SMP ZINGO MAGIA X-012/S, ZINGO MAGIA X-012/SD, ZINGO MAGIA X-012/P, ZINGO MAGIA X-012/PD Installation Instructions Manual

INSTALLATION INSTRUCTIONS

MODEL SHOWN = X-012/S

ZINGO MAGIA

X-012/S, X-012/SD, X-012/P & X-012/PD

NO PART OF THIS MANUAL OR DOCUMENT MAY BE COPIED OR RE-PRODUCED IN ANY FORM OR BY ANY MEANS WITH OUT THE EXPRESS

WRITTEN PERMISSION OF SMP (PLAYGROUNDS) LTD.

E: sales@smp.co.uk - W: smp.co.uk - T: +44(0)845 260 1655

INTENTIONALLY LEFT BLANK

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

CONTENTS

1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

2 PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

2.1 ESTABISH ORIENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

2.2 MARK OUT HOLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

2.3 ESTABLISH DATUM LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

3 PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

4 INSTALLATION & ASSEMBLY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

4.1 SAFE WORKING PRACTICE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

4.2 RISKS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

4.3 CONTROL MEASURES: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

4.4 ASSEMBLY METHOD OF CLAMPS TO POSTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

4.5 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

5 POST INSTALLATION INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 40

Appendix A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

1 PLASTIC SLIDE ENTRY FRAME ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

2 PLASTIC SLIDE & PANELS ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

ISSUE B

Contents Page 1

ZINGO X-012 © SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

INTENTIONALLY LEFT BLANK

Contents Page 2 ISSUE B

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

1 SPECIFICATIONS

REFERENCE

OVERALL HEIGHT (H) m 2.80

OVERALL LENGTH (L) m 4.50 4.67

OVERALL WIDTH (W) m 3.37 3.74

OVERALL WEIGHT kg 540 590

HEAVIEST PART kg 31.00 91.00

LARGEST PART L x W x H m 2.50 x 0.40 x 0.30 INFORMATION TO FOLLOW

CONCRETE - RUBBER m

CONCRETE - LOOSE FILL m

MINIMUM SPACE L x W x H m 7.50 x 6.83 x 3.70

FALLING SPACE AREA m

IMPACT AREA (WET POUR) m

LOOSE FILL AREA (SAND/BARK) m

MANHOURS hr

MANPOWER

CONSTRUCTIONAL SPACE m 10.00 x 9.00

MAXIMUM FREE FALL HEIGHT m 1.2

3

3

2

2

2

X-012/S X-012/P

ST. STEEL SLIDE PLASTIC SLIDE

0.78 0.77

0.78 0.77

34.63 INFORMATION TO FOLLOW

35.25 INFORMATION TO FOLLOW

37.50 INFORMATION TO FOLLOW

Concrete mix is recommended at:

1 part cement;

2 parts sand;

4 parts aggregate;

by volume with 20mm aggregate

(20 N/mm

2

min compressive strength)

SMP Playgrounds Ltd. recommends an effective Impact Absorbing Surface tested to EN11 77 & BS7188 beneath

this range of play equipment. Refer to manufacturers instructions for details of installation. The surface should have

a Critical Fall Height greater than the Maximum Freefall Height of the equipment. Subject to a risk assessment & for

certain Fall Heights a grass surface may be used.

Constructional Space (shown in the above table) is the approximate working area required to layout and assemble

the equipment.

For the safe operation of this equipment it must be installed on horizontal ground with the required minimum space.

If a loose fill surface is selected for this item it will require a very high level of maintenance to ensure a sufficient

thickness is in place at all times to provide ‘critical fall height’ protection.

The concrete foundations indicated are for average ground. Care should be taken concerning abnormal conditions.

2PREPARATION

All equipment assembly and fixings must conform to EN1176.

Before commencing the installation the surrounding area must be sufficiently fenced and signs erected to warn the

public of the risk of injury.

Tools / ancillary equipment: Plumbline, 10m tape measure, Spirit level, Adjustable set square, Step ladder, Bolt

cutters, 10mm A/F Socket, Torque wrench, 3/16” A/F Allen key.

Minimum Personal Protective Equipment:- Hard hat, Gloves, Armoured boots, Goggles.

