SMK RXT9400 5800E, RXR9400 6000E User Manual

two

way

Installation &

user manual

Contents

INSTALLER MANUAL

Important information

General

1. Technical data

2. Description

Installation:

1. Positioning the unit

2. Connection.

3. Parts description.

4. Gas connection.

4.1. Pilot and magnetic group.

4.2. Touch control buttons

4.3. ODS

4.4. Electronic parts.

4.5. Battery connections

5. Pairing.

6. Initial configuration.

USER MANUAL

1. Working with the touch control.

1.1. Switching on.

1.2. Regulating the flame level.

1.3. Switching off.

Consult the instructions before using this system.

The installation of this system must fulfil all the

certifications in force.

Place this label on the appliance

Contains FCC ID XO5RXR9400-6000E

This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

The user is cautioned that any changes or

modifications not expressly approved by Copreci

could void the users authority to operate the

equipment.

2. Remote control.

2.1. Description:

2.1.1. LCD display.

2.1.2. Four buttons:

2.1.1. LCD display.

2.1.2. OFF button

2.1.2. Left, middle and right button

2.2. Menu system.

2.3. Switching on

2.4. Adjust Menu

2.5. Setting the control mode

2.6. Day programming menu (Menu Æ Adjust MenuÆ Change Program)

2.6. Other features

3. Troubleshooting

Revision history

Date Changes Final

15/06/2009 Preliminary document

23/06/2009 Corrections to English

Important information

• All cables must be connected as described in the installation

manual

• The gas installation must be carried out by a professional

installer.

• Electronics components must be installed in a cool area,

below the fire. If temperature rises above 70 ºC (158 ºF), the

appliance switches off.

• The control unit should be positioned as shown in the

illustration.

• Use only alkaline batteries, and insert batteries with the

polarity correctly aligned.

• No maintenance is required. Cleaning the valve with soapy

water can damage it.

• No component should ever be repaired; if a part

malfunctions, it should always be replaced by a

qualified technician.

• Any change to the type of gas must be carried by a

professional installer.

• Do not pour liquids on any of the components.

• Once the installation process is completed, the

installer should ensure that the appliance is working

properly.

• RF range is dependent on the appliance

characteristics. Manufacturers must check that the

communication distance of their appliance is

adequate.

General

1. Technical data

• Max. flow rate

• Temperature range

• Maximum working pressure

• Inlet connection

• Main burner connection

• Pilot outlet connection

• Power supply

480 l/hr (air -1mbar)

0-70ºC (32-158 º F)

50 mbar

M12x1, ¼’’

M13x1, ¼’’

M8x1, 1/8’’

4.5 V

• Power supply current

• Protection

• Working position

• Power range

• Electronics equipped with

micro-processor

• Classification

• System type

2. Description

r_emotion is Copreci’s new control system for gas heaters. A system than includes a remote control handset for

significantly improving the user’s communication with the device.

r_emotion consists of a gas valve with an inlet and two outlets (pilot and main outlet), a motor that provides stepby-step sequence adjustment, and a control unit that offers a wide range of possibilities.

1.3A

IP20 (with cover)

