Page 1

Model No. 1668-0 (5,500 Watt AC Generator) Manual No. 190313GS Revision 3 (01/19/2004)

5500 Watt

Generator

Questions? Help is just a moment away!

Contact the Local Snapper Service Center

Web: www.snapper.com or www.briggsandstratton.com

Owner’s Manual

Page 2

2

Snapper 5500 Watt Generator

TABLE OF CONTENTS

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Know Your Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Schematic/Wiring Diagram . . . . . . . . . . . . . . . . . . . . . 14-15

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Last Page

EQUIPMENT

DESCRIPTION

Read this manual carefully and become

familiar with your generator. Know its

applications, its limitations and any hazards

involved.

This manual describes an engine–driven, revolving field,

alternating current (AC) generator designed to supply

electrical power for operating compatible electrical lighting,

appliances, tools and motor loads.The generator’s revolving

field is driven at about 3,600 rpm by a single-cylinder engine.

CAUTION! DO NOT exceed the generator’s

wattage/amperage capacity. See “Don’t Overload

Generator” on page 11.

Every effort has been made to ensure that information in this

manual is accurate and current. However,we reserve the

right to change, alter or otherwise improve the product and

this document at any time without prior notice.

The Emission Control System for this generator is warranted

for standards set by the Environmental Protection Agency. For

warranty information refer to the engine owner’s manual.

SAFETY RULES

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

Hazard Symbols and Meanings

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark arrester,

it must be maintained in effective working order.

Fire

Explosion

Toxic Fumes

Hot Surface

Electrical Shock

Electrocution

Electrical Shock

Explosive Pressure

Chemical Burn

Page 3

3

Snapper 5500 Watt Generator

• DO NOT allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

• Wear protective goggles, rubber apron, and rubber gloves.

Storage batteries give off explosive hydrogen gas

during recharging.

Hydrogen gas stays around battery for a long

time after battery has been charged.

Slightest spark will ignite hydrogen and cause

explosion.

You can be blinded or severely injured.

Battery electrolyte fluid contains acid and is

extremely caustic.

Contact with battery fluid will cause severe

chemical burns.

DANGER

• Operate generator ONLY outdoors.

• Keep at least 2 feet of clearance on all sides of generator for

adequate ventilation.

• DO NOT operate generator inside any building or enclosure,

including the generator compartment of a recreational vehicle (RV).

Running generator gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide will cause nausea,

fainting or death.

DANGER

• When using generator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

• Use a ground circuit fault interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT operate generator in the rain.

• DO NOT handle generator or electrical cords while standing

in water, while barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or

service generator.

Generator produces powerful voltage.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

DANGER

WHEN ADDING FUEL

• Turn generator OFF and let it cool at least 2 minutes before

removing gas cap.Loosen cap slowly to relieve pressure in tank.

• Fill fuel tank outdoors.

• DO NOT overfill tank.Allow space for fuel expansion.

• Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which causes fuel

to spill.

• This generator is not for use in mobile equipment or marine

applications.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• This generator does not meet U. S. Coast Guard Regulation

33CFR-183 and should not be used on marine applications.

• Failure to use the appropriate U. S. Coast Guard approved

generator could result in bodily injury and/or property

damage.

WARNING

Page 4

Snapper 5500 Watt Generator

4

• DO NOT tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

speed.

• DO NOT modify generator in any way.

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

CAUTION

• See “Don’t Overload Generator” on page 11.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator

before stopping generator.

Exceeding generator’s wattage/amperage capacity can

damage generator and/or electrical devices connected

to it.

CAUTION

• Use generator only for intended uses.

• If you have questions about intended use, ask dealer or call

1-800-317-7833.

• Operate generator only on level surfaces.

• DO NOT expose generator to excessive moisture, dust, dirt,

or corrosive vapors.

• DO NOT insert any objects through cooling slots.

• If connected devices overheat, turn them off and disconnect

them from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

Improper treatment of generator can damage it and

shorten its life.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

GENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

Unintentional sparking can result in fire or

electric shock.

WARNING

• DO NOT touch hot surfaces.

