USER'S MANUAL

ELECTROFISHING BOATS

for all SRI H and EH Model Electrofishing Boats

USER'S MANUAL

ELECTROFISHING BOATS

TABLE Of CONTENTS

INTRODUCTION/BOAT

Overview .....................................................................1

Receiving Your New Boat ............................................2

Batteries and Charging ................................................3

Generator Raw Water Filter .........................................4

CONSOLE

Control Panel Items .....................................................5

GPP Controls ...............................................................6

GPP Patch Panel ..........................................................7

GPP Patch Panel Configurations ..................................8

Auxiliary Foot Switch ...................................................9

COMPONENTS & ISLAND LAYOUT

Pre-Launch ................................................................11

Launching ..................................................................12

Underway Operation ................................................................ 13

Fuel Systems .............................................................. 14

GPP ELECTROfISHER

Electrofisher Control Panel ......................................... 16

Engine Maintenance ..................................................19

Winterize ................................................................... 20

Specifications ............................................................. 22

Trouble Shooting .......................................................23

BOATING SAfETY

Standard Rules ...........................................................31

Right of Way .............................................................33

Lightning Protection ..................................................35

ELECTROfISHING SAfETY

Electrofishing .............................................................40

Preventing Electrical Shock ........................................42

Electrofishing Boat Safety ..........................................43

Electrofishing Principles ..............................................44

Reference and Training Materials ...............................47

Items manufactured by companies other than Smith-Root carry the original manufacturer’s warranty. Please contact

product manufacturer for return instructions.

All Smith-Root, Inc. manufactured products are covered by a one-year warranty.

Credit & Refund Policy: Customers returning equipment - in new condition - will be given a refund within ve days from the date of the return. A

authorization must accompany returns. Valid equipment returns include, but are not limited to, ordering incorrect equipment, funding decits and defective

equipment returned for reimbursement. All returns are subject to a restocking fee and applicable shipping charges. The restocking fee is gured at 10% of

the purchase price but not less than $20.00. Customers receiving equipment in damaged condition will be referred to the shipping company for insurance

reimbursement.

© 2007 Smith-Root, Inc. Vancouver, WA - USA

return

USER'S MANUAL

ELECTROfISHER BOAT MANUAL

OVERVIEW

All Smith-Root boats are heavy- duty electroshing

work boats designed to provide safe and stable

working conditions. They provide the sheries

researcher with the utmost in electroshing

efciency and equipment reliability. The quality

workmanship and attention to detail that go

into every Smith-Root electroshing boat are

demonstrated by our ever-growing number of

satised customers.

The modular design of our boats provide exibility

in use. The forward work deck provides a safe

area for netting and other sampling operations.

The gunwale top is smooth to prevent abrasion

and net snags. Forward work lights illuminate the

entire front area of the boat. Stern lights provide

illumination to the rear of the boat.

INTRODUCTION

BOAT HULL

The hulls are constructed of a rugged aluminum alloy that gives superior impact strength and excellent resistance to water and

weather corrosion. The fabrication features all-welded seams. H models feature hard machine-rivets at all critical rib support

points. Seams are double welded at the bottom-to-gunwale sections, providing extreme impact strength. The forward work

®

decking is anti-skid Dri-Dek

Smith-Root H and EH model boats are heavy-duty electroshing work boats designed to provide the sheries researcher with

the utmost in electroshing efciency and equipment reliability.

H model boats feature a sled-style hull, available from 14' to 18' in length, perfect for shallow water shing operations. For

rough water conditions, our EH models offer our rugged modied "V" hull available in 18' to 21' lengths.

mat and the walkways are aluminum treadplate.

All Smith-Root boats come equipped with an extra heavy-duty transom. Transoms are 20”, 25" or 27" high and are built with

a double H-frame-style reinforcing. This transom is highly resistant to damage on or off the trailer. Side heights are 24" for the

H-series and 30" for the EH-series boats.

smith-root.com

1

ELECTROfISHING

BOATS

RECEIVING & INSPECTION

Before using your new electroshing boat, please

read and perform the following procedures.

During shipping it is possible for damage to occur.

Also, nuts, bolts, or screws may have vibrated loose.

1. Give your boat a good visual inspection for

possible shipping damage.

PILOT DECK

2. Make sure battery selector switch is OFF.

3. Remove the six 1/4-20 bolts holding the pilot deck

cover on. The pilot deck is located between the

Console and the Generator housing (7/16" wrench

required).

TS-5

6. Inspect the center

console. Remove

the top mounting

Phillips screw from

the outboard throttle

and gear shift control

box. Remove the

1/4-20 bolt in front of

the outboard control

box on the side of

the console. Remove

the two 1/4-20 bolts

on the other side of

the console (Phillips

screwdriver and 7/16"

wrench are required).

7. Rotate the console

forward, resting

it on the top of

the sh tank lids.

Make sure your Battery Selector Switch, located on the

port side of steering & control console, is in the "OFF"

position.

8. Check all the screws on the terminal strips, used and not used, for

tightness. Check all instrument mounting screws and electrical

connections. Check all the hardware mounting screws and boat

ground buss bar screws (Phillips and at-blade screwdrivers,

5/16", 3/8", 7/16" and 1/2" wrenches are required).

Remove the pilot deck cover revealing the TS-5

terminal strip and pump compartment. Remove

protective cover over terminal strip.

4. Check all of the screws on the TS-5 terminal

strip, pump bases, and boat ground buss bar

to make sure that none have vibrated loose

(Phillips screwdriver required).

5. After thorough inspection of this area, replace

the pilot deck cover and tighten bolts.

2

9. Rotate the console back to its upright position. Re-secure the

console fasteners.

10. Open the access hatch on the front of the console (the circuit

breaker and patch panel compartment). Visually inspect

all the breaker holders for tightness. Close and latch the

compartment.

11. Check tightness of all mounting bolts around the sh holding

tank, battery compartment, console, pilot deck and generator

housing (7/16" wrench is required).

2007

The Control Console is mounted on the central island

structure. The electrosher control panel is mounted at the top

of the consoles within comfortable reach of the boat operator.

An adjustable audio tone and the high voltage indicator lamp

are activated whenever electrosher output is present. The

console also contains a GPP Patch Panel allowing complete

selection of anode/cathode boom congurations. Consoles

hinge forward to provide easy access to all steering controls,

switches, circuit breakers, and wiring terminals for the entire

electrical system. All wiring terminals are clearly labeled

for easy identication and servicing. A schematic diagram is

provided which shows all wiring and terminal designations

for the entire boat. Two spare switches and 2 accessory

plugs are provided on the console for additional electrical

equipment.

USER'S MANUAL

CONTROL CONSOLE

Outboard controls are mounted on the right side of the control

console.

Work-Up Lights and 12V Accessory plug

Console Cover provides complete weather protection to the

steering and control console. Constructed of heavy duty

canvas with reinforced corners.

Work-Up Lights are provided on the front of the console,

(pictured above). The lights are recessed and aimed to light up

the sh tank and not shine in crew member's eyes.

Batteries are housed under fire

extinguisher/storage compartment

(not shown)

BATTERY AND CHARGING SYSTEMS

All models of boats come with three marine batteries housed

in chemical resistant enclosures (two in main compartment,

one in enclosure at stern). A 40 amp charging system utilizes

Outboard cranking battery in stowed

position at stern

power from the GPP generator. Charging from the outboard

motor is also incorporated in the charging system.

The battery compartment provides space for two marine

batteries. The Storage compartment above the batteries

provide space for a marine re extinguisher and miscellaneous

small items. There is a separate cranking battery for the

outboard motor.

smith-root.com

3

ELECTROfISHING

BOATS

CONTROL CONSOLE

BATTERY MAINTENANCE CHARGER

The Battery/Charging system includes a charger that connects to a 110V

service (via its receptacle, shown at right) when the boat is not in use for

extended periods of time. It automatically brings the battery's level to a full

charge and maintains it. LEDs indicate battery charging status (inset).

BATTERY SELECTOR SWITCH

The Battery Selector Switch is located on the left side of the control

console. It allows you to switch between the two separate main batteries,

run on both simultaneously or to shut both batteries off when boat is not in

use. Switch should be in 'BOTH' position when charging.

GENERATOR RAW WATER fILTRATION

The Generator requires raw water for coolant purposes. The Raw Water

Filter located on left side of control console must be inspected daily and

any potential obstruction removed in order to prevent damage to the intake

system. Bowl is translucent to facilitate inspection.

110V inlet on

console lower front;

LED indicators on

console side (right)

Battery

Selector Sw.

