Page 1

1 | SmithsEP.co.uk | Issue 001 - September 2018

Installation, commissioning

and user manual

Unit heater

Solano

Issue 001 | September 2018

ENGLISH | UK | IRL | SmithsEP.co.uk

Page 2

2 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

1. INTRODUCTION

HEATER heating and ventilation devices are designed to be applied in the buildings of small and medium capacity,

especially such as: production and warehouse halls, car showrooms and service stations, sports halls and stadiums, sacral

buildings and churches, retail stores and wholesales outlets, agricultural facilities, exhibition surfaces.

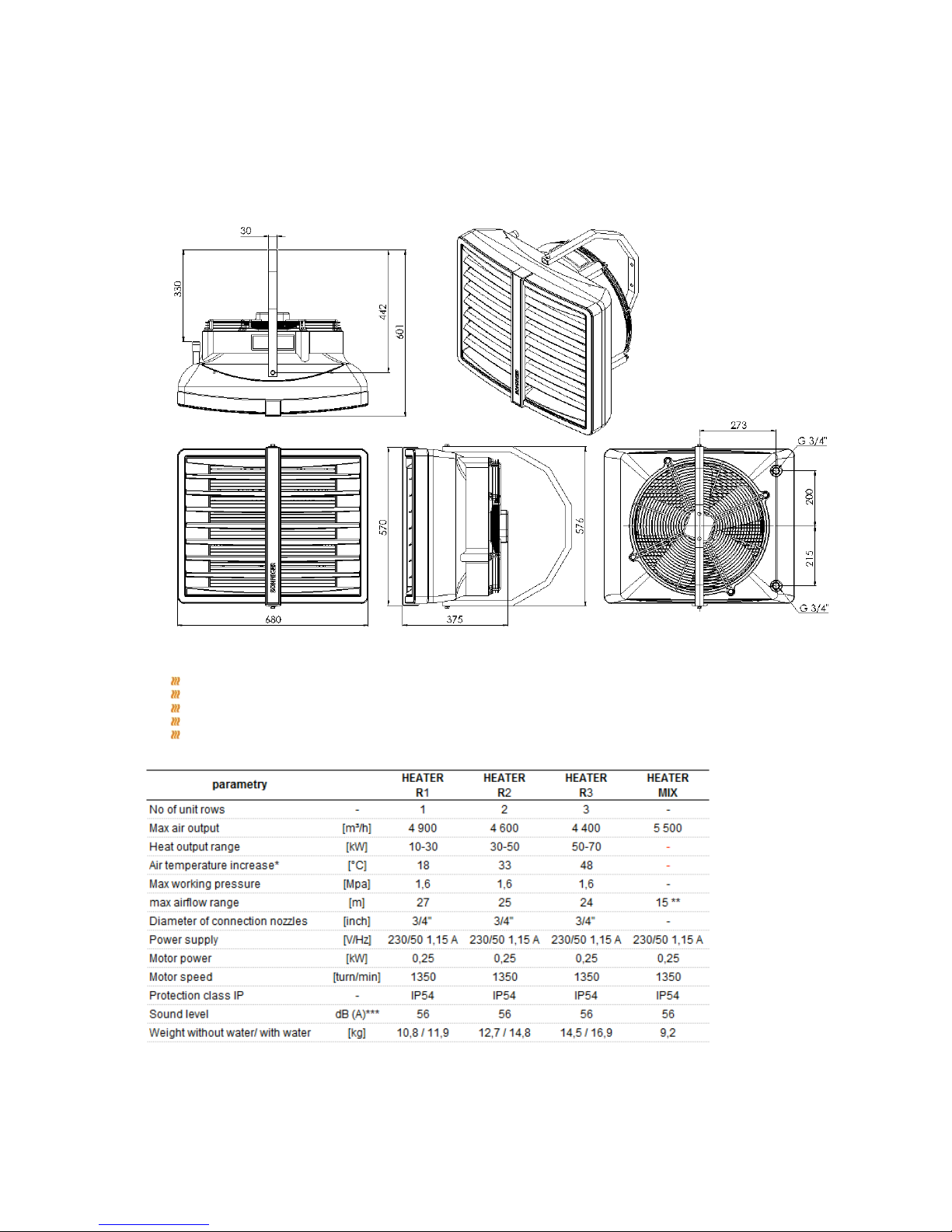

2. DIMENSION AND BASIC TECHNICAL PARAMETERS

Basic elements of HEATER devices :

Casing made of highly resistant EPP (expended polyprophylene) material

Regulated air–conduits

Installation bracket

3 step axial fan 450 mm dimension; fan is protected from direct access to revolving elements with safety netting

Heat exchanger – (Cu/AL) made of copper tubes placed in an aluminum lamellar exchanger /block with stub

connection ½’, ¾”.Stub connections are equipped with air-release valves and heat outlet vent.

