snapmaker A150 User guide

Make Something Wonderful

Three years ago, when we were designing

the Snapmaker Original, we broke the

rules of traditional desktop 3D printers and

created the first modular 3-in-1 3D printer

on the market. At first, The Verge and a lot

of other reviewers doubted that “Snapmaker

is an upcoming Kickstarter project with a

lofty goal: to be the holy trinity for at-home

makers by using detachable modules to

convert between a 3D printer, a CNC carver,

and a laser engraver,” and that “At the price

that Snapmaker is selling, it’s possible the

whole thing is too good to be true.” We

knew people had a lot of uncertainty about

our project and were hesitant to back us

because of the complexity of designing

and making such a product. Despite all the

doubts, we worked hard on pushing the

boundaries of possibility, and we eventually

made the impossible possible. Not only did

we fulfill all the rewards, but we also sold

over 10,000 units all over the world in 2018.

Welcome to

the World

of Making

And in 2019, we launched the Snapmaker

2.0. We went beyond our limits once again.

Our goal is to build a system behind our

modular 3D printers and give you the best

maker tools that can work for all your

projects. As creatives, we all desire to make

something wonderful and creativity makes

us feel alive. The Snapmaker 2.0 will help you

turn your idea into reality. This Quick Start

Guide will guide you through your maker

journey and take you from building your own

3D Printer, Laser Cutter, and CNC Carver to

making your first creations utilizing all these

modules. Congratulations on becoming part

of the Snapmaker community! Thousands

of people like you are using the Snapmaker

to explore, make, and share in the world of

making. We believe that wonderful things

will happen when creative minds meet the

ideal tools. Have fun making and see you in

our community!

Team Snapmaker

Happy Making

This machine is built for innovators. Our goal is to assist

you to make the world a better place with a machine

we built with love. The project could be as small as a

Christmas gift, or as ambitious as exploring unknown

territories of our mankind. Dream big and make it happen.

Modular System

Snapmaker is not only a 3D printer, but also a powerful

machine that you can customize with addons. You can

equip your Snapmaker with an enclosure to protect

you and your family from laser and contaminants. New

addons are coming soon with more exciting features.

Please stay tuned.

CONTENTS

01

12

26

42

58

Before You Start

Machine Assembly

3D Printing

Laser Engraving and Cutting

CNC Carving

BEFORE

YOU

START

Before You Start

Copyright © 2020 Snapmaker. All rights reserved.

This language version of the manual is verified by the manufacturer (Original Instruction). No part of this

publication, including pictures may be reproduced or made public, whether by printing, photocopying, microfilm

or by any other means whatsoever, without the prior written permission of Snapmaker.

|

2

1.1 Disclaimer

Please read and understand the contents of the manual of this product carefully. Failure to read the manual

may lead to personal injury, inferior results or damage to the Snapmaker products. Always make sure that

anyone who uses this product knows and understands the contents of this manual to make the most out of it.

This manual is provided for reference purposes only, we do not warrant the accuracy or completeness of the

information provided by this manual. We reserve the right to modify or revise this manual in our sole discretion

at any time without notice, users can download the most up-to-date version of this manual on our official

website.

When making objects using Snapmaker products, users remain responsible to ensure that they do not infringe

any third party intellectual property rights or violate any applicable laws or regulations. The conditions or

methods used for assembling, handling, storage, use, maintaining or disposal of this product are beyond

our control. For this reason, we do not assume responsibility and expressly disclaim liability for loss, injuries,

damage, or expense arising out of or in any way connected with the assembly, handling, storage, use,

maintaining or disposal of this product.

1.2 Intended Use

Snapmaker modular 3D printers come with improved 3-in-1 capabilities for 3D printing, laser engraving or

cutting, and CNC carving. Snapmaker modular 3D printers are the ideal choice for beginners, hobbyists who

prefer more customized options, as well as engineers and designers who want to make large objects or fine

parts with outstanding fabrication quality. Snapmaker modular 3D printers are intended for use under the

guidance in the product manual. When making objects using Snapmaker modular 3D printers, users remain

responsible to qualify and validate the application of the created object for its intended use, especially for

applications in strictly regulated areas like medical devices and aeronautics.

1.3 Safety and Compliance

General Safety Information

- Always operate this machine indoors on a solid horizontal table or workbench.

- Do not expose this machine to rain or wet conditions.

- Keep children and bystanders away while operating this machine. It requires the supervision and

assistance of an adult when children use this machine.

- Stay alert, watch what you are doing and use common sense when operating this machine. Do not use this

machine while you are tired or under the influence of drugs, alcohol or medication.

- Do not reach inside the machine or touch the moving parts while the machine is still in operation, as it may

cause injury.

- Do not leave the machine unattended while it is still on.

In all EU member states, operation of 5150-5250 MHz is restricted to indoor use only.

Quick Start Guide | 3

Before You Start

Turn off the machine immediately and stop using this product, if any of the following occurs:

- You smell burning in this machine at any point.

- The machine stops working unexpectedly.

- You see any damage to the interior components of this machine.

- Unusual lights, sparks, or sounds come out of this machine which were not occurring previously.

3D Printing Safety

- Do not touch the nozzle, Print Sheet and Heated Bed when the machine is printing or heating.

- Always unplug the power cord from the electrical outlet before performing maintenance or modifications.

- Set up the printer in a well-ventilated place when printing with ABS. The melting of some materials may

release toxic fumes.

Laser Safety

- The Laser Module is a class 4 laser product. You should operate the Laser Module only if you have

sufficient knowledge of (i) the physical properties of laser radiation, (ii) Laser Hazard Classes and

associated health implications, and (iii) safety measures.

- This laser product should be used exclusively for recreational purposes.

