Page 1

Fan Speed Control with the EMC2102 Device

Insert EVB graphic/photo here

(this text can be removed on master page view)

Copyright © 2007 SMSC or its subsidiaries. All rights reserved.

Circuit diagrams and other information relating to SMSC products are included as a means of illustrating typical applications. Consequently, complete information

sufficient for construction purposes is not necessarily given. Although the information has been checked and is believed to be accurate, no responsibility is assumed

for inaccuracies. SMSC reserves the right to make changes to specifications and product descriptions at any time without notice. Contact your local SMSC sales office

to obtain the latest specifications before placing your product order. The provision of this information does not convey to the purchaser of the described semiconductor

devices any licenses under any patent rights or other intellectual property rights of SMSC or others. All sales are expressly conditional on your agreement to the terms

and conditions of the most recently dated version of SMSC's standard Terms of Sale Agreement dated before the date of your order (the "Terms of Sale Agreement").

The product may contain design defects or errors known as anomalies which may cause the product's functions to deviate from published specifications. Anomaly

sheets are available upon request. SMSC products are not designed, intended, authorized or warranted for use in any life support or other application where product

failure could cause or contribute to personal injury or severe property damage. Any and all such uses without prior written approval of an Officer of SMSC and further

testing and/or modification will be fully at the risk of the customer. Copies of this document or other SMSC literature, as well as the Terms of Sale Agreement, may be

obtained by visiting SMSC’s website at http://www.smsc.com. SMSC is a registered trademark of Standard Microsystems Corporation (“SMSC”). Product names and

company names are the trademarks of their respective holders.

SMSC DISCLAIMS AND EXCLUDES ANY AND ALL WARRANTIES, INCLUDING WITHOUT LIMITATION ANY AND ALL IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, AND AGAINST INFRINGEMENT AND THE LIKE, AND ANY AND ALL WARRANTIES

ARISING FROM ANY COURSE OF DEALING OR USAGE OF TRADE. IN NO EVENT SHALL SMSC BE LIABLE FOR ANY DIRECT, INCIDENTAL, INDIRECT,

SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES; OR FOR LOST DATA, PROFITS, SAVINGS OR REVENUES OF ANY KIND; REGARDLESS OF THE

FORM OF ACTION, WHETHER BASED ON CONTRACT; TORT; NEGLIGENCE OF SMSC OR OTHERS; STRICT LIABILITY; BREACH OF WARRANTY; OR

OTHERWISE; WHETHER OR NOT ANY REMEDY OF BUYER IS HELD TO HAVE FAILED OF ITS ESSENTIAL PURPOSE, AND WHETHER OR NOT SMSC HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SMSC EMC2102 USER MANUAL Revision 0.2 (09-17-07)

Page 2

Fan Speed Control with the EMC2102 Device

Table of Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 The Evaluation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Basic Operation Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Experiment 1 - Manual Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.1 ChipMan Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.2 Setting Up the ChipMan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.3 Plotting From ChipMan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Experiment 2 - RPM Based Closed-Loop Fan Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.2 Basic RPM Based Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.3 Effects of Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.4 Register Change Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Experiment 3 - Spin-up Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.1 Fan Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3.3 Forced Kick Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3.4 Spin-Up Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3.5 Spin-Up Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3.6 Register Change Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Experiment 4 - RPM Drive Mode Rate Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4.1 General Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4.2 Controlling the Ramp Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4.3 Register Change Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Experiment 5 - Optimizing RPM Control Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.1 General Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.2 Fan Configuration Register (52h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.3 FAN Minimum Drive Register (55h) and Valid TACH Count (56h) . . . . . . . . . . . . . . . . . 24

5.5.4 Register Change Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6 Experiment 6 - Limits and Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6.1 General Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6.2 Fan Spin and Stall Interrupts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6.3 Register Change Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.7 Experiment 7 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7.1 Repetitious Spin-up Routine Caused by Incorrect Settings. . . . . . . . . . . . . . . . . . . . . . . 28

6 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 DC Fan Basics - Poles, Tach Meter Pulses and Edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Characterizing a DC Fan with EVB-EMC2102 and ChipMan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.1 General Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.2 Set the Correct LIMIT2K Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.3 Determine the Number of Poles and the Maximum Fan Speed . . . . . . . . . . . . . . . . . . . 37

6.2.4 Determine the Minimum Startup Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.5 Determine the Stall Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.6 Determine the Minimum Valid TACH Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.7 Determine the Spin-up Levels (rpm60 and rpm75) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

2

Page 3

Fan Speed Control with the EMC2102 Device

6.2.8 Using the Tested Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

3

Page 4

Fan Speed Control with the EMC2102 Device

List of Figures

Figure 4.1 EMC2102 Fan Control Evaluation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4.2 EVB-EMC2102 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

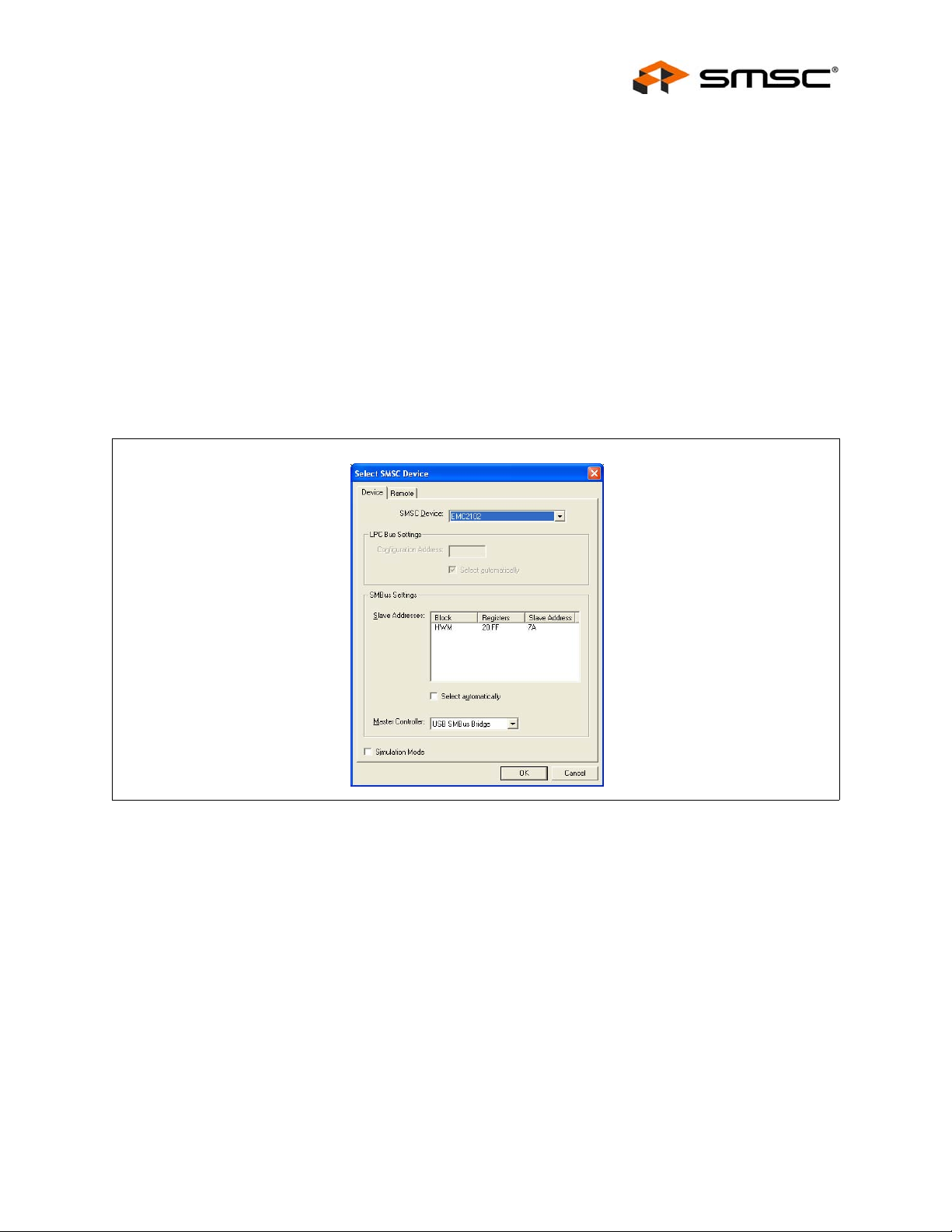

Figure 5.1 ChipMan Message for First Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5.2 ChipMan Device Selection Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