*for temperatures of 90/70 and inlet temperature of O˚C

**maximum height of assembly for vertical airflow, max working range of up to 380m². Horizontal range of isothermal stream at

velocity boundary/speed limit of 0,5 m/s

***measurement obtained when 5 m away from the device

Page 3

3 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

3. GENERAL INFORMATION

HEATER heating and ventilation devices are manufactured in compliance with standards concerning quality, ecology, utility and

work comfort.

HEATER devices are delivered ready-to-use in a cardboard package that is to protect from mechanical damages. The package

consists of: the device, the Manual (Operation and Maintenance Documentation) and Guarantee. If the optional automatic

control ordered, it shall be delivered in a separate package. Make sure all the aforementioned elements are in the package

immediately after the delivery. In the absence of any element, please fill in the suitable carrier document.

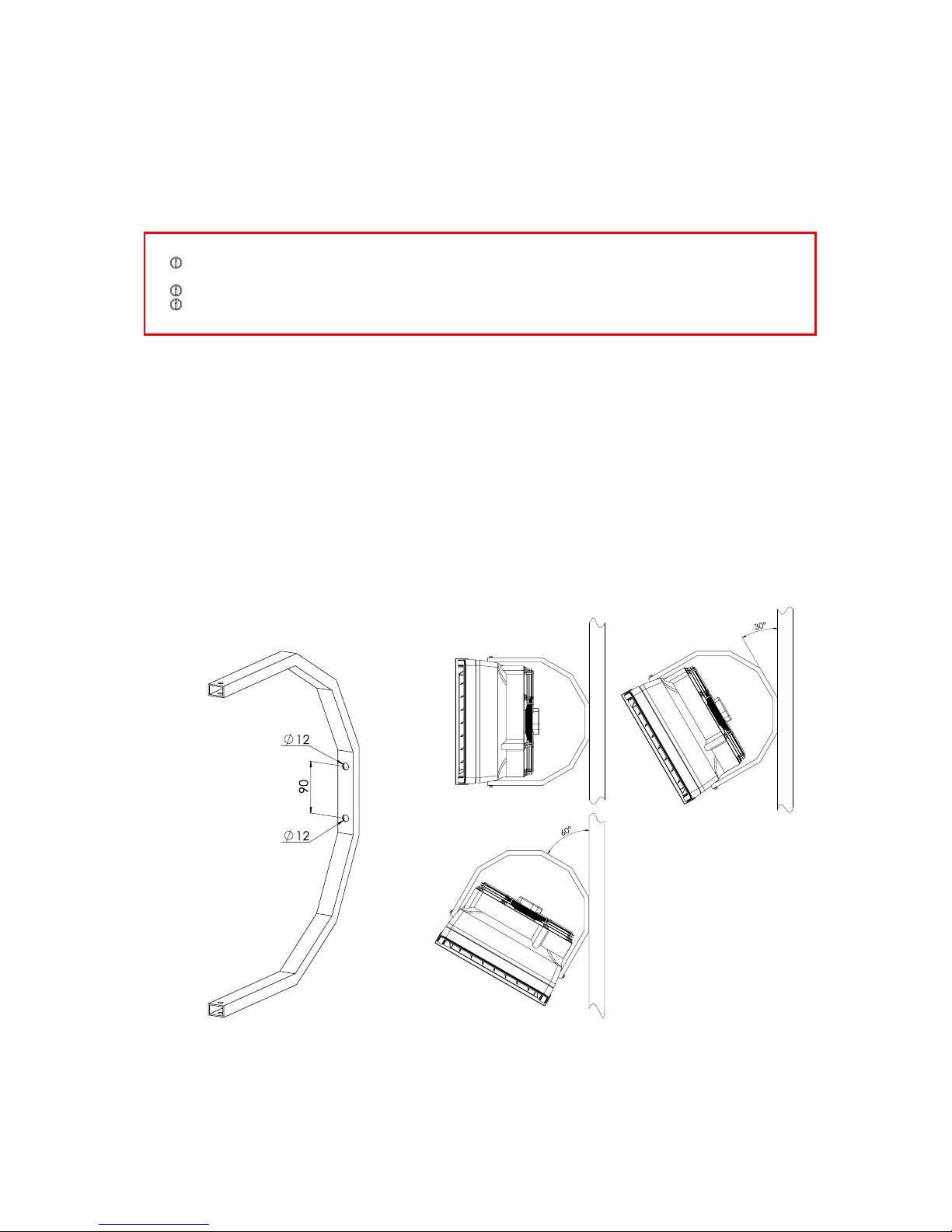

4. ASSEMBLY

Prior to any installation procedures, take the following aspects into consideration: easy access for maintenance works, access to

water and electrical installation, appropriate air distribution in a room.

