Page 1

i

;

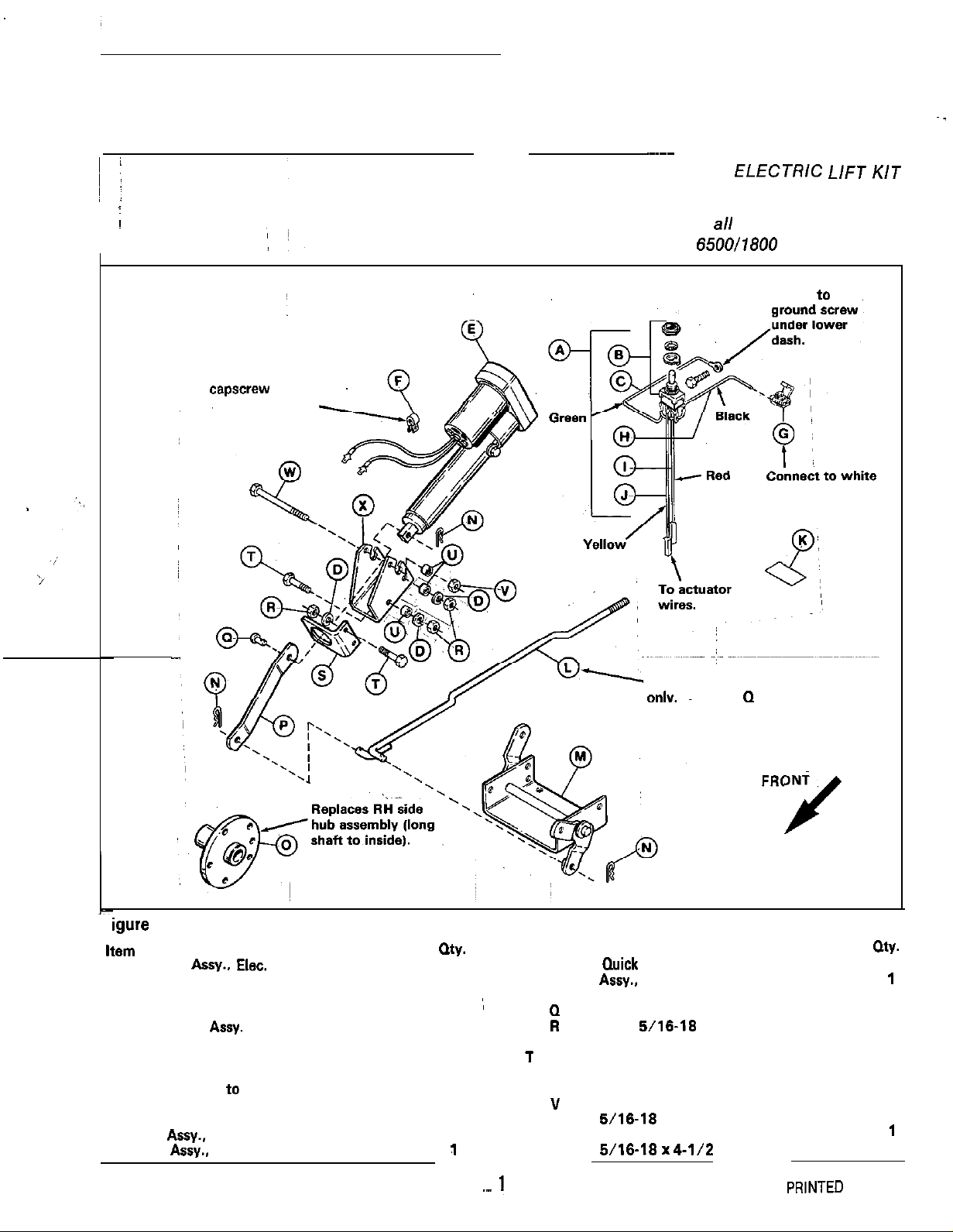

KIT PARTS

Mount to top

capscrew

support bracket.