Battery Charger

Raw Water Filtration

4

Battery Selector Switch

Generator Raw Water Filter

2007

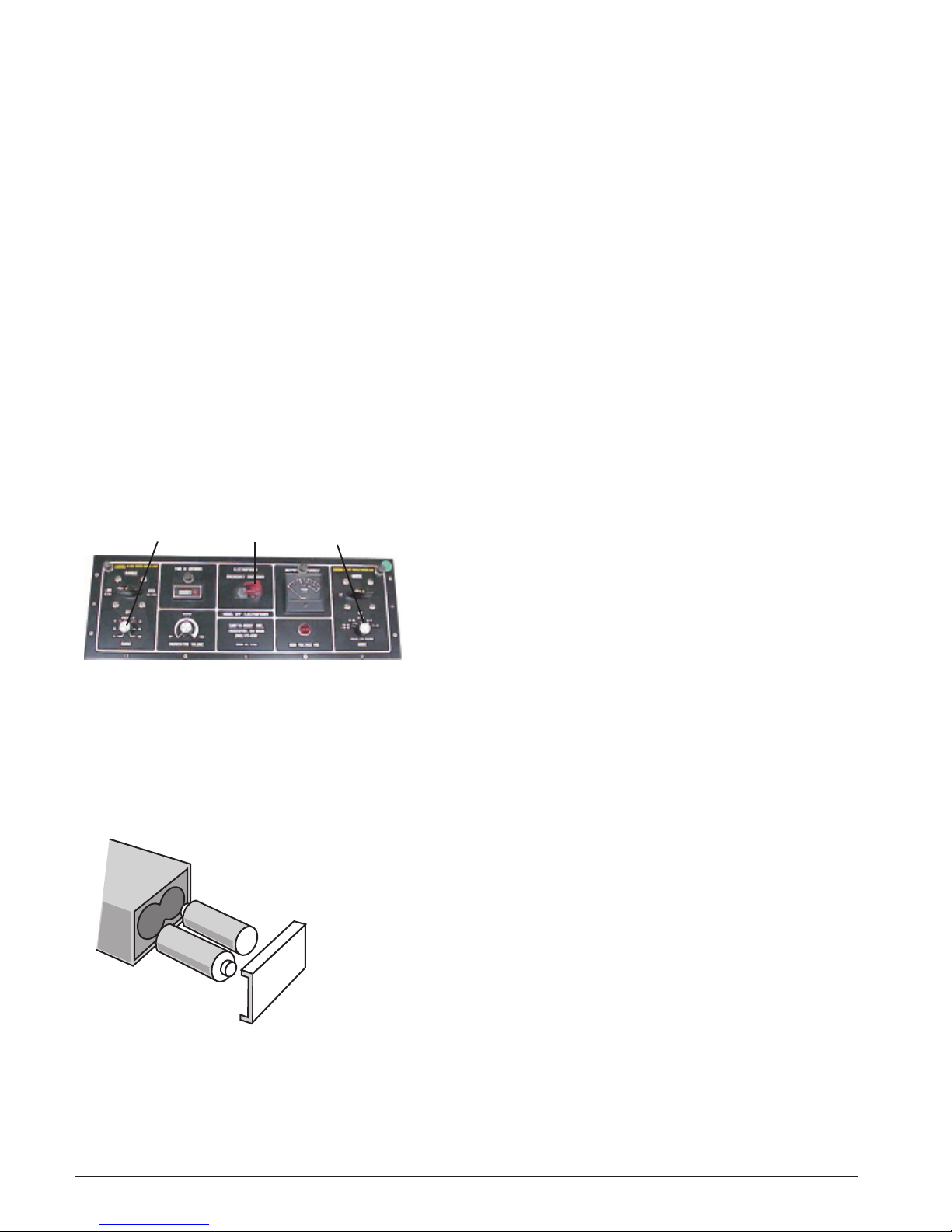

UPPER PANEL ITEMS

VENTILATION FAN -1. cools and clears vapors from generator

compartment. Button must be pressed while starting the generator.

DEPTH FINDER2. - indicates water depth below boat

TILT & TRIM - 3. outboard tilt and trim indicator (optional, not shown)

VOLTMETER - 4. expanded voltmeter 12V system

USER'S MANUAL

CONTROL CONSOLE

5. indicates fuel level of selected tank. Outboard powered.

FUEL GAUGE -

GENERATOR OFF - 6. kills generator engine with key in “on” position

GENERATOR LOW OIL 7. - comes on if oil pressure is low

GENERATOR START8. - ignition and 12V accessory power

15

9

12

26

1

10

13

16

11

14

17

2

3

4

18

5

19

21

23

24

7

6

8

20

22

25

27

28

29

30

31

MAIN PANEL CONTROLS

HEADLIGHTS9. - illuminates water forward. 12V, generator not

required

WORK LIGHTS10. - illuminates water around front work deck.

Generator powered

TANK PUMP11. - fills livewell and provides flow through water

system

BACKUP LIGHTS 12. - illuminates behind boat

TANK LIGHTS 13. - illuminates fish holding tank

RECIRCULATION PUMP 14. - water for aeration, can be used on

trailer

HORN - 15. operates loud marine horn

SPARE #1 16. - For wiring an additonal console accessory

LOWER PANEL ITEMS

BATTERY CHARGER INPUT 26. -For connecting 110V service to

battery maintenance-charger when not in use

DEPTH FINDER FUSE 27. - 1 amp

OUTBOARD HOURS METER FUSE 28. - 5 amp

17. - records outboard total hours

29. - 5 amp

smith-root.com

OUTBOARD HOURS

BILGE PUMP - 18. switches bilge pump from auto to manual

DASH LIGHTS - 19. illuminates dash panel.

NAVIGATION LIGHTS 20. - operates Coast Guard approved

navigation lights

FUEL GAUGE SWITCH 21. - toggles between port and starboard

tank sender unit. Outboard powered.

DECK LIGHTS - 22. illuminates walkways and workdeck

GENERATOR HOURS 23. - records total generator hours

SPARE #2 24. - for wiring an accessory under the pilot deck

WORKDECK FOOT SWITCH 25. - allows for and/or operation of foot

switches

FUEL GAUGE FUSE

IGNITION PROTECTION 30. - 15 amp

12V ACCESSORY PLUG 31. - For additional electrical equipment

5

ELECTROfISHING

BOATS

GPP CONTROLS

Inset: Range switch as seen on a 7.5 or 9.0 GPP.

1

6

2

7 8

ELECTROfISHER CONTROLS

RANGE SWITCH:1. Selects the output voltage

range between high and low or switches

the output to OFF (Caution!: The position

of this switch should not be changed

when current is flowing, i.e. foot switches

engaged!).

TIME IN SECONDS:2. Records the actual

shocking time. It counts only when high

voltage is applied.

EMERGENCY SHUTDOWN:3. Provides a local

override of remote foot switches.

OUTPUT CURRENT METER:4. Shows the

current flowing between the anode and

cathode in amps and indicates when the

RANGE switch should be moved to the LOW

position. For 7.5 and 9.0 GPPs, follow the

output table.

3

MODE:5. Selects the type of output pulses,

AC or DC (Caution!: The position of this

switch should not be changed when

current is flowing, i.e. foot switches

engaged!).

PERCENT OF RANGE:6. Adjusts the output

pulses to a percent of the selected range, i.e.

high/low. Pulse width is also automatically

adjusted between 6 and 1 millisecond pulse

duration.

ENUNCIATOR VOLUME*:7. Controls volume of

output of warning tone.

HIGH VOLTAGE:8. Red indicator lamp shows

when voltage is present on output power

terminals.

PULSES PER SECOND9. : Selects the number

of pulses in the output wave form.

4

5

9

*Enunciator Volume: The Audio Alarm warning tone indicates an output voltage. The control adjusts the volume of the Audio

Alarm or turns the Audio Alarm off.

Note: Switch the Range switch to the OFF position when the GPP is not in use. The Audio Alarm warning tone will sound if the

generator is running without the electrodes in the water and the switch is not OFF.

6

2007

On the front of the console is a hinged lid, with corner

cutouts for the optional foot switch cables, that houses the

GPP Patch Panel. Inside, the GPP Patch Panel consist of four

parts:The patch panel, main panel with circuit breakers and

auxiliary foot switch/command center.

Work-up lights can be seen above patch panel door.

USER'S MANUAL

GPP PATCH PANEL

Work-up light switch

Breaker panel light

(Above) Work-Up Lights

and Patch Panel Light

Switches

(Left) Aux. Foot Switch/

Command Center Switch.

Open door view of Patch Panel and Circuit Breakers.

smith-root.com

7

ELECTROfISHING

BOATS

GPP PATCH PANEL

CONfIGURATIONS

PATCH PANEL CONfIGURATIONS STARTING WITH THE MOST COMMONLY USED.

Port and starboard booms as

anodes - boat and insulated

cathode array as cathode (most

common arrangement).

Port and starboard arrays as

anodes - insulated cathode array

as cathode. Boat ground isolated,

required in California and BC.

Port boom as anode - starboard

boom as cathode - boat hull and

cathode array isolated.

Starboard boom as anode - port

boom as cathode - boat hull and

cathode array isolated.

8

2007

USER'S MANUAL

fOOT SWITCH OPERATION

WORK DECK fOOT SWITCH SETTINGS

The Both and Separate foot switch position switch is located on the lower starboard side of the console.

The switch controls the function of the work deck foot switches. In the separate position, each foot

switch controls the output. In the Both position, the two foot switches must be pushed simultaneously

to activate output. The Command Center foot switch is located on the aft side of the console and is

operated by the helmsman.