• Allow equipment to cool before touching.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

WARNING

Page 5

Snapper 5500 Watt Generator

5

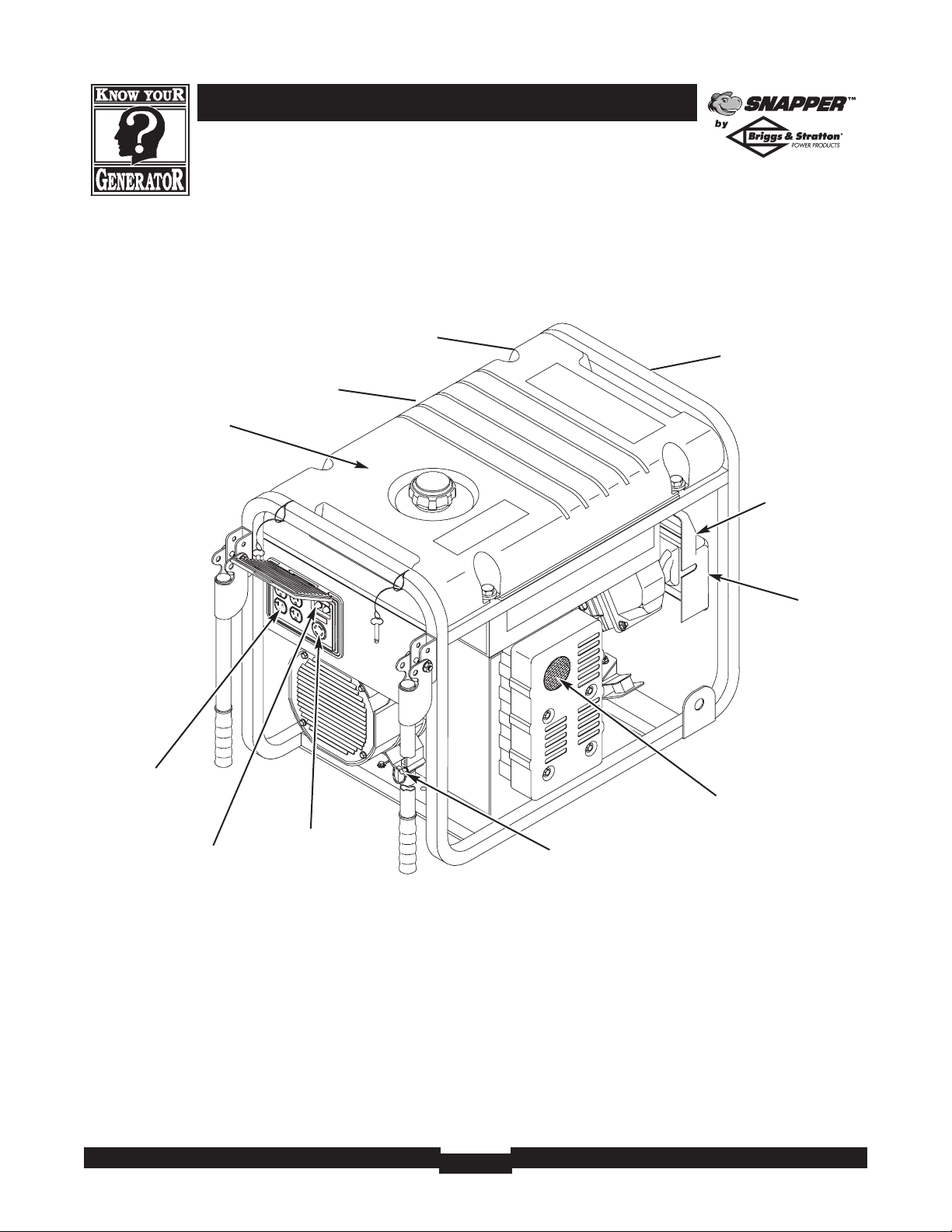

120 Volt AC, 20 Amp, Duplex Receptacles — May be

used to supply electrical power for the operation of

120 Volt AC, 20 Amp, single phase, 60 Hz electrical, lighting,

appliance, tool and motor loads.

120/240 Volt AC, 30 Amp Locking Receptacle — May

be used to supply electrical power for the operation of

120 and/or 240 Volt AC, 30 Amp, single phase, 60 Hz

electrical, lighting, appliance, tool and motor loads.

Air Cleaner — Uses a dry type filter element to limit the

amount of dirt and dust sucked into the engine.

Choke Lever — Used when starting a cold engine.

Circuit Breakers (AC) — Push to reset circuit breakers are

provided to protect the generator against electrical overload.

Fuel Tank — Capacity of seven (7) U.S.gallons.

Grounding Fastener — If required, please consult a

qualified electrician, electrical inspector, or local agency

having jurisdiction.

Oil Fill — Add engine oil here.

Recoil starter — Used to start the engine.

Rocker Switch — Set this switch to "On" before using

recoil starter. Set switch to "Off" to switch off engine.

Spark Arrester Muffler — Exhaust muffler lowers

engine noise and is equipped with a spark arrester screen.

KNOW YOUR GENERATOR

Read this owner’s manual and safety rules before operating your generator.