- Never expose yourself to the laser beam. Proper use and care of the Laser Module are essential to safe

operation.

- Operate the Laser Module in a well-ventilated place or with an air filter. The melting of some materials may

release toxic fumes.

- Always unplug the power cord from the electrical outlet before performing maintenance or modifications.

- Remove any reflective material from the work area underneath the Laser Module, as it can cause

scattered radiation.

- Operate the machine with an enclosure covered and wear the Laser Safety Goggles.

The laser safety goggles block direct, reflected, and scattered laser

beams and radiation with the wavelength between 190 and 540

nanometers (nm) and the optical density higher than 6 (OD 6+), from

entering your eyes, thus providing protection while you operate with

the Laser Module.

The lenses might be burned when subjected to high energy laser

beams, and if this happens, you must stop using the damaged

goggles and use a new pair. Also, due to the qualities of polycarbonate

which is used to synthesize the lenses, you should use PH neutral

detergent or water to clean them and avoid scraping them.

CNC Safety

- For experienced users and users aged 18 and above.

- Operate the machine with an enclosure covered and wear the CNC Safety Goggles.

- Always have the material securely clamped. Never attempt to hold the workpiece with your hands

throughout the CNC carving process.

- Always unplug the power cord from the electrical outlet before performing maintenance or modifications.

- If the bit or workpiece become jammed or bogged down, turn off the machine immediately. Wait for all

moving parts to stop and unplug the cable, and then work to free the jammed material.

- -Do not touch the bit or collet after use, as doing so can cause burn hazards.

- Discharge from CNC carving and cutting contains chemicals known to cause cancer and harm to reproductive

system. To reduce exposure, operate the CNC Module in a well-ventilated place and take safety precautions

such as wearing an N-95 mask.

|

4

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio / TV technician for help.

Caution: Any changes or modifications to this device not explicitly approved by manufacturer could void your

authority to operate this equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. This

equipment should be installed and operated with minimum distance 20cm between the radiator & your body.

ISEDC Compliance

This device complies with Innovation, Science and Economic Development Canada License exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received,

including inter ference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d' Innovation, Sciences et Développement économique Canada

applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes :

(1) l'appareil nedoit pas produire de brouillage, et(2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

The device is compliance with RF exposure guidelines, users can obtain Canadian information on RF exposure

nd compliance. The minimum distance from body to use the device is 20cm.

Le présent appareil est conforme Après examen de ce matériel aux conformité ou aux limites d’intensité

de champ RF, les utilisateurs peuvent sur l’exposition aux radiofréquences et compliance d’acquérir les

informations correspondantes. La distance minimale du corps à utiliser le dispositif est de 20cm.

