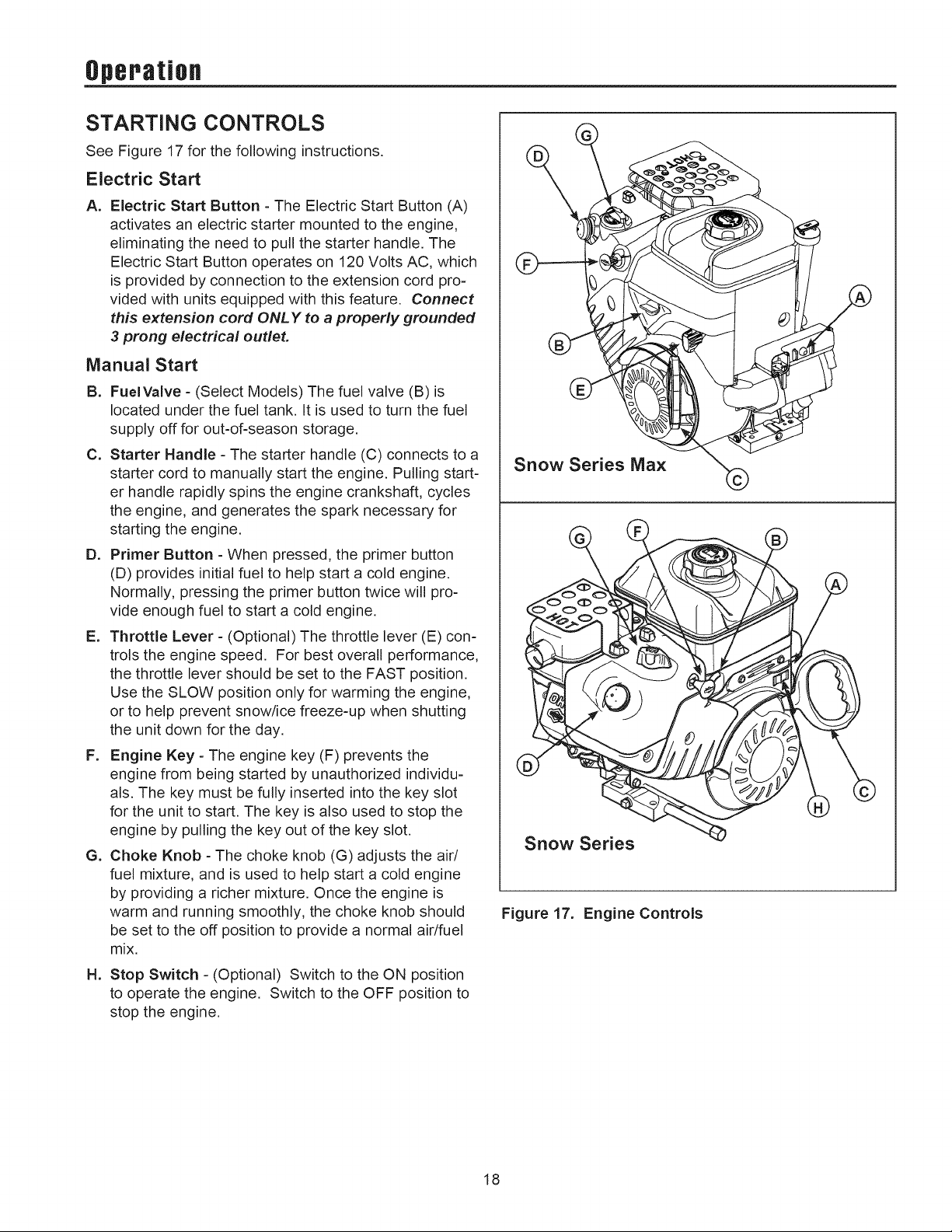

STARTING CONTROLS

See Figure 17 for the following instructions.

Electric Start

A=

Electric Start Button - The Electric Start Button (A)

activates an electric starter mounted to the engine,

eliminating the need to pull the starter handle. The

Electric Start Button operates on 120 Volts AC, which

is provided by connection to the extension cord pro-

vided with units equipped with this feature. Connect

this extension cord ONLY to a properly grounded

3 prong electrical outlet.

Manual Start

B. FuelValve - (Select Models) The fuel valve (B) is

located under the fuel tank. It is used to turn the fuel

supply off for out-of-season storage.

Co Starter Handle - The starter handle (C) connects to a

starter cord to manually start the engine. Pulling start-

er handle rapidly spins the engine crankshaft, cycles

the engine, and generates the spark necessary for

starting the engine.

D. Primer Button - When pressed, the primer button

(D) provides initial fuel to help start a cold engine.

Normally, pressing the primer button twice will pro-

vide enough fuel to start a cold engine.

E. Throttle Lever - (Optional) The throttle lever (E) con-

trols the engine speed. For best overall performance,

the throttle lever should be set to the FAST position.

Use the SLOW position only for warming the engine,

or to help prevent snow/ice freeze-up when shutting

the unit down for the day.

F. Engine Key - The engine key (F) prevents the

engine from being started by unauthorized individu-

als. The key must be fully inserted into the key slot

for the unit to start. The key is also used to stop the

engine by pulling the key out of the key slot.

G. Choke Knob - The choke knob (G) adjusts the air/

fuel mixture, and is used to help start a cold engine

by providing a richer mixture. Once the engine is

warm and running smoothly, the choke knob should

be set to the off position to provide a normal air/fuel

mix.

Snow Series Max

Snow Series

Figure 17. Engine Controls

Ho Stop Switch - (Optional) Switch to the ON position

to operate the engine. Switch to the OFF position to

stop the engine.

18

Page 18

Operation

STARTING THE ENGINE

WARNING

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than you

can let go. Broken bones, fractures, bruises or

sprains could result. When starting engine, pull

the starter cord slowly until resistance is felt and

then pull rapidly to avoid kickback.

WARNING

Gasoline and its vapors are extremely flammable

and explosive. Fire or explosion can cause severe

burns or death. When starting the engine, ensure

that spark plug, muffler, fuel cap and air cleaner

are in place and secured. Do not crank engine

with spark plug removed, if engine floods, set

choke (if equipped) to open/run position.

A CAUTION

This engine was shipped from Briggs & Stratton

with oil. Before you start the engine, make sure

you check oil according to the instructions in the

Engine Owner's Manual.

, Check the oil level. See "How To Check/Add Oil"

section in Engine Owner's Manual.

2. Make sure equipment drive controls, if equipped, are

disengaged. See the equipment manual for location

and operation of these controls.

