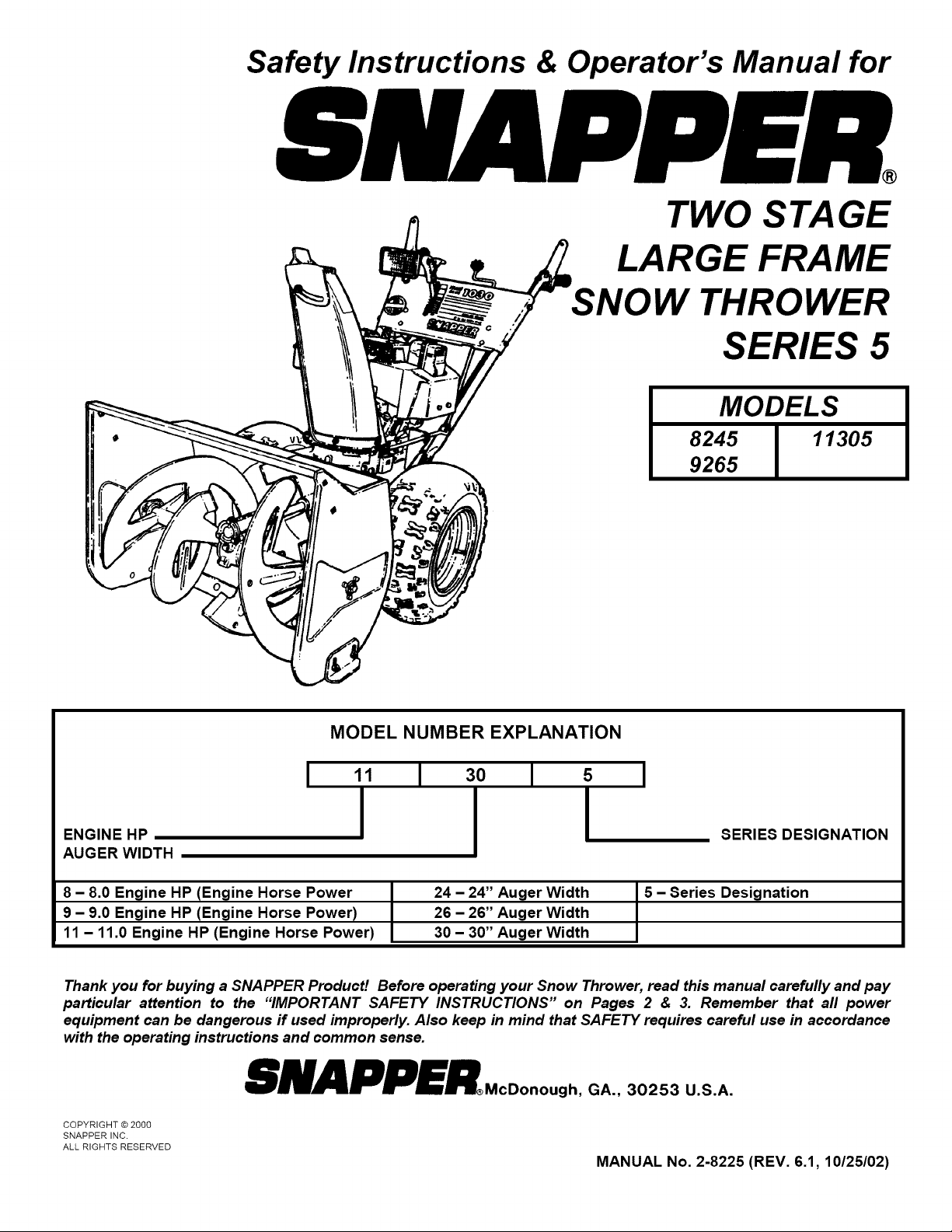

Snapper 9265, 8245, 11305 Owner’s Manual

Safety Instructions & Operator's Manual for

TWO STAGE

LARGE FRAME

W THROWER

SERIES 5

MODELS

8245 11305

9265

MODEL NUMBER EXPLANATION

I

ENGINE HP

AUGER WIDTH

8 - 8.0 Engine HP (Engine Horse Power

9 - 9.0 Engine HP (Engine Horse Power)

11 - 11.0 Engine HP (Engine Horse Power)

Thank you for buying a SNAPPER Product! Before operating your Snow Thrower, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 & 3. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in accordance

with the operating instructions and common sense.

11 I a0 I s I

24 - 24" Auger Width

26 - 26" Auger Width

30 - 30" Auger Width

SERIES DESIGNATION

5 - Series Designation

SNAPPERMcDonough,GA., 30253 U.S.A.

COPYRIGHT © 2000

SNAPPER INC.

ALL RIGHTS RESERVED

MANUAL No. 2-8225 (REV. 6.1, 10/25/02)

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This powerful machine is capable of amputating hands and feet and can throw objects that can cause injury

and damage! Failure to comply with the following instructions may result in serious injury to the operator or

other persons. The owner of the snow thrower must understand these instructions and, furthermore, must

allow only persons who understand these instructions to operate snow thrower. Each person operating the

snow thrower must be of sound mind and body and must not be under the influence of any substance which

might impair vision, dexterity, or judgment. If you have any questions pertaining to your snow thrower which

your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER,

McDonough, Georgia 30253. Phone: 800/935-2967.

PROTECTION FOR CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the snow removal

activity. Never assume that the children will remain

where you last saw them.

1. DO NOT allow children in the area when snow

thrower is being operated.

2. DO NOT allow pre-teenage children to operate

snow thrower.

3. ALLOW only responsible adults and teenagers

with mature judgment to operate the machine

and then only after being thoroughly instructed

and under the close supervision of an

experienced adult operator.

4. Keep the area clear of all persons, particularly

small children and pets.

5. Know how to STOP the snow thrower and

disengage the controls quickly.

PREPARATION

1. Warn everyone in advance to stay clear of area.

Keep especially watchful for children and pets

darting into area while operating.

2. Read, understand, and follow instructions and

warnings in this manual and on the machine.

Know the controls and the proper use of the

snow thrower before starting.

3. Data indicates that operators, age 60 and above,

are involved in a large percentage of snow

thrower-related injuries. These operators should

evaluate their ability to operate the snow thrower

safely enough to protect themselves and others

from serious injury.

4. Disengage all clutches and shift into neutral

before starting the engine (motor).

5. Wear adequate winter clothing including boots

which will give you maximum footing on slippery

surfaces. Exercise CAUTION to avoid slipping or

falling.

6. Before the first snow fall, check the area to be

cleared and remove all objects such as

doormats, sticks, toys, wires, rocks, etc., which

could be hurled or jam the snow thrower

PREPARATION

(Continued From Previous Column)

7. Survey the area to be cleared beforehand and

plan where snow is to be blown. Be prepared to

release auger/impeller clutch or to change

discharge chute direction quickly to discharge

away from windows, cars, buildings and

doorways to avoid property damage or personal

injury from hurled objects.

8. Use only approved extension cords and

receptacles in good condition and with sufficient

capacity to carry the current to the machine if

equipped with electric starting motors.

9. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Store only in an

approved fuel container. Never remove fuel cap

or add fuel with the engine running. Add fuel

outdoors only with the engine stopped and cool.

Clean spilled fuel and oil from machine. DO NOT

smoke. DO NOT run engine indoors.

OPERATIONAL PRECAUTIONS

1. Before starting, make visual check to make sure

auger/impeller housing is clear and all guards

and shields are in place and tight.

2. DO NOT operate machine without proper guards

shields, deflectors, or other safety protective

devices in place and functioning properly.

3. Should the auger/impeller become clogged,

release the auger/impeller clutch control and, as

an additional precaution, STOP the engine

before attempting to unclog the auger/impeller or

discharge chute.

4. DO NOT attempt to unclog the auger/impeller or

discharge chute by reaching in with your hands.

Use a long stick or similar implement to unclog.

5. DO NOT attempt to unclog the auger/impeller or

discharge chute with the engine running. STOP

engine and remove key.

6. STOP engine (motor) and remove key before

leaving the operator position for any reason.

IMPORTANT SAFETY INSTRUCTIONS

OPERATIONAL PRECAUTIONS

(Continued From Previous Page)

7. DO NOT put hands or feet near or under

rotating parts. Keep clear of the discharge

opening at all times.

8. Start engine only where exhaust fumes will be

safely dissipated. Allow a brief warm-up period,

and practice operation of controls outside

before putting the machine to work.

9. After striking a foreign object, STOP the engine

(motor), remove the key, and remove the wire

from spark plug. Thoroughly inspect the snow

thrower for any damage, and repair the damage

before restarting and operating the snow

thrower.

10. STOP the engine if the machine starts to vibrate

excessively as this normally indicates

mechanical problems. Remove the key and

disconnect the spark plug wire to prevent

unintentional starting before servicing or

repairing the machine.

11. DO NOT clear snow across the face of slopes.

Exercise extreme CAUTION when changing

direction on slopes. DO NOT attempt to clear

steep slopes.

12. DO NOT leave machine unattended with the

engine running. STOP engine and remove key

to prevent unauthorized operation.

13. Release clutch control and make sure

auger/impeller has STOPPED before adjusting

deflector, or placing hands near auger/impeller.

14. DO NOT use snow thrower on surfaces above

ground level, such as, a roof of a building.

15. Exercise extreme CAUTION when operating on

or crossing gravel drives, walks, or roads. Stay

alert for hidden hazards or traffic.

16. DO NOT overload the machine capacity by

attempting to clear snow at too fast a rate.

17. Never operate the machine at high transport

speeds on slippery surfaces. Look behind and

use care when backing.

18. Disengage power to the auger/impeller when

snow thrower is transported or not in use.

19. Use only attachments and accessories

approved by the manufacturer of the snow

thrower (such as wheels weights,

counterweights, cabs and the like).

