OPERATOR’S

MANUAL

42”/48”

Turbo Blower Assembly

Mfg.

No:

1691810

Mfg. No. 1691998

FORM 170460604

PRINTED IN U.S.A.

12/93-3ooccI

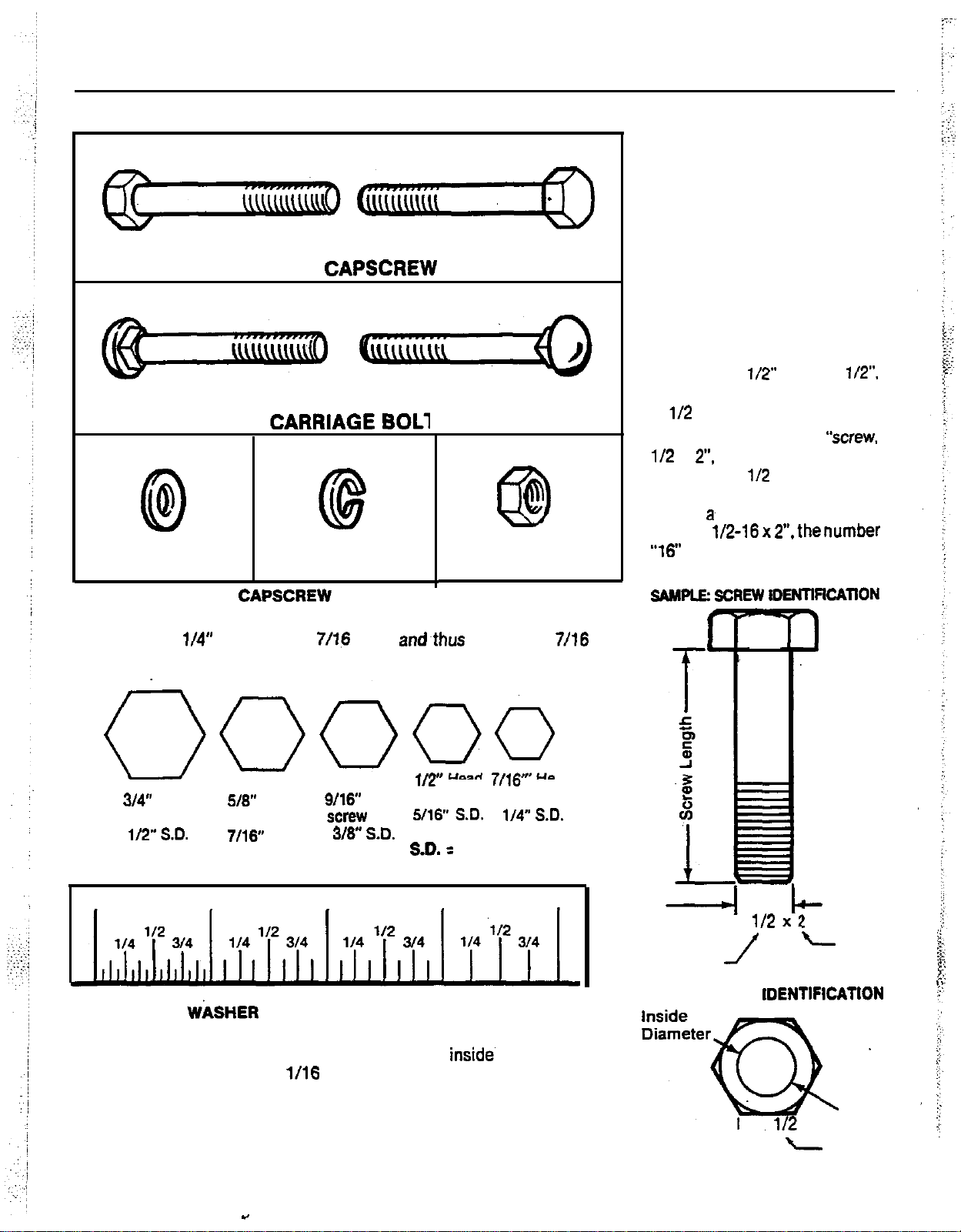

HEX CAPSCREW

p.

a

PLAIN WASHER LOCKWASHER

HEX CAPSCREW IDENTIFICATION

Shown below are actual size hex heads for standard screw sizes.

Example: a

wrench. To measure length, use the scale below.

l/4”

screw has a

7116

head and.thus requires a

NUT

7716

STANDARD

FASTENER

IDENTIFICATION

CHART

Hardware sizes are given in the

illustrations throughout this

manual.

If a washer or nut is identified

as “washer.

this means the inside diameter

is

l/2

inch.

If a screw is identified as

l/2

x

2”.

diameter is

shaft of the screw is 2 inches

long. If

“screw.

“16”

means that the screw has

16 threads per inch.

SAMPLE: SCREW iDENllflCAllON

l/2” or “nut.

this means the shaft

l/2

inch and the

a~

screw is identified as

l/2-16~2”.thenumber

-

172”.

‘Wrew.

3

~0000

34”

Head

screw with screw with

112”

SD.

0

Place the washer or nut on the above scale to

determine inside diameter. The actual

ameter can vary

comparison.

518”

7116”

1

WASHER AND NUT IDENTIFICATION

Head

S.D.

l/16

t/2” Heed 7fl6” Head

6716”

Head screw with screw with

screw

with

310”

SD.

2 3

inch. Use the scale for

5716”

SD. l/4” SC.

SD. =

Shaft Diameter

insides

di-

c

4

Screw

Shaft

Diameter

SAMPLE: NUT IDENTlFlCATlON

1

l/2

Nut.

112

Shaft

!

Diameter

c

Screw

Length

-

Inside

Diameter

ir

.$J

*.y

‘:i

Table of Contents

Safety Decal ................................

Safety Rules

Installation

Lawn Tractor

Front-Cut Rider .........................

Operation

Standard Fastener Identification Chart

NOE

this reason, a replacement roller is supplied with the turbo blower kit.

