Page 1

0 Bimpliuilg

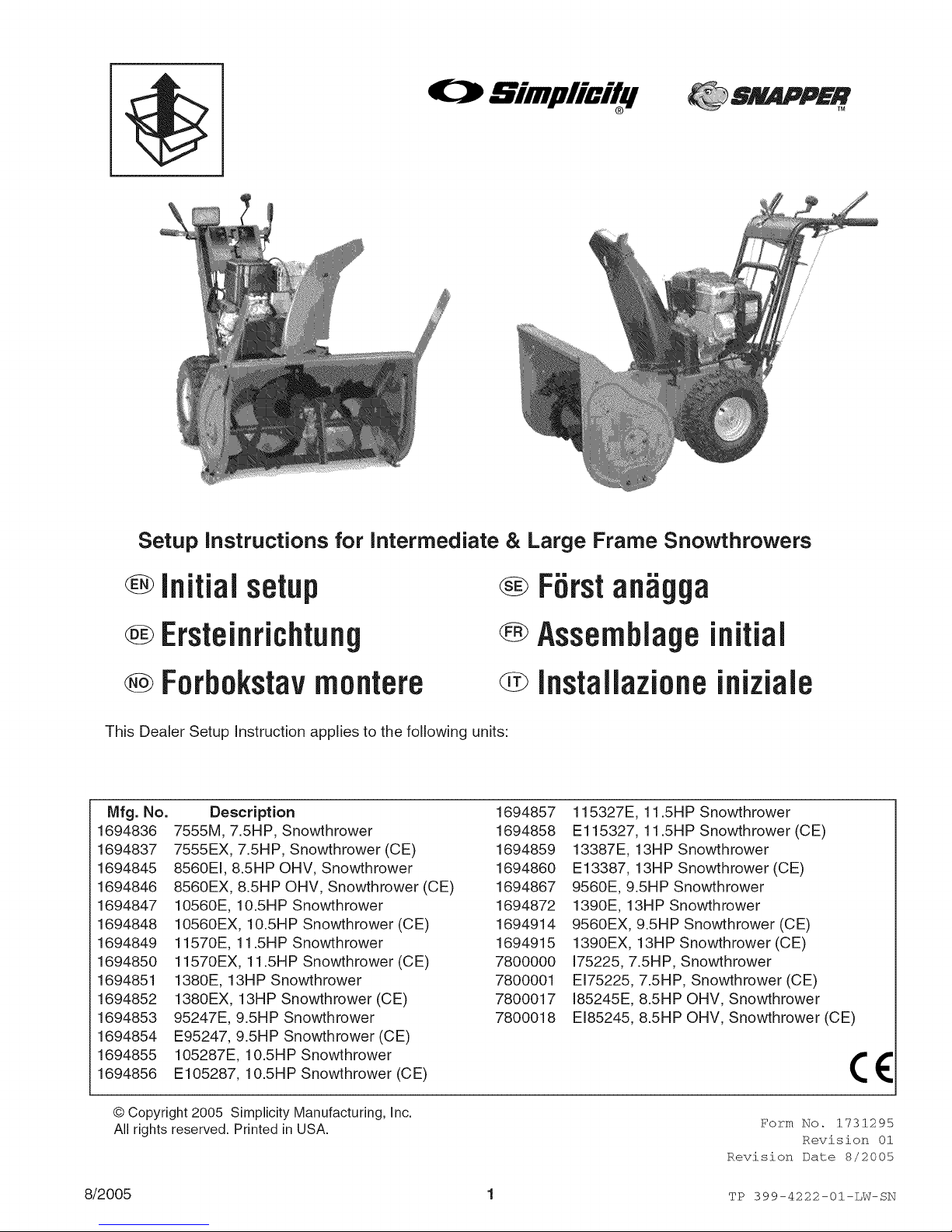

Setup instructions for intermediate & Large Frame Snowthrowers

/

/

/

Initial setup

Ersteinrichtung

Forbokstavrnontere

This Dealer Setup Instruction applies to the following units:

Mfg. No.

1694836

1694837

1694845

1694846

1694847

1694848

1694849

1694850

1694851

1694852

1694853

1694854

1694855

1694856

Description

7555M, 7.5HP, Snowthrower

7555EX, 7.5HP, Snowthrower (CE)

8560EI, 8.5HP OHV, Snowthrower

8560EX, 8.5HP OHV, Snowthrower (CE)

10560E, IO.5HP Snowthrower

10560EX, IO.5HP Snowthrower (CE)

11570E, 11.5HP Snowthrower

11570EX, 11.5HP Snowthrower (CE)

1380E, 13HP Snowthrower

1380EX, 13HP Snowthrower (CE)

95247E, 9.5HP Snowthrower

E95247, 9.5HP Snowthrower (CE)

105287E, 10.5HP Snowthrower

E105287, 10.5HP Snowthrower (CE)

FiJrstan igga

Assemblage

Instaliazione

1694857

1694858

1694859

1694860

1694867

1694872

1694914

1694915

7800000

7800001

7800017

7800018

115327E, 11.5HP Snowthrower

E115327, 11.5HP Snowthrower (CE)

13387E, 13HP Snowthrower

E13387, 13HP Snowthrower (CE)

9560E, 9.5HP Snowthrower

1390E, 13HP Snowthrower

9560EX, 9.5HP Snowthrower (CE)

1390EX, 13HP Snowthrower (CE)

175225, 7.5HP, Snowthrower

EI75225, 7.5HP, Snowthrower (CE)

185245E, 8.5HP OHV, Snowthrower

EI85245, 8.5HP OHV, Snowthrower (CE)

initial

iniziale

© Copyright 2005 Simplicity Manufacturing, Inc.

All rights reserved. Printed in USA.

8/2005 1 TP 399-4222-01-LW-SN

Form No. 1731295

Revision 01

Revision Date 8/2005

Page 2

SAFETY RULES

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

The triangle _IL in text signifies important cautions or warnings which must be followed.

GENERAL OPERATION

• Read, understand, and follow all instructions in the

manual and on the unit before starting.

• Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown.

• Be sure the area is clear of other people. Stop unit if any-

one enters the area.

• Always look down and behind before and while travelling in

reverse.

• Be aware of the discharge direction and do not point it at

anyone. Do not point the discharge at glass enclosures,

automobiles, or windows.

• Disengage all clutches (release drive and auger control

levers) before starting the engine.

• Never leave a running unit unattended. Always disengage

the auger and traction controls, stop engine, and remove

keys.

• Stop engine before unclogging chute.

• Operate only in daylight or good artificial light.

• Do not operate the unit while under the influence of alcohol

or drugs.

• Watch for traffic when operating near or crossing road-

ways.

• Use extra care when loading or unloading the unit into a

trailer or truck.

• Keep in mind the operator is responsible for accidents

occurring to other people or property.

• Data indicates that operators, age 60 years and above, are

involved in a large percentage of power equipment-related

injuries. These operators should evaluate their ability to

operate the unit safely enough to protect themselves and

others from injury.

• All operators should seek and obtain professional and prac-

tical instruction.

• Always wear substantial footwear and appropriate winter

clothing. Wear foot-ware that improves traction on slippery

slopes. DO NOT wear long scarves or loose clothing that

could become entangled in moving parts.

• Before using, always visually check that all hardware is

present, in-tact, and secure. Replace worn or damaged

parts.

• Never operate the machine with defective guards, or with-

out safety protective devises in place.

• Stop engine before: refuelling, removing an attachment,

making adjustments (unless the adjustment can be made

from the operator's position).

• Follow the manufacturer's recommendation for wheel

weights or counterweights.

• Adjust skid shoe height to clear gravel or crushed rock sur-

faces.

• Do not touch snowthrower parts which may be hot from

operation. Allow such parts to cool before attempting to

service the unit.

CLEARING A CLOGGED DISCHARGE CHUTE

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snowthrowers. Always use a clean out tool, not your hands, to

clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

SLOPE OPERATION

WARNING

Never operate on slopes greater than 17.6 percent (10 °) which

is a rise of 3-1/2 feet (106 cm) vertically in 20 feet (607 cm)

horizontally.

When operating on slopes use additional wheel weights or

counterweights, See your dealer to determine which weights

are available and appropriate for your unit.

Select slow ground speed before driving onto slope. Travel UP

and DOWN the slope, never across the face, use caution when

changing directions and DO NOT START OR STOP ON

SLOPE.

Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. All slopes

require extra caution. Ifyou cannot back up the slope or if you feel

uneasy on it, do not operate on it.

EMISSIONS

• Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

• Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Do

e

See your authorized dealer for recommendations counter-

weights to improve stability.

• Travel up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could over-

turn the unit. Snow can hide obstacles.

• Use slow speed. Tires may lose traction on slopes. Choose

a low gear so that you will not have to stop or shift while on

the slope.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Always keep unit in gear especially when traveling down-

hill.

Do Not

= Do not start or stop on a slope. If tires lose traction, disen-

gage the auger and proceed slowly straight down the

slope.

= Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

= Do not operate near drop-offs, ditches, or embankments.

The unit could suddenly turn over if a wheel is over the

edge of a cliff or ditch, or if an edge caves in.

= Do not operate on wet surfaces. Reduced traction could

cause sliding.

= Do not shift to neutral and coast down hills.

TP 399-4222-@1 -LW-SN 2 8/2005

Page 3

intermediate & Large Frame Snowthrowers

Contents:

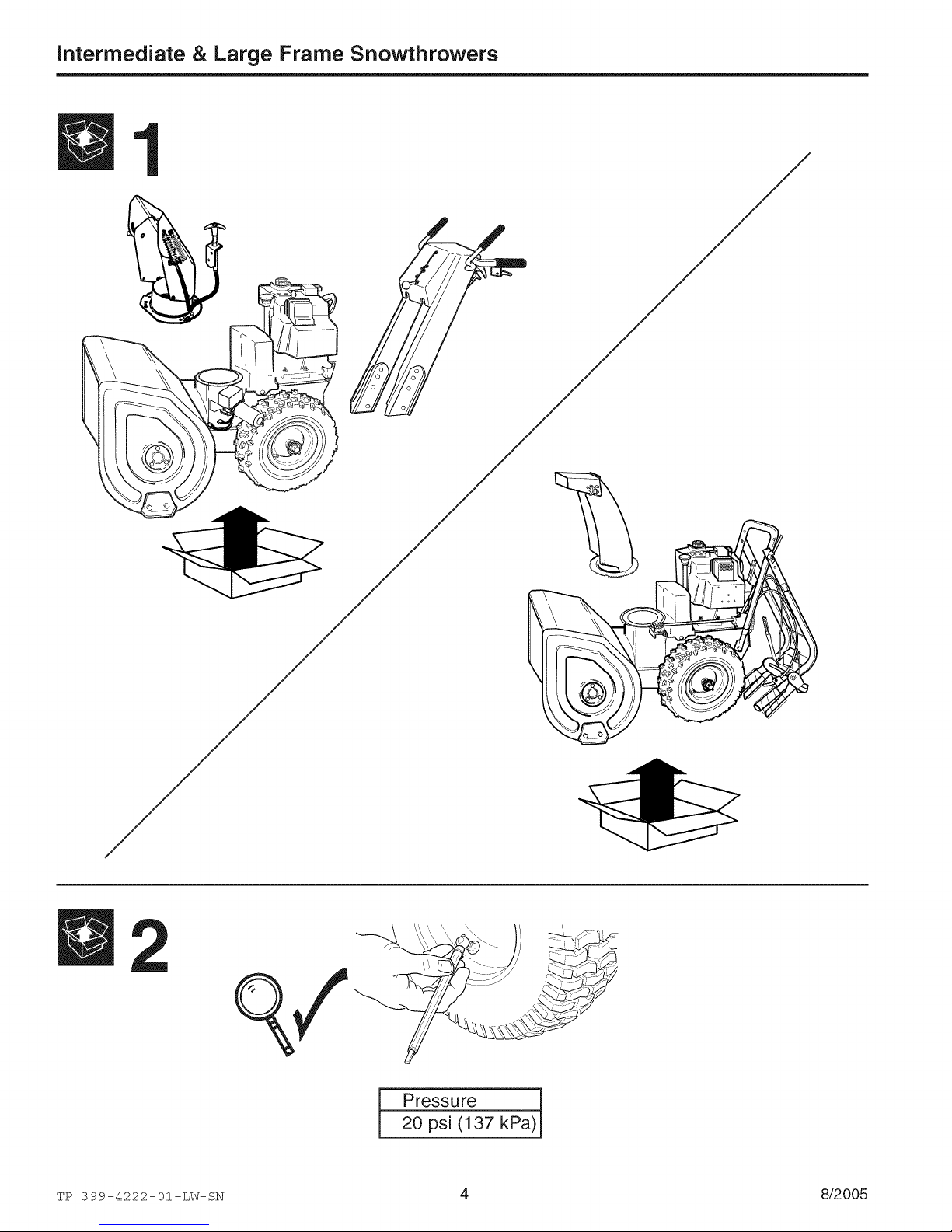

1. Uncrate ......................................... 4

2. Check Tire Pressure ..................... 4

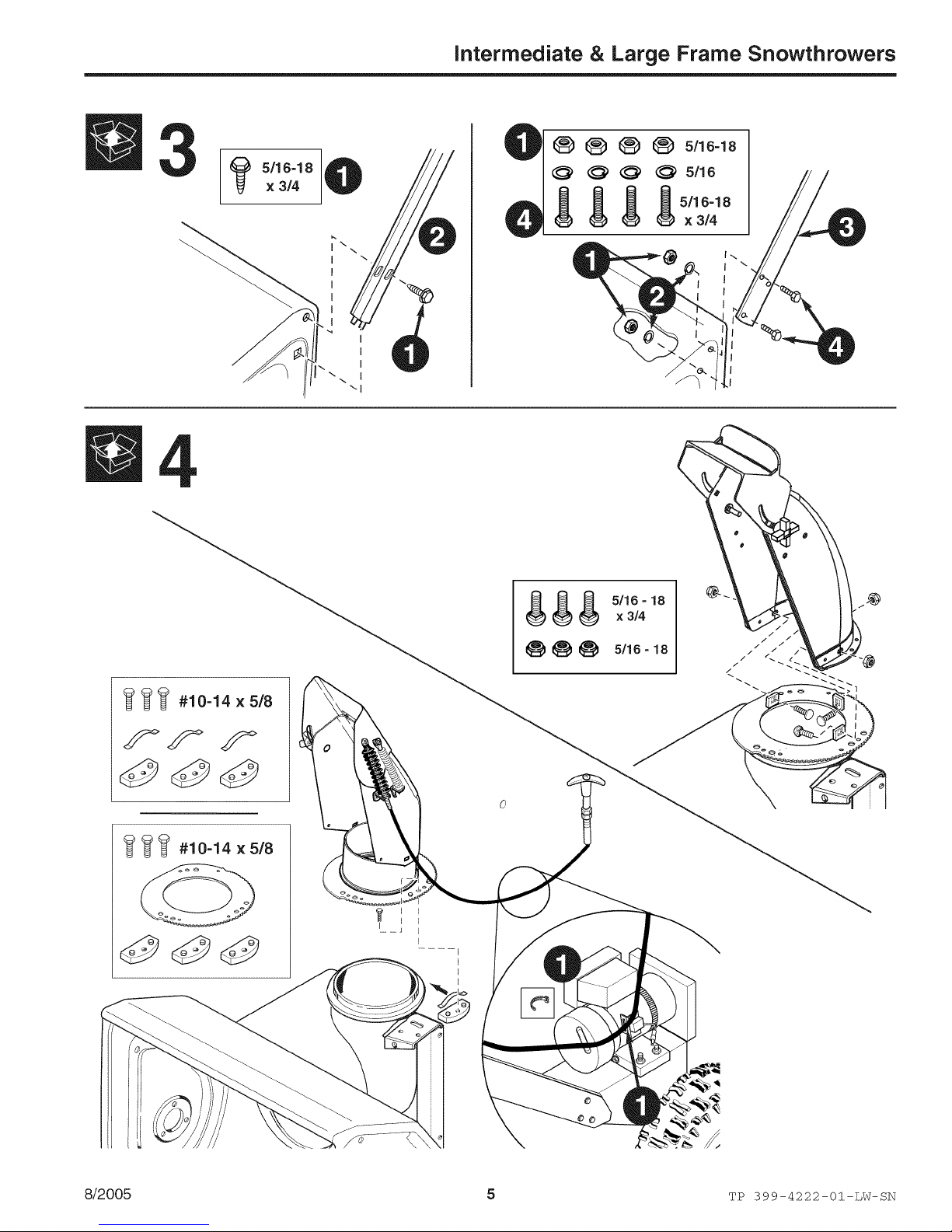

3. Install Drift Cutters ........................ 5

4. Install Chute .................................. 5

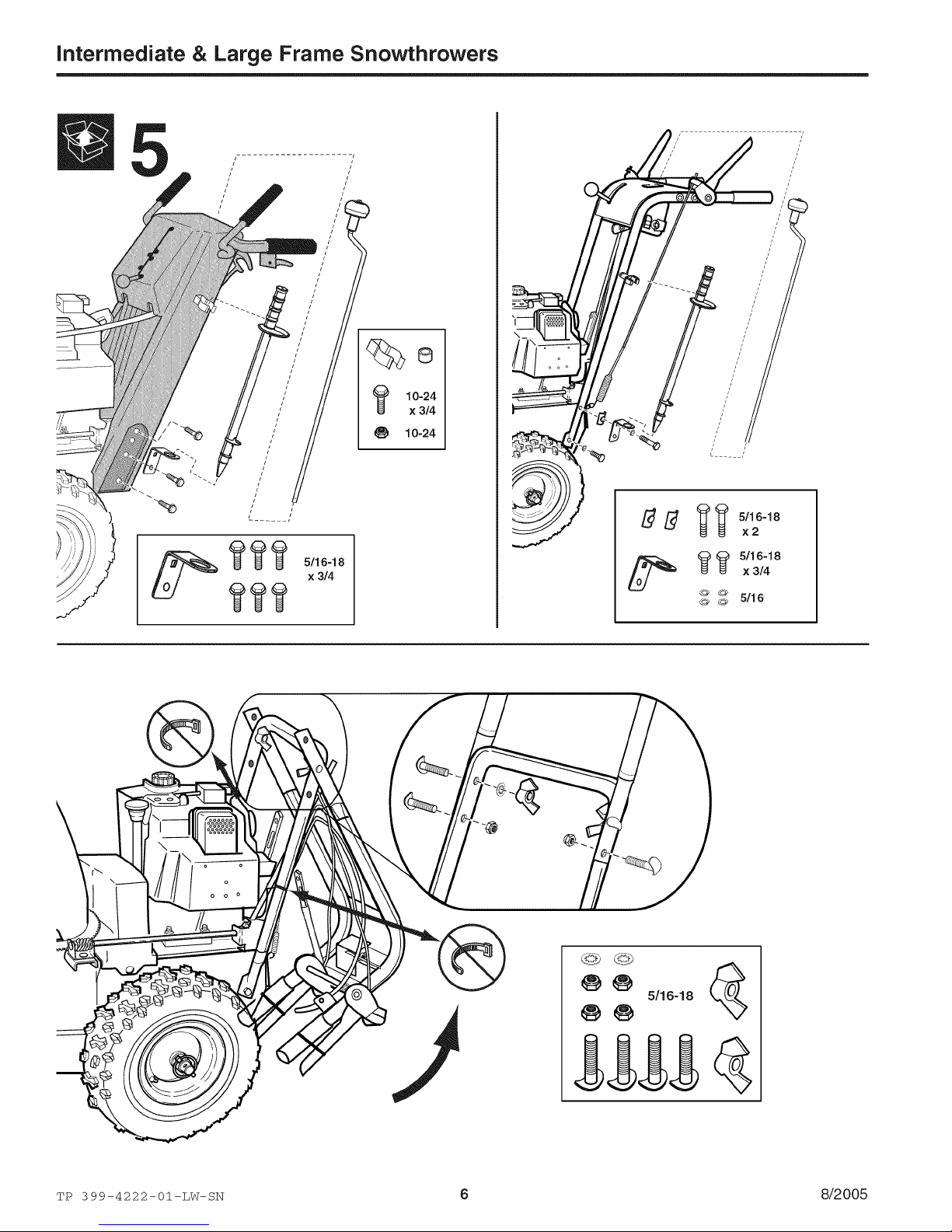

5. Install Handles .............................. 6

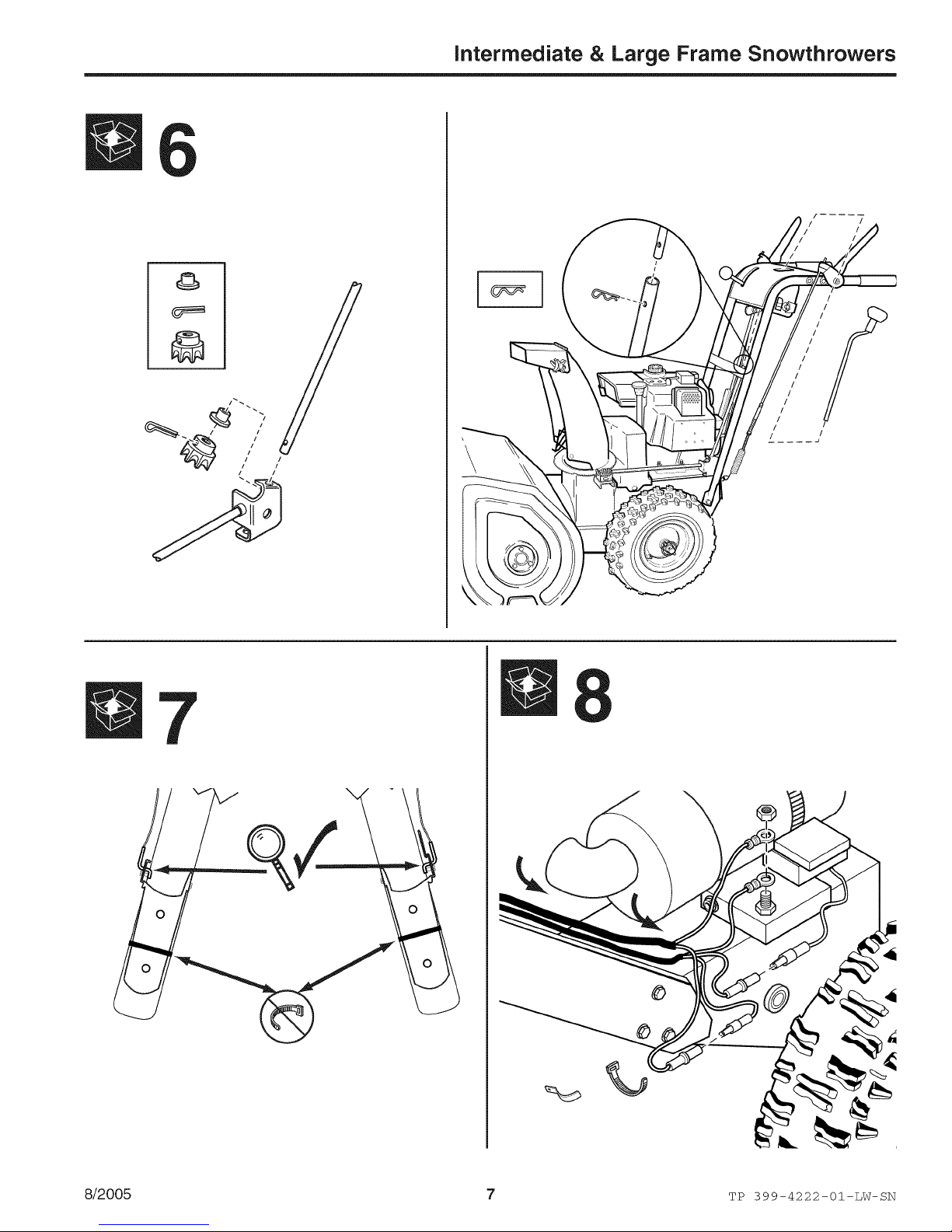

6. Connect Spout Rotator ................. 7

7. Tube Handle Levers ..................... 7

8. Electrical Connections .................. 7

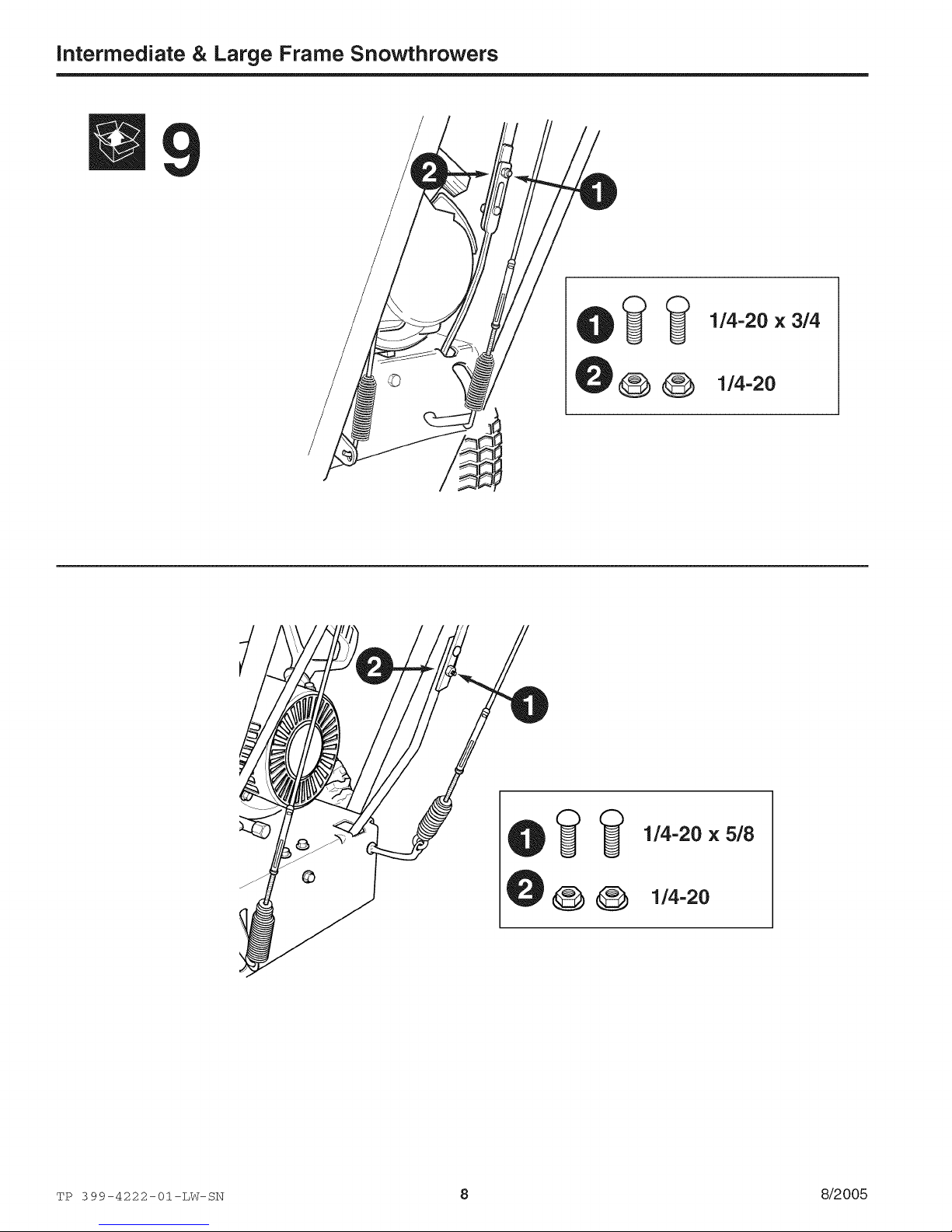

9. Speed Selector Connection .......... 8

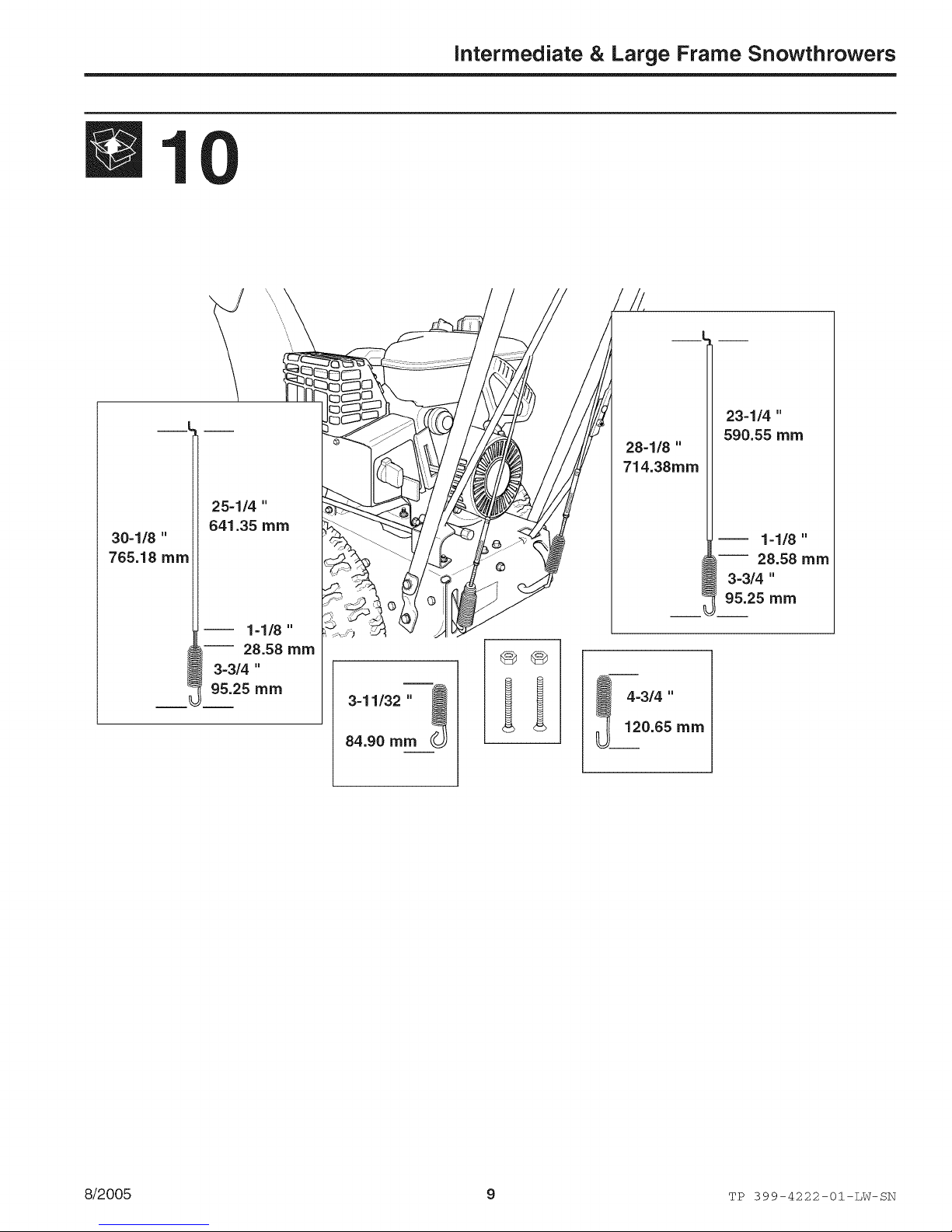

10. Auger Drive Connection ............. 9

10. Traction Drive Connection .......... 9

11. Speed Selector Adjustment ...... 10

12. Auger Drive Tension ................. 10

13. Traction Drive Tension ............. 11

14. Connect Chute Control ............. 22

15. Connect Easy Turn ................... 22

16. Easy Turn Cable Adjustment....23

17. Auger Gear Case Lubrication ...24

18. Checks Before Each Start-up ...25

Inhaltsverzeichnis:

1. packen Sie aus ................................ 4

2. PrQfungdes Reifendrucks ................4

3. bringen Sie an Schneeantrieb

Scherblock ............................................ 5

4. bringen Sie an Rutsche ................... 5

5. bringen Sie an Lenkstangen ...........6

6. schlieBen Sie TQIlerotator ............... 7

7. Schlauch-Handgriff-Hebel ............ 7

8. electrial Anschl0sse ...................... 7

9. Geschwindigkeit W&hlcaooenction .8

10. Schneckenwelle Antrieb

connenction .......................................... 9

10. Zugkraft-Antrieb connenction ........ 9

11. Einstellung des

Gangwahlschalters .............................. 10

12. Spannung des

Schneckenantriebs .............................. 10

13. pannung des Fahrantriebs ........... 11

14. SchlieBen Sie RutschcSteuerung

An ...................................................... 22

15. schlieBen Sie an Easy Turn ........22

16. Einstellung des Easy

Turn-Seilzugs ...................................... 23

17. PrQfung des Olstands im

Schneckenf6rderer-Getriebegeh&use .24

18. SicherheitsprQfungen vor jeder

Inbetriebnahme ................................... 25

Artillel:

1. Dekasse ........................................ 4

2. Kontrol av lufttrykket i dekkene .....4

3. Insetallere Bakke Skjsere .............. 5

4. Insetallere Ventil ........................... 5

5. Insetallere Sykkelstyre .................. 6

6. Forbindelse Ventil Rotator ............ 7

7. ro rh&ndtakvektstenger .................. 7

8. elektrisk forbindelse ...................... 7

9. Fart Skiftenokkel Forbindelse ....... 8

10. Skrue Forero Forbindelse ........... 9

10. Fengsle Fart Forbindelse ............ 9

11. Justering av hastighetsvelgerenl0

12. Stramming av skovledrivet ....... 10

13. Stramming av friksjonsdrivet ....11

14. Forbindelse Chute Control ........ 22

15. Forbindelse Easy Turn ............. 22

16. Justering av Easy Turn-kabelen23

17. Smor akselene og

kontrollspakene ............................... 24

18. Folgende kontroller skal utfores

for hver ..................................... 25

Inneh_ll:

1. Depacke ....................................... 4

2. Kontroll av ringtrycket ................... 4

3. Installera Trave Klippa .................. 5

4. Installera Tub ................................ 5

5. Installera Styrst&ng ....................... 6

6. Ansluta Tub Rotera ...................... 7

7. Modeller med r6rhandtag

h&vst&ng ........................................... 7

8. Electrical f6rh&llande .................... 7

9. Fart Urval F6rbindelse ................. 8

10. Skruv Aktur F6rbindelse ............. 9

10. Tag Aktur F6rbindelse ................ 9

11. Justering av hastighetsv&ljaren 10

12. Skruvens drivremssp&nning .....10

13. Hjuldrivningens

drivremssp&nning ........................... 11

14. Ansluta Tub Kontroll ................ 22

15. Ansluta Easy Turn ................... 22

16. Justering av

Easy Turn-kabeln ........................... 23

17. Kontroll av sm6rjmedelsniv&n i

skruvens v&xell&da .......................... 24

18. Kontroller f6re varje

anv&ndning ...................................... 25

Matieres:

1. D6paqueter ................................... 4

2. Contr61e de la pression

des pneus .......................................... 4

3. Emm6nagent Amas de Neige

Coupeur ............................................ 5

4. Emm6nagent Chute ...................... 5

5. Emm6nagent Guidon .................... 6

6. Connecter Rotateur de Bec ......... 7

7. Leviers De Poign6e De Tube .......7

8. raccordements electrial ................ 7

9. Galoper Select Connexion ............ 8

10. Pas de Vis Traquer Connexion...9

10. Grippe Traquer Connexion ......... 9

11. R6glage du s61ecteur de vitessel0

12. Tension de la commande

de fraise .......................................... 10

13. Tension de la commande

de traction ........................................ 11

14. Connecter Glissi_re Contr61e ...22

15. Connecter Easy Turn ................ 22

16. R6glage du c&ble Easy Turn ....23

17. Niveau d'huile de la bofte

d'engrenages de la fraise ................ 24

18. Contr61es avant chaque

d6marrage ....................................... 25

@

Indice:

1. Deimpaccare ................................ 4

2. Controllo della pressione degli

pneumatici ......................................... 4

3. Mettere Catasta Tagliato .............. 5

4. Mettere Solco ............................... 5

5. Mettere Manici .............................. 6

6. Copulare Tubo Rotare ................. 7

7. Leve Della Maniglia Del Tubo .......7

8. Collegamenti Elettrici .................... 7

7. Velocit& Eletta Congiuntura .......... 8

10. Trapano Andara Congiuntura .....9

10. Acchiappare Andara

Congiuntura ....................................... 9

11. Regolazione del cambio ........... 10

12. Tensione della cinghia di trasmis-

sione della coclea ............................ 10

13. Tensione della cinghia di trasmis-

sione della trazione .......................... 11

14. Copulare Solco Controllo ......... 22

15. Copulare Easy Turn ................. 22

16. Regolazione del cavo

Easy Turn ....................................... 23

17. Controllo della lubrificazione della

scatola ingranaggi della coclea .......24

18. Controlli prima

dell'avviamento ............................... 25

8/2005 3 TP 399-4222 -O_.-LW-SN

Page 4

intermediate & Large Frame Snowthrowers

TP 399-4222-01 -LW-SN 4 8/2005

Pressure ]

l 20 psi(137 kPa)j

Page 5

intermediate & Large Frame Snowthrowers

I

I

I

I

I

I

I

I

8/2005 5 TP 399-4222-O_.-LW-SN

Page 6

intermediate & Large Frame Snowthrowers

/

/

/

/

/

o

o o o

_,_ _ _,10.10x3,4

c_ c_ 5/16

TP 399-4222-01 -LW-SN 6 8/2005

Page 7

intermediate & Large Frame Snowthrowers

/

/ // ///_

7

//

/

//

/ /

l /

/

/

8/2005 7 TP 399-4222 -O_.=LW-SN

Page 8

intermediate & Large Frame Snowthrowers

1/4=20 × 3/4

1/4=20

TP 399-4222-@l-LW-SN 8 8/2005

1/4=20 x 5/8

1/4=20

Page 9

30-1/8 "

765.18 mm

intermediate & Large Frame Snowthrowers

23-1/4 "

590.55 mm

28=1/8 "

714.38m m

25=1/4 "

641.35 mm

1-1/8 "

-- 28.58 mm

3=3/4 "

95.25 mm

1=1/8 "

-- 28.58 mm

3-3/4 "

95.25 mm

3=11/32 "

84.90 mm

4=3/4 "

120.65 mm

8/2005 9 TP 399-4222-O_.-LW-SN

Page 10

intermediate & Large Frame Snowthrowers

Speed Selector

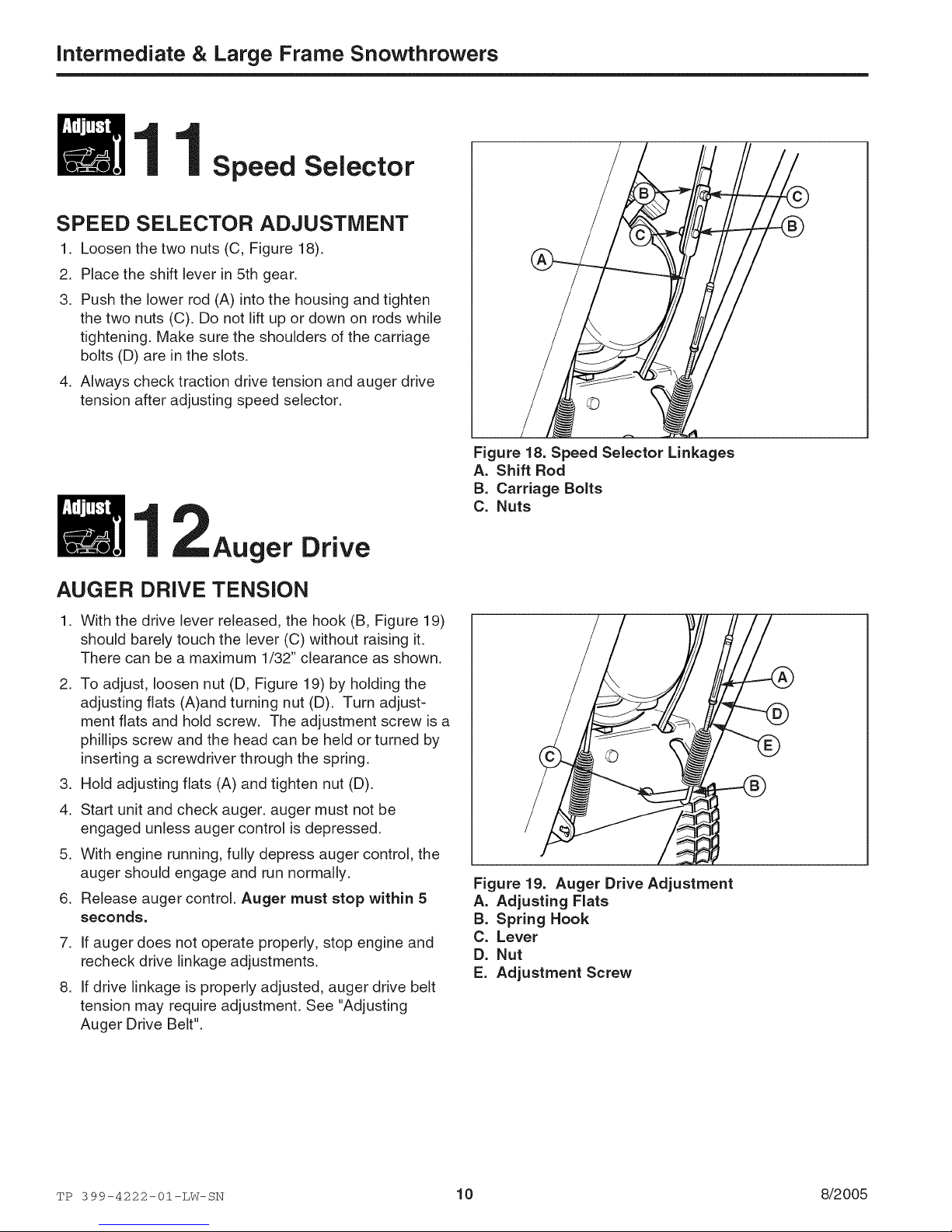

SPEED SELECTOR ADJUSTMENT

1. Loosen the two nuts (C, Figure 18).

2. Place the shift lever in 5th gear.

3. Push the lower rod (A) into the housing and tighten

the two nuts (C). Do not lift up or down on rods while

tightening. Make sure the shoulders of the carriage

bolts (D) are in the slots.

4. Always check traction drive tension and auger drive

tension after adjusting speed selector.

Figure 18. Speed Selector Linkages

A. Shift Rod

B. Carriage Bolts

C. Nuts

S

Auger Drive

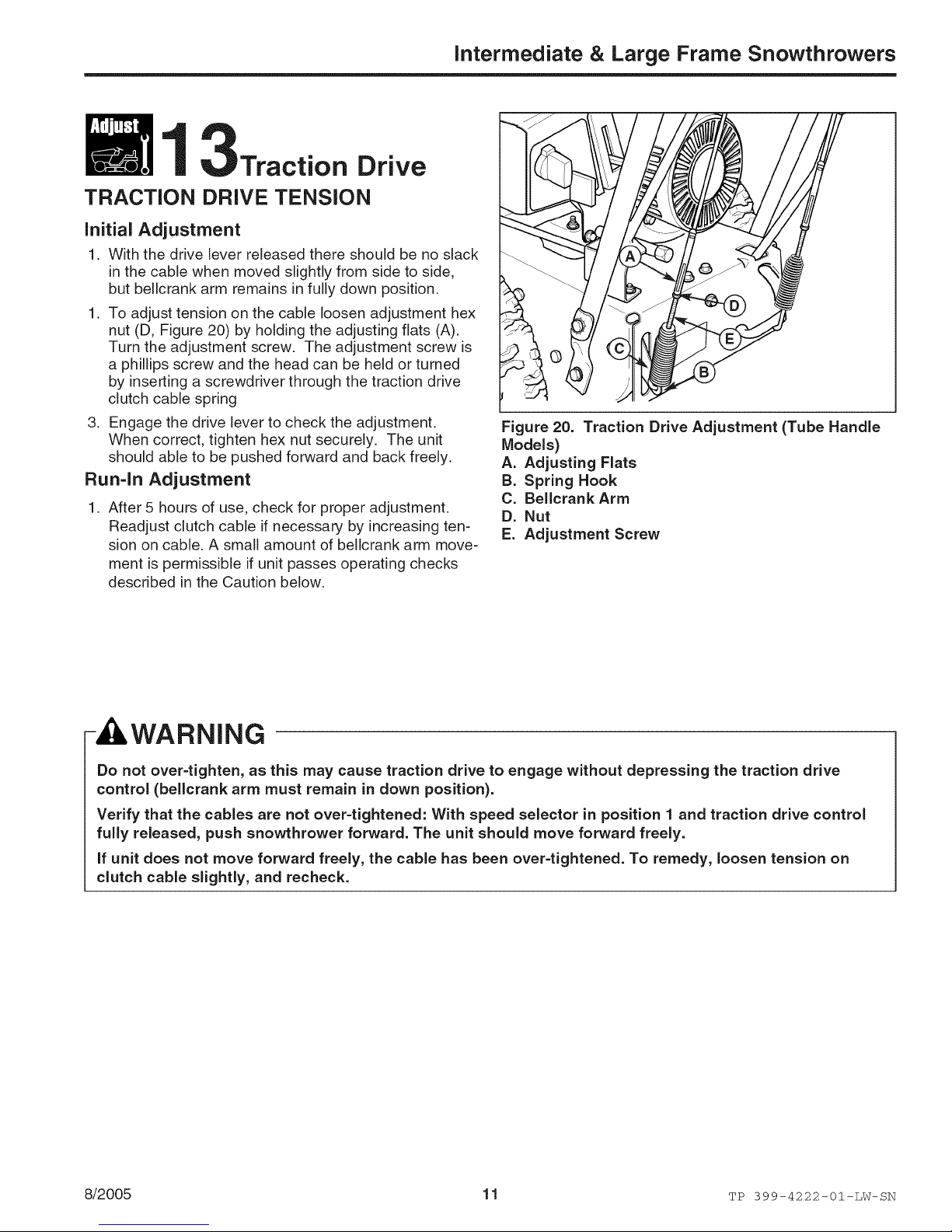

AUGER DRIVE TENSION

.

With the drive lever released, the hook (B, Figure 19)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32" clearance as shown.

2. To adjust, loosen nut (D, Figure 19) by holding the

adjusting flats (A)and turning nut (D). Turn adjust-

ment flats and hold screw. The adjustment screw is a

phillips screw and the head can be held or turned by

inserting a screwdriver through the spring.

3. Hold adjusting flats (A) and tighten nut (D).

4. Start unit and check auger, auger must not be

engaged unless auger control is depressed.

5. With engine running, fully depress auger control, the

auger should engage and run normally.

6. Release auger control. Auger must stop within 5

seconds.

7. If auger does not operate properly, stop engine and

recheck drive linkage adjustments.

8. If drive linkage is properly adjusted, auger drive belt

tension may require adjustment. See "Adjusting

Auger Drive Belt".

Figure 19. Auger Drive Adjustment

A. Adjusting Flats

B. Spring Hook

C. Lever

D. Nut

E. Adjustment Screw

TP 399-4222-01 -LW-SN 10 8/2005

Page 11

1 3TractionDr ve

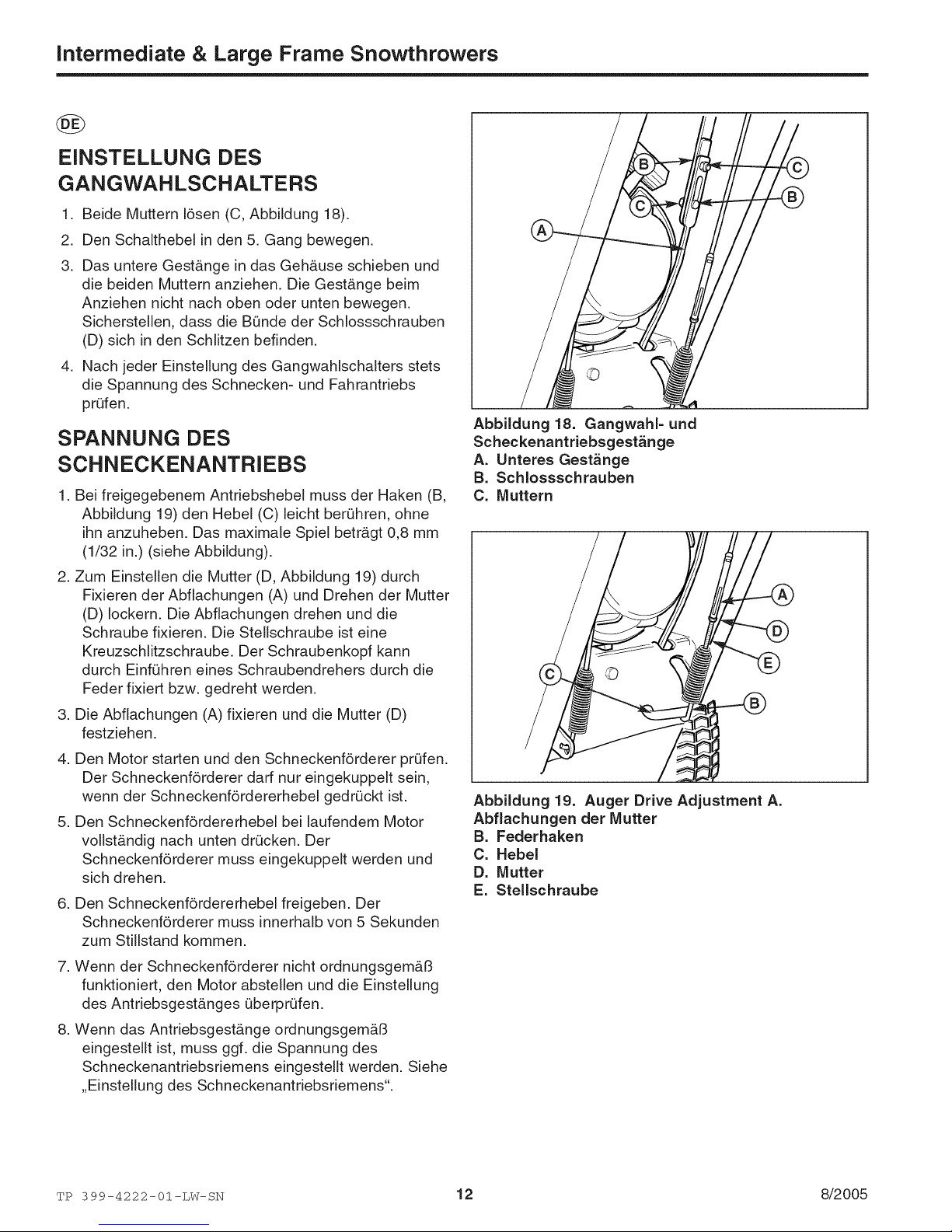

TRACTION DRIVE TENSION

Initial Adjustment

1. With the drive lever released there should be no slack

in the cable when moved slightly from side to side,

but bellcrank arm remains in fully down position.

1. To adjust tension on the cable loosen adjustment hex

nut (D, Figure 20) by holding the adjusting flats (A).

Turn the adjustment screw. The adjustment screw is

a phillips screw and the head can be held or turned

by inserting a screwdriver through the traction drive

clutch cable spring

3. Engage the drive lever to check the adjustment.

When correct, tighten hex nut securely. The unit

should able to be pushed forward and back freely.

Run-In Adjustment

1. After 5 hours of use, check for proper adjustment.

Readjust clutch cable if necessary by increasing ten-

sion on cable. A small amount of bellcrank arm move-

ment is permissible if unit passes operating checks

described in the Caution below.

intermediate & Large Frame Snowthrowers

@

Figure 20. Traction Drive Adjustment (Tube Handle

Models)

A. Adjusting Flats

B. Spring Hook

C. Bellcrank Arm

D. Nut

E. Adjustment Screw

F ,WARNING

Do not over4ighten, as this may cause traction drive to engage without depressing the traction drive

control (bellcrank arm must remain in down position).

Verify that the cables are not over=tightened: With speed selector in position 1 and traction drive control

fully released, push snowthrower forward. The unit should move forward freely.

If unit does not move forward freely, the cable has been over=tightened. To remedy, loosen tension on

clutch cable slightly, and recheck.