Compare the illustrations with your generator, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

120 Volt AC, 20 Amp

Duplex Receptacles

Fuel Tank

Choke Lever

Recoil Starter

Rocker Switch

(on engine shroud)

Circuit

Breakers (AC)

120/240 Volt AC,

30 Amp Receptacle

Spark Arrester Muffler

Air Cleaner

Grounding Fastener

Oil Fill

Page 6

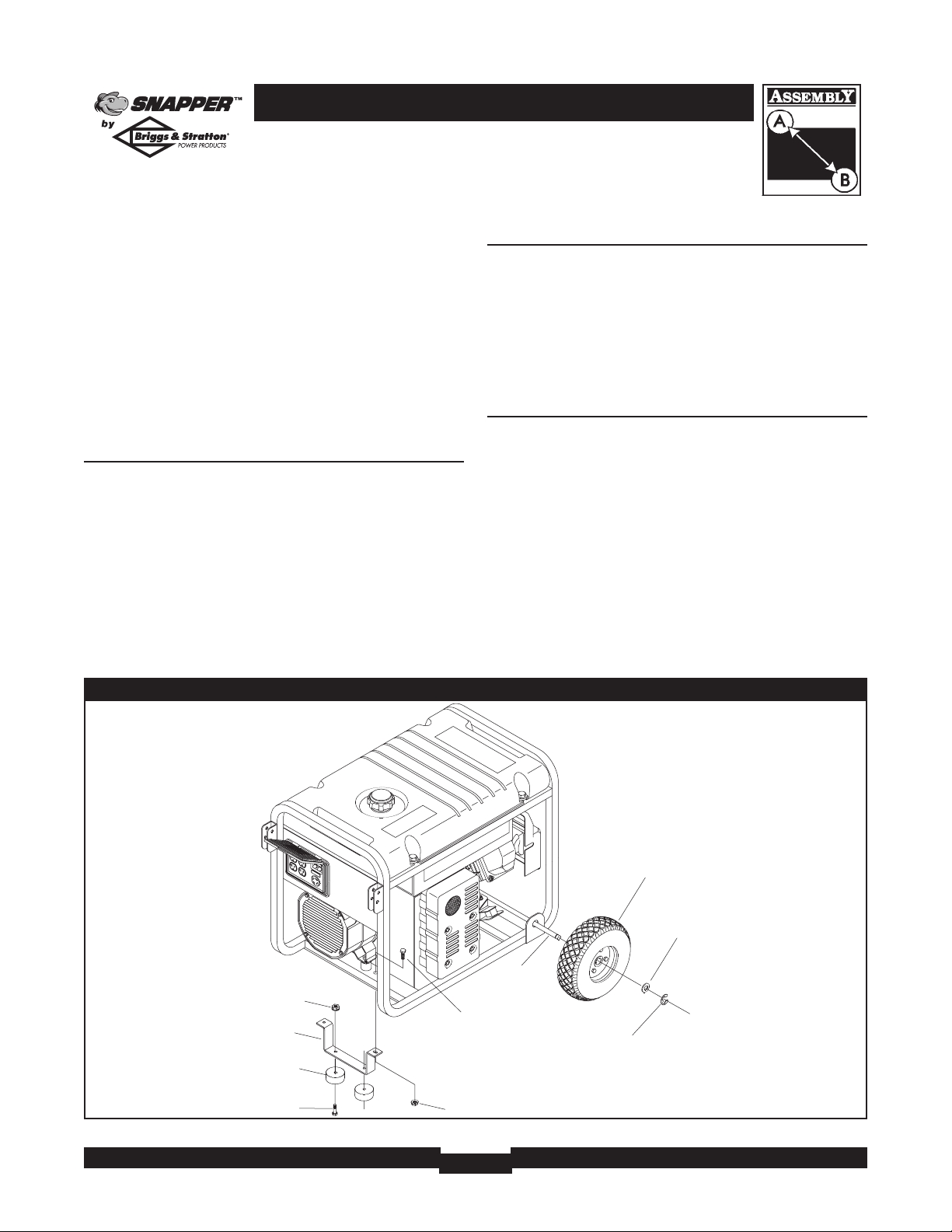

ASSEMBLY

Your generator requires some assembly and is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, contact the local Snapper service center.

IMPORTANT: Any attempt to run the unit before it has

been serviced with the recommended oil will result in an

engine failure.

Remove Generator From Carton

• Set the carton on a rigid flat surface with “This Side Up”

arrows pointing upward.

• Carefully open the top flaps of the shipping carton.

• Cut down corners at one end of carton from top to

bottom and lay that side of carton down flat.

• Remove all packing material, carton fillers, etc.

• Remove the generator from the shipping carton.