The additional weight of the turbo blower may cause the end roller on the mower deck to wear faster. For

................................

...........................

..................................

.......

.......

.......

.......

.......

.......

.......

......

......

......

......

......

......

......

......

......

......

......

......

(I

......

......

......

......

......

......

......

......

......

......

. . . .

. . . . 2

. . . .

. . . .

. . . .

13

. . . .

15

1

3

8

A

DANGER

Located on Blower Housing

,Safety

ROTATING BLADES

SHUT OFF MOWER

AND TRACTOR

BEFORE SERVICING

OR CLEANING BLOWER

AND MOWER.

Decal

1

Safety Rules

Read these safety rulesand the safety rules in

Manual and follow them closely. Failure to obey these rules

A

could result in loss of control of vehicle, severe personal injury

to yourself, or damage to property or equipment. The triangle in the

text signifies important cautions or warnings which must be followed.

WARNING

A

When blower assembly is removed from mower deck, the deflector

must be installed as described in Operating Without Collection System.

1.

Know the tractor or ridercontrolsand how

to stop quickly. READ THE OWNERS

MANUAL.

2. Disengage the PTO, shut the engine off

and wait for all moving parts to stop before

attaching, adjusting, or disconnecting any

part of the collection system.

3. Check the collection system to make sure

it is bolted tightly to tractor or rider.

4. Check the latch handle to make sure it is

engaged so the dump cart’s box is locked

to the frame.

5. Look behind to make sure the area is clear

before backing up.

6. DO NOT turn sharply when the tractor or

rider is alongside a building or any object.

7. DO NOT carry passengers in the cart.

8.

A

CAUTION: For added tractor or rider

stability and to prevent tipping or loss of

control;

a. Use reduced speed on uneven ground

and when turning corners.

b. Reduce loads on hillsides. It is rec-

ommended that the collection system

be kept only half full when negotiating

any slopes. Start mowing on slopes

when the collection system is empty.

c.

Mow up and down the face of slopes;

never acrossthe face of any slope.

yo,ur

Operator’s

9. AWARNING:

slopes, use

operate on slopes greater than 30%

(16.7”).

10.

ACAUTION: Objects may be thrown

from mower.

For your safety:

a. DO NOT remove the cover while the

mower blades are tyrning. Shut off the

engine before openmg the door or

removing the grass chute.

b. Be sure the complete collection

system is in place (cover secure and

grass chute connected) before

operating the mower.

c. DO check the twin bag cover fre-

quently for wear and tear. Replace with

new cover for safety protection.

11. For best results when mowing grass: Set

the mower to cut from 1 to 2 inches of

grass. If grass isexceptionallytall, set your

mower as high as possible for first cutting.

Lower cutting height at succeeding

cuttings until proper height is reached. It

may be necessary to mow tall grass at a

slower tractor speed.

When operating on

,front

countennreight.

Never

installation - Lawn

,Tractors

NOTE

Two spacers are packaged with turbo biower.

Installation on tractor requires use of

spacer (see step 11); the

1/2”spacerwill

4-l/16”

not be

used.

1. Remove mower deflector and arbor cover as

follows:

a. Remove the mower deflector by removing

two carriage bolts, lockwashers and nuts.

Install this hardware on the deflector for use

when blower is removed for side discharge.