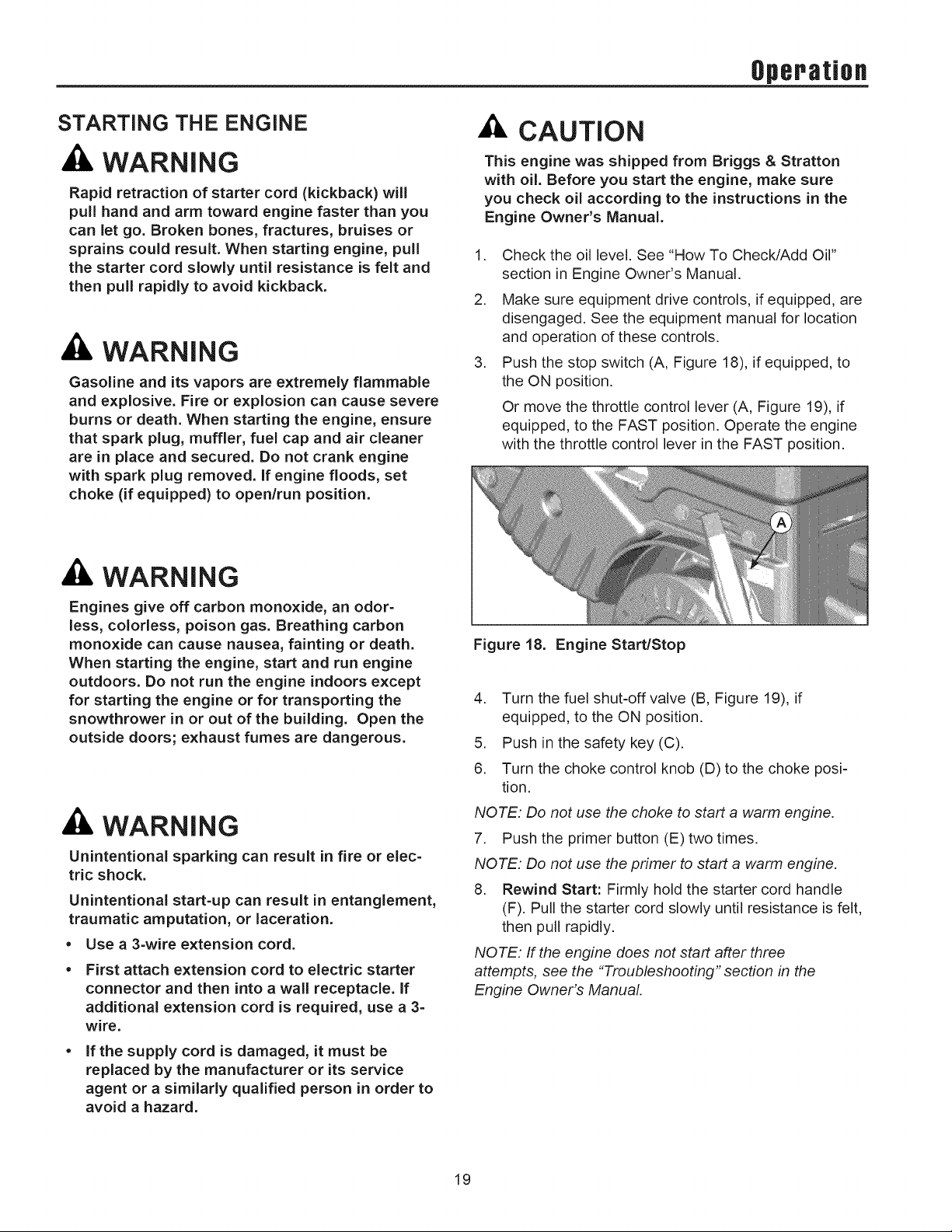

3. Push the stop switch (A, Figure 18), if equipped, to

the ON position.

Or move the throttle control lever (A, Figure 19), if

equipped, to the FAST position. Operate the engine

with the throttle control lever in the FAST position.

WARNING

Engines give off carbon monoxide, an odor-

less, colorless, poison gas. Breathing carbon

monoxide can cause nausea, fainting or death.

When starting the engine, start and run engine

outdoors. Do not run the engine indoors except

for starting the engine or for transporting the

snowthrower in or out of the building. Open the

outside doors; exhaust fumes are dangerous.

WARNING

Unintentional sparking can result in fire or elec-

tric shock.

Unintentional start-up can result in entanglement,

traumatic amputation, or laceration.

• Use a 3-wire extension cord.

First attach extension cord to electric starter

connector and then into a wall receptacle. If

additional extension cord is required, use a 3-

wire.

Figure 18. Engine Start/Stop

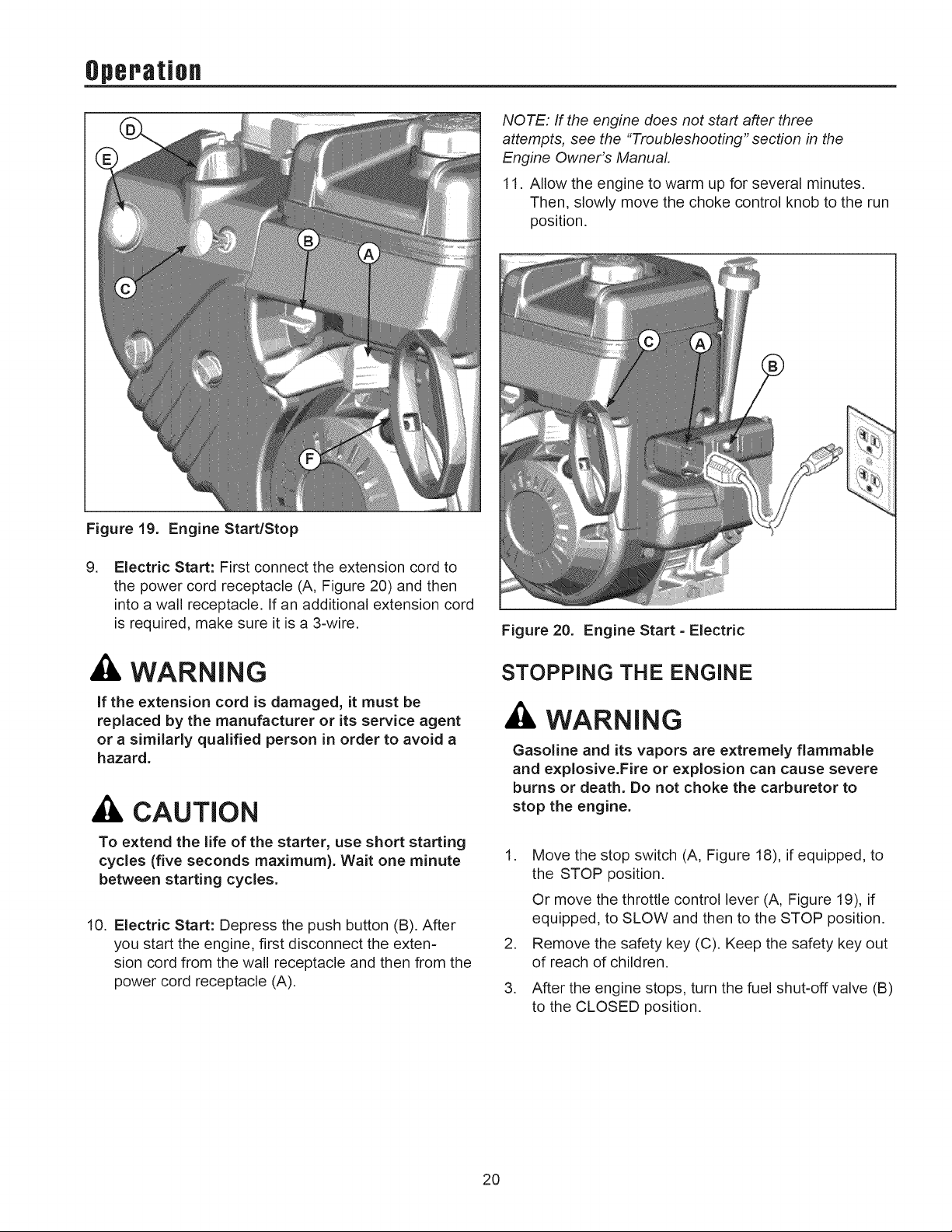

4. Turn the fuel shut-off valve (B, Figure 19), if

equipped, to the ON position.

5. Push in the safety key (C).

6. Turn the choke control knob (D) to the choke posi-

tion.

NOTE: Do not use the choke to start a warm engine.

7. Push the primer button (E) two times.

NOTE: Do not use the primer to start a warm engine.

8. Rewind Start: Firmly hold the starter cord handle

(F). Pull the starter cord slowly until resistance is felt,

then pull rapidly.

NOTE: If the engine does not start after three

attempts, see the "Troubleshooting" section in the

Engine Owner's Manual.

if the supply cord is damaged, it must be

replaced by the manufacturer or its service

agent or a similarly qualified person in order to

avoid a hazard.