8/2005 11 TP 399-4222-0_.-LW-SN

Page 12

intermediate & Large Frame Snowthrowers

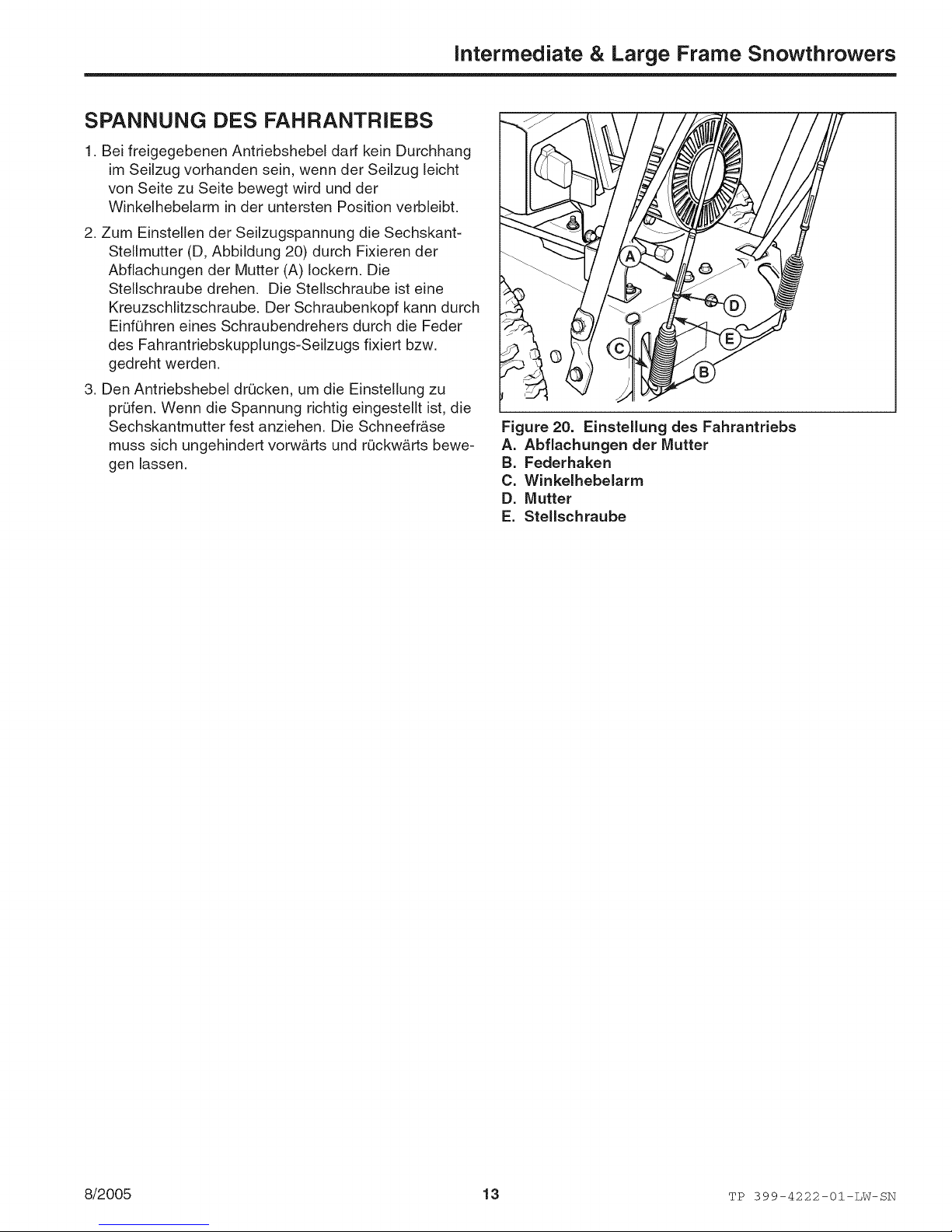

EINSTELLUNG DES

GANGWAHLSCHALTERS

1. Beide Muttern 16sen(C, Abbildung 18).

2. Den Schalthebel in den 5. Gang bewegen.

3. Das untere Gest&nge in das Geh&use schieben und

die beiden Muttern anziehen. Die Gest&nge beim

Anziehen nicht nach oben oder unten bewegen.

Sicherstellen, dass die BQnde der Schlossschrauben

(D) sich in den Schlitzen befinden.

4. Nach jeder Einstellung des Gangwahlschalters stets

die Spannung des Schnecken- und Fahrantriebs

prQfen.

SPANNUNG DES

SCHNECKENANTRIEBS

1. Bei freigegebenem Antriebshebel muss der Haken (B,

Abbildung 19) den Hebel (C) leicht berQhren, ohne

ihn anzuheben. Das maximale Spiel betr> 0,8 mm

(1/32 in.) (siehe Abbildung).

2. Zum Einstellen die Mutter (D, Abbildung 19) durch

Fixieren der Abfiachungen (A) und Drehen der Mutter

(D) Iockern. Die Abflachungen drehen und die

Schraube fixieren. Die Stellschraube ist eine

Kreuzschlitzschraube. Der Schraubenkopf kann

durch EinfQhren eines Schraubendrehers durch die

Feder fixiert bzw. gedreht werden.

3. Die Abflachungen (A) fixieren und die Mutter (D)

festziehen.

Abbildung 18. Gangwahl= und

Scheckenantriebsgest_nge

A. Unteres Gest_nge

B. Schlossschrauben

C. Muttern

4. Den Motor starten und den Schneckenf6rderer prQfen.

Der Schneckenf6rderer darf nur eingekuppelt sein,

wenn der Schneckenf6rdererhebel gedrQckt ist.

5. Den Schneckenf6rdererhebel bei laufendem Motor

vollst&ndig nach unten drQcken. Der

Schneckenf6rderer muss eingekuppelt werden und

sich drehen.

6. Den Schneckenf6rdererhebel freigeben. Der

Schneckenf6rderer muss innerhalb von 5 Sekunden

zum Stillstand kommen.

7. Wenn der Schneckenf6rderer nicht ordnungsgem&B

funktioniert, den Motor abstellen und die Einstellung

des Antriebsgest&nges QberprQfen.

8. Wenn das Antriebsgestb.nge ordnungsgem&B

eingestellt ist, muss ggf. die Spannung des

Schneckenantriebsriemens eingestellt werden. Siehe

,,Einstellung des Schneckenantriebsriemens".

TP 399-4222-01 -LW-SN 12 8/2005

Abbildung 19. Auger Drive Adjustment A.

Abflachungen tier Mutter

B. Federhaken

C. Hebel

D. Mutter

E. Stellschraube

Page 13

SPANNUNG DES FAHRANTRIEBS

1. Bei freigegebenen Antriebshebel darf kein Durchhang

im Seilzug vorhanden sein, wenn der Seilzug leicht

von Seite zu Seite bewegt wird und der

Winkelhebelarm in der untersten Position verbleibt.

2. Zum Einstellen der Seilzugspannung die Sechskant-

Stellmutter (D, Abbildung 20) durch Fixieren der

Abflachungen der Mutter (A) Iockern. Die

Stellschraube drehen. Die Stellschraube ist eine

Kreuzschlitzschraube. Der Schraubenkopf kann durch

Einf0hren eines Schraubendrehers durch die Feder

des Fahrantriebskupplungs-Seilzugs fixiert bzw.

gedreht werden.

3. Den Antriebshebel dr0cken, um die Einstellung zu

pr@en. Wenn die Spannung richtig eingestellt ist, die

Sechskantmutter fest anziehen. Die Schneefr_.se

muss sich ungehindert vorw_rts und rOckw_rts bewe-

gen lassen.

intermediate & Large Frame Snowthrowers

@

Figure 20. Einstellung des Fahrantriebs

A. Abflachungen tier Mutter

B. Federhaken

C. Winkelhebelarm

D. Mutter

E. Stellsehraube

_2005 13 TP 399-4222-01-LW-SN

Page 14

intermediate & Large Frame Snowthrowers

JUSTERING AV HASTIGHETSVEL-

GEREN

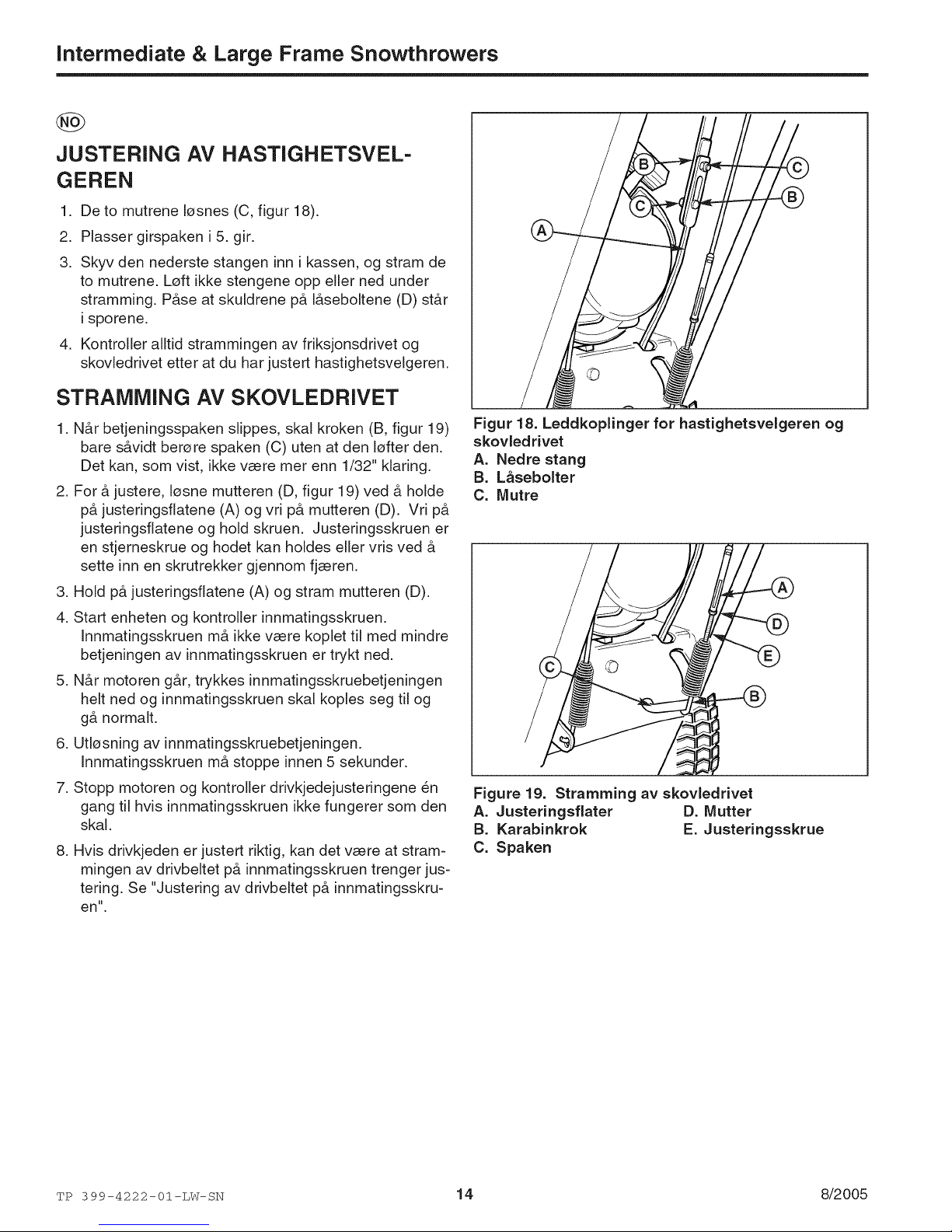

1. De to mutrene Iosnes (C, figur 18).

2. Plasser girspaken i 5. gir.

3. Skyv den nederste stangen inn i kassen, og stram de

to mutrene. Loft ikke stengene opp eller ned under

stramming. P&se at skuldrene p& I&seboltene (D) st&r

i sporene.

4. Kontroller alltid strammingen av friksjonsdrivet og

skovledrivet etter at du hat justert hastighetsvelgeren.

STRAiVliVllNG AV SKOVLEDRIVET

1. N&r betjeningsspaken slippes, skal kroken (B, figur 19)

bare s&vidt before spaken (C) uten at den Iofter den.

Det kan, som vist, ikke v_ere met enn 1/32" klaring.

2. For & justere, Iosne mutteren (D, figur 19) ved & holde

p& justeringsflatene (A) og vri p& mutteren (D). Vri p&

justeringsflatene og hold skruen. Justeringsskruen er

en stjemeskrue og hodet kan holdes eller vris ved &

sette inn en skrutrekker gjennom fjaeren.

3. Hold p& justeringsfiatene (A) og stram mutteren (D).

4. Start enheten og kontroller innmatingsskruen.

Innmatingsskruen m& ikke vaere koplet tilmed mindre

betjeningen av innmatingsskruen er trykt ned.

5. N&r motoren g&r, trykkes innmatingsskruebetjeningen

heir ned og innmatingsskruen skal koples seg til og

g& normalt.

6. Utlosning av innmatingsskruebetjeningen.

Innmatingsskruen m& stoppe innen 5 sekunder.

7. Stopp motoren og kontroller drivkjedejusteringene en

gang til hvis innmatingsskruen ikke fungerer som den

skal.

8. Hvis drivkjeden er justert riktig, kan det v_ere at stram-

mingen av drivbeltet p& innmatingsskruen trenger jus-

tering. Se "Justering av drivbeltet p& innmatingsskru-

en".

Figur 18. Leddkoplinger for hastighetsvelgeren og

skovledrivet

A. Nedre stang

B. L&sebolter

C. Mutre

Figure 19. Stramming av skovledrivet

A. Justeringsfiater D. Mutter

B. Karabinkrok E. Justeringsskrue

C. Spaken

TP 399-4222-01 -LW-SN 14 8/2005

Page 15

intermediate & Large Frame Snowthrowers

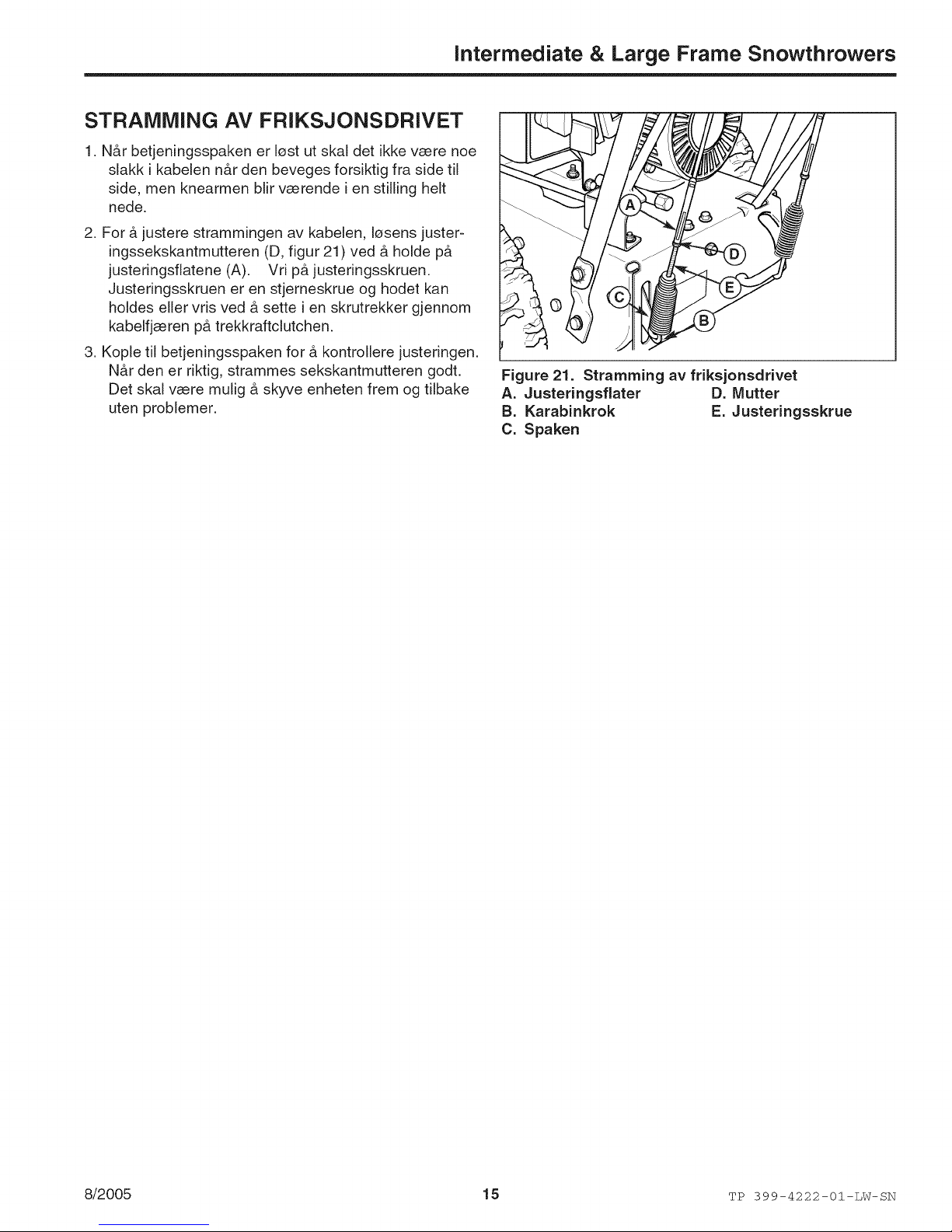

STRAMMING AV FRIKSJONSDRIVET

1. N&r betjeningsspaken er lost ut skal det ikke vaere hoe

slakk i kabelen n&r den beveges forsiktig fra side til

side, men knearmen blir vaerende i en stilling heir

nede.

