Snapper I8245E, I5225, 860, 1694605, 1694604 Owner’s Manual

...

0 Bimpliuilg

/

/

ODEL

1

555,824,

170, 1

,1

initial setup

Ersteinrichtung

Forbokstavrnontere

This Dealer Setup Instruction applies to the following units:

Mfg. No.

1694587

1694595

85665

80494

85666

80495

1694588

1694596

1694602

1694589

1694597

1694606

1694590

Description

555M, 5HP Snowthrower

555M, 5HP Snowthrower(CE)

15225, 5HP Snowthrower

EI5225, 5HP Snowthrower(CE)

18245E, 8HP OHV Snowthrower

E!8245, 8HP OHV Snowthrower(CE)

860E, 8HP OHV Snowthrower

860M, 8HP OHV Snowthrower (CE)

9247E, 9HP Snowthrower

9560E, 9.5HP Snowthrower

9560M, 9.5HP Snowthrower (CE)

E9247, 9HP Snowthrower (CE)

1060E, 10HP Snowthrower

SROWTHROWERS

FiJrstan_gga

Assemblage

Instaliazione

Mfg. No.

1694598

1694603

1694607

1694591

1694599

1694604

1694608

1694592

1694600

1694605

1694609

1694593

1694601

Description

1060M, 10HP Snowthrower (CE)

10287E, 10HP Snowthrower

E10287, 10HP Snowthrower (CE)

1170E, 11HP Snowthrower

1170M, 11HP Snowthrower (CE)

11327E, 11HP Snowthrower

E11327, 11HP Snowthrower (CE)

1280E, 12HP Snowthrower

1280M, 12HP Snowthrower (CE)

12387E, 12HP Snowthrower

E12387, 12HP Snowthrower (CE)

1390E, 13HP Snowthrower

1390M, 13HP Snowthrower (CE)

initial

iniziale

© Copyright 2004 Simplicity Manufacturing, Inc.

All rights reserved. Printed in USA.

6/2004 1 TP 399-4079-00-LW-SN

Form No. 1727047

Revision 00

Revision Date 6/2004

SAFETY RULES

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

The triangle _IL in text signifies important cautions or warnings which must be followed.

GENERAL OPERATION

• Read, understand, and follow all instructions in the

manual and on the unit before starting.

• Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown.

• Be sure the area is clear of other people. Stop unit if any-

one enters the area.

• Always look down and behind before and while travelling in

reverse.

• Be aware of the discharge direction and do not point it at

anyone. Do not point the discharge at glass enclosures,

automobiles, or windows.

• Disengage all clutches (release drive and auger control

levers) before starting the engine.

• Never leave a running unit unattended. Always disengage

the auger and traction controls, stop engine, and remove

keys.

• Stop engine before unclogging chute.

• Operate only in daylight or good artificial light.

• Do not operate the unit while under the influence of alcohol

or drugs.

• Watch for traffic when operating near or crossing road-

ways.

• Use extra care when loading or unloading the unit into a

trailer or truck.

• Keep in mind the operator is responsible for accidents

occurring to other people or property.

• Data indicates that operators, age 60 years and above, are

involved in a large percentage of power equipment-related

injuries. These operators should evaluate their ability to

operate the unit safely enough to protect themselves and

others from injury.

• All operators should seek and obtain professional and prac-

tical instruction.

Always wear substantial footwear and appropriate winter

clothing. Wear foot-ware that improves traction on slippery

slopes. DO NOT wear long scarves or loose clothing that

could become entangled in moving parts.

Before using, always visually check that all hardware is

present, in-tact, and secure. Replace worn or damaged

parts.

Never operate the machine with defective guards, or with-

out safety protective devises in place.

Stop engine before: refuelling, removing an attachment,

making adjustments (unless the adjustment can be made

from the operator's position).

Follow the manufacturer's recommendation for wheel

weights or counterweights.

Adjust skid shoe height to clear gravel or crushed rock sur-

faces.

Do not touch snowthrower parts which may be hot from

operation. Allow such parts to cool before attempting to

service the unit.

CLEARING A CLOGGED DISCHARGE CHUTE

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snowthrowers. Always use a clean out tool, not your hands, to

clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

SLOPE OPERATION

WARNING

Never operate on slopes greater than 17.6 percent (10 °) which

is a rise of 3-1/2 feet (106 cm) vertically in 20 feet (607 cm)

horizontally.

When operating on slopes use additional wheel weights or

counterweights. See your dealer to determine which weights

are available and appropriate for your unit.

Select slow ground speed before driving onto slope. Travel UP

and DOWN the slope, never across the face, use caution when

changing directions and DO NOT START OR STOP ON

SLOPE.

Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. All slopes

require extra caution. Ifyou cannot back up the slope or if you feel

uneasy on it, do not operate on it.

EMISSIONS

• Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

• Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Do

e

See your authorized dealer for recommendations counter-

weights to improve stability.

• Travel up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could over-

turn the unit. Snow can hide obstacles.

• Use slow speed. Tires may lose traction on slopes. Choose

a low gear so that you will not have to stop or shift while on

the slope.

• Keep all movement on the slopes slow and gradual. Do not

make sudden changes in speed or direction.

• Always keep unit in gear especially when traveling down-

hill.

Do Not

Do not start or stop on a slope. If tires lose traction, disen-

gage the auger and proceed slowly straight down the

slope.

Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

Do not operate near drop-offs, ditches, or embankments.

The unit could suddenly turn over if a wheel is over the

edge of a cliff or ditch, or if an edge caves in.

Do not operate on wet surfaces. Reduced traction could

cause sliding.

Do not shift to neutral and coast down hills.

TP 399-4079-00-LW-SN 2 6/2004

intermediate & Large Frame Snowthrowers

Contents:

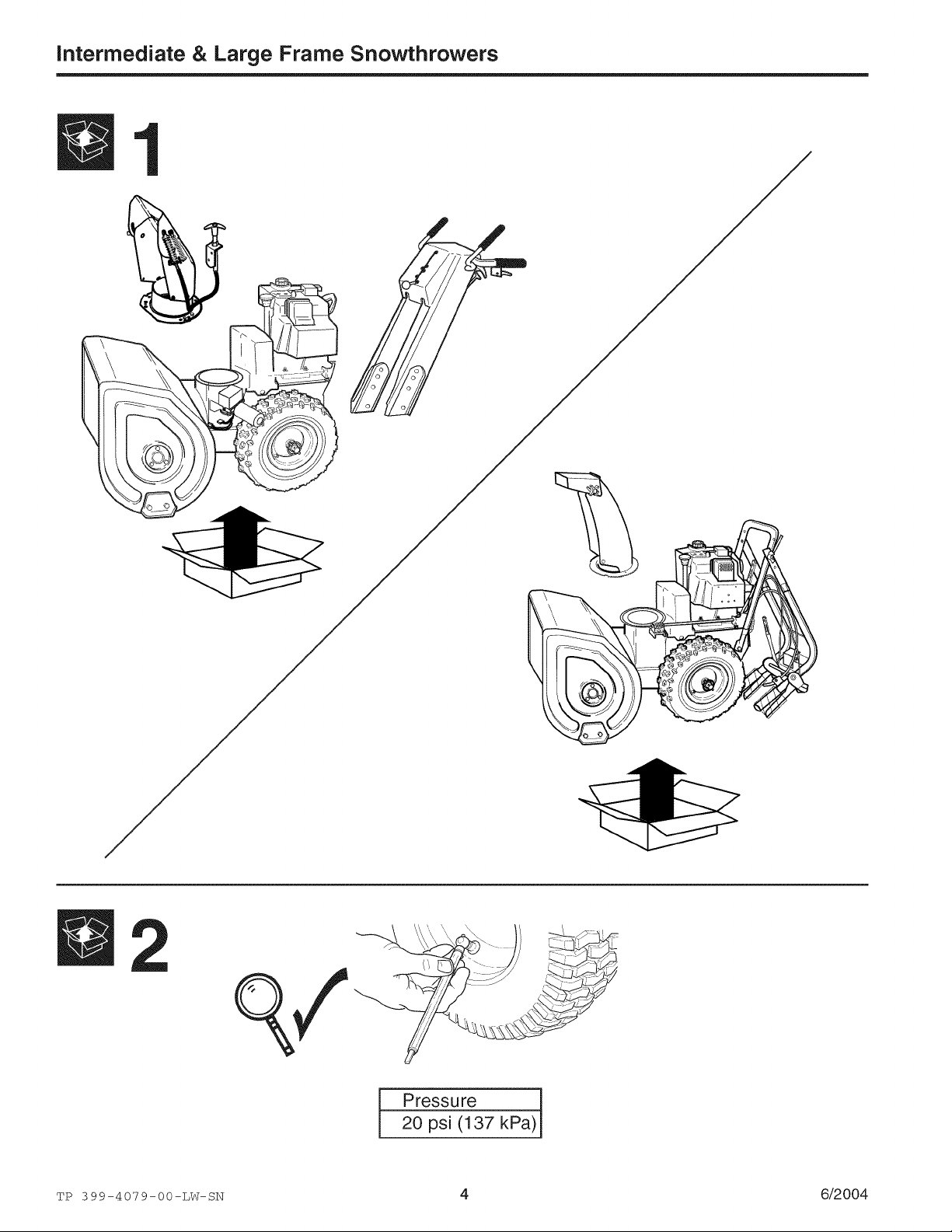

1. Uncrate ......................................... 4

2. Check Tire Pressure ..................... 4

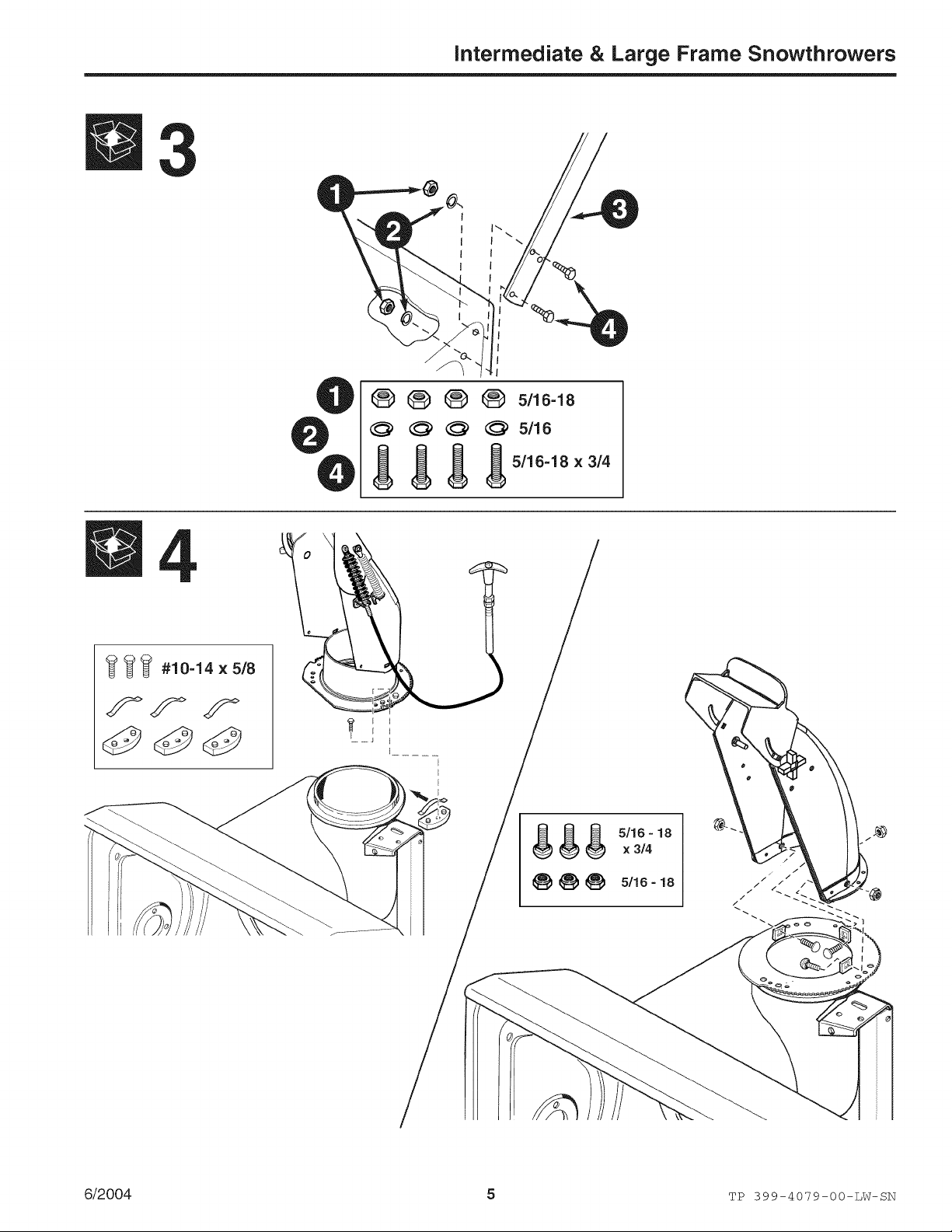

3. Install Drift Cutters ........................ 5

4. Install Chute .................................. 5

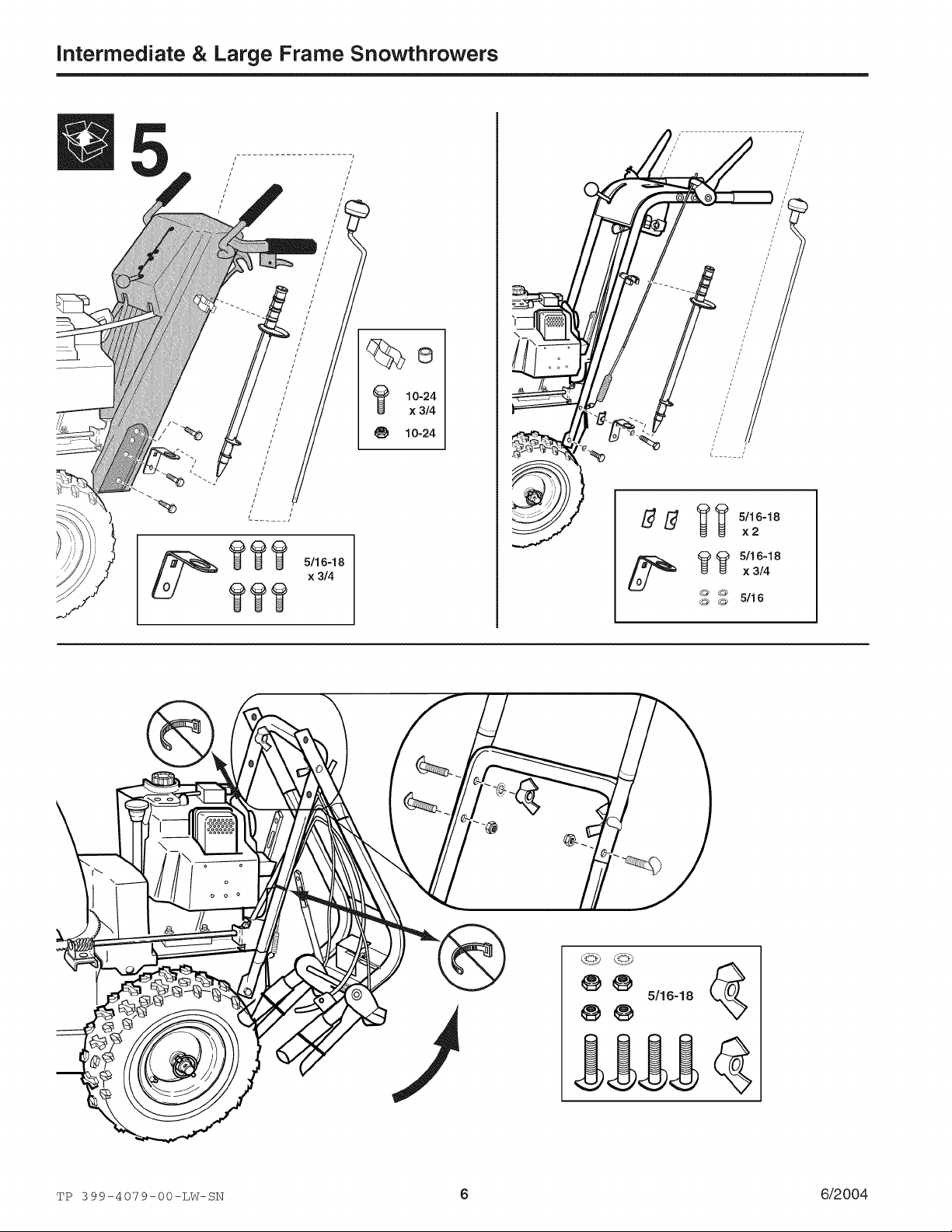

5. Install Handles .............................. 6

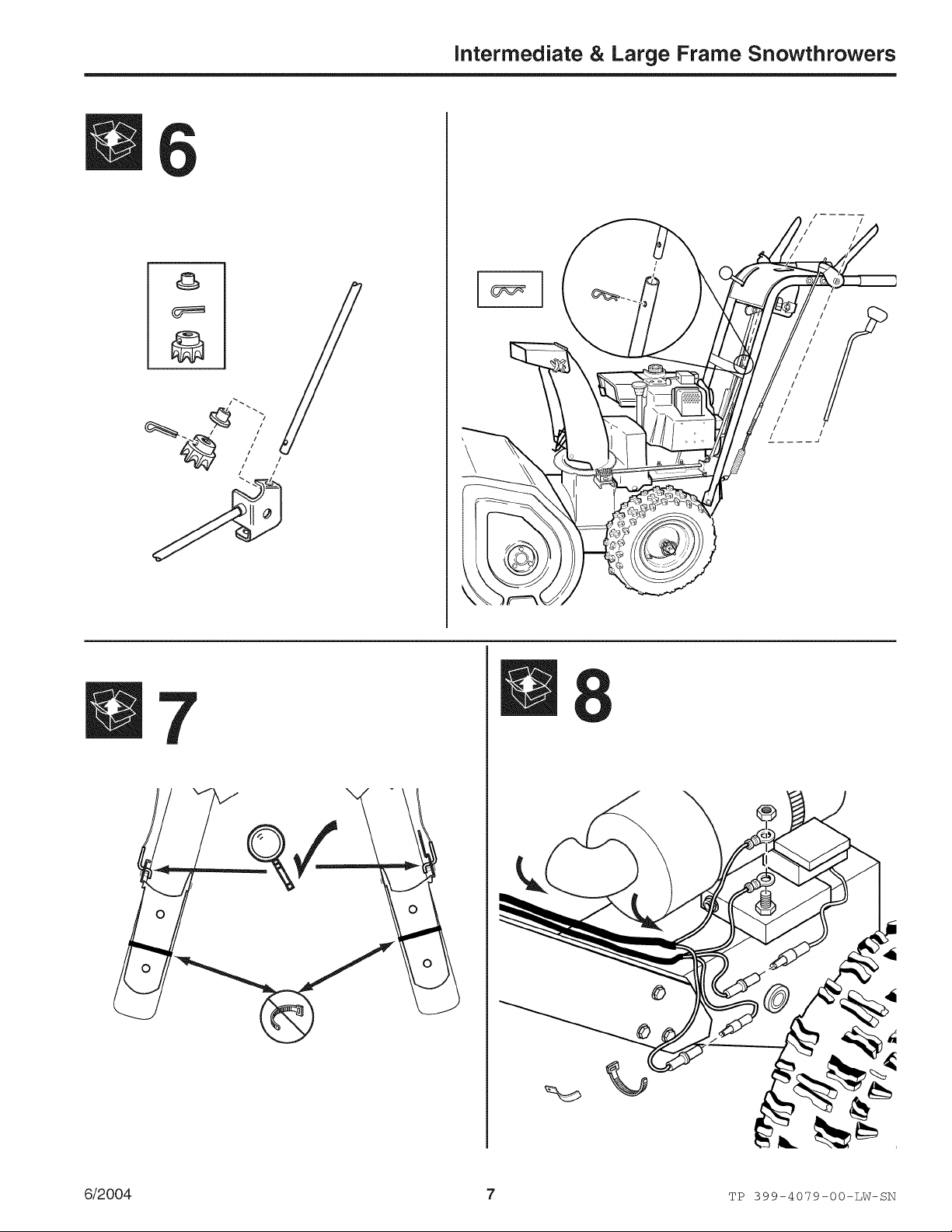

6. Connect Spout Rotator ................. 7

7. Tube Handle Levers ..................... 7

8. Electrical Connections .................. 7

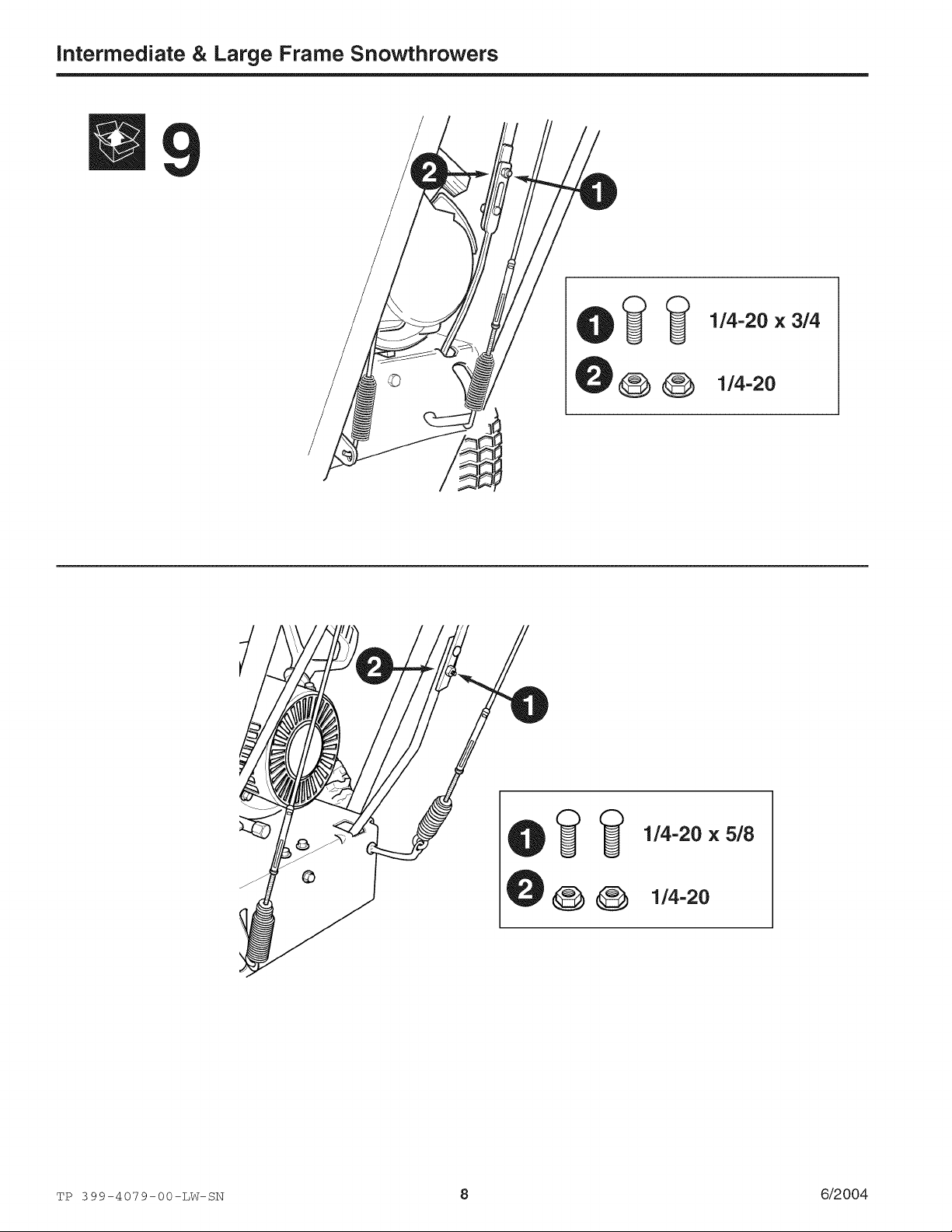

9. Speed Selector Connection .......... 8

10. Auger Drive Connection ............. 9

10. Traction Drive Connection .......... 9

11. Speed Selector Adjustment ...... 10

12. Auger Drive Tension ................. 10

13. Traction Drive Tension ............. 11

14. Connect Chute Control ............. 22

15. Connect Easy Turn ................... 22

16. Easy Turn Cable Adjustment....23

17. Auger Gear Case Lubrication ...24

18. Checks Before Each Start-up ...25

Inhaltsverzeichnis:

1. packen Sie aus ................................ 4

2. PrQfungdes Reifendrucks ................4

3. bringen Sie an Schneeantrieb

Scherblock ............................................ 5

4. bringen Sie an Rutsche ................... 5

5. bringen Sie an Lenkstangen ........... 6

6. schlieBen Sie TQIlerotator ............... 7

7. Schlauch-Handgriff-Hebel ............ 7

8. electrial Anschl0sse ...................... 7

9. Geschwindigkeit W&hlcaooenction .8

10. Schneckenwelle Antrieb connenction

9

10. Zugkraft-Antrieb connenction ........9

11. Einstellung des

Gangwahlschalters .............................. 10

12. Spannung des

Schneckenantriebs .............................. 10

13. pannung des Fahrantriebs ........... 11

14. SchlieBen Sie RutschcSteuerung

An ...................................................... 22

15. schlieBen Sie an Easy Turn ........22

16. Einstellung des Easy

Turn-Seilzugs ...................................... 23

17. PrQfung des Olstands im

Schneckenf6rderer-Getriebegeh&use .24

18. SicherheitsprOfungen vor jeder

Inbetriebnahme ................................... 25

Artillel:

1. Dekasse ........................................ 4

2. Kontrol av lufttrykket i dekkene .....4

3. Insetallere Bakke Skjsere .............. 5

4. Insetallere Ventil ........................... 5

5. Insetallere Sykkelstyre .................. 6

6. Forbindelse Ventil Rotator ............ 7

7. ro rh&ndtakvektstenger .................. 7

8. elektrisk forbindelse ...................... 7

9. Fart Skiftenokkel Forbindelse ....... 8

10. Skrue Forero Forbindelse ........... 9

10. Fengsle Fart Forbindelse ............ 9

11. Justering av hastighetsvelgerenl0

12. Stramming av skovledrivet ....... 10

13. Stramming av friksjonsdrivet ....11

14. Forbindelse Chute Control ........22

15. Forbindelse Easy Turn ............. 22

16. Justering av Easy Turn-kabelen23

17. Smor akselene og

kontrollspakene ............................... 24

18. Folgende kontroller skal utfores

for hver ..................................... 25

Inneh_ll:

1. Depacke ....................................... 4

2. Kontroll av ringtrycket ................... 4

3. Installera Trave Klippa .................. 5

4. Installera Tub ................................ 5

5. Installera Styrst&ng ....................... 6

6. Ansluta Tub Rotera ...................... 7

7. Modeller med r6rhandtag

h&vst&ng ........................................... 7

8. Electrical f6rh&llande .................... 7

9. Fart Urval F6rbindelse ................. 8

10. Skruv Aktur F6rbindelse ............. 9

10. Tag Aktur F6rbindelse ................ 9

11. Justering av hastighetsv&ljaren 10

12. Skruvens drivremssp&nning .....10

13. Hjuldrivningens

drivremssp&nning ........................... 11

14. Ansluta Tub Kontroll ................ 22

15. Ansluta Easy Turn ................... 22

16. Justering av

Easy Turn-kabeln ........................... 23

17. Kontroll av smSrjmedelsniv&n i

skruvens v&xell&da .......................... 24

18. Kontroller f6re varje

anv&ndning ...................................... 25

Matieres:

1. D6paqueter ................................... 4

2. Contr61e de la pression

des pneus .......................................... 4

3. Emm6nagent Amas de Neige

Coupeur ............................................ 5

4. Emm6nagent Chute ...................... 5

5. Emm6nagent Guidon .................... 6

6. Connecter Rotateur de Bec ......... 7

7. Leviers De Poign6e De Tube ....... 7

8. raccordements electrial ................ 7

9. Galoper Select Connexion ............ 8

10. Pas de Vis Traquer Connexion...9

10. Grippe Traquer Connexion ......... 9

11. R6glage du s61ecteur de vitessel0

12. Tension de la commande

de fraise .......................................... 10

13. Tension de la commande

de traction ........................................ 11

14. Connecter Glissi_re Contr61e ...22

15. Connecter Easy Turn ................ 22

16. R6glage du c&ble Easy Turn ....23

17. Niveau d'huile de la bofte

d'engrenages de la fraise ................ 24

18. Contr61es avant chaque

d6marrage ....................................... 25

@

Indice:

1. Deimpaccare ................................ 4

2. Controllo della pressione degli

pneumatici ......................................... 4

3. Mettere Catasta Tagliato .............. 5

4. Mettere Solco ............................... 5

5. Mettere Manici .............................. 6

6. Copulare Tubo Rotare ................. 7

7. Leve Della Maniglia Del Tubo .......7

8. Collegamenti Elettrici .................... 7

7. Velocit& Eletta Congiuntura .......... 8

10. Trapano Andara Congiuntura .....9

10. Acchiappare Andara

Congiuntura ....................................... 9

11. Regolazione del cambio ........... 10

12. Tensione della cinghia di trasmis-

sione della coclea ............................ 10

13. Tensione della cinghia di trasmis-

sione della trazione .......................... 11

14. Copulare Solco Controllo ......... 22

15. Copulare Easy Turn ................. 22

16. Regolazione del cavo

Easy Turn ....................................... 23

17. Controllo della lubrificazione della

scatola ingranaggi della coclea ....... 24

18. Controlli prima

dell'avviamento ............................... 25

6/2004 3 TP 399-4079-00-LW-SN

intermediate & Large Frame Snowthrowers

Pressure ]

l 20 psi(137 kPa)]

TP 399-4079-00-LW-SN 4 6/2004

Ig13

intermediate & Large Frame Snowthrowers

® ® ® ® sno-18

@ @ @ ¢:_ 5/16

1_I_1_#1o-14,s/8

SSS

I

I

6/2004 5 TP 399-4079-OO-LW-SN

intermediate & Large Frame Snowthrowers

10-24

x 3/4

® lo-24

o

o o o

5/16=18

x 3/4

_,= _ _,10.10x3,4

c_ <_ 5/16

TP 399-4079-00-LW-SN 6 6/2004

// /

l /

intermediate & Large Frame Snowthrowers

/

/ // ///_

/

/

7

6/2004 7 TP 399-4079-00-LW-SN

intermediate & Large Frame Snowthrowers

1/4=20 × 3/4

1/4=20

1/4=20 x 5/8

1/4=20

TP 399-4079-00-LW-SN 8 6/2004

intermediate & Large Frame Snowthrowers

1/4=20 LH

1/4-20 RH

6=5/16"

180.33 mm

3-7/16"

87.31 mm

!

I

5-13/32"

137.31 mm

t

i

!

!

4-3/4"

120.65 mm

i

i

23=1/4 "

28=1/8 "

714.38m m

25-1/4 "

30=1/8 "

765.18 mm

6/2004 9 TP 399-4079-00-LW-SN

641.35 mm

1=1/8 "

-- 28.58 mm

3-3/4 "

95.25 mm

® ®

3=11/32 "

4-3/4 "120.65 mm

84.90 mm

590.55 mm

1-1/8 "

-- 28.58 mm

3=3/4 "

95.25 mm

intermediate & Large Frame Snowthrowers

Speed Selector

SPEED SELECTOR ADJUSTMENT

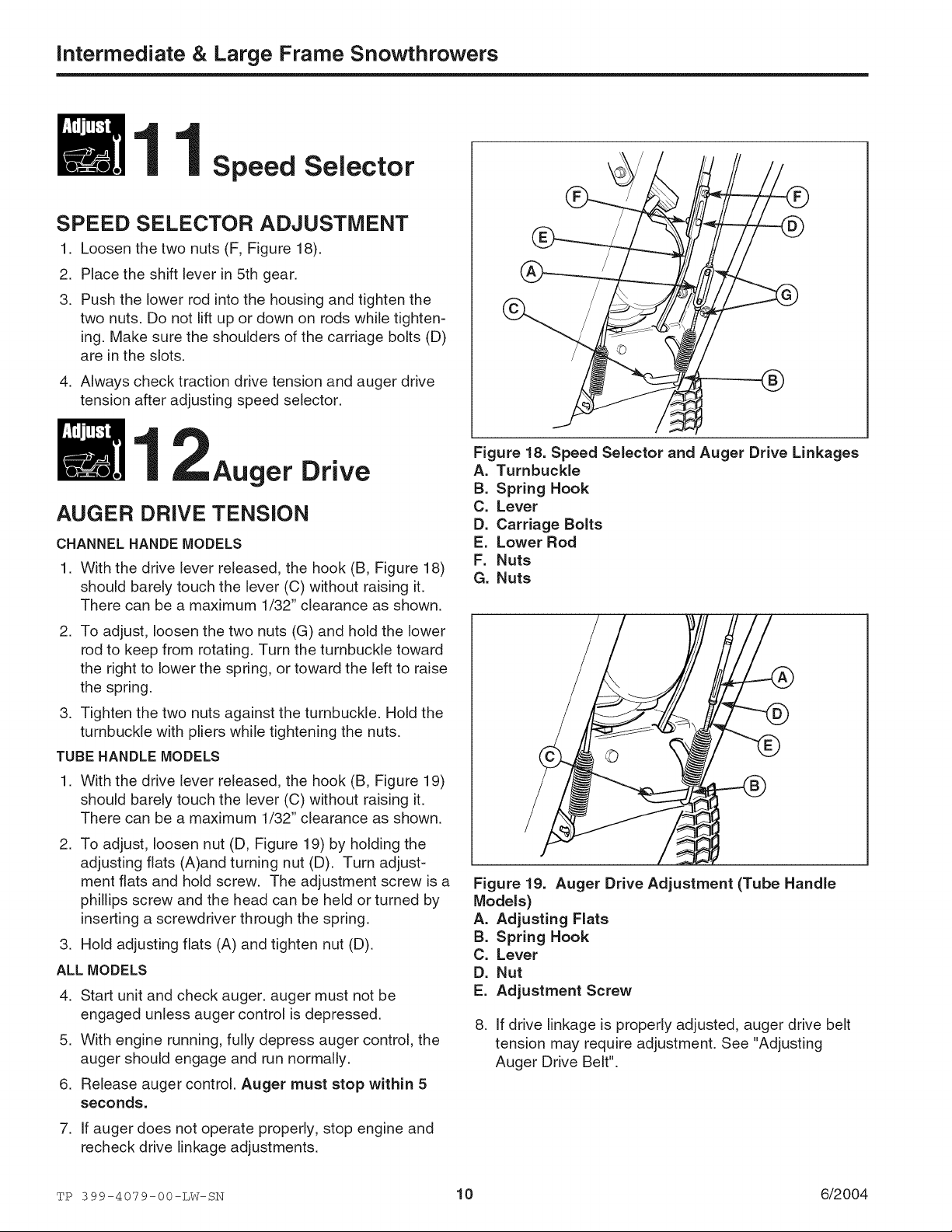

1. Loosen the two nuts (F, Figure 18).

2. Place the shift lever in 5th gear.

3. Push the lower rod into the housing and tighten the

two nuts. Do not lift up or down on rods while tighten-

ing. Make sure the shoulders of the carriage bolts (D)

are in the slots.

4. Always check traction drive tension and auger drive

tension after adjusting speed selector.