20. Never operate the snow thrower without good

visibility or light. Always be sure of your

footing, and keep a firm hold on the handles.

Walk; never run.

MAINTENANCE AND STORAGE

1. DO NOT store machine or fuel container inside

where fumes may reach an open flame, spark,

or pilot light as in a water heater, furnace,

clothes dryer or other gas appliance. Allow

engine to cool before storing machine in an

enclosure. Store fuel container out of reach of

children in a well ventilated, unoccupied

building.

2. Keep machine and engine free of excess oil,

grease and spilled fuel to reduce fire hazard.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from

open flame.

4. Inspect all bolts, nuts and screws frequently

and keep properly tightened.

5. Use only recommended shear bolts (if

equipped) to prevent possible damage to

machine.

6. Service engine and make adjustments only

when engine is stopped. Remove key, remove

wire from spark plug, secure wire away from

plug, and disconnect cord from electric starting

motors to prevent accidental starting.

7. DO NOT change engine governor speed

settings or overspeed engine.

8. DO NOT test for spark by grounding the spark

plug next to spark plug hole. Spark from the

plug could ignite gas exiting engine.

9. Have machine serviced by an authorized

SNAPPER dealer at least once a year and have

the dealer install any new safety devices.

10. Use only genuine SNAPPER replacement parts

to assure that original standards are

maintained.

TABLE OF CONTENTS

SECTION 1 - IMPORTANT SAFETY INSTRUCTIONS .......................... 2-3

TABLE OF CONTENTS ............................................................................ 4

SECTION 2 - OPERATING INSTRUCTIONS ....................................... 5-10

Introduction ................................................................................................................. 5

Pre-start Checklist ................................................................................................... 6-7

Starting & Stopping Engine (Recoil Start Models) ............................................. 7-10

Starting & Stopping Engine (Electric Start Models) .......................................... 9-10

Starting & Stopping Auger/Impeller ..................................................................... 8-10

Starting & Stopping Wheel Drive ......................................................................... 8-10

Free Wheel Machine ................................................................................................. 10

SECTION 3 - MAINTENANCE INSTRUCTIONS ................................ 11-12

Checking Auger Drive Belt ...................................................................................... 11

Checking Wheel Drive Belt ...................................................................................... 11

Lubricate Gear Case ................................................................................................. 11

Lubricate Auger & Bearing ...................................................................................... 11

General Lubrication .................................................................................................. 11

Annually (End of Season) ........................................................................................ 12

Changing Engine Oil .......................................................................................... 12

Changing Spark Plug......................................................................................... 12

Storage Procedure ................................................................................................... 12

Maintenance and Service Parts .............................................................................. 12

SECTION 4 - ADJUSTMENTS AND REPAIR .................................... 13-18

Auger/Impeller & Wheel Drive Belt Adjustment ................................................ 13-14

Auger/Impeller & Wheel Drive Belt Replacement ............................................. 14-15

Skid Shoe Adjustment ............................................................................................. 16

Single Handle Control Adjustment ......................................................................... 17

Auger Shear Bolt Replacement ............................................................................... 18

Chute Crank Adjustment ......................................................................................... 18

Rubber Drive Tire Replacement .............................................................................. 18

TROUBLESHOOTING ............................................................................ 19

SERVICE SCHEDULE ............................................................................ 19

WARRANTY ............................................................................................ 20

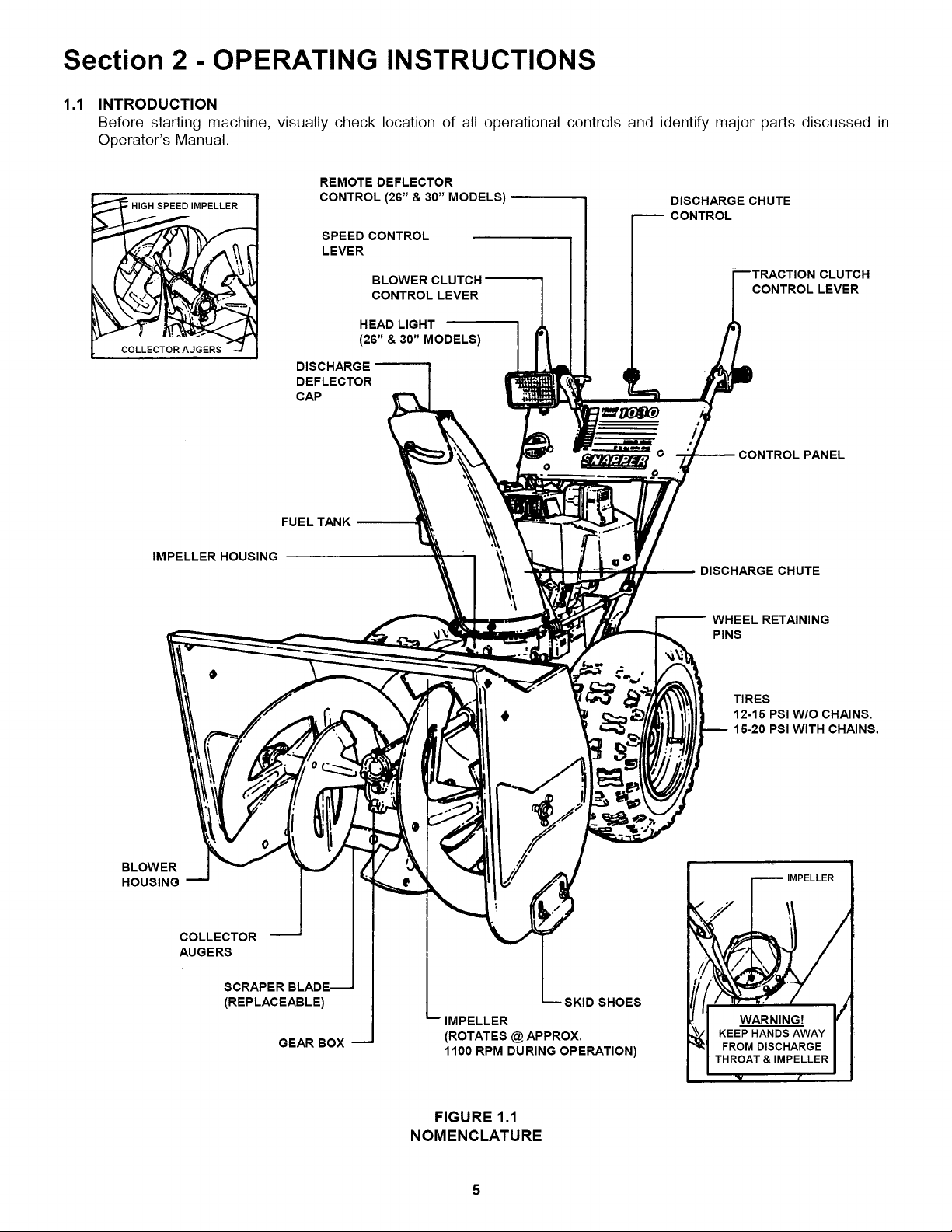

Section 2 - OPERATING INSTRUCTIONS

1.1 INTRODUCTION

Before starting machine, visually check location of all operational controls and identify major parts discussed in

Operator's Manual.

REMOTE DEFLECTOR

HIGH SPEED IMPELLER

CONTROL (26" & 30" MODELS)

SPEED CONTROL

LEVER

BLOWERCLUTCH_

CONTROL LEVER /

HEAD LIGHT

(26"&30"MODELS)

DISCHARGE_

DEFLECTOR

CAP

DISCHARGE CHUTE

_CONTROL

--TRACTION CLUTCH

CONTROL LEVER

PANEL

IMPELLER HOUSING

BLOWER

HOUSING

COLLECTOR

AUGERS

FUEL TANK

DISCHARGE CHUTE

WHEEL RETAINING

PINS

TIRES

12-16 PSI W/O CHAINS.

16-20 PSI WITH CHAINS.

(REPLACEABLE)

GEAR BOX

SKID SHOES

IMPELLER

(ROTATES @ APPROX.