Quick Start Guide | 5

Before You Start

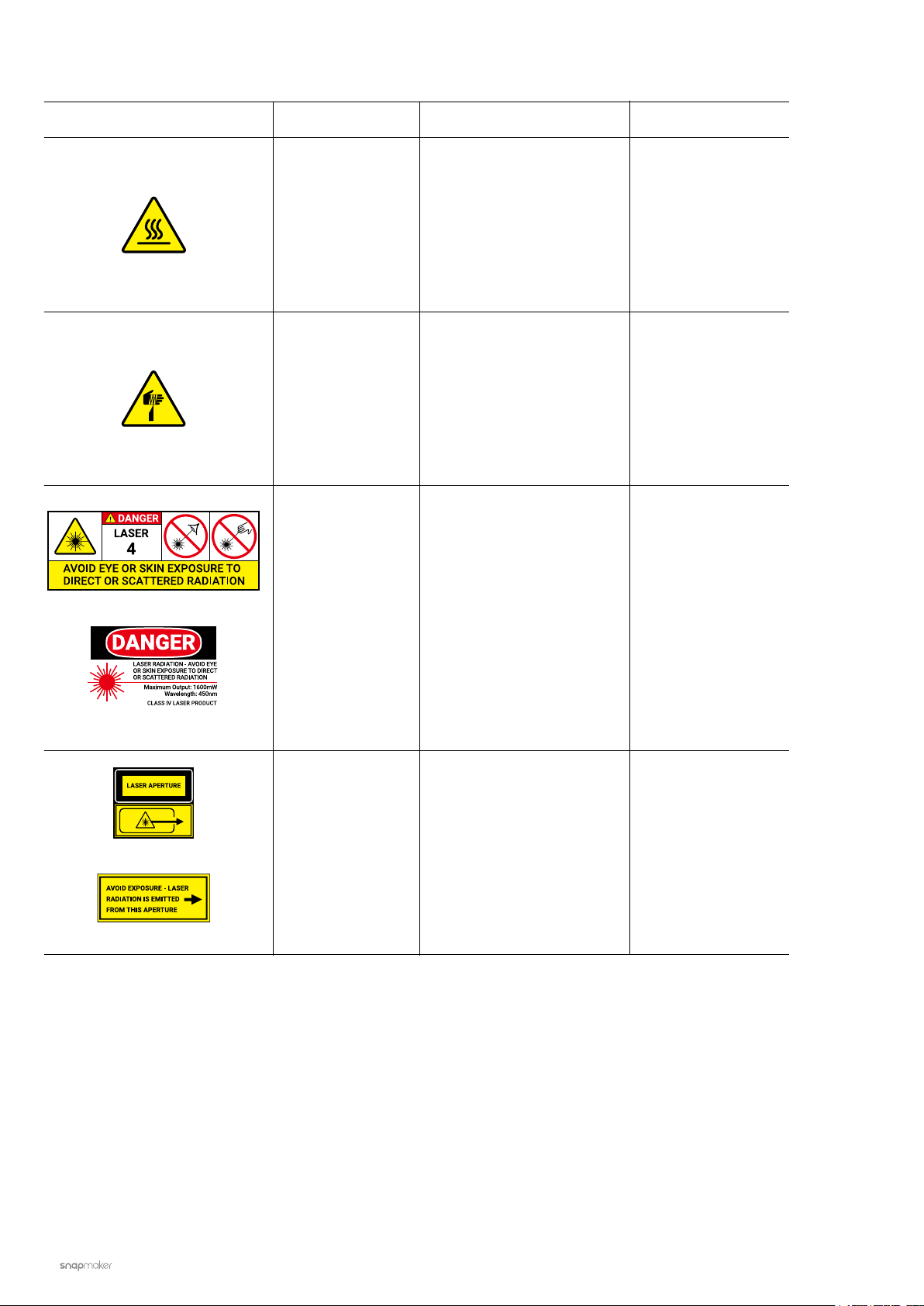

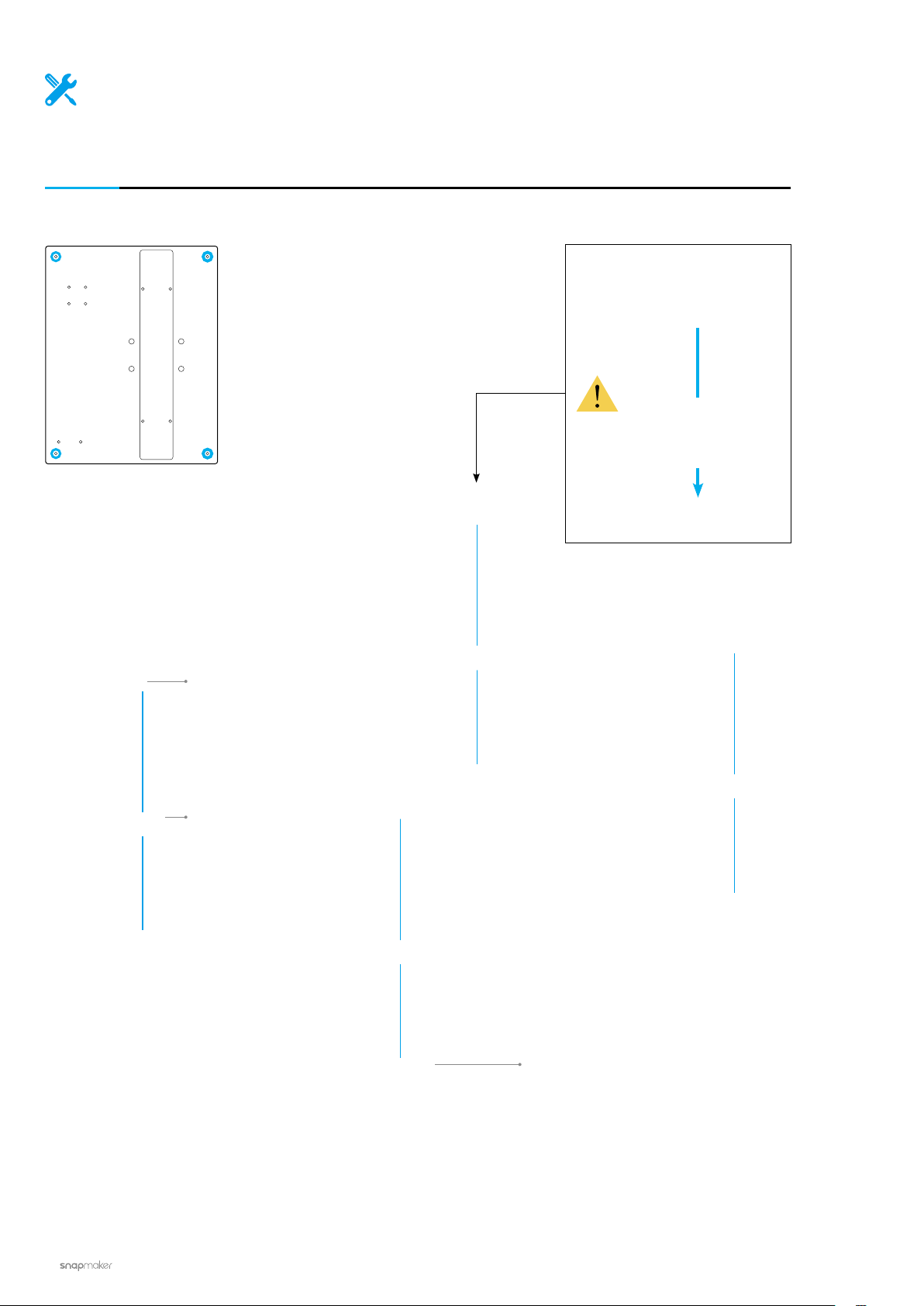

1.4 Labels on Your Snapmaker

Safety Labels Hazard Warning Location

IEC 60825

Hot surface

Sharp objects

Laser radiation

Avoid contact with

hot surface.

Take care to avoid injury

from sharp objects (e.g.

CNC Bits).

Class 4 laser product.

Avoid eyes and skin

exposure to direct or

scattered radiation.

On the 3D Printing

Module, Print Sheet

and Heated Bed

On the CNC Module

On the Laser Module

FDA

IEC 60825

FDA

Laser aperture

Laser radiation is emitted

On the Laser Module

from this aperture.

|

6

1.5 Specifications

General

Frame Material

Connectivity

Touchscreen

Software

Supported File Types

Supported OS

Rated Power

3D Printing

Build Volume

Heated Bed Temperature

Layer Resolution

Nozzle Temperature

Nozzle Diameter

Supported Materials

Aluminum Alloys

Wi-Fi, USB Cable, USB Disk

5”TFT, Android System

Snapmaker Luban and third-party software

.stl, .obj, .svg, .jpeg, .png, more formats to be added

MacOS, Windows, Linux

320 W

A150: 160 x 160 x 145 mm

A250: 230 x 250 x 235 mm

A350: 320 x 350 x 330 mm

A150: Up to 110°C

A250: Up to 100°C

A350: Up to 80°C

50 - 300 microns

Up to 275°C

0.4 mm

PLA, ABS, TPU, Wooded PLA, etc.

