Page 1

Portable Generator Owner’s Manual

Model No. 1666-0 (1,000 Watt AC Generator) Manual No. 190091 Revision 0 (11/09/2001)

G1000

Page 2

2

Snapper G1000 Generator

TABLE OF CONTENTS

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Know Your Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Product Specifications / Maintenance. . . . . . . . . . . . . 10-12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . 16-23

Emission Control System Warranty . . . . . . . . . . . . . . . . 37

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Last Page

EQUIPMENT

DESCRIPTION

Read this manual carefully and become familiar

with your generator. Know its applications, its

limitations and any hazards involved.

This generator is an engine–driven, revolving field, alternating

current (AC) generator. It was designed to supply electrical

power for operating compatible electrical lighting, appliances,

tools and motor loads. The generator’s revolving field is

driven at about 3,600 rpm by a single-cylinder engine.

CAUTION! Do Not exceed the generator’s

wattage/amperage capacity. See “Don’t Overload the

Generator” on page 9.

Every effort has been made to ensure that information in

this manual is accurate and current. However, Generac

reserves the right to change, alter or otherwise improve the

product and this document at any time without prior notice.

The Emission Control System for this generator is warranted

for standards set by the Environmental Protection Agency.

For warranty information refer to the engine owner’s manual.

SAFETY RULES

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION, WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER

indicates a hazard which, if not avoided, will result in death

or serious injury. WARNING indicates a hazard which, if

not avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, might

result in minor or moderate injury. CAUTION, when

used without the alert symbol, indicates a situation that

could result in equipment damage. Follow safety messages

to avoid or reduce the risk of injury or death.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

• Operate generator ONLY outdoors.

• Keep at least 2 feet of clearance on all sides of generator for

adaquate ventilation.

• Do not operate generator inside any building or enclosure,

including the generator compartment of a recreational vehicle

(RV).

Running generator gives off carbon monoxide,

an ordorless, colorless, poison gas.

Breathing carbon monoxide will cause nausea,

fainting or death.

DANGER

WHEN ADDING FUEL

• Turn generator OFF and let it cool at least 2 minutes before

removing gas cap. Loosen cap slowly to relieve pressure in tank.

• Fill fuel tank outdoors.

• Do not overfill tank. Allow space for fuel expansion.

• Keep gasoline away from sparks, open flames, pilot lights, heat,

and other ignition sources.

• Do not light a cigarette or smoke.

WHEN OPERATING EQUIPMENT

• Do not tip engine or equipment at angle which causes

gasoline to spill.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• Disconnect spark plug wire.

WHEN STORING GASOLINE OR EQUIPMENT WITH

FUEL IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite gasoline vapors.

Gasoline and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

WARNING

Page 3

3

Snapper G1000 Generator

• When using generator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

• National Electric Code requires generator to be properly

grounded to an approved earth ground. Call an electrician for

local grounding requirements.

• Use a ground circuit fault interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

• Do not touch bare wires or receptacles.

• Do not use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• Do not operate generator in the rain.

• Do not handle generator or electrical cords while standing in

water, while barefoot, or while hands or feet are wet.

• Do not allow unqualified persons or children to operate or

service generator.

Generator produces powerful voltage.

Failure to properly ground generator can result

in electrocution.

Failure to isolate generator from power utility

can result in death or injury to electric utility

workers due to backfeed of electrical energy.

WARNING

• Do not allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

• Wear protective goggles, rubber apron, and rubber gloves.

Storage batteries give off explosive hydrogen gas

during recharging.

Hydrogen gas stays around battery for a long

time after battery has been charged.

Slightest spark will ignite hydrogen and cause

explosion.

You can be blinded or severely injured.

Battery electrolyte fluid contains acid and is

extremely caustic.

Contact with battery fluid will cause severe

chemical burns.

DANGER

• Do not touch hot surfaces.

• Allow equipment to cool before touching.

Running engines produce heat. Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

WARNING

• Do not tamper with governed speed. Generator supplies

correct rated frequency and voltage when running at governed

speed.

• Do not modify generator in any way.

Excessively high operating speeds increase risk of injury

and damage to generator.

Excessively low speeds impose a heavy load.

CAUTION

• See “Don’t Overload Your Generator” on page 9.

• Start generator and let engine stabilize before connecting

electrical loads.

• Connect electrical loads in OFF position, then turn ON for

operation.

• Turn electrical loads OFF and disconnect from generator

before stopping generator.

Exceeding generators wattage/amperage cappacity can

damage generator and/or electrical devices connected

to it.

CAUTION

• Use generator only for intended uses.

• If you have questions about intended use, ask dealer or

contact Snapper.

• Operate generator only on level surfaces.

• Do not expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• Do not insert any objects through cooling slots.

• If connected devices overheat, turn them off and disconnect

them from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively.

Improper treatment of generator can damage it and

shorten its life.

CAUTION

Page 4

4

Snapper G1000 Generator

12 Volt DC, 8.3 Amp Accessory Jack — May be used

to power 12 Volt DC electrical devices or recharge 12 Volt

DC batteries.

120 Volt AC, 7.5 Amp Receptacles — May be used to

supply electrical power for the operation of 120 Volt AC,

single phase, 60 Hz electrical lighting, appliance, tool and

motor loads.

Air Cleaner — Uses a foam element to limit the amount

of dirt and dust that enters the engine.

Choke Lever — Used to manually provide proper starting

mixture when engine is cold.

Circuit Breaker (AC) — Receptacles are provided with a

push-to-reset circuit breaker to protect the generator

against electrical overload.

Engine ON/OFF Switch — Used to stop a running

engine.

Fuel Shut-Off Valve — Use this valve to turn the fuel

supply on and off.

Fuel Tank — Capacity of 1.2 U.S. gallons (4.5 liters) of

fuel.

Grounding Lug — Use this connection to properly

ground the generator. See ”Grounding the Generator” on

page 6.

Oil Fill/Drain — Access to oil fill dipstick and engine oil

drain plug.

Recoil Starter — Used for starting the engine.

Spark Plug — Access to engine spark plug.

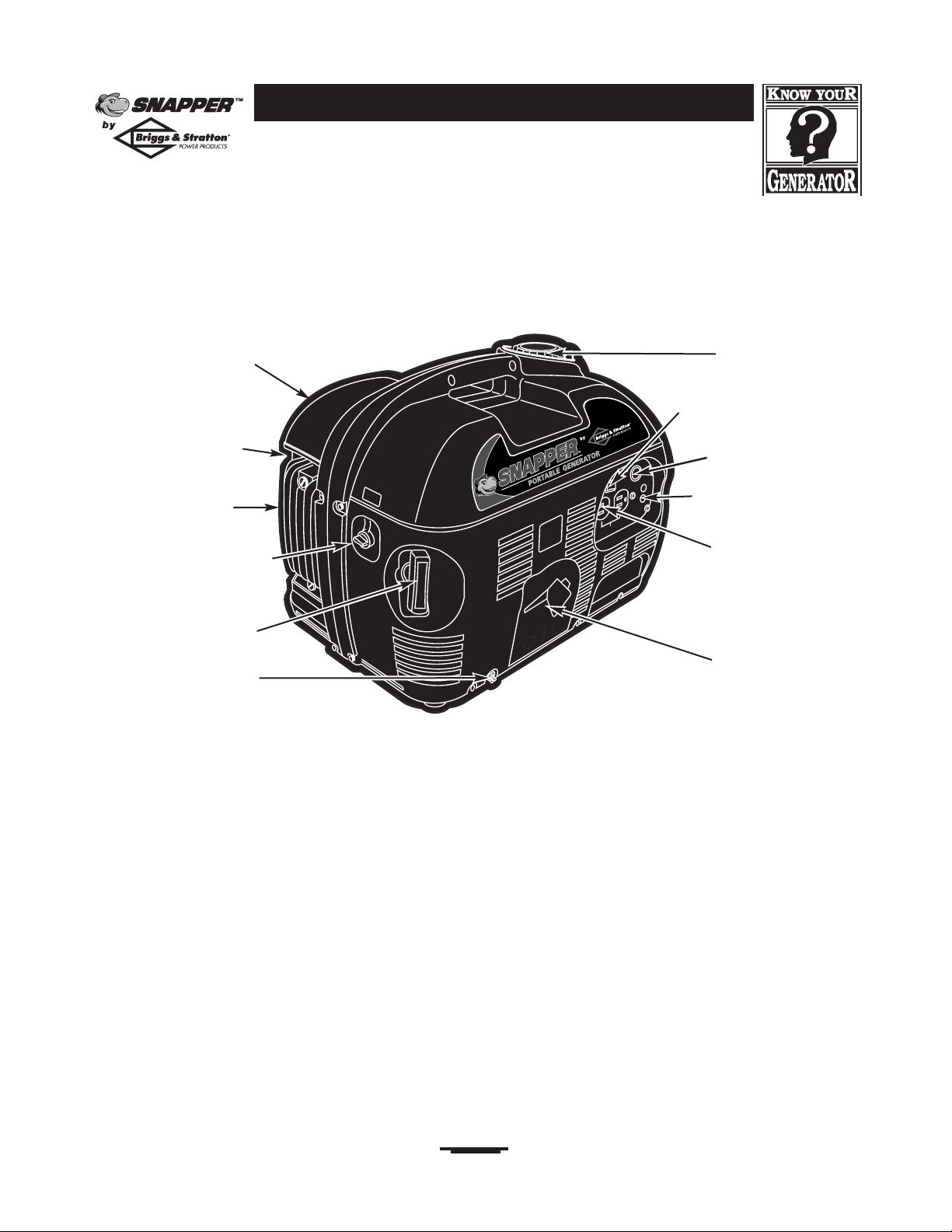

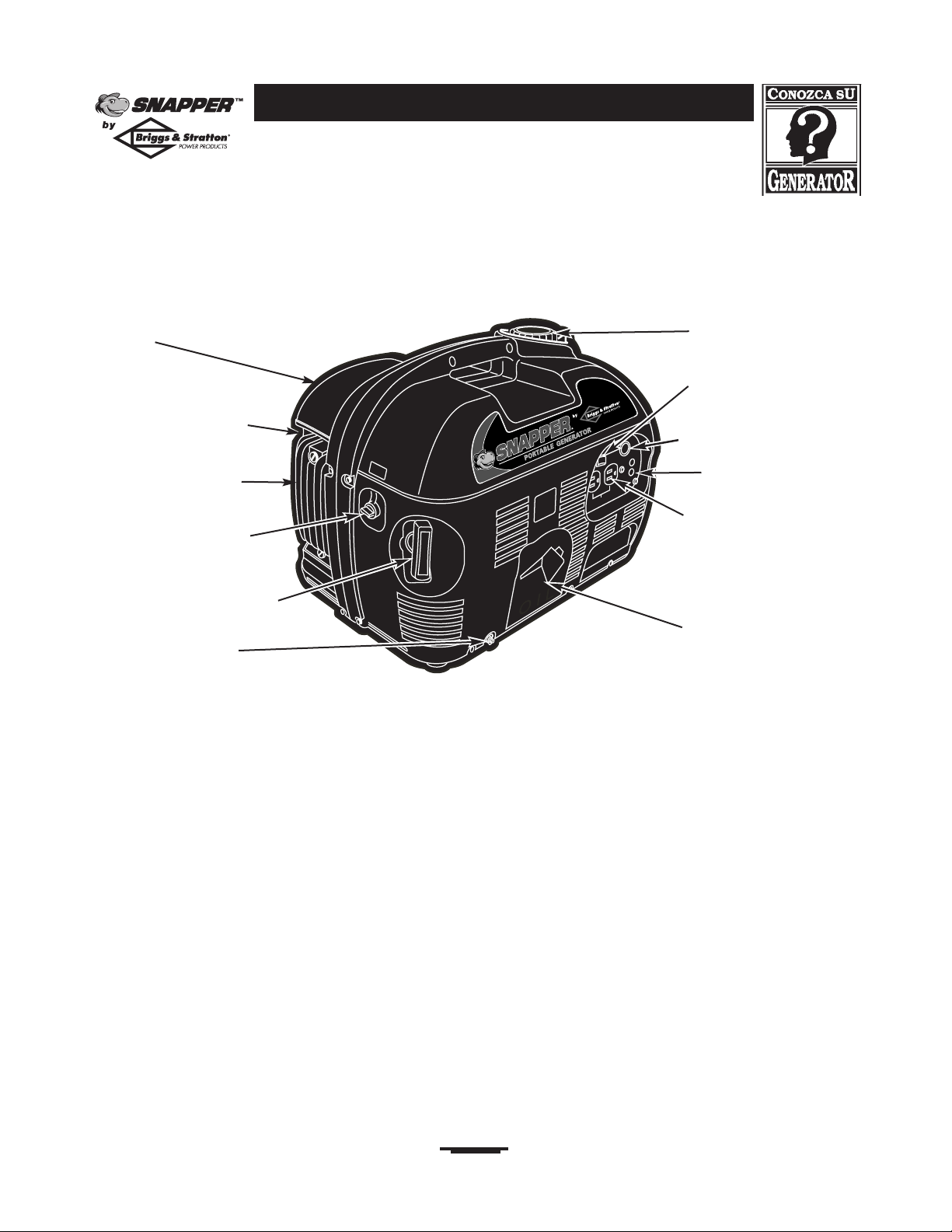

KNOW YOUR GENERATOR

Read this owner’s manual and safety rules before operating your generator.

Compare the illustrations with your generator to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

120 Volt AC, 7.5 Amp

Receptacle

Recoil Starter

Circuit Breaker (AC)

Oil Fill/Drain

(inside cover)

Choke Lever

Spark Plug (inside

cover)

Fuel Tank

Air Cleaner

Grounding Lug

12 Volt DC, 8.3 Amp

Accessory Jack

Engine ON/OFF Switch

Fuel Shut-Off Valve

Page 5

5

Snapper G1000 Generator

CONTENTS

Check all contents. If any parts are missing or damaged, call

the generator helpline at 1-800-270-1408. Shipped with

your generator is:

• Main unit

• Owner’s manual

• Battery charge cables

BEFORE STARTING ENGINE

Add Oil

NOTE: When adding oil to the engine crankcase in the

future, use only high quality detergent oil rated with API

service classification SG, SF/CC, CD. If your expected

operating temperature is below 32°F (0°C), use SAE

10W-30. Otherwise use SAE 30.

SAE 10W-30 is recommended for general all temperature

use. Multi-viscosity oils (10W30, etc.) improve starting in

cold weather, but these oils will result in increased oil

consumption. Check your engine oil level more frequently

to avoid possible damage from running low on oil.