2. For & justere strammingen av kabelen, Iosens juster-

ingssekskantmutteren (D, figur 21) ved & holde p&

justeringsflatene (A). Vri p&justeringsskruen.

Justeringsskruen er en stjemeskrue og hodet kan

holdes eller vris ved & sette i en skrutrekker gjennom

kabelfjaeren p& trekkraftclutchen.

3. Kople til betjeningsspaken for & kontrollere justeringen.

N&r den er riktig, strammes sekskantmutteren godt.

Det skal v_ere mulig & skyve enheten frem og tilbake

uten problemer.

Figure 21. Stramming av friksjonsdrivet

A. Justeringsflater D. Mutter

B. Karabinkrok E. Justeringsskrue

C. Spaken

_2005 15 TP 399-4222-Ol-LW-SN

Page 16

intermediate & Large Frame Snowthrowers

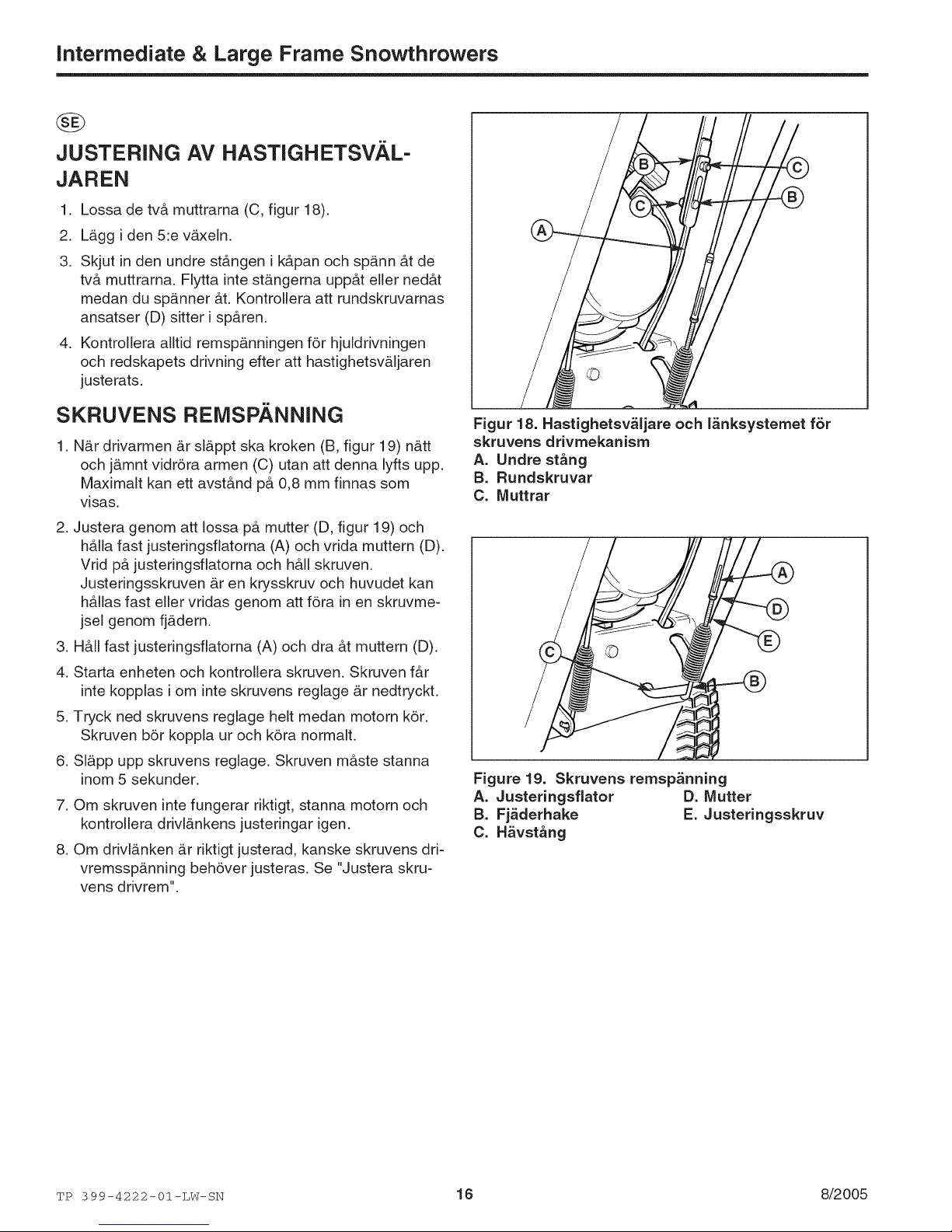

JUSTERING AV HASTIGHETSVJi, L-

JAREN

1. Lossa de tv& muttrarna (C, figur 18).

2. L&gg i den 5:e v&xeln.

3. Skjut in den undre st&ngen i k&pan och sp&nn &t de

tv& muttrarna. Flytta inte st&ngerna upp&t eller ned&t

medan du sp&nner &t. Kontrollera att rundskruvarnas

ansatser (D) sitter i sp&ren.

4. Kontrollera alltid remsp&nningen f6r hjuldrivningen

och redskapets drivning efter att hastighetsv&ljaren

justerats.

SKRUVENS REMSPANNING

1. N&r drivarmen &r sl_.ppt ska kroken (B, figur 19) nb.tt

och jb.mnt vidr6ra armen (C) utan att denna lyfts upp.

Maximalt kan ett avst&nd p& 0,8 mm finnas som

visas.

2. Justera genom att Iossa p& mutter (D, figur 19) och

h&lla fast justeringsfiatorna (A) och vrida muttern (D).

Vrid p& justeringsflatorna och h&ll skruven.

Justeringsskruven &r en krysskruv och huvudet kan

h&llas fast eller vridas genom att f6ra in en skruvme-

jsel genom fj&dern.

3. H&II fast justeringsflatorna (A) och dra &t muttern (D).

4. Starta enheten och kontrollera skruven. Skruven f&r

inte kopplas i om inte skruvens reglage &r nedtryckt.

5. Tryck ned skruvens reglage belt medan motorn k6r.

Skruven b6r koppla ur och k6ra normalt.

6. Sl_.pp upp skruvens reglage. Skruven m&ste stanna

inom 5 sekunder.

7. Om skruven inte fungerar riktigt, stanna motorn och

kontrollera drivl&nkens justeringar igen.

8. Om drivl&nken &r riktigt justerad, kanske skruvens dri-

vremssp&nning beh6ver justeras. Se "Justera skru-

vens drivrem".

Figur 18. Hastighetsv_ljare och I_nksystemet f6r

skruvens drivmekanism

A. Undre st&ng

B. Rundskruvar

C. Muttrar

Figure 19. Skruvens remsp_nning

A. Justeringsflator D, Mutter

B. Fj_derhake E. Justeringsskruv

C. H_vst_ng

TP 399-4222-01 -LW-SN 16 8/2005

Page 17

intermediate & Large Frame Snowthrowers

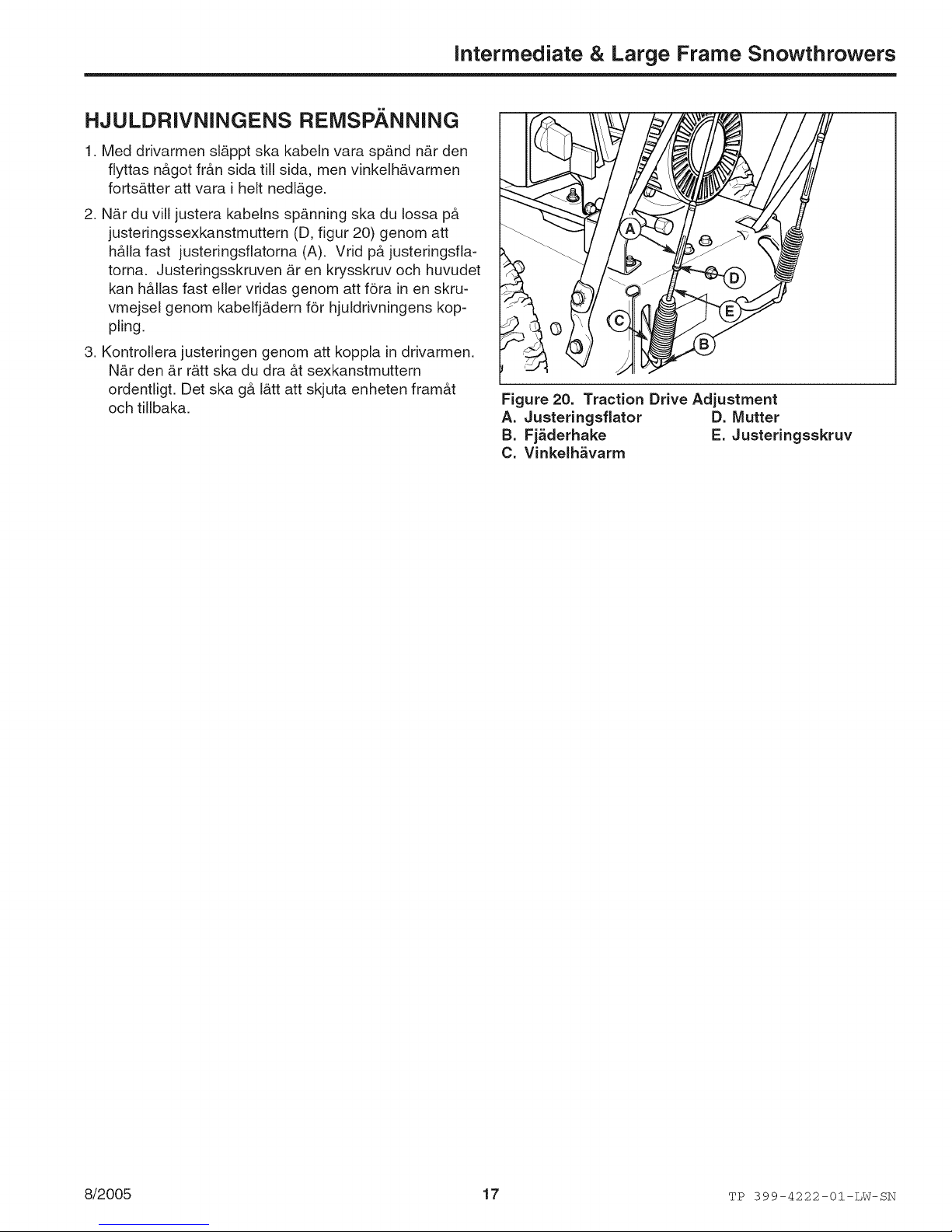

HJULDRIVNINGENS REMSPANNING

1. Med drivarmen sl_.ppt ska kabeln vara sp&nd n_.r den

flyttas n&got fr&n sida till sida, men vinkelh&varmen

forts&tter att vara i belt nedl&ge.

2. N&r du viii justera kabelns sp&nning ska du Iossa p&

justeringssexkanstmuttern (D, figur 20) genom att

h&lla fast justeringsflatorna (A). Vrid p& justeringsfla-

torna. Justeringsskruven _.ren krysskruv och huvudet

kan h&llas fast eller vridas genom att f6ra in en skru-

vmejsel genom kabelfj&dern f6r hjuldrivningens kop-

piing.

3. Kontrollera justeringen genom att koppla in drivarmen.

N&r den &r r&tt ska du dra &t sexkanstmuttern

ordentligt. Det ska g& I&tt att skjuta enheten fram&t

och tillbaka.

@

Figure 20. Traction Drive Adjustment

A. Justeringsflator D, Mutter

B. Fj_derhake E. Justeringsskruv

C. Vinkelh_varm

_2005 17 TP 399-4222-01-LW-SN

Page 18

intermediate & Large Frame Snowthrowers

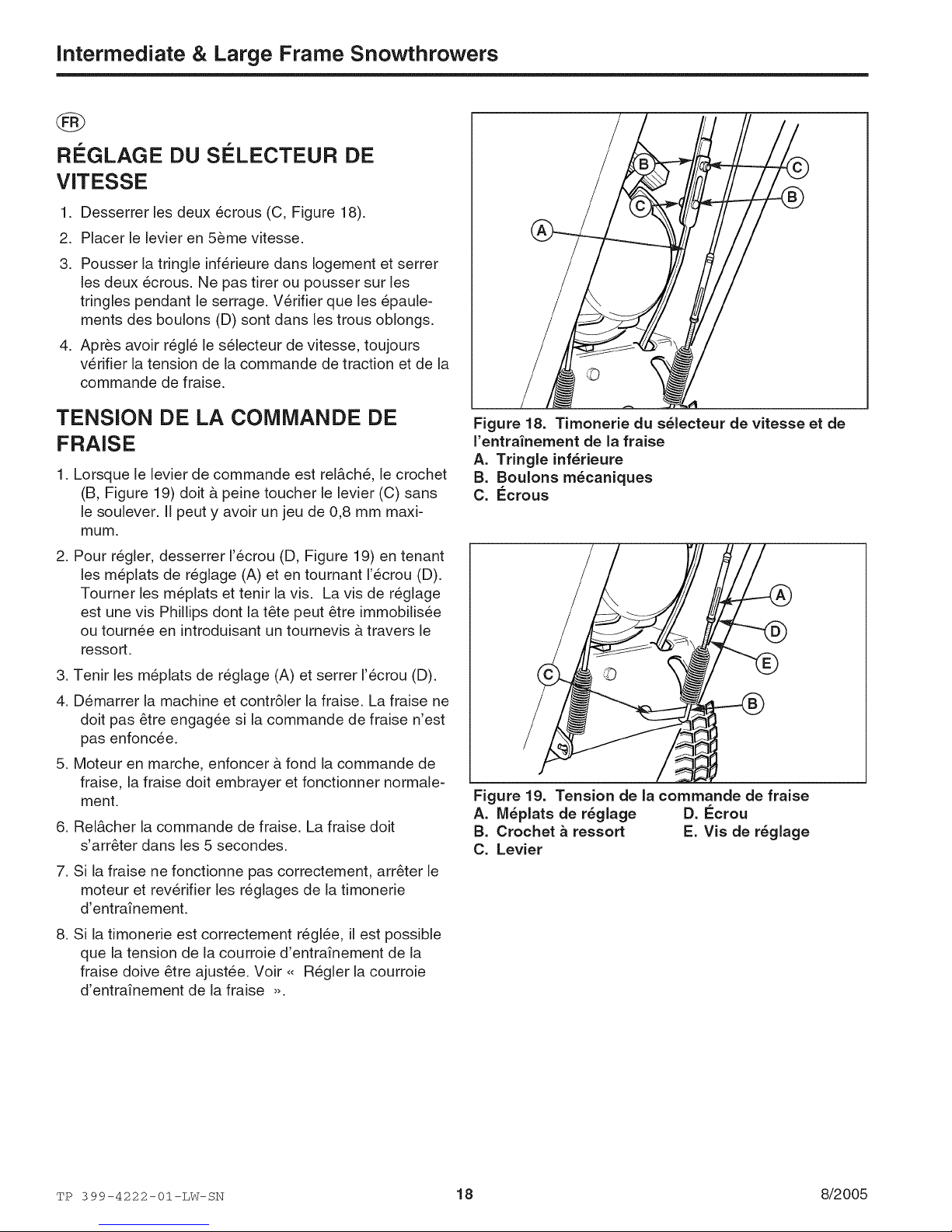

REGLAGE DU SELECTEUR DE

VITESSE

1. Desserrer les deux ecrous (C, Figure 18).

2. Placer le levier en 5eme vitesse.

3. Pousser la tringle inferieure dans Iogement et serrer

les deux ecrous. Ne pas tirer ou pousser sur les

tringles pendant le serrage. Verifier que les epaule-

ments des boulons (D) sont dans les trous oblongs.

4. Apres avoir regle le selecteur de vitesse, to@ours

verifier la tension de la commande de traction et de la

commancle de fraise.

TENSION DE LA COMMANDE DE

FRAISE

1. Lorsque le levier de commande est rel&che, le crochet

(B, Figure 19) doit & peine toucher le levier (C) sans

le so@ever. II peut y avoir un jeu de 0,8 mm maxi-

mum.

2. Pour regler, desserrer I'ecrou (D, Figure 19) en tenant

les m@lats de reglage (A) et en tournant I'ecrou (D).

Tourner les m@lats et tenir la vis. La vis de reglage

est une vis Phillips dont la t_te peut _tre immobilisee

ou tournee en introduisant un tournevis &travers le

ressort.

3. Tenir les m@lats de reglage (A) et serrer I'ecrou (D).

4. Demarrer la machine et contr61er la fraise. La fraise ne

doit pas _tre engagee si la commande de fraise n'est

pas enfoncee.

5. Moteur en marche, enfoncer ,%.fond la commande de

fraise, la fraise doit embrayer et fonctionner normale-

ment.

6. Rel&cher la commande de fraise. La fraise doit

s'arr_ter dans les 5 secondes.

7. Si la fraise ne fonctionne pas correctement, arr_ter le

moteur et reverifier les reglages de la timonerie

d'entrafnement.

Figure 18. Timonerie du s_lecteur de vitesse et de

I'entra'inement de la fraise

A. Tringle inf_rieure

B. Boulons m_caniques

C. Ecrous

Figure 19. Tension de la commande de fraise

A. IVl_plats de r_glage D. l_crou

B. Crochet & ressort E. Vis de r_glage

C. Levier

8. Si la timonerie est correctement reglee, il est possible

que la tension de la courroie d'entrafnement de la

fraise doive _tre ajustee. Voir _, Regler la courroie

d'entrafnement de la fraise >_.