Every HEATER unit is equipped with a set of 3 interchangeable color inserts; in order to change the color, remove the insert

from the front panel and place the desired one back in place.

*It is advisable to mount the device to the wall or the ceiling on original mounting brackets, supporting mount pins (not delivered

with the device) or supporting constructions (shapes and dimensions of the supporting construction may be individually

designed in compliance with durability and strength requirements).

In case of mounting to the ceiling, pay attention to the fact that air-release/venting of the device may be difficult so it is advisable

to place vent at the highest point of the pipework.

The device may be mounted to the wall with the use of a mounting bracket at the angle of 0°, 30° or 60 °. A mounting bracket

holder is made of curved profile. It has two holes for vertical assembly. Assembly to the wall and/or to the ceiling is possible at

different angles but it requires making necessary holes in the holder.

ATTENTION !

! Przed Before mounting read the manual carefully and adhere to the rules concerning the mounting procedures. Not

applying may result in inappropriate functioning of the device and the loss of the guarantee rights.

! Pay special attention when working with electrical elements of the device.

! Any installation operations must be carried out by qualified persons with appropriate authorizations

Page 4

4 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

HTG-0001_0 7_z e_s zpilkami

A

A

S

N

T

P

N

3. INSTALACJA ELEKTRYCZNA

NOTICE !

! To sustain proper functioning of the device keep a safe distance– 200mm from its sides and 300 mm from its

backside (from the fan)