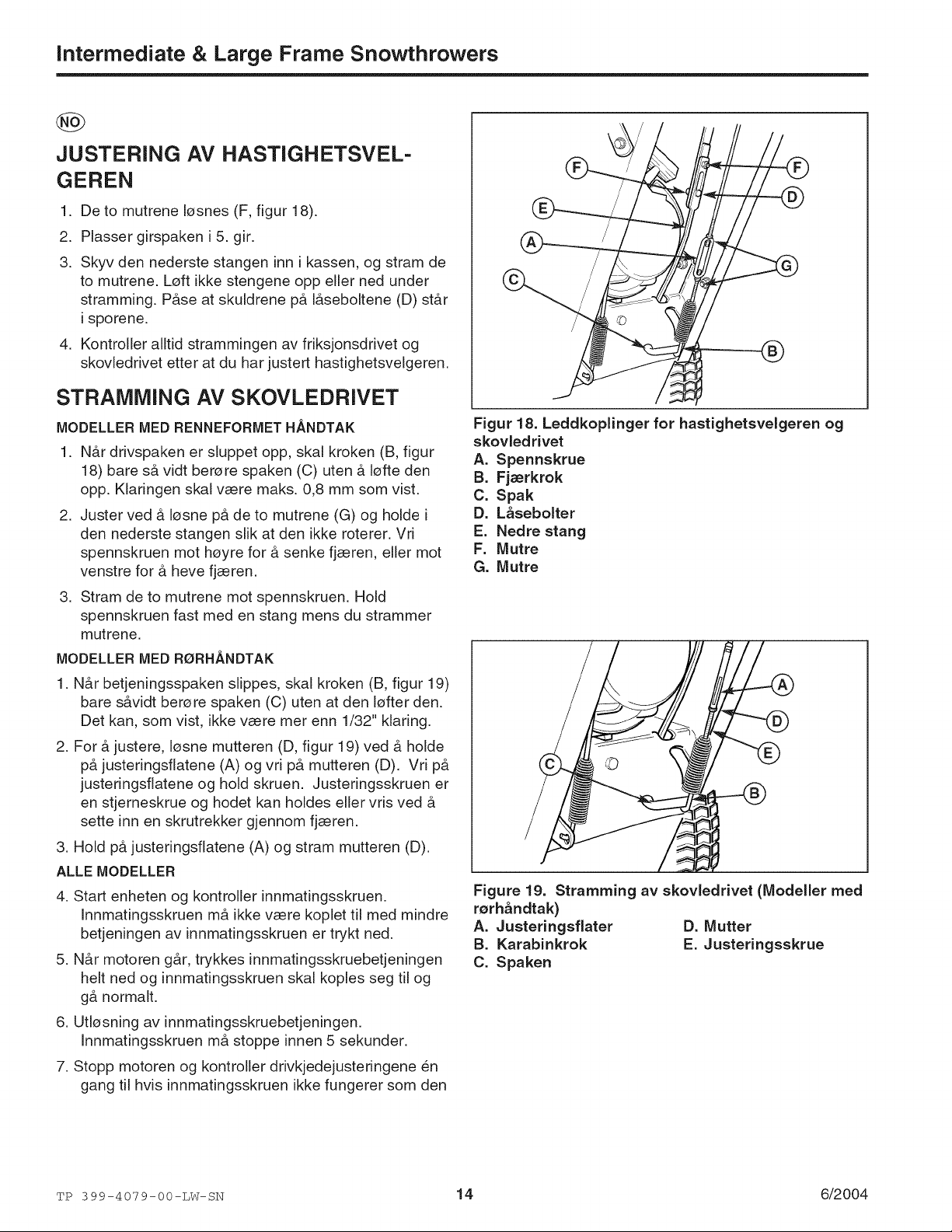

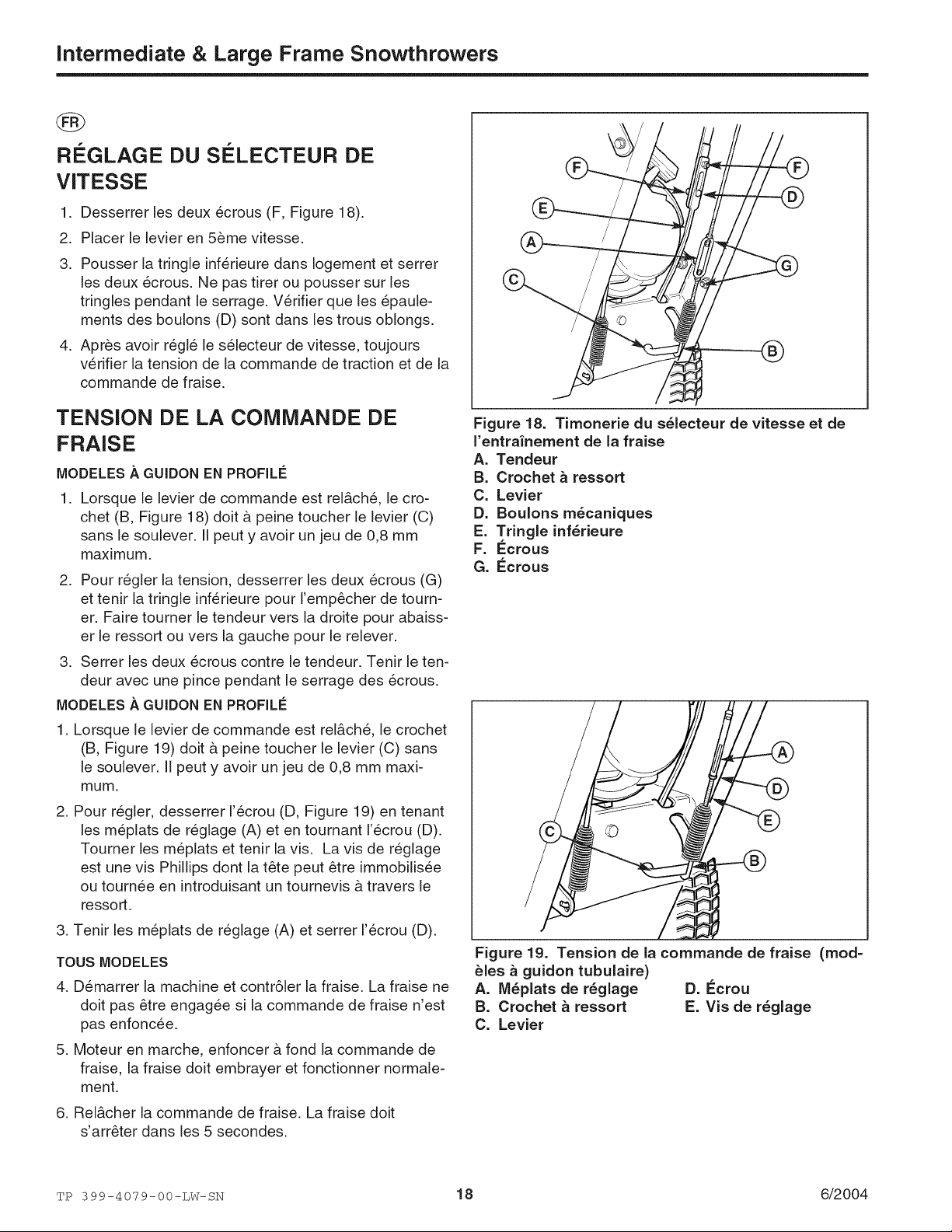

Figure 18. Speed Selector and Auger Drive Linkages

Auger Drive

AUGER DRIVE TENSION

CHANNEL HANDE MODELS

1. With the drive lever released, the hook (B, Figure 18)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32" clearance as shown.

A. Turnbuckle

B. Spring Hook

C. Lever

D. Carriage Bolts

E. Lower Rod

F. Nuts

G. Nuts

2. To adjust, loosen the two nuts (G) and hold the lower

rod to keep from rotating. Turn the turnbuckle toward

the right to lower the spring, or toward the left to raise

the spring.

3. Tighten the two nuts against the turnbuckle. Hold the

turnbuckle with pliers while tightening the nuts.

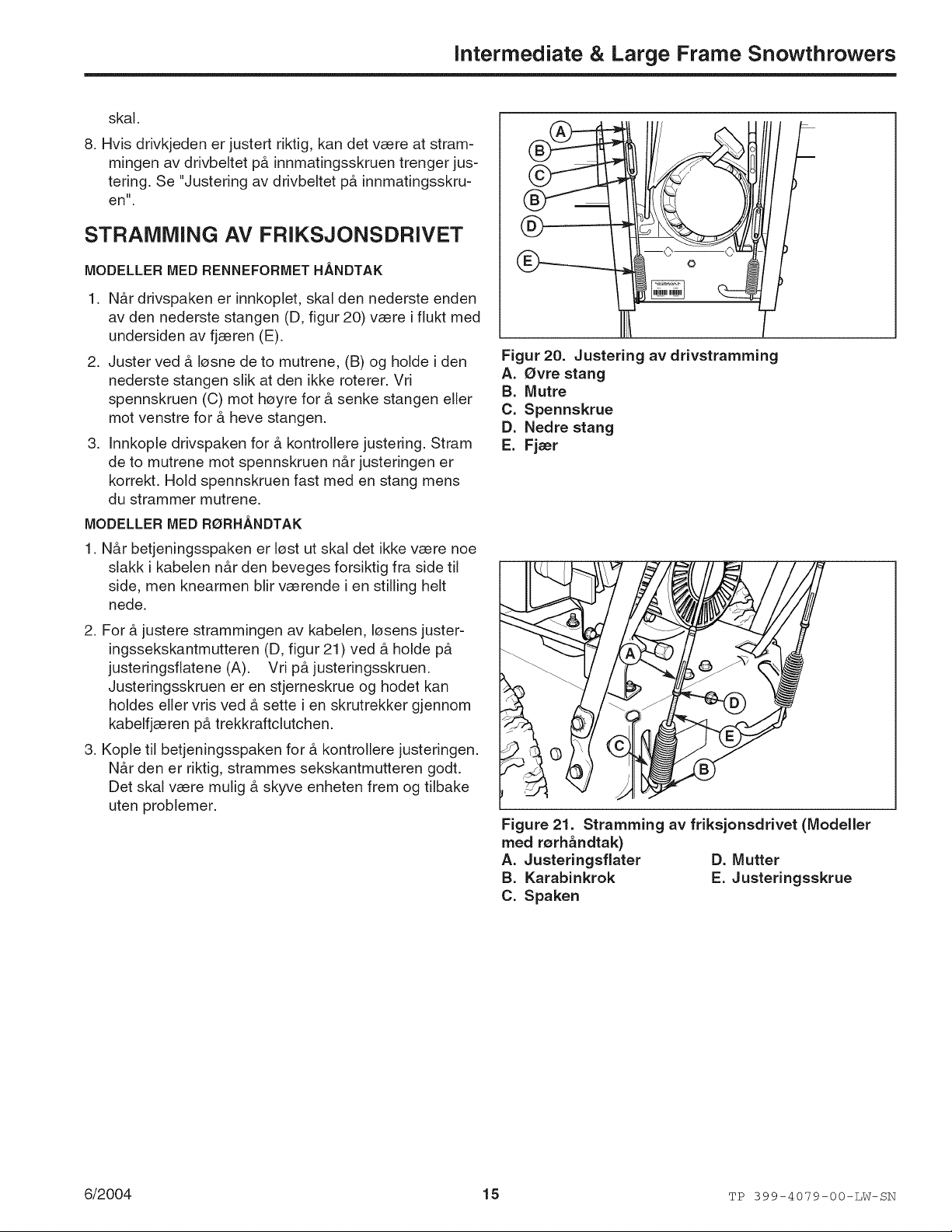

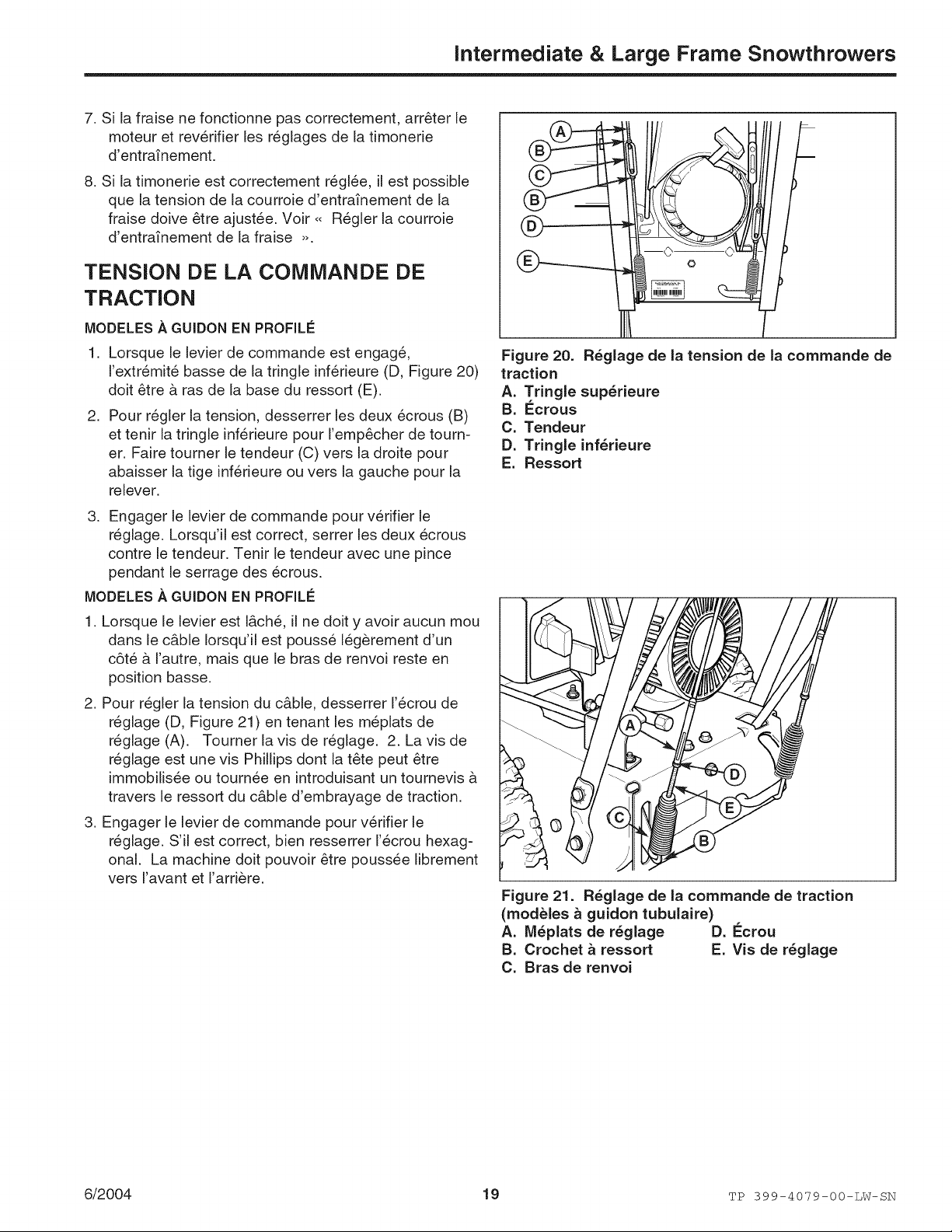

TUBE HANDLE MODELS

.