TP 399-4222-01 -LW-SN 18 8/2005

Page 19

intermediate & Large Frame Snowthrowers

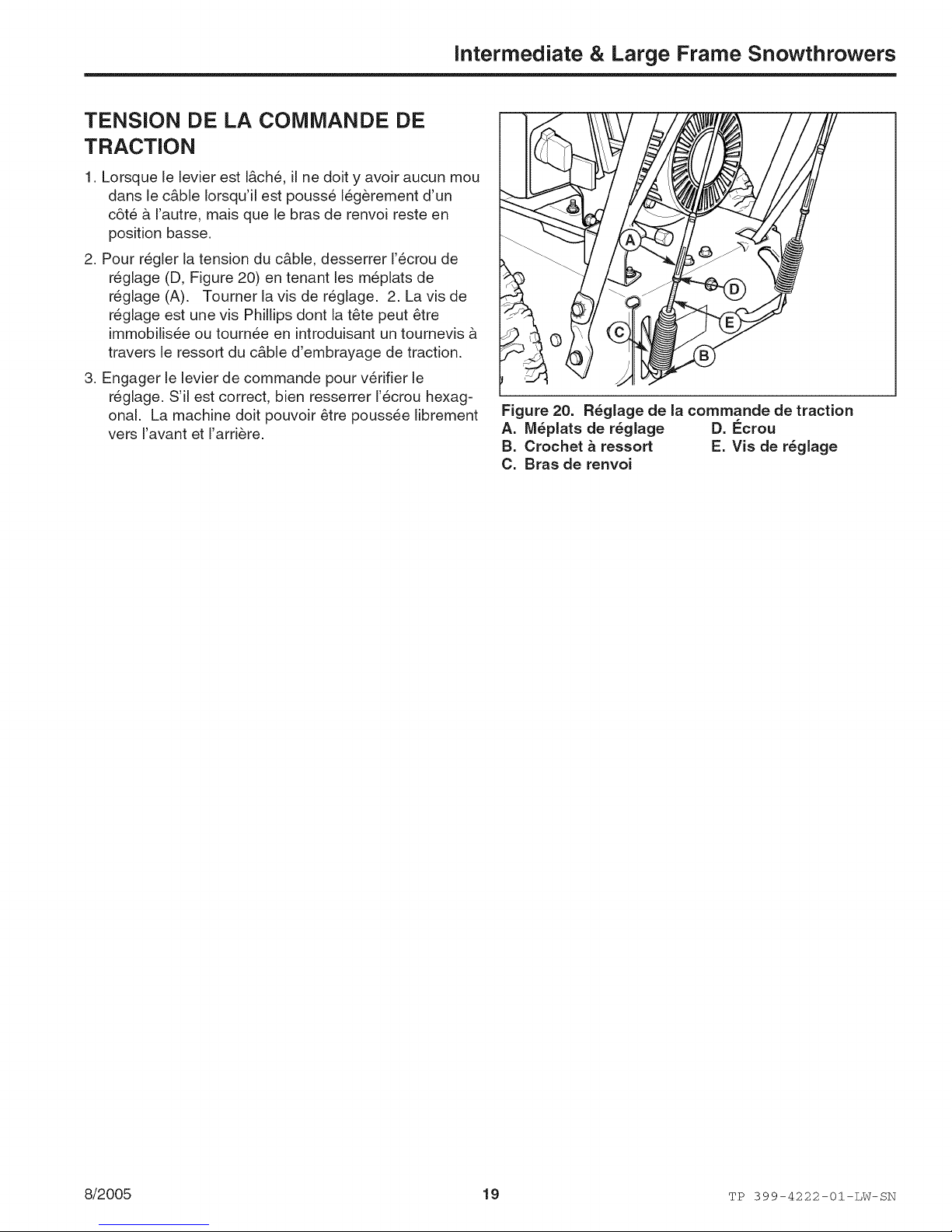

TENSION DE LA COiVliVlANDE DE

TRACTION

1. Lorsque le ievier est I&che, il ne doit y avoir aucun mou

dans le c&ble Iorsqu'il est pousse legerement d'un

cSte & I'autre, mais que le bras de renvoi reste en

position basse.

2. Pour regler la tension du c&ble, desserrer I'ecrou de

reglage (D, Figure 20) en tenant les m@lats de

reglage (A). Toumer la vis de reglage. 2. La vis de

reglage est une vis Phillips dont la t_te peut _tre

immobilisee ou tournee en introduisant un toumevis &

travers le ressort du c&ble d'embrayage de traction.

3. Engager le levier de commande pour v@ifier le

reglage. S'il est correct, bien resserrer I'ecrou hexag-

onal. La machine doit pouvoir _tre poussee librement

vers I'avant et I'arri@e.

Figure 20. R_glage de la commande de traction

A. IVl_plats de r_glage D. l_crou

B. Crochet _ ressort E. Vis de r_glage

C. Bras de renvoi

8/2005 19 TP 399-4222-O_.-LW-SN

Page 20

Intermediate & Large Frame Snowthrowers

@

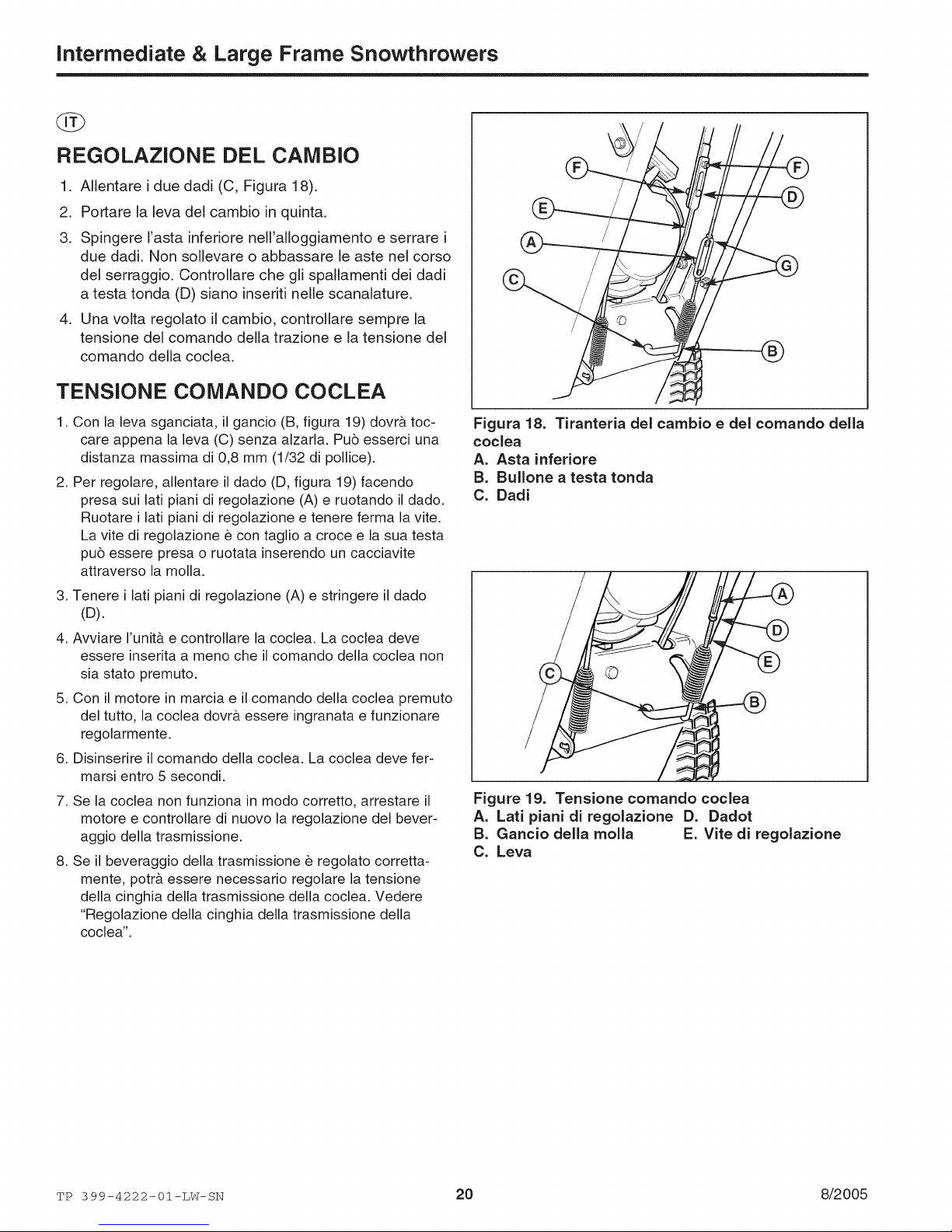

REGOLAZIONE DEL CAMBIO

1. Allentare i due dadi (C, Figura 18).

2. Portare la leva del cambio in quint&

3. Spingere I'asta inferiore nell'alloggiamento e serrare i

due dadi. Non sollevare o abbassare le aste nel corso

del serraggio. Controllare che gli spallamenti dei dadi

a testa tonda (D) siano inseriti nelle scanalature.

4. Una volta regolato il cambio, controllare sempre la

tensione del comando della trazione e la tensione del

comando della coclea.

TENSIONE COMANDO COCLEA

1. Con la leva sganciata, il gancio (B, figura 19) dovr& toc-

care appena la leva (C) senza alzarla. Pu6 esserci una

distanza massima di 0,8 mm (1/32 di pollice).

2. Per regolare, allentare il dado (D, figura 19) facendo

presa sui lati piani di regolazione (A) e ruotando il dado.

Ruotare i lati piani di regolazione e tenere ferma la vite.

La vite di regolazione e con taglio a croce e la sua testa

pu6 essere presa o ruotata inserendo un cacciavite

attraverso la molla.

3. Tenere i lati piani di regolazione (A) e stringere il dado

(D).

4.Avviare l'unit&e controllarelacoclea.La coclea deve

essere inseritaa meno che ilcomando dellacoclea non

siastatopremuto.

5.Con ilmotore inmarcia e ilcomando dellacoclea premuto

deltutto,lacoclea dovr& essere ingranatae funzionare

regolarmente.

6.Disinserireilcomando dellacoclea.La cocleadeve fer-

marsientro5 secondi.

7. Se la coclea non funziona in modo corretto, arrestare il

motore e controllare di nuovo la regolazione del bever-

aggio della trasmissione.

8. Se il beveraggio della trasmissione e regolato corretta-

mente, potr& essere necessario regolare la tensione

della cingMa della trasmissione della coclea. Vedere

"Regolazione della cinghia della trasmissione della

coclea".

Figura 18. Tiranteria del cambio e del comando delia

coclea

A. Asta inferiore

B. Bullone a testa tonda

C. Dadi

Figure 19. Tensione comando coclea

A. Lati piani di regolazione D. Dadot

B. Gancio della molla E. Vite di regolazione

C. Leva

TP 399-4222-01 -LW-SN 20 8/2005

Page 21

TENSIONE DEL COiVlANDO DELLA

TRAZIONE

1. Con la leva della trasmissione sganciata non ci dovr&

essere lasco nel cavo, quando Io si muove leggermente

da lato a lato, ma la leva a squadra rimane nella sua

posizione piQ bassa.

2. Per regolare la tensione del cavo, allentare i dadi esago-

nail di regolazione (D, figura 21) facendo presa sui lati

piani di regolazione (A). Ruotare la vite di regolazione.

2. La vite di regolazione e con taglio a croce e la sua

testa pub essere presa o ruotata inserendo un cacciavite

attraverso la molla del cavo della frizione della trasmis-

sione della trazione.

3. Ingranare la leva della trasmissione per controllare la

regolazione. Quando si sia ottenuta la tensione corretta,

serrare il dado esagonale in modo sicuro. Si deve poter

spingere liberamente I'unit& avanti e indietro.

intermediate & Large Frame Snowthrowers

Figure 20. tensione del comando della trazione

A. Lati piani di regolazione D. Dadot

B. Gancio della molla E. Vite di regolazione

C. Leva a squadra

_2005 21 TP 399-4222-Ol-LW-SN

Page 22

intermediate & Large Frame Snowthrowers

4

_ 1/4=20

× 3/4

TP 399-4222-01 -LW-SN 22 8/2005

Page 23

intermediate & Large Frame Snowthrowers

1

Easy Turn TM Cable Adjustment

if the Easy Turn TM cable has stretched, the gears will not disen-

gage when the control lever is activated. Adjust the cable using

the following procedure.

1. Turn the engine off and disconnect the spark plug wire.

2. Loosen the jam nut (B, Figure 21).

3. Turn the adjustment nut (A) to lengthen or shorten the

cable. The cable should be tightened just until all slack is

removed from the lever, however it must not engage the

Easy Turn TM release without depressing the control lever.

4. Tighten the jam nut.

@

EINSTELLUNG DES EASY TURN(TiVl)-

SEILZUGS

Wenn sich der Easy Turn(tm)-Seilzug gedehnt hat, werden die

Zahnr&der bei Bet&tigung des Bedienhebels evtl. nicht aus-

gekuppelt. Den Seilzug wie folgt einstellen:

1. Motor abstellen und ZQndkabel abklemmen.

2. Die Gegenmutter 16sen (B, Abbildung 21).

3. Die Stellmutter (A) drehen, um den Seilzug zu verl&ngern

oder zu verk0rzen. Der Seilzug sollte so gespannt werden,

dass der Hebel kein Spiel mehr aufweist. Dabei muss

jedoch darauf geachtet werden, dass die Easy Tum(tm)-

Freigabe nur beim Dr0cken des Bedienhebels bet&tigt wird.

4. Die Gegenmutter anziehen.

@

JUSTERING AV EASY TURN TM KABELEN

Hvis Easy Turn TM kablen er forstrukket, blir ikke tannhjulene

utkoplet n&r du aktiverer kontrollspaken. Juster kabelen p& fol-

gende m&te.

1. SI& av motoren og frakople tennpluggledningen.

2. Losne sperremutteren (B, figur 21).

3. Vri justeringsmutteren (A) for & forkorte eller forlenge kabe-

len. Kabelen skal strammes slik at det ikke er slak i spak-

en, men kabelen skal derimot ikke innkople Easy Turn TM

funksjonen uten at kontrollspaken blir trykket inn.

4. Stram sperremutteren

@

JUSTERING AV EASY TURNTM-KABELN

Om Easy Turn -kabeln t_njts ut kommer dreven inte att kop-

plas ur n&r reglaget anv&nds. Justera kabeln enligt f61jande:

1. St&ng av motorn och ta bort t&ndstiftskabeln.

2. Lossa I&smuttern (B, figur 21).

3. Vrid justeringsmuttern (A) f6r att f6rl&nga eller f6rkorta

kabeln. Kabeln b6r endast sp&nnas tills allt spel i reglaget

f6rsvinner. Dock ska Easy Turn -mekanismen inte kunna

kopplas ur utan att reglaget trycks in.

4. Sp&nn &t I&smuttern.

TM

TM

Figure 21. Cable Adjustment

REGLAGE DU CABLE EASY TURN(TIVi)

Si le c&ble Easy Turn(tm) est d6tendu, les pignons ne se

d6brayent pas Iorsque le levier de commande est actionn& Le

c&ble se r_gle de la mani_re suivante.

1. Couper le moteur et d6brancher le c&ble de bougie.

2. Desserrer le contre-6crou (B, Figure 21).

3,

Tourner 1'6crou de r6glage (A) de mani_re & allonger ou

raccourcir le c&ble. Le c&ble dolt 6tre juste assez tendu

pour 61iminer tout jeu au niveau du levier, mais sans pour

autant engager le m6canisme Easy Turn@m) Iorsque le levi-

er de commande est au repos.

4. Serrer le contre-6crou.

@

REGOLAZIONE DEL CAVO EASY TURN(TiVl)

Se il cavo Easy Turn(tm) si _ allentato, gli ingranaggi non si

disinseriranno all'attivazione della leva di comando. Regolare il

cavo, seguendo la procedura seguente.

1. Spegnere il motore e scollegare il filo della candela.

2. Allentare il controdado (B, Figura 21).

3,

Girare il dado di regolazione (A) in modo da allungare o

accorciare il cavo. IIcavo va stretto quel tanto che basta

per la rimozione di tutta la lentezza dalla leva ma non deve

far sbloccare I'Easy Turn(tm) senza che venga premuta la

leva di comando.

4. Serrare il controdado.

8/2005 23 TP 399-4222 -0_. =LW-SN

Page 24

intermediate & Large Frame Snowthrowers

AUGER GEAR CASE LUBRiCATiON

1. Place the snowthrower on a level surface.

2. Remove the pipe plug (A, Figure 22).

3. Check the lubricant level. It should be level with the

lower edge of the plug opening. If not, add Simplicity

Winter Weight Worm Gear Oil (available from your

dealer).

4. Re-install pipe plug, and tighten securely.

Figure 22. Auger Lubrication

A. Pipe Plug

\

TP 399-4222-01 -LW-SN 24 8/2005

Page 25

intermediate & Large Frame Snowthrowers

CHECKS BEFORE EACH START-UP

1. Make sure all safety guards are in place and all nuts, bolts

and clips are secure.

2. Check to make sure that the clean-out is attached to the

handle on the machine. Do not operate the machine without

the clean-out tool properly stored on the handle.

3. Check the engine oil level. See your engine Owner's

Manual for procedure and specifications.

4. Check to make sure spark plug wire is attached and spark

plug is tightened securely. If necessary, torque spark plug

to 15 ft. Ibs.

5. Check the fuel supply. Fill the tank no closer than 1/4 to 1/2

inch of top of tank to provide space for expansion. See your

engine Owner's Manual for fuel recommendations.