Left to Right - Both and Separate work deck switch on console front; Command Center Foot Switch; Work

deck foot switches.

COMMAND CENTER & AUXILIARY fOOT SWITCH SETTINGS

The Patch Panel cables have been unplugged in the following pictures so the Auxiliary Foot

Switch & Control panel can be seen.

Note:The Both/Separate switch only affects the work deck foot switches and has

no effect on the Auxiliary or Command Center foot switches.

1. Auxiliary foot switch inactive/command center foot switch inactive

- (not required, no foot switch plug needed to operate normally).

Note: one or both work deck switches must be operated.

2. Operation of command center foot switch required. Operation of

auxiliary foot switches not required. Note: one or both work deck

switches must be operated. The Command Center (Pilot) foot

switch or Auxiliary foot switches will not activate the shocker

alone. One of the work deck foot switches must be pushed

(separate position).

3. When using an auxiliary

foot switch, the toggle

switch must be in the active

position. Electrosher will

not operate without auxiliary

foot switches depressed.

Note: one or both work deck

switches must be operated.

Auxiliary Foot Switch

smith-root.com

9

ELECTROfISHING

Generator Test Water Drain

Generator Exhaust Pipe

Heat Exchanger Winterizing Drain

Livewell Winterizing Drain

Livewell Drain Pipe

Generator Oil Drain

Generator Winterizing Drain

Generator

System

Raw Water

Intake (Gen. &

Livewell fill)

Steering

Console

Battery

Compartment

Generator

Raw Water

Filter

Recirc.

Pump

Muffler

System

Fish Holding Tank

(Livewell)

Battery Compartment

Storage Compartment

Hinged Battery/Storage

Compartment Lid with

Fire Extinguisher attached

Battery On/Off Switch

Pilot Deck & Pump Compartment

GPP Generator Housing

Control console

Fish holding tank

BOATS

COMPONENTS & ISLAND LAYOUT

Above - Profile of typical boat, showing arrangement of major components.

Above - Arrangement below island super-structure showing

A

C

B

D

Generator, Battery compartment, pumps, Livewell plumbing

and winterizing/maintenance drains.

E

Right - Drain manifold details:

A- Generator Test Water ; B- Heat Exchanger Winterize Drain;

C-Generator Winterize Drain ; D- Livewell Winterize Drain; EGenerator Oil Drain.

10

2007

USER'S MANUAL

PRE-LAUNCH CHECKLIST

8. Check boat for required equipment:

Life jackets for all personnel on board, plus one extra•

Rubber coats, rubber boots, and rain gear•

Rubber gloves•

Dip nets•

Tools•

Spare bilge plug•

9. Be sure to store all personal gear before launching the

boat.

10. Locate the bilge plug and install before launching.

1. Check your batteries.

Note: If the batteries need to be charged, use built in

charger.

2. Turn the battery selector switch and boat ignition "On"

to test the electrical system.

Note: DO NOT run pumps without water. The

impellers will become damaged very quickly.

3. Check the generator oil level. See Electrosher section;

Generator Owner's Manual for details.

4. Check the outboard oil. See Motor Section - Outboard

Owner's Manual for details.

5. Check the generator and outboard motor fuel supply.

6. Check the re extinguishers. (The gauge should be in the

green).

7. Check the sh holding tank for stand-pipes and

cleanliness.

11. Give everything one nal visual inspection before

launching.

smith-root.com

11

ELECTROfISHING

BOATS

LAUNCHING INSTRUCTIONS

1. Don’t forget to install the Bilge Plug.

(Oh yes, you will, we all have!)

2. Remove Tie-down strap. Disconnect the trailer lights.

3. DO NOT disconnect your winch line or safety chain

until the boat is in the water and outboard is warmed-up.

4. Back the boat into the water.

“Caution” If your tow-vehicle has an automatic

transmission, after starting down the launch, shift your

transmission to neutral, and use the weight of the tow-

vehicle to launch your boat. Your transmission’s pulling

backward may cancel out your rear brakes. On a steep,

sandy, or slippery launch, your front brakes may be

inadequate to stop at the desired launch position.

5. Launch Position. Do not over-launch your boat. Don’t

back the trailer in over the top of the fenders.

6. Start the outboard and let it warm up on the trailer.

While it is warming up, check the Bilge Plug for

leakage. Verify outboard motor water pump operation

by looking for a steady stream of water coming out to

the water pump indicator.

7. After warming up, shift the outboard into forward to

hold the boat rmly against the bow receiver. Now have

a crewmember unhook the safety chain and winch line.

Once the bow is unhooked, shift into reverse and back

off the trailer.

8. Loading and unloading your boat at the boat launch can

be a tricky situation. Wind and current affect launch

conditions severely. It is better to load and unload

without additional crewmembers on board. Additional

weight and crewmembers moving about in the boat will

drastically change low speed maneuverability of the

boat.

9. Either beach or dock the boat to load your

crewmembers. Before leaving the dock or beach, make

sure all hands have put on their personal otation

devices (life jackets). Now you are ready to get

underway.

12

2007

USER'S MANUAL

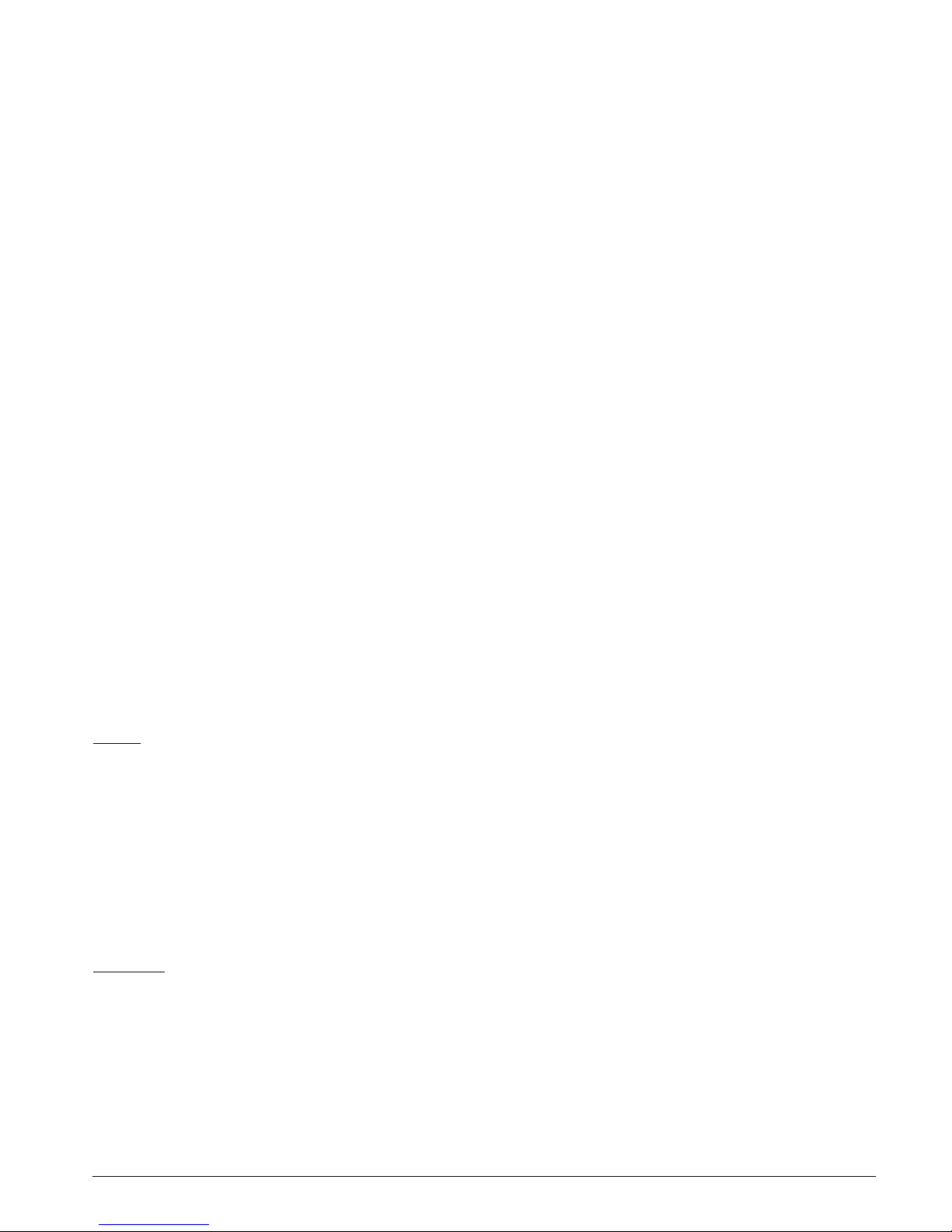

Chain support

Boom clutch

assembly

Boom

base

Navigation light

Lower trailering position

Upper underway position

Boom support

chain

Stretch cord

Stretch cord

Boom holder

Boom holder

Boat hull area

Bow

Work deck safety rail

Boom support

chain

Head &

work

lights

Boom extension

Boom extension

UNDERWAY

UNDERWAY OPERATING AND ELECTROfISHING PREPARATION

UNDERWAY OPERATING TIPS:

1. Before starting your outboard engine, read the information

in the “Motor” section for fuel mixture ratio and break-in

procedures. Prior to getting underway, run the outboard

at a fast idle for the first 1 1/2 to 2 minutes. This will

allow engine to be completely warmed up and will ensure

all working parts are well lubricated.