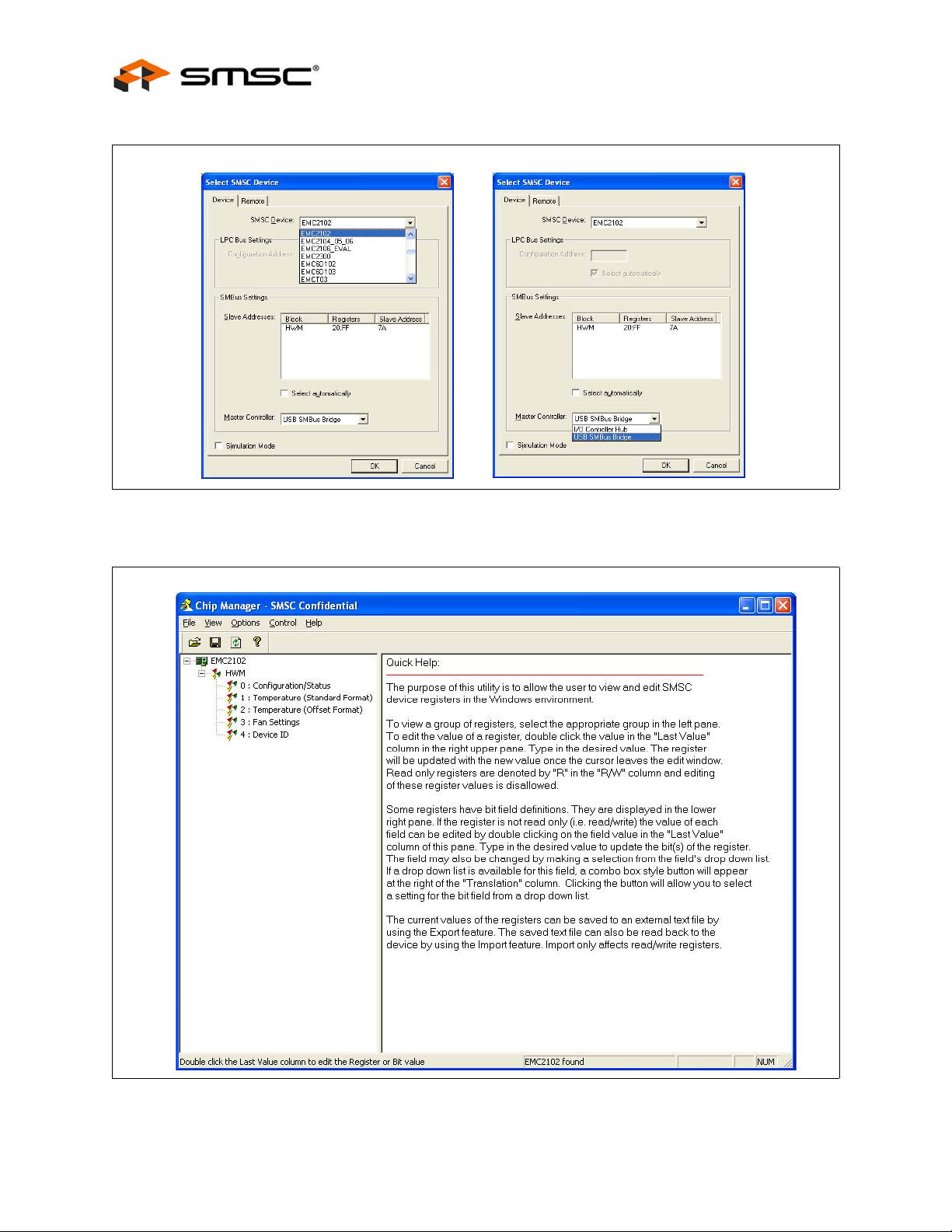

Figure 5.3 Selecting the Device and Master Controller Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5.4 ChipMan Operation Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

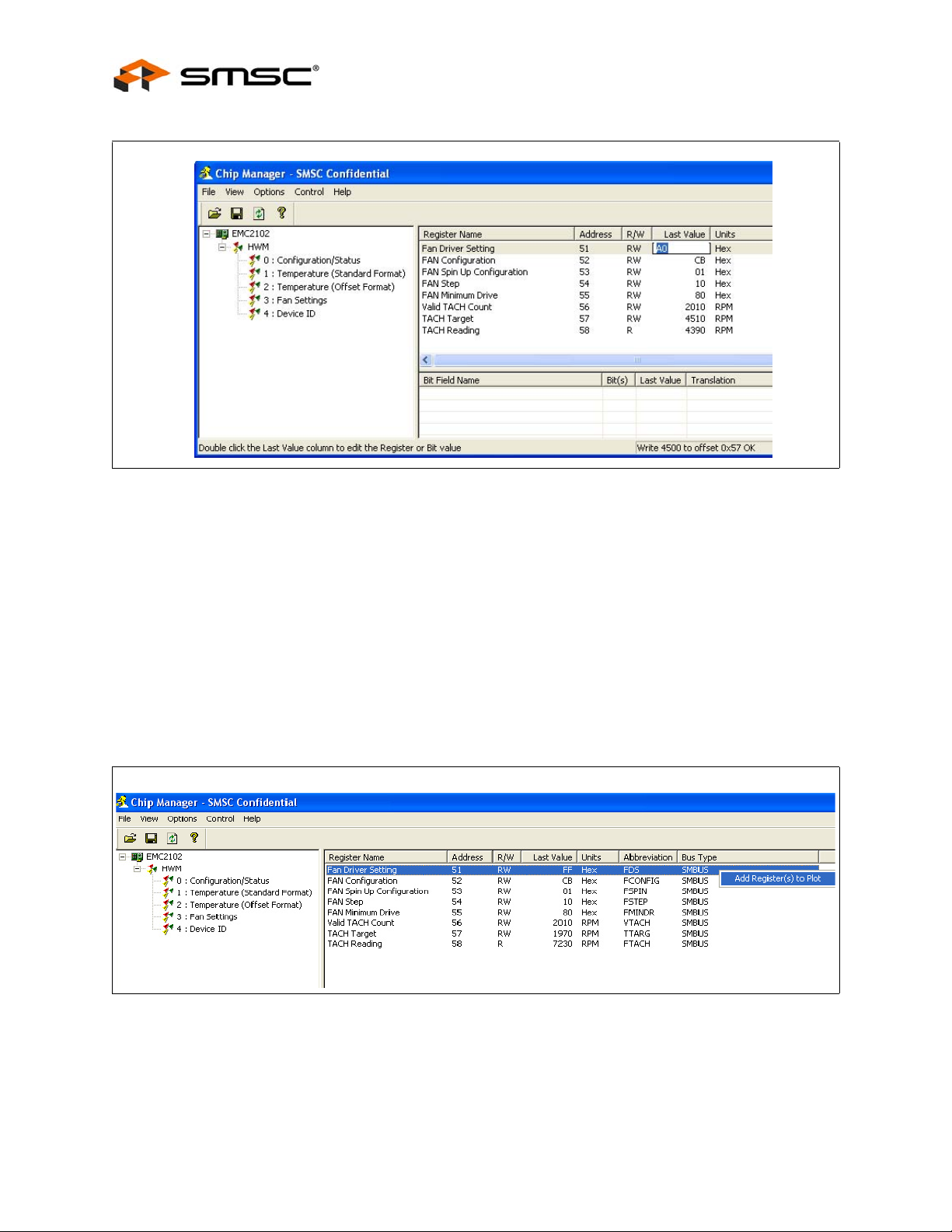

Figure 5.5 Changing Fan Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5.6 Plotting from the ChipMan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5.8 Plot Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5.7 Plot Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5.9 Plots for Proper Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5.10 Effects of Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5.11 Fan Control Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 5.12 Forced Kick Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 5.13 60% Spin Level Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 5.14 Reduced Spin-up Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 5.15 Default Ramp Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 5.16 Default Step Size with Different UPDATE Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5.17 Default UPDATE with Different Step Size Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5.18 Exceptionally Slow Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 5.19 Update Time Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 5.20 Minimum Drive Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 5.21 Valid Tach Count Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 5.22 Fan Spin and Stall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 5.23 Fan Spin-up Routine Restarted Repeatedly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 5.24 Theoretical Plot of Case 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 5.25 Spin-up Case 1 Fix 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 5.26 Spin-up Case 1 Fix 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 5.27 Theoretical Plot of Case 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 5.28 Spin-up Case 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5.29 Theoretical Plot of Case 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5.30 Spin-up Case 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 5.31 Spin-up Routine Restarted During Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 5.32 Theoretical Plot of Case 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5.33 Spin-up Case 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5.34 Spin-up Case 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 5.35 Spin-up Case 5 Fix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 6.1 A Typical 2-pole DC Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 6.2 Output Signal of a 2-pole Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 6.3 Fan TACH Measurement With EMC2102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

4

Page 5

Fan Speed Control with the EMC2102 Device

List of Tables

Table 5.1 Register Change Summary for Experiment 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 5.2 Register Change Summary for Experiment 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5.3 Register Change Summary for Experiment 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 5.4 Register Change Summary for Experiment 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

5

Page 6

1 Overview

SMSC has introduced a series of Environmental Monitoring and Control (EMC) device s with integrated

fan control. This fan controller family devices feature the advanced closed-loop fan control technology

developed by SMSC’s engineering team.

This user manual provides detailed information about fan control features supported by one of those

EMC devices -- EMC2102, with detailed hand-on experiments for configuring the devices in real

applications.

2 Audience

This user manual assumes that the reader is familiar with the functionality of the EMC2102 device and

its evaluation board. The goal of the user manual is to help users to evaluate the new EMC device

using Chip Manager (ChipMan) software provided by SMSC. This user manual also can be used as a

reference material for other EMC devices which have fan control features.