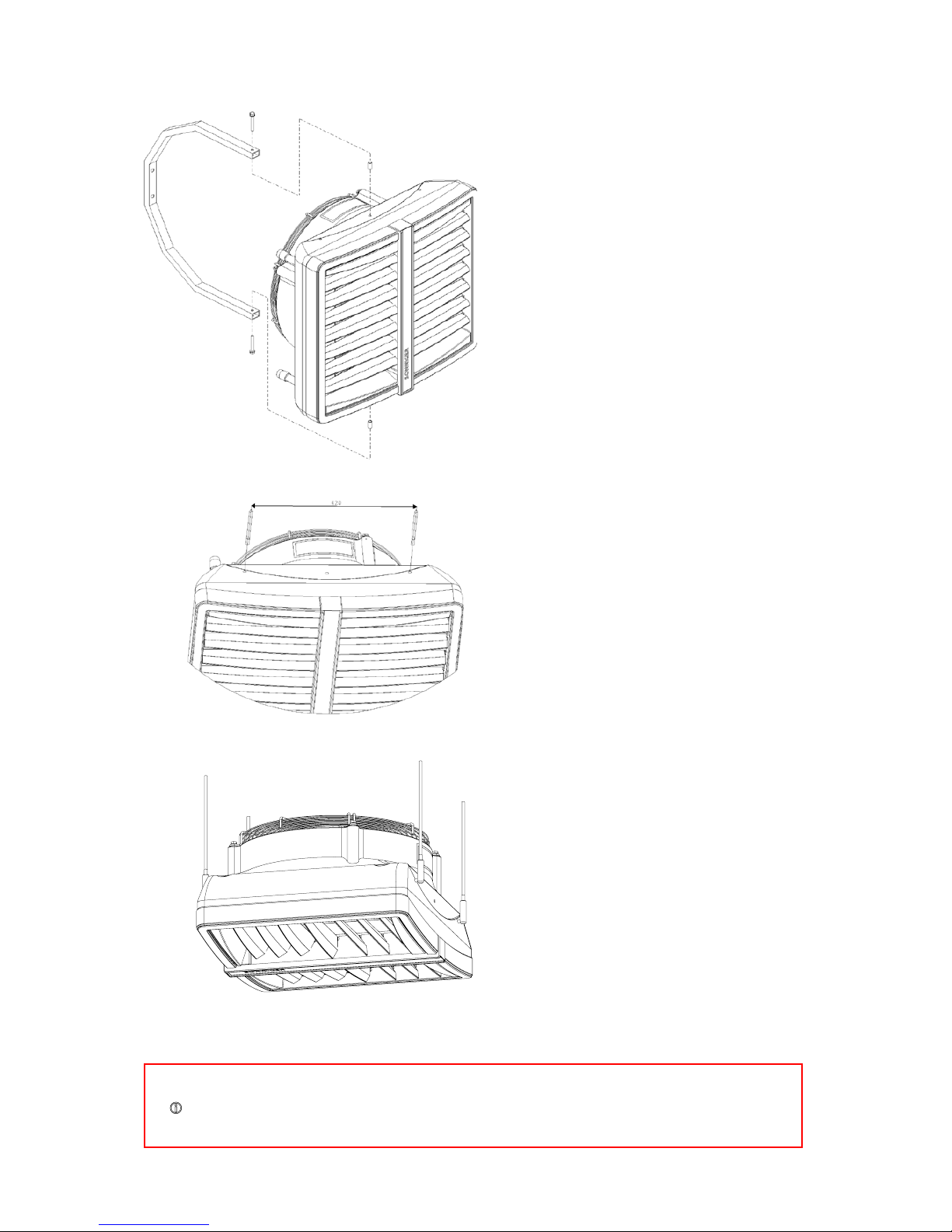

Mounting bracket to the heater

The bracket set consist of: a holder, two

sleeves, two M8 screws and washers. In

order to mount the bracket, drill two Ø1213mm holes in places visibly marked on

the casing. Insert sleeves into drilled

holes and place the bracket in. The

included holder must be screwed with M8

screws with washers.

Installation of mounting pins

To mount the heater to the ceiling, use

M8 mounting pins. Drill two Ø8-9mm

holes in places visibly marked on the

casing. Mounting pins may be screwed

into the frame not deeper than 20 mm.

.

Assembly of HEATERMIX air mixer

To mount HEATERMIX air mixer to the

ceiling, use M8 mounting pins. Drill two

Ø8-9mm holes in places visibly marked

on the casing. Mounting pins may be

screwed into the frame of a heat

exchanger to the maximum depth of

20mm. Mounting pins and connecting

elements are not included with the unit.

Page 5

5 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

5. ELECTRICAL INSTALLATION

The electrical installation and connection to power supply must be done in compliance with the existing regulations and

standards for building industry.

The fan’s engine is equipped with the internal temperature limit fuse protecting the engine from its overheating.

The unit set does not consist of: a feeding cable, a master switch (see diagram)

The electrical installation must be done by an authorized person, acquainted with the Manual. The connection of the feeding

cable and master switch must be done in compliance with electrical diagram (with or without the automatic control, depending

on the option chosen). Any and all damages incurred as a result of the aforementioned causes are not provided with the

Guarantee and the user will be charged with any costs of the device exchange. The connection of the automatic control should

be carried out in accordance with the electrical diagram.

In case of any doubts or problems, unplug the device and contact the device’s installer or SONNIGER Authorized Service.

6. WATER INSTALLATION

The installation of the unit should be done in a way enabling maintenance service; on both stub pipes manual closing valves

should be installed in order to cut off the device. Feeding cables of the heater shall be connected in accordance with the

symbols/marking on the casing (inlet/outlet). In case of electromagnetic valve (with the option of the automatic control) it should

be installed on the outlet as it may be damaged otherwise. When the pipework is being connected to the exchanger, secure the

connections of the heater from oscillating torque (see figure) that may cause leakage in the exchanger.

OUT G 3/4"

IN G 3/4"

WATER DRAIN

AIR VENT

7. AUTOMATIC CONTROL – INSTALLATION

A set of automatic control may be used (powered 230V) that consists of the following:

COMFORT panel – including room thermostat and switch for regulation of 3 speeds of fan. One

COMFORT panel may regulate up to 3 pcs of HEATER units

2-way water valve with actuator; valve should be installed on a return stub of the heater

INTELLIGENT electronic control panel with an automatic speed controller, weekly program and BMS

communication. One INTELLIGENT panel may regulate up to 2 pcs of HEATER units

Splitter MULTI 6 - control up to 6 pcs of HEATER units from one COMFORT or INTELLIGENT Panel

The system is ready to start once the connections between the thermostat and the valve actuator are done, 230V power is

supplied to the thermostat and the fan’s motor is powered by the revs controller.