Carton Contents

Check all contents. If any parts are missing or damaged,

contact the local Snapper service center.

• The generator

• Generator and engine owner’s manuals

• Locking 30 Amp plug

• Engine oil

• Wheel kit

Install Wheel Kit

The wheel kit is designed to greatly improve the portability

of your generator.

NOTE:Wheel kit is not intended for over-the-road use.

You will need a socket wrench with 1/2" or 13mm sockets

and a needle-nose pliers to install this kit.

Refer to Figure 1 and install the wheel kit as follows:

1. Place the bottom of the generator cradle on a flat,

even surface.Temporarily place unit on blocks to ease

assembly.

2. Slide axle through both axle mounting brackets on

cradle frame, as shown in Figure 1.

3. Slide a wheel over the axle.

Support Leg

Hex Nut

Axle

Flat Washer

Wheel

E-Ring

Figure 1 — Install Wheel Kit

Cap Screw

Hex Nut

Cap Screw

Vibration Mount

Use existing hardware

to attach left side of

support leg to unit

Snapper 5500 Watt Generator

6

Page 7

Snapper 5500 Watt Generator

7

NOTE: Be sure to install both wheels with the air

pressure valve on the outboard side.

4. Place the e-ring onto the groove in the axle.You may

add the flat washer if desired.

NOTE: Use retaining pins instead of e-clip, if applicable.

5. Place one end of the needle nose pliers on the bottom

of the axle and the other end of the pliers on top of

the e-ring. Seat the e-ring by pressing the pliers closed.

6. Repeat step 3 through 5 to secure second wheel.

7. Remove the temporary blocks.

8. Attach the vibration mounts to the support leg with

30mm capscrews and lock nuts.

9. To aid support leg assembly, rest generator on cradle,

engine end down. Remove the existing hardware from

the left unit vibration mount with 13mm wrench. Use

the same hardware to attach the support leg.

10. Attach the other side of the support leg with a 20mm

cap screw and lock nut. Rest generator on wheels and

support leg.

11. Check each fastener to ensure it is secure and the

tires are inflated between 15-40 PSI.

BEFORE STARTING THE

ENGINE

Add Engine Oil and Fuel

• Place generator on a level surface.

• Refer to engine owner’s manual and follow oil and fuel

recommendations and instructions.

NOTE: Check oil often during engine break–in. Refer to

engine owner’s manual for recommendations.

NOTE:The generator assembly rotates on a prelubricated

and sealed ball bearing that requires no additional

lubrication for the life of the bearing.

CAUTION

• Refer to engine manual for oil and fuel fill information.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

Any attempt to crank or start the engine before it has

been properly filled with the recommended oil will result

in equipment failure.

Page 8

Snapper 5500 Watt Generator

8

USING THE GENERATOR

System Ground

The generator has a system ground that connects the

generator frame components to the ground terminals on

the AC output receptacles.The system ground is connected

to the AC neutral wire (see “Equipment Description”,

earlier in this manual).

Special Requirements

There may be Federal or State Occupational Safety and

Health Administration (OSHA) regulations, local codes, or

ordinances that apply to the intended use of the generator.

Please consult a qualified electrician, electrical inspector, or

the local agency having jurisdiction.

• In some areas, generators are required to be registered

with local utility companies.

• If the generator is used at a construction site, there may

be additional regulations which must be observed.

Connecting to a Building’s Electrical

System

Connections for standby power to a building’s electrical

system must be made by a qualified electrician.The

connection must isolate the generator power from utility

power, and must comply with all applicable laws and

electrical codes.

OPERATING THE

GENERATOR

Starting the Engine

Disconnect all electrical loads from the generator. Use the

following start instruction steps by numerical order:

1. Make sure unit is on a level surface.

IMPORTANT: Failure to start and operate unit on a level

surface will cause the unit not to start or shut down during

operation.

2. Turn the fuel valve to the “On” position (Figure 2).

3. Start engine according to engine owner’s manual.

NOTE:If engine starts after 3 pulls but fails to run, or if

unit shuts down during operation, make sure unit is on a

level surface and check for proper oil level in crankcase.

This unit may be equipped with a low oil protection device.

See engine manual.

Fuel Valve is shown

in the On position

Figure 2 — Fuel Valve

• When using generator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

• Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• DO NOT touch bare wires or receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT operate generator in the rain.

• DO NOT handle generator or electrical cords while standing

in water, while barefoot, or while hands or feet are wet.

• DO NOT allow unqualified persons or children to operate or

service generator.

Generator produces powerful voltage.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

DANGER

• See “Don’t Overload Generator” on page 11.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator

before stopping generator.