3 References

The following documents should be referenced when using this user manual:

EMC2102 Device Datasheet

EVB-EMC2102 Evaluation Board User Manual

EVB-EMC2102 Evaluation Board Schematics

ChipMan Software User Manual

Fan Speed Control with the EMC2102 Device

4 The Evaluation System

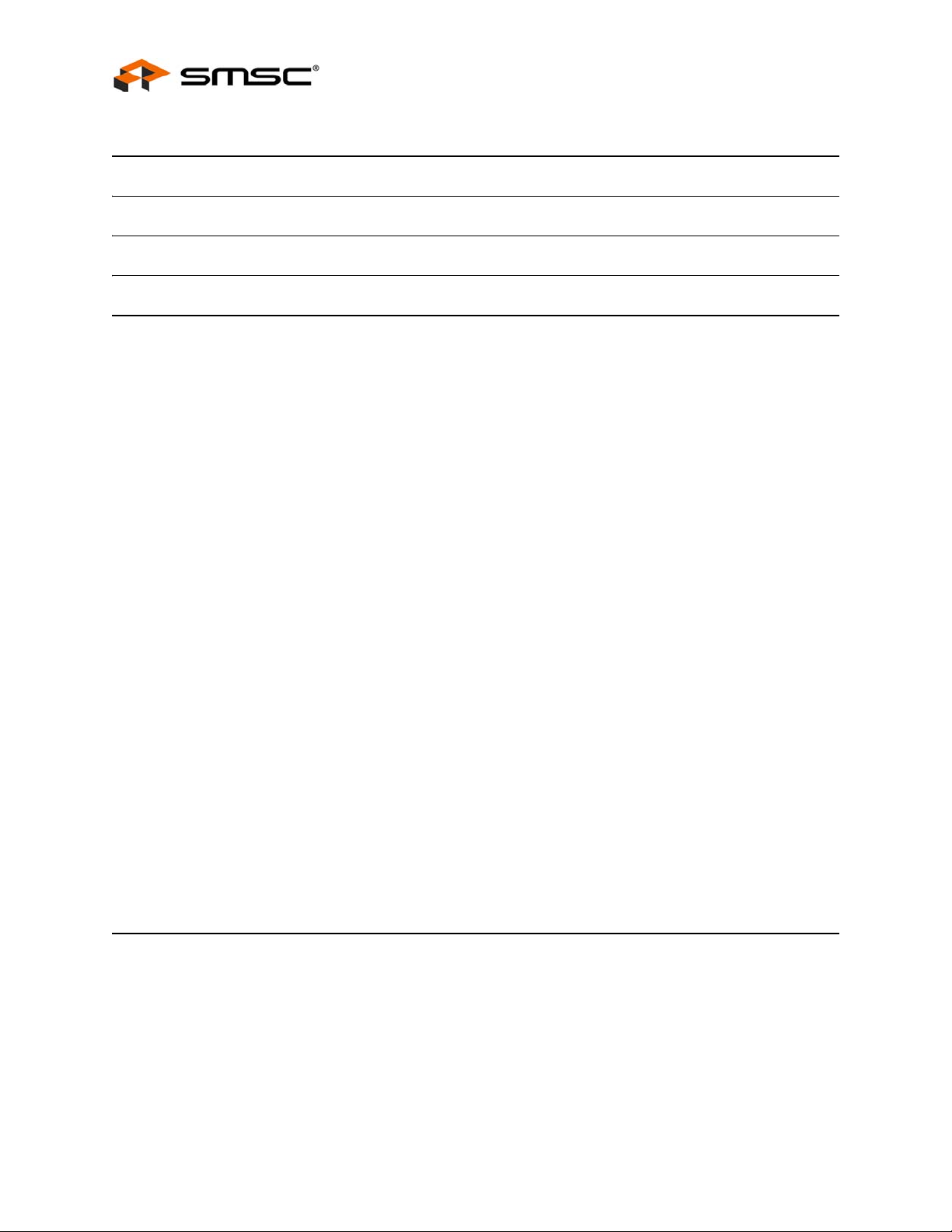

The evaluation system used for this user manual has two major parts, as shown in Figure 4.1,

"EMC2102 Fan Control Evaluation System":

An EMC2102 evaluation board (EVB-EMC2102) with on-board 5V DC fan (Figure 4.2)

A PC with SMSC ChipMan software installed (requiring XML file for EMC2102 device)

This user manual contains several groups of user experiments which cover most of the fan control

features of the EMC2102 fan controller device. All examples are based on the 2102 device evaluation

board (EVB-EMC2102) and its software, but the methods and the results will apply to other EMC2102

applications.

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

6

Page 7

Fan Speed Control with the EMC2102 Device

PC w/ ChipMan Software

Figure 4.1 EMC2102 Fan Control Evaluation System

USB Cable

EVB-EMC2102

SMSC EMC2102

Figure 4.2 EVB-EMC2102 Board

USER MANUAL Revision 0.2 (09-17-07)

7

Page 8

5 Basic Operation Experiments

In this chapter basic operation experiments will be provided to help users to get familiar with the

system.

5.1 Experiment 1 - Manual Fan Control

This experiment is designed to gain familiarity with both the EMC2102 device, and the application

software, ChipMan.

The ChipMan application can be used to configure the EMC2102 devi ce and to monitor the status of

the device. It includes tools to capture and plot data at rates up to 10Hz. Additionally, ChipMan can

be used to review previously saved data.

5.1.1 ChipMan Installation

Install the ChipMan application and device driver on a PC by running Setup.exe from the EMC2102

Evaluation System Software CD provided by SMSC. A revision history and install/uninstall notes may

be found in the readme.txt file on the disk.

ChipMan uses definition files and data files to identify the devices it supports, to load specific values

into registers, and monitor, plot, or record the values of any register set in the device. ChipMan

definition files are XML files conforming to XML Version="1.0" and Encoding="utf-8". The data files for

downloading values to the device are CMF files, specific to the ChipMa n application.

Fan Speed Control with the EMC2102 Device

The CMF files may be located anywhere on the hard drive, but the XML files MUST reside in the

ChipMan directory, typically located at: C:\Program Files\SMSC\ChipMan\Chips. An XML file usually

names with the device name that supports (EMC2102.xml, EMC2103-2.xml, etc.)

During the installation of the ChipMan application, it is possible to specify a non-default installation

directory. If this was done, substitute the path provided at that installation for "C:\Program Files" to

store the XML files in the proper location.

Connect the USB cable to an available USB port on the PC, (The o ther end, “mini-B” end, of the USB

cable should be connected to an EMC Evaluation Board). The “Find New Hardware” wizard will pop

up on the PC’s screen for USB driver installation. Follow the instructions on the screen to complete

the installation process.