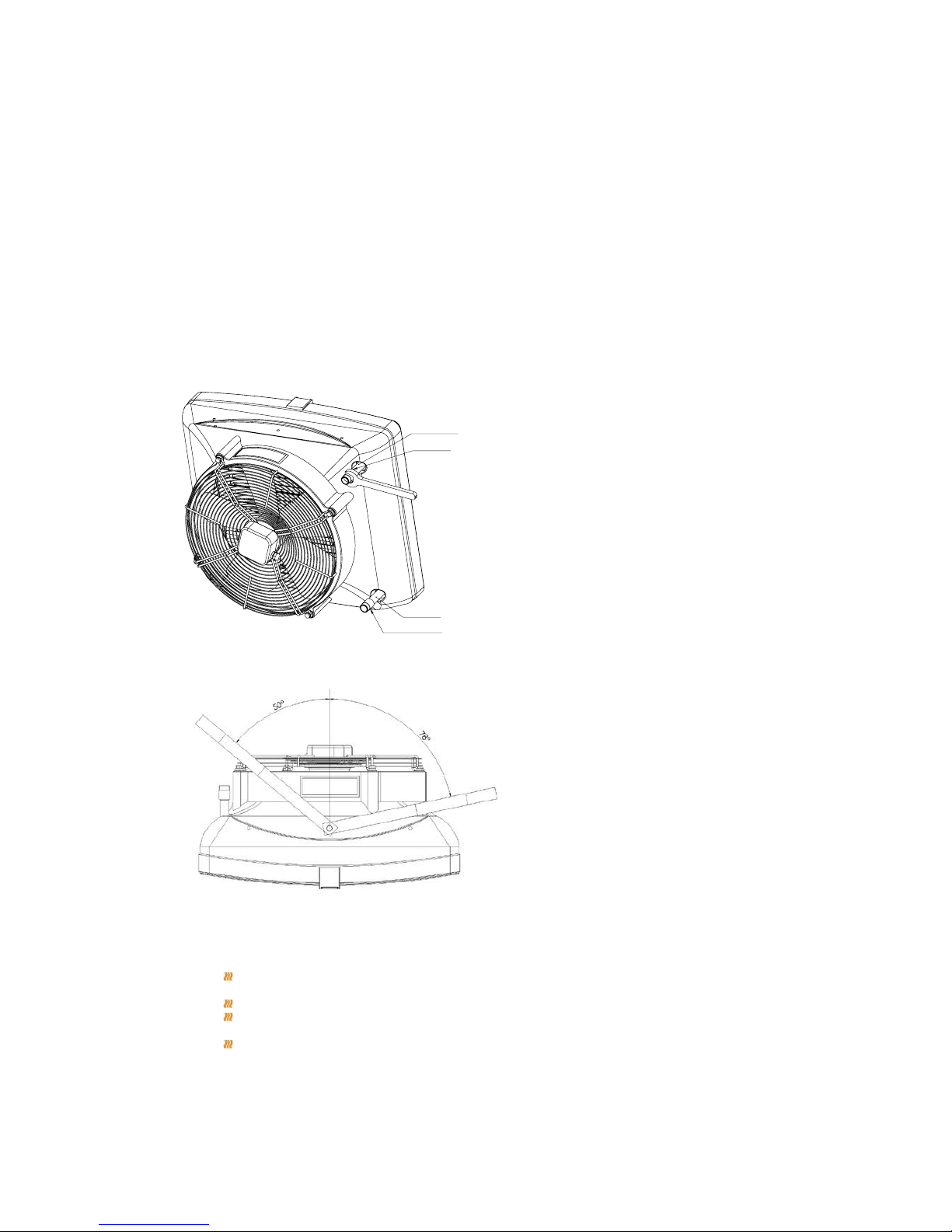

Heating medium

The connector pipes are at the back of the

device. When connecting the hydraulic

pipes/connections, make sure you secure the

connector pipes against rotational torque.

Notice that the connector pipes are not

strained by the pipes. The valve of heating

medium is on the supply pipe and the vent is

on the return pipe.

Use flexible connections to allow the heater to

be turned to the sides. Depending on the

flexible connections, the maximum turn is 78°

to both sides. Figure shows maximum angle to

one side and 50° to the other with minimal

distance left for connections.

Page 6

6 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

8. FIRST START

Do all the connections (electrical, water and automatic control), check for tightness of all connections done by an installer and

air-release/vent the device then start the device in the following sequence:

1. Switch on the mains,

2. Set requested speed of fan on revs controller,

3. Set requested temperature on thermostat,

The fan operates continuously irrespective of whether the heater’s valve is opened or not.

9. TURNING OFF

To switch the device off do the following:

1. Set minimum temperature on thermostat – after 7 seconds valve will be closed and heating switched off.

2. Set main switch to the “0” position (off); fan will be switched off and the thermostat will be off the power.

10. OPERATION

The engine and fan used in HEATER units are maintenance-free devices but regular check-ups are advised, especially motor

and bearing (fan’s rotor should rotate freely, free from any axial and radial throws and undesired knocks/rattles).

11. MAINTENANCE

The heat exchanger requires systematical cleaning all dirts /impurities off. Before the start of the heating period the heat

exchanger is advised to be cleaned with compressed air directed to the air outlets; there is no need for dismantling of the

device. Pay special attention when cleaning the exchanger’s fin due to high possibility of damaging them. If fins are bent use a

tool specifically designated to carry out such repairs. If the device has not been used for a longer period of time, unplug it before

the next use.

The heat exchanger is not equipped with any fire protection device. The heat exchanger may be damaged if the room

temperature goes below 0 C.