on lift lever

~

~

INSTALLATION.,

~~~~~

INSTRUCTIONS

ELECTRlC

MFG. NO. 1691531

For use with a// mounted attachments

on

6500/1800 Series Tractors

Mount to

ignition wire.

L//=T KIT

~-

Fi

igure 1. Kit Parts

Item

A Harness

8 Switch, Electric 171883

C Wire, Switch to Ground

D Lockwasher

E Power Lift

F Clamp, Insulated 826818

G Connectors, Self-Stripping 1606761

H Wire, Switch to Ignition

I

J Wire, Switch to Lift

K Decal, Lift Switch 1669833

L Rod

M Arm

Description Part No.

Assy.. Elec.

Assy.

Wire, Switch to Lift 1702077

Assy.,

Lift 1701680

Assy..

lift 1701808

Lift 1702082

171868

1817366

1667764

1702075

1702076

my.

Used for rear attachments

onlv.

Use item Q for mowers.

FRONT

J

Item Description

1

1

1

;

4

1

1

1

1

1

1

1

1

1

1,

.-

N Pin,

0 Hub

P Link, Actuator

Q Pin, Pivot

R

S Bracket, Actuator, Front

1 Capscrew, Hex Hd..

u Spacer

”

W Capscrew, Hex Hd..

Quick

Assy..

Wheel

Nut, Hex.

Nut. Hex Lock,

5/16-18

5/16-18x 1

6/16-18

5,‘16-18 x

4-l/2

Part No.

1960033 3

1701914

1701881 1 ~

102004 2

1917372 4

1701878 1

1921333 4

1665699 3

1823362 1

1925892

FORM 1702100

PR,NTED IN U.S.A.

oty.

1

1

882

Page 2

WARNING

A

Before installing the kit or making any adjustments:

disengage the PTO; set the parking brake; stop the

engine and remove the key.

WARNING

A

When disconnecting the battery cables, always

disconnect the negative cable first. When

connecting cables, always connect the negative

cable last. The positive terminal can easily be

shorted to the frame with

Do not touch any wires or electrical components

such as the solenoid, unless the battery cables

INSTALLATION

1. Park tractor on flat, level surface. Turn tractor off.

Disengage PTO, and allow all moving parts to stop.

Engage the parking brake.

,2.

Disconnect the battery cables and position away

from terminals.

a

tool if this is not done.

are

Remove rear right-hand wheel assembly.

Remove tive

secure kit hub assembly (0, figure 1) to wheel. Do not

install on tractor.

Prepare template (provided on last page) by cutting

out all dashed areas. Use this template to drill five

1

l/32”

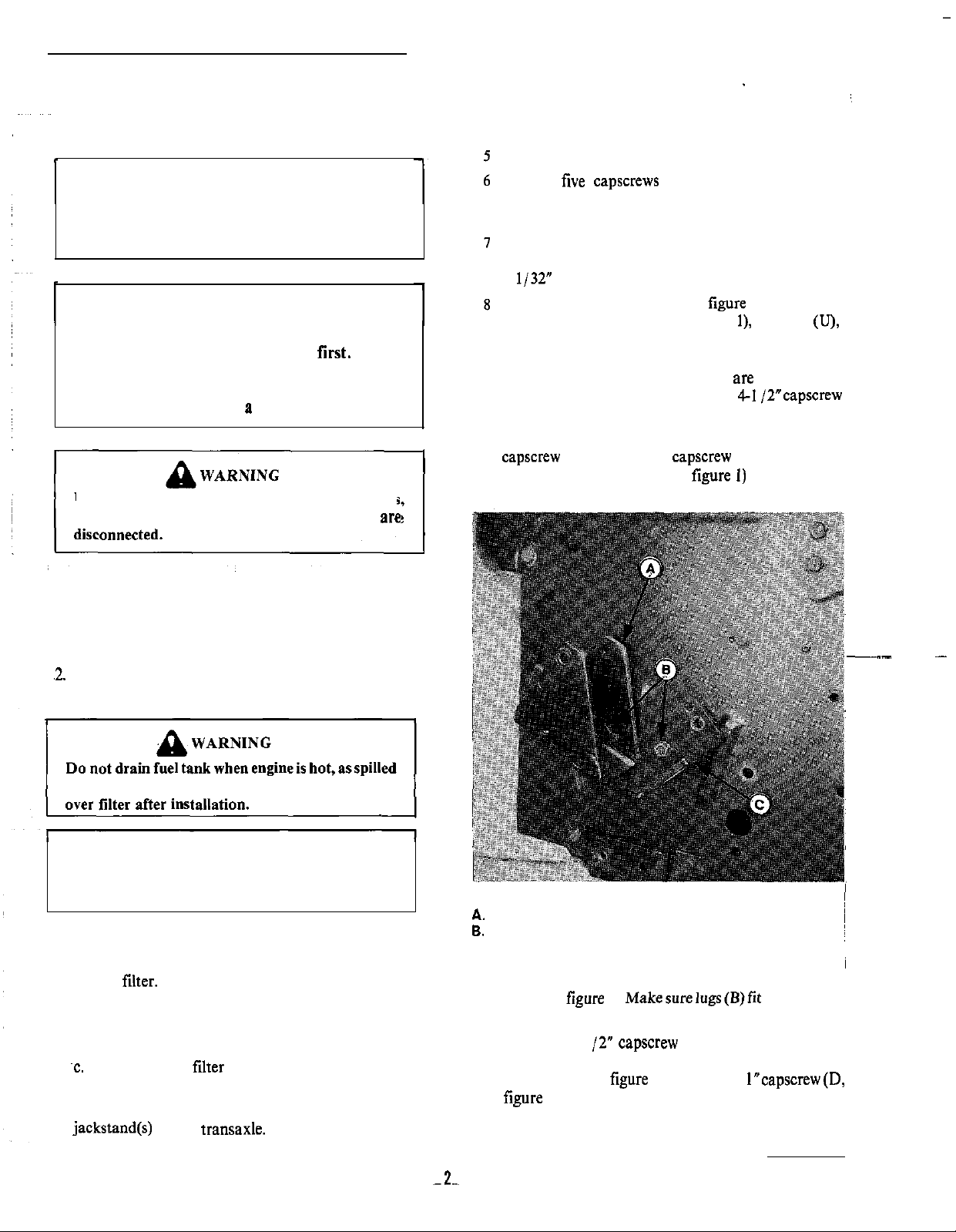

Install rear actuator bracket (X, figure 1 or A, figure

2) with two capscrews (T, figure l), spacers (U),

lockwashers (D), and nuts (R). Install bolts from

outside in, putting spacers between bracket and

wrapper. Lockwashers and nuts

inside of wrapper. Do not install the

(W) at this time.

9. Install front bracket (C, figure 2) with bottom

capscrew (B) only. Install capscrew from inside out.

,

Secure with lockwasher (D, figure 1) and nut (R).

capscrews

holes in wrapper.

from wheel assembly and

are installed on

4-I

/2”capscrew

.-

gasoline may ignite. Insure clamps grip hose firmly

WARNING

A

Handle gasoline with care. It is highly flammable.

Use an approved gasoline container.

3. Drain the fuel tank as follows.

a. Place an approved gasoline container below the

filter.

fuel

b. Use a pliers to spread the fuel filter clamps and

slide away from filter. Do not spread more than

necessary.

~c.

Pull hoses off filter and allow gasoline to drain

into container.

4. Raise rear right-hand side of tractor up and place

jackstand

under transaxle.

Figure 2. Bracket Installation

A.

Rear Bracket

6.

1” capscrews

C. Front Bracket