6. Check the Scraper Bar to make sure it is set at the desired

height. Adjust the Skid Shoes if necessary.

7. Check the Drive Control (B, Figure 23), and Auger Control

(C) for proper operation. If adjustment is required, see the

Service section for procedures.

8 .Check the Chute Direction Control (D or F Figure 23) for

proper operation. The discharge chute should rotate freely

in both directions. See the Service section for adjustment

procedures and troubleshooting.

9. Check the Chute Deflector (E, Figure 23) for proper opera-

tion. The deflector should pivot freely up and down when

the Chute Deflector Knob is loosened.

10. Position the chute at the desired starting direction and set

the deflector at the desired angle.

11. Check the Speed Selector (A, Figure 23) for smooth opera-

tion. The control must move freely into each speed position

gate and remain in position when released. If the Speed

Selector does not move freely into all forward and reverse

speed positions, contact your local authorized dealer for

assistance.

WARNING

This unit is a "two=stage" snowthrower.

The first stage is the auger, which feeds the snow

back into the impeller housing. The second stage

is the impeller, which throws the snow out the

discharge chute. If bodily contact is made with

the auger or impeller when they are rotating,

severe personal injury will occur.

To avoid injury, keep others and yourself away

from the auger and the discharge chute whenever

the engine is running. Read and follow all of the

safety rules and warnings in this manual.

DANGER

Do not clean out discharge chute with hands.

Contact with moving parts inside chute will

cause serious injury. Use clean out tool provided

with machine. Use the following procedure to

remove objects or clear the chute:

1. Stop the engine. Remove the key

2. Wait 10 seconds to be sure the auger/impeller

blades have stopped rotating.

3. Always use the clean-out tool. DO NOT use your

hands.

WARNING

®

Figure 23. Controls (from operator's position)

A. Speed Selector

B. Traction & Free=Hand TM Control

C. Auger Engage Control

D. Chute Direction Control

E. Chute Deflector (not shown)

F. Remote Deflector Control

G. Chute Direction Control (Electric)

_2005 25 TP 399-4222-Ol-LW-SN

For your safety, operation on slopes should be in

an up and down direction only. If it becomes

necessary to move across the face of a slope, use

caution and do not blow snow. Be very careful

when changing direction on a slope.

Proper winter footwear is recommended for the

operator to help prevent slipping. Never attempt

to clean snow from excessively steep slopes. The

maximum slope for any operation is 17.7% (10°).

WARNING

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is hot or running. Always move outdoors

to fill the tank. Keep snowthrower and gasoline

away from open flame or spark

Page 26

intermediate & Large Frame Snowthrowers

WARNUNG WARNUNG

Kraftstoff ist leicht entflarnrnbar und muss rnit

_uBerster Vorsicht gehandhabt werden. Den

Kraftstofftank niernals bei laufendern oder heil3ern

Motor befiJllen. Den Tank nut irn Freien f_llen.

Schneefr_se und Kraftstoff von offenen Flarnrnen

und Funken fernhalten.

Sicherheitspr_fungen vor jeder

Inbetriebnahrne

1. Sicherstellen, dass alle Sicherheitsabdeckungen instal-

liert und alle Muttern, Schrauben und Klemmschellen

fest angezogen sind.

2. Sicherstellen, dass das Reinigungswerkzeug am Griff

der Maschine befestigt ist. Die Maschine nur verwen-

den, wenn das Reinigungswerkzeug ordnungsgem_@

am Griff angebracht ist.

3. Motor61stand prQfen. Anweisungen und Spezifikationen

der Betriebsanleitung des Motors entnehmen.

4. Sicherstellen, dass das ZQndkabel angeschlossen und

die ZQndkerze fest angezogen ist. Die ZQndkerze nach

Bedarf mit einem Drehmoment von 20,3 Nm (15 ft. Ibs.)

anziehen.

5. Kraftstoffzufuhr prQfen. Im Tank immer 8 mm bis 12 mm

vom Deckelrand freilassen, damit der Kraftstoff sich aus-

dehnen kann. Kraftstoffempfehlungen der

Betriebsanleitung des Motors entnehmen.

6. SchQrfleiste prQfen um sicherzustellen, dass sie auf die

gewQnschte H6he eingestellt ist. Gleitschuhe nach

Bedarf einstellen.

7.

Antriebshebel (B, Abbildung 23) und

Schneckenf6rdererhebel (C) auf ordnungsgemABe

Funktion prQfen. Ggf. notwendige Einstellungsverfahren

dem Abschnitt "Service" entnehmen.

8.

Auswurfrichtungs-Einstellhebel (D / F Abbildung 23) auf

ordnungsgemABe Funktion prQfen. Der Auswurfschacht

muss sich in beiden Richtungen frei drehen. Ggf.

notwendige Einstellungsverfahren und

AbhilfemaBnahmen dem Abschnitt "Service" entnehmen.

9. Ablenkblech des Auswurfschachts (E, Abbildung 23) auf

ordnungsgemABe Funktion prQfen. Das Ablenkblech

muss sich frei nach oben und unten bewegen lassen,

wenn der Knopf des Auswurfschacht-Ablenkblechs

gel6st ist.

10. Auswurfschacht in der gewQnschten Startrichtung posi-

tionieren und das Ablenkblech auf den gewQnschten

Winkel einstellen.

Dieses Ger_t ist eine Zweistufen=Schneefr_se.

Bei tier ersten Stufe wird tier Schnee von tier

Schnecke nach hinten in alas Auswurfgeh_use

gef6rdert. Bei tier zweiten Stufe schleudert alas

Auswurfgebl_se den Schnee aus dern

Auswurfschacht. Kontakt rnit dern rotierenden

Schneckenf6rderer oder Auswurfgebl_se f_hrt zu

schweren Verletzungen.

Urn Verletzungen zu verrneiden, sich selbst und

andere Personen vorn Schneckenf6rderer und

Auswurfschacht fernhalten, wenn tier Motor I_uft.

Alle Sicherheitsbestimrnungen und Warnhinweise

in dieser Anleitung lesen und befolgen.

WARNUNG

Den Auswurfschacht nicht rnit den H_nden

reinigen. Kontakt der H_inde rnit beweglichen

Teilen irn Auswurfschacht kann schwere

Verletzungen verursachen. Ausschliel31ich das an

tier Maschine angebrachte Reinigungswerkzeug

verwenden. Zurn Entfernen yon Objekten oder

Reinigen des Auswurfschachts das folgende

Verfahren verwenden:

1. Den Motor abstellen und den Z_ndschl_ssel

abziehen.

2.10 Sekunden lang warren, urn sicherzustellen,

dass Schneckenf6rderer/Auswurfrad zurn

Stillstand gekornrnen sind.

3. AusschlieBlich das Reinigungswerkzeug

verwenden. HICHT rnit den H_nden in den

Schacht fassen.

-& WARNUNG

Der Betrieb an H_ngen sollte zur Sicherheit des

Bedieners Bergaufw_rts und Bergabw_irts

erfolgen. Wenn alas Ger_t quer zurn Hang bewegt

werden muss, vorsichtig vorgehen und keinen

Schnee auswerfen. Bei Richtungs_nderungen an

H_ngen ist besondere Vorsicht geboten.

Geeignetes Schuhwerk tragen, urn Ausrutschen

zu verrneiden. Das Ger_t niernals an besonders

steilen H_ngen betreiben. Die rnaxirnale Steigung

betr_gt 17,7 Prozent (10°).

11. Gangwahlschalter (A, Abbildung 23) auf

Leichtgb_ngigkeit prQfen. Der Schalter muss sich leicht in

alle Gangpositionen bewegen lassen und bei Freigabe in

der jeweiligen Position fixiert bleiben. Wenn sich der

TP 399-4222-01 -LW-SN 26 8/2005

Gangwahlschalter nicht in alle VorwArts- und

RQckwArtsgAnge bewegen IAsst, an den FachhAndler

wenden.

Page 27

intermediate & Large Frame Snowthrowers

ADVARSEL

ADVARSEL

Bet=sir= er meget brer=r=bart ogm& behar=dles

forsiktig. Tar=ker=m& aldri fylles opp mer=s

motorer= er varm eller i gang. Du m& alltid

oppholde deg uter=ders r=&rdu fyller opp tar=ker=.

Hold der= roterer=de sr=ofreserer= og ber=sir=er=

borte fra &per=flamme eller gr=ister.

FOLGENDE KONTROLLER SKAL

UTFORES FOR HVER OPPSTART

1. P&se at alle sikkerhetsvern er p& plass, og at alle

mutre, bolter og klemmer er godt strammet.

2. Kontroller for & v_ere sikker p& at stakeverktoyet er

festet til h&ndtaket p& maskinen. Ikke bruk maskinen

uten at stakeverktoyet er p& @ass i h&ndtaket silk det

skal v_ere.

3. Kontroller oljeniv&et i motoren. SI& opp i bruker-h&nd-

boken for motoren for & finne fremgangsm&te og spe-

sifikasjoner.

4. Kontroller at tennpluggledningen er tilkoplet og at ten-

npluggen er strammet godt. Stram eventuelt ten-

npluggen til 20 Nm (15 ft.lbs.)

5. Kontroller drivstoffniv&et. Fyll tanken til maks. 8 ti112

mm fra den overste kanten i tanken, silk at det er tom

for ekspansjon. SI& opp i brukerh&ndboken for

motoren for & finne anbefalinger for drivstoff.

6. Kontroller at skrapebladet er innstilt til riktig hoyde.

Juster eventuelt meiene, hvis nodvendig.

7. Kontroller at driv-kontrollen (B, figur 23) og innko-

plingskontrollen for skovlen (C) fungerer p& riktig

m&te. SI& opp p& kapittelet Service hvis det er nod-

vendig med justeringer.

8. Kontroller at retningskontrollen for utkasterroret (D / F

figur 23) fungerer p& riktig m&te. Utkasterroret skal

bevege seg fritt i begge retninger. SI& opp p& kapit-

telet Service hvis du trenger opplysninger om juster-

ingsprosedyrer og feilsoking.

9. Kontroller at deflektoren p& utkasterroret (E, figur 23)

fungerer p& riktig m&te. Deflektoren skal kunne

svinges fritt opp og ned n&r deflektorknappen p&

utkasterroret er Iosnet.

10. Vri utkasterroret til riktig startstilling, og still defiek-

toren i riktig vinkel.

11. Kontroller at hastighetsvelgeren (A, figur 23) fungerer

som den skal. Kontrollen skal kunne flyttes fritt til alle

hastighetsstillingene og forbli i den aktuelle stillingen

n&r du slipper opp kontrollen. Ta kontakt med

n_ermeste autoriserte forhandler for & f& hjelp hvis

hastighetsvelgeren ikke kan flyttes fritt til alle

hastighetsstillingene forover og i revers.

Der=r=e maskir=er= er er= "to4rir=r=s" sr=efreser.

Det ferste trir=r=et er skovler=, sore mater sneer=

tilbake inn i drivkraftsstativet. Det andre trir=r=et er

drivfjaerer=, sore kaster sr=eer= ut gjer=r=om

utkasterreret. Hvis kropper= kommer i kor=takt

meal skovler= eller drivfjaerer= mer=s roterir=g p&g&r,

vii alvorlig kroppsskade fir=r=esteal.

For & ur=r=g&skade, m& du holde deg selv og

andre borte fra skovler= og utkasterreret hver gag

motorer= er i gang. Les og felg alle

sikkerhetsregler=e og advarsler=e i der=r=e

h&ndboker=.

ADVARSEL

Ikke stake er= utmatertut reed her=der=e..& komme

i kor=takt reed bevegelige deler ir=r=iutmatertuter=

vii fete til alvorlig skade. Bruk stakeverkteyet

sore felger reed maskir=er=. Bruk felger=de

fremgar=gsm&te ved fjerr=ir=g av gjer=star=der i

eller for & &pr=e utmatertuter=.

1. Stopp motorer=. Taut r=ekkeler=.

2. Vent i 10 sekur=der for & vaere sikker p&at

ir=r=matir=gsskruer=/viftehjulet bar sluttet & rotere.

3. AIItid bruk stakeverkteyet. IKKE bruk her=der=e

dine.

-ADVARSEL

Av sikkerhetsmessige &rsaker bet all drift i

bakker bare utferes i opp= og r=edretr=ir=ger. Hvis

det blir r=edver=dig & bevege seg p&tvers over er=

bakke, m& du vaere forsiktig og ikke kaste sneer=.

Vaer ytterst forsiktig hvis du m& er=dre retr=ir=g

mer=s du befir=r=er deg i er=bakke.

Passer=de fottey til vir=terbruk ar=befales for

vedkommer=de sore bruker sr=efreserer= for &

ur=r=g&&skli. Du m& aldri preve & fjerr=e sr=e fra

meget store bakker. Den maksimale bakker= til

bruk av sr=ofreserer= er 17,7% (10°).

_2005 27 TP 399-4222-Ol-LW-SN

Page 28

intermediate & Large Frame Snowthrowers

VARNING!

VARNING!

Bensin _r mycket ant_ndbart och m&ste hanteras

meal f6rsiktighet. Fyll aldrig p& tanken medan

motorn _r varm eller ig&ng. Fyll alltid p& tanken

utomhus. F6rvara inte sn6slungan eller bensinen

i n_rheten av 6ppen I&ga eller gnista.

KONTROLLER FORE VARJE

ANVANDNING

1. Kontrollera att samtliga s&kerhetsanordningar finns

p& plats samt att alia muttrar, b@tar och kl&mmor sit-

ter ordenfligt fast.

2. Kontrollera att reng6ringsverktyget &r fastsatt p&

maskinens handtag. K6r inte maskinen utan att

reng6ringsverktyget &r fastsatt p& r&tt s&tt p& hand-

taget.

3. Kontrollera motorns oljeniv&. Se instruktionsboken f6r

motorn f6r f6rfaranden och specifikationer.

4. Kontrollera att t&ndstiftskabeln sitter ordenfligt fast

och att t&ndstiftet &r ordenfligt fastsp&nt. Vid behov,

momentdrag t&ndstiftet reed 20 Nm (15 ft Ibs).

5. Kontrollera br&nslef6rs6rjningen. Fyll inte upp tanken

mer &n 8 till 12 mm under tankens 6vre del s& att m6j-

lighet ges f6r expansion. Se instruktionsboken f6r

motorn f6r br&nslerekommendation.

.

Kontrollera att skrapbladet &r inst&llt p& 6nskad h6jd.

Justera medarna vid behov.

.

Kontrollera att hjuldrivningens kopplingsgrepp (B,

figur 23) och redskapets kopplingsgrepp (C) fungerar

p& r&tt s_.tt.Om justering kr&vs, se avsnittet Service

f6r r&tt f6rfarande.

Den h_r sn6slungan _r av "tv_stegstyp'.

F6rsta steget bestir av skruven sore f6r in sn6

bak_t till skovelhjulets k_pa. Det andra steget

bestir av skovelhjulet sore slungar ut sn6n

genom utkastet. Om kroppskontakt uppst_r meal

skruven eller skovelhjulet d_ dessa roterar,

resulterar detta i allvarlig personskada.

Undvik skada genom att h_lla b_de dig sj_lv och

andra borta fr_n skruven och utkastet medan

motorn _r ig_ng. L_s igenom och f61j samtliga

s_kerhetsregler och varningar i derma handbok.

VARNING!

Rensa inte utkastet meal h_nderna. Kontakt meal

r6rliga delar inuti utkastet orsakar allvarlig

skada. Anv_ind reng6ringsverktyget sore

medf61jer maskinen. Ta bort f6rem_l eller rensa

utkastet genom f61jande f6rfarande:

1. Stanna motorn. Ta ur t_ndningsnyckeln

2. V_nta 10 sekunder f6r att s_kerst_lla att

skruvens/skovelhjulets blad bar slutat rotera.

3. Anv_nd alltid reng6ringsverktyget. Anv_nd

INTE h_nderna.

8. Kontrollera att utkastets reglage (D / F figur 23)

fungerar p& r&tt s&tt. Utkastet ska kunna rotera fritt &t

b&da h&llen. Se avsnittet Service f6r justeringsf6r-

faranden och fels6kning.

9. Kontrollera att utkastets stb.nkskydd (E, figur 23)

fungerar pA r&tt s&tt. St&nkskyddet ska kunna vridas

fritt upp&t och nedAt n&r vredet f6r utkastets st&nksky-

dd Iossas.

10. St&ll in utkastet p& 6nskad startriktning och st&ll in

st&nkskyddet pA 6nskad vinkel.

11. Kontrollera att hastighetsv&ljaren (A, figur 23) funger-

ar j&mnt. Reglaget m&ste I&tt kunna f6ras till varje

hastighetsl&ge och stanna d_.r n_.rdet sl&pps. Om

hastighetsv&ljaren inte kan f6ras fritt mellan alia

hastighetsl&gena b&de framAt och bak&t, ska du kon-

takta din auktoriserade &terf6rs&ljare f6r hj&lp.

TP 399-4222-01 -LW-SN 28 8/2005

VARNING!

F6r din personliga s_kerhet b6r anv_ndning p&

sluttande mark endast ske i r6relse uppf6r och

nedf6r sluttningen. Om du m&ste f6rflytta dig

utmed sluttningen ska du iaktta f6rsiktighet och

inte aktivera sn6slungan. Var mycket f6rsiktig d&

du _ndrar riktning p& sluttande mark.

Vi rekommenderar att du sore anv_ndare b_r

fotbekl_idnad I_mplig f6r vintertid f6r att inte

tappa fotf_stet. F6rs6k aldrig rensa bort sn6 fr&n

extremt branta sluttningar. Maximal lutning f6r all

anv_ndning 6verstiger ej 17,7 % (10°).