19

Page 19

(Jperstion

NOTE: If the engine does not start after three

attempts, see the "Troubleshooting" section in the

Engine Owner's Manual.

11. Allow the engine to warm up for several minutes.

Then, slowly move the choke control knob to the run

position.

Figure 19. Engine Start/Stop

, Electric Start: First connect the extension cord to

the power cord receptacle (A, Figure 20) and then

into a wall receptacle. If an additional extension cord

is required, make sure it is a 3-wire.

A WARNING

If the extension cord is damaged, it must be

replaced by the manufacturer or its service agent

or a similarly qualified person in order to avoid a

hazard.

CAUTION

To extend the life of the starter, use short starting

cycles (five seconds maximum). Wait one minute

between starting cycles.

10. Electric Start: Depress the push button (B). After

you start the engine, first disconnect the exten-

sion cord from the wall receptacle and then from the

power cord receptacle (A).

Figure 20. Engine Start - Electric

STOPPING THE ENGINE

WARNING

Gasoline and its vapors are extremely flammable

and explosive.Fire or explosion can cause severe

burns or death. Do not choke the carburetor to

stop the engine.

,

Move the stop switch (A, Figure 18), if equipped, to

the STOP position.

Or move the throttle control lever (A, Figure 19), if

equipped, to SLOW and then to the STOP position.

,

Remove the safety key (C). Keep the safety key out

of reach of children.

,

After the engine stops, turn the fuel shut-off valve (B)

to the CLOSED position.

2O

Page 20

OperstJon

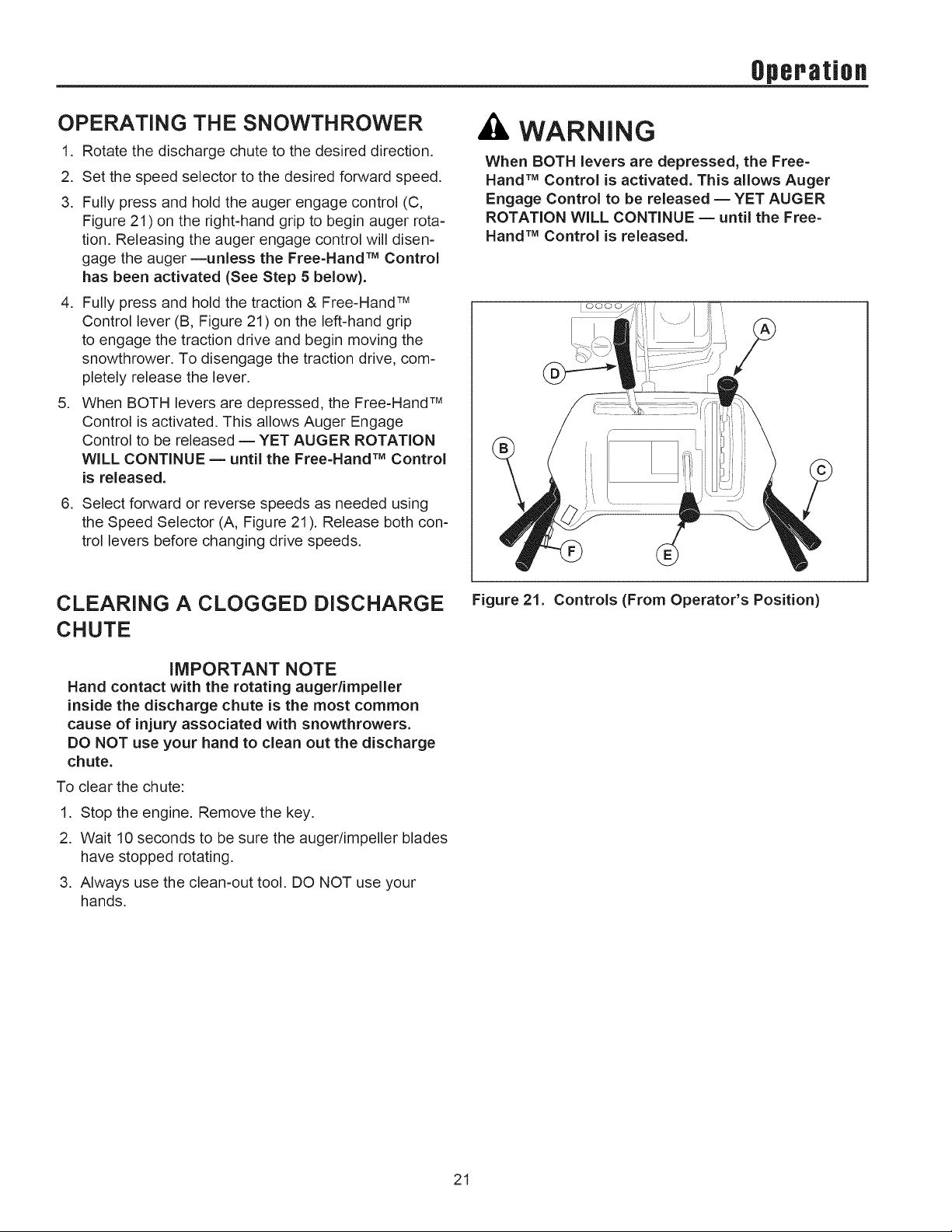

OPERATING THE SNOWTHROWER

1. Rotate the discharge chute to the desired direction.

2. Set the speed selector to the desired forward speed.

3. Fully press and hold the auger engage control (C,

Figure 21) on the right-hand grip to begin auger rota-

tion. Releasing the auger engage control will disen-

gage the auger--unless the Free=Hand TM Control

has been activated (See Step 5 below).

4. Fully press and hold the traction & Free-Hand TM

Control lever (B, Figure 21) on the left-hand grip

to engage the traction drive and begin moving the

snowthrower. To disengage the traction drive, com-

pletely release the lever.

.

When BOTH levers are depressed, the Free-Hand TM

Control is activated. This allows Auger Engage

Control to be released -- YET AUGER ROTATION

WILL CONTINUE -- until the Free=Hand TM Control

is released.

6. Select forward or reverse speeds as needed using

the Speed Selector (A, Figure 21). Release both con-

trol levers before changing drive speeds.

A WARNING

When BOTH levers are depressed, the Free=

Hand TM Control is activated. This allows Auger

Engage Control to be released m YET AUGER

ROTATION WILL CONTINUE m until the Free=

Hand TM Control is released.

CLEARING A CLOGGED DISCHARGE

CHUTE

IMPORTANT NOTE

Hand contact with the rotating auger/impeller

inside the discharge chute is the most common

cause of injury associated with snowthrowers.

DO NOT use your hand to clean out the discharge

chute.

To clear the chute:

1. Stop the engine. Remove the key.

2. Wait 10 seconds to be sure the auger/impeller blades

have stopped rotating.

3. Always use the clean-out tool. DO NOT use your

hands.

Figure 21. Controls (From Operator's Position)

21

Page 21

OperstJon

GROUND SPEED SELECTOR

Use the speed selector (A, Figure 21) to control the drive

speed of the snowthrower. There are six forward speeds

and two reverse speeds.

Use the lower speeds to blow deep or wet snow. Use the

higher speeds to blow light snow or to drive the snow-

thrower without blowing snow.

To change speeds, release the auger control lever (B,

Figure 21), then move the speed selector to the desired

setting. Fully depress the control levers to resume.

ENGINE SPEED

Always run the snowthrower at full throttle.