ISSUE B

Page 1

ZINGO X-012 © SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

2.1 ESTABISH ORIENTATION

i) See Specifications for equipments ‘Minimum space’.

ii) Measure out the site to ensure the space required fits into the allotted area, it is horizontal and free from

trip points or other obstructions.

iii) Ensure the equipment is to be provided with an effective Impact Absorbing Surface which has a tested

critical fall height rating greater than the maximum freefall height of the equipment.

2.2 MARK OUT HOLES

Consult SMP layout drawing for structure position on site.

See FIG.3, 4 & 5 for concrete foundation spacings.

NOTE: This is a minimum guide only. Hole excavation should be done progressively as the steelwork is erected.

2.3 ESTABLISH DATUM LEVEL

i) If a rubber tiled Impact Absorbing surface is to be laid, see separate instructions (base may incorporate

up to 2% falls etc.).

ii) If equipment is to sit in loose fill or wet pour rubber surfaces allowances will need to be made for its

recommended thickness. With certain loose fill materials, a greater thickness than 300mm may be

required. This will need to be determined by allowing 100mm for dispersal in addition to the thickness

required for the freefall height of the unit. For installation with a loose-fill type surface all legs on the

structure have be marked with a 'Basic Level Mark' to indicate the recommended 'Finished Surface Level'

of the surface.