2. During this warm up time, have a crew member move the

booms from the lower trailering positions to the upper

underway position. When attaching the arrays, attach the

safety line rst, then connect the quick connector . Do not

unfold your arrays at this time.

3. Check your trim. Trim your bow up or down to suit your

boat load and water conditions. If your boat wants to

porpoise, trim your bow down. For more information,

see “Motor” section.

4. When you reach the job site, throttle-down slowly.

Throttling-down slowly will prevent chill-shocking the

outboard power head and prolongs engine life.

PREPARING THE BOAT fOR

ELECTROfISHING

1. Raise and inspect the booms, boom extensions, and

arrays to see that they are in good working order. When

attaching the arrays, connect the safety line rst, then

attach the quick connector. Do not unfold your arrays at

this time.

2. Loosen clutches and lift the booms from the underway

position. Swing booms forward to about 45

forward. Tighten boom clutch assemblies to hold booms

in position. Adjust anode depth with chain adjustments,

elements extended about 2ft. into the water.

3. After the booms are adjusted, start the generator and

allow it to warm up for a minute or two. Check to see if

cooling water is being discharged with the exhaust.

4. See “Electrosher” section to operate electrosher.

o

from

smith-root.com

13

ELECTROfISHING

Aux. Fuel Tank

Shut Off

Port Tank

Shut Off

Starboard Tank

Shut Off

Water Seperator

Viewing Chamber

Fuel Filter

Water Seperator

To Generator

To Outboard Motor

BOATS

fUEL SYSTEM

Smith-Root boats come with a water separator fuel lter and

generator fuel pump.

Always use outboard manufacturer's recommended fuel.

MAINTENANCE

Check fuel lter viewing chamber for signs of water daily.

Refer to your OEM Manual.

TO RE-PRIME YOUR OUTBOARD fUEL

SYSTEM

First plug the auxiliary fuel hose to the auxiliary fuel tank

(the tank that comes with the outboard motor). Then open

the port tank shut off valve and pump the priming bulb 18

or 20 times. Then close the port tank valve and open the

starboard tank valve. Now pump priming bulb 5 or 6 times.

Now close Starboard tank valve and pump priming bulb

until it becomes rm. Your fuel lter, generator fuel pump,

outboard fuel pump and carburetors are now primed. Now

remove auxiliary fuel tank hose from tank and adjust shut

off valves to suit your needs.

14

2007

USER'S MANUAL

GPP OPERATION

GAS POWERED PULSATOR

smith-root.com

15

ELECTROfISHING

2!.'%

4)-%).3%#/.$3 %,%#42/&)3(%2

%-%2'%.#93(54$/7.

-/$%,'00%,%#42/&)3(%2

%.5-#)!4/26/,5-%

2!.'%

3-)4(2//4).#

6!.#/56%27!

()'(6/,4!'%).$

/54054#522%.4 -/$%

!#

$#

$#

$# $#

$#

!#

$#

05,3%30%23%#/.$

-/$%

3%2)!,./

-%$)5-

/&& ()'(

,/7 ()'(

/&&

0%2#%.4!'%/&

BOATS

ELECTROfISHER CONTROLS

1 - RANGE: Selects the output voltage range between high and low or switches the output to OFF

(Caution!: The position of this switch should not be changed when current is owing i.e. foot switches

engaged!)

2 - TIME IN SECONDS: Records the actual shocking time. It counts only when high voltage is applied.

3 - EMERGENCY SHUTDOWN: Provides a local override of remote foot switches.

4 - OUTPUT CURRENT: Shows the current owing between the anode and cathode in amps.

Low range indicates that the RANGE switch should be moved to the LOW position. For 7.5 and 9.0

GPPs, follow the output table.

5 - MODE: Selects the type of output pulses, AC, DC or OFF (Caution!: The position of this switch should

not be changed when current is owing i.e. foot switches engaged!).

6 - PERCENT OF RANGE: Adjusts the output pulses to a percent of the selected range, i.e. high/low. Pulse

width is also automatically adjusted between 6 and 1 millisecond pulse duration.

7 -ENUNCIATOR VOLUME: The Audio Alarm warning tone indicates an output voltage. The control adjusts

the volume of the Audio Alarm or turns the Audio Alarm off*.

8 - HIGH VOLTAGE: Red indicator lamp shows when voltage is present on output power terminals.

9 - PULSES PER SECOND: Selects the number of pulses in the output wave form.

*Note: Switch the Mode and Range switches to the OFF position when the GPP is not in use. The Audio

Alarm warning tone will sound if the generator is running without the electrodes in the water and the

switches are not OFF.

16

2007

USER'S MANUAL

GPP OPERATION

POWER SUPPLY CONTROLS

GENERATOR. Your GPP is powered by a specially

manufactured gas-powered generator. The generator is

wound so that the output voltages are taken directly from the

generator, eliminating the need for a transformer or voltage-

doubler. The generator has a self-excited, revolving field.

This rotor connects directly to the engine crankshaft with a

tapered t. The stationary armature has a separate excitation

winding, and multiple windings to supply AC power.

Two 12 VAC windings on the generator provide up to 500

watts of 12 volts AC power. They will run the 12 volt work

lights and will recharge batteries.

ENGINE. This instruction section covers the electrosher and

the generator, but not the engine. Please read instructions in

the engine manufacturer’s section. The engine manufacturer

has established an excellent worldwide service organization.

Engine service is usually available from an authorized engine

dealer near you: Check your Yellow Pages or contact SmithRoot, Inc. for a dealer near you.

ENGINE GOVERNOR. The engine must be run at 3600

rpm to supply the power it was designed to produce. The

governor on the engine holds the speed as nearly constant

as possible. The governor is set at the proper speed in the

factory. Do not adjust the governor without proper tools.

VOLTAGE VARIATION. All engines slow down when a

load is applied. When the electrical load on the generator

is increased, the engine speed drops. This results in a lower

voltage when the generator is loaded to its full capacity than

when unloaded.

FREQUENCY VARIATION. The AC frequency is around

60 cycles per second. The inevitable variations in engine

speed produce slight variations in the AC frequency. This has

no noticeable effect on the operation of motors, lights, and

your GPP electrosher. However, clocks and other timing

devices will not keep perfect time when used on generators.

MODIFICATIONS to the power supply that are not

authorized may impair the function and safety of the unit.

ELECTROfISHER CONTROLS

MODE The large switch (located at top right of control

panel) selects the type of output pulses, AC, DC or OFF

(Caution: The position of this switch should not be changed

when current is flowing, i.e. foot switches engaged). The

small switch labeled PULSES PER SECOND selects the

number of pulses in the output wave form 120, 60, 30, 15,

7.5 Hz. This switch selection may be changed at any time.

However, it must be in the 120 position for AC output (gives

60 Hz. AC out).

Outputs on all selections are fast-rising slow-falling pulses (a

ltered DC output option is available).

RANGE selects the output voltage range between high and

low or switches the output to OFF. (Caution: The position of

this switch should not be changed when current is owing,

i.e. foot switches engaged).

PERCENT OF RANGE adjusts the output pulses to a

percent of the selected range, i.e. high/low. Pulse width is

also automatically adjusted between 6 and 1 millisecond

pulse duration.

HIGH VOLTAGE red indicator lamp shows when voltage is

present on output power terminals.

ENUNCIATOR VOLUME The Audio Alarm warning tone

indicates an output voltage. The control adjusts the volume of

the Audio Alarm or turns the Audio Alarm off.

Note: Switch the Mode and Range switches to the OFF

position when the GPP is not in use. The Audio Alarm

warning tone will sound if the generator is running without

the electrodes in the water and the switches are not OFF.

OUTPUT CURRENT this meter shows the current owing

between the anode and cathode in amps. LOW RANGE

indicates that the RANGE switch should be moved to the

LOW position. For 7.5 and 9.0 GPPs, follow the output

table.

TIME IN SECONDS records the actual shocking time. It

counts only when high voltage is applied. The timer helps

evaluate capture effectiveness. The counter can be reset to

zero by pushing the small red button on front panel.

smith-root.com

17

ELECTROfISHING

BOATS

EMERGENCY SHUTDOWN provides a local override of

remote foot switches.

ELECTROFISHER OUTPUT PATCH PANEL: Located

in a locking compartment in the forward section of the

steering and control console with the Circuit Breaker panel.

This compartment should never be opened with the GPP

Electrosher in operation.

The patch panel consists of four large “banana jacks” and

Four cables terminated with large “banana plugs”.

Using the patch panel, it is possible to easily change the

output conguration of your boat to optimize it for various

conditions that are encountered. Congurations supported

are: boat as cathode one or two booms as anode, one boom as

anode second boom as cathode, cathode array (if equipped)

as cathode and one or two booms as anode.