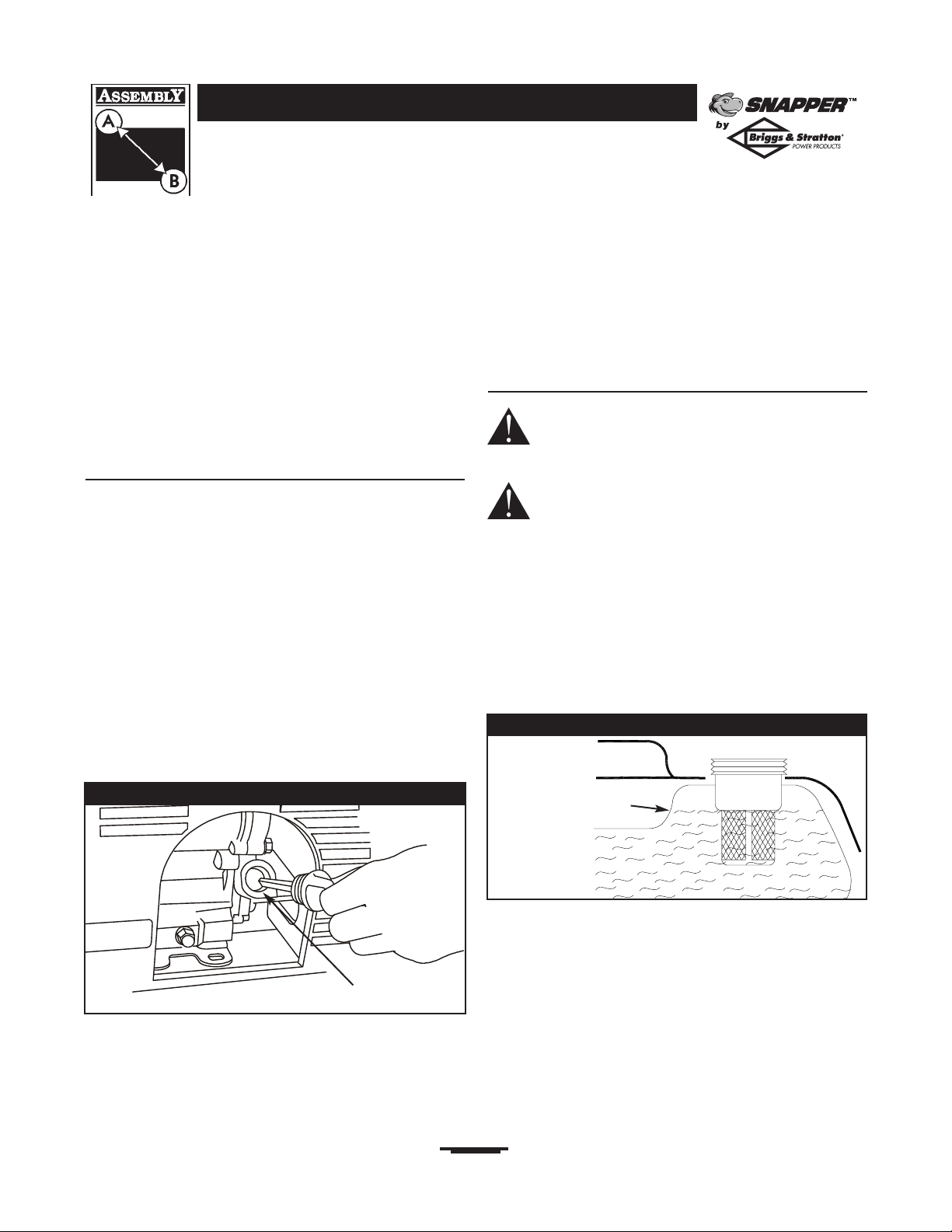

To Add Engine Oil:

• Place the generator on a level surface.

• Remove the oil fill cover.

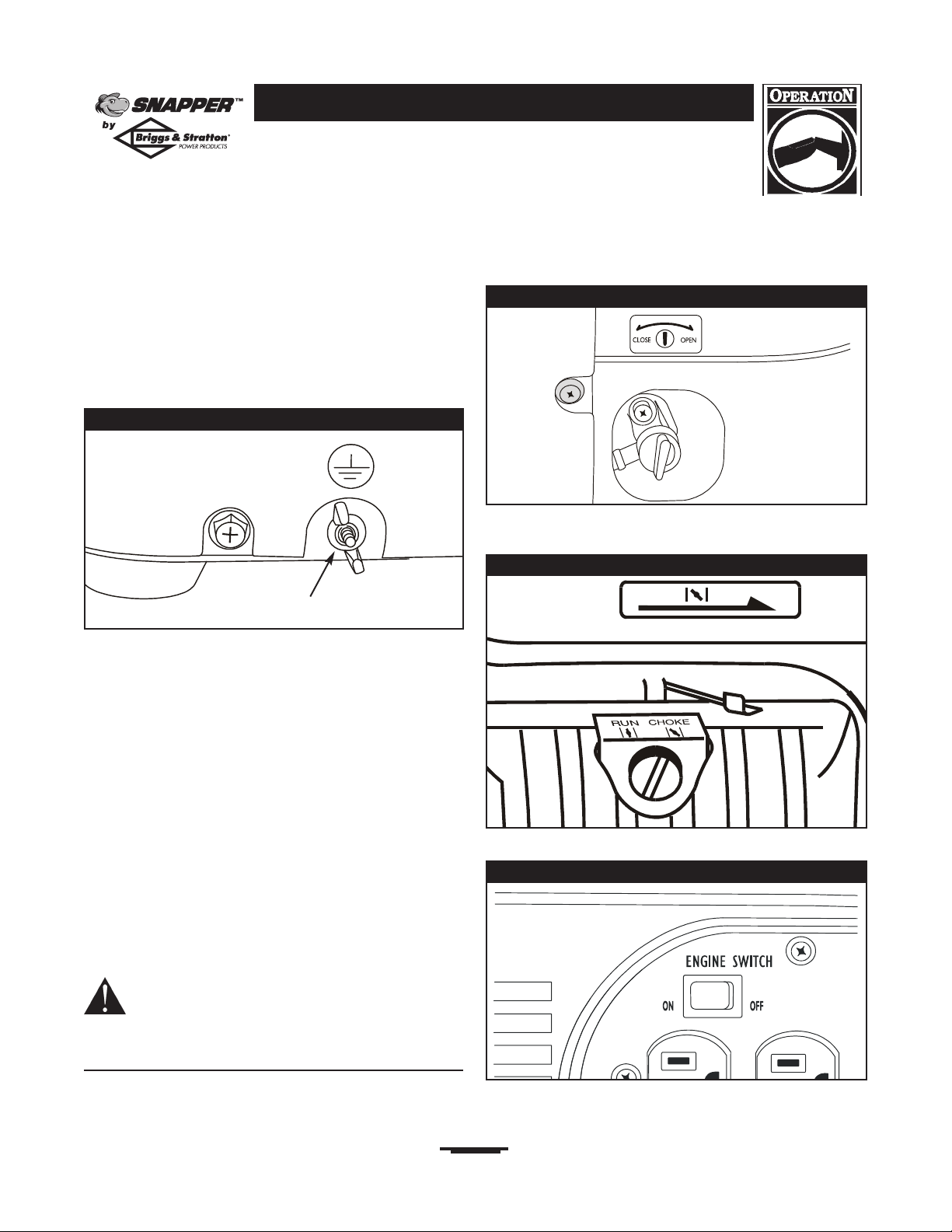

• Remove oil filler cap and wipe dipstick clean (Figure 1).

• If the oil level is not at the point of overflowing from the

oil filler neck, slowly fill engine with recommended oil.

• Reinstall oil filler cap and tighten securely.

• Replace the oil fill cover.

• Check the engine oil level before starting each time

thereafter.

Add Gasoline

WARNING! Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot. Do Not

light a cigarette or smoke when filling the fuel tank.

CAUTION! Do Not overfill the fuel tank.

Always leave room for expansion.

• Use clean fresh UNLEADED gasoline with an octane

rating of 86 to 90. Do Not use premium or leaded

gasoline. Do Not mix oil with gasoline.

• Clean area around fuel fill cap, remove cap.

• Check the fuel level.

• If fuel level is low, slowly add recommended gasoline to

fuel tank, up to the shoulder of the fuel strainer

(Figure 2). Be careful not to overfill (there should be no

fuel in the filler neck).

NOTE: Occasionally clear the fuel strainer of any dirt,

rust, or other particulate matter.

• Install fuel cap and wipe up any spilled gasoline.

Occasionally you may hear a light “spark knock” or

“pinging” (metallic rapping noise) while operating under

heavy loads. This is no cause for concern. If spark knock or

pinging occurs at a steady engine speed under normal load,

change brands of gasoline. If pinging or spark knock

persists, see your local repair center.

Oil Filler Neck

Figure 1 — Adding Engine Oil

Fill to This Level

Figure 2 — Fuel Level

Page 6

6

Snapper G1000 Generator

GROUNDING THE

GENERATOR

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properly connected to an approved earth ground. Local

electrical codes may also require proper grounding of the

unit. For that purpose, a GROUNDING WING NUT is

provided on the generator housing (Figure 3).

Generally, connecting a No. 12 AWG (American Wire

Gauge) stranded copper wire to the grounding wing nut

and to an earth-driven copper or brass grounding rod

(electrode) provides adequate protection against electrical

shock. Be careful to keep the grounding wire attached after

connecting the stranded copper wire. However, local codes

may vary widely. Consult with a local electrician for

grounding requirements in your area.

Properly grounding the generator helps prevent electrical

shock if a ground fault condition exists in the generator or

in connected electrical devices. Proper grounding also helps

dissipate static electricity, which often builds up in

ungrounded devices.

OPERATING THE

GENERATOR

CAUTION! Never start or stop the engine with

electrical loads connected to the unit and with the

connected devices turned ON.

Starting the Engine

Disconnect all electrical loads from the generator. Use the

following start instructions:

• Be sure the spark plug wire is attached to the spark plug.

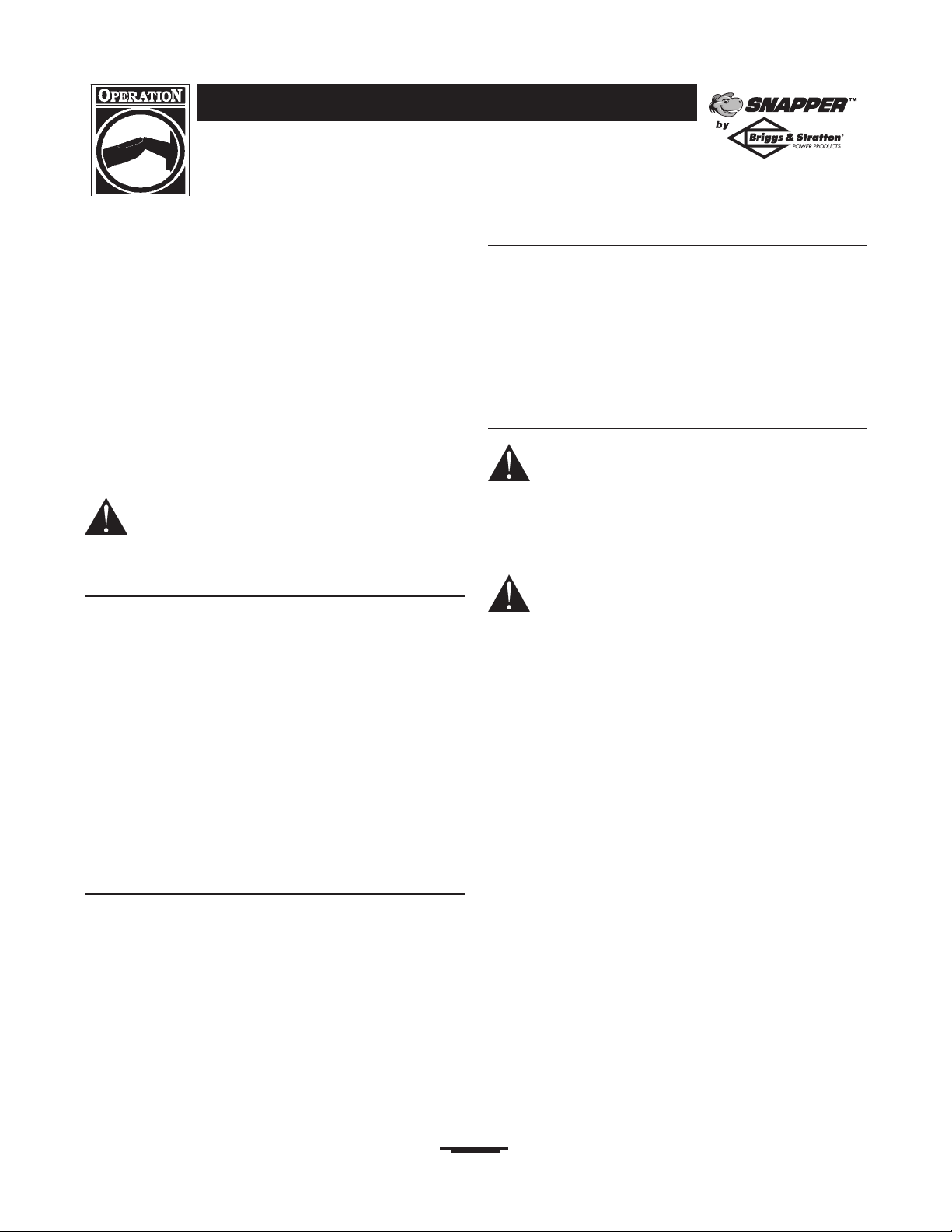

• Turn the fuel valve to the “Open” position (fully

clockwise) (Figure 4).

• Slide the choke lever to the “Choke” position (all the

way to the right) (Figure 5).

• Place the engine switch in the “On” position (Figure 6).

Figure 5 — Choke Lever

Figure 4 — Fuel Valve in Open Position

Figure 6 — Engine Switch in On Position

Figure 3 — Grounding Wing Nut

Grounding Wing Nut

Page 7

7

Snapper G1000 Generator

• Grasp starter grip and slowly pull the rope until you feel

some resistance, then pull the cord out with a rapid full

arm stroke. Let rope return slowly. Do Not let rope

“snap back” against the unit.

NOTE: If engine starts after 3 pulls, but fails to run for

more than 10 seconds, check for proper oil level in

crankcase. This unit is equipped with a Oil Alert System

(see page 7).

• Slide the choke lever left to the “Run” position as the

engine warms up.

NOTE: Under no load conditions, the engine speed may

vary slightly faster or slower until engine temperatures

stabilize.

CAUTION! Breathing Hazard! Never run engine in

enclosed poorly ventilated areas. Engine exhaust

contains carbon monoxide, an odorless and deadly gas.

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Do Not connect 240 Volt loads to 120 Volt receptacles.

• Do Not connect 3–phase loads to the generator.

• Do Not connect 50 Hz loads to the generator.

• Plug in and turn on the desired 120 Volt AC, single

phase, 60 Hertz electrical loads.

• DO NOT OVERLOAD THE GENERATOR. Add up

the rated watts (or amps) of all loads to be connected at

one time. This total should not be greater than the rated

wattage/amperage capacity of the generator. See “Don’t

Overload the Generator” on page 9.

Stopping the Engine

• Unplug all electrical loads from the unit. Never start or

stop engine with electrical devices plugged in and turned

on.

• Let engine run at no–load for two minutes to stabilize

the internal temperatures.

• Move engine switch to the “Off” position.

• Turn the fuel valve to the “Close” position (fully

counterclockwise).

NOTE: In an emergency, stop the engine by moving the

engine switch to the “Off” position.

Oil Alert System

The Oil Alert System is designed to prevent engine damage

caused by an insufficient amount of oil in the crankcase.

Before the oil level in the crankcase can fall below a safe

limit, the Oil Alert System will automatically shut down the

engine (the engine switch will remain in the “On” position).

If the Oil Alert System causes the engine to shut down,

add engine oil.

Charging a Battery

WARNING! Storage batteries emit explosive gas

while charging that remains around a battery for a

long time after it has been charged. The slightest

spark can ignite the gas, causing an explosion that

can shatter the battery and cause blindness or

other injury.

WARNING! Do Not permit smoking, open

flame, sparks or any other source of heat around a

battery. Do Not use a lighter or other flame for

checking battery fluid levels. Wear protective

goggles, rubber apron and rubber gloves when

working around a battery. Battery electrolyte fluid is

an extremely caustic sulfuric acid solution that can

cause severe burns. Do Not permit fluid contact

with eyes, skin, clothing, etc. If spill occurs, flush

area with clear water immediately.