Page 2

ISSUE B

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

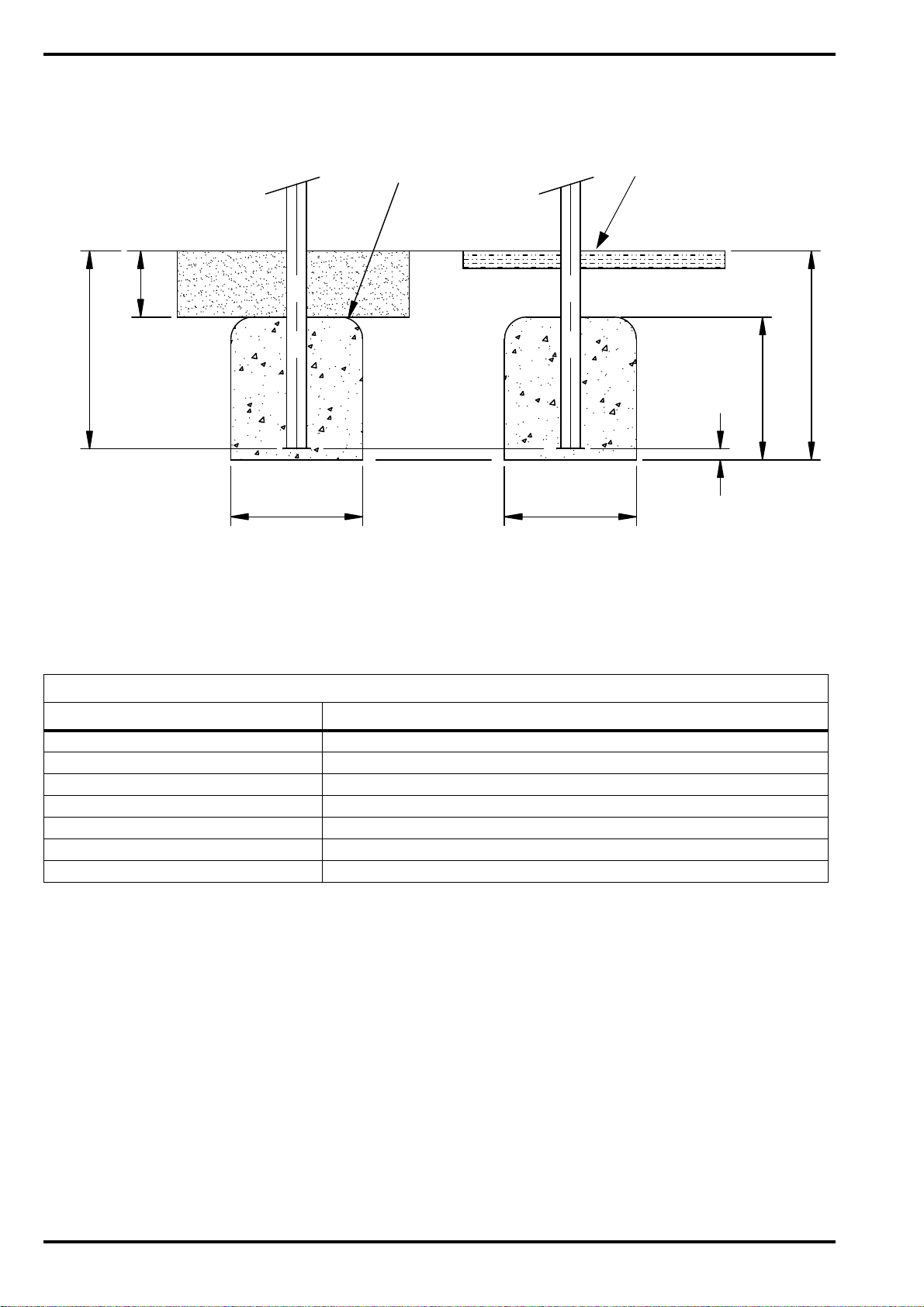

FIG.1

L

W

H

F. S . L .

ISSUE B

Page 3

ZINGO X-012 © SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

300

50 REF

900

F. S . L .

F. S . L .

LOOSE FILL SURFACE OPTION RUBBER SURFACE OPTION

THICKNESS OF WET POUR

OR RUBBER TILES TO

SUIT 1.30m FALL HEIGHT

FIG.2 EXCAVATIONS FOR LEG FOUNDATIONS

LOOSE FILL

R100 TYP

300 SQ. 300 SQ.

950

650

300mm THICKNESS OF LOOSEFILL SURFACE WILL NEED TO BE CONFIRMED IS SUFFICENT DEPENDING

ON THE SPECIFIC LOOSEFILL MATERIAL SELECTED.