Laser

Work Area

Laser

Wavelength

Safety Class

Supported Materials

CNC

Work Area

Shank Diameter

Spindle Speed

Supported Materials

A150: 160 x 160 mm

A250: 230 x 250 mm

A350: 320 x 350 mm

1,600 mW 450 nm Laser Diode

450 nm

Class 4

Wood, leather, plastic, fabric, paper, nontransparent acrylic, etc.

A150: 160 x 160 x 90 mm

A250: 230 x 250 x 180 mm

A350: 320 x 350 x 275 mm

0.5 mm - 6.35 mm (0.02 - 0.25 inches)

6,000 - 12,000 RPM

Wood, acrylic, PCB, carbon fiber sheet, jade, etc.

Note: Design and specifications are subject to change without notice.

Quick Start Guide | 7

Before You Start

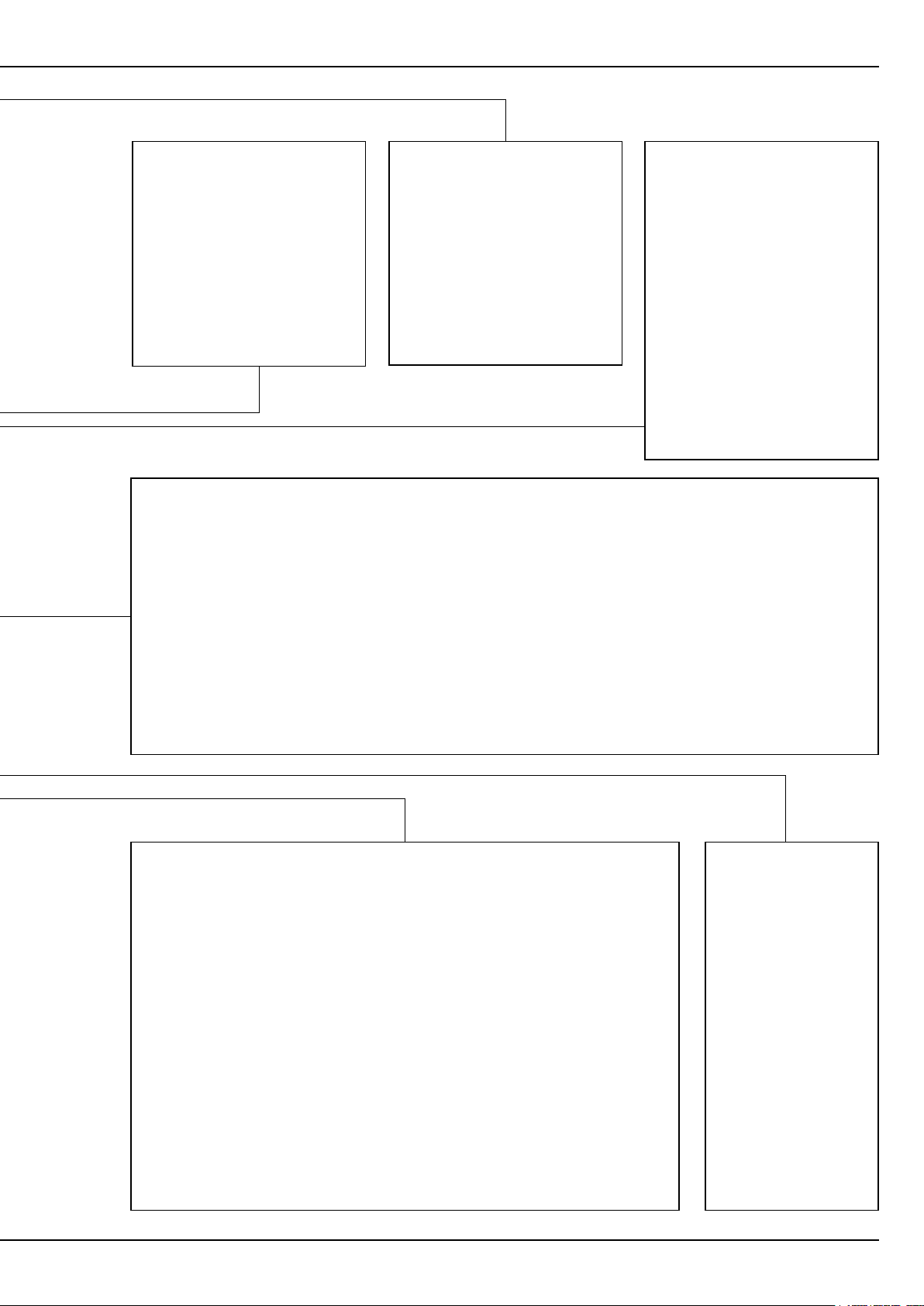

1.6 Parts List

Linear Module x 3

3D Printing Module x 1 Laser Module x 1

Touchscreen x 1

Toolhead Cable x 1

Touchscreen Holder x 1

CNC Module x 1

Controller x 1

Base Plate x 1

|

8

DC Power Cable x 1

Power Module x 1 Quick Start Guide x 1

Laser Safety Goggles x 1

Arched Fixture x 4Fixture Accessory x 4

CNC Safety Goggles x 1

Filament Holder Sheet x 1 Filament Holder Tube x 1

AC Power Cable x 1

USB Cable x 1

Tool Box x 1

CNC Carving Platform x 1 Laser Engraving/Cutting Platform x 1