Your generator has the capability of recharging a discharged

12 Volt automotive or utility style storage battery. Do Not

use the unit to charge any 6 Volt batteries. Do Not use

the unit to crank an engine having a discharged battery.

To recharge 12 Volt batteries, proceed as follows:

• If necessary, clean battery posts or terminals.

• Check fluid level in all battery cells. If necessary, add

ONLY distilled water to cover separators in battery

cells. Do Not use tap water.

• If the battery is equipped with vent caps, make sure they

are installed and are tight.

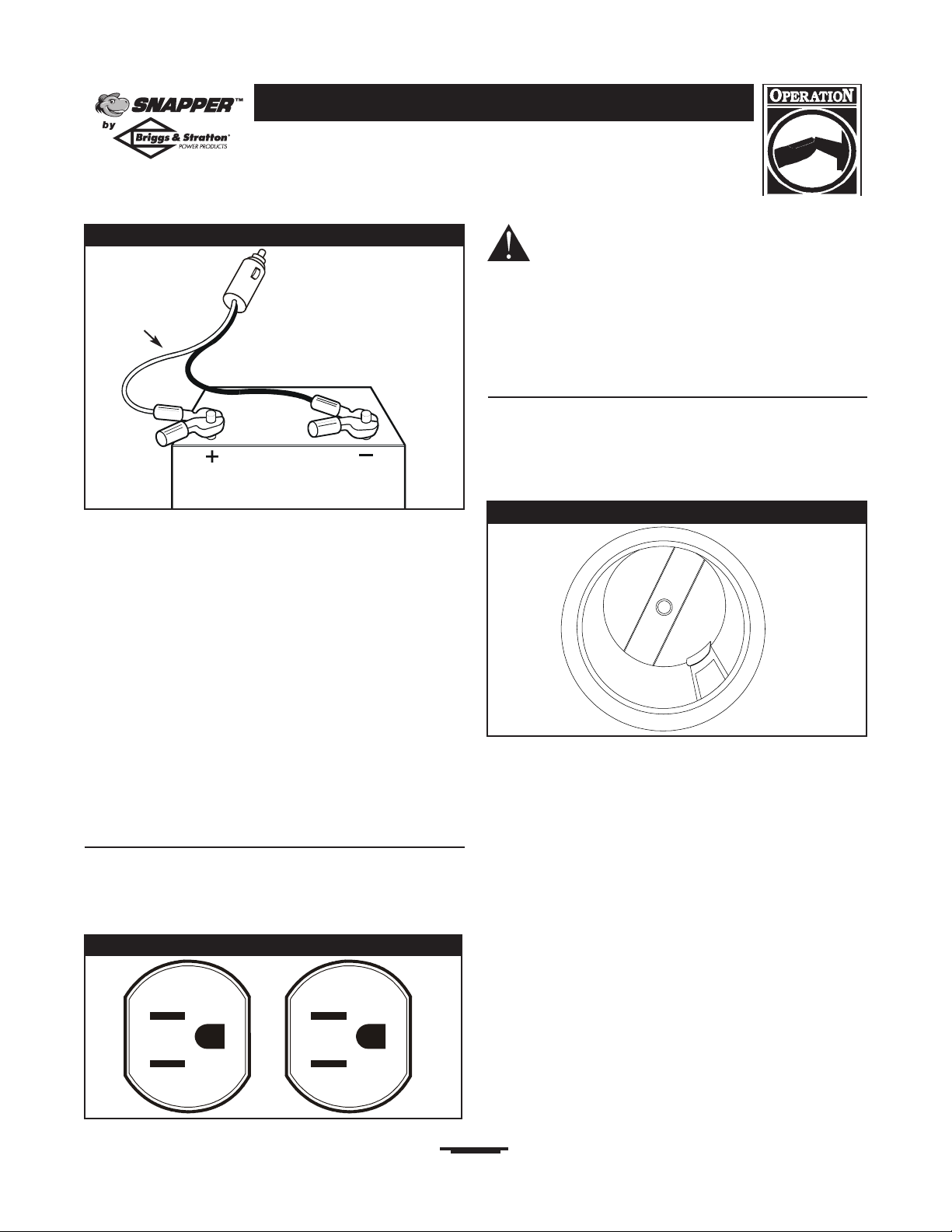

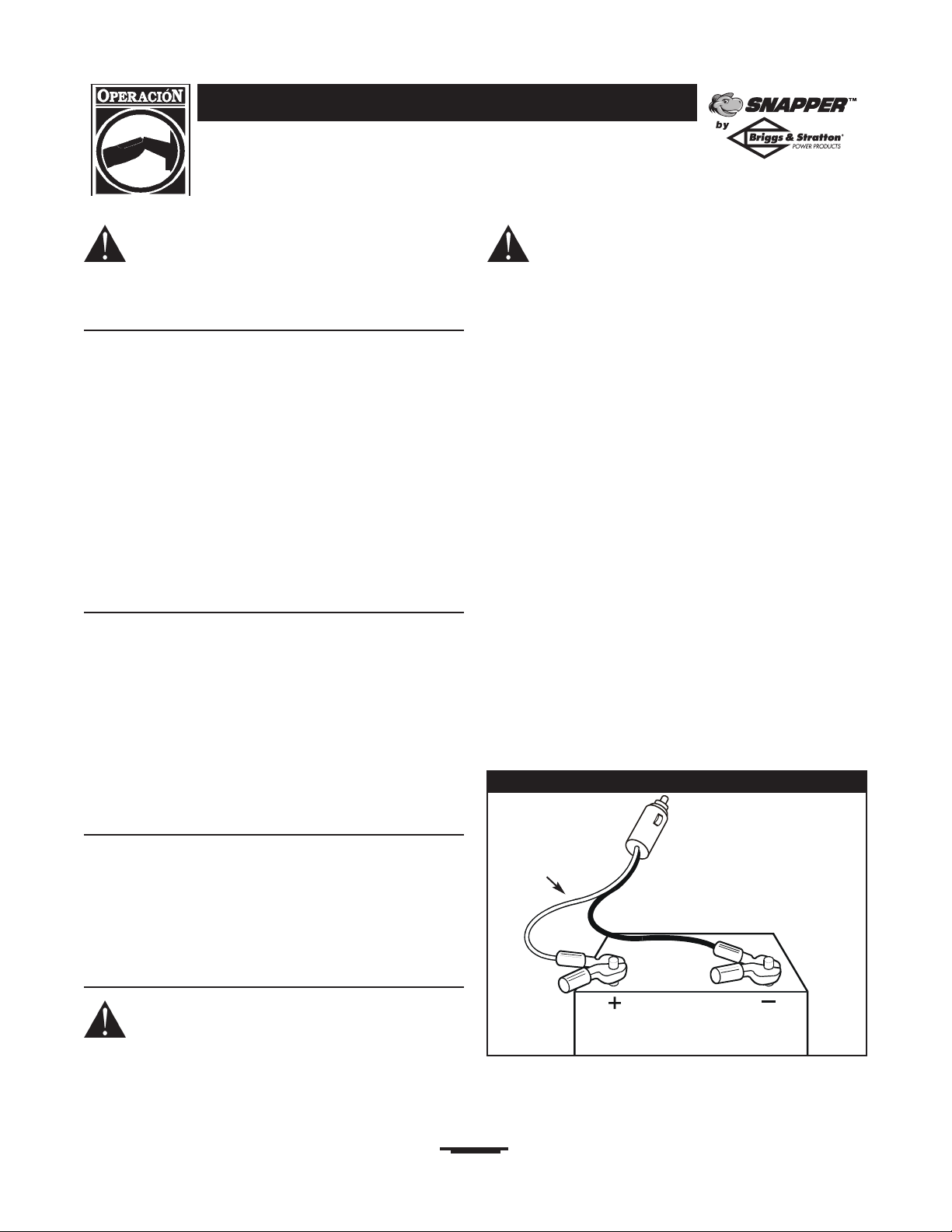

• Connect battery charge cable connector plug to the

12 Volt DC panel receptacle.

• Connect battery charge cable clamp with red handle to

battery post or terminal indicated by Positive, POS or

(+) (Figure 7).

Page 8

8

Snapper G1000 Generator

• Connect battery charge cable clamp with black handle

to battery post or terminal indicated by Negative,

NEG, or (–) (Figure 7).

• Start generator. Let the engine run while battery recharges.

• When battery has charged, shut down engine (see

“Stopping The Engine”)

NOTE: Use an automotive hydrometer to test battery

state of charge and condition. Follow the hydrometer

manufacturer’s instructions carefully. Generally, a battery is

considered to be at 100% state of charge when specific

gravity of its fluid (as measured by hydrometer) is 1.260 or

higher.

CONNECTOR PLUGS

120 Volt AC Receptacle

Each outlet socket is protected against overload by a

7.5 Amp push-to-reset circuit breaker. Use each receptacle

to operate 120 Volt AC, single phase, 60 Hz electrical loads

requiring up to 1,000 watts (1.0 kW) of power (Figure 8).

CAUTION! Although each receptacle is rated

for 120 Volts at 15 Amps (1,440 watts or 1.44 kW),

the generator is rated for a total of 1,000 watts.

Powering loads that exceed the wattage capacity of

the generator can damage it or cause serious

injuries. The total of loads powered through these

receptacles should not exceed 7.5 Amps.

12 Volt DC Accessory Jack

This receptacle allows you to recharge a 12 Volt

automotive or utility style storage battery with the battery

charge cable provided. Camping-style air pumps, lanterns,

fans, or other 12 Volt devices having a cigarette lighter-type

plug may also be powered by this outlet (Figure 9).

This receptacle can not recharge 6 Volt batteries and can

not be used to crank an engine having a discharged battery.

See “Charging a Battery” (page 7) before attempting to

recharge a battery.

EXTENSION CORDS

Use only high quality, well-insulated extension cords with

the generator’s 120 Volt electrical receptacles.

Check the ratings of all extension cords before you use

them. Such cords should be rated for 125 Volt AC loads at

15 Amps (or greater) for most electrical devices. Some

devices, however, may not require this type of extension

cord. Check the owner’s manuals of those devices for their

recommendations.

Keep extension cords as short as possible, preferably less

than 15 feet long, to prevent voltage drop and possible

overheating of wires.

Figure 8 — 120 Volt AC, 15 Amp Duplex Receptacle

Figure 9 — 12 Volt DC Accessory Jack

Red Lead

To 12 Volt DC Panel

Receptacle

Positive

Negative

Figure 7 — Battery Connections

Page 9

9

Snapper G1000 Generator

DON'T OVERLOAD YOUR

GENERATOR

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

will power at the same time. Follow these simple steps:

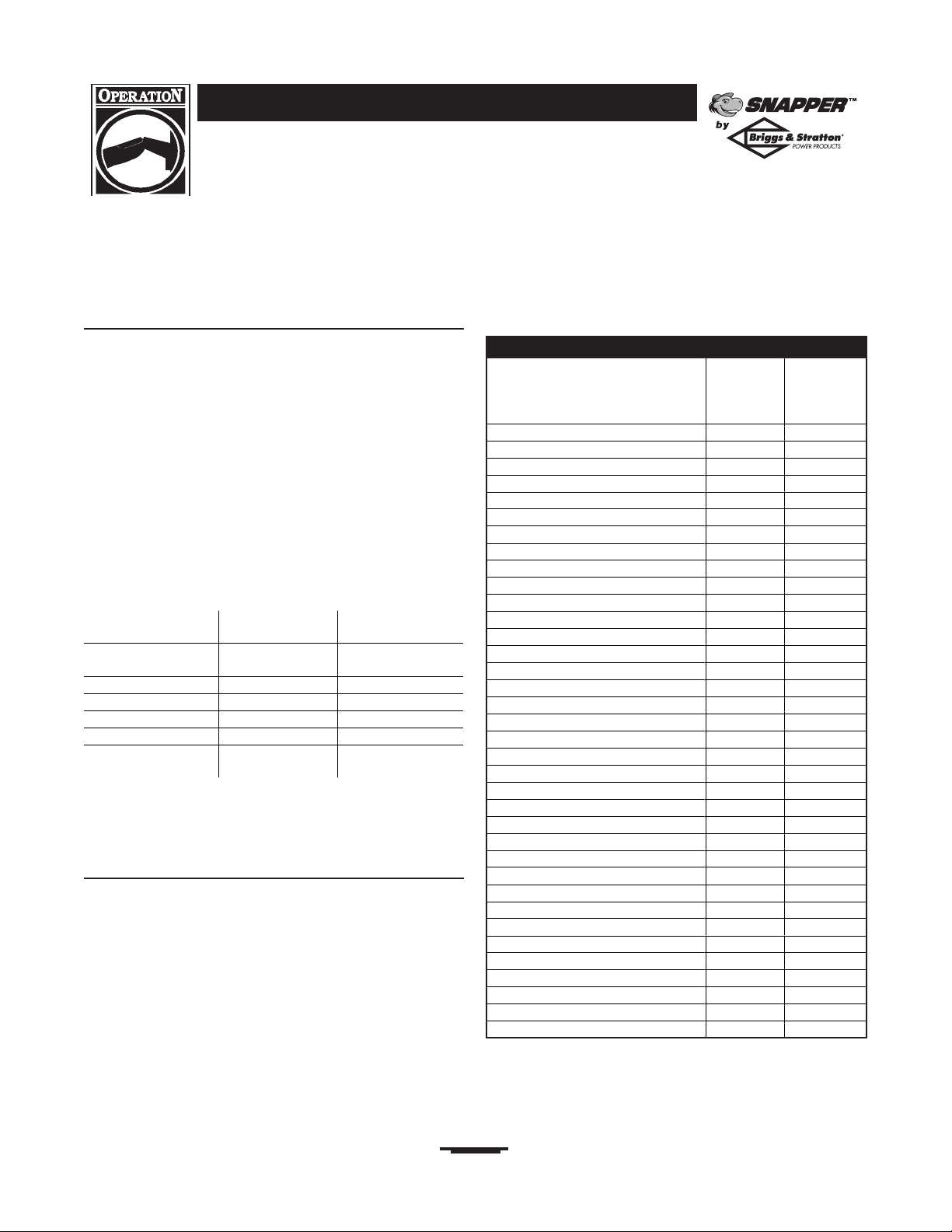

1. Select the items you will power at the same time.

2. Total the rated (running) watts of these items. This is

the amount of power your generator must produce to

keep your items running. See Figure 10.

3. Estimate how many surge (starting) watts you will

need. Surge wattage is the short burst of power

needed to start electric motor-driven tools or

appliances such as a circular saw or refrigerator.

Because not all motors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Example:

Total Rated (Running) Watts = 3075

Highest Additional Surge Watts = 1800

Total Generator Output Required = 4875

Power Management

To prolong the life of your generator and attached devices,

it is important to take care when adding electrical loads to

your generator. There should be nothing connected to the

generator outlets before starting it's engine. The correct

and safe way to manage generator power is to sequentially

add loads as follows:

1. With nothing connected to the generator, start the

engine as described in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

Never add more loads than the generator capacity. Take

special care to consider surge loads in generator capacity,

as described above.

*Wattages listed are approximate only. Check tool or

appliance for actual wattage.