FOUNDATION SIZES FOR FIG.3 & FIG.4

REFERENCE L x W x D

FOUNDATION ‘A’ m 0.30 x 0.30 x 0.95

FOUNDATION ‘B’ m 0.94 x 0.30 x 0.70

FOUNDATION ‘C’ m 0.60 x 0.30 x 0.65

FOUNDATION ‘D’ m 0.40 x 0.30 x 0.70

FOUNDATION ‘E’ m 0.30 x 0.30 x 0.70

FOUNDATION ‘F’ m 0.30 x 0.30 x 0.65

FOUNDATION ‘G’ m 0.30 x 0.30 x 0.80

Page 4

ISSUE B

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

2560

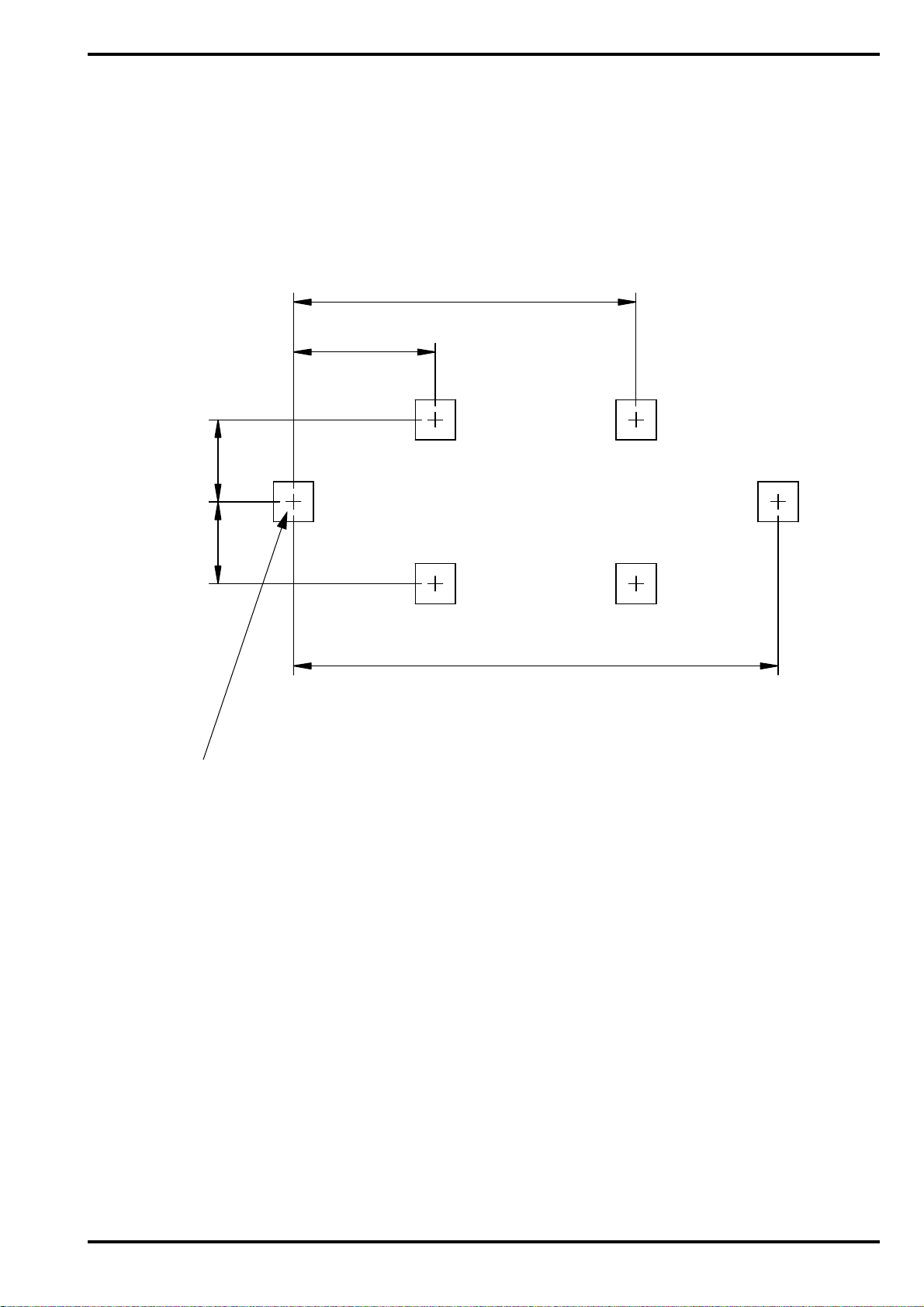

FIG.3

CONCRETE FOUNDATIONS - PRIMARY

ALL DIMENSIONS IN MM

A

STRAIGHT LEG - 1200 DECK

(ITEM 1). WE RECOMMEND

THIS LEG IS INSTALLED

FIRST TO PROVIDE A DATUM FOR

THE REST OF THE STRUCTURE

1060

3620

615

615

A

A A

A

A

ISSUE B