Multipoise

8000-40000 BTU/h

RUCMB-22600

AMVVXK

Permanent

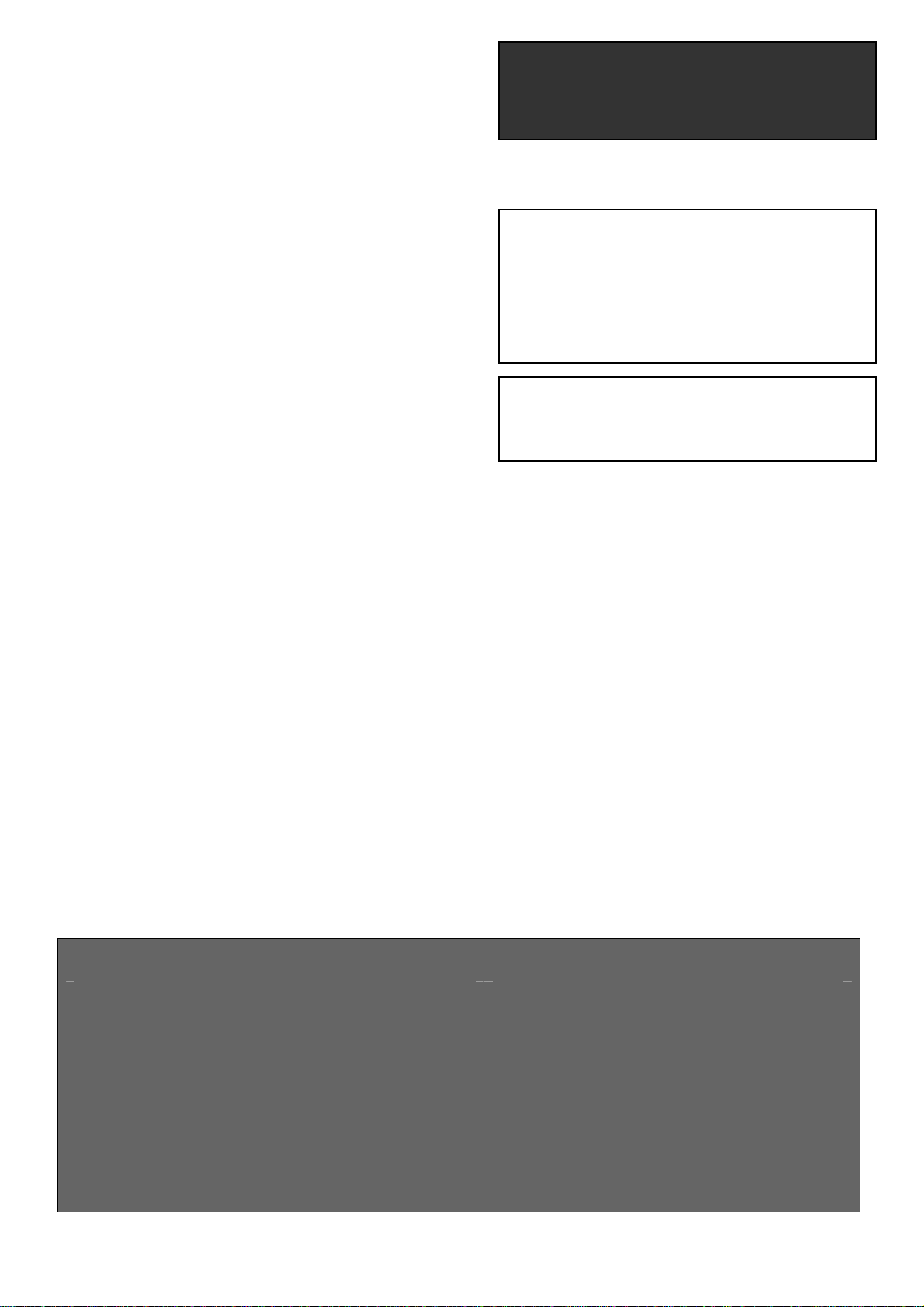

Figure 1. Connection scheme

Installation

3. Positioning the unit

The valve, the control unit and the batteries must be

installed in a position which avoids excessive heat,

humidity, dust, fat and oil. The maximum working

temperature for these parts is 70ºC (158 ºF). Attention

should be paid to the specified maximum temperature

for the alkaline batteries used to power the system.

The control unit should not be covered by metal casing

so that RF communication is not impeded.

The touch control can also be damaged by excessive

heat and should not be placed on a hot surface.

4. Connection.

4.1. Parts description.

Suggested positioning of the valve,

control unit and batteries.

