Smith Performance Sprayers Industrial Series, Contractor Series, S103E Use And Care Manual

Stainless Steel

Compression Sprayer

Use and Care Manual

Industrial and Contractor Series

S103E

#190448

CAUTION: Read and follow all instructions

Do Not Return This Sprayer To The Store

For Help, Information or Parts, Call : 1-800-311-9903

The Fountainhead Group, Inc.

23 Garden St., New York Mills, NY 13417

1-800-311-9903

www.TheFountainheadGroup.com

www.smithperformancesprayers.com

Manual No. 183282

Rev A: 06/15/17

5 1/2” X 8 1/2” Booklet

ECN17-010

SAFETY PRECAUTIONS

• Read owner’s manual completely before operating this sprayer.

• Always use goggles, gloves, and protective clothing when using sprayer. Refer to the appropriate

technical bulletin for the chemical being sprayed for additional protective clothing required.

• Read and follow all instructions and cautions on label, material safety data sheets and technical bulletins

of products used in this sprayer.

• Never use ammable liquids, chlorine, bleach, caustics, acids, hot water, or other corrosive solutions or

heat, pressure or gas producing chemicals in the tank for the S103E Sprayer.

• Do not leave sprayer in the sun when not in use.

• Spray when air is calm to prevent drift of chemicals.

• Do not use sprayer near open ame or anything that could cause ignition of the spray.

• Always inspect hose and all hose connections before each use. A damaged hose, or loose hose

connection can result in unintended exposure to the pressurized chemical, resulting in serious injury or

property damage.

• Do not lift or carry sprayer by the hose, shut-o valve, or extension. Carry by pump handle only,

making sure handle is properly locked in place before lifting.

• Do not pressurize with any mechanical device such as an air compressor, since this can create a

dangerous pressure level and bursting of parts resulting in serious injury. Only use original pump.

• Do not store chemicals in this tank.

• Always release pressure when sprayer is not in use and before removing pump from tank.

• Do not stand with face or body over top of tank when pumping or loosening pump, to prevent pump or

solution from striking you, resulting in serious injury.

• Clean and rinse sprayer thoroughly after each use.

• Never attempt to alter sprayer from original condition.

• Always use replacement parts from original manufacturer.

• Keep the sprayer and all chemicals out of the reach of children.