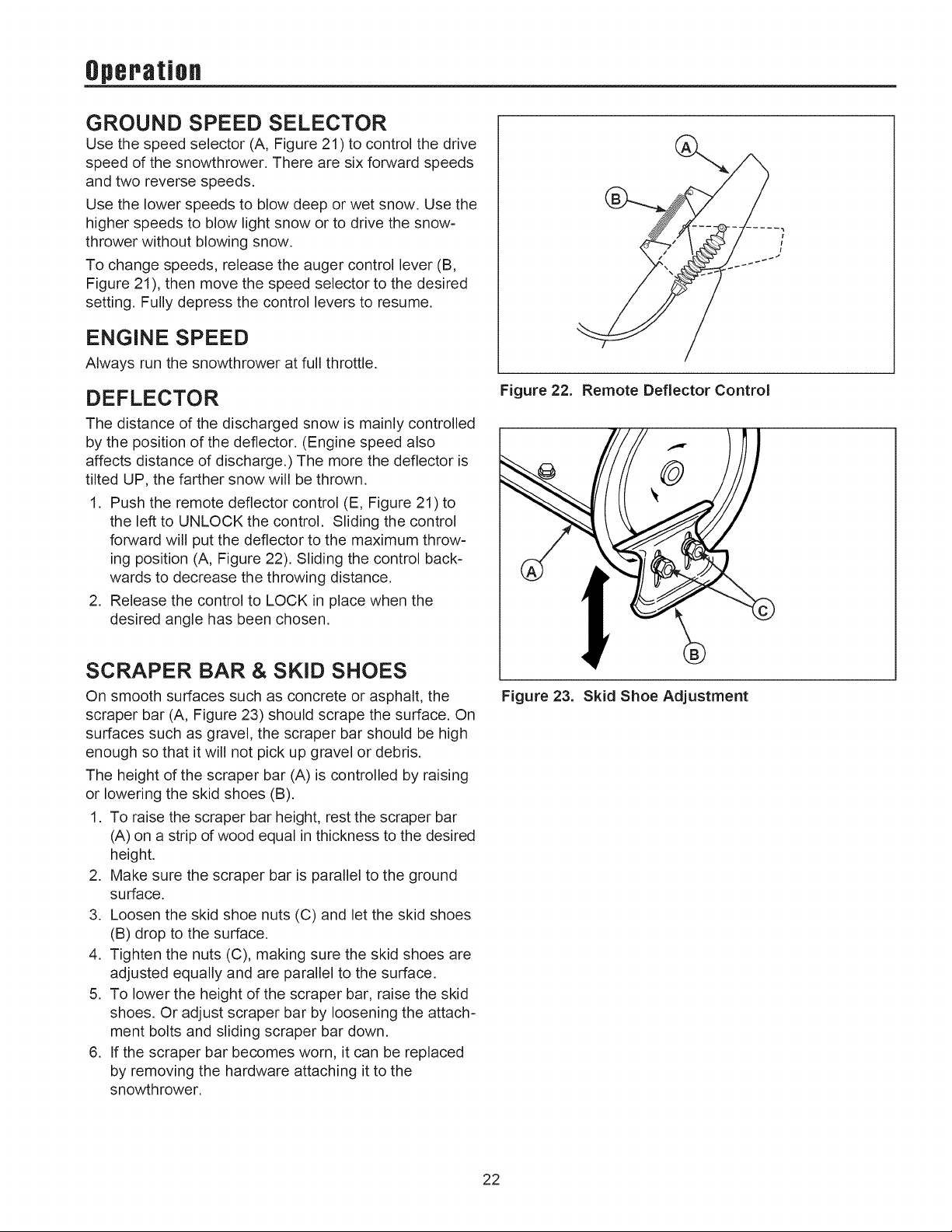

DEFLECTOR

The distance of the discharged snow is mainly controlled

by the position of the deflector. (Engine speed also

affects distance of discharge.) The more the deflector is

tilted UP, the farther snow will be thrown.

1. Push the remote deflector control (E, Figure 21) to

the left to UNLOCK the control. Sliding the control

forward will put the deflector to the maximum throw-

ing position (A, Figure 22). Sliding the control back-

wards to decrease the throwing distance.

2. Release the control to LOCK in place when the

desired angle has been chosen.

Figure 22.

Remote Deflector Control

1

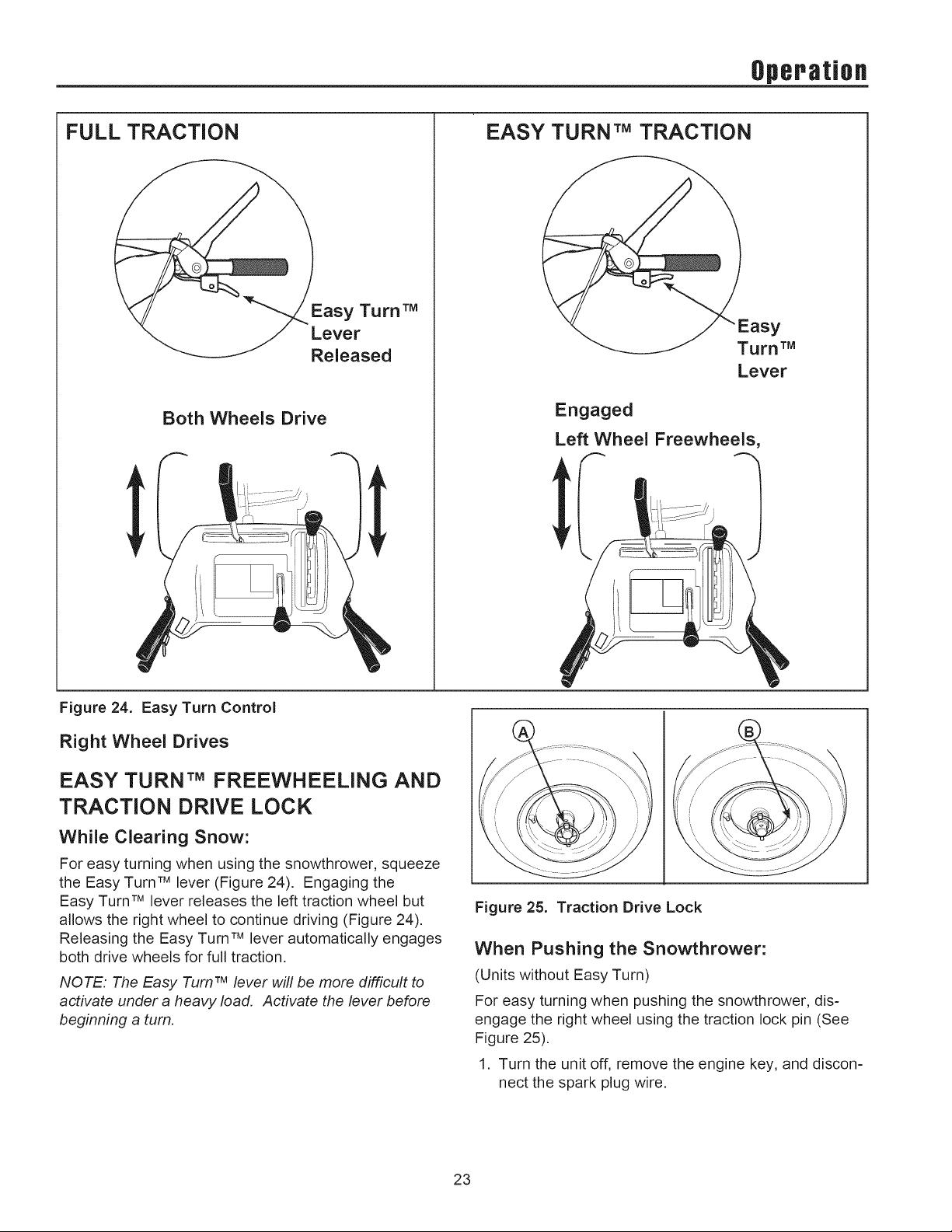

SCRAPER BAR & SKiD SHOES

On smooth surfaces such as concrete or asphalt, the

scraper bar (A, Figure 23) should scrape the surface. On

surfaces such as gravel, the scraper bar should be high

enough so that it will not pick up gravel or debris.