1.- Valve 2.- Control unit 3.- Remote

4.- ODS / pilot 5.- ODS cable 6.- Battery box

7.- Touch control 8.- Touch control cable 9.- Assembly parts

r_emotion, gas control system - Installer and user manual 2

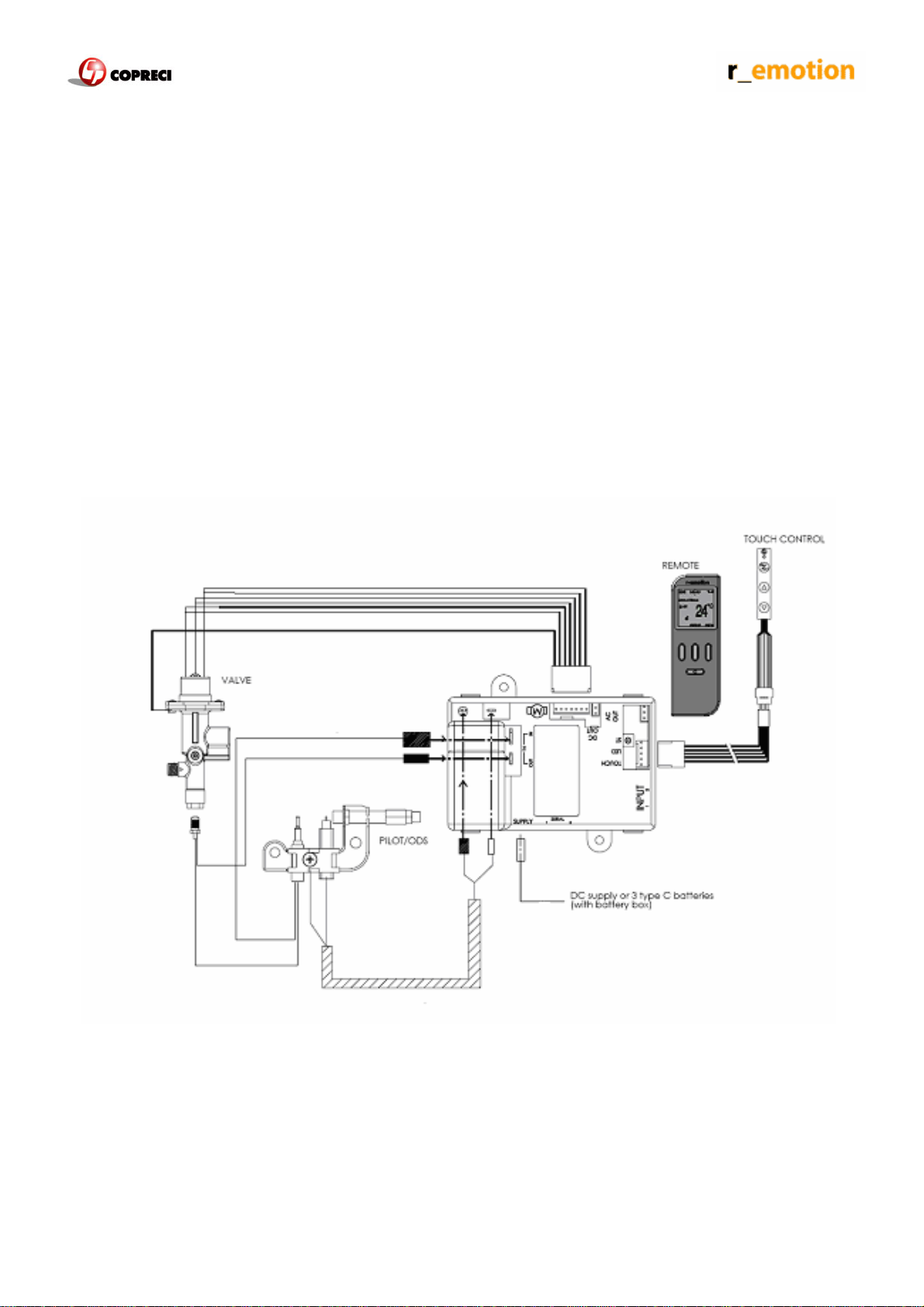

4.2. Gas connection.

As can be seen in the illustration, the gas valve has

one inlet (1) and two outlets: the pilot outlet (2) and the

main burner outlet (3).

Maximum torque to tighten inlet and outlet nuts is 8

N•m(5.9Lbft).

The gas comes through the inlet (1) and when the

valve is turned on, the gas will start flowing to the pilot

outlet (2). After the ignition cycle (which lasts

approximately 10 seconds) has finished, different flame

levels can be selected, allowing gas through the main

burner outlet (3).

All the necessary parts for carrying out the installation

can be found in the box.

4.3. Pilot and magnetic group.

Leak testing:

Brush soapy solution onto the valve and

pipe connection areas. If expanding bubbles

appear, there is a leak. Close gas source

immediately and retighten the connections.