5.1.2 Setting Up the ChipMan

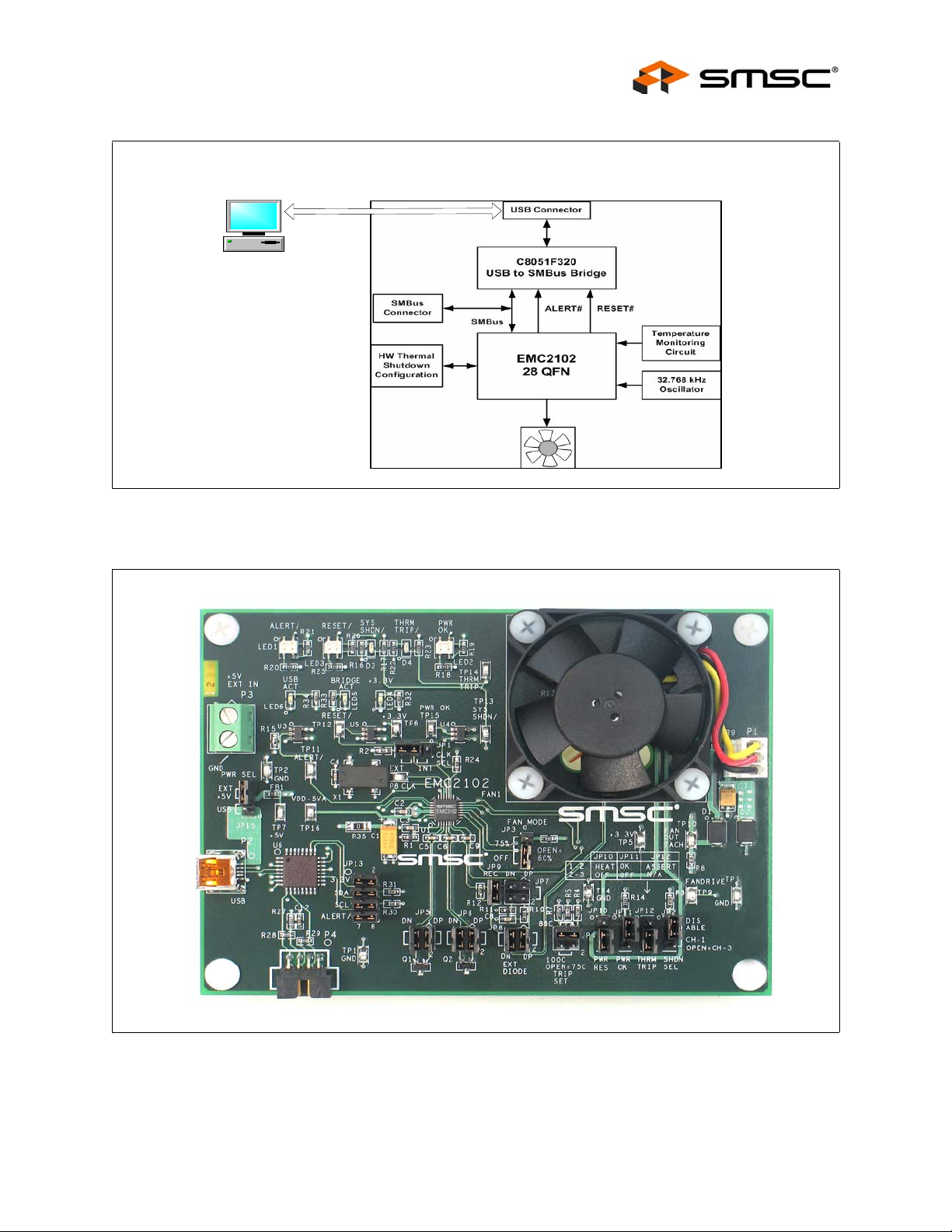

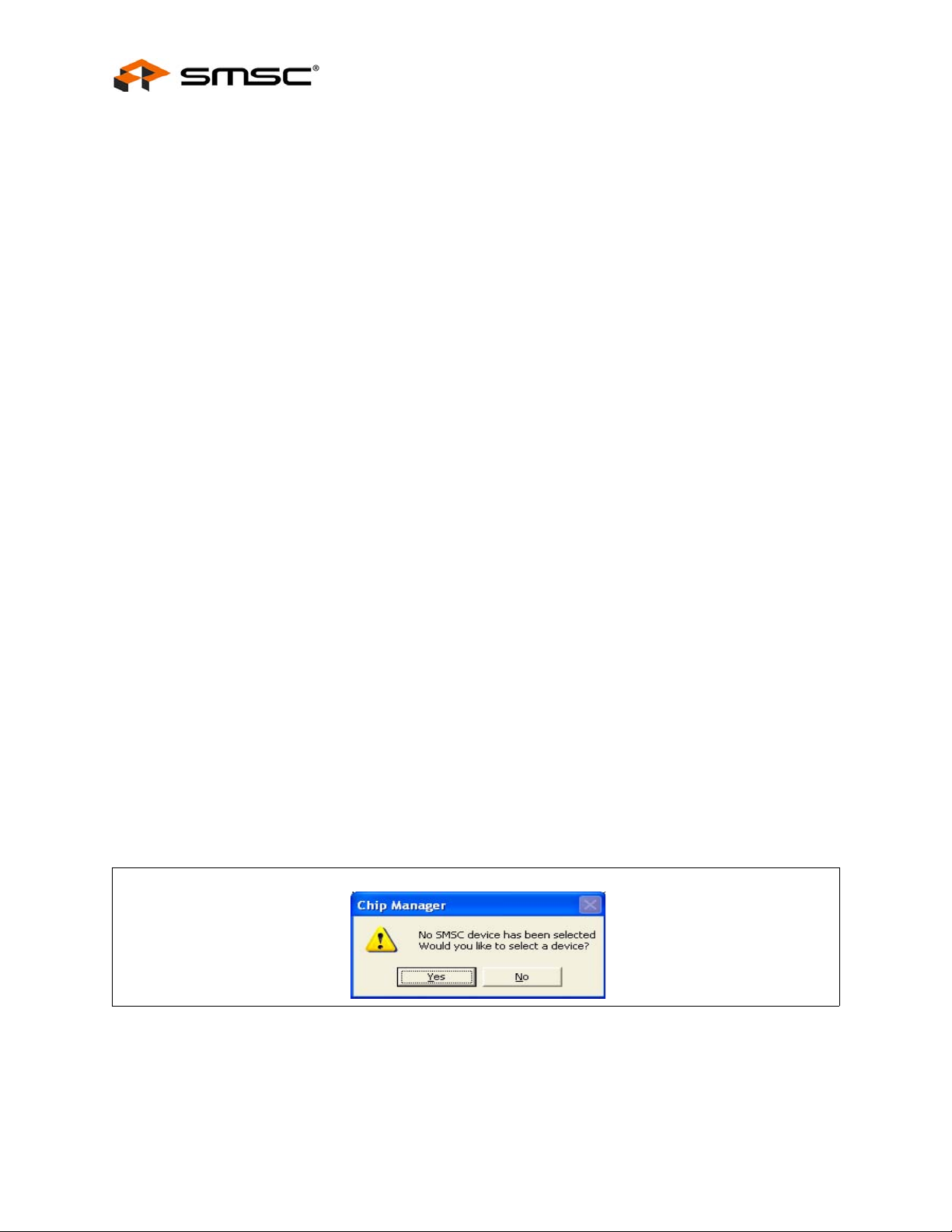

Once the ChipMan has been installed, start the software by selecting Start -> Programs -> SMSC ->

Chip Manager. If this is the first operation, the application will guide you to select a device, as shown

in Figure 5.1 below.

Answer "Yes", then the device selection menu as shown in Figure 5.2, "ChipMan Device Selection

Window" will appear.

Click on the Pull-Down menu at the top, select EMC2102 as shown in Figure 5.3, "Selecting the Device

and Master Controller Type", and click OK. The ChipMan operation window will then appear, as shown

Revision 0.2 (09-17-07)

Figure 5.1 ChipMan Message for First Operation

USER MANUAL SMSC EMC2102

8

Page 9

Fan Speed Control with the EMC2102 Device

in Figure 5.4, "ChipMan Operation Window". Click on the HWM icon to show the different windows

available.

The EMC2102 WatchDog will have timed out at this point, and the on-board DC fan will be running at

100%.

Note: Starting the ChipMan application without the USB cable/EVB connected to the PC, an error

message "Supported company ID on device not found" will pop-up. Plug in the USB cable a nd

click on “Abort”, another pop-up window will ask if you want to select an SMSC device. Click

on “Yes” and then select the device as shown in Figure 5.3.

In the same device selection window the user al so has the options to chose the SMBus Slave Address

(Default is 7A for EVB-EMC2102, use “Select automatically” is recommended), the Master Controller

type (Default is USB SMBus Bridge, see note 1 be low) and if the ChipMan needs to be configured to

run in simulation mode. In the simulation mode, users can practice the software functions without

connecting a USB cable/EVB to the PC.

For more help with ChipMan, select Help -> Contents for an html based help documen t.

SMSC EMC2102

Figure 5.2 ChipMan Device Selection Window

USER MANUAL Revision 0.2 (09-17-07)

9

Page 10

Figure 5.3 Selecting the Device and Master Controller Type

Fan Speed Control with the EMC2102 Device

Revision 0.2 (09-17-07)

Figure 5.4 ChipMan Operation Window

USER MANUAL SMSC EMC2102

10

Page 11

Fan Speed Control with the EMC2102 Device

Notes:

1. The EVB-EMC2102 needs to be configured using the USB SMBus Bridge to work properly. If in

the device selection window the Master Controller type is set to I/O Controller Hub then the

"Supported company ID on device not found" message will pop-up again.

2. Disconnecting the USB cable and reconnecting it without restarting the ChipMan may cause

register reading errors (all zeros). This problem can be cleared by re-selecting the EMC2102 device

through the device selection window (Options -> Select De vice).

3. The SMBus Slave Address could vary depending on the device. If a correct XML file is installed,

the ChipMan should be able to select the correct slave address automati cally. Refer to the device

datasheet for more details about the SMBus protocol and its configurations.

4. The SMSC ChipMan application allows viewing and changing register values for a variety of

devices. The ChipMan software only needs to be installed once to support all of these devices.

The list of supported devices may be found in the pulldown menu under Options -> Sel ect Device.

The next step will be to load the CMF file. Simply select File at the to p of the window, and "Import"

from the pull-down menu. A pop-up window will let the user to locate the right CMF.

Select the appropriate file and click "open". The CMF file will then load up the values into the EMC2102

device.

SMSC provides all CMF files for the operation experiments introduced in this user manual to help

customers to evaluate the EMC2102 device. Customers can also export their own configurations to

CMF files through the pull-down menu File -> Export/Export As.

The CMF file used for the Experiment 1 is EMC2102_manual.cmf.

To ensure the ChipMan application and the EMC2102 are communicating, select File -> Import and

then select the file emc2102_manual.cmf. This will import a configuration file to disable EMC2102’s

RPM control function and then set a valid fan control outp ut value. The on-board DC fan’s speed will

be reduced to about 5000 rpm at this time.

Select "3: Fan Settings" in the ChipMan window by double-clicking. The window as shown in

Figure 5.5, "Changing Fan Speed" will open. Double-click the "last value" of Fan Driver Setting register

(51h) and enter a new drive value (should be greater than 9Ah for the on-board DC fan). The fan

should respond, and the TACH Reading register (58h) should indicate an RPM reading.

It is recommended to set Autorefresh Registers option in ChipMan for all experiments in this user

manual. Select Options -> Autorefresh registers.

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

11

Page 12

Figure 5.5 Changing Fan Speed

Fan Speed Control with the EMC2102 Device

5.1.3 Plotting From ChipMan

The ChipMan software has the ability to plot register values in real-time, u p to 10Hz continuous rate.

To select a register to plot, highlight its name or value, and right-click. A menu with a single entry "Add

register to Plot" will appear (Figure 5.6, "Plotting from the ChipMan"). Click the entry then a plot window

should appear, with a legend on top. When additional registers with the same data type are selected,

they are added to the existing plot window. In the experiment shown in Figure 5.7, "Plot Windows",

Drive Setting, TACH Target, and TACH Reading were selected. Note both the Tach register s are being

plotted on the same graph.

The last step is to start the plots. All plots can be started simultaneously by selecting the "Control"

pulldown from the main application window and then "Plot -> start all plots". Individual plots may be

paused at any time without loss of captured data on the other plot windows.

Revision 0.2 (09-17-07)

Figure 5.6 Plotting from the ChipMan

USER MANUAL SMSC EMC2102

12

Page 13

Fan Speed Control with the EMC2102 Device

The two plots shown in Figure 5.8, "Plot Examples" are in sync. If the scaled data is desired for

analysis or archival, the data may be stored in a semi-colon separated text file from each of the plot

windows. Simply select File Export, and enter a filename in the Save wind ow.