Page 5

ZINGO X-012 © SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

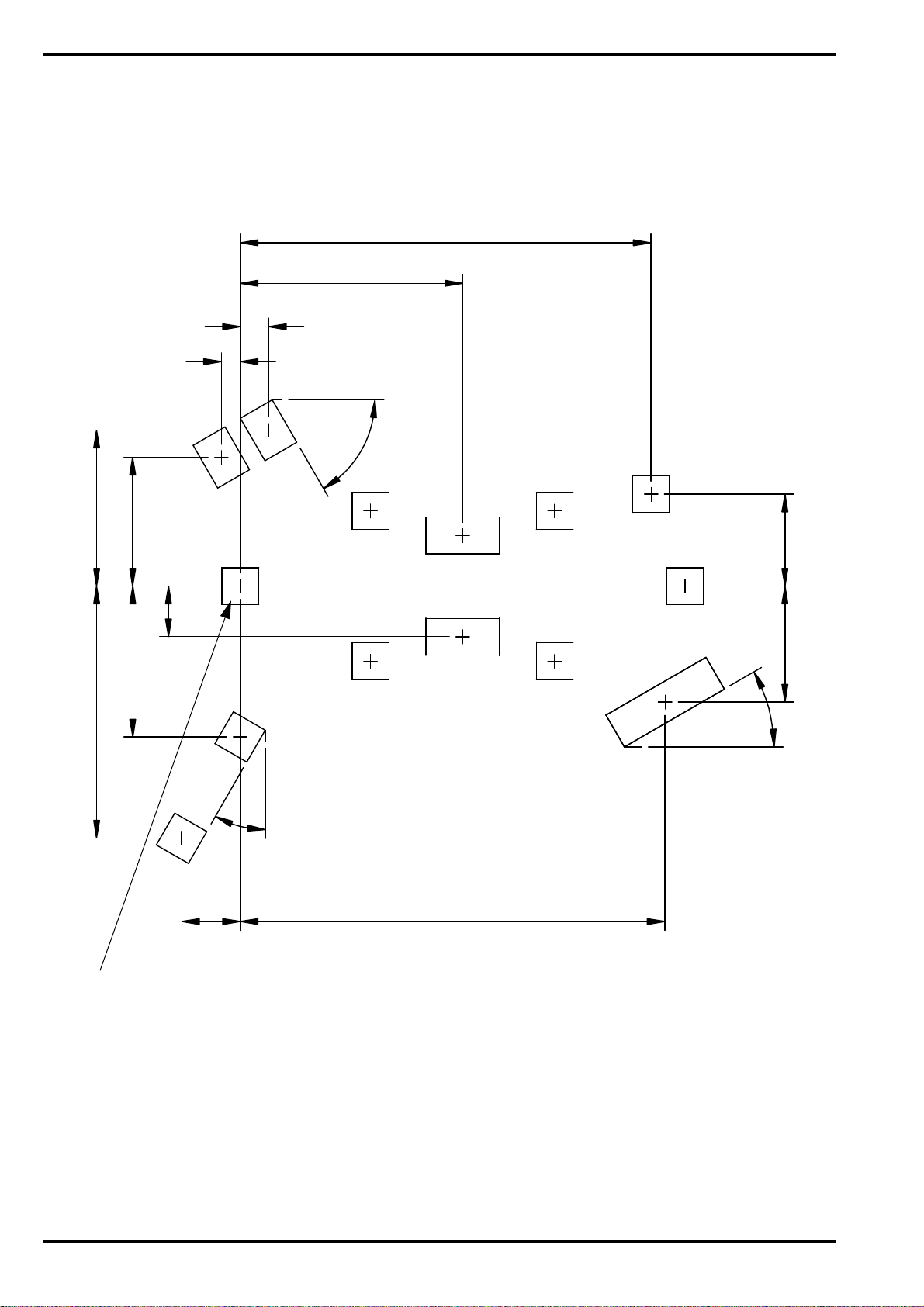

FIG.4 STAINLESS STEEL CONCRETE FOUNDATIONS - SECONDARY

ALL DIMENSIONS IN MM

STRAIGHT LEG - 1200 DECK

(ITEM 1). WE RECOMMEND THIS

LEG IS INSTALLED FIRST TO

PROVIDE A DATUM FOR THE REST

OF THE STRUCTURE

3345

1050

A

A

A

A

A

A

1810

230

155

3460

480

30°

60°

30°

C

C

E

F

F

D

D

1270

1230

2055

945 750

415

B

Page 6

ISSUE B

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

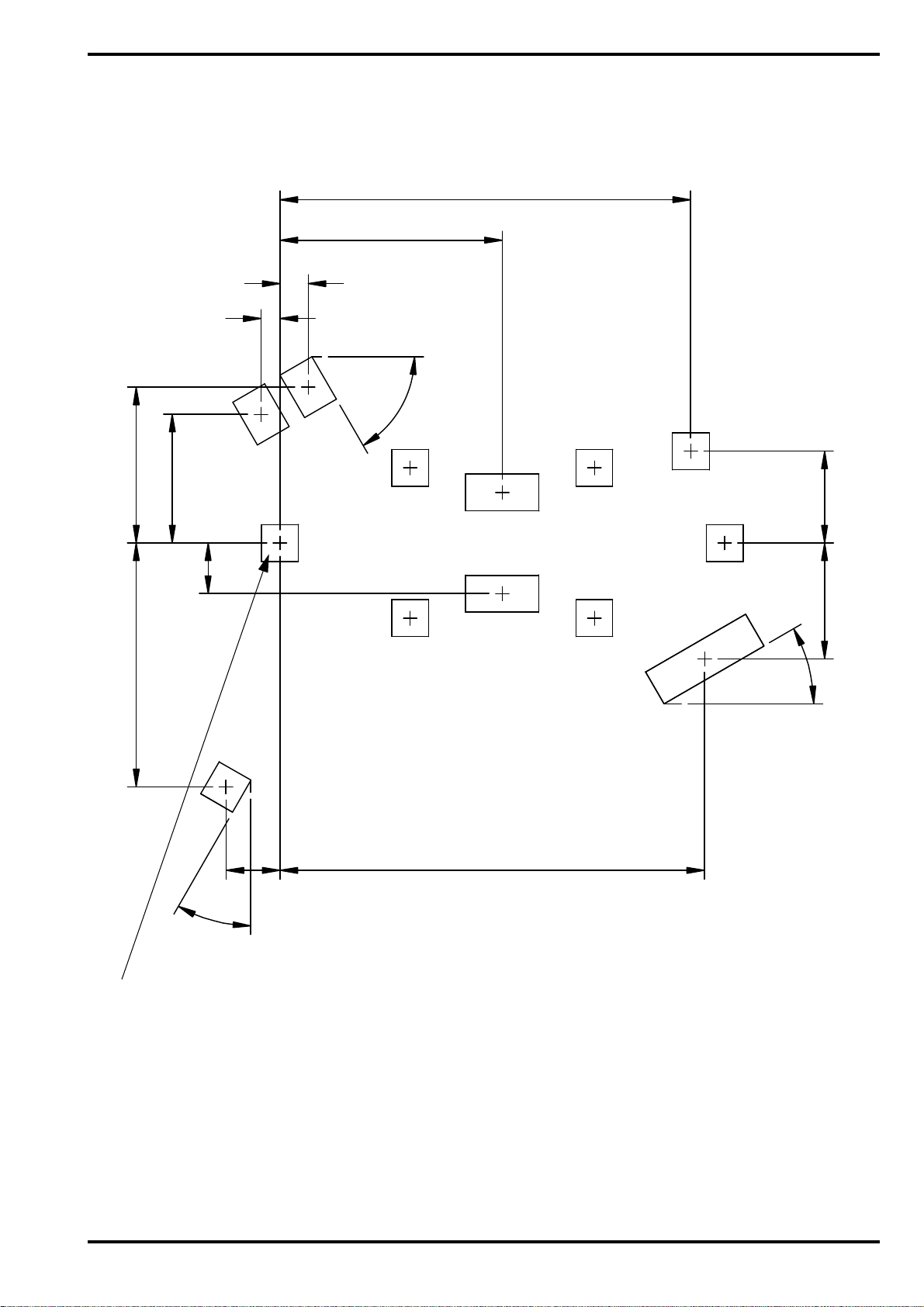

FIG.5

PLASTIC SLIDE CONCRETE FOUNDATIONS - SECONDARY

ALL DIMENSIONS IN MM

STRAIGHT LEG - 1200 DECK