1100 RPM DURING OPERATION)

FIGURE 1.1

NOMENCLATURE

Section 2 - OPERATING INSTRUCTIONS

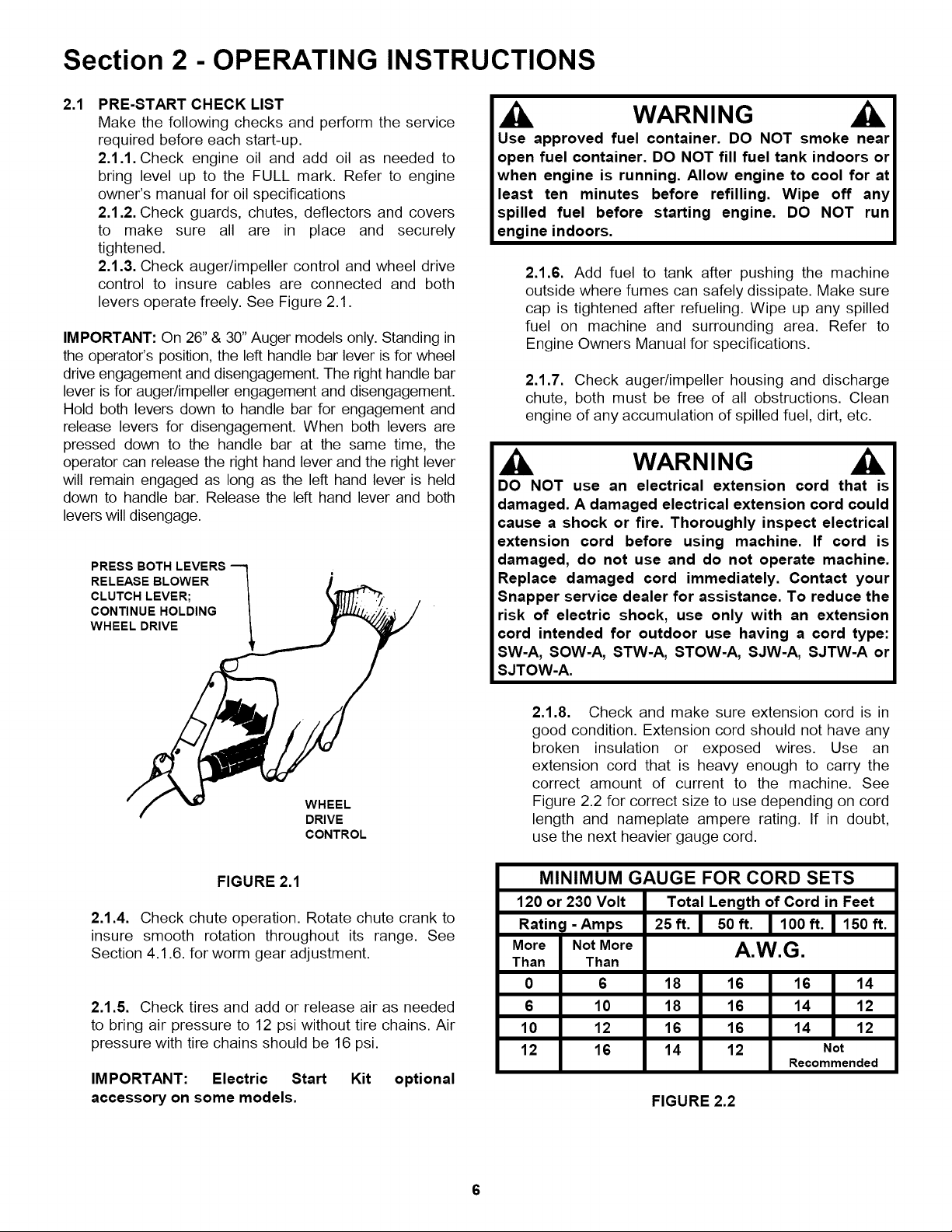

2.1 PRE-START CHECK LIST

Make the following checks and perform the service

required before each start-up.

2.1.1. Check engine oil and add oil as needed to

bring level up to the FULL mark. Refer to engine

owner's manual for oil specifications

2.1.2. Check guards, chutes, deflectors and covers

to make sure all are in place and securely

tightened.

2.1.3. Check auger/impeller control and wheel drive

control to insure cables are connected and both

levers operate freely. See Figure 2.1.

IMPORTANT: On 26" & 30" Auger models only. Standing in

the operator's position, the left handle bar lever is for wheel

drive engagement and disengagement. The right handle bar

lever is for auger/impeller engagement and disengagement.

Hold both levers down to handle bar for engagement and

release levers for disengagement. When both levers are

pressed down to the handle bar at the same time, the

operator can release the right hand lever and the right lever

will remain engaged as long as the left hand lever is held

down to handle bar. Release the left hand lever and both

levers will disengage.

PRESS BOTH LEVERS --'1

RELEASE BLOWER

CLUTCH LEVER;

CONTINUE HOLDING

WHEEL DRIVE

WARNING

Use approved fuel container. DO NOT smoke near

open fuel container. DO NOT fill fuel tank indoors or

when engine is running. Allow engine to cool for at

least ten minutes before refilling. Wipe off any

spilled fuel before starting engine. DO NOT run

engine indoors.

2.1.6. Add fuel to tank after pushing the machine

outside where fumes can safely dissipate. Make sure

cap is tightened after refueling. Wipe up any spilled

fuel on machine and surrounding area. Refer to

Engine Owners Manual for specifications.

2.1.7. Check auger/impeller housing and discharge

chute, both must be free of all obstructions. Clean

engine of any accumulation of spilled fuel, dirt, etc.

WARNING

DO NOT use an electrical extension cord that is

damaged. A damaged electrical extension cord could

cause a shock or fire. Thoroughly inspect electrical

extension cord before using machine. If cord is

damaged, do not use and do not operate machine.

Replace damaged cord immediately. Contact your

Snapper service dealer for assistance. To reduce the

risk of electric shock, use only with an extension

cord intended for outdoor use having a cord type:

SW-A, SOW-A, STW-A, STOW-A, SJW-A, SJTW-A or

SJTOW-A.

WHEEL

DRIVE

CONTROL

FIGURE 2.1

2.1.4. Check chute operation. Rotate chute crank to

insure smooth rotation throughout its range. See

Section 4.1.6. for worm gear adjustment.

2.1.5. Check tires and add or release air as needed

to bring air pressure to 12 psi without tire chains. Air

pressure with tire chains should be 16 psi.

IMPORTANT: Electric Start Kit optional

accessory on some models.

2.1.8. Check and make sure extension cord is in

good condition. Extension cord should not have any

broken insulation or exposed wires. Use an

extension cord that is heavy enough to carry the

correct amount of current to the machine. See

Figure 2.2 for correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gauge cord.

MINIMUM GAUGE FOR CORD SETS

120 or 230 Volt Total Length of Cord in Feet

Rating-Amps 25 ft. I 50 ft. I 100 ft. I 150 ft.

More Not More ,7,.,,,.,A.W._'_.

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not

FIGURE 2.2

Recommended

Section 2 - OPERATING INSTRUCTIONS

2.1

PRE-START CHECK LIST

2.1.9. Check the AC electrical outlet that will be

used and make sure it is a polarized outlet. The

machine has a polarized plug (one blade of plug is

wider than the other) that will accept a polarized

extension cord. The extension cord will fit into a

polarized outlet (receptacle) only one way. If plug

does not fit fully into your outlet, reverse the plug. If

it still does not fit, contact a qualified electrician to

install a proper polarized outlet. DO NOT modify or

change this polarized plug in any way.

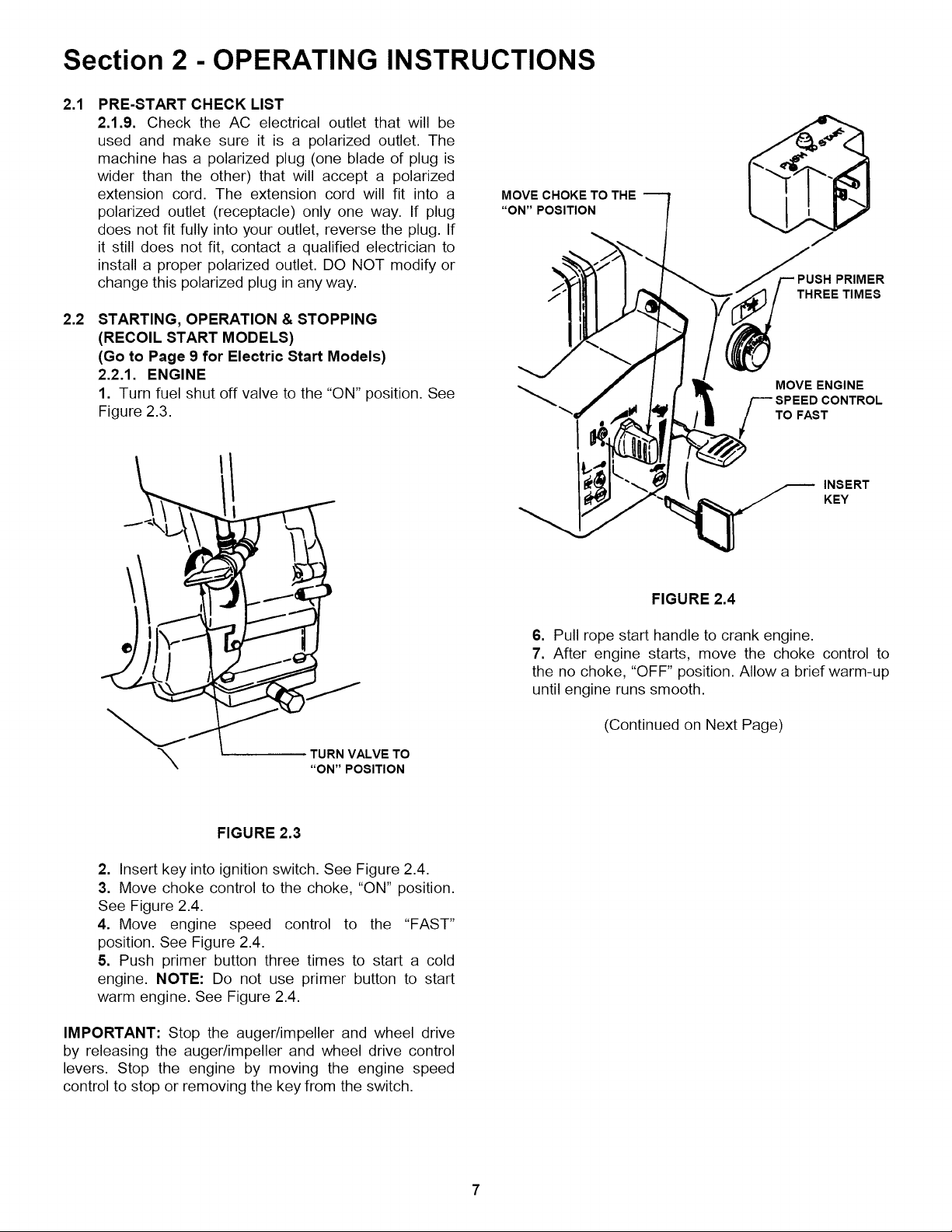

2.2

STARTING, OPERATION & STOPPING

(RECOIL START MODELS)

(Go to Page 9 for Electric Start Models)

2.2.1. ENGINE

1. Turn fuel shut off valve to the "ON" position. See

Figure 2.3.