Exceeding generator’s wattage/amperage capacity can

damage generator and/or electrical devices connected

to it.

CAUTION

Page 9

9

Snapper 5500 Watt Generator

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Plug in and turn on the desired 120 and/or 240 Volt AC,

single phase, 60 Hz electrical loads.

• DO NOT connect 240 Volt loads to the 120 Volt duplex

receptacles.

• DO NOT connect 3–phase loads to the generator.

• DO NOT connect 50 Hz loads to the generator.

• DO NOT OVERLOAD THE GENERATOR. See

“Don’t Overload Generator” on page 11.

Stopping the Engine

1. Unplug all electrical loads from generator panel

receptacles. NEVER start or stop engine with electrical

devices plugged in and turned ON.

2. Let engine run at no-load for several minutes to stabilize

internal temperatures of engine and generator.

3. Turn engine off according to engine owner’s manual.

4. Move fuel valve to “Off” position.

COLD WEATHER

OPERATION

Under certain weather conditions (temperatures below

40°F [4°C] and a high dew point), your generator may

experience icing of the carburetor and/or the crankcase

breather system.

Build a structure that will enclose three sides and the top

of the generator:

1. Make sure entire muffler-side of generator is exposed.

Note generator may appear different from that shown

in Figure 3.

2. Ensure a minimum of two feet clearance between open

side of box and nearest object.

3. Face exposed end away from wind and elements.

4. Enclosure should hold enough heat created by the

generator to prevent problems.

Figure 3 — Permanent Cold Weather Shelter

Wind

• Operate generator ONLY outdoors.

• Keep at least 2 feet of clearance on all sides of generator for

adequate ventilation.

• DO NOT operate generator inside any building or enclosure,

including the generator compartment of a recreational vehicle (RV).

• Remove generator from shelter when temperature is above

40°F [4°C].

Running generator gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide will cause nausea,

fainting or death.

DANGER

Page 10

RECEPTACLES

120/240 Volt AC, 30 Amp, Locking

Receptacle

Use a NEMA L14–30 plug with this receptacle. Connect a

4–wire cord set rated for 250 Volt AC loads at 30 Amps (or

greater) (Figure 4).You can use the same 4–wire cord if you

plan to run a 120 Volt load.

This receptacle powers 120/240 Volt AC, 60 Hz, single

phase loads requiring up to 5,500 watts of power (5.5 kW)

at 30 Amps for 120 Volts or 240 Volts.The outlet is

protected by a push–to–reset circuit breaker.

120 Volt AC, 20 Amp, Duplex

Receptacles

Each duplex receptacle (Figure 5) is protected against

overload by a push–to–reset circuit breaker.

Use each receptacle to operate 120 Volt AC, single–phase,

60 Hz electrical loads requiring up to 2,400 watts (2.4 kW)

at 20 Amps of current. Use cord sets that are rated for

125 Volt AC loads at 20 Amps (or greater).

Snapper 5500 Watt Generator

10

Figure 5 — 120 Volt, 20 Amp Duplex Receptacle

Figure 4 — 120/240 Volt AC, 30 Amp Receptacle

4-Wire Cord Set

240V

120V

120V

W (Neutral)

X (Hot)

Y (Hot)

NEMA L14-30

Ground (Green)

• NEVER attempt to power a device requiring more

amperage than generator or receptacle can supply.

• DO NOT overload the generator. See “Don’t Overload

Generator”.

Receptacles may be marked with rating value greater

than generator output capacity.

CAUTION

Page 11

11

Snapper 5500 Watt Generator

DON'T OVERLOAD

GENERATOR

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items. This is

the amount of power your generator must produce to

keep your items running. See Figure 6.

3. Estimate how many surge (starting) watts you will

need. Surge wattage is the short burst of power

needed to start electric motor-driven tools or

appliances such as a circular saw or refrigerator.

Because not all motors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Example:

Total Rated (Running) Watts = 3075

Highest Additional Surge Watts = 1800

Total Generator Output Required = 4875

Power Management

To prolong the life of your generator and attached devices,

it is important to take care when adding electrical loads to

your generator.There should be nothing connected to the

generator outlets before starting it's engine.The correct

and safe way to manage generator power is to sequentially

add loads as follows:

1. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

NEVER add more loads than the generator capacity.Take

special care to consider surge loads in generator capacity,

as described above.

*Wattages listed are approximate only. Check tool or

appliance for actual wattage.

Tool or Appliance

Rated (Running)

Watts

Additional Surge

(Starting) Watts

Window Air

Conditioner

1200 1800

Refrigerator 800 1600

Deep Freezer 500 500

Television 500 Light (75 Watts) 75 -

3075 Total

Running Watts

1800 Highest

Surge Watts

Tool or Appliance

Rated*

(Running)

Watts

Additional

Surge

(Starting)

Watts

Essentials

Light Bulb - 75 watt

75

-

Deep Freezer

500

500

Sump Pump

800

1200

Refrigerator/Freezer - 18 Cu. Ft.