Figure 5.7 Plot Windows

TACH Target (57h)

Fan Driver Setting (51h)

TACH Reading (58h)

Figure 5.8 Plot Examples

5.2 Experiment 2 - RPM Based Closed-Loop Fan Control

The experiment 2 is designed to gain familiarity with the close d-loop RPM controller implemented in

the EMC2102. This experiment will discuss the effects of gain, spin-up, and minimum settings on the

closed-loop performance.

The cmf file for this experiment is EMC2102_RPM.cmf.

5.2.1 Getting Started

For all these tests, the Fan Drive Setting register (51h), the TACH Target register (57h) and the TACH

Reading registers (58h) are selected to plot. As bits are switched in each of the tests, the register name

and address will be provided.

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

13

Page 14

5.2.2 Basic RPM Based Fan Control

The EMC2102 defaults will enable closed-loop operation. Prior to other options, exa mine the various

parameters on ChipMan window page 3: Fan Settings. The registers of most interest are the FAN

Minimum Drive (55h), and Valid Tach Count (56h). The closed-loop controller will not drive below the

minimum drive value, and will not respond to a TACH Target RPM speed less than the speed defined

by the Valid Tach Count register.

Note: The TACH reading is a reciprocal function of the fan speed, i.e. a higher TACH reading value

means a slower fan rpm speed. Refer to 6 "Appendix" for more details.

Same as Experiment 1, select Fan Drive Setting (51h), TACH Target (57h), and TACH Reading (58h)

for plotting. Start the plot windows in order to see the response, and command a series of Tach

Targets, starting at 4500 RPM, and going up in 500 RPM steps. The plots in Figure 5.9, "Plots for

Proper Control Settings" will be representative of the response generated.

Fan Speed Control with the EMC2102 Device

TACH Target (57h)

Fan Driver Setting (51h)

Figure 5.9 Plots for Proper Control Settings

Using this basic setup, it is possible to explore how well the fan is controlled using default values.

5.2.3 Effects of Loading

The EMC2102 has the ability to overcome changes in fan current requirements for a given RPM setting

due to aging, a blocked vent, dust, etc. This is because the controller does not rely on absolute drive

settings, but rather on driving the PID loop error to "0" (i.e., driving the TACH reading to equal to the

TACH target). To illustrate this feature, simply command an RPM setting (6000 RPM for this

experiment), and then use a piece of paper to cover the window of the fan. This will reduce the air

flow through the fan and decrease the wind resistance. With the same Fan Drive Setting value (~ 240d

in register 51h, set by devices’ RPM controller), less wind resistance will make the fan runn ing faster.

Once the PID controller inside the EMC2102 detects the difference between the TACH reading and

the TACH target (6000 RPM), it will adjust the output values (down to ~210d in this experiment) to

bring the fan speed back to the target, as shown in Figure 5.10, "Effects of Loading".

TACH Reading (58h)

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

14

Page 15

Fan Speed Control with the EMC2102 Device

Figure 5.10 Effects of Loading

5.2.4 Register Change Summary

Fan was covered

The cover was removed

Table 5.1, "Register Change Summary for Experiment 2" lists all register value changes from the

default cmf load to accomplish the tests.

REGISTER

NAME ADDRESS

Fan

Configuration

Table 5.1 Register Change Summary for Experiment 2

DEFAULT

VALUE

52h 4Bh

(0100 1011b)

NEW

VALUE COMMENT

CBh

(1100 1011b)

Enables the RPM based closed-loop fan

control Algorithm

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

15

Page 16

Fan Speed Control with the EMC2102 Device

5.3 Experiment 3 - Spin-up Configuration Options

This experiment is designed to gain familiarity with the various spin-up options available in the

EMC2102 devices.

This experiment will discuss the effects of Spin-Up Time and Spin-Up Levels. These parameters are

important to ensure a valid start, while minimizing the turn-on overshoot for initial low RPM settings.

(More examples regarding these two parameters can be found in Section 5.7.1, "Repetitious Spin-up

Routine Caused by Incorrect Settings").

The CMF file for this experiment is the same as for Experiment 1 , EMC2102_default.cmf.

5.3.1 Fan Control Parameters

The spin-up routine is a special algorith m that the EMC2102 uses to boot up the fan. In manual control

(open loop) mode, it is only invoked when starting from a ‘0’ value in the FAN Drive Setting register

51h.

In the RPM control (closed-loop) mode, the spin-up routine is invoked when the device is driving a

stalled fan to a valid target speed, i.e., the raw data value in register 57h (TACH Target) is smaller

than the one in register 56h (Valid TACH Count). During the normal operation while the fan is running,

the spin-up routine could also be invoked if the fan speed fell to below the valid fan sp eed, i.e, the raw

data value in register 58h (TACH Reading) is greater than the one in register 56h (Valid TACH Count),

since the fan will be considered as stalled by the controller.

There are several parameters that control the fan’s behavior during and a fter the spin-up routine, as

shown in Figure 5.11, "Fan Control Parameters".

When the spin-up routine is operating, the fan driver is set to full scale for one quarter of th e total user

defined spin up time. For the remaining spin up time, the fan driver output is set a user defined level

(60% or 75% of full drive). After the spin-up routine has finished, the RPM algori thm controls the fan

speed to the TACH targets. At this point if the EMC2102 cannot detect a valid fan speed (the

hexadecimal value in the TACH Reading register is higher than the Valid TACH Count re gister setting,

which means the fan speed is below the valid speed), i t will try to restart the fan.

Fan Drive Setting

(51h)

Use Normal

Closed-loop Algorithm

Fan Step

(54h[5:0])

Algorithm controlled drive

Prev Drive

Use Spin-Up Algorithm

100%

Spin Up Level =

60% ~ 75%

(53h[2])

New Target Count

¼ of Spin Up Time

The spin-up LEVEL (60% or 75%, defined by 53h[2]) has corresponding Fan Driver Setting

hexadecimal values (register 51h) which cab be calculated using FFh as 100% and 00h as 0%. For

Revision 0.2 (09-17-07)

TACH Target

Changed

Spin Up Time

(53h[1:0])

Update Time

Check TACH

(52h[2:0])

Target Count

Reached

Figure 5.11 Fan Control Parameters

USER MANUAL SMSC EMC2102

16

Page 17

Fan Speed Control with the EMC2102 Device

the 60% drive the register 51h value is 153d o r 99h, and for 75% it is 191d or BFh. Those two drive

settings will run a DC fan at two different speeds and we will call them rpm60 an d rpm75. Depending

on the fan, the speed for the same drive setting will vary.

All data and plot examples in this document were taken using an EVB-EMC2102 board with the onboard DC fan. This fan has an rpm60 of 4500 rpm, and an rpm75 of 5650 rpm.

5.3.2 Getting Started

For all these tests, the Fan Drive Setting register (51h), the TACH Target register (57h) and the TACH

Reading registers (58h) are selected to plot. As bits are switched in each of the tests, the register name

and address will be provided.

5.3.3 Forced Kick Function

The EMC2102 has a forced 100% kick at turn-on. This feature drives the fan at maximum voltage for

¼ of the time set by the SPINUP_TIME[1:0] bits in register 53h. The plots in Figure 5.12, "Forced Kick

Function" illustrate this function with a spin-up time of 2 .0 sec while the TACH Target register (57h) is

changed from 0 rpm to 5200 rpm.

Selecting a different "Time per Division" value in the pull-down menu in the center bottom of the plotting

window, to make the 100% kick pulse can be viewed. This scale change affects both playback, and

real-time mode. The rate at which data is recorded is unaffected by changing this parameter.

100% Kick Pulse for 500 ms

75% Spin-Up

Spin-Up

Time = 2 s

5.3.4 Spin-Up Level

Depending on the application, the value of LEVEL (spin-up level, bit[1] in register 53h) may need to

be adjusted to achieve the best fan control result. The plots in Figure 5.13, "60% Spin Level Setting"

show the same experiment as Section 5.3.3, "Forced Kick Function" with a 60% spin-up level. Note

the a smaller overshoot at the lower LEVEL setting.

(1/4 of Spin-Up Time)

Level

Normal Fan Drive

(for 5200 rpm)

Figure 5.12 Forced Kick Function

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

17

Page 18

Figure 5.13 60% Spin Level Setting

Note: When a fan starts, the first TACH count captured by the EMC2102 may not reflect the fan’s

speed correctly, since the counting clock (32.768 kHz) could only partially fill the counting

window, which will cause a higher speed reading. Also for some fans, the tachometer may not

work immediately after the fan starts therefore some invalid TACH signals (very short, noisy

pulses) could be sent out at the beginning. In eithe r case, the invalid TACH counts could be

displayed on the ChipMan plots (Figure 5.13), but will never be used to control the fan because

the EMC2102 will not look at the TACH reading until the end of spin-up routine.

Fan Speed Control with the EMC2102 Device

Invalid TACH Count

5.3.5 Spin-Up Time

The EMC2102 FAN Spin Up Configuration register (53h) contains 2 bits to set the overall spin-up time.

This parameter allows for tailoring of rapid and slow response fans. Repeat the experiment in

Section 5.3.3 with 500 ms SPINUP_TIME. This will provide a quicker response with smaller overshoot,

as shown in Figure 5.14, "Reduced Spin-up Time".

In general, spin-up time should be tailored for the fan type being used or the effect may be undesirable.

