Snapper 1694851 1380E, 1694852 1380EX, 1694845 8560EI, 1694846 8560EX, 1694847 10560E User Manual

...

8/2005 1

TP 399-4222-01-LW-SN

Form No. 1731295

Revision 01

Revision Date 8/2005

© Copyright 2005 Simplicity Manufacturing, Inc.

All rights reserved. Printed in USA.

This Dealer Setup Instruction applies to the following units:

DE

FR

Initial setup

Ersteinrichtung

Forbokstav montere

Först anägga

Assemblage initial

Installazione iniziale

EN

IT

Setup Instructions for Intermediate & Large Frame Snowthrowers

NO

Mfg. No. Description

1694836 7555M, 7.5HP, Snowthrower

1694837 7555EX, 7.5HP, Snowthrower (CE)

1694845 8560EI, 8.5HP OHV, Snowthrower

1694846 8560EX, 8.5HP OHV, Snowthrower (CE)

1694847 10560E, 10.5HP Snowthrower

1694848 10560EX, 10.5HP Snowthrower (CE)

1694849 11570E, 11.5HP Snowthrower

1694850 11570EX, 11.5HP Snowthrower (CE)

1694851 1380E, 13HP Snowthrower

1694852 1380EX, 13HP Snowthrower (CE)

1694853 95247E, 9.5HP Snowthrower

1694854 E95247, 9.5HP Snowthrower (CE)

1694855 105287E, 10.5HP Snowthrower

1694856 E105287, 10.5HP Snowthrower (CE)

SE

1694857 115327E, 11.5HP Snowthrower

1694858 E115327, 11.5HP Snowthrower (CE)

1694859 13387E, 13HP Snowthrower

1694860 E13387, 13HP Snowthrower (CE)

1694867 9560E, 9.5HP Snowthrower

1694872 1390E, 13HP Snowthrower

1694914 9560EX, 9.5HP Snowthrower (CE)

1694915 1390EX, 13HP Snowthrower (CE)

7800000 I75225, 7.5HP, Snowthrower

7800001 EI75225, 7.5HP, Snowthrower (CE)

7800017 I85245E, 8.5HP OHV, Snowthrower

7800018 EI85245, 8.5HP OHV, Snowthrower (CE)

TP 399-4222-01-LW-SN

8/20052

SAFETY RULES

GENERAL OPERATION

• Read, understand, and follow all instructions in the

manual and on the unit before starting.

• Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown.

• Be sure the area is clear of other people. Stop unit if anyone enters the area.

• Always look down and behind before and while travelling in

reverse.

• Be aware of the discharge direction and do not point it at

anyone. Do not point the discharge at glass enclosures,

automobiles, or windows.

• Disengage all clutches (release drive and auger control

levers) before starting the engine.

• Never leave a running unit unattended. Always disengage

the auger and traction controls, stop engine, and remove

keys.

• Stop engine before unclogging chute.

• Operate only in daylight or good artificial light.

• Do not operate the unit while under the influence of alcohol

or drugs.

• Watch for traffic when operating near or crossing roadways.

• Use extra care when loading or unloading the unit into a

trailer or truck.

• Keep in mind the operator is responsible for accidents

occurring to other people or property.

• Data indicates that operators, age 60 years and above, are

involved in a large percentage of power equipment-related

injuries. These operators should evaluate their ability to

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

The triangle in text signifies important cautions or warnings which must be followed.

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. All slopes

require extra caution. If you cannot back up the slope or if you feel

uneasy on it, do not operate on it.

Do

• See your authorized dealer for recommendations counterweights to improve stability.

• Travel up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could overturn the unit. Snow can hide obstacles.

• Use slow speed. Tires may lose traction on slopes. Choose

a low gear so that you will not have to stop or shift while on

the slope.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Always keep unit in gear especially when traveling downhill.

Do Not

• Do not start or stop on a slope. If tires lose traction, disengage the auger and proceed slowly straight down the

slope.

• Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

• Do not operate near drop-offs, ditches, or embankments.

The unit could suddenly turn over if a wheel is over the

edge of a cliff or ditch, or if an edge caves in.

• Do not operate on wet surfaces. Reduced traction could

cause sliding.

• Do not shift to neutral and coast down hills.

EMISSIONS

• Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

• Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

WARNING

Never operate on slopes greater than 17.6 percent (10°) which

is a rise of 3-1/2 feet (106 cm) vertically in 20 feet (607 cm)

horizontally.

When operating on slopes use additional wheel weights or

counterweights. See your dealer to determine which weights

are available and appropriate for your unit.

Select slow ground speed before driving onto slope. Travel UP

and DOWN the slope, never across the face, use caution when

changing directions and DO NOT START OR STOP ON

SLOPE.

operate the unit safely enough to protect themselves and

others from injury.

• All operators should seek and obtain professional and practical instruction.

• Always wear substantial footwear and appropriate winter

clothing. Wear foot-ware that improves traction on slippery

slopes. DO NOT wear long scarves or loose clothing that

could become entangled in moving parts.

• Before using, always visually check that all hardware is

present, in-tact, and secure. Replace worn or damaged

parts.

• Never operate the machine with defective guards, or without safety protective devises in place.