Heated Bed x 1

Material Bag x 1

Print Sheet x 1

Filament x 1

Quick Start Guide | 9

Before You Start

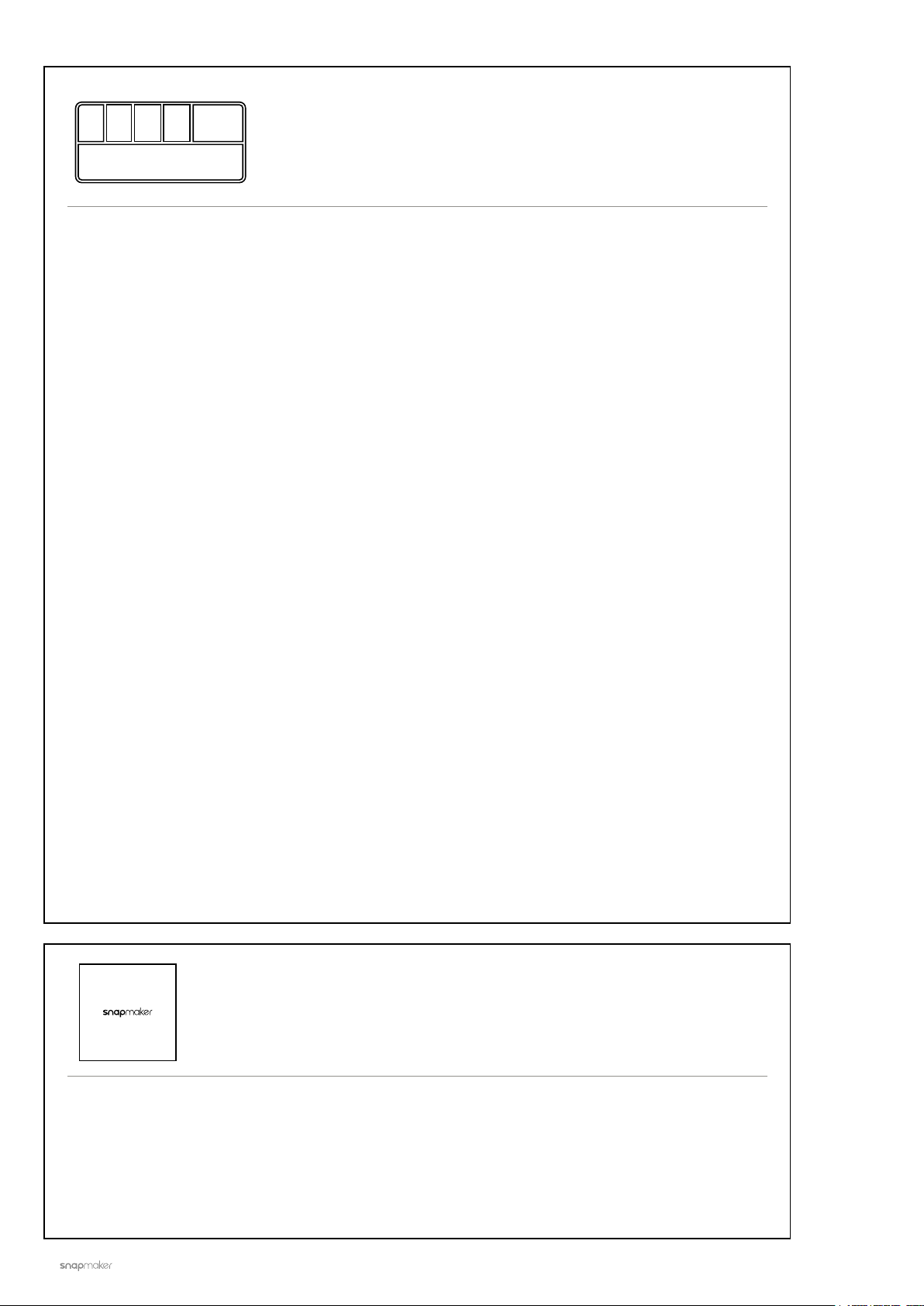

Tool Box

M4 x 10 Hex Socket

Head Screw x 7

Wing Nut x 4

Divider x 6 Cable Holder x 1

Tweezers x 1

Foot x 4 + M4 x 10 Hex Socket

Head Screw x 4

M4 x 8 Screw x 22

Hot End Kit x 1

Cable Tie x 1

Ball End Mill x 1Flat End Mill x 1

M4 x 70 Screw x 4M4 x 30 Screw x 4

ER11 Collet (Only for 3.175 mm

CNC Bits) x 1 + ER11 Nut x 1

Steel Strip Adjustor (For

Maintenance) x 1

Silicone Plug x 8

Diagonal Pliers x 1

USB Disk x 1

Palette Knife x 1

Material Bag

17mm Open-End Wrench x 1

14mm Open-End Wrench x 1

Screwdriver x 1

10

Wiping Cloth x 1CNC Material x 1 Laser Material x 2 Calibration Card x 2

|

1.7 Video Tutorials

Apart from this Quick Start Guide, we also make video tutorials. Read this guide to finish assembly, and if you

are feeling adventurous, tricks that are not included in this guide can be found in the video tutorials. Visit our

website at https://support.snapmaker.com/hc/en-us-> select Snapmaker 2.0 -> Go to Video Tutorial.