The height of the scraper bar (A) is controlled by raising

or lowering the skid shoes (B).

1. To raise the scraper bar height, rest the scraper bar

(A) on a strip of wood equal in thickness to the desired

height.

2. Make sure the scraper bar is parallel to the ground

surface.

3. Loosen the skid shoe nuts (C) and let the skid shoes

(B) drop to the surface.

4. Tighten the nuts (C), making sure the skid shoes are

adjusted equally and are parallel to the surface.

5. To lower the height of the scraper bar, raise the skid

shoes. Or adjust scraper bar by loosening the attach-

ment bolts and sliding scraper bar down.

6. If the scraper bar becomes worn, it can be replaced

by removing the hardware attaching it to the

snowthrower.

Figure 23.

Skid Shoe Adjustment

22

Page 22

Operation

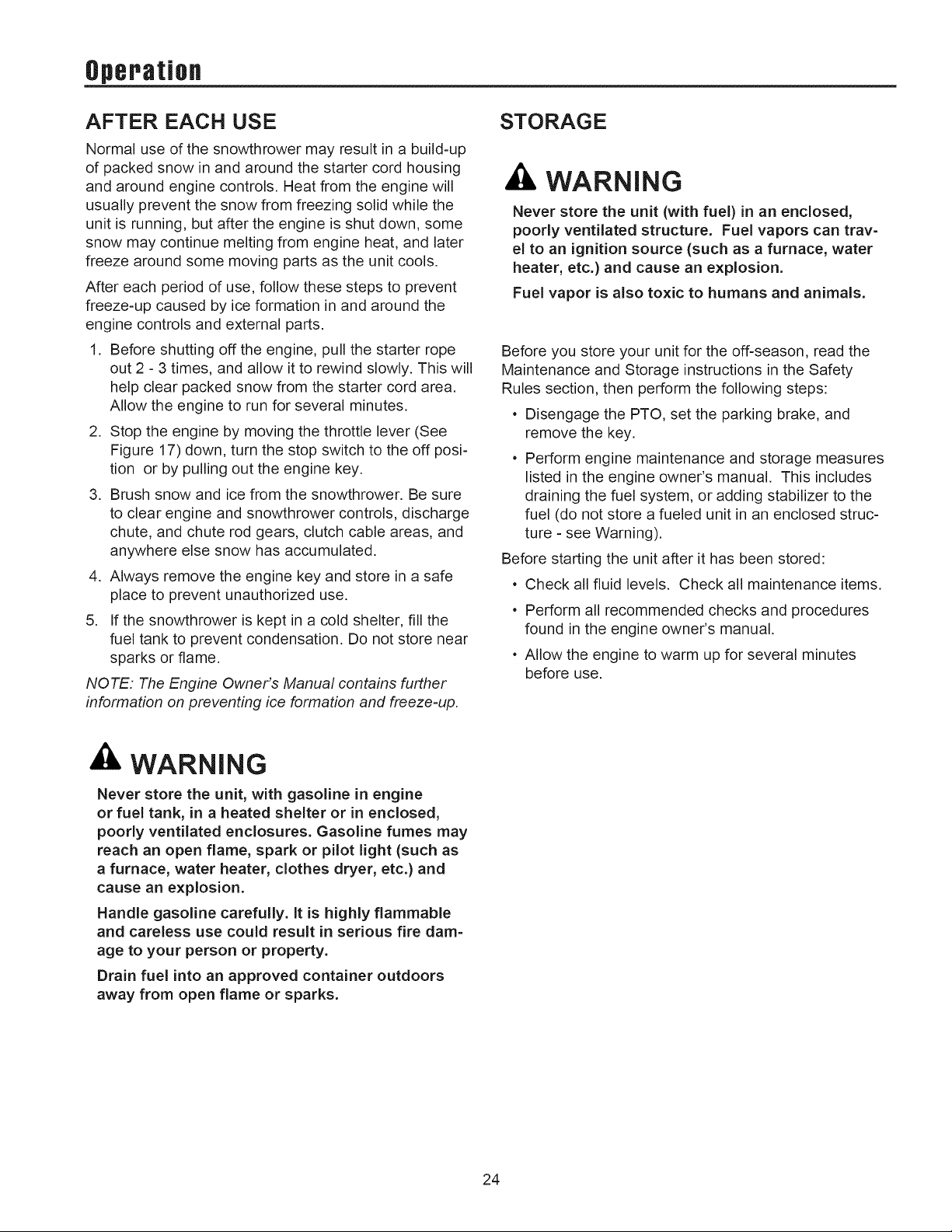

FULL TRACTION

Both Wheels Drive

Easy Turn TM

Lever

Released

EASY TURN TM TRACTION

Y

Turn TM

Lever

Engaged

Left Wheel Freewheels,

Figure 24. Easy Turn Control

Right Wheel Drives

EASY TURN TM FREEWHEELING AND

TRACTION DRIVE LOCK

While Clearing Snow:

For easy turning when using the snowthrower, squeeze

the Easy Turn TM lever (Figure 24). Engaging the

Easy Turn TM lever releases the left traction wheel but

allows the right wheel to continue driving (Figure 24).

Releasing the Easy Turn TMlever automatically engages

both drive wheels for full traction.

NOTE: The Easy Turn TM lever will be more difficult to

activate under a heavy load. Activate the lever before

beginning a turn.

Figure 25. Traction Drive Lock

When Pushing the Snowthrower:

(Units without Easy Turn)

For easy turning when pushing the snowthrower, dis-

engage the right wheel using the traction lock pin (See

Figure 25).

1. Turn the unit off, remove the engine key, and discon-

nect the spark plug wire.

23

Page 23

OperstJon

AFTER EACH USE

Normal use of the snowthrower may result in a build-up

of packed snow in and around the starter cord housing

and around engine controls. Heat from the engine will

usually prevent the snow from freezing solid while the

unit is running, but after the engine is shut down, some

snow may continue melting from engine heat, and later

freeze around some moving parts as the unit cools.

After each period of use, follow these steps to prevent

freeze-up caused by ice formation in and around the

engine controls and external parts.

1. Before shutting off the engine, pull the starter rope

out 2 - 3 times, and allow it to rewind slowly. This will

help clear packed snow from the starter cord area.

Allow the engine to run for several minutes.

2. Stop the engine by moving the throttle lever (See

Figure 17) down, turn the stop switch to the off posi-

tion or by pulling out the engine key.

, Brush snow and ice from the snowthrower. Be sure

to clear engine and snowthrower controls, discharge

chute, and chute rod gears, clutch cable areas, and

anywhere else snow has accumulated.

4. Always remove the engine key and store in a safe

place to prevent unauthorized use.

5. If the snowthrower is kept in a cold shelter, fill the

fuel tank to prevent condensation. Do not store near

sparks or flame.

NOTE: The Engine Owner's Manual contains further

information on preventing ice formation and freeze=up.

STORAGE

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can trav-

el to an ignition source (such as a furnace, water

heater, etc.) and cause an explosion.

Fuel vapor is also toxic to humans and animals.

Before you store your unit for the off-season, read the

Maintenance and Storage instructions in the Safety

Rules section, then perform the following steps:

Disengage the PTO, set the parking brake, and

remove the key.

Perform engine maintenance and storage measures

listed in the engine owner's manual. This includes

draining the fuel system, or adding stabilizer to the

fuel (do not store a fueled unit in an enclosed struc-

ture - see Warning).

Before starting the unit after it has been stored:

• Check all fluid levels. Check all maintenance items.

• Perform all recommended checks and procedures

found in the engine owner's manual.

• Allow the engine to warm up for several minutes

before use.