Anti-freeze liquid must be added to the water circulation/system. Anti-freeze liquid must be appropriate for the material the

exchanger is made of (copper) as well as other elements of the hydraulic system/circulation. The liquid must be diluted with

water according to the solution recommended by the anti-freeze manufacturer.

NOTICE !

! In case of any metallic knocks, vibration or increase in sound level check if the fan mounting/fixing does not work loose

contact the installer or SONNIGER Authorized Service

COMFORT panel description

ON/OFF – turning ON/OFF a unit

I-II-III – switch for fan speed regulation

HEAT - thermostat sends signal for valve and actuator and fan, fan turns off when temperature in room is

achieved, valve/actuator closes water supply.

FAN – function not active, unit will not operate when FAN switch is selected

COOL – termostat sends signal only to fan, fan begins operation starting from temperature which is set on

thermostat (function used to air mixer HEATER MIX or for room ventilation in summer season)

Page 7

7 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

12. TECHNICAL PARAMETERS HEATER

Page 8

8 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

13. ELECTRICAL CONNECTION DIAGRAMS

1. Connecting HEATER with no automatic control

* The unit set does not consist of: a master switch, a fuse, a feeding cable

2. Connecting a few HEATER units with COMFORT panel, valves and actuators.

* The unit set does not consist of: a master switch, a fuse, a feeding cable

* One COMFORT panel may regulate up to 3 pcs of HEATER units

HEAT - thermostat sends signal for valve/actuator and fan, fan turns off when temperature in room is achieved,

valve/actuator closes water supply.

FAN – function not active, unit will not operate when FAN switch is selected

COOL – termostat sends signal only to fan, fan begins operation starting from temperature which is set on thermostat

(function used to air mixer HEATER MIX or for room ventilation in summer season)

Attention! You can use additional jumper on the contacts 4-5 of COMFORT Panel, in this case you may only use function of

changing speed of fan I-II-III and ON / OFF. The thermostat and switches HEAT / FAN / COOL remain not active.

Additional jumper on terminals 4-5 might be applied when for ex different (supplied by user) thermostat is used to control the

system.

Fan wiring description

U1 high speed – brown

U2 middle speed – grey

U3 low speed – red

N neutral – blue

PE protection - yellow/green

Page 9

9 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

3. Connecting HEATER units with INTELLIGENT panel.

Panel Intelligent controls actuators/valves and automatically regulates fans’ speed depending on the required room

temperature. Fans speed changs automatically for lower rate, when temperature in a room gets closer to desired one.

Additional functions – weekly thermostat, availability of BMS communication signals

Possibility to connect outside temperature sensor NTC, supplied with cable lenght 5 m, max cable length 20 m.

* One INTELLIGENT panel may regulate up to 2 pcs of HEATER units

* The unit set does not consist of: a master switch, a fuse, a feeding cable

4. Splitter MULTI 6 - control up to 6 pieces of HEATERs from one COMFORT or INTELLIGENT Panel

MULTI 6 Splitter allows to connect and control more fan heaters (up to 6 pcs.) and valves with actuators (up to 6 pcs.). Control of fans

and valves is done using COMFORT or INTELLIGENT panel.

To connect more than 6 fans and valves, it is possible to connect Splitter MULTI 6 with each other (maximum extension of up to 10

MULTI 6 splitters). In such case, in the first Splitter MULTI 6 there should be connector DS-N left open, in other Splitters MULTI 6

(2..10) connector DS-N must be closed.

Fan wiring description

U1 high speed – brown

U2 middle speed – grey

U3 low speed – red

N neutral – blue

PE protection - yellow/green

Page 10

10 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

5. Connection of HEATER unit with transformer speed regulator.

* When using transformer speed regulator please use only maximum speed connector on a fan - U1 high speed

Page 11

11 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

14. PANEL INTELLIGENT – programmable controller manual

Panel Intelligent controls actuators/valves and automatically regulates fan’s speed depending on the required room

temperature. Fans speed changes automatically for lower rate, when temperature in a room gets closer to desired one.

Additional functions of Panel Intelligent:

• Weekly thermostat

• Automatic or manual 3-step fan speed adjustment.

• Control room temperature ( by opening/closing the vale, or by adjusting air volume automatically).

• Antifreeze mode- protection against dropping room temperature below critical level.

• Possibility to connect external NTC temperature sensor.