Tool or Appliance

Rated (Running)

Watts

Additional Surge

(Starting) Watts

Window Air

Conditioner

1200 1800

Refrigerator 800 1600

Deep Freezer 500 500

Television 500 Light (75 Watts) 75 -

3075 Total

Running Watts

1800 Highest

Surge Watts

Tool or Appliance

Rated*

(Running)

Watts

Additional

Surge

(Starting)

Watts

Essentials

Light Bulb - 75 watt 75 Deep Freezer 500 500

Sump Pump 800 1200

Refrigerator/Freezer - 18 Cu. Ft. 800 1600

Water Well Pump - 1/3 HP 1000 2000

Heating/Cooling

Window AC - 10,000 BTU 1200 1800

Window Fan 300 600

Furnace Fan Blower - 1/2 HP 800 1300

Kitchen

Microwave Oven - 1000 Watt 1000 Coffee Maker 1500 Electric Stove - Single Element 1500 Hot Plate 2500 -

Family Room

DVD/CD Player 100 VCR 100 Stereo Receiver 450 Color Television - 27” 500 Personal Computer w/17” monitor 800 -

Other

Security System 180 AM/FM Clock Radio 300 Garage Door Opener - 1/2 HP 480 520

Electric Water Heater - 40 Gallon 4000 -

DIY/Job Site

Quartz Halogen Work Light 1000 Airless Sprayer - 1/3 HP 600 1200

Reciprocating Saw 960 960

Electric Drill - 1/2 HP 1000 1000

Circular Saw - 7 1/4” 1500 1500

Miter Saw - 10” 1800 1800

Table Planer - 6” 1800 1800

Table Saw/Radial Arm Saw - 10” 2000 2000

Air Compressor - 1-1/2 HP 2500 2500

Figure 10 - Wattage Reference Chart

Page 10

10

Snapper G1000 Generator

PRODUCT

SPECIFICATIONS

Generator Specifications

Rated Surge Watts . . . . . . . . . . . . . . . 1,000 Watts

Rated Running Watts . . . . . . . . . . . . . 900 Watts

Rated Maximum Current

At 120 Volts AC . . . . . . . . . . . . . .7.5 Amps

At 12 Volts DC . . . . . . . . . . . . . . .8.3 Amps

Phase . . . . . . . . . . . . . . . . . . . . . . . .Single Phase

Rated Frequency . . . . . . . . . . . . . . . .60 Hertz

Packaged Weight . . . . . . . . . . . . . . . .61.0 lbs.

Engine Specifications

Model

. . . . . . . . . . . . . . . . . . . . . . . .

Mitsubishi GM82

Rated Horsepower . . . . . . . . . . . . . . 2.4 at 4000 rpm

Displacement . . . . . . . . . . . . . . . . . . . 80cc

Spark Plug Type: . . . . . . . . . . . . . . . . . NGK BP6HS or

equivalent

Set Gap To: . . . . . . . . . . . . . . . . . . . . . 0.030inch (0.75mm)

Gasoline Capacity . . . . . . . . . . . . . . . 1.2 U.S. gallons (4.5 l)

GENERAL MAINTENANCE

RECOMMENDATIONS

The generator warranty does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, operator must maintain

generator as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your generator.

All adjustments in this section should be made at least

once each season. Follow the requirements in the

“Maintenance Schedule” chart shown below in Figure 11.

NOTE: Once a year you should clean or replace the spark

plug and replace the air filter. A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer.

GENERATOR

MAINTENANCE

Generator maintenance consists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors. Cooling air

slots in the generator must not become clogged with snow,

leaves or any other foreign material.

1 Clean more often under dirty or dusty conditions. Replace air cleaner parts if very dirty.

2 Check every 10 hours or 3 months.

3 These items should be serviced by an authorized dealer, unless the owner has the proper tools and is mechanically

proficient.

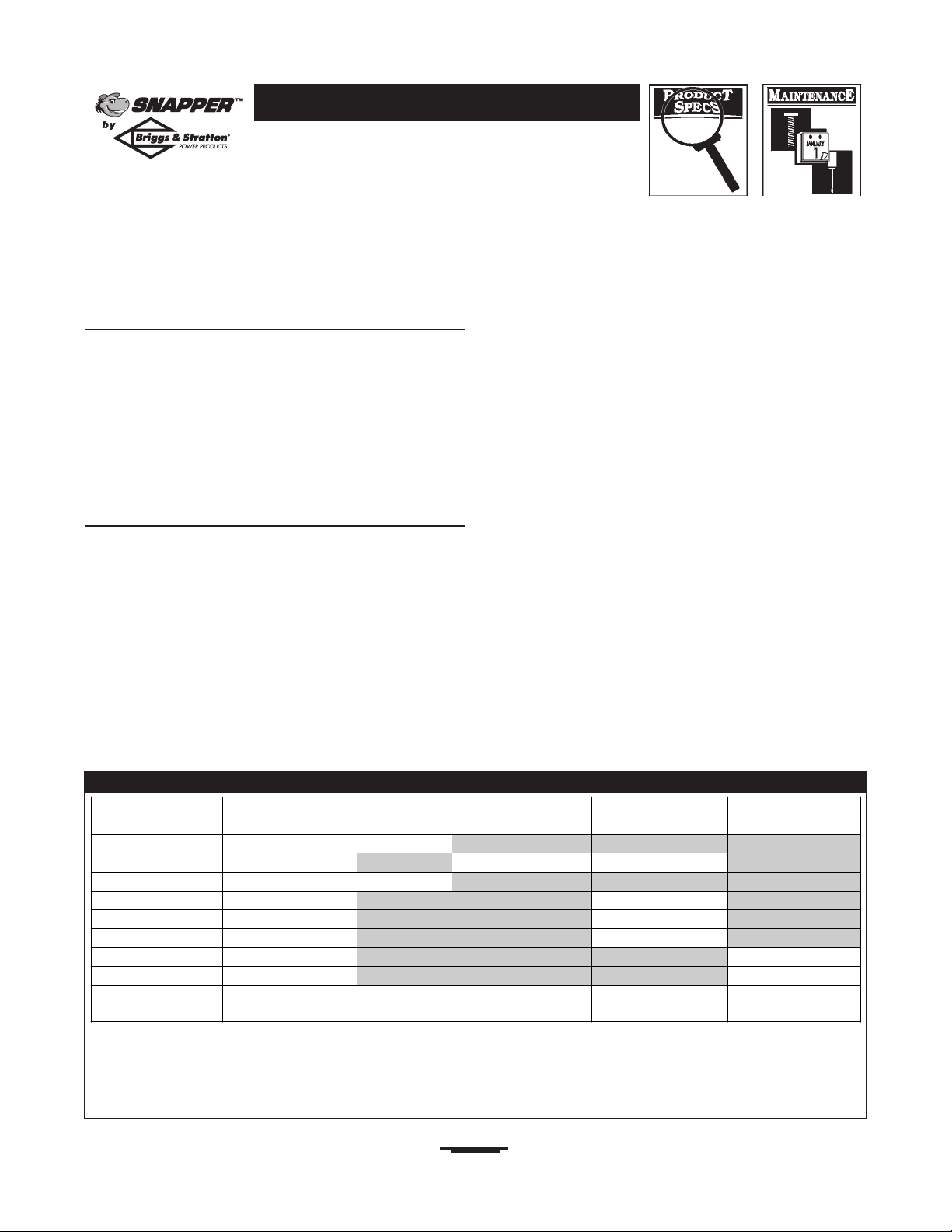

Item

Operation

Each use

First Month or

25 hours

Every 3 months

or 50 hours

Every 6 months

or 100 hours

Engine oil

Check level X

Change X X

Air cleaner

Check X

Clean

X (1)

Spark arrester

Check – Clean

X (2,3)

Spark plug

Check – Clean

X

Valve clearance

Check – Adjust

X (3)

Fuel tank strainer

Clean X

Fuel line

Check (Replace if

necessary)

Every 3 years (3)

Figure 11 – Maintenance Schedule

Page 11

11

Snapper G1000 Generator

Check the cleanliness of the generator frequently and clean

when dust, dirt, oil, moisture or other foreign substances

are visible on its exterior surface.

NOTE: Do Not use a garden hose to clean generator.

Water can enter engine fuel system and cause problems. In

addition, if water enters generator through cooling air

slots, some of the water will be retained in voids and

cracks of the rotor and stator winding insulation. Water

and dirt buildup on the generator internal windings will

eventually decrease the insulation resistance of these

windings.

To Clean the Generator

• Use a damp cloth to wipe exterior surfaces clean.

• Soft, bristle brush may be used to loosen caked on dirt

or oil.

CAUTION! Never insert any object or tool

through the air cooling slots, even if the engine is

not running.

• A vacuum cleaner may be used to pick up loose dirt and

debris.

• Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspect cooling air slots and opening on

generator. These openings must be kept clean and

unobstructed.

DANGER! When working on the generator,

always disconnect spark plug wire from spark plug

and keep it away from spark plug.

ENGINE MAINTENANCE

Checking Oil Level

Oil level should be checked prior to each use or at least

every 5 hours of operation. Keep oil level maintained.

Changing Engine Oil

See the Maintenance schedule on page 10 for

recommended oil change intervals. If you are using your

generator under extremely dirty or dusty conditions, or in

extremely hot weather, change the oil more often.

Change the oil while the engine is still warm from running,

as follows:

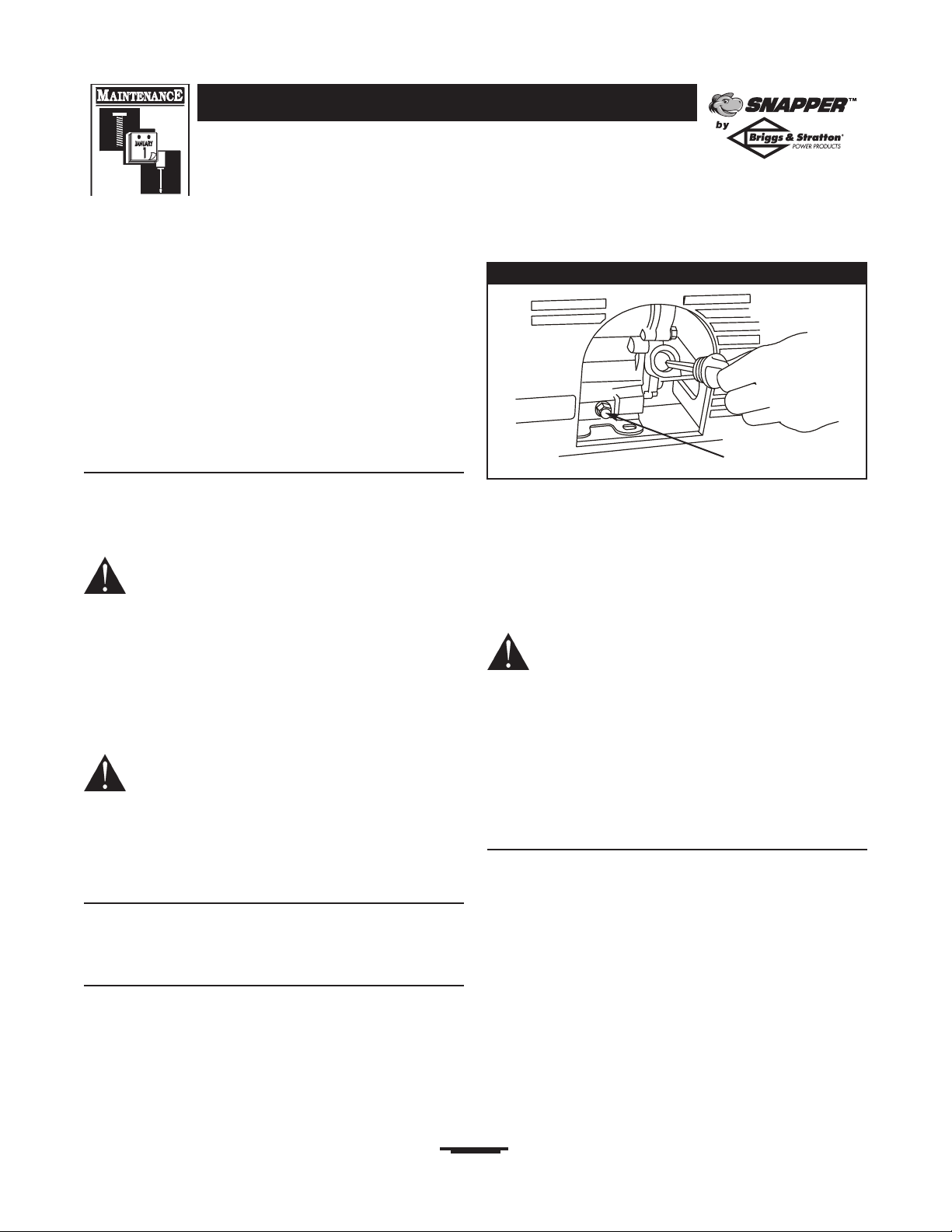

• Remove the oil fill cover and clean area around oil drain

plug (Figure 12).

• Remove oil drain plug, sealing washer, and oil filler cap.

Drain oil completely into a suitable container.

• Install oil drain plug and sealing washer. Tighten securely.

• Refill with recommended oil and check the level. See

page 5 for oil recommendations.

• Wipe up any spilled oil.

CAUTION! Avoid prolonged or repeated skin

contact with used motor oil. Used motor oil has

been shown to cause skin cancer in certain

laboratory animals. Thoroughly wash exposed areas

with soap and water.

KEEP OUT OF REACH OF CHILDREN. DON'T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

• Replace oil fill cover.

Clean/Replace Spark Plug

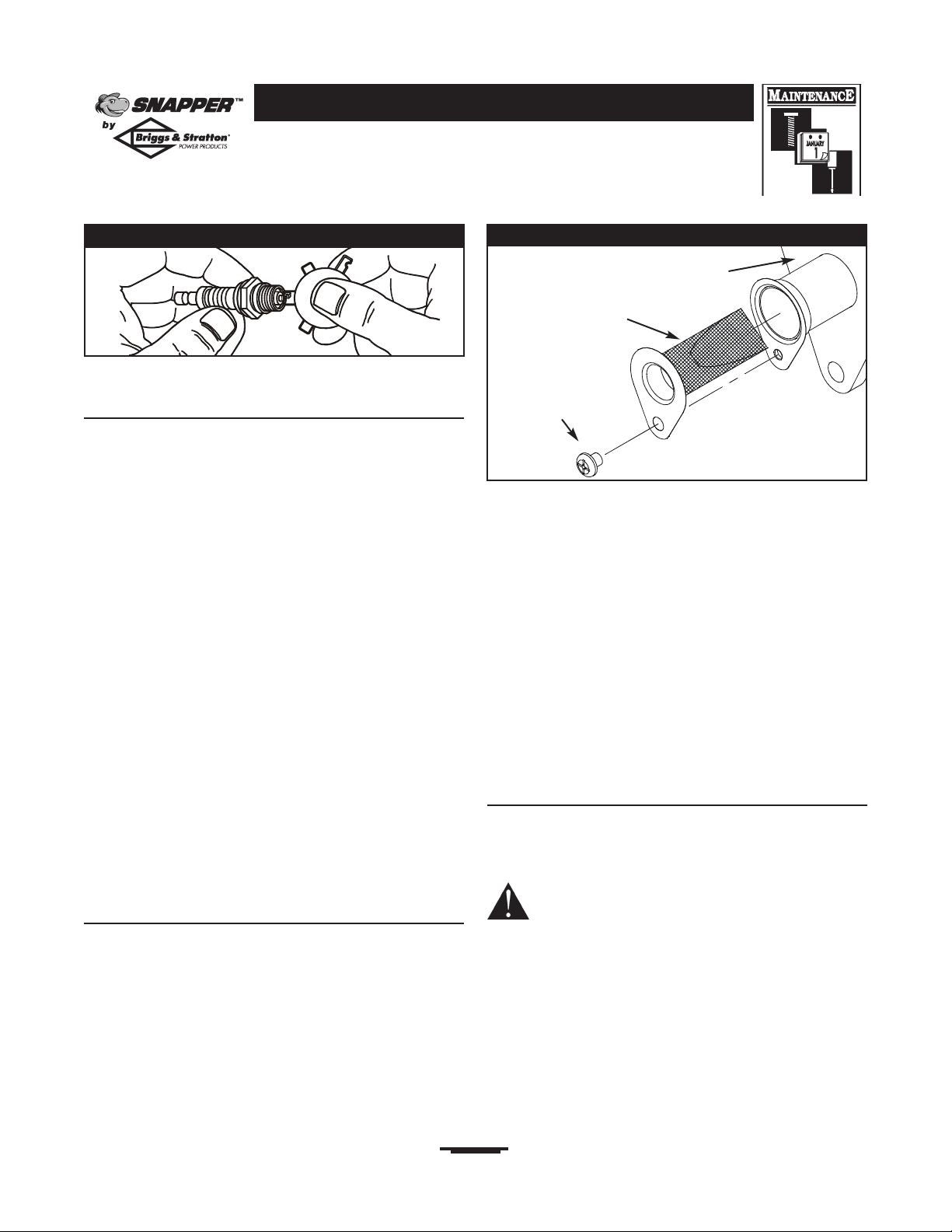

Check and clean the spark plug every 50 hours of

operation or every three months, whichever comes first.