MOVE CHOKE TO THE

"ON" POSITION

PUSH PRIMER

THREE TIMES

MOVE ENGINE

F--SPEEDCONTROL

"" / TO FAST

I

INSERT

KEY

\

FIGURE 2.3

2. Insert key into ignition switch. See Figure 2.4.

3. Move choke control to the choke, "ON" position.

See Figure 2.4.

4. Move engine speed control to the "FAST"

position. See Figure 2.4.

5. Push primer button three times to start a cold

engine. NOTE: Do not use primer button to start

warm engine. See Figure 2.4.

IMPORTANT: Stop the auger/impeller and wheel drive

by releasing the auger/impeller and wheel drive control

levers. Stop the engine by moving the engine speed

control to stop or removing the key from the switch.

, TURN VALVE TO

"ON" POSITION

FIGURE 2.4

6. Pull rope start handle to crank engine.

7. After engine starts, move the choke control to

the no choke, "OFF" position. Allow a brief warm-up

until engine runs smooth.

(Continued on Next Page)

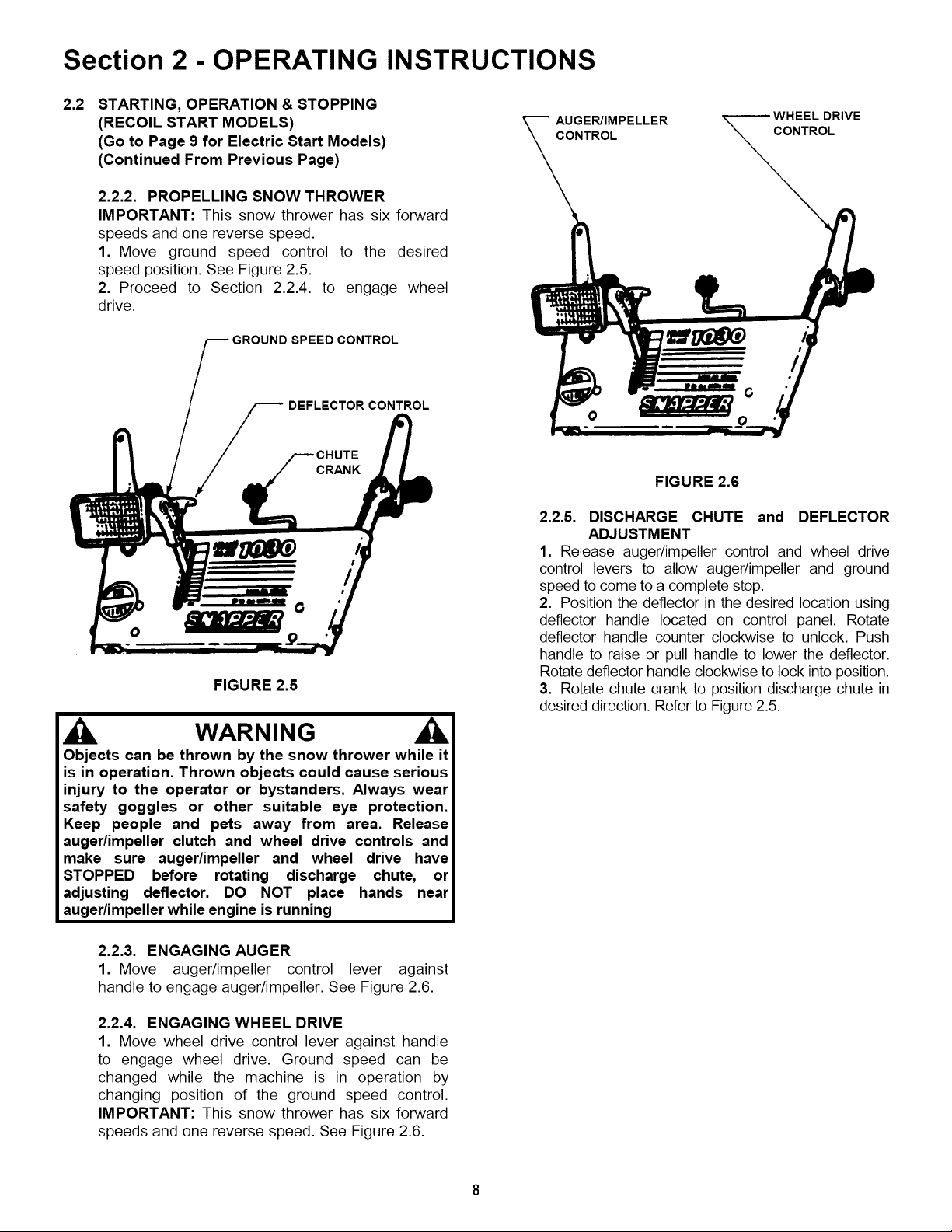

Section 2 - OPERATING INSTRUCTIONS

2.2

STARTING, OPERATION & STOPPING

(RECOIL START MODELS)

(Go to Page 9 for Electric Start Models)

(Continued From Previous Page)

AUGEWIMPELLER

CONTROL

2.2.2. PROPELLING SNOW THROWER

IMPORTANT: This snow thrower has six forward

speeds and one reverse speed.

1. Move ground speed control to the desired

speed position. See Figure 2.5.

2. Proceed to Section 2.2.4. to engage wheel

drive.

SPEED CONTROL

DEFLECTOR CONTROL

CHUTE

CRANK

O

FIGURE 2.5

oDLRIVE

o

FIGURE 2.6

2.2.5. DISCHARGE CHUTE and DEFLECTOR

ADJUSTMENT

1. Release auger/impeller control and wheel drive

control levers to allow auger/impeller and ground

speed to come to a complete stop.

2. Position the deflector in the desired location using

deflector handle located on control panel. Rotate

deflector handle counter clockwise to unlock. Push

handle to raise or pull handle to lower the deflector.

Rotate deflector handle clockwise to lock into position.

3. Rotate chute crank to position discharge chute in

desired direction. Refer to Figure 2.5.

Objects can be thrown by the snow thrower while it

is in operation. Thrown objects could cause serious

injury to the operator or bystanders. Always wear

safety goggles or other suitable eye protection.

Keep people and pets away from area. Release

auger/impeller clutch and wheel drive controls and

make sure auger/impeller and wheel drive have

STOPPED before rotating discharge chute, or

adjusting deflector. DO NOT place hands near

auger/impeller while engine is running

2.2.3. ENGAGING AUGER

1. Move auger/impeller control lever against

handle to engage auger/impeller. See Figure 2.6.

2.2.4. ENGAGING WHEEL DRIVE

1. Move wheel drive control lever against handle

to engage wheel drive. Ground speed can be

changed while the machine is in operation by

changing position of the ground speed control.

IMPORTANT: This snow thrower has six forward

speeds and one reverse speed, See Figure 2,6,

Section 2 - OPERATING INSTRUCTIONS

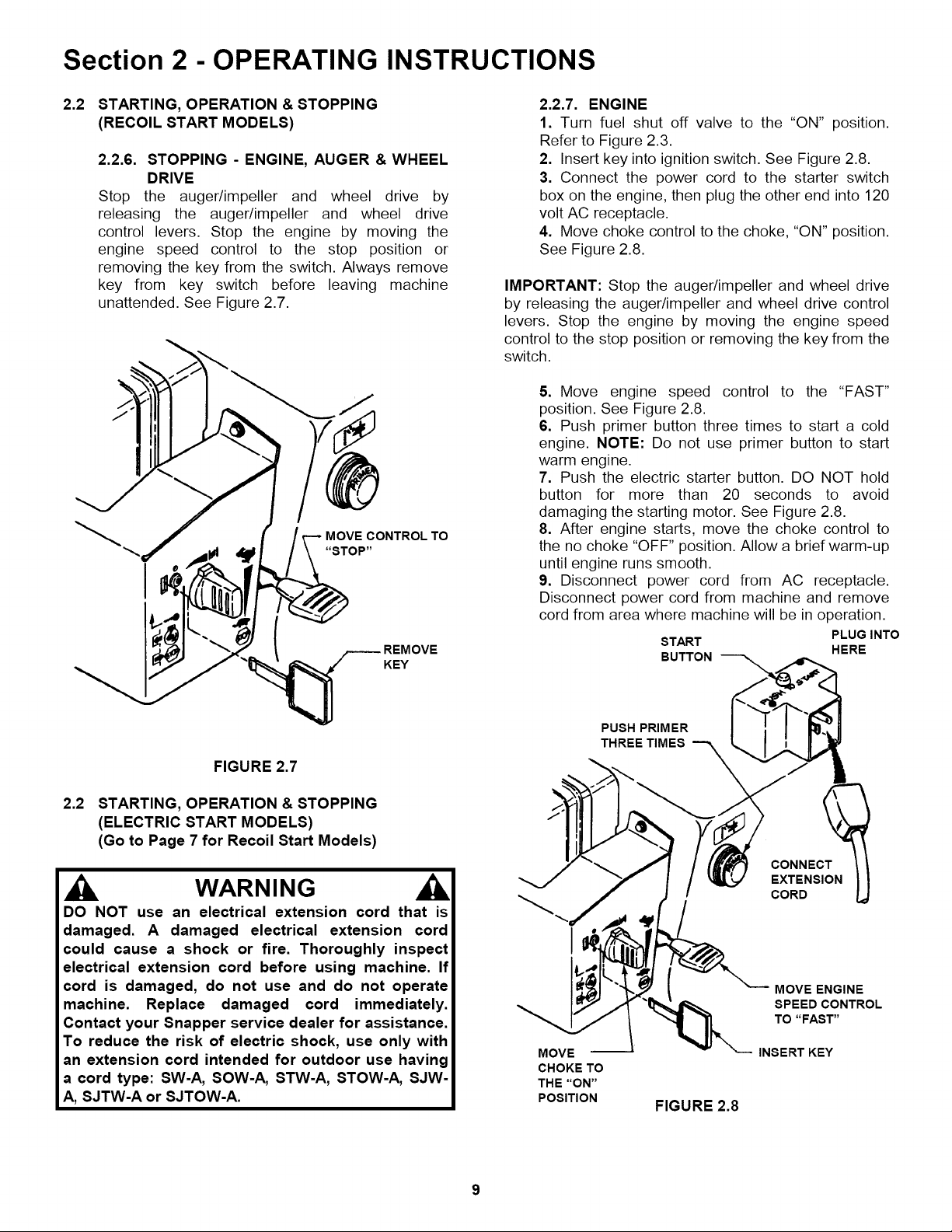

2.2 STARTING, OPERATION & STOPPING

(RECOIL START MODELS)

2.2.6. STOPPING - ENGINE, AUGER & WHEEL

DRIVE

Stop the auger/impeller and wheel drive by

releasing the auger/impeller and wheel drive

control levers. Stop the engine by moving the

engine speed control to the stop position or

removing the key from the switch. Always remove

key from key switch before leaving machine

unattended. See Figure 2.7.