Power is supplied from the banana jacks to the boat

component designated by the plug wire connected.

When not actually being used, plugs may be left unconnected;

however, the normal configuration is port and starboard

booms patched as anodes and boat and/or cathode array

patched as cathodes.

If this selector switch is in the “INACTIVE” position, the

pilot deck foot switch has no effect. Also located in the

Circuit Breaker panel compartment are the “AUXILIARY

FOOT SWITCH & CONTROL” switch and plug. If you

are using an auxiliary foot switch, plug it into the 4 pin

socket and switch the “CONTROL” switch to “ACTIVE.”

This puts your auxiliary foot switch into the control circuit.

When not using an auxiliary foot switch, make sure that the

“CONTROL” switch is in the “INACTIVE” position.

1. Set Emergency Shutdown Switch to OFF.

2. Place the anode and cathode in the water.

(not touching each other).

3. Check engine oil level; if low, ll with type recommended

in engine operating manual for your operating

environment. The low oil light on boat operator panel

will illuminate under low oil conditions.

4. Open fuel tank shut-off valves (if so equipped) if using an

auxiliary tank prime system with squeeze bulb.

5. Turn to the start position (full clockwise), release to

the run or ignition on position when engine reaches full

operating RPMs.

ELECTROfISHER SAfETY SWITCH

OPERATION:

Adjust foot switch system to desired conguration. On the

lower right-hand corner of the Console Control Panel is a

foot switches control switch. In the “BOTH” position both

work deck foot switches and the boat operator's foot switch

must be engaged simultaneously to activate the GPP. In the

“SEPARATE” position only one (either one) work deck switch

and boat operator's switch needs to be engaged to activate the

GPP. The function of the boat operators foot switch (pilot

deck switch) is selected by a switch located in the Circuit

Breaker panel compartment marked “COMMAND CENTER

FOOT SWITCH”. If this switch is in the “ACTIVE” position,

the boat operator foot switch must be pushed for the GPP to

work.

18

6. On the Electrosher, set the MODE selector switch to the

desired mode. If you are not sure which mode you desire,

start with 120 pps DC (this will put the maximum amount

of power in the water at the selected voltage).

7. Set the PERCENT OF RANGE to the minimum.

8. Set the RANGE selector switch to LOW.

9. Set EMERGENCY SHUTDOWN switch to ON.

10. Set the ENUNCIATOR VOLUME to mid-range.

11. Activate the remote control switch (foot switch). The high

voltage indicator lamp and audio alarm should both come

on and the ammeter will deect.

2007

USER'S MANUAL

Maximum GPP Amperage (2.5 - 5.0)

Model High Low

2.5

5.0

8 Amps

16 Amps

4 Amps

8 Amps

7.5 120 V 170 V 62.5 A

31.3 A

20.8 A

10.4 A

240 V

360 V

720 V

340 V

500 V

1000 V

150 A60 V 85 V

75 A120 V 170 V

37.5 A240 V 340 V

18.8 A480 V 680 V

9.0

Maximum GPP Amperage (7.5 - 9.0)

Model DCAC Amperage

GPP OPERATION

12. Adjust the PERCENT OF RANGE switch to achieve

optimum response by the sh. Deactivate the shutdown

switch when switching to HIGH RANGE. Damage to

the range selector switch may result from switching

under load. Experimentation will be required to learn

what mode and voltage settings are best for various water

conditions and types of sh.

See charts below:

13. If the ammeter shows LOW RANGE and the RANGE

selector is in the HIGH position, switch to the LOW

GPP Amperages by Model

position. The low voltage windings on the generator are

capable of delivering more current than the high voltage

windings. If erratic operation occurs in the high range,

switch to the low range. Do not operate the generator

above the power ranges indicated on the meter, or possible

engine and generator damage may occur.

ENGINE & GENERATOR MAINTENANCE

Before cleaning or inspecting, make certain all moving

parts have stopped and cooled down. Do not put hands, feet,

tools or other objects near rotating parts. Always wear eye

protection.

1. CHANGE ENGINE OIL after rst ve hours of operation.

Thereafter, refer to the OEM maintenance schedule which

can be found in the Generator's OEM Manual.

To drain the engine oil; place one end of a 3/8" dia.

hose on the oil drain and thread the other end through

the transom drain hole. Place the end of the hose onto a

container. Turn the handle on the shut-off valve and let

the oil drain into the container. (Be sure to dispose of the

oil properly). Rell the engine with new oil. Check dip

stick for proper oil level.

2. SPARK PLUG. Clean and reset gap to specs found in

OEM Manual every 100 hours of operation.

3. FUEL. Every 250 hours replace the in-line fuel lter or

clean the bowl.

4. CHECK GUARDS. Operate the generator engine only

with the guards and shields in place and working correctly.

If rotating parts are left exposed they are hazardous.

13. If you have been working your GPP hard, run it for

another ve minutes under no load before shutting the

generator down. This allows the electrical components to

cool down slowly, extending their life considerably.

14. Turn the fuel valves to the OFF position when the boat is

transported over long distances or on rough roads.

15. Turn the battery switches to OFF when not in use, except

when charging the batteries.

5. INSPECT GENERATOR BRUSHES after every 100

smith-root.com

hours of operation and replace when worn to 3/8 inch

(1cm) or less. Consult Generator's OEM Manual.

19

ELECTROfISHING

BOATS

WINTERIzATION

OUTBOARD

1. Disconnect or shut off fuel.

2. Run engine to eliminate fuel from carburetors (until

engine quits).

Note: Do not run engine without water; use hose adapter

recommended by outboard manufacturer.

Note: Do not run engine tilted up.

3. Remove spark plugs.

4. Spray fogging oil in each cylinder.

5. Cycle the engine (manually or electrically).

6. Spray each cylinder again and replace the spark plugs.

Note: Do not connect plug wires.

7. Spray fogging oil into carburetor air intakes.

8. Cycle the engine (manually or electrically).

9. Replace plug wires.

10. Replace engine shroud.

11. Store boat with outboard tilted down, if possible.

12. Check owner's manual for additional advice.

E

C

A

10. Drain water strainer located on side of console.

11. Open cover from generator water pump and lubricate

impeller with silicone grease.

B

D

BATTERIES

Connect Automatic Battery Charger with maintenance

oat feature to the connector labeled "Battery Charger"

on the Console.

GENERATOR

1. Leave fuel valves turned off. Start engine to drain carburetor

bowl.

2. Remove spark plug and spray fogging oil into cylinders.

3. Cycle engine (manually or electrically).

4. Spray cylinders again and replace spark plugs.

Do not reconnect plug wires.

5. Cycle engine again.

6. Now replace the plug wires.

7. Change the oil and lter:

a. Connect hose to 3/8" pipe tting marked "Oil Drain"

located behind Generator Housing.

b. Route Oil Drain Hose through Stern Drain in

Transom.

8. Open Winterizing Drain Valve (behind Gen. Housing) to

drain raw water from Generator.

9. Drain the water from the generator cooling hose by

removing the cap from the "T" tting located inside the

generator compartment, below the compartment light.

Replace the cap and tighten by hand.

20

2007

fUEL SYSTEM

1. When you ll up the onboard fuel tanks for the last trip

of the year, add a fuel stabilizer to it.

2. After returning from the last eld trip, top off the fuel

tanks with fuel and conditioner.

3. With fuel shut-off valves turned off, remove and discard

the old fuel lter.

4. Install a new fuel lter per manufacturer's instructions.

5. Do not re-prime the fuel lter at this time.

6. Leave fuel shut-off valves turned off.

7. Note: Leaving your fuel tanks full will minimize

condensation build-up inside the fuel tank.

fISH TANK DRAINING

1. Locate Livewell Winterizing Drain valve. Open valves to

drain any water into bilge.