This will help your engine start easier and run better.

• Remove spark plug access cover. Remove spark plug cap.

• Clean the area around the spark plug.

• Remove and inspect the spark plug.

• Replace the spark plug if electrodes are pitted or burned

or the porcelain is cracked. Use recommended plug for

replacement.

• Check electrode gap with wire feeler gauge and set spark

plug gap between 0.028 and 0.031 inch (0.7 to 0.8 mm) if

necessary (Figure 13).

Figure 12 — Oil Drain Plug

Oil Drain Plug

Page 12

• Reinstall spark plug.

Service Air Cleaner

Your engine will not run properly and may be damaged if

you run it using a dirty air filter element.

Check the air filter every use and clean or replace the air

filter element every 50 hours of operation or every three

months, whichever comes first. Clean or replace more

often if operating under dusty or dirty conditions.

To clean or replace air filter element:

• Loosen the air cleaner cover screws, remove the air

cleaner cover, and remove the element (see page 20).

• Wipe clean the inside of the filter housing and cover

thoroughly.

• Wash the element in a solution of household detergent

and warm water, then rinse thoroughly. Or wash in

nonflammable or high flash point solvent. Allow the

element to dry thoroughly.

• Soak the element in clean engine oil and squeeze out the

excess oil. Do Not twist. The engine will smoke during

initial start-up if too much oil is left in the element.

NOTE: If you need to order a new air filter element,

please contact the local dealer.

• Reinstall the air cleaner element and the cover. Hand

tighten the air cleaner cover screws.

Clean Spark Arrester Screen

The engine muffler is equipped with a removable spark

arrester screen. Inspect and clean the screen every

10 hours of operation or every three months, as shown in

Figure 14:

• Loosen the screw on the muffler and remove the spark

arrester screen.

• Use a brass or stiff-bristle brush to remove carbon

deposits from the spark arrester surface.

• Inspect the spark arrester for breaks or tears and

replace it if necessary.

NOTE: If you need to order a new spark arrester, please

contact the local dealer.

• Install the clean screen in the reverse order of removal.

NOTE: If you use your generator on any forest-covered,

brush-covered or grass-covered unimproved land, it must

have a spark arrester installed. The spark arrester must be

maintained in good condition by the owner/operator.

STORAGE INSTRUCTIONS

Transporting and Storage

When transporting the generator, turn the engine switch

to “Off” and the fuel valve to “Close”. Keep the generator

level to prevent fuel spillage.

WARNING! Contact with a hot engine or

exhaust system can cause serious burns or fires. Let

the engine cool before transporting or storing the

generator.

Take care to not drop or strike the generator when

transporting. Do Not place heavy objects on the

generator.

The generator should be started at least once every seven

days and allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than 30 days,

use the following guidelines to prepare it for storage.

12

Snapper G1000 Generator

Figure 13 — Service Spark Plug

Spark Arrester

Screen

Muffler

Spark Arrester

Attachment Screw

Figure 14 – Service Spark Arrester Screen

Page 13

Long Term Storage Instructions

WARNING! Never store engine with fuel in

tank indoors or in enclosed, poorly ventilated areas

where fumes may reach an open flame, spark or

pilot light as on a furnace, water heater, clothes

dryer or other gas appliance.

Be sure the storage area is free from excessive

humidity and dust.

One Month to One Year

Drain the carburetor float bowl (see “Protect Fuel System”)

and fuel tank into a suitable container. After removal from

storage, fill with fresh gasoline before starting.

More than One Year

It is important to prevent gum deposits from forming in

essential fuel system parts such as the carburetor, fuel filter,

fuel hose or tank during storage. Also, experience indicates

that alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leads to separation

and formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow these

instructions:

Protect Fuel System

WARNING! Drain fuel into approved container

outdoors, away from open flame. Be sure engine is

cool. Do Not smoke.

• Drain carburetor float bowl and fuel tank into a suitable

container by loosening the drain screw (Figure 15).

• Retighten drain screw before refueling.

Change Oil

While engine is still warm, change oil as described on

page 11. Refill with recommended grade.

Oil Cylinder Bore

• Remove spark plug and pour about one tablespoon of

clean engine oil into the cylinder.

CAUTION! Avoid spray from spark plug hole

when cranking engine slowly.

• Cover spark plug hole with rag. Crank slowly several

times to distribute oil.

• Install spark plug. Do Not connect spark plug wire.

• Slowly pull the starter grip until resistance is felt. At this

point, the piston is coming up on its compression stroke

and both the intake and exhaust valves are closed.

Storing the engine in this position will help to protect it

from internal corrosion.

Generator

• Clean the generator as outlined on page 11 (“To Clean

the Generator”).

• Check that cooling air slots and openings on generator

are open and unobstructed.

Other Storage Tips

• Do Not store gasoline from one season to another.

• Replace the gasoline can if it starts to rust. Rust and/or

dirt in gasoline will cause problems.

• If possible, store your unit indoors. BE SURE TO

EMPTY THE FUEL TANK.

• Cover your unit with a suitable protective cover that

does not retain moisture.

IMPORTANT: Never cover your generator while engine

and exhaust area are warm.

• Store generator in clean, dry area.

13

Snapper G1000 Generator

Carburetor Fuel

Drain Screw

Drain Screw

Access Hole

Figure 15 – Drain Fuel From Carburetor

Page 14

14

Snapper G1000 Generator

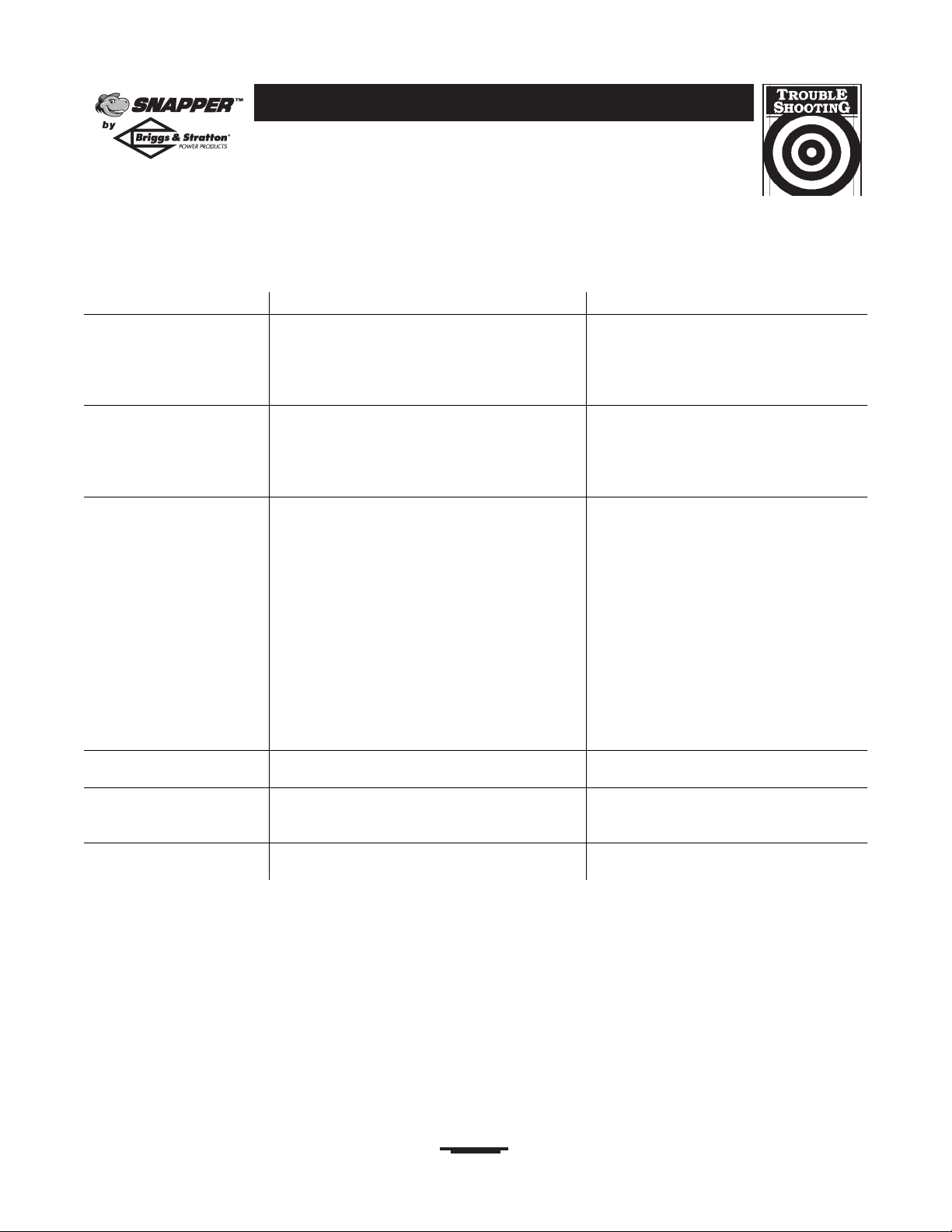

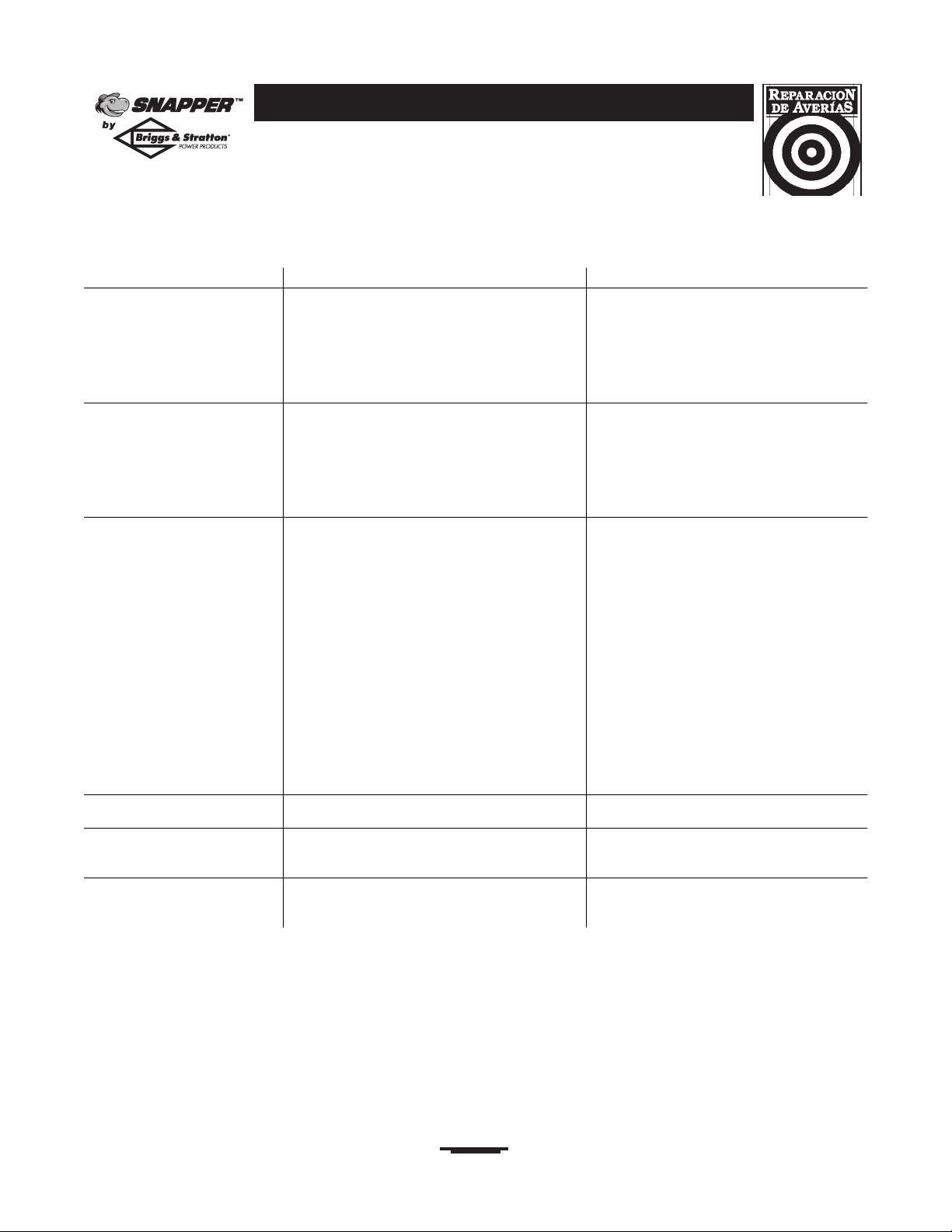

TROUBLESHOOTING

Problem

Cause

Correction

Engine is running, but

no AC or DC output is

available.

1. One of the circuit breakers is open.

2. Fault in generator.

3. Poor connection or defective cord set.

4. Connected device is bad.

1. Reset circuit breaker.

2. Contact Snapper service facility.

3. Check and repair.

4. Connect another device that is in

good condition.

Engine runs good at

no-load but “bogs

down" when loads are

connected.

1. Short circuit in a connected load.

2. Engine speed is too slow.

3. Generator is overloaded.

4. Shorted generator circuit.

1. Disconnect shorted electrical load.

2. Contact Snapper service facility.

3. See “Don't Overload the Generator”

on page 9.

4. Contact Snapper service facility.

Engine will not start;

or starts and runs

rough.

1. Engine switch set to “Off”.

2. Dirty air cleaner.

3. Out of gasoline.

4. Stale gasoline.

5. Spark plug wire not connected to spark

plug.

6. Bad spark plug.

7. Water in gasoline.

8. Overchoked or flooded.

9. Excessively rich fuel mixture.

10. Intake valve stuck open or closed.

11. Engine has lost compression.

1. Set switch to “On”.

2. Clean or replace air cleaner.

3. Fill fuel tank.

4. Drain gas tank and carburetor; fill

with fresh fuel.

5. Connect wire to spark plug.

6. Replace spark plug.

7. Drain gas tank and carburetor; fill

with fresh fuel.

8. Wait 5 minutes and re-crank engine.

9. Contact Snapper service facility.

10. Contact Snapper service facility.

11. Contact Snapper service facility.

Engine shuts down

when running.

1. Out of gasoline.

2. Low oil level.

1. Fill fuel tank.

2. Fill crankcase to proper level.

Engine lacks power.

1. Load is too high.

2. Dirty air filter.

1. See “Don't Overload the Generator”

on page 9.

2. Replace air filter.

Engine “hunts” or

falters.

Carburetor is running too rich or too lean.