• Stop engine before: refuelling, removing an attachment,

making adjustments (unless the adjustment can be made

from the operator’s position).

• Follow the manufacturer’s recommendation for wheel

weights or counterweights.

• Adjust skid shoe height to clear gravel or crushed rock surfaces.

• Do not touch snowthrower parts which may be hot from

operation. Allow such parts to cool before attempting to

service the unit.

CLEARING A CLOGGED DISCHARGE CHUTE

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snowthrowers. Always use a clean out tool, not your hands. to

clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

Intermediate & Large Frame Snowthrowers

8/2005 3

TP 399-4222-01-LW-SN

Contents:

1. Uncrate .........................................4

2. Check Tire Pressure.....................4

3. Install Drift Cutters ........................5

4. Install Chute..................................5

5. Install Handles ..............................6

6. Connect Spout Rotator .................7

7. Tube Handle Levers .....................7

8. Electrical Connections ..................7

9. Speed Selector Connection..........8

10. Auger Drive Connection .............9

10. Traction Drive Connection ..........9

11. Speed Selector Adjustment ......10

12. Auger Drive Tension.................10

13. Traction Drive Tension .............11

14. Connect Chute Control .............22

15. Connect Easy Turn...................22

16. Easy Turn Cable Adjustment....23

17. Auger Gear Case Lubrication ...24

18. Checks Before Each Start-up ...25

Inhaltsverzeichnis:

1. packen Sie aus ................................4

2. Prüfung des Reifendrucks................4

3. bringen Sie an Schneeantrieb

Scherblock ............................................5

4. bringen Sie an Rutsche ...................5

5. bringen Sie an Lenkstangen ...........6

6. schließen Sie Tüllerotator ...............7

7. Schlauch-Handgriff-Hebel ............7

8. electrial Anschlüsse......................7

9. Geschwindigkeit Wählcaooenction .8

10. Schneckenwelle Antrieb

connenction ..........................................9

10. Zugkraft-Antrieb connenction ........9

11. Einstellung des

Gangwahlschalters..............................10

12. Spannung des

Schneckenantriebs..............................10

13. pannung des Fahrantriebs ...........11

14. Schließen Sie RutschcSteuerung

An ......................................................22

15. schließen Sie an Easy Turn ........22

16. Einstellung des Easy

Turn-Seilzugs ......................................23

17. Prüfung des Ölstands im

Schneckenförderer-Getriebegehäuse .24

18. Sicherheitsprüfungen vor jeder

Inbetriebnahme ...................................25

Innehåll:

1. Depacke, ......................................4

2. Kontroll av ringtrycket ...................4

3. Installera Trave Klippa..................5

4. Installera Tub................................5

5. Installera Styrstång.......................6

6. Ansluta Tub Rotera ......................7

7. Modeller med rörhandtag

hävstång ...........................................7

8. Electrical förhållande ....................7

9. Fart Urval Förbindelse .................8

10. Skruv Aktur Förbindelse .............9

10. Tag Aktur Förbindelse ................9

11. Justering av hastighetsväljaren 10

12. Skruvens drivremsspänning .....10

13. Hjuldrivningens

drivremsspänning ...........................11

14. Ansluta Tub Kontroll ................22

15. Ansluta Easy Turn ...................22

16. Justering av

Easy Turn-kabeln ...........................23

17. Kontroll av smörjmedelsnivån i

skruvens växellåda ..........................24

18. Kontroller före varje

användning ......................................25

Artillel:

1. Dekasse........................................4

2. Kontrol av lufttrykket i dekkene.....4

3. Insetallere Bakke Skjære..............5

4. Insetallere Ventil ...........................5

5. Insetallere Sykkelstyre..................6

6. Forbindelse Ventil Rotator ............7

7. rørhåndtakvektstenger..................7

8. elektrisk forbindelse......................7

9. Fart Skiftenøkkel Forbindelse.......8

10. Skrue Forerø Forbindelse...........9

10. Fengsle Fart Forbindelse............9

11. Justering av hastighetsvelgeren10

12. Stramming av skovledrivet .......10

13. Stramming av friksjonsdrivet ....11

14. Forbindelse Chute Control........22

15. Forbindelse Easy Turn .............22

16. Justering av Easy Turn-kabelen23

17. Smør akselene og

kontrollspakene ...............................24

18. Følgende kontroller skal utføres

før hver .....................................25

Matières:

1. Dépaqueter...................................4

2. Contrôle de la pression

des pneus ..........................................4

3. Emménagent Amas de Neige

Coupeur............................................5

4. Emménagent Chute......................5

5. Emménagent Guidon....................6

6. Connecter Rotateur de Bec .........7

7. Leviers De Poignée De Tube .......7

8. raccordements electrial ................7

9. Galoper Select Connexion............8

10. Pas de Vis Traquer Connexion...9

10. Grippe Traquer Connexion .........9

11. Réglage du sélecteur de vitesse10

12. Tension de la commande

de fraise..........................................10

13. Tension de la commande

de traction........................................11

14. Connecter Glissière Contrôle ...22

15. Connecter Easy Turn................22

16. Réglage du câble Easy Turn ....23

17. Niveau d’huile de la boîte

d’engrenages de la fraise ................24

18. Contrôles avant chaque

démarrage .......................................25

Indice:

1. Deimpaccare ................................4

2. Controllo della pressione degli

pneumatici .........................................4

3. Mettere Catasta Tagliato ..............5

4. Mettere Solco ...............................5

5. Mettere Manici ..............................6

6. Copulare Tubo Rotare .................7

7. Leve Della Maniglia Del Tubo.......7

8. Collegamenti Elettrici....................7

7. Velocità Eletta Congiuntura ..........8

10. Trapano Andara Congiuntura .....9

10. Acchiappare Andara

Congiuntura .......................................9

11. Regolazione del cambio ...........10

12. Tensione della cinghia di trasmis-

sione della coclea ............................10

13. Tensione della cinghia di trasmis-

sione della trazione..........................11

14. Copulare Solco Controllo.........22

15. Copulare Easy Turn.................22

16. Regolazione del cavo

Easy Turn .......................................23

17. Controllo della lubrificazione della

scatola ingranaggi della coclea .......24

18. Controlli prima

dell’avviamento...............................25

EN

DE

NO

SE

FR

IT

Intermediate & Large Frame Snowthrowers

TP 399-4222-01-LW-SN

8/20054

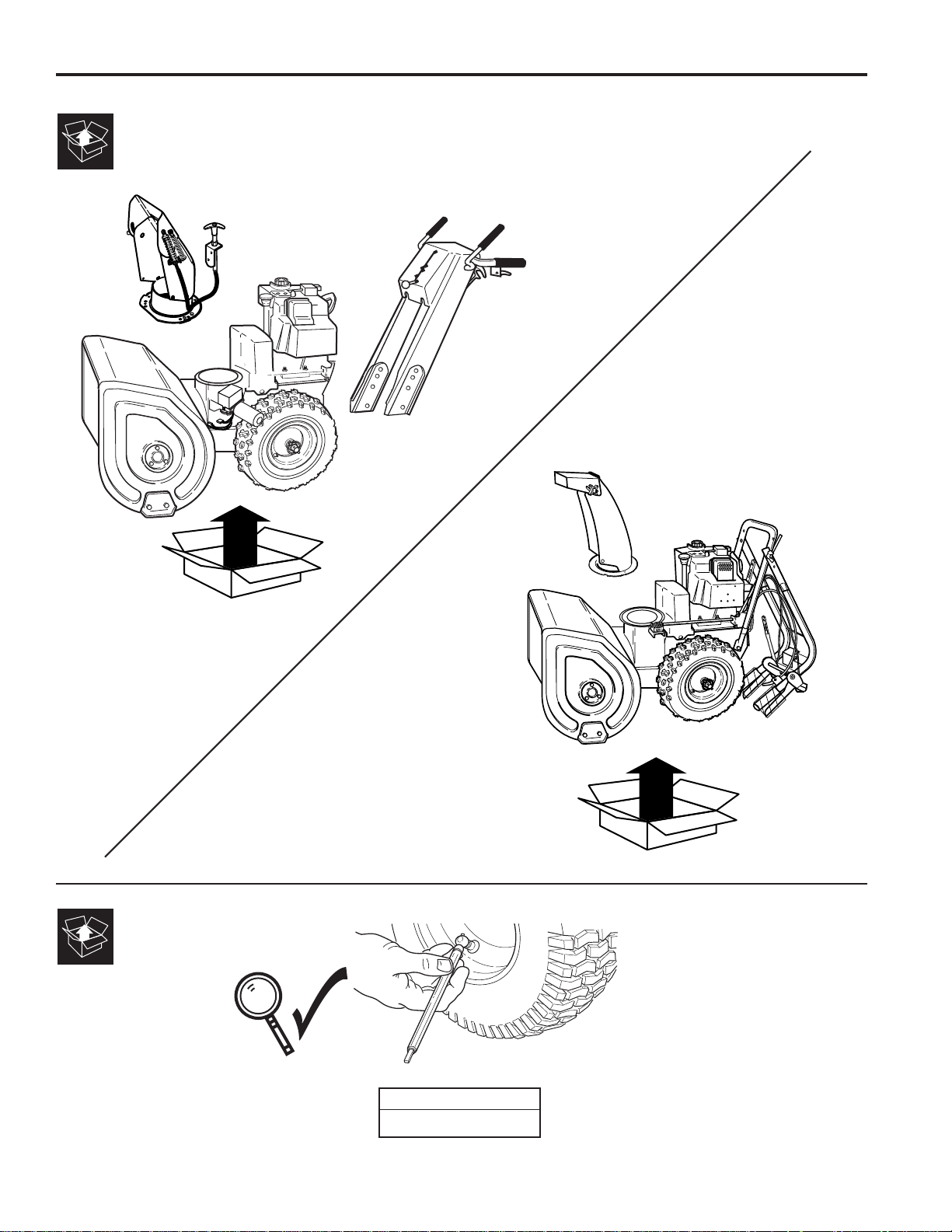

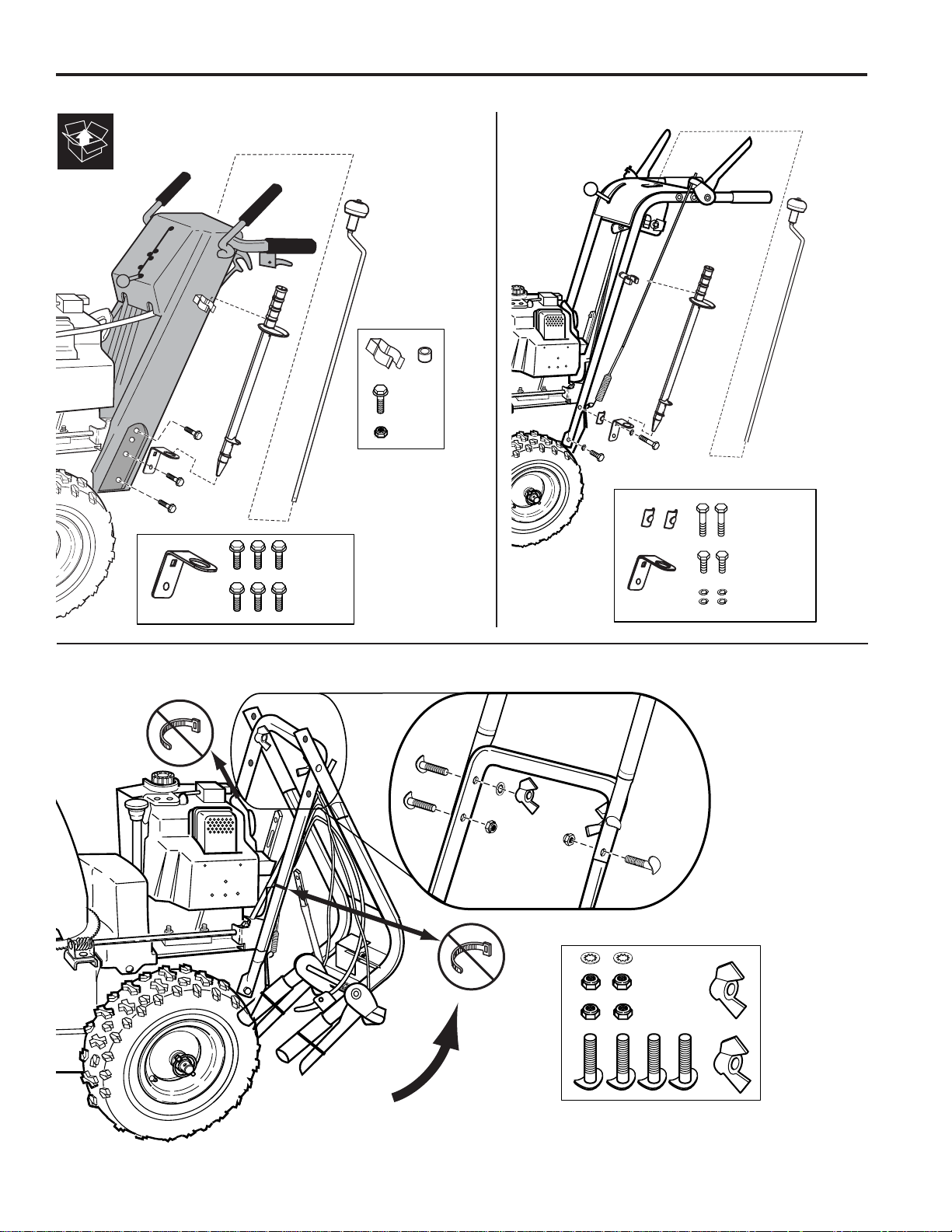

1

2

Pressure

20 psi (137 kPa)