MOVE CONTROL TO

"STOP"

_REMOVE

KEY

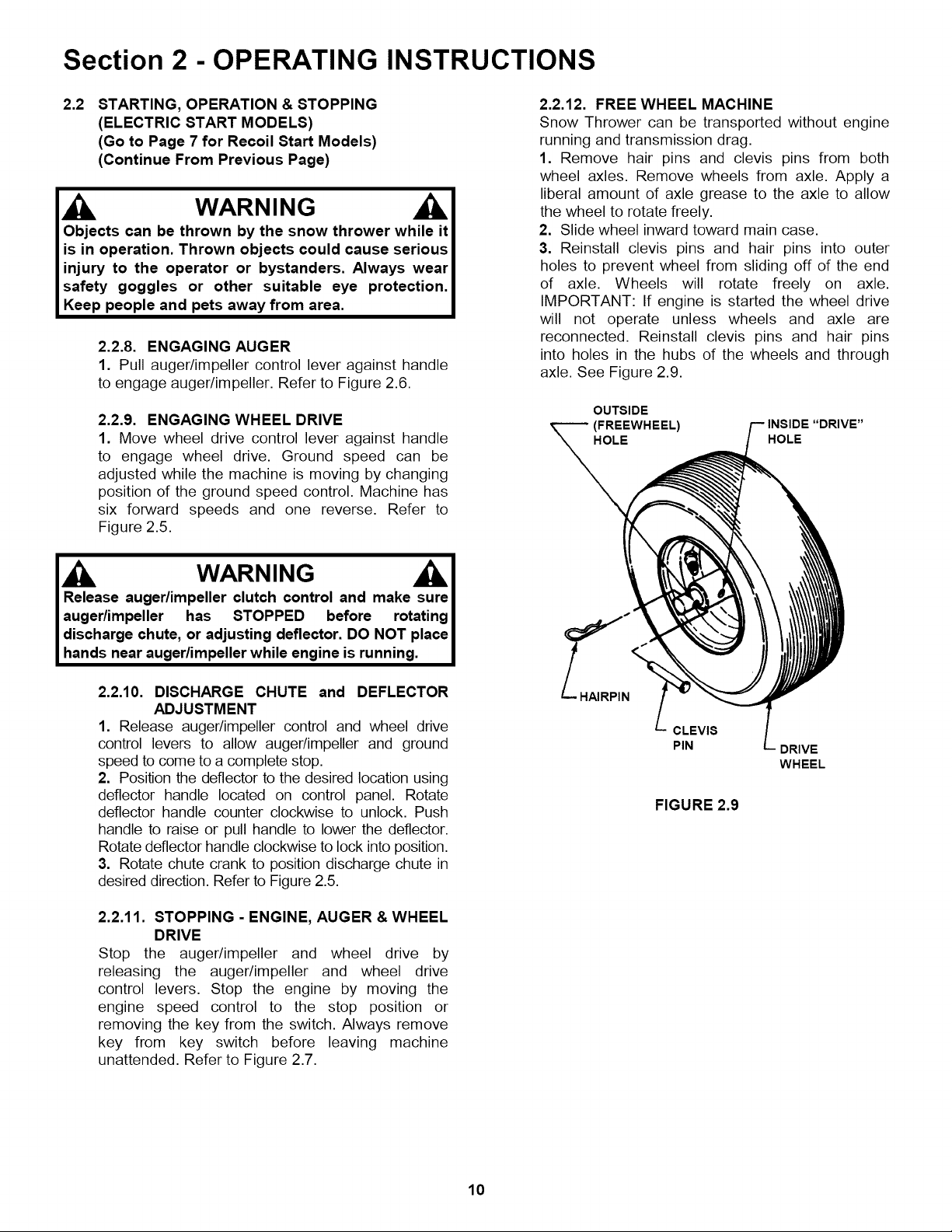

2.2.7. ENGINE

1. Turn fuel shut off valve to the "ON" position.

Refer to Figure 2.3.

2. Insert key into ignition switch. See Figure 2.8.

3. Connect the power cord to the starter switch

box on the engine, then plug the other end into 120

volt AC receptacle.

4. Move choke control to the choke, "ON" position.

See Figure 2.8.

IMPORTANT: Stop the auger/impeller and wheel drive

by releasing the auger/impeller and wheel drive control

levers. Stop the engine by moving the engine speed

control to the stop position or removing the key from the

switch.

5. Move engine speed control to the "FAST"

position. See Figure 2.8.

6. Push primer button three times to start a cold

engine. NOTE: Do not use primer button to start

warm engine.

7. Push the electric starter button. DO NOT hold

button for more than 20 seconds to avoid

damaging the starting motor. See Figure 2.8.

8. After engine starts, move the choke control to

the no choke "OFF" position. Allow a brief warm-up

until engine runs smooth.

9. Disconnect power cord from AC receptacle.

Disconnect power cord from machine and remove

cord from area where machine will be in operation.

START

BUTTON _

PLUG INTO

HERE

FIGURE 2.7

2.2 STARTING, OPERATION & STOPPING

(ELECTRIC START MODELS)

(Go to Page 7 for Recoil Start Models)

WARNING

DO NOT use an electrical extension cord that is

damaged. A damaged electrical extension cord

could cause a shock or fire. Thoroughly inspect

electrical extension cord before using machine. If

cord is damaged, do not use and do not operate

machine. Replace damaged cord immediately.

Contact your Snapper service dealer for assistance.

To reduce the risk of electric shock, use only with

an extension cord intended for outdoor use having

a cord type: SW-A, SOW-A, STW-A, STOW-A, SJW-

A, SJTW-A or SJTOW-A.

MOVE

CHOKE TO

THE"ON"

POSITION

PUSH PRIMER

THREE TIMES

MOVE ENGINE

SPEED CONTROL

TO"FAST"

INSERT KEY

FIGURE 2.8

Section 2 - OPERATING INSTRUCTIONS

2.2

STARTING, OPERATION & STOPPING

(ELECTRIC START MODELS)

(Go to Page 7 for Recoil Start Models)

(Continue From Previous Page)

WARNING

Objects can be thrown by the snow thrower while it

is in operation. Thrown objects could cause serious

injury to the operator or bystanders. Always wear

safety goggles or other suitable eye protection.

Keep people and pets away from area.

2.2.8. ENGAGING AUGER

1. Pull auger/impeller control lever against handle

to engage auger/impeller. Refer to Figure 2.6.

2.2.9. ENGAGING WHEEL DRIVE

1. Move wheel drive control lever against handle

to engage wheel drive. Ground speed can be

adjusted while the machine is moving by changing

position of the ground speed control. Machine has

six forward speeds and one reverse. Refer to

Figure 2.5.