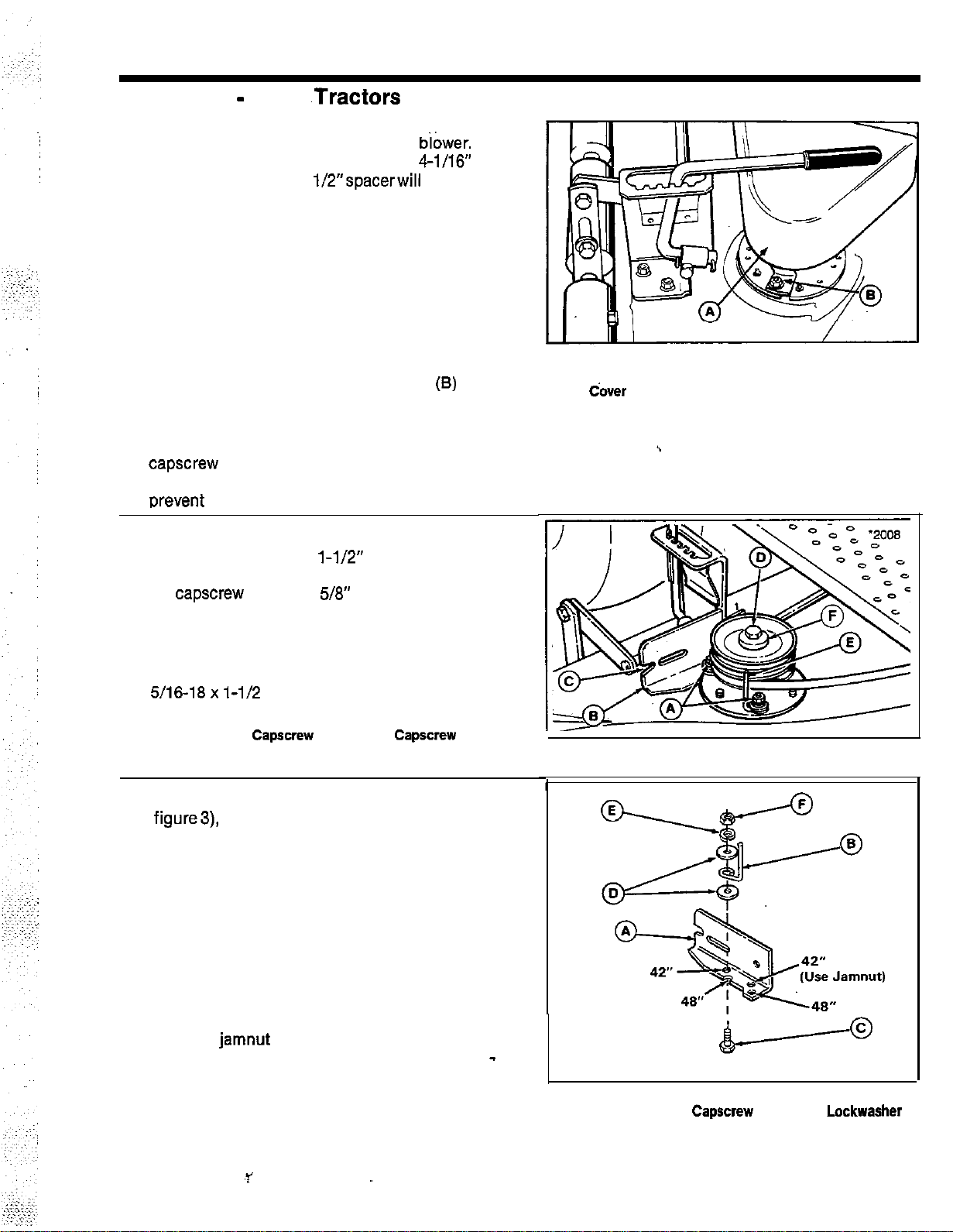

b. Remove the right hand arbor cover (A, figure

1) by removing washers and nuts in frontthat

hold cover to deck. Also, remove nuts

(8)

and

washers that secure rear tabs to arbor.

2. Slip mower belt off the right hand pulley.

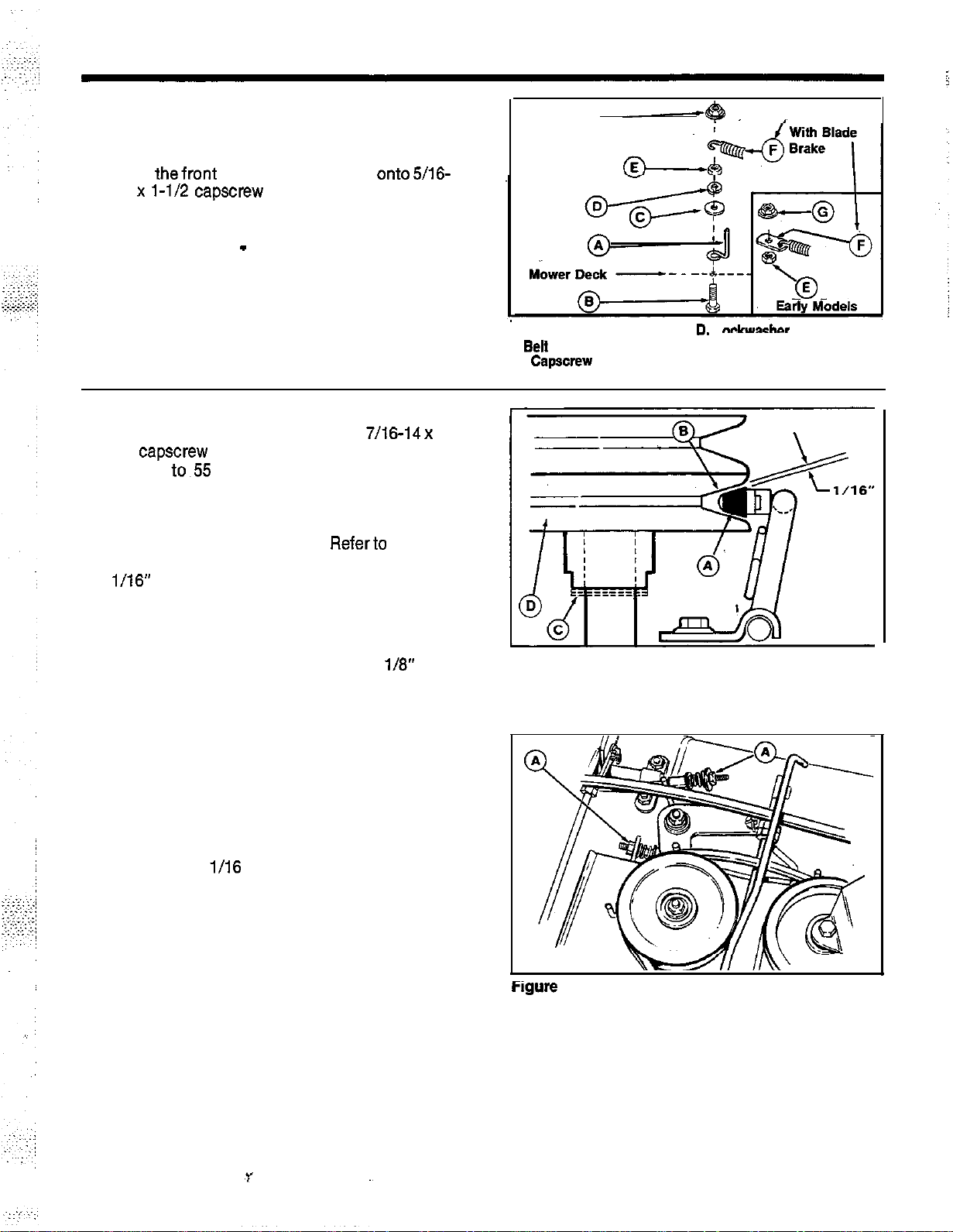

Remove the pulley from the arbor by removing

capscrew

(D, figure 2) and washers (F). Save

washers for reinstallation. Use wood block to

orevent blade from turning.

NOTE

Later model decks have

l-1/2”

taptite screws,

rather than 1” taptite screws, location A, figure

2. If

capscrew protrudes 5/S” above arbor, new

capscrews do not need to be installed

3. Remove brake spring or spring anchor (if

equipped) and two taptite screws from arbor at

locations A, figure 2. Replace these with two

5/16-18x l-1/2 capscrews (A).

Figure 1.

A. Arbor Cover

B. Nut dover

D.