800

1600

Water Well Pump - 1/3 HP

1000

2000

Heating/Cooling

Window AC - 10,000 BTU

1200

1800

Window Fan

300

600

Furnace Fan Blower - 1/2 HP

800

1300

Kitchen

Microwave Oven - 1000 Watt

1000

-

Coffee Maker

1500

-

Electric Stove - Single Element

1500

-

Hot Plate

2500

-

Family Room

DVD/CD Player

100

-

VCR

100

-

Stereo Receiver

450

-

Color Television - 27”

500

-

Personal Computer w/17” monitor

800

-

Other

Security System

180

-

AM/FM Clock Radio

300

-

Garage Door Opener - 1/2 HP

480

520

Electric Water Heater - 40 Gallon

4000

-

DIY/Job Site

Quartz Halogen Work Light

1000

-

Airless Sprayer - 1/3 HP

600

1200

Reciprocating Saw

960

960

Electric Drill - 1/2 HP

1000

1000

Circular Saw - 7 1/4”

1500

1500

Miter Saw - 10”

1800

1800

Table Planer - 6”

1800

1800

Table Saw/Radial Arm Saw - 10”

2000

2000

Air Compressor - 1-1/2 HP

2500

2500

Figure 6 - Wattage Reference Chart

Page 12

Snapper 5500 Watt Generator

12

SPECIFICATIONS

Maximum Surge Watts . . . . . . . . . . . . . . . . . .8,500 watts

Continuous Wattage Capacity . . . . . . . . . . . .5,500 watts

Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0

Rated Maximum Continuous AC Load Current:

At 120 Volts . . . . . . . . . . . . . . . . . . . . . . . . .45.8 Amps

At 240 Volts . . . . . . . . . . . . . . . . . . . . . . . . .22.9 Amps

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–phase

Rated Frequency . . . . . . . . . . . . . . . . . . . . . . . . .60 Hertz

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . 7 U.S. gallons

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 175 lbs.

GENERAL MAINTENANCE

RECOMMENDATIONS

The Owner/Operator is responsible for making sure that

all periodic maintenance tasks are completed on a timely

basis; that all discrepancies are corrected; and that the unit

is kept clean and properly stored. NEVER operate a

damaged or defective generator.

NOTE: If equipped with inflatable tires, make sure tires are

inflated to the value marked on the tire or within 15 and

40 psi.

Engine Maintenance

See engine owner’s manual for instructions.

KEEP OUT OF REACH OF CHILDREN. DON'T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

Generator Maintenance

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors. Cooling air

slots in the generator must not become clogged with snow,

leaves or any other foreign material.

NOTE: DO NOT use a garden hose to clean generator.

Water can enter engine fuel system and cause problems. In

addition, if water enters generator through cooling air slots,

some of the water will be retained in voids and cracks of

the rotor and stator winding insulation.Water and dirt

buildup on the generator internal windings will eventually

decrease the insulation resistance of these windings.

Generator Cleaning

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt or oil.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and opening on

generator.These openings must be kept clean and

unobstructed.

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Avoid prolonged or repeated skin contact with used

motor oil.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

GENERATOR

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

Unintentional sparking can result in fire or

electric shock.

WARNING

• DO NOT expose generator to excessive moisture, dust, dirt,

or corrosive vapors.

• DO NOT insert any objects through cooling slots.

Improper treatment of generator can damage it and

shorten its life.

CAUTION

Page 13

Snapper 5500 Watt Generator

13

STORAGE

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than

30 days, use the following guidelines to prepare it for

storage.

Generator Storage

• Clean the generator as outlined in “Generator Cleaning”.

• Check that cooling air slots and openings on generator

are open and unobstructed.

Engine Storage

See engine owner’s manual for instructions.

Other Storage Tips

• To prevent gum from forming in fuel system or on

essential carburetor parts, add fuel stabilizer into fuel

tank and fill with fresh gasoline. Run the unit for several

minutes to circulate the additive through the carburetor.

The unit and fuel can then be stored for up to

24 months. Fuel stabilizer can be purchased locally.

• DO NOT store gasoline from one season to another

unless it has been treated as described above.

• Replace fuel container if it starts to rust. Rust and/or dirt

in fuel can cause problems if it's used with this unit.

• Store unit in a clean and dry area.

• DO NOT place a storage cover over a hot generator.

• Let equipment cool for a sufficient time before placing the

cover on the equipment.