Contact Snapper service facility.

Page 15

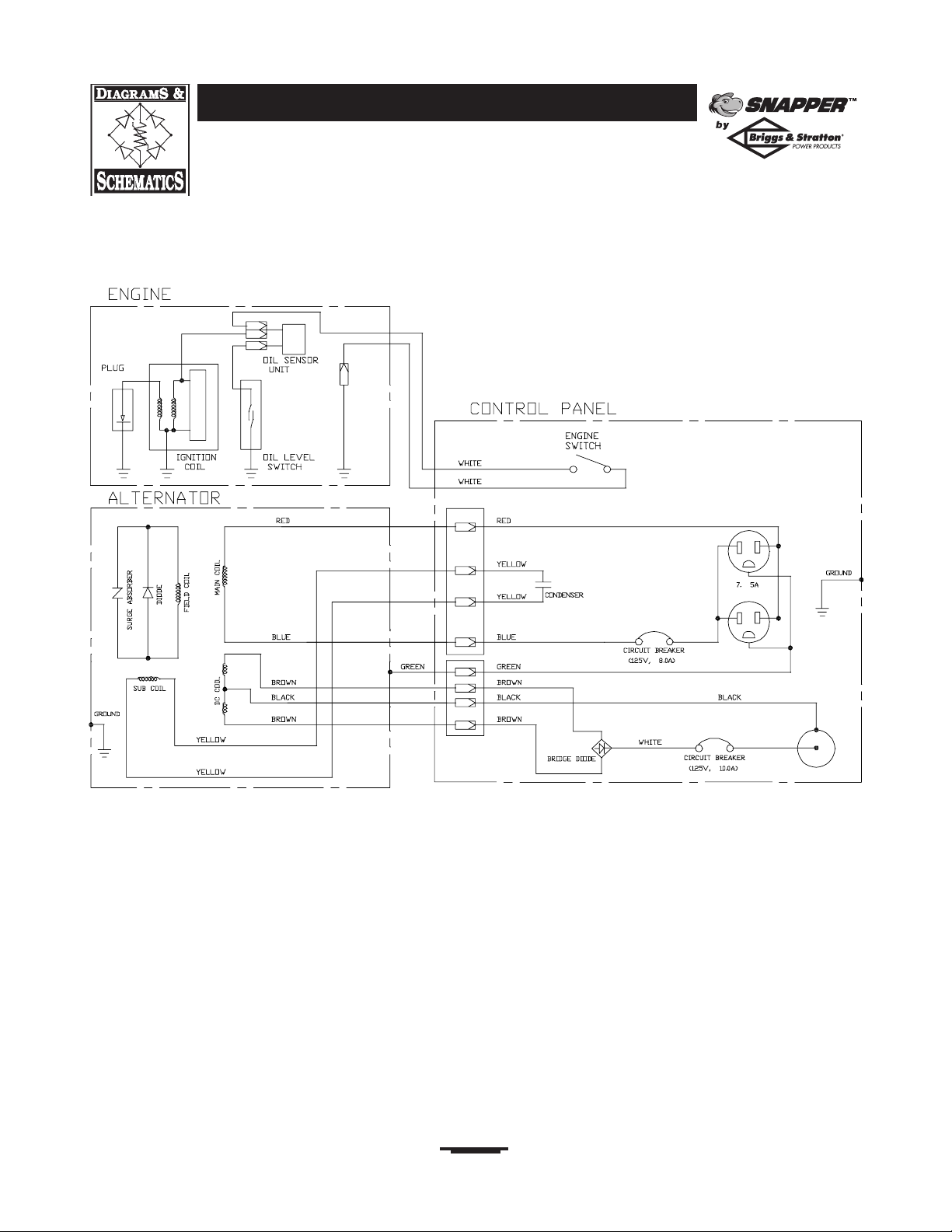

WIRING DIAGRAM

15

Snapper G1000 Generator

Page 16

16

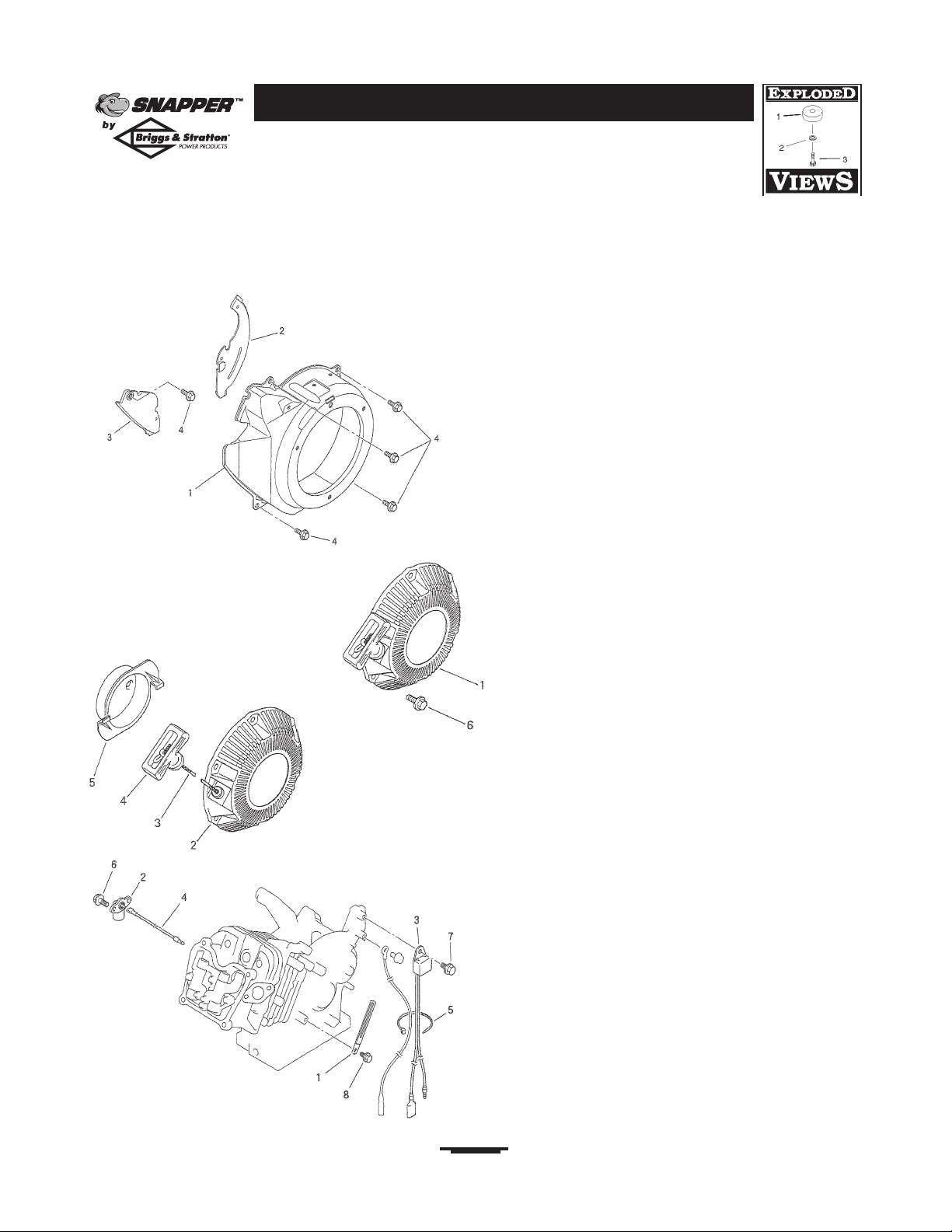

EXPLODED VIEW AND PARTS LIST – MAIN UNIT

Snapper G1000 Generator

Item Part # Qty Description

1 NSP 1 ENG, MITSUB, 2.4HP

2 187378GS 1 ROTOR

3 187411GS 1 BRG

4 187379GS 1 STATOR

5 187430GS 1 LEAD, GREEN

6 187409GS 1 BUSHING, LEAD WIRE, G790B

7 187381GS 1 RBC, 1K

8 187399GS 3 SCREW, SELF TAP, M6-12

9 187382GS 1 FAN, COOLING

10 187388GS 1 BOLT, RTR

11 187389GS 3 BOLT, STATOR

12 187405GS 1 INSLTN, HEAT SEALED, #1

13 187384GS 1 MFFLR, SEALED

14 187407GS 1 INSLTN, HEAT SEALED, #2

15 187403GS 1 DUCT, AIR

Item Part # Qty Description

16 187392GS 2 PHMS, M6-1.0, W/L/FW

17 187383GS 1 BASE, GEN

18 187390GS 4 BOLT, FLNG, M6-1.0 X 10

19 187385GS 4 MNT, VIBR

20 187427GS 4 HHCS, FLNG, M8-1.25 X 12

21 187424GS 1 NUT, WING, M5 X 0.8

22 187423GS 1 NUT, M5 X 0.8

23 187419GS 2 WSHR, LOCK

24 187420GS 2 WSHR, FLAT

25 187401GS 2 NUT, M8-1.25, FLANGE

26 187415GS 1 PHMS, M5-0.8 X 20

27 187413GS 2 CNNCTR

28 187434GS 4 HHCS, FLNG

29 187431GS 1 STND, ENG

Page 17

17

Snapper G1000 Generator

Item Part # Qty Description

1 187436GS 1 CAP, FUEL

2 187439GS 1 PACKING, TANK

3 187438GS 1 FLTR, FUEL

4 187769GS 3 U-PACKING

5 187437GS 1 TANK, FUEL, 4.5L

6 187766GS 1 DECAL, CHOKE

7 187756GS 4 BOLT, COVER (M5-16)

8 187875GS 1 HSG, GEN, MFFLR

9 190200GS 1 DECAL, WARNING

10 187772GS 1 COVER, SPARK PLUG

11 187757GS 5 BOLT, COVER (M6-16)

12 187760GS 11 PHMS, M4-12 W/FW

13 187435GS 1 CVR, MFFLR, GEN

14 187775GS 3 BOLT, MFFLR CVR (M6-16)

15 187768GS 1 DECAL CAUTION HOT

16 187774GS 4 BOLT, COVER (M6-20)

17 187761GS 8 NUT, M4X0.6 W/FW

18 187463GS 1 INSLTN, MFFLR

19 187874GS 1 HSG, GEN

20 NSP 1 DECAL, EMISSIONS

21 187457GS 1 CONDENSER, 300V

22 187765GS 1 DECAL, CAUTION FUEL

23 187759GS 2 BOLT, COVER (M5-10)