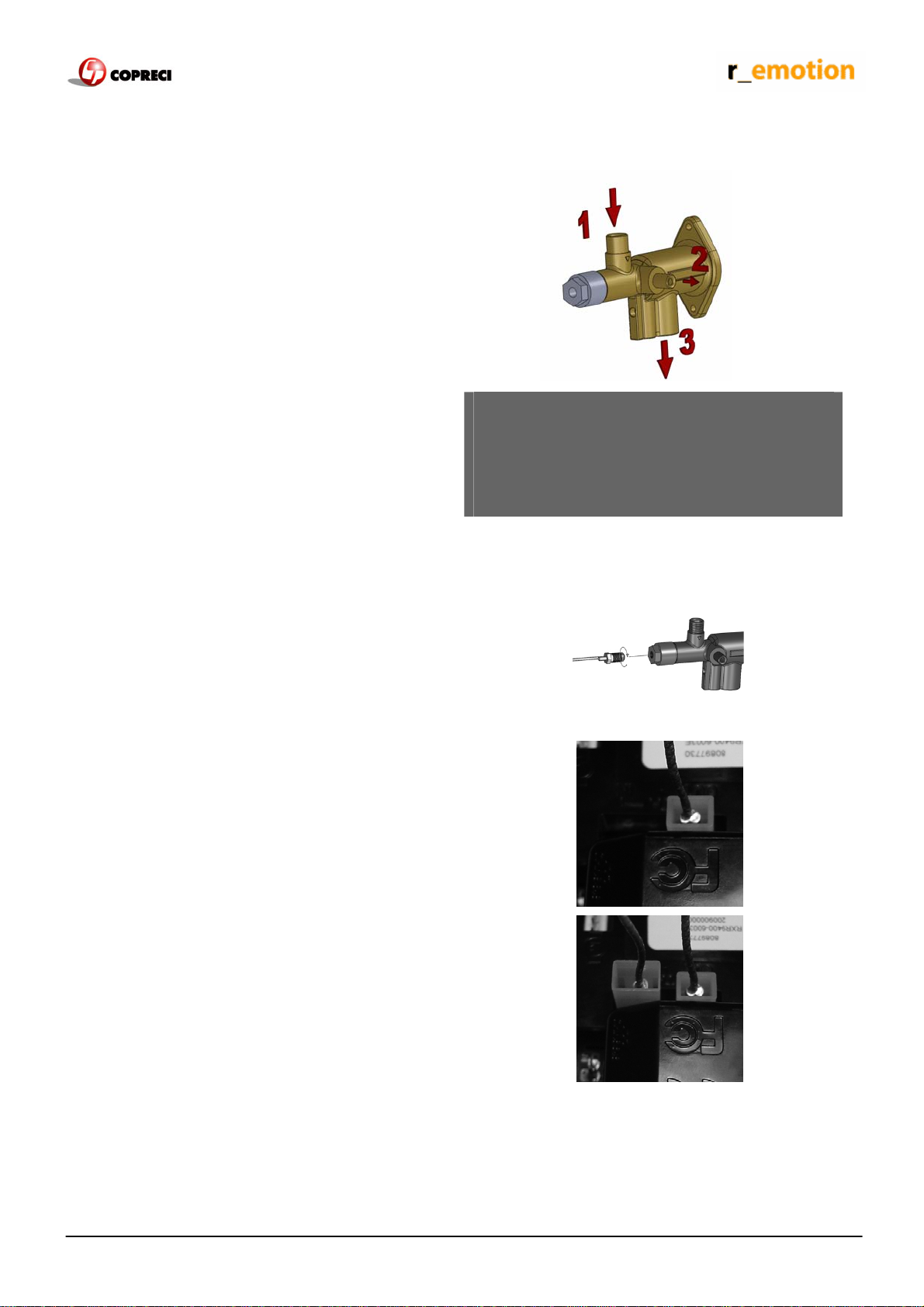

Insert the thread of the ODS / pilot (4) in the top of the

valve (1) and turn tight. Maximum torque to tighten is

4N•m (2.9LbFt).

Insert the smaller connector of the ODS in the “TH

OUT” male connector on control unit.

Insert the larger connector of the ODS in the “TH IN”

male connector on the control unit.

r_emotion, gas control system - Installer and user manual 3

Loading...

Loading...