WARNING

Never store the unit, with gasoline in engine

or fuel tank, in a heated shelter or in enclosed,

poorly ventilated enclosures. Gasoline fumes may

reach an open flame, spark or pilot light (such as

a furnace, water heater, clothes dryer, etc.) and

cause an explosion.

Handle gasoline carefully. It is highly flammable

and careless use could result in serious fire dam-

age to your person or property.

Drain fuel into an approved container outdoors

away from open flame or sparks.

24

Page 24

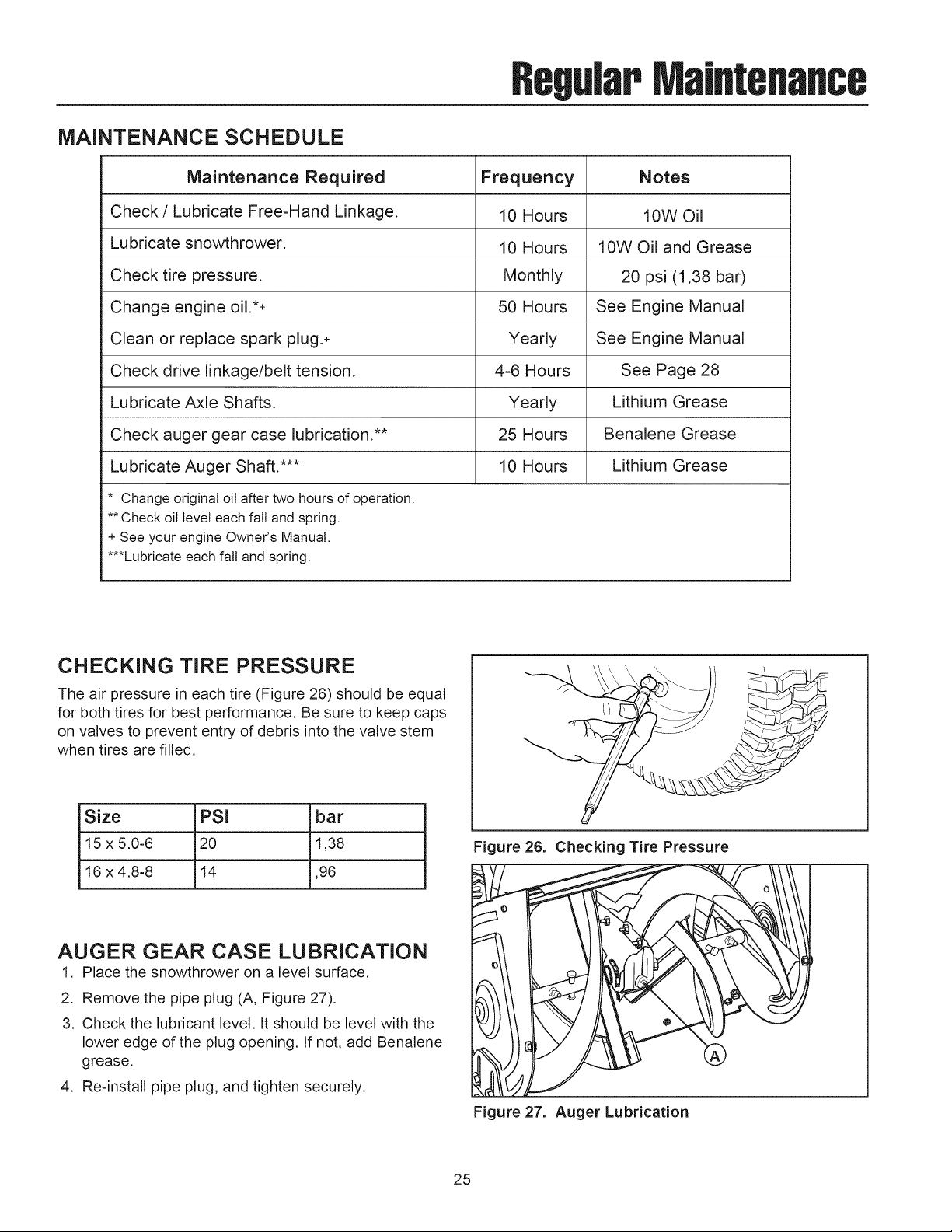

MAINTENANCE SCHEDULE

RegularMaintenance

Maintenance Required

Check/Lubricate Free-Hand Linkage.

Lubricate snowthrower.

Check tire pressure.

Change engine oil.*+

Clean or replace spark plug.+

Check drive linkage/belt tension.

Lubricate Axle Shafts.

Check auger gear case lubrication.**

Lubricate Auger Shaft.***

* Changeoriginal oil after two hoursof operation.

** Check oil level each fall and spring.

+ See your engine Owner's Manual.

***Lubricate each fall and spring.

Frequency Notes

10 Hours 10W Oil

10 Hours 10W Oil and Grease

Monthly 20 psi (1,38 bar)

50 Hours See Engine Manual

Yearly See Engine Manual

4-6 Hours See Page 28

Yearly Lithium Grease

25 Hours Benalene Grease

10 Hours Lithium Grease

CHECKING TIRE PRESSURE

The air pressure in each tire (Figure 26) should be equal

for both tires for best performance. Be sure to keep caps

on valves to prevent entry of debris into the valve stem

when tires are filled.

Size PSi

15 x 5.0-6 20

16 x 4.8-8 14

bar

1,38

,96

AUGER GEAR CASE LUBRICATION

1. Place the snowthrower on a level surface.

2. Remove the pipe plug (A, Figure 27).

3. Check the lubricant level. Itshould be level with the

lower edge of the plug opening. If not, add Benalene

grease.

4. Re-install pipe plug, and tighten securely.

Figure 26. Checking Tire Pressure

Figure 27. Auger Lubrication

25

Page 25

ReguJapMaintenance

LUBRICATION

iMPORTANT NOTE

it is very important that grease fittings on the

auger shaft are lubricated regularly, if auger rusts

to shaft, damage to worm gear may occur if shear

pins do not break.

To prevent wheels rusting to axles, it is also nec=

essary to remove the wheeJs and grease the axles

regularly.

Remove wheels and grease axles once each year.

Apply 5W=30 synthetic motor oil to the friction disk drive

hex shaft (A, Figure 29).

Apply medium weight (10W) oil to points shown (See

Figures 28-31).

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts, pulley grooves, drive disc, and friction disc.

LUBRICATION NOTES:

Grease locations indicated by grease gun symbol.

Use grease fittings when present. Disassemble

parts to apply grease to moving parts when grease

fittings are not installed.

Figure 29. Drive Lubrication

\

Oil locations indicated by oil can symbol. Do not

allow oil to drip onto traction drive or friction disc.

Do not lubricate remote deflector control.

I

Figure 30. Lubricate Axles and Control Levers

Figure 31. Deflector Hinge

Figure 28. Lubricate Spout Rotator

26

Page 26

CHECK / LUBRICATE FREE-HAND

LINKAGE

Check the function of the Free=Hand controls. The con-

trois should function as described in the CONTROLS

section. It is critical for the safe operation of the unit

that the controls disengage when released.

Lubricate as shown in Figure 32.

IMPORTANT NOTE

If the controls do not function properly, lubricate them. If

lubrication does not rectify the problem, see your autho=

rized service dealer. Under no circumstances should the

unit be used if the controls are not functioning properly.

IMPORTANT NOTE

It is very important that grease fittings on the auger shaft

are lubricated regularly. If auger rusts to the shaft, dam-

age to worm gear may occur if shear pins do not break.

ReguJapMaintenance

Figure 32. Lubricate Free=Hand Control

LUBRICATE AUGER SHAFT

ASSEMBLY

1. Remove cotter pin (C, Figure 33) and shear pin (B).

2. Use a grease gun and squirt several shots of grease

into grease fitting (A).