With the drive lever released, the hook (B, Figure 19)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32" clearance as shown.

2. To adjust, loosen nut (D, Figure 19) by holding the

adjusting flats (A)and turning nut (D). Turn adjust-

ment flats and hold screw. The adjustment screw is a

phillips screw and the head can be held or turned by

inserting a screwdriver through the spring.

3. Hold adjusting flats (A) and tighten nut (D).

ALL MODELS

4. Start unit and check auger, auger must not be

engaged unless auger control is depressed.

5. With engine running, fully depress auger control, the

auger should engage and run normally.

6. Release auger control. Auger must stop within 5

seconds.

Figure 19. Auger Drive Adjustment (Tube Handle

Models)

A. Adjusting Flats

B. Spring Hook

C. Lever

D. Nut

E. Adjustment Screw

8. If drive linkage is properly adjusted, auger drive belt

tension may require adjustment. See "Adjusting

Auger Drive Belt".

7. If auger does not operate properly, stop engine and

recheck drive linkage adjustments.

TP 399-4079-00-LW-SN 10 6/2004

intermediate & Large Frame Snowthrowers

N 13 ,oo,,oo

Drive

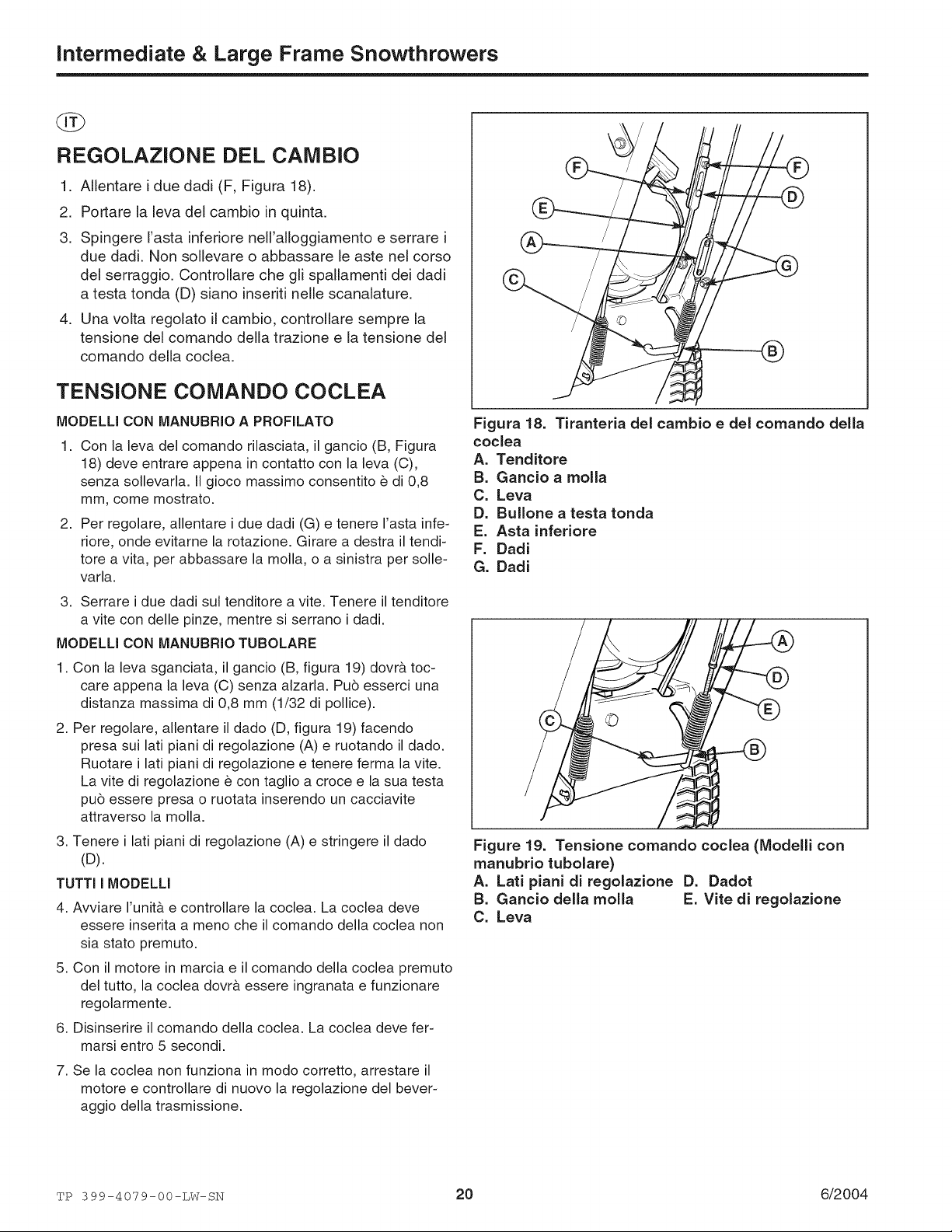

TRACTION DRIVE TENSION

Initial Adjustment

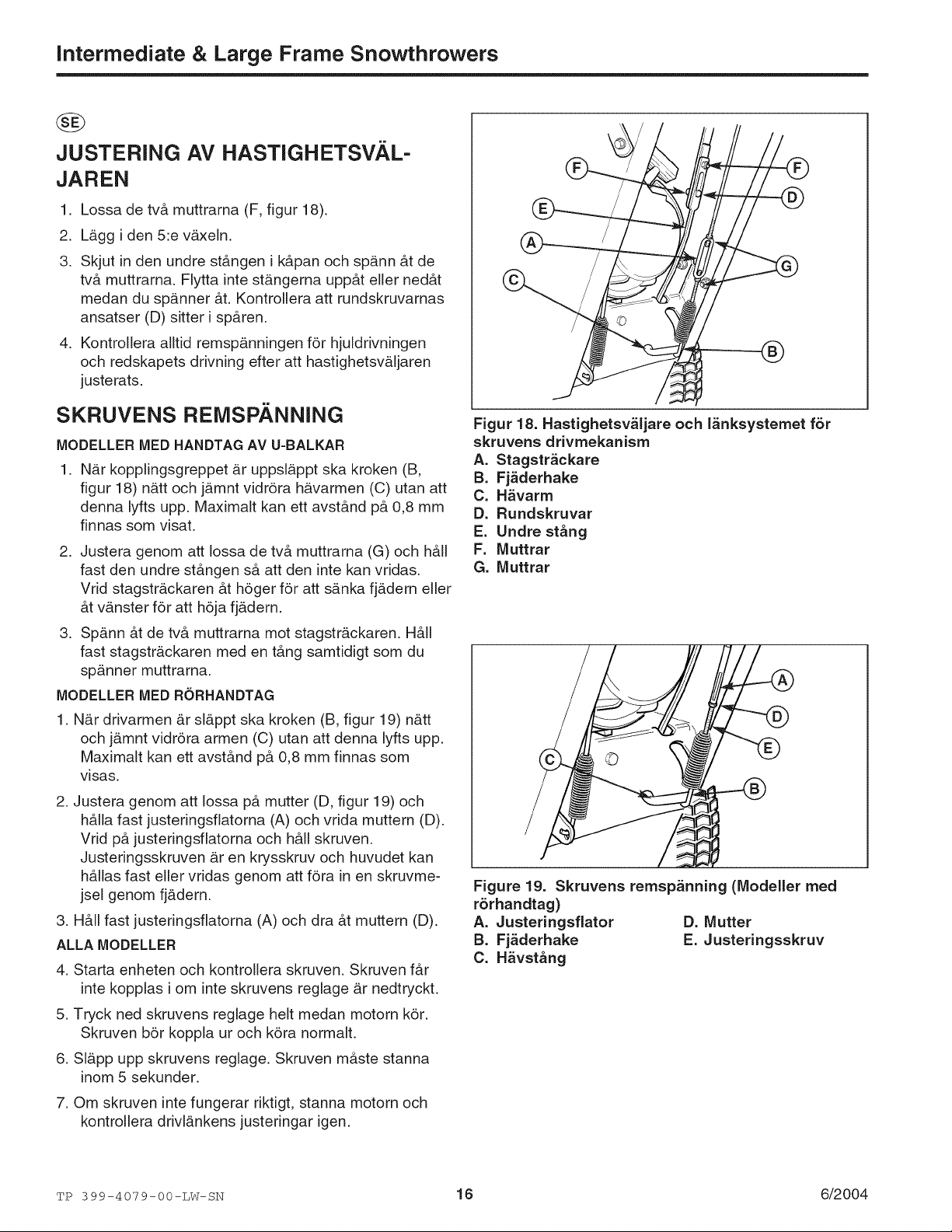

CHANNEL HANDLE MODELS

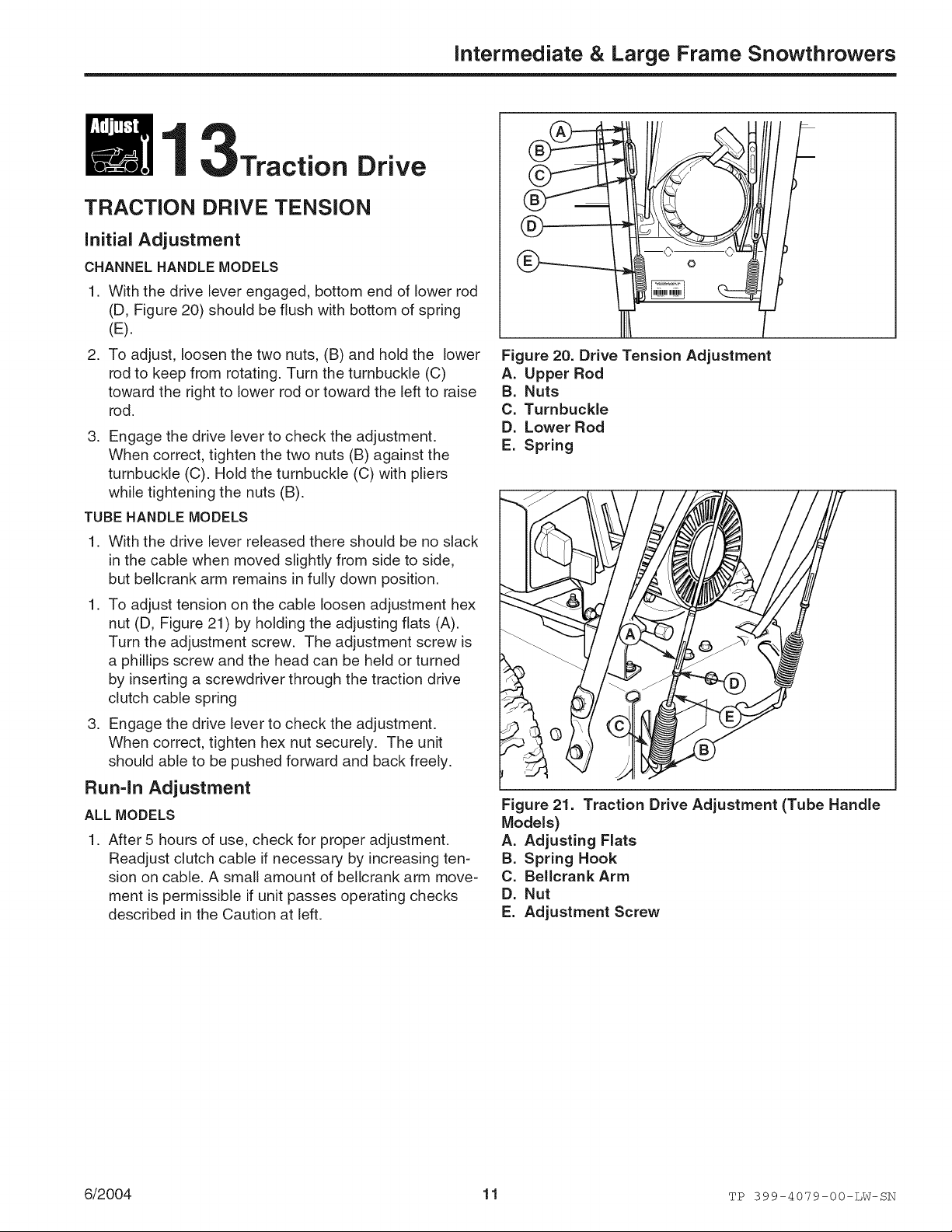

1. With the drive lever engaged, bottom end of lower rod

(D, Figure 20) should be flush with bottom of spring

(E).