• BMS communication by MODBUS protocol

Panel Intelligent can be connected to BMS (Building Management System) and allows to set up and read performance

parameters on local site in below areas: ON/OFF of a system, Fan speed manual mode, Temperature mode,

HEATING/VENATILATION mode. Exact protocol addresses are available in dedicated Panel Intellingent BMS manual

BMS Communication data

DESCRIPTION of PANEL INTELLIGENT

1. Fan Speed: LOW, MED, HI and AUTO

2. ROOM TEMP. or NTC EXTERNAL SENSOR TEMP.

(measured temperature)

3. SET TEMP. (desired room temperature)

4. Cooling Mode

5. Heating Mode

6. Weekday

7. Clock

8. Buttons Lock

9. ON/OFF status of time zones

10. Automatic programable mode

11. Manual mode

12. 6Time Zones for each day

13. Anti-freeze indication

14. Ventilation Mode

FUNCTION MODES

MANUAL MODE- Fan is operating with chosen speed

(LOW, MED or HI). There are three additional modes:

Heating, Cooling and Ventilation. According to set

temperature, valve is opened/ closed. In programmable

mode is possible to set weekly programmer.

AUTOMATIC PROGRAMMABLE MODE- air volume V

is regulated automatically depending on differential

between pre-set Set Temperature (3) and measured

Room Temperature (2) ( there is no possibility to

change fan speed manually).

In this mode there is possibility to resign from the

valve, heating source will control flow and proper

temperature of water.

FAN FUNCTION

Continuous- after reaching pre-set temperature (3)

valve is closed, fan operating with pre-set speed V(1)

Thermostatic- after reaching pre-set temperature (3)

valve is closed, fan stops operating.

WORKING MODE

Heating - valve is open and fan is on when Room

Temp. < Set Temp.

Cooling- valve is open and fan is on when Room

Temp. > Set Temp.

Ventilation- fan is turned ON and operate with pre-set

speed.

Communication type

RS485

Protocol

MODBUS-RTU

Transmission speed [bps]

2400

Parity Even

Number of data bits

8

Number of stop bits

1

Page 12

12 | SmithsEP.co.uk | Issue 001 - September 2018

Technical Documentation waterfan HEATER v201803

SETTINGSMENU

• When Panel Intelligent is switched off, press and

hold MODE for 3 seconds.

• To change option use MODE button.

• To change value use +/- buttons.

Setting

menu

Option

Value

1

Temperature

calibration

–9°C ~ +9°C

2

Fan status

C1: Thermostatic mode

C2: Continuous mode

3

Temperature

sensor

0: Internal Sensor

1: External Sensor NTC

4 Antifreeze

0: Off

1: On

5

Antifreeze

range

+5°C ~ +10°C

6 Modbus ID

1~247 (01~F7)

BUTTON LOCK/UNLOCK

• To LOCK buttons press and hold + and then – and

hold both of them for 5 seconds.

• To UNLOCK buttons press and hold + and then –

and hold both of them for 5 seconds.

CLOCK SETTING

• When controller is turned off, press and hold FAN

button for 3 seconds and enter time clock setting.

• Option sequence as follows: hour, minute weekday.

• To change option use FAN button

• To change value use + and – buttons.

PROGRAMING

Setting mode

• Push shortly MODE button (15) to select Manual

Mode or Programmable Mode.

• Push MODE button (15) for 3 seconds and select

Cooling Mode, Heating Mode or Ventilation Mode.

Setting of fan speed

• Push FAN button (16) for 3 seconds to select fan

speed LOW, MID, HIGH , AUTO

Weekly thermostat

• Push FAN button (16) for 3 seconds and program

time, setpoints and time zones accordingly.

Monday to Friday – all settings will be the same for

each day between Monday and Friday

• 1st time zone setting (Hour and Minute) –> FAN–>

1st time zone status ON or OFF –> FAN–>, 1st

time zone temperature setting –> FAN–> …..6th

time setting (Hour and Minute) –> FAN–>, .. the

same procedure for each time zone (max 6 zones)

It is possible to set up individual time zone setting

separately for Saturday and Sunday on basis of above

procedure.

EXAMPLESETTINGSofWEEKLYTHERMOSTAT

Mon-Fri

Saturday

Sunday

S N S N S N

1 06:00 ~ 08:00

ON

17°C

ON

17°C

ON

17°C

2 08:00 ~ 11:30

ON

20°C

ON

17°C

ON

17°C

3 11:30 ~ 13:30

ON

20°C

ON

17°C

ON

17°C

4 13:30 ~ 17:00

ON

20°C

ON

17°C

ON

17°C

5 17:00 ~ 22:00

ON 17°C ON 17°C ON 17°C

6 22:00 ~ 06:00

ON

15°C

ON

15°C

ON

15°C

1-6 available time zones

S1 : Status; N: Setpoint

Remarks

During setting, displays can be set while they are flickering.

When the beginning time is flickering, it is able to be set (10

mins each step) via scrolling +/- buttons. The time setting is

the beginning of current time zone, also the end time of last

time zone

When ON/OFF is flickering, it is able to be set via scrolling +/ buttons. When status in ON, thermostat will run according to

setpoint ; when status is OFF, thermostat will be switch off.