5/16-18

x 3/4

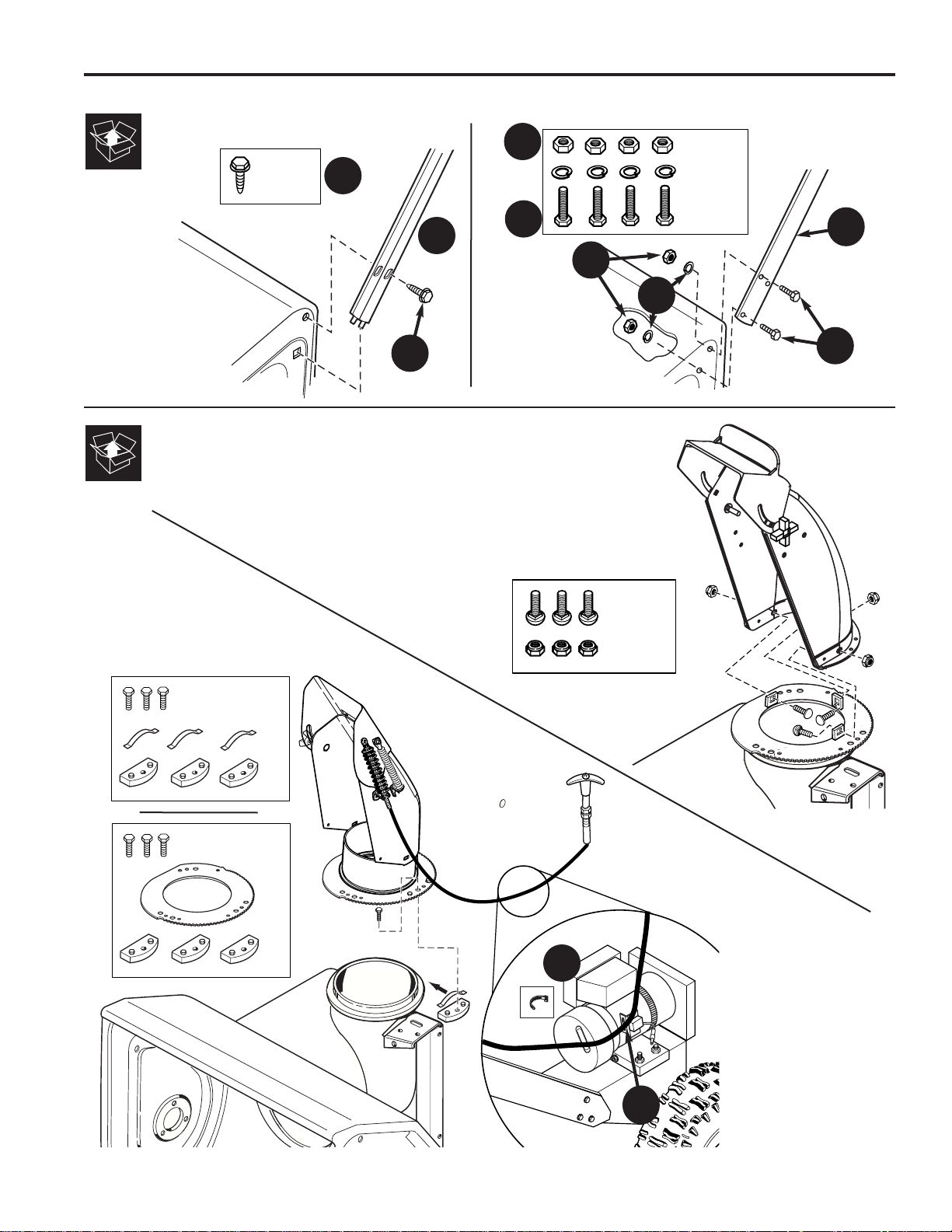

Intermediate & Large Frame Snowthrowers

8/2005 5

TP 399-4222-01-LW-SN

5/16

5/16-18

5/16-18

x 3/4

3

1

2

3

4

1

2

4

#10-14 x 5/8

#10-14 x 5/8

4

1

1

5/16 - 18

x 3/4

5/16 - 18

1

1

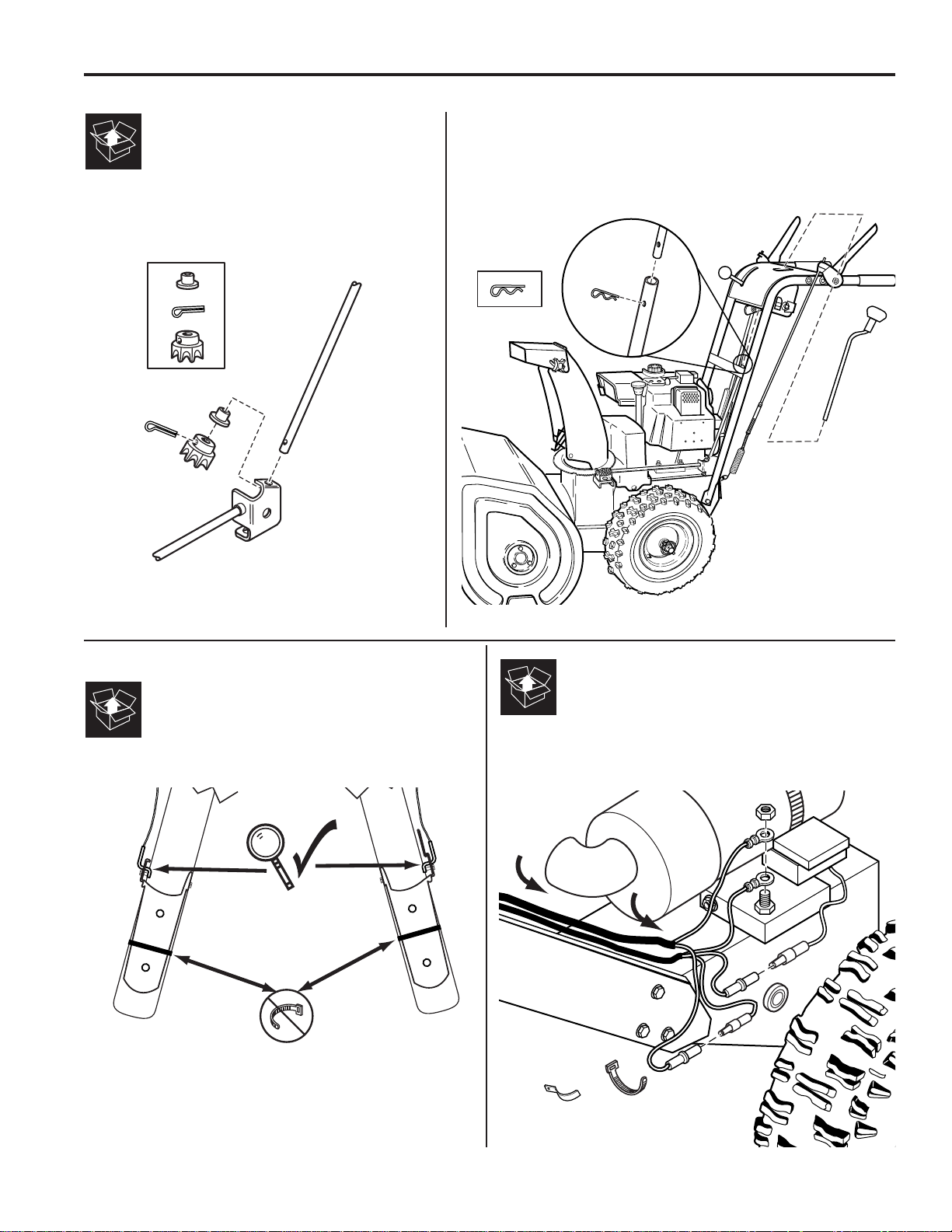

Intermediate & Large Frame Snowthrowers

TP 399-4222-01-LW-SN

8/20056

5/16-18

x 3/4

10-24

x 3/4

10-24

5