2. To adjust, loosen the two nuts, (B) and hold the lower

rod to keep from rotating. Turn the turnbuckle (C)

toward the right to lower rod or toward the left to raise

rod.

3. Engage the drive lever to check the adjustment.

When correct, tighten the two nuts (B) against the

turnbuckle (C). Hold the turnbuckle (C) with pliers

while tightening the nuts (B).

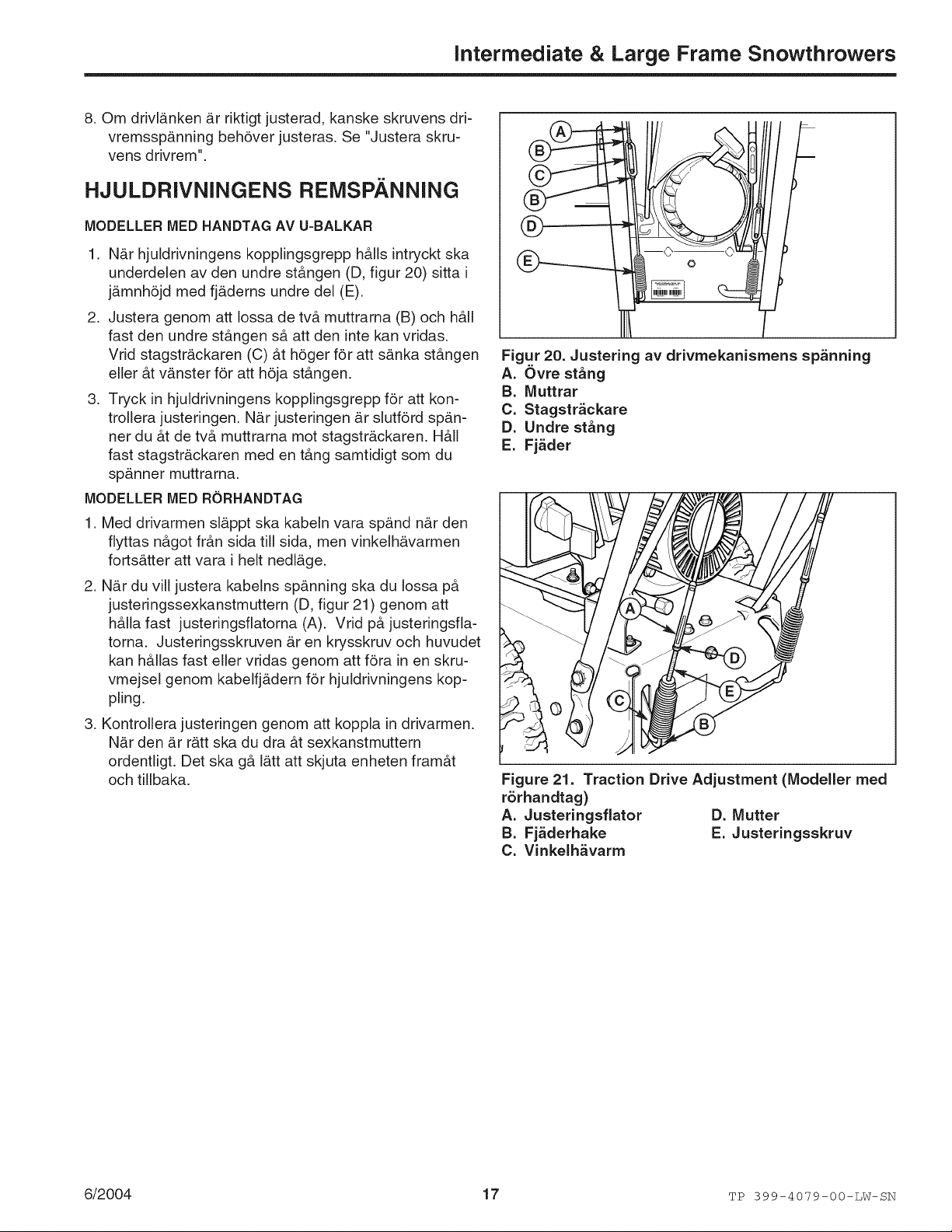

TUBE HANDLE MODELS

1. With the drive lever released there should be no slack

in the cable when moved slightly from side to side,

but bellcrank arm remains in fully down position.

1. To adjust tension on the cable loosen adjustment hex

nut (D, Figure 21) by holding the adjusting flats (A).

Turn the adjustment screw. The adjustment screw is

a phillips screw and the head can be held or turned

by inserting a screwdriver through the traction drive

clutch cable spring

3. Engage the drive lever to check the adjustment.

When correct, tighten hex nut securely. The unit

should able to be pushed forward and back freely.

Run-in Adjustment

ALL MODELS

1. After 5 hours of use, check for proper adjustment.

Readjust clutch cable if necessary by increasing ten-

sion on cable. A small amount of bellcrank arm move-

ment is permissible if unit passes operating checks

described in the Caution at left.

/

®

/

Figure 20. Drive Tension Adjustment

A. Upper Rod

B. Nuts

C. Turnbuckle

D. Lower Rod

E. Spring

@

Figure 21. Traction Drive Adjustment (Tube Handle

Models)

A. Adjusting Fiats

B. Spring Hook

C. Bellcrank Arm

D. Nut

E. Adjustment Screw

6/2004 11 TP 399-4079-00-LW-SN

intermediate & Large Frame Snowthrowers

EINSTELLUNG DES

GANGWAHLSCHALTERS

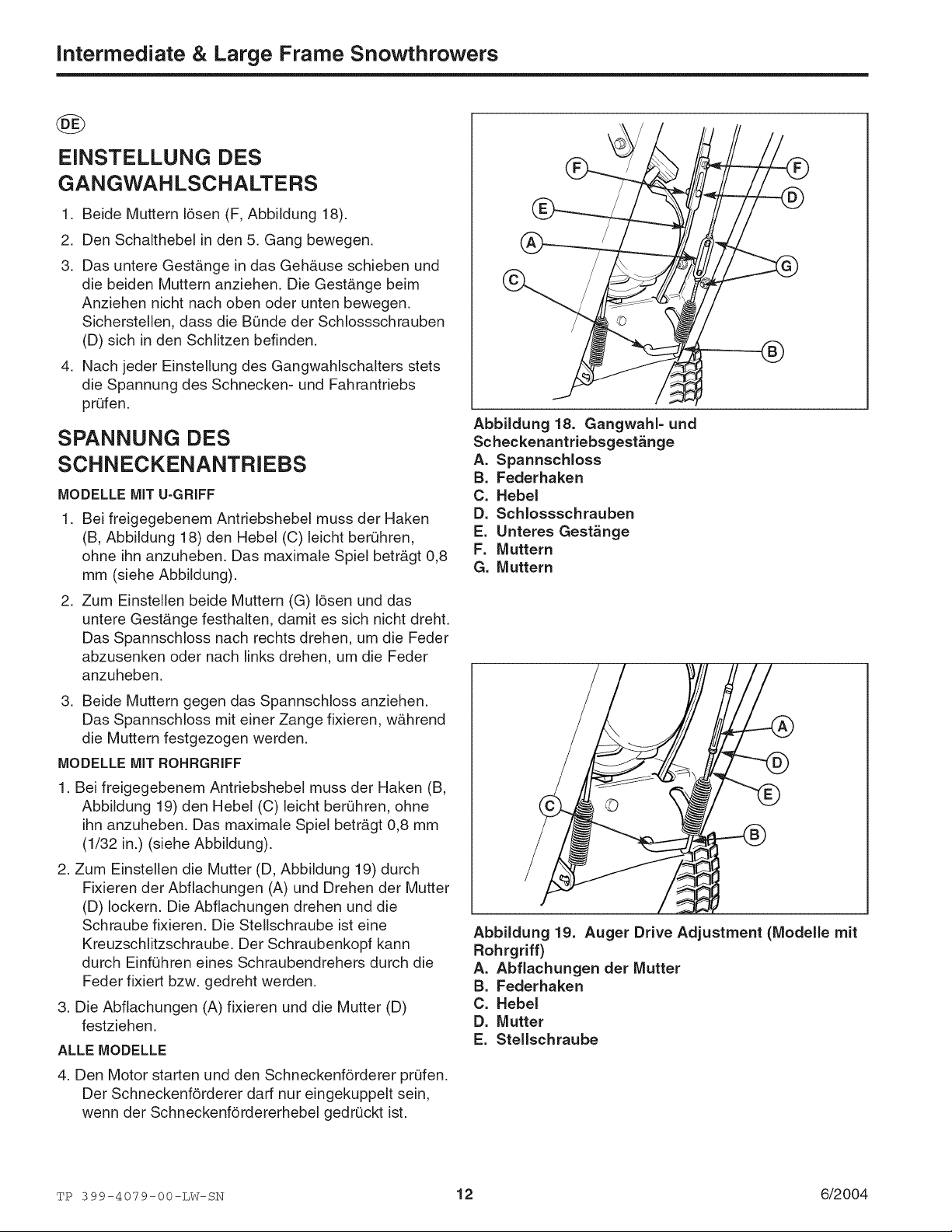

1. Beide Muttern 16sen (F, Abbildung 18).

2. Den Schalthebel in den 5. Gang bewegen.

3. Das untere Gest&nge in das Geh&use schieben und

die beiden Muttern anziehen. Die Gest&nge beim

Anziehen nicht nach oben oder unten bewegen.

Sicherstellen, dass die BQnde der Schlossschrauben

(D) sich in den Schlitzen befinden.

4. Nach jeder Einstellung des Gangwahlschalters stets

die Spannung des Schnecken- und Fahrantriebs

prQfen.

SPANNUNG DES

SCHNECKENANTRIEBS

IVIODELLE MIT U=GRIFF

1. Bei freigegebenem Antriebshebel muss der Haken

(B, Abbildung 18) den Hebel (C) leicht berQhren,

ohne ihn anzuheben. Das maximale Spiel betr> 0,8

mm (siehe Abbildung).

2. Zum Einstellen beide Muttern (G) 16senund das

untere Gest&nge festhalten, damit es sich nicht dreht.

Das Spannschloss nach rechts drehen, um die Feder

abzusenken oder nach links drehen, um die Feder

anzuheben.

Abbildung 18. Gangwahl- und

Scheckenantriebsgest_nge

A. Spannschloss

B. Federhaken

C. Hebel

D. Schlossschrauben

E. Unteres Gest_nge

F. Muttern

G. Muttern

3. Beide Muttern gegen das Spannschloss anziehen.

Das Spannschloss mit einer Zange fixieren, w&hrend

die Muttern festgezogen werden.

MODELLE MIT ROHRGRIFF

1. Bei freigegebenem Antriebshebel muss der Haken (B,

Abbildung 19) den Hebel (C) leicht berQhren, ohne

ihn anzuheben. Das maximale Spiel betr> 0,8 mm

(1/32 in.) (siehe Abbildung).

2. Zum Einstellen die Mutter (D, Abbildung 19) durch

Fixieren der Abflachungen (A) und Drehen der Mutter

(D) Iockern. Die Abflachungen drehen und die

Schraube fixieren. Die Stellschraube ist eine

Kreuzschlitzschraube. Der Schraubenkopf kann

durch EinfQhren eines Schraubendrehers durch die

Feder fixiert bzw. gedreht werden.

3. Die Abflachungen (A) fixieren und die Mutter (D)

festziehen.

ALLE MODELLE

4. Den Motor starten und den Schneckenf6rderer prOfen.

Der Schneckenf6rderer darf nur eingekuppelt sein,

wenn der Schneckenf6rdererhebel gedrQckt ist.

Abbildung 19. Auger Drive Adjustment (Modelle mit

Rohrgriff)

A. Abflachungen der Mutter

B. Federhaken

C. Hebel

D. Mutter

E. Stellschraube

TP 399-4079-00-LW-SN 12 6/2004

5. Den Schneckenf6rdererhebel bei laufendem Motor

vollst&ndig nach unten drQcken. Der

Schneckenf6rderer muss eingekuppelt werden und

sich drehen.