Storage covers can be flammable.

WARNING

TROUBLESHOOTING

Problem Cause Correction

No AC output is available, but

generator is running.

1. One of the circuit breakers is

open.

2. Fault in generator.

3. Poor connection or defective cord

set.

4. Connected device is bad.

1. Reset circuit breaker.

2. Contact Authorized service facility.

3. Check and repair.

4. Connect another device that is in

good condition.

Generator runs good at no-load

but "bogs" down" when loads are

connected.

1. Short circuit in a connected load.

2. Generator is overloaded.

3. Shorted generator circuit.

1. Disconnect shorted electrical load.

2. See "Don't Overload Generator".

3. Contact Authorized service facility.

Generator will not start; or starts

and runs rough.

Low oil level. Fill crankcase to proper level or place

generator on level surface.

Generator shuts down during

operation.

1. Out of fuel.

2. Low oil level.

1. Fill fuel tank.

2. Fill crankcase to proper level or

place generator on level surface.

Generator lacks power. Load is too high. See "Don't Overload Generator".

Page 14

Snapper 5500 Watt Generator

14

SCHEMATIC

Page 15

15

Snapper 5500 Watt Generator

WIRING DIAGRAM

Page 16

Snapper 5500 Watt Generator

16

EXPLODED VIEW – MAIN UNIT

Page 17

17

Snapper 5500 Watt Generator

PARTS LIST – MAIN UNIT

Item Part # Description

1 M190305GS CRADLE

2 70642GS MOUNT,Vibration

4 66365GGS HOUSING, Engine Adapter

5 187746GS ASSY, Rotor

6 187745GS ASSY, Stator

8 96796GS WASHER

10 86307GS SCREW

11 99383GS SCREW

12 67022GS GROMMET, Rubber

13 189127GS GROMMET, Rubber

14 189009GS BRACKET, Muffler

15 695398 GASKET, Exhaust

16 66476GS SCREW, w/Lock Washer

17 189008GS MUFFLER

18 60706GS SCREW

19 83083GS SCREEN, Spark Arrest

20 81917GS PIN, Roll

21 67989GS NUT

23 193646GS KIT, Grounding Hardware

24 194390GS SHIELD, Heat

25 SRV66825DGS CARRIER, Rear Bearing

26 74908GS SCREW

27 86308AGS BOLT

28 84409GS SLEEVING, Flexo

29 22695GS FASTEN, On Tab Housing 6P

30 84242GS GROMMET, Plastic

31 77816GS DECAL, Hot Muffler

32 91825GS ASSY, Brush Holder

33 66849GS SCREW

34 B4871GS COVER, Bearing Carrier

35 23762GS WASHER

37 B2153GS SCREW

38 56893GS SCREW

40 77395GS NUT, Lock

41 192980GS KIT,Valve, Fuel Tank

Item Part # Description

43 83465GS GROMMET,Tank

44 78831BGS SCREW

45 B4363GS CAP, Fuel Gauge

48 14353621GS WIRE, Ground

50 B4986GS DECAL, Ground, Green

51 92982GS DECAL, Danger

52 189235GS DECAL, Start Instructions

53 85652GS MOUNT,Vibration

54 92665GS INSULATION

56 85000GS CLIP, Insulation

57 193500GS ASSY,Tank, Fuel 7-Gallon (Includes

Items 41, 51, 52 & 78)

58 189157GS ASSY, Control Panel (see page 19)