Revision 0.2 (09-17-07)

Figure 5.14 Reduced Spin-up Time

USER MANUAL SMSC EMC2102

18

Page 19

Fan Speed Control with the EMC2102 Device

5.3.6 Register Change Summary

Table 5.2, "Register Change Summary for Experiment 3" lists all register value changes from the

default cmf load to accomplish the tests.

Table 5.2 Register Change Summary for Experiment 3

REGISTER

NAME ADDRESS

FAN Spin Up

Configuration

DEFAULT

VALUE

53h 01h

(00000001b)

NEW

VALUE COMMENT

03h SPINUP_TIME of 2.0 sec

05h Change the LEVEL from 60% to 75%

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

19

Page 20

Fan Speed Control with the EMC2102 Device

5.4 Experiment 4 - RPM Drive Mode Rate Controls

This experiment is designed to gain familiarity with the rate control options avail able in the EMC2102

devices.

This experiment will discuss the effects of Maximum Fan Step and Update rate that can be used to

control the ramp rate of a fan. The two parameters ensure the fan reaches the desired drive in a

reasonable time with no oscillations.

The CMF file for this experiment is the same as for Experiment 1 , EMC1202_default.cmf.

5.4.1 General Setup

For all these tests, the Fan Drive Setting register (51h) and the TACH Reading registers (58h) are

selected to plot. As bits are switched in each of the tests, the register name and address will be

provided.

5.4.2 Controlling the Ramp Rate

Controlling the ramp rate can improve the performanc e of the fan control loop by limiting the slew rate

of the fan drive. The EMC2102 uses the UPDATE bits in the FAN Configuration register (52h, bits [2:0])

to determine the time interval between two updates of the controller output, and uses the FAN Step

register (54h) to determine the maximum allowed hexadecimal co unt (STEP) of the output (Refer to

Figure 5.11 "Fan Co ntrol Parameters" for more details). These two parameters can only work in the

RPM control mode. When the RPM control function is disabled (52h[7]= 0), any change in the Fan

Drive Setting register (51h) will immediately change the output.

The plots in Figure 5.15, "Default Ramp Rate" illustrate the drive and response with the default

UPDATE (400ms) and default STEP SIZE (Max. 16 drive settings per update), while changing the fan

target speed from 4000 rpm to 6000rpm.

Figure 5.15 Default Ramp Rate

The ramping rate in this mode can be accelerated or slowed down , depending on application and the

values of register 52h (UPDATE) and 54h (STEP SIZE). In the next experiment (Figure 5.16, "Default

Step Size with Different UPDATE Settings"), the default STEP SIZ E with different UPDATE (400 ms

and 100 ms) were used, The 100 ms setting has the effect of speeding the loop up by a factor of 4,

as that is the ratio between minimum (100ms) and default (400ms) UPDATE settings.

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

20

Page 21

Fan Speed Control with the EMC2102 Device

Figure 5.16 Default Step Size with Different UPDATE Settings

In the next experiment (Figure 5.17, "Default UPDATE with Different Step Size Settings"), two different

maximum step sizes, 16 and 63, were used. with the 63 STEP SIZE setting, the output takes less

steps (updates) from 4000 rpm to 7500 rpm because it gives the fan more power to follow the desi red

rpm settings.

UPDATE

= 100 ms

UPDATE

= 400 ms

STEp SIZE

= 63

STEp SIZE

= 16

Figure 5.17 Default UPDATE with Different Step Size Settings

In the last experiment, an extremely slow ramp rate is demonstrated. The UPDATE was set to

maximum (1600 ms), and the STEP SIZE was changed to 01h (Figure 5.18, "Exceptionally Slow

Rate"). Note the large scale of the “Time per division” in the figure.

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

21

Page 22

Figure 5.18 Exceptionally Slow Rate

5.4.3 Register Change Summary

Fan Speed Control with the EMC2102 Device

Table 5.3, "Register Change Summary for Experiment 4" lists all register value changes from the

default cmf load to accomplish the tests.

Table 5.3 Register Change Summary for Experiment 4

REGISTER

NAME ADDRESS

FAN Step 54h 10h 01h Demonstrate RRC long duration

Fan

Configuration

52h CBh C8h, CFh Demonstrate min (C8h) and max (CFh) UPDA TE rates

DEFAULT

VALUE

NEW

VALUE COMMENT

applied to RRC

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

22

Page 23

Fan Speed Control with the EMC2102 Device

5.5 Experiment 5 - Optimizing RPM Control Response

This experiment is designed to gain familiarity with the parameters that affect the closed-l oop control ler

implemented in the EMC2102. All these registers are located on the Fan Setting page in ChipMan.

This experiment will go through each register, examining the effects of parametric changes on the

closed-loop controller in RPM mode.

5.5.1 General Setup

For all these tests, the Fan Drive Setting register (51h), the TACH Target register (57h) and the TACH

Reading registers (58h) are selected to plot. As bits are switched in each of the tests, the register name

and address will be provided.

5.5.2 Fan Configuration Register (52h)

The Fan Configuration Register stores the basic operation parameters of the closed-loop controller.

The EN bit turns on the RPM controller, and locks out manual updates to the Fan Drive Setting register

(51h).

The next two parameters, LIMIT2K and EDGES[1:0] (both in register 52h) describe the fan itself. The

EDGES[1:0] tell the controller how many tach edges to examine to determine the fan speed. The

LIMIT2K parameter tells the RPM controller how to interpret the TACH Target register (57h). The value

of this parameter provides an operating range for the fan by specifying the minimum rpm: the 500 rpm

setting is for low speed fans and the 2000 rpm setting is typical for notebook and desktop fans (high

speed fans). (Please refer to Section 6.1, "DC Fan Basics - Poles, Tach Meter Pulses and Edges" for

more details about the TACH edges and ranges.)

For all experiments in this suite, the default values have been used. This keeps the scaling of those

values fixed, allowing the ChipMan application to appropri ately scale the counts to RPM values.

The UPDATE[2:0] parameter controls the speed at which the RPM controller updates the output drive,

as already been discussed in Section 5.4, "Experiment 4 - RPM Drive Mode Rate Controls". This

parameter is independent of the TACH Reading updates, which are controlled by the EDGES[1:0]

parameter. The plots in Figure 5.19, "Update Time Modifications" show the effect of UPDATE on the

closed-loop performance when starting the on-board fan. The numbers (in unit of second) in the left

plot indicate the UPDATE value used for that sequence. By experimenting with the different update

times you can determine the most stable setting for the fan to be controlled.

0.1s 0.2s 0.4s 0.8s 1.6s

Invalid TACH signals

(Ignored by Controller)

SMSC EMC2102

Figure 5.19 Update Time Modifications

USER MANUAL Revision 0.2 (09-17-07)

23

Page 24

Fan Speed Control with the EMC2102 Device

5.5.3 FAN Minimum Drive Register (55h) and Valid TACH Count (56h)

These two registers assist the user in defining the operational environment for a given fan. The

Minimum Drive register is an absolute minimum value the RPM controller may drive to in an attempt

to achieve low RPM settings. The Valid Tach Count register is used to compare against the Tach Target

register. No value less than the Valid Tach Count will be accepted by the controller. To examine this

feature, set the minimum drive to C0h, and command an RPM setting of less than 5500 RPM. The fan

will start at about 5600 rpm (51h = C0h). Set the target to 6000 rpm, and the fan speed follow s. Drop

the fan target speed from 6000 rpm to 4500 rpm, the real fan speed will only drop to about 5560 rpm,

as shown in Figure 5.20, "Minimum Drive Setting".

Fan starts at

Minimum Drive

Fan will not run below

Minimum Drtive

Figure 5.20 Minimum Drive Setting

Likewise, the Valid TACH Count register operation is simple to show. Start the fan at 6000 RPM with

all default setting, and then set the Valid TACH register to 5000 RPM. Enter a comman d of 4800 RPM,

and the fan will not respond as shown in Figure 5.21, "Valid Tach Count Setting".

Target of 4800 rpm

Figure 5.21 Valid Tach Count Setting

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

24

Page 25

Fan Speed Control with the EMC2102 Device

5.5.4 Register Change Summary

Table 5.4, "Register Change Summary for Experiment 7" lists all register value changes from the

default cmf load to accomplish the tests.

Table 5.4 Register Change Summary for Experiment 7

REGISTER

NAME ADDRESS

Fan

Configuration

Valid Tach

Count

DEFAULT

VALUE

52Bh CBh 4Bh Disable RPM based fan control algorithm

ABh C8h - CFh Demonstrate UPDATE effect

56H 2010d 5000d C hanged from 2010 RPM to 5000 RPM to show

NEW

VALUE COMMENT

the effect in closed-loop

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

25

Page 26

5.6 Experiment 6 - Limits and Alerts

This experiment is designed to gain familiarity with the control registers for generating fan related

alarms and alerts associated with the EMC2102.

The CMF file for this experiment is EMC2102_default.cmf.

5.6.1 General Setup

For all these tests, the Fan Drive Setting register (51h), the TACH Target register (57h) and the TACH

Reading registers (58h) are selected to plot. As bits are switched in each of the tests, the register name

and address will be provided.

5.6.2 Fan Spin and Stall Interrupts

The Configuration/Status page in the ChipMan application contains all the Interrupt configuration and

status registers for the fan. In this experiment, the Fan Stall and Fan Spin status bits will be checked.

In order to see the status bits change, the Interru pt Status 2 register (23h) is plotted along with other

registers listed above. The Interrupt Mask register (24h) should be set to 10h (default) for this set of

experiments.