USER'S MANUAL

WINTERIzATION

BOAT WINTERIzING CHECK Off LIST

OUTBOARD COMPLETED BY

1. Run carburetor ............................................................❏ ____________________________________________________

2. Fog engine ..................................................................❏ ____________________________________________________

3. Re-Install plugs and wires ..........................................❏ ____________________________________________________

4. Check owners manual. ................................................❏ ____________________________________________________

GENERATOR

1. Run carburetor/s dry ...................................................❏ ____________________________________________________

2. Fog engine ..................................................................❏ ____________________________________________________

3. Re-Install plugs & wires .............................................❏ ____________________________________________________

4. Change oil and oil lter ..............................................❏ ____________________________________________________

5. Drain raw cooling water from Gen .............................❏ ____________________________________________________

6. Check owner's manual. ...............................................❏ ____________________________________________________

BATTERIES

1. Connect Maintenance/Float Charger ..........................❏ ____________________________________________________

PUMPS

1. Remove and store impellors .......................................❏ ____________________________________________________

fUEL SYSTEM

1. Add fuel stabilizer......................................................❏ ____________________________________________________

2. Shut off fuel valve/s. ...................................................❏ ____________________________________________________

3. Install new fuel lter. ..................................................❏ ____________________________________________________

LIVEWELL TANK

1. Drain Tank. .................................................................❏ ____________________________________________________

smith-root.com

21

ELECTROfISHING

BOATS

SPECIFICATIONS

Conductivity Range 10 to 5,500 microsiemens/cm

Rated Output Power 5,000 W 7,500 W 9,000 W

Rated Output

Max. Current

12 VAC Auxiliary Power* 2 @ 500 W 42 A 2 @ 500 W 42 A 2 @ 500 W 42 A

Output Pulse Modes Pulsed AC & DC Pulsed AC & DC Pulsed DC

DC Output Peak 0 to 500 V Low

AC Output RMS 0 to 350 V Low

Output Pulse Frequency 7.5, 15, 30, 60& 120 Hz 7.5, 15, 30, 60 & 120 Hz 7.5, 15, 30, 60 & 120 Hz

Output Current Metering AC & DC 0 to 25 A AC & DC 0 to 199 A DC 0 to 199 A

High Voltage Output Indicator Panel Lamp & Audio Tone Panel Lamp & Audio Tone Panel Lamp & Audio Tone

Output and Safety Control Foot Switch & Panel Switch Foot Switch & Panel Switch Foot Switch & Panel Switch

Seconds Timer LCD Display 0 to 999,999 0 to 999,999 0 to 999,999

Cooling Method Convection Convection Fan Cooled

Output Connectors CPC with 15” Cable CPC with 15” Cable POS. CAM CONN. 15” Cable

Engine Size 11 HP 16 HP 16 HP

Generator Weight 210 lb 228 lb 238 lb

Pulsator Weight 20 lb 30 lb 35 lb

Generator Dimensions 28” L x 21.5” W x 20” H 28” L x 21.5” W x 20” H 28” L x 21.5” W x 20” H

Pulsator Dimensions 17.5” L x 17.5” W x 13” H 20” L x 15” W x 16” H 20” L x 15” W x 16” H

* Note: 12 VAC auxiliary power subtracts from Electrosher power available.

Specication subject to change without notice.

SPECIfICATIONS

5.0 GPP 7.5 GPP 9.0 GPP

3

10 to 11,000 microsiemens/cm3100 to 25,000 microsiemens/cm

16 A 62 A 150 A

0 to 1000 V High

0 to 700 V High

0 to 1000 V in 4 steps 0 to 680 V in 4 steps

0 to 700 V in 4 steps N/A

3

22

2007

GPP TROUBLESHOOTING

Buss Bar

W/L Brkr

Batt. Chrgr.

r Power &

nal Strip

OLTAGE

GPP Contlr.

12 Vac

Relay

Board

12 Vac

12 Vac

Anode

Board

12 Vac

Cathode

Anode

Dash Lights

3

4

5

6

7

8

9

10

GPP Grnd.

Buss Bar

W/L Brkr

GPP Contlr.

GPP Contlr.

12 Vac

Relay

Board

12 Vac

Relay

Board

12 Vac

Gen Grnd.

1

2

3

4

5

6

1

4

6

7

TS-1

Figure 1.1

Economy Model:

Top center of Dash Panel.

Standard Model:

Circuit Breaker panel inside

Patch Panel compartment.

Figure 1.3

Figure 1.2

PROCEDURE #1:

CHECK GENERATOR AC VOLTAGES INSIDE

CONSOLE.

TEST 12 VOLT AC OUTPUT*

A. Set GPP Voltage Range Switch to “off”. Start

Generator. Set engine speed to 3600 RPMs.

B. Check the VAC on TS-1 using a voltmeter (g.

1.1) pairs: (1&4 and 6&7). They should read

14.5V, 60Hz. If 14.5-Volts AC are not present, go

to C or D. If Voltages are okay, go to Procedure

2.

C. Flash Generator.

USER'S MANUAL

Restart Procedure 1.

D. Test Battery Charger Circuit. Pull out on center

button of the circuit breaker (Fig. 1.2, 1.3). If

14.5 volts are present, Battery charging circuit is

shorted and needs to be repaired.

E. If still no 14.5 Volts AC, shut off generator and

then remove wire pairs (1&4 and 6&7) from

generator to TS-1 (g. 1.1). Retest for 14.5 volts

connected directly to each pair (black/black,

white/white).

If 14.5 volts are now present, a short circuit

exists inside the console.

F. Check each wire pair to the boat ground.

Measurements should be greater than 500 ohms.

If resistance is low, wire insulation may be

damaged and shorting to ground.

Go to Procedure 3.

*High voltage is present inside the console while the generator

is running. Only qualified personnel should attempt high voltage

measurements.

smith-root.com

23

ELECTROfISHING

Generator Power to GPP Terminal Strip

DANGER HIGH VOLTAGE

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

120VAC

Foot Sw.

Foot Sw.

Foot Sw.

GPP Control Strip

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

TS-0

9&10

11&12

7 & 8

1 & 2

3 & 4

5 & 6

Figure 2.1

High voltage is present inside the console

while the generator is running.

Only qualified personnel should attempt

high voltage measurements.

WARNING

!

*

High voltage is present inside the console

while the generator is running.

Only qualified personnel should attempt

high voltage measurements.

WARNING

!

BOATS

PROCEDURE #2:

TEST HIGH VOLTAGE AC OUTPUT INSIDE CONSOLE*

A. Set Voltage Selector Switch to “OFF”.

B. Check each of the high voltage terminal

pairs on TS-0 for 120 Volts AC * (fig.

2.1) Pairs: 1&2, 3&4, 5&6, 7&8, 9&10,

and 11&12.

C. If voltage measures 120 Volts AC for

each pair, go to E.

D. If voltage measures low, check terminals

1-12 to boat ground. All terminals should

show open or high resistance (Greater

than 500 Ohms). If resistance is low,

wire insulation may be damaged and

shorting to ground.

Go to Procedure 3.

E. Switch GPP Voltage Range Switch to

“LOW”. Retest all of Procedure 2. If low

voltages are found, one or more windings

may be out of phase.

F. Switch GPP Voltage Range Switch to

“HIGH”.

Retest all of Procedure 2.

G. Measure voltages on TS-0, pins 1 to 12.

They should read 720 VAC RMS.

If Voltage Is Okay, go to Procedure 6

If voltage NOT Okay, contact SRI.

24

2007

A. Turn Generator off.

Foot Sw.

Foot Sw.

GPP

GPP

GPP Control Strip

Foot Sw.

#11

#12

#13

#14

#15

120

VAC

120

TS-0

15

13

5 Amp

Fast-Blow

Fuse

B. Connect a jumper wire across the foot switch connection

(PINS 13 & 15) on TS0 to bypass the foot switches. (Fig.

3.1)

C. Connect console “Patch Panel” as shown. (Fig. 3.2)

D. Connect test load to boom and cathode (See Procedure 6).

Warning - Keep all personnel clear of booms and the test

load while the generator is running.

E. Switch mode switch to 120 PPS.

USER'S MANUAL

GPP TROUBLESHOOTING

PROCEDURE #3: TEST GPP BOX

CONTROL CIRCUIT

F. Turn Percent of Range Control to 50%.

G. Switch output voltage selector switch to low range.

H. Switch the Emergency Shutdown Switch to OFF position

I. Start the Generator.

J. Switch the Emergency Shutdown Switch to the ON

K. The red light on the front panel should now be illuminated

L. If the red light is not illuminated and the amp meter indicates

(Caution: this is now the only on/off control for the GPP

control box).(Fig. 3.3)

position.

and the amp meter should indicate amperage.

no amperage:

a. Generator off.

b. Check the light bulb.

c. Check the fuse on the GPP main circuit board.

d. Replace fuse if blown (Fig. 3.4). A blown fuse may

indicate a short circuit in power to Work Lights or

Audio Alarm.

e. Disconnect Audio Alarm from GPP control box.

Fig.3.1

Fig.3.2

Fig.3.3

Fig.3.4

f. Test Booms individually for shorts due to damage

to insulation of cables using a Hi-pot tester.

Return to start of Procedure 3.

smith-root.com

M. If Red light and amp meter indicate output, go to

Procedure 4.

N. If no output indication then return GPP control box

to Smith-Root, Inc. for service.

25

ELECTROfISHING

+

+

BOATS

PROCEDURE #4:

TEST THE GPP'S OUTPUT

WARNING – KEEP ALL PERSONNEL CLEAR OF

BOOMS AND TEST LOAD WHILE GENERATOR

RUNNING.

A. Maintain GPP settings from procedure #3.

B. Start Generator.

C. Switch the Emergency Shutdown Switch (1) to

the ON position.

2 1 3

F. Adjusting the percent of range (2) up to 100

percent will increase the amperage shown on

the front panel meter.

G. Set the percent of range at 50 percent.

a. Switch the Mode switch (3) from

120 PPS to 60 PPS. The amperage

should drop by 1/2.

Fig. 4.1

D. When the red light is on, the current meter

should show amperage and the seconds counter

should be counting.