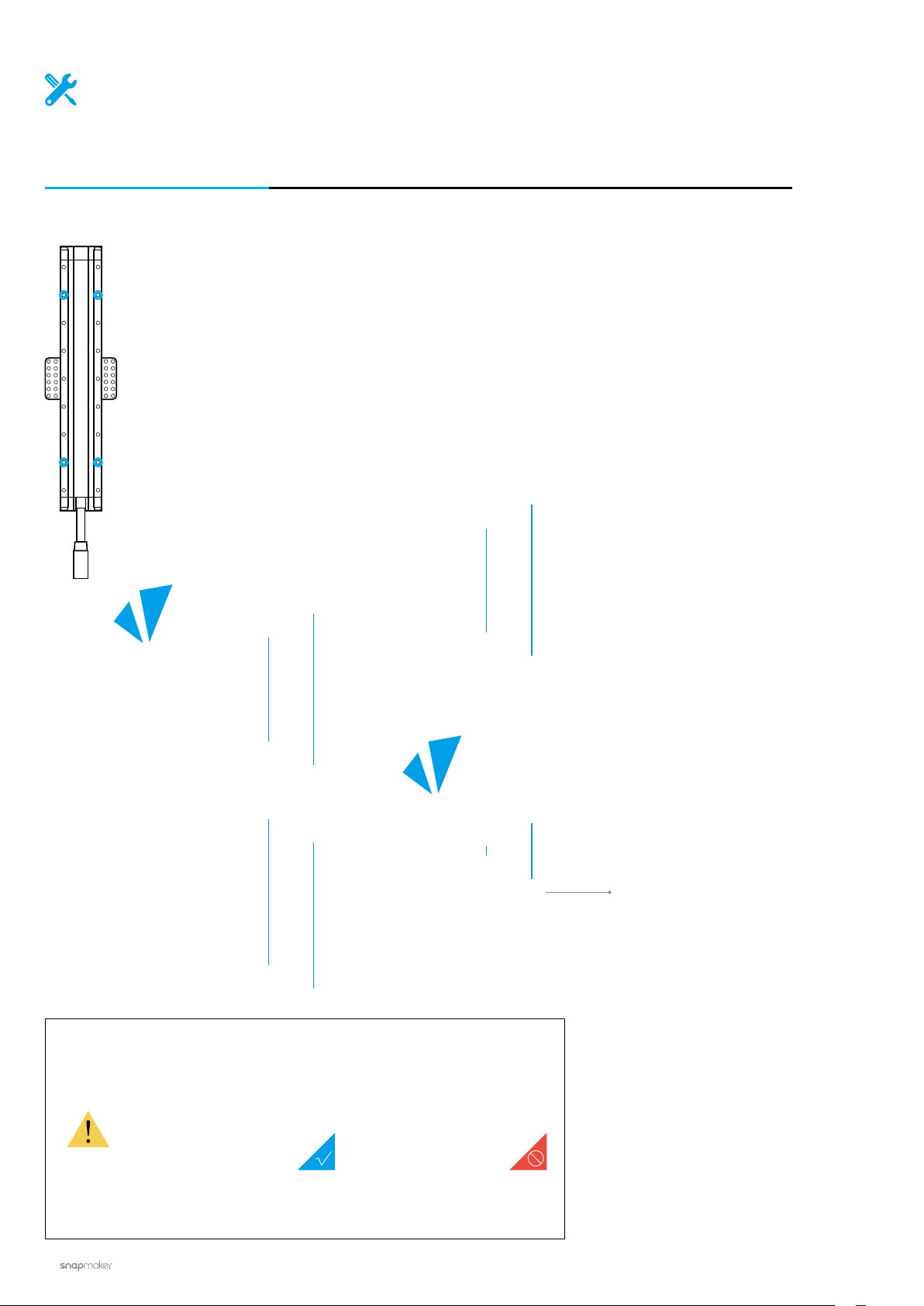

1.8 Used Symbols

CAUTION

NOTE

TIPS

Ignoring this type of message might result in malfunction or damage of the

machine and injuries to users.

Details you should be aware of throughout the process.

Tips offer you convenient operations and additional options.

Make sure that the highlighted part is facing the right way.

Do not tighten the screws when this symbol appears. Always tighten the

screws when it is absent.

1.9 Get the Screwdriver Ready

The screwdriver head H 2.5 is used for assembling the machine. The other heads are used for maintenance.

Make sure the screw head holder has been put back inside of the handle before use.

Quick Start Guide | 11

Machine Assembly

12

|

MACHINE

ASSEMBLY

Quick Start Guide | 13

Machine Assembly

01

/10

Attach the feet to the Base Plate.