Start the plotting function within ChipMan, and force the fan to stop spinning. This will induce a Fan

Stall condition. The plot of the Status Register will show a peak of 1 count for the stall condition,

followed by peaks of 2 counts for each time the spin-up routine is invoked, as shown in Figure 5.22,

"Fan Spin and Stall". In order to see the spikes mentioned above, the max scale on the register 27h

plot needs to be modified. To do this, simply double click the 255 at the top of the "Y" axis, type a

different maximum value (10) and enter. And then double click the 0 at the bottom of the "Y" axis, type

a minimum value and enter. The scale will be changed.

Fan Speed Control with the EMC2102 Device

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

26

Page 27

Fan Speed Control with the EMC2102 Device

Fan Drive Setting

(51h)

TACH Target (57h)

TACH Reading (58h)

Stall

Interrupt Status 2

(23h)

Figure 5.22 Fan Spin and Stall

5.6.3 Register Change Summary

All register values are default for the tests in this section.

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

27

Page 28

Fan Speed Control with the EMC2102 Device

5.7 Experiment 7 - Troubleshooting

5.7.1 Repetitious Spin-up Routine Caused by Incorrect Settings

At the end of spin-up routine (see Section 5.3.1, "F an Control Parameters"), the EMC2102 checks the

TACH Reading register (58h). If the value in this register is greater th an the Valid TACH Count (56h),

which means the fan is running at a speed slower than the minimum valid speed, the spin-up routine

will be restarted (Figure 5.23, "Fan Spin-up Routine Restarted Repeatedly").

Figure 5.23 Fan Spin-up Routine Restarted Repeatedly

Depending on the fan characters and EMC2102 settings, there are several situations at the end of

spin-up routine which will be discussed.

Notes: F or ease of understanding, all TACH values will be converted to RPM values in the following

examples.

5.7.1.1 Case 1 - Spin-up Lvel RPM < Valid RPM < Target RPM

In this case, the spin-up level rpm (rpm60 or rpm75) is smaller than both valid rpm (function of 56h)

and target rpm (function of 57h). The theoretical plot of this situation is shown in Figure 5.24,

"Theoretical Plot of Case 1".

Since the fan speed at the end of spin-up routine is always below the minimum valid speed (a function

of 56h), the EMC2102 will think the fan is not running, and will try to restart the fan with spin-up routine

over and over.

Using the EVB-EMC2102 to test this situation with rpm60 (~4500 rpm), simply set the Valid TACH

register (56h) with 4800 rpm and start the fan with TACH Target (57h) = 5000 rpm. The repeating spinup routines can be observed (Figure 5.25, "Spin-up Case 1 Fix 1").

For rpm75 (~5650 rpm), set 56h = 6000 rpm and 57h = 6500 rp m, as shown in Figure 5.26, "Spin-up

Case 1 Fix 2".

There are mainly two ways to fix this problem. If the spin-up LEVEL in 53h is 60%, the n change it to

75%, as shown in Figure 5.25.

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

28

Page 29

Fan Speed Control with the EMC2102 Device

Fan Speed

(RPM)

RPM for

100% Drive

Target Speed

Valid Speed

rpm60 or rpm75

Fan Speed

¼ of Spin Up Time

Spin Up Time

Check TACH

Figure 5.24 Theoretical Plot of Case 1

SMSC EMC2102

Spin Up Level

Changed to 75%

Figure 5.25 Spin-up Case 1 Fix 1

If the fan is already set to 75% level, we will need to lower the valid speed (function of 56h, Valid

TACH) to a value below the rpm75, to fix the problem.

To test this situation, set spin-up level to 75% (53h [2] = 1), set the Valid TACH Count (56h) = 6000

rpm and then start the fan (57h) with 6500 rpm. The spin-up routine will run rep eatedly.

Change the Valid TACH Count (56h) to 5800 rp m, the problem cannot be fixed since the valid speed

is still higher than the fan speed (rpm75 = 5650 rpm).

Set 56h = 5580 rpm which is below 5650 rpm (the rpm75), the system gets out of the spin-up routine

(Figure 5.26).

USER MANUAL Revision 0.2 (09-17-07)

29

Page 30

Valid Speed = 6000 rpm

Fan Drive Setting (51h)

Valid Speed = 5800 rpm

Valid Speed = 5580 rpm

Fan Speed Control with the EMC2102 Device

Figure 5.26 Spin-up Case 1 Fix 2

5.7.1.2 Case 2 - Valid RPM << Target RPM < Spin-up Level RPM

In this case, the target speed is smaller than the spin-up level speed (rpm60 or rpm75) and is much

bigger than the valid speed. The theoretical plot of this si tuation is shown in Figure 5.27, "Theoretical

Plot of Case 2".

Since the fan speed at the end of spin-up routine is always higher than the minimum valid speed, the

EMC2102 will go to the normal operation after the spin-up routi ne.

Using the EVB-EMC2102 to test this situation with rpm75 (~5650 rpm), simply set the Valid TACH

register (56h) with 4500 rpm and start the fan with TACH Target (57h) = 5 500 rpm (Figure 5.28, "Spin-

up Case 2").

Fan Speed

(RPM)

RPM for

100% Drive

rpm60 or rpm75

Fan Speed

Target Speed

Valid Speed

¼ of Spin Up Time

Revision 0.2 (09-17-07)

Spin Up Time

Check TACH

Figure 5.27 Theoretical Plot of Case 2

USER MANUAL SMSC EMC2102

30

Page 31

Fan Speed Control with the EMC2102 Device

Fan Drive Setting (51h)

Figure 5.28 Spin-up Case 2

5.7.1.3 Case 3 - Valid RPM =< Target RPM << Spin-up Level RPM

In this case, the target speed is only a little greater than the valid speed, and both of them a re much

smaller than the spin-up level speed (rpm60 or rpm75). The theoretical plot of this situation is sho wn

in Figure 5.29, "Theoretical Plot of Case 3".

Fan Speed

(RPM)

RPM for

100% Drive

rpm60 or rpm75

Fan Speed

Target Speed

Valid Speed

¼ of Spin Up Time

Spin Up Time

Check TACH

Figure 5.29 Theoretical Plot of Case 3

SMSC EMC2102

Since the fan speed at the end of spin-up routine is higher than the minimum valid speed, the

EMC2102 should go to the normal operation after the spin-up routine. However, because the large

speed difference between the spin-up level speed (rpm60 or rpm75) and the target speed, the clo sedloop controller will try to make a big adjustment o f its output to reach the target speed. With incorrect

settings (such as big output step or short update time), this adjustment could easily cause an

undershoot and make the fan speed below the valid rpm, a nd than make the spin-up routine restart.

USER MANUAL Revision 0.2 (09-17-07)

31

Page 32

Fan Speed Control with the EMC2102 Device

Using the EVB-EMC2102 to test this situation with rpm75 (~5650 rpm), simply set the Valid TACH

register (56h) with 4500 rpm, set the UPDATE (52h[2:0]) = 100ms and start the fan with 4700 rpm, the

spin-up routine starts over ‘and over (Figure 5.30, "Spin-up Case 3").

To fix this prob lem, change the UPDATE (52h[2:0]) back to 400 ms. It will give the fan more time to

reach the speed of the previous step and reduce the overshoot/undershoot. Another solution is to

decrease the Fan Step settings which will force the controller to take smaller steps to achieve the target

speed.

When the target speed is too close to the valid speed, the problem will not only occur when the fan

starts. It may also cause problems in the normal operation after the spin-up, since the fan speed

reading errors (caused by fan load changes, tachometer truncation errors, circuit noises, etc.) could

drop it below the valid speed and cause a spin-up routine restart. (Figure 5.31, "Spin-up Routine

Restarted During Normal Operation").

UPDATE = 400 ms

UPDATE = 100 ms

Undershoots cause

the fun runs below

valid speed

Figure 5.30 Spin-up Case 3

Revision 0.2 (09-17-07)

Figure 5.31 Spin-up Routine Restarted During Normal Operation

USER MANUAL SMSC EMC2102

32

Page 33

Fan Speed Control with the EMC2102 Device

5.7.1.4 Case 4 - 4.Valid RPM < Spin-up Level RPM (rpm60 or rpm75) < Target RPM

In this case, the spin-up level speed (rpm60 or rpm75) is greater than the valid speed and smaller than

the target speed, as shown in Figure 5.32, "Theoretical Plot of Case 4".

At the end of spin-up routine, the closed-loop control will drive the fan up to reach the target, therefore

the fan speed will never be lower than the valid speed. The EMC 2102 will go to the normal operation

after the spin-up routine.

Using the EVB-EMC2102 to test this situation with rpm60 (~4500 rpm), simply set the Valid TACH

register (56h) with 3500 rpm and start the fan with TACH Target (57h) = 5 000 rpm (Figure 5.33, "Spin-

up Case 4").

Fan Speed

(RPM)

RPM for

100% Drive

Target Speed

rpm60 or rpm75

Fan Speed

Valid Speed

¼ of Spin Up Time

Spin Up Time

Check TACH

Figure 5.32 Theoretical Plot of Case 4

SMSC EMC2102

Figure 5.33 Spin-up Case 4

USER MANUAL Revision 0.2 (09-17-07)

33

Page 34

Fan Speed Control with the EMC2102 Device

5.7.1.5 Case 5 - Correct RPM Relationships with a Slow Response DC Fan

In this case, the spin-up routine is too short to make the fan reach a speed h ighe r than the vali d speed.