5/16-18

5/16-18

x 3/4

5/16

5/16-18

x 2

Intermediate & Large Frame Snowthrowers

8/2005 7

TP 399-4222-01-LW-SN

6

7

8

Intermediate & Large Frame Snowthrowers

TP 399-4222-01-LW-SN

8/20058

1/4-20

1/4-20 x 3/4

1

2

9

1

2

1/4-20

1/4-20 x 5/8

1

2

1

2

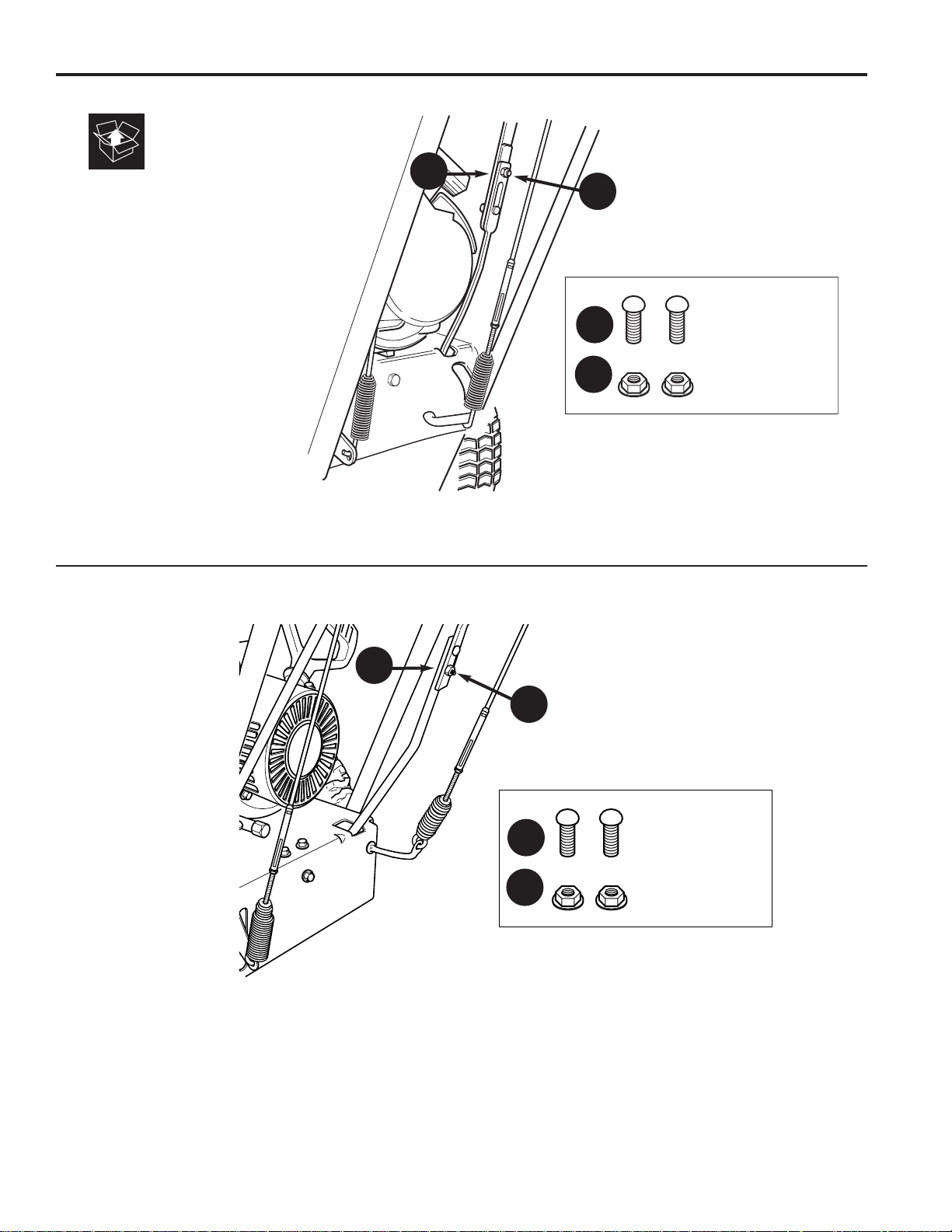

Intermediate & Large Frame Snowthrowers

8/2005 9

TP 399-4222-01-LW-SN

10

84.90 mm

3-11/32 "