10. Insert cylinder (A, figure 3) through brackets as

shown in

rear bracket slots.

11.

Install top 4-l /2” capscrew (C) on rear bracket (with

spacer between bracket and wrapper) and secure

with locknut (V, figure I). Install top l”capscrew(D,

figure 3, from inside wrapper) in front bracket and

secure with lockwasher and nut.

figure 3.

Makesurelugs(B)fit

-,2.-

securely into

Page 3

Figure 3. Cylinder ~lnstallation

A. Cylinder

6.

Lugs

c.

4-l/2” Capscrew

D.

1”

Capscrew

(from inside out)

12. Remove the manual lift lever as follows:

Figure 5. Electric Lift Lever

A. Lift Lever Bracket

S.

Bracket Support

c. capscrew

D.

Wire Clip

E.

Actuator Link

F.

Clevis

G. Spring Clip

Pin

a. Remove the two capscrews and lockwashen (B,

figure 4). Leave the retaining nuts in place.

b. Remove the lever by removing four

lockwashers and nuts (A). Save the hardware for

reinstallation.

!

capscrews,

,~~.

Reinstall bracket support (B), reusing existing

14.

hardware. In top

capscrew (C), install clip (F, figure

or D, figure 5). Clip and wiring are shown installed in

figure 5.

15.

Mount actuator link (E) between cylinder and new

lift lever as shown in figure 5. Install clevis pins

(F)

..~

I

from outside and spring clips (G) on inside. When

alignment is correct, tighten all mounting hardware.

NOTE

For rear-mounted attachments, lift rod (L, figure 1)

.

must be installed. Refer to last section of this

instruction sheet.

SWITCH INSTALLATION

16. A 31/64” hole must be drilled in the lower dash to

mount the switch (see figure 6). Measure two inches

Figure 4. Manual Lift Lever

A. Capscrews, Lockwashers and Nuts

B.

Capscrews and Lockwashers

~

~

down from upper dash and draw a line. Then,

measure three inches from right side of lower dash

and draw a vertical line. Drill the hole at point

where

these two lines meet (figure 6).

c. Remove lift lever bracket support (B, figure 5).

Retain hardware for

reinsta%nl

13. Install new electric lift. lever bracket (A) reusing

existing hardware (mounted in same location).

Page 4

Figure 6. Tractor Dash

A. Wood Block:

) 17.,

Pry off the throttle control knob by using a claw in kit.

hammer and block of wood as shown in figure 6.

lg.,

Remove throttle cable from left-side engine clamp.

Loosen

capscrew and washer that secures throttle

6.

Hammer C. Screws

~

~ cable to intake manifold. Note pinch mark on cable

‘,

before removing from under capscrew. Cable must ,~

~~‘~~

be reinstalled in same position for correct RPM

settings. Remove cable from engine.

19. Remove nut (A, figure

7).

flatwashers (B) and

capscrew (C) securing steering wheel to shaft. Pull

steering wheel off shaft.

Figure 7. Steering Wheel

A,

5/16

Locknut

6. l/4

Flat Washers

C. 5116 x

D. Steering Wheel

E. Cap

3-l/2

Capscrew

-4

20. Remove the upper and lower dash hardware as

follows.

a. Remove the

two

screws (C, figure 6) and washers.

b. Raise the hood and loosen the two screws, plain

washers, dished washers and nuts from front side

of dash (see figure 8).

c. Remove four

capscrews

and washers securing

lower dash.

d.

Both dashboards can now be lifted up for access to

wiring.

21. Remove the ignition switch by removing nut. Retain

lockwasher for reinstallation.

22.

Reach thru the hole in top of lower dash and install

the switch (A, figure I). Position the switch so that