6. Den Schneckenf6rdererhebel freigeben. Der

Schneckenf6rderer muss innerhalb von 5 Sekunden

zum Stillstand kommen.

7. Wenn der Schneckenf6rderer nicht ordnungsgem&B

funktioniert, den Motor abstellen und die Einstellung

des Antriebsgest&nges QberprQfen.

8. Wenn das Antriebsgestb.nge ordnungsgem&B

eingestellt ist, muss ggf. die Spannung des

Schneckenantriebsriemens eingestellt werden. Siehe

,,Einstellung des Schneckenantriebsriemens".

SPANNUNG DES FAHRANTRIEBS

MODELLE MIT U=GRIFF

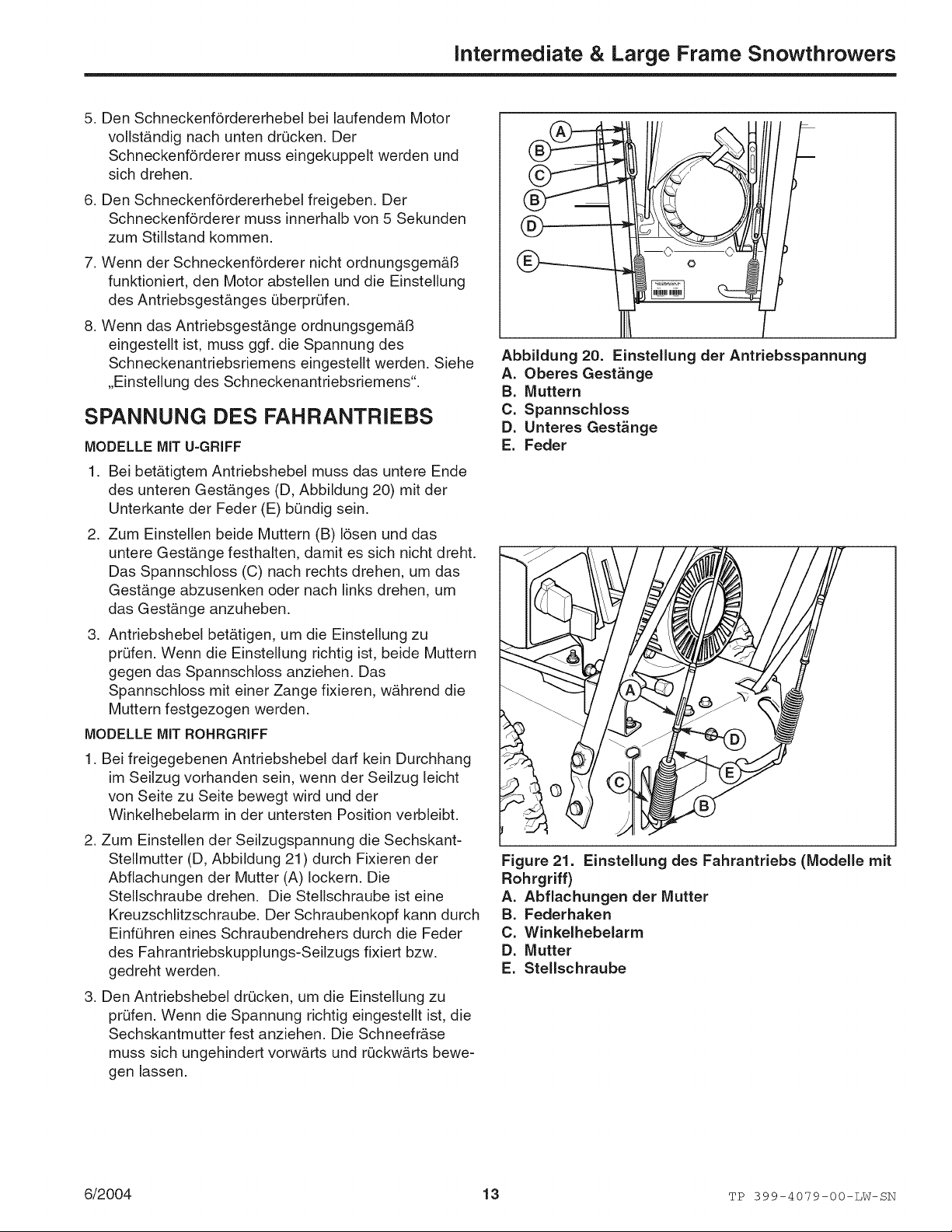

1. Bei betb.tigtem Antriebshebel muss das untere Ende

des unteren Gest&nges (D, Abbildung 20) mit der

Unterkante der Feder (E) bQndig sein.

2. Zum Einstellen beide Muttern (B) 16senund das

untere Gest&nge festhalten, damit es sich nicht dreht.

Das Spannschloss (C) nach rechts drehen, um das

Gestb.nge abzusenken oder nach links drehen, um

das Gest&nge anzuheben.

3. Antriebshebel bet&tigen, um die Einstellung zu

prQfen. Wenn die Einstellung richtig ist, beide Muttern

gegen das Spannschloss anziehen. Das

Spannschloss mit einer Zange fixieren, w&hrend die

Muttern festgezogen werden.

IVIODELLEMIT ROHRGRIFF

1. Bei freigegebenen Antriebshebel darf kein Durchhang

im Seilzug vorhanden sein, wenn der Seilzug leicht

von Seite zu Seite bewegt wird und der

Winkelhebelarm in der untersten Position verbleibt.

intermediate & Large Frame Snowthrowers

®

Abbildung 20. Einstellung der Antriebsspannung

A. Oberes Gest_nge

B. Muttern

C. Spannschloss

D. Unteres Gest_nge

E. Feder

2. Zum Einstellen der Seilzugspannung die Sechskant-

Stellmutter (D, Abbildung 21 ) durch Fixieren der

Abflachungen der Mutter (A) Iockern. Die

Stellschraube drehen. Die Stellschraube ist eine

Kreuzschlitzschraube. Der Schraubenkopf kann durch

EinfQhren eines Schraubendrehers durch die Feder

des Fahrantriebskupplungs-Seilzugs fixiert bzw.

gedreht werden.

3. Den Antriebshebel drQcken, um die Einstellung zu

prQfen. Wenn die Spannung richtig eingestellt ist, die

Sechskantmutter fest anziehen. Die Schneefr&se

muss sich ungehindert vorw&rts und rQckw&rts bewe-

gen lassen.

6/2004 13 TP 399-4079-00-LW-SN

Figure 21. Einstellung des Fahrantriebs (Modelle mit

Rohrgriff)

A. Abflachungen der Mutter

B. Federhaken

C. Winkelhebelarm

D. Mutter

E. Stellschraube

intermediate & Large Frame Snowthrowers

JUSTERING AV HASTIGHETSVEL-

GEREN

1. De to mutrene Iosnes (F, figur 18).

2. Plasser girspaken i 5. gir.

3. Skyv den nederste stangen inn i kassen, og stram de

to mutrene. Loft ikke stengene opp eller ned under

stramming. P&se at skuldrene p& I&seboltene (D) st&r

i sporene.

4. Kontroller alltid strammingen av friksjonsdrivet og

skovledrivet etter at du hat justert hastighetsvelgeren.

STRAMMING AV SKOVLEDRIVET

MODELLER MED RENNEFORMET HANDTAK

1. N&r drivspaken er sluppet opp, skal kroken (B, figur

18) bare s& vidt berQre spaken (C) uten & Iofte den

opp. Klaringen skal v_ere maks. 0,8 mm som vist.

2. Juster ved & Iosne p& de to mutrene (G) og holde i

den nederste stangen slik at den ikke roterer. Vri

spennskruen mot hoyre for & senke fjaeren, eller mot

venstre for & heve fjaeren.

3. Stram de to mutrene mot spennskruen. Hold

spennskruen fast med en stang mens du strammer

mutrene.

MODELLER MED RORHANDTAK

1. N&r betjeningsspaken slippes, skal kroken (B, figur 19)

bare s&vidt before spaken (C) uten at den Iofter den.

Det kan, som vist, ikke v_ere met enn 1/32" klaring.

2. For & justere, Iosne mutteren (D, figur 19) ved & holde

p& justeringsflatene (A) og vri p& mutteren (D). Vri p&

justeringsflatene og hold skruen. Justeringsskruen er

en stjemeskrue og hodet kan holdes eller vris ved &

sette inn en skrutrekker gjennom fjaeren.

3. Hold p& justeringsflatene (A) og stram mutteren (D).

ALLE MODELLER

4. Start enheten og kontroller innmatingsskruen.

Innmatingsskruen m& ikke vaere koplet til med mindre

betjeningen av innmatingsskruen er trykt ned.

5. N&r motoren g&r, trykkes innmatingsskruebetjeningen

heir ned og innmatingsskruen skal koples seg til og

g& normalt.

6. Utlosning av innmatingsskruebetjeningen.

Innmatingsskruen m& stoppe innen 5 sekunder.

7. Stopp motoren og kontroller drivkjedejusteringene en

gang til hvis innmatingsskruen ikke fungerer som den

Figur 18. Leddkoplinger for hastighetsvelgeren og

skovledrivet

A. Spennskrue

B. Fjaerkrok

C. Spak

D. L&sebolter

E. Nedre stang

F. Mutre

G. Mutre

Figure 19. Stramming av skovledrivet (Modeller reed

rerh_ndtak)

A. Justeringsflater D. Mutter

B. Karabinkrok E. Justeringsskrue

C. Spaken

TP 399-4079-00-LW-SN 14 6/2004

intermediate & Large Frame Snowthrowers

skal.

8. Hvis drivkjeden er justert riktig, kan det vaere at stram-

mingen av drivbeltet p& innmatingsskruen trenger jus-

tering. Se "Justering av drivbeltet p& innmatingsskru-

en",

STRAiVliVllNG AV FRIKSJONSDRIVET

MODELLER IVIED RENNEFORMET HANDTAK

1. N&r drivspaken er innkoplet, skal den nederste enden

av den nederste stangen (D, figur 20) vaere i flukt med

undersiden av fj_eren (E).

2. Juster ved & Iosne de to mutrene, (B) og holde i den

nederste stangen slik at den ikke roterer. Vri

spennskruen (C) mot hoyre for & senke stangen eller

mot venstre for & heve stangen.

3. Innkople drivspaken for & kontrollere justering. Stram

de to mutrene mot spennskruen n&r justeringen er

korrekt. Hold spennskruen fast med en stang mens

du strammer mutrene.

MODELLER IVIEDRORHANDTAK

1. N&r betjeningsspaken er lost ut skal det ikke vaere noe

slakk i kabelen n&r den beveges forsiktig fra side til

side, men knearmen blir vaerende i en stilling belt

nede.

2. For & justere strammingen av kabelen, Iosens juster-

ingssekskantmutteren (D, figur 21) ved &holde p&

justeringsflatene (A). Vri p&justeringsskruen.

Justeringsskruen er en stjerneskrue og hodet kan

holdes eller vris ved & sette i en skrutrekker gjennom

kabelfjaeren p& trekkraftclutchen.

3. Kople til betjeningsspaken for & kontrollere justeringen.

N&r den er riktig, strammes sekskantmutteren godt.

Det skal vaere mulig & skyve enheten frem og tilbake

uten problemer.

®

Figur 20. Justering av drivstramming

A. _vre stang

B. Mutre

C. Spennskrue

D. Nedre stang

E. Fjaer

Figure 21. Stramming av friksjonsdrivet (Modeller

reed rerh_ndtak)

A. Justeringsflater D. Mutter

B. Karabinkrok E. Justeringsskrue

C. Spaken

6/2004 15 TP 399-4079-00-LW-SN

intermediate & Large Frame Snowthrowers

JUSTERING AV HASTIGHETSVI ,L-

JAREN

1. Lossa de tv& muttrarna (F, figur 18).

2. L&gg i den 5:e v&xeln.

3. Skjut in den undre st&ngen i k&pan och sp&nn &t de

tv& muttrarna. Flytta inte st&ngerna upp&t eller ned&t

medan du sp&nner &t. Kontrollera att rundskruvarnas

ansatser (D) sitter i sp&ren.

4. Kontrollera alltid remsp&nningen f6r hjuldrivningen

och redskapets drivning efter att hastighetsv&ljaren

justerats.

SKRUVENS REMSPI NNING

IVIODELLER MED HANDTAG AV U-BALKAR

,

N&r kopplingsgreppet &r uppsl_.ppt ska kroken (B,

figur 18) n&tt och j&mnt vidr6ra h&varmen (C) utan att

denna lyfts upp. Maximalt kan ett avst&nd p& 0,8 mm

finnas som visat.

2. Justera genom att Iossa de tv& muttrarna (G) och h&ll

fast den undre st&ngen s& att den inte kan vridas.