Item Part # Qty Description

24 187462GS 1 DIODE, BRIDGE

26 190201GS 1 DECAL, GEN, SNAPPER

27 187773GS 1 COVER, OIL FILL

28 187460GS 1 CB, DC

29 187454GS 1 CB, 8A, 125V

30 187873GS 1 OUTLET, ACCESSORY DC

31 187450GS 1 SWITCH, ENG, ON/OFF

32 187812GS 1 CPNL

33 187456GS 1 RECPTCL, 15A, 125V

34 187763GS 1 DECAL, CAUTION OIL

35 187876GS 1 CABLE, BATTERY CHARGE

36 190089GS 1 DECAL, MODEL

37 187764GS 1 DECAL, FUEL SHUTOFF

38 187447GS 1 INSLTN, HTSHLD, TANK #1

39 187448GS 1 INSLTN, HTSHLD, TANK #2

40 187442GS 2 BRKT, TANK, FUEL

41 187758GS 1 BRKT, FUEL COCK

42 187443GS 1 COCK, FUEL

43 187770GS 1 PHMS, M5-10 W/FW

44 187579GS 1 CLIP, FUEL HOSE

45 187440GS 1 FLTR, FUEL

46 187578GS 1 HOSE, FUEL

EXPLODED VIEW AND PARTS LIST – MAIN UNIT

Page 18

18

Snapper G1000 Generator

EXPLODED VIEW AND PARTS LIST – ENGINE

Cylinder Block, Cylinder Head

Item Part # Qty Description

1 187404GS 1 ASSY, CYL HEAD

2 187406GS 2 TPPT, CYL HEAD

3 187408GS 2 VLV, EXH

4 187410GS 2 SPRNG, VLV

5 187412GS 2 RTNR, VLV SPG

6 187414GS 2 ROD, PUSH

7 187416GS 1 ASSY, RCKR, ARM

8 187417GS 2 NUT, CYL HEAD

9 187418GS 2 SCRW, ADJST

10 187421GS 1 PLT, CYL HEAD

Item Part # Qty Description

11 187422GS 1 SEAL, VLV STEM

12 187423GS 4 NUT, M5 X 0.8

13 187426GS 4 BOLT, FLNG

14 187428GS 2 PIN, DWL

15 187429GS 1 GSKT, HEAD

16 187468GS 1 CVR, VALVE

17 187470GS 4 BOLT, VALVE CVR

18 187472GS 1 GSKT, VALVE CVR

19 187569GS 2 BOLT, STUD

Item Part # Qty Description

1 187380GS 1 BLOCK, CYL

2 187386GS 1 ASSY, GOV, GEAR

3 187387GS 1 SLIDER, GOV

4 187391GS 1 SHFT, GOV

5 187393GS 2 PLUG, DRAIN

6 187394GS 2 SEAL, OIL

7 187395GS 1 BRG, BALL

8 187400GS 1 WSHR, CYLBLOCK

9 187402GS 2 GSKT, CYLBLOCK

Page 19

19

Snapper G1000 Generator

EXPLODED VIEW AND PARTS LIST – ENGINE

Crankcase Cover, Crankshaft/Camshaft

Item Part # Qty Description

1 187394GS 2 SEAL, OIL

2 187473GS 1 CVR, CRANKCASE

3 187474GS 1 DIPSTICK, OIL

4 187475GS 1 O-RING, DIPSTICK

5 187477GS 1 BRG, PTO

6 187478GS 6 BOLT, CRANKCASE CVR

7 187428GS 2 PIN, DWL

8 187479GS 1 GSKT, CRANKCASE CVR

Item Part # Qty Description

1 187481GS 1 ASSY, CRNKSHFT

2 187484GS 1 GEAR, CRNKSHFT

3 187486GS 2 KEY, WOODRFF

4 187487GS 1 GEAR, CRNKSHFT

6 187488GS 1 ASSY, CAMSHAFT

7 187489GS 1 PIN, CMPR REL

8 187490GS 1 RNG, SNP, CMPRSSN

REL

Page 20

20

Snapper G1000 Generator

EXPLODED VIEW AND PARTS LIST – ENGINE

Piston/Rod, Magneto/Flywheel, Air Cleaner

Item Part # Qty Description

1 187526GS 1 ROD, CNNCTNG, STD

1 187527GS 1 ROD, CNNCTNG, US.25

1 187528GS 1 ROD, CNNCTNG, US.50

2 187529GS 2 BOLT, CNNCTNG ROD

3 187530GS 1 ASSY, PSTN, STD

3 187531GS 1 ASSY, PSTN, OS.25

3 187532GS 1 ASSY, PSTN, OS.50

4 187533GS 1 PIN, PISTON

5 187534GS 1 SET, RING, PSTN, STD

5 187535GS 1 SET, RING, PSTN, OS.25

5 187537GS 1 SET, RING, PSTN, OS.50

6 187539GS 2 CLIP, SPRING, PSTN PIN

Item Part # Qty Description

1 187540GS 1 FLYWHL

2 187541GS 1 COIL, IGNITION

3 187543GS 1 FAN

4 187544GS 1 CLIP, MAGNETO

5 187545GS 2 BOLT, MAGNETO

6 187546GS 1 NUT

Item Part # Qty Description

1 187492GS 1 HSNG, AIR CLNR

2 187494GS 1 CVR, AIR CLNR

3 187496GS 1 SPRT, AIR CLNR

4 187497GS 1 ELEMENT, AIR CLNR

5 187498GS 1 BRTHR, AIR CLNR

6 187500GS 2 STUD, AIR CLNR

7 187501GS 2 SCREW, AIR CLNR CVR

8 187503GS 2 NUT, AIR CLNR CVR

9 187504GS 1 GSKT, CARB

10 187576GS 1 DECAL, CHOKE

Page 21

21

Snapper G1000 Generator

EXPLODED VIEW AND PARTS LIST – ENGINE

Carburetor, Control/Linkages

Item Part # Qty Description

1 187469GS 1 CARB, COMPLETE

2 187471GS 1 JET, MAIN

3 187476GS 1 SHFT, THROTTL

4 187480GS 1 VLV, NEEDLE

5 187482GS 1 CLIP, CARB

6 187483GS 1 PIN, CARB

7 187485GS 1 VLV, THRTTL

8 187491GS 3 HHCS, CARB

9 187493GS 1 VLV, CHOKE

10 187495GS 1 GSKT, CARB

11 187499GS 1 CHMBR, FLOAT

12 187502GS 1 SPRING, CARB

13 187509GS 1 HHCS, CARB

14 187511GS 1 GSKT, CARB

15 187525GS 1 BOLT, CARB

16 187536GS 1 FLOAT, CARB

17 187538GS 1 NZZL, MAIN, CARB

18 187542GS 1 HHCS, CARB

19 187502GS 1 SPRING, CARB

20 187547GS 1 ADJSTR, CARB

21 187548GS 1 LEVER, CHOKE

22 187549GS 1 JET, PILOT

23 187550GS 1 SPRING, CARB

24 187551GS 1 CAP, CARB

25 187552GS 2 PACKING, CARB

26 187553GS 1 SEAL, CARB

27 187554GS 1 SEAL, CARB

28 187556GS 1 INSLTR, CARB

29 187504GS 2 GSKT, CARB

Item Part # Qty Description

1 187505GS 1 BRKT, SPEED CNTRL

2 187506GS 1 SPRING, SPEED CNTRL

3 187507GS 1 SCREW, SPEED CNTRL

4 187508GS 1 SHFT, GOV

5 187510GS 1 RING, SNAP, GOV ROD

6 187512GS 1 LEVER, GOV

7 187513GS 1 ROD, GOV

8 187514GS 1 SPRING, GOV LEVER

9 187515GS 1 WSHR, GOV LEVER

10 187516GS 1 CVR, TOP

11 187517GS 1 CLIP, GOV ROD

12 187518GS 1 BOLT, SPEED CNTRL BKT

13 187519GS 1 BOLT, TOP CVR

14 187520GS 2 NUT, GOV LEVER

15 187570GS 1 SPRING, GOV

Page 22

22

Snapper G1000 Generator

EXPLODED VIEW AND PARTS LIST – ENGINE

Fan Cover, Recoil Starter, Oil Sensor

Item Part # Qty Description

1 187521GS 1 CVR, FAN

2 187522GS 1 CVR, FAN

3 187523GS 1 CVR, FAN

4 187524GS 4 BOLT, FAN CVR

Item Part # Qty Description

1 187557GS 1 ASSY, RECOIL, STRTR

2 187558GS 1 STRTR, RECOIL

3 187559GS 1 ROPE, RECOIL

4 187560GS 1 HNDL, RECOIL

5 187561GS 1 PULLEY, STRTR

6 187562GS 3 BOLT, FLNG

Item Part # Qty Description

1 187563GS 1 CLAMP, OILSNSR

2 187564GS 1 SNSR, OIL

3 187565GS 1 UNIT, OILSNSR

4 187566GS 1 WIRE, LEAD

5 187567GS 1 BAND, OILSNSR

6 187470GS 2 BOLT, VALVE CVR

7 187524GS 1 BOLT, FAN CVR

8 187568GS 1 BOLT, FLNG

Page 23

23

Snapper G1000 Generator

EXPLODED VIEW AND PARTS LIST – ENGINE

Lead Wires, Muffler, Gasket Set

Item Part # Qty Description

1 187571GS 1 WIRE, LEAD

2 187572GS 1 PLUG, SPARK

3 187573GS 1 CAP, PLUG

4 187574GS 1 TIEWRAP, LEAD WIRE

5 187575GS 1 WIRE, LEAD

Item Part # Qty Description

1 187449GS 3 NUT, FLNG

2 188261GS 1 PIPE, TAIL

3 187446GS 1 GSKT, MFFLR

4 187455GS 2 NUT, CONICAL

5 187451GS 1 GSKT, MFFLR

6 187444GS 1 MFFLR

7 188263GS 1 SCREEN, SPARK

8 188262GS 1 SCREW

Item Part # Qty Description

1 187461GS 1 SET, GSKT (Includes items 2-6)

2 187429GS 1 GSKT, HEAD

3 187472GS 1 GSKT, VALVE CVR

4 187479GS 1 GSKT, CRANKCASE CVR

5 187504GS 3 GSKT, CARB

6 187451GS 1 GSKT, MFFLR

Page 24

24

Snapper G1000 Generador

TABLA DE CONTENIDOS

Reglas De Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Conozca Su Generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ensamblaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-31

Especificaciones Del Producto / Mantenimiento . . . . . . . . . 32-34

Almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35

Diagnosticos De Averías. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Digrama Eléctrico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Piezas De Recambio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-23

Garantia Del Sistema De Control De Emisiones . . . . . . . . . . . 38

Garantia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DESCRIPCIÓN DEL EQUIPO

Lea este manual de manera cuidadosa y familiarícese con

su generador. Conozca sus usos, sus limitaciones y

cualquier peligro relacionado con el mismo.

Este generador funciona en base a un motor, de campo eléctrico

giratorio y de corriente alterna (AC). Fue diseñado con la

finalidad de proveer energía eléctrica para luces eléctricas,

aparatos, herramientas compatibles y cargas de motor. El campo

giratorio del generador funciona a una velocidad de 3,6000 rpm

usando un motor con un solo cilindro.

¡PRECAUCIÓN! No sobrepase la capacidad de vataje y

amperaje del generador. Revise "No sobrecargue el Generador" en

la página 31.

Se ha hecho cada esfuerzo posible para asegurarse que la

información que aparece en este manual es exacta y se encuentra

actualizada. Sin embargo, Generac se reserva el derecho a

cambiar, alterar o de otra manera mejorar, el producto y este

documento en cualquier momento, sin previo aviso.

El Sistema de Control de Emisiones para este generador está

garantizado para juegos estándares por la Agencia de Protección

Ambiental. Para mayor información acerca de la garantía, consulte

con el manual del propietario del motor.

INSTRUCCIONES DE SEGURIDAD

El símbolo de alerta de seguridad ( ) es usado con una palabra

(PELIGRO, ADVERTENCIA, PRECAUCIÓN), un mensaje por

escrito o una ilustración, para alertarlo acerca de cualquier

situación de peligro que pueda existir. PELIGRO indica un riesgo

el cual, si no se evita, causará la muerte o una herida grave.

ADVERTENCIA indica un riesgo el cual, si no se evita, puede

causar la muerte o una herida grave. PRECAUCIÓN indica un

riesgo, el cual, si no se evita, puede causar heridas menores o

moderadas. PRECAUCIÓN, cuando se usa sin el símbolo de

alerta, indica una situación que podría resultar en el daño del

equipo. Siga los mensajes de seguridad para evitar o reducir los

riesgos de heridas e inclusive la muerte.

El escape del motor de este producto contiene

elementos químicos reconocidos en el Estado de

California por producir cáncer, defectos de nacimiento u

otros daños de tipo reproductivo.

ADVERTENCIA

• Opere el generador SOLAMENTE al aire libre.

• Mantenga al menos 2 pies de espacio libre alrededor del

generador, para la adecuada ventilación.

• No opere el generador dentro de un edificio o lugar cerrado,

incluyendo el compartimiento del generador en un vehículo

recreativo o RV.

Al generador funcionar, se produce monóxido de

carbono, un gas inodoro y venenoso.

El respirar el monóxido de carbono, producirá

náusea, desmayo o la muerte.

PELIGRO

CUANDO AÑADA COMBUSTIBLE

• Apague el generador (posición OFF) y déjelo enfriar al menos por

2 minutos antes de remover la tapa de la gasolina. Afloje la tapa

lentamente para dejar que la presión salga del tanque.

• Llene el tanque al aire libre.

• No llene demasiado el tanque. Permita al menos espacio para la

expansión del combustible.

• Mantenga la gasolina alejada de chispas, llamas abiertas, pilotos, calor

y otras fuentes de ignición.

• No encienda un cigarrillo o fume.

CUANDO OPERE EL EQUIPO

• No incline el motor o el equipo, de tal manera que la gasolina se

pueda derramar.

CUANDO TRANSPORTE O REPARE EL EQUIPO

• Transporte o repare el equipo con el tanque de combustible vacío, o

con la válvula para apagar el combustible, apagada (posición OFF).

• Desconecte el cable de la bujía.

CUANDO ALMACENE O GUARDE EL EQUIPO CON

COMBUSTIBLE EN EL TANQUE

• Almacene alejado de calderas, estufas, calentadores de agua,

secadoras de ropa u otros aparatos electrodomésticos que posean

pilotos u otras fuentes de ignición, porque ellos pueden encender los

vapores de la gasolina.

La gasolina y sus vapores son extremadamente

inflamables y explosivos.

El fuego o una explosión pueden causar quemaduras

severas e inclusive la muerte.

ADVERTENCIA

Page 25

25

Snapper G1000 Generador

• Cuando use un generador como poder de energía auxiliar, notifique a

la compañía de utilidades. Use el equipo de transferencia aprobado

para aislar el generador de otra utilidad eléctrica.

• Los Códigos Nacionales para la Electricidad, requieren que los

generadores estén haciendo tierra de una manera aprobada. Llame a

un electricista para conocer los requisitos locales para hacer tierra.

• Use un interruptor para la falla del circuito de tierra (GFCI) en

cualquier área bastante húmeda o que sea altamente conductiva, tales

como terrazas de metal o trabajo hecho con acero.

• No toque los alambres pelados o receptáculos.

• No use un generador con cables eléctricos que estén malgastados,

rotos, pelados o dañados de cualquier forma.

• No opere el generador bajo la lluvia.

• No maneje el generador o cables eléctricos mientras esté parado en

agua, descalzo o cuando las manos y los pies estén mojados.

• No permita que personas descalificadas o niños operen o sirvan al

generador.

Los generadores producen un voltaje muy poderoso.

Si no hace tierra apropiadamente con un generador,

puede hacer que ocurra un electrocutamiento.

Si no aísla el generador de utilidades de energía,

puede hacer que los trabajadores de electricidad

sufran heridas graves e inclusive la muerte, debido a

la retroalimentación de la energía eléctrica.

ADVERTENCIA

• No permita ninguna llama abierta, chispa, calor, o encienda un

cigarrillo durante y por varios minutos después de haber recargado la

batería.

• Lleve puestos las gafas protectoras, delantal y guantes de goma.

Las baterías almacenadas producen hidrógeno

explosivo mientras estén siendo recargadas.

El hidrógeno puede permanecer cerca de la batería

por un periodo largo de tiempo, después que la

batería haya sido recargada.

Una pequeña chispa puede encender el hidrógeno y

causar una explosión.

Usted puede quedar ciego o sufrir heridas muy graves.

El fluido de electrolito de la batería contiene ácido y

es extremadamente cáustico.

El contacto con el fluido de la batería puede causar

quemaduras químicas severas.

PELIGRO

• No toque las superficies calientes.

• Permita que el equipo se enfríe antes de tocarlo.

Los motores al funcionar producen calor. La

temperatura del silenciador y de las áreas cercanas

puede alcanzar o pasar los 150°F (65°C).

Quemaduras severas pueden ocurrir al hacer contacto.

ADVERTENCIA

• No cambie ninguna velocidad determinada. El generador suministra

una frecuencia y un voltaje calificado cuando funciona a una velocidad

determinada.

• No modifique al generador en ninguna forma.

Las velocidades de operación en exceso, aumentan los riesgos

de heridas y daños al generador.

Las velocidades bajan en exceso, imponen una carga muy pesada.

PRECAUCIÓN

• Vea "No sobrecargue su generador" en la página 31.

• Encienda su generador y deje que el motor se estabilice antes de

conectar las cargas eléctricas.

• Conecte las cargas eléctricas en la posición de apagado (OFF), luego

encienda (ON) para su operación.

• Apague (OFF) las cargas eléctricas y desconéctelas del generador

antes de parar el generador.

El sobrepasar la capacidad del amperaje y vataje del generador,

puede dañar al generador y los aparatos eléctricos conectados

al mismo.

PRECAUCIÓN

• Use el generador solamente con la finalidad para el cual fue diseñado.

• Si usted tiene alguna pregunta acerca de las finalidades de uso del

generador, pregúntele a su concesionario o contacte a Snapper.

• Opere el generador solamente en superficies niveladas.

• No exponga al generador a una humedad excesiva, polvo, suciedad o

vapores corrosivos.

• No inserte cualquier objeto a través de las ranuras de enfriamiento.

• Si los aparatos conectados se sobrecalientan, apáguelos y

desconéctelos del generador.

• Apague el generador si:

-Se pierde la salida eléctrica;

-El equipo produce chispas, humo o emite llamas;

-La unidad vibra de una manera excesiva.

El tratamiento inadecuado del generador puede dañarlo y

acortar su vida productiva.

PRECAUCIÓN

Page 26

26

Snapper G1000 Generador

CONOZCA SU GENERADOR

Lea este manual del propietario y las reglas de seguridad antes de operar su generador.

Compare las ilustraciones con su generador para familiarizarse con la ubicación de los diferentes controles y ajustes. Conserve este

manual para referencias futuras.

Arrancador de Retroceso — Usado para encender el motor.

Bujía — Acceso al enchufe de la bujía.

Circuito Breaker (AC) — Se proporcionan receptáculos con

un circuito breaker de re-encendido a presión para proteger el

generador en contra de sobrecarga eléctrica.

Clavija Accesoria de 12 Voltios DC, 8.3 Amperios —

Puede utilizarse para proporcionar energía a dispositivos

eléctricos o para recargar baterías de 12 Volts DC.

Conexión de Tierra — Utilice esta conexión para conectar a

tierra de forma correcta el generador. Vea la sección “Conexión a

Tierra el Generador” en la página 28.

Interruptor de Encendido (APAGADO/ENCENDIDO) —

Utilizado para detener un motor en funcionamiento.

Llenado/Drenaje de Aceite — Acceso a la varilla de relleno de

aceite y a la tapa de drenaje de aceite.

Palanca de Ahogador — Utilizada para proporcionar de

manera manual la mezcla de arranque adecuada cuando el motor

se encuentra frío.

Purificador de Aire — Utiliza un elemento de espuma para

limitar la cantidad de mugre y polvo que entra en el motor.

Receptáculos de 120 Voltios AC, 7.5 Amperios — Pueden

ser utilizados para proporcionar energía eléctrica para la

operación de cargas eléctricas de alumbrado, de aparatos y de

herramientas de 120 Voltios AC, de una fase, a 60 Herzios.

Tanque de Combustible — Tiene una capacidad de 1.2 galones

(4.5 litros) de combustible.

Válvula de Corte de Combustible — Use esta válvula para

niciar o detener el suministro de combustible.