Since the EMC2102 cannot detect a valid TACH at the end of spin-up routine, it will try to restart the

fan. Depending on the fan, it is possible that after several spin-up cycles, the fan can rea ch the valid

speed and operate normally.

Using the EVB-EMC2102 to test this situation with rpm60 (~4500 rpm), simply set the SPINUP_TIME

(53h[1:0]) = 250 ms, Valid TACH (56h) = 4400 rpm, and start the fan wi th TACH Target (57h) = 5500

rpm. Multiple spin-up routines will be observed (Figure 5.34, "Spin-up Case 5").

Figure 5.34 Spin-up Case 5

To fix this problem, stop the fan an d set the SPINUP_TIME = 2s, and restart the fan with 5500 rpm.

Increasing Spin-up time will make a longer 100% "kick" time and provide the fa n with more power to

speed-up (Figure 5.35, "Spin-up Case 5 Fix").

The problem also can be fixed by changing the spin up level from 60% to 75% if not do ne already, as

previously discussed.

Longer 100% kick provides more

driving power to speed-up the fan

Revision 0.2 (09-17-07)

Figure 5.35 Spin-up Case 5 Fix

USER MANUAL SMSC EMC2102

34

Page 35

Fan Speed Control with the EMC2102 Device

n

6 Appendix

6.1 DC Fan Basics - Poles, Tach Meter Pulses and Edges

An n-pole fan has n pairs of North-South magnetic poles which are generated by electromagnet coils.

At anytime, only one pair of coils are driven and which coil pair gets driven is determined by a

component called Hall Sensor. The architecture of a typical 2-pole DC fan is shown in Figure 6.1, "A

Typical 2-pole DC Fan".

Prote ctio

Diode

Hall

+

Sensor

S -

N +

-

1

S -

+

-

N +

VDD

TACH

Ha ll

Sensor

Mot or

Wind i n g

Driver

Mot or

Winding

Mot or

Winding

1

2

GND

Figure 6.1 A Typical 2-pole DC Fan

The output of the hall sensor is also the TACH (or Tachometer) signal. When the magnetic field around

the Hall Sensor changes its direction, the sensor ’s output level will follow the change to create a square

wave signal as shown in Figure 6.2, "Output Signal of a 2-pole Fan".

Assuming 2-pole fan is running at a speed of 6000 RPM, it will rotate 100 revolutions per second. With

2 pulses per revolution, the TACH pulse signal frequency will be 200Hz (Figure 6.2). Since a higher

RPM will yield a higher TACH frequency, or a shorter period between pulses, th e TACH signal can be

used by the EMC devices to determine the speed of the fan. Generally speaking, we h ave:

TACH Pulse Frequency (in HZ) = (RPM / 60) x (# of Pole)

1 complete fan revolution

= 2 pulses (5 edges)

Fan Tach Signal

Figure 6.2 Output Signal of a 2-pole Fan

EMC2102 uses a clock (32.768KHz for example) to fill in a window between a programmable n umber

of Tachometer edges. A counter starts on a specific rising edge and keeps counting until it sees the

‘set’ number of edges, and then saves the counted pulse numbers into register 58h, the TACH Reading

register.

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

35

Page 36

T

P

Fan Speed Control with the EMC2102 Device

Note: Although users can set the number of edges (in register 52h) to eith er 3, 5, 7 o r 9, it is stron gly

recommended using the default value 5 while driving a 2-pole DC fan. This equal to one

complete fan revolution for a 2-pole fan.

5 EDGES

3 EDGES

Fan Tach Signal

32.768kHz

Clock

n-EDGE WINDOW

7 EDGES

T

WINDOW

Figure 6.3 Fan TACH Measur ement With EMC2102

ChipMan translates TACH counts to the RPM value and displays the fan speed. For applications not

using ChipMan software, the following equation can be used to convert the TACH Reading values to

the real RPM speeds.

where:

RPM *

EDGES

=

oles

1−

983040

*

COUN

m

EDGES = number of edges set by register 52h[4:3]

COUNT = TACH Reading (58h) value [1]

Poles = number of pole pairs in the DC fan

m = factor defined by LIMIT2K (52h[6])

(m = 1 for 500 rpm and m = 4 for 2000 rpm)

6.2 Characterizing a DC Fan with EVB-EMC2102 and ChipMan

As a very important component in the closed-loop, the DC fan’s characteristics have a great impact

on the control system’s performance. Using the EVB-EMC2102 and ChipMan software tool, a 5V DC

fan’s characteristics can be easily tested.

In general, the following parameters need to be characterized:

Minimum Startup Spee d

Stall Spee d

Minimum Valid TACH Speed

Maximum Fan Speed

Spin-up Level (i.e., rpm60 and rpm75. Refer to Section 5.3.1, "Fan Control Parameters" for more

details)

6.2.1 General Setup

Setup the system and make sure the hardware and software are working as discussed in Section

5.1, "Experiment 1 - Manual Fan Control".

Unplug the on-board DC fan from connector P1

Connect the DC fan to be tested to P1 (refer to EVB-EMC2102 User Manual for the DC fan

connector pinouts)

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

36

Page 37

Fan Speed Control with the EMC2102 Device

Verify the device is in Manual Mode (52h[7] = 0)

6.2.2 Set the Correct LIMIT2K Value

Register 52h (FAN Configuration) bit 6 (LIMIT2K) is a fan dependent parameter as discussed in

Section 5.5.2, "Fan Configuration Register (52h)". When reading the TACH Reading register (58h),

ChipMan uses the default LIMIT2K value (2000 rpm) to convert it to an rpm sp eed

If the RANGE is set to 500 rpm, the TACH Reading value on the ChipMan display should be

multiplied by 0.5

6.2.3 Determine the Number of Poles and the Maximum Fan Speed

Set the device in Manual Mode (52h[7] = 0)

Start the fan with 100% output drive (register 51h = 255h)

EMC2102 assumes that it is driving a 2-pole fan by default. If the fan speed in registe r 58h does

not match the fan’s maximum speed specified in its datasheet, then it is not a 2-pole fan. The

EDGES value in register 52h has to be modified, or all speed read ings displ ayed b y Chip Man have

to be re-calculated using Equation 1

The value in 58h also can be compared to the fan’s tachometer output frequency obtained by an

oscilloscope to verify its correctness

Record the rpm values in the TACH Reading register (58h) as the maximum fan speed

The maximum fan speed for the EVB-EMC2102 on-board DC fan is abou t 7000 rpm

6.2.4 Determine the Minimum Startup Speed

Set the device in Manual Mode (52h[7] = 0)

Write a value (for example 80h) to Fan Driver Setting register (51h)

If the fan cannot start, then increase the drive value until the fan start

If the fan starts at the first drive value, then stop the fan (51h = 0) and write a smaller value to

register 51h

Repeat the above steps until the minimum startup speed is determined. Record the drive value in

51h and the fan speed in register 58h

The minimal start speed for the EVB-EMC2102 on-bo ard DC fan is about 4500 rpm with output

drive of 9Eh

6.2.5 Determine the Stall Speed

While the fan is running, reduce the fan drive value in register 51h, step by step, until the fan stops

Write down the drive value in 51h and the fan speed in register 58h before the fan stops

The stall speed for the EVB-EMC2102 on-board DC fan is about 3000 rpm (~70h)

6.2.6 Determine the Minimum Valid TACH Speed

While the fan is running in non-RPM mode, reduce the fan drive value in register 51h, step by step

Monitor the rpm values in the TACH Reading register (58h)

Using an oscilloscope to observe the fan’s Tachometer signal

When invalid, the TACH signal will become erratic with incorrect values (usually much less TACH

counts or very high rpm) in register 58h

The TACH signal may be valid until the fan stalls. If it happens, the fan’s stall speed could be used

as the minimum valid TACH speed

SMSC EMC2102

USER MANUAL Revision 0.2 (09-17-07)

37

Page 38

6.2.7 Determine the Spin-up Levels (rpm60 and rpm75)

Drive the fan with 60% of the maximum output (register 51h = 99h) and the rpm value in the TACH

Reading register (58h) will be the fan’s rpm60

Drive the fan with 75% of the maximum output (register 51h = BFh ) and the rp m value in th e TACH

Reading register (58h) will be the fan’s rpm75

6.2.8 Using the Tested Parameters

All parameters discussed above will vary from fan to fan and with fan aging, therefore some margins

have to be added when selecting the fan control settings. A minimum of 10% of full fan speed is

recommended for margins.

6.2.8.1 Spin-up LEVEL (Register 53h[2])

This parameter has to be set so that the corresponding fan speed is greater than Minimum Startup

Speed + Margin.

6.2.8.2 Minimum Fan Speed

To avoid stalling, the fan speed (a function of Fan Driver Setting [51h] or a function of TACH Target

[57h]) needs to be greater than Stall Speed + Margin at all times.

Fan Speed Control with the EMC2102 Device

6.2.8.3 Valid TACH Count Speed (Function of Register 56h)

The EMC2102 will not respond to any TACH Target (57h) value that has a corresponding speed sl ower

than Minimum Valid TACH Speed + Margin, unless the value is FFh which will stop the fan. This

ensures that the RPM control algorithm will not drive too low.

6.2.8.4 Maximum Fan Speed

Use the measured maximum fan speed minus margin as the Maximum Fan Speed.

Revision 0.2 (09-17-07)

USER MANUAL SMSC EMC2102

38

Loading...

Loading...