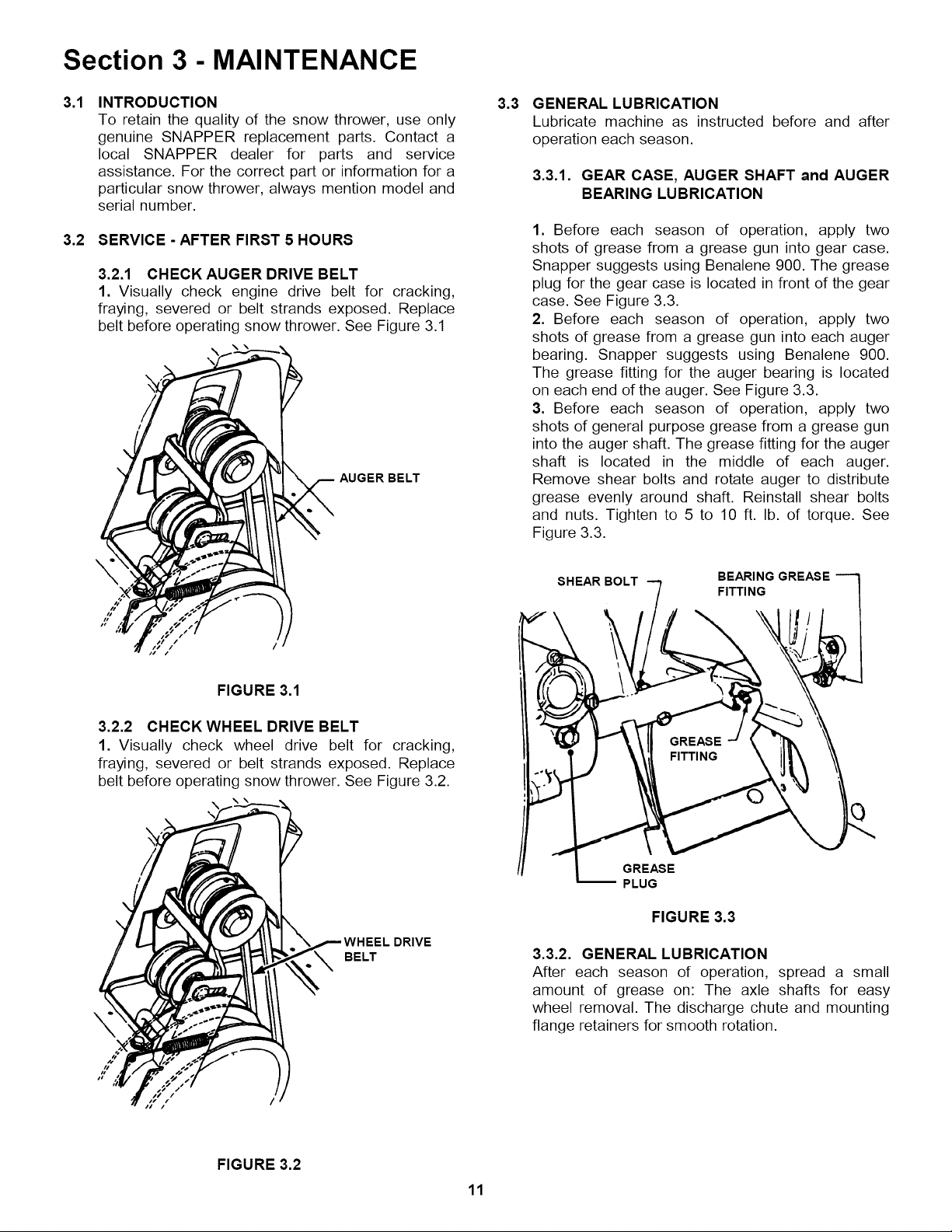

2.2.12. FREE WHEEL MACHINE

Snow Thrower can be transported without engine

running and transmission drag.

1. Remove hair pins and clevis pins from both

wheel axles. Remove wheels from axle. Apply a

liberal amount of axle grease to the axle to allow

the wheel to rotate freely.

2. Slide wheel inward toward main case.

3. Reinstall clevis pins and hair pins into outer

holes to prevent wheel from sliding off of the end

of axle. Wheels will rotate freely on axle.

IMPORTANT: If engine is started the wheel drive

will not operate unless wheels and axle are

reconnected. Reinstall clevis pins and hair pins

into holes in the hubs of the wheels and through

axle. See Figure 2.9.

OUTSIDE

INSIDE "DRIVE"

HOLE

EWHEEL)

WARNING

Release auger/impeller clutch control and make sure

auger/impeller has STOPPED before rotating

discharge chute, or adjusting deflector. DO NOT place

hands near auger/impeller while engine is running.

2.2.10. DISCHARGE CHUTE and DEFLECTOR

ADJUSTMENT

1. Release auger/impeller control and wheel drive

control levers to allow auger/impeller and ground

speed to come to a complete stop.

2. Position the deflector to the desired location using

deflector handle located on control panel. Rotate

deflector handle counter clockwise to unlock. Push

handle to raise or pull handle to lower the deflector.

Rotate deflector handle clockwise to lock into position.

3. Rotate chute crank to position discharge chute in

desired direction. Refer to Figure 2.5.

2.2.11. STOPPING - ENGINE, AUGER & WHEEL

DRIVE

Stop the auger/impeller and wheel drive by

releasing the auger/impeller and wheel drive

control levers. Stop the engine by moving the

engine speed control to the stop position or

removing the key from the switch. Always remove

key from key switch before leaving machine

unattended. Refer to Figure 2.7.

CLEVIS

PIN

FIGURE 2.9

DRIVE

WHEEL

10

Section 3 - MAINTENANCE

3.1 INTRODUCTION

To retain the quality of the snow thrower, use only

genuine SNAPPER replacement parts. Contact a

local SNAPPER dealer for parts and service

assistance. For the correct part or information for a

particular snow thrower, always mention model and

serial number.

3.2 SERVICE - AFTER FIRST 5 HOURS

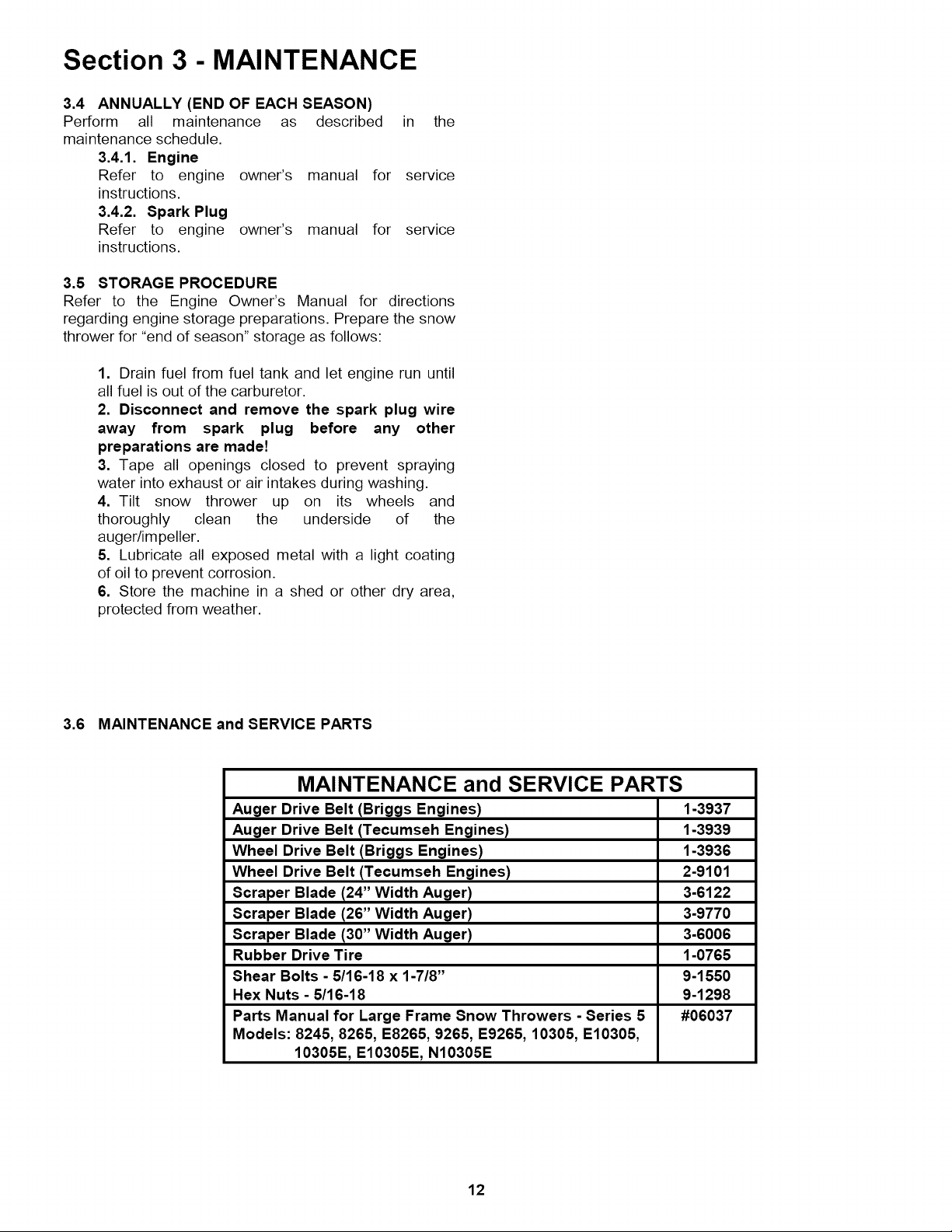

3.2.1 CHECK AUGER DRIVE BELT

1. Visually check engine drive belt for cracking,

fraying, severed or belt strands exposed. Replace

belt before operating snow thrower. See Figure 3.1

AUGER BELT

3.3 GENERAL LUBRICATION

Lubricate machine as instructed before and after

operation each season.

3.3.1. GEAR CASE, AUGER SHAFT and AUGER

BEARING LUBRICATION

1. Before each season of operation, apply two

shots of grease from a grease gun into gear case.

Snapper suggests using Benalene 900. The grease

plug for the gear case is located in front of the gear

case. See Figure 3.3.

2. Before each season of operation, apply two

shots of grease from a grease gun into each auger

bearing. Snapper suggests using Benalene 900.

The grease fitting for the auger bearing is located

on each end of the auger. See Figure 3.3.

3. Before each season of operation, apply two

shots of general purpose grease from a grease gun

into the auger shaft. The grease fitting for the auger

shaft is located in the middle of each auger.

Remove shear bolts and rotate auger to distribute

grease evenly around shaft. Reinstall shear bolts

and nuts. Tighten to 5 to 10 ft. lb. of torque. See

Figure 3.3.

FIGURE 3.1

3.2.2 CHECK WHEEL DRIVE BELT

1. Visually check wheel drive belt for cracking,

fraying, severed or belt strands exposed. Replace

belt before operating snow thrower. See Figure 3.2.

DRIVE

BELT

\

SHEAR BOLT

FITTING

BEARING GREASE

0

GREASE

PLUG

FIGURE 3.3

3.3.2. GENERAL LUBRICATION

After each season of operation, spread a small

amount of grease on: The axle shafts for easy

wheel removal. The discharge chute and mounting

flange retainers for smooth rotation.

FIGURE 3.2

11

Section 3 - MAINTENANCE

3.4

ANNUALLY (END OF EACH SEASON)

Perform all maintenance as

maintenance schedule.

3.4.1. Engine

Refer to engine

instructions.

3.4.2. Spark Plug

Refer to engine

instructions.

3.5 STORAGE PROCEDURE

Refer to the Engine Owner's Manual for directions

regarding engine storage preparations. Prepare the snow

thrower for "end of season" storage as follows:

1. Drain fuel from fuel tank and let engine run until

all fuel is out of the carburetor.

2. Disconnect and remove the spark plug wire

away from spark plug before any other

preparations are made!

3. Tape all openings closed to prevent spraying

water into exhaust or air intakes during washing.