A.

capscrew

B. Arbor Bracket E. Belt Stop, Front

C. Notch F. Washers

capscrew

4. Before installing arbor bracket (B, figure 2 &A,

figure3),

removewasherfrom underneath blade

brake bracket (rear capscrew). Arbor bracket is

same thickness as washer and will replace

washer. Loosen the front flange nut and remove

the rear flange nut on the blade brake bracket.

NOTE

Rear belt stop should be installed facing inside

of deck.

5. Install the arbor bracket (A, figure 3) and rear

belt stop (B) as shown. Note the different holes

for the 42” and 43” mowers. On the 42” deck,

install a

jamnut

at rear bracket location instead

of flange whiz nut. Tighten nut (F) snug only -

belt stop will be adjusted in step 8.

3

Figure 2.

I.

Figure 3.

A Arbor Bracket C.

B. Belt Stop D. Large Washers

CapSxew

E.

Lockwasher

F. Jam Locknut

NOTE

Front belt stop should be installed facing

outside of deck.

‘6. Install

thefront

18 x l-1/2

shown. If removed, reinstall brake spring or

spring anchor (F) before flange nut(G). Tighten

nut (E) snug only

step 8.

belt stop (A, figure4)

capscrew

(installed in step 3) as

-

belt stop will be adjusted in

onto5/16-

G Mower Decks

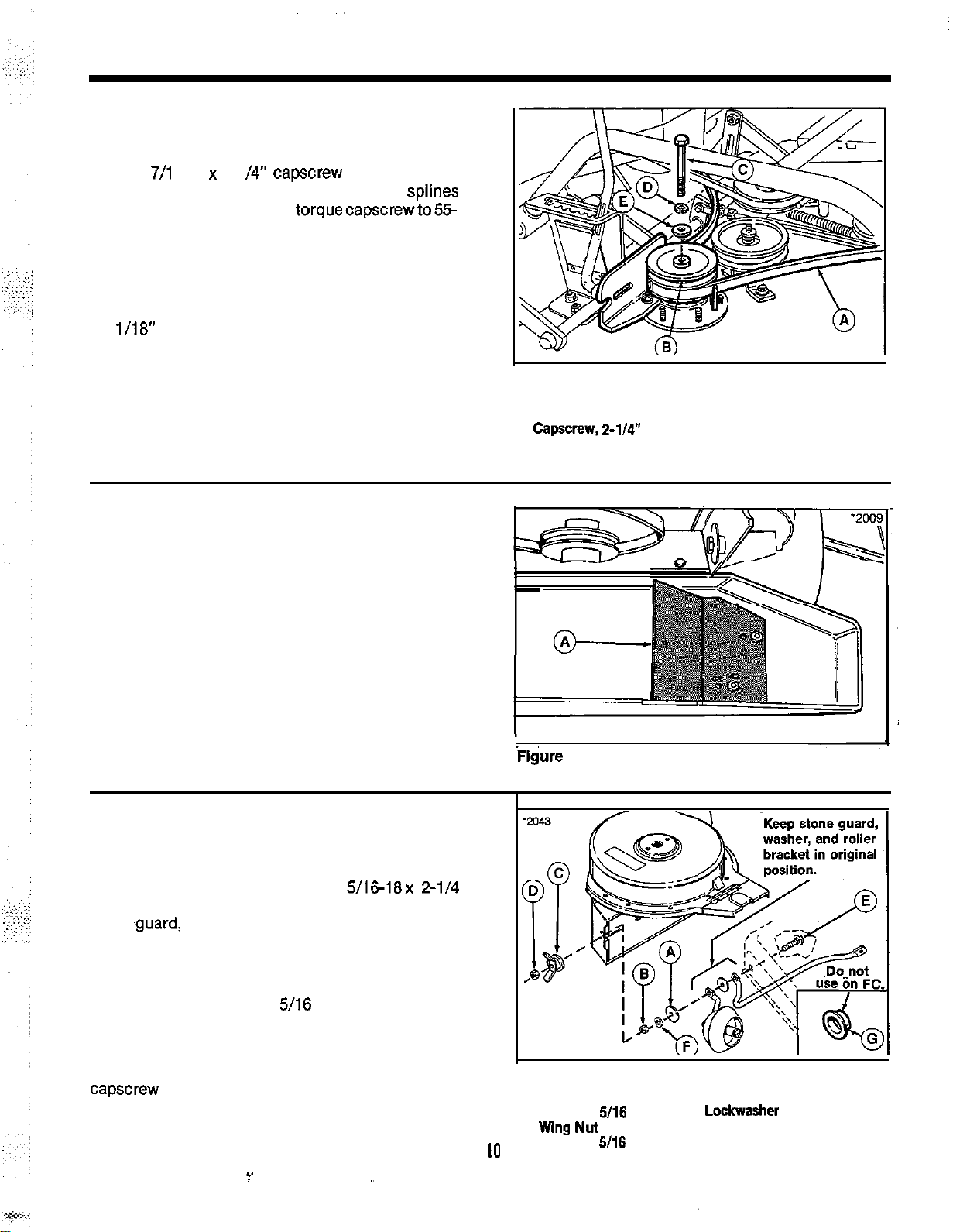

7. Install new double-groove arbor pulley (D,

figure 5) with hub down. Use new 7/16-14 x 2-

1/4

capscrew

Torque

prevent blade from turning. It may be necessary

to add washer(s) (C, figure 5, two provided)

underneath the new pulley to properly align

brake pad and bottom groove. Referto figure 5.

Add washers to adjust top-to-bottom alignment:

l/16” clearance must be adjusted after belt is

installed and PTO is engaged.

8. Slip the mower drive belt onto the lower groove

of the new pulley (D, figure 2). With the mower

PTO engaged, adjust the belt stops

belt. Tighten the hardware.