Receptáculos de 120 Voltios

AC, 7.5 Amperios

Arrancador de Retroceso

Circuito Breaker (AC)

Llenado/Drenaje de Aceite

(cubierta del interior)

Palanca de Ahogador

Bujía (cubierta del interior)

Tanque de Combustible

Purificador de Aire

Conexión de Tierra

Clavija Accesoria de 12 Voltios

DC, 8.3 Amperios

Interruptor de Encendido

Válvula de Corte de

Combustible

Page 27

27

Snapper G1000 Generador

CONTENIDO DEL EMPAQUE

Si cualquiera de las partes no están presente o se encuentran

dañadas, llame a la línea de ayuda del generador al

1-800-270-1408.

Verifique el contenido contra la lista de artículos detallados a

continuación:

• Unidad principal

• Manual del propietario

• Cable para recargar la batería

ANTES DE DARLE ARRANQUE AL

GENERADOR

Añadir Aceite de Motor

NOTA: Cuando agregue aceite al compartimiento del motor en

el futuro, utilice únicamente aceite detergente de alta calidad

reconocido con la clasificación API de servicio SF, SG/CC, CD. Si

su ha la temperatura operadora esperada es abajo 32ºF (0ºC), el

uso SAE 10W-30. De otro modo uso SAE 30.

SAE 10W-30 es el recomendado para uso general bajo todas las

temperaturas. Este aceite de multi-viscosidad mejorará el

arranque en climas fríos, pero provocará un incremento en el

consumo de aceite. Verifique el nivel de aceite del motor con

mayor frecuencia para evitar posibles daños ocasionados por el

funcionamiento del motor con aceite insuficiente.

Para Añadir Aceite al Motor:

• Coloque el generador sobre una superficie nivelada.

• Quite la cubierta de relleno de aceite.

• Remueva la tapa del rellenador de aceite y limpie la varilla

(Figura 16).

• Si el nivel de aceite no se encuentra en el punto de

desbordamiento del cuello del rellenador de aceite, llene

lentamente el motor con el aceite recomendado.

• Reinstale la tapa del rellenador de aceite y sujételo de forma

segura.

• Reemplace la cubierta de relleno de aceite.

• Verifique el nivel de aceite del motor antes de arrancarlo en

cada ocasión de ahora en adelante.

Añadir Gasolina

¡ADVERTENCIA! Nunca llene el tanque de

combustible en interiores. Nunca llene tampoco el tanque

de combustible mientras el motor se encuentre funcionando

o cuando esté caliente. No encienda un cigarrillo ni fume

cuando esté llenando el tanque de combustible.

¡PRECAUCIÓN! No sobrellene el tanque de

combustible. Siempre deje espacio para la expansión.

• Use gasoline SIN PLOMO limpia y fresca con una octanaje de

bombeo de 86-90. No utilice gasolina premium o con plomo.

No mezcle el aceite con la gasolina.

• Limpie el área alrededor de la tapa de llenado de combustible,

quite la tapa.

• Verifique el nivel de combustible.

• Si el nivel de combustible es bajo, añada lentamente la gasolina

recomendada al tanque de combustible, hasta el borde del filtro

de combustible (Figura 17). Tenga cuidado de no sobrellenarlo

(no debe haber combustible en el cuello del rellenador).

NOTA: Ocasionalmente limpie el filtro de combustible de

cualquier mugre, óxido u otra materia en forma de partículas.

• Instale la tapa del combustible y limpie cualquier gasolina

derramada.

De manera ocasional usted podrá escuchar un ligero “golpe de

bujía” o “silbido” (ruido de golpeteo metálico) mientras opera

bajo cargas pesadas. No es motivo para preocuparse. Si ocurre un

golpe de bujía o se oye un silbido a una velocidad estable del

motor bajo carga normal, cambie la marca de la gasolina. Si

persiste el silbido o el golpe de bujía, consulte a su centro de

reparaciones.

Cuello del Rellenador de Aceite

Figura 16 — Adición Del Aceite De Motor

Llene a Este Nivel

Figura 17 — Nivel Del Combustible

Page 28

28

Snapper G1000 Generador

CONEXION A TIERRA DEL

GENERADOR

El Código Eléctrico Nacional exige que el bastidor y las partes

externas conductoras de electricidad del generador se encuentren

conectadas adecuadamente a una tierra física aprobada. Los

códigos eléctricos locales también podrían exigir la conexión a

tierra de la unidad. Para tal propósito, se ha suministrado una

tuerca mariposa para conexión a tierra en la base del armazón

(Figura 18).

Por lo general, la conexión de un alambre de cobre trenzado No.

12 AWG (American Wire Gauge) a la aleta y a una barra de

conexión a tierra de cobre o bronce (electrodo) proporciona una

protección adecuada contra las descargas eléctricas. Sin embargo,

los códigos locales pueden variar substancialmente. Consulte con

un electricista local para conocer los requisitos de conexión a

tierra de su área.

La conexión a tierra adecuada del generador ayudará a evitar las

descargas eléctricas en el caso de que exista una condición de

falla a tierra en el generador o en los dispositivos eléctricos

conectados. La conexión a tierra adecuada también ayuda a

disipar la electricidad estática, la cual se acumula frecuentemente

en dispositivos no conectados a tierra.

CÓMO UTILIZAR SU

GENERADOR

¡PRECAUCIÓN! Nunca inicie o detenga el motor

cuando haya dispositivos eléctricos conectados a los

receptáculos y que estén encendidos.

Para Arrancar el Motor

Desconecte todas las cargas eléctricas de los receptáculos del

generador antes de encender el motor. Use las instrucciones

siguientes del comienzo:

• Asegúrese de que el cable de la bujía se encuentre conectado

a la bujía.

• Gire la válvula de combustible a la posición “Open”

(“ABIERTO”) (completamente en la dirección de las manecillas

del reloj) (Figura 19).

• Deslice el nivel del ahogador a la posición “Choke”

(“Estrangulación”) (por completo hacia la derecha) (Figura 20).

• Coloque el interruptor del motor en la posición “On”

(ENCENDIDO) (Figura 21).

• Sujete la manija y jale lentamente la cuerda hasta que sienta

algo de resistencia; entonces jale la cuerda hacia fuera con un

jalón completo de su brazo. Permita que la cuerda regrese

lentamente. No deje que la cuerda “chicotée de regreso” en

contra de la unidad.

NOTA: Si el motor arranca después de tres accionamientos,

pero sólo funciona por 10 segundos, revise el nivel de aceite del

motor en la caja del cigüeñal (cárter). Esta unidad está equipada

con un Aceite Sistema Alerta (vea página 29).

• Deslice el nivel del ahogador a la posición “Run” mientras el

motor se calienta.

NOTA: Bajo condiciones sin carga, la velocidad del motor puede

variar ligeramente más rápido o más lento hasta que la

temperatura del motor se estabilice.

Figura 19 — Válvula del Combustible en la Posición Abierta

Figura 20 — Coloque el Interruptor del Motor

Figura 21 — Interruptor del Motor en la Posición de Trabajo

Figura 18 — Poner a Tierra la Tuerca de Ala

Conexión de Tierra

Page 29

29

Snapper G1000 Generador

¡PRECAUCIÓN! ¡Peligro al respirar! Nunca haga

funcionar el motor en áreas con ventilación deficiente. El

escape contiene monóxido de carbono, un gas inodoro y

mortal.

Conexion de Cargas Elecricas

• Deje que el motor se estabilice y se caliente por unos

minutos después del arranque.

• No conecte cargas de 240 Voltios a los tomacorrientes de

120 Voltios.

• No conecte cargas trifásicas a los tomacorrientes.

• No conecte cargas de 50 Hertzios al generador.

• Enchufe y encienda las cargas eléctricas AC de 120 Voltios,

monofásicas de 60 Hertzios deseadas.

• NO SOBRECARGUE EL GENERADOR. Sume los vatios

asignados (o amperios) de todas las cargas que se van a

conectar al mismo tiempo. Este total no debe ser mayor que

la capacidad del vatiaje/amperaje nominal del generador. Vea

“No Sobrecargue el Generador” en la página 31.

Detener el Motor

• Desconecte todas las cargas eléctricas de la unidad. Nunca

arranque o detenga el motor con dispositivos eléctricos

conectados a él y encendidos.

• Permita que el motor funcione sin carga durante dos minutos

para estabilizar las temperaturas internas de la unidad.

• Mueva el interruptor del motor a la posición “Off” (apagado).

• Gire la válvula a la posición “Close” ( “CERRADA” )

(totalmente en contra del sentido de las manecillas del reloj).

NOTA: En una emergencia, detenga el motor moviendo el

interruptor del motor a la posición “Off”.

Aceite Sistema Alerta

El Aceite Sistema Alerta es diseñado a previene el daño de motor

causado por una cantidad insuficiente de aceite en el cárter. Antes el

nivel de aceite en el cárter puede la caída debajo de un límite seguro,

el Aceite Sistema Alerta hace cerró automáticamente el motor (el

interruptor de motor hace permanece en el “On” la posición).

Si el Aceite Sistema Alerta causa que el motor para cierre, agrega

motor aceite.

Procedimiento de Carga de la Bateria

¡ADVERTENCIA! Las baterías de acumuladores

producen gas explosivo cuando son cargadas, el cual

permanece alrededor de la batería por un período de

tiempo prolongado después de haber sido cargada. La

chispa más pequeña podría encender el combustible y

causar una explosión que puede destruir la batería, causar

ceguera y otras lesiones serias.

¡ADVERTENCIA! No permita que se fume, llamas

abiertas, chispas o cualquier otra fuente de calor alrededor

de la batería. No utilice un encendedor o cualquier clase

de llama para revisar los niveles del líquido de la batería.

Use anteojos de protección, delantal de caucho y guantes

de caucho cuando trabaje alrededor de la batería. El

líquido electrólito de la batería es una solución de ácido

sulfúrico cáustico, la cual puede causar quemaduras

severas. No permita que el líquido entre en contacto con

los ojos, piel, ropa, etc. Si ocurren derrames, limpie

inmediatamente el área con agua limpia.

Su generador tiene la capacidad de recargar baterías descargadas

de acumuladores tipo servicio o automotriz de 12 Voltios. No

utilice la unidad para cargar baterías de 6 Voltios. No use la

unidad para mover motores que tengan la batería descargada.

Para recargar baterías de 12 Voltios, lleve a cabo los

siguientes procedimientos:

• Limpie los terminales de la batería si es necesario.

• Revise el nivel del líquido en todas las celdas de la batería. Si

es necesario, añada agua destilada UNICAMENTE hasta cubrir

los separadores de las celdas de la batería. No use agua de

grifo.

• Si la batería está equipada con tapas de desfogue, asegúrese

de que están instaladas y apretadas.

• Conecte el enchufe conector del cable de carga de la batería

al tomacorrientes del panel.

• Conecte el sujetador del cable de carga de la batería que

tiene la manija roja al terminal o borne de la batería marcado

con el signo POSITIVO, POS o (+) (Figura 22).

• Conecte el sujetador del cable de carga de la batería que

tiene la manija negra al terminal o borne de la batería

marcado con el signo NEGATIVO, NEG o (-) (Figura 22).

Roja

Positivo

Negativo

Figura 22 — Conexiones De la Batería

Page 30

30

Snapper G1000 Generador

• Arranque el motor. Deje que el motor funcione mientras la

batería se recarga.

• Cuando la batería haya cargado, apague el motor (vea “Parado

del Motor” a continuación).

NOTA: Use un hidrómetro para automóviles para probar el

estado de carga y condición de la batería. Siga cuidadosamente las

instrucciones del fabricante del hidrómetro. Por lo general, se

considera que una batería está en un estado de carga del 100%

cuando la gravedad específica de su líquido (medida por el

hidrómetro) es de 1.260 o más.

ENCHUFES DE CONEXIÓN

Receptáculo de 120 Voltios AC

Cada enchufe está protegido contra una sobrecarga por un

circuito breaker de re-encendido a presión de 7.5 Amperios.

Utilice cada receptáculo para operar cargas eléctricas de

120 Voltios, de una fase, 60 Herzios, que requieran hasta

1,000 watts (1.0kW) de energía (Figura 23).

¡PRECAUCIÓN! Aunque cada receptáculo está

preparado para soportar 120 Voltios a 15 Amperios

(1,440 watts o 1.44 kW), el generador está listo para

aguantar un total de 1,000 watts. Las cargas de energía que

excedan la capacidad de wataje del generador, pueden

dañarlo o provocar heridas graves a las personas

alrededor. El total de cargas proporcionadas por estos

receptáculos no deberían exceder los 7.5 Amperios.

Clavija Accesoria de 12 Voltios DC,

8.3 Amperios

Este receptáculo le permite recargar una batería de 12 Voltios

automotriz o de almacenamiento estilo suministro eléctrico, con

el cable de batería que se proporciona. Las bombas de aire estilo

campamento, linternas, ventiladores u otros dispositivos de

12 Voltios que posean un enchufe estilo encendedor de cigarrillos,

también pueden ser cargadas por este enchufe (Figura 24).

Este receptáculo no puede recargar las baterías de 6 Voltios y no

puede ser utilizado tampoco para arrancar un motor que tenga la

batería descargada. Consulte “Cargando una Batería” (página 29)

antes de intentar recargar cualquier batería.

CABLES DE EXTENSIÓN

Utilice únicamente cables de extensión de alta calidad, aislados de

forma apropiada, con los receptáculos eléctricos de 120 Voltios

del generador. Verifique las capacidades de todos los cables de

extensión antes de utilizarlos. Tales cables deben tener la

capacidad de soportar cargas de 125 Voltios AC a 15 Amperios (o

superiores) para la mayoría de aparatos eléctricos. Algunos

dispositivos, sin embargo, quizás no requieran este tipo de cable

de extensión. Verifique los manuales del propietario de dichos

aparatos para conocer sus recomendaciones al respecto.

Conserve los cables de extensión tan cortos como sea posible,

preferiblemente a una longitud menor de 15 pies, para prevenir

una baja del voltaje y un posible sobrecalentamiento de alambres.

Figura 23 — CA De 120 Voltios, Receptáculo A dos caras

De 15 Amperios

Figura 24 — Accesorio Gato De la Cc. De 12 Voltios

Page 31

31

Snapper G1000 Generador

NO SOBRECARGUE EL

GENERADOR

Capacidad

Usted debe asegurarse que su generador puede proveer el

suficiente vataje calificado (cuando esté funcionando) y de carga

(al encender) para los aparatos a los cuales va a proveer la

energía, al mismo tiempo. Siga estos pasos:

1. Seleccione los aparatos que recibirán la energía, al mismo

tiempo.

2. Totalice los vatios calificados (cuando esté funcionando) de

estos aparatos. Esta es la cantidad de energía que su

generador debe producir para mantener eso aparatos

funcionando adecuadamente. Vea la Figura 25.

3. Calcule la cantidad de vatios de carga (al encender) que

usted necesitará. El vataje de carga es la cantidad mínima de

electricidad, necesaria para encender herramientas o

aparatos con motores eléctricos, tales como, sierras

circulares o refrigeradores. Debido a que no todos los

motores se encienden al mismo momento, el vataje total de

carga se puede estimar al añadir solamente el(los) aparato(s)

con el vataje adicional más alto, al total del vataje calificado,

obtenido en el paso 2.

Ejemplo:

Vataje Total Calificado (cuando esté funcionando) = 3075

Vataje de Carga Adicional más alto = 1800

Salida Total Requerida del Generador = 4875

Control de la Energía

Para prolongar la vida de su generador y los aparatos que estén

conectados al mismo, es muy importante cuidarlo cuando se le

añaden cargas eléctricas. Nada debería estar conectado a los

tomacorrientes del generador antes de que su motor sea

encendido. La forma correcta y más segura para controlar la

energía del generador, es la de añadir en secuencias las cargas,

como se describe a continuación:

1. Sin tener nada conectado al generador, encienda el motor de