3. Rotate auger assembly (D) several times to distribute

the grease evenly. Repeat Step 2.

4. Reinstall shear pin (B) and cotter pin (C).

5. Repeat procedure for other side.

Figure 33. Lubricate Auger Shaft Assembly

27

Page 27

Troubleshooting, , & Service

TROUBLESHOOTING

This section provides troubleshooting and service instruc-

tions. Locate the problem and check the possible cause/

remedy in the order listed.

Also, refer to the Engine Owner's Manual for additional

information.

For problems not covered here, contact your authorized

service dealer.

Problem Remedy

Engine fails to start. Push key in to the ON position.

Engine starts hard or runs poorly.

Key is OFF.

Failure to prime cold engine

Fuel valve is in CLOSED position.

Out of fuel.

Choke OFF - cold engine.

Engine flooded.

No spark.

Water in fuel, or old fuel.

Fuel mixture too rich.

Possible Cause

WARNING

Before performing any adjustment or service to

snowthrower, stop the engine and wait for mov=

ing parts to stop. Remove the key. To prevent

accidental starting, disconnect the spark plug

wire and fasten away from the plug.

Press primer button twice and

restart.

Turn valve to OPEN position.

Fill fuel tank.

Turn choke to ON, set throttle to

FAST.

Turn choke to OFF; try starting.

Check gap. Gap plug, clean elec-

trode, or replace plug as necessary.

Drain tank. (Dispose of fuel at an

authorized hazardous waste facility.)

Fill with fresh fuel.

Move choke to OFF position.

Scraper bar does not clean hard

surface.

Auger does not rotate.

Carburetor adjusted incorrectly.

Spark plug faulty, fouled, or gapped

improperly.

Fuel cap vent is blocked.

Skid shoes improperly adjusted.

Skid shoes improperly adjusted.

Auger control not engaged.

Foreign matter blocking auger.

Auger drive clutch cable slack. Tighten to remove slack. See auger

Auger drive belt slipping. Check auger drive belt adjustment.

Broken belt. Replace belt.

Shear pin broken. Replace shear pin.

See your authorized service dealer

for adjustments.

Clean and gap, or replace.

Clear vent.

RAISE skid shoes (this lowers the

scraper bar).

LOWER skid shoes (this raises the

scraper bar.)

Engage auger control.

STOP engine and REMOVE the

key. DISCONNECT the spark plug

wire. Clear auger using clean-

out tool. See warning in SAFETY

RULES.

clutch cable adjustment.

28

Page 28

Problem

Auger rotates, but snow is not=

thrown far enough.

Poor traction.

Auger does not stop when

auger lever is released.

Possible Cause

Chute deflector too low.

Engine speed too slow.

Ground speed too fast.

Snowthrower discharge chute

clogged.

Auger belt loose or worn.

Tires slipping.

Free=Hand TM control is ACTIVE.

Auger clutch rod too tight or bent.

Remedy

Adjust deflector as necessary,

Set speed to full throttle.

Use slower speed selector setting.

STOP engine and REMOVE the key.

DISCONNECT the spark plug wire.

Clear auger using clean-out tool, See

warning in SAFETY RULES.

Check auger drive belt adjustment

Check tire pressure and tread,

Release both auger engage control

AND Free-Hand TM control to stop

auger.

Loosen or straighten clutch rod.

Snowthrower does not stop

when drive lever is released.

Discharge control is difficult to

operate.

Snowthrower veers to one

side.

Auger drive belt out of adjustment.

ment.

Traction drive clutch rod bent or

too tight.

Traction drive clutch rod loose.

Drive belt loose, broken, or

stretched.

Drive roller chain damaged.

Traction lock pins in free-Wheeling

position (OUTER hole).

Friction disc worn.

Gearing needs lubrication

Worm gear not adjusted properly.

Control rod gears misaligned.

Tire pressure not equal.

One wheel is set in free-wheeling

mode. (Traction Lock Pin is in the

OUTER hole).

Adjust auger belt.

Adjust auger belt guide.Auger belt guide out of adjust-

Loosen rod to remove slack or replace.

See adjustment procedure.

Tighten to remove slack. See adjust-

ment procedure.

Replace drive belt.

Replace chain.

Change traction lock pins to INNER

hole to engage traction drive.

Replace disc (see your authorized

service dealer).

Oil or grease as required.

Adjust worm gear. See adjustment pro-

cedure.

Adjust gear bracket. See adjustment

procedure.

Check tire pressure.

Make certain the left traction lock pin is

in the INNER holes (to engage traction

drive).

Excessive vibration.

Drive fails to move snowthrow= Traction drive out of adjustment. Readjust drive, or shift speed selector

er at slow speeds, setting up one speed faster.

Loose parts or damaged auger.

29

STOP engine and REMOVE the key.

DISCONNECT the spark plug wire.

Tighten all hardware. Replace auger if

necessary. If vibration continues, see

your dealer.

Page 29

Adjustments

AUGER DRIVE ADJUSTMENT

WARNING

Do not over=tighten, as this may lift the lever and

cause auger drive to be engaged without depress=

ing the Auger Control.

1. Check that the auger cable (A, Figure 34) is on top of

cable button (B) as show in Figure 34.

2. With the drive lever released, the hook (B, Figure 35)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32" clearance as shown.

3. To adjust, loosen nut (D) by holding the adjusting

flats (A) and turning nut (D). Turn adjustment flats

and hold screw. The adjustment screw is a phillips

screw and the head can be held or turned by insert-

ing a screwdriver through the spring (F).

,

Hold adjusting flats (A) and tighten nut (D).

5.

Start unit and check auger. Auger must not be

engaged unless auger control is depressed.

6. With engine running, fully depress auger control, the

auger should engage and run normally.

7. Release auger control. Auger must stop within 5

seconds.

,

If auger does not operate properly, stop engine and

recheck drive linkage adjustments.

,

If auger linkage is properly adjusted, auger drive

belt tension may require adjustment. See "Belt

Adjustment" in this section of the manual.

Figure 34. Auger Cable Button

Figure 35. Auger Drive Adjustment

TRACTION DRIVE CABLE

ADJUSTMENT

initial Adjustment

WARNING

Do not over=tighten, as this may cause traction

drive to engage without depressing the traction

drive control (arm must remain in down position).

Verify that the cables are not over=tightened: With

speed selector in position 1 and traction drive

control fully released, push snowthrower forward.

The unit should move forward freely.

If unit does not move forward freely, the cable has

been over=tightened. To remedy, loosen tension

on clutch cable slightly, and recheck.

1. With the drive lever released there should be no

slack in cable when moved slightly from side to side.

2. To adjust tension on the cable slide the cable boot

(A, Figure 36) off the cable adjustment bracket (D).

3. Remove the "Z" hook (C) from the cable adjustment

bracket (D) to a different adjustment hole. The cable

should have no slack. The cable should have no ten-

sion or load.

NOTE: If the cable is too slack the unit will not drive. If

the cable is too tight the drive will be engaged without

pushing the handles down.

4. Slide the cable boot (A) over the cable adjustment

bracket.

30

Page 30

Figure 36. Traction Drive Cable Adjustment

Run=in Adjustment

1. After 5 hours of use, check for proper adjustment.

Readjust clutch cable if necessary by increasing ten-

sion on cable. A small amount of arm movement is

permissible if unit passes operating checks described

in the Warning above.

Adjustments

\

\

4-5/16"

(10.95cm)

Figure 37. Friction Disc Measurement

WARNING

Gasoline is highly flammable and must be han-

dled with care. Drain gasoline outdoors. Never

drain the tank when the engine is still hot from

recent operation. Do not allow open flame, smok-

ing or matches in the area. Avoid over=filling and

wipe up any spills.