E. If there is no display in the seconds counter,

replace the “N” cell batteries in the counter

Fig. 4.2

b. Switch the Mode switch from 60

PPS to 30 PPS. The amperage

should drop again by 1/2.

c. Switch the Mode switch from 30

PPS to 15 PPS. The amperage

should drop again by 1/2.

d. Switch the Mode switch from 15

PPS to 7.5 PPS. The amperage

should drop again by 1/2.

H. Switch the Emergency Shutdown Switch to the

OFF position.

I. Switch the voltage switch to the high range.

J. Return to C and retest settings in the High

Range.

IF NO OUTPUT, RETURN CONTROL BOX TO

SRI.

(the batteries should be replaced every 5 years).

(Figure 4.2)

26

2007

PROCEDURE #5: TEST BOAT fOOTSWITCH CIRCUITS

Foot Sw.

Foot Sw.

GPP

GPP

GPP Control Strip

Foot Sw.

#11

#12

#13

#14

#15

120

VAC

120

TS-0

15

13

A. Turn Generator off.

B. Remove foot switch jumper from Procedure 3 from

TS-0 (pins 13 & 15). (Fig. 5.1).

C. Set foot switch control to “Separate”(Fig. 5.2).

D. Switch to “inactive”, the Command Center foot switch

and the Auxiliary foot switch from inside the front

compartment of the console (Fig. 5.3).

USER'S MANUAL

GPP TROUBLESHOOTING

E. Start Generator.

F. Close each work deck foot switch circuit (push on

switch).

G. The red light should turn on.

H. Set the foot switch control to “BOTH”.

I. Close both of the bow foot switches at the same time.

J. The red light should turn on.

K. Switch the Command Center foot switch to

“ACTIVE.”

L. Close both of the Work Deck foot switches and the

Command Center foot switch.

M. The red light should turn on.

Foot switch problems can be caused by:

1. Misadjusted switch (try pushing on the switch directly

with your nger).

Fig. 5.1

Fig. 5.2

2. Broken wire (this will need to be traced with an

3. Broken switch (try a jumper across the switch).

4. Incorrect Switch settings.

Ohmmeter).

smith-root.com

Fig. 5.3

27

ELECTROfISHING

Anode

Boom

Figure 1.2

Water

From Anode

Plastic Bucket

Aluminum Plate

From Cathode

Maximum GPP Amperage (2.5 - 5.0)

Model High Low

2.5

5.0

8 Amps

16 Amps

4 Amps

8 Amps

7.5 120 V 170 V 62.5 A

31.3 A

20.8 A

10.4 A

240 V

360 V

720 V

340 V

500 V

1000 V

150 A60 V 85 V

75 A120 V 170 V

37.5 A240 V 340 V

18.8 A480 V 680 V

9.0

Maximum GPP Amperage (7.5 - 9.0)

Model DCAC Amperage

! !

! !

Cathode

Figure 1.3

BOATS

PROCEDURE #6:

CONSTRUCT A TEST LOAD

Warning! – Keep all personnel clear of booms and test load

while generator is running!

1. Construct a test load using a plastic bucket with

the metal handle removed (Fig. 1.1).

2. Connect the test load to the boat as shown (Figs.

1.2-1.3).

3. Add tap water to the bucket.

4. Set the “Mode Switch” on the GPP control box to

AC & 120 PPS/ 60 AC.

5. Start the generator.

6. Control the GPP output with the Emergency Shut

Down switch or Footswitch.

7. By turning the percent of range control up to

100% and checking the amp meter on the GPP

control box, the correct load can be determined. See

below

Fig. 6.1

8. The amp meter will increase to the maximum as

you turn up the Percent of Range.

9. The load may be increased by slowly adding table

salt to the water in the bucket.

10. If the load is too great for the range selected, the

GPP will operate erratically.

11. If the amp meter starts to show a decrease in

amps or is erratic as the percent of range nears

100%, the generator is overloading. The water may

need to be changed, or decrease the portions of

electrodes immersed in the water .

28

Every effort should be made to keep all personnel away from test load bucket and booms.

Danger! High voltage is present during test load procedure.

It may be necessary to form a barricade around testing area and post

appropriate signs warning of high voltage.

Fig. 6.2

Fig. 6.3

2007

1

2

3

4

5

6

7

8

9

10

11

12

Frame Ground

Stator end with end cover removed

120VAC

120VAC

GPP Control Strip

120VAC

1

120VAC

2

3

120VAC

4

120VAC

5

120VAC

6

120VAC

7

120VAC

8

9

120VAC

10

120VAC

11

120VAC

12

Foot Sw.

13

Foot Sw.

14

Foot Sw.

15

TS-0

DANGER HIGH VOLTAGE

Generator Power to GPP Terminal Strip

GPP Grnd.

Buss Bar

W/L Brkr

Batt. Chrgr.

GPP Power, Generator Power &

GPP Acc. Items Terminal Strip

DANGER HIGH VOLTAGE

GPP Contlr.

GPP Contlr.

Cathode

Array

Gen Grnd.

1

Relay Board

2

12 Vac

3

12 Vac

4

12 Vac

6

12 Vac

7

Dash Lights

8

Anode

9

Anode

10

Cathode

11

Cathode

12

Strb. Boom

13

Port Boom

14

15

TS-1

5

Relay Board

Black 14

Black 10

Black 10

White 10

White 10

These wires white 14 ga.

GPP TROUBLESHOOTING

BOAT GENERATOR STATOR WIRING DIAGRAM:

5.0 AND 7.5 GPP

USER'S MANUAL

Generator Terminals

1 - 2 = 115 Volts @ 1250 VA

Respectively through

11 - 12 = 115 Volts @ 1250 VA

(Pairings of Odd # on Left & Even # on Right.)

Output @ Binding Posts

Black wires 12 Volts @ 500 VA

White wires 12 Volts @ 500 VA

smith-root.com

29

ELECTROfISHING BOATS

STANDARD BOATING RULES

ELECTROfISHING

BOATS

Standards Boating Rules Contents:

Right-Of-Way

Buoys and Other Markers

Lightning and Thunderstorm Protection

Guide to Personal Thunderstorm Protection

.................................................................................................................................33

...............................................................................................................34

.........................................................................................35

...................................................................................38

32

2007

RIGHT-Of-WAY

USER'S MANUAL

STANDARD BOATING RULES

Meeting: If you are meeting another power vessel head on,

and are close enough to run the risk of collision, neither of

you has the right-of-way! Both of you should alter course

to avoid an accident. You should keep the other vessel on

your port (left) side. This rule doesn't apply if both of you

will clear one another if you continue on your set course and

speed.

Crossing: When two power driven vessels are crossing each

other's path close enough to run the risk of collision, the vessel

which has the other on the starboard (right) side must keep out

of the way of the other. If the other vessel is on your right,

you must keep out of its way; you are the Give-Way vessel.

If the other vessel is on your port (left) side, remember that

you should maintain course and direction, provided the other

vessel gives you the right-of-way as it should.

Overtaking: If you are passing another vessel, you are

the "Give-Way" vessel. This means that the other vessel is

expected to maintain its course and speed. You must stay out

of its way until you are clear of it. Likewise, if another vessel

is passing you, you should maintain your speed and direction

so that the other vessel can steer itself around you.

smith-root.com

33

ELECTROfISHING

BOATS

OTHER SPECIAL SITUATIONS

There are three other rules you need to know when driving

your boat around other vessels.

Narrow channels and bends: When navigating in narrow

channels, you should keep to the right when it is safe and

practical to do so. If the operator of a power-driven vessel is

preparing to go around a bend that may obstruct the view of

other water vessels, the operator should sound a prolonged

blast on the whistle (4 to 6 seconds). If another vessel is

around the bend, it too should sound the whistle. Even if

no reply is heard, however, the vessel should still proceed

around the bend with caution. If you navigate such waters

with your boat, you must carry a portable air horn available

from local marine supply stores.

Fishing vessel right-of-way: All vessels which are shing

with nets, lines or trawls are considered to be "shing

vessels" under the International Rules. Vessels with trolling

lines are not considered shing vessels. Fishing vessels

have the right-of-way regardless of position. Fishing vessels

cannot, however, impede the passage of other vessels in

narrow channels.

Sailing vessel right-of-way: Sailing vessels should

normally be given the right-of-way. The exceptions to this

are:

1. When the sailing vessel is overtaking the power-driven

vessel, the power-driven vessel has the right-of-way.

2. Sailing vessels should keep clear of any shing vessel.

3. In a narrow channel, a sailing vessel should not hamper

the safe passage of a power-driven vessel which can

navigate only in such a channel.

Reading buoys and other markers: The waters of the

United States are marked for safe navigation by the lateral

system of buoyage. Simply put, buoys and markers have

an arrangement of shapes, colors, numbers and lights to

show which side of the buoy a boater should pass on when

navigating in a particular direction. The markings on these

buoys are oriented from the perspective of being entered

from seaward (the boater is going towards the port). This

means red buoys are passed on the starboard (right) side

when proceeding from open water into port, and black buoys

are to the port (left) side. When navigating out of port, your

position with respect to the buoys should be reversed; red

buoys should be to port and black buoys to starboard.