Vrid stagstr&ckaren &t h6ger f6r att s&nka fj&dern eller

&t v&nster f6r att h6ja fj&dern.

3. Sp&nn &t de tv& muttrarna mot stagstr&ckaren. H&II

fast stagstr&ckaren med en t&ng samtidigt som du

sp&nner muttrarna.

MODELLER IVIEDRORHANDTAG

1. N&r drivarmen &r sl_.ppt ska kroken (B, figur 19) nb.tt

och jb.mnt vidr6ra armen (C) utan att denna lyfts upp.

Maximalt kan ett avst&nd p& 0,8 mm finnas som

visas.

2. Justera genom att Iossa p& mutter (D, figur 19) och

h&lla fast justeringsfiatorna (A) och vrida muttern (D).

Vrid p& justeringsflatorna och h&ll skruven.

Justeringsskruven &ren krysskruv och huvudet kan

h&llas fast eller vridas genom att f6ra in en skruvme-

jsel genom fj&dern.

3. H&II fast justeringsflatorna (A) och dra &t muttern (D).

ALLA MODELLER

4. Starta enheten och kontrollera skruven. Skruven f&r

inte kopplas i om inte skruvens reglage &r nedtryckt.

5. Tryck ned skruvens reglage belt medan motorn k6r.

Skruven b6r koppla ur och k6ra normalt.

6. Sl_.pp upp skruvens reglage. Skruven m&ste stanna

inom 5 sekunder.

7. Om skruven inte fungerar riktigt, stanna motorn och

kontrollera drivl&nkens justeringar igen.

Figur 18. Hastighetsv_ljare och I_nksystemet f6r

skruvens drivmekanism

A. Stagstr_ckare

B. Fj_derhake

C. H_varm

D. Rundskruvar

E. Undre st&rig

F. Muttrar

G. Muttrar

Figure 19. Skruvens remsp_nning (Modeller reed

r6rhandtag)

A. Justeringsflator D, Mutter

B. Fj_derhake E. Justeringsskruv

C. H_vst_ng

TP 399-4079-00-LW-SN 16 6/2004

intermediate & Large Frame Snowthrowers

8. Om drivl&nken _.r riktigt justerad, kanske skruvens dri-

vremssp&nning beh6ver justeras. Se "Justera skru-

vens drivrem".

HJULDRIVNINGENS REMSPJ NNING

/

IVIODELLER iViED HANDTAG AV U=BALKAR

1. N_.r hjuldrivningens kopplingsgrepp h&fls intrycktska

underdelen av den undre st&ngen (D, figur 20) sitta i

j&mnh6jd med fj&derns undre del (E).

2. Justera genom art Iossa de tv& muttrama (B) och h&ll

fast den undre st&ngen s& att den inte kan vridas.

Vrid stagstr_.ckaren (C) &t h6ger f6r art s&nka st&ngen

eller &t v&nster f6r art h6ja st&ngen.

3. Tryck in hjuldrivningens kopplingsgrepp f6r att kon-

trollera justeringen. N_.r justeringen _.r slutf6rd sp&n-

ner du &t de tv& muttrama mot stagstr_.ckaren. H&fl

fast stagstr&ckaren med en t&ng samfidigt som du

sp&nner muttrama.

IVIODELLERIVIEDRORHANDTAG

1. Med drivarmen sl_.ppt ska kabeln vara sp&nd n_.rden

flyttas n&got fr&n sida till sida, men vinkelh&varmen

forts&tter art vara i heir nedl&ge.

2. N&r du viii justera kabelns sp&nning ska du Iossa p&

justeringssexkanstmuttern (D, figur 21) genom art

h&lla fast justeringsflatoma (A). Vrid p& justeringsfla-

toma. Justeringsskruven _.ren krysskruv och huvudet

kan h&llas fast eller vridas genom art f6ra in en skru-

vmejsel genom kabelfj&dern f6r hjuldrivningens kop-

piing.

3. Kontrollera justeringen genom art koppla in drivarmen.

N_.rden Ar rAtt ska du dra &t sexkanstmuttem

ordentligt. Det ska g& IAtt art skjuta enheten fram&t

och tillbaka.

®

/

Figur 20. Justering av drivmekanismens sp_nning

A. (Svre st&rig

B. Muttrar

C. Stagstr_ckare

D. Undre st_ng

E. Finder

@

Figure 21. Traction Drive Adjustment (Modeller meal

r8rhandtag)

A. Justeringsflator D. Mutter

B. Fj_derhake E. Justeringsskruv

C. Vinkelh_varm

6/2004 17 TP 399-4079-00-LW-SN

intermediate & Large Frame Snowthrowers

REGLAGE DU SELECTEUR DE

VITESSE

1. Desserrer les deux ecrous (F, Figure 18).

2. Placer le levier en 5eme vitesse.

3. Pousser la tringle inferieure dans Iogement et serrer

les deux ecrous. Ne pas tirer ou pousser sur les

tringles pendant le serrage. Verifier que les epaule-

ments des boulons (D) sont dans les trous oblongs.

4. Apres avoir regle le selecteur de vitesse, toujours

verifier la tension de la commande de traction et de la

commande de fraise.

TENSION DE LA COMMANDE DE

FRAISE

MODELES .&GUIDON EN PROFILE[

.

Lorsque le levier de commande est rei&che, le cro-

chet (B, Figure 18) doit& peine toucher le levier (C)

sans le soulever. II peut y avoir un jeu de 0,8 mm

maximum.

2. Pour regler la tension, desserrer les deux ecrous (G)

et tenir la tringle inferieure pour I'emp_cher de tourn-

er. Faire tourner le tendeur vers la droite pour abaiss-

er le ressort ou vers la gauche pour le relever.

3. Serrer les deux ecrous contre le tendeur. Tenir le ten-

deur avec une pince pendant le serrage des ecrous.

MODELES .&.GUIDON EN PROFILE

1. Lorsque le levier de commande est rel&che, le crochet

(B, Figure 19) doit& peine toucher le levier (C) sans

le soulever. II peut y avoir un jeu de 0,8 mm maxi-

mum.

2. Pour regler, desserrer I'ecrou (D, Figure 19) en tenant

les m@lats de reglage (A) et en toumant I'_crou (D).

Toumer les m@lats et tenir la vis. La vis de reglage

est une vis Phillips dont la t6te peut _tre immobilisee

ou tournee en introduisant un tournevis &travers le

ressort.

3. Tenir les m@lats de reglage (A) et setter I'ecrou (D).

TOUS MODELES

4. Demarrer la machine et contr61er la fraise. La fraise ne

doit pas _tre engagee si la commande de fraise n'est

pas enfoncee.

5. Moteur en marche, enfoncer & fond la commande de

fraise, la fraise doit embrayer et fonctionner normale-

merit.

6. Rel&cher la commande de fraise. La fraise doit

s'arr_ter darts les 5 secondes.

Figure 18. Timonerie du s_lecteur de vitesse et de

I'entra_nement de la fraise

A. Tendeur

B. Crochet _ ressort

C. Levier

D. Boulons m_caniques

E. Tringle inf_rieure

F. i_crous

G. Ecrous

Figure 19. Tension de la commande de fraise (mod-

Ules _ guidon tubulaire)

A. M_plats de r_glage D. l_crou

B. Crochet & ressort E. Vis de r_glage

C. Levier

TP 399-4079-00-LW-SN 18 6/2004

intermediate & Large Frame Snowthrowers

7. Si la fraise ne fonctionne pas correctement, arr_ter le

moteur et rev@ifier les reglages de la timonerie

d'entrafnement.

8. Si la timonerie est correctement reglee, il est possible

que la tension de la courroie d'entrafnement de la

fraise doive _tre ajustee. Voir _ Regler la courroie

d'entrafnement de la fraise >_.

TENSION DE LA COMMANDE DE

TRACTION

MODELES ._ GUIDON EN PROFILI_

1. Lorsque le levier de commande est engage,

I'extremite basse de la tringle inf@ieure (D, Figure 20)

doit _tre & ras de la base du ressort (E).

2. Pour regler la tension, desserrer les deux ecrous (B)

et tenir la tringle inf@ieure pour I'emp_cher de tourn-

er. Faire tourner le tendeur (C) vers la droite pour

abaisser la tige inf@ieure ou vers la gauche pour la

relever.

®

Figure 20. R_glage de la tension de la commande de

traction

A. Tringle sup_rieure

B. Ecrous

C. Tendeur

D. Tringle inf_rieure

E. Ressort

3. Engager le levier de commande pour v@ifier le

reglage. Lorsqu'il est correct, serrer les deux ecrous

contre le tendeur. Tenir le tendeur avec une pince

pendant le serrage des ecrous.

MODELES ._ GUIDON EN PROFILI_

1. Lorsque le levier est I&ch6, il ne doit y avoir aucun mou

dans le c&ble Iorsqu'il est pousse legerement d'un

c6te & I'autre, mais que le bras de renvoi reste en

position basse.

2. Pour regler la tension du c&ble, desserrer I'ecrou de

reglage (D, Figure 21) en tenant les m_plats de

reglage (A). Tourner la vis de reglage. 2. La vis de

reglage est une vis Phillips dont la t_te peut _tre

immobilisee ou tournee en introduisant un tournevis &

travers le ressort du c&ble d'embrayage de traction.

3. Engager le levier de commande pour v@ifier le

reglage. S'il est correct, bien resserrer I'ecrou hexag-

onal. La machine doit pouvoir _tre poussee librement

vers I'avant et I'arriere.

@

Figure 21. R_glage de la commande de traction

(modUles _ guidon tubulaire)

A. IVl_plats de r_glage D. l_crou

B. Crochet _ ressort E. Vis de r_glage

C. Bras de renvoi

6/2004 19 TP 399-4079-00-LW-SN

intermediate & Large Frame Snowthrowers

@b

REGOLAZIONE DEL CAMBIO

1. Allentare idue dadi (F, Figura 18).

2. Portare la leva del cambio in quint&

3. Spingere I'asta inferiore nell'alloggiamento e serrare i

due dadi. Non sollevare o abbassare le aste nel corso

del serraggio. Controllare che gli spallamenti dei dadi

a testa tonda (D) siano inseriti nelle scanalature.

4. Una volta regolato il cambio, controllare sempre la

tensione del comando della trazione e la tensione del

comando della coclea.

TENSIONE COMANDO COCLEA

MODELLI CON MANUBRIO A PROFILATO

1,

Con la leva del comando rilasciata, il gancio (B, Figura

18) deve entrare appena in contatto con la leva (C),

senza sollevarla. II gioco massimo consentito e di 0,8

mm, come mostrato.

2,

Per regolare, allentare i due dadi (G) e tenere I'asta infe-

riore, onde evitarne la rotazione. Girare a destra il tendi-

tore a vita, per abbassare la molla, o a sinistra per solle-

varla.

3. Serrate i due dadi sul tenditore a vite. Tenere il tenditore

a vite con delle pinze, mentre si serrano i dadi.

MODELLI CON MANUBRIO TUBOLARE

1. Con la leva sganciata, il gancio (B, figura 19) dovr& toc-

care appena la leva (C) senza alzarla. Pu6 esserci una

distanza massima di 0,8 mm (1/32 di pollice).

2. Per regolare, allentare il dado (D, figura 19) facendo

presa sui lati piani di regolazione (A) e ruotando il dado.

Ruotare i lati piani di regolazione e tenere ferma la vite.

La vite di regolazione e con taglio a croce e la sua testa

pu6 essere presa o ruotata inserendo un cacciavite

attraverso la molla.

3. Tenere i lati piani di regolazione (A) e stringere il dado

(D).

TUTTI I MODELLI

4. Avviare I'unit& e controllare la coclea. La coclea deve

essere inserita a meno che il comando della coclea non

sia stato premuto.

5. Con il motore in marcia e il comando della coclea premuto

del tutto, la coclea dovr& essere ingranata e funzionare

regolarmente.

6. Disinserire il comando della coclea. La coclea deve fer-

marsi entro 5 secondi.

7. Se la coclea non funziona in modo corretto, arrestare il

motore e controllare di nuovo la regolazione del bever-

aggio della trasmissione.

Figura 18. Tiranteria del cambio e del comando della

coclea

A. Tenditore

B. Gancio a molla

C. Leva

D. Bullone a testa tonda

E. Asta inferiore

F. Dadi

G. Dadi

Figure 19. Tensione comando coclea (Modelli con

manubrio tubolare)

A. Lati piani di regolazione D. Dadot

B. Gancio della rnolla E. Vite di regolazione

C. Leva

TP 399-4079-00-LW-SN 20 6/2004

Loading...

Loading...