(ITEM 1). WE RECOMMEND THIS

LEG IS INSTALLED FIRST TO

PROVIDE A DATUM FOR THE

OF THE STRUCTURE

REST

3345

1050

A

A

A

A

A

A

1810

230

155

3460

440

30°

60°

30°

C

C

E

G

D

D

1270

1990

945 750

415

B

ISSUE B

Page 7

ZINGO X-012 © SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

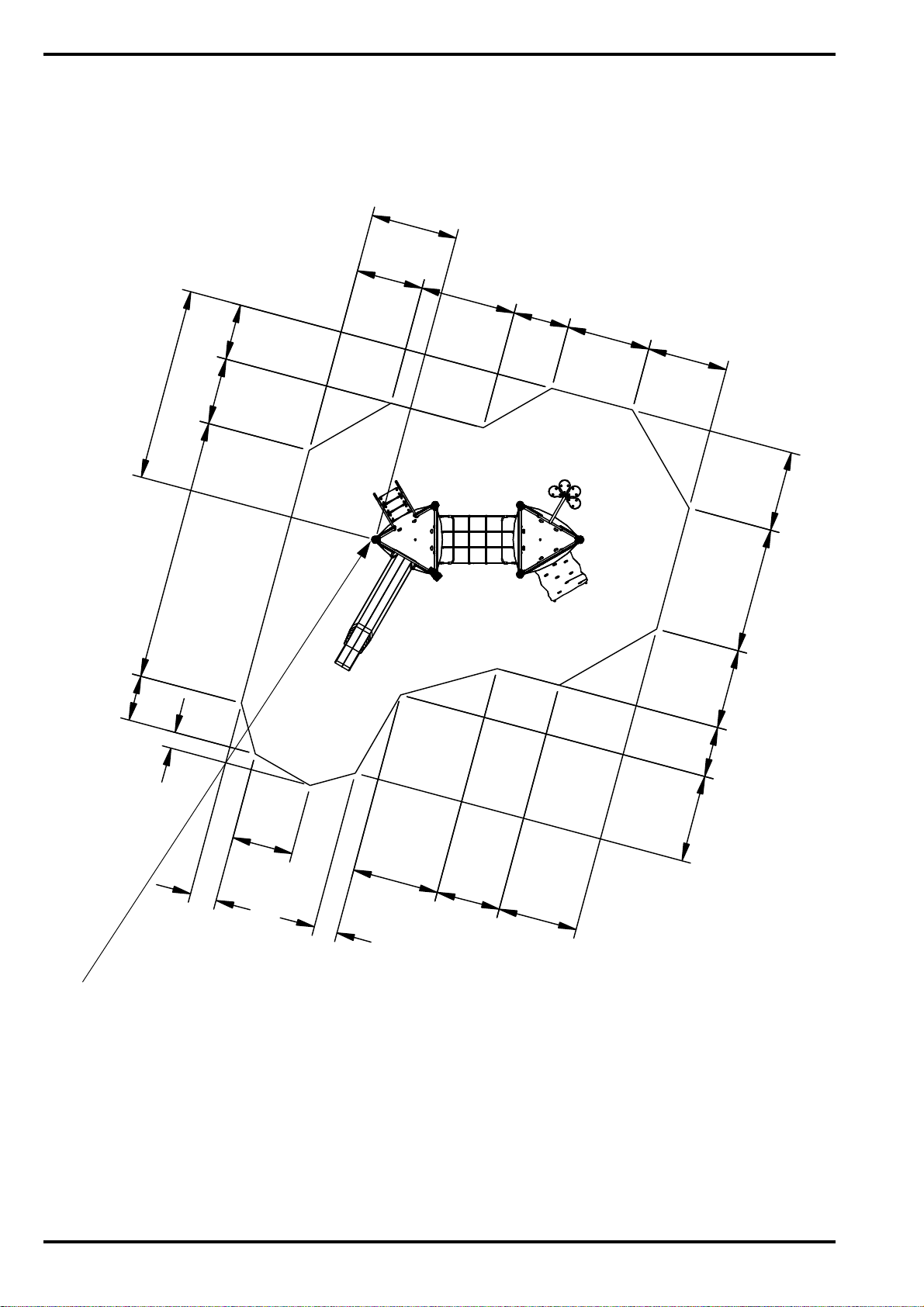

FIG.6

WET POUR AREA - STAINLESS STEEL SLIDE

STRAIGHT LEG - 1200 DECK

(ITEM 1).

1

5

3

7

ALL DIMENSIONS IN MM

1

1

8

0

1

6

8

8

9

8

8

1

4

7

7

1

4

1

7

4

6

9

1

0

8

2

4

1

4

1

5

3

0

1

1

3

5

1

4

0

7

9

8

8

1

1

8

0

4

6

2

5

3

3

9

1

8

0

5

2

8

5

1

5

4

4

8

9

1

1

4

0

7

2

2

1

0

1

4

1

7

Page 8

ISSUE B

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

FIG.7

WET POUR AREA - PLASTIC SLIDE

INFORMATION TO FOLLOW

ISSUE B

Page 9

ZINGO X-012 © SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ

FIG.8

LOOSE FILL AREA - STAINLESS STEEL SLIDE

STRAIGHT LEG - 1200 DECK

(ITEM 1).

1633

2558

ALL DIMENSIONS IN MM

701

1228

4491

1145

1334 3440

813

795

971

1228

3090

1225

556

802

1395

1334

2809

1145

Page 10

ISSUE B

© SMP (PLAYGROUNDS) LTD, TEN ACRE LANE, THORPE, EGHAM, SURREY, TW20 8RJ ZINGO X-012

FIG.9 LOOSE FILL AREA - PLASTIC SLIDE

INFORMATION TO FOLLOW

ISSUE B

Page 11

Loading...

Loading...