120.65 mm

4-3/4 "

95.25 mm

3-3/4 "

590.55 mm

23-1/4 "

714.38mm

28-1/8 "

28.58 mm

1-1/8 "

95.25 mm

3-3/4 "

641.35 mm

25-1/4 "

765.18 mm

30-1/8 "

28.58 mm

1-1/8 "

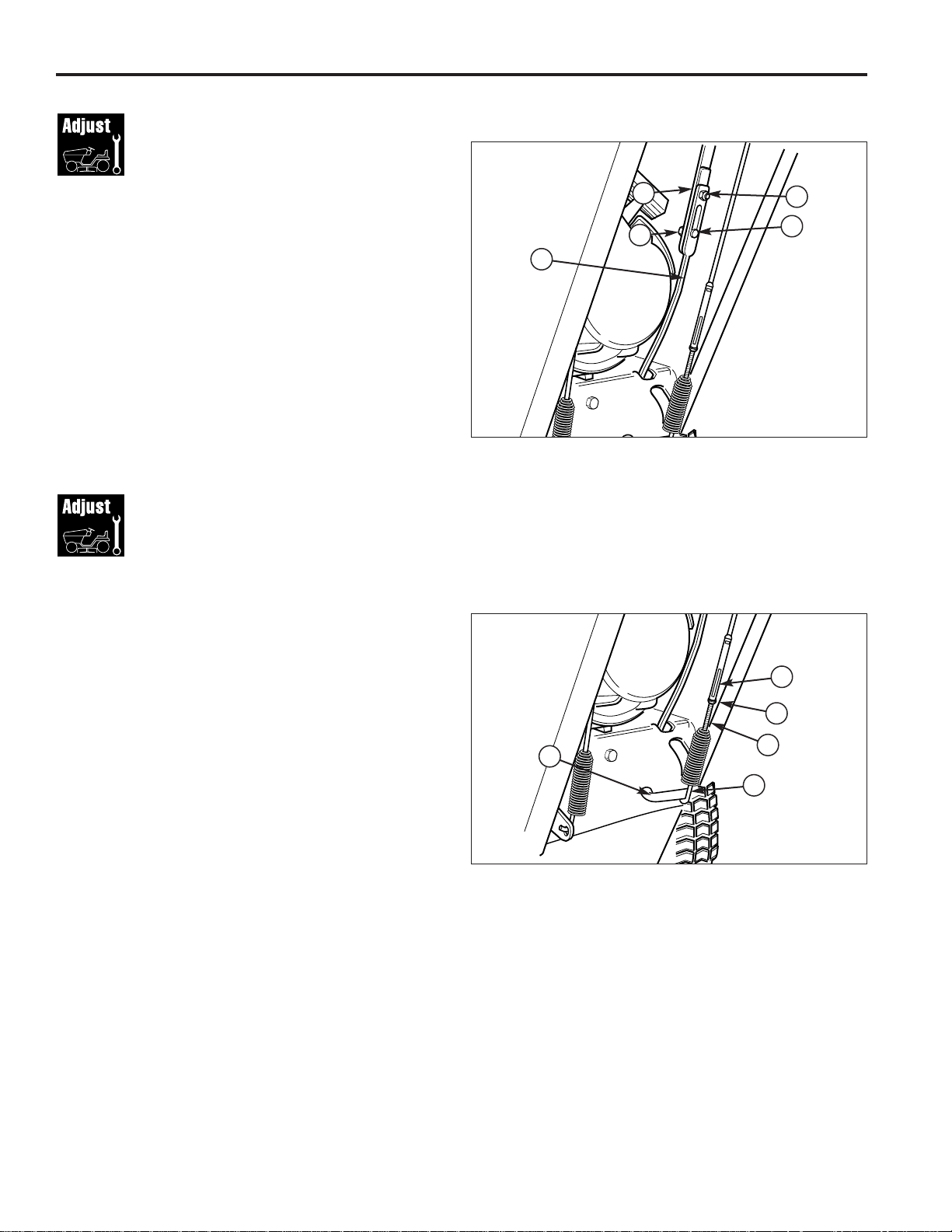

11Speed Selector

SPEED SELECTOR ADJUSTMENT

1. Loosen the two nuts (C, Figure 18).

2. Place the shift lever in 5th gear.

3. Push the lower rod (A) into the housing and tighten

the two nuts (C). Do not lift up or down on rods while

tightening. Make sure the shoulders of the carriage

bolts (D) are in the slots.