9. If mower is equipped with blade brake, adjust

the brake after installing new double groove

pulley as follows:

a. Engage the PTO lever. Be sure that mower

drive belt tension is correctly adjusted (see

Operator’s Manual).

b. Inspect the brake pad (A, figure5) to V-pulley

(B) clearance. With PTO engaged, clearance

should be

c. If adjustment is required, turn adjusting nuts

(A, figure 6) until proper clearance is

reached.

and washers removed in step 2.

to~55

to 70 ft. Ibs. Use wood block to

l/l6

inch as shown in figure 5.

l/8”

from

Figure 4.

a

Belt

stop

B.

Capscrew

C. Large Washer

Figure 5.

A. Brake Pad

B. Bottom Groove

D.

,

n**.“rchn*

E. Nut

F.

Spring or Spring

G. Flange Locknut

C. Washers (If required)

D. Double-Groove Pulley

Anchor

Figure

6.

A. Blade Brake Adjustment Nuts

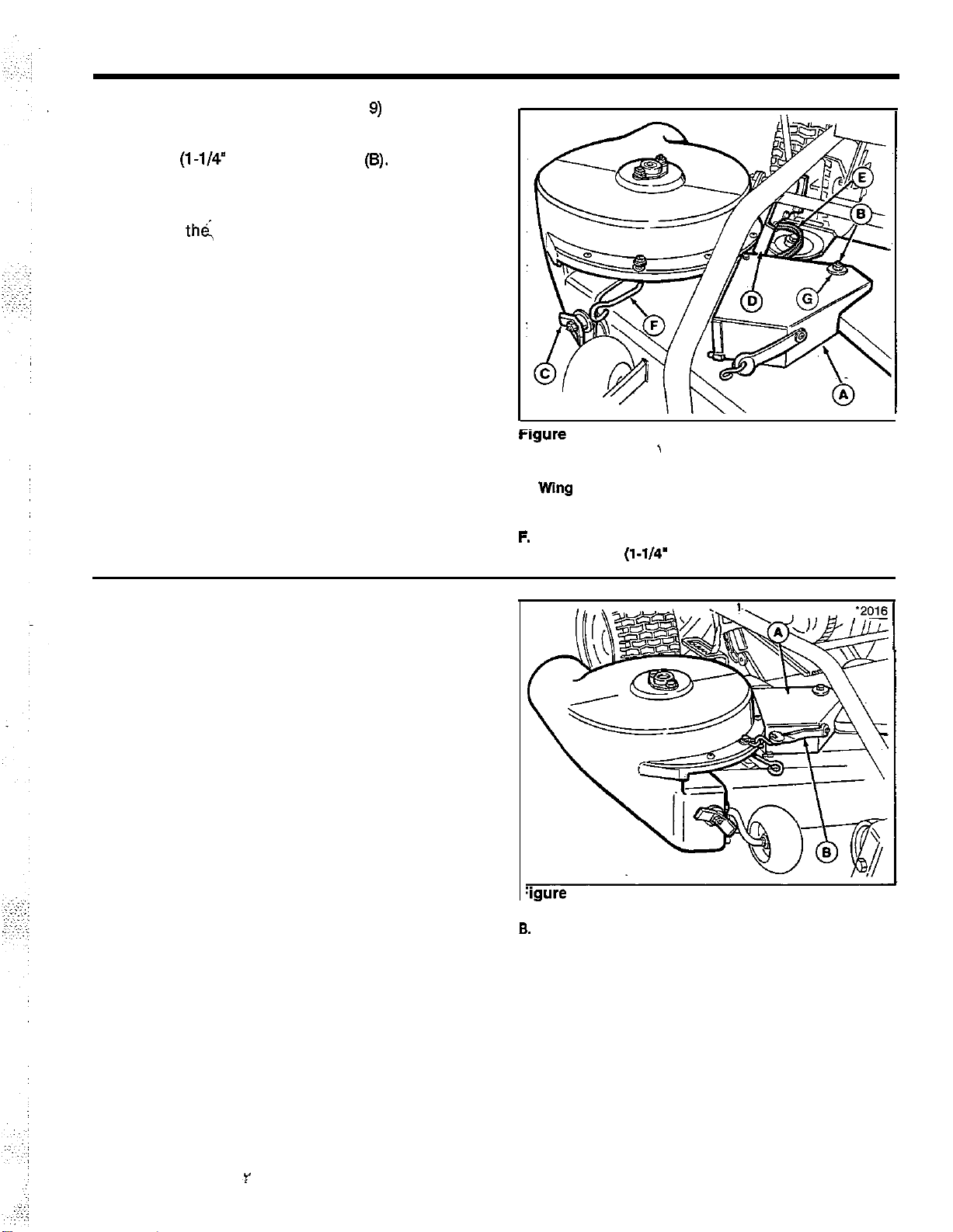

10. The baffle (A, figure 7) is installed in the blower

housing for use with 42” mower. For use with

48” mower, remove the baffleand install in holes

marked 48”.

I

Figure 7.

A Battle

: . . . . -..._

NOTE

On42”and 48” mowersthecapscrewinstalled

in next step is used in the hole occupied by a

screw held in place by a retaining nut. (This

screw secured the right-front corner of the

arbor cover.) Remove this screw(s) from

mower deck by tapping out with a hammer or

prying off the retaining nut.

11. Install the pulley cover (B, figure 8) with

hardware shown, items E through M. (Figure 8

shows blower housing but it is not installed at

this point of the procedure.)

In

A. Blower Housing

q

. Pulley Cover

C. Hook

D. Clip

E.

Capscrew

F. Washer,

G. Large Washer, 5/16

H. Spacer

I.

Lockwasher, S/16

J. Nut. 506

K.

La&

L. Large Washer, 5/16

M. Locknut, S/16

N. Wing Nut

5

Washer, S/16

5116

I

12. Install wing nut (D, figure 9) as follows:

a. Remove existing hardware from front end of

stone guard.

b. From inside deck, install new

5/16-18 x

carriage bolt (F, figure 9). Then install the cup

(A), 5/16 lockwasher (6). and

506

Tighten the nut.

c. Thread the wing nut (D) far enough onto the

screw so that the 5/16 locknut (E) can be

threaded on flush with the end of screw.