Page 29

intermediate & Large Frame Snowthrowers

AVERTISSEMENT

AVERTISSEMENT

L'essence est hautement inflammable et doit _tre

manipul_e avec precaution. Ne jamais remplir le

r_servoir alors que le moteur est chaud ou en

marche. Toujours remplir le r_servoir en plein air.

Tenir la d_neigeuse _ fraise et ressence & I'_cart

de flammes nues ou d'_tincelles.

CONTROLES AVANT CHAQUE

Di MARRAGE

1. Verifier que tous les capots de protection sont en

place et que tous les ecrous, boulons et attaches sont

bien serres.

2. Verifier que I'outil de nettoyage est attache au guidon

de la machine. Ne pas utiliser la machine sans I'outil

de nettoyage correctement range sur le guidon

3. Contr61er le niveau d'huile du moteur. Se reporter aux

instructions et caracteristiques figurant dans le mode

d'emploi du moteur.

4. Verifier que le c&ble de bougie est branche et que la

bougie est correctement serree. Au besoin, serrer la

bougie & un couple de 20 Nm (15 ft-lb).

5. Contr61er I'alimentation en essence. Ne pas remplir &

moins de 8 & 12 mm du haut du reservoir afin de

laisser un volume suffisant pour la dilatation. Voir le

carburant recommande dans le mode d'emploi du

moteur.

6. Verifier que la racle est & la hauteur souhaitee. Regler

les patins au besoin.

7. Contr61er le bon fonctionnement de la commande

d'avance (B, Figure 23) et de la commande de fraise

(C). Si des reglages s'averent necessaires, se

reporter aux instructions de la section Entretien et

r@aration.

8. Contr61er le bon fonctionnement de la commande de

direction d'ejection (D / F Figure 23). La manche

d'ejection doit tourner librement dans les deux sens.

Se reporter aux instructions de reglage et de d@an-

nage dans la section Entretien et reparation du

manuel.

9. Contr61er le bon fonctionnement du deflecteur d'ejec-

tion (E, Figure 23). Le deflecteur doit pivoter librement

vers le haut et la bas Iorsque le bouton de reglage est

desserre.

10. Tourner la manche dans la direction initiale souhaitee

puis regler I'angle du deflecteur.

11. Contr61er le fonctionnement du selecteur de vitesse

(A, Figure 23). La manette doit passer librement d'un

rapport de vitesse & I'autre et rester en position

Cette machine est une d_neigeuse & fraise & <<

deux _tages ,>.

Le premier _tage est la fraise, qui envoie la neige

vers la turbine. Le second _tage est la turbine, qui

projette la neige vers la manche d'_jection. Tout

contact du corps avec la fraise ou la turbine en

rotation peut entrainer des dommages corporels

graves.

Pour _carter tout risque de blessure, I'utilisateur

et autres personnes pr_sentes doivent se tenir

I'_cart de la fraise et de la manche d'_jection

Iorsque le moteur est en marche. Life et respecter

I'ensemble des r_gles de s_curit_ et

avertissements figurant dans ce manuel.

AVERTISSEMENT

Ne pas nettoyer la manche d'_jection avec les

mains. Le contact avec des pi_ces en

mouvement _ I'int_rieur de la manche causera

des blessures graves. Utiliser I'outil de

nettoyage fourni avec la machine. Pour extraire

des objets ou d_gager la manche :

1. Arr_ter le moteur. Retirer la cir.

2. Attendre 10 secondes pour s'assurer que les

pales de la fraise/turbine ont cess_ de tourner.

3. Toujours utiliser I'outil de nettoyage. NE PAS

se servir des mains.

AVERTISSEMENT

Pour des raisons de s_curit_, le travail sur les

terrains en pente dolt se faire en montant ou en

descendant uniquement. S'il est n_cessaire de se

d_placer horizontalement en travers de la pente,

avancer avec precaution sans chasser la neige.

Faire preuve de beaucoup de prudence lots des

changements de direction sur une pente.

Pour _viter de glisser, il est conseill_ de porter

des chaussures ou bottes d'hiver appropri_es. Ne

jamais tenter de d_neiger des terrains trop

inclines. La pente maximale pouvant 6tre

d_neig_e est de 17,7% (10°).

Iorsqu'elle est rel&chee. S'il n'est pas possible de

placer sans difficulte le selecteur de vitesse dans

toutes les positions avant et arriere, contacter le

revendeur local agre&

_2005 29 TP 399-4222-01-LW-SN

Page 30

intermediate & Large Frame Snowthrowers

AVVERTENZA

AVVERTENZA

La benzina _ altamente infiammabile e va

maneggiata con cautela. Mai fare rifornimento

con il motore caldo o avviato. Riempire il

serbatoio sempre alraperto. Tenere Io

spazzaneve e la benzina a distanza da fiamme

libere o scintille.

FUNZIONAMENTO GENERALE

CONTROLL! PRIMA DELL'AVVIAMEN-

TO

1. Controllare che tutte le protezioni siano installate e

che tutti i dadi, i bulloni e le clip siano fissati.

2. Controllare il livello dell'olio motore. Per la procedura

e le caratteristiche tecniche, fare riferimento al man-

uale dell'operatore del motore.

3. Controllare il livello dell'olio motore. Per la procedura

e le caratteristiche tecniche, fare riferimento al man-

uale dell'operatore del motore.

4. Controllare che il filo della candela sia collegato e la

candela sia fissata saldamente in sede. Se neces-

sario, serrare la candela ad una coppia di 20 Nm (15

piedi-libbre).

5. Controllare I'alimentazione del combustibile. Riempire

il serbatoio fino a 8-12 mm dalla sommitb., in modo da

lasciare spazio per I'espansione del combustibile. Per

il tipo di combustibile consigliato, fare riferimento al

manuale dell'operatore del motore.

6. Controllare la barra del raschiatore, per controllare

che sia impostata all'altezza corretta. Regolare i patti-

ni, se necessario.

7. Controllare che il comando della trasmissione (B,

Figura 23) e quello della coclea (C) funzionino corret-

tamente. Qualora sia necessario effettuare una rego-

lazione, fare riferimento al capitolo Manutenzione, per

le procedure corrette.

8. Controllare che il comando di orientamento dello

scivolo (D / F Figura 23) funzioni correttamente. Lo

scivolo di scarico deve essere libero di girare in

entrambe le direzioni. Per le procedure di regolazione

e I'individuazione dei guasti, fare riferimento al capito-

Io Manutenzione.

9. Controllare che il deflettore dello scivolo (E, Figura

23) funzioni correttamente. II deflettore deve essere

libero di ruotare in alto ed in basso, una volta allenta-

ta la manopola del deflettore dello scivolo.

10. Orientare Io scivolo nella direzione iniziale necessaria

ed impostare il deflettore all'angolo desiderato.

Questa unit& _ uno spazzaneve "a due fasi".

Nella prima fase la coclea alimenta la neve

attraverso I'alloggiamento della girante. Nella

seconda fase la girante espelle la neve attraverso

Io scivolo di scarico. II contatto con la coclea e la

girante nel corso del Ioro funzionamento pub

provocare infortuni gravi.

Per evitare infortuni, tenersi e tenere gli astanti a

distanza dalla coclea e dallo scivolo di scarico

con il motore in funzione. Leggere e seguire tutte

le norme di sicurezza e le avvertenze contenute

nel presente manuale.

AVVERTENZA

Non pulire Io scivolo di scarico con le mani. II

contatto con gli elementi moventi alrintemo

dello scivolo causeranno lesioni gravi. Usare

solo I'utensile per la pulizia in dotazione all'unit_.

Per togliere oggetti dallo scivolo eseguire la

procedura seguente:

1. Fermare il motore. Rimuovere la chiavetta.

2. Attendere 10 secondi per essere sicuri che le

lame della coclea/girante hanno smesso di

muoversi.

3. Usare sempre I'utensile per la pulizia. NON

usare le mani.

AVVERTENZA

Per garantire la sicurezza personale, guidare la

macchina esclusivamente in salita ed in discesa

lungo un pendio. Qualora si renda necessario

procedere trasversalmente sul pendio, fare

attenzione e non spazzare la neve. Prestare molta

attenzione quando si effettua una svolta su un

pendio.

Onde evitare di scivolare, I'operatore dovrebbe

calzare scarpe adatte. Non tentare mai di

rimuovere la neve lungo pendii troppo scoscesi.

L'inclinazione massima per il funzionamento su

pendii _ di 17,7% (10°).

1.Controllare che la leva del cambio (A, Figura 23)

possa essere manovrata agevolmente. IIcomando

deve essere in grado di ingranare le varie marce e

restare in sede una volta rilasciato. Seil cambio non

in grado di passare da una marcia all'altra (marcia

avanti e retromarcia), rivolgersi alia concessionaria di

fiducia per assistenza.

TP 399-4222-01. -LW-SN 30 8/2005

Page 31

intermediate & Large Frame Snowthrowers

NOTES

8/2005 31 TP 399-4222-O_.-LW-SN

Page 32

intermediate & Large Frame Snowthrowers

NOTES

MANUFACTURING, INC.

500 N Spring Street / PO Box 997

Port Washington, Wl 53074-0997 USA

TP 399-4222-01-LW-SN

32

© 2005 Simplicity Manufacturing, Inc. All Rights Reserved

8/2005

Page 33

0 Bimpliuilg

Setup instructions for intermediate & Large Frame Snowthrowers

/

/

/

Initial setup

Ersteinrichtung

Forbokstavrnontere

This Dealer Setup Instruction applies to the following units:

Mfg. No.

1694836

1694837

1694845

1694846

1694847

1694848

1694849

1694850

1694851

1694852

1694853

1694854

1694855

1694856

Description

7555M, 7.5HP, Snowthrower

7555EX, 7.5HP, Snowthrower (CE)

8560EI, 8.5HP OHV, Snowthrower

8560EX, 8.5HP OHV, Snowthrower (CE)

10560E, IO.5HP Snowthrower

10560EX, IO.5HP Snowthrower (CE)

11570E, 11.5HP Snowthrower

11570EX, 11.5HP Snowthrower (CE)

1380E, 13HP Snowthrower

1380EX, 13HP Snowthrower (CE)

95247E, 9.5HP Snowthrower

E95247, 9.5HP Snowthrower (CE)

105287E, 10.5HP Snowthrower

E105287, 10.5HP Snowthrower (CE)

FiJrstan igga

Assemblage

Instaliazione

1694857

1694858

1694859

1694860

1694867

1694872

1694914

1694915

7800000

7800001

7800017

7800018

115327E, 11.5HP Snowthrower

E115327, 11.5HP Snowthrower (CE)

13387E, 13HP Snowthrower

E13387, 13HP Snowthrower (CE)

9560E, 9.5HP Snowthrower

1390E, 13HP Snowthrower

9560EX, 9.5HP Snowthrower (CE)

1390EX, 13HP Snowthrower (CE)

175225, 7.5HP, Snowthrower

EI75225, 7.5HP, Snowthrower (CE)

185245E, 8.5HP OHV, Snowthrower

EI85245, 8.5HP OHV, Snowthrower (CE)

initial

iniziale

© Copyright 2005 Simplicity Manufacturing, Inc.

All rights reserved. Printed in USA.

8/2005 1 TP 399-4222-01-LW-SN

Form No. 1731295

Revision 01

Revision Date 8/2005

Page 34

SAFETY RULES

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

The triangle _IL in text signifies important cautions or warnings which must be followed.

GENERAL OPERATION

• Read, understand, and follow all instructions in the

manual and on the unit before starting.

• Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown.

• Be sure the area is clear of other people. Stop unit if any-

one enters the area.

• Always look down and behind before and while travelling in

reverse.

• Be aware of the discharge direction and do not point it at

anyone. Do not point the discharge at glass enclosures,

automobiles, or windows.

• Disengage all clutches (release drive and auger control

levers) before starting the engine.

• Never leave a running unit unattended. Always disengage

the auger and traction controls, stop engine, and remove

keys.

• Stop engine before unclogging chute.

• Operate only in daylight or good artificial light.

• Do not operate the unit while under the influence of alcohol

or drugs.

• Watch for traffic when operating near or crossing road-

ways.

• Use extra care when loading or unloading the unit into a

trailer or truck.

• Keep in mind the operator is responsible for accidents

occurring to other people or property.

• Data indicates that operators, age 60 years and above, are

involved in a large percentage of power equipment-related

injuries. These operators should evaluate their ability to

operate the unit safely enough to protect themselves and

others from injury.

• All operators should seek and obtain professional and prac-

tical instruction.

• Always wear substantial footwear and appropriate winter

clothing. Wear foot-ware that improves traction on slippery

slopes. DO NOT wear long scarves or loose clothing that

could become entangled in moving parts.

• Before using, always visually check that all hardware is

present, in-tact, and secure. Replace worn or damaged

parts.

• Never operate the machine with defective guards, or with-

out safety protective devises in place.

• Stop engine before: refuelling, removing an attachment,

making adjustments (unless the adjustment can be made

from the operator's position).

• Follow the manufacturer's recommendation for wheel

weights or counterweights.

• Adjust skid shoe height to clear gravel or crushed rock sur-

faces.

• Do not touch snowthrower parts which may be hot from

operation. Allow such parts to cool before attempting to

service the unit.

CLEARING A CLOGGED DISCHARGE CHUTE

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snowthrowers. Always use a clean out tool, not your hands, to

clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

SLOPE OPERATION

WARNING

Never operate on slopes greater than 17.6 percent (10 °) which

is a rise of 3-1/2 feet (106 cm) vertically in 20 feet (607 cm)

horizontally.

When operating on slopes use additional wheel weights or

counterweights, See your dealer to determine which weights

are available and appropriate for your unit.

Select slow ground speed before driving onto slope. Travel UP

and DOWN the slope, never across the face, use caution when

changing directions and DO NOT START OR STOP ON

SLOPE.

Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. All slopes

require extra caution. Ifyou cannot back up the slope or if you feel

uneasy on it, do not operate on it.

EMISSIONS

• Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

• Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Do

e

See your authorized dealer for recommendations counter-

weights to improve stability.

• Travel up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could over-

turn the unit. Snow can hide obstacles.

• Use slow speed. Tires may lose traction on slopes. Choose

a low gear so that you will not have to stop or shift while on

the slope.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Always keep unit in gear especially when traveling down-

hill.

Do Not

= Do not start or stop on a slope. If tires lose traction, disen-

gage the auger and proceed slowly straight down the

slope.

= Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

= Do not operate near drop-offs, ditches, or embankments.

The unit could suddenly turn over if a wheel is over the

edge of a cliff or ditch, or if an edge caves in.

= Do not operate on wet surfaces. Reduced traction could

cause sliding.

= Do not shift to neutral and coast down hills.

TP 399-4222-@1 -LW-SN 2 8/2005

Page 35

intermediate & Large Frame Snowthrowers

Contents:

1. Uncrate ......................................... 4

2. Check Tire Pressure ..................... 4

3. Install Drift Cutters ........................ 5

4. Install Chute .................................. 5

5. Install Handles .............................. 6

6. Connect Spout Rotator ................. 7

7. Tube Handle Levers ..................... 7

8. Electrical Connections .................. 7

9. Speed Selector Connection .......... 8

10. Auger Drive Connection ............. 9

10. Traction Drive Connection .......... 9

11. Speed Selector Adjustment ...... 10

12. Auger Drive Tension ................. 10

13. Traction Drive Tension ............. 11

14. Connect Chute Control ............. 22

15. Connect Easy Turn ................... 22

16. Easy Turn Cable Adjustment....23

17. Auger Gear Case Lubrication ...24

18. Checks Before Each Start-up ...25

Inhaltsverzeichnis:

1. packen Sie aus ................................ 4

2. PrQfungdes Reifendrucks ................4

3. bringen Sie an Schneeantrieb

Scherblock ............................................ 5

4. bringen Sie an Rutsche ................... 5

5. bringen Sie an Lenkstangen ...........6

6. schlieBen Sie TQIlerotator ............... 7

7. Schlauch-Handgriff-Hebel ............ 7

8. electrial Anschl0sse ...................... 7

9. Geschwindigkeit W&hlcaooenction .8

10. Schneckenwelle Antrieb

connenction .......................................... 9

10. Zugkraft-Antrieb connenction ........ 9

11. Einstellung des

Gangwahlschalters .............................. 10

12. Spannung des

Schneckenantriebs .............................. 10

13. pannung des Fahrantriebs ........... 11

14. SchlieBen Sie RutschcSteuerung

An ...................................................... 22

15. schlieBen Sie an Easy Turn ........22

16. Einstellung des Easy

Turn-Seilzugs ...................................... 23

17. PrQfung des Olstands im

Schneckenf6rderer-Getriebegeh&use .24

18. SicherheitsprQfungen vor jeder

Inbetriebnahme ................................... 25

Artillel:

1. Dekasse ........................................ 4

2. Kontrol av lufttrykket i dekkene .....4

3. Insetallere Bakke Skjsere .............. 5

4. Insetallere Ventil ........................... 5

5. Insetallere Sykkelstyre .................. 6

6. Forbindelse Ventil Rotator ............ 7

7. ro rh&ndtakvektstenger .................. 7

8. elektrisk forbindelse ...................... 7

9. Fart Skiftenokkel Forbindelse ....... 8

10. Skrue Forero Forbindelse ........... 9

10. Fengsle Fart Forbindelse ............ 9

11. Justering av hastighetsvelgerenl0

12. Stramming av skovledrivet ....... 10

13. Stramming av friksjonsdrivet ....11