4. Tilt snow thrower up on its wheels and

thoroughly clean the underside of the

auger/impeller.

5. Lubricate all exposed metal with a light coating

of oil to prevent corrosion.

6. Store the machine in a shed or other dry area,

protected from weather.

owner's manual for service

owner's manual for service

described in the

3.6 MAINTENANCE and SERVICE PARTS

MAINTENANCE and SERVICE PARTS

Auger Drive Belt (Briggs Engines) 1-3937

Auger Drive Belt (Tecumseh Engines) 1-3939

Wheel Drive Belt (Briggs Engines) 1-3936

Wheel Drive Belt (Tecumseh Engines) 2-9101

Scraper Blade (24" Width Auger) 3-6122

Scraper Blade (26" Width Auger) 3-9770

Scraper Blade (30" Width Auger) 3-6006

Rubber Drive Tire 1-0765

Shear Bolts - 5/16-18 x 1-7/8" 9-1550

Hex Nuts - 5/16-18 9-1298

Parts Manual for Large Frame Snow Throwers - Series 5 #06037

Models: 8245, 8265, E8265, 9265, E9265, 10305, E10305,

10305E, E10305E, N10305E

12

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any adjustments, maintenance,

service, or repairs, with engine running. Stop auger.

Stop engine. Remove key. Disconnect spark plug

wire and secure wire away from spark plug.

4.1 AUGER/IMPELLER and WHEEL DRIVE BELT

ADJUSTMENT/REPLACEMENT

When operating machine release the auger/impeller

clutch control. The auger/impeller should come to a

complete stop in 5 seconds. If the auger/impeller does

not come to a complete stop in the required time,

check and adjust belt tension. Inspect belts frequently

for signs of excessive wear. Observe drive belts for

slippage due to wear when operating machine. If

slippage does occur, adjust/replace as follows.

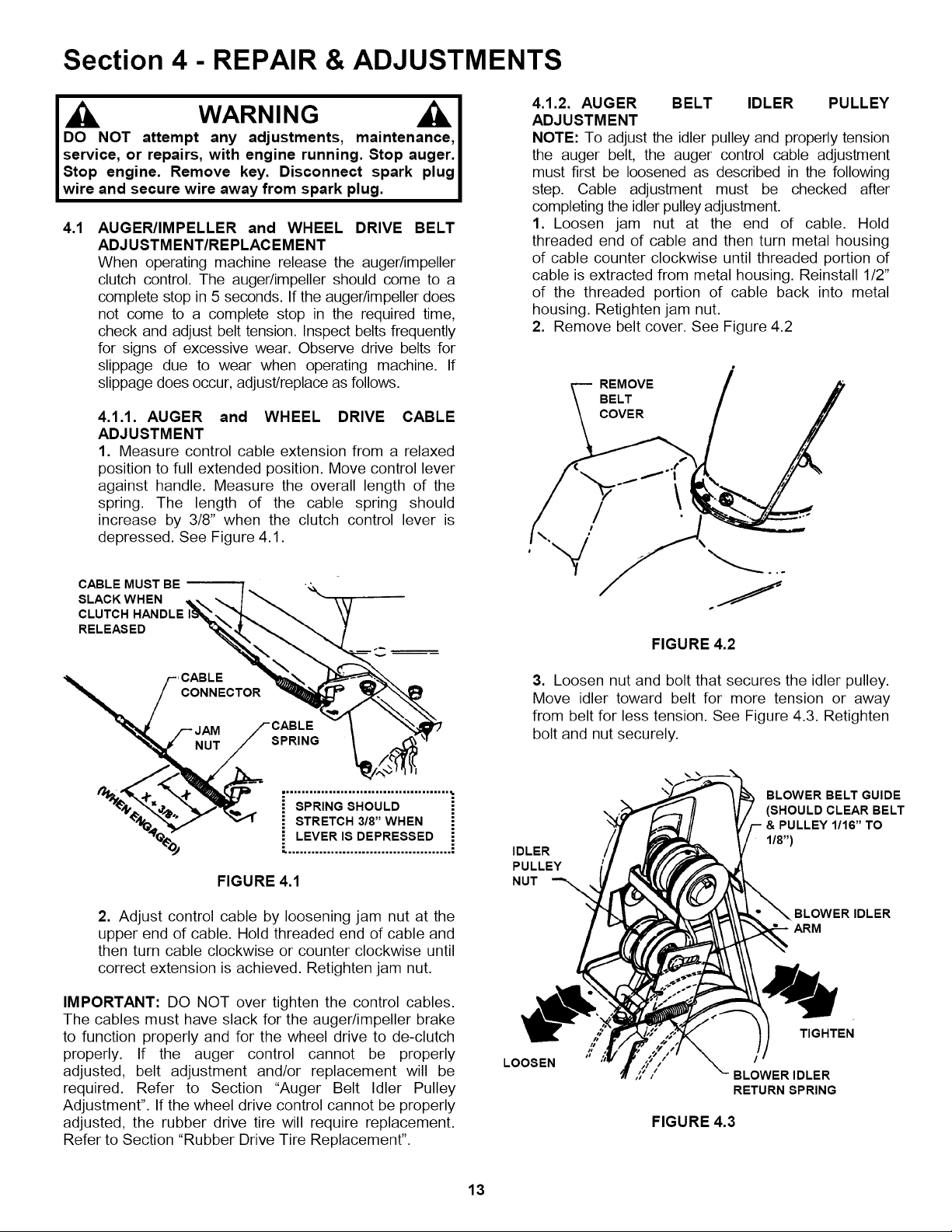

4.1.1. AUGER and WHEEL DRIVE CABLE

ADJUSTMENT

1. Measure control cable extension from a relaxed

position to full extended position. Move control lever

against handle. Measure the overall length of the

spring. The length of the cable spring should

increase by 318" when the clutch control lever is

depressed. See Figure 4.1.

4.1.2. AUGER BELT IDLER PULLEY

ADJUSTMENT

NOTE: To adjust the idler pulley and properly tension

the auger belt, the auger control cable adjustment

must first be loosened as described in the following

step. Cable adjustment must be checked after

completing the idler pulley adjustment.

1. Loosen jam nut at the end of cable. Hold

threaded end of cable and then turn metal housing

of cable counter clockwise until threaded portion of

cable is extracted from metal housing. Reinstall 1/2"

of the threaded portion of cable back into metal

housing. Retighten jam nut.

2. Remove belt cover. See Figure 4.2

REMOVE

BELT

COVER

\

CABLE MUST BE

SLACK WHEN '_',_ _ I _'

CLUTCH HANDLE IS_,_\ "_

RELEASED _, ....

F' CABLE _'_ A

"_ /CONNECTOR

_-- JAM fCABLE

SPRING

............................................ , O HOOLO

°%,.'.<?.. >_

°v_'4f__"_.,_ STRETCH 3/8" WHEN

,q,.7

_,_j LEVER IS DEPRESSED

FIGURE 4.1

2. Adjust control cable by loosening jam nut at the

upper end of cable. Hold threaded end of cable and

then turn cable clockwise or counter clockwise until

correct extension is achieved. Retighten jam nut.

IMPORTANT: DO NOT over tighten the control cables.

The cables must have slack for the auger/impeller brake

to function properly and for the wheel drive to de-clutch

properly. If the auger control cannot be properly

adjusted, belt adjustment and/or replacement will be

required. Refer to Section "Auger Belt Idler Pulley

Adjustment". If the wheel drive control cannot be properly

adjusted, the rubber drive tire will require replacement.

Refer to Section "Rubber Drive Tire Replacement".

el

FIGURE 4.2

3. Loosen nut and bolt that secures the idler pulley.

Move idler toward belt for more tension or away

from belt for less tension. See Figure 4.3. Retighten

bolt and nut securely.

BLOWER BELT GUIDE

(SHOULD CLEAR BELT

& PULLEY 1/1G" TO

IDLER

PULLEY

NUT

LOOSEN

FIGURE 4.3

1/8-)

BLOWER IDLER

ARM

TIGHTEN

BLOWER IDLER

RETURN SPRING

13

Section 4 - REPAIR & ADJUSTMENTS

DO NOT attempt any adjustments, maintenance,

service, or repairs, with engine running. Stop auger.

Stop engine. Remove key. Disconnect spark plug

wire and secure wire away from spark plug. Before

tilting machine, drain all the fuel from fuel tank.

Allow engine to run, outdoors where fumes can be

safely dissipated, until all fuel is removed from

carburetor.