2-l/4

nut (C).

Figu’ie

9.

A. cup

q . Lockwasher,

C. Nut.

5116

5116

Q. Wing Nut

E. Lrxknut,

F. Carriase Bolt

5116

13. Install the new baffle (A, figure 10) in deck on

stone guard using existing hardware. Hardware

may be installed with nut to inside or nut to

outside.

Figure 10.

A. Battle

B. Carriage Bolt

C. Mower Discharge

14. Install the blower assembly as follows:

a. Pivot cover (B, figure 8) away to expose the

arbor.

b. Align the notch (G, figure 11) with spaceron

arbor bracket. Align spacer(C) with notch

(C,

figure 2) on arbor bracket. Slide theassembly

into place as shown in figure 13, while

aligning front notch between cup and wing

nut (D, figure 13). Tighten wing nut.

Figure 11.

A. Blower Drive Belt

B. Idler Pulley C. Space

D. Belt Retainer

E. Baffle

F. Driven Pulley

G. Notch

Omening

Hdok

Over Stone Guard

B&e

6

6

c. Place mower in low cut position. Raise the

flap (A, figure 12) and push on the belt

retainer (E) to obtain slack in the belt. Install

the blower drive belt (D) in the top groove of

the pulley(B).

d. Rotate the pivoting cover (A, figure 13) into

place and attach the hook (B) to the clip (C)

on the housing.

Figure 12

A. Flap

6. Pulley

c.

Ben

D. Drive Belt

E. Belt

Retainer

\

Figure 13.

k

pdley Cover

9.

Hook

C. Clip

D. Wing Nut

7

Installation - Front Cut Riders

NOTES

1. Two spacers are packaged with the turbo

blower. Installation on the Front-Cut Rider

requires use of the

The

4-l/16”

2. The replacement right hand belt cover (seestep

15),along

for the right hand idler pulley (see step

packaged with the collection system.

INSTALLATION

1. Remove right hand mower belt cover by

removing flat washer and flange nut (A) and

front taptite screw (B). Loosen hardware at

center location (C). Belt cover can bediscarded

as new belt cover and arbor cover will replace

original cover. Save all hardware for installing

new cover.

2. Remove the deflector mounting hardware and

reinstall in deflector for future use. Deflector

must be reinstalled if turbo blower is removed

from mower deck.

spacer will not be used.

with

l/2”

spacer (see step 14).

thenew3/8-16x2-1M”capscrew

4)

is

Figure 1. (Later

A. Flange Nut

B. Tapttle Screw

C. Mounting Hardware - Center Location

Mode\1

Shown)

WARNING

e

Use caution when moving spring-loaded idler

pulley. Spring tension isstrong. Do not remove

belt from spring-loaded idler pulley. Remove

belt from left and right hand pulleys.

I

3. Pull spring-loaded idler pulley away from belt

and remove belt from right hand arbor pulley

and idler pulley.

4. Remove the idler pulley

from the top) and install new 3/8-16 x

capscrew

mounting hardware may need to be loosened to

install 2-l/4”

existing flat washer

existing flat washer(B),

(D) to secure capscrew. Install large washer(E)

onto capscrew.

nut (D), and large washer(E) are packaged with

the collection system.

Existing flange nut will be used in step 15 to

secure new belt cover.

from the bottom. Pulley bracket

capscrew

(8)

Capscrew

NOTE

capscrew

(A) from bottom. Install

on top of bracket, pulley,

lockwasher(C),and

(A), lockwasher (C),

(installed

2-114”

nut

,

F

igure 2.

A.

2-114” Capscrew

B. Flat

C.

D. Nut

Washer (Existing)

Lockwasher

E. Large Flat Washer,

13/X? x l-l/2X 118

-

Pulley

I

6.

Remove the capscrew, lockwasher, and flat washer

securing right hand arbor pulley. Retain the washers

for reinstallation (step 9). Use a wood block to

prevent blade from turning.

SunRunnerNanguard

6. On early models without bet stop (A, figure 3)

remove two self-tapping screws from arbor and

install two

Parts will be installed on these capscrews in steps 7

and 8 as shown in figures 3 and 4.

7. Install the bracket (F, figure 4) with hardware as

shown in figures 3 and 4. On early models, install the

rear belt stop (C) facing the inside of mower deck as

shown in figure 4. Use washers (B & D) and

lo&washer (H) only for securing belt stop (C) on

early models. Use jam nut at locations A and E.

8.

On early models, install the front belt stop (D, figure

3) onto front

washer,lockwasher,andnut.Tightensnugonly.The

beL

stop should face the inside of mower deck as

shown in figure 3.

.5/l

6-18 x

Models

l-1/2”

capscrew

capscrews (A, figure 3).

(installed in step 6) with

Figure 3. (Early Model)

A.

capscrews, l-112’

B. Rear Mounting Bracket

Figure 3A. (Later Model)

A. Ben Stop (Existing)

B. Rear Mounting Bracket

C. Rear Belt Stop

D. Front Belt

Stop

FCll3OO Models

6. On later models with

figure

3A), it is not necessary to change capscrews

as new belt stops are not required.

7. install the bracket (F, figure 4) with hardware as

shown in figure 3A and 4. Use

4) to secure bracket (F).

factoty-installed belt stop (A,

jamnuts (A & E, figure

9

Figure 4.

A. Jam Locknut,

B. Washer,

c.

Beit

stop

D. Washer,

E. Jam Locknuf

F. Arbor Bracket

5/16

5116

5116

5116

(A,

figure 3A).

G.

Capecrew, 6116-18 x l-112

H. Lockwasher, 5/16

I.

spacer

J.

Washer,

K. Screw, Self-Tapping, I/4-20

L. Left-Hand

spaal

Mtg. Hole

9.