4. Always check traction drive tension and auger drive

tension after adjusting speed selector.

Figure 18. Speed Selector Linkages

A. Shift Rod

B. Carriage Bolts

C. Nuts

B

C

A

Intermediate & Large Frame Snowthrowers

TP 399-4222-01-LW-SN

8/200510

Figure 19. Auger Drive Adjustment

A. Adjusting Flats

B. Spring Hook

C. Lever

D. Nut

E. Adjustment Screw

A

C

D

E

B

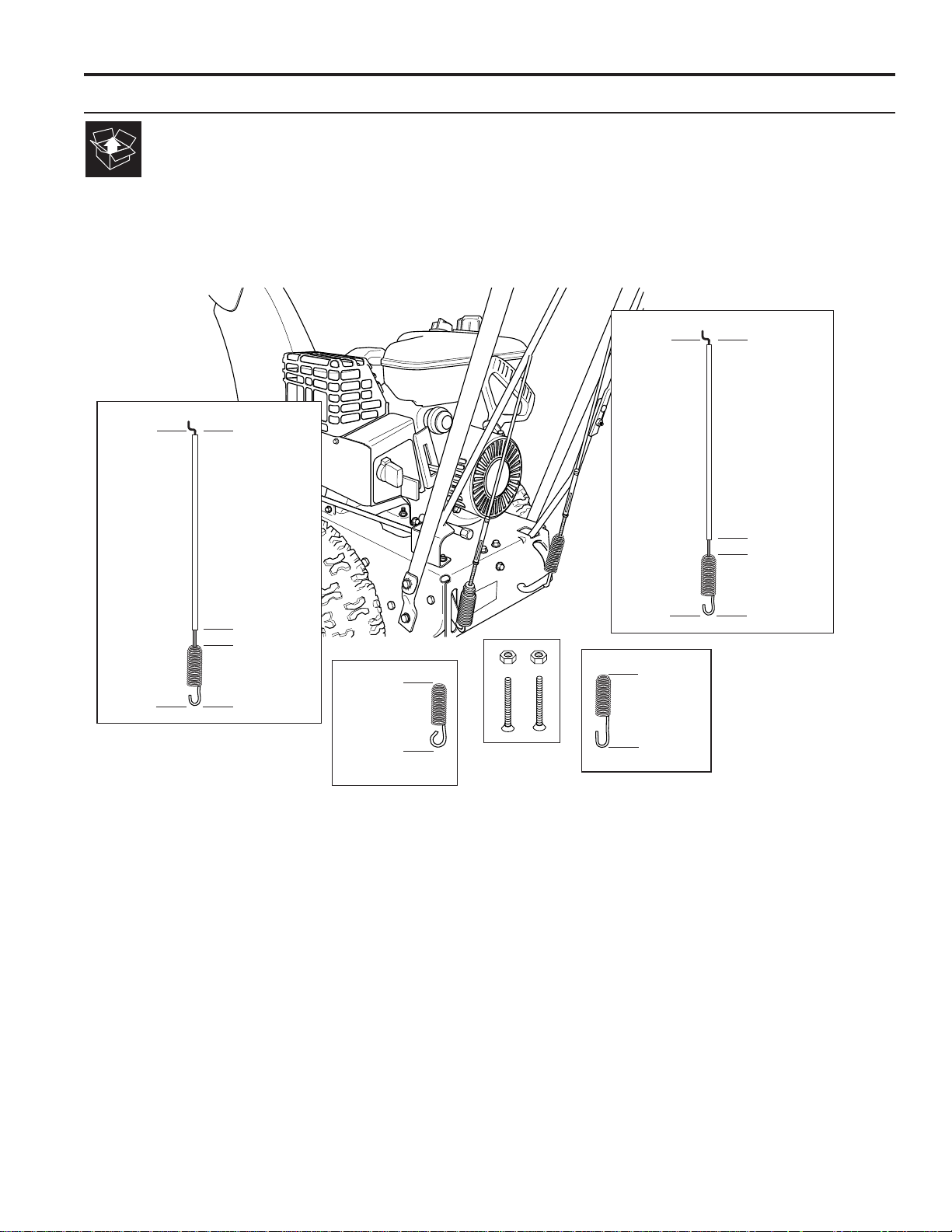

12

Auger Drive

AUGER DRIVE TENSION

1. With the drive lever released, the hook (B, Figure 19)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32” clearance as shown.

2. To adjust, loosen nut (D, Figure 19) by holding the

adjusting flats (A)and turning nut (D). Turn adjustment flats and hold screw. The adjustment screw is a

phillips screw and the head can be held or turned by

inserting a screwdriver through the spring.

3. Hold adjusting flats (A) and tighten nut (D).

4. Start unit and check auger. auger must not be

engaged unless auger control is depressed.

5. With engine running, fully depress auger control, the

auger should engage and run normally.

6. Release auger control. Auger must stop within 5

seconds.

7. If auger does not operate properly, stop engine and

recheck drive linkage adjustments.

8. If drive linkage is properly adjusted, auger drive belt

tension may require adjustment. See "Adjusting

Auger Drive Belt".

B

C

Loading...

Loading...