When the setpoint is flickering , it is able to be set via scrolling

+/ - buttons. Even choosing OFF status, setpoint is able to

set. And this setpoint will be the working if someone switch

thermostat ON manually this time; however in next time zone,

it will run according to automatic programmable setting.

ELECTRICALCONNECTIONSCHEME

WARNING!

RISK OF ELECRICAL SHOCK. Disconnect power supply

before making any electrical connections. Contact with

components carrying hazardous voltage can cause

electrical shock and may result in severe personal injury

Page 13

13 | SmithsEP.co.uk | Issue 001 - September 2018

Registering your product

Thank you for purchasing a Smith’s product. It has been designed

and manufactured to the highest quality standards to ensure it gives

you efcient and trouble-free service for many years. To back up our

commitment, included with your product is the following warranty:

5 years from date of purchase

This gives you the peace of mind that in the unlikely event of product

failure, we will repair or replace the product completely free of charge

providing the product has been installed, used and maintained in

accordance with the instructions. Your statutory rights are not affected by

this warranty.

It is important to register as soon as possible online at: smithsep.co.uk/

product-registration/. This will ensure you will receive prompt and efcient

service if your product requires attention within the warranty period. If

you do not register your product, you will be required to produce proof of

purchase prior to receiving service.

For more details please visit our website: SmithsEP.co.uk

Disposal

As part of the policy of continuous product improvement, Smith’s

Environmental Products LTD reserves the right to alter specication

without prior notice.

Products with this symbol (crossed out wheelie bin) cannot be disposed as

household waste. Old electrical and electronic equipment must be recycled

at a facility capable of handling these products and their waste

by-products. If you are purchasing replacement equipment your retailer

may offer a ‘take back’ scheme, or will be able to give details of the

nearest approved authorised treatment facility. Proper recycling and waste

disposal will help conserve resources whilst preventing detrimental effects

on our health and the environment.

WEEE Registered Code: WEE/ED0093VW

Approved CQS ISO

9001:2015

After sales and spares

If you experience any problems with the use of your product, please

contact our after-sales ofce +44 (0) 1245 324560.

For product information, customer services or sales support call us on

+44 (0) 1245 324900

For the Republic of Ireland, contact MT Agencies on 01 864 3363

Sales: sales@SmithsEP.co.uk

General information: info@SmithsEP.co.uk

Smith’s Environmental Products Ltd

Blackall Industrial Estate, South Woodham Ferrers,

Chelmsford, Essex CM3 5UW

SmithsEP.co.uk

@SmithsEP_UK

#ThinkSmiths

Page 14

14 | SmithsEP.co.uk | Issue 001 - September 2018

Notes

Page 15

15 | SmithsEP.co.uk | Issue 001 - September 2018

Notes

Page 16

16 | SmithsEP.co.uk | Issue 001 - September 2018

Smith’s, providing comfort for the built environment

To view the full product information

download the datasheet at:

www.SmithsEP.co.uk

For product information, customer services or sales support

call us on +44 (0) 1245 324900

For the Republic of Ireland, contact MT Agencies on

01 864 3363

Sales: sales@SmithsEP.co.uk

General information: info@SmithsEP.co.uk

Smith’s Environmental Products Ltd

Blackall Industrial Estate, South Woodham Ferrers,

Chelmsford, Essex CM3 5UW

SmithsEP.co.uk

@SmithsEP_UK

#ThinkSmiths

Issue 001 | September 2018

Happy to help

Smith’s Environmental Products Ltd is one of the leading

manufacturers of heating and cooling products in the UK.

We are committed to achieving the highest standards and

our faith is supported by a free ve year parts and labour

guarantee with every product. Our customer service is

second to none and we are happy to offer any help and

guidance that you might need.

Stockists

All products are available nationally from Builders’

Merchants, Plumbers’ Merchants, Heating Equipment

Distributors and Kitchen Equipment Distributors. In the

event of difculty, please contact us or visit our website

SmithsEP.co.uk for details of your nearest stockist.

Information and advice

Full technical specications and list prices is available to

download from our website or in hard copy from our ofce.

Also available on our website are price lists, individual

product data sheets, installation & user guides, where to

buy, who to contact and a media centre.

Alternatively contact our ofce 9.00am to 5.00pm Monday

to Friday.

As part our commitment to continuous improvement

Smith’s Environmental Products may change the

specifications of its products without prior notification

or public announcement. All descriptions, illustrations,

drawings and specifications in this publication present only

general particulars and shall not form part of any contract.

All dimensions are in mm unless otherwise stated.

Loading...

Loading...