Slip the mower drive belt (A, figure 5) around the

bottom groove of double-groove pulley (B).

Install pulley with hub down and secure with

new

7/l

6-14 x 2-l

/4”

capscrew (C) and washers

(D and E) removed in step 5. Make sure splines

arecorrectlyalignedand torquecapscrewto55-

60 ft. Ibs. Use a wood block to prevent the blade

from turning.

10. Reinstall the mower drive belt by pulling on the

spring-loaded idler pulley to provide slack in

belt. With belt installed, adjust the belt stops

l/18”

from belt and tighten mounting hardware.

11. The baffle (A, figure 6) is installed in the blower

housing for use with 42” mower. For use with

48” mower, remove the baff le and install in holes

marked 48”.

Figure 5.

A. Mower Belt

B. Double-Groove Pulley

C.

Capscrew, Z-114”

D. Lockwasher ,

E. Flat Washer

-

12. Install wing nut assembly as follows:

a. Remove existing hardware from front end of

stone guard.

b. From inside deck, install new

5/16-18x 2-l/4

carriage bolt (E, figure7) through deck, stone

.guard,

washer, and roller bracket. Then

install the large washer (A), lockwasher (F),

and nut (B).

c. Thread the wing nut (C) far enough onto the

screw so that the 5/16 locknut (D) can be

threaded on flush with the end of screw.

NOTE

On front-cut riders, do not install cup (G) onto

capscrew to retain blower housing. Cup is used only

for tractor applications.

IO

I

Figure

6.

A. Baffle

Figure 7.

A. Large Washer

B. Jam Nut,

C.

Wing

D. Locknut,

5/16

Nut

5116

E. Carriage Bolt

F.

Lockwasher

G. Cup

13. Install the new baffle (A, figure 8) in deck on

stone guard using existing hardware. Hardware

may be installed with nut to inside or nut to

outside.

14. On new arbor cover, install on top of weld

figure 9) the largest washer (B

spacer (C), lo&washer(D), and nut (Q as shown in

figures.

in next step).

15. On

reusing front taptite screw (G) removed in step 1.

Install flat washer (I) and flange nut

step 4) to secure belt cover. Tighten flat washer and

flange nut (H) loosened in step 1.

(Largeflatwasher(F) shownwillbeinstalled

2-l/2” idler cover bolt, install

l-i/Z”

O.D.),

beit

cover to deck

(J,

removed in

bolt

(A,

l/2’

H&k 8&fle

Over Stone Guard

‘igure 8.

a Baffle

s.

Carriage Bolt

C. Mower Discharge Opening

6

Figure 9.

A.

Weld Bolt

8. Large Washer,

C. Spacer,

D.

Lockwasher

E. Nut

F. Large Washer

0. Taptite

H. Center Hardware

I.

Flat Washer

J. Flange Nut

112”

Screw

11

I-112”

O.D.

16. Make sure that flat washer (F, figure 9) is on top of

spacer assembly and install new arbor belt cover (A,

figure 10) as shown in figure 10. Secure with flat

washer (l-1/4” O.D.) and locknut

should be free to pivot.

17. Install the blower assembly as follows:

a. Align th& notch on blower assembly with

spacer on arbor bracket. Align spacer on

blower assembly with notch on arbor bracket.

Slide the assembly into place as shown in

figure 10 while aligning front notch between

cup and wing nut. Tighten wing nut (C, figure

10).

b. Raise the flap (D, figure 10) and install the

blower drive belt (E) in the top groove of the

pulley. Push on lever (F) to provide slack to

install belt.

NOTE

On later models with single (front) belt stop,

belt stop must be on outside of both mower

belt and turbo belt.

(8).

Belt cover

Figure

10.

A. Arbor Cover

B. Locknut

C.

Wing

Nut

D. Flap

E. Blower Belt

F.

Lever

G. Rat Washer

(l-1/4’

’

O.D.)

18. With belt installed, pivot arbor cover (A, figure

11) into position as shown in figure 11. Secure

with rubber strap (B) to blower housing.

:igure

11.

A

Arbor Cover

8.

Rubber Strap

12

Operation

WARNING

A

For safety reasons, grass and debris should

not be removed from any

collection system until engine is shut off, key

removed, and all moving parts have stopped.

I

WARNING

A

Before raising cart or twin-bag cover, shut off

engine, remove key, and set parking brake.

OPERATING WITHOUT COLLECTION SYSTEM

part

of turbo or

BEFORE OPERATION

Clear the lawn of all sticks, stones, wire and other

debris which maybecaughtorthrown bythemower

blades.

Clean the tube with mild detergent (other products

may damage tube). The flow of grass can be seen

I

through the tube while moving.

Check grass condition. If wet, wait until later in the

day. If grass is wet plugging may occur.

For -efficient bagging, air circulation under the

mower deck, through the chute and into the bag is

very important. For this reason, you should remove

grass and debris from underside of mower deck,

discharge chute and cover.

The tube and elbow can be removed

for cleaning. ,

asan assembly

When blower assembly is removed

mower deck. the deflector must be installed as

described in this section.

1. To operate without the grass collection system,

remove the blower assembly by loosening the

front wing nut on blower housing and slipping

belt off of the pulley. Reinstall the mower

deflector (figure 1) and the original hardware.

Install two carriage bolts from bottom and install

washers and nuts (A). Install the front washers

(8) and nut (C). Be sure flat washers and

lockwashers are used at all three locations.

2. Pivotthecover(A,figure2)

and hook rubber strap into the notch (C) on the

arbor bracket.

overthearborpulley

from

1

1

Figure 1.

A. Nut

6. Washer

C. Nut

A. cover

S.