ASSEMBLY INSTRUCTIONS

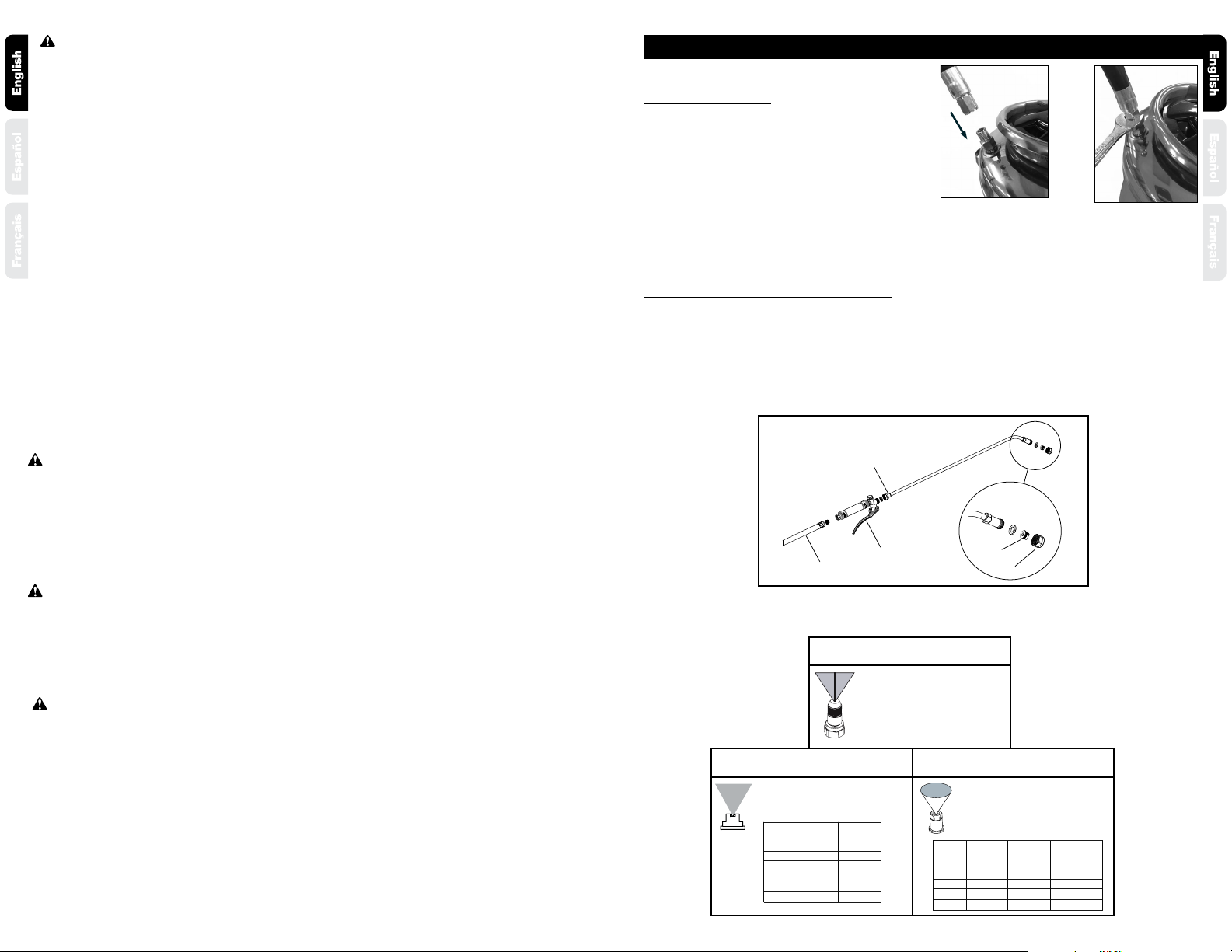

Assemble Hose To Tank

1. Wrap teon tape around tank tting threads 2X in

clockwise direction, if needed.

2. Align hose and screw on to tank. (See Figure A).

3. Tighten with a 5/8” wrench. (See Figure B).

Figure A

Assemble Hose, Extension, Shut-O & Nozzle

1. Attach hose to shut-o and tighten securely using a 9/16” wrench. Do not overtighten. Use a 3/4” wrench

to hold the shut-o handle while tightening the hose. (See Figure C)

2. Install the extension onto the shut-o assembly and tighten the nut securely using a 13/16” wrench.

(See Figure C)

3. Install selected nozzle into the extension nut and tighten nut securely using a 13/16” wrench.

(See Figure C)

Figure B

WARNING

ALWAYS CLEAN THE SPRAYER AND SHUT-OFF THOROUGHLY AFTER EACH USE

OR WHEN CHANGING APPLICATIONS AS DESCRIBED IN THE CLEANING SECTION.

FAILURE TO COMPLETELY CLEAN MAY CAUSE CROSS-CONTAMINATION.

CAUTION

Always empty, clean and dry tank, pump system, shut-o, hose, and extension after each use. FAILURE TO

DO SO MAY WEAKEN SPRAYER COMPONENTS, CAUSING COMPONENTS TO RUPTURE WHEN PRESSURIZED.

Additionally, FAILURE TO CLEAN AND PROPERLY MAINTAIN YOUR SPRAYER WILL VOID MANUFACTURER’S

WARRANTY.

WARNING

The sprayer is operated with liquid under pressure. Failure to observe caution and to follow instructions

for operating and cleaning can cause tank, hose and other parts to be weakened and rupture under

pressure. This can result in serious injury from high pressure discharge of liquids or forcible ejection of

parts. Do not use ammable materials in this sprayer. Material could ignite or explode, causing serious

injury and/or possible death. For safe use of this product, you must read and follow all instructions before

use.

TEST SPRAYER WITH WATER BEFORE USING ANY CHEMICALS.

Do not return sprayer to store, if you experience problems or have questions contact

our toll free Customer Service Center, M-F 8A.M. - 5P.M., EST, at 1-800-311-9903, or

e-mail: Info@TheFGI.com, or access online at: www.TheFountainheadGroup.com.

Page 2 Page 3

EXTENSION

SHUT-OFF

HOSE

BRASS ADJUSTABLE

FAN NOZZLE USES:

Used on

1. Industrial and Concrete Series (Orange)

BRASS FLAT FAN TIP

NOZZLE USES:

Used on

1. Industrial and Concrete Series (Orange)

SPRAY

ANGLE:

65°

80°

80°

80°

95°

110°

SPRAY

PATTERN:

FAN

FAN

FAN

FAN

FAN

FAN

FLOW

RATE:

.2 GPM

.2 GPM

.4 GPM

.5 GPM

.5 GPM

1 GPM

Figure C

SPRAY

ANGLE:

80°

80°

80°

80°

80°

NOZZLE

NUT

CERAMIC CONEJET TIP

NOZZLE USES:

Used on

1. Turf and Argiculture Series (Green)

2. Industrial and Concrete Series (Orange)

3. Cleaning and Restore Series (Blue)

4. Pest Control Series (White)

SPRAY

PATTERN:

FAN

FAN

FAN

FAN

FAN

FLOW

RATE:

.07 GPM

.10 GPM

.10 GPM

.13 GPM

.20 GPM

COLOR

#4 GREEN

#6 RED

#10 BLACK

#8 GRAY

#12 BROWN

Loading...

Loading...