34

Many bodies of water used by boaters are entirely within

the boundaries of a particular state. The Uniform State

Waterway Marking System has been devised for these

waters. This system uses buoys and signs with distinctive

shapes and colors to show regulatory or advisory

information. These markers are white with black letters and

orange boarders. They signify speed zones, restricted areas,

danger areas, and general information.

Remember, markings may vary by geographic location.

Always consult local boating authorities before driving your

boat in unfamiliar waters.

2007

LIGHTNING AND THUNDERSTORM

PROTECTION fOR SAILBOATS, POWER

BOATS, SMALL BOATS AND SHIPS.

1. GENERAL PRINCIPLES

USER'S MANUAL

LIGHTNING PROTECTION

Successful protection of persons and watercraft from

lightning is dependent upon a combination of proper design

and maintenance of equipment, and on crew behavior.

Proper design is covered in this and following sections.

Maintenance of equipment and personnel behavior is also

covered. In view of the wide variation in structural design

of boats, specic recommendations cannot be made for all

cases. However, basic guidelines should be considered

and used in designing and installing a lightning protection

system for any given craft.

A grounded conductor or lightning protective mast will

generally divert itself to direct hits which might otherwise

fall within a cone-shaped space, the apex of which is the top

of the conductor or lightning protective mast and the base is

a circle at the surface of the water having a radius related to

the height. For a mast height not exceeding 50 ft., (15 m)

above the water, this radius is approximately equal to the

mast height.

To provide an adequately grounded conductor or lightning

protective mast, the entire circuit from the top of the mast

to the ground should have a conductivity not less than that

of a No.8 AWG copper conductor and the path to ground

followed by the conductor should be essentially straight.

To remove all known risk of melting the conductor while

carrying lightning current, conductivity equal to No.6 AWG

or no. 4 AWG copper would be necessary. However, the risk

in using No.8 AWG is considered adequately small in the

applications under consideration, and in many cases will be

mitigated by the presence of electrically paralleling stays.

This statement should not be interpreted as permitting the

use of conductors of conductivity less than that of No. 8

AWG copper.

If there are metal objects of considerable size within

a few feet of the grounding conductor, there will be a

strong tendency for sparks or sideashes to jump from the

grounding conductor to the metal object at the closest point.

To prevent damage from such sideashes, an interconnecting

conductor at least equal to no. 8 AWG copper should be

provided at all places where they are likely to occur. Large

metallic objects that are not part of the electrical system of

the boat and that are not already grounded due to their own

functional or other requirements may be grounded to the

ground plate, provided that it is not practical to interconnect

with the lightning conductor or bonding systems.

Lightning protection provisions are quite likely to receive

scant attention after installation and therefore their

composition and assembly should be strong and materials

used should be highly resistant to corrosion.

2 INSTALLATION RECOMMENDATIONS

Lightning Protective Mast. A lightning protective mast

should be of adequate height and should be mechanically

strong in order to withstand exposure to use and weather.

If the mast is of nonconducting material, the associated

lightning or grounded conductor should be essentially

straight, securely fastened to the mast, should extend at least

6 in. (150 mm) above the mast, should preferably terminate

in a receiving point, should be led as directly as practical to

the grounding connection.

Radio Antenna. A radio antenna may serve as a lightning

protective mast provided it has conductivity equivalent to

No. 8 AWG copper and is equipped with lightning arresters,

lightning protective gaps, or means for grounding during

electrical storms. The grounding of metal rod-type radio

antennas constitutes sufcient protection for wooden boats,

without masts or spars, provided the following conditions

are met:

The antenna and all conductors in the grounding circuit of

the antenna have a conductivity equivalent to No.8 AWG

copper.

The top of the antenna is not more than 50 ft. (15m) above

the water, and a line drawn from the top of the antenna

downward toward the water at an angle of 45 degrees to the

vertical does not intercept any part of the boat.

smith-root.com

35

ELECTROfISHING

BOATS

Because a loading coil presents a high impedance to the

ow of lightning current, the portion of an antenna above

the bottom of a loading coil is not effective as a lightning

protective mast unless the coil is provided with a suitable

protective device for bypassing the lightning current.

Nonconducting antenna masts with spirally wrapped

conductors are not considered

suitable for lightning protection

purposes.

3 MATERIALS

The materials used in the making

of a protective system should be

resistant to corrosion. The use of

combinations of metals that form

galvanic or electrolytic couples

should be avoided.

In those cases where it is impractical

to avoid a junction of dissimilar

metals, the corrosion effects can

reduce the use of suitable platings

or special connectors, available

for such purposes. Except for the

use of conducting materials that

are otherwise part of the structure

of the boat, only copper should be

used as the conductor. Where copper

is used, it should be of the grade

ordinarily required for commercial

electrical work, generally designated

as being 98 percent conductivity when annealed.

Figure 2. Diagrams the zone of protection provided by

a grounded mast or antenna not more than 50 ft (15 m)

above the water. This protective zone is largely immune

to direct strokes of lightning. No part of the vessel to be

protected should extend outside the zone of protection.

Thus in the cabin cruiser illustrated, adequate lightning

protection is afforded only by the grounded antenna

equipped with a lightning arrester or gap on the coil.

Copper Conductor. Copper cable conductors should be of

a diameter not less than No.8 AWG. The size of any strand

of cable should be not less than No. 17 AWG. The thickness

of any copper ribbon or strip should not be less than No. 20

AWG. Where other materials are used, the gauge should be

such as to give conductivity equal to or greater than No. 8

AWG stranded copper cable.

Joints. Joints should be mechanically strong and should

be so made that they have an electrical resistance not in

excess of that of 2 ft (0.6 m) of

conductor.

4. INTERCONNECTION

OF METALLIC MASSES

Metallic masses aboard boats

that are a permanent part of

the boat or are permanently

installed within or about it and

whose function would not be

seriously affected by grounding

should, with exception of

those of comparatively small

size, be made a part of the

lightning conductor system by

interconnection with it.

The object of interconnecting

the metal parts of a boat with

the conductor is to prevent

damage from sideashes,

especially in the case of many

metal objects that are nearby.

The main principle to be

observed in the prevention

of such damage is to identify on a boat the places where

sideashes are most likely to occur and to provide metallic

paths for them.

To minimize ow of lightning discharge current through

engine bearings, it may be preferable to bond engine blocks

directly to the ground plate rather than to an intermediate

point on the lightning conductor.

EXTERIOR BODIES OF METAL

Metal situated wholly on the exterior of boats should be

electrically connected to the grounding conductor.

Exterior metal bodies on boats include any large masses such

36

2007

USER'S MANUAL

LIGHTNING PROTECTION

as horizontal handrails on cabin tops, smoke stacks from

galley stoves, davits, or metal signal masts.

INTERIOR BODIES OF METAL

Metal situated wholly in the interior of boats and which at

any point comes within 6 ft (1.8 m) of a lightning conductor

should be electrically interconnected with this lightning

conductor.

Interior bodies of metal include engines, water and gasoline

tanks, and control rods for steering gear or reversing gear. It

is not intended that small metal objects such as compasses,

clocks, galley stoves, medicine chests, and other parts of the

boat’s hardware be grounded.

Metal that projects through cabin tops, decks or sides of

boats above the sheer should be bonded to the nearest

lightning conductor at the point where the metal emerges

from the boat and should be grounded at its lower or extreme

end within the boat.

Radio transmitter antennas should be (a) equipped with

means for grounding during electrical storms or (b)

transmitters and antennas should be protected by lightning

arresters or lightning protective gaps.

Ground Connection. A ground connection for a boat may

consist of any metal surface that is normally submerged in

the water and that has an area of 1 square foot (0.093 m2).

Propellers and metallic rudder surfaces may be used for

this purpose. The ground plate as required by the Federal

Communications Commission for radio transmitters should

be considered adequate. A metal hull itself constitutes an

adequate ground.

Vessels with Metal Hulls. If there is an electrical

contact between metal hulls and metal masts or other

metallic superstructure of adequate height to meet the

recommendations of Section 2, no further protection

against lightning is necessary. Boats with ungrounded or

nonconducting objects projecting above the metal masts

or superstructure should have these objects grounded or

protected with a grounded conductor, respectively, in order

to protect them.

smith-root.com

PROTECTION OF SAILBOATS (NONMETALLIC)

Sailboats. Sailboats with metallic standing rigging will be

adequately protected provided that all rigging is grounded,

so that the mast and rigging meet the recommendations of

Sections 2 and 3.

Open Day-Sailors. Open sailboats will be adequately

protected if any shrouds, backstays, or preventors, and

any continuous metallic track on the mast and boom are

grounded. These should be electrically connected at the

lower or forward end and grounded to a copper plate on the

hull or to a metal rudder, centerboard, or keel.

Cruising Sailboats. All stays and all sail tracks should

be grounded on cruising sailboats since it is assumed that

persons will be in proximity of fore-stays as well as afterstays. Grounding of other objects on cruising boats should

be in accordance with the foregoing subsections.

PROTECTION OF POWER BOATS

(NONMETALLIC)

Power boats may be adequately protected by a grounded

radio antenna and other suitable grounded lightning

protective mast provided the height of the mast meets the