M4 x 10 Hex Socket Head Screw x 4

Foot x 4

Base Plate x 1

14

|

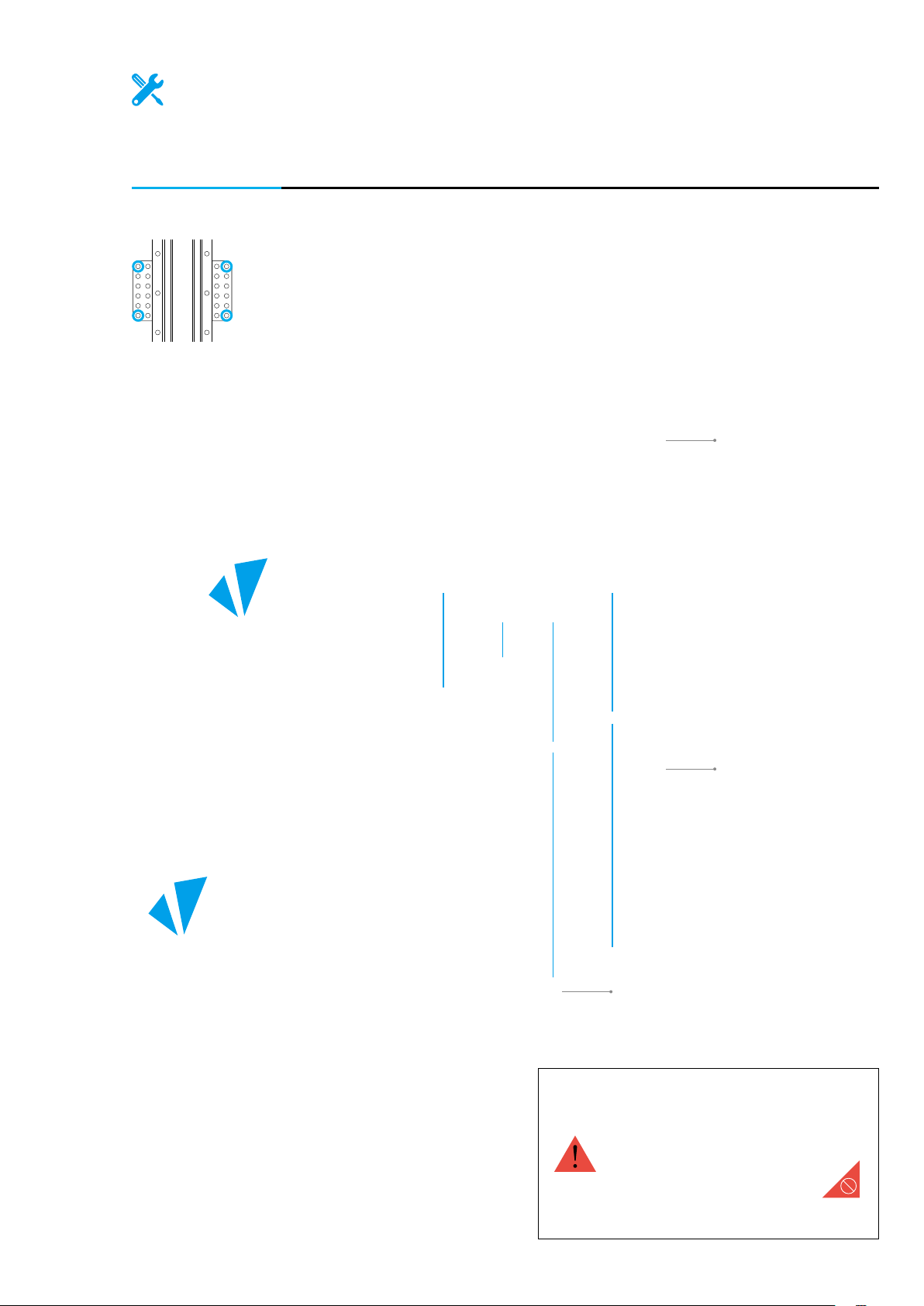

02

/10

Attach the Heated Bed to any one of the Linear Modules (Y axis).

Heated Bed x 1

Linear Module x 1

M4 x 8 Screw x 4

Do not press the steel strip.

Quick Start Guide | 15

Machine Assembly

03

/10

Attach the Y axis to the Base Plate.

16

M4 x 8 Screw x 4

Make sure the Y axis is accurately mounted onto the

groove of the Base Plate.