Rubber Strap

C. Notch

Figure 2. Front Cut Rider Shown

13

i

.:::).‘,:,::::

~._,,

,

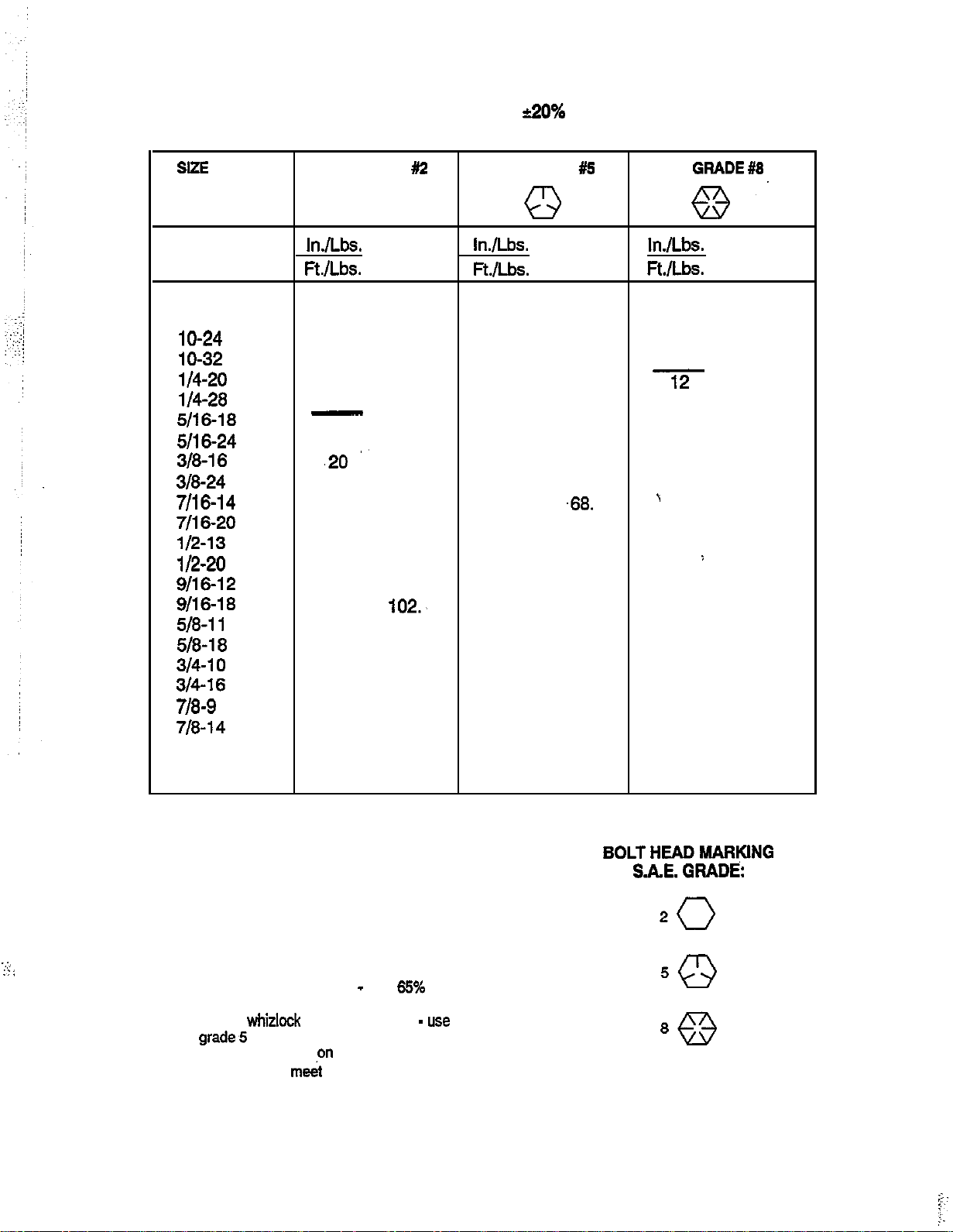

TORQUE SPECIFICATIONS FOR

STANDARD MACHINE HARDWARE

TOLERANCE

+200/o

SIZE

8-32

8-36

lo-24

lo-32

l/4-20

l/4-28

5116-18

5116-24

318-16

318-24

7116-14

7116-20

l/2-13

112-20

9116-12

9116-18

518-11

518-18

314-10

3/4-16

718-g

718-14

1-8

1-12

SAE GRADE #2 SAE GRADE

0

InJLbs.

Ft.lLbs.

Nm.

19

20

27

31 3.5

66

76

11

12

,,

,20

'23

30

35

50

55

65

75

90

100

160

180

140

155

220

240

In./Lbs.

Ft./Lb.s.

2.1

2.3

3.1

7.6

8.6

15.

16.3

27.2

31.3

40.8

47.6

68.

74.8

83.4

102.,

122.4

136.

217.6

244.8

190.4

210.8

299.2

326.4

Q

Nm.

30 3.4 41 4.6

31 3.5

43 4.9

49 5.5

-8 10.9

10 13.6

17 23.1 25 34.

19 25.8

30 40.8 45 61.2

35 47.6

50

55 74.8 80 108.8

75 102. 110 149.6

90 122.4

110 149.8

120 163.2

150 204. 220 299.2

180 244.8 240 326.4

260 353.6 386 525.

300 408. 420 571.2

400 544. 600 816.

440 598.4 660 897.6

580 788.8

640 870.4

A15

.68.

SAE

GRADE #8

8.

InAbs.

Ft.Rbs.

43 4.9

60 6.8

68 7.7

12

'

1,000 1,360.

16.3

14 19.

25 34.

50 68.

70 95.2

i

120 163.2

150' 204.

170 231.2

900 1,224.

Nm.

,

..:,,

:::

NOTE:

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread

forming screws, sheet metal screws and socket head

setscrews.

2. Recommended seating torque values for locknuts:

a. For prevailing torque locknuts

torques.

b. For flange whizlock nuts (and screws) -

of grade,5 torques.

3. Unless otherwise noted

torque values must meet this specification.

-

use 65% of grade 5

usa

135%

on assembly drawings all

BOLTHEADMARKING

S.A.E.GRADE:

20

Loading...

Loading...