59 189164GS NUT, Palnut

60 J92039GS SHIELD, Heat

64 189521AGS WIRE, Ground, Panel

67 73054GS DECAL, Fuel Shut-off

69 B4135GS PIN,with Lanyard

70 194034GS KIT, Fold Down Handle Hardware

74 B193200GS ASSY, Handle (Includes Item 79)

75 M190018GS PLATE, Stiffener

76 30340GS HOSE, Fuel

77 48031CGS CLAMP, Hose

78 188333GS DECAL, Instruction, Fuel Level

79 189718GS GRIP, Handle

80 84346GS SCREW

900 NSP ENGINE

Parts Not Illustrated

190313GS MANUAL, Owner's

BB3061GS BOTTLE,Oil

43438GS PLUG, 250V, 30A

275092GS MANUAL, Engine

B4177GS CHARGER, Battery

193669GS KIT, Decals

Page 18

Snapper 5500 Watt Generator

18

EXPLODED VIEW AND PARTS LIST – WHEEL KIT

Item Part # Description

1 22247GS WASHER

2 B4966GS WHEEL

3 191267GGS AXLE

4 191265GS E-RING

5 39253GS SCREW

6 B187101GS LEG, Support

7 191413GS VIBE MOUNT, with Washer

8 22413GS SCREW

9 52858GS NUT, Lock

10 192432GS NUT, Lock

Page 19

19

Snapper 5500 Watt Generator

EXPLODED VIEW AND PARTS LIST – CONTROL PANEL

Item Part # Description

1 188914GS COVER, Lid, Control Panel

2 188889GS CONTROL PANEL, Compact

3 189167GS CLIP, Hinge Pin Retainer

4 189182GS SPRING, Hinge, Pin

5 189166GS PIN, Hinge, Cover, Compact

6 68759GS OUTLET, 120V, 20A, Duplex

7 189165GS NUT, Palnut, Pushnut

8 84198GS CAP, Circuit Breaker

9 75207GS BREAKER, Circuit

10 43437GS OUTLET, 120/240V Locking, 30A

11 189164GS NUT, Palnut, Pushnut

12 84543CGS SCREW

13 93857GS BAR, Retaining

14 188890GS COVER, Back, Control Panel

15 82308GS SCREW

16 22694GS HOUSING, Receptacle

17 192241GS SCREW

Page 20

SNAPPER™ OWNER WARRANTY POLICY Effective January 1, 2003

WARRANTY PERIOD*

* The warranty period begins on the date of purchase by the first retail consumer or commercial end user,and continues for the

period of time stated in the table above. "Consumer use" means personal residential household use by a retail consumer.

"Commercial use" means all other uses, including use for commercial, income producing or rental purposes. Once equipment has

been used commercially, it shall thereafter be considered to be in commercial use for purposes of this warranty.

** The engine and starting batteries are warranted solely by the manufacturers of those products.

WARRANTY REGISTRATION IS NOT NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON POWER PRODUCTS

EQUIPMENT. SAVE YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE

DATE AT THE TIME WARRANTY SERVICE IS REQUESTED,THE MANUFACTURING DATE OF THE EQUIPMENT WILL BE USED

TO DETERMINE THE WARRANTY PERIOD.

About your equipment warranty:

We welcome warranty repair and apologize to you for being inconvenienced.Any Authorized service dealer may perform warranty

repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For

example, warranty service would not apply if equipment damage occurred because of misuse, lack of routine maintenance, shipping,

handling, warehousing or improper installation. Similarly, the warranty is void if the manufacturing date or the serial number on the

equipment has been removed or the equipment has been altered or modified. During the warranty period, the Authorized service

dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal use and service.

This warranty will not cover following repairs and equipment:

• Normal Wear: Outdoor power equipment, like all mechanical devices, needs periodic parts, service and replacement to

perform well.This warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance:This warranty does not apply to equipment or parts that have been subjected to improper or

unauthorized installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper

maintenance, repair or storage so as, in our judgment, to adversely affect its performance and reliability.This warranty also does not

cover normal maintenance such as adjustments, fuel system cleaning and obstruction (due to chemical, dirt, carbon or lime, etc.).

• Other Exclusions:Also excluded from this warranty are wear items such as quick couplers, oil gauges, belts, o-rings, filters,

pump packing, etc., pumps which have been run without water supplied or damage or malfunctions resulting from accidents,

abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration.Accessory parts such as guns,

hoses, wands and nozzles are excluded from the product warranty.Also excluded is used, reconditioned, and demonstration

equipment; equipment used for prime power in place of utility power and equipment used in life support applications.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

LIMITED WARRANTY

“This Snapper™ product is distributed under license to Briggs & Stratton Power Products. Briggs & Stratton Power Products will

repair or replace, free of charge, any part, or parts of the equipment** that are defective in material or workmanship or both.

Transportation charges on parts submitted for repair or replacement under this warranty must be borne by purchaser.This

warranty is effective for the time periods and subject to the conditions provided for in this policy. For warranty service, find your

nearest Authorized service dealer by calling 1-800-317-7833.Warranty service may only be performed by a Briggs & Stratton

Power Products Authorized service dealer.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO THE TIME PERIOD SPECIFIED, OR TO THE EXTENT PERMITTED

BY LAW. ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER

ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some countries or

states do not allow limitations on how long an implied warranty lasts, and some countries or states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you.This warranty gives

you specific legal rights and you may also have other rights that vary from country to country or state to state.”

PRODUCTS** CONSUMER USE COMMERCIAL USE FACTORY RECONDITIONED UNITS

Portable Generator 1 year 90 days 90 days

(Side Valve Engine Powered)

Portable Generator 2 years 1 year 90 days

(Overhead Valve Engine Powered) (2nd year parts only)

Gasoline Powered Pressure Washer 1 year 90 days 90 days

Loading...

Loading...