FRiCTiON DISC MEASUREMENT

1. Remove the gas from the gas tank.

2. Disconnect the spark plug wire.

3. Stand snowthrower on the front of the auger housing

(C, Figure 44). 13.

4. Loosen the capscrews (A, Figure 44) on each side of

the bottom panel (B). 14.

5. Remove the bottom panel (B).

6. Position the shift speed lever in the lowest forward

speed.

7. Note the position of the friction disc (A, Figure 37).

The correct distance from the right side of the friction

wheel to the outside of the frame is 4-5/16" (10.95

cm). If the friction disc is not in the correct position,

adjust as follows.

8. Position the shift speed lever in the lowest forward

speed.

Figure 38. Speed Selector Linkage

,

Loosen the jam nut (B, Figure 38).

10.

Remove Iocknut (D).

11.

Move the friction disc (A, Figure 37) to the correct

distance, 4-5/16" (10.95 cm).

12.

Turn the ball joint (C, Figure 38) until it is aligned

with the mounting hole in the shifter rod (E). When

aligned, attach the ball joint (C) to the shifter rod (E)

and tighten the jam nut (B).

Check that the snowthrower operates in R1. If not

follow procedures 1-11 and readjust as necessary.

Install the bottom panel (B, Figure 44) and tighten the

capscrews (A).

31

Page 31

Adjustments

EASY TURN TM CABLE ADJUSTMENT

If the Easy Turn TM cable has stretched, the gears will not

disengage when the control lever is activated. Adjust the

cable using the following procedure.

1. Turn the engine off and disconnect the spark plug

wire.

2. Loosen the jam nut (B, Figure 39).

3. Turn the adjustment nut (A) to lengthen or shorten

the cable. The cable should be tightened just until all

slack is removed from the lever, however it must not

engage the Easy Turn TM release without depressing

the control lever.

4. Tighten the jam nut.

BELT ADJUSTMENT

Auger Drive Belt

If your snowthrower will not discharge snow, check the

control cable adjustment. If it is correct, then check

the condition of the auger drive belt. If it is damaged or

loose, replace it. See "Belt Replacement" in this section

of the manual.

,

Disconnect spark plug wire.

2.

Remove screw (B, Figure 40) from belt cover (A).

Remove belt cover (A).

,

Loosen nut (D, Figure 39) on auger idler pulley (B)

and move auger idler pulley towards belt about 1/8

inch (3 mm).

4. Tighten nut (D).

5. Engage auger drive clutch. Check tension on belt

(opposite idler pulley). Belt should deflect about 1/2

inch (12.5 mm) with moderate pressure, see Figure

25). You may have to move the idler pulley more

than once to obtain the correct tension.

Figure 39. Cable Adjustment

Figure 40. Belt Cover

6. Reinstall belt cover (A, Figure 40) securing with

screws (B).

7. Whenever belts are adjusted or replaced, the cables

will need to be adjusted. See "Cable Adjustment" in

this section of the manual.

8. Attach the spark plug wire.

Traction Drive Belt

The traction drive belt has constant spring pressure and

does not require an adjustment. Ifthe traction drive belt

is slipping,replace the belt. See "Belt Replacement" in

this section of the manual.

__'_k_ coj/ ,,,.-- ,,_ 1/2"(12.5mm)

eflection

Figure 41. Auger Belt Deflection

32

Page 32

SHEAR PIN REPLACEMENT

Adjustments & Service

WARNING

Do not go near the discharge chute or auger

when the engine is running. Do not run the engine

with any cover or guard removed.

Under most circumstances, if the auger strikes an object

which could cause damage to the unit, the shear pin will

break. (This protects the gear box and other parts from

damage.)

The shear pins are located on the auger shaft as shown

in Figure 42. To replace the shear pins, tap out the bro-

ken pin with a pin punch, and install a new shear pin and

cotter pin. Do NOT replace shear pins with anything

other than the correct grade replacement shear pin.

(Use of bolts, screws or a harder shear pin will lead to

damaged equipment.)

Replacement Shear Pins, Part Number 1668344 are

available at www.sears.com or by calling 1=800=4=MY=

HOME,

BELT GUIDE ADJUSTMENT

1. Disconnect spark plug wire.

2. Remove screw (B, Figure 40) from belt cover (A).

Remove belt cover (A).

3. Engage auger drive and measure the distance

between the belt guide (B, Figure 43) and the belt

(D). The distance should be 1/8 inch (3.18 mm).

4. If adjustment is necessary, loosen belt guide cap-

screw (C). Move belt guide (B) to correct position.

Tighten capscrew (C).

6. Reinstall belt cover (A, Figure 40) securing with

screws (B).

7. Reconnect spark plug wire.

I

Figure 42.

!

Shear Pins

18 mm)

Figure 43. Belt Guide

33

Page 33

SGPvic6

BELT REPLACEMENT

Auger Drive Belt

The drive belts are of special construction and must be

replaced with original factory replacement belts avail-

able from your nearest authorized service center. Some

steps require the assistance of a second person. If the

auger drive belt is damaged, the snow thrower will not

discharge snow. Replace the damaged belt as follows.

.

Disconnect the spark plug wire.

2.

Loosen the capscrews (A, Figure 44) on each side of

the bottom panel (B).

3. Remove the bottom panel (B).

4. Loosen screw (B, Figure 40) from belt cover (A).

Remove belt cover (A).

.

Loosen the belt guide (B, Figure 45). Pull the belt

guide away from the auger drive pulley (C).

.

Pull the auger idler pulley (K) away from the auger

drive belt (D) and slip the belt off of the idler.

7. Remove the auger drive belt (D) from the engine pul-

ley. To remove the auger drive belt (D), the auger

drive pulley (C) may have to be partially rotated.

8. Index or point the spout rotator to the center of the

machine so the rotator control is in the center of the

dash panel.

.

Using a 7/16 wrench, remove the 2 carriage bolts (A,

Figure 45) and 2 lock nuts (B) from chute rod (C).

10. Remove the upper four capscrews (A, Figure 47) that

hold together the auger housing (C) and the frame

(D). Loosen the lower two capscrews (B). The auger

housing (C) and the frame (D) can now be split apart

for removal of the belt.

Figure 44. Bottom Cover

Figure 45. Split Rod Assembly

11. Remove the old auger drive belt (D, Figure 46) from

the impeller pulley. Replace the auger drive belt with

an original factory replacement belt available from an

authorized service center.

12. Install the new auger drive belt (D) onto the impeller

pulley.

Figure 46. Pulleys and Belts

34

Page 34

NOTE: To assemble the auger housing to the frame,

have someone hold the auger clutch lever in the

ENGAGED position. This will move the idler arm and pul-

ley enough to allow the auger drive pulley to move back

into position.

14.Assemble the auger housing (C, Figure 47) to the

frame with the four upper capscrews (A) that were

removed in Step 10. Tighten the 2 lower capscrews

(B).

15. Index or point the spout rotator to the center of the

machine so the rotator control is in the center of the

dash panel.

16. Install small carriage bolts (A, Figure 46) and cap-

screws (B) and tighten with 7/16 wrench.

19. Install the auger drive belt (D, Figure 46) onto the

impeller pulley (H).

20. Slip the auger drive belt (D) under the auger idler pul-

ley (K).

21. Adjust the auger drive belt. See "How To Adjust The

Auger Drive Belt" in the Service section.

22. Adjust the belt guide. See "How To Adjust The Belt

Guide" in the Service section.

Adjustments & Service

Figure 47. Frame and Axle Housing

23. Install the belt cover (A, Figure 40). Tighten screws

(B).

24. Check the adjustment of the cables. See "How To

Check And Adjust The Cables" in the Adjustment

section.

25. Install the bottom panel (B, Figure 44).

26. Tighten the capscrews (A) on each side of the bottom

panel (B).

27. Connect the spark plug wire.

35

Page 35