4.1.2. AUGER DRIVE BELT ADJUSTMENT

(IDLER PULLEY ADJUSTMENT)

(Continued From Previous Page)

4. Recheck cable for proper extension (3/8").

5. Reinstall belt cover.

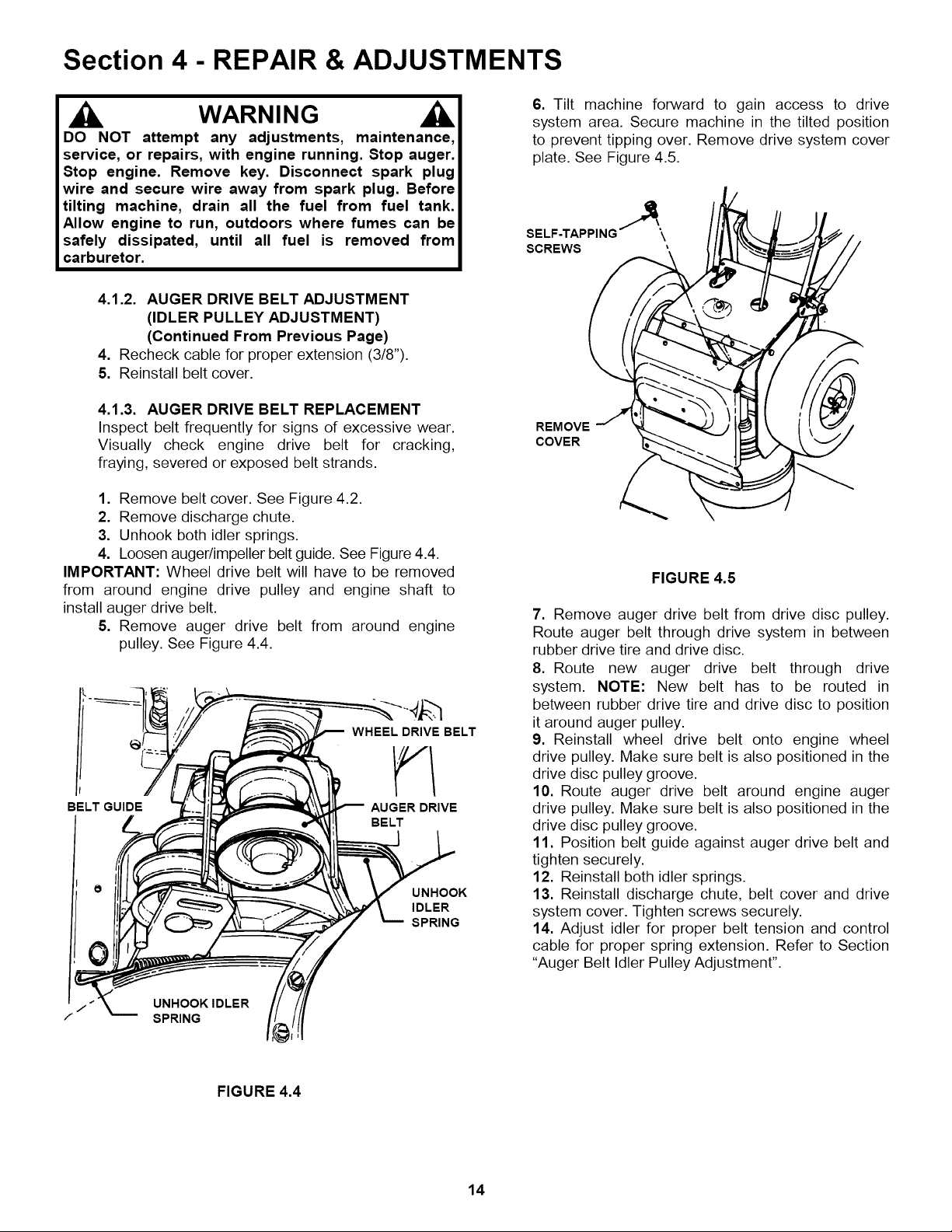

4.1.3. AUGER DRIVE BELT REPLACEMENT

Inspect belt frequently for signs of excessive wear.

Visually check engine drive belt for cracking,

fraying, severed or exposed belt strands.

1. Remove belt cover. See Figure 4.2.

2. Remove discharge chute.

3. Unhook both idler springs.

4. Loosen auger/impeller belt guide. See Figure 4.4.

IMPORTANT: Wheel drive belt will have to be removed

from around engine drive pulley and engine shaft to

install auger drive belt.

5. Remove auger drive belt from around engine

pulley. See Figure 4.4.

6. Tilt machine forward to gain access to drive

system area. Secure machine in the tilted position

to prevent tipping over. Remove drive system cover

plate. See Figure 4.5.

SELF-TAPPING "_\

SCREWS

REMOVE

COVER

FIGURE 4.5

7. Remove auger drive belt from drive disc pulley.

Route auger belt through drive system in between

rubber drive tire and drive disc.

8. Route new auger drive belt through drive

system. NOTE: New belt has to be routed in

between rubber drive tire and drive disc to position

it around auger pulley.

9. Reinstall wheel drive belt onto engine wheel

drive pulley. Make sure belt is also positioned in the

drive disc pulley groove.

10. Route auger drive belt around engine auger

drive pulley. Make sure belt is also positioned in the

drive disc pulley groove.

11. Position belt guide against auger drive belt and

tighten securely.

12. Reinstall both idler springs.

13. Reinstall discharge chute, belt cover and drive

system cover. Tighten screws securely.

14. Adjust idler for proper belt tension and control

cable for proper spring extension. Refer to Section

"Auger Belt Idler Pulley Adjustment".

FIGURE 4.4

14

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any adjustments, maintenance,

service, or repairs, with engine running. Stop auger.

Stop engine. Remove key. Disconnect spark plug

wire and secure wire away from spark plug. Before

tilting machine, drain all the fuel from fuel tank. Allow

engine to run, outdoors where fumes can be safely

dissipated, until all fuel is removed from carburetor.

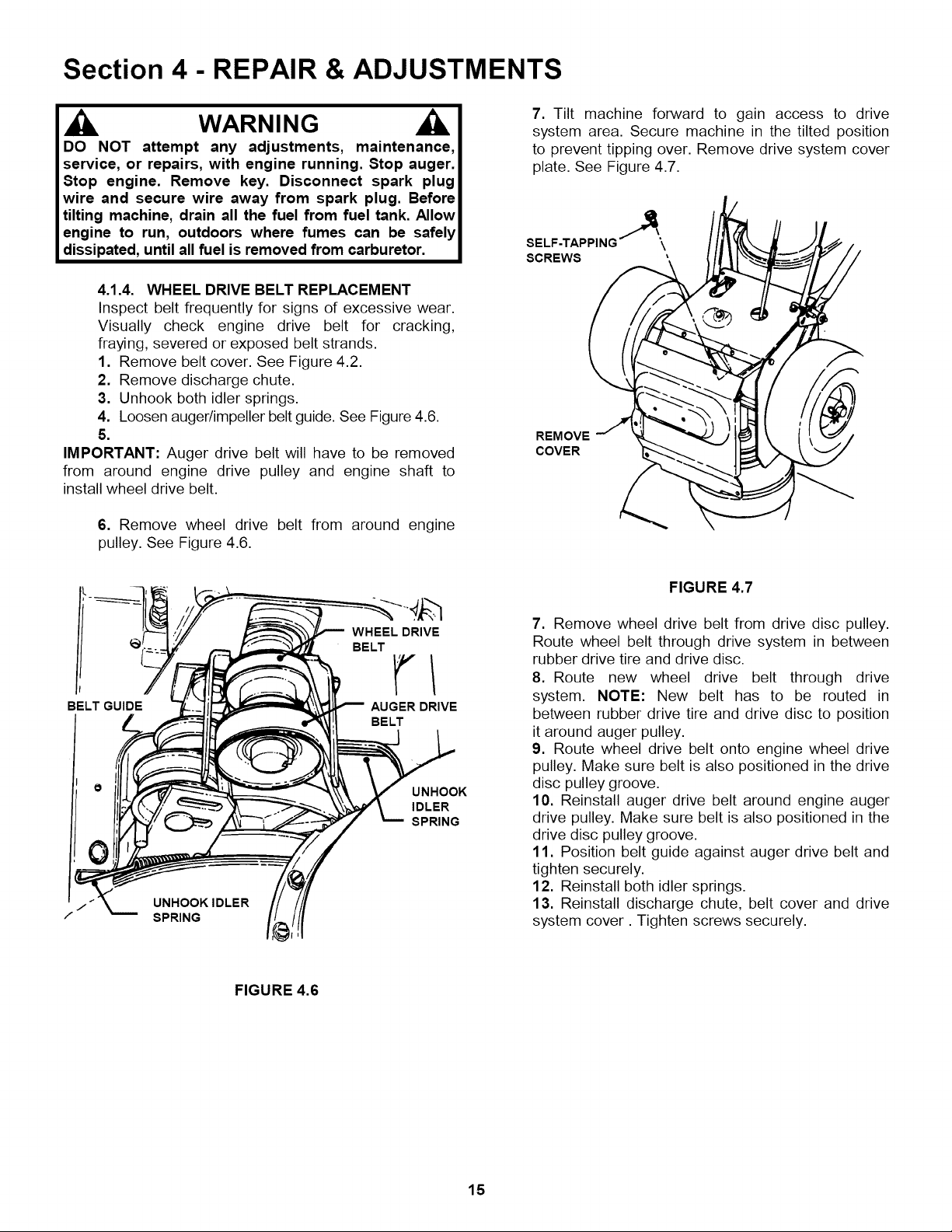

4.1.4. WHEEL DRIVE BELT REPLACEMENT

Inspect belt frequently for signs of excessive wear.

Visually check engine drive belt for cracking,

fraying, severed or exposed belt strands.

1. Remove belt cover. See Figure 4.2.

2. Remove discharge chute.

3. Unhook both idler springs.

4. Loosen auger/impeller belt guide. See Figure 4.6.

5.

IMPORTANT: Auger drive belt will have to be removed

from around engine drive pulley and engine shaft to

install wheel drive belt.

6. Remove wheel drive belt from around engine

pulley. See Figure 4.6.

7. Tilt machine forward to gain access to drive

system area. Secure machine in the tilted position

to prevent tipping over. Remove drive system cover

plate. See Figure 4.7.

SELF-TAPPING "_\

SCREWS

REMOVE

COVER

BELT GUIDE

/ -'J

FIGURE 4.7

7. Remove wheel drive belt from drive disc pulley.

Route wheel belt through drive system in between

rubber drive tire and drive disc.

8. Route new wheel drive belt through drive

system. NOTE: New belt has to be routed in

between rubber drive tire and drive disc to position

it around auger pulley.

9. Route wheel drive belt onto engine wheel drive

pulley. Make sure belt is also positioned in the drive

disc pulley groove.

10. Reinstall auger drive belt around engine auger

drive pulley. Make sure belt is also positioned in the

drive disc pulley groove.

11. Position belt guide against auger drive belt and

tighten securely.

12. Reinstall both idler springs.

13. Reinstall discharge chute, belt cover and drive

system cover. Tighten screws securely.

FIGURE 4.6

15

Loading...

Loading...