slot in threads is up. From outside the dash, place the

washers (B) on switch, aligning tab washer in slot in

threads. Install and tighten the nut securely.

23. Connect black switch wire to white wire from

ignition switch with connector (C, figure 1) provided

24.)

Lift up lower dash and locate taptite screw securing

two

black ground wires. Route green wire (C, figure.

1~

1) from switch and ground under this screw.

25. Route the yellow and red wires from switch down

behind the steering shaft. Wires should follow wiring

harness and be routed cut lower dash cutout,

underneath shift quadrant panel and thru square,

hole for seat latch. Refer to figure 5. Wires should

then be attached to wire clip (D, figure 5).

26.

Connect the yellow wire to yellow wire from cylinder.

Connect the red wire to the red wire from cylinder.

27. This completes installation of the kit. Make the

following test to see if installation is correct.

a. Reinstall ignition switch with lockwasherand nut.

b. Connect the battery cables - negative cable last.

c.

Turn the ignition switch to ON.

d. Flip the lift switch up, the lift arm should go back.

e.

Flip the lift switch down, the lift arm should go

forward.

f. If switch does not check OK, disconnect the

battery cables, Then go thru the instructions and ~

make sure all connections are tight.

g. Reconnect the battery cables to perform above

test again. Before proceeding with following

instructions, disconnect the battery cables.

28. Reinstall lower dash with four capscrews and

washers. Position the upper dash over the fuel tank.

Install the original hardware (figure 8).

:

~

‘---

:

:

:

Page 5

REAR-MOUNTED ATTACHMENTS

-

LIFT ROD INSTALLATION

Lift rod (L, figure 1) is used only for rear mounted

attachments. To install, remove bottom clevis pin (Q)

and install lift rod (A, figure 9) to actuator link(B) and lift

arm (C). Secure with clevis pins (D) as shown.

Figure 8. Upper

UaSn

I _

29. Align the steering wheel and push down onto shaft.

30. Reinstall capscrew (C, figure

7),

flat washers, and

locknuts to secure steering wheel. Torque nut to 10 ft.

Ibs.

31. Reconnect throttle cable to engine and position

under manifold

capscrew and washer. Cable must be

in original position for correct RPM setting. Tighten

capscrew and place cable in left-side engine clamp.

32. Push throttle control knob back on the lever. Tap

knob with a hammer to seat.

33.

Make sure the fuel lines are connected securely to the

fuel filter with the clamps.

34. Install the rear right-band wheel assembly.

35. Raise rear of tractor up and rembve

jackstand

36. Connect the battery cables - negative cable last.

37. Apply the decal to the right side of the switch.

38. This completes the installation.

I

I

Figure 9. Lift Rod

A. Lift Rod

6.

Actuator Link

C. Lift Arm

D.

Spring Clips

~

5-.

Page 6

.-.

1

/

! ‘1

\

./

\

\

\

\

\

\

I

Align with holes In rlght

hand side of axle support;

wrapper - two places

(remove bolts and reinstall

If

necessary).

I

\

1

\

\

I

1

\

I

\

\

\

Al

i

I

I

t

t

I

:---m

CUTOU’r

(TEMPLATE ONLY)

ON DOTTED LINE.

----I

f ,’

i

I

1

I

I

---_

--I’

’ Align with holes In rlght

“hand side of axle support

I

wrapper -

I’

I’

(remove bolts and

reinstall If

l

two places

necessary).

Loading...

Loading...