|

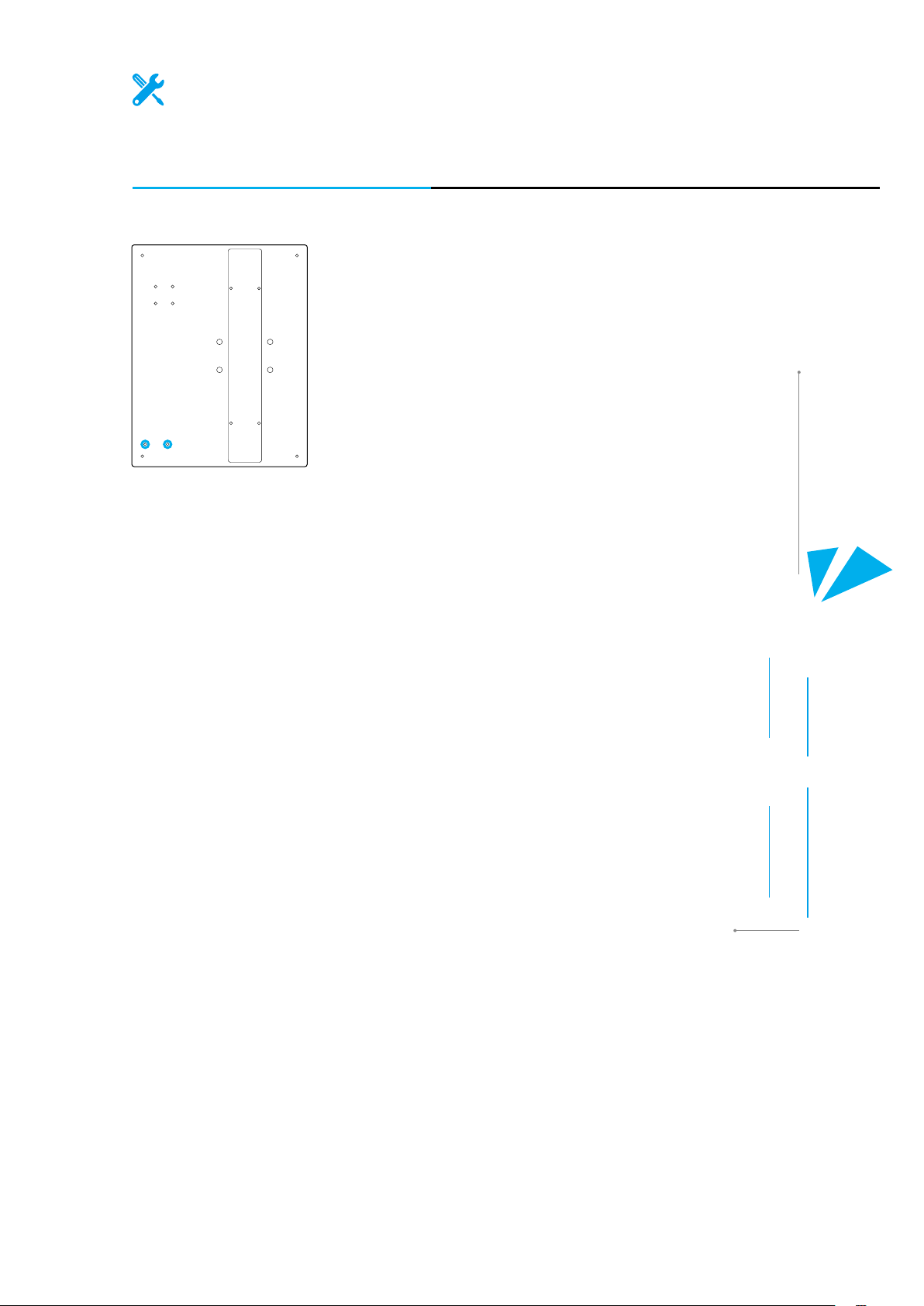

04

/10

Attach the Touchscreen Holder to the Base Plate.

Touchscreen Holder x 1

M4 x 8 Screw x 2

Quick Start Guide | 17

Machine Assembly

05

/10

Attach the Z axis to the Base Plate.

Linear Module x 1

18

M4 x 8 Screw x 4

|

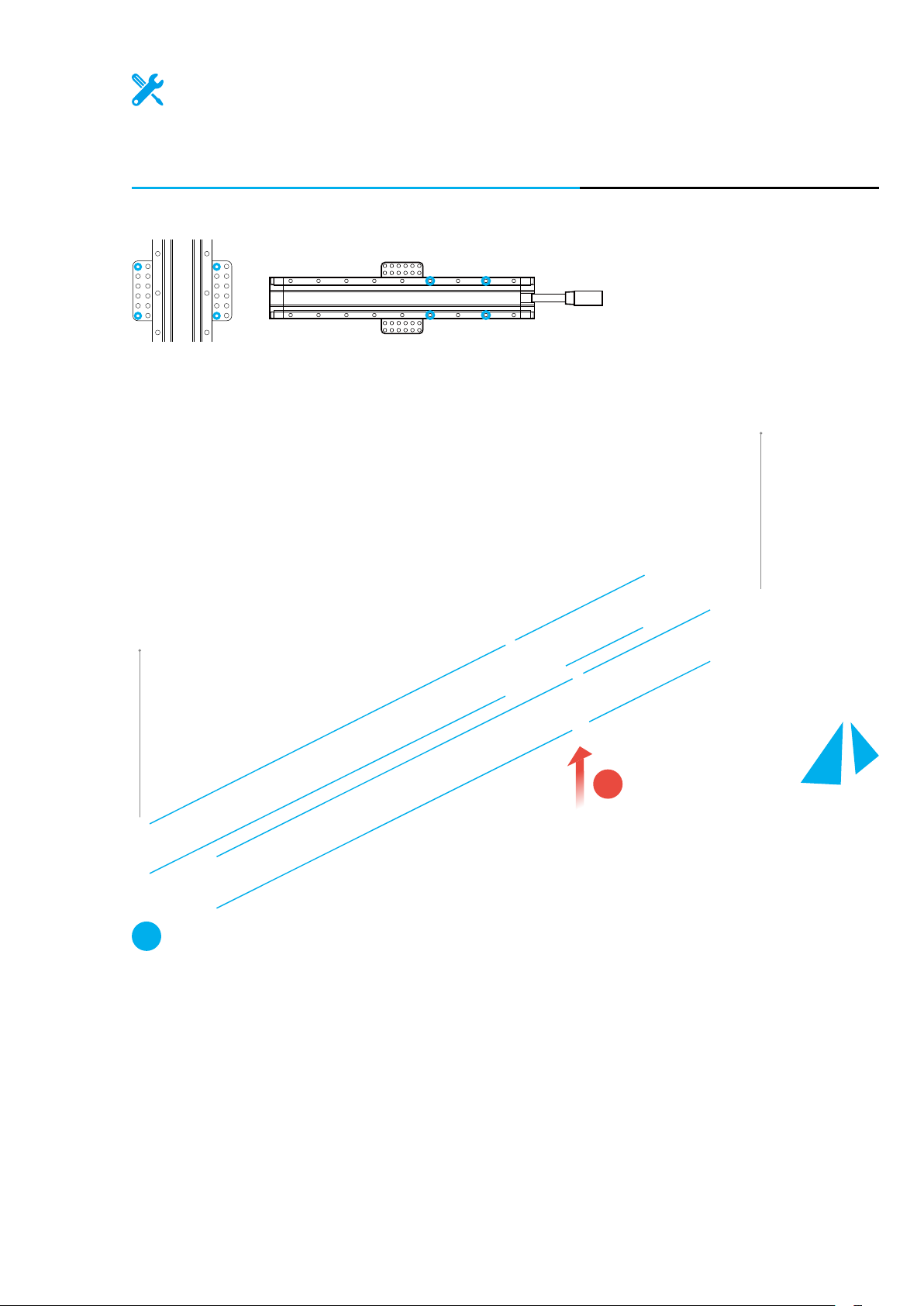

06

/10

Move the Z-axis slider to the top, and then attach the X axis to the Z axis.

Linear Module x 1

M4 x 8 Screw x 4

2

1

Quick Start Guide | 19

Loading...

Loading...